Page 1

PANARAY®LT Systems

3202™II / 4402™II / 9702™II

®

®

3202 II

©

1997 Bose Corporation

4402 II

9702 II

Service Manual

Part Number 190489

Page 2

Contents

Specifications................................................................................................................................3-8

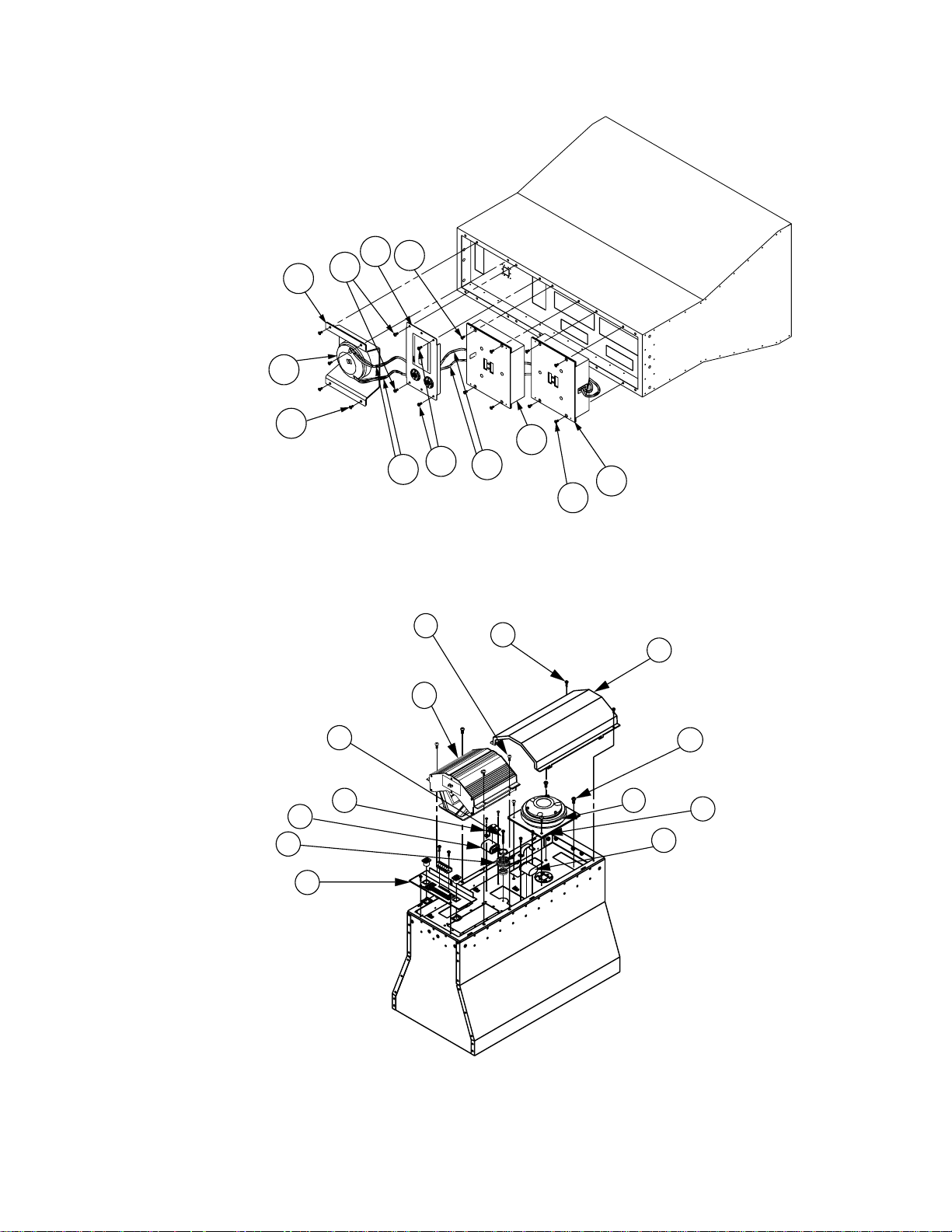

Figure 1. Panaray

®

Exploded View .................................................................................................. 9

Figure 2. Panaray Series II Exploded View...................................................................................... 9

Disassembly/Assembly Procedures ....................................................................................... 10-12

Diaphragm Replacement Procedure ............................................................................................ 13

Test Procedures ............................................................................................................................. 14

Figure 3. Connection Diagram ....................................................................................................... 14

Part List Notes................................................................................................................................ 15

Figure 4. Panaray Series II Exploded View....................................................................................16

Panaray Lt Series II Part List......................................................................................................... 16

Panaray Lt Part List ....................................................................................................................... 17

Figure 5. Panaray Exploded View.................................................................................................. 17

Packing Part List ............................................................................................................................ 18

Figure 6. Packing ........................................................................................................................... 18

CAUTION: THE PANARAY LOUDSPEAKERS CONTAIN NO USER-SERVICEABLE

PARTS. TO PREVENT WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY

SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

2

Page 3

SPECIFICATIONS

3202™ II

Mechanical Specification

Dimensions:

Weight: 106lb 48kg

Components: One High-frequency

Frequency Range: 160Hz to 16kHz (± 3dB) Crossover frequency 2kHz

Nominal Impedance: Passive 2-Way

Maximum Acoustic Output:

(IEC Noise)

42"H x 22.2"W front/

12.2"W x 37.2"D rear

Compression Driver

Two Mid-range Drivers

Bi-amplified

Mid-frequency

High-frequency

Passive 2-Way

106.7 x 56.4cm

30.9 x 94.5cm

t1.4hp

Vee Four Mid-range

Driver Assembly

16Ω

16Ω

8Ω

134dB SPL, 1m (rms)

140dB SPL, 1m (peak)

Bi-amplified 134dB SPL, 1m (rms)

Sensitivity: (Pink Noise) Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

Beamwidth (-6dB point): Horizontal

Vertical

Maximum Recommended

Amplifier Power:

Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

140dB SPL, 1m (peak)

110dB-SPL, 1w, 1m

107dB SPL, 1w, 1m

111dB SPL, 1w, 1m

27 degrees

20 degrees

1200W into 16Ω

1200W into 16Ω

150W into 8Ω

3

Page 4

SPECIFICATIONS

4402™ II

Mechanical Specification

Dimensions:

Weight: 70lb 32kg

Components: One High-Power

Frequency Range: 160Hz to 16kHz (± 3dB)

Nominal Impedance: Passive 2-Way

Maximum Acoustic Output:

(IEC Noise)

34"H x 19.2"W front

12.2"W x 25.3"D rear

Compression Driver

One Mid-range Driver

Bi-amplified

Mid-frequency

High-frequency

Passive 2-Way 130dB SPL, 1m (rms)

86.4 x 48.8cm

31.0 x 64.3cm

t1.4hp

Vee Four Mid-range

Driver Assembly

Crossover frequency 2kHz

8Ω

8Ω

8Ω

136dB SPL, 1m (peak)

Bi-amplified 130dB SPL, 1m (rms)

Sensitivity: (Pink Noise) Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

Beamwidth (-6dB point): Horizontal

Vertical

Maximum Recommended

Amplifier Power:

Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

136dB SPL, 1m (peak)

108dB SPL, 1w, 1m

106dB SPL, 1w, 1m

107dB SPL, 1w, 1m

36 degrees

36 degrees

600W into 8Ω

600W into 8Ω

150W into 8Ω

4

Page 5

SPECIFICATIONS

9702™ II

Mechanical Specification

Dimensions:

Weight: 60lb 27k g

Components: One High-Power

Frequency Range: 160Hz to 16kHz (± 3dB)

Nominal Impedance: Passive 2-Way

Maximum Acoustic Output:

(IEC Noise)

34"H x 22.3"W front

12.2"W x 15.8"D rear

Compression Driver

One Mid-range Driver

Bi-amplified

Mid-frequency

High-frequency

Passive 2-Way

86.4 x 56.6cm

31.0 x 40.1cm

t1.4hp

Vee Four Mid-range

Driver Assembly

Crossover frequency 2kHz

8Ω

8Ω

8Ω

128dB SPL, 1m (rms)

134dB SPL, 1m (peak)

Bi-amplified

Sensitivity: (Pink Noise) Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

Beamwidth (-6dB point): Horizontal

Vertical

Maximum Recommended

Amplifier Power:

Passive 2-Way

Bi-amplified

Mid-frequency

High-frequency

128dB SPL, 1m (rms)

134dB SPL, 1m (peak)

104dB SPL, 1w,1m

105dB SPL, 1w, 1m

104dB SPL, 1w, 1m

87 degrees

70 degrees

600W into 8Ω

600W into 8Ω

150W into 8Ω

5

Page 6

SPECIFICATIONS

3202™

Mechanical Specification

Dimensions:

Weight: 98lb 44.5kg

Components: One High-frequency

Frequency Range: 160Hz to 16Hz ±3dB

Nominal Impedance: Mid-frequency

Maximum Acoustic Output: Mid-frequency 130dB SPL, 1m (rms)

Sensitivity: Mid-frequency

Beamwidth (-6dB point): Horizontal

42"H x 22.2"W front

12.2"W x 33.5"D rear

Compression Driver

One Mid-range Driver

High-frequency

High-frequency 130dB SPL, 1m (rms)

High-frequency

Vertical

106.7 x 56.4cm

30.9 x 85.1cm

t1.4

M10

8Ω

8Ω

136dB SPL, 1m (peak)

136dB SPL, 1m (peak)

109dB SPL, 1w, 1m

114dB SPL, 1w, 1m

27 degrees

20 degrees

Recommended Amplifier

Power:

Mid-frequency

High-frequency

6

600W

150W

Page 7

SPECIFICATIONS

4402™

Mechanical Specification

Dimensions:

Weight: 66lb 30k g

Components: One High-frequency

Frequency Range: 160Hz to 16kHz ±3dB

Nominal Impedance: Mid-frequency

Maximum Acoustic Output: Mid-frequency 124dB SPL, 1m (rms)

Sensitivity: Mid-frequency

34"H x 19.2"W front

12.2"W x 21.6"D rear

Compression Driver

One Mid-range Driver

High-frequency

High-frequency 128dB SPL, 1m (rms)

High-frequency

86.4 x 48.8cm

31.0 x 54.9cm

t1.4

M10

16Ω

8Ω

130dB SPL, 1m (peak)

134dB SPL, 1m (peak)

105dB SPL, 1w, 1m

112dB SPL, 1w, 1m

Beamwidth (-6dB point): Horizontal

Vertical

Recommended Amplifier

Power:

Mid-frequency

High-frequency

40 degrees

40 degrees

300W

150W

7

Page 8

SPECIFICATIONS

9702™

Mechanical Specification

Dimensions:

Weight: 66lb 30k g

Components: One High-frequency

Frequency Range: 160Hz to 16kHz ±3dB

Nominal Impedance: Mid-frequency

Maximum Acoustic Output: Mid-frequency 122dB SPL, 1m (rms)

Sensitivity: Mid-frequency

34"H x 22.3"W front

12.2"W x 12.1"D rear

Compression Driver

One Mid-range Driver

High-frequency

High-frequency 124dB SPL, 1m (rms)

High-frequency

86.4 x 56.6cm

31.0 x 30.7cm

t1.4

M10

16Ω

8Ω

128dB SPL, 1m (peak)

130dB SPL, 1m (peak)

103dB SPL, 1w, 1m

105dB SPL, 1w, 1m

Beamwidth (-6dB point): Horizontal

Vertical

Recommended Amplifier

Power:

Mid-frequency

High-frequency

87 degrees

70 degrees

300W

150W

8

Page 9

7

5

3

8

2

4

1

5

6

10

9

11

®

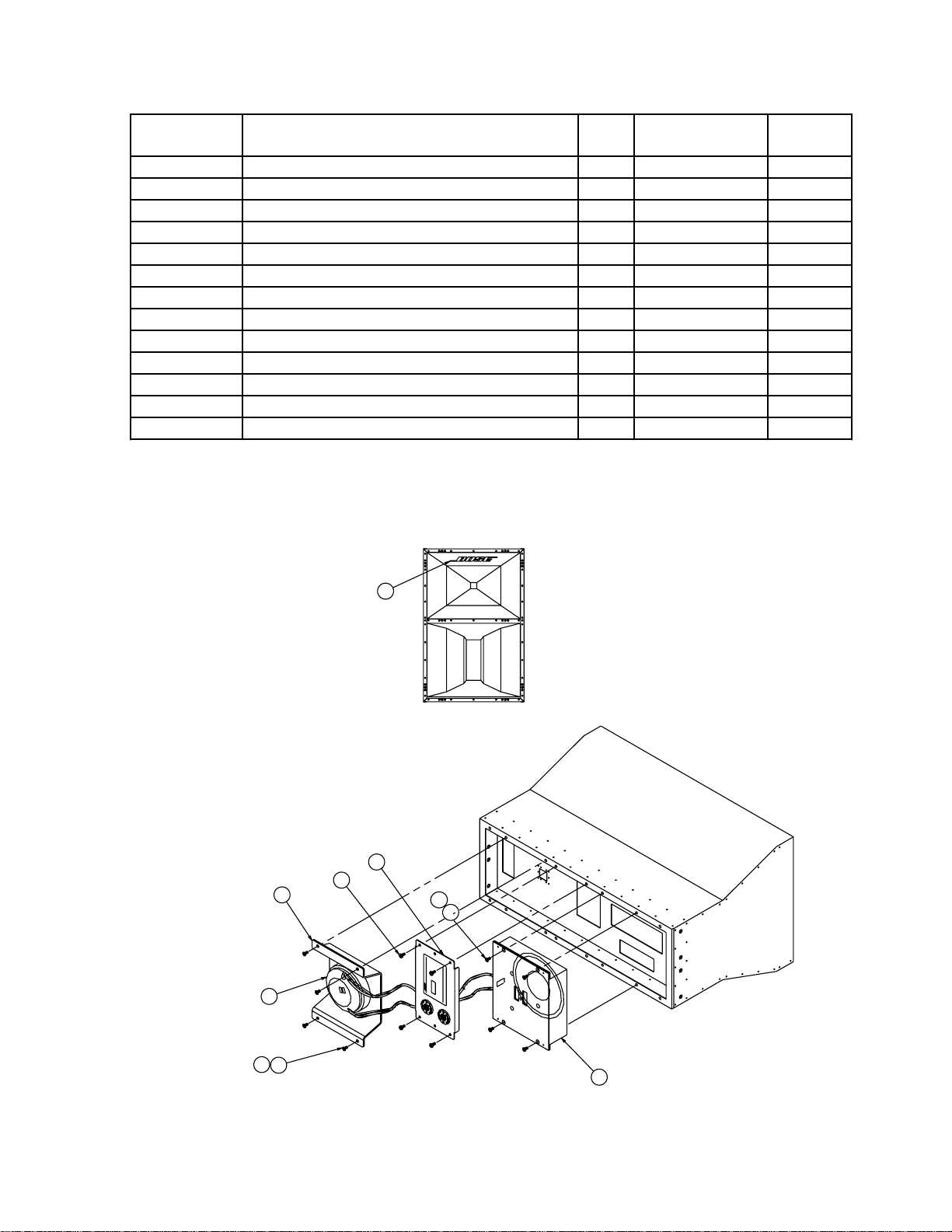

Figure 1. Panaray

Exploded View

5

2

19

12

11

13

6

7

15

4

1

3

10

Figure 2. Panaray Series II Exploded View

9

Page 10

DISASSEMBLY/ASSEMBLY PROCEDURES

3202™/4402™/9702™ SERIES I

Note: Numbers in parentheses correspond

to the item call outs in Figure 1.

1. Compression Driver Removal

1.1 Disconnect the Neutrik Speakon™

connector(s) and the weather protector, (if

used).

1.2 Disconnect the red and black wires (6)

from the compression driver terminals.

Note: On some models, the connectors

may have been soldered.

1.3 Remove the four screws (4) holding

the compression driver assembly (3) to the

cabinet.

1.4 Remove the four screws holding the

compression driver (2) to the mounting

plate.

2. Compression Driver Replacement

2.1 Place the new compression driver on

to the mounting plate, and secure it to the

plate.

2.2 Place the compression driver assembly (3) on to the cabinet and secure it to

the cabinet.

Note: Tighten screws in the following

order: clockwise with a torque setting of 5

inch-pounds. Counter clockwise with a

torque setting of 15 inch-pounds. Clockwise with a torque setting of 25 inchpounds.

2.3 Reconnect the red and black wires (6)

to the terminals on the driver.

3. M-10 Driver Removal

3.1 Perform procedure 1.1.

3.2 Remove the bottom two screws (5) on

the connector panel (7).

3.3 Loosen the two top screws on the

connector panel. This will allow room for

the M-10 driver when lifting it out of the

cabinet.

3.4 Remove the four screws (8) holding

the M-10 driver (1) to the cabinet.

Note: Do not let the driver fall out of the

cabinet.

3.5 Disconnect the green and white wires

(10) from the M-10 driver.

4. M-10 Driver Replacement

4.1 Reconnect the green and white wires

onto the new M-10 driver.

4.2 Place the new M-10 driver (1) onto the

cabinet, carefully routing the green and

white wires around the side of the driver.

4.3 Secure the M-10 driver to the cabinet.

4.4 Replace the two screws (5) in the

bottom of the connector panel, and tighten

all four screws.

4.5 Perform procedure 2.4 and 2.5.

Note: To remove the lower M-10 driver (9)

from the model 3202 simply remove the

four screws (11) holding the driver to the

cabinet, and disconnect the speaker wires.

2.4 Perform the test procedures on page

13.

2.5 Reconnect the Neutrik Speakon

connector to the speaker panel and replace the weather protector, (if used).

10

Page 11

DISASSEMBLY/ASSEMBLY PROCEDURES

3202™/4402™/9702™ SERIES II

Caution: The rear of the Panaray® LT

loudspeakers can become extremely hot

during normal use. Do not attempt to

service the loudspeakers until they have

cooled to room temperature.

Note: Numbers in parentheses correspond

to the item call outs in Figure 2.

1. Compression Driver Removal

1.1 Disconnect the Neutrik Speakon™

connector from the connector panel (6).

1.2 Remove the two screws (7) holding the

cover assembly on to the cabinet. Slide the

cover assembly (15) up and remove it from

the cabinet.

1.3 Disconnect the red and black wires

from the terminals of the compression

driver (1).

Note: On some models, the connectors

may have been soldered.

2.3 Reconnect the red and black wires

on the compression driver terminals.

Take care to place the red wire on the

positive(+) terminal and the black wire

on the negative (-) terminal.

2.4 Perform the test procedures on page

13.

2.5 Align the cover assembly (15) tabs

with the slots in the cabinet and slide the

cover into place. Secure the cover to the

cabinet.

2.6 Reconnect the Neutrik Speakon

connector to the connector panel.

3. Vee Four Driver Removal

3.1 Perform steps 1.1 and 1.2.

3.2 Disconnect the green and white wires

from the Vee Four terminals.

1.4 Remove the four screws (4) holding

the compression driver assembly (1) to the

cabinet.

1.5 Remove the compression driver assembly from the cabinet.

1.6 Remove the four screws holding the

compression driver to the mounting plate

(3).

2. Compression Driver Replacement

2.1 Place the new driver on to the mount-

ing plate (3) and secure it to the plate.

2.2 Place the compression driver assembly

(1) into the cabinet and secure it to the

cabinet.

3.3 Remove the four screws (5) holding

the Vee Four driver assembly (2) to the

cabinet.

3.4 Remove the Vee Four driver assembly

(2) from the cabinet.

4. Vee Four Driver Replacement

4.1 Place the new Vee Four driver assem-

bly into the cabinet.

4.2 Secure the driver assembly (2) to the

cabinet using the screws supplied with the

new driver assembly package.

4.3 Reconnect the green and white wires

to the terminals on the driver assembly.

Take care to place the green wire on to the

positive (+) terminal and the white wire on

to the negative (-) terminal.

11

4.4 Perform steps 2.4 thru 2.6.

Page 12

DISASSEMBLY/ASSEMBLY PROCEDURES

3202™/4402™/9702™ SERIES II

Note: The 3202 II loudspeaker has two V ee

Four driver assemblies. The cover does not

need to be removed to access the lower

driver assembly.

5. Vee Four Lower Driver Removal

5.1 Disconnect the two wires connected to

the terminals on the driver assembly.

5.2 Remove the four screws holding the

driver assembly to the cabinet.

5.3 Remove the driver assembly.

6. Vee Four Lower Driver Replacement

6.1 Place the new Vee Four driver assem-

bly onto the cabinet.

6.2 Secure driver assembly to the cabinet

using the screws provided in the new driver

assembly packaging.

8.3 Place the new inductor assembly (13)

into the cabinet and secure it to the cabinet.

Connect the wires to the capacitor and wire

harness.

8.4 Perform the test procedures on page

13.

8.5 Perform step and 2.5.

6.3 Perform the test procedures on page

13.

7. Crossover Component Removal

7.1 Perform steps 1.1 and 1.2.

7.2 To remove the capacitors remove the

screws from the bracket (12) and disconnect the wires.

7.3 To remove the inductor assembly (13)

remove the screw (19) from the center of

the inductor. Disconnect the inductor from

the capacitor and the wire harness and

remove the inductor.

8. Crossover Component Replacement

8.1 Reconnect the wires to the new ca-

pacitor and place it into the cabinet. Place

the bracket (12) over the capacitor and

secure it to the cabinet.

12

Page 13

DIAPHRAGM REPLACEMENT PROCEDURE

Note: Use a clean, well lit work area to

replace the diaphragm. The work area must

be free of magnetic materials that might be

attracted to the magnet in the compression

driver.

1. Rear Cover Removal

1.1 Carefully clean the outside of the

compression driver with a damp cloth.

1.2 Place the compression driver so the

rear is facing up.

1.3 Remove the three stainless steel

hexhead screws with a 5/32" hex wrench

by first loosening each screw one turn.

Then alternately loosen each screw until

they are removed from the rear cover.

1.4 Gently lift the rear cover straight up.

Set it down on its outside to keep the inside

clean.

2. Diaphragm Removal

2.1 Remove the black diaphragm assem-

bly by gently lifting and rotating it.

Note: If the gap is still not clean

replace the entire compression driver.

C. The front plate may have some small

smudges from fingerprints but there should

be no debris (from a shattered aluminum

diaphragm or any other source) and it

should feel smooth to the touch with no pits

in the metal.

4. Diaphragm Kit Replacement

4.1 Remove the replacement diaphragm

from its carton. Set it down so the coil is

facing up.

4.2 Grasp the diaphragm assembly around

its edges and gently place it onto the front

of the compression driver assembly.

Note: Take care not to damage the bobbin

as it comes in contact with the driver

assembly.

4.3 Slowly and gently rotate the diaphragm assembly so that the coil is worked

into the gap and the diaphragm assembly

rests smoothly against the front of the

compression driver.

3. Compression Driver Magnet Inspection

Procedure

3.1 Examine the gap in which the coil of

the diaphragm sits by doing the following

steps.

A. Gently insert one end of a piece of

paper (approximately 1" x 1/2") into the

gap. Move the paper around the perimeter

of the gap. You should not feel any debris

or obstructions with the paper.

B. To remove the debris (if any) from

the gap, fold a piece of masking tap so that

both sides are sticky. Insert the tape into

the gap and work into and around the gap,

removing any debris. Check the gap with a

piece of paper. Once the gap is clean make

sure that there is no debris on the front

plate.

4.4 Align the holes in the diaphragm

assembly with the holes in the compression

driver.

4.5 Place the rear cover back on by aligning the three screw holes and the three

post holes.

Note: Make sure the assembly fits together

flush, and the holes are aligned.

4.6 Place screw with lock washer into each

of the three holes. Tighten screws in this

order: clockwise with a torque setting of 5

inch-pounds. Counter clockwise with a

torque setting of 15 inch-pounds. Clockwise

with a torque setting of 25 inch-pounds.

4.7 Perform step 2 in the Disassembly/

Assembly Procedures.

4.8 Perform Test Procedures.

13

Page 14

High-Frequency -

Mid-Range -

High-Frequency +

Mid-Range +

IF THE JUMPERS ARE NOT USED

CONNECT TO THE TERMINAL BLOCK

ACCORDING TO THIS PIN LAY-OUT.

TEST PROCEDURES

pin 1 +

pin 2 +

pin 1 -

pin 2 -

CONNECT TEST CABLES

HERE AT THE TERMINAL

BLOCK.

JUMPER

JUMPERIF JUMPERS ARE USED

Figure 3. Connection Diagram

Note: Connect the cables to the terminal

block as shown in Figure 3.

1. Rub and Tick Test

1.1 Apply an 8Vrms, 10Hz signal to the

input terminals of the speaker.

1.2 No extraneous noise such as rubbing,

scraping or ticking should be heard.

2. Phase Test

2.1 Disconnect the connectors at the V-4

or M-10 terminals. Momentarily apply

±1Vdc to the terminals. Observe polarity

8

when connecting the dc power supply. All

the drivers should move outward.

3. Frequency Power Sweep Test

3.1 Apply an 8Vrms, 10Hz signal to the

speaker input terminals.

3.2 Sweep the Loudspeaker from 10Hz to

2kHz.

3.3 Lower the applied voltage to 4Vrms

and sweep the loudspeaker from 1kHz to

5kHz.

3.4 Listen for any buzzes, rattles or other

extraneous noises from the loudspeaker.

14

Page 15

PART LIST NOTES

1. There are two high-frequency compression drivers available.

Part number 176605 is used for the original Panaray

Part number 186100 is used for the Panaray LT Series II Systems.

2. The replacement diaphragm kit is used to repair both the original and series II high-frequency compression drivers.

3. There are two Vee Four mid-range driver assemblies used on the 3202™ II.

4. There are two M-10 drivers used on the 3202 panaray loudspeaker.

®

LT Systems.

15

Page 16

PANARAY® LT SERIES II PART LIST

Item

Number

Desription Qty Part

Number

1 Driver, Compression, T1.4 HP 1 186100 1

1 Replacement Diaphragm Kit (T1.4) 1 181470 2

2 Sys Assy, Vee Four, Blk 1 190700-001 3

3 Bracket, High Freq. Driver 1 176896

4 Screw, Mach, .25-20, Pan, XREC 12 176801-16

5 Screw, Mach, . 25-20, Flat, XREC, SS 4 176614-08

6 Connector Panel Assy, LT II 1 187976-03 3202™-II

6 Connector Panel Assy, LT II 1 187976-02

7 Screw, Tapp, 8-11X.75, Pan, XRC/SQ 8 187942-12

8 Conn, Speakon, Panel Mount 2 187887

9 Clip, Tinnerman 2 187943

10 Cap, Filter, Oval, 10%, 6uF 1 187890

11 Cap, Filter, Oval, 3uF 1 176668

12 Strap, Mounting, Cap 2 176669

13 Inductor, .63uH 1 187889

14 Spacer, Round, 1.150x.074 1 130913

15 Cover Assy, Back, LT II 1 176897-01 3202-II

15 Cover Assy, Back, LT II 1 176897-02

16 Label, Bose, Logo 1 183067

17 Clip, Cable, Dbl Face Adh, .25" 4 145716

18 Connector, Terminal Blockstrip 1 188629-004

19 Screw, Pan Head, 1.5" #6-32 1 146092-24

20 Screw, Mach, 6-32, FH, XREC 2 187935-10

21 Nut, Hex, W/Lock washer 2 133803-06

Note

NL4MP

1+

2-

1-

2+

8

(QTY 4)

5

4

2

19

11

(QTY 2)

13

14

(QTY 2)

21

20

18

(QTY 2)

27

V4

V4

PIN 1PIN 2-

PIN 2+

PIN 1+

8

(QTY 2)

7

6

(QTY 2)

9

(QTY 4)

17

CLIP

15

7

(QTY 2)

16

(QTY 4)

4

5

3

1

(QTY 4)

8

(QTY 2)

12

10

Figure 4. Panaray® Series II Exploded View

Page 17

PANARAY® LT PART LIST

Item

Number

Description Qty Part

Number

1 Driver Assy, Midrange, 10" M10 1 176606 4

2 Driver, Compression, T1.4 1 176605

2 Diaphragm Kit, Driver, T1.4 1 181470 2

3 Bracket, High-Freq. Driver 1 176665

4 Screw, Mach, .25-20, Flat, XREC 8 176601-12

5 Screw, Mach, .25-20, Pan, XREC 4 176801-16

6 Screw, Mach, .25-20, Flat, XREC, SS 8 176614-08

7 Connector Panel Assy 1 176675 3202™

7 Connector Panel Assy 1 176720 4402™

7 Connector Panel Assy 1 176864 9702™

7 Cap, Filter, Oval , 3uF 1 176668

7 Stip, Mounting, 3uF Cap 1 176669

8 Label, Bose, Logo 1 183067

Note

8

(NOTE 1)

3

2

7

5

6

4

4

6

1

Figure 5. Panaray Exploded View

Page 18

PACKING PART LIST

Item

Number

1 Packing, Insert, eps 148044 4

2 Poly B ag N/A 1 3202™ II

2 Poly B ag N/A 1 4402™ II

2 Poly B ag N/A 1 9702™ II

3 Tray, Packing 181 674 2 3202 II

3 Tray, Packing 181 676 2 4402 II

3 Tray, Packing 181 678 2 9702 II

4 Packing, Insert, Crease

Sheet

Desription Part

Number

181679 2

Oty Note

3

4

3

2

1

Figure 6. Packing

18

Loading...

Loading...