Page 1

www.BOSTITCH.com

Instruction manual

Manuel d’instructions

Manual de’instrucciones

BTE360

8.5 A

Orbital Reciprocating Saw

Scie alternative à action orbitale

Sierra alternativa de acción orbital

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA:

LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Page 2

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION: Indicates a potentially haz ard ous situation which, if not avoided, may

result in minor or mod er ate injury.

NOTICE: Used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

General Power Tool Safety Warnings

WARNING: Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground

fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, nonskid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position before

connecting to power source and/ or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench

or a key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

2

Page 3

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your application. The

correct power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended

could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Specific Safety Rules

• Hold power tool by insulated gripping surfaces, when performing an operation

where the cutting accessory may contact hidden wiring. Cutting accessory

contacting a “live” wire may make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

• Use clamps or another practical way to secure and support the workpiece to a

stable platform. Holding the work by hand or against your body leaves it unstable and

may lead to loss of control.

• Keep hands away from cutting area. Never reach underneath the material for any

reason. Hold front of saw by grasping the contoured gripping area. Do not insert

fingers or thumb into the vicinity of the reciprocating blade and blade clamp. Do not

stabilize the saw by gripping the shoe.

• Keep blades sharp. Dull blades may cause the saw to swerve or stall under pressure.

• Use extra caution when cutting overhead and pay particular attention to overhead

wires which may be hidden from view. Anticipate the path of falling branches and

debris ahead of time.

• When cutting pipe or conduit ensure that they are free from water, electrical

wiring, etc.

• Hold saw firmly with both hands for all cutting operations. During cutting

operations, the blade may suddenly bind in the work and may cause the saw to

kickback towards the operator.

WARNING: Always wear proper personal hearing protection that conforms

to ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

3

Page 4

WARNING: Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• leadfromlead-basedpaints,

• crystallinesilicafrombricksandcementandothermasonryproducts,and

• arsenicandchromiumfromchemically-treatedlumber.

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are specially designed to filter

out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or

lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may

cause serious and permanent respiratory or other injury. Always use NIOSH/

OSHA approved respiratory protection appropriate for the dust exposure. Direct

particles away from face and body.

WARNING: Do not operate this tool for long periods of time. Vibration caused by

the operating action of this tool may cause permanent injury to fingers, hands, and arms.

Use gloves to provide extra cushion, take frequent rest periods, and limit daily time of use.

SYMBOLS

• The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V ..................volts A ...................amperes

Hz ................hertz W .................. watts

min ..............minutes

............direct current

................Class I Construction .................earthing terminal

(grounded)

................Class II Construction …/min ..........revolutions or reciprocation

(double insulated) per minute

...........

Read instruction manual before use

................Use proper eye protection ..................

................alternating current

n

o .................no load speed

.................safety alert symbol

................

Use proper respiratory protection

Use proper hearing protection

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means

your tool will operate on standard 60 Hz household power. Do not operate AC tools on

DC. A rating of 120 volts AC/DC means that your tool will operate on standard 60 Hz

AC or DC power. This information is printed on the nameplate. Lower voltage will cause

loss of power and can result in over-heating. All Bostitch tools are factory-tested; if this

tool does not operate, check the power supply.

Extension Cord

When using an extension cord,

be sure to use one heavy

enough to carry the current your

product will draw. An undersized

cord will cause a drop in line

voltage resulting in loss of power

and overheating. The following

table shows the correct size to

use depending on cord length

and nameplate ampere rating.

If in doubt, use the next heavier

gage. The smaller the gauge

number, the heavier the cord.

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gauge

Than Than

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Minimum Gauge for Cord Sets

4

Page 5

SAVE THESE INSTRUCTIONS

E

F

G

D

Functional Description

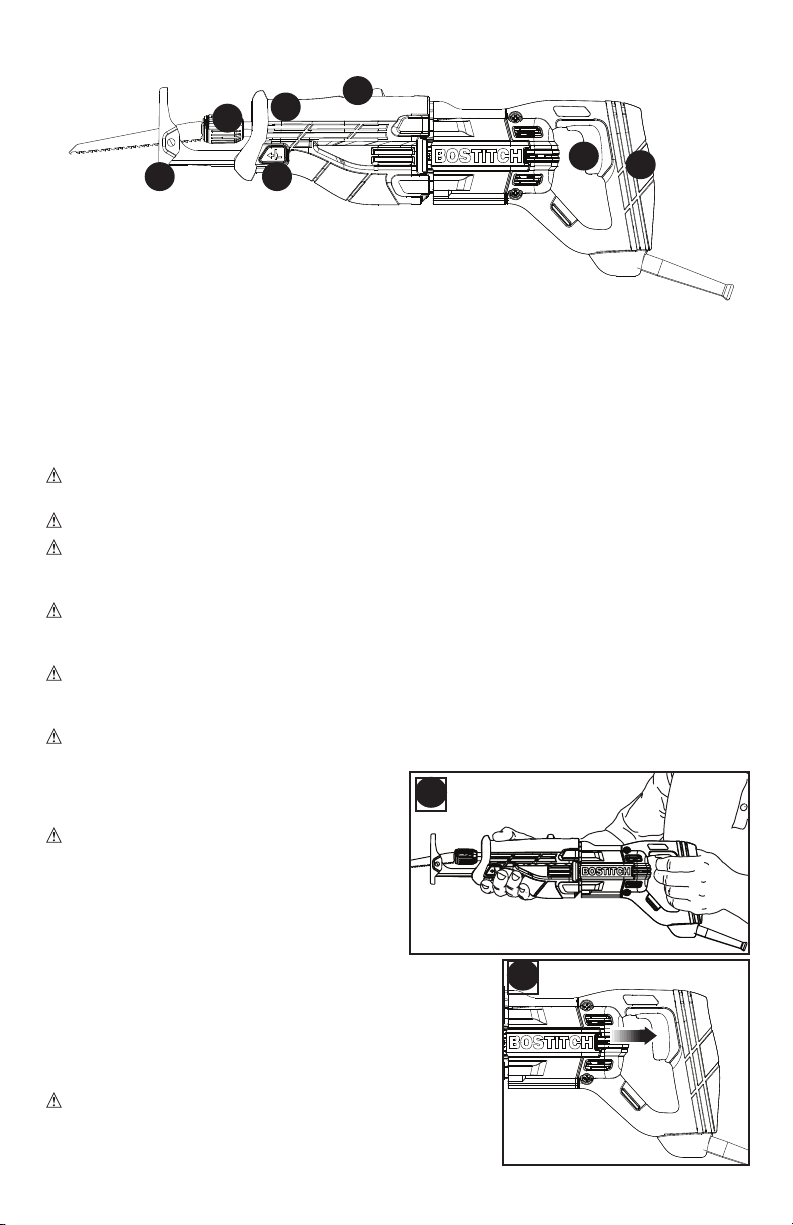

A. Trigger Switch E. Secondary Gripping Handle

B. Main Handle F. Blade Clamp

C. Orbital Action Selector G. Adjustable Shoe

D. Adjustable Shoe Button

OPERATION/SET-UP

WARNING: CUT HAZARD. Turn off and disconnect tool from power source before

making any adjustments or removing or installing attachments or accessories.

WARNING: Hold saw firmly with both hands for all cutting operations.

WARNING: Inspect work area for hidden electrical wiring, gas pipes or water pipes

before making blind or plunge cuts. Failure to do so may result in electrical shock, fire,

explosion, or property damage.

WARNING: CUT HAZARD. Blade breakage may occur if the blade does not extend

past the shoe and the workpiece during the cut. Increased risk of personal injury, as well

as damage to the shoe and workpiece may result.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

WARNING:

anchored or clamped to prevent slipping.

• Switch on saw motor before applying

pressure.

• Place blade lightly against work to be cut.

CUT HAZARD. Before cutting any type of material, be sure it is firmly

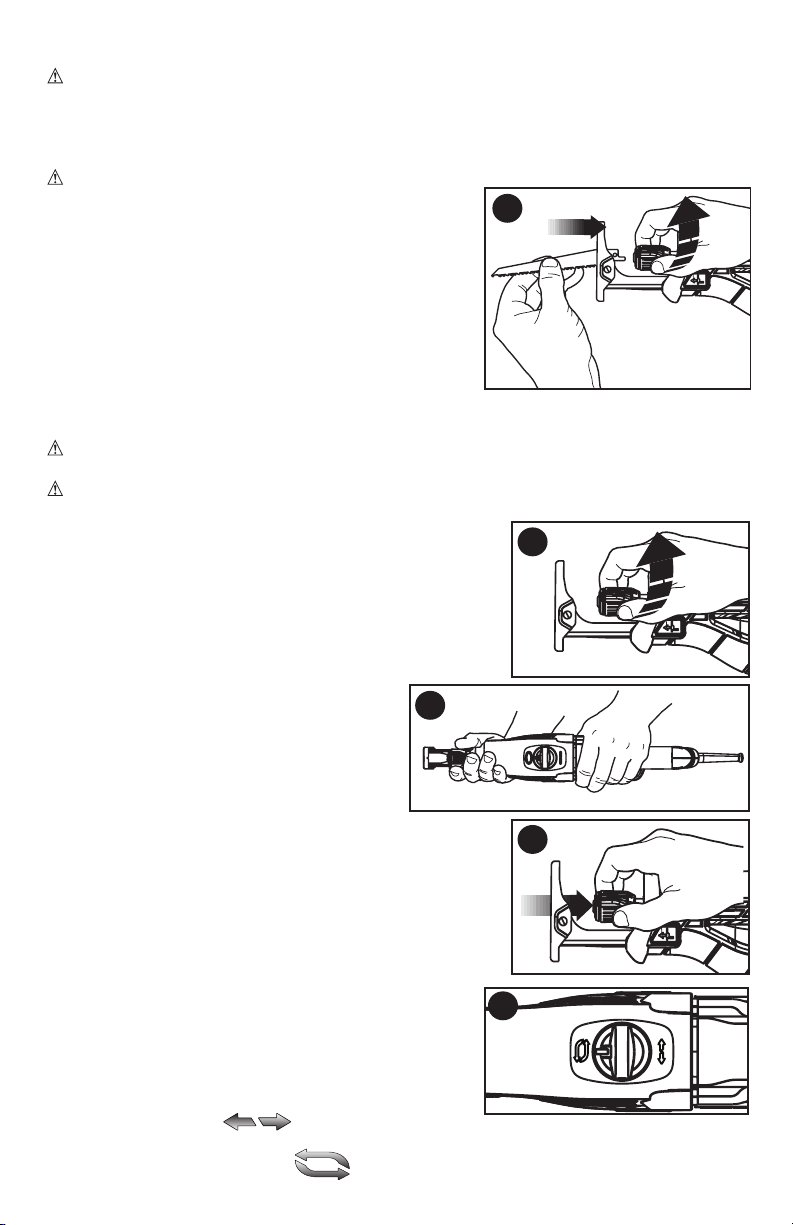

WARNING: CUT HAZARD. Never

hold and use the product with your fingers

wrapped around shoe adjustment button.

Always hold saw firmly with both hands while

cutting as shown in Figure 1. Whenever

possible, the saw shoe must be held firmly

against the material being cut. This will

prevent the saw from jumping or vibrating and

minimize blade breakage.

C

A

B

1

2

VARIABLE SPEED SWITCH (FIGURE 2)

The variable speed trigger switch will give you added

versatility. The further the trigger is depressed the higher the

speed of the saw. To turn the tool “OFF” release the trigger.

WARNING: CUT HAZARD. This tool has no

provision to lock the switch in the ON position, and should

never be locked in the ON position by any other means.

5

Page 6

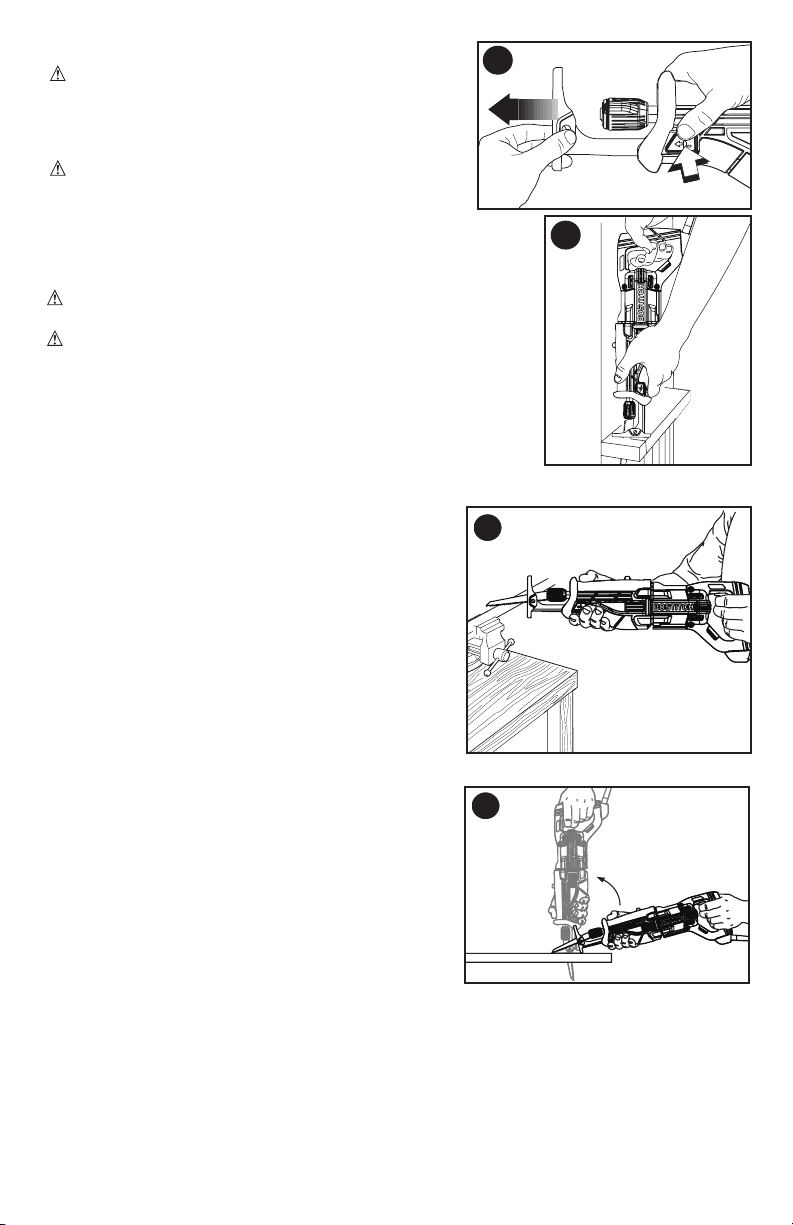

BLADE INSTALLATION AND REMOVAL (FIGURE 3)

WARNING: CUT HAZARD. Turn off and disconnect tool from power source

before making any adjustments or removing or installing attachments or accessories.

The blade should extend past the shoe and the thickness of the workpiece during the

cut. Select the blade best suitable for the material to be cut and use the shortest blade

suitable for the thickness of the material. Do not use jigsaw blades with this tool.

WARNING: CUT HAZARD. Blade breakage

may occur if the blade does not extend past the shoe

and the workpiece during the cut. Increased risk of

personal injury, as well as damage to the shoe and

workpiece may result.

TO INSTALL BLADE INTO SAW

1. Point tool away from body.

2. Rotate blade clamp collar in the direction shown in

figure 3.

3. Insert blade shank fully into blade clamp collar.

4. Release blade clamp collar to lock blade into position.

NOTE: Blade can be installed with the teeth up to

assist in flush-to cutting.

TO REMOVE BLADE FROM SAW

3

WARNING: CUT HAZARD. Turn off and disconnect tool from power source

before making any adjustments or removing or installing attachments or accessories.

WARNING: Burn hazard. Do not touch the blade immediately after use. Contact

with the blade may result in personal injury.

1. Rotate blade clamp collar to release position.

2. Remove blade.

TO REMOVE A BROKEN BLADE

If the blade breaks so that the broken piece is caught

inside the clamp, take the following steps to remove the

remainder of the blade from the saw.

1. Rotate blade clamp collar clockwise as viewed from the

back of the saw and hold in place (Figure 4).

2. Turn the saw on its left side as viewed

from the back of the saw (Figure 5).

3a. If the blade has broken inside the

clamp, slide a flat object into the opening of

the clamp

remove the flat object. This will disengage the

pin inside the clamp.

3b. If the blade has broken outside the

clamp, slide a flat object into the opening of the clamp

(Figure 6)

remove the flat object. This will disengage the pin inside

the clamp.

4. While still holding the clamp collar open and the saw

on its side, face the clamp opening down and shake until

the broken blade falls out.

(Figure 6)

to the left of the blade as far as it can go, then

as far as it can go, then

5

4

6

ORBITAL ACTION SELECTOR (FIGURE 7)

BTE360 has dual blade motion: straight reciprocating

motion or orbital motion.

Straight reciprocating motion is used for all metal

cutting operations and for wood cutting applications

where finish is more important than speed. To set the

saw for straight reciprocating motion, turn the selector

to the position marked

Orbital motion is used for fast cutting of wood. To set the saw for orbital action, turn the

selector to the position marked

6

7

Page 7

ADJUSTABLE SHOE - (FIGURE 8)

WARNING: CUT HAZARD. Blade breakage

may occur if the blade does not extend past the

shoe and the workpiece during the cut. Increased

risk of personal injury, as well as damage to the

shoe and workpiece may result.

8

WARNING: CUT HAZARD. Turn off and

disconnect tool from power source before making

any adjustments or removing or installing

attachments or accessories.

• The shoe will adjust to limit the depth of cut. Push the

button (shown in Figure 8) on the hand grip and slide the

shoe out to the desired depth and release the button.

9

CAUTION: CUT HAZARD. To prevent loss of control,

never use tool without shoe.

CAUTION: RISK OF PERSONAL INJURY AND

PROPERTY DAMAGE. Ensure the shoe is locked into

position before using tool.

FLUSH CUTTING (FIGURE 9)

• The compact design of the recipro cating saw motor housing

and pivoting shoe permit close cutting to floors, corners and

other difficult areas.

• To maximize flush cutting capabilities, insert the blade shaft

into the blade clamp with the teeth of the blade facing up.

• Turn the saw upside down so you are as close to

the work surface as possible.

METAL CUTTING (FIGURE 10)

• Use a finer blade for ferrous metals and a coarse

blade for non-ferrous materials.

• In thin gauge sheet metals it is best to clamp

wood to the underside of the sheet. This will

ensure a clean cut without excess vibration or

tearing of metal.

• Avoid forcing cutting blade as this reduces blade

life and causes costly blade breakage.

NOTE: Spread a thin film of oil or other coolant

along the line ahead of the saw cut for easier

operation and longer blade life.

POCKET CUTTING - WOOD ONLY (FIGURE 11)

• Measure the surface area to be cut and mark

clearly with a pencil, chalk or scriber.

• Insert blade in blade clamp and tighten blade

clamp securely.

• Tip the saw backward until the back edge of the

shoe is resting on the work surface and the fully

extended moving blade will clear the surface.

• Grip unit with both hands, switch motor on

permitting blade to obtain maximum speed.

• Begin a slow, deliberate upward swing with the

main handle of the saw.

• The blade will begin to feed into material. Always

be sure blade is completely through material before continuing with pocket cut.

NOTE: In areas where blade visibility is limited, use the edge of the shoe as a guide.

PROJECT TIPS

• Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor

while cutting.

• When cutting, always ensure that the shoe is held firmly against the workpiece and

the workpiece is secured from moving/deflecting. This will improve operator control

and minimize vibration.

• For longer blade life, use bi-metal blades. These utilize a carbon steel back welded

to high speed steel teeth making the blade more flexible and less prone to breaking.

10

11

7

Page 8

Problem Possible Cause Possible Solution

TROUBLESHOOTING

• Unit will not start. • Cord not plugged in. • Plug tool into a working outlet.

• Circuit fuse is blown. • Replace circuit fuse. (If the

product repeatedly causes the

circuit fuse to blow, discontinue

use immediately and have it

serviced at a Bostitch

service center or authorized

servicer.)

• Circuit breaker is tripped. • Reset circuit breaker. (If the

product repeatedly causes the

circuit breaker to trip,

discontinue use immediately

and have it serviced at a

Bostitch service center or

authorized servicer.)

• Cord or switch is damaged. • Have cord or switch replaced

at a Bostitch Service

Center or Authorized Servicer

• Broken blade stuck • Broken blade is held in place • Follow the steps under “To

inside clamp. by pin inside clamp. Remove a Broken Blade” to

disengage pin.

For assistance with your product, visit our website at www.bostitch.com. for a list of

service centers, or call the Bostitch Customer Care Center at (800) 262-2161.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service

website at www.bostitch.com. You can also order parts from your nearest Bostitch

Factory Service Center or Bostitch Authorized Warranty Service Center. Or, you can

call our Customer Care Center at (800) 262 2161.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information

about Bostitch, its factory service centers or authorized warranty

8

Page 9

service centers, visit our website at www.

at (800) 262 2161. All repairs made by our service centers are fully guaranteed against

defective material and workmanship. We cannot guarantee repairs made or attempted by

others.

You can also write to us for information at Bostitch, 701 E. Joppa Road, Towson,

Maryland 21286 - Attention: Product Service. Be sure to include all of the information

shown on the nameplate of your tool (model number, type, serial number, etc.).

bostitch

.com or call our Customer Care Center

ACCESSORIES

WARNING: Since accessories, other than those offered by Bostitch have not been

tested with this product, use of such accessories with this tool could be hazardous. To

reduce the risk of injury, only Bostitch recommended accessories should be used with

this product.

A complete line of accessories is available from your Bostitch Factory Service Center or

a Bostitch Authorized Warranty Service Center. Please visit our Web Site

www.bostitch.com for a catalog or for the name of your nearest supplier.

THREE YEAR LIMITED WARRANTY

Bostitch will repair or replace, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase for tools (two years for batteries).

This warranty does not cover part failure due to normal wear or tool abuse. For further detail

of warranty coverage and warranty repair information, visit www.

262-2161. This warranty does not apply to accessories or damage caused where repairs

have been made or attempted by others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states or provinces.

In addition to the warranty, Bostitch tools are covered by our: 1 YEAR FREE SERVICE:

Bostitch will maintain the tool and replace worn parts caused by normal use, for free,

any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your Bostitch Power Tool for any reason, you can return it within 90 days

from the date of purchase with a receipt for a full refund – no questions asked.

bostitch

.com or call (800)

Imported by Bostitch

701 E. Joppa Road

Towson, Maryland 21286

9

Page 10

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

www.BOSTITCH.com

products sold in Latin America, see country specific warranty information contained in

the packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www.bostitch.com

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (800) 262-2161 for a free replacement.

Manuel d’instructions

BTE360

8.5A

Scie alternative à action orbitale

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il

contient concernent VOTRE SÉCURITÉ et visent à ÉVITER TOUT PROBLÈME. Les

symboles ci-dessous servent à vous aider à reconnaître cette information.

DANGER : Indique une situation dangereuse imminente qui, si elle n’est pas évitée,

causera la mort ou des graves blessures.

AVERTISSEMENT : Indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, pourrait causer la mort ou de graves blessures.

MISE EN GARDE : Indique une situation potentiellement dangereuse qui, si elle

n’est pas évitée, pourrait causer des blessures mineures ou modérées.

AVIS : Utilisé sans le symbole d’alerte à la sécurité, indique une

situationvpotentiellement dangereuse qui, si elle n’est pas évitée, peut résulter en des

dommages à la propriété.

10

Page 11

Avertissements de sécurité généraux pour les outils électriques

AVERTISSEMENT : Lire tous les avertissements de sécurité et toutes

les directives. Le non-respect des avertissements et des directives pourrait se

solder par un choc électrique, un incendie et/ou une blessure grave.

Conserver tous les avertissements et toutes les directives pour un usage ultérieur.

Le terme «outil électrique» cité dans les avertissements se rapporte à votre

outil électrique à alimentation sur secteur (avec fil) ou par piles (sans fil).

1) Sécurité du lieu de travail

a) Tenir la zone de travail propre et bien éclairée. Les endroits sombres sont

souvent des causes d’accidents.

b) Ne pas faire fonctionner d’outils électriques dans un milieu déflagrant, soit en

présence de liquides inflammables, de gaz ou de poussière. Les outils

électriques produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

c) Éloigner les enfants et les curieux au moment d’utiliser un outil électrique.

Une distraction pourrait vous en faire perdre la maîtrise.

2) Sécurité en matière d’électricité

a) Les fiches des outils électriques doivent correspondre à la prise. Ne jamais

modifier la fiche en aucune façon. Ne jamais utiliser de fiche d’adaptation avec

un outil électrique mis à la terre. Le risque de choc électrique sera réduit par

l’utilisation de fiches non modifiées correspondant à la prise.

b) Éviter tout contact physique avec des surfaces mises à la terre comme des

tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc

électrique est plus élevé si votre corps est mis à la terre.

c) Ne pas exposer les outils électriques à la pluie ou à d’autres conditions où il

pourrait être mouillé. La pénétration de l’eau dans un outil électrique augmente le

risque de choc électrique.

d) Ne pas utiliser abusivement le cordon d’alimentation. Ne jamais utiliser le

cordon pour transporter, tirer ou débrancher un outil électrique. Tenir le cordon

éloigné de la chaleur, de l’huile, des bords tranchants ou des pièces mobiles.

Les cordons endommagés ou emmêlés augmentent les risques de choc électrique.

e) Pour l’utilisation d’un outil électrique à l’extérieur, se servir d’une rallonge

convenant à une telle utilisation. L’utilisation d’une rallonge conçue pour

l’extérieur réduit les risques de choc électrique.

f) S’il est impossible d’éviter l’utilisation d’un outil électrique dans un endroit

humide, brancher l’outil dans une prise ou sur un circuit d’alimentation dotés

d’un disjoncteur de fuite à la terre (GFCI). L’utilisation de ce type de disjoncteur

réduit les risques de choc électrique.

3) Sécurité personnelle

a) Être vigilant, surveiller le travail effectué et faire preuve de jugement lorsqu’un outil

électrique est utilisé. Ne pas utiliser d’outil électrique en cas de fatigue ou sous

l’influence de drogues, d’alcool ou de médicaments. Un simple moment d’inattention

en utilisant un outil électrique peut entraîner des blessures corporelles graves.

b) Utiliser des équipements de protection individuelle. Toujours porter une protection

oculaire. L’utilisation d’équipements de protection comme un masque antipoussière, des

chaussures antidérapantes, un casque de sécurité ou des protecteurs auditifs lorsque la

situation le requiert réduira les risques de blessures corporelles.

c) Empêcher les démarrages intempestifs. S’assurer que l’interrupteur se trouve

à la position d’arrêt avant de relier l’outil à une source d’alimentation et/ou

d’insérer un bloc-piles, de ramasser ou de transporter l’outil. Transporter un outil

électrique alors que le doigt repose sur l’interrupteur ou brancher un outil électrique

dont l’interrupteur est à la position de marche risque de provoquer un accident.

d) Retirer toute clé de réglage ou clé standard avant de démarrer l’outil. Une clé

standard ou une clé de réglage attachée à une partie pivotante peut causer des blessures.

e) Ne pas trop tendre les bras. Conserver son équilibre en tout temps. Cela

permet de mieux maîtriser l’outil électrique dans les situations imprévues.

f) S’habiller de manière appropriée. Ne pas porter de vêtements amples ni de

bijoux. Garder les cheveux, les vêtements et les gants à l’écart des pièces

mobiles. Les vêtements amples, les bijoux ou les cheveux longs risquent de rester

coincés dans les pièces mobiles.

g) Si des composants sont fournis pour le raccordement de dispositifs de

dépoussiérage et de ramassage, s’assurer que ceux-ci sont bien raccordés et

11

Page 12

utilisés. L’utilisation d’un dispositif de dépoussiérage peut réduire les dangers

engendrés par les poussières.

4) Utilisation et entretien d’un outil électrique

a) Ne pas forcer un outil électrique. Utiliser l’outil électrique approprié à

l’application. L’outil électrique approprié effectuera un meilleur travail, de façon

plus sûre et à la vitesse pour laquelle il a été conçu.

b) Ne pas utiliser un outil électrique dont l’interrupteur est défectueux. Tout outil

électrique dont l’interrupteur est défectueux est dangereux et doit être réparé.

c) Débrancher la fiche du secteur ou le bloc-piles de l’outil électrique avant de

faire tout réglage ou changement d’accessoire, ou avant de ranger l’outil

électrique. Ces mesures préventives réduisent les risques de démarrage

accidentel de l’outil électrique.

d) Ranger les outils électriques hors de la portée des enfants, et ne permettre

à aucune personne n’étant pas familière avec un outil électrique (ou son

manuel d’instruction) d’utiliser ce dernier. Les outils électriques deviennent

dangereux entre les mains d’utilisateurs inexpérimentés.

e) Entretenir les outils électriques. Vérifier les pièces mobiles pour s’assurer

qu’elles sont bien alignées et tournent librement, qu’elles sont en bon état et

ne sont affectées par aucun trouble susceptible de nuire au bon

fonctionnement de l’outil électrique. En cas de dommage, faire réparer l’outil

électrique avant toute nouvelle utilisation. Beaucoup d’accidents sont causés

par des outils électriques mal entretenus.

f) S’assurer que les outils de coupe sont aiguisés et propres. Les outils de

coupe bien entretenus et affûtés sont moins susceptibles de se coincer et sont

plus faciles à contrôler.

g) Utiliser l’outil électrique, les accessoires, les forets, etc. conformément aux

présentes directives en tenant compte des conditions de travail et du travail à

effectuer. L’utilisation d’un outil électrique pour toute opération autre que celle pour

laquelle il a été conçu est dangereuse.

5) Réparation

a) Faire réparer l’outil électrique par un réparateur professionnel en n’utilisant

que des pièces de rechange identiques. Cela permettra de maintenir une

utilisation sécuritaire de l’outil électrique.

Consignes de sécurité particulières

• Tenez l ‘outil par les surfaces isolées lorsque vous effectuez une opération où

l’accessoire de coupe peut communiquer avec des fils cachés ou son propre

cordon. Le contact avec un fil sous tension peut mettre les parties métalliques de l’outil

sous tension, et pourrait donner à l’opérateur un choc électrique.

• Utiliser des brides de fixation ou un autre dispositif de fixation permettant de fixer

solidement et de soutenir la pièce sur une plateforme stable. Tenir la pièce avec la main

ou contre son corps la rend instable et risque de provoquer une perte de maîtrise de l’outil.

• Tenir fermement la scie des deux mains pour toutes les opérations de coupe.

Il peut arriver, durant les opérations de coupe, que la lame se coince dans la pièce,

causant ainsi un effet de rebond vers l’opérateur.

• Tenir les mains éloignées de la zone de découpe. Ne jamais mettre la main sous le

matériau pour quelque raison que ce soit. Tenir la partie avant de la scie par sa zone de

prise profilée. Ne pas mettre les doigts ou le pouce à proximité de la scie alternative et

du mécanisme de serrage de la lame. Ne pas stabiliser la scie en saisissant la semelle.

• Maintenir les lames affûtées. Les lames émoussées peuvent faire zigzaguer la lame

ou la bloquer sous la pression.

• Être très prudent pour effectuer une coupe au-dessus de votre tête et porter une

attention accrue aux fils en hauteur et aux canalisations de gaz ou d’eau pouvant être

cachés. Prévoir la direction de la chute des branches et de débris.

• Au moment de couper un tuyau ou un conduit, s’assurer qu’ils sont exempts d’eau,

de câblage électrique, etc.

• Ne pas toucher la pièce ni la lame immédiatement après avoir utilisé l’outil. En

effet, elles peuvent devenir très chaudes.

AVERTISSEMENT : TOUJOURS porter des lunettes de sécurité. Les lunettes de

vue ne constituent PAS des lunettes de sécurité. Utiliser également un masque facial

ou anti-poussière si l’opération de découpe génère de la poussière. TOUJOURS

PORTER UN ÉQUIPEMENT DE PROTECTION HOMOLOGUÉ :

•protectionoculaireconformeàlanormeANSIZ87.1(CAN/CSAZ94.3);

12

Page 13

•protectionauditiveANSIS12.6(S3.19);

•protectiondesvoiesrespiratoiresconformesauxnormesNIOSH/OSHA/MSHA.

AVERTISSEMENT : Certains outils électriques, tels que les sableuses, les

scies, les meules, les perceuses ou certains autres outils de construction,

peuvent produire de la poussière contenant des produits chimiques reconnus

par l’État de la Californie comme étant susceptibles d’entraîner le cancer, des

malformations congénitales ou pouvant être nocifs pour le système reproductif.

Parmi ces produits chimiques, on retrouve :

· le plomb dans les peintures à base de plomb,

· la silice cristalline dans les briques et le ciment et autres produits de maçonnerie,

· l’arsenic et le chrome dans le bois de sciage ayant subi un traitement chimique.

Le risque associé à de telles expositions varie selon la fréquence avec laquelle on

effectue ces travaux. Pour réduire l’exposition à de tels produits, il faut travailler dans un

endroit bien aéré et utiliser le matériel de sécurité approprié, tel un masque

anti-poussières spécialement conçu pour filtrer les particules microscopiques.

• Éviter tout contact prolongé avec la poussière soulevée par cet outil ou autres

outils électriques. Porter des vêtements de protection et nettoyer les parties

exposées du corps à l’eau savonneuse. S’assurer de bien se protéger afin d’éviter

d’absorber par la bouche, les yeux ou la peau des produits chimiques nocifs.

AVERTISSEMENT : Cet outil peut produire et répandre de la poussière

susceptible de causer des dommages sérieux et permanents au système

respiratoire. Toujours utiliser un appareil respiratoire anti-poussières approprié approuvé

par le NIOSH ou l’OSHA. Diriger les particules dans le sens opposé du visage et du corps.

AVERTISSEMENT : Toujours porter une protection auditive appropriée

conformément à la norme ANSI S12.6 (S3.19) lors de l’utilisation du produit. Dans

certaines conditions et selon la durée d’utilisation, le bruit émis par ce produit pourrait

contribuer à une perte auditive.

AVERTISSEMENT : Ne pas utiliser cet outil pendant des périodes prolongées.

Les vibrations causées par l’action de fonctionnement de l’outil peuvent blesser en

permanence les doigts, les mains et les bras. Porter des gants pour amortir les

vibrations, faire des pauses fréquentes et limiter le temps d’utilisation quotidien de l’outil.

SYMBOLES

• L’étiquette apposée sur votre outil pourrait comprendre les symboles suivants. Les

symboles et leurs définitions sont indiqués ci-après :

V ................. volts A ............... ampères

Hz ............... hertz W .............. watts

min ..............minutes

ou DC......courant continu

................Construction de classe I

(mis à la terre)

...............

RPM ou .../min..........tours à la minute

.............. Lire le mode d’emploi avant l’utilisation

............Utiliser une protection respiratoire adéquate.

...........Utiliser une protection oculaire adéquate.

............Utiliser une protection auditive adéquate.

MOTEUR

S’assurer que le bloc d’alimentation est compatible avec l’inscription de la plaque

signalétique. 120 volts c.a. signifie seulement que l’outil fonctionnera sur une

alimentation domestique standard de 60 Hz. Ne pas faire fonctionner des outils à

courant alternatif (c.a.) sur un courant continu (c.c.). Un régime nominal de 120 volts

c.a./c.c. signifie que l’outil fonctionnera avec une alimentation standard 60 Hz c.a. ou c.c.

Ce renseignement figure sur la plaque signalétique. Une plus faible tension entraînera

une baisse de régime, ce qui peut entraîner une surchauffe. Tous les outils Bostitch

sont testés en usine; si cet outil ne fonctionne pas, vérifier le bloc d’alimentation.

Construction de classe II ............symbole d´avertissement

13

ou AC.....courant alternatif

n

o ............. sous vide

.............. borne de mise à la minute

Page 14

RALLONGES

L’utilisation d’une rallonge conçue pour l’extérieur réduit les risques de choc électrique.

Lorsque qu’une rallonge électrique est utilisée, s’assurer d’en utiliser une de calibre

suffisamment élevé pour assurer le transport du courant nécessaire au fonctionnement

de votre appareil. Un cordon de calibre inférieur causera une chute de tension de ligne et

donc une perte de puissance et une surchauffe. Le tableau suivant indique le calibre

approprié à utiliser selon la longueur du cordon et l’intensité nominale de la plaque

signalétique. En cas de doute, utiliser le calibre suivant le plus gros. Plus le numéro de

calibre est petit, plus le cordon est lourd.

Tension Longueur totale du cordon en pieds

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Intensité (A)

Au Au Calibre moyen des fils (AWG)

moins plus

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Non recommandé

Calibre minimal des cordons de rallonge

CONSERVER CES DIRECTIVES

E

F

A

G

D

B

Functional Description

C

A. Détente E. Poignée secondaire

B. Poignée principale F. Mécanisme de serrage de lame

C. Sélecteur de mouvement orbital G. Semelle réglable

D. Bouton de la semelle réglable

FONCTIONNEMENT/RÉGLAGE

AVERTISSEMENT : RISQUE DE COUPURE. Arrêter et débrancher l’outil avant

d’effectuer un réglage ou de retirer ou d’installer une pièce ou un accessoire.

AVERTISSEMENT : tenir fermement la scie des deux mains pour toutes les

opérations de coupe.

AVERTISSEMENT : inspecter la zone de travail à la recherche de câblage

électrique et de canalisations de gaz ou d’eau cachés avant d’effectuer des coupes sans

visibilité ou en plongée. Négliger de suivre ces directives risque de provoquer un choc

électrique, un incendie, une explosion ou des dommages matériels.

AVERTISSEMENT : RISQUE DE COUPURE. Un bris de lame est possible si la

lame ne dépasse pas la semelle et la pièce en cours de coupe. Un bris de lame

représente un risque accru de blessures personnelles ainsi que de dommages à la

semelle et à la pièce.

AVERTISSEMENT : TOUJOURS porter des lunettes de sécurité. Les lunettes

de vue ne constituent PAS des lunettes de sécurité. Utiliser également un masque facial

14

Page 15

ou anti-poussière si l’opération de découpe génère de la poussière. TOUJOURS

PORTER UN ÉQUIPEMENT DE PROTECTION HOMOLOGUÉ :

AVERTISSEMENT : RISQUE DE COUPURE. Avant de couper tout matériau,

s’assurer que ce dernier est bien ancré ou serré dans un étau pour éviter tout glissement.

• Placer la lame légèrement contre la pièce à couper.

• Mettre en marche le moteur de la scie avant d’appliquer toute pression.

AVERTISSEMENT : RISQUE DE

COUPURE. Ne jamais tenir et utiliser le

produit avec les doigts enroulés autour du

bouton qui affiche les réglages. Toujours

tenir fermement la scie avec les deux mains en

cours de coupe comme indiqué à la figure 1.

Autant que possible, la semelle de la scie doit

être solidement appuyée contre le matériau à

couper. Cela évite tout écart ou vibration de la

scie et réduira le bris de lame.

1

GÂCHETTE DE VITESSE VARIABLE

(FIGURE 2)

La gâchette de vitesse variable offre une polyvalence

supplémentaire. Au fur et à mesure que la gâchette est

enfoncée, la vitesse de la scie augmente. Pour mettre

l’outil hors tension, relâcher la gâchette.

2

AVERTISSEMENT : risque de coupure. L’outil

ne comporte pas de dispositif de verrouillage de la gâchette

en position sous tension, et il ne doit jamais être verrouillé

en position de marche par quelque moyen que ce soit.

INSTALLATION ET DÉPOSE DE LA LAME (FIGURE 3)

AVERTISSEMENT : risque de coupure. Éteindre l’outil et le débrancher

avant d’effectuer tout réglage ou d’enlever ou d’installer tout accessoire.

La lame doit dépasser la semelle et l’épaisseur de la pièce au cours de la coupe.

Sélectionner la meilleure lame pour le matériau à couper et utiliser la lame la plus

courte possible adéquate pour l’épaisseur du matériau. Ne pas utiliser de lames pour

scie sauteuse avec cet outil.

AVERTISSEMENT : risque de coupure. Un bris de lame est possible si la

lame ne dépasse pas la semelle et la pièce en cours de coupe. Un bris de lame

représente un risque accru de blessures personnelles ainsi que des dommages à la

semelle et à la pièce.

POUR INSÉRER LA LAME DANS LA SCIE

1. Pointer l’outil loin du corps.

2. Tourner le collet de fixation de la lame dans le sens

illustré à la figure 3.

3. Insérer entièrement la queue de lame dans le collet

de fixation de la lame.

4. Relâcher le collet de fixation de la lame pour

bloquer la lame en position.

REMARQUE : la lame peut être installée, les dents

vers le haut, pour aider à couper à ras.

3

POUR DÉPOSER LA LAME DE LA SCIE

AVERTISSEMENT : RISQUE DE COUPURE. Arrêter et débrancher l’outil avant

d’effectuer un réglage ou de retirer ou d’installer une pièce ou un accessoire.

AVERTISSEMENT : risque de brûlure. Ne pas toucher la lame immédiatement

après usage. Un contact avec la lame risque de provoquer une blessure corporelle.

1. Tourner le collet de fixation de la lame pour la dégager.

2. Déposer la lame.

15

Page 16

POUR RETIRER UNE LAME BRISÉE

Si la lame se brise d’une telle façon que la pièce brisée est

prise à l’intérieur du collet de fixation, suivre la démarche

suivante pour extraire le bout de lame de la scie.

1. Tourner le collet de fixation de la lame dans le sens horaire,

vu de l’arrière de la scie, et tenir en place (figure 4).

2. Tourner la scie sur son flanc gauche, vu de l’arrière de la

scie (figure 5).

3a. Si la lame s’est brisée à l’intérieur du collet de fixation,

glisser un objet plat dans l’ouverture du

collet (figure 6) aussi loin que possible, puis

retirer l’objet plat. Cette action désengagera

la goupille à l’intérieur du collet de fixation.

3b. Si la lame s’est brisée à l’extérieur du

collet de fixation, glisser un objet plat dans

l’ouverture du collet (figure 6) vers la

gauche de la lame, aussi loin que possible,

puis retirer l’objet plat. Cette action désengagera la

goupille à l’intérieur du collet de fixation.

4. En gardant toujours le collet de fixation ouvert et la scie

sur son flanc, orienter l’ouverture du collet vers le bas et

secouer jusqu’à ce que la lame brisée s’échappe.

5

4

6

SÉLECTEUR DE MOUVEMENT ORBITAL

(FIGURE 7)

Le modèle BTE360 comporte une lame à deux mouvements

mouvement alternatif vertical ou mouvement orbital.

Le mouvement alternatif vertical s’utilise pour toutes les

coupes sur métal et pour des applications sur bois où la

finition est plus importante que la vitesse de coupe. Pour

régler la scie à la position de mouvement alternatif vertical,

tourner le sélecteur à la position marquée

Le mouvement orbital s’utilise pour une coupe rapide du

bois. Pour régler la scie sur le mouvement orbital, tourner le sélecteur à la position marquée

:

7

SEMELLE RÉGLABLE (FIGURE 8)

AVERTISSEMENT : RISQUE DE COUPURE.

Un bris de lame est possible si la lame ne dépasse pas la

semelle et la pièce en cours de coupe. Un bris de lame

représente un risque accru de blessures personnelles

ainsi que des dommages à la semelle et à la pièce.

8

AVERTISSEMENT : RISQUE DE COUPURE.

Éteindre l’outil et le débrancher avant d’effectuer tout

réglage ou d’enlever ou d’installer tout accessoire.

• La semelle se réglera de manière à limiter la

profondeur de la coupe. Enfoncer le bouton (illustré à la figure 8) logé sur la poignée,

puis glisser la semelle à la profondeur souhaitée et relâcher le bouton.

MISE EN GARDE : RISQUE DE COUPURE. Pour éviter une perte de maîtrise, ne

jamais utiliser l’outil sans la semelle.

MISE EN GARDE : RISQUE DE BLESSURES

CORPORELLES ET DE DOMMAGES MATÉRIELS. S’assurer

que la semelle est verrouillée en position avant d’utiliser l’outil.

9

COUPE À RAS (FIGURE 9)

• Le modèle compact du boîtier du moteur et de la semelle

pivotante de la scie alternative permet une coupe à ras au sol,

dans les coins et à d’autres endroits difficiles d’accès.

• Pour optimiser la capacité de coupe à ras, insérer l’arbre de la

lame dans le mécanisme de serrage de lame de manière à ce

que les dents de la lame soient vers le haut.

• Inverser la scie de manière à être aussi près que possible de

la surface de travail.

16

Page 17

COUPE DU MÉTAL (FIGURE 10)

• Utiliser une lame plus fine pour les métaux

ferreux et une lame grossière pour les matériaux

non ferreux.

• Pour la tôle de fin calibre, il est préférable de fixer

un morceau de bois sous la feuille de tôle. Cela

permet d’assurer une coupe nette sans vibration

excessive ou déchirure de la tôle.

• Éviter de forcer la lame de coupe, car cela réduit sa

durée de vie et provoque des bris de lame coûteux.

REMARQUE : étendre un mince film d’huile ou de

tout autre fluide de refroidissement le long de la ligne

devant le trait de scie pour faciliter le fonctionnement

de l’outil et accroître la durée de vie de la lame.

10

DÉCOUPE EN POCHE – BOIS SEULEMENT (FIGURE 11)

• Mesurer la zone à couper et la marquer

clairement avec un crayon, une craie ou une

pointe à tracer.

• Insérer la lame dans le mécanisme de serrage de

lame et serrer ce dernier solidement.

• Incliner la scie vers l’arrière de manière à ce que

le bord arrière de la semelle repose contre la

surface de la pièce et la surface sera dégagée de

toute la portée de la lame mobile.

• Saisir l’outil des deux mains, puis mettre le

moteur en marche et laisser la lame atteindre sa

vitesse maximale.

• Saisir la principale poignée de la scie et imprimer lentement un mouvement

ascendant franc.

• La lame pénétrera dans le matériau. Toujours s’assurer que la lame a bien

transpercé tout le matériau avant de continuer la coupe en poche.

REMARQUE : dans les endroits où la visibilité de la lame est limitée, utiliser le bord de

la semelle comme guide.

11

CONSEILS POUR LES PROJETS

• Effectuer une coupe uniquement au moyen de lames affûtées; la coupe est plus

nette, plus rapide et l’effort subi par le moteur est moindre durant la coupe.

• Durant la coupe, toujours s’assurer que la semelle est tenue fermement contre la pièce

et que cette dernière est solidement fixée afin d’éviter qu’elle ne se déplace/dévie.

Cela permet à l’opérateur d’avoir une plus grande maîtrise et de réduire les vibrations.

• Pour assurer une durée de vie accrue à la lame, utiliser des lames bimétalliques.

Cette lame est constituée d’acier au carbone soudé à l’envers sur les dents en acier

à coupe rapide, ce qui rend la lame plus flexible et donc moins sujette à se briser.

DÉPANNAGE

Problème Cause possible Solution possible

• L’appareil refuse de • Cordon d’alimentation • Brancher l’outil dans

démarrer. non branché. une prise qui fonctionne.

• Le fusible du circuit est grillé. • Remplacer le fusible du

circuit. (Si le produit fait

griller de façon répétée

le fusible du circuit, arrêter

immédiatement d’utiliser

le produit et le faire

réparer dans un centre de

réparation Bostitch ou

un centre de réparation

autorisé.)

• Le disjoncteur est déclenché. • Remettre le disjoncteur

à zéro . (Si le produit fait

déclencher de façon

répétée le disjoncteur,

17

Page 18

arrêter immédiatement

d’utiliser le produit et le

faire réparer dans un

centre de réparation

de réparation autorisé.)

• Le cordon d’alimentation • Faire remplacer le

ou la prise de courant est cordon ou l’interrupteur

endommagé(e). au centre de réparation

centre de réparation autorisé.

• Lame brisée prise • La lame brisée est retenue par • Suivre la démarche

à l’intérieur du collet une goupille dans le collet de indiquée à la rubrique

de fixation. fixation. « Pour retirer une lame

brisée » pour désengager

la goupille.

Pour de l’aide avec l’outil, consulter notre site Web www.bostitch.com pour

l’emplacement du centre de réparation le plus près ou communiquer avec l’assistance

Bostitch au (800) 262 2161.

Bostitch

Bostitch

ou un centre

ou à un

ENTRETIEN

N’utiliser qu’un détergent doux et un chiffon humide pour nettoyer l’appareil. Ne jamais

laisser de liquide pénétrer dans l’appareil et n’immerger aucune partie de l’appareil dans

un liquide.

PIÈCES DE RECHANGE

Utiliser seulement des pièces de rechange identiques. Pour obtenir une liste des

pièces de rechange ou pour en commander, consulter le site Web www.bostitch.com. Il est

également possible de commander des pièces au centre de réparation de l’usine

Bostitch et au centre de réparation sous garantie autorisé Bostitch le plus près. Ou

composer le (800) 262 2161. pour le service à la clientèle.

ENTRETIEN ET RÉPARATION

Ce produit n’est pas réparable par l’utilisateur. Aucune pièce à l’intérieur du chargeur

ne peut être réparée par l’utilisateur. Pour éviter tout dommage aux composants

internes sensibles à l’électricité statique, faire effectuer toute réparation par un centre

de réparation autorisé. Pour de plus amples renseignements à propos de Bostitch, ses

centres de réparation en usine ou ses centres de réparation sous garantie autorisés,

visiter notre site Web au www.bostitch.com ou communiquer avec notre centre de service

à la clientèle en composant le (800) 262 2161. Toutes les réparations effectuées dans

nos centres de réparation sont entièrement garanties contre les défauts de matériaux et

de main-d’oeuvre. Nous ne pouvons pas garantir les réparations effectuées en partie ou

totalement par d’autres.

Pour de plus amples renseignements par courrier, écrire à Bostitch, 701 E. Joppa Road,

Towson, Maryland 21286 - à l’attention de : Product Service. S’assurer d’indiquer toutes

les informations figurant sur la plaque signalétique de l’outil (numéro du modèle, type,

numéro de série, etc.).

ACCESSOIRES

AVERTISSEMENT :

n’ont pas été testés avec ce produit, l’utilisation de ceux-ci avec l’outil pourrait s’avérer

dangereuse. Pour réduire le risque de blessures, utiliser exclusivement les accessoires

Bostitch recommandés avec le produit.

Les centres de réparation de l’usine Bostitch ou les centres de réparation sous garantie

autorisés Bostitch sont en mesure de vous fournir la gamme complète d’accessoires.

Consulter le site Web www.bostitch.com pour obtenir un catalogue ou le nom du

fournisseur local.

Puisque les accessoires autres que ceux offerts par Bostitch

18

Page 19

GARANTIE LIMITÉE DE TROIS ANS

Bostitch réparera ou remplacera gratuitement tous les outils défectueux présentant

des défauts de matériau ou de fabrication pendant trois ans à compter de la date

d’achat [garantie de deux ans pour les blocs-piles]. Cette garantie ne couvre pas des

défaillances de pièce dues à une usure normale ou à une mauvaise utilisation de l’outil.

Pour plus de détails relatifs à la couverture de la garantie et aux réparations sous

garantie, visiter le site www.bostitch.com ou composer le (800) 262 2161. Cette garantie

ne s’applique pas aux accessoires ni aux dommages causés par des réparations

réalisées ou tentées par des tiers. Cette garantie vous accorde des droits légaux

spécifiques et il est possible que vous ayez d’autres droits qui varient d’un État ou d’une

province à l’autre.

En plus de la garantie, les outils Bostitch sont couverts par notre :

SERVICE D’ENTRETIEN GRATUIT D’UN (1) AN : Bostitch entretiendra l’outil et

remplacera les pièces usées par une utilisation normale, et ce, gratuitement et à tout

instant pendant la première année à compter de la date d’achat.

GARANTIE DE REMBOURSEMENT DE 90 JOURS : Si l’utilisateur n’est pas

entièrement satisfait des performances de son outil électrique Bostitch pour une raison

quelconque, il peut le retourner accompagné du reçu dans les 90 jours suivant la date

d’achat, et nous le lui rembourserons entièrement - sans poser de question.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits vendus en Amérique

latine. Pour ceux-ci, veuillez consulter les informations relatives à la garantie spécifique

présente dans l’emballage, appeler l’entreprise locale ou consulter le site Web pour les

informations relatives à cette garantie.

Pour enregistrer l’outil en vue d’obtenir un service de garantie, consulter notre site Web

au www.bostitch.com.

REMPLACEMENT DES ÉTIQUETTES D’AVERTISSEMENT

Si vos étiquettes d’avertissement sont illisibles ou manquantes, contactez le (800) 262

2161 pour en obtenir le remplacement gratuit.

Importé par Bostitch

701 E. Joppa Road

Towson, Maryland 21286

19

Page 20

www.BOSTITCH.com

Manual de’instrucciones

BTE360

8.5 A

Sierra alternativa de acción orbital

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

Es importante que lea y comprenda este manual. La información que contiene se

relaciona con la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS.

Los símbolos que siguen se utilizan para ayudarlo a reconocer esta información.

PELIGRO: indica una situación de peligro inminente que, si no se evita

provocará la muerte o lesiones graves.

ADVERTENCIA: indica una situación de peligro potencial que, si no se evita,

provocará la muerte o lesiones graves.

PRECAUCIÓN: indica una situación de peligro potencial que, si no se evita,

provocará lesiones leves o moderadas.

PRECAUCIÓN:

peligro potencial que, si no se evita, puede provocar daños en la propiedad.

PAUTAS DE SEGURIDAD/DEFINICIONES

utilizado sin el símbolo de alerta de seguridad indica una situación de

20

Page 21

Advertencias generales de seguridad para herramientas eléctricas

ADVERTENCIA: Lea todas las advertencias de seguridad e instrucciones El

incumplimiento de las advertencias e instrucciones puede provocar descargas

eléctricas, incendios o lesiones graves.

Conserve todas las advertencias e instrucciones para futuras consultas.

El término “herramienta eléctrica” incluido en las advertencias hace referencia

a las herramientas eléctricas operadas con corriente (con cable eléctrico) o a

las herramientas eléctricas operadas con baterías (inalámbricas).

1) Seguridad en el área de trabajo

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas y

oscuras propician accidentes.

b) No opere herramientas eléctricas en atmósferas explosivas, como ambientes

donde se encuentran líquidos, gases o polvo inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga a los niños y espectadores alejados de la herramienta eléctrica en

funcionamiento. Las distracciones pueden provocar la pérdida de control.

2) Seguridad eléctrica

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente. Nunca

modifique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con conexión a tierra. Los enchufes no modificados y que se

adaptan a los tomacorrientes reducirán el riesgo de descarga eléctrica.

b) Evite el contacto corporal con superficies puestas a tierra, como por ejemplo

tuberías, radiadores, rangos y refrigeradores. Existe mayor riesgo de descarga

eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de

humedad. Si ingresa agua a una herramienta eléctrica, aumentará el riesgo de

descarga eléctrica.

d) No maltrate al cable. Nunca utilice el cable para transportar, tirar o

desenchufar la herramienta eléctrica. Mantenga el cable lejos del calor,

aceite, bordes afilados o piezas móviles. Los cables dañados o enredados

aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable

prolongador adecuado para tal uso. Utilice un cable adecuado para uso en

exteriores a fin de reducir el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible de

evitar, utilice un suministro protegido con un interruptor de circuito por falla

a tierra (GFCI). El uso de un GFCI reduce el riesgo de descargas eléctricas.

3) Seguridad personal

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido común

cuando emplee una herramienta eléctrica. No utilice una herramienta eléctrica si

está cansado o bajo el efecto de drogas, alcohol o medicamentos. Un momento de

descuido mientras se opera una herramienta eléctrica puede provocar lesiones

personales graves.

b) Utilice equipos de protección personal. Siempre utilice protección para los

ojos. En las condiciones adecuadas, el uso de equipos de protección, como

máscaras para polvo, calzado de seguridad antideslizante, cascos o protección

auditiva, reducirá las lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté en la

posición de apagado antes de conectarlo a la fuente de energía o paquete de

baterías, o antes de levantar o transportar la herramienta. Transportar

herramientas eléctricas con el dedo apoyado en el interruptor o enchufar

herramientas eléctricas con el interruptor en la posición de encendido puede

propiciar accidentes.

d) Retire las clavijas de ajuste o llaves de tuercas antes de encender la

herramienta eléctrica. Una llave de tuercas o una clavija de ajuste que se deje

conectada a una pieza giratoria de la herramienta eléctrica pueden provocar

lesiones personales.

e) No se estire. Conserve el equilibrio adecuado y manténgase parado

correctamente en todo momento. Esto permite un mejor control de la

herramienta eléctrica en situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga el

cabello, la ropa y los guantes alejados de las piezas en movimiento. Las

21

Page 22

ropas holgadas, las joyas o el cabello largo pueden quedar atrapados en las

piezas en movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con fines de

recolección y extracción de polvo, asegúrese de que estén conectados y

que se utilicen correctamente. El uso de dispositivos de recolección de polvo

puede reducir los peligros relacionados con el polvo.

4) Uso y mantenimiento de la herramienta eléctrica

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica correcta

para el trabajo que realizará. La herramienta eléctrica correcta hará el trabajo

mejor y más seguro a la velocidad para la que fue diseñada.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con el

interruptor. Toda herramienta eléctrica que no puede ser controlada mediante el

interruptor es peligrosa y debe ser reparada.

c) Desconecte el enchufe de la fuente de energía y/o el paquete de baterías de

la herramienta eléctrica antes de realizar ajustes, cambiar accesorios o

almacenar herramientas eléctricas. Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta eléctrica en forma accidental.

d) Guarde las herramientas eléctricas que no están en uso fuera del alcance de

los niños y no permite que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son

peligrosas en las manos de usuarios no entrenados.

e) Mantenimiento de las herramientas eléctricas. Controle que no haya piezas

móviles mal alineadas o trabadas, piezas rotas y toda otra situación que

pueda afectar el funcionamiento de las herramientas eléctricas. Si encuentra

daños, haga reparar la herramienta eléctrica antes de utilizarla. Se producen

muchos accidentes a causa de las herramientas eléctricas que carecen de un

mantenimiento adecuado.

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de

corte con mantenimiento adecuado, con los bordes de corte afilados son menos

propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la herramienta,

etc. de acuerdo con estas instrucciones y teniendo en cuenta las condiciones

de trabajo y el trabajo que debe realizarse. El uso de la herramienta eléctrica

para operaciones diferentes de aquéllas para las que fue diseñada podría originar

una situación peligrosa.

5) Mantenimiento

a) Haga que una persona de reparaciones calificada realice el mantenimiento

de su herramienta eléctrica y utilice piezas de repuesto idénticas solamente.

Esto garantizará la seguridad de la herramienta eléctrica.

Normas específicas de seguridad

• Sujete la herramienta por las superficies aisladas, cuando realice una operación en

la que el accesorio de corte puede ponerse en contacto con cables ocultos o con su

propio cable. Entra en contacto con un cable “vivo” puede hacer que las partes metálicas

de la herramienta de poder “vivir” y que el operario reciba una descarga eléctrica.

• Utilice abrazaderas u otra forma práctica para asegurar y sostener la pieza de

trabajo sobre una plataforma estable. Sostener el trabajo con la mano o contra el

cuerpo no brinda la estabilidad requerida y puede llevar a la pérdida del control.

• Sostenga la sierra firmemente con ambas manos para todas las operaciones de

corte. Durante las operaciones de corte, es posible que la hoja se atasque repentinamente

en la pieza de trabajo y provoque que la sierra genere un retroceso hacia el operador.

• Mantenga las manos lejos de las zonas de corte. Nunca se estire por debajo del

material por ningún motivo. Sostenga la parte frontal de la sierra desde el área de

sujeción contorneada. No inserte los dedos en la zona cercana a la hoja alternativa y a

la abrazadera de la hoja. No estabilice la sierra sujetando la zapata.

• Mantenga las hojas afiladas. Las hojas sin filo pueden hacer que la sierra se desvíe o

atasque al recibir presión.

• Tome precauciones adicionales al cortar en lugares altos y preste atención

especial a los cables y tubería de gas o agua en altura que puedan estar ocultas.

Prevea el trayecto de la caída de las ramas y los desechos con anticipación.

• Al cortar tuberías o conductos, asegúrese de que no contengan agua, cableado eléctrico, etc.

• No toque la pieza de trabajo ni la hoja inmediatamente después de operar la

herramienta. Pueden estar muy calientes.

22

Page 23

ADVERTENCIA: USE SIEMPRE LENTES DE SEGURIDAD. Los anteojos de uso

diario NO son lentes de seguridad. Utilice también máscaras faciales o para polvo si el

corte produce polvillo. UTILICE SIEMPRE EQUIPOS DE SEGURIDAD CERTIFICADOS:

•ProtecciónparalosojossegúnlanormaANSIZ87.1(CAN/CSAZ94.3)

•ProtecciónauditivasegúnlanormaANSIS12.6(S3.19)

•ProtecciónrespiratoriasegúnlasnormasNIOSH/OSHA/MSHA

ADVERTENCIA: parte del polvo producido por las herramientas eléctricas al

lijar, aserrar, esmerilar, taladrar y realizar otras actividades de la construcción,

contiene productos químicos reconocidos por el Estado de California como

causantes de cáncer, defectos de nacimiento u otros problemas reproductivos.

Algunos de estos productos químicos son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, el cemento y otros productos de mampostería, y

• el arsénico y el cromo de la madera con tratamiento químico.

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice

este tipo de trabajo. Para reducir la exposición a estos productos químicos: trabaje

en áreas bien ventiladas y trabaje con equipos de seguridad aprobados, como las

máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con el polvo procedente del lijado, serrado,

esmerilado y taladrado eléctricos, así como de otras actividades del sector

de la construcción. Lleve ropa protectora y lave con agua y jabón las zonas

expuestas. Si permite que el polvo se introduzca en la boca u ojos o quede sobre la

piel, puede favorecer la absorción de productos químicos peligrosos.

ADVERTENCIA: El uso de esta herramienta puede generar o dispersar polvo

lo cual puede causar lesiones respiratorias serias y permanentes y otros tipos

de lesión. Siempre use protección respiratoria aprobada por NIOSH/OSHA para la

exposición al polvo. Dirija las partículas en dirección opuesta a su cara y cuerpo.

ADVERTENCIA: Durante el uso, utilice siempre protección auditiva adecuada

que cumpla con la norma ANSI S12.6 (S3.19). Enciertascircunstanciasysegúnel

período de uso, el ruido de este producto puede contribuir a la pérdida de audición.

ADVERTENCIA: No opere esta herramienta durante períodos largos de

tiempo. La vibración causada por la acción de operación de esta herramienta puede

causar lesiones permanentes a los dedos, las manos y los brazos. Utilice guantes para

una mayor amortiguación, tome descansos frecuentes y limite el tiempo de uso diario.

Símbolos

• La etiqueta de su herramienta puede incluir los siguientes símbolos. Los símbolos y

sus definiciones son los siguientes:

V ................. voltios A ............... amperios

Hz ............... hertz W .............. vatios

min ..............minutos

o DC.....corriente directa

................Construcción Clase I

(mis à la terre)

...............

RPM o .../min.......revoluciones o minuto seguridad

.......Lea el manual de instrucciones antes del uso

............Use protección adecuada para las vías respiratorias

...........Use protección adecuada para los ojos

............Use protección adecuada para los oídos

MOTOR

Asegúrese de que el suministro de energía concuerde con lo marcado en la placa. CA de 120

voltios solamente significa que su herramienta funcionará con la energía doméstica estándar de

60 Hz. No haga funcionar herramientas para corriente alternante (CA) con corriente directa (CD).

Una capacidad nominal de CA/CD de 120 voltios significa que su herramienta funcionará con

energía estándar de CA o CD de 60 Hz. Esta información está impresa en la placa. Un voltaje

menor producirá pérdida de potencia y puede provocar sobrecalentamiento. Todas las herramientas

Bostitch son probadas en fábrica. Si esta herramienta no funciona, controle el suministro eléctrico.

Construcción de clase II

o AC.....corriente alterna

n

o ............. no velocidad sin carga

..............

............simbolo de alerta

terminal a tierra

23

Page 24

CABLES PROLONGADORES

Utilice un cable adecuado

para uso en exteriores a

fin de reducir el riesgo de

descarga eléctrica. Cuando

utilice un cable prolongador,

asegúrese de que tenga la

capacidad para conducir la

corriente que su producto

exige. Un cable de menor

capacidad provocará una

disminución en el voltaje de

la línea que producirá pérdida

de potencia y sobrecalentamiento. La siguiente tabla muestra la medida correcta que

debe utilizar según la longitud del cable y la capacidad nominal en amperios indicada

en la placa. En caso de duda, utilice el calibre inmediatamente superior. Cuanto menor

es el número de calibre, más grueso es el cable.

Volts Longitud total del cable en pies

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Amperaje

0 - 6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 No se recomienda

Calibre mínimo para cables de extensión

Más de No más de American Wire Gage

CONSERVE ESTAS INSTRUCCIONES

E

F

G

D

C

A

B

Functional Description

A. Interruptor disparador E. Mango de agarre secundario

B. Mango principal F. Abrazadera de la hoja

C. Selector de acción orbital G. Zapata ajustable

D. Botón de zapata ajustable

OPERACIÓN/CONFIGURACIÓN

ADVERTENCIA: PELIGRO DE CORTE. Apague y desenchufe la herramienta

antes de realizar cualquier tipo de ajuste o quitar o instalar suplementos o accesorios.

ADVERTENCIA: Sostenga la sierra firmemente con ambas manos para todas las

operaciones de corte.

ADVERTENCIA: Inspeccione el área de trabajo en busca de cables eléctricos,

tubería oculta de gas o agua antes de realizar cortes a ciegas o de rebaje. El

incumplimiento de esta instrucción puede provocar descarga eléctrica, incendio,

explosión o daños a la propiedad.

ADVERTENCIA: PELIGRO DE CORTE. La hoja puede romperse si ésta no se

extiende más allá de la zapata y la pieza de trabajo durante el corte. Es posible que haya

más riesgos de lesiones personales además de daños en la zapata y en la pieza de trabajo.

ADVERTENCIA: USE SIEMPRE

LENTES DE SEGURIDAD. Los anteojos de

uso diario NO son lentes de seguridad. Utilice

también máscaras faciales o para polvo si el

corte produce polvillo. UTILICE SIEMPRE

EQUIPOS DE SEGURIDAD CERTIFICADOS.

1

ADVERTENCIA: PELIGRO DE

CORTE. Antes de cortar cualquier tipo de

material,asegúresedequeestésujetadoo

fijado firmemente para evitar el deslizamiento.

24

Page 25

• Coloque la hoja levemente contra la pieza de trabajo que desea cortar.

• Encienda el motor de la sierra antes de aplicar presión.

ADVERTENCIA: PELIGRO DE

los dedos alrededor del botón de ajuste de la zapata. Al cortar, siempre sujete la sierra

firmemente con ambas manos como se muestra en la Figura 1. Siempre que sea posible,

la zapata de la sierra debe sujetarse con firmeza contra el material que desee

evitará que la sierra salte o vibre y

CORTE. Nunca sostenga ni use el producto

minimizará el daño a la hoja.

con

cortar. Esto

ENCENDIDO DE VELOCIDAD VARIABLE (FIGURA 2)

El gatillo de velocidad variable le dará mas versatilidad.

Cuanto más apriete el gatillo mas alta será la velocidad

de la sierra. Para apagar le herramienta suelte el gatillo.

2

ADVERTENCIA: Riesgo de corte. Esta

herramienta no cuenta con un dispositivo para fijar el

encendido en marcha y nunca debe ser cerrado en

marcha por ningún dispositivo.

INSTALACIÓN Y EXTRACCIÓN DE LA

HOJA (FIGURA 3)

ADVERTENCIA: RIESGO DE CORTE. Apague y

desconecte la herramienta de la fuente de energía antes

de realizar cualquier ajuste o de extraer o instalar aditamentos o accesorios.

La hoja debe extenderse más allá de la zapata y el espesor de la pieza de trabajo

durante el corte. Seleccione la hoja más adecuada para el material que desee cortar

y utilice la hoja más corta apropiada para el espesor del material. No utilice hojas de

sierra caladora con esta herramienta.

ADVERTENCIA: RIESGO DE CORTE. La hoja puede romperse si ésta no se

extiende más allá de la zapata y la pieza de trabajo durante el corte. El resultado puede ser

un mayor riesgo de lesiones personales además de daños a la zapata y la pieza de trabajo.

PARA INSTALAR LA HOJA EN LA SIERRA

1. Apunte la herramienta lejos del cuerpo.

2. Gire el anillo de la abrazadera de la hoja en la

dirección que se muestra en la Figura 3.

3. Inserte el vástago de la hoja completamente dentro

del anillo de la abrazadera de la hoja.

4. Suelte el anillo de la abrazadera de la hoja para

bloquear la hoja en posición.

NOTA: La hoja se puede instalar con los dientes

hacia arriba para contribuir a un corte al ras.

3

PARA RETIRAR LA HOJA DE LA SIERRA

ADVERTENCIA: PELIGRO DE CORTE. Apague y desenchufe la herramienta