Page 1

AV28 General Test Procedures

1. Initial Product Test

Note: Before taking the unit apart or performing any repair process, an attempt to verify the cus-

tomer complaint must be made.

1.1 Read any customer note included with the unit.

2. Attempt to verify the complaint before opening the unit or performing any repairs.

2.1 Customer complaint not verified, discuss with customer.

2.2 Customer complaint verified, troubleshoot and repair the unit. Refer to the AV28 Troubleshoot-

ing Tips/Preventative Repair Measures document.

®

3. Check the software revision of the unit. Refer to the Bose

http://serviceops.bose.com for information regarding the latest software revision.

3.1 With the system off and powered applied, press “Store” and “Enter”.

4. Verify Performance and all functions using the following procedures.

4.1 Tuner performance procedures.

service extranet site,

4.2 Input/Output performance procedures.

4.3 CD performance procedures.

4.4 User Interface Performance Verification.

Required Test Equipement and Cables

1. Audio Signal Generator.

2. Oscilliscope

3. Volt Meter

4. AM/FM Signal Generator.

5. AV28 remote control part number 256119-001.

6. PS28 or PS48 bass module with cubes (to test digital audio Zone ouputs).

7. AV28 test cable part number 264565.

8. RCA to bare wire cables (to connect cube speakers to bass module).

Rear cable part number 180644; black.

Left/Center/Right part number 180643-4; black.

Note: AC2 connector part number 195505-001 to connect bare wire to Jewel® Cube speaker.

9. Test CDs as listed below or equivalent.

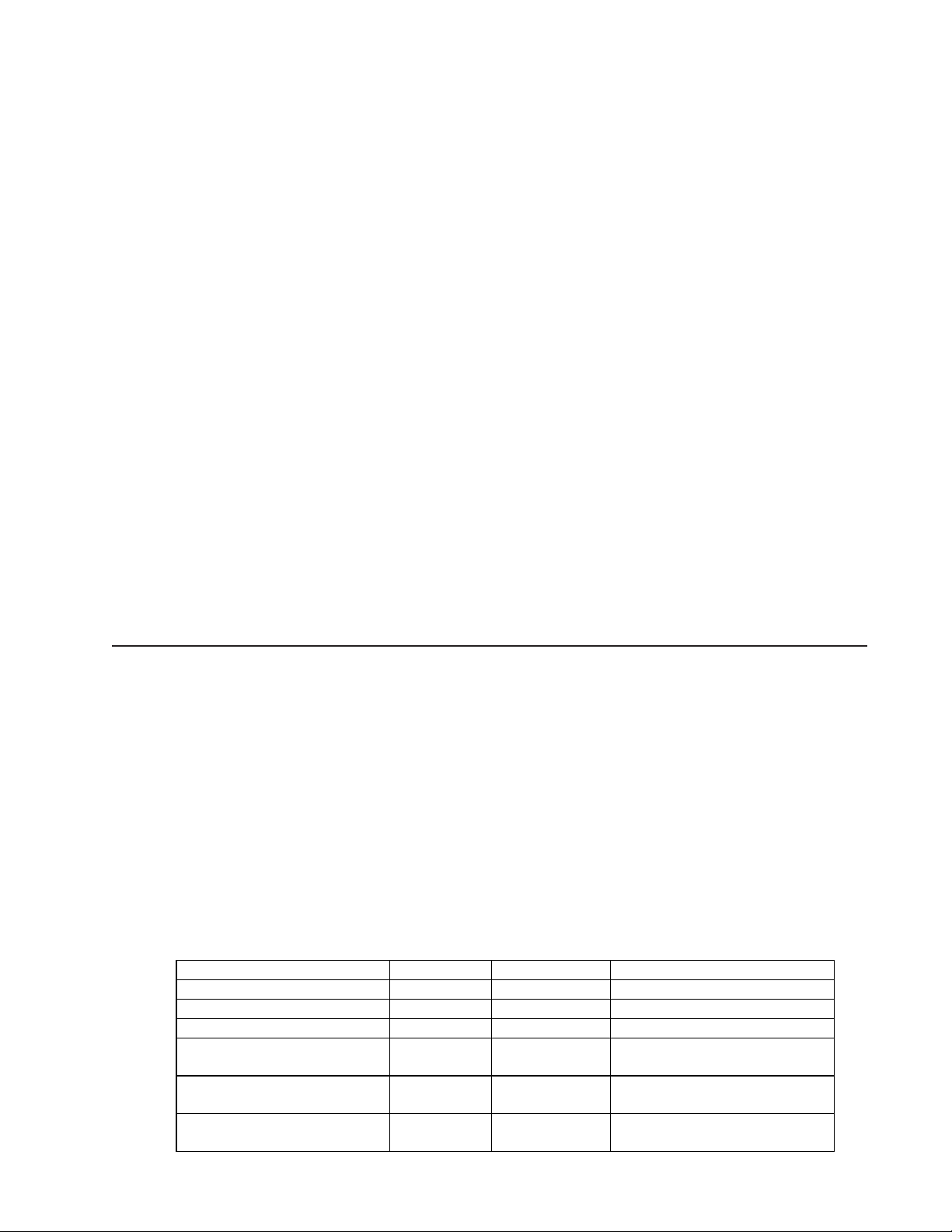

Parameter Nominal Limit Suggested Test disc

Defect Tracking (void) 1.0 mm 0.8 mm Pierre Vernay, test CD#2

Defect Tracking (black dot) 1.0 mm 0.8 mm ABEX test disc TCD-725R

Defect Tracking (scratch) 1.6 mm 1.0 mm ABEX test disc TCD-721 R

Defect Tracking

(finger print)

Defect Tracking

(warped disc)

Defect Tracking

(eccentric disc)

75 mm 65 mm ABEX test disc TCD-725R

1.0 mm 0.7 mm ABEX test disc TCD-732RA

210 mm 140 mm ABEX test disc TCD-714R

1

Page 2

AV28 Performance Verification Procedures

AM Performance Tests

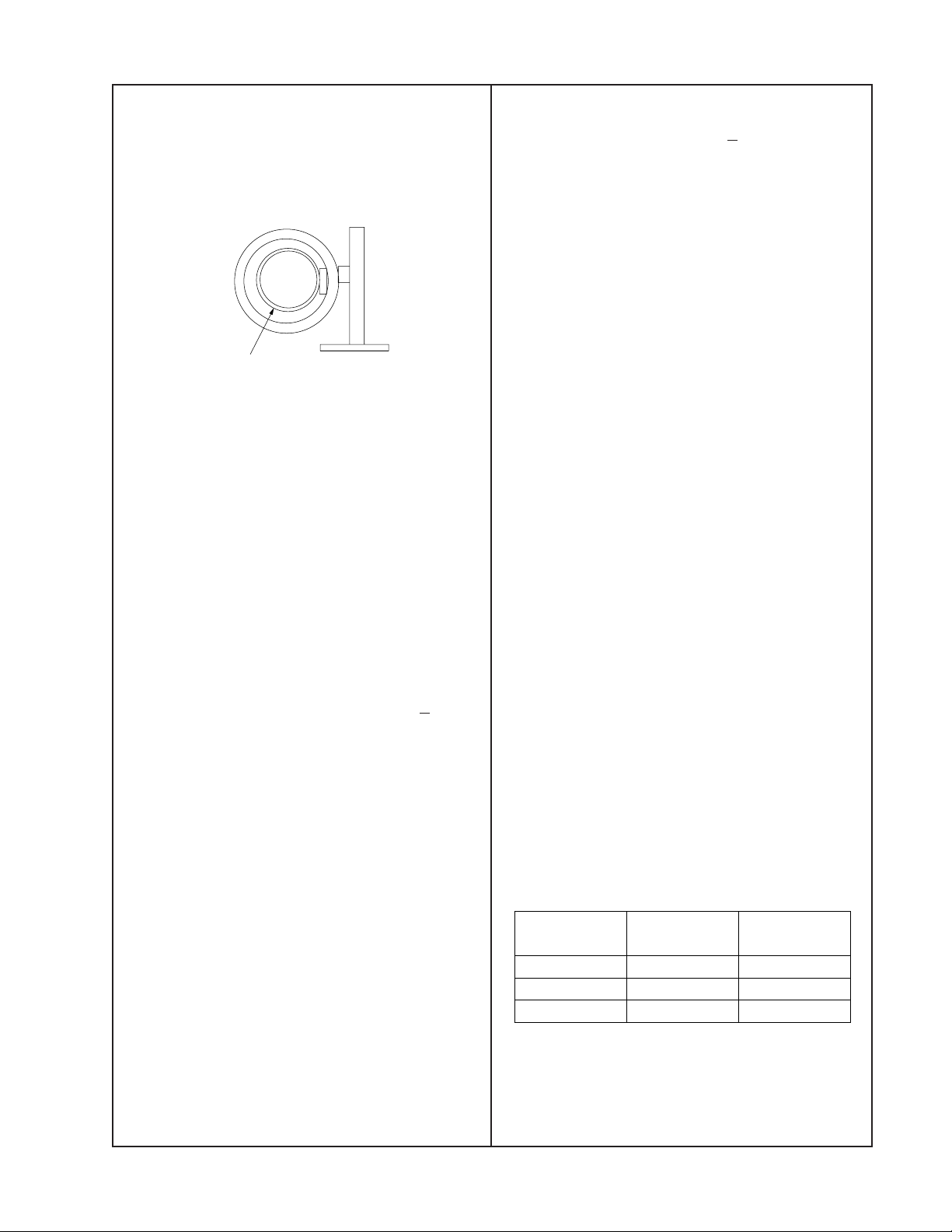

AM Tuner General Test Setup

Setup a loop antenna as shown.

Test Loop

External AM

Loop Antenna

positioned inside

test loop antenna

Figure 1. AM Test Setup

1. AM Sensitivity Test

1.1 Set the RF generator output to 70 dBuV/M,

30% AM modulation, 400Hz and the unit and

RF generator to 1080 kHz.

1.2 Reference a dB meter to the left or right line

level output.

3.2 Measure the distortion at the left or right

line level output. It should be < 3.0%.

4. FM Stop Level Test

4.1 Set the RF generator to 98.9 MHz, 1 kHz

mono modulation, pilot off, 75 kHz deviation, 36

dBuV/M, at the unit’s FM antenna input.

4.2 Place the unit into seek and verify that it

stops at 98.9 MHz.

4.3 Reduce the RF generator to 25 dBf.

4.4 Tune the unit to 98.1 MHz and then place

the unit into seek. Verify the radio does not stop

at 98.9 MHz.

5. Serial Data Verification

5.1 Connect an Oscilloscope to the serial data

output connector J704 pin 2.

5.2 Press volume up or down on the console.

Observe a digital wave form on the oscilloscope.

1.3 Turn off the RF generator’s modulation.

1.4 The line level output should measure < -20

dB, SNR.

2. AM Stop Level Test

2.1 Set the RF generator to 1130 kHz, AM

modulation, 400 Hz modulation, 65 dBuV/M.

2.2 Place the unit into seek and verify the unit

stops at 1130 kHz.

2.3 Switch the RF generator for a 55 dbuV/M

field intensity and verify the unit does not stop

at 1130 kHz.

3. FM Sensitivity Test

3.1 Set the RF generator to 98.1 MHz, 1 kHz

mono modulation, pilot off, 75 kHz deviation, 46

dBuV/M at the unit’s FM antenna input.

6. TV Sensor Verification

6.1 Apply a signal to the TV Sensor input J105

pin 2 at the level and frequency listed in the

following table. The signal should be applied to

the ring of a 3.5mm jack.

6.2 Measure the output of the detector, U303

pin 8, at J103 pin 19.

Note: Off <.8Vrms, On >2.5Vrms. Settling time

is .1 seconds to turn on, 2.0 seconds to turn

off.

Input

Frequency

Input

Amplitude

Detector

Output

60 Hz 200 mVrms <.8Vrms

15.75 kHz 30 mVrms >2.5 Vrms

31.5 kHz 30 mVrms >2.5Vrms

Note: If a unit fails any of these tests, refer to

the appropriate service manual for alignment

procedures. Replace any defective component

found.

2

Page 3

AV28 Performance Verification Procedures

5. Inputs/Outputs Verification

Test Functional test for

the...

Speaker Zones output,

1

TV S-Video, composite

video output, and DVD.

2 Analog audio Inputs

Digital (S/PDIF) and

3

optical audio inputs.

Record digital (S/PDIF)

audio output, Record

4

Optical output, Record

analog output and CD.

5 S-Video and Composite

video input

Connect the Media

Center...

Speaker Zones 1, 2

output...

TV S-video output... a TV S-Video input...

TV composite video

output...

TV analog audio

input...

VCR analog audio

input...

AUX analog audio

input...

Tape analog audio

input...

TV digital (S/PDIF)

audio input...

VCR digital (S/PDIF)

audio input...

AUX digital (S/PDIF)

audio input...

Tape digital

(S/PDIF) audio

input...

Optical input... the optical output of a

Record digital

(S/PDIF) output...

Record optical

output...

Record analog

output...

S-Video input... to the S-Video output of

Composite video

input...

To... and select the

an AM28/35 powered

speaker...

a TV composite video

input...

an analog source...

a digital (S/PDIF)

source...

source...

the digital (S/PDIF)

input of a device...

the optical input of a

device...

to the analog input of a

device...

a source...

to the Composite video

output of a source...

console

source...

DVD

(insert a DVD).

TV.

VCR.

AUX.

Tape.

TV.

VCR.

AUX.

Tape.

TV and assign

the optical input

to TV.

CD.

(insert a CD).

VCR. a clean

Listen/look for..

a clean

undistorted picture

from the TV. A

clean undistorted

audio output from

the PS28/35

powered speaker.

a clean

undistorted audio

output from the

PS28/35 powered

speaker

connected to the

console's Speaker

Zones output.

a clean

undistorted audio

output from the

PS28/35 powered

speaker

connected to the

console's Speaker

Zones output.

a clean

undistorted audio

output from the

source.

Sundistorted

output

from

the...

Video

output.

Compo

-site

video

output

Note:

1. The remote control is needed to turn on the Zone 2 output and should be used to verify the unit’s

ability to respond to remote commands. Refer to the Zone 2 Operation section on page 76.

6. CD Performance Test

6.1 The media center should be able to play the test discs listed in the following table.

Parameter Nominal Limit Suggested Test disc

Defect Tracking (void) 1.0 mm 0.8 mm Pierre Vernay, test CD#2

Defect Tracking (black dot) 1.0 mm 0.8 mm ABEX test disc TCD-725R

Defect Tracking (scratch) 1.6 mm 1.0 mm ABEX test disc TCD-721 R

Defect Tracking

(finger print)

Defect Tracking

(warped disc)

Defect Tracking

(eccentric disc)

75 um 65 um ABEX test disc TCD-725R

1.0 mm 0.7 mm ABEX test disc TCD-732RA

210 mm 140 mm ABEX test disc TCD-714R

3

Page 4

AV28 User Interface Performance Verification

7. User interface test

7.1 Press each button on the console keypad

and ensure its operation.

7.1.1 Press the On/Off button. Ensure the unit

turns on.

7.1.2 To ensure remote operation, select at

least one function (i.e. FM/AM) and ensure the

unit responds appropriately to the remote

control.

7.1.3 Press the volume up (/\) and down (\/)

button on the console keypad and ensure the

unit responds appropriately.

7.1.4 With the Radio tuned to a station, press

the Store button on the console keypad. The

display shows, STORE TO PRESET <number>? Press Store again or press Enter to

save the preset. The display shows “STATION

SAVED to <number>.

7.1.5 Using the remote tune to the preset

station you set in procedure 7.1.3. Press Erase

on the media center. The display shows,

ERASE PRESET <number>? Press Erase

again to delete the preset. The display shows,

PRESET <number> ERASED.

7.1.6 Press the Source button. Ensure, with

each press, the display cycles through the

various sources.

7.1.7 Press the Open/Close button. Ensure the

DVD/CD drawer opens and then press it once

more to shut the drawer.

7.1.8 Press the All Off button. Ensure the unit

shuts off.

4

Loading...

Loading...