Bostitch BRN175 User Manual

BRN175

COIL ROOFING NAILER

CLAVADORA PARA TECHOS CON BOBINA

CLOUEUSE DE TOITURE À ROULEAU

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL

TO UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP

THESE INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY

QUESTIONS, CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES DEBERÁN ESTUDIAR ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE SEGURIDAD Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA

HERRAMIENTA PARA FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE

CON SU REPRESENTANTE DE BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER

UNE ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX AVERTISSEMENTS. GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI VOUS

AVEZ DES QUESTIONS, CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE BOSTITCH.

9R209323RA 01/15

BRN175_9R209323_MAN_kf V2_multi.indd 1 1/28/15 7:41 AM

BOSTITCH FASTENING SYSTEMS

1 - ENG

INTRODUCTION

The BOSTITCH BRN175 is a precision-built tool, designed for high speed, high volume fastening. These tools

will deliver efficient, dependable service when used correctly and with care. As with any fine tool, for best performance the manufacturer’s instructions must be followed. Please study this manual before operating the tool

and understand the safety warnings and cautions. The instructions on installation, operation and maintenance

should be read carefully, and the manual kept for reference. NOTE: Additional safety measures may be required

because of your particular application of the tool. Contact your BOSTITCH representative or distributor with any

questions concerning the tool and its use. BOSTITCH, 701 E. Joppa Road, Towson, Maryland 21286, U.S. &

Canada Only, É.-U. et Canada seulement

INDEX

Safety instructions .....................................3

Fastener specifications .................................4

Tool parts identification, trigger............................5

Loading the tool ................................... 6 & 7

Actuating the tool .....................................8

Tool operation ........................................8

Adjusting depth .......................................9

Directional exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Clearing a jam........................................10

Trouble shooting, tool specifications ......................13

NOTE:

BOSTITCH tools have been engineered to provide excellent customer satisfaction and are designed to achieve

maximum performance when used with precision BOSTITCH fasteners engineered to the same exacting

standards. BOSTITCH cannot assume responsibility for product performance if our tools are used with

fasteners or accessories not meeting the specific requirements established for genuine BOSTITCH nails,

staples and accessories.

LIMITED WARRANTY — U.S. and Canada Only

BOSTITCH Fastening Systems “BOSTITCH” warrants to the original retail purchaser that the product purchased is

free from defects in material and workmanship, and agrees to repair or replace, at BOSTITCH’s option, any defective

BOSTITCH branded pneumatic stapler or nailer for a period of seven (7) years from date of purchase (one (1) year

from the date of purchase for compressors and tools used in production applications). Warranty is not transferable.

Proof of purchase date required. This warranty covers only damage resulting from defects in material or workmanship;

it does not cover conditions or malfunctions resulting from normal wear, neglect, abuse, accident or repairs attempted

or made by other than our national repair center or authorized warranty service centers. Driver blades, bumpers,

o-rings, pistons and piston rings are considered normally wearing parts. For optimal performance of your BOSTITCH

tool always use genuine BOSTITCH fasteners and replacement parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and countries do not allow limitations on how long an implied warranty lasts, or the exclusion or limitation

of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights, and you may also have other rights which vary from state to state and country to country.

To obtain warranty service in the U.S. return the product, together with proof of purchase, to the U.S. BOSTITCH

National or Regional Independent Authorized

Warranty Service Center. In the U.S. you may call us at 1-800-556-6696 or visit www.BOSTITCH.com for the

location most convenient for you. In Canada please call us at 1-800-567-7705 or visit www.BOSTITCH.com.

2 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 2 1/28/15 7:41 AM

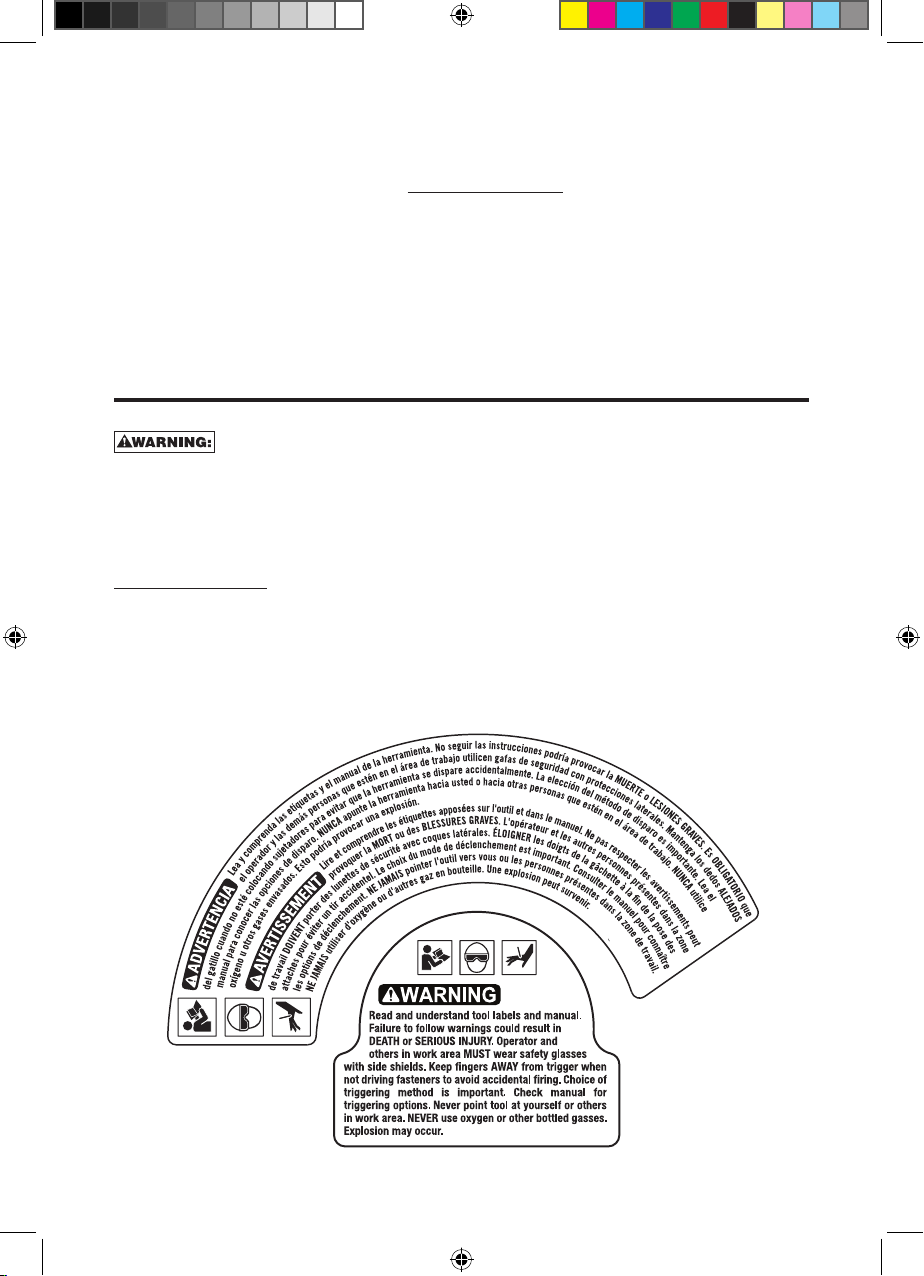

DEFINITIONS - SAFETY GUIDELINES

When using any pneumatic tool, all safety precautions , as outlined below, should be followed to avoid the

risk of death or serious injury. Read and understand the instructions before operating the tool. This manual

contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

Indicates a situation which, if not avoided, may result in property damage.

SAFETY INSTRUCTIONS

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator and

others in the work area when connecting to air supply, loading, operating or servicing this

tool. Eye protection is required to guard against flying fasteners and debris, which could

cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards Institute,

ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded spectacles

and face shields alone do not provide adequate protection.

Additional Safety Protection will be required in some environments. For example, the

working area may include exposure to noise level which can lead to hearing damage. The

employer and user must ensure that any necessary hearing protection is provided and used

by the operator and others in the work area. Some environments will require the use of

head protection equipment. When required, the employer and user must ensure that head

protection conforming to ANSI Z89.1 is used.

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

never connect to a supply which can exceed 200 psi as tool may burst, possibly causing

injury.

The connector on the tool must not hold pressure when air supply is disconnected. If a wrong

fitting is used, the tool can remain charged with air after disconnecting and thus will be able

to drive a fastener even after the air line is disconnected possibly causing injury.

Do not pull trigger or depress contact arm while connected to the air supply as the tool may

cycle, possibly causing injury.

Always disconnect air supply: 1.) Before making adjustments; 2.) When servicing the tool; 3.)

When clearing a jam; 4.) When tool is not in use; 5.) When moving to a different work area, as

accidental actuation may occur, possibly causing injury.

LOADING TOOL

When loading tool: 1.) Never place a hand or any part of body in fastener discharge area

of tool; 2.) Never point tool at anyone; 3.) Do not pull the trigger or depress the trip as

accidental actuation may occur, possibly causing injury.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull the trigger

unless nose is directed toward the work; 3.) Keep others a safe distance from the tool while

tool is in operation as accidental actuation may occur, possibly causing injury.

The operator must not hold the trigger pulled on contact arm tools except during fastening

operation as serious injury could result if the trip accidentally contacted someone or

something, causing the tool to cycle.

Keep hands and body away from the discharge area of the tool. A contact arm tool may

bounce from the recoil of driving a fastener and an unwanted second fastener may be driven

possibly causing injury.

3 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 3 1/28/15 7:41 AM

Check operation of the contact arm mechanism frequently. Do not use the tool if the arm is

proper operation of the contact arm mechanism.

any other material that is -- or the vapors, fumes or byproducts of which are -- flammable, combustible or explosive.

Using the nailer in any such environment could cause an EXPLOSION resulting in personal injury or death to user

and bystanders.

not working correctly as accidental driving of a fastener may result. Do not interfere with the

Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as this

may cause deflection of fasteners which could cause injury.

Do not drive fasteners close to the edge of the work piece as the wood may split, allowing the

fastener to be deflected possibly causing injury.

This nailer produces SPARKS during operation. NEVER use the nailer near flammable substances,

gases or vapors including lacquer, paint, benzine, thinner, gasoline, adhesives, mastics, glues or

MAINTAINING THE TOOL

When working on air tools note the warnings in this manual and use extra care when

evaluating problem tools.

State of California to cause cancer, birth defects and other reproductive harm.

Use of this product may expose you to chemicals known to the

Avoid inhaling vapors and dust, and wash hands after using.

• Avoid prolonged contact with dust from power sanding, sawing,

grinding, drilling, and other construction activities. Wear protective

clothing and wash exposed areas with soap and water. Allowing dust

to get into your mouth, eyes, or lay on the skin may promote absorption

of harmful chemicals.

Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory or other injury. Always use NIOSH/OSHA

approved respiratory protection appropriate for the dust exposure. Direct particles

away from face and body. Always operate tool in well-ventilated area and provide

for proper dust removal. Use dust collection system wherever possible.

ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT

safety glasses. Also use face or dust mask if operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA respiratory protection.

Before operating this tool, carefully read and understand all instructions in

Important Safety Instructions.

SAVE THESE INSTRUCTIONS

NAIL SPECIFICATIONS

BRN175

Nails 0.120" (3mm) diameter, 15º wire collated roofing nails

Lengths 3/4" (19 mm) - 1-3/4" (44.5 mm)

Air Inlet 1/4" NPT (6.4mm)

NOTE: Use only BOSTITCH approved fasteners

4 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 4 1/28/15 7:41 AM

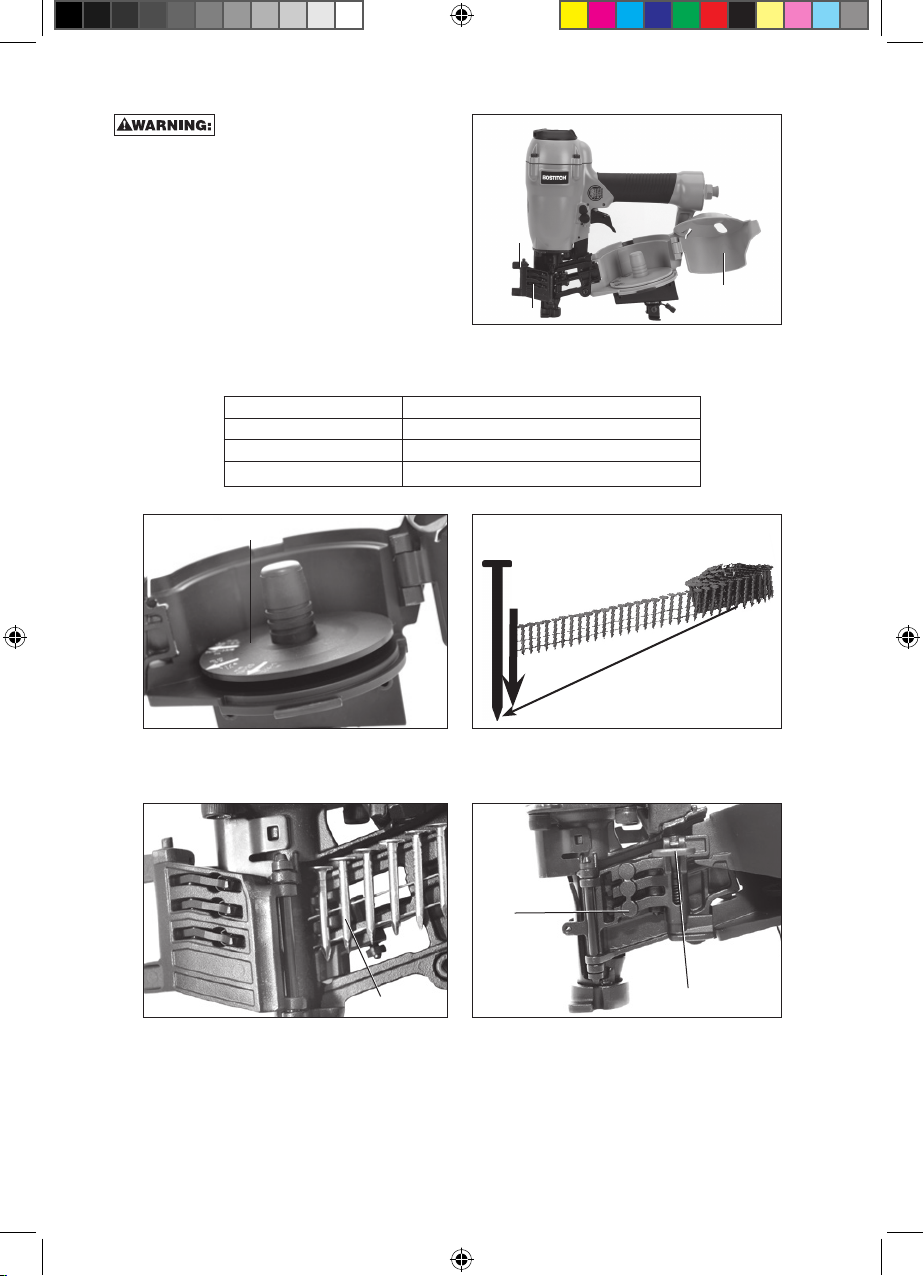

Fig. 1

A. Exhaust deflector

B. Selectable trigger

C. Canister

D. Door latch

E. Safety contact tip

F. Depth adjustment wheel

G. Door

H. Tool-Free Shingle Guide

I. Trigger lock button

J. Mode selector button

TOOL PARTS:

A

B

I

J

F

C

E

D

G

H

ASSEMBLY:

fasteners from magazine before making adjustments or personal injury may

result.

TRIGGER

avoid accidental actuation. Never carry a tool with finger on the trigger. In bump

action mode (contact actuation mode), the tool will drive a fastener if the contact

trip is bumped while the trigger is depressed.

The BRN175 is equipped with a selectable trigger. This trigger allows the operator

to select either single sequential action trigger mode or bump action trigger mode.

In accordance with the ANSI Standard SNT-101-2002, the trigger is assembled

in the single sequential action trigger mode. To change the trigger mode, see

Actuating Tool instructions in the Operation section of the manual. The selectable

trigger also has a trigger lock button to keep the trigger locked at all times when

the tool is not in use.

AIR FITTING

This tool uses a 1/4" N.P.T. male plug. The inside diameter should be .275" (7mm)

or larger. The fitting must be capable of discharging tool air pressure when

disconnected from the air supply. A 3/8" (9.5mm) male quick connector coupling

is available from BOSTITCH and may be used when a 1/4" (6.4mm) supply line is

not available.

NOTE: A 3/8" (9.5mm) supply line (and fittings) are required for maximum tool

performance.

is disconnected from the power supply. Always use hose connectors that shut off

air supply from compressor when the tool is disconnected.

Disconnect air line from tool, engage trigger lock and remove

Keep fingers AWAY from the trigger when not driving fasteners to

Always use couplings that relieve all pressure from the tool when it

5 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 5 1/28/15 7:41 AM

To install an air fitting

1. Wrap the male end of the fitting with thread seal tape prior to assembly to

eliminate air leaks.

2. To install a 1/4" (6.4mm) fitting: screw it directly into the air inlet and tighten

firmly. NOTE: If an adapter is in the air inlet, remove it prior to inserting the

fitting.

3. To install a 3/8" (9.5mm) fitting: screw the fitting into the 3/8" (9.5mm) adapter

and then into the air inlet of the tool and tighten firmly.

OPERATION:

PREPARING THE TOOL

Tools at the beginning of this manual. Always wear eye and ear protection when

operating this tool. Keep the nailer pointed away from yourself and others. For

safe operation, complete the following procedures and checks before each use of

the nailer.

tool oil or a non-detergent SAE 20 weight oil. Oil with additives or detergent will

damage tool parts.

1. Before you use the nailer, be sure that the compressor tanks have been

properly drained.

2. Lubricate tool:

a. Use BOSTITCH pneumatic tool oil or a non-detergent S.A.E. 20 weight oil.

b. Use a filter when possible.

c. Add 5 to 7 drops of oil in the air fitting a least twice a day.

3. Wear eye and ear protection.

4. Ensure canister is empty of all fasteners.

5. Check for smooth and proper operation of contact trip. Do not use tool if

assembly is not functioning properly. NEVER tamper with the contact trip.

NEVER use a tool that has the contact trip restrained in the actuated position.

6. Check air supply: Ensure air pressure does not exceed recommended

operating limits; 70 to 120 psi, (4.9 to 8.3 bar, 5 to 8.5 kg/cm

7. Keep tool pointed away from yourself and others.

8. Connect air hose.

9. Check for audible leaks around valves and gaskets. Never use a tool that leaks

or has damaged parts.

supply and engage trigger lock before performing maintenance, clearing a

jammed fastener, leaving work area, moving tool to another location or handing

the tool to another person.

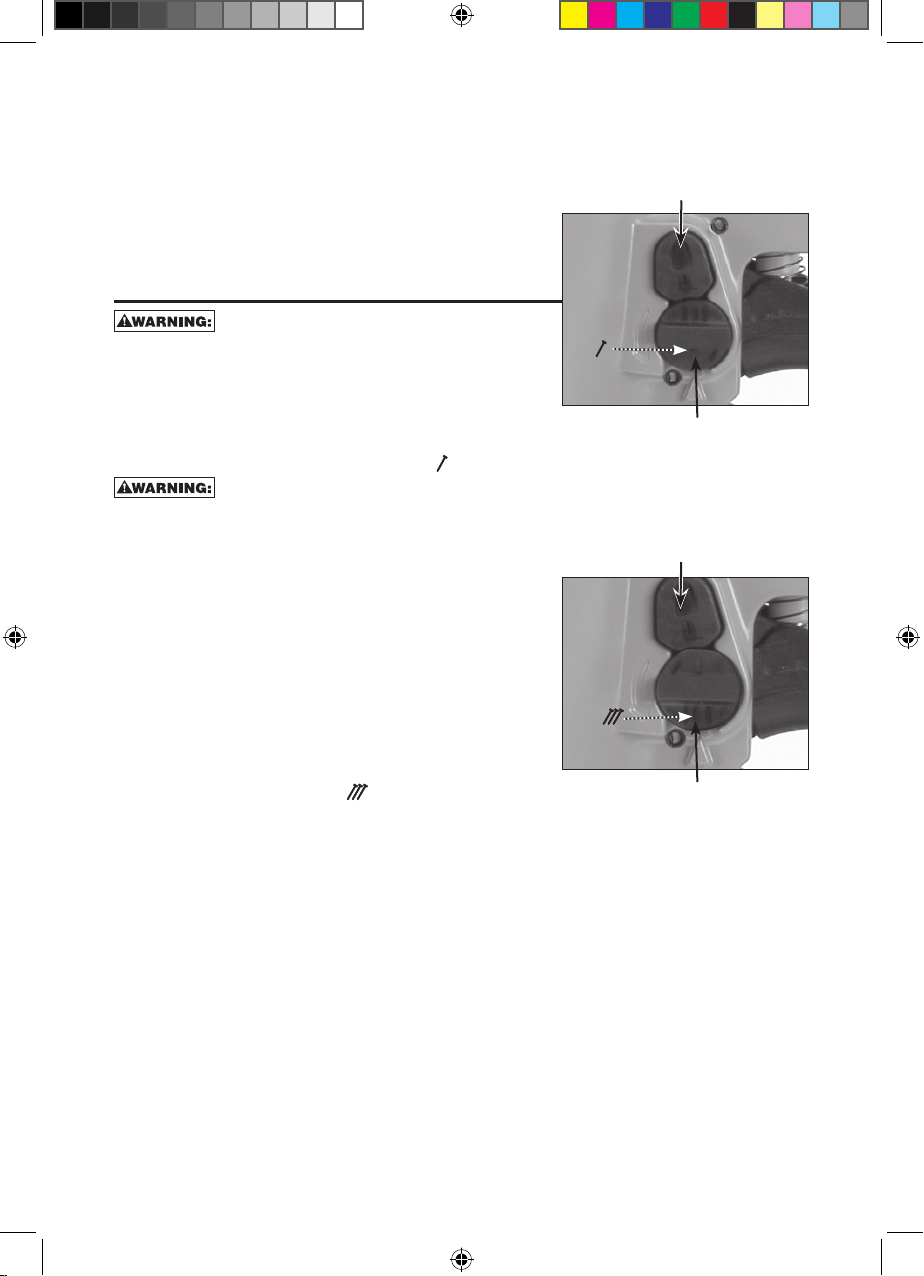

LOADING THE TOOL (FIG. 1–6)

personal injury may result.

Read the section titled Important Safety Instructions for Pneumatic

To reduce the risk of damage to the tool, only use BOSTITCH pneumatic

DO NOT use detergent oil or additives as they will damage O-rings and

rubber parts.

2

).

To reduce the risk of personal injury, disconnect tool from air

Keep the tool pointed away from yourself and others. Serious

6 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 6 1/28/15 7:41 AM

Never load nails with

Fig. 2

the contact trip or trigger activated.

Personal injury may result.

1. Read all Safety Warnings before

using tool.

2. Connect the air supply to the tool.

E

3. Lift the canister door latch (E) to

open the nail guide door (H).

4. Rotate the canister door (I) open.

5. Adjust the nail platform (J) to

H

properly accommodate the nail

length being used. Pull the nail platform (J) up or down for desired nail.

Platform Position Nail Length

lowest position 1-1/2" (38 mm) - 1 3/4" (44.5mm)

center position 1-1/4" (32 mm)

upper position 3/4" (19 mm) - 1" (25 mm)

I

Fig. 3

Fig. 5

J

M

Fig. 4

K

L

Fig. 6

E

H

6. Place the coil on the nail platform (J). NOTE: Observe fastener icon (K) Fig. 4.

Insert fasteners (L) with points down.

IMPORTANT: Fasteners must point in the same direction as they will be driven.

7. Uncoil enough nails [approximately 3" (76mm)] to reach the nose of the tool.

8. Insert the first nail into the nose and the second nail (M) between the two rails

of the feed pawl as shown in Fig. 5.

7 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 7 1/28/15 7:41 AM

NOTE: Be careful not to deform the coil of nails during the loading process.

Otherwise, the nail guide door will not close and the nails might not feed

consistently.

9. Close the canister door (I) completely.

Trigger lock button

10. Close the nail guide door (H) making sure the

door latch (E) is completely engaged as shown

in Fig. 6.

Fig. 7

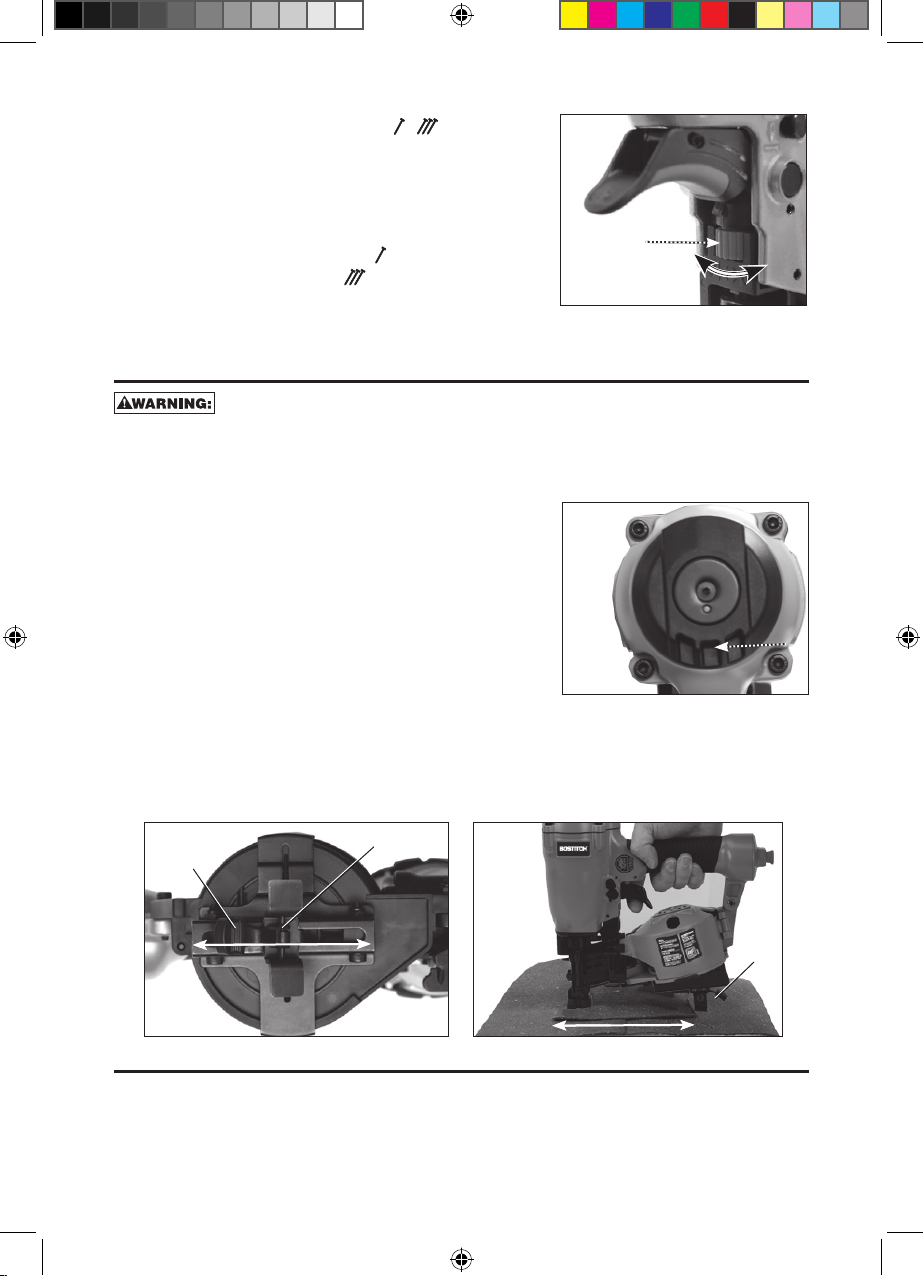

ACTUATING TOOL:

wear proper eye ANSI Z87.1 (CAN/CSA Z94.3)

S

and hearing protection ANSI S12.6 (S3.19) when

operating this tool. The tool can be actuated using

one of two modes: single sequential actuation

To reduce the risk of injury, A LWAYS

trigger mode and contact actuation trigger mode.

Single Sequential actuation trigger -

(Fig. 7)

Trigger mode selector button

Allow the tool to recoil off the work surface after actuation. If

the contact trip remains depressed a nail will be driven each time the trigger is

released and pulled, which could result in accidental actuation, possibly causing

injury.

Trigger lock button

The sequential actuation trigger’s intended use is

for intermittent fastening where accurate fastener

Fig. 8

placement is desired.

To operate the tool in Single sequential actuation

mode:

1. Depress the contact trip firmly against the

work surface.

2. Pull the trigger.

C

3. Allow the tool to recoil from the work surface.

Contact actuation trigger -

(Fig. 8)

Trigger mode selector button

The contact actuation trigger is intended for rapid fastening on flat, stationary

surfaces.

Using the contact actuation trigger, two methods are available: place actuation

and contact actuation.

To operate the tool using the PLACE ACTUATION method:

1. Depress the contact trip against the work surface.

2. Pull the trigger to drive the fastener.

3. Allow the tool to recoil off the work surface

To operate the tool using the CONTACT ACTUATION method:

1. Pull the trigger.

2. Depress the contact trip against the work surface. As long as the trigger is

pulled, the tool will drive a fastener every time the contact trip is depressed.

This allows the user to rapidly drive multiple fastener in sequence.

8 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 8 1/28/15 7:41 AM

Changing the Actuation Mode -

1. Push the (red) trigger lock button down

2. Rotate the (black) selectable trigger button

counterclockwise

3. Align the triangular indicator to the desired

mode

• For Sequential Mode

• For Contact Mode

4. Then push the trigger lock button back up to

the un-locked position.

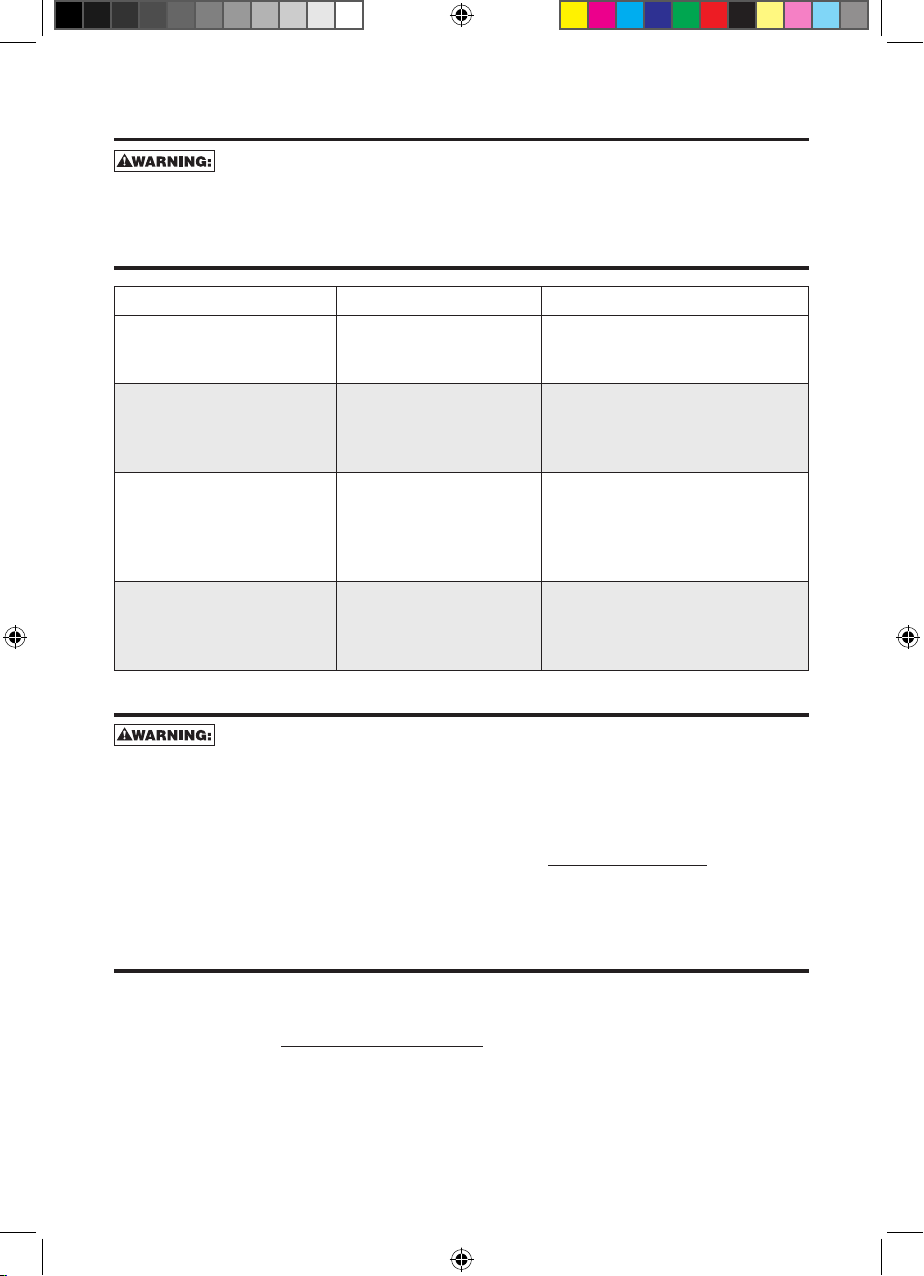

ADJUSTING DEPTH (FIG. 9):

Fig. 9

G

attempting to adjust depth, ALWAYS:

To reduce risk of serious injury from accidental actuation when

• Disconnect air supply and engage trigger lock.

• Avoid contact with trigger during adjustments.

The depth that the fastener is driven can be adjusted using the depth adjustment

next to the trigger of the tool.

The depth of drive

Fig. 10

is factory adjusted to a nominal setting. Test

drive a fastener and check depth. If a change is

desired:

1. To drive the nail shallower, rotate the depth

setting wheel (G) to the right.

2. To drive a nail deeper, rotate the depth setting

wheel (G) to the left.

A

The adjustment knob has detents every 1/4 turn.

Test drive another fastener and check depth.

Repeat as necessary to achieve desired results. The amount of air pressure

required will vary depending on the size of the fastener and the material being

fastened. Experiment with the air pressure setting to determine the lowest setting that will consistently perform the job at hand. Air pressure in excess of that

required can cause premature wear and/or damage to the tool.

Fig. 11

O

P

Fig. 12

O

R

Q

DIRECTIONAL EXHAUST DEFLECTOR:

Adjust directional exhaust deflector (A) Fig. 10, so that the exhaust air blast will

be directed away from the operator. The exhaust deflector can be adjusted any

position for directing the exhaust blast away from the operator. Grasp the deflector and rotate it to the desired position for the current application.

9 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 9 1/28/15 7:41 AM

SHINGLE GUIDE (FIG. 11, 12)

Adjust shingle guide (O):

1. Loosen the adjusting lever (P) and slide the

locking plate to desired position.

2. Tighten adjusting lever firmly.

The locking plate (O) can be used as an aid to

position the shingle being nailed a specific

distance (Q) from the front edge of the previous

row of shingles (R) as shown.

CLEARING A JAMMED NAIL (FIG. 1,9)

Fig. 13

ger lock lift the canister door latch, open the canister door, and remove

fasteners from magazine before making adjustments or personal injury may

result.

If a nail becomes jammed in the nosepiece, keep the tool pointed away from you

and follow these instructions to clear:

1. Disconnect the air supply from the tool.

2. Engage trigger lock.

2. Lift the canister door latch (E) to open the nail guide door (H).

3. Open the canister door.

4. Remove the jammed nail.

5. Correct any deformation that may have occurred to the nail coil.

NOTE: Should nails continue to jam frequently in nosepiece, have tool serviced by

an authorized BOSTITCH service center.

Disconnect air line from tool, engage trig-

COLD WEATHER OPERATION

When operating tools at temperatures below freezing:

1. Make sure compressor tanks have been properly drained prior to use.

2. Keep tool as warm as possible prior to use.

3. Make certain all fasteners have been removed from canister.

4. Put 5 to 7 drops of BOSTITCH pneumatic tool oil in the air inlet.

5. Lower air pressure to 80 psi (5.5 bar) or less.

6. Reconnect air and load nails into canister.

7. Actuate the tool 5 or 6 times into scrap lumber to lubricate O-rings.

8. Turn pressure up to operating level (not to exceed 120 psi) and use tool as

normal.

9. Re-lubricate at least once daily.

10. Always drain the compressor tanks at least once a day.

HOT WEATHER OPERATION

Tool should operate normally. However, keep tool out of direct sunlight as

excessive heat can deteriorate bumpers, O-rings and other rubber parts resulting

in increased maintenance.

10 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 10 1/28/15 7:41 AM

MAINTENANCE:

fasteners from magazine before making adjustments or personal injury may

result.

Disconnect air line from tool, engage trigger lock and remove

DAILY MAINTENANCE CHART:

ACTION WHY HOW

Lubricate tool with 5-7

drops of BOSTITCH

Pneumatic Tool Oil

Drain compressor

tanks and hoses daily

Clean canister, feed

piston area and contact

trip mechanism.

Before each use, check

to insure all screws,

nuts and fasteners are

tight and undamaged.

Prevents failure

of o-rings

Prevents

accumulation

of moisture in

compressor and nailer

Permits smooth

operation of

magazine,

reduces wear and

prevents jams.

Prevents jams, leaks

and premature

failure of tool parts.

Insert drops into air fitting

on end cap of tool

Open petcocks or other drain

valves on compressor tanks.

Allow any accumulated

water to drain from hoses

Blow clean with compressor

air. The use of oils, lubricants

periodically or solvents is

not recommended as they

tend to attract debris.

Tighten loose screws

or other fasteners using

the appropriate hex

wrench or screwdriver.

CLEANING

metallic parts of the tool. These chemicals may weaken the materials used in these

parts. Use a cloth dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

Never use solvents or other harsh chemicals for cleaning the non-

REPAIRS

For assistance with your tool, visit our website at www.bostitch.com for a list of

service centers, or call the BOSTITCH Customer Care Center at 1-800-556-6696. In

Canada please call us at 1-800-567-7705 or visit www.BOSTITCH.com.

SERVICE:

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our

service website at http:/www.bostitch.com. You can also order parts from your

nearest BOSTITCH Factory Service Center or BOSTITCH Authorized Warranty

Service Center. Or, you can call our Customer Care Center at 1-800-556-6696. In

Canada please call us at 1-800-567-7705 or visit www.BOSTITCH.com.

11 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 11 1/28/15 7:41 AM

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For

information about BOSTITCH, its factory service centers or authorized warranty

service centers, visit our website at www.bostitch.com or you c

an call our Customer

Care Center at 1-800-556-6696. In Canada please call us at 1-800-567-7705 or visit

www.BOSTITCH.com

. All repairs made by our service centers are fully guaranteed

against defective material and workmanship. We cannot guarantee repairs made or

attempted by others.

You can also write to us for information at BOSTITCH, 701 E. Joppa Road, Towson,

Maryland 21286 - Attention: Product Service. Be sure to include all of the information

shown on the nameplate of your tool (model number, type, serial number, etc.).

ACCESSORIES:

Since accessories, other than those offered by BOSTITCH, have

not been tested with this product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only BOSTITCH recommended accessories

should be used with this product.

A complete line of accessories is available from your BOSTITCH Factory Service

Center or a BOSTITCH Authorized Warranty Service Center. Please visit our Web Site

www.bostitch.com for a catalog or for the name of your nearest supplier.

12 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 12 1/28/15 7:41 AM

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call

for a free replacement.

In Canada please call us at 1-800-567-7705 or visit

1-800-556-6696

www.BOSTITCH.com.

TROUBLE SHOOTING GUIDE:

MANY COMMON PROBLEMS CAN BE SOLVED EASILY BY UTILIZING THE CHART

BELOW. FOR MORE SERIOUS OR PERSISTENT PROBLEMS, CONTACT A BOSTITCH

SERVICE CENTER OR CALL 1-800-556-6696.

air from tool and engage trigger lock, before all repairs.

SYMPTOM PROBLEMS SOLUTIONS

Air leak near

top of tool or in

trigger area

Tool does nothing or

operates sluggishly

Air leak near

bottom of tool

Tool jams frequently Incorrect fasteners. Verify approved fasteners

Other Contact a BOSTITCH

To reduce the risk of serious personal injury, ALWAYS disconnect

Loose screws. Tighten screws.

Worn or damaged

Install Overhaul Kit.

o-rings or seals.

Inadequate air supply. Verify adequate air supply.

Inadequate lubrication. Put 5 or 7 drops of

oil into air inlet.

Worn or damaged

Install Overhaul Kit.

o-rings or seals.

Loose screws. Tighten screws.

Worn or damaged

Install Overhaul Kit.

o-rings or bumper.

of correct size and 15°

collation angle.

Damaged fasteners.

Bent collation wire.

Canister or nose

Replace with undamaged

fasteners.

Tighten screws.

screws loose

Canister is dirty. Clean magazine.

Driver tip is worn

Install Driver Maintenance Kit.

or damaged.

Authorized Warranty

Service Center

TOOL SPECIFICATIONS

BRN175

Height (inch/mm) 10.63/ 270

Width (inch/mm) 4.33/ 110

Length (inch/mm) 10.24/ 260

Weight (lbs/kg) 4.78/ 2.17

Recommended Operating Pressure 70-120 psi (4.8 to 8.3 bar)

Air Consumption per 100 cycles 4.13 CFM

Loading capacity 120 nails

13 - ENG

BRN175_9R209323_MAN_kf V2_multi.indd 13 1/28/15 7:41 AM

INTRODUCCIÓN

Las BOSTITCH BRN175 es una herramienta construida con precisión, diseñada para la fijación de alta velocidad

y de alto volumen. Estas herramientas ofrecen un servicio confiable y eficiente cuando se utilizan de la manera

correcta y con cuidado. Al igual que con cualquier herramienta fina, deben observarse las instrucciones del

fabricante para un mejor rendimiento. Estudie este manual antes de utilizar la herramienta y comprenda las

advertencias y precauciones de seguridad. Las instrucciones de instalación, operación y mantenimiento deben

leerse con atención y debe conservarse el manual para tener como referencia. NOTA: Pueden requerirse medidas

adicionales de seguridad debido a las aplicaciones específicas de la herramienta. Contacte a su representante o

distribuidor de BOSTITCH si tiene preguntas con respecto a la herramienta y su uso. BOSTITCH, 701 E. Joppa

Road, Towson, Maryland 21286, EE. UU. y Canadá solamente, É.-U. et Canada seulement

ÍNDICE

Instrucciones de seguridad .......................................3

Especificaciones de los clavos .....................................4

Identificación de partes de la herramienta, gatillo.......................5

Carga de la herramienta ......................................6 & 7

Herramienta de accionamiento ....................................8

Funcionamiento ................................................8

Ajuste de la profundidad .........................................9

Deflector de escape direccional ...................................9

Eliminación de un clavo atascado..................................10

Cuadro de mantenimiento diario, especificaciones de la herramienta . . . . . . 13

NOTA:

Las herramientas BOSTITCH han sido diseñadas para proporcionar una excelente satisfacción del cliente y están

destinadas para alcanzar un máximo rendimiento cuando se usan con las fijaciones de precisión BOSTITCH,

diseñadas con los mismos estándares de precisión. BOSTITCH no puede asumir la responsabilidad por el

rendimiento del producto si nuestras herramientas se usan con fijaciones o accesorios que no cumplen

los requisitos específicos establecidos para clavos, grapas y accesorios originales de BOSTITCH.

GARANTÍA LIMITADA - Solo EE. UU. y Canadá

Sistemas de fijación BOSTITCH “BOSTITCH” garantiza al comprador minorista original que el producto comprado

está libre de defectos en material y mano de obra, y acepta reparar o reemplazar, a opción de BOSTITCH, toda

grapadora o clavadora de marca BOSTITCH defectuosa por un período de siete (7) años desde la fecha de compra

(y un [1] año desde la fecha de compra, en el caso de compresores y herramientas utilizados en aplicaciones

de producción). La garantía no es transferible. Se requiere prueba de la fecha de compra. Esta garantía cubre

únicamente daños derivados de defectos en el material o en la mano de obra; no cubre condiciones o averías

resultantes del desgaste normal, negligencia, abuso, accidente o reparaciones que se hayan intentado o realizado

a través de otro servicio que no sea el centro de reparación nacional o un centro de servicio de garantía autorizado.

Las hojas de transmisión, protecciones, juntas tóricas, pistones y anillos del pistón se consideran piezas de desgaste

normal. Para un rendimiento óptimo de su herramienta BOSTITCH, use siempre fijaciones y piezas de repuesto

originales de BOSTITCH.

ESTA GARANTÍA REEMPLAZA TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, QUE INCLUYE, ENTRE

OTROS, LAS GARANTÍAS IMPLÍCITAS DE COMERCIABILIDAD O APTITUD PARA UN PROPÓSITO EN

PARTICULAR. BOSTITCH NO SERÁ RESPONSABLE POR DAÑOS INCIDENTALES O RESULTANTES.

Algunos estados y países no permiten las limitaciones al plazo de una garantía implícita, o la exclusión o limitación

de daños incidentales o resultantes, por lo que las limitaciones o exclusiones anteriores pueden no ser de aplicación

para usted. Esta garantía le ofrece derechos legales específicos, y también puede tener otros derechos que pueden

variar de un estado a otro y de un país a otro. Para obtener el servicio de garantía en los EE. UU., devuelva el

producto, junto con el comprobante de compra, al Centro de servicio nacional de BOSTITCH en los EE. UU. o el

centro de servicio de garantía

independiente regional autorizado. En los EE. UU., puede contactarnos al 1-800-556-6696 o visitar www.BOSTITCH.

com para conocer la ubicación más conveniente para usted. En Canadá, contáctenos al 1-800-567-7705 o visite

www.BOSTITCH.com.

14 - SP

BRN175_9R209323_MAN_kf V2_multi.indd 14 1/28/15 7:41 AM

Loading...

Loading...