Page 1

CONTENTS

Safety Information.............................................................................................................................2

Warranty .............................................................................................................................................2

Product Description ..........................................................................................................................3

Specifications .................................................................................................................................... 4

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................5

Part List Notes ................................................................................................................................... 5

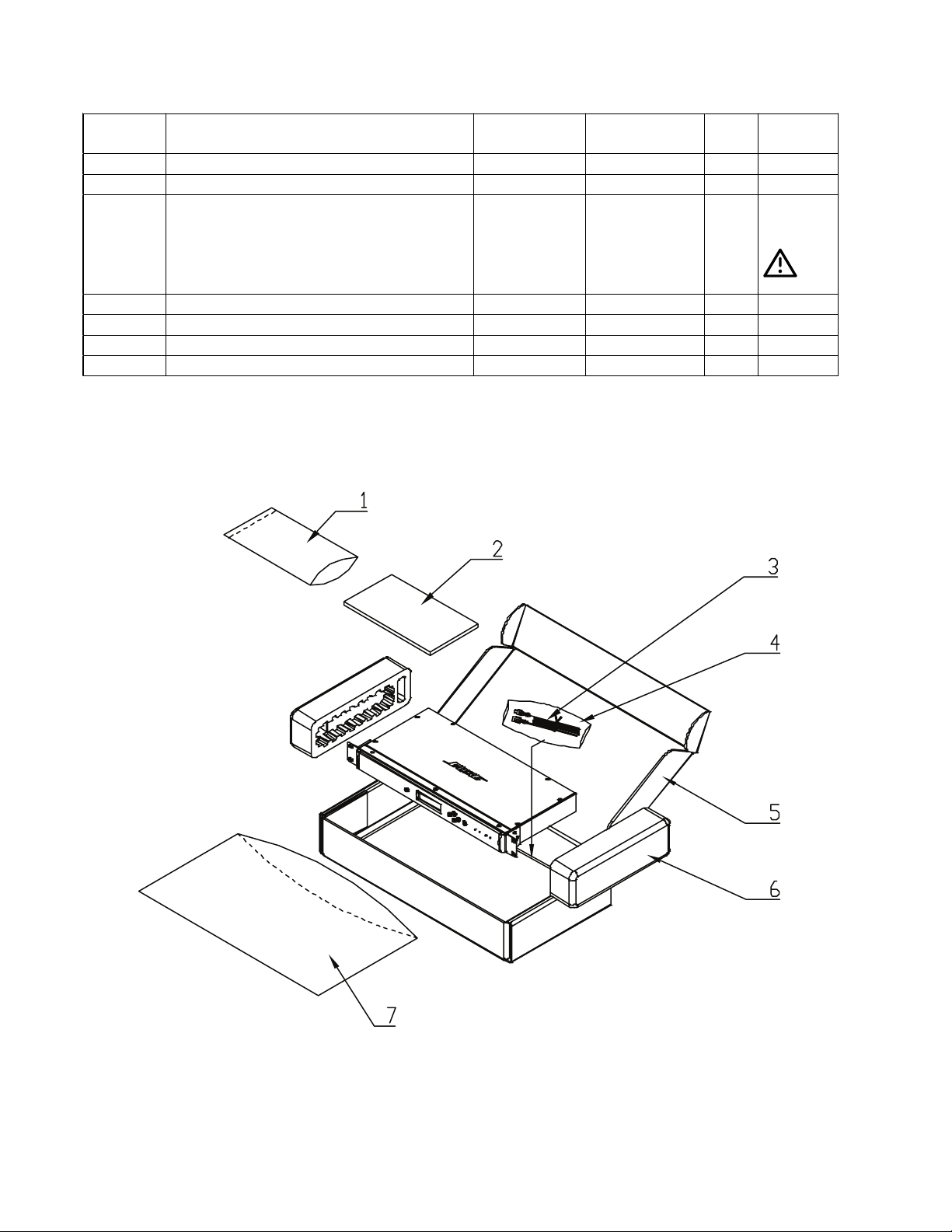

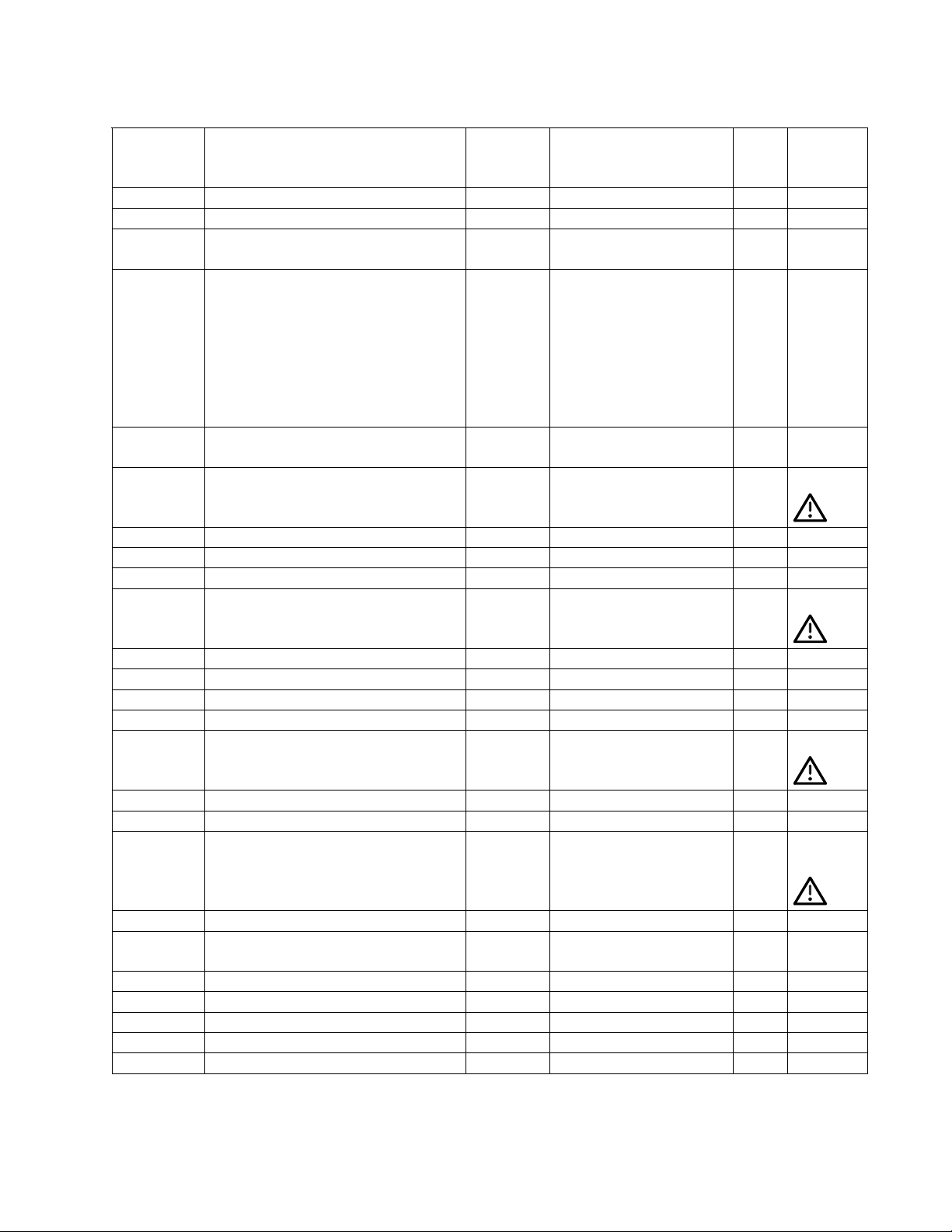

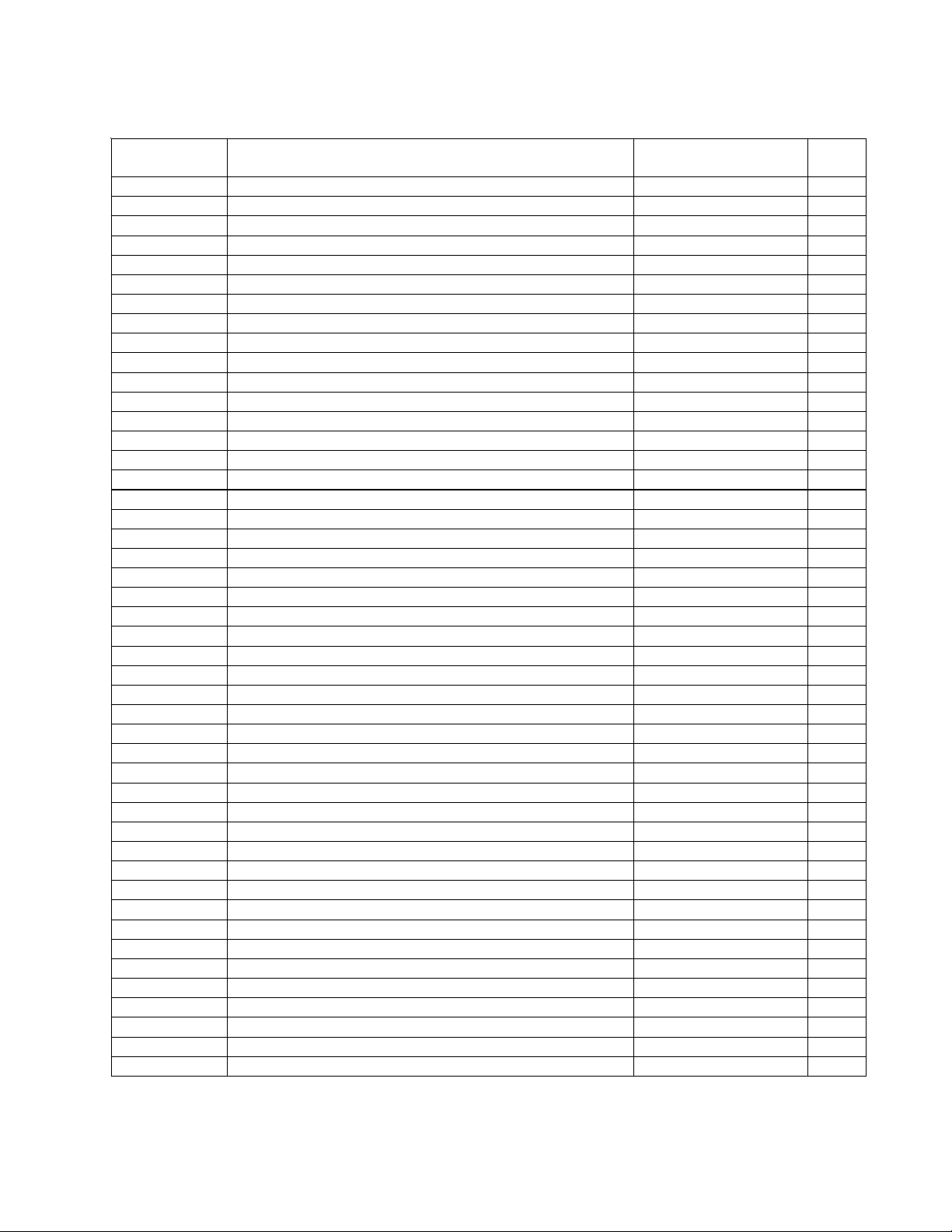

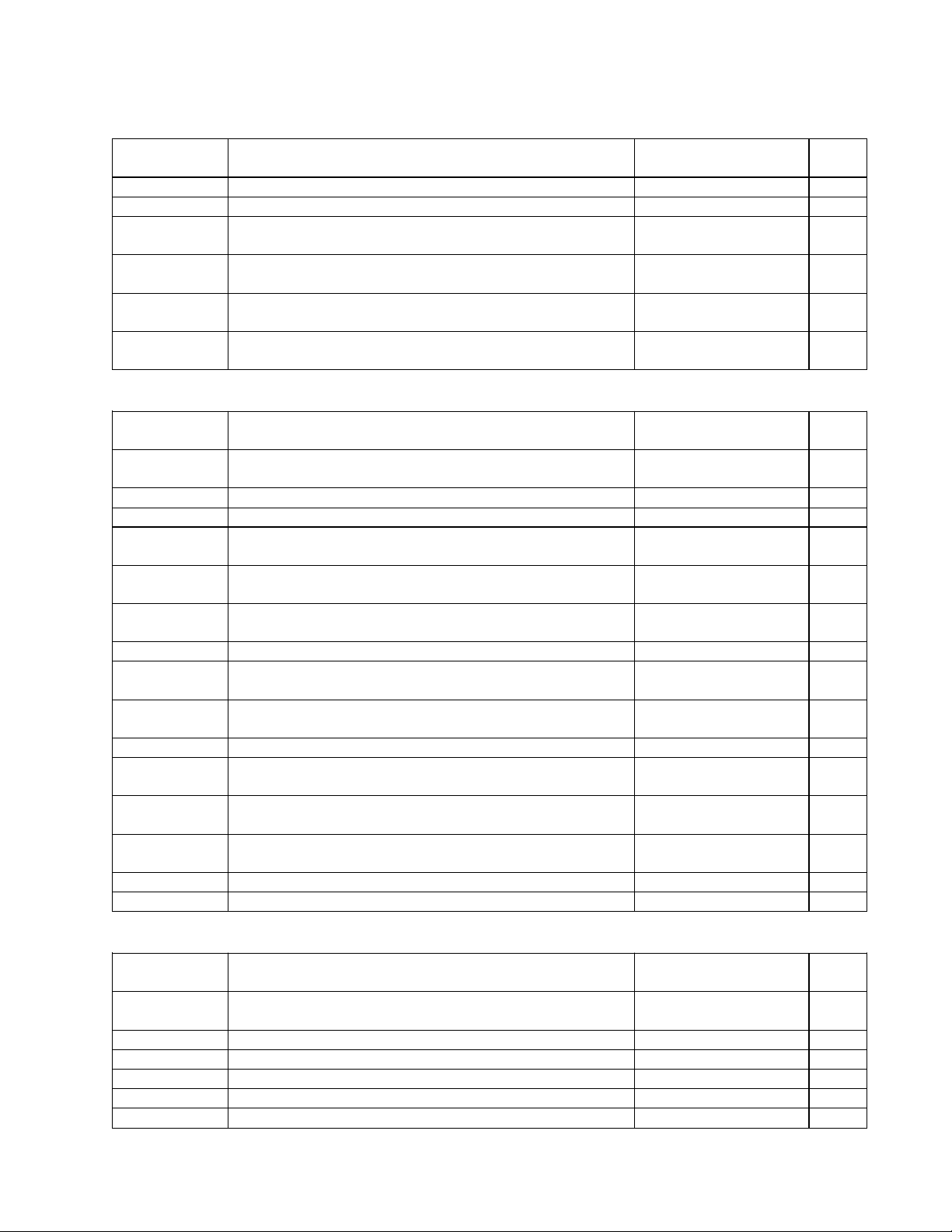

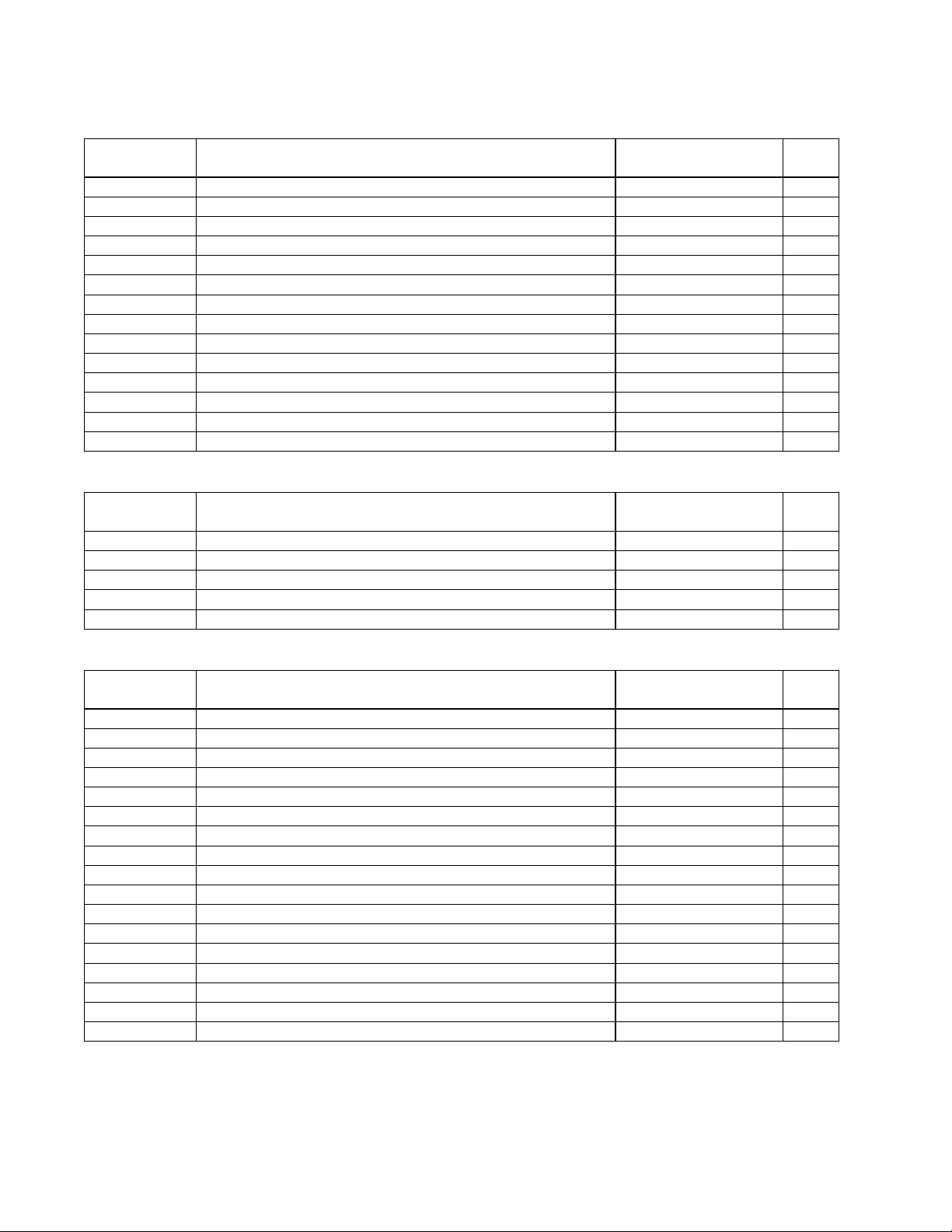

Packaging Part List, Panaray® Digital Controller II (see Figure 1) ............................................... 6

Figure 1. Panaray Digital Controller II Packaging View .................................................................... 6

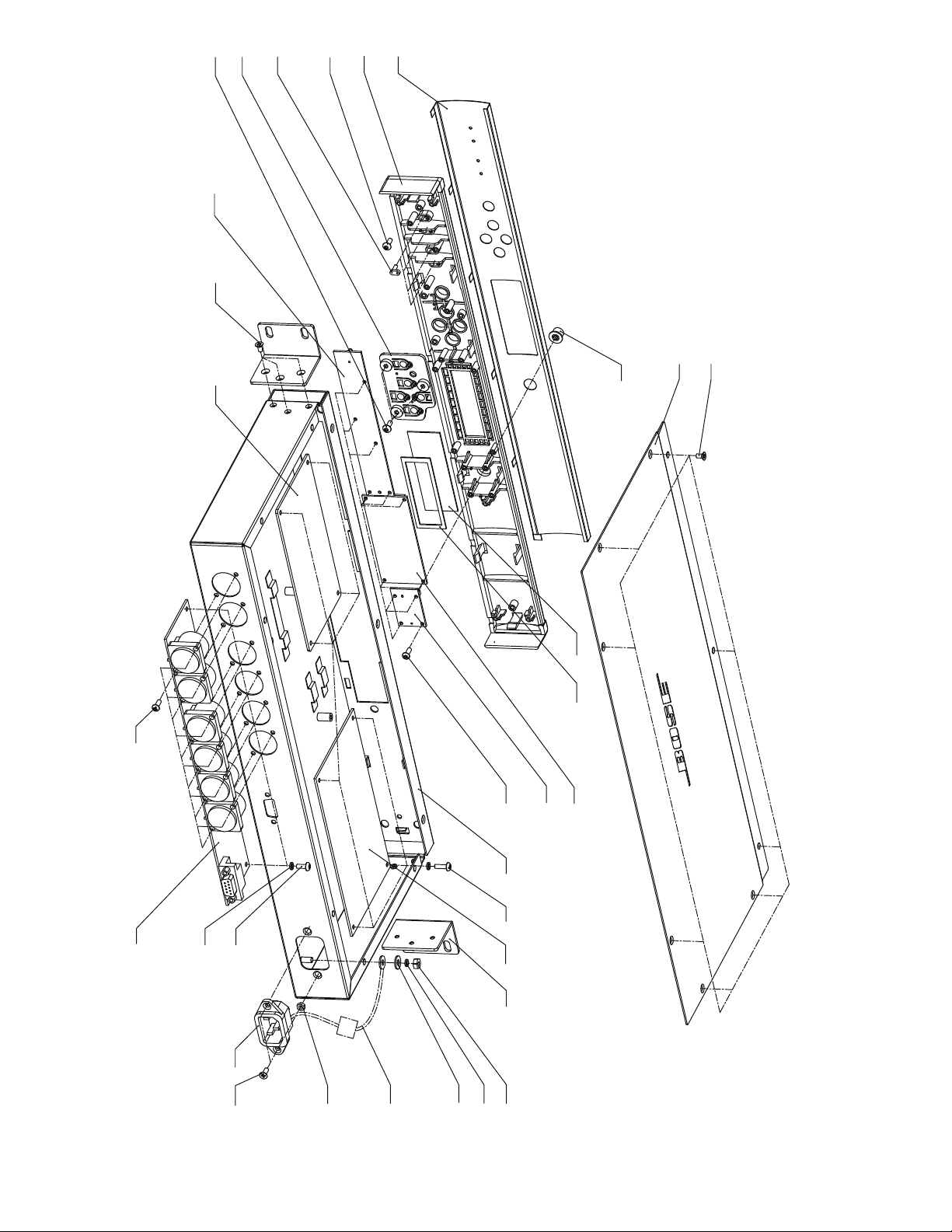

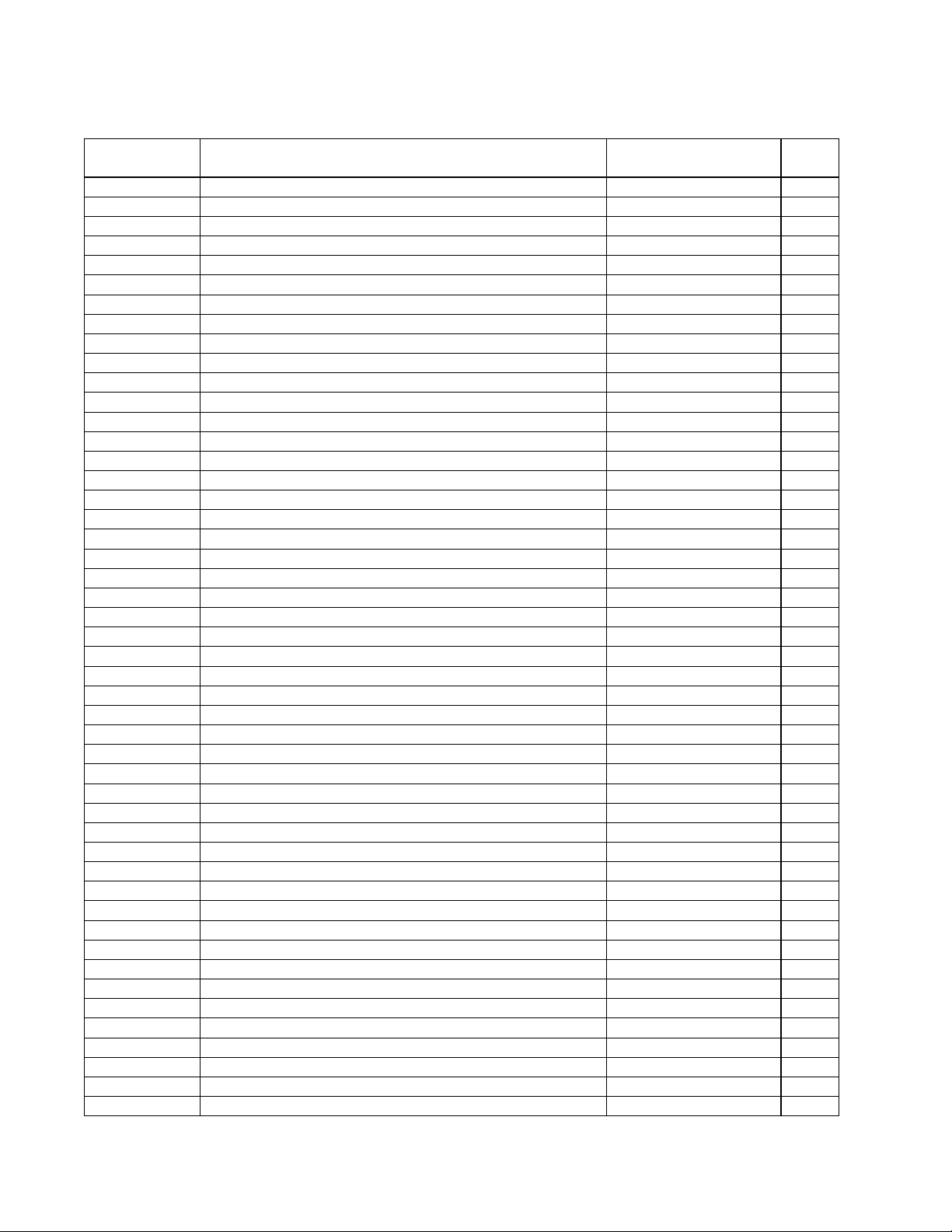

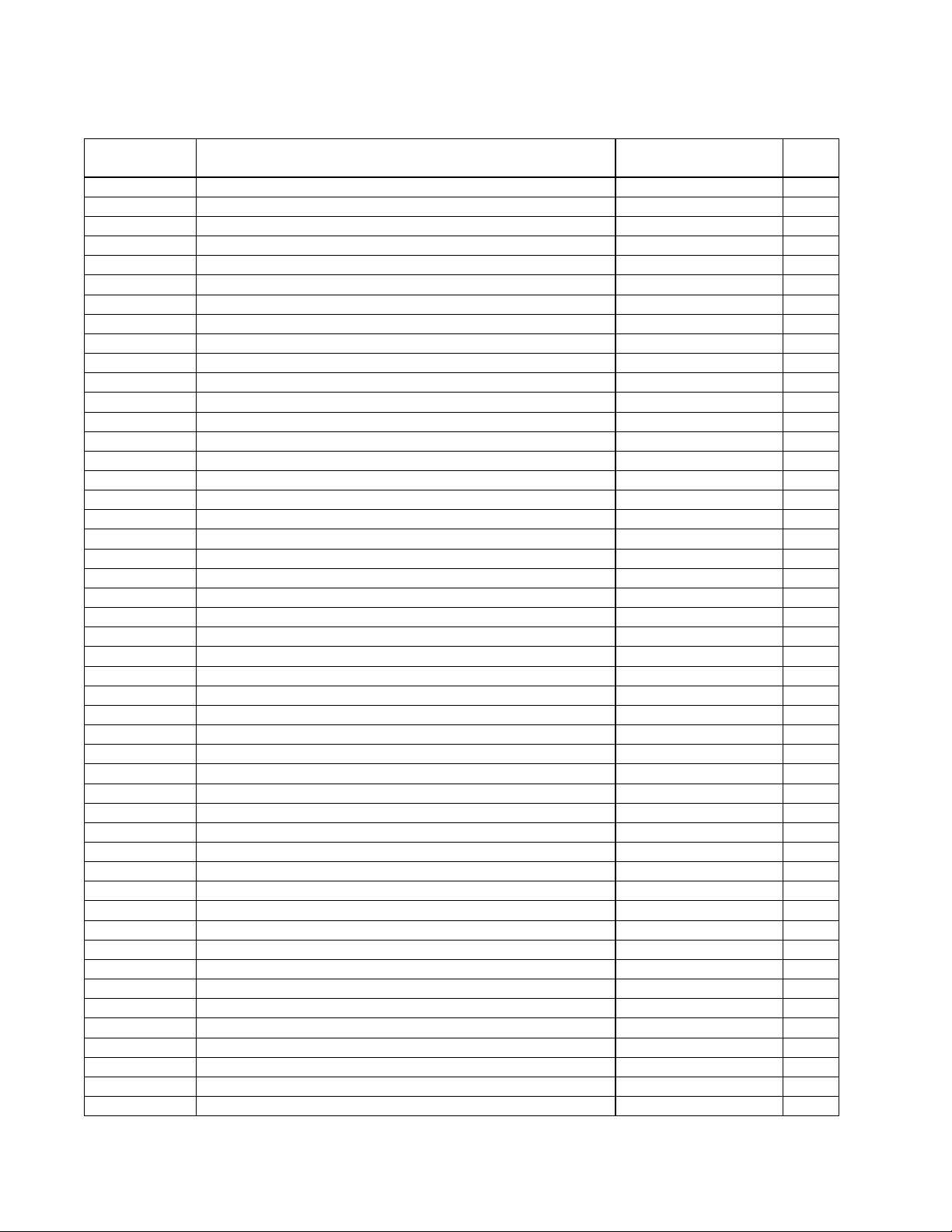

Main Part List, Panaray System Digital Controller II (see Figure 2) .............................................7

Figure 2. Panaray System Digital Controller II Exploded View ......................................................... 8

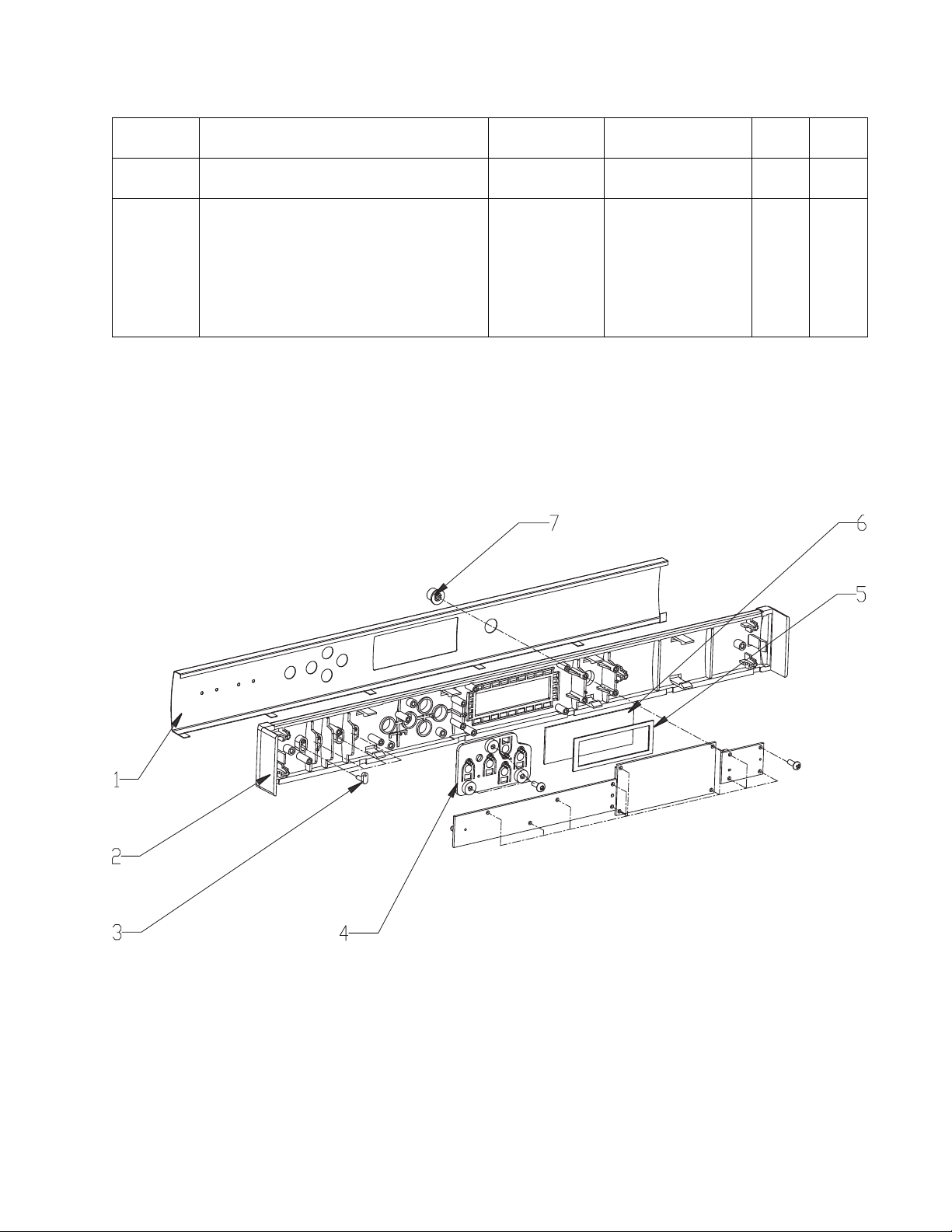

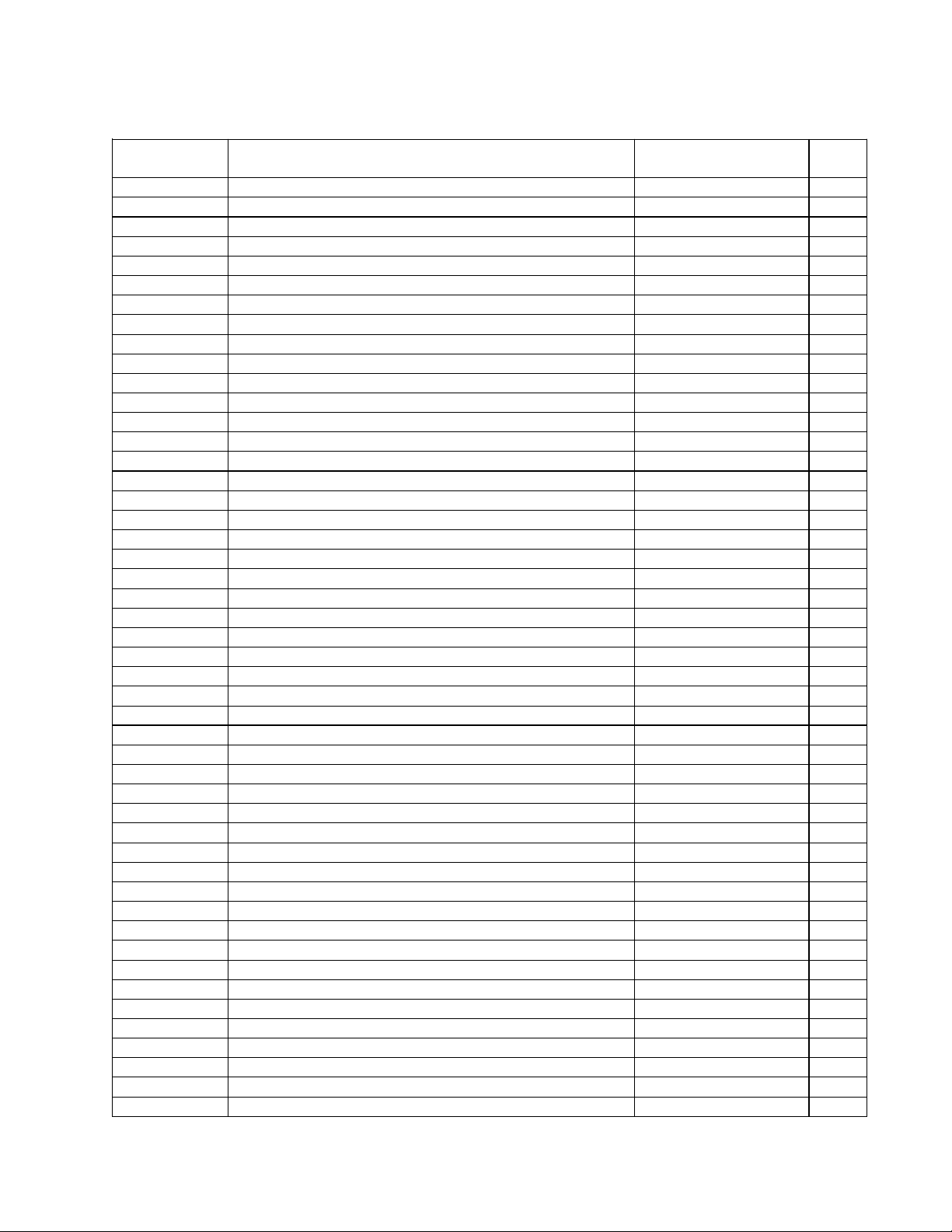

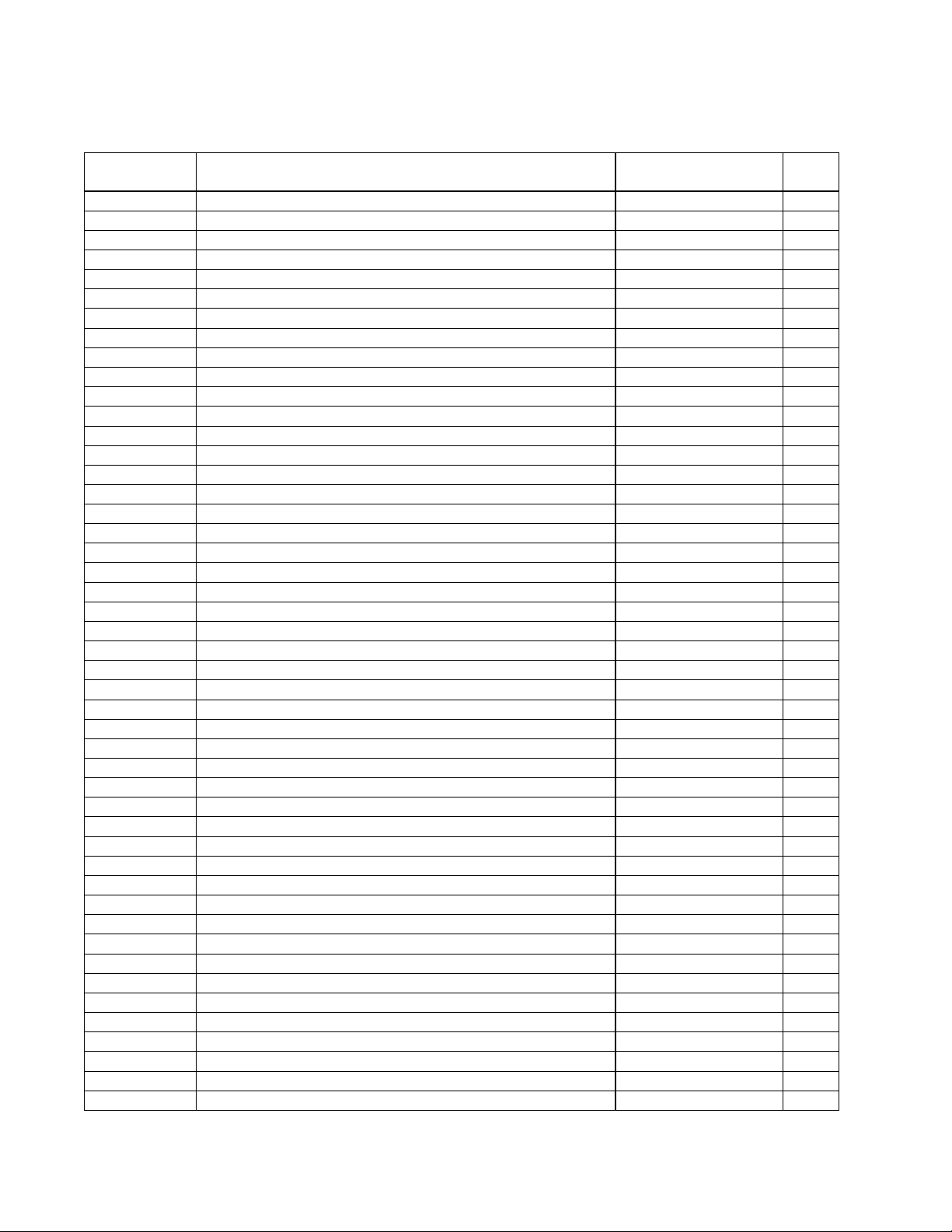

Main Part List, Front Panel Sub-assembly (see Figure 3) ............................................................. 9

Figure 3. Front Panel Sub-assembly Exploded View ....................................................................... 9

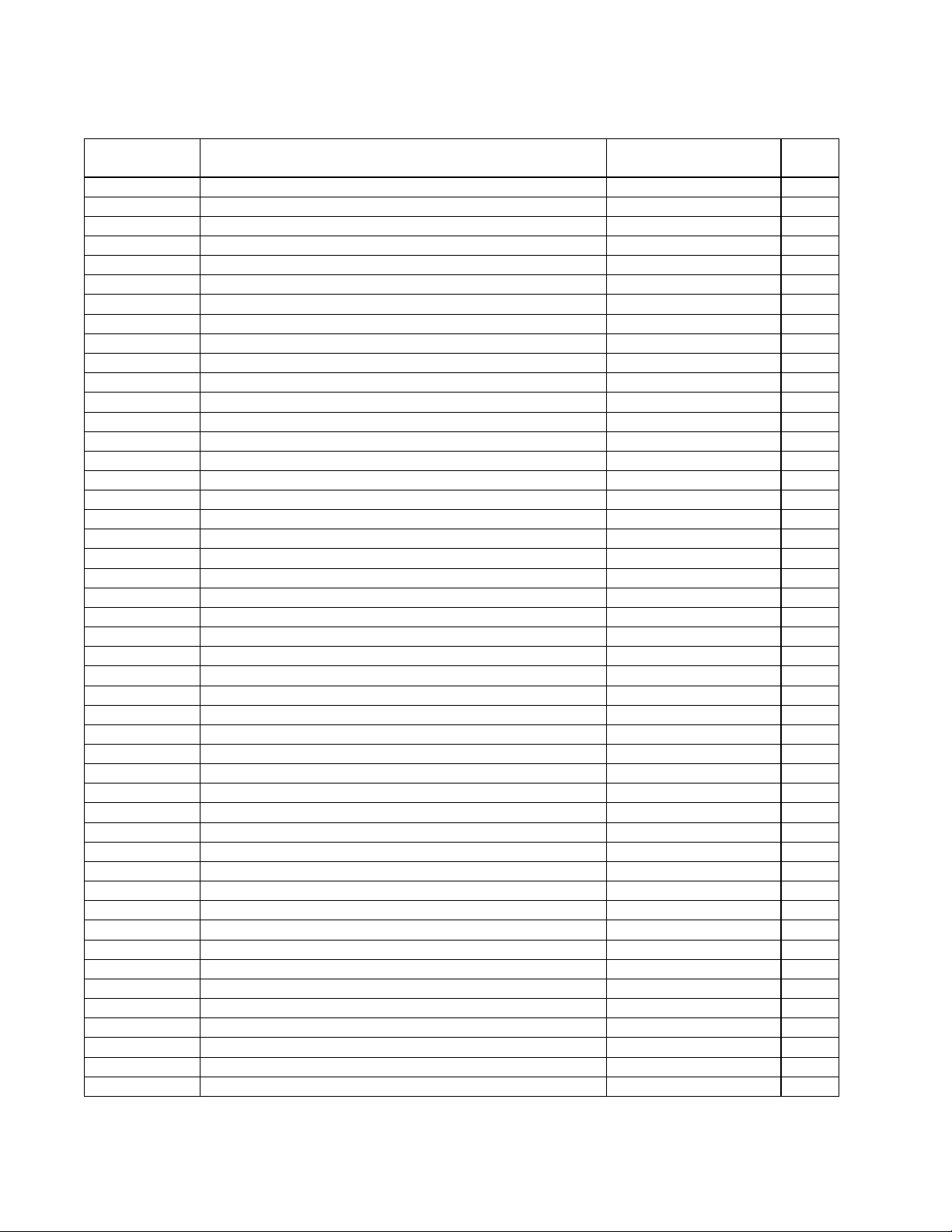

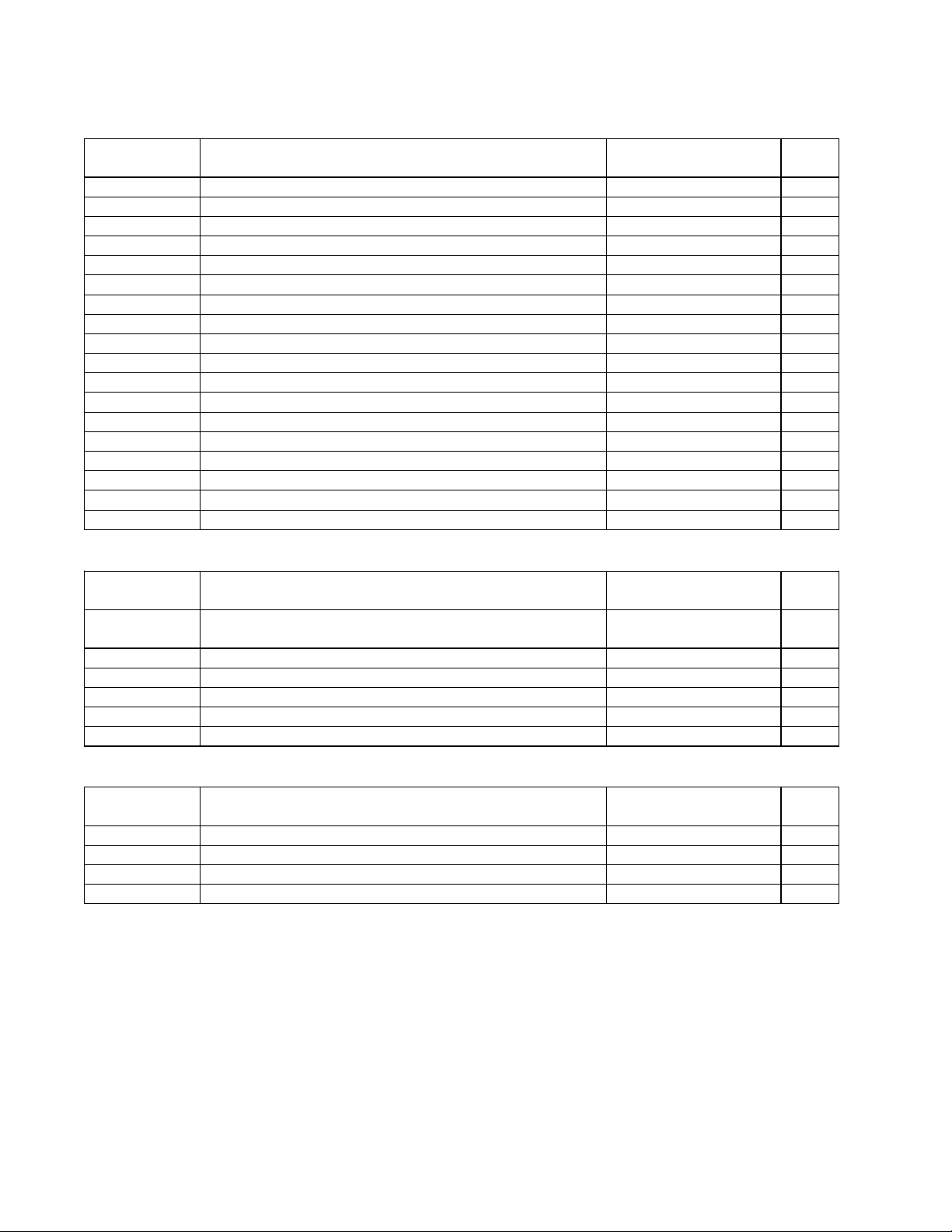

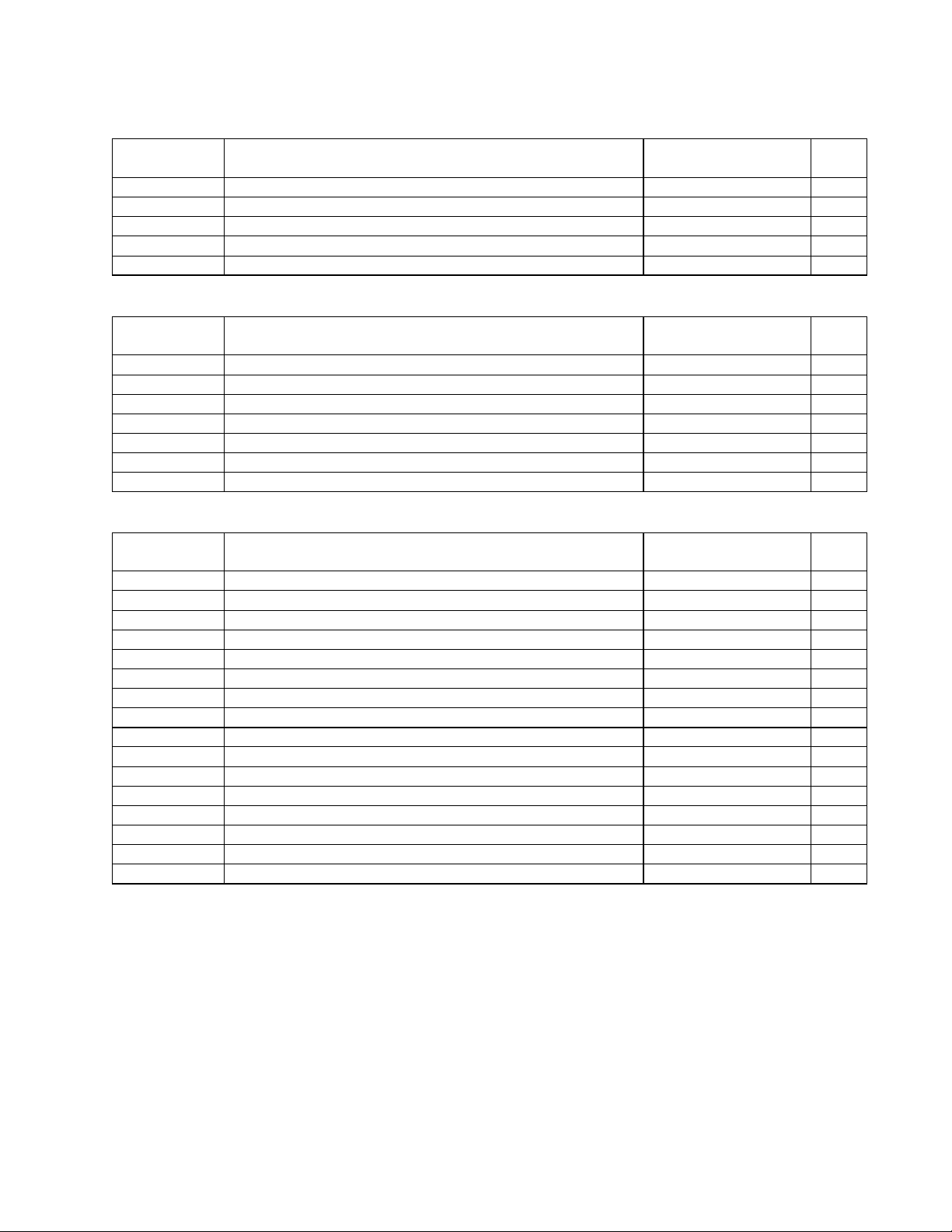

Electrical Part Lists ................................................................................................................... 10-26

Digital Signal Processor (DSP) PCB Assembly ...................................................................... 10-15

Input/Output PCB Assembly .................................................................................................... 16-20

Button and LED PCB Assembly.....................................................................................................21

Switch PCB Assembly ....................................................................................................................22

Switch Mode Power Supply (SMPS) PCB Assembly ............................................................. 23-26

Disassembly Procedures ......................................................................................................... 27-28

Test Procedures ........................................................................................................................ 29-30

Figure 4. DSP PCB Top Etch Layer and Component Layout ......................................................... 31

Figure 5. DSP PCB Internal Etch Layer 1 and Component Layout ................................................32

Figure 6. DSP PCB Internal Etch Layer 2 and Component Layout ................................................33

Figure 7. DSP PCB Bottom Etch Layer and Component Layout .................................................... 34

Figure 8. Input/Output PCB Top Etch and Component Layout ....................................................... 35

Figure 9. Input/Output PCB Bottom Etch and Component Layout .................................................35

Figure 10. Button and LED PCB Top Etch and Component Layout ...............................................36

Figure 11. Button and LED PCB Top Etch and Component Layout ...............................................36

Figure 12. Standby Switch PCB Top Etch and Component Layout ................................................36

Figure 13. Standby Switch PCB Bottom Etch and Component Layout ..........................................36

Figure 14. Switch Mode Power Supply PCB Top Etch and Component Layout .............................37

Figure 15. Switch Mode Power Supply PCB Bottom Etch and Component Layout ....................... 37

Software Update Installation Procedure ................................................................................. 38-40

Panaray Digital Controller II EQ Curves.................................................................................. 41-54

Theory of Operation .................................................................................................................. 55-57

Panaray Digital Controller II Block Diagram .................................................................................58

Integrated Circuit Diagrams ..................................................................................................... 59-61

Service Manual Revision History...................................................................................................62

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® Panaray® System Digital Controller II

contains no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose Panaray System Digital Controller II is covered by a limited 1-year transferable

limited warranty. Warranty period for Europe is 2 years.

2

Page 3

Product Description

The Bose® Panaray® System Digital Controller II is the next generation of the Bose Panaray

Digital Controller. It is a 1U rack mount controller with 2 inputs and 4 outputs, and it’s primary

purpose is to provide selectable loudspeaker EQ. It utilizes a TI TMS320D707RPF digital signal

processor to provide Bose speaker equalizer curves for all current and future speaker products.

The unit’s firmware is field upgradeable via a serial port and will not support dual mono preset

operation.

The controller is a world-wide product that utilizes a switch-mode power supply, allowing it to

operate on any line voltage from 100V to 240VAC, 50/60Hz. The Controller II is also RoHS and

WEEE compliant.

The Panaray System Digital Controller II replaces the Panaray System Digital Controller.

The controller utilizes a digital signal processing (DSP) architecture to provide Bose speaker

equalizer curves for all current and future loudspeakers.

The DSP engine has the capability to run the following operations simultaneously:

- Parametric EQ: One stereo (or mono) seven band parametric equalizer capable of the

following

• Seven band parametric

• Six band parametric with high pass

• Six band parametric with low pass

• Five band parametric with a high pass and low pass

- Crossover: Two mono or a single stereo crossover

• Choice of Butterworth, Linkwitz Riley, and Bessel Filters

• These support 1st, 2nd, 3rd and 4th order slopes.

• Output Limiter: Four mono or two stereo output limiters capable of being assigned

to any of the four outputs.

- Routing: Independent routing of input program material to any of the four outputs.

- Line Delay: Delay is available only to presets located in the Bass Array bank

• None of these settings are user programmable.

• The controller has the ability to accommodate up to 180 ROM presets capable of

supporting all combinations of Bose speakers products. The speaker presets are

not editable by the end user.

3

Page 4

SPECIFICATIONS

Front Panel Controls

Standby Power ON/OFF

Input/Output LEDs Signal (present) LED - green

Range is -40dB to -3dB

1 x LEDs for CH1 and CH2

Signal (clip) LED - red

Range is 0dB

1 x LEDs for CH1 and CH2

Display 2 x 16 backlit LCD display - blue background

with white characters

Up/Down/Left/Right Buttons Navigate EQ and utility menus

Select/Load Button Selects Bose

Rear Panel Connectors

Analog Inputs Two analog, balanced, differential XLR

Analog Outputs Four analog, balanced, differential, XLR

Communication Port DB-9 serial connector, RS232 (for updates only)

IEC Power IEC power cord input

®

EQ for speakers selected

Electrical Specifications

Analog Inputs Two balanced XLR connectors, CH1 and CH2

Input Impedance, Differential 2k Ohm

Maximum Input Level +18 dBu

Sensitivity Range at Full Scale Selectable 0/+6/+12/+18 dBu

A to D Conversion 24 bit, 128x oversampling bitstream

Dynamic Range 103 dB (typical)

THD 0.003% (typical)

Frequency Response 20Hz to 20kHz, +0/-1dB

Crosstalk 100 dB (typical)

Analog Outputs Four balanced, differential XLR connectors

Output Impedance, Differential 200 Ohms

Maximum Ouput Level (balanced) +18 dBu

Output Ranges, Balanced Selectable 0/+6/+12/+18 dBu

Throughput Delay 1.52ms

Conversion 44.1kHz

Mains Voltage 100 to 240VAC, 50 to 60Hz (auto-select)

Power Consumption < 15 Watts

Environmental Operating temperature: 32 - 104 degrees F (0 - 40 C)

Storage temperature: -4 -122 degrees F (-20 - 50 C)

Humidity: 95% relative humidity

Dimensions 19”W x 8.27”D x 1.77”H (483 x 210 x 45mm)

System Weight Product: 5.9lb (2.7kg)

Shipping: 7.8lb (3.5kg)

4

Page 5

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

5

Page 6

PACKAGING PART LIST

Panaray® Digital Controller II (see Figure 1)

Item

Number

1 POLYBAG 475X335X0.1 - 1497-7802+0 1

2 OWNERS MANUAL 298164 4301-7227+0 1

3 LINE CORD, 120V, US/CA 298165 7012-7340+0 1 3

LINE CORD, 230V, EURO 298166 7012-6601+0

LINE CORD, 100V, JAPAN 298167 7012-5530+0

LINE CORD, 240V, UK/SING 298168 7012-6603+0

LINE CORD, 240V, AUS 298169 7012-5430+0

4 PE BAG 350X120X0.05 - 1497-7762+0 1

5 CARTON 298162 1480-9201+1 1

6 CARTON PACKAGING 298163 1490-4621+0 1

7 POLYBAG - - 1

Description Bose® Part

Number

Vendor Part

Number

Qty. Note

Figure 1. Panaray Digital Controller II Packaging View

6

Page 7

MAIN PART LIST

Panaray® System Digital Controller II (see Figure 2)

Item

Number

1 SCREW, MACHINE, CS, M3X6 - 2901-3006+3000 9 4

2 COVER, TOP 298519 1405-9901+0 1 4

- FRONT PANEL ASSEMBLY,

CONSISTS OF ITEMS 3 – 10

3 KNOB, POWER - 2447-3502+0 1 4

4 COVER, FRONT, ALUMINUM 298157 1405-9801+0 1

5 PANEL, FRONT - 1467-6801+0 1 4

6 SCREW, B-TITE, M3X8, BZ - 2954-3008+3000 5 4

7 LIGHT PIPE 298517 4155-1861+0 4

8 ARROW AND LOAD BUTTONS 298518 2447-3201+0 1

9 LENS, LCD, 72X26X1 - 3717-3006+0 1 4

10 SPONGE, LCD, 71.6X25.6X2.0 - 4149-0991+0 1 4

11 LCD DISPLAY, 3.3V, WHT

SEG/BLUE BKGND, LMB162A

12 POWER SWITCH PCB ASSY 298158 SVC-BASIC14+SW 1 2, 3

13 SCREW, B-TITE, PAN, M2.3X8 - 2950-2308+3000 13 4

14 CHASSIS - 1405-9601+0 1 4

15 SCREW, MACHINE, M3X8, BZ - 2904-3008+3000 8 4

16 SWITCH-MODE P/S, AC100-

240V, O/P, 15W

17 RACK EARS 298161 1405-9701+0 2

18 NUT, M4, BLK - 2640-4030+0703 1 4

19 WASHER, SPRING, M4X1X7 - 2607-4010+0703 1 4

20 WASHER, METAL, M4X0.8X10 - 2600-4008+1003 1 4

21 CHOKE, EARTH, TOROIDAL,

200uH, #18 WIRE, GREEN /

YELLOW

22 NUT, M3, NI - 2640-3022+0544 2 4

23 SCREW, M3X8, C'SINK, BLK - 2901-3008+3000 2 4

24 INLET, AC, UL/CSA/VDE,

250V, 10A (Rong Feng

Industrial Co., SS-7B, 250V,

10A VDE,15A UL/CSA)

25 SCREW, M3X6, BINDING, BLK - 2904-3006+3000 2 4

26 WASHER, SPRING,

M3X0.9X5.5, BZ

27 INPUT/OUTPUT PCB ASSY 298152 SVC-BASIC14+I/O 1 2

28 SCREW, 3X8, TAPPING - 2950-3008+3000 12 4

29 DSP PCB ASSY 298154 SVC-BASIC14+DSP 1 2

30 SCREW, MACHINE, CS, M3X6 - 2901-3006+3000 6 4

31 BUTTON AND LED PCB ASSY 298160 SVC-BASIC14+KEY 1 2

Description Bose®

Part

Number

299033 SVC-BASIC14+FPAN 1

298159 8902-0005+0 1

298155 8902-0009+0 1 2, 3

- 1806-3917+0 1 3, 4

298153 2113-1144+0 1 3

- 2607-3009+0553 10 4

Vendor Part Number Qty. Note

7

Page 8

6

31

30

29

5

7

8

6

4

1

3

2

28

27

26

25

24

23

22

21

13

14

15

16

17

201918

12

109

11

Figure 2. Panaray System Digital Controller II Exploded View

8

Page 9

MAIN PART LIST

Front Panel Sub-assembly (see Figure 3)

Item

Number

- FRONT PANEL SUBASSEMBLY

CONSISTS OF:

1 COVER, FRONT, ALUMINUM 298157 1405-9801+0 1 4

2 PANEL, FRONT - 1467-6801+0 1 4

3 LED LIGHT PIPE 298517 4155-1861+0 4 4

4 ARROW AND LOAD BUTTONS 298518 2447-3201+0 1 4

5 SPONGE FRAME, LCD - 4149-0991+0 1 4

6 LENS, LCD - 3717-3006+0 1 4

7 BUTTON, POWER - 2447-3502+0 1 4

Description Bose® Part

Number

299033 SVC-

Vendor Part

Number

BASIC14+FPAN

Qty. Note

1

Figure 3. Front Panel Sub-assembly Exploded View

9

Page 10

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Resistors

Reference

Designator

R101 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R102 220RX4, RCFA, 0603, 1/16W, 5% 4703-221J+P-04 4

R103 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R104 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R105 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R106 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R107 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R108 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R109 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R110 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R111 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R112 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R113 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R114 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R115 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R116 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R117 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R118 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R119 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R120 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R121 10KX4, RCFA, 0603, 1/16W, 5% 4703-103J+P-04 4

R124 10KX4, RCFA, 0603, 1/16W, 5% 4703-103J+P-04 4

R125 10KX4, RCFA, 0603, 1/16W, 5% 4703-103J+P-04 4

R126 1KX4, RCFA, 0603, 1/16W, 5% 4703-102J+P-04 4

R127 220RX4, RCFA, 0603, 1/16W, 5% 4703-221J+P-04 4

R128 10KX4, RCFA, 0603, 1/16W, 5% 4703-103J+P-04 4

R129 33RX4, RCFA, 0603, 1/16W, 5% 4703-330J+P-04 4

R500 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R501 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R502 33 OHM, 0603, RMG, 1/16W, 1% 4723-330A+P 4

R503 33 OHM, 0603, RMG, 1/16W, 1% 4723-330A+P 4

R504 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R505 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R506 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R507 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R508 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R509 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R510 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R511 200 OHM, 0603, RMG, 1/16W, 1% 4723-201A+P 4

R512 100 OHM, 0603, RMG, 1/16W, 1% 4723-101A+P 4

R513 10 OHM, 0603, RMG, 1/16W, 1% 4723-100A+P-R 4

R514 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R515 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R516 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R517 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R518 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R519 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

Description Vendor Part

Number

Note

10

Page 11

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Resistors (continued)

Reference

Designator

R520 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R521 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R522 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R523 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R524 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R525 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R526 330 OHM, 0603, RMG, 1/16W, 1% 4723-331A+P 4

R527 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R528 330 OHM, 0603, RMG, 1/16W, 1% 4723-331A+P 4

R529 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R530 330 OHM, 0603, RMG, 1/16W, 1% 4723-331A+P 4

R531 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R532 330 OHM, 0603, RMG, 1/16W, 1% 4723-331A+P 4

R533 2.2K, 0603/1608, RMG, 1/16W, 1% 4723-222A+P 4

R534 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R535 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R536 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R537 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R538 40.2 OHM, 0603, RMG, 1/16W, 1% 4723-40R2+P 4

R539 40.2 OHM, 0603, RMG, 1/16W, 1% 4723-40R2+P 4

R540 40.2 OHM, 0603, RMG, 1/16W, 1% 4723-40R2+P 4

R541 40.2 OHM, 0603, RMG, 1/16W, 1% 4723-40R2+P 4

R542 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R543 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R544 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R545 270 OHM, 0603/1608, RMG, 1/16W, 1% 4723-271A+P 4

R546 2K, 0603/1608, RMG, 1/16W, 1% 4723-202A+P 4

R547 2K, 0603/1608, RMG, 1/16W, 1% 4723-202A+P 4

R548 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R549 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R550 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R551 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R552 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R553 1K, 0603/1608, RMG, 1/16W, 1% 4723-102A+P 4

R554 33K, 0603/1608, RMG, 1/16W, 5% 4723-333J+P 4

R555 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R556 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R557 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R710 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R810 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R902 33 OHM, 0603, RMG, 1/16W, 1% 4723-330A+P 4

R903 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R904 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R905 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R906 220 OHM, 0603/1608, RMG, 1/16W, 1% 4723-221A+P 4

R907 150 OHM, 0603, RMG, 1/16W, 1% 4723-151A+P 4

Description Vendor Part

Number

Note

11

Page 12

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors

Reference

Designator

C500 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C501 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C502 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C503 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C504 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C505 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C506 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C507 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C508 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C509 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C510 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C511 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C512 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C513 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C514 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C515 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C516 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C518 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C520 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C521 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C522 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C523 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C524 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C525 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C526 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C527 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C528 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C529 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C530 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C531 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C532 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C533 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C534 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C535 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C536 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C537 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C538 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C539 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C540 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C541 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C542 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C543 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C544 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C545 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C546 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C547 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C548 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C549 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

Description Vendor Part

Number

Note

12

Page 13

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

C550 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C551 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C552 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C553 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C554 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C555 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C556 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C557 1uF, CC, 0805, 50V, +80/-20% 150F-105Z+J-BD 4

C558 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C559 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C560 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C561 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C562 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C563 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C564 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C565 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C566 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C567 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C568 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C569 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C570 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C571 0.22uF, CC, 0603, 50V, +80/-20% 150F-224Z+P-AC 4

C572 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C573 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C574 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C575 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C576 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C577 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C578 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C579 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C580 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C583 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

C584 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

C748 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C749 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C750 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C751 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C752 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

CT500 10uF, SM, CE, 16V, 20%, 4X5.4, PSI, VS 157D-106M+3-GJK 4

CT501 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT502 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT503 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT504 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT505 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT506 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT507 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT508 10uF, SM, CE, 16V, 20%, 4X5.4, PSI, VS 157D-106M+3-GJK 4

CT509 10uF, SM, CE, 16V, 20%, 4X5.4, PSI, VS 157D-106M+3-GJK 4

Description Vendor Part

Number

Note

13

Page 14

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Capacitors (continued)

Reference

Designator

CT510 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT511 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT512 10uF, SM, CT, 25V, 20%, 3.2x6 154E-106M+3-FK 4

CT513 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT514 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT515 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT516 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT517 10uF, SM, CT, 25V, 20%, 3.2x6 154E-106M+3-FK 4

CT518 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT519 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT521 10uF, SM, CT, 25V, 20%, 3.2x6 154E-106M+3-FK 4

CT522 10uF, SM, CT, 25V, 20%, 3.2x6 154E-106M+3-FK 4

CT531 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT532 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

CT533 1uF, SM, CT, 16V, 20%, 1.6X3.2 154D-105M+3-CF 4

CT534 1uF, SM, CT, 16V, 20%, 1.6X3.2 154D-105M+3-CF 4

CT535 10uF, SM, CE, 16V, 20%, 4X5.4, PSI, VS 157D-106M+3-GJK 4

CT720 10uF, SMD, CT, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

Reference

Designator

L500 EMI FILTER, FERRITE, CHIP, EXCCET103U, SMD,

PANASONIC

L501 INDUCTOR, CHIP, 10uH, LEMF3225T100K 1803-0055+0 4

L502 INDUCTOR, CHIP, 10uH, LEMF3225T100K 1803-0055+0 4

FB500 FERRITE BEAD, SEBW201209U121MT, 0805 1808-0872+0 4

FB501 FERRITE BEAD, 4.5X1.6X1.6, BLM41PG102SN1L 1808-0871+0 4

FB505 FERRITE BEAD, 4.5X1.6X1.6, BLM41PG102SN1L 1808-0871+0 4

Description Vendor Part

Number

Note

Inductors and Ferrite Beads

Description Vendor Part

Number

2705-0020+0 4

Note

Diodes

Reference

Designator

D500 BAV99, SOT23, PHILIPS 4840-8970+3 4

D501 BAV99, SOT23, PHILIPS 4840-8970+3 4

D502 BAV99, SOT23, PHILIPS 4840-8970+3 4

D503 BAV99, SOT23, PHILIPS 4840-8970+3 4

Description Vendor Part

Number

Note

14

Page 15

ELECTRICAL PART LIST

Digital Signal Processor (DSP) PCB Assembly

Transistors

Reference

Designator

Q500 RN2402,(T5L/F/T), SMD2214530R2, TOSHIBA 4852-4020+3 4

Q501 RN2402,(T5L/F/T), SMD2214530R2, TOSHIBA 4852-4020+3 4

Q502 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA,

2214470R2

Q503 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA,

2214470R2

Q504 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA,

2214470R2

Q505 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA,

2214470R2

Reference

Designator

U500 4M FLASH, S29AL004D-90TFI02, STANDARD,

TSOP48

U501 DSP, TMS320D707RFP/S, PQFP144, TI 3132-3381+0 4

U502 PLD, EPM3064A-10, TQPF44, ALTERA 3132-3331+0 4

U503 SUPPLY VOLTAGE SUPERVISOR, TL7705BCD,

SOP-8, TI

U504 LOW-DROP LINEAR REGULATOR,

TPS726126DCQ, SOT223-5, TI

U505 SN74LV245ADWR, OCTAL B TRANSCEIVER,

SOT163-1/SO

U507 OCTAL BUFFER, SMD, SN74LVC541ADWR, TI 3132-3341+0 4

U508 24BIT DAC W/VOL, CTRL, 20P, CS4392-KZZ,

TSSOP

U509 24BIT DAC W/VOL CTRL, 20P, CS4392-KZZ,

TSSOP

U511 NJM5532M-#ZZZB, DUAL OP AMP 3131-4850+0 4

U512 STEREO A/D CONVERTER, PCM1804DB, 24BIT,

SSOP28

U513 LC2MOS, 5 OHM, RON, SPST, SW, ADG452BRZ,

SOIC16, ADI

U514 LC2MOS, 5 OHM, RON, SPST, SW, ADG452BRZ,

SOIC16, ADI

U515 AUDIO OP AMP, OPA1632D, SO-8, TI 3132-3321+0 4

U516 AUDIO OP AMP, OPA1632D, SO-8, TI 3132-3321+0 4

Description Vendor Part

Number

4851-4020+3 4

4851-4020+3 4

4851-4020+3 4

4851-4020+3 4

Note

Integrated Circuits

Description Vendor Part

Number

3132-3571+0 4

3132-3401+0 4

3132-3391+0 4

3132-0680+0 4

3132-0730+0 4

3132-0730+0 4

3132-3311+0 4

3132-3361+0 4

3132-3361+0 4

Note

Miscellaneous

Reference

Designator

Y500 CRYSTAL, 22.5792MHZ +/-50 PPM, 3.3V, 7X5X1.8,

SMD7050

J500 HEADER, 2X5P, P2.54, ST, MALE 2101-3121+0 4

CON500 2P, ST,.WAFER, P=2.5 2102-021S+004 4

CN500 HEADER, IDC, 24P, 2XP2.54, 3510 SERIES 2101-3123+0 4

CN501 WIRE-CONN, 8P, P2.5, #26, UL1007, L=260, F/M 7012-7651+0 4

CN502 HEADER, IDC, 30P, 2XP2.54, 3510 SERIES 2101-3122+0 4

Description Vendor Part

Number

2300-3279+0 4

Note

15

Page 16

ELECTRICAL PART LIST

Input/Output PCB Assembly

Resistors

Reference

Designator

R316 0 OHM, RMG, 0603, 1/16W, 5% 4723-000J+P 4

R317 0 OHM, RMG, 0603, 1/16W, 5% 4723-000J+P 4

R318 10 OHM, RMG, 0603/1608, 1/16W, 5% 4723-100J+P 4

R601 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R602 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R612 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R613 100 OHM, RMG, 0603, 1/16W, 1% 4723-101A+P 4

R701 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R702 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R703 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R704 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R705 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R706 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R707 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R708 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R709 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R710 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R711 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R712 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R713 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R714 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R715 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R716 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R717 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R718 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R719 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R720 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R721 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R722 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R723 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R724 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R725 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R726 330 OHM, RMG, 0603, 1/16W, 1% 4723-331A+P 4

R727 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R728 499 OHM, RMG, 0603, 1/16W, 1% 4723-4990+P 4

R729 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R730 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R731 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R732 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R733 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R734 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R735 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R736 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R737 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R738 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R739 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R740 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R751N 8.2K, RMG, 0603/1608, 1/16W, 1% 4723-822A+P 4

Description Vendor Part

Number

Note

16

Page 17

ELECTRICAL PART LIST

Input/Output PCB Assembly

Resistors (continued)

Reference

Designator

R752N 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R753N 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R758N 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R780 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R782 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R783 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R784 2K, RMG, 0603/1608, 1/16W, 1% 4723-202A+P 4

R785 2.7K, RMG, 0603/1608, 1/16W, 5% 4723-272J+P 4

R786 2.7K, RMG, 0603/1608, 1/16W, 5% 4723-272J+P 4

R789 10K, RMG, 0603/1608, 1/16W, 1% 4723-103A+P 4

R790 2.7K, RMG, 0603/1608, 1/16W, 5% 4723-272J+P 4

R800 10 OHM, RMG, 0603/1608, 1/16W, 5% 4723-100J+P 4

R801 10 OHM, RMG, 0603/1608, 1/16W, 5% 4723-100J+P 4

R802 10 OHM, RMG, 0603/1608, 1/16W, 5% 4723-100J+P 4

R803 10 OHM, RMG, 0603/1608, 1/16W, 5% 4723-100J+P 4

R812 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R813 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R814 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R815 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R816 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R817 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R818 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

R819 51 OHM, RMG, 0603, 1/16W, 1% 4723-510A+P 4

Description Vendor Part

Number

Note

Capacitors

Reference

Designator

C210 0.047uF, CC, 0603, 16V, 10%, 0.8x1.6 150D-473K+P-AC 4

C211 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C212 0.33uF, CC, 0603, 16V, 10% 150D-334K+P-AC 4

C213 0.33uF, CC, 0603, 16V, 10% 150D-334K+P-AC 4

C214 0.33uF, CC, 0603, 16V, 10% 150D-334K+P-AC 4

C312 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C313 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C314 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C315 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C316 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C317 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C318 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C319 1000pF, CC, 0603/1608, 50V, 10%, 1X2 150F-102K+P-AC 4

C701 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

C702 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C703 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C704 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C705 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C706 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C707 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C708 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

Description Vendor Part

Number

Note

17

Page 18

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors (continued)

Reference

Designator

C709 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C710 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C711 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C712 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C713 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C714 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C715 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

C716 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C717 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C718 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C719 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C720 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C721 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C722 2700pF, CC, 0603/1608, 50V, 10% 150F-272K+P-AC 4

C723 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C724 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C725 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C726 560pF, CC, 0603/1608, 50V, 10%, 1X2 150F-561K+P-AC 4

C727 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C728 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C729 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C730 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C731 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C732 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C733 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C734 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C743 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C744 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C745 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

C746 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C747 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

C748 0.01uF, CC, 0603, 50V, 10%, 1x2 150F-103K+P-AC 4

CE215 100uF, CE, 25V, 20%, GS, RLT, 6.3X11, JAM/MAN 157E-107M+K-LUG 4

CT501 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT502 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT503 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT504 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT505 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT506 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT507 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT508 100uF, CE, 25V, 20%, 5X11, RLT, RUBYCON, YK 157E-107M+K-IUY 4

CT701 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT702 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT703 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT704 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT705 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT706 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

Description Vendor Part

Number

Note

18

Page 19

ELECTRICAL PART LIST

Input/Output PCB Assembly

Capacitors (continued)

Reference

Designator

CT707 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT708 10uF, CT, 25V, 20%, 3.2x6, SM 154E-106M+3-FK 4

CT717 100uF, CE, 25V, 20%, GS, RLT, 6.3X11, JAM/MAN 157E-107M+K-LUG 4

CT718 100uF, CE, 25V, 20%, GS, RLT, 6.3X11, JAM/MAN 157E-107M+K-LUG 4

CT719 100uF, CE, 25V, 20%, GS, RLT, 6.3X11, JAM/MAN 157E-107M+K-LUG 4

Reference

Designator

L701 FERRITE BEAD INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L702 FERRITE BEAD INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

L703 FERRITE BEAD INDUCTOR, BL01RN1A1F1J 1808-0680+0 4

FB701 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

FB702 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

FB703 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

FB704 WIRE JUMPER, ROLLER FORM, D=0.6MM 635N-0002+0 4

Reference

Designator

D601 BAV99, SOT23, PHILIPS 4840-8970+3 4

D602 BAV99, SOT23, PHILIPS 4840-8970+3 4

D603 BAV99, SOT23, PHILIPS 4840-8970+3 4

D604 BAV99, SOT23, PHILIPS 4840-8970+3 4

D701 BAV99, SOT23, PHILIPS 4840-8970+3 4

D702 BAV99, SOT23, PHILIPS 4840-8970+3 4

D703 BAV99, SOT23, PHILIPS 4840-8970+3 4

D704 BAV99, SOT23, PHILIPS 4840-8970+3 4

D705 BAV99, SOT23, PHILIPS 4840-8970+3 4

D706 BAV99, SOT23, PHILIPS 4840-8970+3 4

D707 BAV99, SOT23, PHILIPS 4840-8970+3 4

D708 BAV99, SOT23, PHILIPS 4840-8970+3 4

D800 LL4148, SM 4804-1480+3 4

D801 LL4148, SM 4804-1480+3 4

D802 LL4148, SM 4804-1480+3 4

D803 LL4148, SM 4804-1480+3 4

Description Vendor Part

Number

Note

Inductors and Ferrite Beads

Description Vendor Part

Number

Note

Diodes

Description Vendor Part

Number

Note

19

Page 20

ELECTRICAL PART LIST

Input/Output PCB Assembly

Transistors

Reference

Designator

Q701N MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q702N MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q704 MPSA06, VCE, 80V, NS, RLT 4860-8890+K 4

Q705 MPS, A56, VCE, 80V, NS, RLT 4860-8910+K 4

Q706 MPSA06, VCE, 80V, NS, RLT 4860-8890+K 4

Q707 MPS, A56, VCE, 80V, NS, RLT 4860-8910+K 4

Q708 MPSA06, VCE, 80V, NS, RLT 4860-8890+K 4

Q709N MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q800 MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q801 MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q802 MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q803 MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Q804 MPSA06, VCE, 80V, NS, RLT 4860-8890+K 4

Q805 MPS, A56, VCE, 80V, NS, RLT 4860-8910+K 4

Reference

Designator

U202 MAX3232ECWE+, RS232, TX, SO16, MAXIM 3132-2521+0 4

U701 NJM2068M-#ZZZB, DUAL OP AMP 3130-6890+0 4

U702 NJM2068M-#ZZZB, DUAL OP AMP 3130-6890+0 4

U703 NJM2068M-#ZZZB, DUAL OP AMP 3130-6890+0 4

U704 NJM2068M-#ZZZB, DUAL OP AMP 3130-6890+0 4

Description Vendor Part

Number

Note

Integrated Circuits

Description Vendor Part

Number

Note

Miscellaneous

Reference

Designator

K1 RELAY, 2P2T, 12V, 140MM, A-12W-K, TAKAMISAWA 4500-0490+0 4

K2 RELAY, 2P2T, 12V, 140MM, A-12W-K, TAKAMISAWA 4500-0490+0 4

K3 RELAY, 2P2T, 12V, 140MM, A-12W-K, TAKAMISAWA 4500-0490+0 4

K4 RELAY, 2P2T, 12V, 140MM, A-12W-K, TAKAMISAWA 4500-0490+0 4

J202 WIRE-CONN, 2P, P2.5, #26, UL1007, L=300, F/M 7012-7541+0 4

J601 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3158+0 4

J602 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3158+0 4

J701 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3159+0 4

J702 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3159+0 4

J703 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3159+0 4

J704 SOCKET, XLR, 3P, FEMALE, AC3FAH2-AU, AMP 2113-3159+0 4

J705 HEADER, IDC, 30P, 2XP2.54, 3510 SERIES 2101-3122+0 4

J706 WIRE-CONN, 6P, P2.5, #26, UL1007, L=150, F/M 7012-7550+0 4

J707 2P, ST. WAFER, P=2.5, COULOMB 2102-021S+004 4

JP601 WAFER, 2 PIN, P=2.54, ST, 6MM 2101-1494+0 4

JP602 WAFER, 2 PIN, P=2.54, ST, 6MM 2101-1494+0 4

P301 SOCKET, DB9, D SUB, RA, FEMALE 2113-1749+0 4

Description Vendor Part

Number

Note

20

Page 21

ELECTRICAL PART LIST

Button and LED PCB Assembly

Resistors

Reference

Designator

R0 100 OHM, RCF, 1W, 5%, AL 4708-101J+1 4

R101 470 OHM, 0603/1608, RMG, 1/16W, 1% 4723-471A+P 4

R102 910 OHM, 0603/1608, RMG, 1/16W, 1% 4723-911A+P 4

R103 470 OHM, 0603/1608, RMG, 1/16W, 1% 4723-471A+P 4

R104 910 OHM, 0603/1608, RMG, 1/16W, 1% 4723-911A+P 4

R105 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R106 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R107 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R108 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R109 10K, 0603/1608, RMG, 1/16W, 1% 4723-103A+P 4

R112 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R113 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

R115 0 OHM, 0603, RMG, 1/16W, 5% 4723-000J+P 4

Reference

Designator

C102 100uF, CE, 16V, 20%, RLT, 5X11, SHOEI 157D-107M+K-IUI 4

C105 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

Description Vendor Part

Number

Note

Capacitors

Description Vendor Part

Number

Note

Diodes

Reference

Designator

D101 SIL, 3144D, GREEN LED, 3MM 3700-9509+0 4

D103 SIL, 3144D, GREEN LED, 3MM 3700-9509+0 4

D102 LED, SIL-3143D, 3MM, RED 3700-9516+0 4

D104 LED, SIL-3143D, 3MM, RED 3700-9516+0 4

Reference

Designator

Q101 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA, 2214470R2 4851-4020+3 4

Q102 RN2402,(T5L/F/T), SMD2214530R2, TOSHIBA 4852-4020+3 4

Reference

Designator

SW101 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

SW102 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

SW103 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

SW104 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

SW105 SW, TACT, SPST, SKQNAED010, H=5, ALPS 5200-4847+0-01 4

J301 WIRE-CONN, 2P, P2.5, #26, UL1007, L=150, RD/BK,

F/M

J302 HEADER, IDC, 24P, 2XP2.54, 3510 SERIES 2101-3123+0 4

J303 16P, ST, WAFER, P=2.0 2102-160S+003 4

Description Vendor Part

Number

Note

Transistors

Description Vendor Part

Number

Note

Miscellaneous

Description Vendor Part

Number

7012-7542+0 4

Note

21

Page 22

ELECTRICAL PART LIST

Switch PCB Assembly

Resistors

Reference

Designator

R910 30K, RMG, 0603/1608, 1/16W, 1% 4723-303A+P 4

R911 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

R912 10 OHM, RMG, 0603/1608, 1/16W, 1% 4723-100A+P 4

R913 1K, RMG, 0603/1608, 1/16W, 1% 4723-102A+P 4

Reference

Designator

C572 0.1uF, CC, 0603/1608, 50V, 10%, 1x2 150F-104K+P-AC 4

CT102 10uF, CT, SMD, 16V, 20%, 1.6X3.2 154D-106M+3-CF 4

Reference

Designator

Q503 NPN, RN1402,(T5L/F/T), SMD, TOSHIBA, 2214470R2 4851-4020+3 4

Q702N MOSFET, N-CHANNEL, 2N7002MTF, SOT-23 4902-MTF0+3 4

Reference

Designator

SW106 SW, PUSH, 2P2T, L=9.6, SFPC12MA02-GK 5200-4920+0-11 4

J104 WIRE-CONN, 2P, P2.5, #26, UL1007, L=100, RD/BK,

F/M

J105 WIRE-SHIELD, 2P, UL1007, L=195, RD/BK, F/M 7010-2105+1.V 4

Description Vendor Part

Number

Note

Capacitors

Description Vendor Part

Number

Note

Transistors

Description Vendor Part

Number

Note

Miscellaneous

Description Vendor Part

Number

7012-7540+0 4

Note

22

Page 23

ELECTRICAL PART LIST

Switch Mode Power Supply (SMPS) PCB Assembly

Resistors

Reference

Designator

RJ1 0 OHM, 0805, SMD, +/-5% 15B-000J81 4

R1 1M, 1206, SMD, +/-5% 15S-105J41 3, 4

R2 1M, 1206, SMD, +/-5% 15S-105J41 3, 4

R3 2M, 1206, SMD, +/-5% 15S-205J41 4

R4 2M, 1206, SMD, +/-5% 15S-205J41 4

R5 51 OHM, 1206, SMD, +/-5% 15S-510J41 4

R6 100 OHM, 0805, SMD, +/-5% 15B-101J81 4

R7 15K, 0805, SMD, +/-5% 15B-153J81 4

R8 2.2K, 1206, SMD, +/-5% 15S-222J41 4

R9 0.51 OHM, 1W, +/-5% 15N-518J01 4

R10 100K, 1W, +/-5% 15N-104J0S 4

R12 4.7K, 1206, SMD, +/-5% 15S-472J41 4

R14 1.2K, 0805, SMD, +/-5% 15B-122J81 4

R15 1K, 0805, SMD, +/-5% 15B-102J81 4

R16 2.2K, 0805, SMD, +/-5% 15M-220181 4

R17 2.74K, 0805, SMD, +/-5% 15M-274181 4

R18 100 OHM, 0805, SMD, +/-5% 15B-101J81 4

R18 22K, 1206, SMD, +/-5% 15S-223J41 4

R19 10K, 1206, SMD, +/-5% 15B-103J41 4

R20 75 OHM, 1206, SMD, +/-5% 15S-750J41 4

R21 75 OHM, 1206, SMD, +/-5% 15S-750J41 4

R22 2.2 OHM, 2W, +/-5% 15N-518J01 4

R23 0 OHM, 0805, SMD, +/-5% 15B-000J81 4

R25 2.2 OHM, 2W, +/-5% 15N-518J01 4

R26 270 OHM, 2W, +/-5% - 4

Description Vendor Part

Number

Capacitors

Note

Reference

Designator

CX1 0.47uF, 275VAC (Liow Gu type GS-L or

Shenzen type MEX-X2 or Tenta type MEX or

Various Rated 250, 275 or280V)

CY1 152pF, 400VAC (Pan Overseas type AH or

Guangdong South Hongming type F or

Various)

CY2 152pF, 400VAC (Pan Overseas type AH or

Guangdong South Hongming type F or

Various)

CY4 102pF, 400VAC (Pan Overseas type AH or

Guangdong South Hongming type F or

Various)

C1 47uF, 400V, 18x25, +/-20% 17A-680MH1 4

C2 103M, 1KV, PIN=5 17C-103KLA 4

Description Vendor Part

Number

17T-474KEU 3, 4

17N-152KHT 3, 4

17N-152KHT 3, 4

17N-102MHT 3, 4

Note

23

Page 24

ELECTRICAL PART LIST

Switch Mode Power Supply (SMPS) PCB Assembly

Capacitors (continued)

Reference

Designator

C3 222M, 1KV, PIN=5 17C-222KLA 4

C4 22uF, 50V, 5x11, +/-20% 17A-220M7B 4

C5 100nF, 50V, 1206, X7R 17S-104M72 4

C6 68pF, 50V, 0805, X7R 17B-680J71 4

C7 1nF, 0805, SMD, 50V, X7R 17B-102K71 4

C8 1nF, 1206, SMD, 250V, X7R 17S-102KD1 4

C9 680uF, 25V, 10x16, +/-20%, Low ESR 17A-681M4B 4

C10 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C11 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C12 1000pF, 1206, SMD, 630V, X7R 17S-101KK1 4

C13 100nF, 0805, SMD, X7R 17B-104K71 4

C14 1nF, 1206, SMD, 250V, X7R 17S-102KD1 4

C15 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C16 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C17 680uF, 25V, 10x16, +/-20%, Low ESR 17A-681M4B 4

C18 680uF, 25V, 10x16, +/-20%, Low ESR 17A-681M4B 4

C19 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C20 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C21 1000uF, 16V, 10x16, +/-20%, Low ESR 17A-102M3B 4

C22 1000uF, 16V, 10x16, +/-20%, Low ESR 17A-102M3B 4

C23 680uF, 25V, 10x16, +/-20%, Low ESR 17A-681M4B 4

C24 47uF, 50V, 6x12, +/-20% 17A-470M7B 4

C25 1nF, 0805, SMD, 50V, X7R 17B-102K71 4

C26 100nF, 0805, SMD, X7R 17B-104K71 4

C27 1000pF, 1206, X7R, SMD, 630V 17S-101KK1 4

C28 100nF, 0805, X7R, SMD 17B-104K71 4

C29 100nF, 0805, X7R, SMD 17B-104K71 4

C30 100nF, 0805, X7R, SMD 17B-104K71 4

C31 100nF, 0805, X7R, SMD 17B-104K71 4

C32 100nF, 0805, X7R, SMD 17B-104K71 4

C33 100nF, 0805, X7R, SMD 17B-104K71 4

C34 47nF, 0805, X7R, SMD, 50V 17B-473M4B 4

C35 100nF, 0805, X7R, SMD 17B-104K71 4

C36 100nF, 0805, X7R, SMD 17B-104K71 4

C37 100nF, 0805, X7R, SMD 17B-104K71 4

C38 1nF, 1206, X7R, SMD, 250V 17S-102KD1 4

C39 100nF, 0805, X7R, SMD 17B-104K71 4

C40 100nF, 0805, X7R, SMD 17B-104K71 4

C41 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C42 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

C43 220uF, 25V, 8x12, +/-20%, Low ESR 17A-221M4B 4

Description Vendor Part

Number

Note

24

Page 25

ELECTRICAL PART LIST

Switch Mode Power Supply (SMPS) PCB Assembly

Inductors

Reference

Designator

LF1 25mH (Vdson (HZ) Electronics Co. model

VD0880)

L1 22Uh GL0603-220J 4

L2 4.7uH, 3A DR0710-4R7M-D180 4

L3 4.7uH, 3A DR0710-4R7M-D180 4

L5 10uH, 1A DR0608-100M-D182 4

L6 3.3uH, 3A ISO-359K01-L01 4

Reference

Designator

ZD1 SMD, 15V, 1/2W, SOD-8 12S-15V02E 4

ZV1 7N471K 15V-07N471 3, 4

D1 UF108, 1A, 800V, D0-41 12H-UF108E 4

D2 UF108, 1A, 800V, D0-41 12H-UF108E 4

D3 UF108, 1A, 800V, D0-41 12H-UF108E 4

D4 UF108, 1A, 800V, D0-41 12H-UF108E 4

D5 FR104, 1A, 400V, D0-41 12H-FR104E 4

D6 UF108, 1A, 800V, D0-41 12H-UF108E 4

D7 FR104, 1A, 400V, D0-41 12H-FR104E 4

D8 SMD, 1N4148, SOD-8 12S-41480E 4

D9 UF204, 2A, 400V, D0-201AD 12H-UF204E 4

D10 UF204, 2A, 400V, D0-201AD 12H-UF204E 4

D11 FR104, 1A, 400V, D0-41 12H-FR104E 4

D12 SR1660CT, 16A, 60V, T0-220AB 12B-R1660P 4

D12 23.2x16x25mm 53E-000601 4

D12 3mm 62S-000100 4

D12 3x8mm 60M-B0308N 4

D13 1N4148, D0-35 12T-41480E 4

D14 FR104, 1A, 400V, D0-41 12H-FR104E 4

Description Vendor Part

Number

UD0880 3, 4

Diodes

Description Vendor Part

Number

Transistors

Note

Note

Reference

Designator

Q1 MOSFET, SSS4N60, 4A, 600V, T0-220F,

FAIRCHILD

Q2 2N5551, T0-92 13T-2N555D 4

Description Vendor Part

Number

13M-S4N60C 4

Note

25

Page 26

ELECTRICAL PART LIST

Switch Mode Power Supply (SMPS) PCB Assembly

Integrated Circuits

Reference

Designator

U1 NCP1200DR2, f=60KH, SOP-8 11S-P1200G 4

U2 KIA431B, 2.5V +/-1%, T0-220, KEC 11W-A431BA 4

U3 LM7812, 12V, T0-220, FAIRCHILD 11W-M7812B 4

U4 KA7912, 12V, T0-220, FAIRCHILD 11W-A7912B 4

U5 LDO, LM1084, 5V, T0-220, FAIRCHILD 11W-N1084B 4

U6 LDO, LM1084, 5V, T0-220, FAIRCHILD 11W-N1084B 4

Reference

Designator

MCR1 MCR100-6, T0-92 13K-R1006E 4

NTC1 5D-9 (5 Ohms) 15H-5D900M 3, 4

PC1 EL817, DIP-4 (Sharp type PC817, Everlight

type EL817or Lite-on type LTV-817)

T1 ER28H (Vdson (HZ) Electronics Co.,

VD0935, ER28. Model VP330A (North

America only)

F1 T1.6A, 250V, WICKMANN (Wickman type

372 or Ever Island type 2000)

J1 0.6x15 32L-006150 4

J2 0.6x10 32L-006100 4

J3 0.6x7.5 32L-006075 4

J4 0.6x7.5 32L-006075 4

J5 0.6x18 32L-006180 4

J6 0.6x18 32L-006180 4

J7 0.6x10 32L-006100 4

J8 0.6x10 32L-006100 4

XS1 2 PIN, 7.92mm, VH (EI Dupont 101F or Kolon

Industries KN3321V0)

XS2 2 PIN, 2.54mm, PH 33U-022540 4

XS3 2 PIN, 2.54mm, PH 33U-022540 4

XS4 8 PIN, 2.54mm, PH 33U-082540 4

XS5 6 PIN, 2.54mm, PH 33U-062540 4

Description Vendor Part

Number

Miscellaneous

Description Vendor Part

Number

11B-EL817Y 3, 4

22P-VD0935-L1 3, 4

31T-130JTA 3, 4

33U-027921 3, 4

Note

Note

26

Page 27

DISASSEMBLY PROCEDURES

Note: Refer to Figure 2 for the following

information.

CAUTION: Be sure AC mains power is

removed before disassembling the unit.

1. Top Cover Removal

1.1 Using a Phillips-head screwdriver,

remove the nine screws (22) that secure the

top cover (23) to the chassis (15). Lift up the

back edge of the top cover and slide it off

the chassis.

2. DSP PCB Removal

2.1 Perform procedure 1.

2.2 Unplug the wire harnesses at connectors

CN500, CN502 and CON500.

2.3 Locate the wire harness that connects to

CN501. Follow the wire harness to the ferrite

bead. Cut the nylon tie-wrap that secures the

ferrite bead to the chassis. Unplug the wire

harness from the switch-mode power supply

PCB (13) at XS4.

Re-assembly Note: Be sure to re-secure

the ferrite bead to the chassis using a nylon

tie-wrap when replacing the DSP PCB.

3.3 Locate the wire harness at J706. Follow

the wire harness to the switch-mode power

supply PCB (13) and unplug it from the

connector at XS5.

3.4 Using a Phillips-head screwdriver,

remove the twelve screws (1) that secure

the XLR jacks to the back of the chassis

(15). Use a 3/8” nut driver to remove the

two jackscrews that secure the 9-pin D-Sub

connector to the chassis.

3.5 Remove the two screws (4) that secure

the Input / Output PCB (2) to the chassis.

3.6 Slide the I/O PCB toward the front of the

chassis and lift it out.

4. Switch-Mode Power Supply PCB

Removal

4.1 Perform procedure 1.

4.2 Unplug the cable harnesses from the AC

line input at XS1, from the DSP PCB (31) at

XS4 and the Input/Output PCB (2) at XS5.

4.3 Unplug the wire harness that runs from

the Button/LED PCB (29) at XS3 and the AC

Power Switch PCB (17) at XS2.

2.4 Using a Phillips-head screwdriver,

remove the four screws (14) that secure the

DSP PCB (31) to the chassis (15).

2.5 Lift out the DSP PCB.

3. Input / Output PCB Removal

3.1 Perform procedure 1.

3.2 Unplug the ribbon cable at J705. Locate

the wire harness that connects to J202.

Follow the wire harness to the ferrite bead.

Cut the nylon tie-wrap that secures the

ferrite bead to the chassis. Unplug the wire

harness from the DSP PCB (31) at CON500.

Re-assembly Note: Be sure to re-secure

the ferrite bead to the chassis using a nylon

tie-wrap when replacing the DSP PCB.

4.4 Using a Phillips-head screwdriver,

remove the four screws (14) that secure the

switch-mode power supply PCB (13) to the

chassis (15). Lift out the PCB assembly.

5. Button/LED PCB Removal

5.1 Perform procedure 1.

5.2 Unplug the ribbon cable from J302.

Unplug the ribbon cable from J303. Unplug

the wire harness from the switch-mode

power supply (13) at XS3.

5.3 Using a right-angle Phillips-head screwdriver, remove the five screws (16) that

secure the PCB to the front panel (19).

5.4 Slide the PCB toward the rear of the

chassis and lift it out.

27

Page 28

DISASSEMBLY PROCEDURES

6. Display PCB Removal

6.1 Perform procedure 1.

6.2 Unplug the Display PCB’s (18) ribbon

cable from the Button/LED PCB (29) at

J303.

6.3 Using a right-angle Phillips-head screwdriver, remove the four screws (16) that

secure the Display PCB (18) to the plastic

front panel (19).

6.4 Lift out the Display PCB.

Re-assembly Note: Be sure to properly

align the Display PCB with the front panel

when re-installing it. The ribbon cable should

be located near the top of the front panel.

7. Power Switch PCB Removal

7.1 Perform procedure 1.

8.3 Using a Phillips-head screwdriver,

remove the two screws (26) that secure the

plastic front panel to the metal chassis (15).

8.4 Using a small flat-tip screwdriver,

release the nine plastic tabs that secure

the front panel to the chassis. It is easiest

to start at one end of the chassis and work

your way across, gently pulling the front

panel away from the chassis as you go.

9. Front Panel End Cap Removal

9.1 Perform procedure 8.

9.2 Once you have the plastic front panel

(19) assembly removed from the chassis

(15), grasp the end cap you wish to remove

and slide it off of the front panel.

10. Arrow and Select/Load Button

Removal

7.2 Unplug the Power Switch PCB (17) wire

harness from the switch-mode power supply

PCB (13) at XS2.

7.3 Using a right-angle Phillips-head screwdriver, remove the four screws (14) that

secure the PCB to the plastic front panel

(19). Lift out the PCB.

7.4 Pull the ON/OFF power button (24) off of

the power switch SW106. You will need to

re-use this button with the new switch.

Re-assembly Note: Attach the power ON/

OFF button to the new switch using a small

amount of general purpose adhesive approved for use on plastic. Be sure that the

vertical line on the power button faces

toward the top of the front panel.

8. Front Panel Removal

8.1 Perform procedure 1.

10.1 Perform procedure 1.

10.2 Remove the Button/LED PCB (29)

using procedure 5.

10.3 Using a Phillips-head screwdriver,

remove the three screws (26) that secure

the plastic arrow and select/load button

assembly (28) to the front panel (19).

8.2 Using a right-angle Phillips head screwdriver, remove the screws (14) that secure

the Button/LED PCB (29), Display PCB (18)

and the Power Switch PCB (17) to the

plastic front panel (19).

28

Page 29

TEST PROCEDURES

Test Conditions

All AC audio measurements should be band

limited to 30 KHz. AC power is to be applied

to product variants as follows:

Country VAC

US/Canada 120VAC/60Hz

Europe 230VAC/50Hz

Japan 100VAC/60Hz

UK/Singapore 230VAC/50Hz

Australia 240VAC/50Hz

1. Idle Current Test

Apply AC mains voltage to the unit and verify

the idle current as follows:

Country Max Current

US/Canada 120 mA

Europe 60 mA

Japan 120 mA

UK/Sing 60 mA

Australia 60 mA

2. Power switch and On-Pop Test

Turn the unit on by pressing the power

switch on the front panel and verify the

correct firmware revision (i.e., 1.4.4).

3.2 Apply a 1kHz, -39dBu signal to Input 1.

Apply a 1kHz, -50dBu signal to Input 2.

Verify that the Signal 1 LED is GREEN.

Verify that the Clip 1 LED is OFF. Verify that

the Signal 2 LED and the Clip 2 LED are

OFF.

3.3 Apply a 1kHz, +3dBu signal to Input 1.

Apply a 1kHz, -39dBu signal to Input 2.

Verify that the Signal 1 LED is GREEN.

Verify that the Clip 1 LED is RED. Verify that

the Signal 2 LED is GREEN and the Clip 2

LED is OFF.

4. Front Panel PCB Test

4.1 Verify that the front panel LCD and

buttons are operational. This can be done

visually by looking at the display and pressing the five up/down/left/right and select/load

buttons.

4.2 Verify that you can navigate through the

various EQ selection menus and the unit’s

utility menus.

5. Output Noise Test

When the units powers on, verify that there

is no audible on-pop when connected to an

amplifier with 36 dBG, and a loudspeaker.

3. Front panel LED Test

Verify that the “Signal” and “Clip” LEDs

operate as follows.

Note: The mode should be ‘stereo neutral’

with the system input gain set to 0 dB.

3.1 Apply a 1kHz, -50dBu signal to Input 1.

Apply a 1kHz, +3dBu signal to Input 2. Verify

that the Signal 1 LED and the Clip 1 LED are

OFF. Verify that the Signal 2 LED is GREEN

and that the Clip 2 LED is RED.

5.1 Terminate all inputs with 600 Ohms,

each leg to ground and undriven. Terminate

all outputs with 400 Ohms, each leg to

ground.

5.2 Set the unit’s input sensitivity to +6dBu

and the output level to +6dBu. Set the mode

to MONO and the EQ to NONE.

5.3 Measure the output noise levels at the

four XLR output connectors. The noise level

should be <-82dBu (20Hz - 22kHz).

29

Page 30

TEST PROCEDURES

6. Maximum Input Signal and Frequency

Response Test

6.1 Terminate all inputs with 600 Ohms,

each leg to ground and undriven. Terminate

all outputs with 400 Ohms, each leg to

ground.

6.2 Set the unit’s input sensitivity to +18dBu

and the output level to +18dBu. Set the

mode to STEREO and the EQ to NONE.

6.3 Apply a 1kHz, +18dBu signal to Input 1

and Input 2.

6.4 Measure the output levels at the output

XLR connectors, outputs 1, 2, 3 and 4. The

output level should be +17dBu +0.1dB with

<0.01% THD+N (20Hz - 30kHz).

6.5 Apply a 20Hz, +18dBu signal to Input 1

and Input 2.

6.6 Measure the output levels at the output

XLR connectors, outputs 1, 2, 3 and 4. The

output level should be +17dBu +0.1dB with

<0.01% THD+N (20Hz - 30kHz).

7. Maximum Output Signal and

THD+N Test

7.1 Terminate all inputs with 600 Ohms,

each leg to ground and undriven. Terminate

all outputs with 400 Ohms, each leg to

ground.

7.2 Set the unit’s input sensitivity to 0dBu

and the output level to +18dBu. Set the

mode to STEREO and the EQ to NONE.

7.3 Apply a 1kHz, 0dBu signal to Input 1

and Input 2.

7.4 Measure the output levels at the output

XLR connectors, outputs 1, 2, 3 and 4.

The output level should be +17dBu +0.1dB

with <0.01% THD+N (20Hz - 30kHz).

8. Turn-off Pop Test

8.1 Turn the unit OFF by pressing the power

switch on the front panel. Verify that there is

no audible off-pop when connected to an

amplifier with 36dBG and a loudspeaker.

6.7 Apply a 20kHz, +18dBu signal to Input 1

and Input 2.

6.8 Measure the output levels at the output

XLR connectors, outputs 1, 2, 3 and 4. The

output level should be +17dBu +0.1dB with

<0.01% THD+N (20Hz - 30kHz).

30

Page 31

Figure 4. DSP PCB Top Etch Layer and Component Layout

31

Page 32

Figure 5. DSP PCB Internal Etch Layer 1 and Component Layout

32

Page 33

Figure 6. DSP PCB Internal Etch Layer 2 and Component Layout

33

Page 34

Figure 7. DSP PCB Bottom Etch Layer and Component Layout

34

Page 35

Figure 8. Input/Output PCB Top Etch and

Component Layout

Figure 9. Input/Output PCB Bottom Etch and

Component Layout

35

Page 36

Figure 12. Standby Switch

PCB Top Etch and

Component Layout

Figure 10. Button and LED

PCB Top Etch and

Component Layout

Figure 11. Button and LED

PCB Top Etch and

Component Layout

36

Figure 13. Standby Switch

PCB Bottom Etch and

Component Layout

Page 37

Figure 14. Switch Mode Power Supply PCB Top Etch and Component Layout

Figure 15. Switch Mode Power Supply PCB Bottom Etch and Component Layout

37

Page 38

Software Update Installation Procedure

Items Required:

PC with Microsoft

®

Windows® 2000 or XP

9 pin serial data cable, Male to Female

Panaray® Digital Controller II software update

Overview:

The firmware on the Panaray Digital Controller II can be updated to the latest features and EQ

curves for Bose® Professional loudspeakers by using a serial data cable and the 9 pin D-sub

connector labeled COM, located on the back panel of the unit. To perform this update, you will

use Hyperterminal, which is a communications program that is included as part of Microsoft

Windows.

Note: This procedure can be used to update your Panaray Digital Controller II to the latest

software revision, or to downgrade it to a previous version to allow the unit to be used with older

Bose Professional loudspeakers that might not be covered by later versions of software.

Update Instructions:

1. Download the Panaray Digital Controller II update files to a folder on your PC’s desktop.

These files can be found on the Bose Professional Products web site at http://

www.pro.bose.com on the Panaray Digital Controller II web page.

2. Connect the serial data cable to the COM1 serial data port on your PC. Connect the other

end of the cable to the 9-pin D-sub connector labeled COM port located on the back of the

Panaray Digital Controller II unit. Note: DO NOT use a null modem cable. This procedure will

not work with a null modem cable.

3. Connect the unit’s AC line cord to AC mains. Do not turn on the unit at this time.

4. Set up the Microsoft® Windows® Hyperterminal program

to allow the PC to communicate with the Panaray Controller.

On the PC, go to START/PROGRAMS/ACCESSORIES/

COMMUNICATIONS/HYPERTERMINAL. A dialog box will

appear for a new connection. Name the connection and

click OK.

5. When the dialog box shown at right opens, select COM1.

Click OK.

38

Page 39

Software Update Installation Procedure (continued)

6. A dialog box for COM1 properties will open. Select the

options as shown at right. Click OK.

Once you click OK, a terminal window

like the one at right will open.

7. On the front panel of the controller, press and hold the LEFT ARROW and the SELECT/

LOAD buttons. While holding down these buttons, press the POWER button to turn on the unit.

You should see the words PSDC II SOFTWARE UPDATE on the unit’s LCD display. The controller is now ready to receive the update files.

8. On your PC, ensure that the Hyperterminal window for your connection indicates that it is

connected. This information is displayed in the bottom left section of the terminal window border.

If it is not connected, click the CALL radio button on the window’s toolbar or go to CALL/CALL.

You should now be connected.

9. In the terminal window, click

TRANFER/SEND FILE.

39

Page 40

Software Update Installation Procedure (continued)

A send file dialog box will open. Click on the Protocol pulldown menu. Select ZMODEM. Click the BROWSE button

next to the file name box.

Navigate to the folder on your PC that

contains the update files. Select the first

update file in the list. Click OPEN.

Click SEND.

The dialog box shown at right should open and the file

transfer to the controller should begin. Once that file has

completed transfer, repeat step 9 of this procedure for the

other three update files.

10. Once all of the update files have completed transfer, turn off the Panray Digital Controller II

using the POWER button. While holding down the RIGHT ARROW button, turn the controller

back on. This will initialize the unit to the factory presets. This completes the software update

procedure.

Note: If you want to verify that the software has been updated. Turn on the Panaray Digital

Controller II while looking at the display on the LCD panel. It will show the software revision

when the unit is first turned on.

40

Page 41

Panaray® Digital Controller II EQ Curves

ColorSwe ep Trace Line Style Thick Data Axis Comment

1 1 Cyan Solid 1 Anl r. Am pl Left 402II

2 1 Green Solid 1 An lr .Am pl Left 402II+502B

3 1 Black Solid 1 Anl r. Am pl Left 402II+502BEX

4 1 Red Solid 1 An lr .Am pl Left 402II+MB

5 1 Magenta Solid 1 An l r.Am p l Left 402II+AWCS

6 1 Blue Sol id 1 An lr .Am pl Left 402II HF

-65

+15

-60

-55

-50

-45

-40

-35

-30

-25

-20

-15

-10

-5

+0

+5

+10

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

ColorSweep Tr ace Line Style Thi ck Data Axis Comment

1 1 Cyan Solid 1 Anl r. Am pl Left 402II

2 1 Green Soli d 1 An lr .Am pl Left 402II+502B

3 1 Black Solid 1 Anl r. Am pl Left 402II+502BEX

4 1 Red Solid 1 An lr .Am pl Left 402II+MB

5 1 Magenta Solid 1 An l r.Am p l Left 402II+AWCS

6 1 Blue Sol id 1 An lr .Am pl Left 402II HF

-80

+10

-70

-60

-50

-40

-30

-20

-10

+0

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

Measured using an Audio Precision ATS-2 analyzer. 0 dBr calibrated to signal level at 1 KHz in

neutral mode. 10-20kHz AE17 bandpass filter applied.

Settings: Input Sensitivity: 12dB

Output Sensitivity: 12dB

Output Level: 0dB

Input Signal Level: -12dBu

402II CH1, 2

402II CH3, 4

41

Page 42

Panaray® Digital Controller II EQ Curves

ColorSweep Trace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 502A

2 1 Green Sol id 1 An l r.Am p l Left 502A+502B

3 1 Black Solid 1 An lr .Am pl Left 502A+MB

4 1 Red Solid 1 An lr .Am pl Left 502A+AWCS

5 1 Magenta Solid 1 An lr .Am pl Left 502A HF

-80

+10

-70

-60

-50

-40

-30

-20

-10

+0

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

+10

+0

-10

-20

d

-30

B

r

-40

A

-50

-60

-70

-80

20 50 100 200 500 1k 2k 5k 10k

ColorSweep Tr ace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 502A

2 1 Green So lid 1 Anl r.Am p l Left 502A+502B

3 1 Black Solid 1 An lr .Am pl Left 502A+MB

4 1 Red Solid 1 An lr .Am pl Left 502A+AWCS

5 1 Magenta Solid 1 An lr .Am pl Left 502A HF

Hz

502A CH1, 2

502A CH3, 4

42

Page 43

Panaray® Digital Controller II EQ Curves

ColorSweep Tr ace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 802III

2 1 Green Sol id 1 An l r.Am p l Left 802II+502B

3 1 Black Solid 1 An lr .Am pl Left 802III+502BEX

4 1 Red Solid 1 An lr .Am pl Left 802III+MB

5 1 Magenta Solid 1 An lr .Am pl Left 802III+AWCS

6 1 Blue Solid 1 Anl r. Amp l Left 802III HF

-80

+10

-70

-60

-50

-40

-30

-20

-10

+0

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

ColorSweep Tr ace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 802III

2 1 Green Sol id 1 An l r.Am p l Left 802III+502B

3 1 Black Solid 1 An lr .Am pl Left 802III+502BEX

4 1 Red Solid 1 An lr .Am pl Left 802III+MB

5 1 Magenta Solid 1 An lr .Am pl Left 802III+AWCS

6 1 Blue Solid 1 Anl r. Amp l Left 802III HF

-80

+10

-70

-60

-50

-40

-30

-20

-10

+0

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

802III CH1, 2

802III CH3, 4

43

Page 44

Panaray® Digital Controller II EQ Curves

ColorSweep Tr ace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 802IIISTK

2 1 Green Sol id 1 An l r.Am p l Left 802IIIST+502B

3 1 Black Solid 1 An lr .Am pl Left 802IIIST+502X

4 1 Red Solid 1 An lr .Am pl Left 802IIISTK+MB

5 1 Magenta Solid 1 An lr .Am pl Left 802IIIST+AWCS

6 1 Blue Solid 1 Anl r. Amp l Left 802IIISTK HF

-80

+10

-70

-60

-50

-40

-30

-20

-10

+0

d

B

r

A

20 50 100 200 500 1k 2k 5k 10k

Hz

ColorSweep Tr ace Line Style Th ick Data Axi s Com ment

1 1 Cyan So lid 1 Anl r.Am p l Left 802IIISTK

2 1 Green Sol id 1 An l r.Am p l Left 802IIIST+502B