Page 1

BTFP12180/BTFP12181

MANUAL CARTON CLOSER

CERRADORA MANUAL DE CAJAS DE CARTÓN

DISPOSITIF DE FERMETURE MANUELLE DE BOITE

BTFP12180

BTFP12181

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL TO

UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE

INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS,

CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES DEBERÁN ESTUDIAR

ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE

SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA

HERRAMIENTA PARA FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON

SU REPRESENTANTE DE BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER UNE

ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX

AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI VOUS

AVEZ DES QUESTIONS, CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE

CONCESSIONNAIRE BOSTITCH.

9R196661RA 06/11

STANLEY FASTENING SYSTEMS L.P.

Page 2

INTRODUCTION

The Bostitch BTFP12180/BTFP12181 series staplers are precision-built tools, designed for manual stapling.

These tools will deliver efficient, dependable service when used correctly and with care. As with any fine

ower tool, for best performance the manufacturer’s instructions must be followed. Please study this manual

p

before operating the tool and understand the safety warnings and cautions. The instructions on installation,

peration and maintenance should be read carefully, and the manuals kept for reference. NOTE: Additional

o

safety measures may be required because of your particular application of the tool. Contact your Bostitch

epresentative or distributor with any questions concerning the tool and its use. Stanley Fastening Systems,

r

L.P., East Greenwich, Rhode Island 02818.

INDEX

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Tool Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Loading the BTFP12180/BTFP12181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Tool Operation Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintaining the Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

NOTE:

Bostitch tools have been engineered to provide excellent customer satisfaction and are designed to achieve

maximum performance when used with precision Bostitch fasteners engineered to the same exacting

standards. Bostitch cannot assume responsibility for product performance if our tools are used with

fasteners or accessories not meeting the specific requirements established for genuine Bostitch nails,

staples and accessories.

LIMITED WARRANTY

Stanley Fastening Systems, L.P. (“Bostitch”) warrants to the original retail purchaser that this product is free

from defects in material and workmanship, and agrees to repair or replace, at Bostitch's option, any defective

product within 1 year from the date of purchase. This warranty is not transferable. It only covers damage

resulting from defects in material or workmanship, and it does not cover conditions or malfunctions resulting

from normal wear, neglect, abuse, accident or repairs attempted or made by other than our regional repair

center or authorized warranty service center. Driver blades, clinchers and o-rings are considered normally

wearing parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS LIMITED TO THE DURATION OF THIS

WARRANTY. BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not allow limitations on

how long an implied warranty lasts, or the exclusion or limitation of incidental or consequential damages, so

the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and

you may also have other rights which vary from state to state.

To obtain warranty service, return the product at your expense together with proof of purchase to a Bostitch

Regional or authorized warranty repair center. You may call us at 1-800-556-6696 for the location of

authorized warranty service centers in your area.

-2-

Page 3

SAFETY INSTRUCTIONS

EYE PROTECTION which conforms to ANSI specifications and provides protection against

lying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

f

thers in the work area when connecting to air supply, loading, operating or servicing this

o

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

AUTION: Additional Safety Protection will be required in some environments. For example,

C

the working area may include exposure to noise level which can lead to hearing damage.

he employer and user must ensure that any necessary hearing protection is provided and

T

sed by the operator and others in the work area. Some environments will require the use

u

of head protection equipment. When required, the employer and user must ensure that head

rotection conforming to ANSI Z89.1 is used.

p

LOADING TOOL

When loading tool: 1.) Never place a hand or any part of body in fastener discharge area of

tool; 2.) Never point tool at anyone; 3.) Do not depress the actuating lever as accidental

actuation may occur, possibly causing injury.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never depress the

actuating lever unless nose is directed toward the work; 3.) Keep others a safe distance from

the tool while tool is in operation as accidental actuation may occur, possibly causing injury.

Keep hands and body away from the discharge area of the tool.

Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as

this may cause deflection of fasteners which could cause injury.

This stapler produces SPARKS during operation. NEVER use the stapler near flammable

substances, gases or vapors including lacquer, paint, benzine, thinner, gasoline, adhesives,

mastics, glues or any other material that is -- or the vapors, fumes or by-products of which are -flammable, combustible or explosive. Using the stapler in any such environment could cause an

EXPLOSION resulting in personal injury or death to user and bystanders.

MAINTAINING THE TOOL

When working on tools note the warnings in this manual and use extra care when

evaluating problem tools.

BTFP12180/BTFP12181 TOOL SPECIFICATIONS

MODEL LENGTH HEIGHT WIDTH WEIGHT

BTFP12180 17.05" (433mm) 8.66” (220mm) 4.53” (115mm) 4.9lbs (2.2kg)

BTFP12181 17.05" (433mm) 8.66” (220mm) 4.53” (115mm) 4.9lbs (2.2kg)

FASTENER SPECIFICATIONS:

MODEL STAPLE SERIES WIRE SIZE CROWN WIDTH FASTENER RANGE

BTFP12180 B58C / B34C

SW7437

BTFP12181

SW9040

.074” x .037”

(1.88 x 94mm)

.074” x .037”

(1.88 x 94mm)

.090” x .040”

(2.29 x 1.02mm)

-3-

1-1/4”

(32mm)

1-3/8”

(35mm)

1-3/8”

(35mm)

5/8” - 3/4”

(15-19mm)

5/8” - 3/4”

(15-19mm)

5/8” - 3/4”*

(15-19mm)

Page 4

LOADING THE BTFP12180/BTFP12181

YE PROTECTION which conforms to ANSI specifications and provides protection against

E

lying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

f

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

he employer and/or user must ensure that proper eye protection is worn. Eye protection

T

equipment must conform to the requirements of the American National Standards Institute,

NSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

A

spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

Never engage in horseplay.

•

• Never pull or depress the actuating lever unless nose is directed at the work.

• Always handle the tool with care.

• Do not depress the actuating lever while loading the tool.

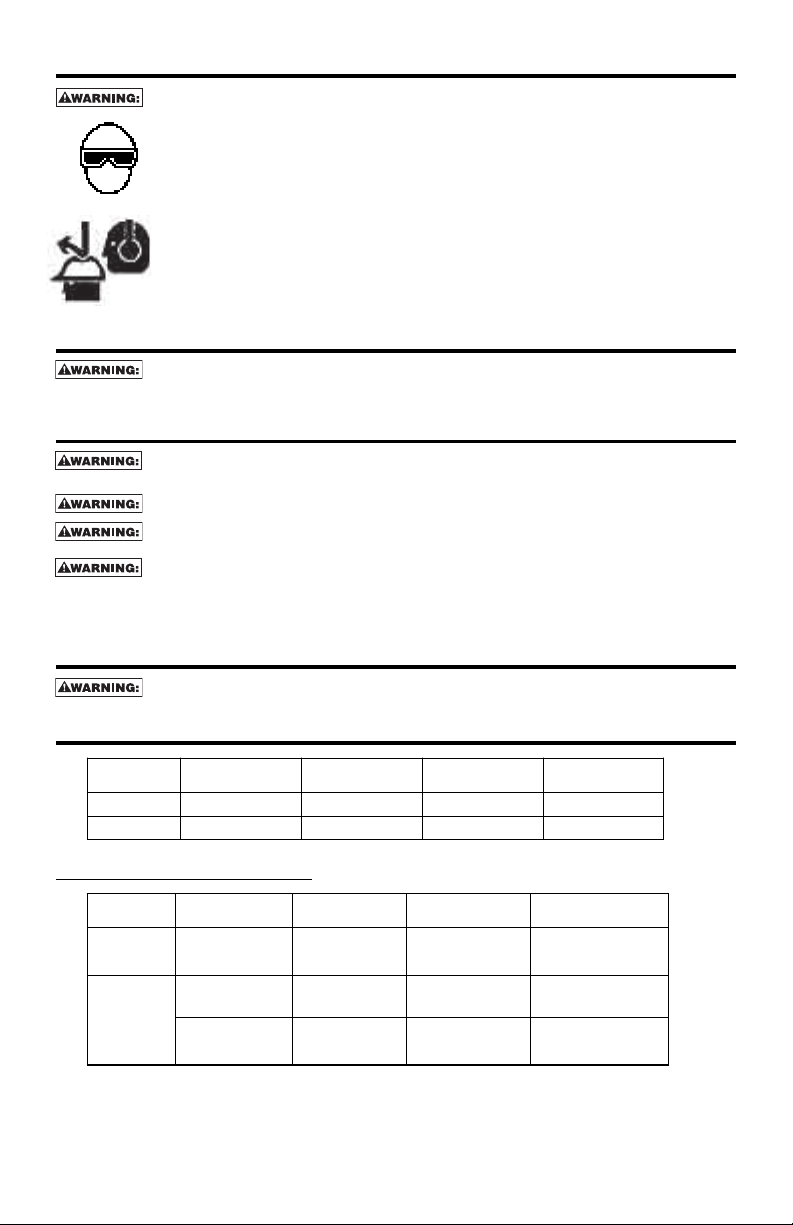

TOOL ADJUSTMENT CHART

STAPLE

LENGTHS

DIAL

POSITION

5/8" (15mm) 3/4" (19mm)

S

L

L

S

ADJUSTING THE BTFP12180/BTFP12181

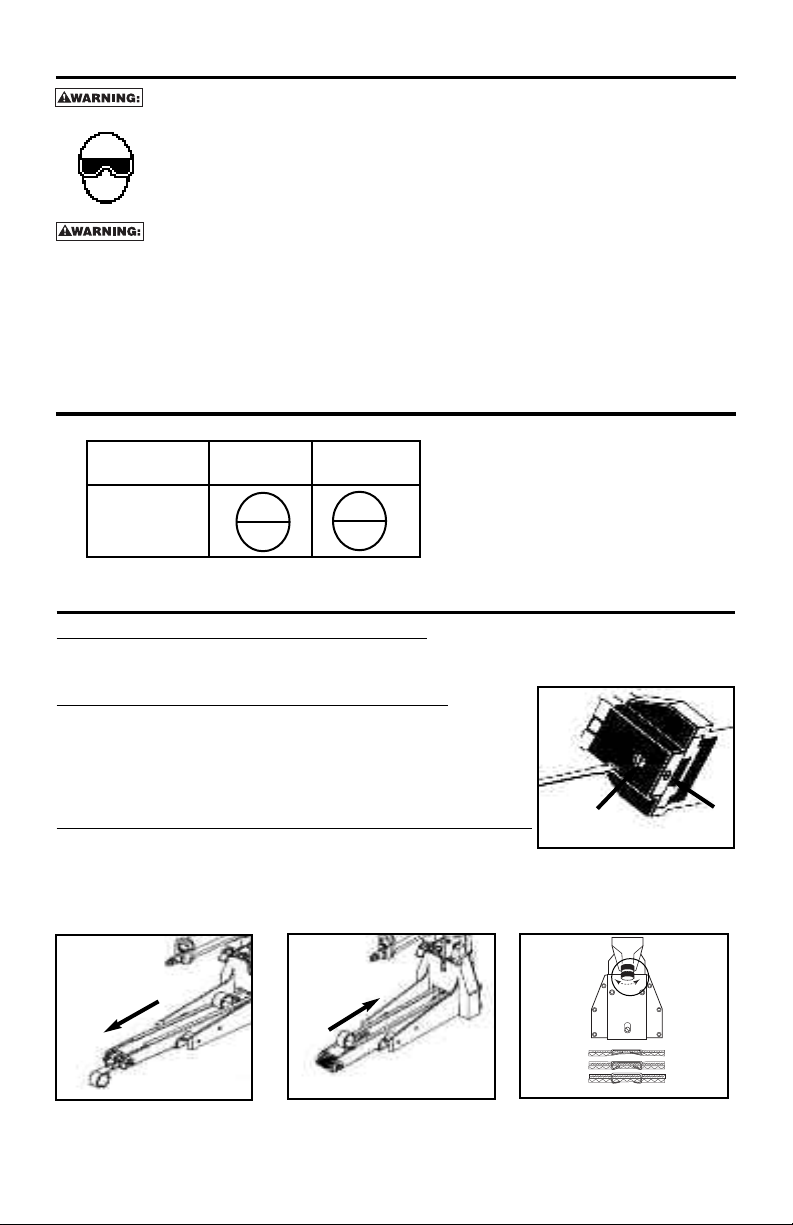

STAPLE SELECTOR (ALL MODELS) (FIG 1)

To adjust the tool for different leg lengths, loosen set-screw (A) and turn dial 180° (B) with a screwdriver

to the desired position as noted in the tables at the front of this manual. Tighten set-screw.

LOADING THE TOOL - BTFP12180/BTFP12181

A) Pull the pusher to the back of the magazine. (Fig 2)

B) Check Staple Leg Length: Adjustment is provided for

different staple leg lengths (see section below).

C) Insert 2 sticks of staples into the channel and gently

release the pusher against the staples. (Fig 3)

CLINCH ADJUSTMENT - BTFP12180/BTFP12181 (FIG 4)

Turn special nut (A) through window clockwise to tighten clinch

and counter-clockwise to loosen clinch. Use a tool to fit 1/8” (3mm)

B

A

FIG.1

FIG.2

FIG.3

FIG.4

-4-

Page 5

OPERATING THE BTFP12180/BTFP12181

S

L

4

OPERATING THE TOOL

rasp actuating lever with one hand and place other hand on top of

G

the tool or grasp secondary fixed handle if installed. Position on box in

line with the desired staple location. There is a small projection on

either side of the frame as an aid in locating the position of the staple. (FIG.5)

ush down firmly and release. Move machine to next staple location

P

and repeat. Strongest closure requires staples close to the end of box.

Check packaging requirements. Check staple clinching in samples of

board being used. Adjustments for tightness of clinch are easy and

nstantaneous- full advantage should be taken of them.

i

JAMMED STAPLE REMOVAL - BTFP12180/BTFP12181

Remove the remaining stick from the magazine. Pry jam

release forward with a screw driver (FIG.6). Remove magazine.

Clear the jam and re-insert the magazine. Pry jam release shut (FIG.7).

SECONDARY HANDLE - BTFP12180/BTFP12181

These models come with an additional handle to fit on the top of the

tool. To fit, position the handle as shown (Fig 8) and insert and tighten

the 4 screws supplied.

IG.5

F

FIG.6

FIG.7

FIG.8

IN ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS MANUAL

OBSERVE THE FOLLOWING FOR SAFE OPERATION

• Use the BOSTITCH tool only for the purpose for which it was designed.

• Never use this tool in a manner that could cause a fastener to be directed toward the user

or others in the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle.

• Do not alter or modify this tool from the original design or function without approval from

BOSTITCH, INC.

• Always be aware that misuse and improper handling of this tool can cause injury to

yourself and others.

• Never leave a tool unattended.

• Do not operate this tool if it does not contain a legible WARNING LABEL.

• Do not continue to use a tool if it is not functioning properly. Notify your

nearest BOSTITCH representative if your tool continues to experience functional problems.

MAINTAINING THE TOOL

When working on Bostitch tools, note the warnings in this manual and use extra care

REPLACEMENT PARTS:

BOSTITCH replacement parts are recommended. Do not use modified parts or parts which will not give

equivalent performance to the original equipment.

evaluating problem tools.

-5-

Page 6

INTRODUCCIÓN

Las engrapadoras Bostitch serie BTFP2180/BTFP2181 son herramientas de precisión, diseñadas para engrapar a mano. Al

gual que con toda herramienta automática de calidad, deben seguirse las instrucciones del fabricante para obtener el óptimo

i

rendimiento. Estudie este manual antes de operar la herramienta y tome nota de las advertencias y precauciones de

seguridad. Deben leerse en detalle las instrucciones sobre la instalación, operación y mantenimiento, y deben conservarse los

anuales para referencia. NOTA: Pueden necesitarse medidas adicionales de seguridad según la aplicación particular de la

m

herramienta. Diríjase al representante o distribuidor de Bostitch si tiene alguna pregunta referente a la herramienta y su uso.

Stanley Fastening Systems, L.P., East Greenwich, Rhode Island 02818.

ÍNDICE

nstrucciones de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

I

Especificaciones de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Carga de la unidad BTFP2180/BTFP2181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-18

evisión funcional de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

R

antenimiento de la herramienta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M

NOTA:

as herramientas Bostitch se han diseñado para brindar una satisfacción excelente al cliente y lograr máximo rendimiento al

L

utilizarse con fijaciones de precisión Bostitch diseñadas con las mismas normas estrictas. Bostitch no puede asumir

responsabilidad alguna por el rendimiento del producto si se utilizan nuestras herramientas con fijaciones o

accesorios que no reúnen los requisitos específicos establecidos para los clavos, grapas y accesorios genuinos de

Bostitch.

GARANTÍA LIMITADA

Stanley Fastening Systems, L.P. (“Bostitch”) garantiza al comprador original al por menor que este producto está exento de

defectos de material y fabricación, además se compromete a reparar o cambiar, a opción de Bostitch, cualquier producto

defectuoso dentro de 1 año de la fecha de compra. Esta garantía no es transferible. Solamente cubre daños resultantes de

defectos en material o fabricación, y no cubre condiciones o desperfectos resultantes del desgaste normal, negligencia, abuso,

accidente o reparaciones intentadas o efectuadas por terceros ajenos a nuestro centro regional de reparaciones o al centro de

servicio bajo garantía. Las aspas del impulsor, los remachadores y las juntas tóricas se consideran componentes de desgaste

normal.

ESTA GARANTÍA REEMPLAZA TODAS LAS DEMÁS GARANTÍAS EXPRESAS. TODA GARANTÍA DE COMERCIABILIDAD

O IDONEIDAD PARA UN FIN PARTICULAR SE LIMITA A LA DURACIÓN DE ESTA GARANTÍA. BOSTITCH NO SERÁ

RESPONSABLE DE DAÑOS FORTUITOS O CONSECUENCIALES.

Esta garantía se limita a ventas dentro de los Estados Unidos y Canadá. Algunos estados no permiten limitaciones a la

duración de una garantía implícita ni la exclusión o limitación de daños fortuitos o consecuenciales, de modo que las

limitaciones o exclusiones anteriores pueden no corresponder a su caso. Esta garantía le concede derechos legales

específicos, y usted puede tener también otros derechos que varían de un estado a otro.

Para obtener servicio bajo la garantía, devuelva el producto con cargo a nosotros junto con su comprobante de compra

dirigido al centro regional o al centro de reparaciones bajo garantía de Bostitch. Puede llamarnos al 1-800-556-6696 para

obtener la dirección de los centros autorizados de servicio bajo garantía en su área.

-6-

Page 7

INSTRUCCIONES DE SEGURIDAD

El operador y otros en el área SIEMPRE deben llevar PROTECCIÓN OCULAR en

conformidad con las especificaciones ANSI y que proteja contra partículas que vuelen por

DELANTE y por el LADO, cuando se haga la conexión al suministro de aire, así como al

cargar, operar o dar servicio a esta herramienta. Se exige protegerse la vista para

esguardarse contra fijaciones o residuos que vuelen, lo cual puede causar lesiones graves

r

a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

de protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

elante y por el costado. NOTA: Las gafas o caretas sin protección lateral por sí solas no

d

dan una protección adecuada.

PRECAUCIÓN: En algunos ambientes se necesitará protección adicional de seguridad. Por

jemplo, el área de trabajo puede exponer a un nivel de ruido que lesione el oído. El

e

empleador y el usuario deben comprobar que se cuente con la protección necesaria del

ído y que el operador y los demás presentes en el área la usen. Algunos ambientes

o

exigirán el uso de casco protector. Cuando sea necesario, el empleador y el usuario deben

verificar que se proteja la cabeza en conformidad con la norma ANSI Z89.1.

CARGA DE LA HERRAMIENTA

Al cargar la herramienta: 1.) Nunca ponga la mano ni ninguna otra parte del cuerpo en el

área aplicadora de descarga de la herramienta; 2.) Nunca apunte la herramienta a ninguna

persona; 3) No presione la palanca de accionamiento, ya que puede accionar la herramienta

de manera accidental y provocar lesiones.

FUNCIONAMIENTO

Siempre maneje la herramienta con cuidado: 1.) Nunca participe en juegos rudos;

2.) Nunca presione la palanca de accionamiento, a menos que la boca de la herramienta esté

apuntando hacia el objeto sobre el que se está trabajando; 3.) Mantenga a los demás a una

distancia segura de la herramienta mientras esté en funcionamiento porque puede

activarse accidentalmente, causando posibles lesiones.

Mantenga las manos y el cuerpo alejados del área de descarga de la herramienta.

No aplique clavos o grapas encima de otras ni con la herramienta en un ángulo demasiado

agudo pues esto puede ocasionar su deflexión, pudiendo causar lesiones.

Esta engrapadora produce CHISPAS durante la operación. NUNCA use la engrapadora cerca de

sustancias inflamables, gases o vapores, incluyendo laca, pintura, benzina, thinner, gasolina,

adhesivos, mastique, pegamentos u otros materiales que sean inflamables, combustibles

o explosivos, o que sus vapores, humos o subproductos también lo sean. Usar la engrapadora en

estos entornos podría causar una EXPLOSIÓN que genere lesiones personales o muerte

al usuario o a las personas que están cerca.

MANTENIMIENTO DE LA HERRAMIENTA

Cuando trabaje con herramientas, tenga en cuenta las advertencias de este manual y tenga

especial cuidado al evaluar herramientas problemáticas.

ESPECIFICACIONES DE LA HERRAMIENTA

BTFP12180/BTFP12181

Todos los tornillos y tuercas son métricos.

MODELO LONGITUD ALTURA ANCHO PESO

BTFP12180 433 mm (17.05 in) 220 mm (8.66 in) 115 mm (4.53 in) 2.2 kg (4.9 lb)

BTFP12181 433 mm (17.05 in) 220 mm (8.66 in) 115 mm (4.53 in) 2.2 kg (4.9 lb)

ESPECIFICACIONES DE CLAVOS:

MODELO

BTFP12180 B58C / B34C

BTFP12181

* Las grapas de 7/8" (22 mm) requieren remaches

SERIE DE

GRAPAS

SW7437

SW9040

TAMAÑO DEL

CABLE

.074” x .037”

(1.88 x 94mm)

.074” x .037”

(1.88 x 94mm)

.090” x .040”

(2.29 x 1.02mm)

ANCHO DE LA

-7-

CORONA

1-1/4”

(32mm)

1-3/8”

(35mm)

1-3/8”

(35mm)

RANGO DEL

SUJETADOR

5/8” - 3/4”

(15-19mm)

5/8” - 3/4”

(15-19mm)

5/8” - 7/8”*

(15-22mm)

Page 8

CARGA DE LA UNIDAD BTFP12180/BTFP12181

El operador y otros en el área SIEMPRE deben llevar PROTECCIÓN OCULAR en

conformidad con las especificaciones ANSI y que proteja contra partículas que vuelen por

ELANTE y por el LADO, cuando se haga la conexión al suministro de aire, así como al

D

argar, operar o dar servicio a esta herramienta. Se exige protegerse la vista para

c

resguardarse contra fijaciones o residuos que vuelen, lo cual puede causar lesiones graves

a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

e protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

d

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

elante y por el costado. NOTA: Las gafas o caretas sin protección lateral por sí solas no

d

an una protección adecuada.

d

ARA PREVENIR LESIONES ACCIDENTALES:

P

• Nunca coloque la mano ni ninguna parte del cuerpo en el área de descarga de

la herramienta mientras el suministro de aire esté conectado.

• Nunca apunte la herramienta hacia ninguna persona. • Nunca participe en juegos rudos.

Nunca jale de la palanca de accionamiento ni la presione a menos que la boca de la

•

herramienta esté apuntando hacia el objeto sobre el que se está trabajando.

• Siempre manipule la herramienta con cuidado.

• No presione la palanca de accionamiento mientras carga la herramienta.

CUADRO DE AJUSTE DE LA HERRAMIENTA

LONGITUDES

DE LAS GRAPAS

POSICIÓN DE

MARCACIÓN

5/8" (15mm) 3/4" (19mm)

S

L

L

S

ADJUSTING THE BTFP12180/BTFP12181

SELECTOR DE GRAPAS (TODOS LOS MODELOS) (FIG. 1)

Para ajustar la herramienta para patas de distinta longitud, afloje el tornillo de fijación (A)

y gire el dial 180° (B) con un destornillador a la posición deseada, según lo indicado en

las tablas en el frente de este manual. Ajuste el tornillo de fijación.

CARGA DE LA HERRAMIENTA - BTFP12180/BTFP12181

A) Jale del empujador hasta el final del cargador. (Fig. 2)

B) Verifique la longitud de las patas de las grapas: Se provee un

ajuste para grapas con patas de distintas longitudes (ver la sección

siguiente).different staple leg lengths (see section below).

C) Insert 2 sticks of staples into the channel and gently release the

pusher against the staples. (Fig 3)

AJUSTE DEL REMACHE - BTFP12180/BTFP12181 (FIG. 4)

Gire la tuerca especial (A) a través de la ventana en sentido horario para ajustar el remache, y en sentido

antihorario para aflojar el remache. Utilice una herramienta de 3 mm (1/8 in) para el ajuste

B

FIG.1

A

FIG.2

FIG.3

FIG.4

-8-

Page 9

USO DE BTFP12180/BTFP12181

S

L

4

USO DE LA HERRAMIENTA

Sostenga la palanca de accionamiento con una mano y ubique la otra

mano sobre la herramienta o sostenga la manija secundaria fija si está

nstalada. Ubique la engrapadora sobre la caja alineada con el lugar

i

onde quiere colocar la grapa. Hay un pequeño saliente a un lado del

d

marco como ayuda para ubicar la posición de la grapa. (FIG. 5) Apriete

irmemente hacia abajo y suelte. Mueva la máquina a la próxima posición

f

repita el procedimiento. Se consigue un cierre más fuerte engrapando

y

cerca del borde de la caja. Verifique los requisitos de empaque. Controle

que las grapas se agarren usando muestras del cartón a engrapar. El remache de las grapas puede

justarse de manera fácil e instantánea. Debe aprovecharse al máximo esta posibilidad.

a

REMOCIÓN DE GRAPAS ATASCADAS BTFP12180/BTFP12181

Remove the remaining stick from the magazine. Pry jam

release forward with a screw driver (FIG.6). Remove magazine.

Clear the jam and re-insert the magazine. Pry jam release shut (FIG.7).

MANIJA SECUNDARIA - BTFP12180/BTFP12181

Estos modelos vienen con una manija adicional para colocar en la parte

superior de la herramienta. Para colocarla, ubique la manija como se

muestra (FIG. 8) e inserte y ajuste los 4 tornillos suministrados.

FIG.5

FIG.6

FIG.7

FIG.8

ADEMÁS DE LAS OTRAS ADVERTENCIAS CONTENIDAS EN ESTE MANUAL

OBSERVE LO SIGUIENTE PARA LA OPERACIÓN SEGURA

• Use la herramienta BOSTITCH solamente para el fin que fue diseñada.

• Nunca use esta herramienta de tal modo que pueda causar la salida de una fijación hacia el usuario u otros

presentes en el área de trabajo.

• No use la herramienta como martillo.

• Siempre lleve la herramienta tomándola por la empuñadura.

• No altere ni modifique el diseño o función original de esta herramienta sin la aprobación de BOSTITCH, INC.

• Siempre tenga presente que el uso indebido o la manipulación incorrecta de esta herramienta puede causarle

lesiones a usted y a los demás.

• Nunca deje la herramienta desatendida.

• No opere esta herramienta si no cuenta con una ETIQUETA DE ADVERTENCIA legible.

• No continúe usando una herramienta si no funciona correctamente. Notifique a su representante de BOSTITCH más

cercano si su herramienta sigue teniendo problemas de funcionamiento.

MANTENIMIENTO DE LA HERRAMIENTA

Cuando trabaje sobre herramientas Bostitch, tenga en cuenta las advertencias de este

manual y tenga especial cuidado al evaluar herramientas problemáticas.

PIEZAS DE REPUESTO:

Se recomienda usar repuestos BOSTITCH. No use piezas modificadas ni componentes que no tengan un rendimiento

equivalente al equipo original.

-9-

Page 10

INTRODUCTION

Les agrafeuses des gammes BTFP21820 et BTFP2181de Bostitch sont des outils de précision conçus pour l'agrafage

neumatique. Ces outils vous donneront un rendement efficace et fiable lorsqu’utilisés correctement et avec soin. Comme

p

pour tout outil de précision, il est important de suivre les instructions du fabricant afin d’obtenir la meilleure performance.

Veuillez étudier ce manuel avant d'utiliser l'outil et comprendre les avertissements et les mises en garde de sécurité. Les

nstructions ayant trait à l’installation, le fonctionnement et l’entretien doivent être lues attentivement et les manuels doivent être

i

conservés pour référence. REMARQUE : Des mesures de sécurité additionnelles peuvent être requises en fonction de

l’utilisation que vous faites de l’outil. Contactez votre représentant ou distributeur Bostitch pour toute question concernant

’outil et son utilisation. Stanley Fastening Systems, L.P., East Greenwich, Rhode Island 02818, É.-U.

l

INDEX

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Caractéristiques techniques de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

hargement de la BTFP2180/BTFP2181 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-27

C

Vérification du fonctionnement de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Entretien de l'outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

REMARQUE :

Les outils Bostitch ont été fabriqués afin d'offrir un degré de satisfaction de la clientèle très élevé et sont conçus pour atteindre

ne performance maximale lorsqu’utilisés avec les attaches Bostitch de précision fabriquées avec les mêmes normes élevées.

u

Bostitch ne peut être tenu responsable de la performance du produit si les outils sont utilisés avec des attaches ou

des accessoires ne répondant pas aux exigences strictes établies pour les clous, agrafes et accessoires d’origine

Bostitch.

GARANTIE LIMITÉE

Stanley Fastening Systems, L.P. (“Bostitch”) garantit à l’acheteur au détail original que ce produit est exempt de défaut de

matériaux et de main-d’œuvre, et accepte de réparer ou de remplacer, à la discrétion de Bostitch, tout produit défectueux dans

l'année suivant la date d’achat. La présente garantie est incessible. Elle couvre uniquement les dommages résultant de défauts

de matériau ou de main-d’œuvre, et ne couvre pas les conditions ou les mauvais fonctionnements découlant de l’usure

normale, la négligence, l’abus, les accidents ou les tentatives de réparation effectuées par quelqu'un d'autre que notre centre

de réparation régional ou un centre de service de garantie autorisé. Les lames du chasse-attache, les pinces et les joints

toriques sont normalement considérés comme des pièces d’usure.

LA PRÉSENTE GARANTIE REMPLACE TOUTES LES AUTRES GARANTIES EXPLICITES. TOUTE GARANTIE DE

QUALITÉ MARCHANDE ET D’ADÉQUATION POUR UNE UTILISATION PRÉCISE EST LIMITÉE À LA DURÉE DE LA

PRÉSENTE GARANTIE. BOSTITCH NE SERA PAS TENU RESPONSABLE DE QUELQUE DOMMAGE ACCESSOIRE OU

IMMATÉRIEL QUE CE SOIT.

La présente garantie est limitée aux produits vendus aux États-Unis et au Canada. Certains territoires ne permettent pas de

limitation de la durée d’une garantie tacite ni l’exclusion de dommages accessoires ou immatériels, de sorte que la limitation

ou l’exclusion pourrait ne pas s’appliquer à vous La présente garantie vous donne des droits légaux spécifiques et vous

pourriez aussi bénéficier d'autres droits variant d'un territoire à l'autre et d’un pays à l’autre.

Pour obtenir le service de garantie aux É.-U., faites parvenir le produit à vos frais avec la preuve d'achat à un centre de service

de garantie Bostitch ou autorisé dans votre région. Vous pouvez nous appeler au 1-800-556-6696 pour connaître

l’emplacement des centres de réparation autorisés de votre région.

-10-

Page 11

CONSIGNES DE SÉCURITÉ

ES LUNETTES DE SÉCURITÉ se conformant aux normes ANSI et qui protègent des

D

particules projetées du côté FRONTAL ainsi que du côté LATÉRAL doivent TOUJOURS être

portées par l’opérateur et toute autre personnes se trouvant dans la zone de travail lors

’une connexion à l’alimentation d'air, du chargement, du fonctionnement ou de l’entretien

d

de cet outil. Une telle protection des yeux est indispensable pour vous protéger contre les

ttaches et débris projetés, susceptibles de causer des blessures sérieuses.

a

L’employeur et/ou l’utilisateur doivent s’assurer que les lunettes de sécurité appropriées

sont portées. L’équipement de protection des yeux doit être conforme à la norme ANSI

87.1 et fournir une protection frontale et latérale. REMARQUE : Les lunettes sans

Z

protection latérale et les masques faciaux ne fournissent pas la protection nécessaire.

ATTENTION : Des articles de sécurité additionnels devront être portés dans certains

nvironnements. Par exemple, la zone de travail peut comporter une exposition à un niveau

e

de bruit qui pourrait causer une diminution de l'acuité auditive. L’employeur et l’utilisateur

oivent s’assurer qu’une protection de l'ouïe est fournie et utilisée par l'opérateur et toute

d

autre personne dans la zone de travail. Certains environnements nécessiteront l’utilisation

d’équipement de protection de la tête. Lorsque requis, l’employeur et l’utilisateur doivent

s’assurer qu’une protection de la tête se conformant à la norme ANSI Z89.1 est utilisée.

CHARGEMENT DE L’OUTIL

Au moment de charger l’outil : 1.) Ne placez jamais la main ou toute autre partie du corps

dans la région de décharge d’attache de l'outil; 2.) Ne dirigez jamais l’outil vers quelqu’un;

3.) N'appuyez pas sur la gâchette pour éviter un déclenchement accidentel et la possibilité

de blessures.

FONCTIONNEMENT

Veillez à toujours manipuler l’outil avec précaution : 1.) Ne vous chahutez jamais;

2.) N'appuyez jamais sur le levier d'enclenchement sans que le nez ne soit directement

positionné vers l'article à agrafer; 3.) Maintenez les autres à une distance sécuritaire alors

que l’outil fonctionne puisqu’il pourrait être actionné accidentellement et causer des

blessures.

Ne placez jamais la main ou le corps dans la zone de décharge de l'outil.

Ne tirez pas d’attache sur une autre attache ou alors que l’outil est à un trop grand angle,

car cela peut causer une déflexion de l’attache et causer des blessures.

La agrafeuse produit des ÉTINCELLES pendant le fonctionnement. NE JAMAIS utiliser la

agrafeuse près de substances, gaz ou vapeurs inflammables, y compris : laque, peinture, benzène,

solvant, essence, adhésifs, mastics, colles ou tous autres produits qui sont, eux ou leurs vapeurs,

brumes ou produits dérivés, inflammables, combustibles ou explosifs. L’utilisation de la agrafeuse

dans un tel environnement pourrait mener à une EXPLOSION pouvant causer des blessures ou

le décès de l’utilisateur ou de personnes à proximité.

ENTRETIEN DE L’OUTIL

Prenez note des avertissements de ce manuel lorsque vous travaillez avec des outils

pneumatiques et prenez toutes les précautions possibles lorsque vous examinez les outils

à problèmes.

CARACTÉRISTIQUES TECHNIQUES DE L’OUTIL

BTFP12180/BTFP12181

Toutes les vis et tous les écrous sont métriques.

MODÈLE LONGUEUR HAUTEUR LARGEUR POIDS

BTFP12180 433 mm (17,05 po) 220 mm (8,66 po) 115 mm (4,53 po) 2,2 kg (4,9 lb)

BTFP12181 433 mm (17,05 po) 220 mm (8,66 po) 115 mm (4,53 po) 2,2 kg (4,9 lb)

CARACTÉRISTIQUES TECHNIQUES DES ATTACHES :

MODÈLE ATTACHES

BTFP12180 B58C / B34C

SW7437

BTFP12181

SW9040

Attaches de 22 mm (7/8 po) nécessitant des pinces à sertir plus profondes

DIMENSION

DU FIL

.074” x .037”

(1.88 x 94mm)

.074” x .037”

(1.88 x 94mm)

.090” x .040”

(2.29 x 1.02mm)

LARGEUR DE

COURONNE

-11-

1-1/4”

(32mm)

1-3/8”

(35mm)

1-3/8”

(35mm)

PORTÉE DE

L'ATTACHE

5/8” - 3/4”

(15-19mm)

5/8” - 3/4”

(15-19mm)

5/8” - 7/8”*

(15-22mm)

Page 12

CHARGEMENT DE LA BTFP12180/BTFP12181

DES LUNETTES DE SÉCURITÉ se conformant aux normes ANSI et qui protègent des

particules projetées du côté FRONTAL ainsi que du côté LATÉRAL doivent TOUJOURS être

portées par l’opérateur et toute autre personnes se trouvant dans la zone de travail lors

’une connexion à l’alimentation d'air, du chargement, du fonctionnement ou de l’entretien

d

e cet outil. Une telle protection des yeux est indispensable pour vous protéger contre les

d

attaches et débris projetés, susceptibles de causer des blessures sérieuses.

’employeur et/ou l’utilisateur doivent s’assurer que les lunettes de sécurité appropriées

L

sont portées. L’équipement de protection des yeux doit être conforme à la norme ANSI

Z87.1 et fournir une protection frontale et latérale. REMARQUE : Les lunettes sans

protection latérale et les masques faciaux ne fournissent pas la protection nécessaire.

AFIN DE PRÉVENIR LES BLESSURES ACCIDENTELLES :

• Ne placez jamais la main ou toute autre partie du corps dans la zone de décharge de clou

de l'outil alors que l’alimentation d’air est connectée.

• Ne dirigez jamais l’outil vers une autre personne. • Ne vous chahutez jamais.

• N'appuyez jamais sur le levier d'enclenchement sans que le nez ne soit directement

ositionné vers l'article à agrafer.

p

Veillez à toujours manipuler l’outil avec précaution.

•

• N'appuyez pas sur le levier d'enclenchement pendant que vous chargez l'outil.

• Do not depress the actuating lever while loading the tool.

TABLEAU DE RÉGLAGES DE L'OUTIL

LONGUEURS

DES ATTACHES

POSITION DE

COMMANDE

5/8" (15mm) 3/4" (19mm)

S

L

L

S

RÉGLAGE DES MODÈLES BTFP12180 et PTFP12181

SÉLECTEUR D'AGRAFES (TOUS LES MODÈLES) (FIG. 1)

Pour régler l'outil selon les longueurs différentes de pointes, dévissez la vis de réglage (A) et tournez

le cadran sur 180° (B) avec un tournevis à la position désirée comme indiqué aux tableaux au début de

ce manuel. Serrez la vis de réglage.

CHARGEMENT DE L'OUTIL - BTFP12180/BTFP12181

A) Tirez le poussoir vers l'arrière du magasin. (Fig. 2)

B) Vérification de la longueur de la pointe d'agrafe : Le réglage est

fourni pour plusieurs longueurs de pointe d'agrafe (voir la section

cidessous).different staple leg lengths (see section below).

C) Insérez 2 bandes d'agrafes dans la coulisse et relâchez doucement

le poussoir contre les agrafes. (Fig. 3)

RÉGLAGE DE L'ENCLUME - BTFP12180 ET PTFP12181 (FIG. 4)

Tournez le boulon spécial (A) par la fenêtre dans le sens des aiguilles d'une montre pour serrer l'enclume

ou dans le sens contraire des aiguilles d'une montre pour augmenter l'espace. Utilisez un outil pour

adapter à 3 mm (1/8 po).

B

A

FIG.1

FIG.2

FIG.3

FIG.4

--12

Page 13

FONCTIONNEMENT POUR BTFP12180 et PTFP12181

S

L

4

FONCTIONNEMENT DE L'OUTIL

Tenez le levier d'enclenchement avec une main et placez l'autre main sur

le dessus de l'outil ou tenez la deuxième poignée si elle est installée.

ositionnez sur la boite et alignez selon l'emplacement de l'agrafe désiré.

P

n petit point de repère situé de chaque côté du boitier est installé pour

U

vous aider à positionner l'agrafe. (FIG. 5) Appuyez fermement puis

elâchez. Déplacez l'outil vers la prochaine position de l'agrafe et répétez.

r

es agrafes positionnées à l'extrémité de la boite offriront une fermeture

D

plus solide. Vérifiez les exigences d'emballage. Vérifiez l'exactitude de

l'enclume en utilisant un échantillon de carton de la boite à agrafer. Les réglages de solidité de l'enclume

ont faciles et instantanés - profitez de tous les avantages qu'ils vous offrent.

s

DÉGAGEMENT D'UNE AGRAFE COINCÉE - BTFP12180

ET PTFP12181

Retirez la bande d'agrafes du magasin. Pliez le levier de déblocage

vers l'avant en utilisant un tournevis (FIG. 6) Retirez le magasin. Dégagez

l'agrafe coincée et réinsérez le magasin. Rabaissez le levier de déblocage

(FIG. 7)

FIG.5

POIGNÉE SECONDAIRE - BTFP12180 ET PTFP12181

Ces modèles sont dotés d'une poignée secondaire à installer sur le

FIG.6

dessus de l'outil. Pour installer la poignée, positionnez-la comme montré à la Fig. 8 puis insérez et vissez

la poignée avec les quatre (4) vis fournies.

FIG.7

FIG.8

EN PLUS DES AUTRES AVERTISSEMENTS DU PRÉSENT MANUEL,

OBSERVEZ CEUX QUI SUIVENT POUR UN FONCTIONNEMENT SÉCURITAIRE

• N'utilisez jamais l’outil pneumatique BOSTITCH dans un but autre que celui pour lequel il a été conçu.

• N’utilisez jamais l’outil d’une manière qui pourrait causer l’éjection d’une attache en direction de l’utilisateur

ou d’autres personnes dans la zone de travail.

• N’utilisez jamais l’outil comme un marteau.

• Veillez à toujours transporter l’outil à l’aide de la poignée. Ne transportez jamais l’outil par le tuyau d’air.

• N’altérez pas ni ne modifiez la conception ou la fonction originales de l'outil sans en recevoir l'autorisation de

BOSTITCH, INC.

• Gardez toujours présent à l’esprit qu’une utilisation ou une manipulation incorrecte de cet outil sont susceptibles

d’occasionner des blessures à vous-même et à d’autres personnes.

• Ne laissez jamais un outil sans surveillance.

• Ne faites pas fonctionner l’outil s’il ne comporte pas une ÉTIQUETTE D’AVERTISSEMENT lisible.

• Cessez d'utiliser un outil qui ne fonctionne pas correctement. Avisez votre représentant BOSTITCH le plus proche si

votre outil continue de mal fonctionner.

ENTRETIEN DE L’OUTIL

Prenez note des avertissements de ce manuel lorsque vous travaillez avec des outils

pneumatiques et prenez toutes les précautions possibles lorsque vous examinez les outils

PIÈCES DE RECHANGE :

Nous recommandons les pièces de rechange BOSTITCH. N’utilisez pas de pièces modifiées ou ne fournissant pas une

performance équivalente à celle de l’équipement d’origine.

à problèmes.

-13-

Loading...

Loading...