Page 1

FreeSpace® DXA 2120

Digital Mixer/Amplifier

(US and non-US units)

©2010 Bose Corporation

Service Manual

Reference Number 294962-SM Rev . 01

Electronic Copy Only

Page 2

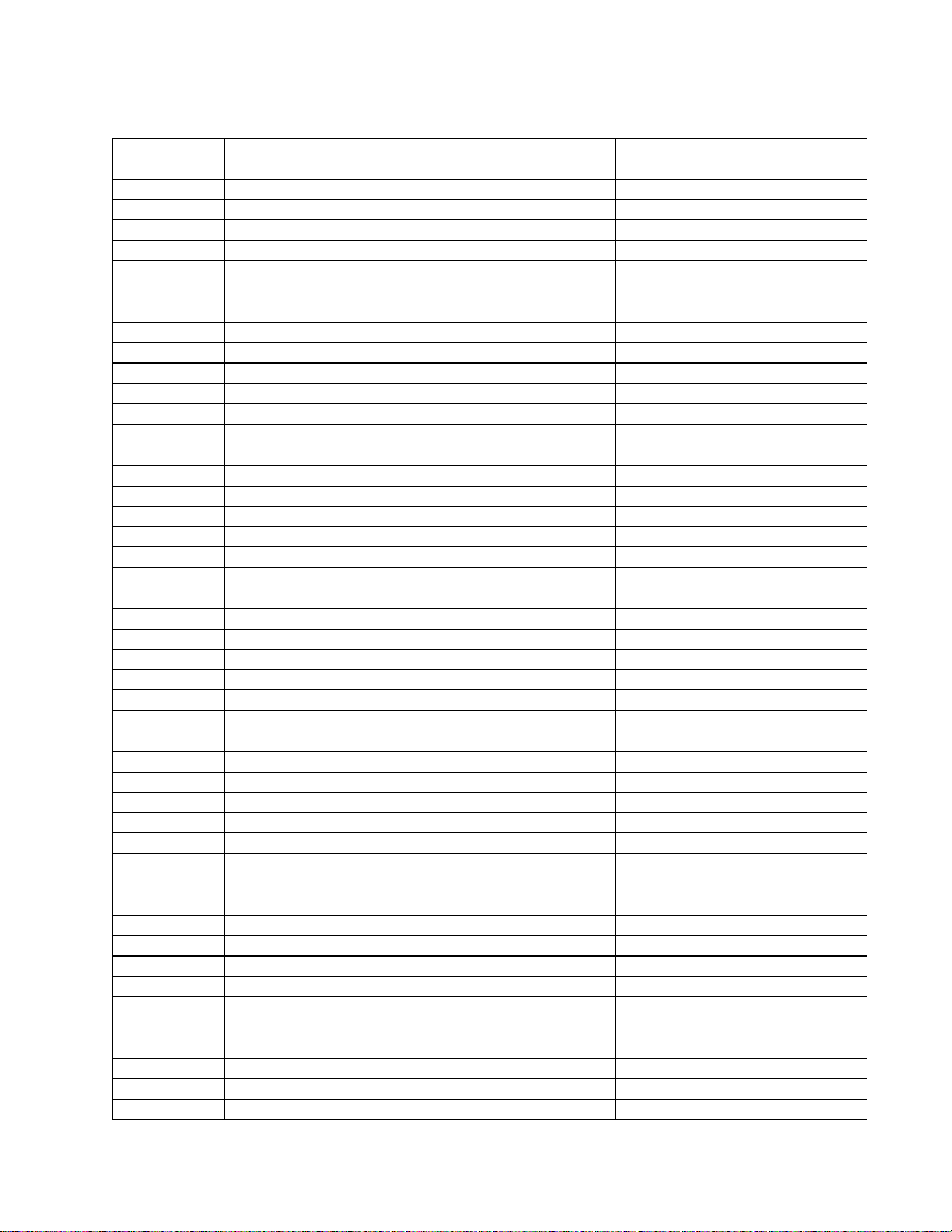

CONTENTS

Safety Information.............................................................................................................................3

Warranty .............................................................................................................................................3

Product Description ..................................................................................................................... 4-7

Specifications................................................................................................................. ............... 8-9

Electrostatic Discharge Sensitive (ESDS) Device Handling..................................................... 10

Part List Notes ................................................................................................................................10

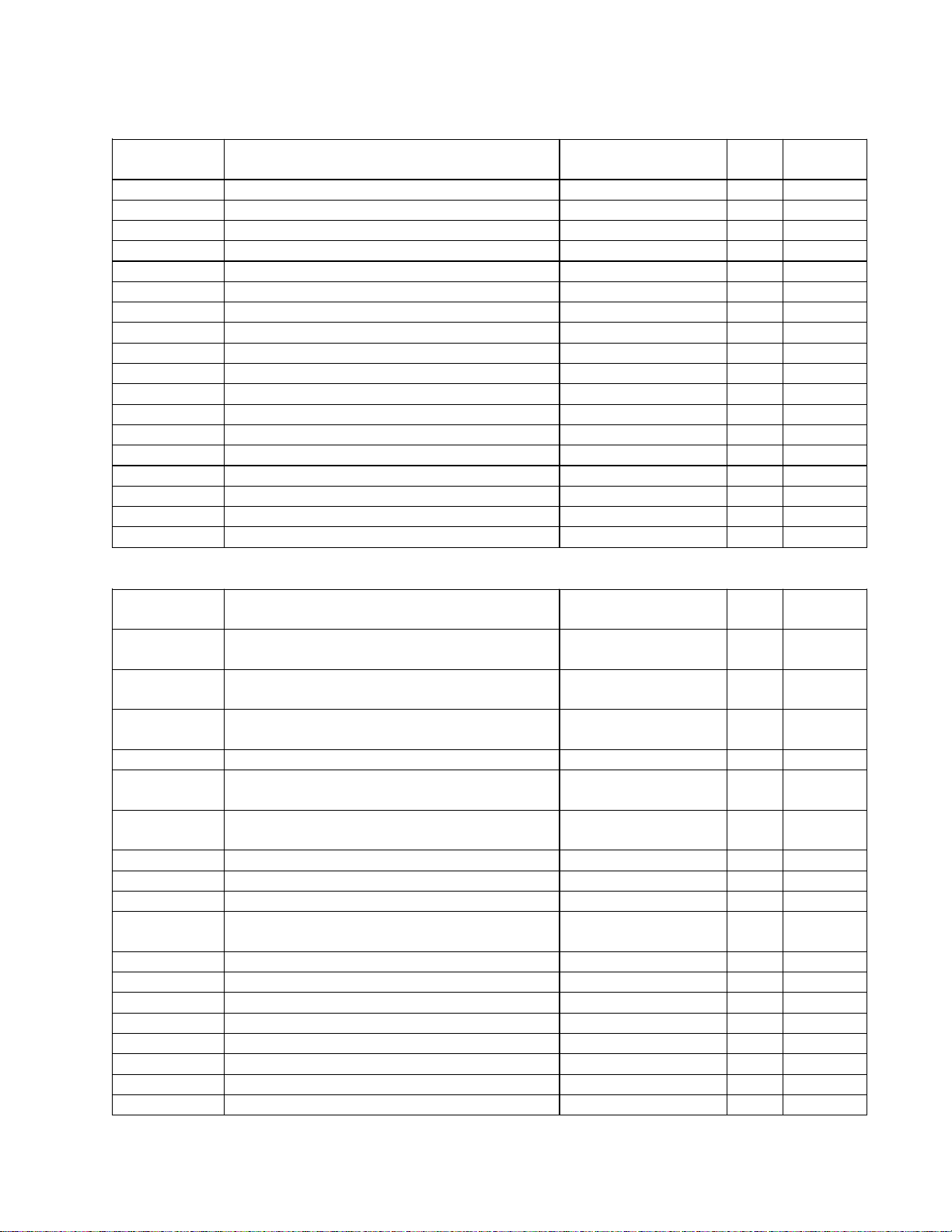

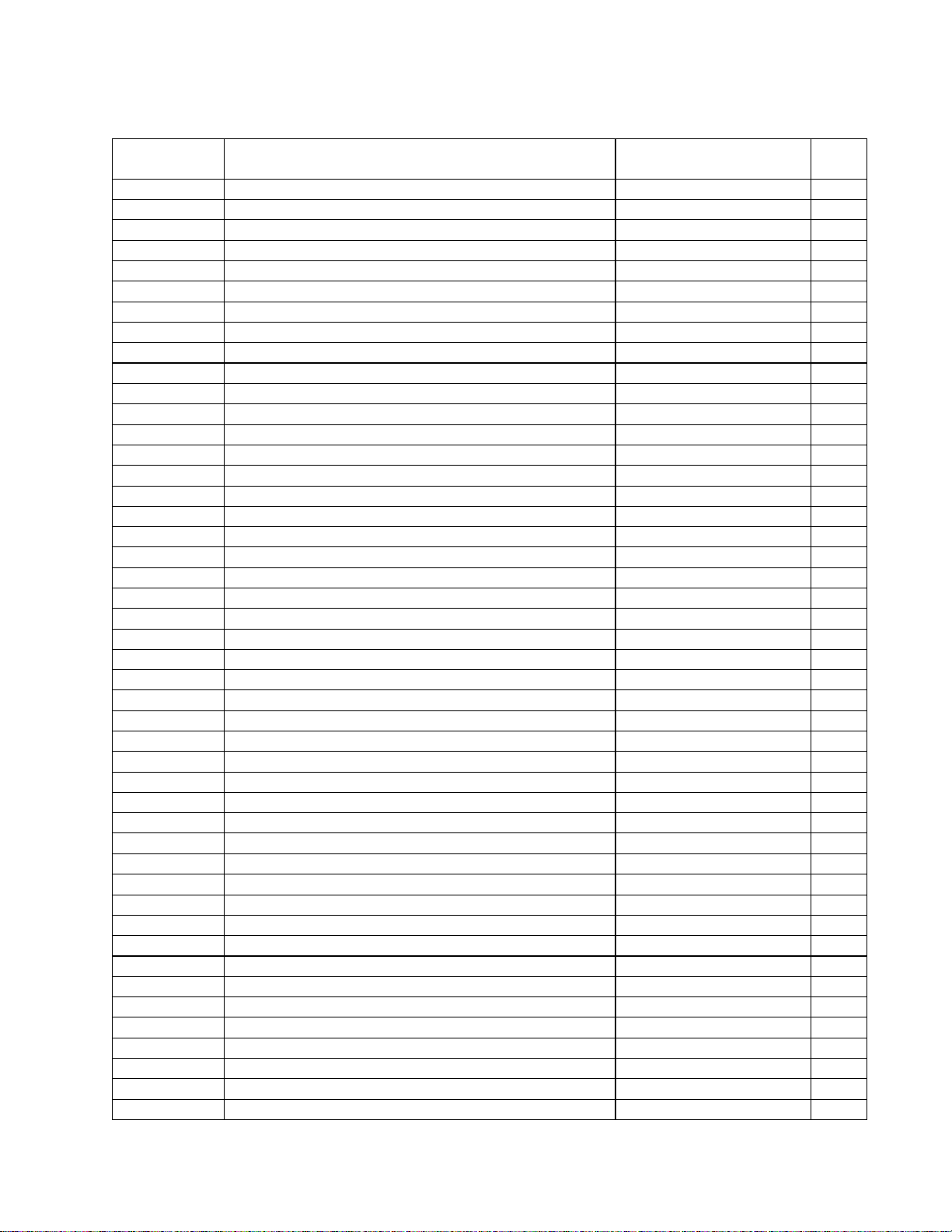

Packaging Part List, FreeSpace® DXA 2120 Amplifier/Mixer (see Figure 1) ............................. 11

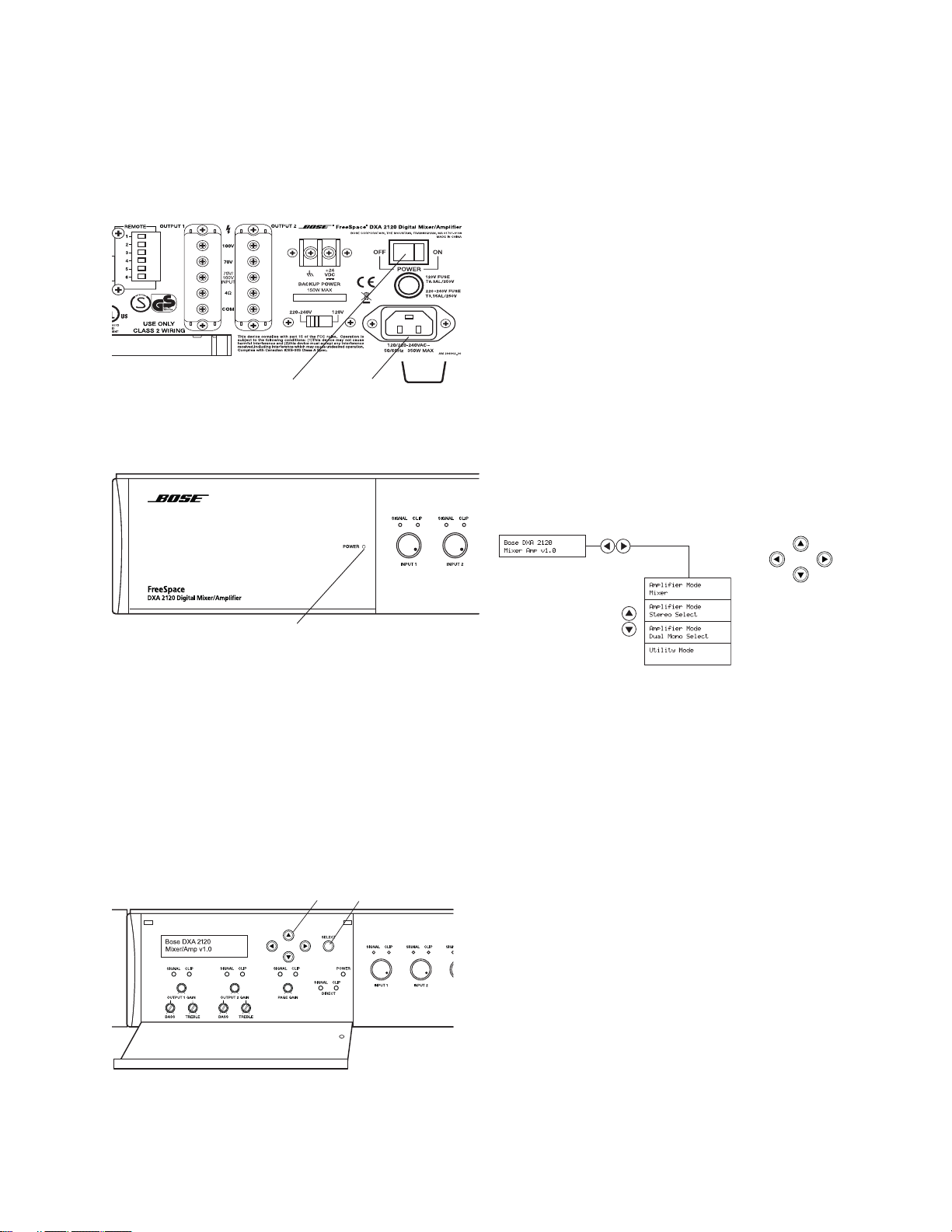

Figure 1. FreeSp ace DXA 2120 Packaging View ............................................................................11

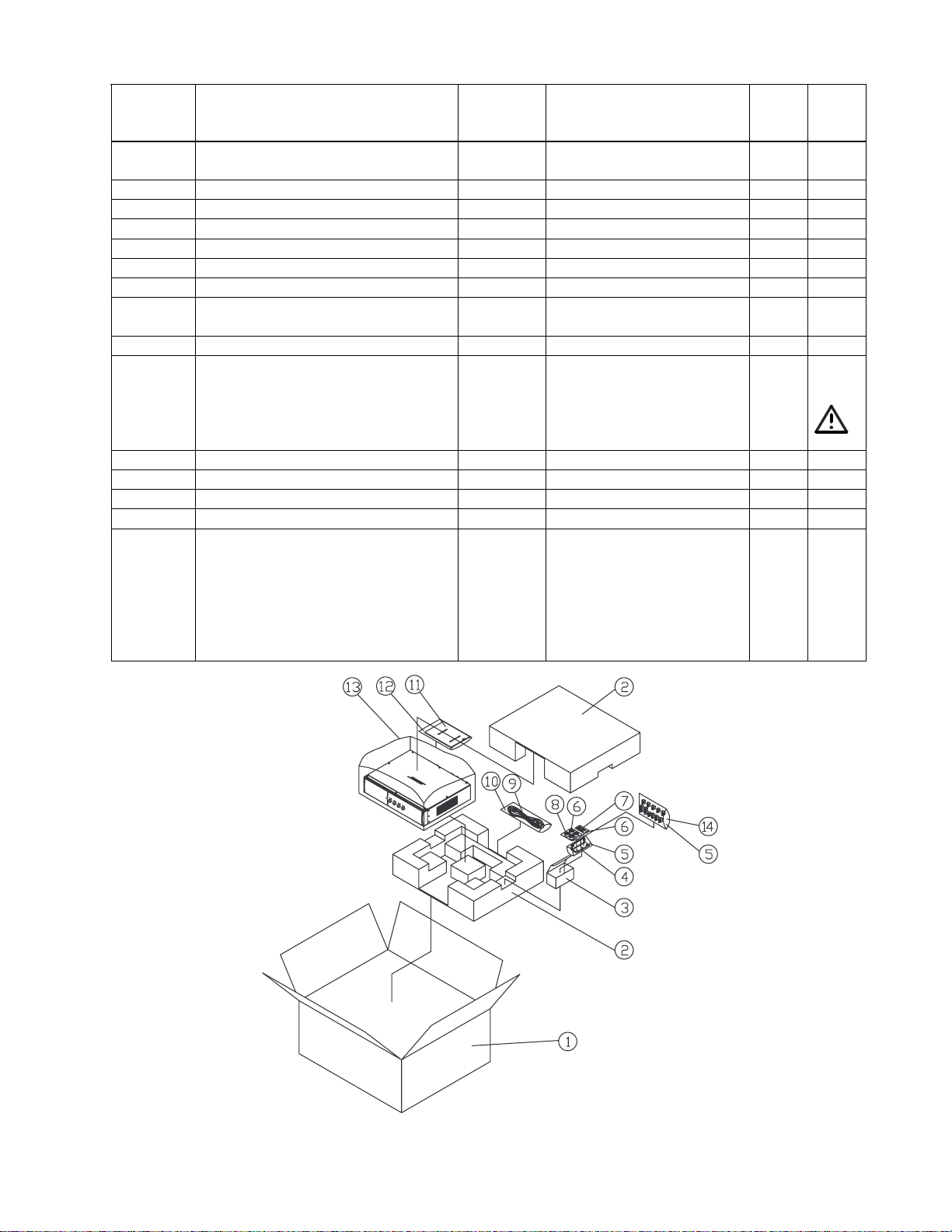

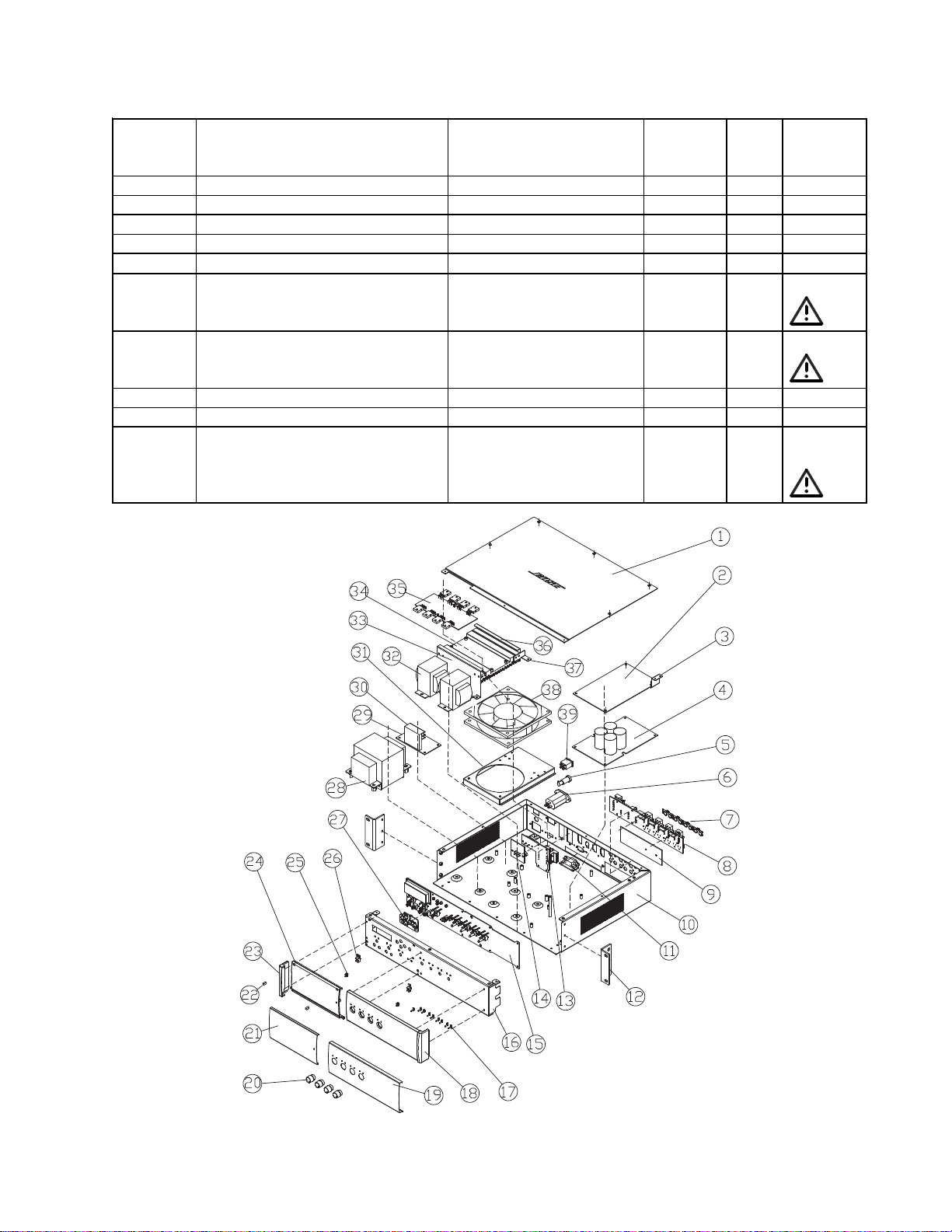

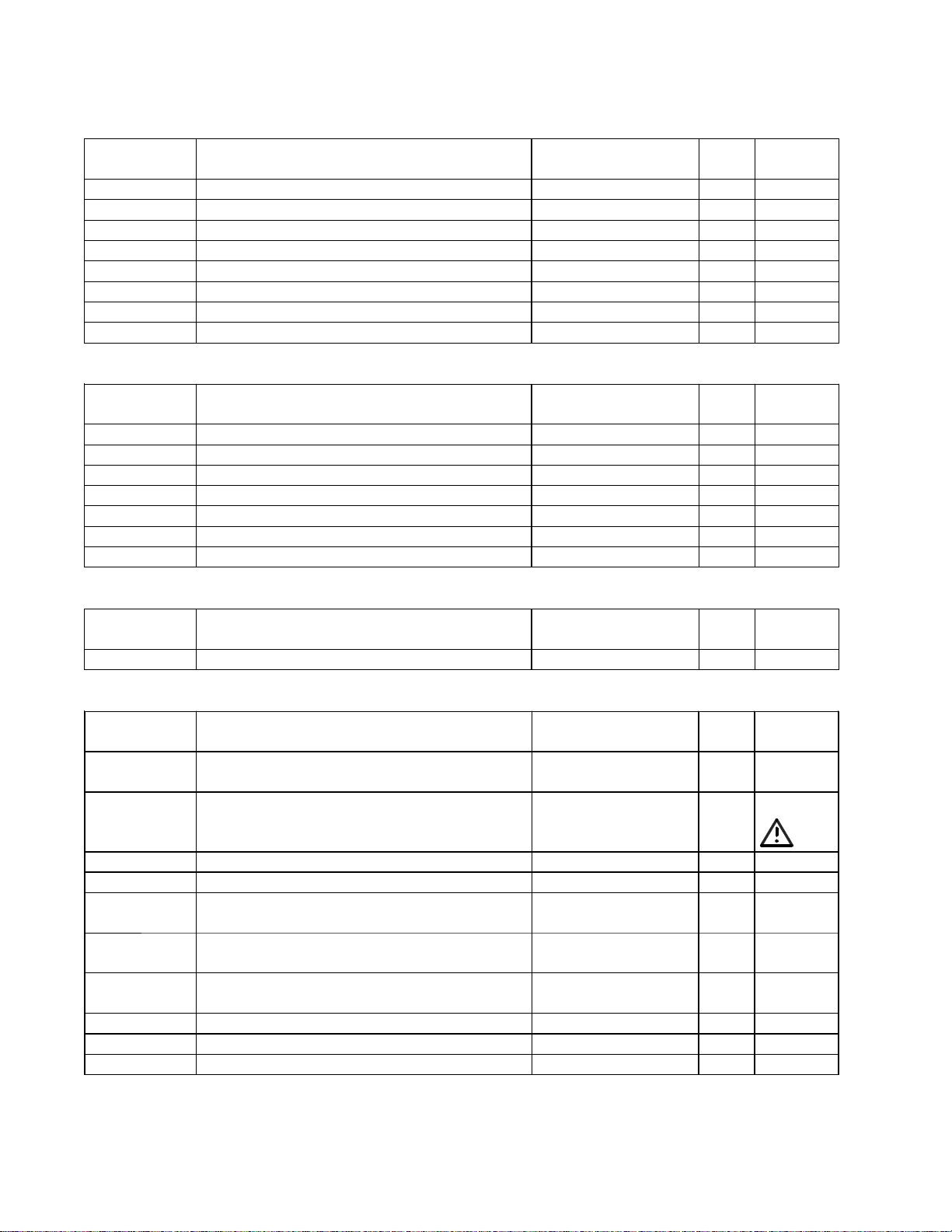

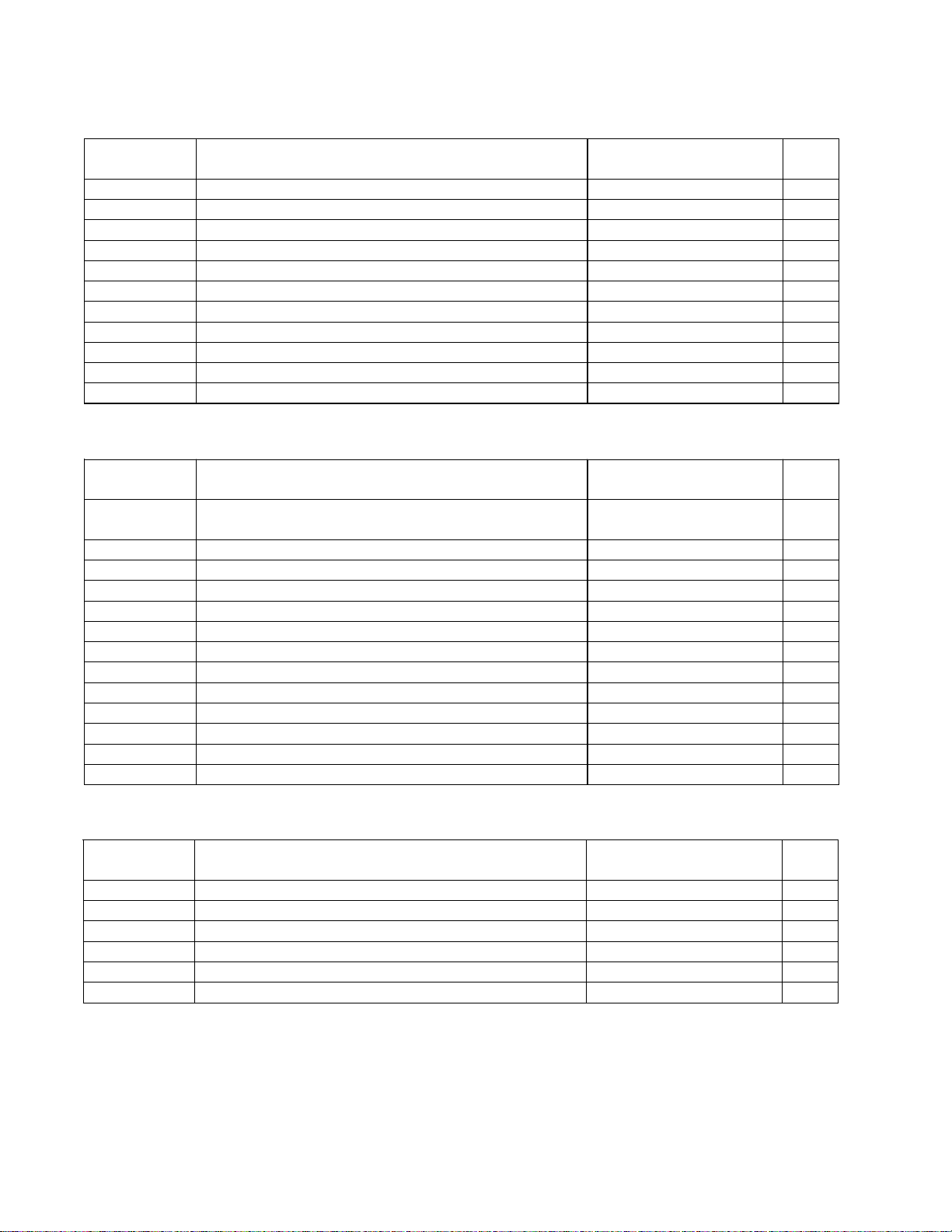

Main Part List, FreeSpace DXA 2120 Amplifier/Mixer (see Figure 2) .........................................12

Figure 2. FreeSp ace DXA 2120 Amplifier/Mixer Exploded View ......................................................13

Electrical Part Lists .................................................................................................................. 14-52

Control PCB Assembly ............................................................................................................. 14-16

DC24 PCB Assembly................................................................................................................. 17-18

Digital Signal Processor (DSP) PCB Assembly ..................................................................... 19-28

Input/Output PCB Assembly .................................................................................................... 29-35

Amplifier PCB Assembly ........................................................................................................... 36-40

PSU PCB Assembly................................................................................................................... 41-44

RCA Input PCB Assembly ......................................................................................................... 45-49

RS-232 PCB Assembly ....................................................................................................................50

Speaker PCB Assembly............................................................................................................ 50-51

V olt PCB Assembly..........................................................................................................................52

Figure 3. FreeSp ace DXA 2120 Amplifier with Top Cover Removed ...............................................53

Disassembly Procedures ......................................................................................................... 54-61

Test Procedures ....................................................................................................................... 62-70

FreeSpace DXA-2120 Firmware Update Procedure.............................................................. 71-72

FreeSpace DXA-2120 Wiring Diagram ..........................................................................................74

Figure 4. DSP and MCU PCB Topside Etch Layout........................................................................75

Figure 5. DSP and MCU PCB Bottom Etch Layout ........................................................................75

Figure 6. Input/Output PCB Topside Etch Layout............................................................................76

Figure 7. Input/Output PCB Bottom Etch Layout ............................................................................76

Figure 8. Volt PCB Topside Etch Layout .........................................................................................77

Figure 9. Volt PCB Bottom Etch Layout..........................................................................................77

Figure 10. Speaker PCB Topside Etch Layout ................................................................................77

Figure 1 1. Speaker PCB Bottom Etch Layout .................................................................................77

Figure 12. RS232 PCB Topside Etch Layout ..................................................................................77

Figure 13. RS232 PCB Bottom Etch Layout...................................................................................77

Figure 14. PSU PCB Topside Etch Layout......................................................................................78

Figure 15. PSU PCB Bottom Etch Layout ......................................................................................78

Figure 16. Amplifier PCB Topside Etch Layout................................................................................79

Figure 17. Amplifier PCB Bottom Etch Layout ................................................................................79

Figure 18. DC24 PCB Topside Etch Layout....................................................................................79

Figure 19. DC24 PCB Bottom Etch Layout ....................................................................................79

Figure 20. Control and Display PCB Topside Etch Layout..............................................................80

Figure 21. Control and Display PCB Bottom Etch Layout...............................................................80

Figure 22. RCA Input and A/D PCB T op side Etch Layout................................................................81

Figure 23. RCA Input and A/D PCB Bottom Etch Layout ................................................................81

Integrated Circuit Diagrams .................................................................................................... 82-91

Troubleshooting .............................................................................................................................92

Service Manual Revision History .................................................................................................93

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® FreeSpace

contains no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

®

DXA 2120 Digital Mixer/Amplifier

WARRANTY

The Bose FreeSpace DXA 2120 Digital Mixer/Amplifier is covered by a limited 2-year transferable limited warranty.

3

Page 4

Product Description

The Bose® FreeSpace® DXA 2120 Digital

Mixer/Amplifier integrates digital signal

processing with two 120-watt output

channels. Designed as a mixer/router for

business music applications, it features

an LCD panel and control buttons behind the front cover for ready access and easy configuration.

The mixer/amplifier provides six inputs, including 4 Mic/Line inputs, 1 Page input, and 1 Direct

input. The Direct input can override all sources playing on the output channels. Each Mic/Line

input provides both RCA and Euroblock jacks. The Euroblock connectors will accept either a Mic

or Line level input. The RCA jacks accept Line level inputs only.

Two output channels are wired for 120 watts at 4 ohms each. For 70/100 volt applications, a

jumper is required for proper configuration. In 70/100V applications, the two outputs will operate

at 100 watts per channel. A third output is available for an auxiliary line out.

Additional features include:

• Signal Mixing: In Mixer Mode, simultaneously combines up to four inputs for any of the

three outputs.

• Signal Routing: In Dual Mono Select Mode, one or two inputs go to each of two outputs in

different zones and can be remotely selected. Or in Stereo Select Mode, two stereo sources

go to one output zone and can be remotely selected.

• Opti-voice

®

Paging: Provides a smooth transition between music and page signals.

• Dynamic Equalization: Maintains tonal balance at all listening levels.

• Room Equalization: Allows easy adjustment of tonal balance in each zone.

• Communications Port: Includes an RS-232 serial port in reserve for system updates.

• Back-up Power: Provides an input terminal for a +24V DC back-up power source.

POWER

Supplied with the product

Included Connectors:

• 3-terminal input connectors (4) for wiring source equipment to 1 - 4 Line/Mic input Euroblock

jacks.

• 4-terminal input connectors (2) for wiring to the single Page and single Direct input jacks.

• 6-terminal input connector (1) for wiring to interface wall controls to the wall panel input jack.

• 3-terminal output connector (1) for wiring to the AUX-out jack.

Included placement aids:

• Non-skid rubber feet (4) for stable placement on a solid, level surface.

• Rack ears (2) with mounting hardware for installation in a rack.

Mixer/Amplifier Accessories

• FreeSpace DXA volume control - A wall-mountable plate with volume control knob that fits

into a standard U.S. double-gang junction.box.

• FreeSpace DXA volume control with A/B select - A wall-mountable plate that fits into a

standard U.S. double-gang junction box. It features volume control and A/B select knobs for

remote source selection.

4

Page 5

Hardware Description

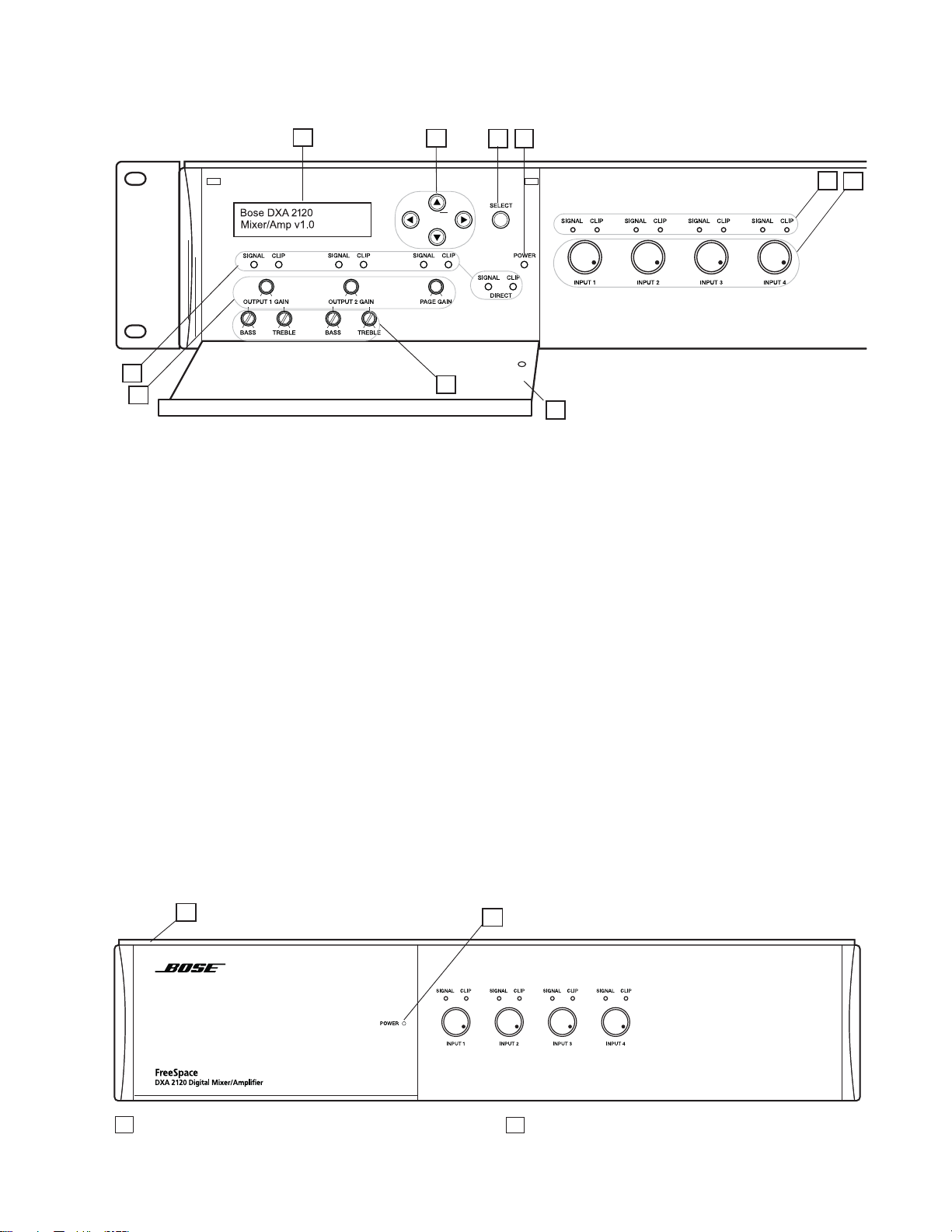

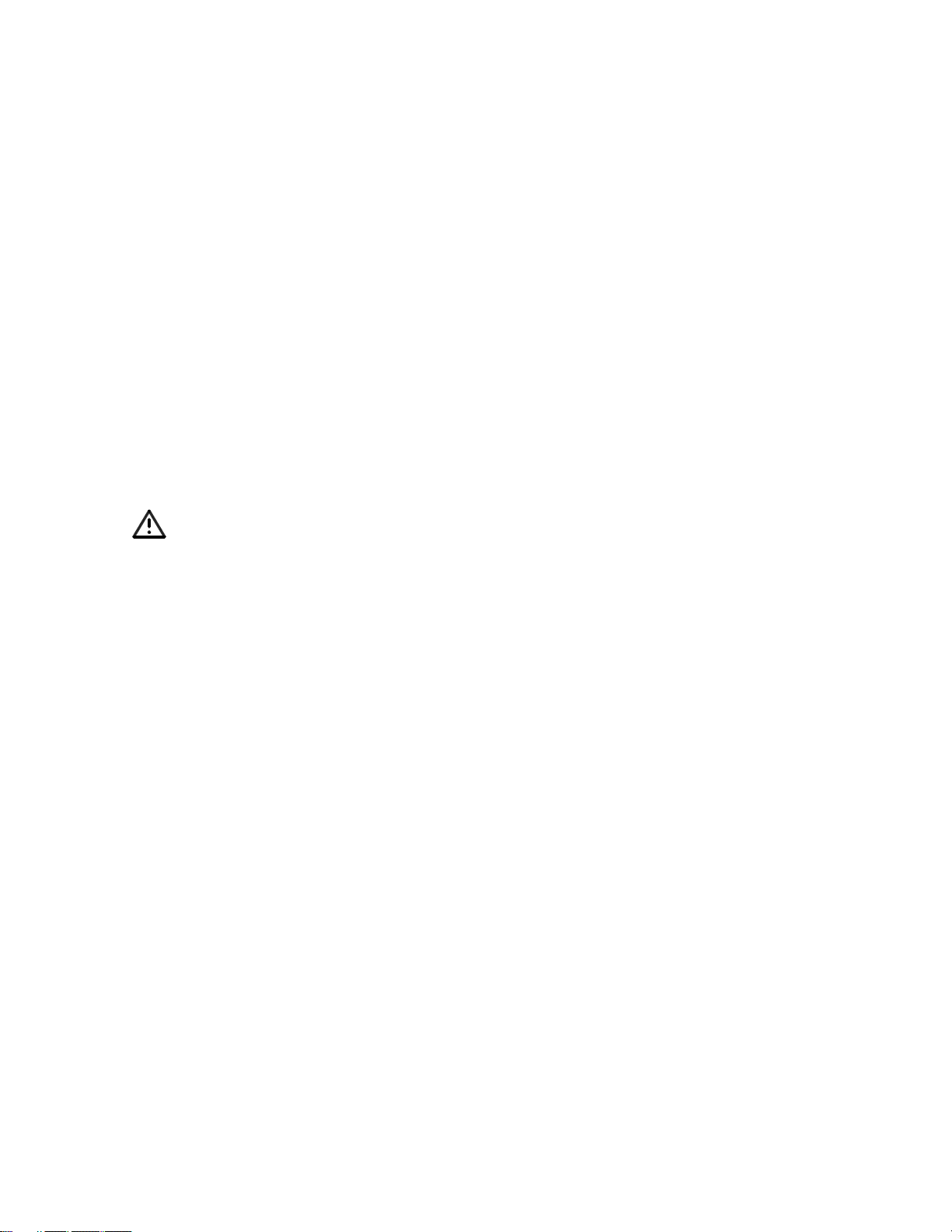

Front panel with open compartment

1

5

6

2

7

System Controls

1 - LCD panel - Displays menu selection for

configuring and viewing system settings.

2 - Directional buttons - Navigate system

menus and setting options as shown on the

LCD.

3 - Select button - Confirms selections and

settings in the system menus.

4 - Power LED - Blue light indicates the

system is on. No light when it is off.

5 - Signal and Clip LEDs - Show signal

states for OUPUT 1, OUTPUT 2, PAGE and

DIRECT.

Signal Unlit = No signal

Clip Unlit = No clipping

Signal Green = Signal present

Clip Red = Clipping

6 - Gain knobs - Adjust gain for OUTPUT 1,

OUTPUT 2 and PAGE.

3

4

8

7 - Bass and Treble knobs - Adjust tonal

balance for OUTPUT 1 and OUTPUT 2.

Control Compartment

8 - Enclosure Door - Conceals system

controls.

Input Controls

9 - SIGNAL and CLIP LEDs - Show signal

states for Inputs 1 - 4.

Signal Unlit = No signal

Clip Unlit = No clipping

Signal Green = Signal present

Clip Red = Clipping

10 - Gain knobs - Adjust gain for INPUT 1 INPUT 4.

9

10

Front panel with compartment closed

1

1 Latch location – Provides access to system controls. 2 Power status window – Reveals Power LED.

2

5

Page 6

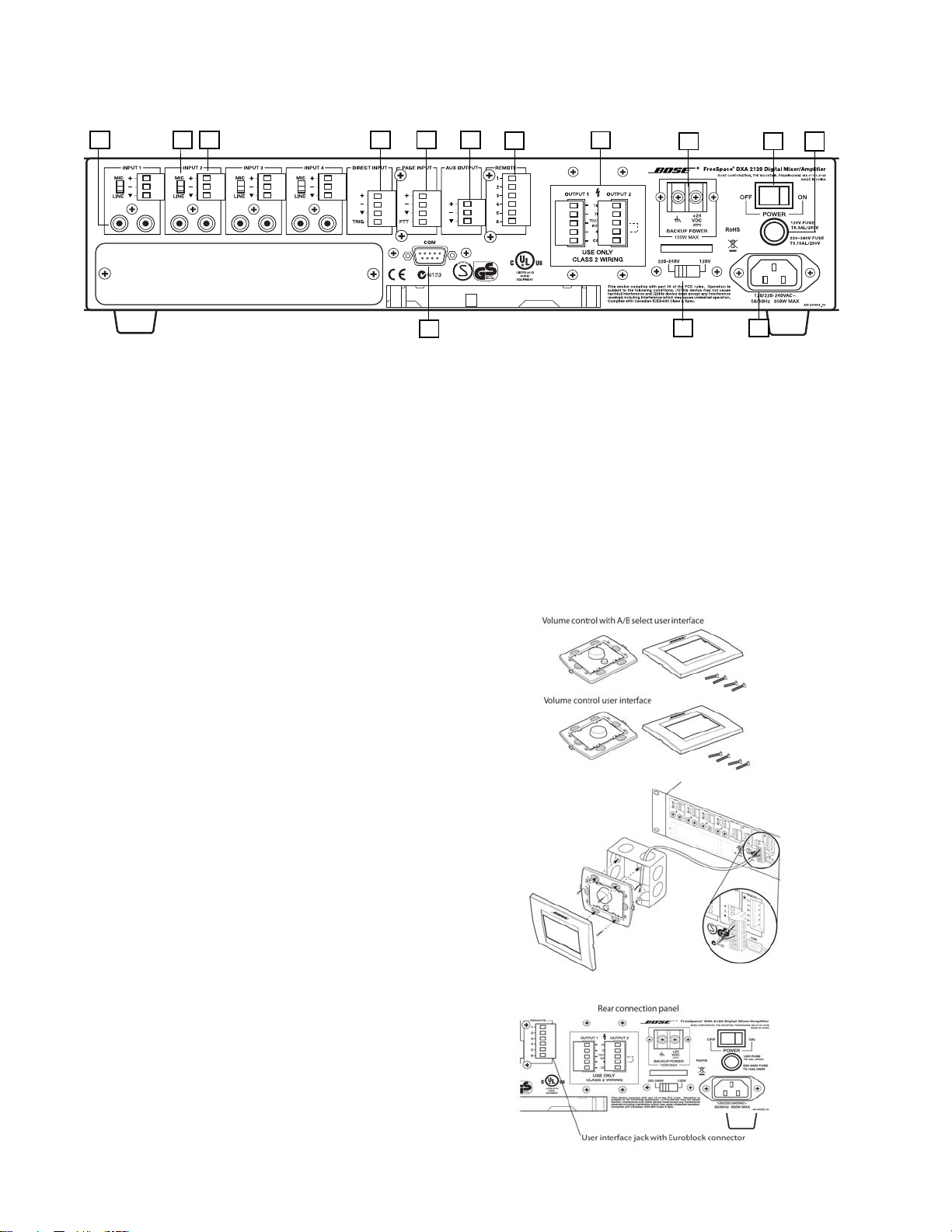

Hardware Description

Rear Panel

1

2

3

4

Audio source inputs

1 - INPUT 1 of 4 - Unbalanced RCA audio

input jack.

2 - MIC/LINE switch - To adjust for the type

if signal input. (Mic connections require

using Euroblock input jacks.)

3 - INPUT 2 of 4 - Balanced Euroblock audio

input jack.

4 - DIRECT INPUT - Balanced override input

jack.

5 - PAGE INPUT - Balanced audio input

jack.

5

14

6

8

7

9 10

13

Communication

14 - COM - RS-232 serial port for system

updates.

Wall Plates

The FreeSpace

®

DXA 2120 is designed to be

compatible with the following Bose user

interfaces:

• Bose Volume Control User Interface

(PC 041966)

• Bose Volume Control with A/B Select

User Interface (PC 041967)

11

12

Outputs

6 - AUX OUTPUT - Line-level signal output

for other amplified equipment.

7 - OUTPUT 1 of 2 - Speaker connections

for two powered outputs of 70V, 100V or 4

ohms.

Control Input

8 - REMOTE - Input jack for Volume control

and Volume control with A/B select wallplate

user interfaces.

Power

9 - BACKUP POWER - For connection to

backup power source.

10 - POWER ON/OFF - AC power switch

11 - FUSE - 120V T6.3A/250V L or 240V

T3.15A/250 L.

12 - AC mains line cord jack - AC line

voltage input.

13 - 120V/220-240V switch - Switches

between 120V and 220-240V AC input

voltage. This switch is not provided on 100V

AC input voltage models.

6

Page 7

System Setup

This section provides instructions on setting

the system for preferred operation. To make

these settings, the system must be connected to power and the AC POWER switch

set to ON.

Rear connection panel

POWER

switch

Front control compartment

AC power cord

jack

• When the system is unlocked, you can

navigate to system setup options.

• Use the arrow and SELECT buttons to

move through the menus and change

settings for the equipment used and the

type of connections made in your instal lation.

• Notice the type of setting in each field:

- Level changes (designated by Lvl) are

made using the GAIN knobs only. These

levels appear in the menu field, but

cannot be changed in the menu.

- Adjustments (designated by Adj) are

made in the menu. To do so:

1. Activate the field by pressing SELECT.

2. Using the up or down arrow, adjust the

value.

3. Press SELECT to confirm the setting

and move on.

Selecting an operation mode

POWER

LED

Note: When the system is unplugged, or if a

power loss occurs, these system settings

are retained in flash memory. However,

continuous system operation during a power

loss requires the use of an optional backup

power source.

System Setup Procedure

When first turned on, pressing any button

next to the LCD activates the display.

Front control panel

Arrow

buttons

SELECT button

• If the system is locked, simultaneously

press the left and right arrow buttons and

hold for five seconds. Lockout Off appears.

Arrow buttons to

the right of the

LCD move forward,

back, up, and down

through menus.

An asterisk (*) marks

the selection made.

Some of the setting menus available for

selections depend on the mode of operation

you choose.

Pressing the right arrow button brings up the

initial selection menu so you can chose the

mode you need:

• Mixer mode: The system can mix up to

four mic/line inputs to each of the two output

channels for use in one or two zones.

• Stereo Select mode: With up to two

stereo sources connected and using both

output channels, the system provides stereo

sound to a single output zone.

• Dual Mono Select mode: With two input

souces connected to each of the two output

channnels, the system provides audio in two

zones.

• Utility - Includes system lockout and an

option to restore all settings to the factory

defaults.

7

Page 8

Specifications

Audio Inputs

Mic Inputs (4 - Balanced): Connectors: 3-pin Euroblock

Input Range: 20 - 20kHz

Input Impedance: 2k ohms (Mic)

25k ohms (Line)

Equivalent Input Noise: -122dB

Line Inputs (4 - Unbalanced): Connectors: Dual RCA (summed to mono)

Input Range: 20 20kHz

Input Impedance: 10k ohms

Maximum Input Level: +10dBu

Page Input (1 - Balanced): Connector: 4-pin Euroblock

Input Range: 20 - 20kHz

Input Impedance: 400 ohms

Equivalent Noise Input: -122dB

Direct Input (1 - Balanced): Connector: 3-pin Euroblock

Input Range: 20 - 20kHz

Input Impedance: 18k ohms

Maximum Input Level: +8dBu

Audio Outputs

Amplifier Outputs (2): Connectors: 5 Terminal Reverse

Euroblock

Minimum Load: 49 ohms @ 70V

98 ohms @ 100V

Output Impedance: 4 ohms

Aux Output (1): Connector: 3-pin Euroblock

Output Impedance: 400 ohms

Maximum Output Level: 2.2 dBV

Performance

Amplifier Power: 120W @ 4 ohms, 100W @ 70/100V

THD (at full rated power): < 0.5%

Crosstalk (below rated power, 1 kHz): < -60 dBV

Signal-to-Noise ratio: 75dB (below rated power, A-weighted)

Frequency Response: 40Hz - 16kHz (+0/-3dB)

Dynamic Range: 83dB

Sampling Rate: 44.1kHz

8

Page 9

Specifications (continued)

A/D and D/A Converters: 24-bit

Communication Port: RS-232 serial port

LED Status Indicators: Power - blue; Signal present - green; Clip - red

Power

Mains Voltage: 100 to 240VAC; 50 to 60Hz

AC Power Consumption: Idle: 39W

Active: 350W

Fuse Type: 120V T6.3A/250 or 240V T3.15A/250 L

DC Backup Power: +24V (+/- 1%)

Connector: 2-terminal barrier strip

Input Voltage Level: +24V

Minimum Input Power: 50W

Maximum Output Power: 150W

Mechanical

Dimensions: 3.5” H x 16.63” W x 13.5” D (8.9 x 42.2 x 34.3 cm)

Weight: Unpackaged: 31.8 lbs

Shipping weight: 39.9 lbs

Environmental

Operating Temperature: 0 - 40 degrees C

Storage Temperature: -40 - 70 degrees C

Humidity: 40 - 90%

9

Page 10

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part.

Refer to the next higher assembly for a replacement part.

10

Page 11

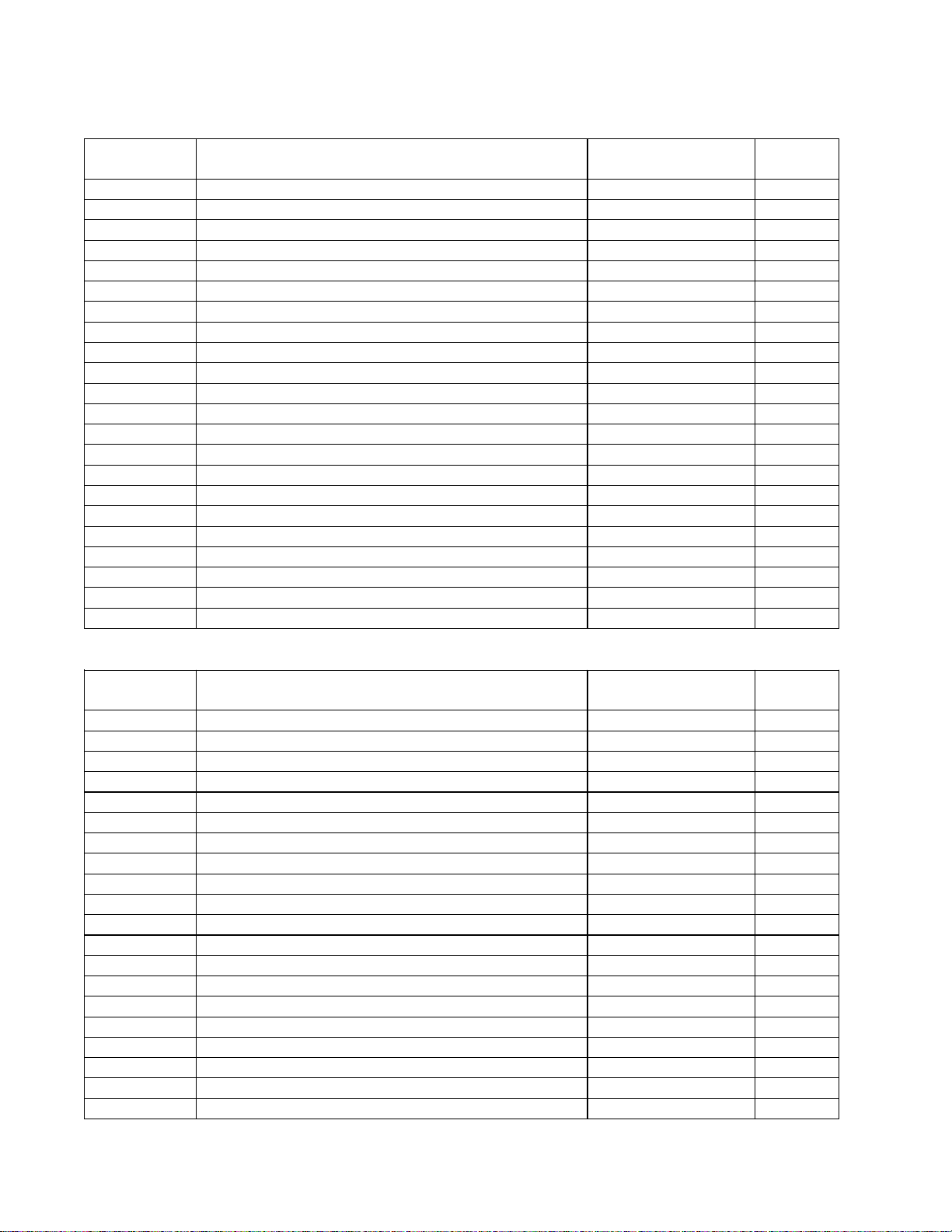

PACKAGING PART LIST

FreeSp ace® DXA 2120 Amplifier/Mixer (see Figure 1)

Item

Number

CARTON KIT, I NCLUDES ITEMS

1, 2 AND 13

1 CARTON 298708 1437-8501+0-3 1

2 PE FOAM - 1493-1761+0 2

3 WHITE BOX - 1480-9401+0 1 4

4 RACK EAR 298706 4135-6291+0 2

5 POLYBAG, .04x5x9 - 1497-1932-0 2 4

6 POLYBAG, .04x5x6 - 1497-2042-0 2 4

7 SCREW, MACHINE, FLAT-CS

(USED WITH RACK EARS)

8 RUBBER FOOT 298707 4157-1121+0 4

9 AC POWER CORD, US/C AN 298165 7012-7340+0 1 3

AC POWER CORD, EURO 298166 7012-6601+0

AC POWER CORD, JAPAN 298167 7012- 553 0+0

AC POWER CORD, UK 298168 7012-660 3+0

AC POWER CORD, AUS 298169 7012- 543 0+0

10 POLYBAG, 10’x14’ - 1497-4122-0 1 4

11 OWNERS MANUAL 298710 4301-7240+0 1

12 PO LY BAG FOR MANUAL - 1497-1062+0 1 4

13 PO LYBAG FOR UNIT - 1497-8012+0 1 4

14 MATING CONN KIT, REAR I/O;

INCLUDES:

– MIC/LINE CONN, 3 POS

– DIRECT/PAG E CONN, 4 POS

– RMT INPUT CON N, 6 POS

– AUX OUTPUT CONN, 3 POS

– SPKR OUTPUT CONN, 5 POS

Description Bose®

Part

Number

298709 SVC-MIXER14+PKG 1

- 2901-4012+3000 6 4

298704

-

-

-

-

-

Vendor Part Number Qty. Note

-

2113-3143+0

2113-3147+0

2113-3149+0

2113-3143+0

2113-3272+0

1

4

2

1

1

2

Figure 1. FreeSpace DXA 2120 Packaging View

11

Page 12

MAIN PART LIST

V

C

FreeSp ace® DXA 2120 Amplifier/Mixer (see Figure 2)

Item

Number

1 TOP COVER, CHA S SIS 1405-8601+0 298 705 1

2 DSP/MCU PCB ASSEMBLY SVC-MIXER14+DSP 298689 1 2

3 BRACKET FOR DSP PCB 4135-6371+0 - 1 4

4 POWER SUPPLY PCB ASSY SVC-MIXER14+PSU 298690 1 2

5 FUSE HOLDER 4153-1100+0 - 1 3,4

6 AC JACK, I EC POWER 2113-3050+0 - 1 3 ,4

7 SHIELD P LA TE, RCA JACK 1454-2 530+ 0 - 1 4

8 I/O PCB ASS EMBLY SVC-M IXE R14+ I/O 298701 1 2

9 RCA IN/A-D BUFF PCB ASSY

( PAR T OF ITEM 8 ABOVE)

10 CHASSIS 1405-8704+0 - 1 4

11 RS-232 PC B ASSEMB LY SV C- M IXE R14+ 232 298702 1 2

12 RACK EAR 4135-6291+0 298706 2

13 SPEAKER PCB ASSEMBLY SVC-MIXER14+SPK 298700 1 2

14 AC VOL T SELECT PCB ASS Y SVC-MIXE R14+ V OLT 298699 1 2

15 FRONT PANEL CONTROL

AND DISPLAY PCB ASSY

16 FRONT PANEL, CHASSIS 1405-9502+0 - 1

17 LIGHT PIPE 4155-1861+0 298517 9

18 FRONT PANEL, FIXED SIDE

WITH END CA P

19 FRONT PANEL, ALUM, RT 1405-8901+0 - 1

20 KNOB, INPUT VOLUME

(INCLUDES ALL 4 KNOBS)

21 DOOR ASSEMBLY SVC-MIXER14+DOOR 298682 1

22 M AGNET , DOOR ASSY 4110-0001+0 2 4

23 END CAP, F RON T PANEL,

LE FT SIDE

24 FRONT PANEL, LEFT 1467-6301+0 - 1

25 SPRING PLATE 4135-6381+0 - 2

26 COVER FOR SPRING 4155-1911+0 - 2

27 KNOB, PUSH 2447-3201+0 - 1

28 AC INP UT XFMR (120/240V) 1806-3927+0 298 698 1 3

28 AC INP UT XFMR (100V ) 1806- 3928+0 301 561 1 3

29 24V BACKUP P/S PCB ASSY SVC-MIXE R14+DC24 298693 1 2

30 HEAT S INK FO R DC- DC P CB 5400- 9761+0 - 1 4

31 BRACKET, FAN GUIDE 4135- 6281+0 - 1 4

32 OUTPUT XFMR, CV, 70/100V 1806-3943+0 298697 2 3

Description

endo r Part Number Bose®

Part

Number

SVC-MIXER14+RCA - 1 2

SVC-MIXER14+CTRL 298685 1 2

SVC-MIXER14+CAP 298683 1

SV

-MIXER14+KNOB 328113001S

1467-6401+0 298681 1

Qty. Note

4

12

Page 13

MAIN PART LIST

V

FreeSp ace® DXA 2120 Amplifier/Mixer (see Figure 2)

Item

Number

33 BRACKET C FO R HE A T SINK 4135-6361+0 - 1 4

34 HEATSINK 5400-9721+0 - 1 4

35 AMPLIFIER PCB ASSEMBLY SVC-MIXER14+AMP 298695 1 2

36 BR ACKET B FOR HEAT SINK 4135-6261+0 - 1 4

37 BR ACKET A FOR HEAT SINK 4135-6251+0 - 1 4

38 FAN, DC, 24V, 2400 RP M 8913-0005+0 298703 1 3

39 AC POWER SWITCH 5200-4942+0 - 1 3,4

- RIBBON CABLE 7012-7870+0 298688 3

- LCD DISPLAY 8902-0005+0 298686 1

- F USE T6.3A 250V 5X20 UL

(120V UNITS)

FUSE T3.15A 250V 5X20MM

UR & SE MKO (220-240V)

Description

endo r Part Number Bose®

Part

Number

5120-0040+0

5120-0079+0

177311-

06300

177311-

03150

Qty. Note

1 3,4

Figure 2. FreeSpace DXA 2120 Amplifier/Mixer Exploded View

13

Page 14

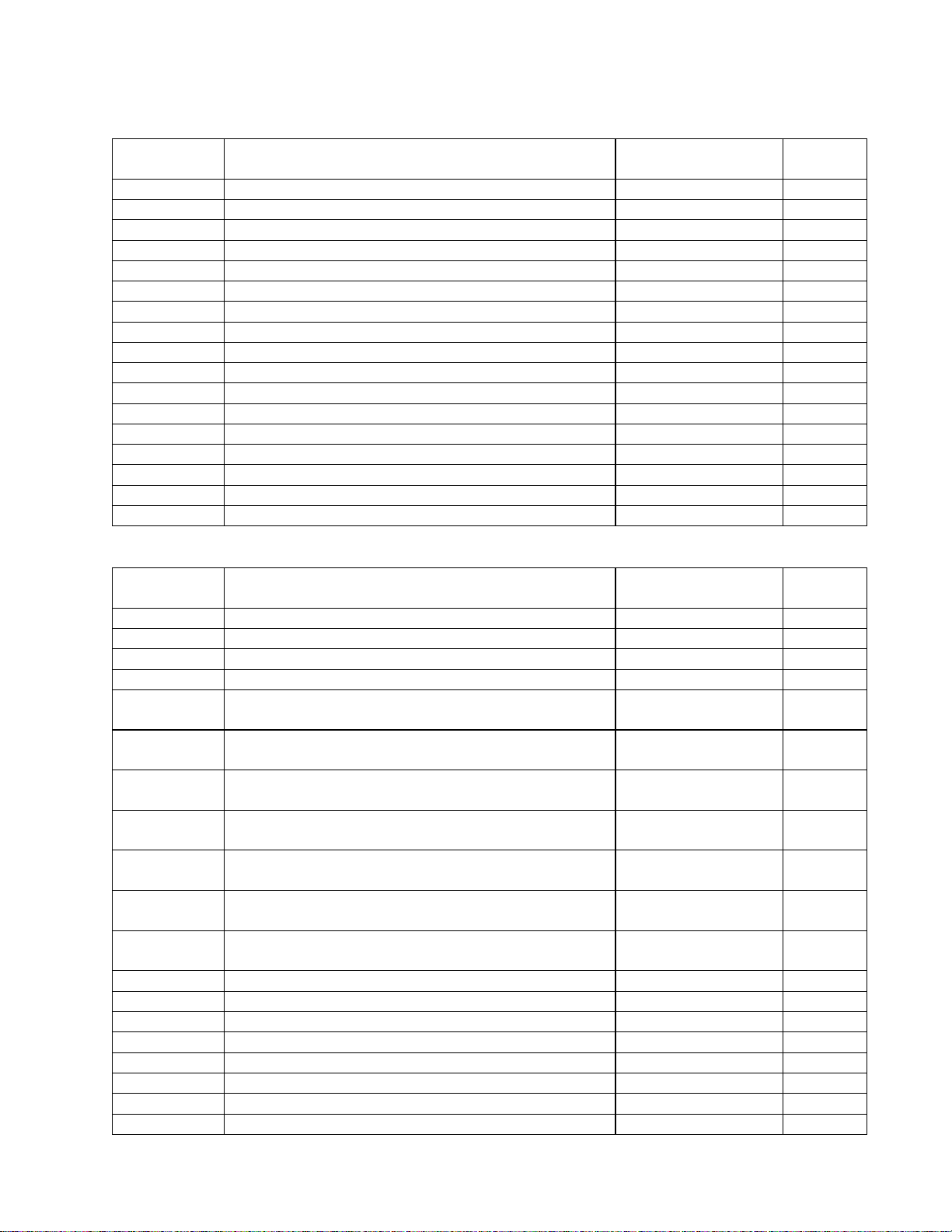

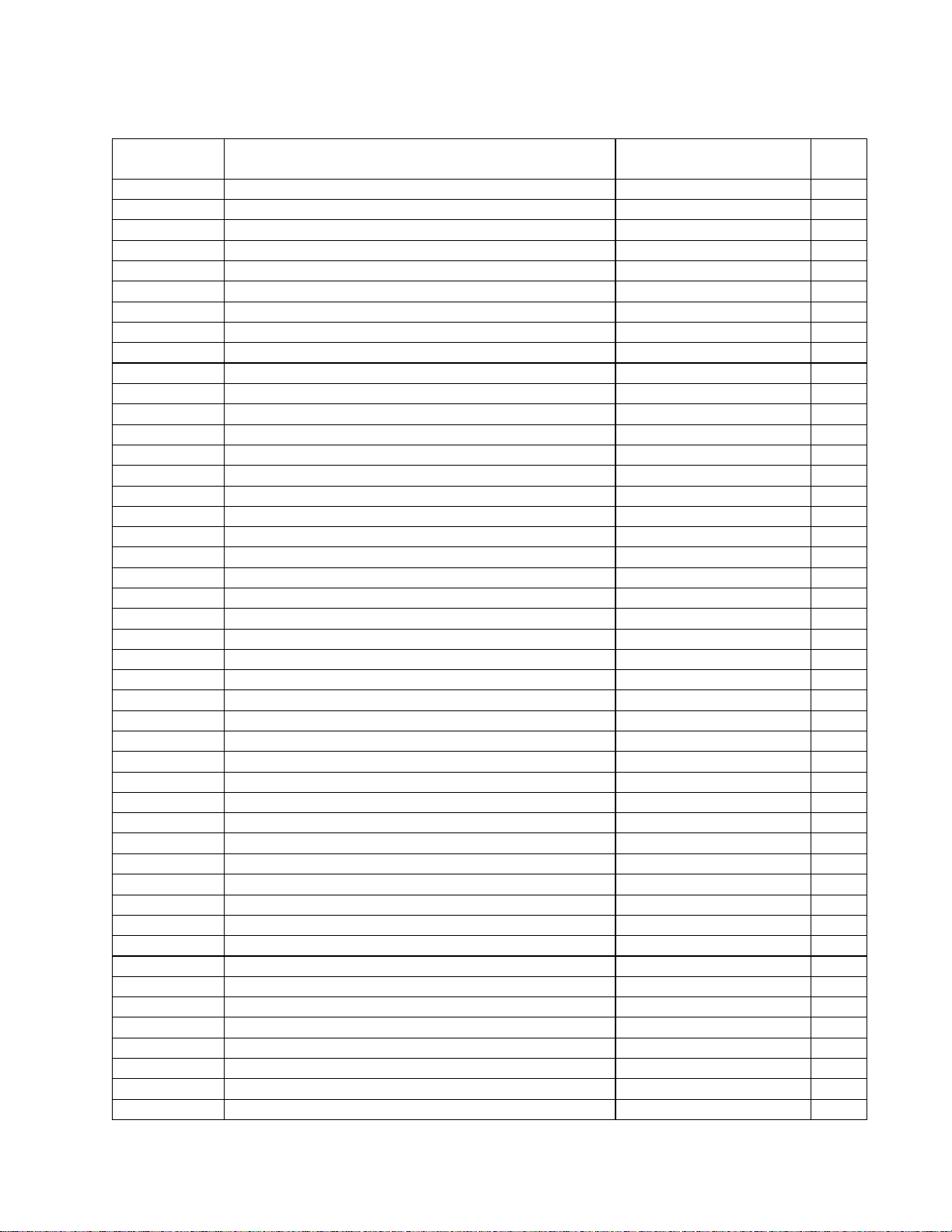

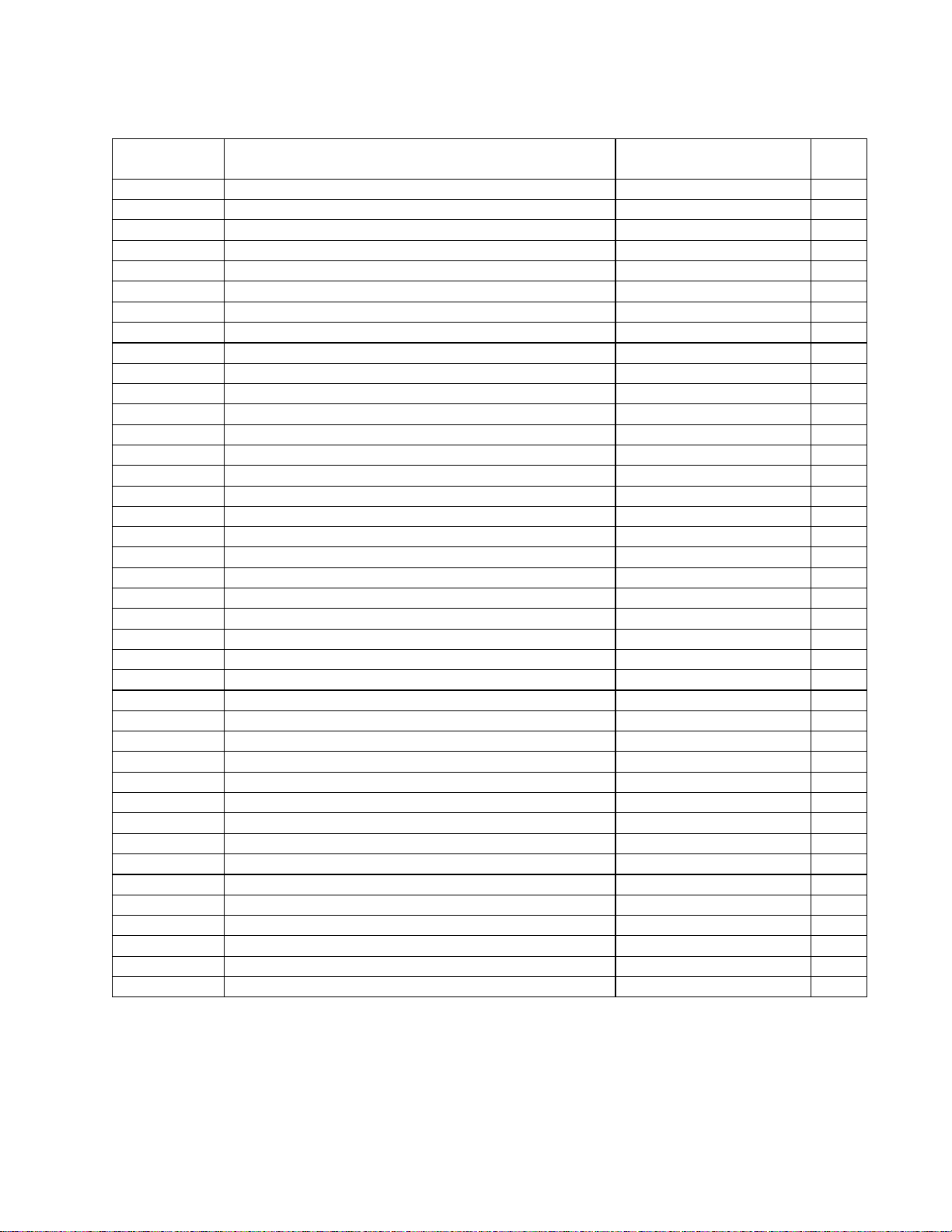

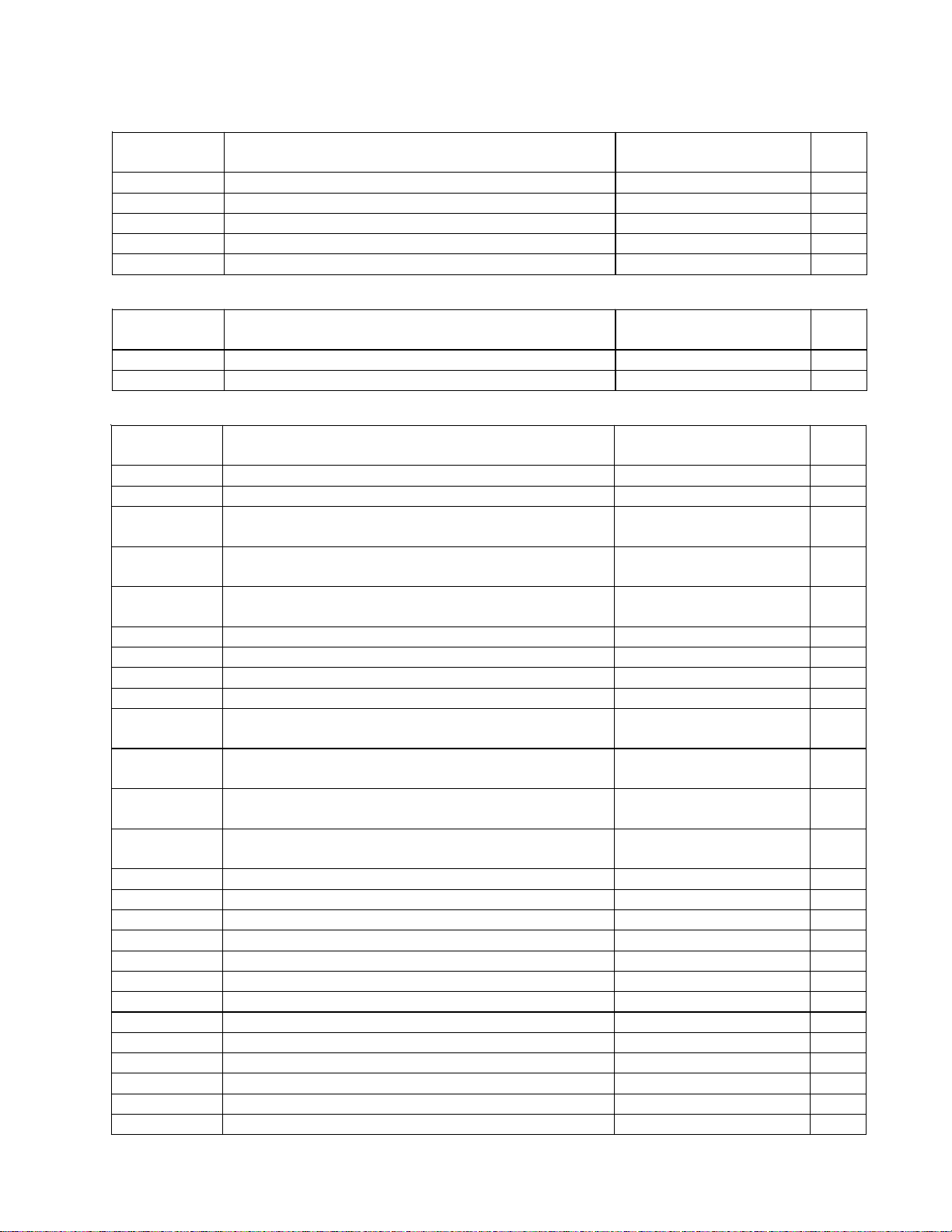

ELECTRICAL PART LIST

Control PCB Assembly

Resistors

Reference

Designator

R401 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R402 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R403 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R404 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R405 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R406 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R407 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R408 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 4

R409 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R410 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R411 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R412 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R413 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R414 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R415 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R416 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

R421 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 4

R422 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 4

R423 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 4

R424 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 4

R425 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 4

R430 300 OHM, RCF, 1/4W, 5%, ATS 4705-301J+C 4

Description Vendor Part

Number

Capacitors

Note

Reference

Designator

C401 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C402 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C403 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C404 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C405 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C406 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C407 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C408 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C409 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C410 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C411 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C421 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C422 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C423 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C424 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C425 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C431 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C432 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 4

C433 10uF, CE, 16V, 20%, RLT, 4X5, SSK, SHOEI 157D-106M+K-GII 4

C434 10uF, CE, 16V, 20%, RLT, 4X5, SSK, SHOEI 157D-106M+K-GII 4

Description Vendor Part

Number

Note

14

Page 15

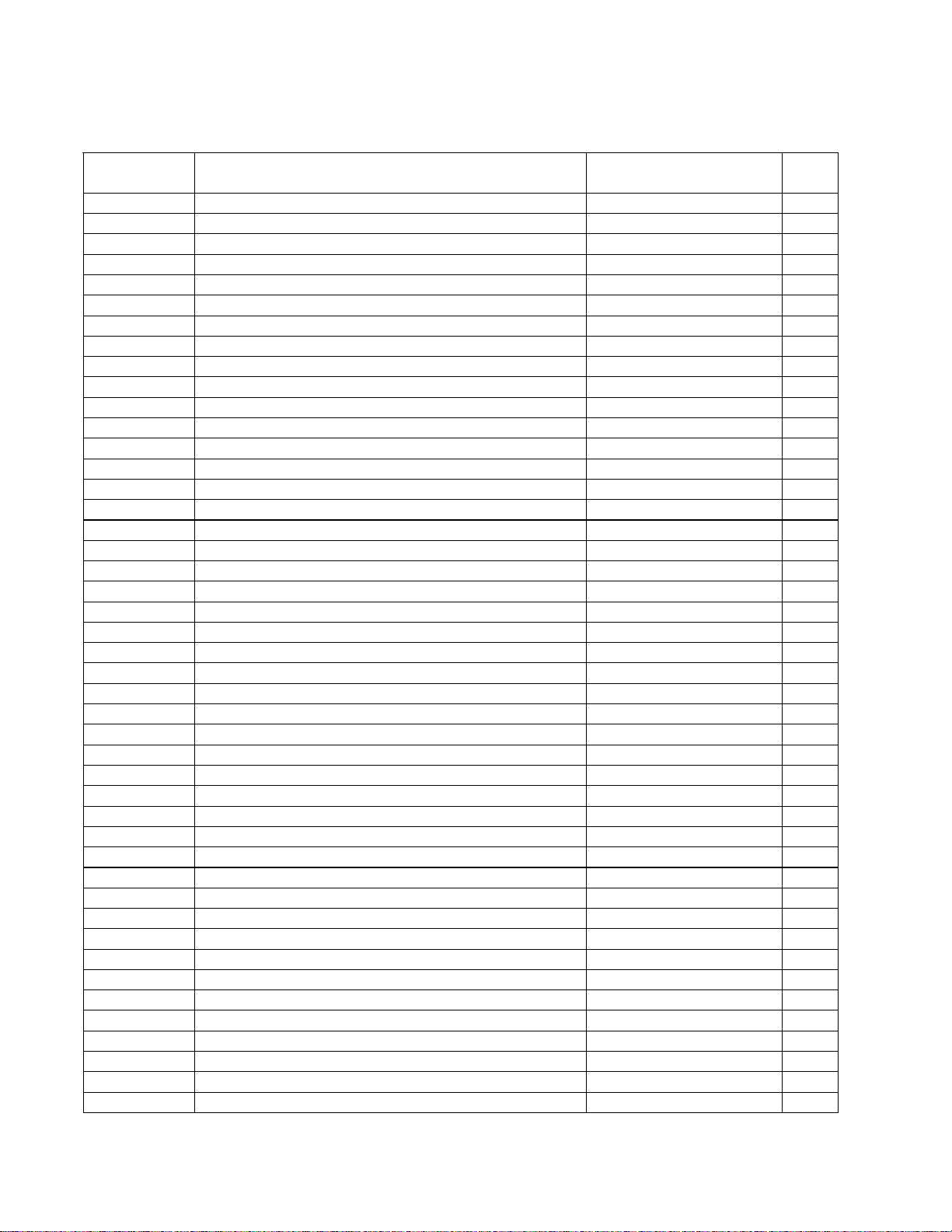

ELECTRICAL PART LIST

Control PCB Assembly

LEDs

Reference

Designator

LED401 LED, SLR342-MG3F, GN (ROHM) 3700-2570+G 4

LED402 LED, SLR342-MG3F, GN (ROHM) 3700-2570+G 4

LED403 LED, SLR342-MG3F, GN (ROHM) 3700-2570+G 4

LED404 LED, SLR342-MG3F, GN (ROHM) 3700-2570+G 4

LED405 LED, CY, D3X8, GN 3700-3616+G 4

LED406 LED, CY, D3X8, GN 3700-3616+G 4

LED407 LED, CY, D3X8, GN 3700-3616+G 4

LED408 LED, CY, D3X8, GN 3700-3616+G 4

LED409 LED, SC, 3.1X3.8, L0.4, RD 3700-1530+R 4

LED410 LED, SC, 3.1X3.8, L0.4, RD 3700-1530+R 4

LED411 LED, SC, 3.1X3.8, L0.4, RD 3700-1530+R 4

LED412 LED, SC, 3.1X3.8, L0.4, RD 3700-1530+R 4

LED413 LED, CY, D3X8, RD 3700-3617+R 4

LED414 LED, CY, D3X8, RD 3700-3617+R 4

LED415 LED, CY, D3X8, RD 3700-3617+R 4

LED416 LED, CY, D3X8, RD 3700-3617+R 4

LED421 LED, CY, D3X8, BL 3700-3615+B 4

Reference

Designator

VR408 VR, 20KBX2, RV09ACF-40-15B, SCREW ADJ 4751-1250+0 4

VR409 VR, 20KBX2, RV09ACF-40-15B, SCREW ADJ 4751-1250+0 4

VR410 VR, 20KBX2, RV09ACF-40-15B, SCREW ADJ 4751-1250+0 4

VR411 VR, 20KBX2, RV09ACF-40-15B, SCREW ADJ 4751-1250+0 4

VR405 VR, ROTARY, 20KB, L20 SHAFT, 40 TEETH,

RV09ACF-40-20K

VR406 VR, ROTARY, 20KB, L20 SHAFT, 40 TEETH,

RV09ACF-40-20K

VR407 VR, ROTARY, 20KB, L20 SHAFT, 40 TEETH,

RV09ACF-40-20K

VR401 VR, ROTARY, 20KB, L25, SHAFT, FLAT,

RV09ACF-40-25F

VR402 VR, ROTARY, 20KB, L25, SHAFT, FLAT,

RV09ACF-40-25F

VR403 VR, ROTARY, 20KB, L25, SHAFT, FLAT,

RV09ACF-40-25F

VR404 VR, ROTARY, 20KB, L25, SHAFT, FLAT,

RV09ACF-40-25F

K401 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

K402 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

K403 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

K404 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

K405 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

CN07A CONN, FFC, 20 PIN, P=1.0MM (HORIZONTAL) 2101- 3051+0 4

CN08A CONN, FFC, 20 PIN, P=1.0MM (HORIZONTAL) 2101- 3051+0 4

CN09A CONN, FFC, 20 PIN, P=1.0MM (HORIZONTAL) 2101- 3051+0 4

Description Vendor Part

Number

Miscellaneous

Description Vendor Part

Number

4751-1260+0 4

4751-1260+0 4

4751-1260+0 4

4751-1270+0 4

4751-1270+0 4

4751-1270+0 4

4751-1270+0 4

Note

Note

15

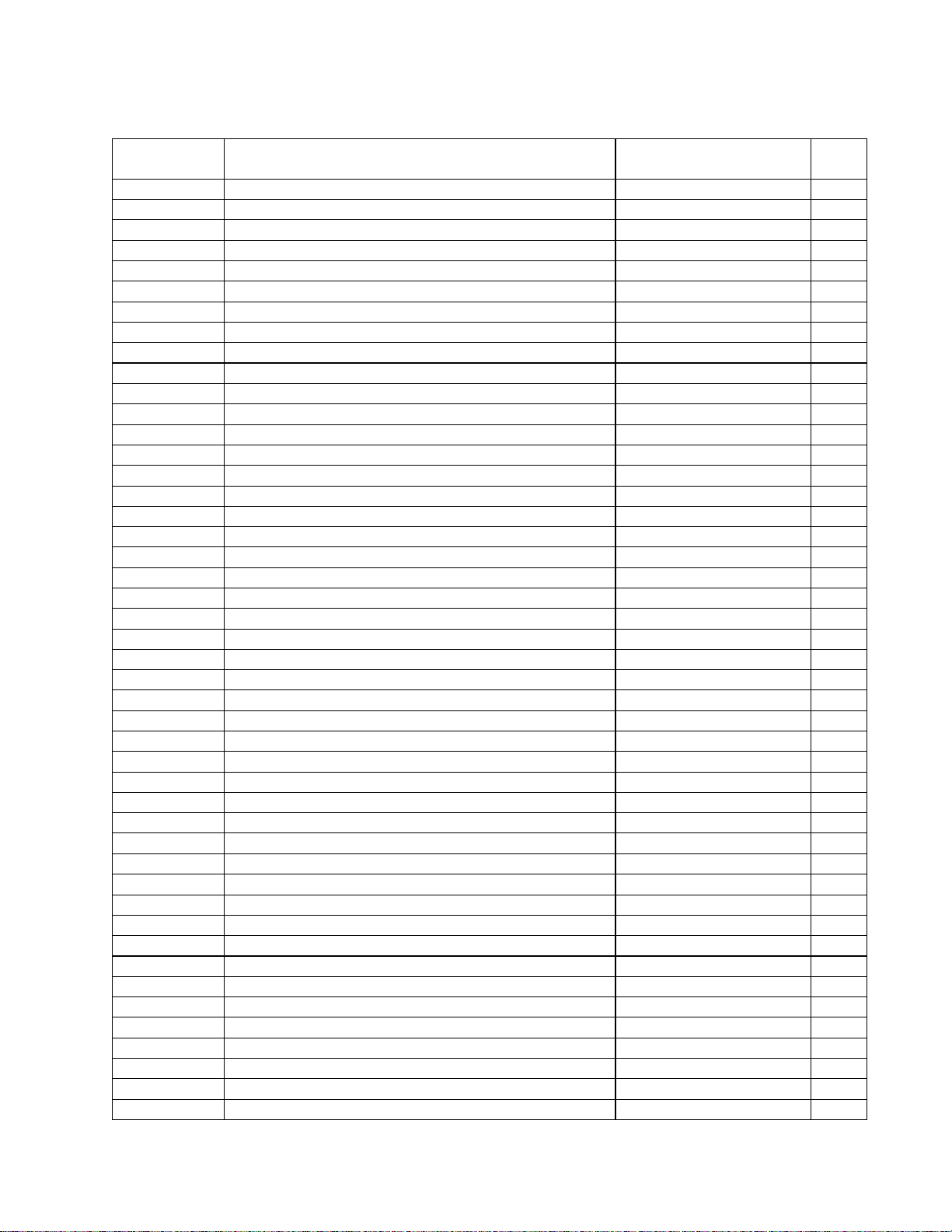

Page 16

ELECTRICAL PART LIST

Control PCB Assembly

Miscellaneous (continued)

Reference

Designator

LCD401 HEADER, 16P, P2. 54, ST, MALE 2101-3141+0 4

\LED401 LED SPACER, H=12.0MM 4171-0081+0 4

\LED402 LED SPACER, H=12.0MM 4171-0081+0 4

\LED403 LED SPACER, H=12.0MM 4171-0081+0 4

\LED404 LED SPACER, H=12.0MM 4171-0081+0 4

\LED405 LED SPACER, H=8.5MM 4157-0331+0 4

\LED406 LED SPACER, H=8.5MM 4157-0331+0 4

\LED407 LED SPACER, H=8.5MM 4157-0331+0 4

\LED408 LED SPACER, H=8.5MM 4157-0331+0 4

\LED409 LED SPACER, H=12.0MM 4171-0081+0 4

\LED410 LED SPACER, H=12.0MM 4171-0081+0 4

\LED411 LED SPACER, H=12.0MM 4171-0081+0 4

\LED412 LED SPACER, H=12.0MM 4171-0081+0 4

\LED413 LED SPACER, H=8.5MM 4157-0331+0 4

\LED414 LED SPACER, H=8.5MM 4157-0331+0 4

\LED415 LED SPACER, H=8.5MM 4157-0331+0 4

\LED416 LED SPACER, H=8.5MM 4157-0331+0 4

\LED421 LED SPACER, H=8.5MM 4157-0331+0 4

Description Vendor Part

Number

Note

16

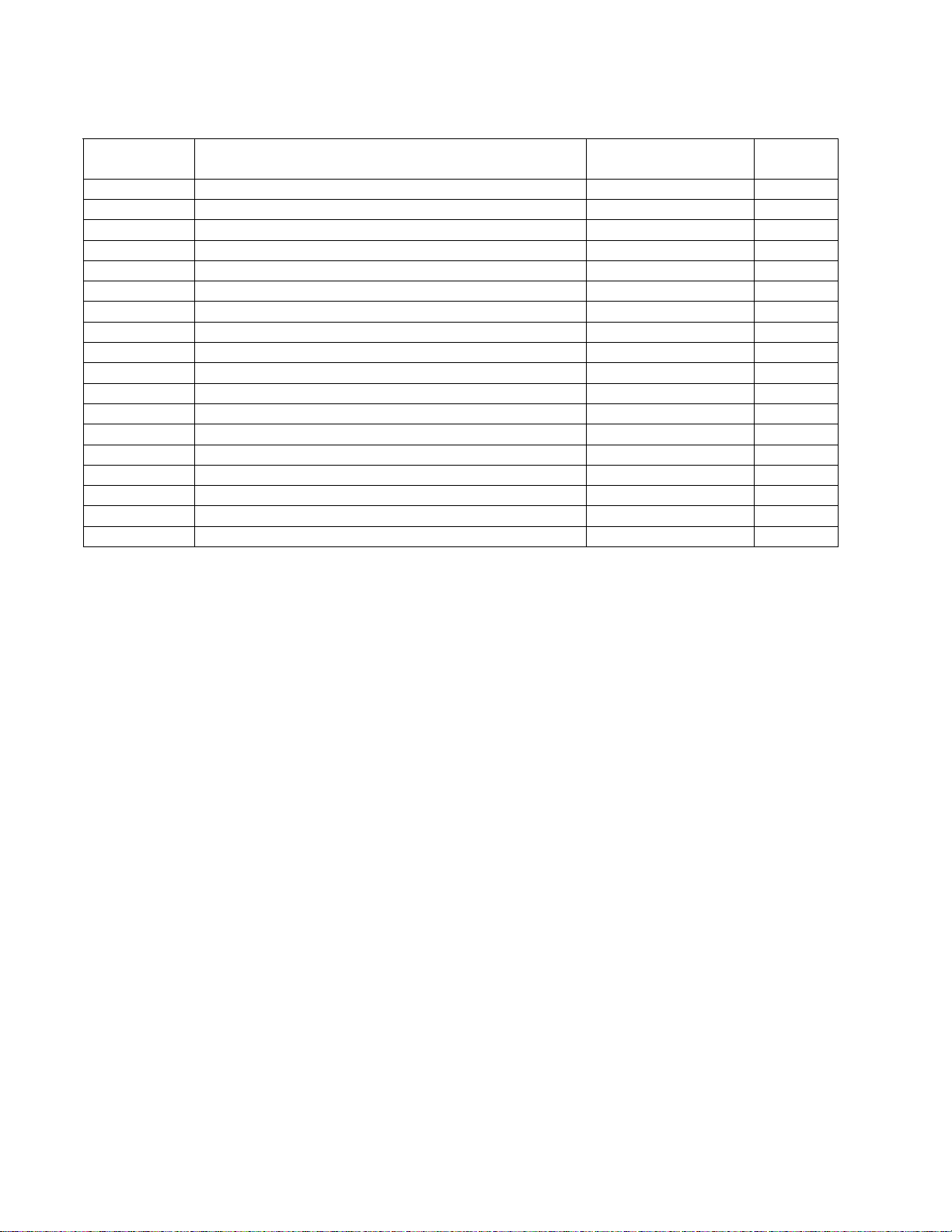

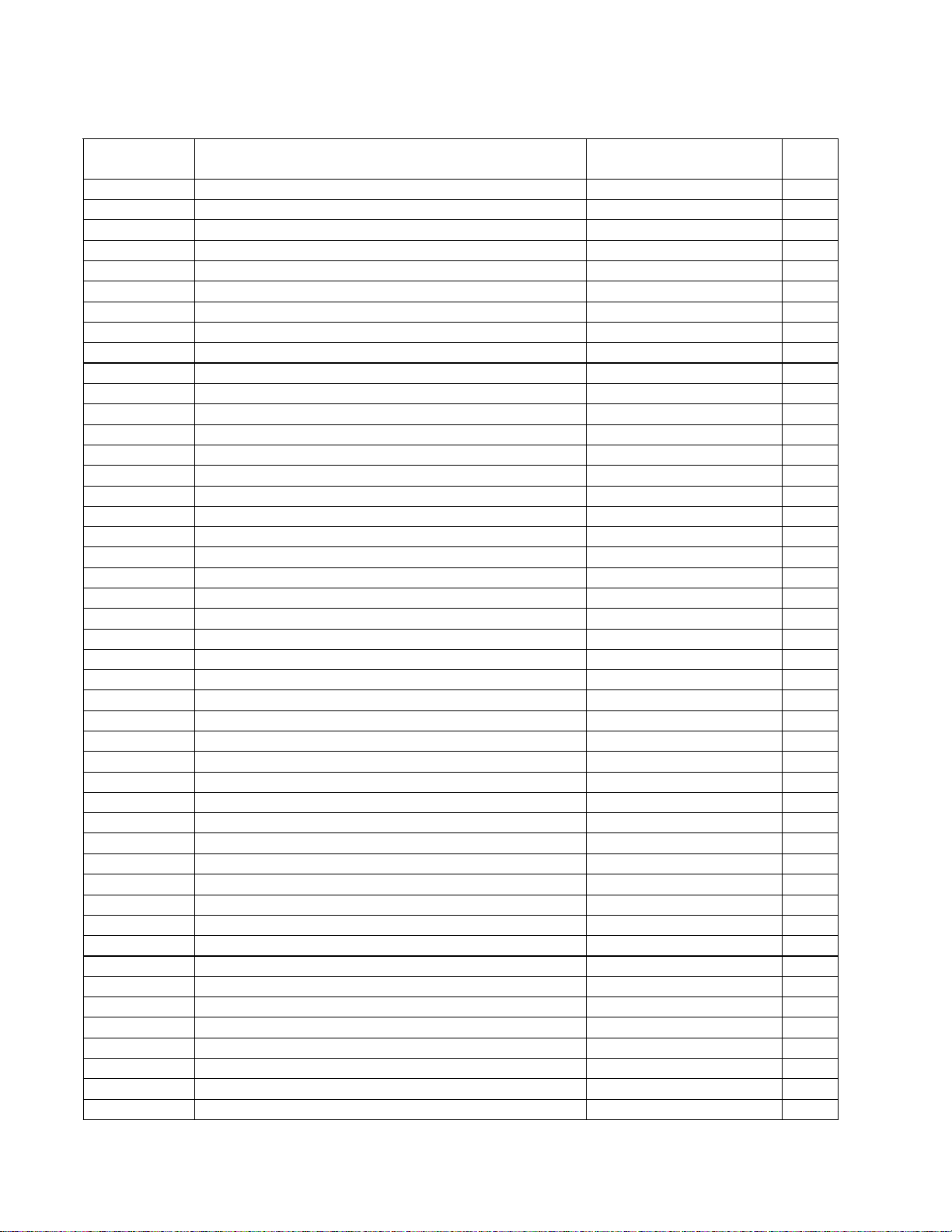

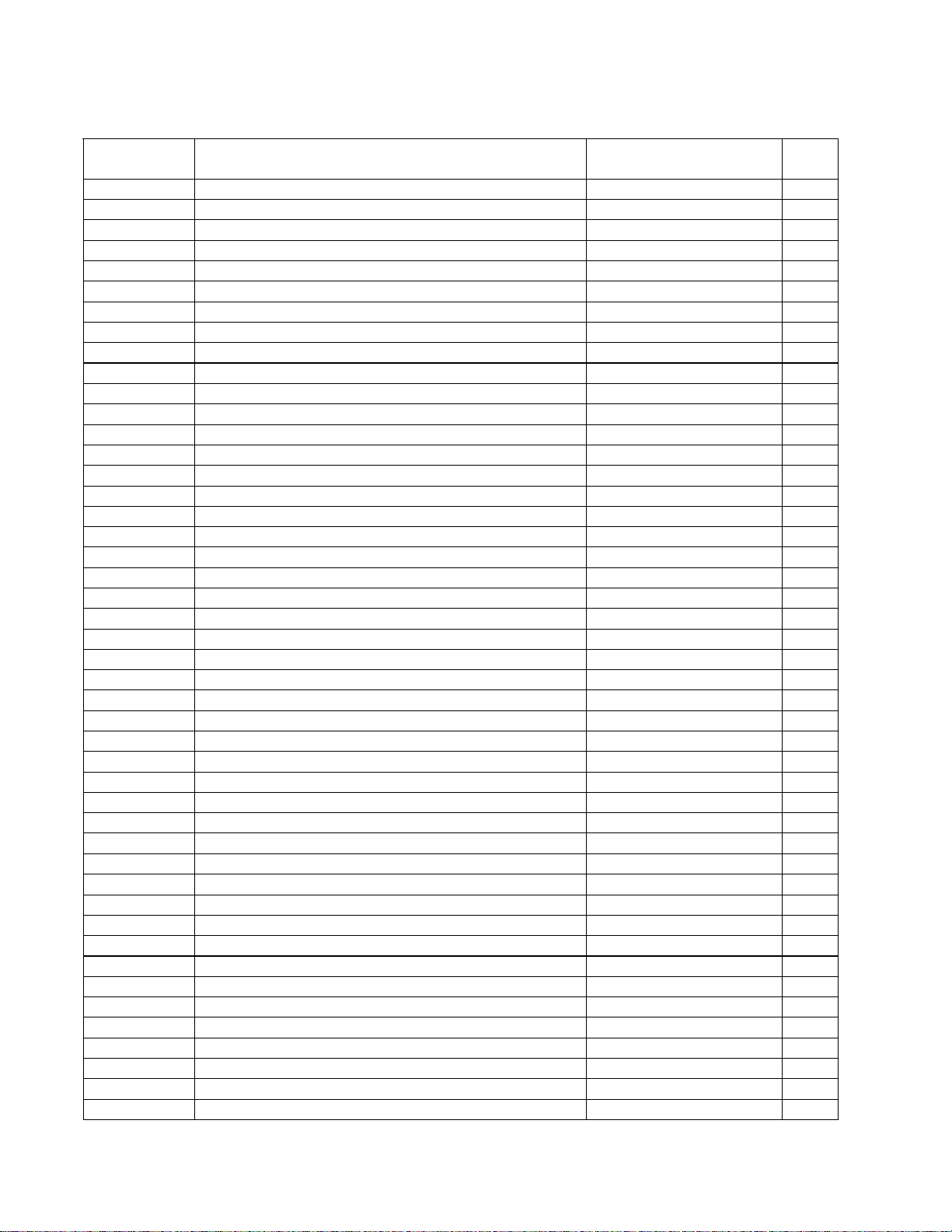

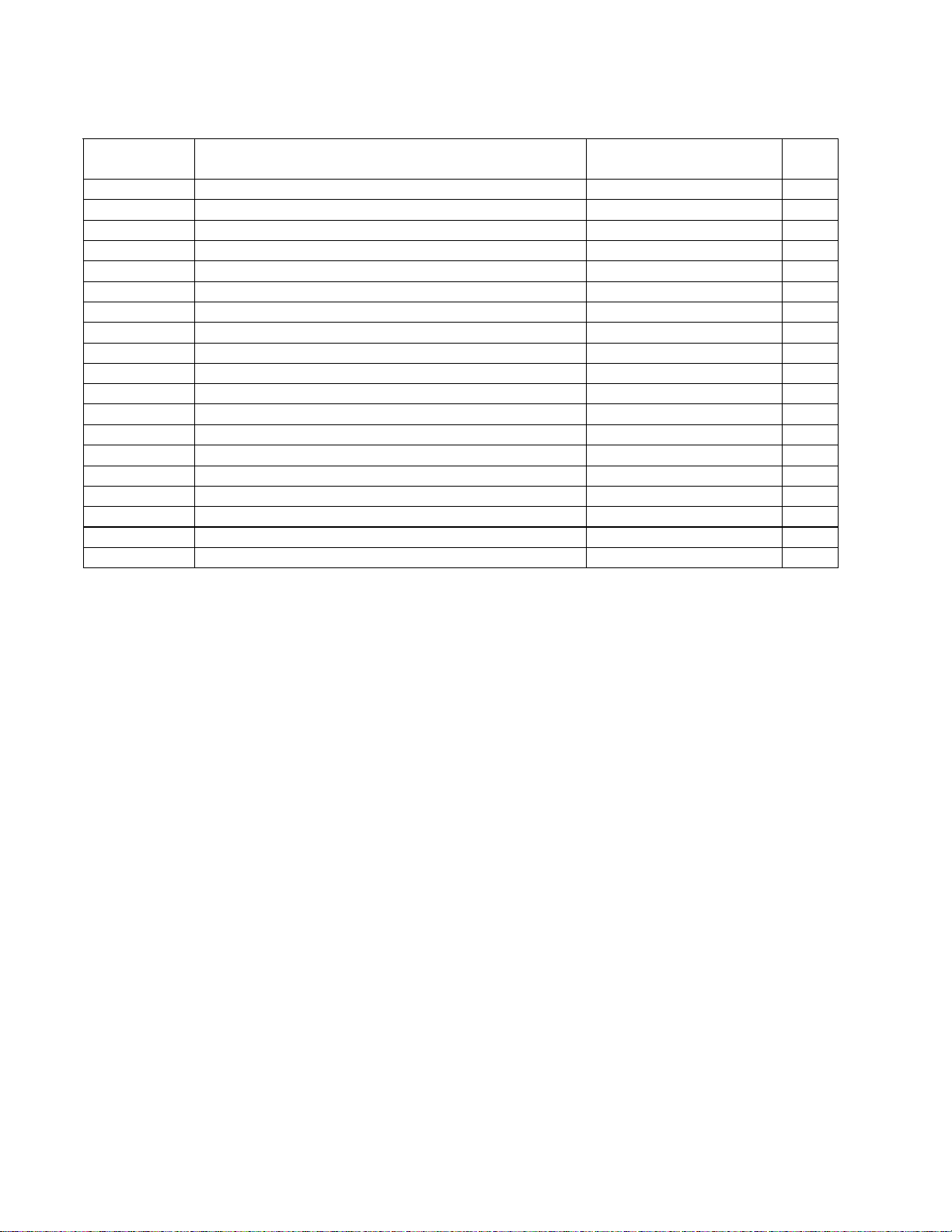

Page 17

ELECTRICAL PART LIST

DC24 PCB Assembly

Resistors

Reference

Designator

R701 100 OHM, RCF, 1/4W, 5%, ATS 4705-101J+C 1 4

R702 10K, RCF, 1/4W, 5%, ATS 4705-103J+C 1 4

R703 15K, RCF, 1/4W, 5%, ATS 4705-153J+C 1 4

R704 4.7K, RCF, 1/4W, 5%, ATS 4705-472J+C 1 4

R705 4.7K, RCF, 1/4W, 5%, ATS 4705-472J+C 1 4

R706 4.7K, RCF, 1/4W, 5%, ATS 4705-472J+C 1 4

R708 15K, RCF, 1/4W, 5%, ATS 4705-153J+C 1 4

R710 150K, RCF, 1/4W, 5%, ATS 4705-154J+C 1 4

R711 24K, RCF, 1/4W, 5%, ATS 4705-243J+C 1 4

R712 3.3K, RCF, 1/4W, 5%, ATS 4705-332J+C 1 4

R713 3.3K, RCF, 1/4W, 5%, ATS 4705-332J+C 1 4

R714 4.7K, RCF, 1/4W, 5%, ATS 4705-472J+C 1 4

R715 4.7K, RCF, 1/4W, 5%, ATS 4705-472J+C 1 4

R716 47 OHM, RCF, 1/4W, 5%, ATS 4705-470J+C 1 4

R717 47 OHM, RCF, 1/4W, 5%, ATS 4705-470J+C 1 4

R718 22 OHM, RCF, 1/2W, 5%, ATS 4707-220J+C 1 4

R719 22 OHM, RCF, 1/2W, 5%, ATS 4707-220J+C 1 4

R720 22 OHM, RCF, 1/2W, 5%, ATS 4707-220J+C 1 4

Reference

Designator

C701 220uF, CE, 6.3V, 20%, RLT, 5X11,

SHOEI

C702 1000pF, CC, 50V, T-10%, 5X5, RLT,

335321025T

C703 47uF, CE, 35V, 20%, RLT, P5.0, 5X11,

YK, RUBYCON

C704 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C705 0.0047uF, CC, 50V, 10%, AT, 3.8x2.5,

MONO

C706 0.0047uF, CC, 50V, 10%, AT, 3.8x2.5,

MONO

C707 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C708 2200uF, CE, 35V, 20%, RL, 16x31.5 157Q-228M+5-5$ 1 4

C709 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C710 1000pF, CC, 50V, T-10%, 5X5, RLT,

335321025T

C711 100uF, CE, 50V, 20%, RLT, 8X12 157F-107M+K-OW 1 4

C712 100uF, CE, 50V, 20%, RLT, 8X12 157F-107M+K-OW 1 4

C713 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C714 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C715 100uF, CE, 50V, 20%, RLT, 8X12 157F-107M+K-OW 1 4

C716 100uF, CE, 50V, 20%, RLT, 8X12 157F-107M+K-OW 1 4

C717 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

C718 0.1uF, CC, 50V, 10%, RLT, 5x5 150F-104K+K-II 1 4

Description Vendor Part

Number

Capacitors

Description Vendor Part

Number

157B-227M+K-IUI 1 4

150F-102K+K-II 1 4

157Q-476M+K-IUY 1 4

150F-472K+2-GD 1 4

150F-472K+2-GD 1 4

150F-102K+K-II 1 4

Qty. Note

Qty. Note

17

Page 18

ELECTRICAL PART LIST

V

DC24 PCB Assembly

Diodes

Reference

Designator

D702 SB580, DO-201AD, RL 480B-5800+5 1 4

D703 SB580, DO-201AD, RL 480B-5800+5 1 4

D704 SB580, DO-201AD, RL 480B-5800+5 1 4

D705 SB580, DO-201AD, RL 480B-5800+5 1 4

D706 SB540-F54, PANJIT 4840-8560+5 1 4

D707 SB540-F54, PANJIT 4840-8560+5 1 4

D708 SB540-F54, PANJIT 4840-8560+5 1 4

D709 SB540-F54, PANJIT 4840-8560+5 1 4

Reference

Designator

Q701 2SC1845, FE, RLT 4860-0190+K 1 4

Q702 2SA992, HFE, 300-600, RLT 4850-992F+K 1 4

Q703 2SA992, HFE, 300-600, RLT 4850-992F+K 1 4

Q704 2SC1845, FE, RLT 4860-0190+K 1 4

Q705 FET , IRFZ44NPBF, TO-220, 60V, 50A 490F-Z440+5 1 4

Q706 FET , IRFZ44NPBF, TO-220, 60V, 50A 490F-Z440+5 1 4

Q707 2SA992, HFE, 300-600, RLT 4850-992F+K 1 4

Description Vendor Part

Number

Transistors

Description Vendor Part

Number

Integrated Circuits

Qty. Note

Qty. Note

Reference

Designator

U701 PWM CONTROLLER, TL494CN 3131-6180+0 1 4

Reference

Designator

T701 TRANSFORMER, DC-DC, 24V, 150W,

Description Vendor Part

Number

Miscellaneous

Description

endor Part

Qty. Note

Qty. Note

Number

1806-3933+0 1 4

24VX2, 15VX2

F701

FUSE, T10A H, 250V

(BOSE

®

PART NUMB E R 325634-0010)

5120-0110+0

1 3

F701A FUSE HOLDER 4132-1011+0 1 4

F701B FUSE HOLDER 4132-1011+0 1 4

B- WIRE-CONN, 1P, #18, UL1015, L=300,

7012-7832+0 1 4

BLK , 250-TERMIN AL

B+ WIRE-CONN, 1P, #18, UL1015, L=250,

7012-7831+0 1 4

R ED, 250-TERMINAL

F ET SCREW, B-TI TE, BIND HEAD, M3X 8 ,

2954-3008+3000 2 4

CR O SS- RECE SS, BZ

FET MICA, T0-220 3100-8000+0 2 4

FET INSULATION BUSHING, 115DEG.C 4154-0841+0 2 4

FET H EAT SI NK , DC, 56X46 5400-9761+0 1 4

18

Page 19

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Resistors

Reference

Designator

R201 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R202 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R203 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R204 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R205 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R206 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R207 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R208 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R209 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R210 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R211 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R229 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R230 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R231 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R232 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R233 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R234 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R235 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R236 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R237 560 OHM, RMG, 1/16W, 5%, 0603/1608 4723-561J+P 4

R238 47K, RMG, 1/16W, 5%, 0603/1608 4723-473J+P 4

R239 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R240 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R241 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R242 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R243 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R244 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R245 560 OHM, RMG, 1/16W, 5%, 0603/1608 4723-561J+P 4

R246 47K, RMG, 1/16W, 5%, 0603/1608 4723-473J+P 4

R247 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R248 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R249 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R250 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R251 560 OHM, RMG, 1/16W, 5%, 0603/1608 4723-561J+P 4

R252 47K, RMG, 1/16W, 5%, 0603/1608 4723-473J+P 4

R253 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R254 1.58K, RMG, 1/16W, 1%, 0603 4723-1581+P 4

R255 12.1K, RMG, 1/10W, 1%, 0805 4720-1212+J 4

R256 560 OHM, RMG, 1/16W, 5%, 0603/1608 4723-561J+P 4

R257 47K, RMG, 1/16W, 5%, 0603/1608 4723-473J+P 4

R258 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R260 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R261 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R262 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R263 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R264 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

Description Vendor Part Number Note

19

Page 20

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Reference

Designator

R265 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R266 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R267 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R268 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R269 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R270 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R271 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R272 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R273 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R274 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R275 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R276 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R277 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R278 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R279 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R280 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R281 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R282 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R283 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R284 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R287 1K, RMG, 1/16W, 5%, 0603/1608 4723-102J+P 4

R289 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R290 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R291 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R292 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R293 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R296 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R297 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R298 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R299 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R300 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R301 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R302 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R303 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R304 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R305 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R306 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R307 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R308 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R310 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R311 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R312 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R313 33RX4, RCFA, 1/16W, 5%, 0603 4703-330J+P-04 4

R314 33 OHM, RMG, 1/16W, 5%, 0603/1608 4723-330J+P 4

R316 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R317 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

Description Vendor Part Number Note

20

Page 21

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Reference

Designator

R318 10 OHM, RMG, 1/16W, 5%, 0603/1608 4723-100J+P 4

R320 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R321 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R322 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R323 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R324 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R325 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R326 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R327 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R328 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R336 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R337 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R338 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R339 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R340 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R341 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R342 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R343 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R344 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R345 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R346 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R347 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R348 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R367 560 OHM, RMG, 1/16W, 5%, 0603/1608 4723-561J+P 4

R369 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R370 2.2K, RMG, 1/16W, 5%, 0603/1608 4723-222J+P 4

R371 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R372 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R373 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R374 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R377 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R378 330 OHM, RMG, 1/16W, 5%, 0603/1608 4723-331J+P 4

R379 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R380 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R381 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R382 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R383 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R384 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R651 10 OHM, RMF, 1W, 5%, ATS, METAL OXIDE 4718-100J+C-X 4

R652 100 OHM, RMG, 1/10W, 5%, 0805 4720-101J+J 4

Description Vendor Part Number Note

21

Page 22

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors

Reference

Designator

C201 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C202 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C203 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C204 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C205 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C206 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C207 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C208 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C209 22uF, CE, 16V, 20%, RLT, 4X7 157D-226M+K-GM 4

C210 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C211 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C212 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C213 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C214 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C215 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C216 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C217 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C218 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C219 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C220 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C221 22uF, CE, 16V, 20%, RLT, 4X7 157D-226M+K-GM 4

C222 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C223 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C224 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C225 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C226 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C227 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C228 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C229 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C230 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C231 47uF, CE, 16V, 20%, RLT, 5X7, ELNA 157D-476M+K-IME 4

C232 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C233 22uF, CE, 16V, 20%, RLT, 4X7 157D-226M+K-GM 4

C234 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C235 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C236 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C237 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C238 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C239 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C240 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C241 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C242 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C243 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C244 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C245 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part Number Note

22

Page 23

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

C246 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C247 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C248 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C249 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C250 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C251 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C252 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C253 2700pF, CC, 50V, 10%, 0603/1608 150F-272K+P-AC 4

C254 2700pF, CC, 50V, 10%, 0603/1608 150F-272K+P-AC 4

C255 470pF, CC, 50V, 10%, 0805, 1.2X2.0 150F-471K+J-BD 4

C256 470pF, CC, 50V, 10%, 0805, 1.2X2.0 150F-471K+J-BD 4

C257 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C258 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C259 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C260 2700pF, CC, 50V, 10%, 0603/1608 150F-272K+P-AC 4

C261 2700pF, CC, 50V, 10%, 0603/1608 150F-272K+P-AC 4

C262 470pF, CC, 50V, 10%, 0805, 1.2X2.0 150F-471K+J-BD 4

C263 470pF, CC, 50V, 10%, 0805, 1.2X2.0 150F-471K+J-BD 4

C264 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C265 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C266 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C267 680pF, CC, 50V, 10%, 0805, 1.2x2.0 150F-681K+J-BD 4

C268 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C269 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C270 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C271 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C272 680pF, CC, 50V, 10%, 0805, 1.2x2.0 150F-681K+J-BD 4

C273 100pF, CC, 50V, 5%, 0603/1608, 1X2 150F-101J+P-AC 4

C274 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C275 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C276 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C281 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C282 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C287 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C288 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C289 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C290 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C291 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C292 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C293 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C294 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C295 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C296 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C297 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C298 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C299 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part Number Note

23

Page 24

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

C300 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C301 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C302 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C303 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C304 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C305 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C306 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C307 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C308 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C309 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C310 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C311 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C312 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C313 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C316 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C317 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C318 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C319 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C320 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C321 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C322 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C323 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C324 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C325 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C326 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C327 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C328 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C329 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C330 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C331 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C332 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C333 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C337 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C338 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C340 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C341 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C342 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C343 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C350 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

C351 330pF, CC, 50V, 10%, 0603/1608, 1X2 150F-331K+P-AC 4

C352 1000pF, CC, 50V, 10%, 0603/1608, 1X2 150F-102K+P-AC 4

C353 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C354 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C355 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C356 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C357 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part Number Note

24

Page 25

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

C358 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C359 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C360 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C361 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C362 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C363 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C364 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C365 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C366 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C367 0.1uF, CE, 50V, 20%, RLT, 4X7 157F-104M+K-GMK 4

C368 0.1uF, CE, 50V, 20%, RLT, 4X7 157F-104M+K-GMK 4

C369 0.1uF, CE, 50V, 20%, RLT, 4X7 157F-104M+K-GMK 4

C370 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C371 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C372 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C373 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C374 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C375 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-LMK 4

C376 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C377 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C378 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C379 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C380 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C381 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C382 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C383 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C384 0.1uF, CE, 50V, 20%, RLT, 4X7 157F-104M+K-GMK 4

C385 2200pF, CC, 50V, 10%, 0603, 0.8x1.6 150F-222K+P-AC 4

C393 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C394 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C395 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C396 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C397 22pF, CTC, 0/60, 5%, 0603, 0.8X1.6 15CH-220J+P-AC 4

C398 22pF, CTC, 0/60, 5%, 0603, 0.8X1.6 15CH-220J+P-AC 4

C653 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C655 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-LMK 4

C656 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-LMK 4

C657 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-LMK 4

C658 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C659 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C660 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

C661 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C662 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

C663 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C664 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

C665 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part Number Note

25

Page 26

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

C666 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

C667 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C668 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C669 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C670 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C671 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-L MK 4

C672 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C673 10uF, CE, 16V, 20%, RLT, 4x7, NICHICON 157D-106M+K-GMK 4

C674 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C675 100uF, CE, 16V, 20%, RLT, 6.5x7, ELNA 157D-107M+K-L MK 4

C676 470uF, CE, 10V, 20%, RLT, 8X11.5, ELNA 157C-477M+K-OVK 4

Description Vendor Part Number Note

Inductors

Reference

Designator

L206 EMI FILTER, FERRITE CHIP, EXCCET103U,

SMD, PANASONIC

L651 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L652 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L653 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L654 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L655 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L656 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L657 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L658 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L659 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L660 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L661 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

L662 FERRITE BEAD, SMD, ACB453215, 125 OHM 1802-0630+0 4

Description Vendor Part Number Note

2705-0020+0 4

Diodes

Reference

Designator

D201 LL4148, SMD 4804-1480+3 4

D202 LL4148, SMD 4804-1480+3 4

D203 LL4148, SMD 4804-1480+3 4

D651 SMD, 1SR154-400TE25 4840-1150+0 4

D652 SMD, 1SR154-400TE25 4840-1150+0 4

D653 SMD, 1SR154-400TE25 4840-1150+0 4

Description Vendor Part Number Note

26

Page 27

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

LEDs

Reference

Designator

LED201 LED, SQ, GREEN, SML-210MT 3700-4808+G 4

LED202 LED, SQ, GREEN, SML-210MT 3700-4808+G 4

LED203 LED, SQ, GREEN, SML-210MT 3700-4808+G 4

LED204 LED, SQ, GREEN, SML-210MT 3700-4808+G 4

LED205 LED, SQ, GREEN, SML-210MT 3700-4808+G 4

Reference

Designator

Q201 FET, J174,_NL, P-CHANNEL, IDSS-20~-100MA 490J-1740+K 4

Q202 2SC1845, FE, RLT 4860-0190+K 4

Reference

Designator

U204 NJM2068M-#ZZZB, DUAL OP-AMP 3130-6890+0 4

U205 NJM2068M-#ZZZB, DUAL OP-AMP 3130-6890+0 4

U207 SN74LV245ADWR, OCTAL B TRANSCEIVER,

SOT163-1/SO

U208 24BIT DAC W/VOL CTRL, 20P, CS4392-KZZ,

TSSOP

U209 24BIT DAC W/VOL CTRL, 20P, CS4392-KZZ,

TSSOP

U210 CS5361-KSZ, 192KHZ A/D, SM, S01C24L 3132-0240+0 4

U211 CS5361-KSZ, 192KHZ A/D, SM, S01C24L 3132-0240+0 4

U212 DSP, TMS320D707RFP/S, PQFP144, TI 3132-3381+0 4

U213 CS5361-KSZ, 192KHZ A/D, SM, S01C24L 3132-0240+0 4

U215 SUPERVISOR, SO8, TPS3307-33DGNR,

TEXAS

U216 4M FLASH, S29AL004D-90TFI02, STANDARD,

TSOP48

U217 SN74LV245ADWR, OCTAL B TRANSCEIVER,

SOT163-1/SO

U218 16-CH DEMULTIPLEXER, 74HC4067M96,

SO24, TEXAS

U219 MAX232D, SO16 3131-9470+0 4

U220 74LCX125M, S01C 3132-0770+0 4

U221 OPTOCOUPLER, 6N137, TTL, DIP8 3132-3291+0 4

U222 MCU, ATMEGA16L, TQFP44 3132-7340+1 4

U225 8-BIT SHIFT REGISTER, 74HC166, SO-16 3132-3281+0 4

U226 8-BIT SHIFT REGISTER, 74HC166, SO-16 3132-3281+0 4

U229 BUS REGISTER, HCF4094, SO16, ST 3132-3191+0 4

U230 BUS REGISTER, HCF4094, SO16, ST 3132-3191+0 4

U231 BUS REGISTER, HCF4094, SO16, ST 3132-3191+0 4

U232 AT24C04N- 10SU-2.7, SOI C-8, EEPROM 3132-1441+1 4

U651 REG, NJM78M05DL1A-#ZZZB 3132-2101+0 4

U652 REG, NCP1117ST33T3G, 3.3V, SOT-223 3132-1481+0 4

U653 LT1587CM, DDPAK, 3-LEAD, M PACKAGE 3132-3023+0 4

Description Vendor Part Number Note

Transistors

Description Vendor Part Number Note

Integrated Circuits

Description Vendor Part Number Note

3132-0680+0 4

3132-0730+0 4

3132-0730+0 4

3132-3016+0 4

3132-3571+0 4

3132-0680+0 4

3132-3021+0 4

27

Page 28

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Miscellaneous

Reference

Designator

C06B WAFER, 4P, P2.0, STRAIGHT 2102-040S+003 4

CN01B 8P, ST, WAFER, P=2.0, COULOMB 2102-080S+003 4

CN02B 8P, ST, WAFER, P=2.0, COULOMB 2102-080S+003 4

CN03B 8P, ST, WAFER, P=2.0, COULOMB 2102-080S+003 4

CN04B 3P, ST, WAFER, P=2.0, COULOMB 2102-030S+003 4

CN05B 3P, ST, WAFER, P=2.0, COULOMB 2102-030S+003 4

CN06B 3P, ST, WAFER, P=2.0, COULOMB 2102-030S+003 4

CN07B CONNECTOR, FFC, 20PIN, P=1.0MM 2101-3041+0 4

CN08B CONNECTOR, FFC, 20PIN, P=1.0MM 2101-3041+0 4

CN09B CONNECTOR, FFC, 20PIN, P=1.0MM 2101-3041+0 4

CN10B 3P, ST, WAFER, P=2.0, COULOMB 2102-030S+003 4

CN11B 6 PIN, WF 2102-060S+003 4

CN12B 11P, ST, WAFER, P=2.0 2102-110S+003 4

CN13B 3P, ST, WAFER, P=2.0, COULOMB 2102-030S+003 4

J201 SHUNT, 2P, P=2.54 2101-0661+0 4

J201 WAFER, 2PIN, P=2.54, ST, 6MM 2101-1494+0 4

K201 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

X201 CRYSTAL OSC, 11.2896M, 3.3V, SMD 2300-3282+0 4

X203 CRYSTAL OSC, 8MHZ, HC-49/U-S 2300-2990+0 4

Description Vendor Part Number Note

28

Page 29

ELECTRICAL PART LIST

Input/Output PCB Assembly

Resistors

Reference

Designator

R101 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R102 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R103 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R104 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R105 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R106 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R107 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R108 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R109 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R110 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R111 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R112 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R113 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R114 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R115 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R116 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R117 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R118 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R119 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R120 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R121 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R122 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R123 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R124 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R125 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R126 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R127 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R128 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R129 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R130 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R131 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R132 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R133 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R134 1K, RMG, 1/16W, 1%, 0603/1608 4723-102A+P 4

R135 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R136 13K, RMG, 1/16W, 1%, 0603 4723-133A+P-R 4

R137 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R138 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R139 31.6K, RMG, 1/10W, 1%, 0805 4720-3162+J 4

R140 68K, RMG, 1/16W, 1%, 0603/1608 4723-683A+P 4

R141 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R142 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R143 1M, RMG, 1/16W, 1%, 0603 4723-105A+P 4

R144 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R145 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R146 200K, RMG, 1/16W, 5%, 0603/1608 4723-204J+P 4

Description Vendor Part

Number

Note

29

Page 30

ELECTRICAL PART LIST

Input/Output PCB Assembly

Resistors (continued)

Reference

Designator

R151 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R152 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R153 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R154 2K, RMG, 1/16W, 1%, 0603/1608 4723-202A+P 4

R155 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R156 20K, RMG, 1/16W, 1%, 0603/1608 4723-203A+P 4

R160 100K, RMG, 1/16W, 1%, 0603 4723-104A+P 4

R161 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R162 10K, RMG, 1/16W, 1%, 0603/1608 4723-103A+P 4

R163 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R164 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R165 200 OHM, RMG, 1/16W, 5%, 0603/1608 4723-201J+P 4

R166 200 OHM, RMG, 1/16W, 5%, 0603/1608 4723-201J+P 4

R167 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R168 100K, RMG, 1/16W, 5%, 0603/1608 4723-104J+P 4

R171 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R172 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R173 0 OHM, RMG, 1/16W, 5%, 0603 4723-000J+P 4

R181 22 OHM, RCF, 1/2W, 5%, ATS 4707-220J+C 4

R182 22 OHM, RCF, 1/2W, 5%, ATS 4707-220J+C 4

R183 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R184 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R185 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R186 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1101 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1102 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1103 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1104 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1105 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1106 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1107 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1108 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1109 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1110 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1111 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1112 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1113 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1114 47 OHM, RMG, 1/16W, 5%, 0603/1608 4723-470J+P 4

R1115 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R1116 10K, RMG, 1/16W, 5%, 0603/1608 4723-103J+P 4

R1121 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1122 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1131 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

R1132 1M, RMG, 1/16W, 5%, 0603/1608 4723-105J+P 4

Description Vendor Part

Number

Note

30

Page 31

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors

Reference

Designator

C101 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C102 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C103 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C104 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C105 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C106 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C107 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C109 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C110 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C111 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C112 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C113 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C114 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C115 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C116 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C117 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C118 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C119 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C120 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C121 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C122 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C123 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C124 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C125 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C126 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C129 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C130 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C131 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C132 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C133 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C134 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C135 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C136 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C137 EMI FILTER, NFM21CC102R1H3D 2705-0040+0 4

C138 EMI FILTER, NFM21CC102R1H3D 2705-0040+0 4

C139 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C140 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C141 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C142 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C143 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C144 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C145 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C146 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C147 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C148 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C149 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part

Number

Note

31

Page 32

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors (continued)

Reference

Designator

C150 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C151 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C152 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C153 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C154 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C155 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C156 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C157 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C158 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C159 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C160 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C161 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C162 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C163 47pF, CC, 50V, 5%, 0603, 1x2 150F-470J+P-AC 4

C164 47pF, CC, 50V, 5%, 0603, 1x2 150F-470J+P-AC 4

C165 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C166 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C167 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C168 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C169 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C170 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C171 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C172 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C173 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C174 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C175 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C176 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C177 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C178 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C179 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C181 100uF, CE, 16V, 20%, SM, 6.6X5.5, NICH 157D- 1 07M+3-MJC 4

C182 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C183 100uF, CE, 16V, 20%, SM, 6.6X5.5, NICH 157D- 1 07M+3-MJC 4

C184 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C185 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C186 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C187 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C188 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C189 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C190 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C191 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C192 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C193 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C194 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C195 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C196 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

Description Vendor Part

Number

Note

32

Page 33

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors (continued)

Reference

Designator

C197 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C198 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C199 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C200 0.1uF, CC, 50V, 10%, 0603/1608, 1x2 150F-104K+P-AC 4

C1101 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1102 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1103 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1104 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1105 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1106 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1107 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1108 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1109 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1110 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1111 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1112 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1113 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1114 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1115 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1116 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1119 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1120 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1121 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1122 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1123 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1124 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1125 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1126 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1127 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1129 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1130 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1131 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1132 1000pF, CC, 50V, 5%, 0603, X7R 150F-102J+P-AC 4

C1133 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1134 10uF, CE, 16V, 20%, SMD, 4X5.4 157D-106M+3-GJ 4

C1139 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1140 10pF, CC, 50V, 5%, 0603 150F-100J+P-AC 4

C1141 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1142 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1143 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1144 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1145 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1146 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1147 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1148 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1149 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

Description Vendor Part

Number

Note

33

Page 34

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors (continued)

Reference

Designator

C1150 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1151 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1152 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1153 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1154 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1155 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1156 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1157 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1158 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1159 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1160 47pF +/-20%, EMI FIL, DSN6NC51H470Q55B 8910-0487+0 4

C1161 1000pF, CC, 50V, T-10%, 5X5, RLT 150F-102K+K-I I 4

C1162 1000pF, CC, 50V, T-10%, 5X5, RLT 150F-102K+K-I I 4