Page 1

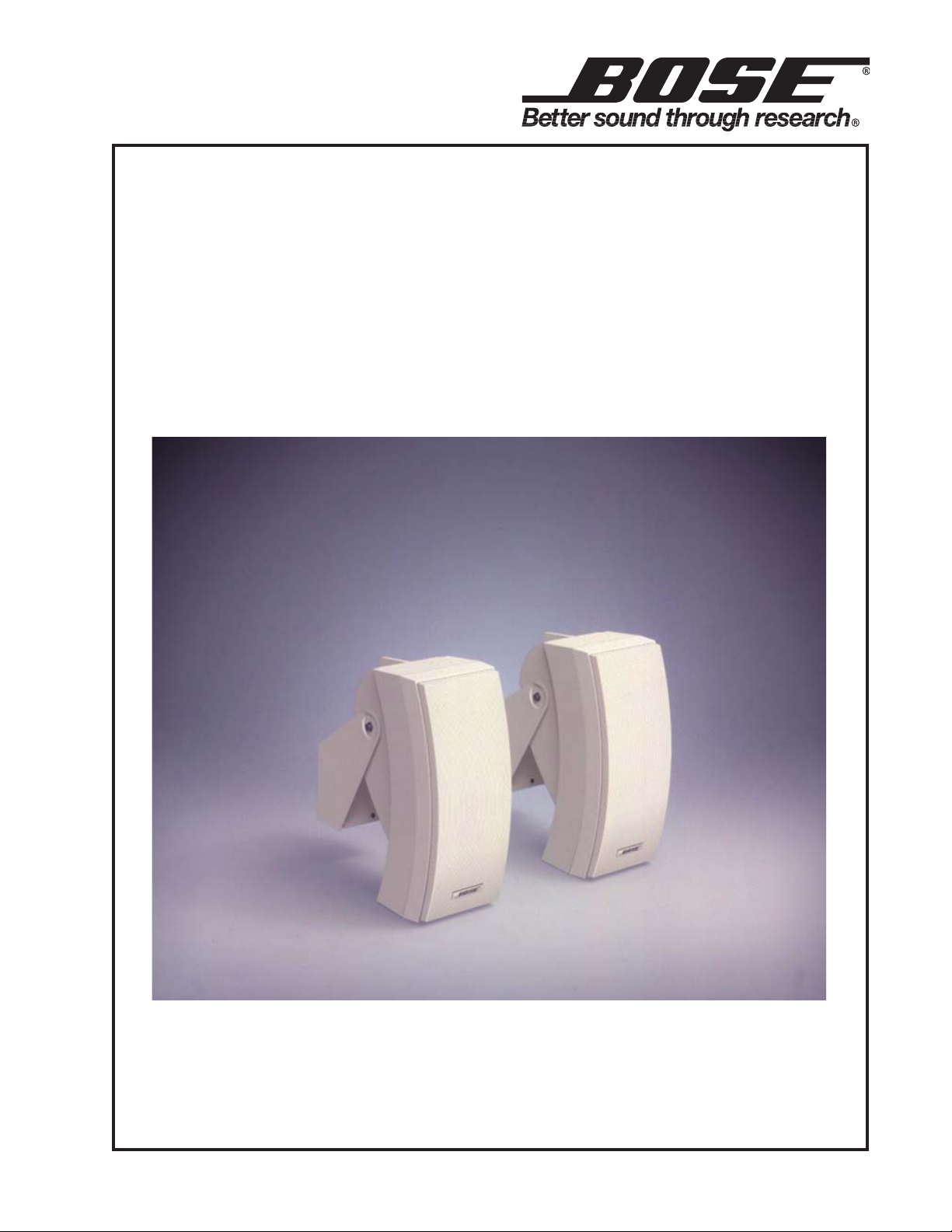

Bose® 302™A Loudspeaker

(Commercial Indoor/Outdoor

70V/100V Distributed Applications)

©2006 Bose Corporation

Service Manual

Part Number 257475 Rev. 02

Page 2

Contents

Product Description ......................................................................................................................... 2

Specifications ....................................................................................................................................3

Disassembly/Assembly Procedures ........................................................................................... 4-5

Transformer Wiring ........................................................................................................................... 5

Figure 2. Transformer Wiring ................................................................................................................ 5

Figure 1. Wiring Diagram ..................................................................................................................... 5

Test Procedures ................................................................................................................................6

Figure 3. Schematic Diagram ..............................................................................................................6

Part List .............................................................................................................................................. 7

Figure 4. Exploded View ...................................................................................................................... 7

Packaging Part List ........................................................................................................................... 8

Figure 5. Packaging View .................................................................................................................... 8

Table of contents ................................................................................................................................. 9

PRODUCT DESCRIPTION

The Bose® 302™ A loudspeaker is designed for surface-mount commercial 70V/100V distributed

indoor and outdoor applications. Designed to be mounted on a wall, ceiling or overhang, the 302A

loudspeaker is packaged with mounting brackets that contain a 70V or 100V multi-tap (12W, 25W,

50W and 100W) transformer. Each 302A loudspeaker contains one 5.25” environmentally resistant

woofer in a two-chamber configuration and two 2.5” environmentally resistant Twiddler™ drivers

vertically stacked and angled for maximum horizontal dispersion.

CAUTION: The Bose

serviceable parts. To prevent warranty infractions, refer

servicing to warranty service centers or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION

OF BOSE

ONLY FOR THE PURPOSE OF SERVICING THE IDENTIFIED

BOSE PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE BOSE PRODUCT, AND SHALL NOT

BE REPRODUCED OR USED FOR ANY OTHER PURPOSE.

The Bose 302A loudspeaker is covered by a five year transferable limited warranty.

CORPORATION WHICH IS BEING FURNISHED

302A loudspeaker contains no user

WARRANTY INFORMATION

2

Page 3

Transducers:

One 5.25" environmental woofer per enclosure

Maximum Acoustic Output:

SPECIFICATIONS

Two 2.5" environmental resistant TwiddlerTM drivers per enclosure

Crossover:

Low frequency cutoff:

Impedance:

Power Handling:

Transformer:

Frequency range:

Sensitivity:

Dispersion:

External Dimensions:

250Hz ±10% at 6dB/octave

-3dB at 75Hz ±5Hz

70V: 25 Ohms at 100W tap setting

100V: 50 Ohms at 100W tap setting

100W continuous per IEC 268-5

Multi-tap 70V/100V (12W, 25W, 50W,100W taps)

75Hz to 16 kHz

>82dB SPL at 1W, 1M (pink noise)

102dB SPL at 1M (pink noise)

102dB SPL at 1M (IEC noise)

(-6dB point, average, 1-4 kHz)

Horizontal 178

Vertical 93

o

o

Single speaker: 13.4"H x 5.7"W x 9.0"D (34 x 14.5 x 23) cm

Packed system: 16"H x 17"W x 14.75"D (40.6 x 43.2 37.47) cm

Weight:

Single speaker: 7.75 lb. (3.5 kg)

Packed system: 32.2 lb. (14.6 kg)

3

Page 4

DISASSEMBLY/ASSEMBLY PROCEDURES

(Refer to Figure 4)

1. Grille and Baffle Removal

1.1 Grasp the edge of the grill (10) and pull it

off.

1.2 Remove the six screws (17) that secure

the baffle to the cabinet and then pull off the

baffle.

2. Grille and Baffle Replacement

2.1 To prevent air leaks, apply a new woofer

mount gasket (13). To prevent wire buzzes,

insert the wires into the cabinet’s wire channel. Line up the baffle so that the baffle’s

woofer mount fits into the groove in the

cabinet. Replace the six screws (17) that

secure the baffle to the cabinet.

2.2 Align the grille (10) with the cabinet so

that the logo (14) is over the Twiddler

drivers (2). Press the grille into place.

TM

5.3 Remove the four screws (16) that secure

the woofer to the baffle. Lift out the woofer.

6. Woofer Replacement

6.1 To prevent air leaks, use a new woofer

gasket (15) and woofer mount gasket (13).

Line up the woofer (1) in the baffle so that the

wire terminal is facing toward the Twiddler

drivers (2). Replace the four screws (16) that

secure the woofer to the baffle.

6.2 Referring to the note taken in procedure

5.2, attach the wires to the woofer.

6.3 Place the foam tape woofer mount gasket

(13) around the edge of the woofer mount

where it contacts the cabinet.

7. RLC Circuit Component Removal

7.1 Perform procedure 1.

3. Twiddler Removal.

3.1 Perform procedure 1.1 and then remove

the four screws (16) that secure the Twiddler

driver (2) to the cabinet.

3.2 Lift out the Twiddler driver, make a note of

the wiring configuration and cut the wires as

close as possible to the wire terminal.

4. Twiddler Replacement

4.1 Referring to the note taken in 3.2, attach

the wires to the Twiddler driver (2).

4.2 Line up the Twiddler driver in the cabinet

and replace the four screws (16) that secure it

in place.

5. Woofer Removal

5.1 Perform procedure 1.

5.2 Make a note of the wiring configuration

and then cut the wires as close as possible to

the woofer’s (1) wire terminal.

7.2 Remove the capacitor (5), resistor (6) or

inductor (4) by cutting its leads. Remove the

screw (16) that secures the inductor to the

cabinet and cut the inductor’s leads.

8. RLC Circuit Component Replacement

8.1 Replace the capacitor (5), resistor (6) or

inductor (4) by soldering its leads to the lug

from which it was removed. Replace the

screw (16) that secures the inductor to the

cabinet. Refer to Figures 1 and 3.

9. Crossover Capacitor Removal

9.1 Perform procedure 1.

9.2 Remove the four screws (16) that secure

the Twiddler driver panel (11) to the baffle.

Pry off the panel.

9.3 Cut the wires as close as possible to the

terminals of the capacitor (3).

4

Page 5

DISASSEMBLY/ASSEMBLY PROCEDURES

(Refer to Figure 4)

10. Crossover Capacitor Replacement

10.1 Connect the leads of the capacitor (3) to

the wires and solder the connections. The

capacitor is wired in series with the woofer’s

(1) positive terminal and the Twiddler

TM

driver’s

(2) positive terminal. Refer to Figure 1 and 3.

10.2 To prevent air leaks, use a new Twiddler

driver panel (11) and gasket (12). Line up the

Twiddler panel with the cabinet and replace

the four screws (16) that secure it to the

baffle.

Boss 3

Boss 1

Red wire

(-) Woofer

(-) Terminal

Green wire

(-) Twid 2

Wiring Schematic

From To Wire

Twiddler

driver 1 (-)

Twiddler

driver 1 (+)

Capacitor

Twiddler

driver 2 (+)

Capacitor

(item number 3)

Woofer (+) Black

Yellow

(item number 3)

Twiddler

Lug at boss 3 Red

driver 2 (-)

Woofer (+) Terminal (+) Yellow

Woofer (-) Terminal (-) Green

Terminal (-) Lug at boss 1 Green

Gray

Figure 1. Wiring Diagram

TRANSFORMER WIRING

The transformer is set at the factory for 70V, 100W operation.

• To change from 70V to 100V operation, replace the orange wire with the yellow wire (orange wire

70V, yellow wire 100V).

• To change from 100W output, replace the red wire with:

• Green for 50W output

• Violet for 25W output

• Blue for 12.5W output

Caution: Do not remove or replace the black ground wire. To prevent wires from shorting, all

wires that are not connected must be covered with shrink tube or a wire nut.

OUTPUT

RED

BLK

INPUT

PARALLEL

INPUT

RED

BLK

100W

WHITE

ORANGE

JUMPER

WIRES

70V

YELLOW

GREEN

VIOLET

BLUE

100V

50W

25W

12.5W

Figure 2. Transformer Wiring

5

Page 6

TEST PROCEDURES

+

-

+

-

Gray

Twiddler driver 2

Twiddler driver 1

Red

15uF

1.5mH

11 Ohm

Woofer

GreenGreen

Yellow

YellowYellow

22uF

+

-

Test setup note: Disconnect the input of the

speaker from the transformer for procedures

1-5.

1. Woofer Rub and Tick Test

1.1 Apply a 1 Vrms, 10Hz signal to the

speaker input terminal. No extraneous noises

such as rubbing, scraping or ticking should be

heard.

Note: To distinguish between normal suspension noise and rubs or ticks, slightly displace

the cone of the woofer with your fingers. If the

noise can be made to go away or get worse, it

is a rub or tick and the woofer should be

replaced. If the noise stays the same, it is

normal suspension noise and the woofer is

okay. Suspension noise will not be heard with

program material.

2. Air Leak Test

4.4 Sweep the signal generator from 5 kHz to

15 kHz and then back to 5 kHz.

4.5 Listen for buzzes, rattles or other noises.

Redress any wire that buzzes; replace the

woofer or Twiddler driver if they are found to

be defective.

5. Woofer Phase Test

5.1 Observing polarity, momentarily apply 8

VDC to the speaker input terminal.

Note: To avoid damaging the speaker, only

momentarily apply the DC voltage.

5.2 The woofer should move outward with the

application of the DC voltage.

2.1 Apply an 8 Vrms, 65Hz signal to the

speaker input terminal.

2.2 Listen for air leaks around the cabinet

seams, the Twiddler™

woofer and Twiddler driver gaskets. Reposition or replace any gasket that is found to

leak. Repairs made to the cabinet seam

should not be visible from the exterior of the

speaker.

Note: A whooshing noise from the ports at

approximately 65Hz and 185Hz is acceptable

(port tuned frequencies).

3. Twiddler Driver Phase Test

3.1 Check the wiring of the Twiddler driver

against Figures 1 and 3.

4. Sweep Test

4.1 Apply an 8 Vrms, 10Hz signal to the

speaker input terminal.

4.2 Sweep the signal generator from 10Hz to

5 kHz and then back to 10Hz.

4.3 Apply a 3 Vrms, 5 kHz signal to the

speaker input terminal.

driver panel, and the

Figure 3. Schematic Diagram

6. Transformer Test

6.1 Connect the output of the transformer to

the speaker input terminal.

6.2 Apply a 35 Vrms, 50Hz signal to the input

of the transformer.

6.3 Sweep the signal generator from 50Hz to

5 KHz. Listen for clean undistorted audio

output.

6

Page 7

MAIN PART LIST

Item

Description Part Number Qty Note

Number

1 WOOFER, 5.25", ENVIRONMENTAL 289780-001 1

2 TWIDDLERTM DRIVER, ENVIROMENTAL 289783-001 2

3 CROSSOVER ASSY, 22UF 291731-002 1

4 INDUCTOR, 1.5mH, 0.8 OHM, FERRITE 147196 1

5 CAPACITOR, BIPOLAR, 15uF 291087-001 1

6 RESISTOR, WW, 5W, 10%, 11.1 OHM 125605-110 1

7 NUT, INSERT 250818 2

8 CONNECTOR, ENVIRONMENTAL, BLACK 250815-01 1

9 CONNECTOR, ENVIRONMENTAL, RED 250815-02 1

10 GRILLE, ALUMINUM, BLACK

GRILLE, ALUMINUM, WHITE

250804-11

250804-12

1

11 PANEL, SEALING, TWIDDLER DRIVER 250820 1

12 FOAM TAPE GASKET 250807 1

13 FOAM TAPE GASKET, WOOFER MOUNT 250808 1

14 LOGO, BLACK CABINET

LOGO, WHITE CABINET

250806-03

250806-04

1

15 GASKET, 134mm, RD, ADH BACKE D 290315-001 1

16 SCREW, TAPP, 8-11X.5, PAN, ASY, SQ 290306-08 17

17 SCREW, TAPP, 8-11X1.0, PAN, ASY, SQ 290306-16 7

18 GASKET .725" ROUND 293356-001 2

19 SCREW, TAPP, 8x3/8, HEX W, SLOT 290304-06 2

20 CONN, TERM, WIRE WRAP, 1 POS, FEM 118008 2

21 TAPE, FOIL 255912 2

22 TAPE, FOAM 255911 1

23 TAPE, FOAM 118223 2

24 TAPE, FILTER FOAM 255910 1

25 SCREW 290305-16 1

Red wire

(-) Woofer

(-) Terminal

25

4

5

6

21

Green wire

23

(-) Twid 2

Figure 4. Exploded View

7

Page 8

3

7

6

4

5

1

8

9

10

2

PACKAGING PART LIST

Item

Description Part Number Qty Note

Number

1 BRACKET/TRANSFORMER, 70V/100V BLACK

BRACKET/T RANSFORMER, 70V/100V WHITE

255901-01

255901-02

1

pkg of 2

2 70V/100V TRANSFORMER ONLY 254426 2

3 HARDWARE KIT, ENV, 4-PACK, BLACK

HARDWARE KIT, ENV, 4-PAC K, WHIT E

290307-003

290307-004

1

4 BAG, POLY, HDPE, 18X26, 1 MIL 255354-001 1 4

5 PACKING , END CAP, TOP 250809 1

6 PACKING, END CAP, BOTTOM 250810 1

7 CARTON, RSC 255902-001 1

8 PACKAGING, CREASE SHEET 255903 1

9 INSTALLER GUIDE 255917 1

10 COMMITMENT LETTER 251001 1

Figure 5. Packaging View

8

Page 9

Date Revision

Description of Change Change

Pages

SERVICE MANUAL REVISION HISTORY

Level

8/02 00 Document release revision 00

Unknown 00 to 01 ECN 33972 and 33783 6,7

02/06 01 to 02 Added RoHS part numbers This product is

1

Driven By

Service

manual

release

now built with

RoHS

compliant

parts.

Affected

All

6,7

9

Page 10

Specifications and Features Subject to Change Without Notice

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 257475 REV. 02 2/2006 For Technical Assistance or Part Orders, Call 1-800-233-4408

Loading...

Loading...