Page 1

2HAB=?A

Thank you for purchasing AP-14 Programmable Logic Controller

(PLC), which means you have got a comprehensive information of

features and facilities of this product. But for your better use we

kindly advise you to read the manual carefully before installation.

Attention

(1) The patent and related documents for the equipment belong to

ARRAY ELECTRONIC CO., LTD and are not allowed to be

copied or reprinted by the third party without permission.

(2) The manufacturer remains the right of designing and improv-

ing the equipment without notice.

(3) Please oblige us with your valuable comments if there is some

defect in the manual, well write them in the next edition.

ARRAY ELECTRONIC CO.,LTD

Page 2

PART ONE

AP-14M PLC

The new type of AP-14M Programmable logic

controller (PLC) is especially designed for sophisticated industrial control. The simple and useful

instructions ensure you to learn it easily within

the short time.

Using traditional handheld programmer, user

can edit and test PLC by single step. In addition,

when th e programming software of EASY2000

(developed for PLC) is in available, you can edit/

read/write programs, step PLC and simulation

by communicating with personal computer.

The compact size of AP-14 PLC is preciously

designed for being assembled in machine for easy

installation and remove.

Page 3

Chapter 1 General Description

of AP-14

1.1 Characteristics of AP-14

(1) The super-mini size of AP-14 is available to be assembled in the machine

The compact size of AP-14 is especially designed for being assembled in machine

and the fixed screw terminal panel for easy installation and remove.

(2) Sufficient capacity of program memory

240-step program capacity provides an effective solution to the sophisticated control, compared with the traditional relays.

(3) Neednt the battery

Using EEPROM (can write 10,000,000 times), programming memory can restore

the original information without back-up battery in event of power supply failure.

(4) The simplest instructions for easy learning and using

The simple and useful instructions ensure to use AP-14 easy and help you to save

time and efforts.

(5) Provide programming software

Provide editing software running on compatible personal computer to program, edit,

debug, simulate, restore, print, check etc.

1-1

Page 4

1.2 Precautions of Operation

1.2.1 Fix the Screw Tightly and Connect to the Cable Contact

Make sure to fix the screw tightly to avoid operation failure.

Make sure to connect to the cable contact to avoid dropping.

Ć

1.2.2 Guide Rail Mounting

The rail is mounted to support DIN rail, so as it being mounted,

please wedge the flexibal block of PLC bottom to the rail tightly,

or the function of shock proof maybe weaken.

1.2.3 Do not Install Under the Following Environments:

Direct sunlight or the temperature<-5¢J or >+55¢J

Dust, conductive powder, corrosive gases, oil fogs or too much salt

Condensation (due to sudden temperature variation) or the relative

humidity<45% or >85%.

Obvious vibration or shock on the product.

1.2.4 Available Power Supply (Please Refer to Chapter 2.5: Knob )

Choose available A. C. power supply for PLC, adjust the power supply

knob to proper version to energize.

1-2

Page 5

1.3 Programming Tools

1.3.1 EASY2000 Programming Software

Program AP-14 on PC

Personal Computer

EASY-2000

AP-14M PLC

EASY-2000 Software (Please refer to PART TWO)

When EASY2000 is in available, you can program, communicate with AP-14M

PLC, read/write programs, simulate or step PLC on Personal Computer.

1-3

Page 6

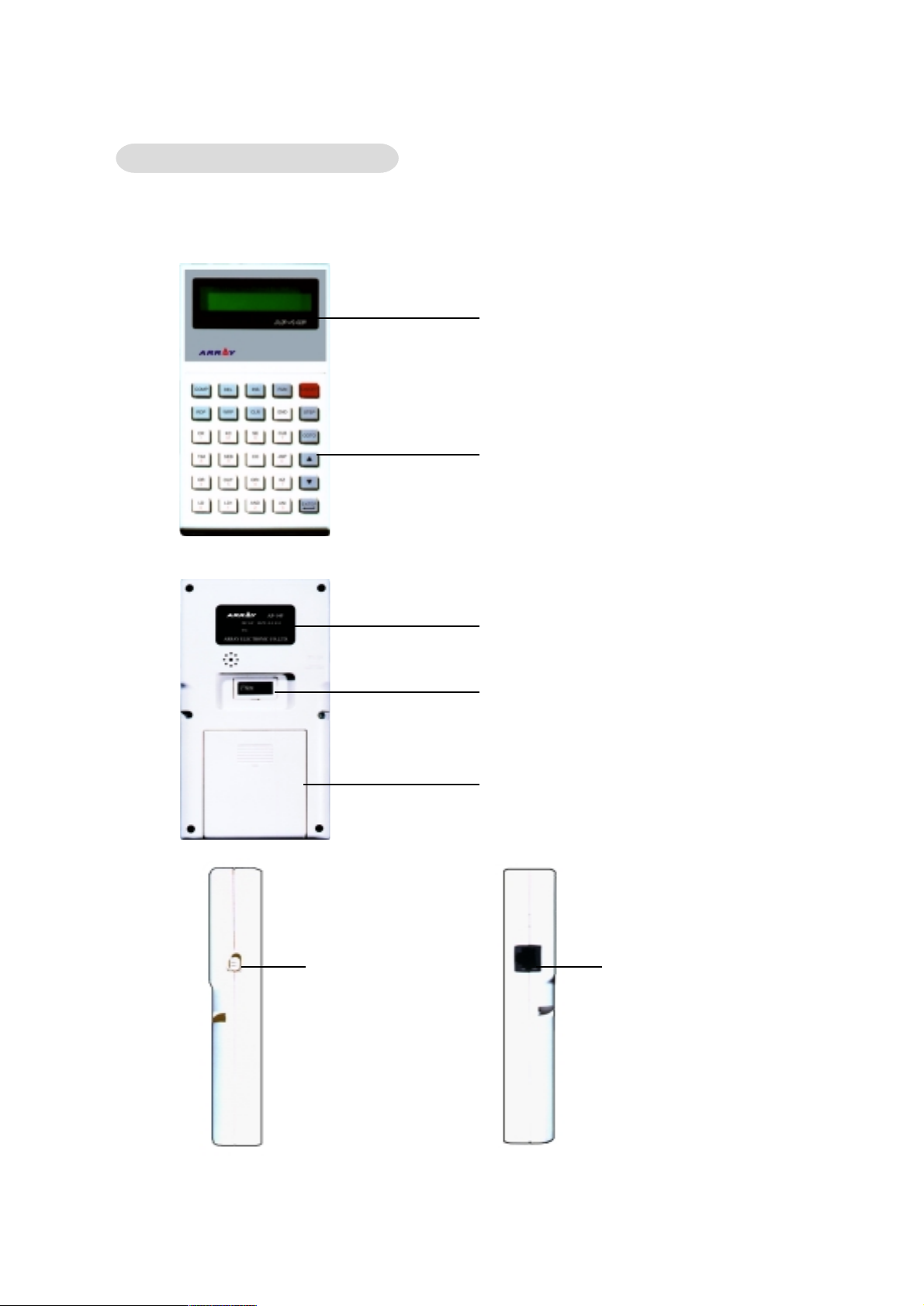

1.3.2 Ap-14P Programmer

Combing portable AP-14P programmer and AP-14M PLC is available to programming edit,

step test, and debug.

Liquid Crystal Display (LCD)

Button

Power Knob

Up(POWER): Power off

Down(BATTERY): Power on

Specification Brand

Special contact for EEPROM writer

(memory is available to replace to

keep changeable programs)

Battery Cover (AA

¡°¡°

¡°4pcs inside)

¡°¡°

Programmer cable contact

1-4

Page 7

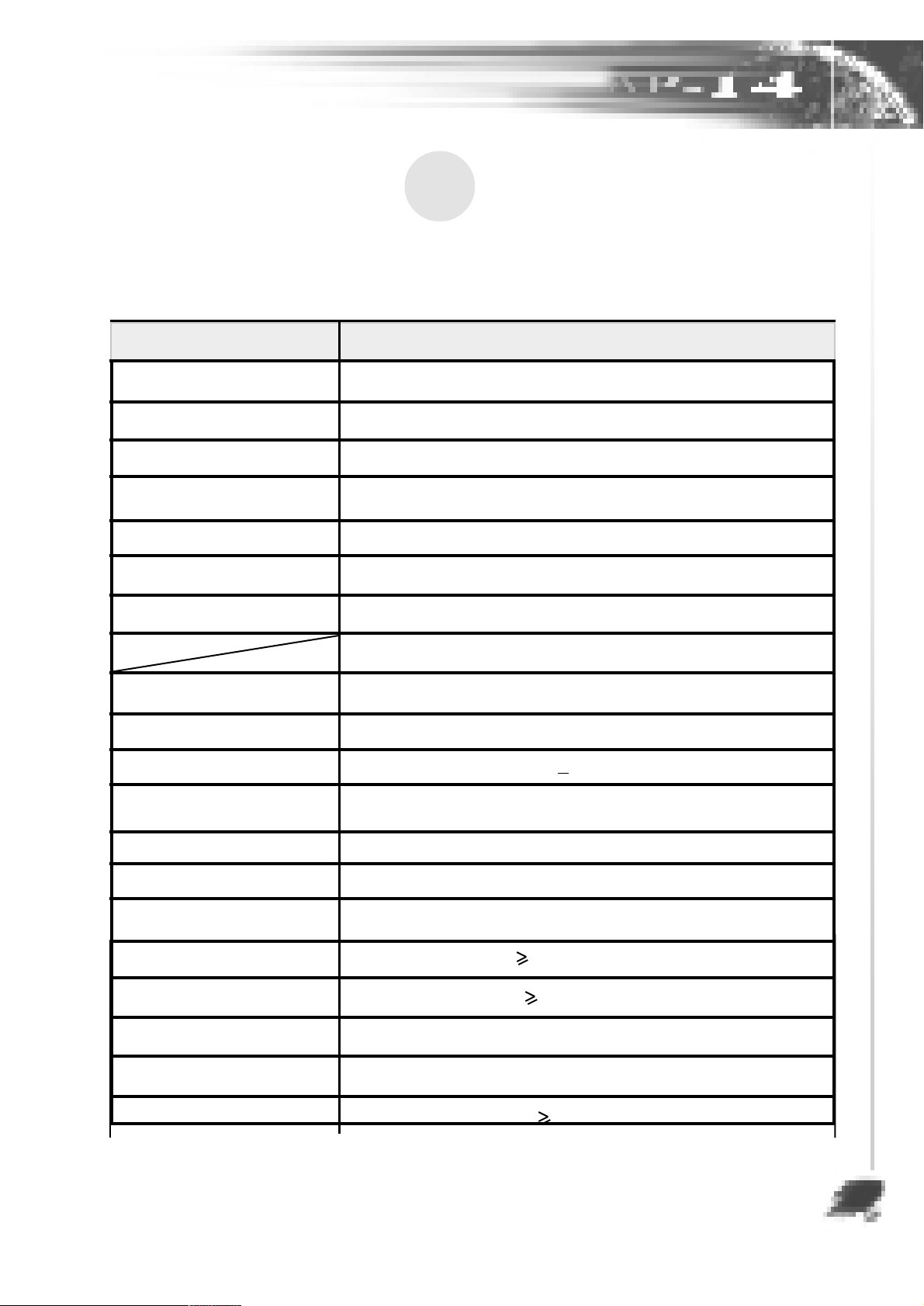

Chapter 2 Specification

2.1 General Specification

Item

Voltage

Power

Cooling method

Operating temperature

Ambient humidity

Storage temperature

Operating environment

Vibration-proof

Shock-proof

Sensor power supply

Specification

AC 110V/220V(50/60Hz single-phase)

12W

Air cooling

- 5¢XC ~ +55 ¢ X C

45~85%RH (non-condensing)

- 25¢XC ~ +75 ¢X C

no dust, no conductive powder, no corrosive

gases, no oil fogs or no too much salt

16.7Hz, X, Y, Z direction 30min

15G, X, Y, Z direction 3times

DC24V( +15%), max 50mA

Momentary interrupt

of the power

Programmer

Control panel indicator

Installation method

Program writing

Age of program storage

Electrostatic Discharge 6KV contact discharge ( super class)

Pulse 2KV power wire

Insulation Resistance

Interrupt time

< 0.5a.c. cycle, interval ¡Ù 1s

Handheld programmer, PC programming software(EASY2000)

ERR: red; others: Green

direct installation (fixed with the screwdriver) or fixed with DIN rail

10,000,000 times

200 years

100M

£[£[

£[

£[£[

2-1

Page 8

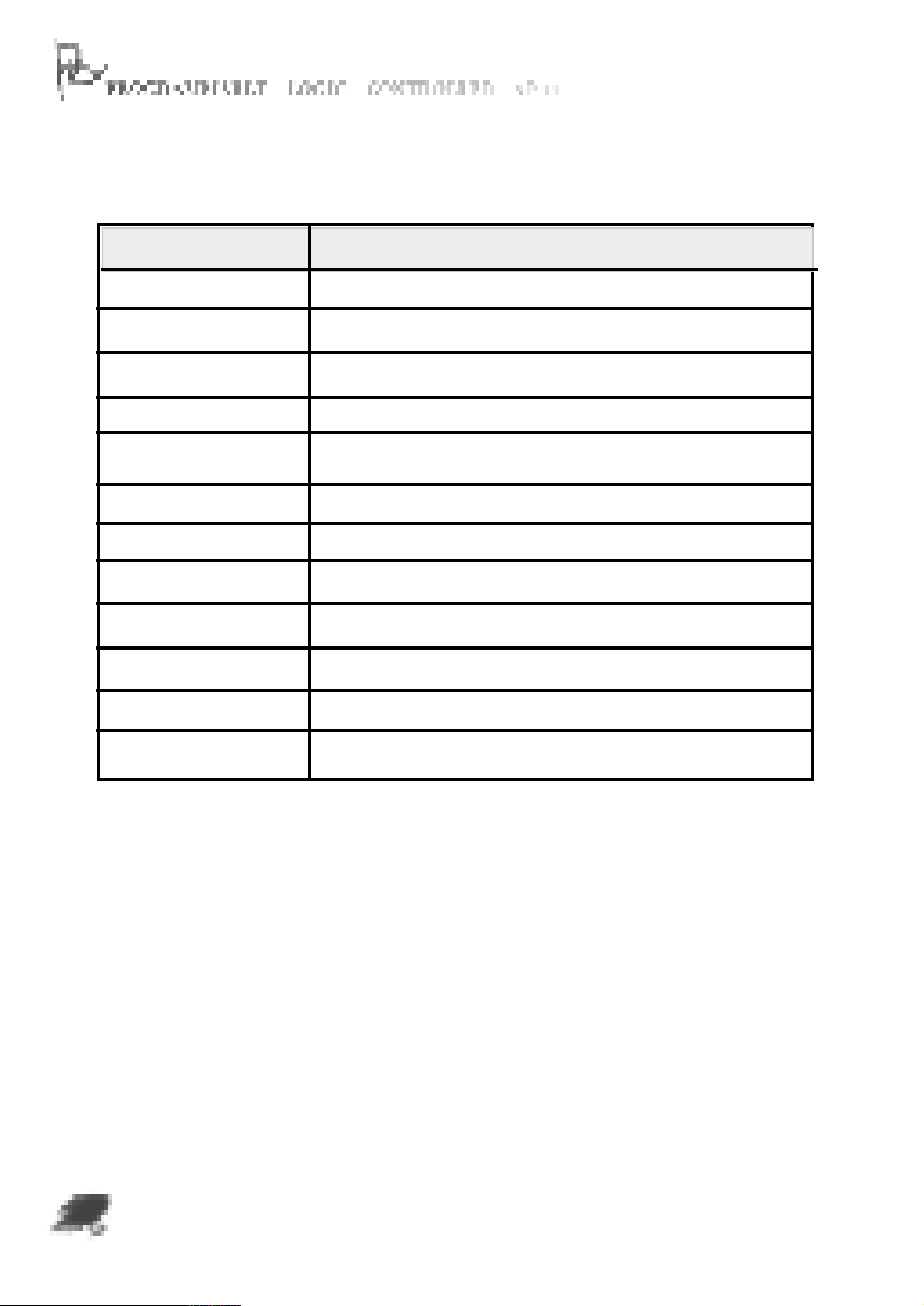

2.2 Function Specification

Item Specification

Operating version Program storage

Control method Cyclic scan

Programming language

Program memory EEPROM

Program memory

240 steps

Special language for the controller(Ladder logic, Instruction list)

capacity

Instruction list

Input relay (I) 8 points I0~I7

Output relay (O) 6 points O0~O5

Internal relay (M) 32 points M00~M31

Timer (T) 4 points T0~T3 the presetting time range:[0.01~255s]

Counter(C) 4 point C0~C3 the presetting count range:[001~255T]

Self diagnostic module

15 instructions(including Basic logic, timer and counter instruction etc)

program checking (Grammar, Circuit); WATCH DOG monitor

2-2

Page 9

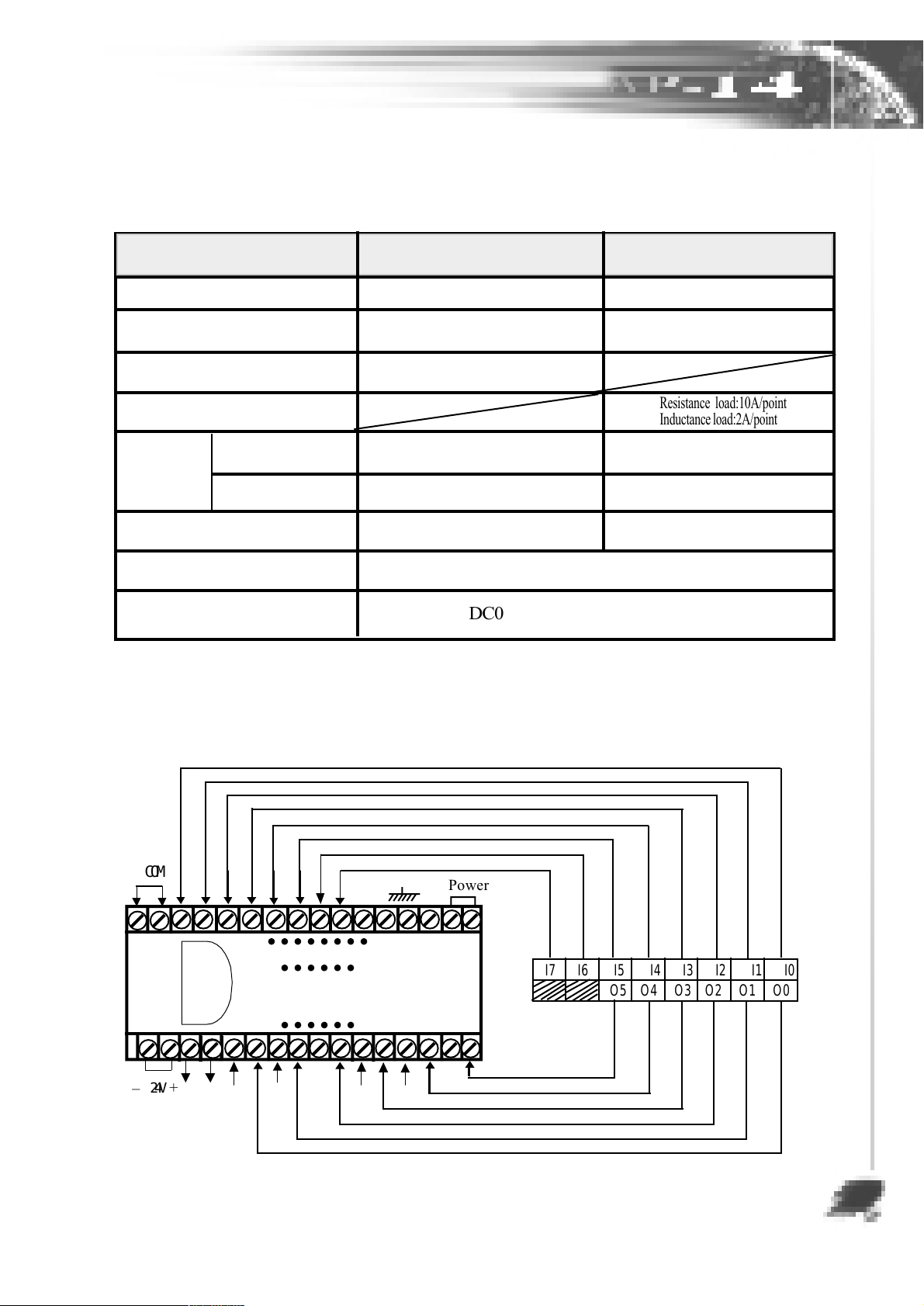

2.3 Input/Output Specification

12

12

12

12

12

12

Item Input part Output part

I/O version photo coupler relay output

I/O defined code I0~I7 O0~O5

Input voltage DC24V

Single-point current

ON/OFF 8mS 8mS

Response

OFF/ON 8mS 8mS

time

I/O signal indication

LED flashes green when

input is active

DC10V~30V(typical value: 24V)

High level voltage range

in input port

(1)

Low level voltage range

in input port

(0)

DC0V~3V(typical value: 24V)

Resistance load:10A/point

Inductance load:2A/point

LED flashes green when

output is active

2.4 Terminal Setting and Address Distributing

COM

_

24V

Power

I7 I6 I5 I4 I3 I2 I1 I0

AP-14M

O5 O4 O3 O2 O1 O0

+

2-3

Page 10

2.5 Name and Function of Sub-parts

(10)

(1)

(2)

(3)

(4)

(1) Input terminal row

Receive/refuse power and signal of input

(2) Program button

Press it when write the programs

(3) Program circuit contact

Combining programmer circuit is available

to write programs

(4) Installation port

Available to install and fix screw

(5) Keeping memory knob

Choose MEMORY modules

(6) Normal/single-operation switch

Choose normal/single operation

(combining with programmer/

EASY2000)

(7) Output terminal row

Receive/refuse the output signal

(9)

(8)

(7)

(6)

(5)

(9) Status display LED

POW(green): light on: normal power

RUN(green): light on: normal operate

PRO(green): light on: write/read programs

S I N (green): light on: single operate

ERR(red): light on: wrong operate

MEM(green): light on: choose

MEMORY modules

(10) Input display LED(green)

Display input status, lights on when input

is active

(11) Voltage knob

Choose 110V/220V

(12) DIN rail installation part

Install the rail which supportsDIN

(13) Slide module

tighten/loose DIN rail

(11)

2-4

(8) Output display LED(green)

display output status, LED lights on

(12)

when output is active

(13)

PROGRAMMABLE

ARRAY ELECTRONIC

Page 11

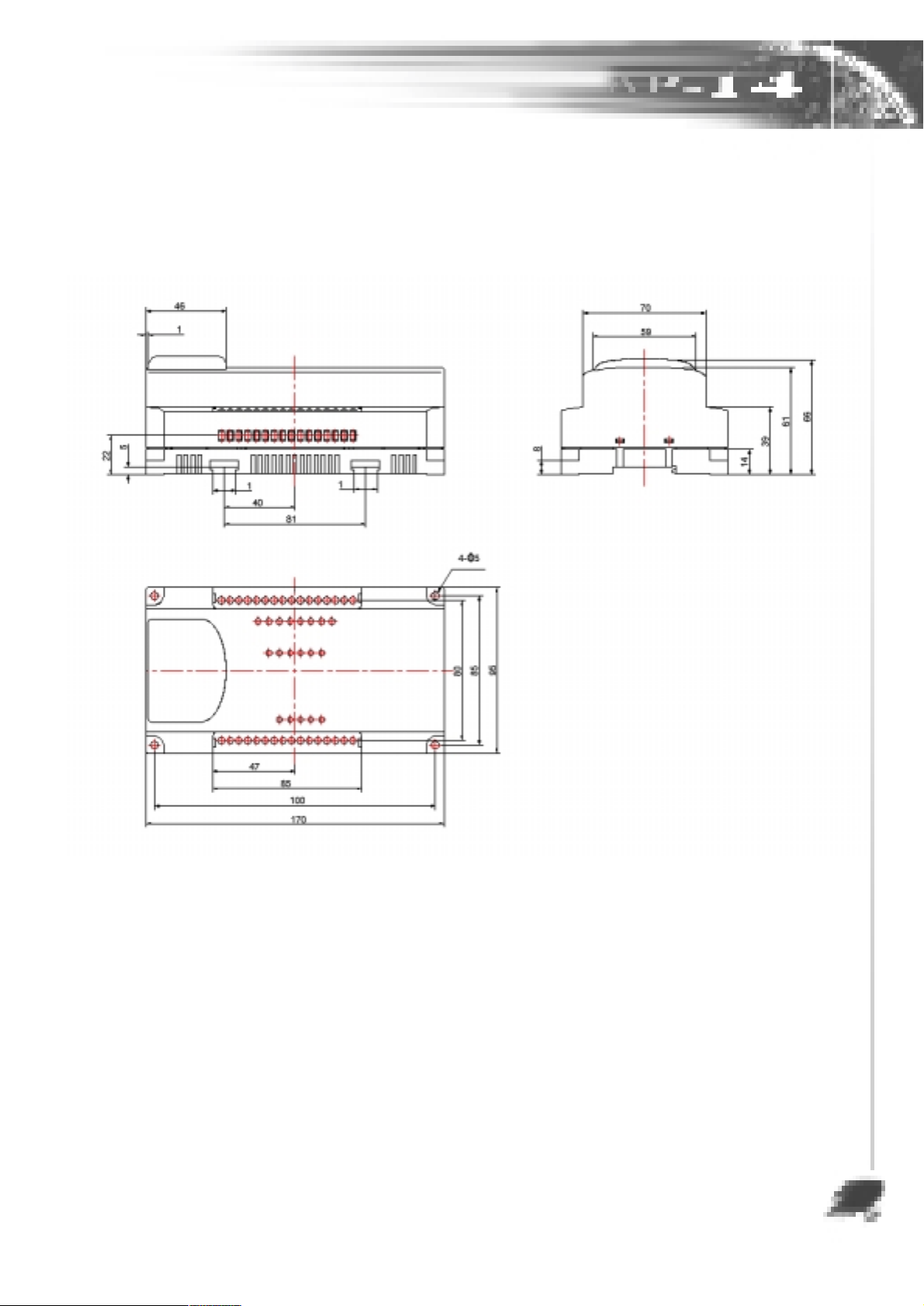

2.6 Dimension and Setting Drawings

[MEASURE: mm]

2-5

Page 12

Chapter 3 Structure and Description

of AP-14 Hardware

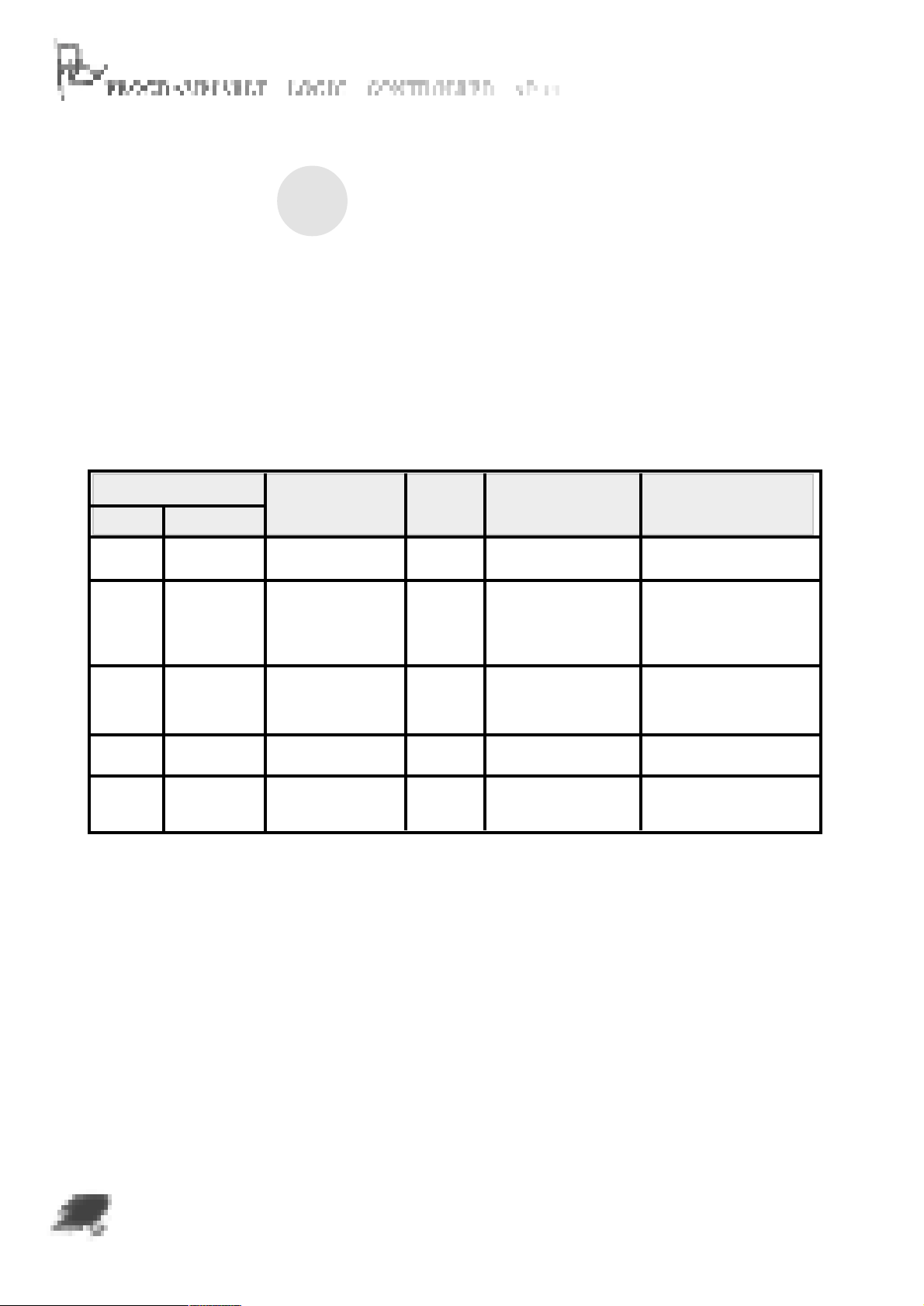

3.1 The Devices Overview

The designated capacity and the initial value are available for application as the following:

Device

symbol

I

O

M

T

C

Input relay

Output relay

Counter

Name

Internal

relay

Timer

Memory

address range

I0-I7

O0-O5

M00-M31

T0-T3

C0-C3

Capacity

8

points

6

points

32

points

4

points

4

points

Initial

value

the output data

OFF(keep the previous state with keeping module if power

failure)

Ditto

Ditto

Ditto

Function

Receive the input

D.C signal

Operate out-load

Control the midway

status of I/O contact,

timer, counter

timer

counter

3-1

Page 13

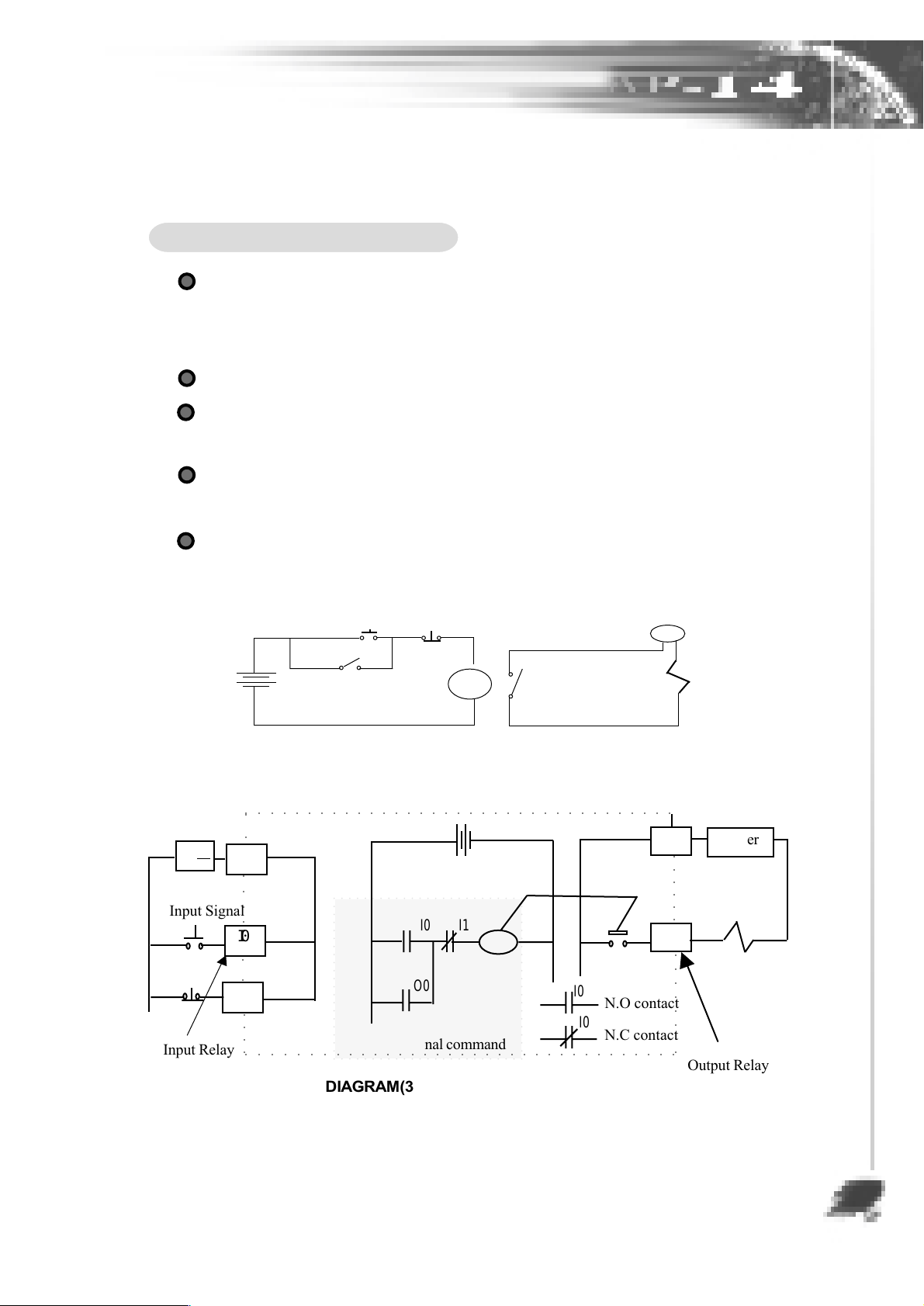

3.2 Description of Various Devices

3.2.1 Input/Output (I/O) Relay

I stands for input relay, Symbol: 10-17, totaling 8, separately connecting positive

power of inputting signal. COM is the public contact for I0-I7 negative terminals,

connecting negative D.C.

O stands for output relay, Symbol: O0-O5, totaling 6.

Bus of programmable logic Controller is available to receive input signal of switch

and send output signal to load.

The normal open contact and normal close contact of I/O relay can be used without

limit.

Function of I/O relay is as the following diagram (3-1):

DC24V

¡Ï

Input Signal

Input Relay

Start

N.O.contact 1

Stop

coil

Power

N.O contact 2

DIAGRAM(3-1)a: Self-keeping Circuit

○○ ○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○

COM

○○○○

O0

I0

○○

I1

○○○○

I0 I1

O0

OUT

I0

N.O contact

I0

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

PLC internal command

N.C contact

DIAGRAM(3-1)b:Self-keeping by PLC I/O Relay

AC

~

Load

O0

○○○○○○

O0

○○○○○○○○

Output Relay

Power

load

3-2

Page 14

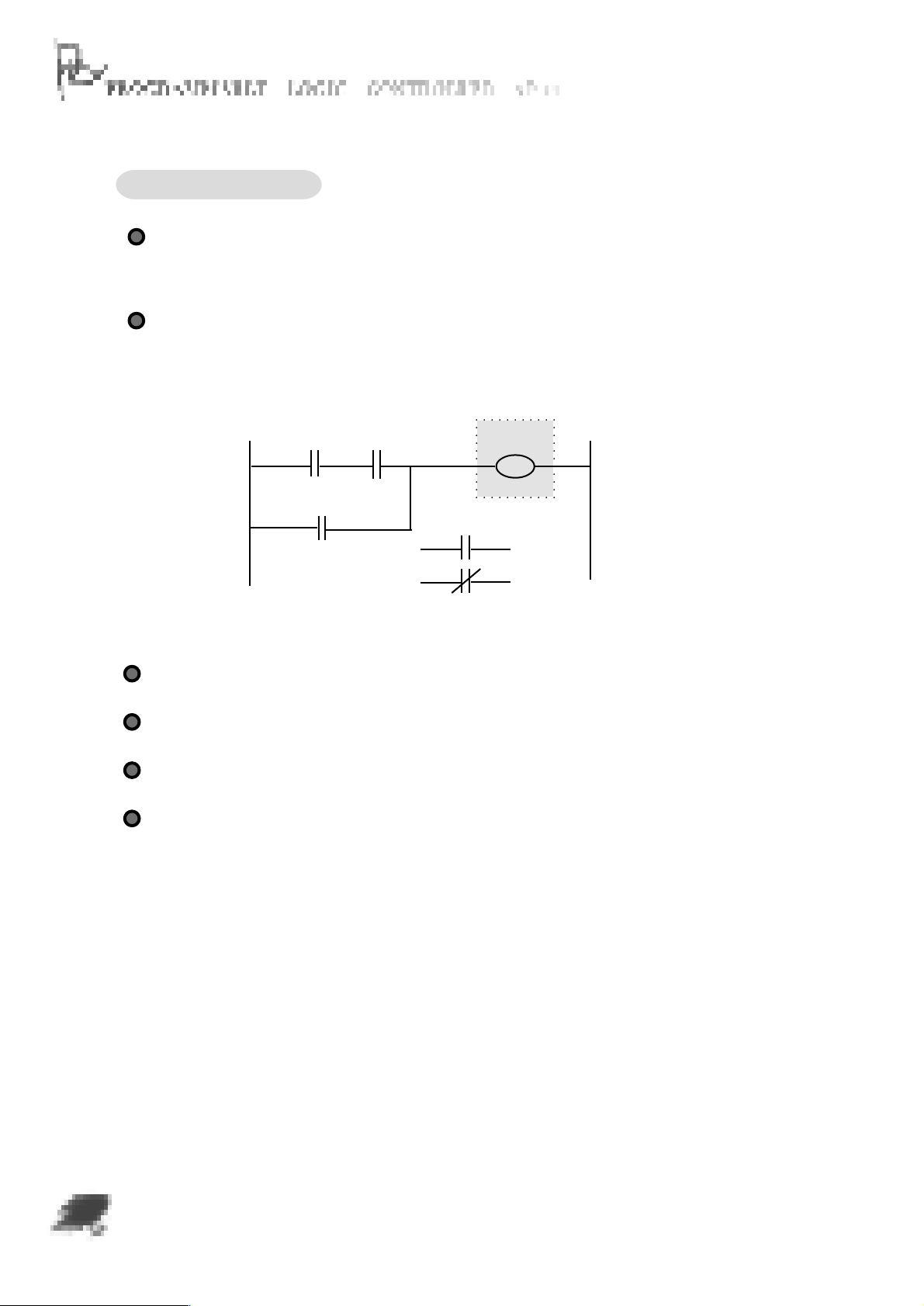

3.2.2 Internal Relay

M stands for internal relay, total 32 internal relays (M00-M31) are available. The N.O.

contact of internal relay is off while the N.C.contact on when machine is powered. Please

see diagram (3-2)

Internal relay contact is unable to output directly

Please see diagram (3-2):

I0 I1

I2

DIAGRAM(3-2)

M00

OUT

M00

N.O CONTACT

M00

N.C CONTACT

If want to change contact state, operate OUT, SE, CR, SEB, CLB etc commands.

Any of PLC contact can operate internal relay, whose coil operates same as output relay.

Internal relay is available to keep intermediate state as the internal contact.

The N.O. contact and N. C. contact of the internal relay can be used without limit.

3-3

Page 15

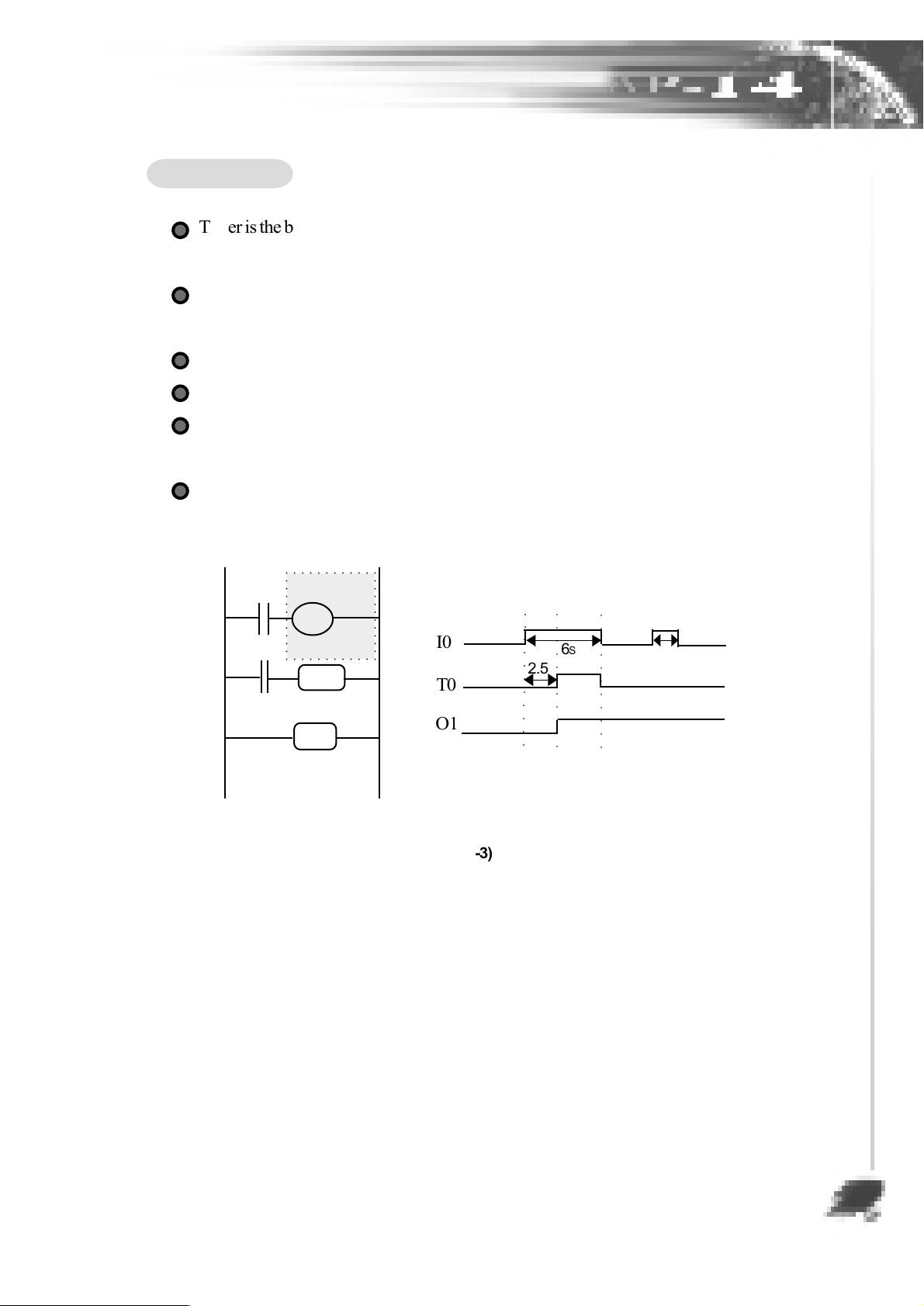

3.2.3 Timer

Timer is the built-in time limit internal relay of the PLC. When it reaches the

presetting data, the output contact operates.

T stands for timer, 4 timers(T0-T3) are available and each with the time range

of [0.01~255]seconds.

Series-timers can time 4,228,250,625 seconds(1,174,514 hours).

The N.O/N.C contact of timer can be used without limit.

With memory module, PLC can keep timing status in event of power failure.

(Refer to chapter 2.5 for more information about memory module)

Timer operating diagram is as the following:

T0

I0

T0

T

O1

SE

KZ002

KC050

I0

T0

○○○○○○○○○○○

○○○○○○○○○○○

65

2.55

25

END

O1

○○○○○○○○○○○

DIAGRAM(3-3)

3-4

Page 16

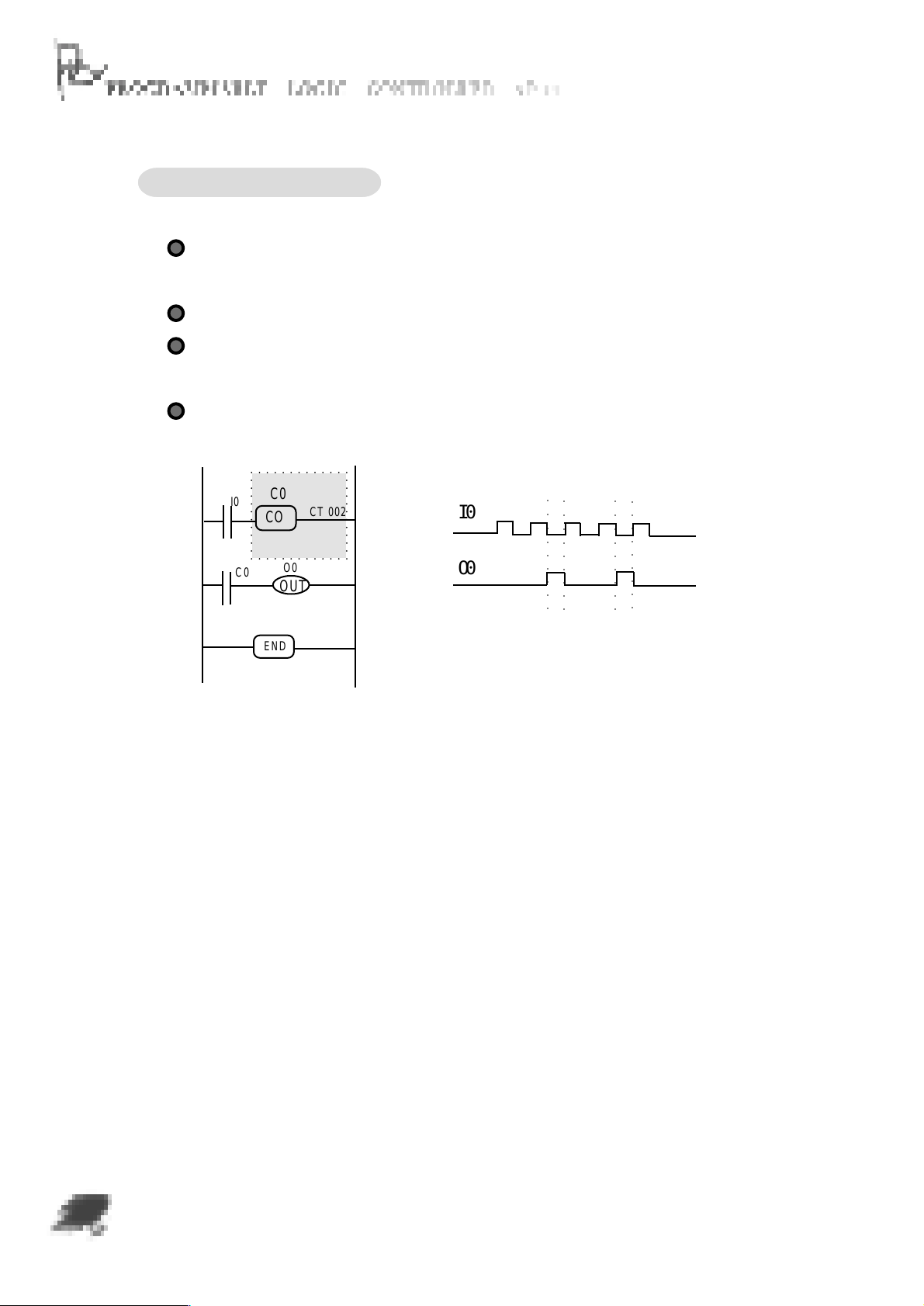

3.2.4 Cycling Counter

C stands for cycling counter, 4 counter (C0-C3)are equipped in PLC and each with

a count range of [001~255]T.

Series-counters can count 4,228,250,625 times.

With memory module, PLC can automatically keep counting status in the event of

power failure. (Refer to chapter 2.5 for more information about memory module)

Cycling Counter operating diagram is as the following:

C0

I0

C0

CO

O0

CT 002

I0

O0

○○ ○○○○○○○

○○ ○○○○○○○

○○ ○○○○○○○

○○○○○○○○○

OUT

END

DIAGRAM(3-4)

3-5

Page 17

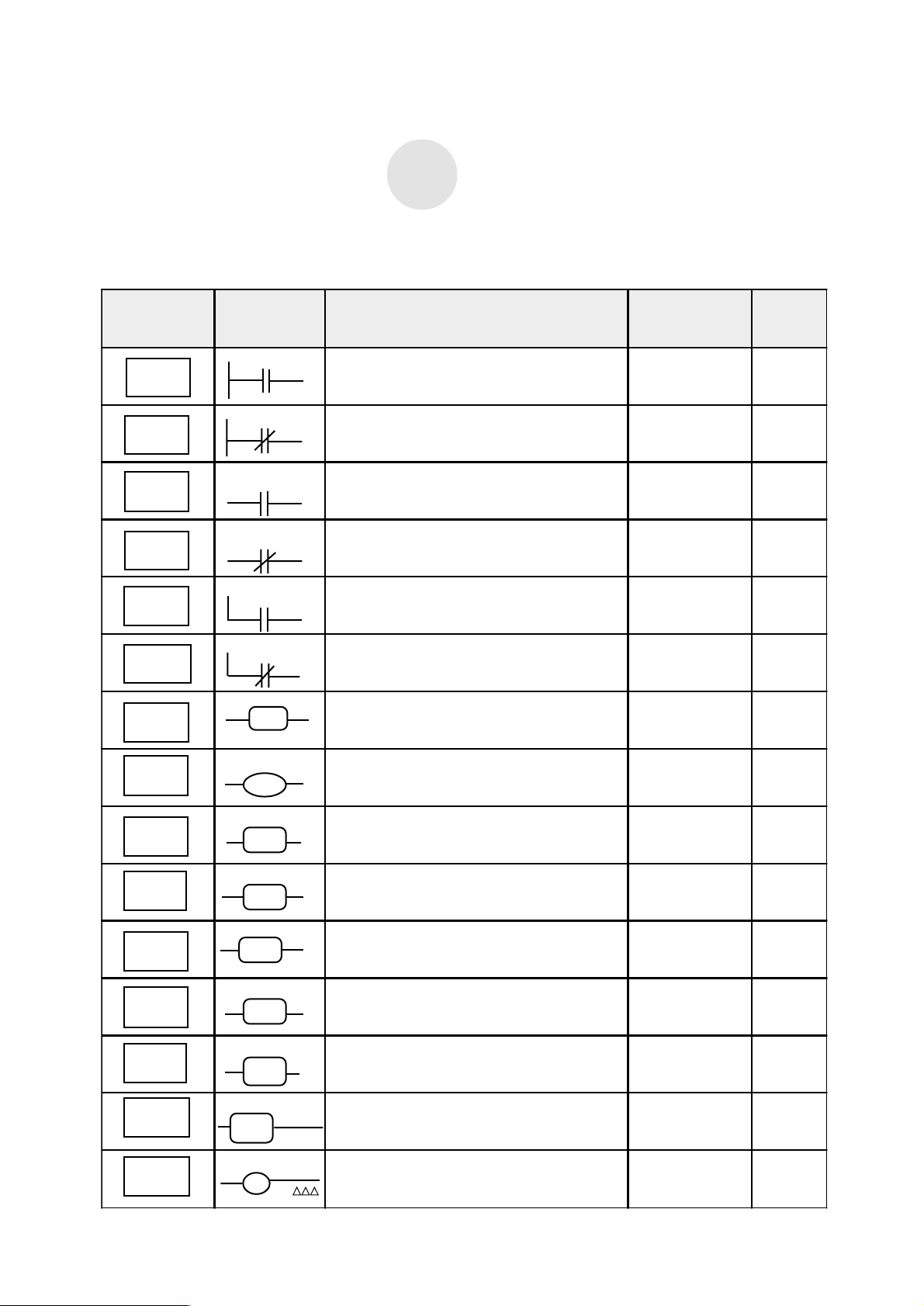

Chapter 4 Instruction

4.1 Instruction Overview

The following diagram shows the instructions of the AP-14 system, totaling 15.

command

symbol

LD

LDI

AND

ANI

OR

ORI

END

X

X

X

X

X

X

END

functionsymbol

combine N.O. contact with the bus

combine N.C. contact with the bus

series-connect an N.O. contact

series-connect an N.C. contact

parallel-connect an N.O. contact

parallel-connect an N.C. contact

program ends

parameter

I, M, O, T, C

I, M, O, T, C

I, M, O, T, C

I, M, O, T, C

I, M, O, T, C

I, M, O, T, C

no operation

parameter

pages

4-2

4-2

4-3

4-3

4-4

4-4

4-3

OUT

SE

SEB

CR

CLB

JMP

CO

TIM

X

OUT

X

SE

X

SEB

X

CR

X

CLB

XXX

JMP

X

CO

X

T

CTXXX

KZXXX

KC

output the operating result

output relay or internal relay setting

internal relay setting

output relay or internal relay resetting

internal relay resetting

program toggle command

Cycling counter C

Timer

M

XXX

O, M

O, M

M

O, M

T

4-3

4-5

4-6

4-7

4-8

4-9

4-10

4-11

4-1

Page 18

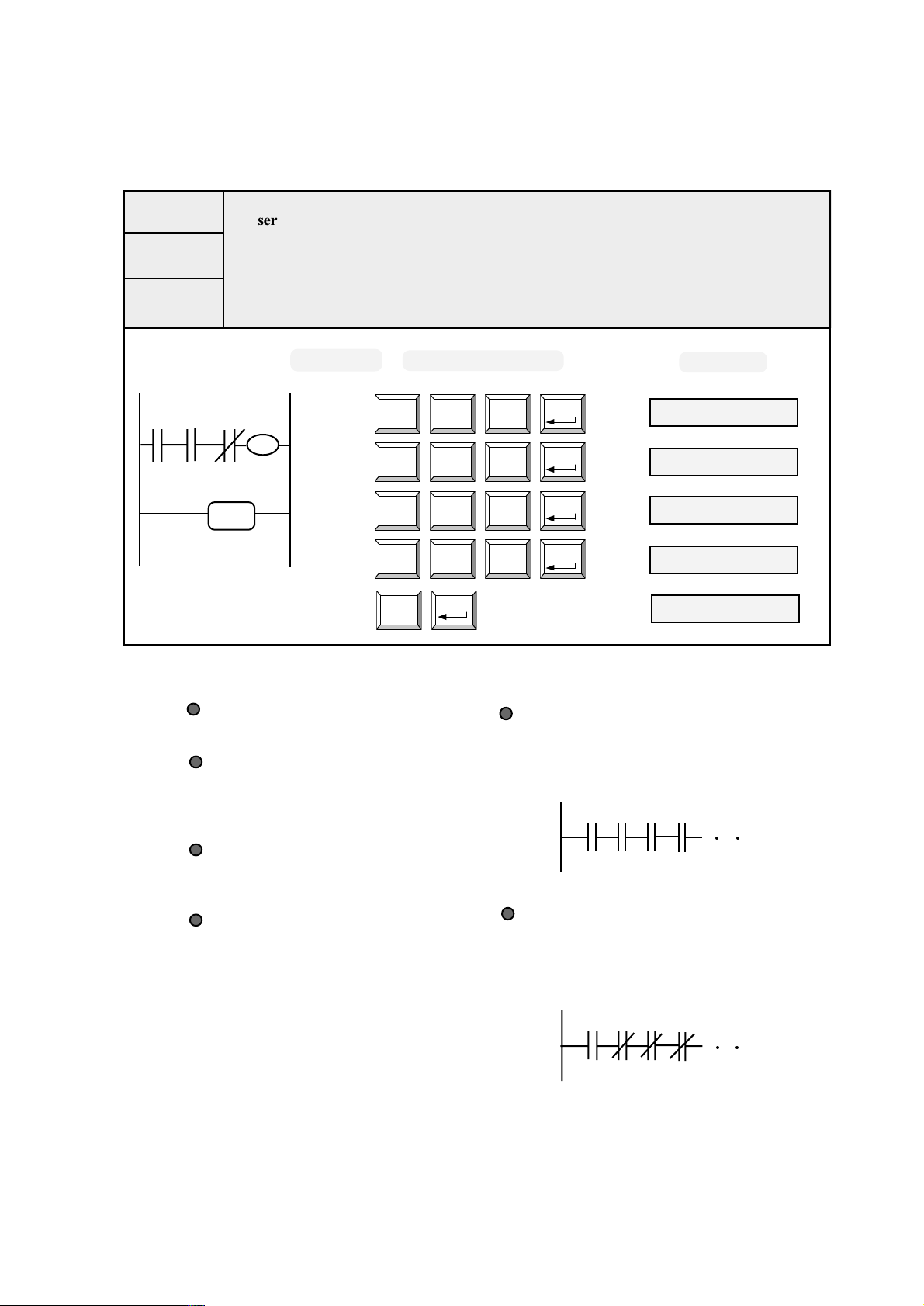

4.2 Description of the Instructions

4.2.1 LD, LDI, OUT

LD

LD

LDI

OUT

combine N.O. contact with bus

LDI

combine N.C. contact with bus

OUT

output operating results

ADDRESS KEY OPERATION

O0

I0

OUT

000

001

O1

I1

OUT

END

002

003

004

DESCRIPTION

LD, LDI commands are available

to combine N.O and N.C contact

with bus.

The operating parameter of LD,

LDI commands are available for:

input relay ¡Boutput relay ¡B

internal relay¡Btimer ¡Bcounter.

OUT command is available to

output the operating result to

the internal relay and output

relay.

The operating parameter of OUT

command is only available for

the internal relay and output

relay.

LD CR LD

0 I 0

OUT SE LD

5 O 0

LDI CR LDI

1 I 1

OUT SE LDI

5 O 1

END

ENTER

ENTER

ENTER

ENTER

ENTER

TECHNICAL ITEMS

N.O. contact: the contact which is

open in static state, in ladder logic

diagram it shows as the following:

N.C. contact: the contact which is

closed in static state, in ladder logic

diagram it shows as the following:

O: the simplest form of OUTPUT

I: the simplest form of INPUT

LCD

000 LD I0

001 OUT O0

002 LDI I1

003 OUT O1

004 END

ATTENTION

Do not use the OUT command

continuously to form a circuit

as the following diagram:

I0

O0

OUT

O1

OUT

O2

OUT

○○○○

4-2

Page 19

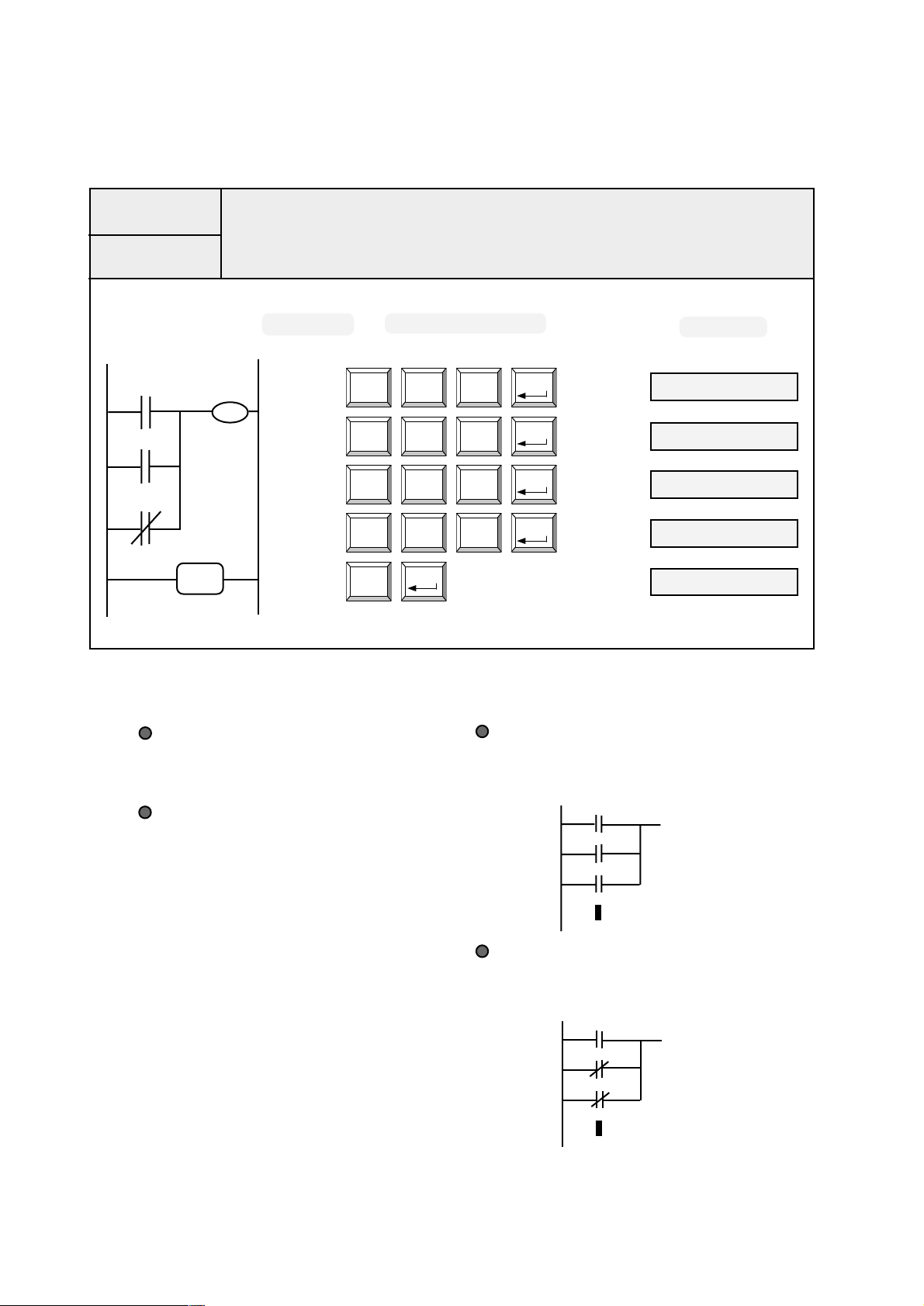

4.2.2 AND, ANI, END

AND

ANI

END

AND

series-connect an N.O. contact

ANI

series-connect an N.C. contact

END

program ends

ADDRESS KEY OPERATION

I2I0 I1

END

O0

OUT

000

001

002

003

LD CR LD

0 I 0

AND CR LDI

2 I 1

ANI CR AND

3 I 2

OUT SE LD

5 O 0

END004

ENTER

ENTER

ENTER

ENTER

ENTER

LCD

000 L D I0

001 AND I1

002 ANI I2

003 OUT O0

004 END

DESCRIPTION

AND: series-connect an N.O. contact

ANI: series-connect an N.C.contact

The operating parameter of AND ¡BANI

command is available for any of these:

input relay ¡Boutput relay¡Binternal

relay ¡Btimer ¡Bcounter.

END command is for the end of a program.

A program is unable to be executed without

it.

Enter END command at the end of each

section before the program operates, thus

it offers easy adjudgment of the opera-

tion, delete the command after the program

confirms.

SUPPLEMENT

AND command is available for continuous

series-connection as needs, the diagram is

as the following:

I0 I3I2I1

○○

ANI command is available for continuous

series-connection as needs, the diagram is

as the following:

I0 I3I2I1

○○

4-3

Page 20

4.2.3 OR, ORI

OR

ORI

I0

I1

I2

O0

OUT

END

OR

parallel-connect an N.O. contact

ORI

parallel-connect an N.C. contact

ADDRESS KEY OPERATION

LD CR LD

0 I 0

001

002 002 ORI I2

003

OR CR LDI

4 I 1

ORI CR AND

6 I 2

OUT SE LD

5 O 0

END004

ENTER

ENTER

ENTER

ENTER

ENTER

000 LD I0000

001 OR I1

003 OUT O0

004 END

LCD

DESCRIPTION

OR: parallel-connect an N.O. contact

ORI: parallel-connect an N.C. contact

The operating parameter of OR¡BORI

command is available for any of these:

input relay¡Boutput relay ¡B internal

relay¡B timer counter

SUPPLEMENT

OR command is available for continuous

parallel-connection as needs, the diagram

is as the following:

I0

I1

I2

ORI command is available for continuous

parallel-connection as needs, the diagram

is as the following:

I0

I1

I2

4-4

Page 21

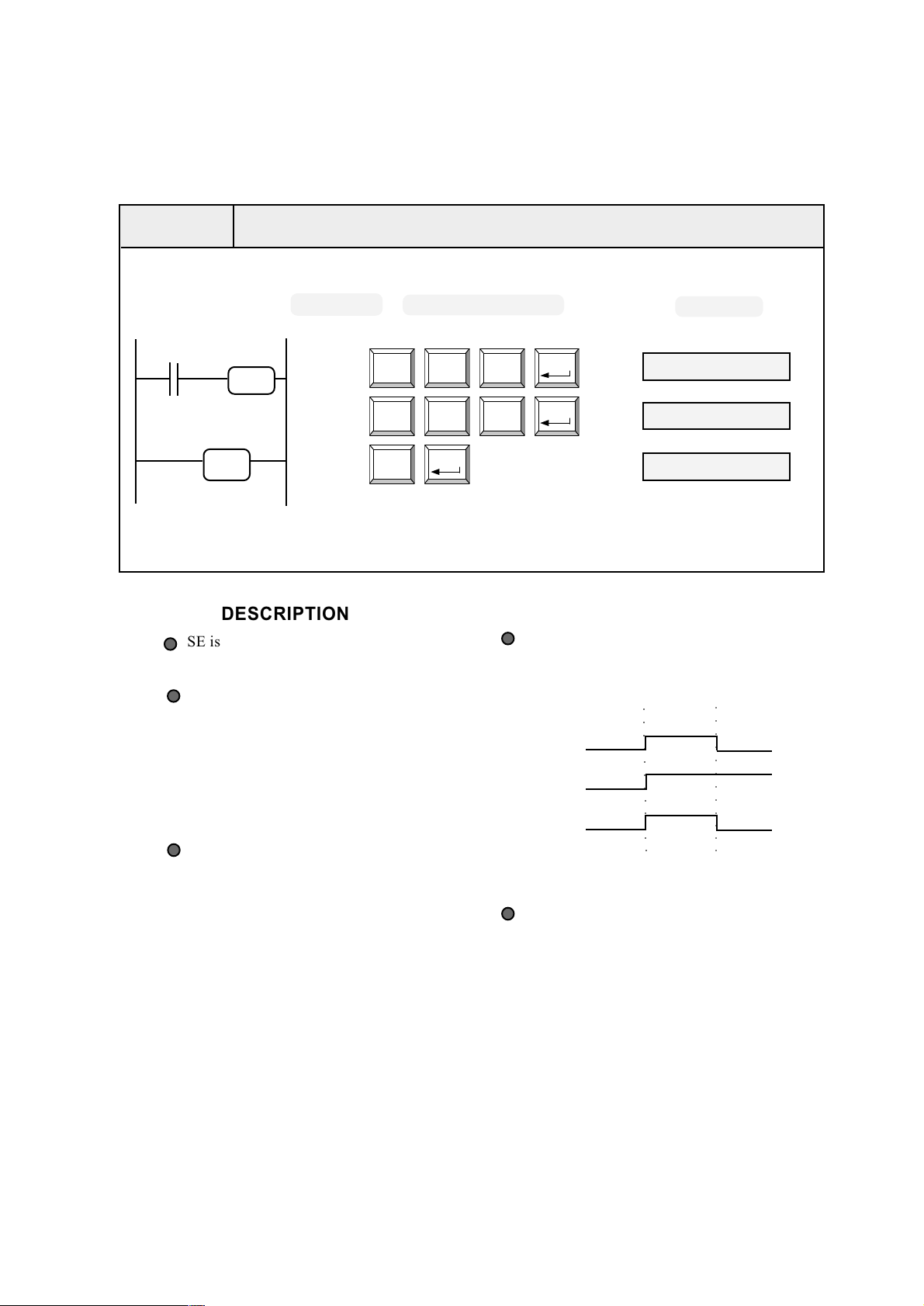

4.2.4 SE

S E

Internal relay and output relay setting command

ADDRESS KEY OPERATION

I0

END

O0

SE

000

001

002

DESCRIPTION

SE is the setting command for

internal relay and output relay.

SE command is available for de-

ciding whether to execute this

command or not by referring to

the previous operating results,

execute it when the result is 1, do

not execute it when the result is 0.

The operating parameter of SE

command is available for internal

relay or output relay.

LD CR LD

0 I 0

SE SE LD

O O 0

END

ENTER

(OPERATE SE)

(OPERATE OUT) O0

LCD

ENTER

ENTER

000 LD I0

001 SE O0

002 END

SUPPLEMENT

The diagram result will be as following when

replacing SE command by out command.

○○○○○○○○○○○○

○○○○○○○○○○○○

I0

O0

The above diagram shows:

when I0 changes from 1 to 0, execute SE

command and the result remains 1 while

it changes from 1 to 0 by executing OUT

command. That is the difference

between SE and OUT command.

4-5

Page 22

4.2.5 SEB

SEB

internal relay setting command

ADDRESS KEY OPERATION

I0

END

M00

SEB

000

001

002

LD CR LD

0 I 0

SE KC LD LD

O M 0 0

END

ENTER

DESCRIPTION

SEB is the setting command for internal relay.

SEB command has the same function as SE, but the operating

parameter of SEB command is only available for internal relay while

SE for either internal relay or output relay.

ENTER

ENTER

LCD

000 LD I0

001 SE M00

002 END

4-6

Operate the above-mentioned commands, the sequence

diagram is as the following:

○○○○○○○○

I0

M00

Page 23

4.2.6 CR

CR

internal relay and output relay reset command

ADDRESS KEY OPERATION

I0

O0

000

SE

I1

O0

001

CR

002

LD CR LD

0 I 0

SE SE LD

O O 0

LD CR LDI

0 I 1

END

003

004

CR SE LD

I O 0

END

ENTER

DESCRIPTION

CR is the reset command for internal relay and

output relay.

CR command is available for deciding whether

to execute this command or not by referring

to the previous operating results, execute it

when the result is 1, do not execute it when

the result is O.

CR command is available for the internal relay

or the output relay.

Operate the above-mentioned commands, the

sequence diagram is as the following:

LCD

ENTER

ENTER

ENTER

ENTER

000 LD I0

001 SE O0

002 LD I1

003 CR O0

004 END

SUPPLEMENT

Change the above-mentioned diagram as the

following:

I0

I1

The sequence diagram is as the following:

I0

O0

CR

O0

SE

END

○○○○○○○○○○○

○○○○○○○○○○○

I0

I1

O0

○○○○○○○○○○○○

○○○○○○○○○○○○

○○○○○○○○○○○○

I1

O0

When SE and CR are both available for

operating number O0, operate the latter

one.The rule is: the latter suppresses the

former.

4-7

Page 24

4.2.7 CLB

CLB

I0

I1

END

M00

SEB

M00

CLB

internal relay reset

ADDRESS KEY OPERATION

LD CR LD

0 I 0

001

002 002 LD I1

003

SEB KC LD LD

9 M 0 0

LD CR LDI

0 I 1

CLB KC LD LD

T M 0 0

END004

ENTER

ENTER

ENTER

ENTER

ENTER

000 L D I0000

001 SEB M00

003 CLB M00

004 END

LCD

DESCRIPTION

CLB is the reset command for internal relay.

CLB command has the same function as

CR, but the CLB operating parameter is

only available for internal relay while CR

for either internal relay or output relay.

Operate the above-mentioned commands,

the sequence diagram is as the following:

○○○○○○○○○○○○

○○○○○○○○○○○○

○○○○○○○○○○○○

I0

I1

M00

SUPPLEMENT

Change the above-mentioned diagram as the

following:

I0

M00

CLB

I1

M00

SEB

END

Operate the above-mentioned commands, the

sequence diagram is as the following:

○○○○○○○○○○

I0

○○○○○○○○○○

I1

M00

4-8

Page 25

4.2.8 JMP

JMP

I1

I2

I1

003

JMP

END

XXX

JMP

JMP command is available for transferring to the following

relative XXX steps

ADDRESS KEY OPERATION

LD CR LDI

0 I 1

JMP LD LD ANI

C 0 0 3

LD CR AND

0 I 2

OUT SE LDI

5 O 1

LD CR LDI

0 I 1

OUT SE AND

5 O 2

END

ENTER

O1

OUT

O2

OUT

000

001

002

003

004

005

006

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

*

*

006 END

LCD

000 LD I1

001 JMP 003

002 LD I2

003 OUT O1

004 LD I1

005 OUT O2

DESCRIPTION

JMP command is available for transferring to the

following relative XXX steps.

JMP command is available for deciding whether

to execute this command or not by referring to the

previous operating result, execute it when the

result is 1, do not execute it when the result is

0.

See the example: when I1 is 1 ( condition of

executing JMP is satisfied to demmand), the

two commands with * fail to be operated.

The range of XXX in JMP command is [000~239],

it must be written as three figures, plus 0 to be

three if it is less than three, e.g. 001 for 1,

011 for 11.

SUPPLEMENT

The sequence diagram is as the following:

○○○○○○○○○○○○○○

○○ ○○○○○○○○○○○

○○○○○○○○○○○○○○

I1

I2

O1

O2

4-9

Page 26

4.2.9 CO

CO

I0

C0

CO

END

C0

OUT

O0

CT 002

X

CO

CT XXX

CO command is available for the cycling counter

ADDRESS KEY OPERATION

000

001

002

003

004

005

LD CR LD

0 I 0

CO JMP LD

C 0

LD LD AND

0 0 2

LD JMP LD

0 C 0

OUT SE LD

5 O 0

END

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

LCD

000 LD I0

001 CO C0

002 CT 002

003 LD C0

004 OUT O0

005 END

DESCRIPTION

CO command is available for the cycling counter,

including two sub word commands: CO X and CT

XXX. X stands for the cycling counter in this comm-

and including such as C0, C1, C2, C3 in a total of 4pcs.

XXX stands for presetting value of counter.

CO command is available for deciding whether to

execute this command or not by referring to the previous

operating result. When the result changes from 1 to 0,

execute it till it reaches the presetting value and the

counter sets 1.

When the data reaches the presetting one, the counter

is 1, if still any active pulse on the former command

and the following pulse comes, counter resets 0 and

counts again. This action cycles on.

The range of XXX in CO command is [000,255],

it must be written as three figures, plus 0 to be

three if it is less than three, e.g. 1 for 001,

11 for 011.

SUPPLEMENT

Operate the above-mentioned commands, the

sequence diagram is as the following:

○○ ○○○○○○○

○○ ○○○○○○○

○○○○○○○○○

○○ ○○○○○○○

I0

C0

O0

While program with programmer, if input CO

and press Enter button, the programmer will

show CT automatically. No need to input CT

CO JMP LD

C 0

The diagram of the programmer LCD is as the

following:

001 CO C0

002 CT

ENTER

4-10

Page 27

4.2.10 TIM

TIM

X

T

KZ XXX

KC¡µ¡µ¡µ

timer

ADDRESS KEY OPERATION LCD

LD CR LD

0 I 0

TIM CLB LD

8 T 0

KZ LD LD AND

7 0 0 2

KC LD OUT LD

M 0 5 0

LD CLB LD

0 T 0

I0

T0

T

T0

O1

SE

KZ002

KC050

000

001

002

003

004

END

005

006

SE SE LDI

O O 1

END

ENTER

DESCRIPTION

TIM command is available for the timer.

TIM command is available for deciding whether to

execute this command or not by referring to the

previous operating result. When the result is 1,

execute it till it gets to the presetting value. When

the result is 0, the timer doesnt work.

When time reaches presetting value, timer sets 1,

if not , the result changes from 1 to 0, and timing

will not be stored, when result comes to 1, timer

runs on again.

The predetermined integer part of XXX ranges

from 000 to 255, it must be written as three figures, plus

0 to be three if it is less than three, e.g. 1 for

001, 11 for 011. The predetermined decimal part

¡µ¡µ¡µ¡µ¡µ¡µ

of

¡µ¡µ¡µ ranges from 000 to 099, it also must be

¡µ¡µ¡µ¡µ¡µ¡µ

written as three figures, too. For example: 10.99S

for KZ010, KC099 .

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

000 LD I0

001 TIM T0

002 KZ 002

003 KC 050

004 LD T0

005 SE O1

006 END

X stands for the cycling counter in a total

of 4pcs as T0, T1, T2, T3 with the range

{0.01-255} S. Accuracy is 0.01S.

TIM includes three essential sub-commands:

TIM, KZ, KC. Everyone is necessary.

The sequence diagram is as the following:

○○○○○○○○○○○

○○○○○○○○○○○

I0

6S

2S

2 .5 S

T0

O1

○○○○○○○○○○○

4-11

Page 28

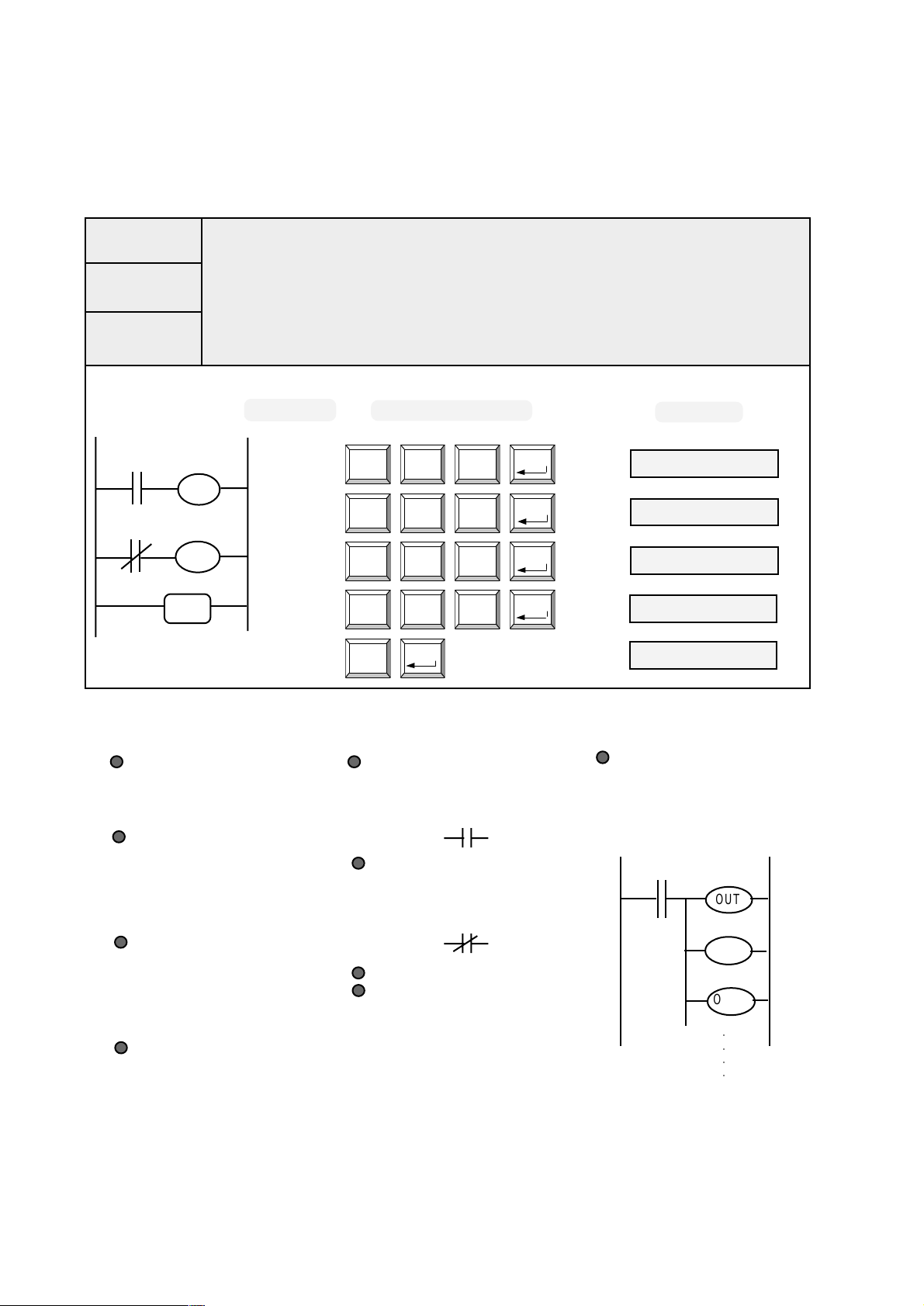

Chapter 5 Programmer

5.1 Description of the Programmer

operation button

function button

power switch

the upper part is the com-

mand botton, the lower

one is the digital and letter

button

DESCRIPTION

Function button

Ć

The following two Function modes can be

designated:

(1) Select ON/OFF of the sound.

(2) Select whether to charge the battery or not

Operation buttons:

compare the programs in the programmer

COMP

EEPROM with those in the PLC EEPROM.

delete the comands and addresses

DEL

insert a line of command in front of the

INS

current address

read the program from the PLC EEPROM

RDP

write the programs in the PLC EEPROM

WRP

clear the contents at the current cursor

CLR

address except line number.

toggle to the designated address.

GOTO

STEP

test by single-step

FUN

operation button

confirming button

display the contents at the previous cursor address

display the contents at the following cursor

address

confirming button

ENTER

when finish one line command, press this button to comfirm. But be careful to press it to

avoid the unnecessary correction under other

situations

ON/OFF power switch

ON/OFF

When the battery supplies the programmer,

push the button down for 3 seconds for power

on. Push the button down again for 3 seconds

for power off .

Instruction Button

The upper part of the button is the command

button for inputting commands: LD/LDI/OR/

ORI/AND/ANI/TIM/CO/SE/SEB/CR/CLB/JMP/

OUT/END/KZ/KC, totaling 17. (refer to Chapter

4: Instruction for details)

digital button and letter button

The lower part consists of the ten digital keys:

1~9 and five letter keys: I, M, O, T, C. Available

for setting address, input relay, output relay,

internal relay,and data of timer and counter

5-1

Page 29

5.2 The Operating Procedure of the Programmer

(a) Adjust the programmer power switch to

BATTERY.

(b) Combine with the programmer cable

(c) Press ON/OFF button for 3 seconds, the

start

LCD displays as the following:

ARRAY electronic

co., ltd

input

programs

check

programs

write

programs

The above mentioned LCD view lasts for 3s,

then the system is in status of inputting program.

(a) the contents at 000 line will be shown if

the program exists in progammer, see following

figure:

000 LD I0

001 OR I1

now you can check the former programs

by pressing and

or press to correct it,

After the program is inputted, press or button to check

whether the inputted program is identical to the original one.

Press the WRP button, write the program to the PLC EEPROM, the LCD

displays as the following:

CLR

Writing

○○

or edit the new program;

(b) it will automatically be in editing

status if no program, see following

figure:

000

001

now you can start new program.

Cut off Power supply

end

Press button for 3s to cut power supply.

ON/OFF

DESCRIPTION

In the process of editing programs, the poor light of

the LCD will be turned off when no keys are pressed

within 20 seconds, press any of the button, the light

turns on. LCD will be turned off if no keys are pressed

after 5 minutes. The power of the programmer will be

cut off and in rest status when no keys are pressed within

10 minutes, as continue editing it must be started again.

Description of the LCD displaying.

(1) graphic marks

Stands for inputting command.

5-2

Write OK!

Stands for result of inputting commands.

Available for digital keys and letter keys.

(2) For error displays

RomERROR: ROM error or wrong symbol

for command.

RamERROR: RAM error

CodeERROR: Code error in RAM

Eeprom ERROR: no menory or some wrong

with program memory

OperationERROR: operation data exceeds the

range (¡Ù256) while running INS/DEL/GOTO;

or other wrong operation, it will display with

an alarm .

Page 30

5.3 Description of the Function Button

FUN

Function Button

Function LCD Operating method

Press the

FUN button

at the first

FUN

Voice knob

time

Press the

FUN button

at the

FUN

battery charge knob

second time

DESCRIPTION

Press the FUN button, the system will return to the

editing state automatically after 5 seconds when no

selection is made.

To decide if the battery needs charge or not, the system

will check the battery voltage automatically. Please

pay attention to the system recommadation

(1) As battery voltage<4.2V, the LCD displays alarm

smybol: # on right bottom as the following:

Speaker (1 OR 0)

1=ON 0=OFF

Charge(1 OR 0)

1=YES 0=NO

select to charge, the LCD displays

as the following:

After charging, the LCD displays

as the following:

Press to turn on the

1

0

1

0

LDI

LD

LDI

LD

sound switch

Press to turn off the

sound switch

Press to charge

the battery

Press not to charge

the battery

Charging

Charge OK!

003 JMP 008

#

(2) As battery voltage<3.8V, the system will switch off

the poower automatically. Now the user should connect

the charger to A.C. supply, plug the charger cable to

programmer and start the programmer, press the button

twice,the programmer is turned into the state of

FUN

selecting charging and then press the button ,

1

LDI

The user may take the charger away and edit.

(3)When the energy of the battery is ran out,

please connect the charger to A.C. supply, plug

the charger cable to programmer to charge the

battery. After 10 hours, take the charger away,

the programmer is ready for programming.

5-3

Page 31

5.4 Description of the Operation Button

5.4.1 Description of the Operation ButtonINS

INS

Insert new command in the designated program address

Basic operating procedure (example)

I0I2I1

O0

OUT

INSERT

I3

END

If insert 003 AND I3 below 002, do as the following:

(1) Press

(2) Press

(3) Press

INS

LD

0

AND CR ANI

2 I 3

LD

0

ANI

3

LCD

000 LD I0

001 AND I1

002 OR I2

003 OUT O0

004 END

INS

INS 003

003

INS 003

003 AND I3

ENTER

(4) Press

the result is as the following:

I3

I1

I0

I2

O0

OUT

END

DESCRIPTION

Insert new command in the designated address, the following command

addresses will increase 1 automatically. If the inserted program exceeds

the maximum address range, the system will show error.

If press with no command being inserted, and press ,

a blank line will be inserted

If no command is inserted when press , can not use

INS

INS

000 LD I0

001 AND I1

002 OR I2

003 AND I3

004 OUT O0

004 END

ENTER

5-4

to exit current state.

Page 32

5.4.2 Description of the Operation ButtonDEL

DEL

delete the contents at the current cursor address including the line number

Basic operating procedure (example)

I1

I0

O0

OUT

I2

DELETE

END

If delete 001 AND I1, do as the following:

(1) press

(2) press

DEL

LD

0

LDI

LD

1

0

LCD

000 LD I0

001 AND I1

002 OR I2

003 OUT O0

004 END

DEL

DEL 001

(3) press

ENTER

Waiting for about 2s, the result will be as the following:

I0

O0

OUT

I2

END

DESCRIPTION

Delete the content at the designated address, thus the

following address decreases 1 automatically and the next

line moves forward.

When deleting some commands, be sure to delete the

relative commands, e.g. when deleting command CO, the

relative command CT should be deleted too.

000 LD I0

001 OR I2

002 OUT O0

003 END

5-5

Page 33

5.4.3 Description of the Operation Button CLR

CLR

clear the program contents instead of row number in order to input new program

Basic operating procedure (example)

I2

I0

I1

CLEAR

O0

OUT

O0

CHANGE TO

END

If change 001 OR I1 to 001 OR O0 , do as the following:

(1) at 001, press

(2) press

OR SE LD

4 O 0

CLR

LCD

000 LD I0

001 OR I1

002 AND I2

003 OUT O0

004 END

001

001 OR O0

(3) press the result will be as the following:

ENTER

(4) after the program is changed, press to browse

and check the changed contents

I0

O0

O0

I2

OUT

END

000 LD I0

001 OR O0

002 AND I2

003 OUT O0

004 END

5-6

Page 34

5.4.4 Description of the Operation Button GOTO

GOTO

search the address

Basic operating procedure (example):

LCD

000 LD I0

I0I2I1 I3

END

the programmer is displaying the 004 address, if read the content of the 002 address, do as the

following two methods:

(A) use , continuously until display the contents at the 002

O0

OUT

press

001 AND I1

002 OR I2

003 AND I3

004 OUT O0

005 END

(B) use

(1) press

(2) press

(3) press after 2 seconds displays the contents

GOTO

GOTO

LD

0

ENTER

LD

0

AND

2

at 002 line address

GO

GO 002

002 OR I2

5-7

Page 35

5.4.5 Description of the Operation Button COMP

compare the contents in the programmer EEPROM with the program in the PLC EEPROM

COMP

Basic operating procedure (example):

I0I2I1

O0

OUT

000 LD I0

001 AND I1

LCD

002 OR I2

003 OUT O0

END

004 END

If compare the program in programmer EEPROM with the written program in PLC EEPROM, do as the following:

(1) Combine programmer with PLC by specified cable,and set programmer

power switch for power supply

(2) press , LCD displays:

COMP

Comping

○○

(3) Compare with the contents in programmer EEPROM and the PLC EEPROM,

they are the same. LCD displays:

COMP OK !

(4) Compare with the contents in programmer EEPROM and the PLC EEPROM,

they are different; AP-14 and AP-14M PLC are in improper connection;

NORMAL/SINGLE or PROGRAM is improperly set.

LCD displays:

COMP ERROR !

5-8

DESCRIPTION

Notes: press PROGRAM switch on PLC before operating the

above mentioned button, and PRO indicator is on, then setNORMAL/

SINGLE switch to NORMAL.

The system will show error in such situations:

(1) The programmer cable doesnt connect to the designated socket.

(2) The programmer cable and the designated socket are in improper

connection.

(3) The program in the PLC EEPROM doesnt keep with that in the

programmer EEPROM.

Find out the reason first, then eliminate it in the event of system error.

Page 36

5.4.6 Description of the Operation Button WRP

WRP

write the programs in the programmer EEPROM to the PLC EEPROM

Basic operating procedure (example):

LCD

I1

I0

END

If write programs in the programmer EEPROM to the PLC EEPROM, do as the following:

(1) Combine programmer with PLC by specified cable,and set programmer

power switch for power supply

(2) Press

WRP

(3) Writing , LCD displays:

O0

OUT

000 LD I0

001 AND I1

002 OUT O0

003 END

Writing

○○

(4) Writing OK , LCD displays:

(5) AP-14 and AP-14M PLC line are in improper connection;

NORMAL/SINGLE or PROGRAM is improperly set.

LCD displays:

DESCRIPTION

When writing, eliminate the unnecessary program content in the PLC

EEPROM and at the same time write in new contents.

Notes: press PROGRAM switch on PLC before operating the above

mentioned button, and PRO indicator is on, then set NORMAL/

SINGLE switch to NORMAL.

Write OK !

Write ERROR!

5-9

Page 37

5.4.7 Description of the Operation Button RDP

read the program in the PLC EEPROM to the programmer EEPROM

RDP

Basic operating procedure (example):

LCD

I0I2I1

O0

OUT

000 LD I0

001 AND I1

002 OR I2

END

003 OUT O0

004 END

If read the program in the PLC EEPROM to the programmer EEPROM, do as the following:

(1) Combine programmer with PLC by specified cable,and set programmer

power switch for power supply

(2) Press

(3) Reading , LCD display:

(4) Reading ok , LCD displays:

RDP

Reading

○○

Read OK !

5-10

(5) AP-14 and AP-14M PLC wire are in improper connection;

NORMAL/SINGLE or PROGRAM is improperly set.

LCD displays:

DESCRIPTION

When altering the program, read the program in the

PLC EEPROM to the programmer EEPROM.

Notes: press PROGRAM switch on PLC before

operating above mentioned the button, and PRO

indicator is on, then set NORMAL/SINGLE switch

to NORMAL.

Read ERROR!

Page 38

5.4.8 Description of the Operation Button STEP

STEP

Basic operating procedure (example):

When finish writting program in PLC by WRP command, press , programmer will send single-

step signal to PLC, and program runs next step on receipt of the signal. LCD displays the operating result

Send signal of single-step to PLC, which will operate program in EEPROM by single-step

LCD

I0

I1

O0

SE

O1

SE

END

000 LDI I0

001 SE O0

002 LDI I1

003 SE O1

004 END

STEP

¡iON/OFF¡j

(1) Combine programmer with PLC by specified

cable,and set programmer power switch for

power supply

(2) press LCD displays:

(3) press LCD displays:

(4) press LCD displays:

(5) press LCD displays:

(6) if AP-14 and AP-14M PLC are in improper connection;

NORMAL/SINGLE or PROGRAM is improperly set.

System will back to the beginning address and displays:

STEP

STEP

STEP

STEP

Notes: set NORMAL/SINGLE switch to SINGLE before

operating the above mentioned command, and SIN indicator is

on.

STEP ON

¡÷

000 LDI I0

STEP ON

001 SE O0

¡÷

STEP ON¡÷

002 LDI I1

¡÷

STEP ON

003 SE O1

000 LDI I0

001 SE O0

5-11

Page 39

Chapter 6 Operation of PLC

Please operate as the following steps:

(1) Dual voltage 110/220V supply versions, and connect the power.

(2) Remove the cover on the left side.

(3) Combine with AP-14 programmer and the PLC programming

interface, using the programming cable. As the following diagram:

DIAGRAM(6-1)

(4) Press the PROGRAM button, the PRO indicator on the control panel lights on, then write the

following program in the programmer.(Referring to Chapter 5: the programmer for details)

M00

M01

M02

END

O0

OUT

O1

OUT

O2

OUT

LDI KC LD LD

1 M 0 0

OUT SE LD

5 O 0

LDI KC LD LDI

1 M 0 1

OUT SE LDI

5 O 1

LDI KC LD AND

1 M 0 2

OUT SE AND

5 O 2

END

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

000 LDI M00

001 OUT O0

002 LDI M01

003 OUT O1

004 LDI M02

005 OUT O2

006 END

6-1

Page 40

(5) Press , then write the program in the PLC EEPROM.

(6) Set NORMAL/SINGLE knob of AP-14 PLC into SINGLE, then back to NORMAL

position again, PLC performs normally. At the same time, RUN indicator is on; If write

programs improperly, e.g. missing ENDcommand, RUNindicator flashes constantly.

(7) If step PLC, set NORMAL/SINGLE knob of AP-14 PLC into SINGLE, the SIN

indicator on the control panel lights on, then press on AP-14P programmer to test

by single-step(every time press the button, PLC will step the next command until come to

END command, then steps from first line again), thus O0¡NO1¡NO2 LED of AP-14M

PLC will be on. After stepping, set NORMAL/SINGLEknob to NORMALfor running

PLC normally.

(8) If the system runs normally, pull down the AP-14P programmer cable.

WRP

STEP

ATTENTION

When the system functions normally, the ERR indicator on the PLC control panel doesnt light

on. If the lamp lights on, there must be problem in the PLC and must be eliminated immediately.

Flashing of ERR indicator: there must be problem in the CPU of the PLC.

Lighting on of the ERR indicator: there must be problem in the PLC memory.

6-2

Page 41

Chapter 7 Installation and Wiring

7.1 Installation Environment

AP-14 products suit the environment badly, but to ensure the long and good operation quality please pay

attention to the following items when installing:

Make sure that the temperature and humidity are in the specified range.

Reduce the vibration and shock to the minimum.

Reduce noise interference as much as possible.

The setting of the control cubicle should be reasonable for the convenience of regular checking.

7.2 Strategy for Different Operating Environments

7.2.1 Temperature

AP-14P system is available between -5¢J to +55¢J(storage temperature: -25¢J¡ã+75 ¢ J), so make sure to use it

in this range. Constant high/low temperature may effect its service life, to avoid this situation, you may adopt the

following methods:

Equip the fan in the control cubicle. Various fan options available: absorbing type ¡Bdischarging type

or cycling type according to the different environment.

Equip the cooling device in addition to that no condensation may occur.

Equip the radiator to improve the ventilation condition in the control cubicle.

Equip the heating apparatus to keep suitable temperature when the ambient temperature is too low.

7.2.2 Humidity

Sudden temperature variation may cause condensing which may reduce the equipment endurance. To keep the

humidity in the control cubicle in the specified range 45-85%, such measures noted below are necessary:

Adopt sealing device and fill with hygroscope agent in the control cubicle.

Equip the air conditioner to keep the air dry.

7.2.3 Specified Shock and Vibration

The continuous shock or vibration may cause the screw and the plug-in components become loose and the

internal components may be damaged as well. Precaution noted below may be adopted:

Equip the shockproof rubber in the control cubicle.

Keep away from the shock sources or vibration sources as far as possible.

¢J

7.2.4 Atmosphere Environment

Too much dust in the operating place may cause such results: the switch may be in poor contact, the filter port

may be blocked and the temperature in the control cubicle may rise up.

Conductive powder will lead to short circuit, Corrosive gases, oil fogs and salt, all of which will accelerate

the age of the components and corrosive of the screw. Precautions noted below may be adopted:

Seal the control cubicle.

Equip the air conditioner in the control cubicle.

Keep far away from severe environment.

7-1

Page 42

7.3 The PLC Devices in the Control Cubicle

For the better ventilation and to avoid too high temperature in the control cubicle, please keep a

distance over 100mm in vertical and over 50mm in horizontal between AP-14 and other machines.

The heater must be avoided mounting under AP-14.(diagram).

over100 mm

Other machine

50 mm

Heater

Over

Over

50 mm

over100 mm

Other

machine

Other machine

High

voltage

machine

7-2

DIAGRAM(7-1)

Page 43

7.4 Strategy for Interference

6

6

6

6

6

6

6

6

6

6

6

6

6

6

The AP-14 system has high interference resistance, but to make the system more stable and work at full

capacity, such measures may be adopted:

7.4.1 Wiring

Main power supply

PLC power supply

I/O power supply

Main circuit power supply

DIAGRAM(7-2)

PLC power supply and I/O power supply must be mutually independent and be wired separately.

Isolate DC24V I/O wire from AC110/220V and the distance must be over 300mm. Adopt mental shield.

7.4.2 Ground (GND)

Good ground can improve the reliability of the product, this equipment has adopted sufficient measures to

resist the interference and is free ground except the special interference resource, it is usually grounded in this

way:

AP-14M PLC

wire over 5.5 mm

2

Distance less

than 50cm

DIAGRAM(7-3)

The system cant ground with high power machines, in areas where theres too much thunder power, the

equipment must be isolated from control cubicle and only the cubicle is grounded.

Control cubicle

2345

2345

2345

2345

2345

2345

AP-14P

2345

2345

2345

2345

2345

2345

2345

2345

Isolating lay

7-3

AP-14 PLC front view

DIAGRAM(7-3)

Page 44

Chapter 8 Application

The following application will illustrate the AP-14M PLC in details.

8.1 Application of I/O (Input/Output)

Control Demand: Dis pla y al arm information by PLC I/O

Ladder Diagram Command List

I0

I1

O0

OUT

O1

OUT

000 LD I0

001 OUT O0

002 LD I1

003 OUT O1

004 LD I2

END

O2

OUT

005 OUT O2

006 END

I2

DESCRIPTION SUPPLEMENT

I0, I1, I2 is available to input the corres-

ponding alarm switch and contact.

O0, O1, O2 is available for the state

indicators of the coresponding switch.

PLC circuit diagram is as the following:

24V

COM COM

I3

I5 I4 I2

I1 I0

I6

I7

AC

AP-14M PLC

O1

+

O0 O2

O3

O4

O5

N

L

8-1

Page 45

8.2 Application of Self-keeping

8.2.1 Control ON/OFF of the Motor in Three Directions

Control demand: There s ON/OFF button in A,B,C, the motor is ONif any of the buttons is pressed.

The motor keeps rotating, till any of the OFF button in A, B, C is pressed.

Ladder Diagram Command List

++

+

I/O

++

I3 I4 I5I0

I1

I2

O0

END

O0

OUT

DESCRIPTION

Input ports:

I0: ON button in A I1: ON button in B

I2: ON button in C I3: OFF button in A

I4: OFF button in B I5: OFF button in C

Output ports:

O0: the contactor coil KM.

In the program, ON buttons are all parallel

-connection and OFF buttons are all series-

connection. The motor is on if any button in

I0¡BI1 ¡BI2 is pressed .Through O0 selfkee-

ping motor operates; and it is off if any button

I3¡BI4¡BI5 is pressed.

000 LD I0

001 OR I1

002 OR I2

003 OR O0

004 ANI I3

005 ANI I4

006 ANI I5

007 OUT O0

008 END

SUPPLEMENT

PLC circuit diagram is as the following:

24V

COM COM

I1 I0

+

I3

I5 I4 I2

AP-14M PLC

O1

O0 O2

K M

DIAGRAM 1

I6

I7

O3

AC

O5O4

N

L

8-2

Self-keeping

Please refer to DIAGRAM 2. When press I0 button,

coil is energized. And N.O contact of relay, path 1and

2 are all close. When release I0 button, path 2 is

open while 1 is still close to energizing coil, this

keeps N.O contact close. This interaction of relay

coil and contacts is named self-keeping circuit.

DC24V

Path 2

I0

Coil KM

DIAGRAM 2

Path 1

N.O contact

of KM

Page 46

This application can also be performed as the following

Control demand: Theres ON/OFF button in A,B,C, the motor is on/off if any of the buttons is pressed.

Ladder Diagram Command List

I0

O0

I1

DESCRIPTION

Input ports:

I3 I4 I5

JMP

I2

END

O0

OUT

000 LD I0

001 OR O0

002 ANI I3

003 OR I1

004 ANI I4

005 OR I2

006 ANI I5

007 OUT O0

008 END

I0: ON button in A I1: ON button in B

I2: ON button in C I3: OFF button in A

I4: OFF button in B I5: OFF button in C

Output ports:

O0: the contactor coil KM.

8-3

Page 47

8.2.2 Control ON/OFF of the Motor by One Button

Control demand: use one button to control ON/OFF of the motor.

Ladder Diagram Command List

I0 O0

I0 M01

M00

I0 M01 M01

M00

M00

OUT

O0

OUT

OUT

END

000 LDI I0

001 AND O0

002 OUT M00

003 LD I0

004 ANI M01

005 OR M00

006 OUT O0

007 LD I0

008 AND M01

009 OR M00

010 OUT M01

011 END

DESCRIPTION SUPPLEMENT

I0: ON/OFF button

O0: the contactor coil

In this program the toggle button is available to

control two states, and the internal relay M00,M01

are capable of reserving the intermediate operating

result.

In this program one contact can be converted to

two and it is the fine reference in programming

the complicated programs.

8-4

PLC circuit diagram is as the following:

COM COM

I1 I0

24V

+

I5 I4 I2

I3

AP-14M PLC

O1

O0 O2

KM

I6

O4

AC

O5

I7

O3

N

L

Page 48

8.3 Application of TIM+ Self-keeping+I/O

8.3.1 Flicker Circuit

TIM

Form a flicker circuit

Ladder Diagram Command List

I1

T2 T1

T

KZ 001

KC 000

000 LD I1

001 ANI T2

002 TIM T1

T1

T2

T

KZ 001

KC 050

003 KZ 001

004 KC 000

005 LD T1

T1

O0

OUT

006 TIM T2

007 KZ 001

008 KC 050

009 LD T1

END

010 OUT O0

DESCRIPTION

After I1 on and T1 times for 1second, start

T2 to time for 1.5seconds, then cut T1 off.

After T1 is restored, then comes T2 to do

the same action again.

The sequence diagram is shown on the right:

011 END

○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○

I1

T1

T2

O1

t1(1.0S) t2 (1.5S)

8-5

Page 49

8.3.2 Trigger Circuit

TIM

Form a trigger circuit (it outputs constant pulse width regardless of the length of input pulse).

Ladder Diagram Command List

M00 T1

M00

OUT

000 LD M00

001 ANI T1

002 OR I1

I1

003 OUT M00

004 LD M00

005 TIM T1

M00

T1

T

KZ 002

KC 050

006 KZ 002

007 KC 050

008 LD M00

M00 T1

O1

OUT

009 ANI T1

010 OUT O1

011 END

END

The operating sequence diagram is as the following:

○○○○○○○○○○○○○○

○○○○○○○○○○○○○○

I1

4.5S 1S

M 00

T1

O1

2.5 S

○○○○○○○○○○○○○○

○○○○○○○○○○○○○○

2.5 S

8-6

Page 50

8.3.3 Delay Circuit

TIM

Ladder Diagram Command List

Form a start-delay and reset-delay circuit.

I1

T1

T

KZ 002

KC 000

000 LD I1

001 TIM T1

002 KZ 002

003 KC 000

O1

T2

I1

KZ 001

T

KC 000

004 LD O1

005 ANI I1

006 TIM T2

T1

O1

T2

O1

OUT

007 KZ 001

008 KC 000

009 LD T1

010 OR O1

011 ANI T2

012 OUT O1

013 END

END

DESCRIPTION

St art-delay circuit: after I1 is on, T1 delays 2 seconds to let O1 output self-keeping.

!!!!

!!Reset-delay circuit: after O1 is off, T2 times for 1second to cut off the self-keeping circuit of O1.

!!!!

○○ ○○○○○○○○○

○○○○○○○○○

Start-delay for 25

○○○○○○○○○○

○○○○○○○○○

Reset-delay for 1s

8-7

Page 51

8.4 Application of CO + TIM + I/O

Control demand: Turn on the electro-magnetic valve to input materials for 2 hours, then run agitator.

Using CO to increase time-delay.

Ladder Diagram Command List

000 LD I 0

I0

O0

O0 T0

T0

C0

O1

O0

OUT

T0

T

C0

CO

O1

OUT

KZ 100

KC 000

CT 072

001 OR O0

002 OUT O0

003 LD O0

004 LDI T0

005 TIM T0

006 KZ 100

007 KC 000

008 LD T0

009 CO C0

010 CT 072

011 LD C0

012 OR O1

END

DESCRIPTION

O0 contacts electromagetic valve,

O1 contacts start-relay of agitators

motor.

M

013 OUT O1

014 END

PLC circuit diagram is as the following:

COM COM

I2

I1 I0

I3

I6 I5 I4

I7

AP-14M PLC

24V

+

O1

O0 O2

KM1

KM0

O3

O4

AC

O5

8-8

N

L

Page 52

8.5 Multi-application

8.5.1 Y- changeover and both Directions of Rotation of the 3-phase Asynchronous

Motor

Control demand: press the start button PB1, the motor starts by Y version and changes to

same time rotating positively. Press the reverse button PB2, the motor runs on, then press the stop button PB3.

Ladder Diagram Command List

I0

O0

SE

O3

SE

I0

M00

SE

T0

KZ 003

T

KC 000

O3

CR

O2

SE

O0

CR

Press PB1,the motor starts by

Y version, rotating directly

Changes to after 3s

000 LD I0

001 SE O0

002 LD I0

003 SE O3

004 LD I0

005 SE M00

006 LD M00

007 TIM T0

008 KZ 003

009 KC 000

010 LD T0

011 CR O3

012 LD T0

013 SE O2

Press PB2, motor reverses

014 LD I1

I0

M00

T0

T0

I1

I2

¡µ¡µ

¡µ after 3seconds at the

¡µ¡µ

015 OR I2

I1

O1

SE

016 CR O0

017 LD I1

I2

I2

I2

I2

END

O1

CR

M00

CR

O2

CR

O3

CR

Press PB3, motor stops

operating

018 SE O1

019 LD I2

020 CR O1

021 LD I2

022 CR M00

023 LD I2

024 CR O2

025 LD I2

026 CR O3

027 END

8-9

Page 53

The circuit diagram of operating motor:

U

V

W

KM direct

M

motor

DESCRIPTION

Input ports:

I0: the start button (PB1)

I1: the reverse button (PB2)

I2: the stop button (PB3)

KM reverse

KM

KM Y

SUPPLEMENT

PLC circuit diagram is as the following:

8-10

Output ports:

O0: the positive rotating a.c.contactor coil

O1: the reverse a.c. contactor coil

O2: ¡µ a.c. contactor coil

O3: Y a.c. contactor coil

COM

24V

COM

+

I2

I1 I0

I3

AP-14M PLC

O0 O2

O1

KM0

I6 I5 I4

KM1

I7

O3

KM2

O4

KM3

N

L

AC

O5

Page 54

8.5.2 Five Groups of the Rush-answer Control System

Control demand: in these five groups of the rush-answer system, if any button is pressed, the indicator of this group

lights on, at the same time the buzzer voices for 3seconds, press the reset button to do the same action again.

Ladder Diagram Command List

000 LD I1

I1 O2 O3 O4 O5

I2 O1 O3 O4 O5

I3 O1 O2 O4 O5

I4 O1 O2 O3 O5

I5 O1 O2 O3 O4

O1

SE

O2

SE

O3

SE

O4

SE

O5

SE

Press any button, the indicator

of this group lights on

001 ANI O2

002 ANI O3

003 ANI O4

004 ANI O5

005 SE O1

006 LD I2

007 ANI O1

008 ANI O3

009 ANI O4

010 ANI O5

011 SE O2

012 LD I3

013 ANI O1

I0

I0

I0

I0

I0

O1

O2

O1

CR

O2

CR

O3

CR

O4

CR

O5

CR

M00

OUT

014 ANI O2

015 ANI O4

016 ANI O5

017 SE O3

018 LD I4

Press the reset switch, indicator

is off.

019 ANI O1

020 ANI O2

021 ANI O3

022 ANI O5

023 SE O4

024 LD I5

025 ANI O1

026 ANI O2

027 ANI O3

028 ANI O4

029 SE O5

030 LD I0

031 CR O1

O3

O4

Restore the intermediate result

in the internal relay M00

032 LD I0

033 CR O2

034 LD I0

035 CR O3

036 LD I0

O5

037 CR O4

038 LD I0

039 CR O5

040 LD O1

041 OR O2

8-11

Page 55

Ladder Diagram Command List

M00

M00

END

T0

T0

T

O0

OUT

DESCRIPTION

Input point:

IO: the reset pushbutton

I1: the first group pushbutton

I2: the second group pushbutton

I3: the third group pushbutton

I4: the fourth group pushbutton

I5: the fifth group pushbutton

KZ 003

KC 000

042 OR O3

043 OR O4

Any indicative lamp lights on,

the buzzer voices for 3s

044 OR O5

045 OUT M00

046 LD M00

047 TIM T0

048 KZ 003

049 KC 000

050 LD M00

051 ANI T0

052 OUT O0

053 END

SUPPLEMENT

PLC circuit diagram is as the following

COM

COM

I2

I1 I0

I3

I5 I4

I6

I7

AC

8 -1 2

Output point:

O0: buzzer

O1: the first group indicative lamp

O2: the second group indicative lamp

O3: the third group indicative lamp

O4: the fourth group indicative lamp

O5: the fifth group indicative lamp

24V

AP-14M PLC

+

O1O0 O2

BZ

O3

O4

O5

N

L

Page 56

8.5.3 Automatic Control of the Water Tank Level with Alarm

Control demand: when the water is lower than the lower limit start sensor r, run motor M to water. When

the level is lower than the lower limit alarm sensor R, the alarm lamp lights on for 60 seconds and the bell

rings for 25 seconds.When the level is higher than the upper limit stop sensor h, switch off motor M to stop

watering immediately. When the level is higher than the upper limit alarm sensor H, the alarm lamp lights

on for 60 seconds and the bell rings for 25 seconds.

Ladder Diagram Command List

I0

I2

I1

I3

O3

T0

I3

T0

T

O0

SE

O0

CR

O3

SE

O3

CR

O2

SE

KZ 025

KC 000

t he lower limit start sensor r is

OFF, start motor to water

the upper limit stop sensor h is

ON, stop motor watering

the lower limit alarm sensor R is

OFF or the upper one H is ON, the

alarm bell rings for 25 sceonds

000 LDI I2

001 SE O0

002 LD I1

003 CR O0

004 LDI I3

005 OR I0

006 SE O3

007 LD O3

008 TIM T0

009 KZ 025

010 KC 000

011 LD T0

012 CR O3

013 LDI I3

014 SE O2

015 LD O2

O2

T1

I0

O1

T2

T1

T

O2

T2

T

O1

CR

END

CR

O1

SE

KZ 060

KC 000

KZ 060

KC 000

the lower limit alarm sensor R is

OFF, the alarm lights on for 60 sec-

onds

the upper one H is ON, the alarm

lights on for 60s

016 TIM T1

017 KZ 060

018 KC 000

019 LD T1

020 CR O2

021 LD I0

022 SE O1

023 LD O1

024 TIM T2

025 KZ 060

026 KC 000

027 LD T2

028 CR O1

029 END

8-13

Page 57

M

the upper limit alarm sensor H

the upper limit stop sensor h

Condenser

DESCRIPTION

Input point:

I0: the upper limit alarm sensorH

I1: the upper limit stop sensor h

I2: the lower limit start sensor r

I3: the lower limit alarm sensor R

Output point:

O0:A.C contact of motor

O1:the upper limit alarm lamp

O2:the lower limit alarm lamp

O3:the alarm bell

the lower limit start sensor r

the lower limit alarm sensor R

SUPPLEMENT

PLC circuit diagram is as the following:

COM COM

I1 I0

I3

I5 I4 I2

I6

I7

AP-14M PLC

24V

+

O1

O0 O2

O3

O4

AC

O5

8 -1 4

KM

N

L

Page 58

8.5.4 The Circuit Controls Traffic Lights at Crossroad

Control demand: switch on the button in east and west, the green light in east and west turns on; the red light

in south and north turns on.Switch on the button in south and north, the green light in south and north turns

on; the red light in east and west turns on.Switch on the automatic button, the green light in south and north

turns on for 13 seconds;the yellow light for 3 seconds and the red light for 16 seconds. When the yellow light

in east and west turns on, the corresponding red light ineast and west turns on for 16 seconds, then the green

light for 13 seconds; yellow light f or 3 seconds and cycles on.

Ladder Diagram Command List

I0

I0 T0

M00 T0

M00

T0

T0

T0

T1

M00

T1

O5

T1

T2

T2

T2

T3

JMP

T

SE

CR

O4

CR

046

M00

SE

O0

SE

O0

CR

O1

SE

T1

T

O1

CR

O5

O5

CR

T2

T

O3

SE

O3

O4

SE

T3

T

KZ 013

KC 000

KZ 003

KC 000

KZ 013

KC 000

KZ 003

KC 000

press the automatic switch PBO,

the green light in south and north

turns on for 13s

the yellow one turns on for 3s

the corresponding red light in east

and west turns on for 16s

the green light turns on for 13s

the yellow one turns on for 3s

000 LDI I 0

001 JMP 046

002 LD I0

003 ANI T0

004 SE M00

005 LD M00

006 TIM T0

007 KZ 013

008 KC 000

009 LD M00

010 SE O0

011 LD T0

012 CR O0

013 LD T0

014 SE O1

015 LD T0

016 TIM T1

017 KZ 003

018 KC 000

019 LD T1

020 CR O1

021 LD M00

022 SE O5

023 LD T1

024 CR O5

025 LDI O5

026 TIM T2

027 KZ 013

028 KC 000

029 LD T1

030 SE O3

031 LD T2

032 CR O3

033 LD T2

034 SE O4

8-15

Page 59

Ladder Diagram Command List

T1

O2

SE

035 LD T2

036 TIM T3

T3

T3

I0

I1

O2

CR

M00

CR

009

JMP

I1

O3

OUT

O2

OUT

O0I2

OUT

the red light in south and north

turns on for 16s

press PB1, the green light in east

and west turns on

press PB1, the red one in south and

north turns on

press PB2,the green one turns on

037 KZ 003

038 KC 000

039 LD T3

040 CR O4

041 LD T1

042 SE O2

043 LD T3

044 CR O2

045 LD T3

046 CR M00

047 LD I0

048 JMP 009

049 LD I1

050 OUT O3

051 LD O2

052 OUT O0

053 LD I2

054 OUT O0

055 LD I2

056 OUT O5

057 END

END

O5I2

OUT

press PB2, the red one in east and

west turns on

8-16

DESCRIPTION

Input point:

I0:the automatic push button (PB0)

I1: the pushbutton in east and west (PB1)

I2: the pushbutton in south and north (PB2)

Output Point:

O0: the green light in south and north

O1: the yellow light in the south and north

O2: the red light in south and north

O3: the green light in east and west

O4: the yellow light in east and west

O5: the red light in east and west

SUPPLEMENT

PLC circuit diagram is as the following:

24V

COM COM

+

I3

I1 I0

AP-14M PLC

I5 I4 I2

I6

O1O0O2

I7

O3

O4

AC

O5

N

L

Page 60

8.5.5 Three Kinds of Liquid Mixed Automatically

Control demand: put liquid A in a condenser, when it reaches the sensor L, shut off the electromagnetic valve A. Put in

liquid B, when it reaches the sensor I, shut off electromagnetic valve B. Put in liquid C, when it reaches the sensor H, shut

off the electromagnetic valve C. Start motor M and cut it off after 25 seconds, open the valve Y, when the liquid reaches the

sen sor and displays 0, open valve Y and shut it off after 15 seconds. The action cycles on.

Ladder Diagram Command List

000 LDI M00

M00

O0

I0

I0 M01

O1

I1

I0 I1 M02

O2

I2

I2

I2 T0

O0

SE

M00

SE

O0

CR

O1

M01

SE

O1

CR

O2

SE

M02

SE

O2

CR

T0

T

OUT

SE

KZ 025

KC 000

001 SE O0

002 LD O0

open the electromagnetic valve A,

put in liquid A, when the sensor L

is ON, close the valve

003 SE M00

004 LD I0

005 CR O0

006 LD I0

007 ANI M01

008 SE O1

open the valve B, put in liquid B,

when the sensor I is ON, close the

valve

009 LD O1

010 SE M01

011 LD I1

012 CR O1

013 LD I0

014 AND I1

015 ANI M02

open the valve C, put in liquid C,

when the sensor H is ON, close

the valve

016 SE O2

017 LD O2

018 SE M02

019 LD I2

020 CR O2

021 LD I2

start motor for 25s, then cut it off

022 TIM T0

023 KZ 025

I2 T0

SE

I0 M00O4 T1

T

O3

KZ 015

KC 000

open the valve Y, output liquid

024 KC 000

025 LD I2

026 ANI T0

027 OUT O4

028 LD I2

029 AND T0

030 SE O3

031 LDI I0

032 AND M00

033 TIM T1

8-17

Page 61

Ladder Diagram Command List

T1

T1

T1

T1

O3

CR

M00

CR

M01

CR

M02

CR

034 KZ 015

035 KC 000

036 LD T1

when the liquid level sensor L

is OFF, close the valve Y after

a delay of 15s

037 CR O3

038 LD T1

039 CR M00

040 LD T1

041 CR M01

042 LD T1

END

043 CR M02

044 END

DESCRIPTION SUPPLEMENT

Input point:

I0: the liquid level sensor L

I1: the liquid level sensor I

I2: the liquid level sensor H

Output point:

O0: the electromagnetic valve A

O1: the electromagnetic valve B

O2: the electromagnetic valve C

O3: output valve Y

O4: the contact of agitators motor M

A

C

M

B

PLC circuit diagram is as the following:

COM COM

I3

I1 I0

AP-14M PLC

24V

+

O0 O2

KM0

I5 I4 I2

O1

I6

KM1

I7

KM2

O3

KM3

O4

AC

O5

KM4

8 -1 8

H

I

L

N

L

Y

Page 62

8.5.6 Automatic Door Control System

control demand: 1.the guard in the office controls the gate through the buttons

2.the gate usual is open or close, but the status will be end at any time

3.the alarm bulb flashes (contact/uncontact) when the door is active

4.with the safe pressure baffle, the operation time is less and is available to avoid

to injure or press person and damage other materials, the door will be open if one

touches (when the safe pressure baffle is in available)

Ladder Diagram Command List

000 LD I 6

I6 O2 I4 I3

I1

O1

OUT

○○

open the door

001 OR I1

002 OR O1

003 ANI O2

004 ANI I4

O1

005 ANI I3

006 OUT O1

O1 T2 T1

O2

T1 T2

T1

I2

I6 O1 I5 I3 O2

O2

END

T

T

O0

OUT

KZ 001

KC 000

KZ 000

KC 050

OUT

When the door is working,

○○

the light flashes for 0.5s,

off for 1s.

○○

close the door

007 LD O1

008 OR O2

009 ANI T2

010 TIM T1

011 KZ O01

012 KC O00

013 LD T1

014 TIM T2

015 KZ 000

016 KC 050

017 LD T1

018 OUT O0

019 LD I2

020 OR O2

021 ANI I6

022 ANI O1

023 ANI I5

024 ANI I3

025 OUT O2

026 END

8-19

Page 63

12345678901234567890123456789012123

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

12345678901234567890123456789012123

Operating the automatic door

Safe Pressure Baffle

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

234567890123456789012345678901212

SUPPLEMENT

PLC circuit diagram is as the following:

S1 S2 S0 S3 S4 S5

COM COM

I2

I1 I0

I3

alarm bulb

I6 I5 I4

I7

AC

AP-14M PLC

24V

+

H1

O1

O0 O2

K1 K2

DESCRIPTION

H1: flashing indicator