Page 1

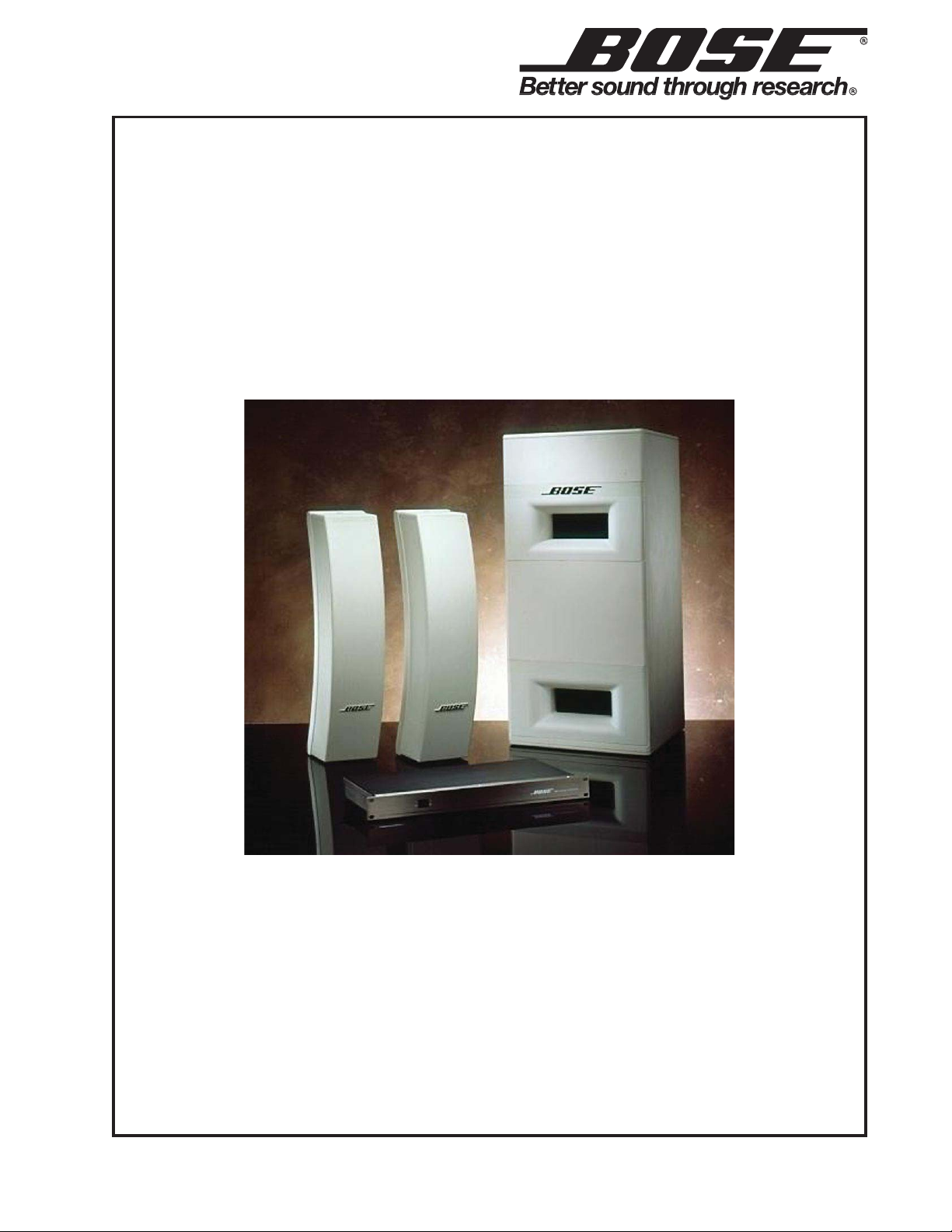

Panaray® Sound System

502 Array, Bass Box and Controller

©2006 Bose Corporation

Service Manual

Reference Number 170310-SM Rev. 03

Electronic Copy Only

Page 2

CONTENTS

Contents......................................................................................................................................... 2-3

Safety Information.............................................................................................................................4

Warranty.............................................................................................................................................4

Specifications................................................................................................................................ 5-7

®

A Array Specifications...............................................................................................................5

502

502B Bass Module Specifications...................................................................................................6

502C Controller Specifications.................................................................................................... 6-7

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................8

Parts Lists and Exploded Views ......................................................................................................8

Parts List Notes.................................................................................................................................9

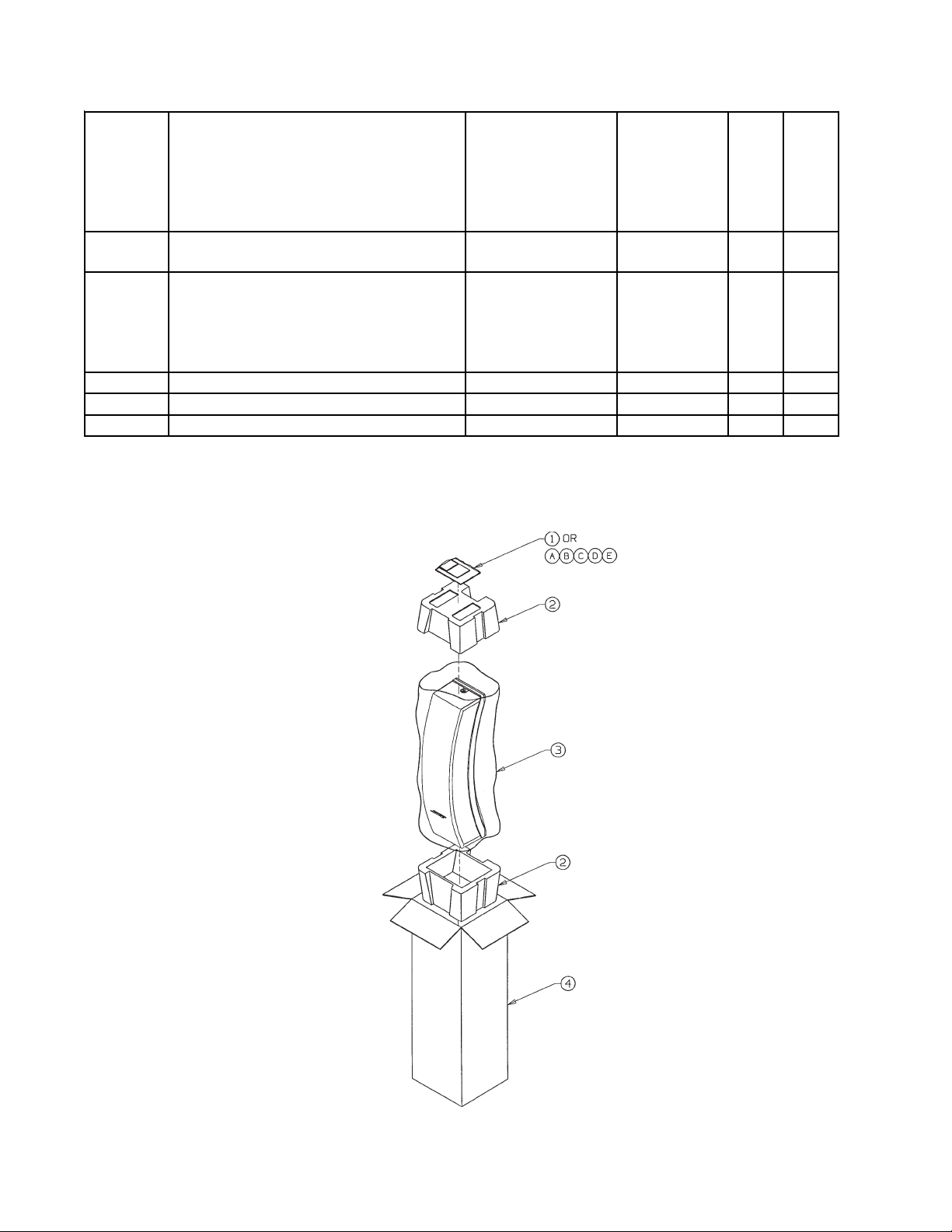

Packaging Part List, 502A Array (see Figure 1)............................................................................10

Figure 1. 502A Array Packaging View ............................................................................................10

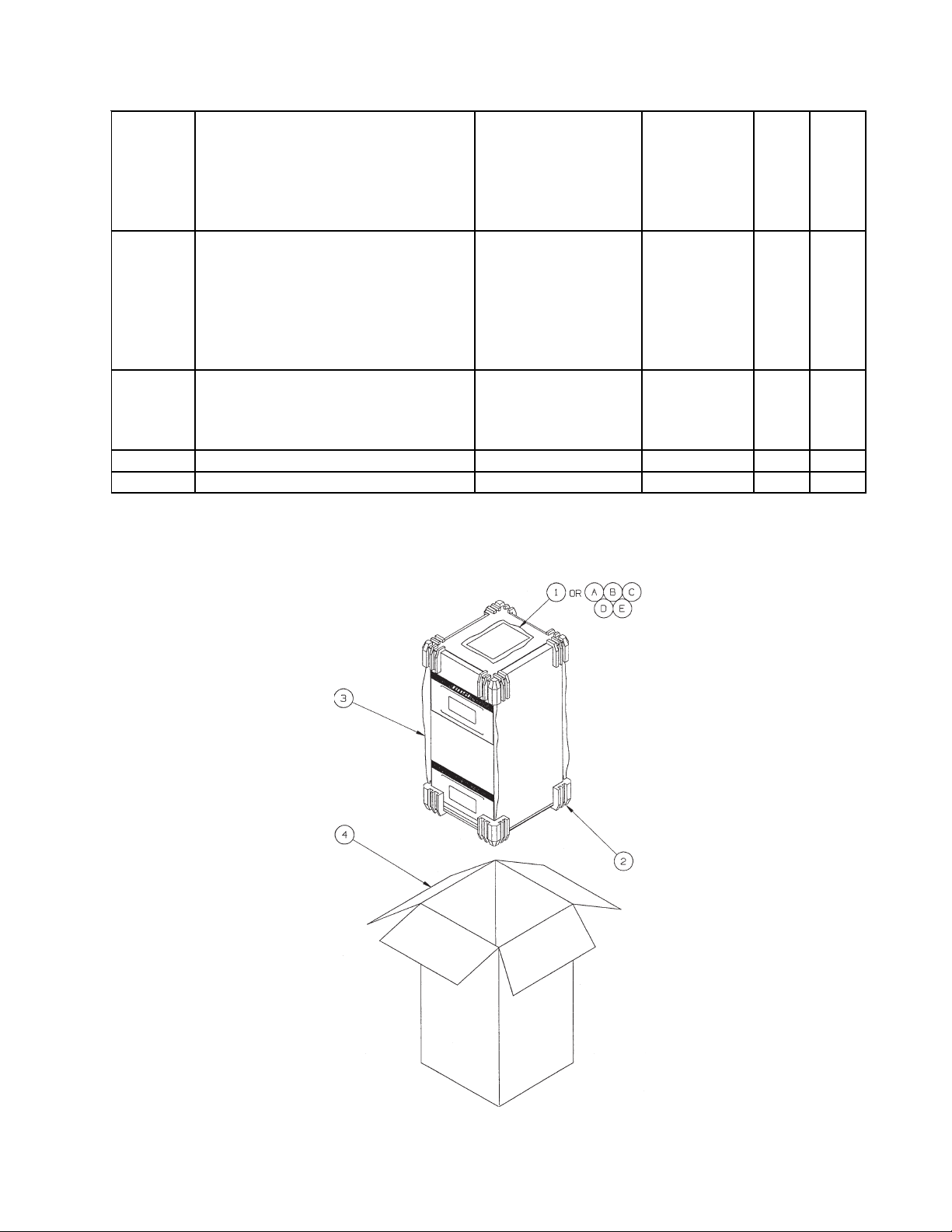

Packaging Part List, 502B Bass Box (see Figure 2) ....................................................................11

Figure 2. 502B Bass Box Packaging Exploded View .....................................................................11

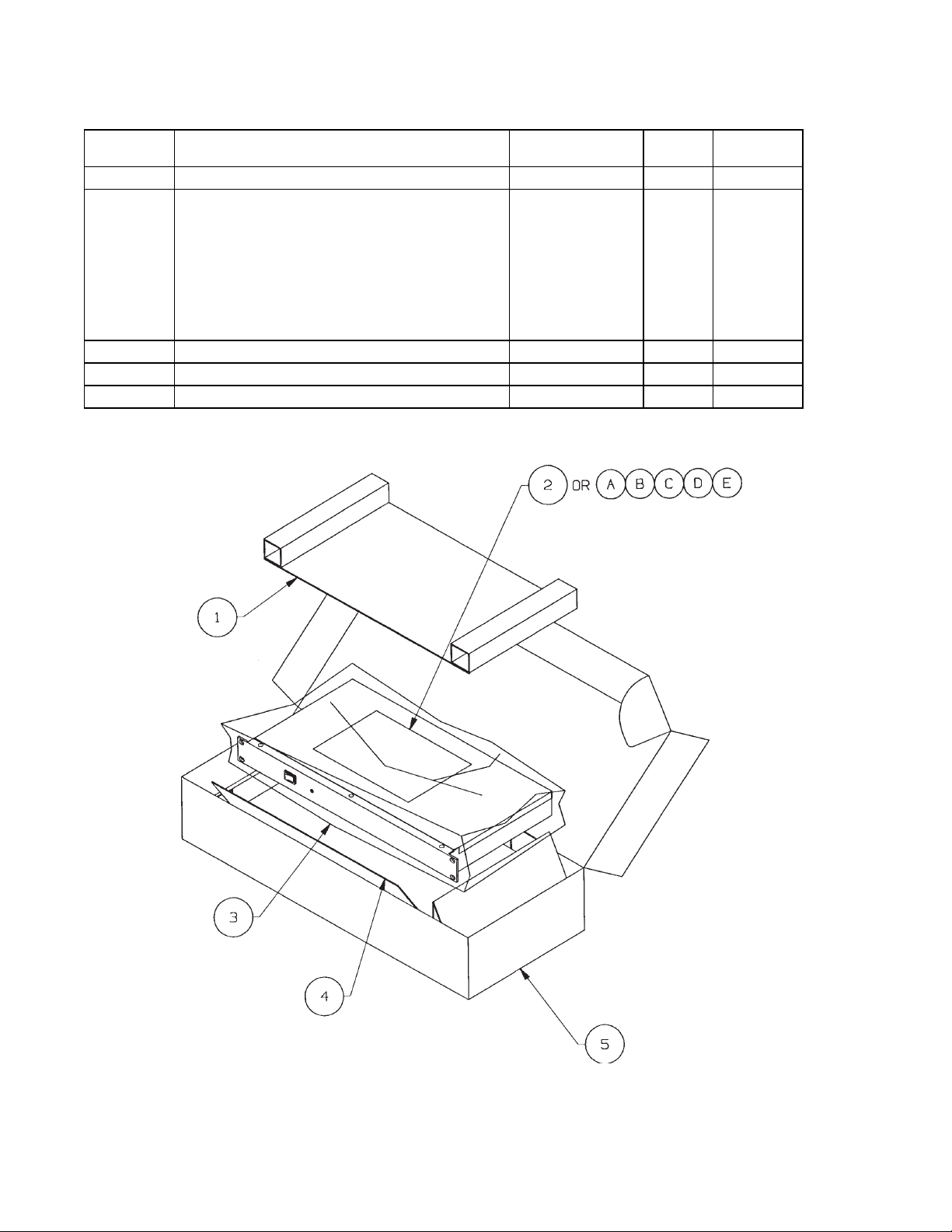

Packaging Part List, 502C Controller (see Figure 3) ...................................................................12

Figure 3. 502C Controller Packaging View.....................................................................................12

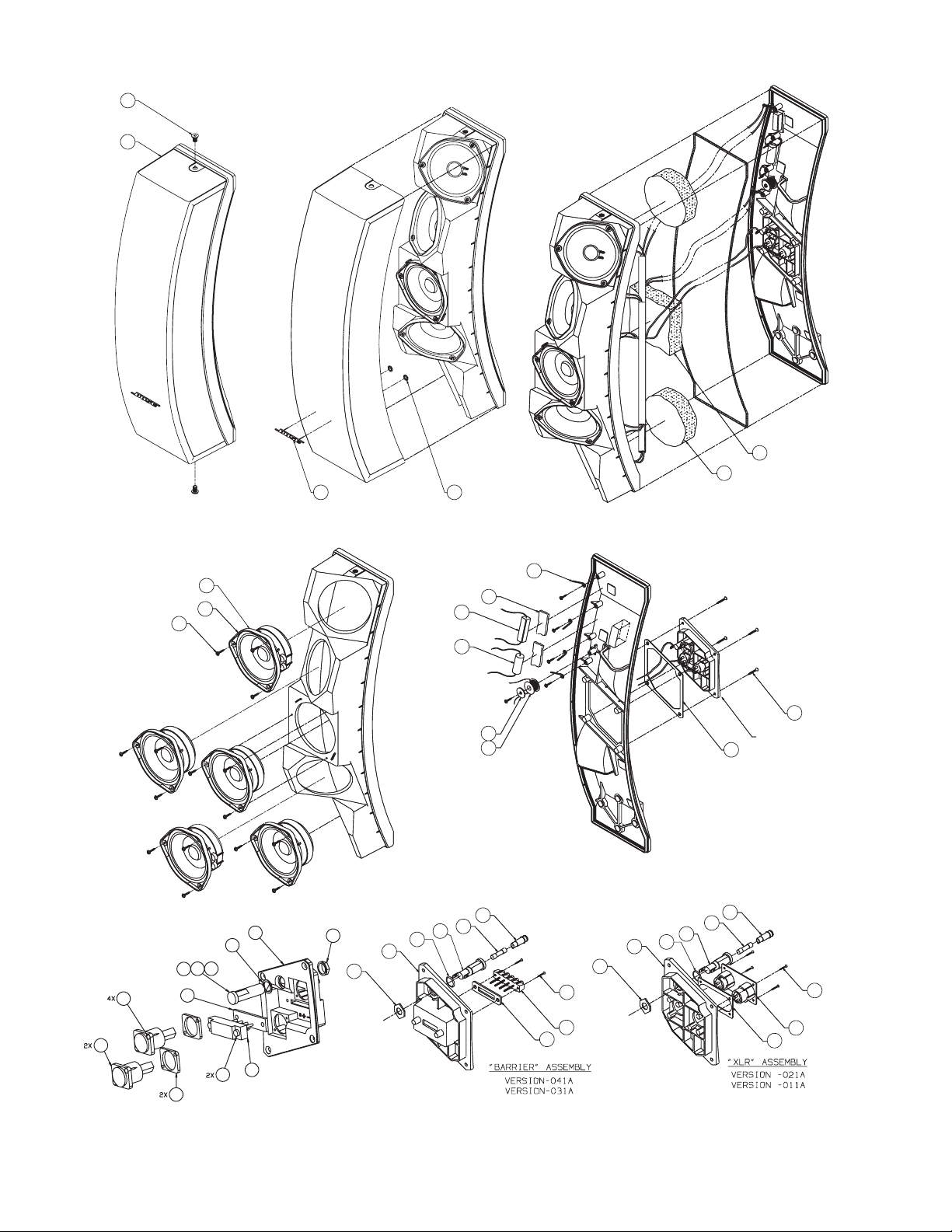

Main Part List, 502A Array (see Figure 4) .....................................................................................13

Figure 4. 502A Array Exploded View ..............................................................................................14

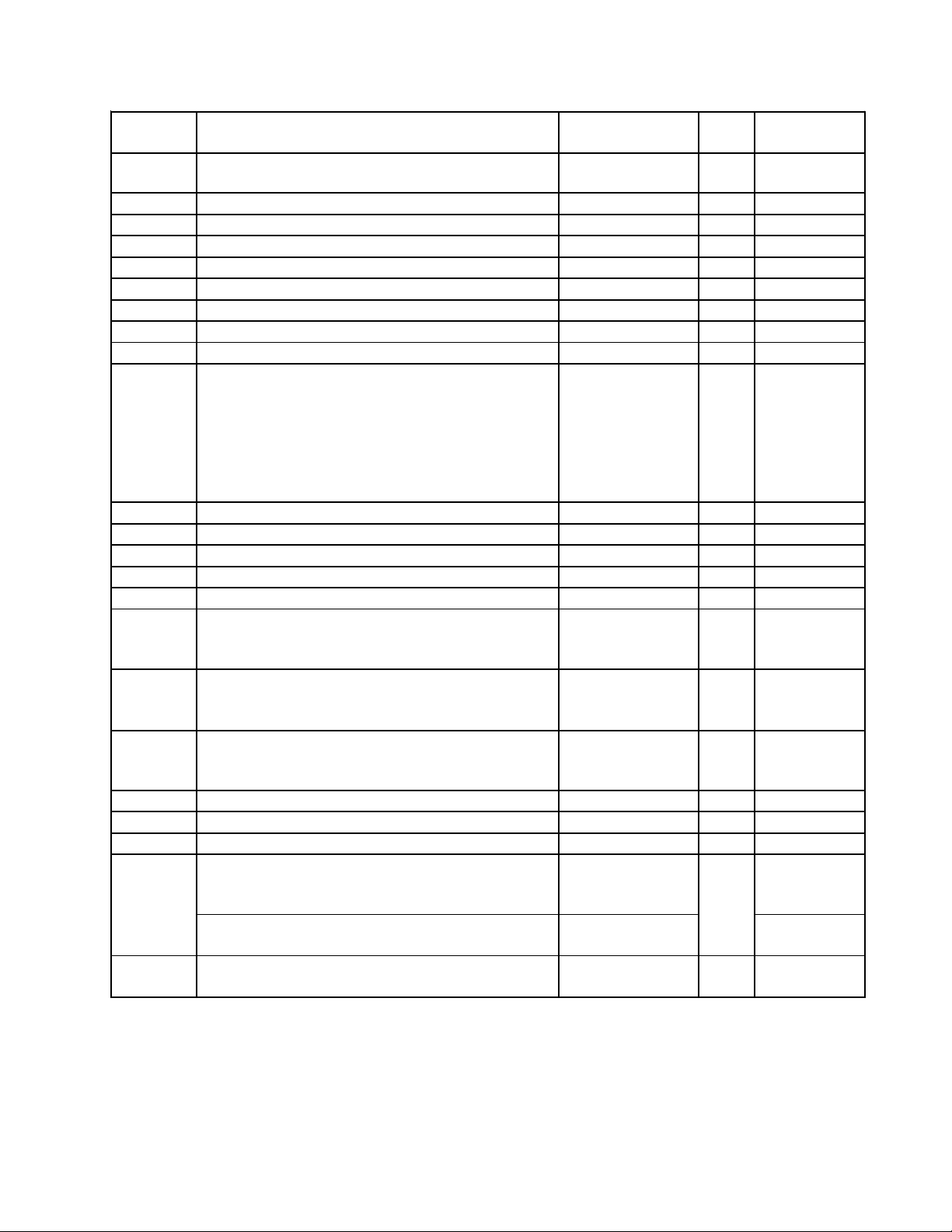

Main Part List, 502B Bass Box (see Figures 5 and 6) .................................................................15

Figure 5. 502B Bass Box Exploded View .......................................................................................16

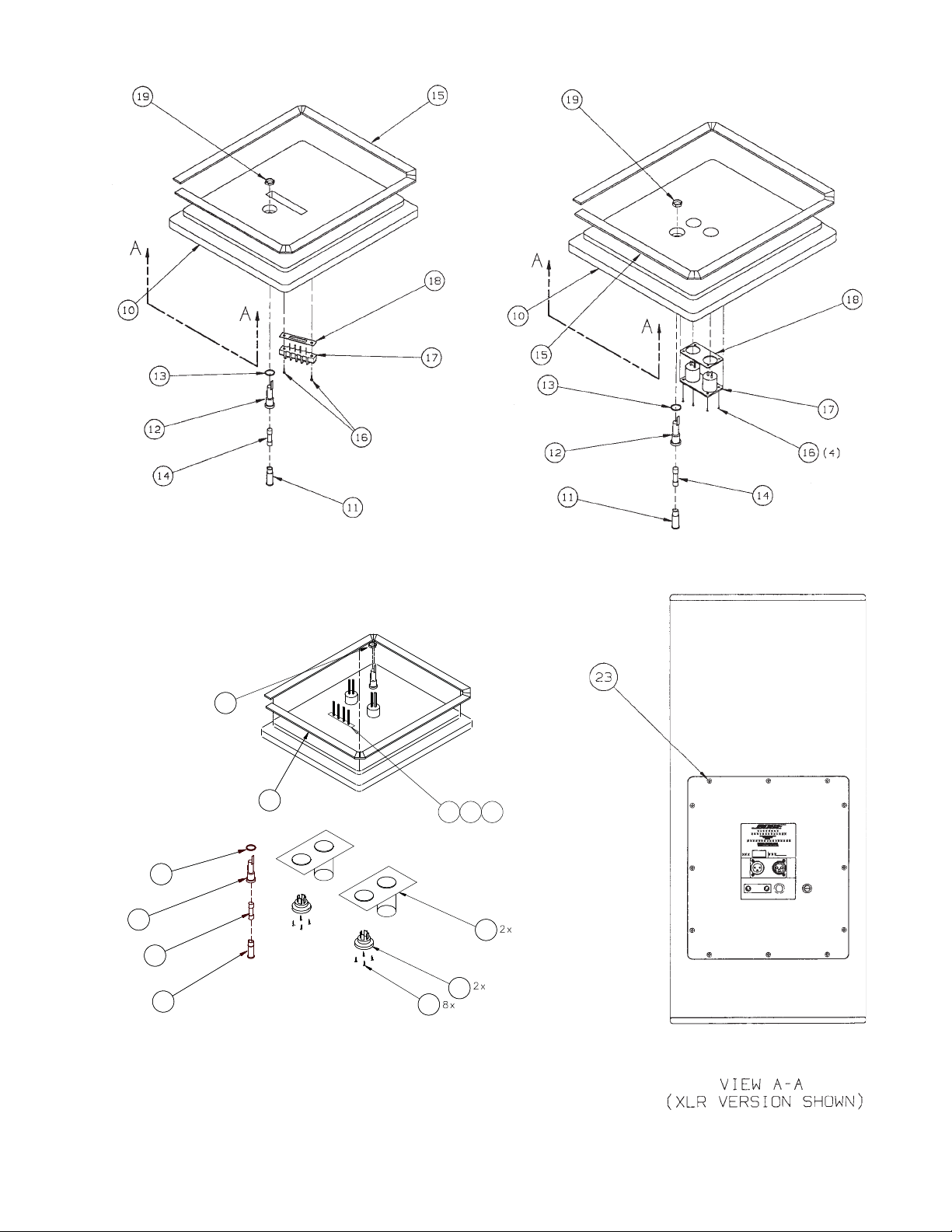

Figure 6. 502B Access Panel and Connector Views ......................................................................17

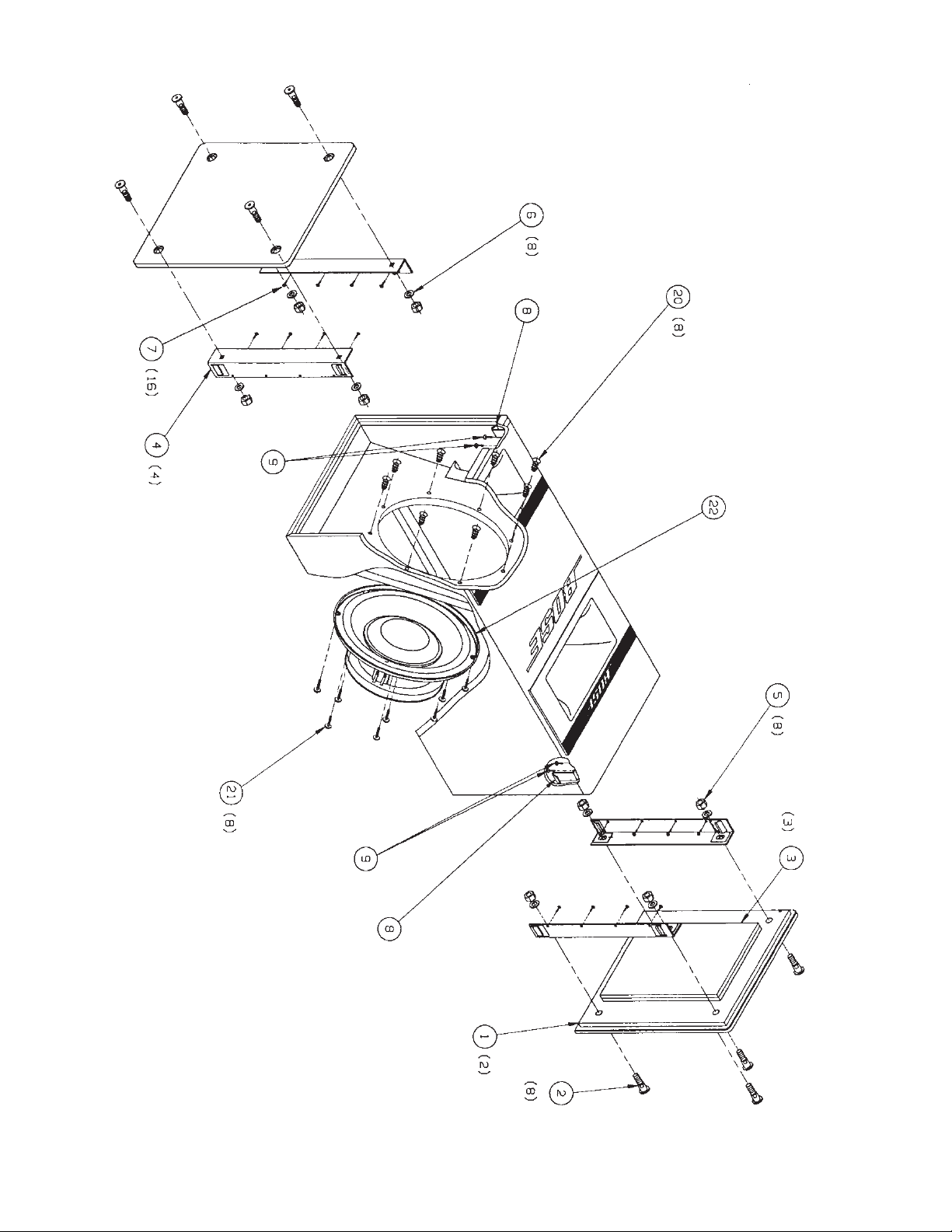

Main Part List, 502C Controller (chassis with removable front panel) (see Figure 7) .............18

Figure 7. 502C Controller Exploded View (removable front panel version)....................................19

Main Part List, 502C Controller (one-piece chassis) (see Figure 8)...........................................20

Figure 8. 502C Controller Exploded View (one-piece chassis version)..........................................20

Electrical Part Lists................................................................................................................... 21-30

502C Controller Main PCB Assembly...................................................................................... 21-30

Disassembly Procedures ...............................................................................................................31

502A Array Procedures ............................................................................................................. 31-34

Figure 9. 502A Array Exploded View ..............................................................................................32

Figure 10. 502A Array Wiring Diagram...........................................................................................33

502B Bass Module Procedures ............................................................................................... 34-35

502C Controller Disassembly Procedures ............................................................................. 35-36

Figure 11. 502B Bass Module Exploded View................................................................................37

Figure 12. 502B Bass Module Connector and Access Panel.........................................................38

Figure 13. 502B Bass Module Wiring Diagrams ............................................................................39

Figure 14. 502C Controller Exploded View (removable front panel version).................................40

Figure 15. 502C Controller Exploded View (one-piece chassis version)........................................40

Test Procedures ..............................................................................................................................41

502A Array T est Procedures ...........................................................................................................41

Figure 16. XLR input pin assignment ............................................................................................41

502B Bass Module Test Procedures ....................................................................................... 41-42

502C Controller Test Procedures ............................................................................................ 42-44

Figure 17. Unbalanced Connections ..............................................................................................45

Figure 18. 502C Controller Back Panel (Barrier Strip Version Shown)...........................................45

Accessory Kit Part Lists........................................................................................................... 46-51

502A PSA-5 Stand Adapter Parts List (see Figure 19) .................................................................46

Figure 19. PSA-5 Stand Adapter Kit ...............................................................................................46

502A CSB-5A Suspension Bracket Kit Parts List (see Figure 20) ..............................................47

Figure 20. CSB-5A Suspension Bracket Kit ...................................................................................47

2

Page 3

CONTENTS

502B CSB-5B Suspension Bracket Kit Parts List (see Figure 21)..............................................48

Figure 21. CSB-5B Suspension Bracket Kit ...................................................................................48

502A WBP-5 Bi-Pivot Bracket Kit Parts List (see Figure 22)....................................................... 49

Figure 22. WBP-5 Bi-Pivot Bracket Kit ...........................................................................................49

502A WCB-5 U-Bracket Kit Parts List (see Figure 23) .................................................................50

Figure 23. WCB-5 U-Bracket Kit ....................................................................................................50

502A CVT-5 Transformer Assembly Kit Parts List (Figure 24) ....................................................51

Figure 24. CVT-5 Exploded View and Packaging...........................................................................51

Figure 25. CVT-5 Schematic ..........................................................................................................52

Theory of Operation.................................................................................................................. 53-55

502C Controller ...............................................................................................................................53

1. Differential Input Stage...............................................................................................................53

2. Equalizer for High Frequency Outputs .....................................................................................53

3. Output mode switch, Low frequency level control, and Normal/Sum mode stage..............53

4. Equalizer for Low Frequency Outputs ......................................................................................53

5. Mode switch ................................................................................................................................53

6. Output stage................................................................................................................................54

7. Power Supply ..............................................................................................................................54

8. Turn On/Off Muting Circuit.................................................................................................. .......54

9. Troubleshooting Tips............................................................................................................ 54-55

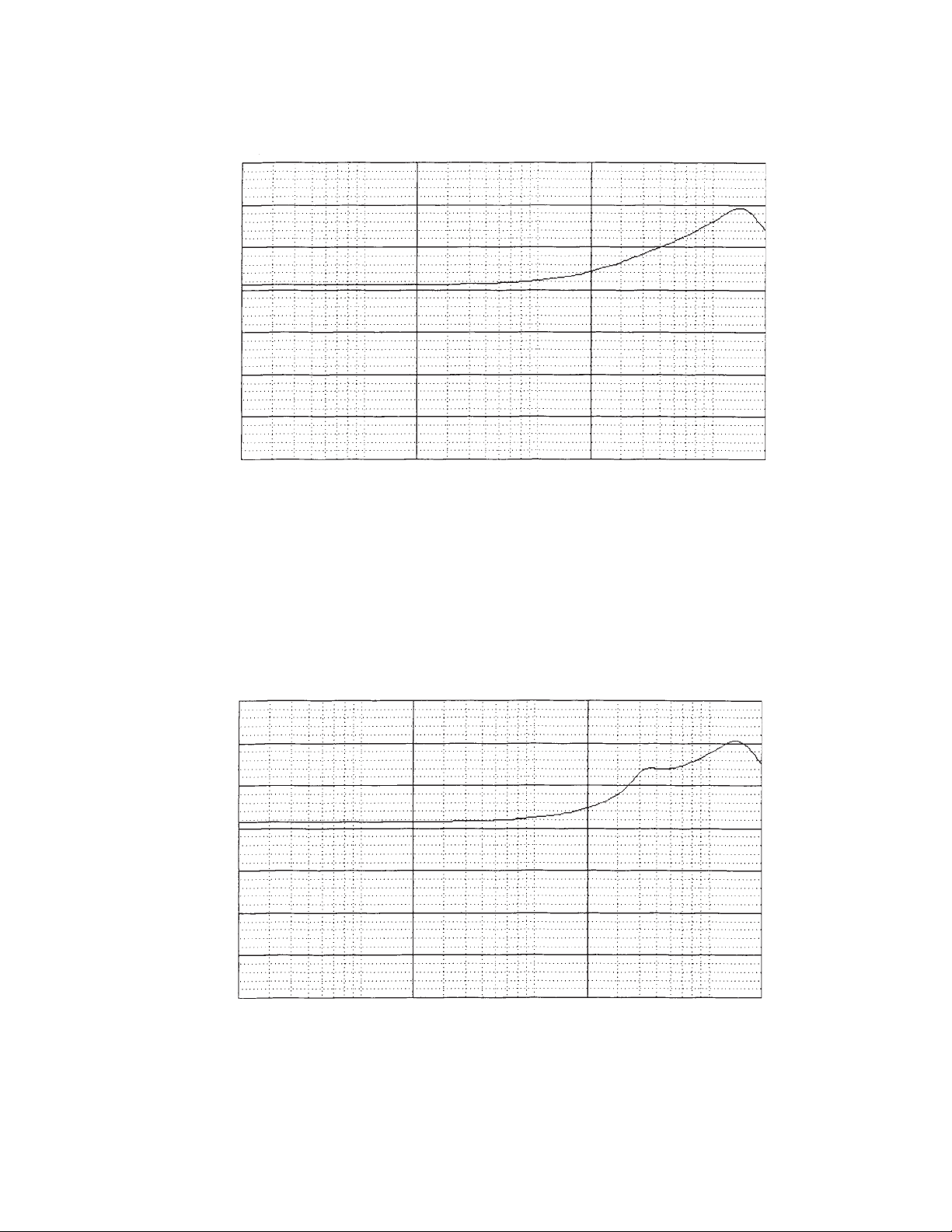

502C Controller EQ Curves ...................................................................................................... 56-61

Figure 26. Low Frequency EQ........................................................................................................56

Figure 27. Low Frequency EQ........................................................................................................56

Figure 28. Low Frequency EQ........................................................................................................57

Figure 29. Low Frequency EQ........................................................................................................57

Figure 30. High Frequency EQ.......................................................................................................58

Figure 31. High Frequency EQ.......................................................................................................58

Figure 32. High Frequency EQ.......................................................................................................59

Figure 33. High Frequency EQ.......................................................................................................59

Figure 34. High Frequency EQ.......................................................................................................60

Figure 35. High Frequency EQ.......................................................................................................60

Figure 36. High Frequency EQ.......................................................................................................61

Figure 37. 502C Controller Block Diagram.....................................................................................62

Service Manual Revision History...................................................................................................63

3

Page 4

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check - With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check - (1) Unplug the power supply and connect a

jumper wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3)

Measure the resistance with an ohmmeter between the jumpered AC plug and each exposed

metallic cabinet part on the unit. When testing 3 wire products, the resistance measured to the

product enclosure should be between 2 and infinite MOhms. Also, the resistance measured to

exposed input/output connectors should be between 4 and infinite MOhms. When testing 2 wire

products, the resistance measured to exposed input/output connectors should be between 4

and infinite MOhms. If it is not within the limits specified, there is the possibility of a shock

hazard, and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® Panaray® 502® Sound System contains

no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose Panaray 502C Controller is covered by a limited 1-year warranty. The Panaray 502A

array speaker and Panaray 502B bass module are covered by a 5-year limited warranty.

4

Page 5

SPECIFICATIONS

502A Array Specifications

Dimensions: 23.5"H x 5.75"W x 6.73"D

(59.7x14.6x17.1 cm)

Weight: 15 lbs. (6.8 kg.)

Transducer Complement: 5 - 4.5 " (11.4 cm) drivers

Enclosure Material: High-impact polystyrene

Nominal Impedance: 8 Ohms, 6.4 Ohms minimum

Sensitivity: 90 dB SPL (1W, 1m, 130 Hz-15 kHz)

Maximum Acoustic Output: 112 dB SPL average, 121 dB SPL peak

Frequency Range: 130 Hz - 15 kHz

Port Tuning Frequency: 135 Hz

Amplifier Power (Recommended): 150 - 600 watts continuous into 8 Ohms

Long-term power handling: 150 watts continuous

Beamwidth: 120° horizontal, 70° vertical

Input Connections: Parallel wired barrier strip (US/Can.)

Parallel wired XLR (Euro/Aus/UK/Japan)

Fusing: 4 ampere AGC (Buss) or 3AG (Littlefuse)

5

Page 6

SPECIFICATIONS

502B Bass Module Specifications

Dimensions: 31.0"H x 14.0"W x 15.5"D

(78.7x 35.6x 39.4 cm)

Weight: 80 lbs. (36.4 kg.)

Transducer Complement: 1 - 12" woofer (high power)

Enclosure Material: 3/4" resin-core, vinyl wrapped

Port: High-impact polystyrene

Nominal Impedance: 8 Ohms, 6.4 Ohms minimum

Sensitivity: 90 dB SPL (1W, 1m, 55 Hz-150 Hz)

Maximum Acoustic Output: 115 dB SPL average, 122 dB SPL peak

Frequency Range: 50 Hz - 150 Hz

Power Handling: 450 watts continuous

Amplifier Power (Recommended): 450 - 1200 watts continuous into 8 Ohms

Input Connections: 2 parallel wired barrier strip (US/Can)

2 parallel wired XLR (Euro/Aus/UK/Japan)

2 parallel wired Speakon® connectors

Fusing: 7 ampere AGC (Buss) or 3AG (Littlefuse)

502C Controller Specifications

Dimensions: 120V/Barrier Strip 1.75"Hx19.0"Wx8.75"D (4.4x48.3x22.2cm)

220-240V/XLR 1.75"Hx19.0"Wx8.0"D (4.4x48.3x20.3cm)

Weight: 5.5 lbs. (2.5 kg.)

Chassis material: 16 gauge steel with painted/zinc coated finish

Cover plate material: Brushed aluminum,painted

Input Connections: Balanced barrier strip (US/Can)

Balanced XLR (Euro/Aus/UK/Japan)

Output Connections: Balanced barrier strip (US/Can)

Balanced High frequency & Low frequency

XLR (Euro/Aus/UK/Japan)

6

Page 7

SPECIFICATIONS

502C Controller Specifications (continued)

Input Impedance: Balanced input, -10 dB level - 14k Ohms

Balanced input, +4 dB level - 6k Ohms

Unbalanced input (+ input), -10 dB level: 12k Ohms

Unbalanced input (+ input), +4 dB level: 4k Ohms

Output Impedance: 100 Ohms nominal

Input Level: -10 dB or +4dB, selectable

Output Level: 8.0 Vrms maximum into 600 Ohms

Low Frequency (LF) Output Mode: Sum or normal

LF Output Level: -18 dB to +3 dB, variable

Crossover Frequency: 140 Hz (Bi-amp), Roll-off slope: -18dB/octave

THD: Midrange distortion of HF output: - 0.1% at 5V, 600 Hz

Low frequency distortion of LF out: - 0.1 % at 5V, 80 Hz

Output Noise: Bi-amp mode, HF outputs - 90µV

Bi-amp mode, LF outputs - 40µV

Passive mode, - 90µV

Offset: All channels - 15mV

Power Requirements: 120 VAC,50/60 Hz, 12 watts (US/Can)

230 VAC,50/60 Hz, 12 watts (Euro)

100 VAC,50/60 Hz, 12 watts (Japan)

240 VAC,50/60 Hz, 12 watts (Aus/UK)

7

Page 8

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PARTS LISTS AND EXPLODED VIEWS

The following section contains parts lists and exploded views for the Panaray® sound system.

The parts lists are broken down as follows:

- 502®A Array Parts List and Exploded View

- 502A Packaging Parts List and Exploded View

- 502B Bass Box Parts List and Exploded View

- 502B Packaging Parts List and Exploded View

- 502C Controller Main Assembly Parts List and Exploded View

- 502C Packaging Parts List and Exploded View

- 502C Electrical Parts List

- Accessory Kits Parts Lists and Exploded Views

NOTE: The notes section for the entire parts list is contained on page 8.

CAUTION: Use only accessory kit parts that are specified by Bose® Corporation in this service

manual. Substitute parts may not have the same safety characteristicsas the original parts.

8

Page 9

PARTS LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. This part splits into 2 pieces. Each piece fits onto a corner of the bass box.

3. Current European units should contain 2 owner's manuals: the original version, P/N 143585,

and the German version of the owner's manual, P/N 171941. Future production units (except in

North America) will contain owner's manuals in 5 languages (German, French, Italian, Spanish

and English).

4. This illustration is typical of the internal layout of the 502® except as follows: (1) Barrier strip

connectors are used in the US/Canada version only. XLR connectors are used on all non-US

versions, and (2) The nut connected to the line cord is used on the US/Canada, UK and Australian units only.

5. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire and/

or other hazards.

6. Refer to the 502C Electrical Parts List for components located on the PCB assembly.

7. This part is not illustrated.

8. These screws hold regulators U13 and U14 to the heatsink.

9. Early production runs of the 502C have 4 screws (instead of 2) that secure the cover to the

chassis.

10. Early production runs of the 502C with XLR connectors have 12 screws (instead of 6) that

secure the connectors to the chassis.

11. Early production runs of the 502C have 6 screws (instead of 4) that secure the front plate to

the cover and chassis.

12. Early production runs of the 502C with XLR connectors have 5 screws (instead of 2) that

secure the PCB to the chassis.

13. The line cord assembly consists of the following items:

(1) Line Cord-P/N 147428 (US/Canada), P/N 147430 (Euro), P/N 147429 (Japan), P/N 149025

(UK), P/N 149026 (Aus.),

(2) Strain Relief Bushing - P/N 144010 (US/Canada/UK/Aus), P/N 144011 (Euro/Japan),

(3) Connector Housing - P/N143964, and

(4) Connector Pin - P/N 143992. These parts are all safety controlled components. See Note 5.

9

Page 10

PACKAGING PART LIST

502A Array (see Figure 1)

Item

Number

1 Literature Kit-Panaray®

which consists of:

A

B

C

D

E

2 Packing, Foam 143573 172321 2

3 Polybag 106595 - 1

4 Carton, 502A 143572 172541 1

*Product code 040170 (gray) and 040171 (white) are the RoHS compliant version of the

502A. Only RoHS compliant parts listed in the above chart can be used in the 502A with

product code 040170 and 040171.

Polybag

Owner's Manual

Registration Card

Warranty Service List

Envelope

Description XLR and Barrier

Version Product

code 003840,

004931, 004932

and 004933

149271 - 1

103351

143585

122157

122766

122785

1

*Speakon

Version

Product

code

040170 and

040171

103351

292721

-

-

-

Qty Note

1

Figure 1. 502A Array Packaging View

10

Page 11

PACKAGING PART LIST

502B Bass Box (see Figure 2)

Item

Number

1 Literature Kit-Panaray®

Which consists of:

A

B

C

D

E

2 Packing End Cap, EPS

3 Polybag 119320 119320 1

4 Carton, 502B 143558 258887 1

*Product code 040090 (black) and 040091 (white) are a RoHS compliant version of

the 502B. Only RoHS compliant parts listed in the above chart can be used in the

502B with product code 040090 and 040091.

1

Polybag

Owners Manual

Registration Card

Warranty Service List

Envelope

(XLR and Barrier versions)

Packing End Cap, EP

(Speakon version)

Description XLR and Barrier

Version

PC 003841,

019769, 004934,

004935, 004936,

007698

149271 - 1

103351

143585

122157

122766

122785

139955

-

*Speakon®

Version PC

040090 and

040091

103351

292040

-

-

-

-

258886

Qty Note

1

1

1

1

1

4 2

Figure 2. 502B Bass Box Packaging Exploded View

11

Page 12

PACKAGING PART LIST

502C Controller (see Figure 3)

Item

Number

Description Part Number Qty. Note

1 Crease Sheet, Die Cut 149823 1

2 Literature Kit, Panaray®, Consists of: 149271 1

A Poly bag 103351 1

B Owner's Manual 143585 1

Owner's Manual (German language) 171941 1 3

C Card, Registration 122157 1

D List, Warranty Service 122766 1

E Envelope 122785 1

3 Poly bag 110892 1

4 Insert 148354 1

5 Carton, 502C 148353 1

Figure 3. 502C Controller Packaging View

12

Page 13

MAIN PART LIST

502A Array (see Figure 4)

Item

Number

1 Grille, Pro Gray

Grille, Arctic White

2 Insert, Threaded, Mach, M8x10.5, Gray

Insert, Threaded, Mach , M8x10.5, Wht

3 Nameplate, Dark Gray/Arctic White

Nameplate, Dark Arctic White/Dark Gray

4 Nut, Push-On,.078 125786 2

5 Driver, 4.5” 291025-001 5

6 Screw, HIRS, 8-10x5/8, PAN, XRC/SQ 289388-010 20

7 Gasket, Driver, 4.5" 128407 5

8 1234356789898989 119094-3R0 1

9 Capacitor, 5µF, Mylar 102770 1

10 Tape, Foam 118223 2

11 Terminal, Connector, Wire wrap 118008 4

12 Inductor, .75mH, Air core 293515-001 1

13 Washer, Flat Aluminum 123840 1

14 Gasket, Connector Panel 290316-001 1

15 Screw, 8-10, OVL HD, 1/2", BK (Gray)

Screw-8-10, OVL HD, 1/2", Zn (White)

Screw, Tapp, 8-10x .5, OVL CSK, BLK

16 Connector Panel, XLR, Gray

Connector Panel, XLR, White

Connector Panel, Barrier, Gray

Connector Panel, Barrier, White

Connector Panel, Speakon

Connector Panel, Speakon, White

17 Fuse holder, Knob with O-Ring 149268 1

18 Fuse-Standard Delay, 4A 104715-400 1

19 Fuse holder Body 149269 1

20 Washer, Neoprene 149270 1

21 Screw, Tapp, 4-16x1/2, PAN (XLR)

Screw, HIRS, 8-10x3/4, PAN (Barrier)

Screw, M2.6x5/8, Phillips, Flat (Speakon)

22 Connector, XLR, Dual

Connector, Barrier Strip, 4 pos.

Connector, Speakon, Panel Mount

23 Gasket, XLR Connector

Gasket , Barrier

Gasket, Speakon (inc. with item 22)

24 Batting, Polyester 142360 2

25 Foam, Acoustic 142361 1

26 Fuse holder Nut 171731 1

Product code 040170 (gray) and 040171 (white) are a RoHS compliant version of the 502A.

Only RoHS compliant parts listed in the above chart can be used in the 502A with product code

040170 and 040171.

Description Part Number Qty. Note

®

, Gray

142342-01

142342-02

143552-01

143552-02

130718-1B21

130718-1C31

148378-08

148379-08

290978-08

142344-01

142344-02

142344-03

142344-04

287072-003

287072-002

145724-08

137527-12

-

145717

148976-04

258213

146874

171243

-

1

2

1

4 Non-RoHS

Non-RoHS

RoHS

1 Non-RoHS

Non-RoHS

Non-RoHS

Non-RoHS

RoHS

RoHS

4

2

4

1

1

2

1

1

2

Non-RoHS

Non-RoHS

Non-RoHS

Non-RoHS

Non-RoHS

Non-RoHS

Non-RoHS

RoHS

RoHS

13

Page 14

2

2x

1

25

24 2x

34

11

4x

2x

10

15x

7

5x

5x

5

6

8

9

15 4x

13

12

17

18

16

20

18

17

19

21

23

26

16

26

20

19

21

16

26

2x

20

19

18

14

17

XLR VARIATION

SHOWN

21

2x

22

22

22

21

23

23

22

23

Figure 4. 502A Array Exploded View

14

Page 15

MAIN PART LIST

p

502B Bass Box (see Figures 5 and 6)

Item

Number

1 Cap, Top/Bottom, Gray

, Top/Bottom, Wh ite

Ca

2 Bolt-Mounting 143580 8

3 Acoustic Foam 145705 3

4 Bracket, Structural 290979 4

5 Nut , Hex, Mach Screw, 7/16-14 29 0980-4414 8

6 Washe r, Loc k, Ext, Stl, Zi nc Plat e 1 08261-43 8

7 Screw, HIRS, 8-10x3/4, HEXW, Hex 293205-010 16

8 Safety, Hook 171556 2

9 Screw, 6-10x1/2,PAN,XRC/SQ 290294-08 4

10 Ac ces s Pane l, Gray, XLR

Access Panel, White, XLR

Acces s Panel, Gr ay, Barr ier

Access P anel, White, Barri er

Access Pane l, 502 BEX, Black

Access Pane l, Gray, Speak on

Access Panel, White, Speakon

11 Fu se holder, Knob wit h O- Ring 149268 1

12 Fu se holder B ody (incl udes nut) 149269 1

13 Washer, Neoprene 149270 1

14 Fuse, Standard Delay,7A 104715-700 1

15 Foam Tape 103068 4

16 Sc rew, Ta pp, 4-16x1/2, (XLR)

Screw, HIRS, 8-10x3/4, (Barrier)

Screw, Tapp, 8-11x1, (Speakon)

17 Connector , XLR, Dual

Connector, Barrier Strip, 4 pos.

Connecto r, Speakon

18 Gasket, XLR Connector

Gasket, Barrier

Gasket, Speakon

19 Fu se holder Nut 171731 1

20 Ins ert , Ba rbed, 10/32”x 20mm 145712- 03 8

21 Sc rew, Mach, 10-32x 1-1½, PAN 2 91008-24 8

22 Woofer, 12”

(used with PC 0038 41, 01976 9, 004934,

004935, 004936, 007698 and 01074 4 only)

Woofer, 12”

(used with PC 0400 90 and 040091 onl y)

23 Screw, Mach, 8-10 x 1, PAN, Gray

Screw, Mach, 8-10 x 1, PAN, White

*Product code 040090 (black ) and 040091 (white) are a RoHS comp liant version of

the 502B. Only RoHS compliant parts listed in the above chart can be used in the

502B with product code 0 40090 and 040091.

Description Part Number Qty. Note

182582-0P

294312

142349-8RU

142349-9RU

142349-8SU

142349-9SU

142349-0CP

292035-001

292035-002

145724-08

289388-16

290988-08

145717

148976-04

258213-002

146874

171243

252384

144392 1 Non-RoHS

291380-001 RoHS

289388-016

289388-016

2

1

Non-RoHS

1

Non-RoHS

1

Non-RoHS

1

Non-RoHS

1

Non-RoHS

1

1

8

2

4

2

1

2

2

1

2

12

12

RoHS

RoHS

Non-RoHS

RoHS

RoHS

Non-RoHS

RoHS

RoHS

Non-RoHS

RoHS

RoHS

15

Page 16

Figure 5. 502B Bass Box Exploded View

16

Page 17

Barrier Strip Version

19

XLR Version

12

14

13

11

15

Speakon® Version

Figure 6. 502B Access Panel and Connector Views

16

16

17

17

18

18

17

Page 18

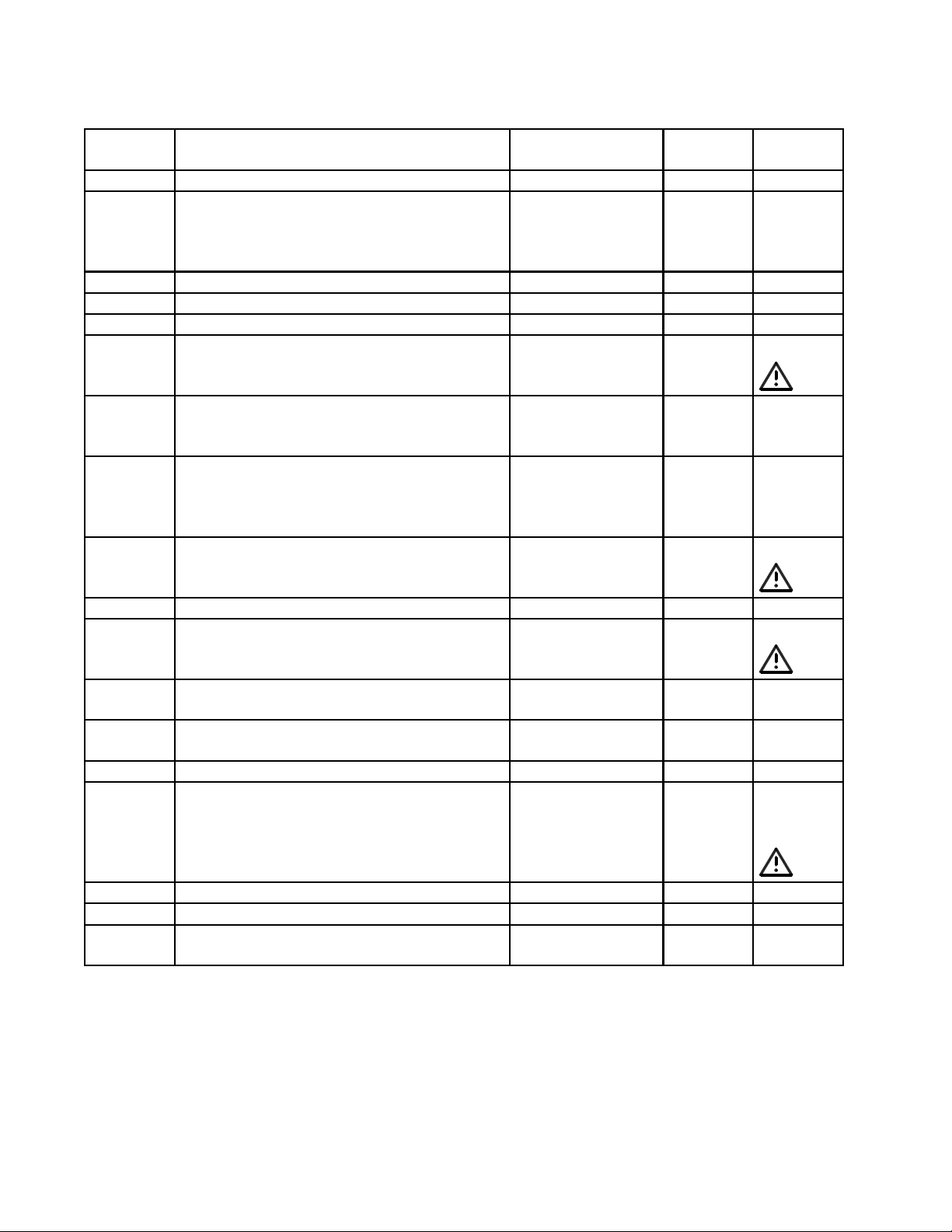

MAIN PART LIST

502C Controller (removable front panel version) (see Figure 7)

Item

Number

1 Cover, Chassis, 502C 173003 1

2 Screw, Tapp, 4-40x.375, PAN, TORX

(US/Can.)

Screw, Tapp, 4-40x.375, PAN, TORX

(Euro/UK/Aus/Japan)

3 Plate, Front, Rack Mount Kit 173004 1

4 Screw, Tapp, 4-40x.312, BTN, XREC 170285-05 4 11

5 Lens, LED, Clear, Front Panel 144023 1

6 Switch, Rocker, SPST, AC Power 143960 1 5

7 PCB Assembly, 502C (US/Can)

PCB Assembly, 502C

(Euro/UK/Aus/Japan)

8 Screw, Mach, 4-40x.25, PAN, TORX

(US/Can)

Screw, Mach, 4-40x.25, PAN, TORX

(Euro/UK/Aus/Japan)

9 Transformer, 120V (US/Can.)

Transformer, 220-240V (Euro/UK/Aus)

Transformer, 100V (Japan)

10 Nut , Hex, STND, W asher, KEPS 118260-08 2

11 Insulat or, Standoff, PCB 143948 1 1, 5

12 Connector, Barrier Strip Assy,

6 position (US/Can.)

13 Screw, Tapp, 4-40x.5, PAN, TORX

(US/Can.)

14 Nut, Hex, #8-32, Steel (US/Can/UK/Aus.) 103237-832 1

15 Line Cord, 3 wire (US/Can.)

Line Cord, 2 wire (Euro)

Line Cord, 2 wire (Japan)

Line Cord, 3 wire (UK)

Line Cord, 3 wire (Aus)

16 Heatsink, PCB Mount 147165 1 1

- Screw, Tapp, 4-40x.375, PAN, XREC 170284-06 4 7, 8

- Chassis, 502, US/Canada

Euro/UK/AUS/Japan

Description Part Number Qty. Note

170284-06

170284-06

143940-1

143940-2

171796-04 5 12

171796-04 2

143950-1

143950-2

143950-3

143971 3

170284-08 6

143975

143977

143976

149023

149024

173002-01

173002-02

2

8

1

1

1 5

1 5, 13

1

1

9

9,10

1, 6

1, 6

1

18

Page 19

Figure 7. 502C Controller Exploded View (removable front panel version)

19

Page 20

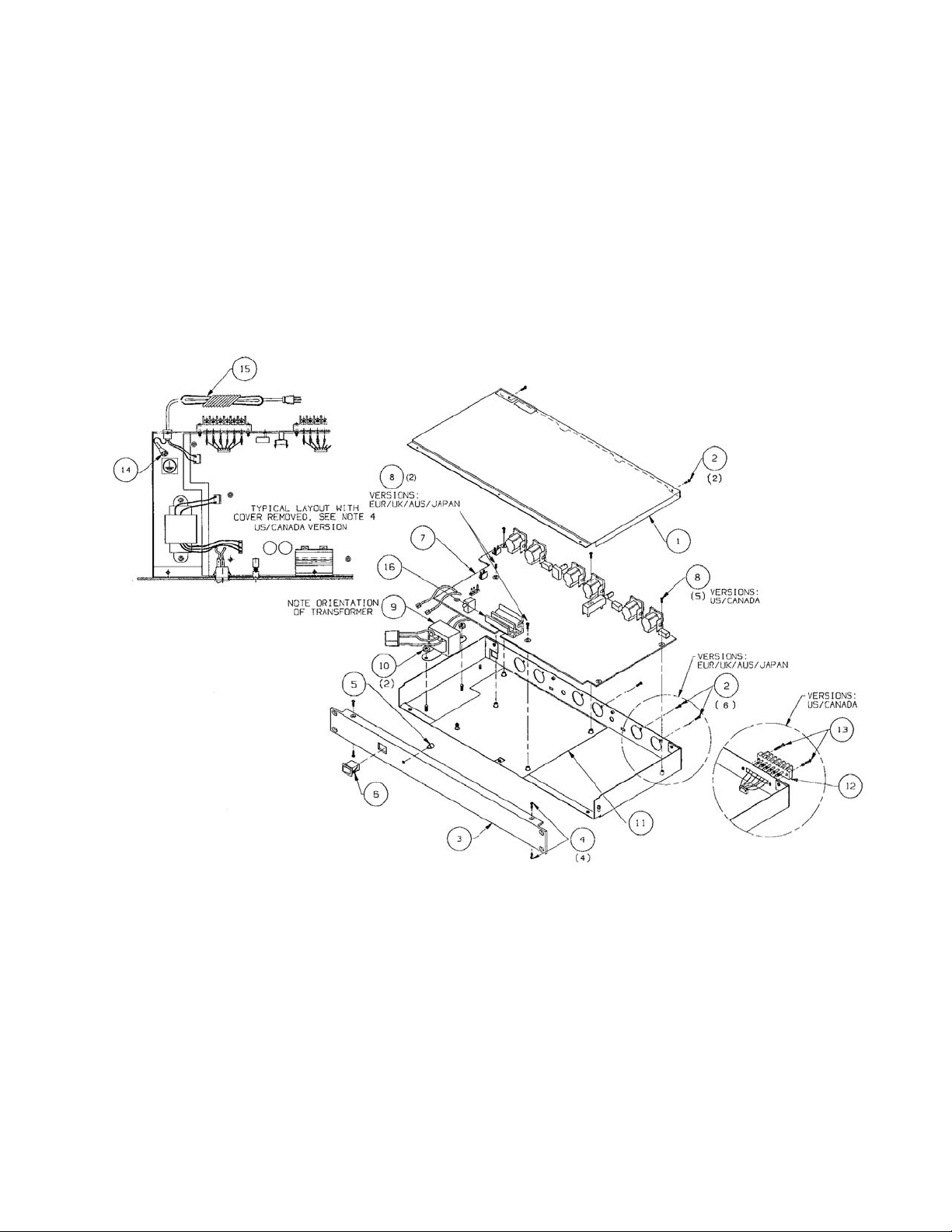

MAIN PART LIST

502C Controller (one-piece chassis version) (see Figure 8)

Item

Number

Description Part Number Qty/

Assy.

1 Screw, 6-32, Mach, Flat, Xrec 190623-008 5

2 Screw, Mach, 4-40x.25, PAN, XREC 103140-04 9

3 Clip, Heatsink 188599 2

4 XFMR, US/Canada/Japan, 100V/120V

EUR/AUS/UK, 220V/240V

180128-1

180128-2

1

1

5 Nut, Hex, 8-32, Keps 118260-08 3

6 Insulator, 9.25x7.56x.015, D/C 143948 1 1, 5

7 Switch, Power, Rocker, SPST 143960 1 5

8 Lens, LED, Clear, Chassis 144023 1

9

Chassis, 502®, US/Canada

Euro/UK/AUS/Japan

198373-001

198373-002

1

1

10 Screw, Tapp, 4-40x.375, PAN, XREC 170284-06 6

11 PCB Assy, 502 (all versions) 143940-2 1 1, 6

12 Cover, Chassis, Controller 198374-001 1

13 Line Cord, 3-Wire, USA/Canada

2-Wire, EU

2-Wire, Japan

3-Wire, UK

3-Wire, Aus

173242

173243

173244

173245

173246

1

1

1

1

1

14 Tape, Foam, 0.50" 198408 1

1

5X

Note

5

1

5

13

5

9

4

C114

C113

14

4

5

2X

6

2

3

7

8

Figure 8. 502C Controller Exploded View (one-piece chassis version)

12

2

11

10

6X

9

20

Page 21

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Resistors

Reference

Designator

W1 0 Ohm Jumper, Chip 124896

W2 0 Ohm Jumper, Chip 124896

W3 0 Ohm Jumper, Chip 124896

W4 0 Ohm Jumper, Chip 124896

W5 0 Ohm Jumper, Chip 124896

W6 0 Ohm Jumper, Chip 124896

W7 0 Ohm Jumper, Chip 124896

W8 0 Ohm Jumper, Chip 124896

W9 0 Ohm Jumper, Chip 124896

W10 0 Ohm Jumper, Chip 124896

W11 0 Ohm Jumper, Chip 124896

W12 0 Ohm Jumper, Chip 124896

W13 0 Ohm Jumper, Chip 124896

R1 1K, 1/8W,1%, Chip 124894-1001

R2 1K, 1/4W, 52mm, MF, 1% 121245-2211001

R3 1K, 1/4W, 52mm, MF, 1% 121245-2211001

R4 1K, 1/8W,1%, Chip 124894-1001

R5 100K, 1/4W, 52mm, CF, 2% 121243-1211042

R6 100K, 1/4W, 52mm, CF, 2% 121243-1211042

R7 2K, 1/8W, 1%, Chip 124894-2001

R8 8.06K, 1/8W, 1%, Chip 124894-8061

R9 8.06K, 1/8W, 1%, Chip 124894-8061

R10 2K, 1/8W, 1%, Chip 124894-2001

R11 3.65K, 1/8W, 1%, Chip 124894-3651

R12 2K, 1/8W, 1%, Chip 124894-2001

R13 4.02K, 1/8W, 1%, Chip 124894-4021

R13 4.02K, 1/8W, 1%, Chip 124894-4021

R14 4.02K, 1/8W, 1%, Chip 124894-4021

R14 4.02K, 1/8W, 1%, Chip 124894-4021

R15 30.1K, 1/8W, 1%, Chip 124894-3012

R17 2K, 1/8W, 1%, Chip 124894-2001

R18 2.32K, 1/8W, 1%, Chip 124894-2321

R19 13K, 1/8W, 1%, Chip 124894-1302

R20 100K, 1/8W, 1%, Chip 124894-1003

R21 511 Ohm, 1/8W, 1%, Chip 124894-5110

R22 3.16K, 1/8W, 1%, Chip 124894-3161

R23 1.33K, 1/8W, 1%, Chip 124894-1331

R24 0 Ohm Jumper, Chip 124896

R25 274 Ohm, 1/8W, 1%, Chip 124894-2740

R26 274 Ohm, 1/8W, 1%, Chip 124894-2740

R27 18.2K, 1/8W, 1%, Chip 124894-1822

R28 8.66K, 1/8W, 1%, Chip 124894-8661

R29 6.34K, 1/8W, 1%, Chip 124894-6341

R30 2.21K, 1/8W, 1%, Chip 124894-2211

R31 1.91K, 1/8W, 1%, Chip 124894-1911

R32 43.2K, 1/8W, 1%, Chip 124894-4322

Description Part Number Note

21

Page 22

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Resistors (continued)

Reference

Designator

R33 3.92K, 1/8W, 1%, Chip 124894-3921

R34 2.43K, 1/8W, 1%, Chip 124894-2431

R35 2K, 1/8W, 1%, Chip 124894-2001

R36 41.2K, 1/8W, 1%, Chip 124894-4122

R37 3.01K, 1/8W, 1%, Chip 124894-3011

R38 6.81K, 1/8W, 1%, Chip 124894-6811

R39 6.81K, 1/8W, 1%, Chip 124894-6811

R40 4.75K, 1/8W, 1%, Chip 124894-4751

R41 5.90K, 1/8W, 1%, Chip 124894-5901

R42 5.11K, 1/8W, 1%, Chip 124894-5111

R43 221K, 1/8W, 1%, Chip 124894-2213

R44 1.10K, 1/8W, 1%, Chip 124894-1101

R45 49.9K, 1/8W, 1%, Chip 124894-4992

R46 68.1K, 1/8W, 1%, Chip 124894-6812

R47 6.98K, 1/8W, 1%, Chip 124894-6981

R48 5.49K, 1/8W, 1%, Chip 124894-5491

R49 14K, 1/8W, 1%, Chip 124894-1402

R50 14K, 1/8W, 1%, Chip 124894-1402

R64 0 Ohm Jumper, Chip 124896

R65 1K, 1/8W,1%, Chip 124894-1001

R66 1K, 1/4W, 52mm, MF, 1% 121245-2211001

R67 1K, 1/4W, 52mm, MF, 1% 121245-2211001

R68 1K, 1/8W,1%, Chip 124894-1001

R69 2K, 1/8W, 1%, Chip 124894-2001

R70 8.06K, 1/8W, 1%, Chip 124894-8061

R71 8.06K, 1/8W, 1%, Chip 124894-8061

R72 2K, 1/8W, 1%, Chip 124894-2001

R73 3.65K, 1/8W, 1%, Chip 124894-3651

R74 2K, 1/8W, 1%, Chip 124894-2001

R75 4.02K, 1/8W, 1%, Chip 124894-4021

R75 4.02K, 1/8W, 1%, Chip 124894-4021

R76 4.02K, 1/8W, 1%, Chip 124894-4021

R77 30.1K, 1/8W, 1%, Chip 124894-3012

R79 2K, 1/8W, 1%, Chip 124894-2001

R80 2.32K, 1/8W, 1%, Chip 124894-2321

R81 13K, 1/8W, 1%, Chip 124894-1302

R82 100K, 1/8W, 1%, Chip 124894-1003

R83 511 Ohm, 1/8W, 1%, Chip 124894-5110

R84 3.16K, 1/8W, 1%, Chip 124894-3161

R85 1.33K, 1/8W, 1%, Chip 124894-1331

R86 0 Ohm Jumper, Chip 124896

R87 274 Ohm, 1/8W, 1%, Chip 124894-2740

R88 274 Ohm, 1/8W, 1%, Chip 124894-2740

R89 18.2K, 1/8W, 1%, Chip 124894-1822

R90 8.66K, 1/8W, 1%, Chip 124894-8661

R91 6.34K, 1/8W, 1%, Chip 124894-6341

Description Part Number Note

22

Page 23

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Resistors (continued)

Reference

Designator

R92 2.21K, 1/8W, 1%, Chip 124894-2211

R93 1.91K, 1/8W, 1%, Chip 124894-1911

R94 43.2K, 1/8W, 1%, Chip 124894-4322

R95 3.92K, 1/8W, 1%, Chip 124894-3921

R96 2.43K, 1/8W, 1%, Chip 124894-2431

R97 2K, 1/8W, 1%, Chip 124894-2001

R98 41.2K, 1/8W, 1%, Chip 124894-4122

R99 3.01K, 1/8W, 1%, Chip 124894-3011

R100 4.75K, 1/8W, 1%, Chip 124894-4751

R101 5.90K, 1/8W, 1%, Chip 124894-5901

R102 5.11K, 1/8W, 1%, Chip 124894-5111

R103 221K, 1/8W, 1%, Chip 124894-2213

R104 1.10K, 1/8W, 1%, Chip 124894-1101

R105 49.9K, 1/8W, 1%, Chip 124894-4992

R106 68.1K, 1/8W, 1%, Chip 124894-6812

R107 6.98K, 1/8W, 1%, Chip 124894-6981

R108 5.49K, 1/8W, 1%, Chip 124894-5491

R109 14K, 1/8W, 1%, Chip 124894-1402

R110 14K, 1/8W, 1%, Chip 124894-1402

R113 0 Ohm Jumper, Chip 124896

R117 0 Ohm Jumper, Chip 124896

R120 0 Ohm Jumper, Chip 124896

R125 0 Ohm Jumper, Chip 124896

R127 5.6K, 52mm, CF, 1/2W, 5% 121243-1515625

R128 100K, 1/4W, 52mm, CF, 2% 121243-1211042

R129 100K, 1/4W, 52mm, CF, 2% 121243-1211042

R130 4.75K, 1/8W, 1%, Chip 124894-4751

R131 4.75K, 1/8W, 1%, Chip 124894-4751

R132 4.75K, 1/8W, 1%, Chip 124894-4751

R133 2.43K, 1/8W, 1%, Chip 124894-2431

R134 4.75K, 1/8W, 1%, Chip 124894-4751

R135 4.75K, 1/8W, 1%, Chip 124894-4751

R136 4.75K, 1/8W, 1%, Chip 124894-4751

R137 2.43K, 1/8W, 1%, Chip 124894-2431

R138 4.75K, 1/8W, 1%, Chip 124894-4751

R139 4.75K, 1/8W, 1%, Chip 124894-4751

R140 4.75K, 1/8W, 1%, Chip 124894-4751

R141 2.43K, 1/8W, 1%, Chip 124894-2431

R142 4.75K, 1/8W, 1%, Chip 124894-4751

R143 4.75K, 1/8W, 1%, Chip 124894-4751

R144 4.75K, 1/8W, 1%, Chip 124894-4751

R145 2.43K, 1/8W, 1%, Chip 124894-2431

R146 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R147 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R148 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R149 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

Description Part Number Note

23

Page 24

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Resistors (continued)

Reference

Designator

R150 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R151 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R152 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R153 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R154 4.75K, 1/8W, 1%, Chip 124894-4751

R155 4.75K, 1/8W, 1%, Chip 124894-4751

R156 0 Ohm Jumper, Chip 124896

R157 10K, 1/2W, 52mm, CF, 5% 121243-1511035

R158 47.5K, 1/8W, 1%, Chip 124894-4752

R159 47.5K, 1/8W, 1%, Chip 124894-4752

R160 1K, 1/8W,1%, Chip 124894-1001

R161 4.32K, 1/8W, 1%, Chip 124894-4321

R162 0 Ohm Jumper, Chip 124896

R166 20K, 1/8W, 1%, Chip 124894-2002

R167 1K, 1/8W,1%, Chip 124894-1001

R168 4.32K, 1/8W, 1%, Chip 124894-4321

R169 0 Ohm Jumper, Chip 124896

R173 20K, 1/8W, 1%, Chip 124894-2002

R174 681 Ohm, 1/8W, 1%, Chip 124894-6810

R175 681 Ohm, 1/8W, 1%, Chip 124894-6810

R176 681 Ohm, 1/8W, 1%, Chip 124894-6810

R177 681 Ohm, 1/8W, 1%, Chip 124894-6810

R180 221K, 1/8W, 1%, Chip 124894-2213

R182 0 Ohm Jumper, Chip 124896

R183 221K, 1/8W, 1%, Chip 124894-2213

R184 49.9K, 1/8W, 1%, Chip 124894-4992

R185 49.9K, 1/8W, 1%, Chip 124894-4992

R191 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R192 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R193 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R194 47 Ohm, 1/4W, 52mm, CF, 2% 121243-1214702

R195 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R196 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R197 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R198 47.5 Ohm, 1/8W, 1%, Chip 124894-47R5

R199 6.81K, 1/8W, 1%, Chip 124894-6811

R200 10K, 1/8W, 1%, Chip 124894-1002

R201 17.8K, 1/8W, 1%, Chip 124894-1782

R203 221 Ohm, 1/8W, 1%, Chip 124894-2210

R204 221 Ohm, 1/8W, 1%, Chip 124894-2210

R205 47.5K, 1/8W, 1%, Chip 124894-4752

R207 47.5K, 1/8W, 1%, Chip 124894-4752

R208 10K, 1/8W, 1%, Chip 124894-1002

R209 47.5K, 1/8W, 1%, Chip 124894-4752

R210 475 Ohm, 1/8W, 1%, Chip 124894-4750

R212 4.75K, 1/8W, 1%, Chip 124894-4751

Description Part Number Note

24

Page 25

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Capacitors

Reference

Designator

C1 1000pF, 10%, Chip 124956-1022

C2 1000pF, 10%, Chip 124956-1022

C3 22µF, 35V, Electrolytic 119944-220

C4 22µF, 35V, Electrolytic 119944-220

C5 0.1µF, +80/-20%, Chip 124959-104

C6 0.1µF, +80/-20%, Chip 124959-104

C7 100pF, 5%, Chip 124956-1012

C8 100pF, 5%, Chip 124956-1012

C9 .01µF, 5%, Film 137127-103

C10 680pF, 10%, Ceramic 137269-681

C11 .01µF, 5%, Film 137127-103

C12 0.0047µF, 5%, Film 137127-472

C13 0.0047µF, 5%, Film 137127-472

C14 .01µF, 5%, Film 137127-103

C15 .01µF, 5%, Film 137127-103

C16 0.1µF, +80/-20%, Chip 124959-104

C17 0.1µF, +80/-20%, Chip 124959-104

C18 .1µF, 5%, Film 137127-104

C19 .047µF, 5%, Film 137127-473

C20 .1µF, 5%, Film 137127-104

C21 100pF, 5%, Chip 124956-1012

C22 .1µF, 5%, Film 137127-104

C23 .1µF, 5%, Film 137127-104

C24 .47µF, 5%, Film 137127-474

C25 .1µF, 5%, Film 137127-104

C26 .1µF, 5%, Film 137127-104

C27 .47µF, 5%, Film 137127-474

C28 .47µF, 5%, Film 137127-474

C29 .22µF, 5%, Film 137127-224

C30 .22µF, 5%, Film 137127-224

C31 .1µF, 5%, Film 137127-104

C32 .1µF, 5%, Film 137127-104

C33 .22µF, 5%, Film 137127-224

C34 .022µF, 5%, Film 137127-223

C35 .18µF, 5%, Film 137127-184

C36 0.1µF, +80/-20%, Chip 124959-104

C37 0.1µF, +80/-20%, Chip 124959-104

C47 1000pF, 10%, Chip 124956-1022

C48 1000pF, 10%, Chip 124956-1022

C49 22µF, 35V, Electrolytic 119944-220

C50 22µF, 35V, Electrolytic 119944-220

C51 0.1µF, +80/-20%, Chip 124959-104

C52 0.1µF, +80/-20%, Chip 124959-104

C55 100pF, 5%, Chip 124956-1012

C56 100pF, 5%, Chip 124956-1012

C57 .01µF, 5%, Film 137127-103

Description Part Number Note

25

Page 26

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Capacitors (continued)

Reference

Designator

C58 680pF, 10%, Ceramic 137269-681

C59 .01µF, 5%, Film 137127-103

C60 0.0047µF, 5%, Film 137127-472

C61 0.0047µF, 5%, Film 137127-472

C62 .01µF, 5%, Film 137127-103

C63 .01µF, 5%, Film 137127-103

C64 0.1µF, +80/-20%, Chip 124959-104

C65 0.1µF, +80/-20%, Chip 124959-104

C66 .1µF, 5%, Film 137127-104

C67 .047µF, 5%, Film 137127-473

C68 .1µF, 5%, Film 137127-104

C69 100pF, 5%, Chip 124956-1012

C70 .1µF, 5%, Film 137127-104

C71 .1µF, 5%, Film 137127-104

C72 .47µF, 5%, Film 137127-474

C73 .1µF, 5%, Film 137127-104

C74 .1µF, 5%, Film 137127-104

C75 .47µF, 5%, Film 137127-474

C76 0.1µF, +80/-20%, Chip 124959-104

C77 0.1µF, +80/-20%, Chip 124959-104

C78 .47µF, 5%, Film 137127-474

C79 .22µF, 5%, Film 137127-224

C80 .22µF, 5%, Film 137127-224

C81 .1µF, 5%, Film 137127-104

C82 .1µF, 5%, Film 137127-104

C83 .22µF, 5%, Film 137127-224

C84 .022µF, 5%, Film 137127-223

C85 .18µF, 5%, Film 137127-184

C86 0.1µF, +80/-20%, Chip 124959-104

C87 0.1µF, +80/-20%, Chip 124959-104

C95 Jumper, 0 Ohm 139942

C97 0.1µF, +80/-20%, Chip 124959-104

C98 0.1µF, +80/-20%, Chip 124959-104

C99 0.1µF, +80/-20%, Chip 124959-104

C100 0.1µF, +80/-20%, Chip 124959-104

C101 100pF, 5%, Chip 124956-1012

C102 100pF, 5%, Chip 124956-1012

C103 100pF, 5%, Chip 124956-1012

C104 100pF, 5%, Chip 124956-1012

C105 100pF, 5%, Chip 124956-1012

C106 100pF, 5%, Chip 124956-1012

C107 100pF, 5%, Chip 124956-1012

C108 100pF, 5%, Chip 124956-1012

C109 .0047µF, 1KV, Ceramic, 20%,

(US/Can)

Description Part Number Note

103447 5

26

Page 27

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Capacitors (continued)

Reference

Designator

C109 .0047µF,20%,Metallized Paper,

(Euro/UK/Aus/Japan)

C110 10,000pF, +80/-20%, Chip 124959-103

C111 10,000pF, +80/-20%, Chip 124959-103

C112 10,000pF, +80/-20%, Chip 124959-103

C113 2200µF, 50V, 105C, Electrolytic, 20% 144000-222H 5

C114 2200µF, 50V, 105C, Electrolytic, 20% 144000-222H 5

C115 1µF, 50V, Electrolytic 137265-1R0

C116 1µF, 50V, Electrolytic 137265-1R0

C117 1µF, 50V, Electrolytic 137265-1R0

C118 1µF, 50V, Electrolytic 137265-1R0

C119 100pF, 5%, Chip 124956-1012

C120 100pF, 5%, Chip 124956-1012

C129 0.1µF, +80/-20%, Chip 124959-104

C130 0.1µF, +80/-20%, Chip 124959-104

C131 0.1µF, +80/-20%, Chip 124959-104

C132 0.1µF, +80/-20%, Chip 124959-104

C133 10,000pF, +80/-20%, Chip 124959-103

C142 1000pF, 10%, Chip 124956-1022

C143 1000pF, 10%, Chip 124956-1022

C144 1000pF, 10%, Chip 124956-1022

C145 1000pF, 10%, Chip 124956-1022

C146 1000pF, 10%, Chip 124956-1022

C147 1000pF, 10%, Chip 124956-1022

C148 1000pF, 10%, Chip 124956-1022

C149 1000pF, 10%, Chip 124956-1022

C150 0.1µF, +80/-20%, Chip 124959-104

C151 0.1µF, +80/-20%, Chip 124959-104

C152 22µF, Bi-polar, Electrolytic, 20% 147522-220

C153 22µF, 35V, Electrolytic 119944-220

C154 22µF, 35V, Electrolytic 119944-220

C155 22µF, 35V, Electrolytic 119944-220

C156 22µF, 35V, Electrolytic 119944-220

C157 22µF, 35V, Electrolytic 119944-220

C158 22µF, 35V, Electrolytic 119944-220

C159 22µF, 35V, Electrolytic 119944-220

C160 22µF, 35V, Electrolytic 119944-220

C161 0.1µF, +80/-20%, Chip 124959-104

C162 100pF, 5%, Chip 124956-1012

C163 100pF, 5%, Chip 124956-1012

C164 100pF, 5%, Chip 124956-1012

Description Part Number Note

146354 5

27

Page 28

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Diodes

Reference

Designator

Z1 Bridge, 100V, 1A 143952

D1 1N4531, 5mm 136603

D2 1N4531, 5mm 136603

D3 1N4531, 5mm 136603

D4 1N4531, 5mm 136603

D5 1N4531, 5mm 136603

D6 1N4531, 5mm 136603

D7 1N4531, 5mm 136603

D8 1N4531, 5mm 136603

D9 1N4148, 52mm, Axial 116997 or 121501

D10 1N4531, 5mm 136603

D11 1N4148, 52mm, Axial 116997 or 121501

D12 1N4531, 5mm 136603

D13 1N4148, 52mm, Axial 116997 or 121501

D14 1N4531, 5mm 136603

D15 1N4148, 52mm, Axial 116997 or 121501

D16 1N4531, 5mm 136603

D17 1N4148, 52mm, Axial 116997 or 121501

D18 1N4531, 5mm 136603

D19 1N4148, 52mm, Axial 116997 or 121501

D20 1N4531, 5mm 136603

D21 1N4148, 52mm, Axial 116997 or 121501

D22 1N4531, 5mm 136603

D23 1N4148, 52mm, Axial 116997 or 121501

D24 1N4531, 5mm 136603

D25 Zener, 18V, 1W, 5% 116995-4746A

D26 Zener, 18V, 1W, 5% 116995-4746A

D27 Zener, 18V, 1W, 5% 116995-4746A

D28 Zener, 18V, 1W, 5% 116995-4746A

D29 Zener, 18V, 1W, 5% 116995-4746A

D30 Zener, 18V, 1W, 5% 116995-4746A

D31 Zener, 18V, 1W, 5% 116995-4746A

D32 Zener, 18V, 1W, 5% 116995-4746A

D33 Zener, 18V, 1W, 5% 116995-4746A

D34 Zener, 18V, 1W, 5% 116995-4746A

D35 Zener, 18V, 1W, 5% 116995-4746A

D36 Zener, 18V, 1W, 5% 116995-4746A

D37 1N4531, 5mm 136603

D38 1N4531, 5mm 136603

D39 1N4531, 5mm 136603

D40 Zener, 7.5V, 1W, 5% 116995-4737A

D41 LED, Green, Right Angle Mount 144027

D42 1N4531, 5mm 136603

D43 1N4531, 5mm 136603

Description Part Number Note

28

Page 29

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Transistors

Reference

Designator

Q1 NPN, 2SC2812, 50T23 134741

Reference

Designator

U1 Op Amp, Quad 144008

U2 Op Amp, Quad 144008

U3 Op Amp, Quad 144008

U4 Op Amp, Quad 144008

U6 Op Amp, Quad 144008

U7 Op Amp, Quad 144008

U8 Op Amp, Quad 144008

U9 Op Amp 108568

U10 Op Amp 108568

U11 Op Amp 108568

U12 Op Amp 108568

U13 Regulator, Voltage, 3 terminal, +15V 143858

U14 Regulator, Voltage, 3 terminal, -15V 143806

U15 LM399N 137929

Description Part Number Note

Integrated Circuits

Description Part Number Note

Potentiometers and Switches

Reference

Designator

R126 Potentiometer, Dual-Ganged, 10K 143959-103

S1 4P4T, PCB Mount 143957

S2 Slide, DPDT 143958

S3 Slide, DPDT 143958

S4 Slide, DPDT 143958

Reference

Designator

K1 Relay, 24VDC, 4P4T 144017

K2 Relay, 24VDC, 4P4T 144017

Description Part Number Note

Relays

Description Part Number Note

29

Page 30

ELECTRICAL PART LIST

502C Controller Main PCB Assembly

Connectors

Reference

Designator

J1 Harness Assy, Quick Disconnect 143968 5

J2 Harness Assy, Quick Disconnect 143968 5

J3 XLR, Female (Euro/Japan/UK/Aus) 189222-001

J4 XLR, Female (Euro/Japan/UK/Aus) 189222-001

P1 Header, 2 pin 143963

P2 Header, 2 pin 143963

P3 Header 143965

P4 Header, 12 pin 170250

P5 Header, 12 pin 170250

P6 Header, 6 pin (US/Can.) 143974

P7 Header, 6 pin (US/Can.) 143974

P8 Header, 6 pin (US/Can.) 143974

P9 XLR, Male (Euro/Japan/UK/Aus) 144004

P10 XLR, Male (Euro/Japan/UK/Aus) 144004

P11 XLR, Male (Euro/Japan/UK/Aus) 144004

P12 XLR, Male (Euro/Japan/UK/Aus) 144004

Description Part Number Note

30

Page 31

DISASSEMBLY PROCEDURES

502A Array Procedures

Note: Refer to Figure 9 for the following

procedures.

1. Grille Removal

1.1 Remove the 2 screws (2) located on

each end of the grille (1) using a 7/64" hex

wrench. Grasp the grille on both ends and

pull it away from the array.

2. Driver Removal

2.1 Perform procedure 1.

2.2 Remove the 3 screws (6) that secure the

driver (5) to the array.

2.3 Lift the driver carefully away from the

array. Make a note of the wiring configuration and cut the wires connected to the driver

terminals as close to the terminals as possible.

Re-assembly Notes:

1. Be sure to observe polarity when connect-

ing the replacement driver. Refer to the

wiring diagram, Figure 10.

2. Be sure that the driver gasket is properly

aligned so that it makes an airtight seal.

3. Passive Component Removal

3.1 Perform procedure 1.

3.2 Remove the 2 drivers located on the end

of the array opposite the serial number (refer

to procedure 2 above), but do not cut any

wires.

3.3 Resistor (8) or capacitor (9) removal:

Unwrap the component's leads from its

wirewrap terminal (11), and remove the

component from the array.

4. Connector Panel Removal

4.1 Remove 4 screws (15) that secure the

panel (16) to the array.

4.2 Grasp the panel and pull it away from

the array.

Re-assembly Note: When re-installing the

connector panel, ensure that the panel

gasket is correctly positioned so that it

makes an airtight seal.

5. Barrier Strip Connector Removal

5.1 Remove the 2 screws (21) that secure

the connector (22) to the connector panel

(16).

5.2 Unwrap the wires from the barrier strip

terminals, and remove the connector.

Re-assembly Note: When re-installing the

barrier strip, ensure that the gasket is

correctly positioned so that it makes an

airtight seal.

6. XLR Connector Removal

6.1 Remove the 4 screws (21) that secure

the connector (22) to the connector panel

(16).

6.2 Make a note of the wiring configuration

and cut the connector's leads as close to its

terminals as possible. Remove the connector from the array.

Re-assembly Notes:

1. Observe polarity when connecting the

replacement XLR connector. Use the notes

from step 6.2.

2. When re-installing the XLR connector,

ensure that the gasket is correctly positioned so that it makes an airtight seal.

3.4 Inductor (12) removal: Remove the

screw (6) and washer (13) that secure the

inductor to the array. Cut the inductor leads

as close to the terminals as possible.

31

Page 32

2

2x

1

25

24 2x

34

11

4x

2x

10

15x

7

5x

5x

5

6

8

9

15 4x

13

12

17

18

16

20

18

17

19

21

22

23

22

21

23

26

16

26

20

19

23

21

22

16

26

2x

20

19

18

14

17

XLR VARIATION

SHOWN

21

22

23

2x

Figure 9. 502A Array Exploded View

32

Page 33

BARRIER

Figure 10. 502A Array Wiring Diagram

33

SPEAKON XLR

Page 34

DISASSEMBLY PROCEDURES

7. Speakon® Connector Removal

7.1 Remove the 4 screws that secure the

connector to the connector panel (16).

7.2 Make a note of the wiring configuration

and cut the connector's leads as close to its

terminals as possible. Remove the connector from the array.

Re-assembly Notes:

1. Observe polarity when connecting the

replacement XLR connector. Use the notes

from step 6.2.

2. When re-installing the connector, ensure

that the gasket is correctly positioned so that

it makes an airtight seal.

8. Fuseholder Removal

8.1 Remove the connector panel using

procedure 4.

8.2 Remove the fuseholder nut (26) from the

fuseholder body (19).

8.3 Unsolder the wires from the fuseholder

terminals.

502B Bass Module Procedures

Note: Refer to Figures 11 and 12 for the

following procedures.

9. Access Panel Removal

9.1 Remove 12 screws (23) that secure the

access panel (10) to the unit.

9.2 Partially insert one of the screws into a

screw hole. Using the screw as a lever,

carefully remove the access panel.

10. Woofer Removal

10.3 Make a note of the wiring configuration

and disconnect the wires from the woofer

terminals. Carefully pull the woofer away

from the unit.

Re-assembly Notes:

1. Observe polarity when connecting the

woofer harness wires to the woofer.

2. Align the woofer gasket to provide an

airtight seal.

11. Barrier Strip Connector Removal

11.1 Remove the 2 screws (16) that secure

the connector (17) to the access panel (10).

11.2 Make a note of the wiring configuration

and unwrap the wires from the connector

terminals. Remove the connector.

Re-assembly Notes:

1. Use the note from step 10.2 to ensure

proper wiring connections.

2. Align the connector gasket to provide an

airtight seal.

12. XLR Connector Removal

12.1 Remove the 4 screws (16) that secure

the connector (17) to the access panel (10).

12.2 Make a note of the wiring configuration

and cut the connector leads as close to the

terminals as possible. Remove the connector.

Re-assembly Notes:

1. Use the note from step 12.2 to ensure

proper wiring connections.

2. Align the connector gasket to provide an

airtight seal.

13. Fuseholder Removal

13.1 Remove the access panel using proce-

dure 9.

10.1 Remove the access panel using procedure 9.

10.2 Remove the 8 screws (21) that secure

the woofer (22) to the unit.

13.2 Remove the fuseholder nut (19) from

the fuseholder body (12).

13.3 Unsolder the wires from the fuseholder

terminals.

34

Page 35

DISASSEMBLY PROCEDURES

14. Speakon® Connector Removal

14.1 Remove the 4 screws that secure the

connector to the access panel.

14.2 Make a note of the wiring configuration

and cut the connector leads as close to the

terminals as possible. Remove the connector.

Re-assembly Notes:

1. Use the note from step 14.2 to ensure

proper wiring connections.

2. Align the connector gasket to provide an

airtight seal.

15. Fuseholder Removal

15.1 Remove the access panel using proce-

dure 9.

15.2 Remove the fuseholder nut (19) from

the fuseholder body (12).

16.2 Remove the 2 top screws (4) that

secure the top cover to the front plate (3).

Earlier units will have 3 screws on top.

16.3 Slide the top cover out from under the

front plate, and lift it off the unit.

16.4 Front Plate Removal: There are two

screws (4) on the bottom that hold the front

plate to the chassis. Remove the screws

and washers and pull the front plate away

from the chassis.

17. Main PCB Removal

17.1 Remove the top cover and front panel

using procedure 16.

17.2 Disconnect the following connectors:

P6-P8 (barrier strip connectors only), P1

(line cord assembly), P2 and P3 (transformer connectors).

15.3 Unsolder the wires from the fuseholder

terminals.

502C Controller Disassembly

Procedures

Notes:

1. Refer to Figure 14 or 15 for the following

procedures.

2. Later production units have fewer screws

than earlier units. These quantity differences

are noted in the procedures below.

3. Unless otherwise specified, a T-10 Torx

bit is recommended for screw removal.

16. Top Cover/Front Plate Removal

WARNING: Be sure to unplug the unit from

the AC Mains before removing the top cover.

There are hazardous voltages inside the

chassis.

16.1 Remove the 2 screws (2) that secure

the top cover (1) to the back of the chassis.

Earlier units will have 4 screws.

17.3 XLR version: Remove the 6 screws

(2) that secure connectors (J3, J4, P9-12)

to the chassis. Earlier units have 12 screws.

17.4 Carefully scrape the glue away from

the terminals of power switch S5 (6).

Disconnect the terminals.

17.5 Barrier strip version: Remove the 5

screws (8) that secure the Main PCB (7) to

the chassis.

17.6 XLR version: Remove the 2 screws

(8) which secure the Main PCB to the chassis. Earlier units have 5 screws.

17.7 Squeeze the 2 metal posts (not shownthey are located in the 2 front corners of the

PCB) that secure the Main PCB to the

chassis bottom. Lift the PCB straight up.

17.8 Slide the PCB out towards the front of

the unit and pull it away from the chassis.

35

Page 36

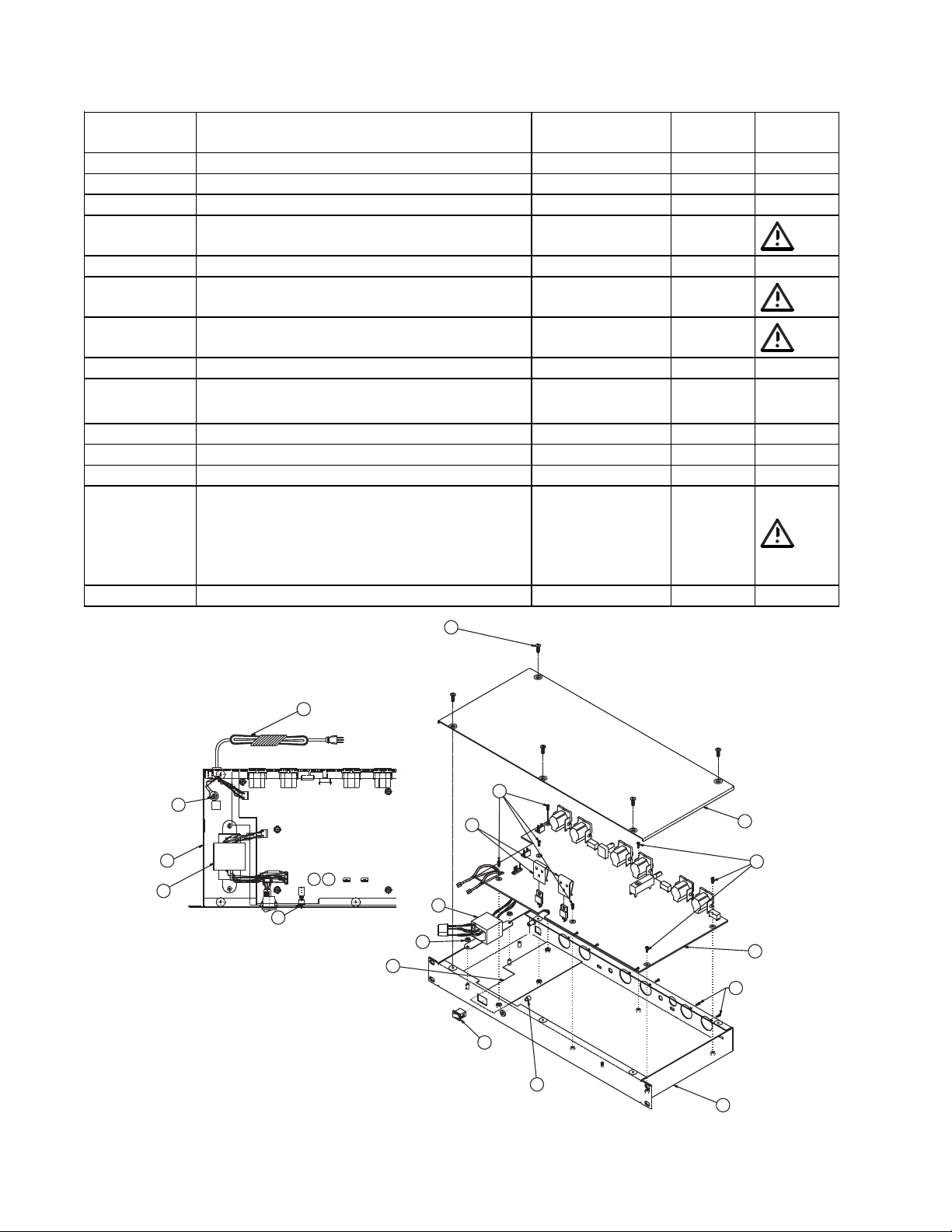

DISASSEMBLY PROCEDURES

18. Transformer Removal

18.1 Remove the top cover using procedure

16.

18.2 Disconnect P2 (transformer primary)

and P3 (transformer secondary) from the

Main PCB (7).

15.3 Remove the two 11/32" hex nuts (10)

and washers that secure the transformer (9)

to the chassis.

15.4 Lift the tranformer out of the chassis.

16. Barrier Strip Connector Removal

16.1 Remove the top cover using procedure

16.

16.2 Remove the 2 screws (13) that secure

the connector (12) to the chassis.

17. XLR Connector Removal

17.1 Remove the top cover and front panel

using procedure 16.

17.2 Remove 6 screws (2) that secure the

connectors to the chassis.

17.3 Remove the Main PCB using procedure 27.

17.4 Unsolder the connector (J3, J4, P9-12)

from the Main PCB (7). Lift out the connector.

16.3 Disconnect either P6, P7 or P8 and pull

the connector through the cutout in the

chassis.

36

Page 37

Figure 11. 502B Bass Module Exploded View

37

Page 38

Barrier Strip Version

19

XLR Version

12

14

13

11

15

16

16

17

17

18

18

Figure 12. 502B Bass Module Connector and Access Panel

38

Page 39

SPEAKON WIRE DIAGRAM

Figure 13. 502B Bass Module Wiring Diagrams

39

Page 40

Figure 14. 502C Controller Exploded View (removable front panel version)

1

5X

13

5

9

4

C114

C113

14

4

5

2X

6

2

3

7

8

12

11

10

6X

9

Figure 15. 502C Controller Exploded View (one-piece chassis version)

40

2

Page 41

TEST PROCEDURES

502A Array T est Procedures

Note: All 502A procedures involve connect-

ing test equipment to the array's input

terminals. For the XLR input pin assignment,

see Figure 16 below.

Figure 16. XLR input pin assignment

1. Phase Test Male

1.1 Remove the grille using disassembly

procedure 1.

1.2 Apply an 8V DC voltage level to the

array's input terminals. Be sure to observe

polarity.

1.3 The cones of all 5 drivers should move

outward with the application of the DC

voltage.

2. Air Leak/Rub and Tick Test

2.1 Apply an 8 Vrms, 10 Hz signal to the

array's input terminals.

3. Shading Network Test

3.1 Apply a 2 Vrms, 2.5 kHz signal to the

array's input terminals.

3.2 Connect a 3 Ohm, 1W resistor in series

between the positive (+) amplifier output

and the array's positive (+) input.

3.3 Measure the voltage across the resistor.

It should be approximately .49V ± 0.1 Vrms.

3.4 If the measured voltage is outside the

specified range, check the following:

(1) Make sure that the passive components

are a 3 Ohm resistor, .75 mH inductor, and

5µF capacitor.

(2) Check all driver connections against the

502A wiring diagram in Figure 10.

4. Sweep Test

4.1 Apply an 8 Vrms, 10 Hz signal to the

array's input terminals.

4.2 Sweep the oscillator slowly from 10 Hz

to 5 kHz. There should not be any buzzes

or rattles from within the array enclosure.

Redress any wire or component that buzzes.

A "whooshing" noise at around 140 Hz is

acceptable.

2.2 Air Leak Test: Block the ports. Listen for

air leaks around the drivers and all cabinet

joints. If there is a "whooshing" noise, there

is probably an air leak in one of these locations. Repair any air leaks as required.

2.3 Rub and Tick Test: No extraneous

noises such as rubbing, scraping, or ticking

should be heard. To distinguish between

normal suspension noise and rubs or ticks,

displace the cone of the driver slightly with

your fingers. If the noise can be made to go

away or get worse, it is a rub or a tick, and

the driver should be replaced. If the noise

stays the same, it is normal suspension

noise and the driver is fine. Suspension

noises will not be heard with program material.

502B Bass Module Test Procedures

Note: All 502B procedures require connect-

ing test equipment to the bass box's input

terminals. For the XLR input pin assignment,

see Figure 16.

1. Phase Test

1.1 Insert one hand into the bottom port of

the 502B. Gently touch the dust cap or cone

of the woofer. (The woofer is located above

the port hole).

1.2 Apply a 20 Vdc level to the 502B's input

terminals. Be sure to observer polarity when

applying the DC level. The woofer cone

should move outward towards the bottom

of the bass box.

41

Page 42

TEST PROCEDURES

1.3 If the woofer cone deflects inward,

check all wiring.

2. Woofer Air Leak/Rub and Tick Test

2.1 Apply a 20 Vrms, 10 Hz signal to the

502B's input terminals.

2.2 Air Leak Test: Block the ports. Listen for

air leaks around the cabinet. If there is a

hissing or "whooshing" noise, there is probably an air leak. Repair any air leaks as

required.

2.3 Rub and Tick Test: No extraneous

noises such as rubbing, scraping, or ticking

should be heard. To distinguish between

normal suspension noise and rubs or ticks,

displace the cone of the woofer slightly with

your fingers. If the noise can be made to go

away or get worse, it is a rub or a tick, and

the woofer should be replaced. If the noise

stays the same, it is normal suspension

noise and the driver is fine. Suspension

noises will not be heard with program material.

3. Sweep Test

3.1 Apply a 20 Vrms, 10 Hz signal to the

502B bass module input terminals.

3.2 Sweep the oscillator slowly from 10 Hz to

300 Hz. There should not be any loud,

extraneous sounds. If there are any loud

buzzes or distortion, the woofer may be

defective.

Note: A "whooshing" noise from the port

around 55 Hz and 105 Hz is acceptable.

There should not be any buzzes or rattles

from within the 502B enclosure. Redress any

wire or component that buzzes or rattles.

502C Controller Test Procedures

Test Setup

Input Connections: Connect an audio

signal generator to the positive (+) and

negative (-) input terminals for Channels 1

or 2. These procedures assume that the

person performing these tests is using test

equipment with unbalanced inputs and

outputs. Refer to Figure 17 for connection

information).

Output Connections: Connect test equipment to the positive (+) and negative (-)

output terminals for Channels 1 or 2 (low

and high frequency outputs).

All tests should be performed for both

channels.

All test equipment must be isolated from

ground (floated).

Some settings on the controller may need

to be changed for the various procedures.

These settings will be indicated throughout

the test procedures. Refer to Figure 18 for

a diagram of the controller's back panel.

The controls on the back panel should be

set as follows (unless otherwise specified):

• Mode switch should be set at 2 (Bi-Amp)

• Output mode switch should be set at

normal

• Input switches should be set at +4 dB

• Low frequency level potentiometer should

be set at +3 dB

1. Clipping Headroom Test

1.1 Apply a 4.73 Vrms, 600 Hz signal to the

input terminals.

42

1.2 Distortion (at an output voltage of 6.29

Vrms) should measure -1% (measure

across the High Frequency outputs).

Page 43

TEST PROCEDURES

2. Gain Test

2.1 Set the input switches to -10 dB.

2.2 Apply a 100 mVrms, 600 Hz signal to the

input terminals.

2.3 Measure the gain at the high frequency

outputs. The gain (referenced to the input)

should be 16.5 ± 1.0 dB.

2.4 Change the input level switches to

+4 dB.

2.5 Measure the gain at the high frequency

outputs. The gain (referenced to the input)

should be 2.5 ± 1.0 dB.

3. Sum Output Mode Gain Test

3.1 Set the input switches to +4 dB.

3.2 Set the output mode switch to Normal

and the low frequency level potentiometer to

+3 dB.

3.3 Apply a 100 mVrms, 80 Hz signal to the

502C's input terminals.

3.4 Measure the gain at the Channel 1, low

frequency output. The gain (referenced to

the input) should be 8.7 ± 1.0 dB.

4. Frequency Response of High Frequency

(HF) Output (Full Range Mode)

4.1 Set the mode switch to 1 (Full Range).

Frequency (Hz) Response (dB)

40 -24.5 ± 2.0

140 +4.3 ± 1.5

600 REF

2200 +3.5 ± 1.5

5000 +12.5 ± 1.5

15000 +19.0 ± 1.5

5. Frequency Response of HF Output

(Bi-Amp Mode)

5.1 Set the mode switch to 2 (Bi-Amp).

5.2 Apply a 100 mVrms, 600 Hz signal to the

502C input terminals and reference your dB

meter to this frequency.

5.3 Measure the frequency response across

the HF outputs according to the table below.

Frequency (Hz) Response (dB)

40 -28.5 ± 2.0

140 +3.7 ± 1.5

600 REF

2200 +3.5 ± 1.5

5000 +12.5 ± 1.5

15000 +19.0 ± 1.5

6. Frequency Response of Low Frequency (LF) Output (Bi-Amp Mode)

6.1 Apply a 100 mVrms, 80 Hz signal to the

502C input terminals and reference your dB

meter to this frequency.

6.2 Measure the frequency response across

the LF outputs according to the table below.

4.2 Apply a 100 mVrms, 600 Hz signal to the

502C's input terminals and reference your

dB meter to this frequency.

4.3 Measure the frequency response across

the HF outputs according to the following

table.

Frequency (Hz) Response (dB)

40 -6.2 ± 2.0

80 REF

100 +1.3 ± 1.0

300 -17.5 ± 2.0

7. Midrange Distortion (Full Range Mode)

7.1 Set the mode switch to 1 (Full Range).

7.2 Apply a 3.75 Vrms, 600 Hz signal to the

502C input terminals.

43

Page 44

TEST PROCEDURES

7.3 Measure the distortion across the HF

outputs. It should be - .1%.

8. High Frequency Distortion (Full Range

Mode)

8.1 Apply a 890 mVrms, 5 kHz signal to the

502C input terminals.

8.2 Measure the distortion across the HF

outputs. It should be - .2%.

9. Low Frequency Distortion (Bi-Amp

Mode)

9.1 Set the mode switch to 2 (Bi-Amp).

9.2 Apply a 1.6 Vrms, 80 Hz signal to the

502C input terminals.

9.3 Measure the distortion across the LF

outputs. It should be - .1%.

11. High Frequency Distortion (Bi-Amp

Mode)

11.1 Apply a 890 mVrms, 5 kHz signal to the

502C input terminals.

11.2 Measure the distortion across the HF

outputs. It should be - .2%.

12. Channel Separation (Bi-Amp Mode)High Frequency

12.1 Set the mode switch to 2 (Bi-Amp).

12.2 Apply a 3.75 Vrms, 600 Hz signal to the

502C's input terminals.

12.3 Measure the channel separation across

the HF outputs. It should be > 40 dB.

10. Midrange Distortion (Bi-Amp Mode)

10.1 Apply a 3.75 Vrms, 600 Hz signal to the

502C input terminals.

10.2 Measure the distortion across the HF

outputs. It should be - .1%.

44

Page 45

Input Connections

Amplifier

Hot (+) Shield/ground

To unbalanced input

on amplifier

Shield and ground

pin 1

Unconnected

pin 3

Amplifier

OUTPUT

Hot (+)

pin 2

To unbalanced input

on amplifier

INPUT LEVEL

–10 +4

SER. NO. D.O.M.

Output Connections

Figure 17. Unbalanced Connections

Input

connectors

INPUT

CH 1

Input

attenuator

switches

High frequency

output

connectors

Bass level

control

HIGH FREQ OUTPUT

MODE

INPUT LEVEL

4

3

–10 +4

CH 2

PROTECTED BY U.S. PATENT 3,038,964

2

1

Mode

switch

2 HC1 HC

LOW FREQ

LEVEL

.

0

.

OUTPUT MODE

.

.

.

.

.

NORM SUM

+3

-18

BOSE CORPORATION, FRAMINGHAM, MA 01701-9168

ENGINEERED AND MANUFACTURED IN U.S.A.

Bass mono

sum switch

Low frequency

output

connectors

LOW FREQ OUTPUT

+– +–+– +–+– +–

CH 1 CH 2

Figure 18. 502C Controller Back Panel (Barrier Strip Version Shown)

45

230V~AC

50/60Hz 12W

LISTED 411F

U

L

®

COMMERCIAL

SOUND

EQUIPMENT

Page 46

ACCESSORY KIT PART LIST

502A PSA-5 Stand Adapter Parts List (see Figure 19)

Item

Number

1 Mounting Bracket 148513 2 1

- Har dware Kit, Consists of: 173535 1

2 Thumbscrew, M8x25mm, Black 173355 4

2 Washer, Thumbscrew 173356 4

3 Bolt, Button Head, 5mm, M8x12mm, Black

4 Bolt, Button Head, 5mm, M8x20mm, Black

5 Lock washer, M8 173450 10

6 Allen Wrench, 5mm 148544-1 1

- Poly bag, Hardware 173358 1 7

- I nstruction Sheet 148515 1 1, 7

- Poly sleeve 173357 2 1, 7

- Car t on, RSC 173359 1 1, 7

- Car t on, Divider 173360 1 1, 7

Description Part Number Qty.

148526-02 8

148526-10 2

Note

5

4

3

2

6

1

Figure 19. PSA-5 Stand Adapter Kit

46

Page 47

ACCESSORY KIT PART LIST

502A CSB-5A Suspension Bracket Kit Parts List (see Figure 20)

Item

Number

1 Suspension Bracket 148519 2 1

- Hardware Kit, Consists of: 173536 1

2 Screw, Mach., Socket Cap, M8x12mm 148514 7

2 Lock washer, M8 173450 7

3 Quick Link, 1/8" 148520-1 5

4 Allen Wrench, 6mmx3" 148544-2 1

- Poly bag, Hardware 173362 1 7

- Instruction Sheet 148521 1 1, 7

- Poly sleeve, Bracket 173361 2 1, 7

- Carton 173363 1 1, 7

- Carton Divider 173364 1 1, 7

Description Part Number Qty.

Note

3

1

4

2

Figure 20. CSB-5A Suspension Bracket Kit

47

Page 48

ACCESSORY KIT PART LIST

502B CSB-5B Suspension Bracket Kit Parts List (see Figure 21)

Item

Number

1 Left Angle Bracket 147005-1 1 1

1 Right Angle Bracket 147005-2 1 1

- Hardware Kit, Consists of: 173537 1

2 Screw, Hex Head, Mach., M8x20mm 148545-10 5

2 Lock washer, M8 173450 5

3 Quick Link, 3/16" 148520-2 2

- Poly bag, Hardware 173376 1 7

- Instruction Sheet 148527 1 1, 7

- Poly slee ve, Bracke t 173375 2 1, 7

- Tube, Packing 173377 1 1, 7

- Carton, Divider 173378 1 1, 7

Description Part Number Qty.

Note

1

2

3

Figure 21. CSB-5B Suspension Bracket Kit

48

Page 49

ACCESSORY KIT PART LIST

502A WBP-5 Bi-Pivot Bracket Kit Parts List (see Figure 22)

Item

Description Part Number Qty. Note

Number

1 Wall Plate Assembly 146995 2 1

2 Attachment Plate, Stamped Metal 149030 2 1

- Hardware Kit, Consists of: 173534 1

3 Screw, Socket Head Cap, M8x25mm 148505 2

3 Nut, Elastic, 8mm 148542 2

4 Screw, Socket Head Cap, M6x25mm 148541 2

4 Nut, Elastic, 6mm 148543 2

5 Safety Cable 148506 2

6 Allen Wrench, 5mm 148544-1 1

7 Allen Wrench, 6mm 148544-2 1

8 Bolt, Button Head, 5mm, M8x16mm 148526-06 11

8 Lock washer, M8 173450 11

- Poly bag (Hardware) 173370 1 7

- I nstruction Sheet 148509 1 1, 7

- Poly sleeve, W all Plate Assembly 173371 2 1, 7

- Poly sleeve, Att achment Plate 173372 2 1, 7

- Carton, RSC 173373 1 1, 7

- Carton, Divider 173374 1 1, 7

1

8