Page 1

FreeSpace® Business Music System

Model E4 Series II

Digital Signal Processor

and Power Amplifier

©2008 Bose Corporation

Service Manual

Reference Number 278977-SM Rev. 01

Electronic Copy Only

Page 2

CONTENTS

Contents.............................................................................................................................................2

Safety Information.............................................................................................................................3

Warranty.............................................................................................................................................3

Product Description..........................................................................................................................4

Specifications.............................................................................................................................. 5-10

Electrostatic Discharge Sensitive (ESDS) Device Handling .......................................................11

Part List Notes................................................................................................................................. 11

Amplifier Module Repair Information............................................................................................11

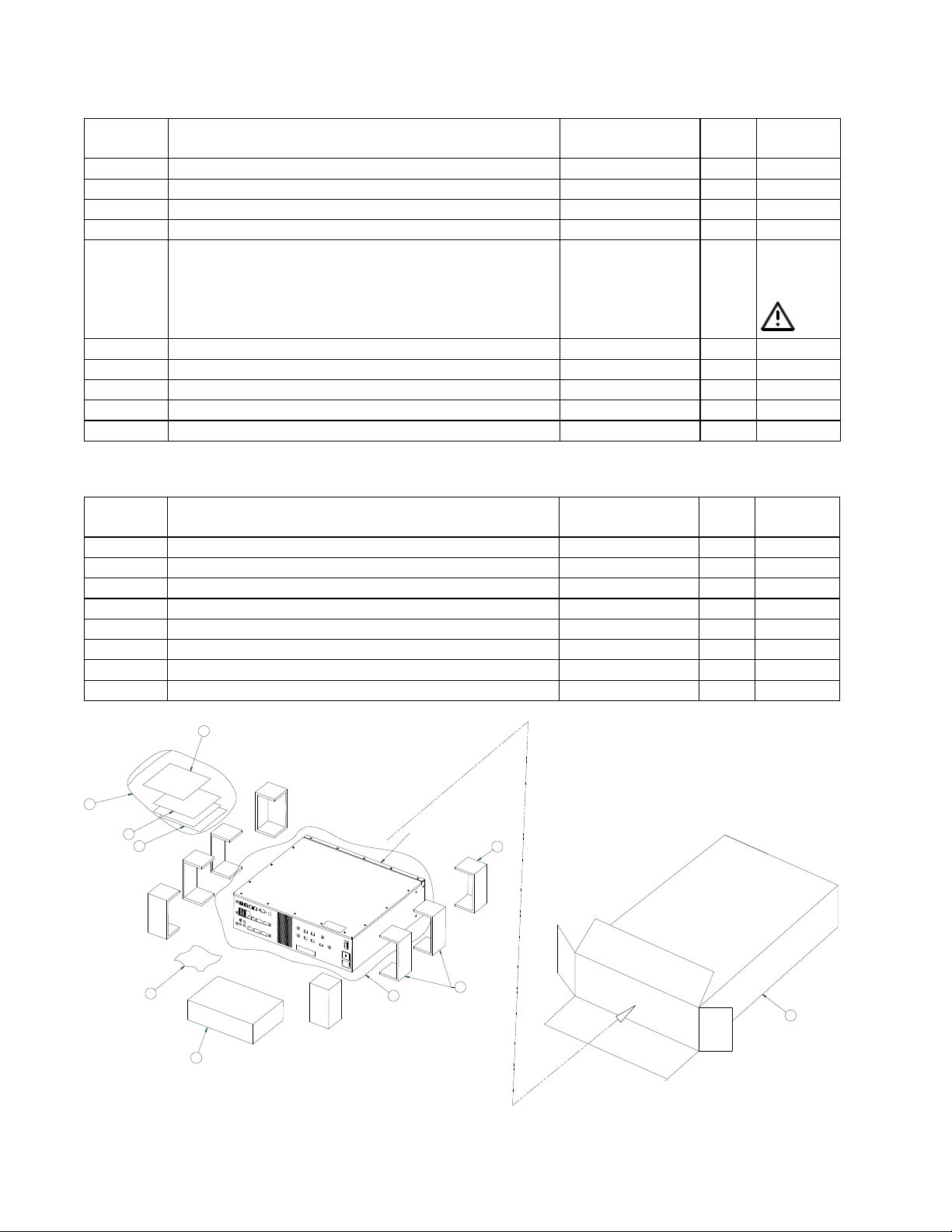

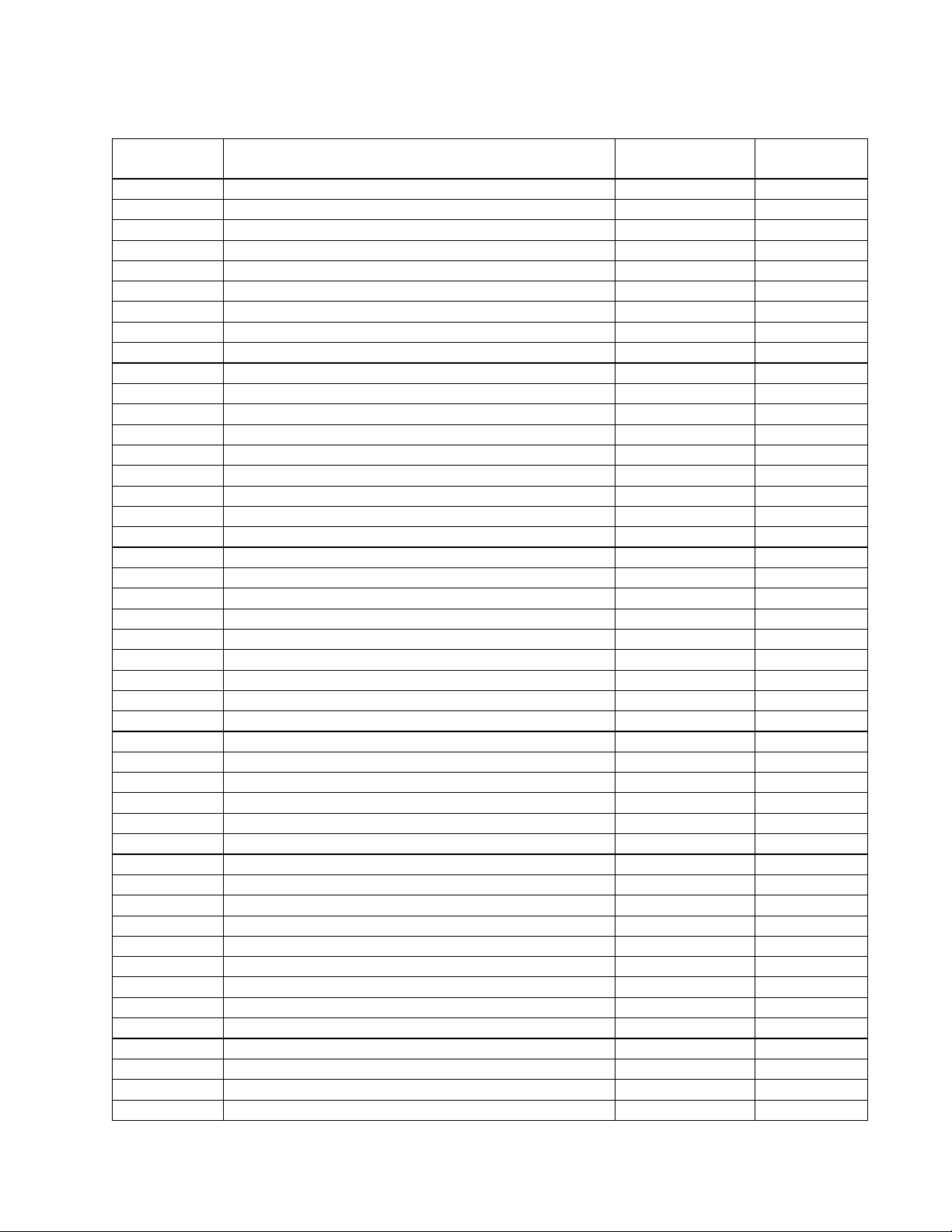

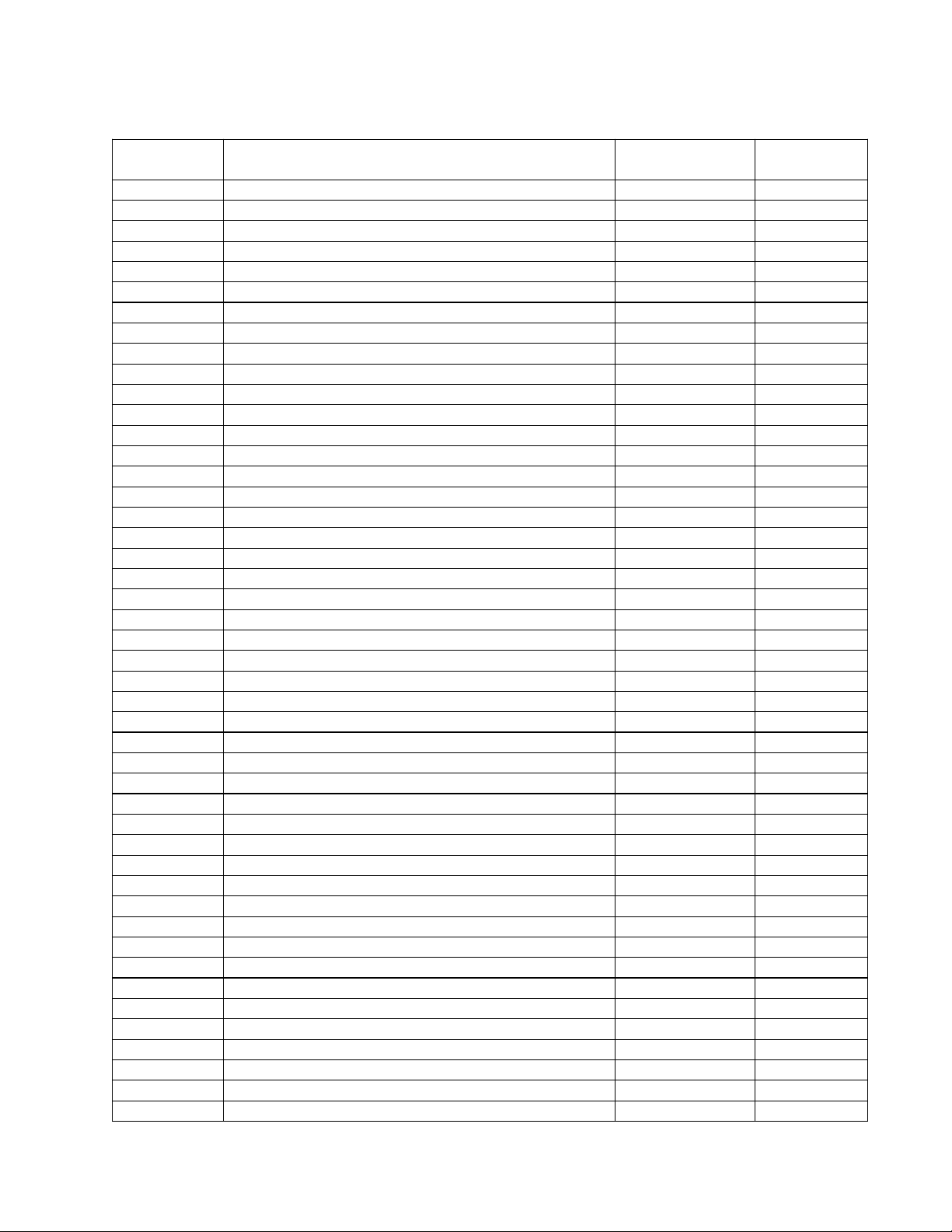

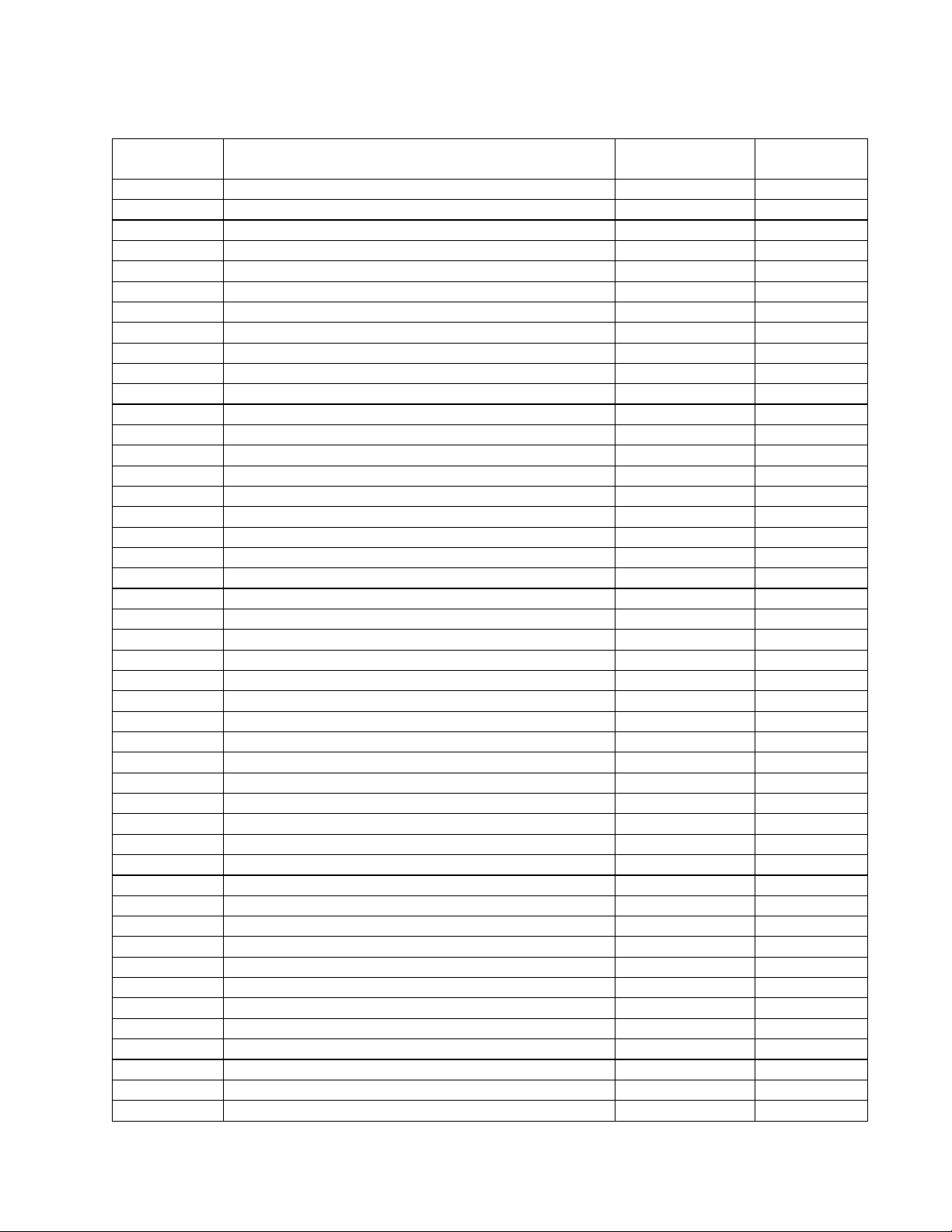

Packaging Part List, FreeSpace

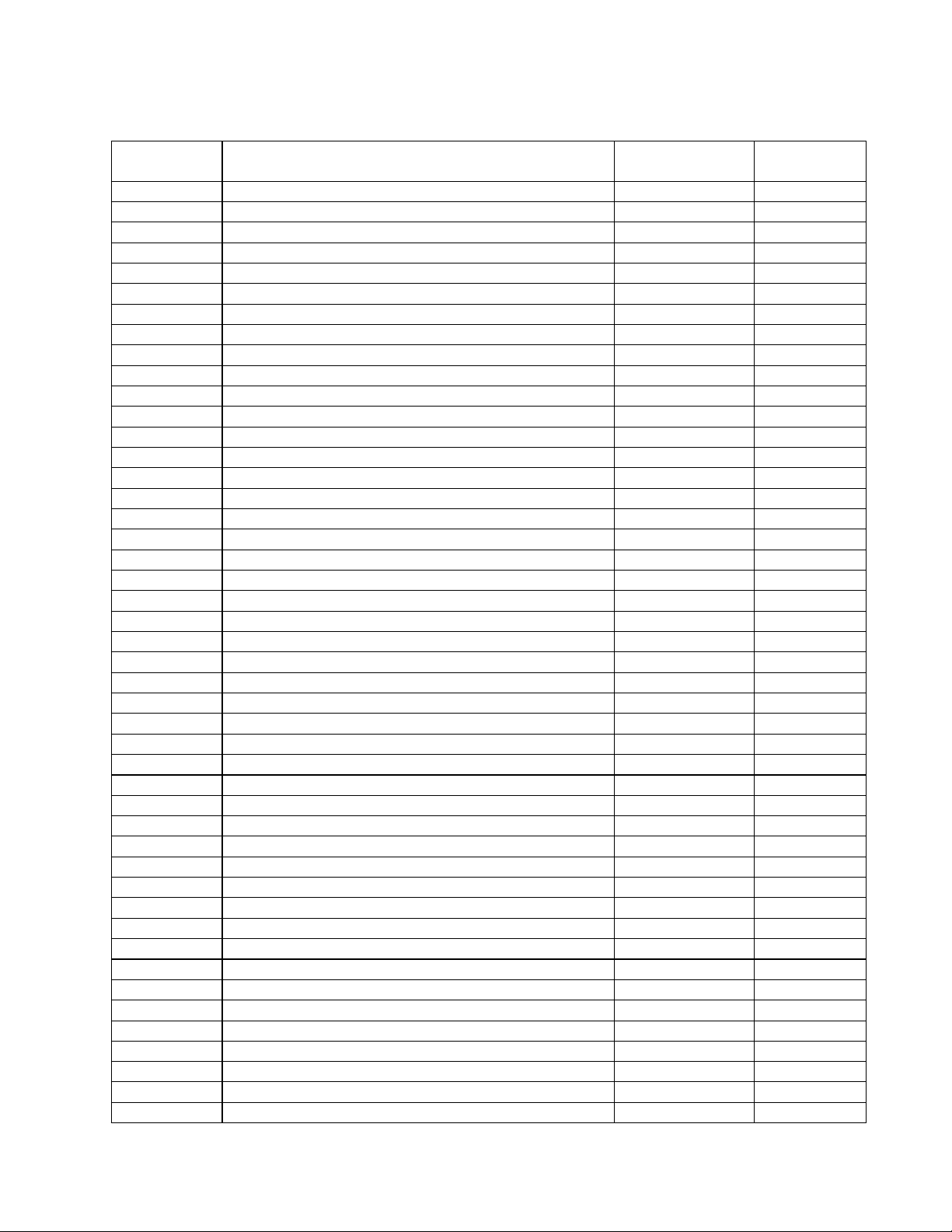

Figure 1. FreeSpace E4 Series II System Packaging View ..............................................................12

Accessory Kit Part List (not shown) .............................................................................................12

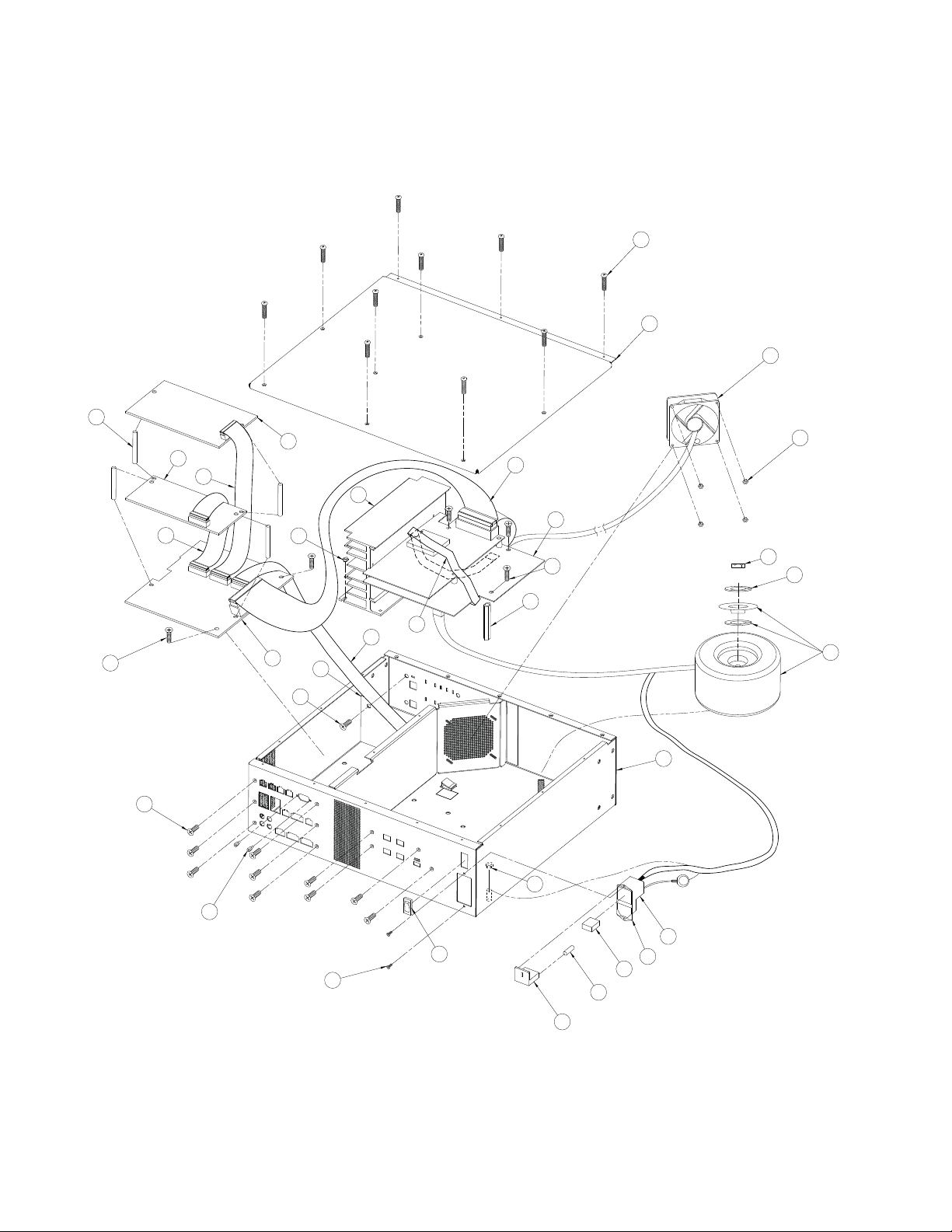

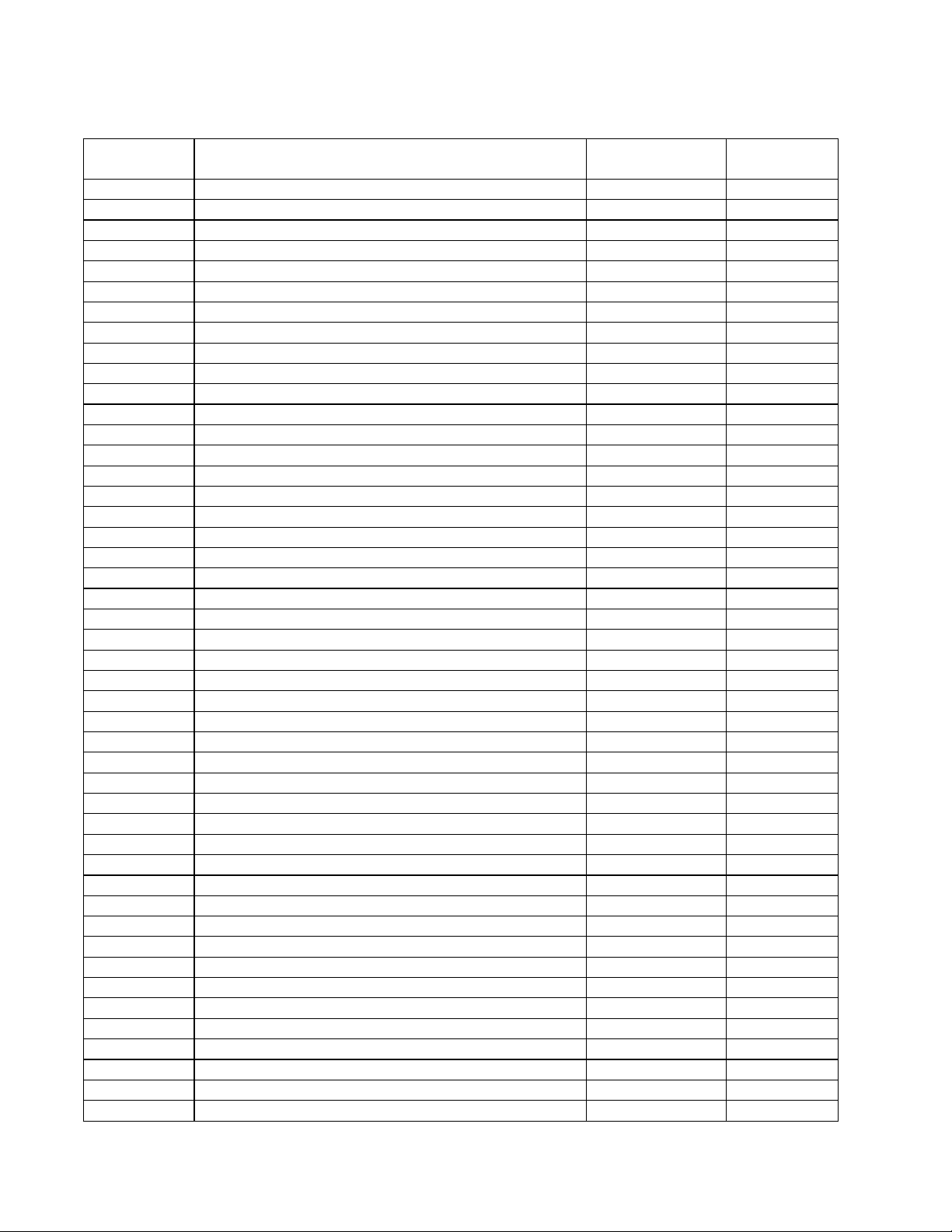

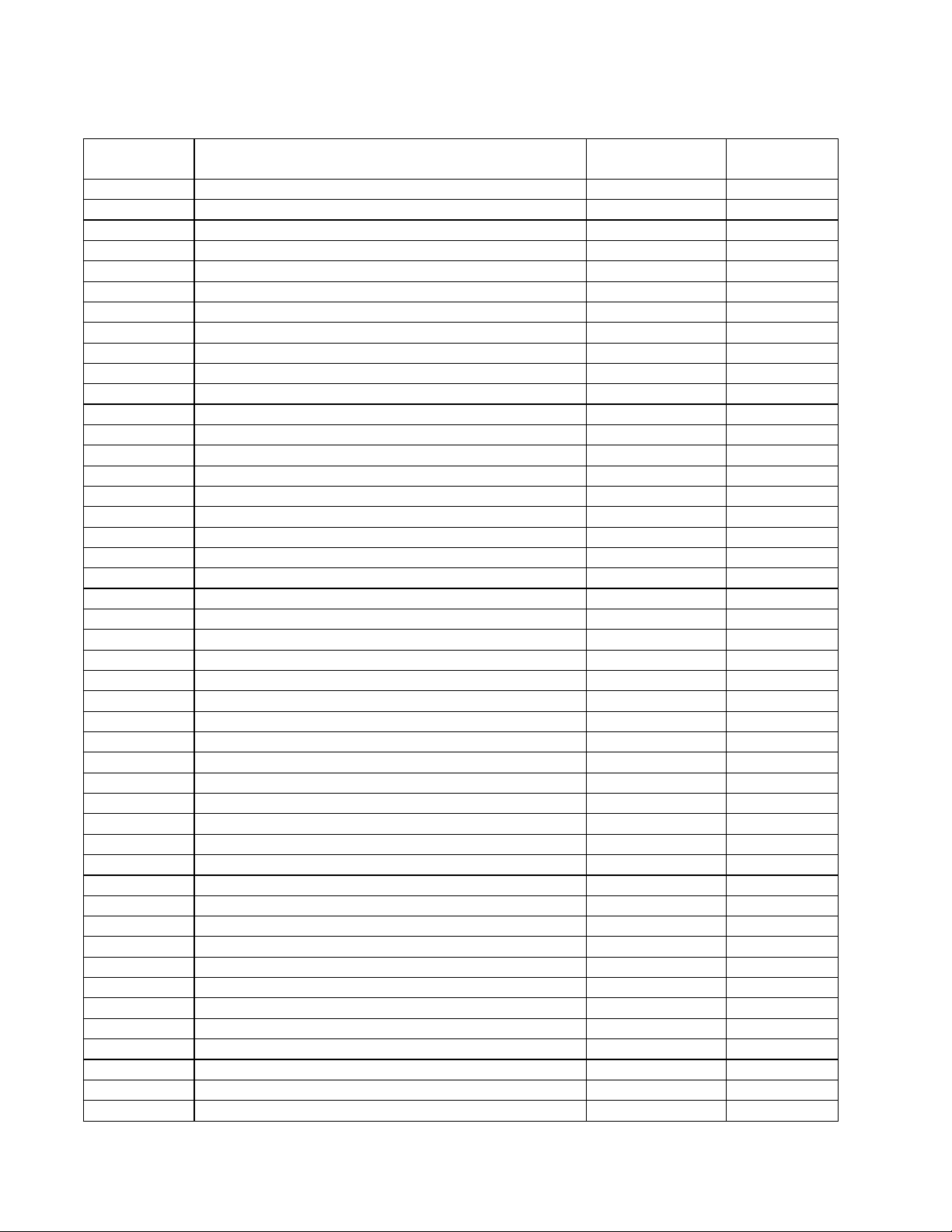

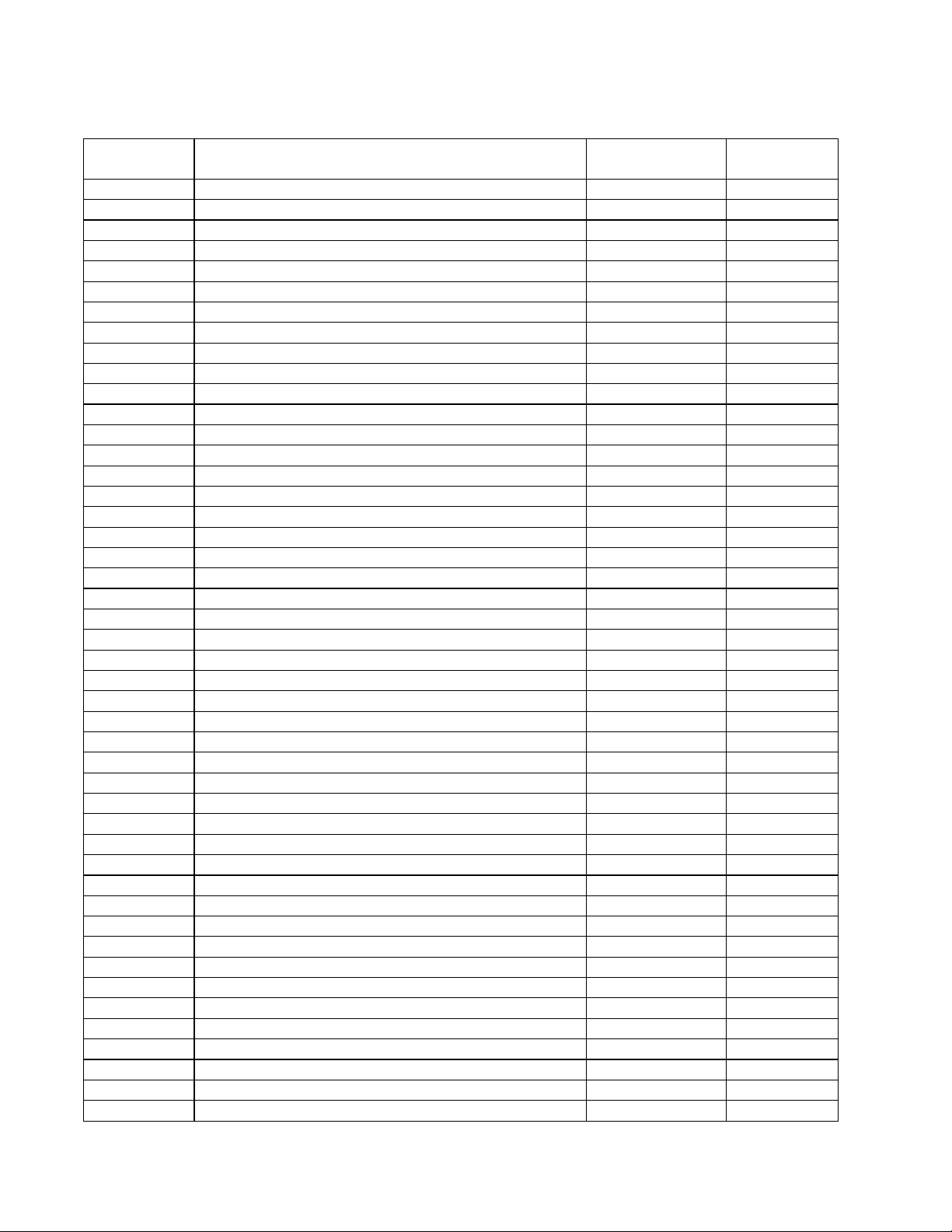

Main Part List, FreeSpace E4 Series II Business Music System (see Figure 2)........................13

Figure 2. FreeSpace E4 Series II Business Music System Exploded View ......................................14

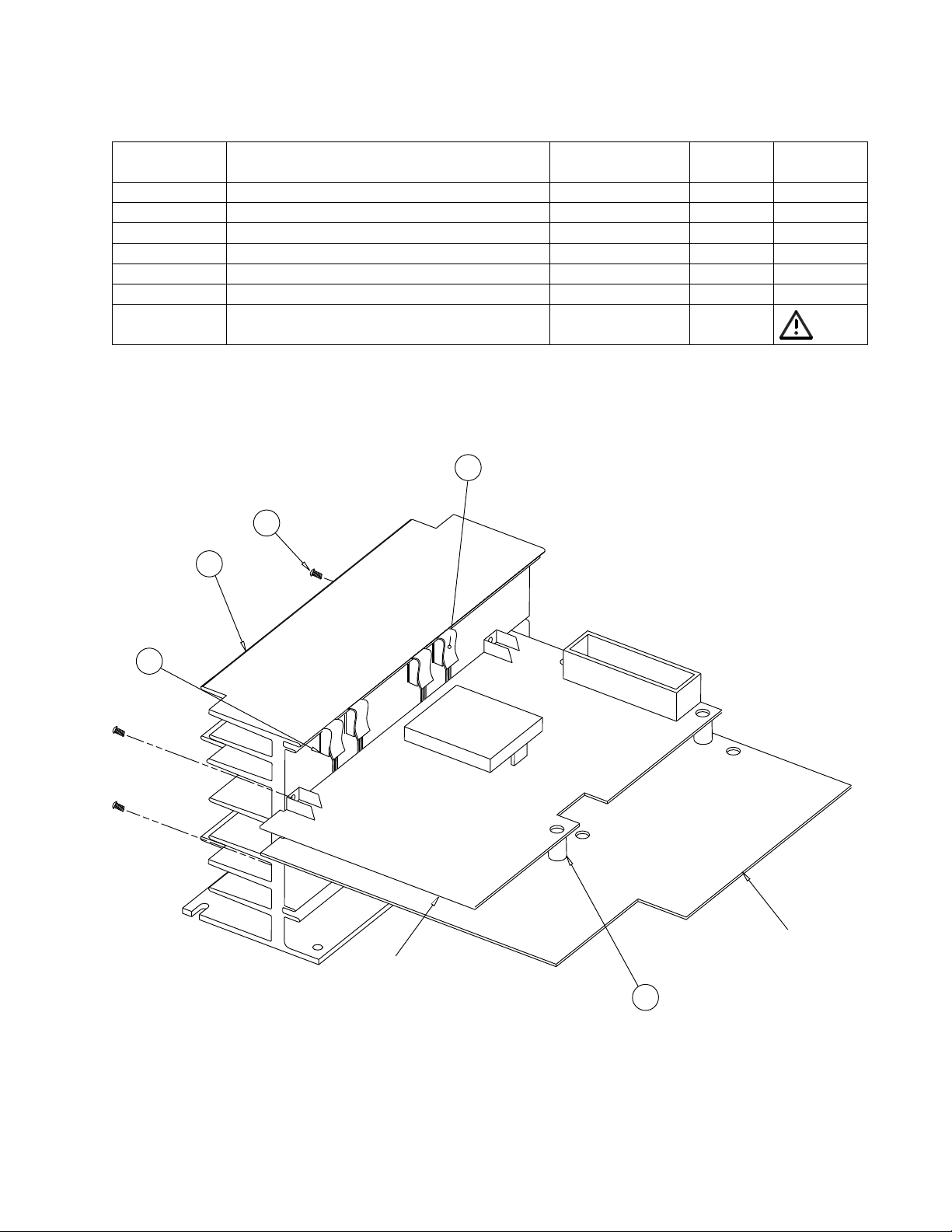

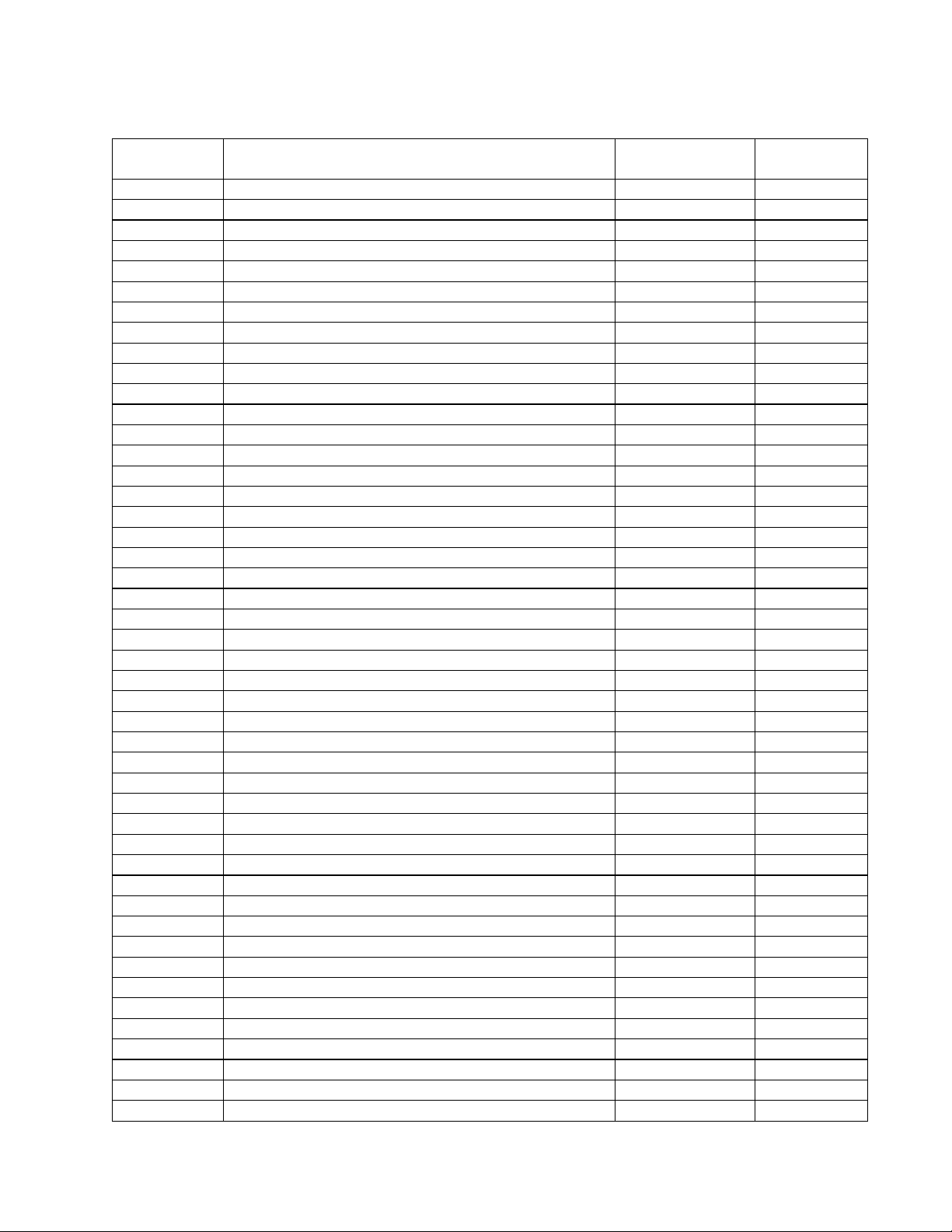

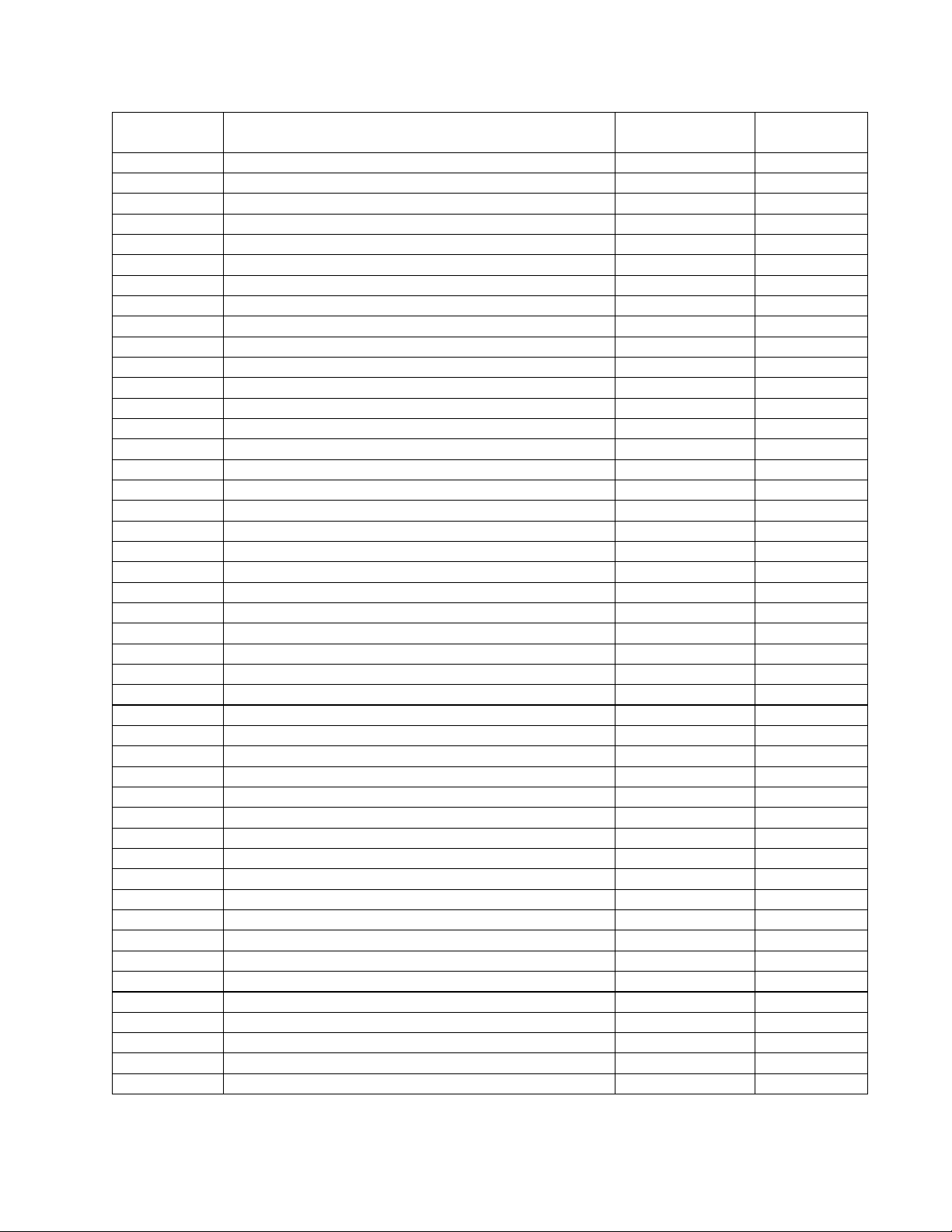

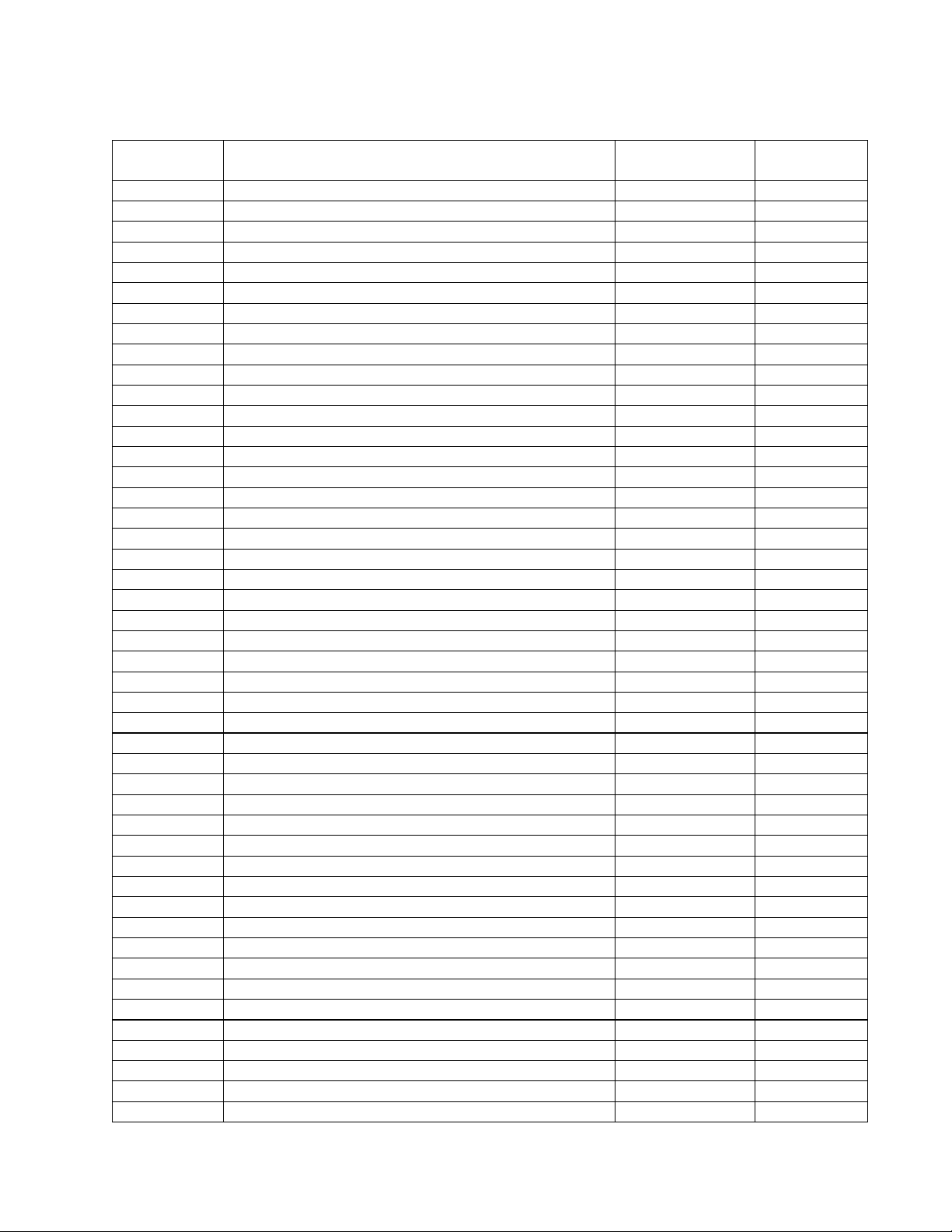

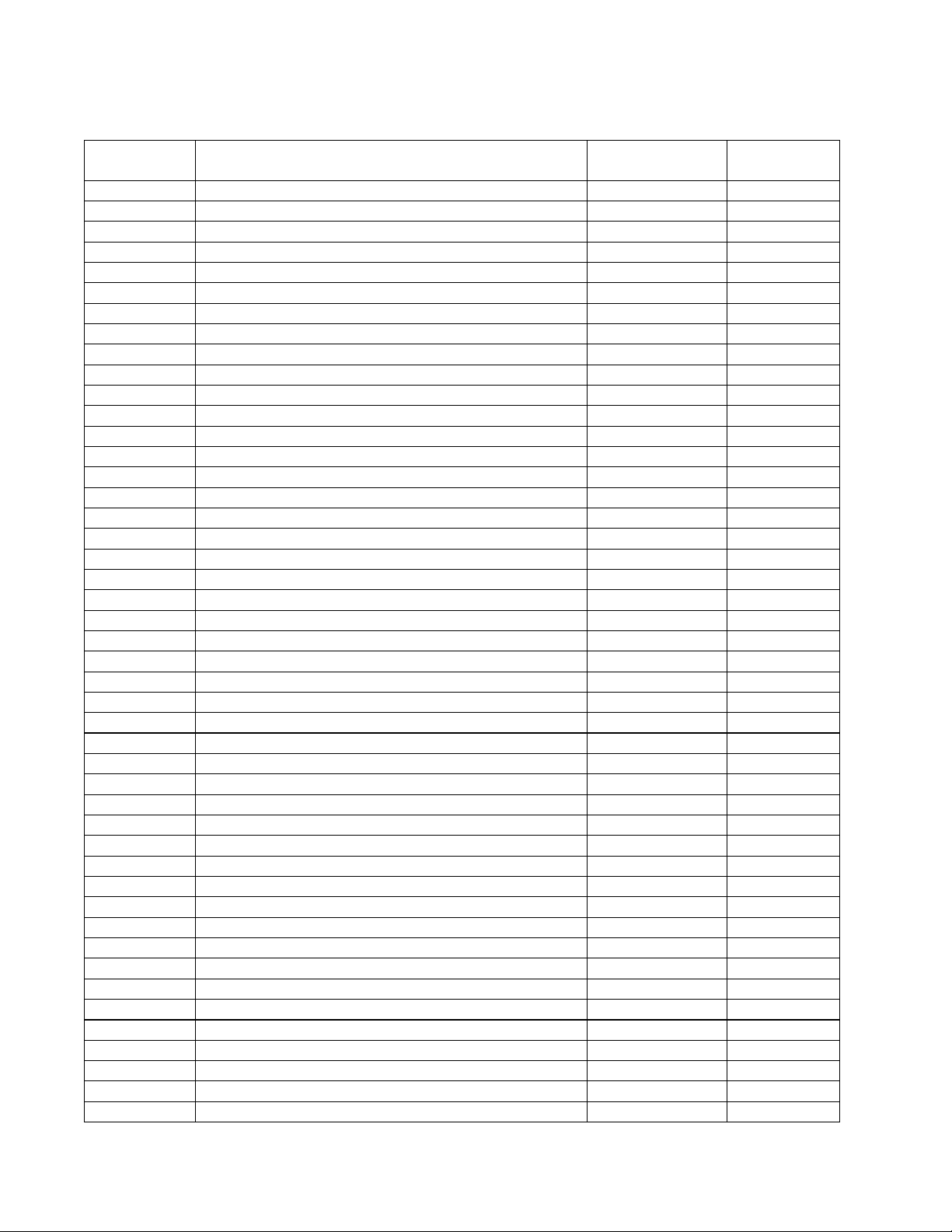

Main Part List, E4 Series II Power Supply / Power Amplifier PCB Module (see Figure 3) .......15

Figure 3. E4 Series II Power Supply / Power Amplifier PCB Module................................................15

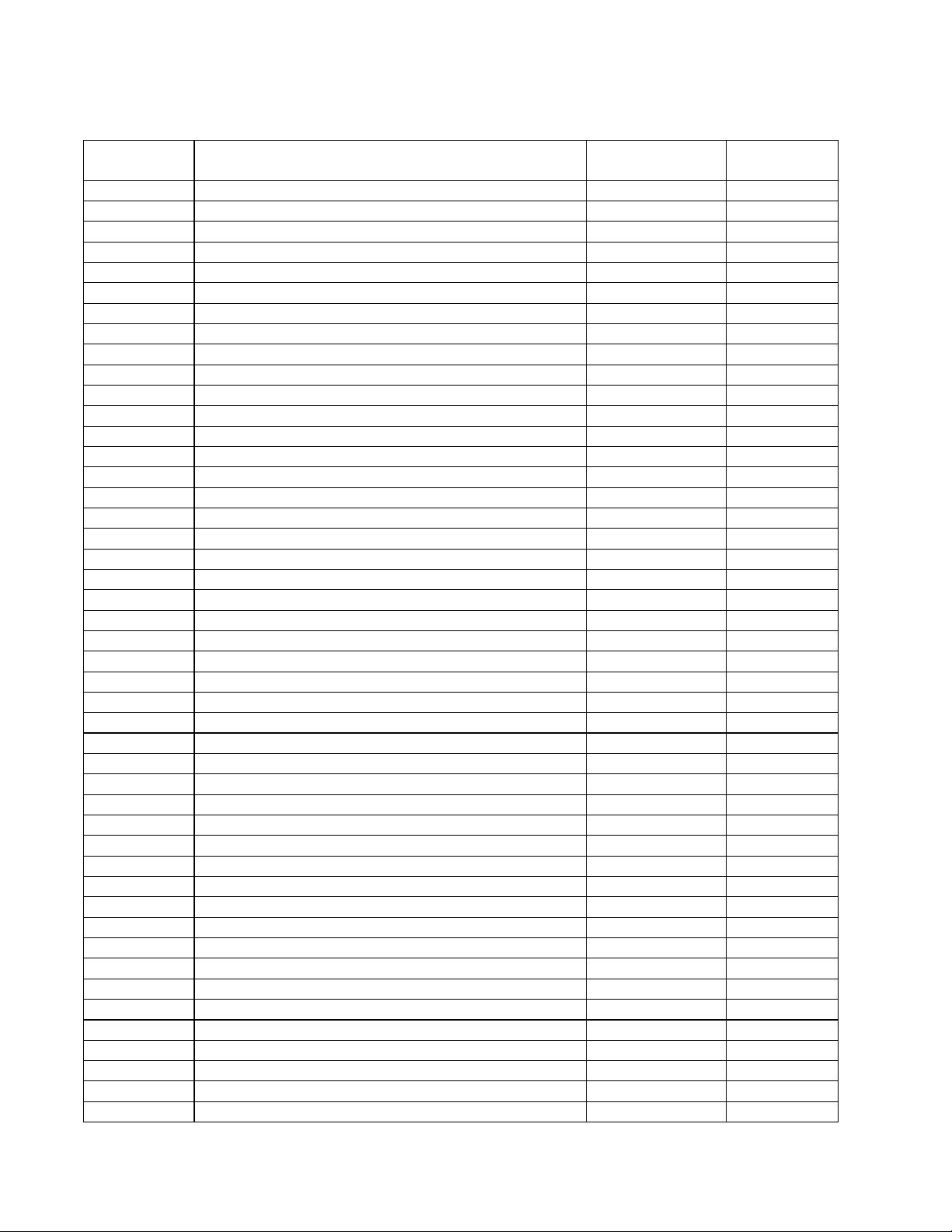

Electrical Part Lists................................................................................................................... 16-72

Digital Signal Processor / User Interface PCB Assembly ..................................................... 16-36

E4 Series II Power Supply / Power Amplifier PCB Assembly ............................................... 37-51

FreeSpace 4400 Power Supply / Power Amplifier PCB Assembly........................................ 52-69

FreeSpace 4400 Power Amplifier Driver PCB Assembly....................................................... 70-72

Disassembly Procedures ......................................................................................................... 73-74

Figure 4. E4 II Amplifier Module Assembly .......................................................................................74

Test Procedure Setup ............................................................................................................... 75-76

Test Procedures ........................................................................................................................ 77-80

Troubleshooting........................................................................................................................ 81-89

Theory of Operation.................................................................................................................. 90-97

Accessories .....................................................................................................................................98

Figure 5. Flash Memory PCB Component Layout ............................................................................99

Figure 6. DSP PCB Assembly Component Layout ...........................................................................99

Figure 7. Wallplate Sense PCB Assembly Component Layout.......................................................100

Figure 8. Mic Sense PCB Assembly Component Layout................................................................100

Figure 9. Front Panel Display PCB Assembly Component Layout .................................................100

Figure 10. E4 Series II Upper and Lower Amplifier PCB Assembly Component Layout ................101

Figure 11. FS 4400 Upper Amplifier PCB Top Etch and Component Layout..................................102

Figure 12. FS 4400 Upper Amplifier PCB Bottom Etch and Component Layout............................103

Figure 13. FS 4400 Lower Amplifier PCB Top Etch and Component Layout..................................104

Figure 14. FS 4400 Lower Amplifier PCB Bottom Etch and Component Layout............................105

Service Bulletin ..................................................................................................................... 106-107

Service Manual Revision History.................................................................................................108

®

E4 Series II Business Music System (see Figure 1) ............12

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

UL6500 / UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position

and then in OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical

return path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the

unit power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products, the resistance measured to exposed input/output connectors should be between 4 and

infinite MOhms. If it is not within the limits specified, there is the possibility of a shock hazard,

and the unit must be repaired and rechecked before it is returned to the customer.

CAUTION: The Bose® E4 Series II Business Music System contains no

user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose E4 Series II Business Music System is covered by a limited 5-year transferable

warranty.

3

Page 4

PRODUCT DESCRIPTION

E-4 Series II Business Music System

The Bose® FreeSpace® E-4 Series II Business Music System is an integrated four-channel

digital signal processor and 400-Watt power amplifier for 70/100V business music applications.

The E-4 chassis provides a total of four source inputs (two Line In, one Mic/Line and one Mic/

Line/Page) to meet the needs of most business music installations. A Music on Hold (MOH)

output is also provided for simple integration into a phone system.

As a single component, the chassis provides all of the processing and control features required

for one to four zone business music applications. These features include:

• Auto Volume: When used with the optional FreeSpace Auto Volume Sense Mic, the E-4

system dynamically controls the program level in each zone so that the audio program

material can always be heard, regardless of the background noise.

• Scheduling: Allows you to program the E-4 system for automated on/off and source

selections according to time of day or day of week.

• Opti-Voice® Paging: Provides the appropriate sound level regardless of variations in

speech projection.

• Source Leveling: Automatically compensates for variations in source input levels.

• Dynamic Equalization: Maintains tonal balance at all listening levels.

• Room Equalization: Provides easy adjustment of tonal balance in each zone.

• Limiting: Protects loudspeakers from unwanted transient power loads.

• Signal Router: Meets the demands of most four-zone systems, allowing for any input signal

to be routed to any of the amplifier outputs.

• RS-232 Connection: Provides easy interfacing to your PC.

• Contact Closure Input: Allows remote power sequencing.

The integrated 400-Watt power amplifier features a patented power-sharing technology which

allocates power to each output.

For example, if you have a two-zone system that requires 5 Watts in zone 1 and 395 Watts in

zone 2, the FreeSpace E-4 Series II system distributes the power based on those needs.

The E-4 Series II also includes an easy-to-replace memory module, which holds a design file

and the current hardware configuration.

4

Page 5

SPECIFICATIONS

Audio Input Source 1 unbalanced RCA, shell grounded through a 301 Ohm resistor

Connectors: Source 2 unbalanced RCA, shell grounded through a 301 Ohm resistor

Page balanced 4 pin Beau style: +, -, ground and contact closure in

Aux/Mic/Line 3 pin Beau style, +, - and ground

Mic 1-4 3 pin Beau style, +, - and ground

Direct In 4 pin Beau style, +, -, ground, and contact closure in

Audio Output

Connectors: Line out 4 pin Beau style, +, -, ground, and contact closure in

MOH out 2 pin Beau style, + and Ground

Amp 1-4 2 pin, Beau style, + and -

Control Connectors: Remote 1-4 RJ-45, 8 pin, ground shell

Standby In 2 pin Beau style, contact closure in and ground

Dimensions: 5.25"H x 16.5"W x 15.5"D (13.3 x 43.8 x 39.4 cm)

Weight: 30 lbs (13.6 kg)

AC Mains input: IEC standard User selectable 100/120 or 220/240V

3 pin 50/60 Hz

receptacle 300 Watts maximum

Overall Performance

Nominal Limits Conditions

Gain: 0 dB +1 dB at 1 kHz; input gain set to nominal 0 dB

Dynamic range: 100 dB >/= 96 dB measured with ADC/DAC full scale mapped to

+17 dBV; this is THD +N measured at FS-60,

through A-weighting filter, and expressed in dB

below full scale

THD+N: .05% .1% at +10 Vrms output, for signal frequencies from

30 Hz to 20 kHz

Crosstalk at 1 kHz: -80 dB </= -70 dB terminate unused input terminals with 100 Ohm

balanced-connected resistors.

Crosstalk at 10 kHz: -60 dB </= -50 dB terminate unused input terminals with 100 Ohm

balanced-connected resistors.

Frequency response: 30 - 20 kHz +3 dB reference 1 kHz, measured at 0 dBV input

Output noise: -70 dBV </= -65 dBV channel noise measured through an A

weighting filter. Gain structure set to deliver

rated power and expressed in dBV

5

Page 6

SPECIFICATIONS

Line Input Source 1 and 2

Nominal Limits Conditions

Source impedance: 200 Ohms 10 to 2k Ohm frequency response specification maintained

with sources over this range

Input impedance

differential: +/> 50k Ohm +/-20% at 1 kHz

CMRR referred to 80 dB >/= 74 dB at 1 kHz, 20 dB gain, 200 Ohm source

output: impedance

Input sensitivity for -20 dBV to +/-1 dB at 1 kHz

codec FS: +17 dBV

Gain, all settings: 20 dB to +/-1 dB 1 kHz, 50 Ohm source

-20 dB

Maximum input level: +17 dBV >/= +17 dBV THD+N </= 0.3%, 30-20 kHz, 0 dB gain

THD+N: .001% .01% at +10 dBV output, 1 kHz, 20 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB

Crosstalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 30 to 20 kHz +/-1.5 dB reference 1 kHz, measured at 20 dB gain and

with 0 dBV output

Page and Aux/Mic Inputs

Nominal Limits Conditions

Source impedance: 200 Ohms 10 to 2k Ohm frequency response specification maintained

with sources over this range

Input impedance

differential: 20k Ohm +/-5% at 1 kHz

Equivalent input noise at 60 dB, at 60 dB, A-weighted RMS, 200 Ohm source

at INA129 gains of 60 -130 dBV -127 dBV termination

dB, 40 dB, 20 dB and at 40 dB, at 40 dB,

0 dB: -127 dBV -125 dBV

at 20 dB, at 20 dB,

-115 dBV -113 dBV

at 0 dB, at 0 dB,

-96 dBV -93 dBV

6

Page 7

SPECIFICATIONS

Page and Aux/Mic Inputs (continued)

Nominal Limits Conditions

CMRR referred 90 dB >/= 70 dB at 1 kHz, 60 dB gain, from source of nominal

to output: 200 Ohms

Input sensitivity for -60 dBV to +/-1 dB at 1 kHz

codec FS: +17 dBV

Gain, all settings: 20 dB to +/-1 dB 1 kHz, 50 Ohm source

-20 dB

Maximum input level: +17 dBV >/= 10 dBV THD+N </= 0.3%, 20-20 kHz, 0 dB gain

THD+N: .001% .01% at +10 dBV output, 1 kHz, 60 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB

Crosstalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 30 Hz to +0/-0.5 dB Reference 1 kHz, measured at 60 dB gain and

20 kHz with 0 dBV output

Sense Mic inputs

Nominal Limits Conditions

Source impedance: 200 Ohms 10 to 2k Ohm frequency response specification maintained

with sources over this range

Input impedance

differential: 20k Ohm +5% at 1 kHz

Equivalent input noise at 60 dB, at 60 dB, A weighted RMS, 200 Ohm source termination

at INA129 gains of 60 -127 dBV -125 dBV

dB, 40 dB and 20 dB: at 40 dB, at 40 dB,

-115 dBV -112 dBV

at 20 dB, at 20 dB,

-96 dBV -93 dBV

CMRR referred

to output: 90 dB >/= 60 dB at 1 kHz, 60 dB gain, from source of nominal

200 Ohm

Phantom power: +12V +/-1V open circuit

Input sensitivity for -60 dBV to +/-1 dB at 1 kHz

codec FS: +20 dBV

Gain, all settings: -60 dB to +/-1 dB 1 kHz, 50 Ohm source

+20 dB

7

Page 8

SPECIFICATIONS

Sense Mic inputs (continued)

Nominal Limits Conditions

Maximum input level: +10 dBV >/= 7 dBV THD+N </= 0.3%, 20-20 kHz, 0 dB gain

THD+N: -84 dB </= -80 dB at +10 dBV output, 1 kHz, 60 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB

Crossalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 20 Hz to +0/-0.5 dB reference 1 kHz, measured at 60 dB gain and

20 kHz with 0 dBV output

Direct Input

Nominal Limits Conditions

Source impedance: 200 Ohms 10 to 2k Ohm frequency response specification maintained

with sources over this range

Input impedance

differential: +/> 10kOhms +/-20% at 1 kHz

CMRR referred

to output: 92 dB >/= 60 dB at 1 kHz, 20 dB gain, 200 Ohm source

impedance

Input sensitivity -20 dBV to +/-1 dB at 1 kHz

for codec FS: +17 dBV

Gain: 0 dB +/-1 dB from input connector to amplifier input stage

Maximum input level: +17 dBV >/= +17 dBV THD+N </= 0.3%, 30-20 kHz, 0 dB gain

THD+N: .001% .01% at +10 dBV output, 1 kHz, 20 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB

Crosstalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 30 Hz to +0/-0.5 dB reference 1 kHz, measured at 20 dB gain and

20 kHz with 0 dBV output

Line Outputs

Nominal Limits Conditions

Output impedance: 200 Ohms +/-1% impedance at 1 kHz, each output

terminal

Maximum output level: +17 dBV >/= +17 dBV 1 kHz, THD less than 0.1%, load 10 k Ohm,

differential

8

Page 9

SPECIFICATIONS

Line Outputs (continued)

Nominal Limits Conditions

CMRR referred

to output: 92 dB >/= 60 dB at 1 kHz, 20 dB gain, 200 Ohm source

impedance

Output noise: -90 dBV </= -85 dBV A-weighted, set for 0 dB gain

THD+N: .001% .01% at +10 dBV output, 1 kHz, 20 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB set for 0 dB gain, no limiting, terminate the

unused input with a 50 Ohm resistor

Crosstalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 30 Hz to +0/-1.0 dB reference 1 kHz, measured at 20 dB gain and

20 kHz with 0 dBV output

Turn on/off pop: 10 mV peak </= 50 mVpk as monitored by a listener, must be inaudible at

full gain using a Model 32 loudspeaker tapped

at 32W, with the unit set for no EQ and the

loudspeaker 3 feet from listener

Music on Hold (MOH)

Nominal Limits Conditions

Output impedance: 400 Ohms +/-1% impedance at 1 kHz

Maximum output level: +17 dBV >/= +17 dBV 1 kHz, THD less than 0.1%, load 10 kOhm,

differential

Output noise: -90 dBV </= -85 dBV A-weighted, set for 0 dB gain

THD+N: .001% .01% at +17 dBV output, 1 kHz, 0 dB gain

Crosstalk at 1 kHz: -90 dB </= -80 dB set for 0 dB gain, no limiting, terminate the

unused input with a 50 Ohm resistor

Crosstalk at 10 kHz: -70 dB </= -60 dB

Frequency response: 20 Hz to +0/-1.0 dB reference 1 kHz, measured at 0 dB gain and

15 kHz with 0 dB output

Turn on/off pop: 10 mV peak </= 50 mVpk as monitored by a listener, must be inaudible at

full gain using a Model 32 loudspeaker tapped

at 32W, with the unit set for no EQ and the

loudspeaker 3 feet from listener

9

Page 10

SPECIFICATIONS

Power Amplifier

Nominal Limits Conditions

Power bandwidth: 30 Hz to 1% THD loaded at 25 Ohms

20 kHz

Frequency response: 30 Hz to +/-3 dB output voltage of 10 Vrms over a load

20 kHz impedance of 12.5 Ohms to 1000 Ohms

THD+N at 70.7 Vrms, .05% .1% 30 Hz to 20 kHz, 25 Ohm load, A weighted

200W:

THD+N at 70.7 Vrms, .5% 1 % 7 kHz, 12.5 Ohm load, A weighted

400W:

THD+N at 100 Vrms, .05% .1% 30 Hz to 20 kHz, 25 Ohm load, A weighted

200W:

THD+N at 100 Vrms, .5% 1% 7 kHz, 12.5 Ohm load, A weighted

400W:

Sensitivity at 70V: 11 dBV +/-1 dBV

Sensitivity at 100V: 14 dBV +/-1 dBV

Gain: 26 dB +/-0.5 dB

Output noise: -70 dBV -65 dBV A-weighted with a 20 kHz filter

Crosstalk at 1 kHz: -90 dB </= -80 dB set for 0 dB gain, no limiting, terminate the

unused input with a 50 Ohm resistor

Crosstalk at 10 kHz: -70 dB </= -60 dB

Turn on/off pop: 10 mV peak </= 50 mVpk as monitored by a listener, must be inaudible at

full gain using a Model 32 loudspeaker tapped

at 32W, with the unit set for no EQ and the

loudspeaker 3 feet from listener

10

Page 11

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

AMPLIFIER MODULE REPAIR INFORMATION

The Amplifier / Power Supply PCB assembly, part number 278982-001, originally used in the

E4 Series II amplifier is no longer available. This is due to the Tripath amplifier driver module

going obsolete.

For amplifier board related failures in the E4 Series II, the amplifier module assembly used in

the FreeSpace® 4400 amplifier must be used as a replacement part. This requires some minor

modifications to the E4 II chassis and a kit of parts that includes adapter brackets, screws and

an EMI gasket. The entire amplifier assembly, including the heatsink, must be replaced. Refer to

service bulletin 278977-B2, located in the back of this manual as well as on the Bose® Service

web sites at http://intranet.bose.com/tsg or http://serviceops.bose.com for more information.

Required Parts:

• FreeSpace 4400 Amplifier Module Assembly , Bose

®

part number 301391

• FreeSpace 4400 Amplifier Module adapter kit, Bose part number 311963

Note: This procedure cannot be used on any of the E4 Series I amplifier versions. In addition,

it cannot be used on the E4 Series II Japan version, product code 036006.

11

Page 12

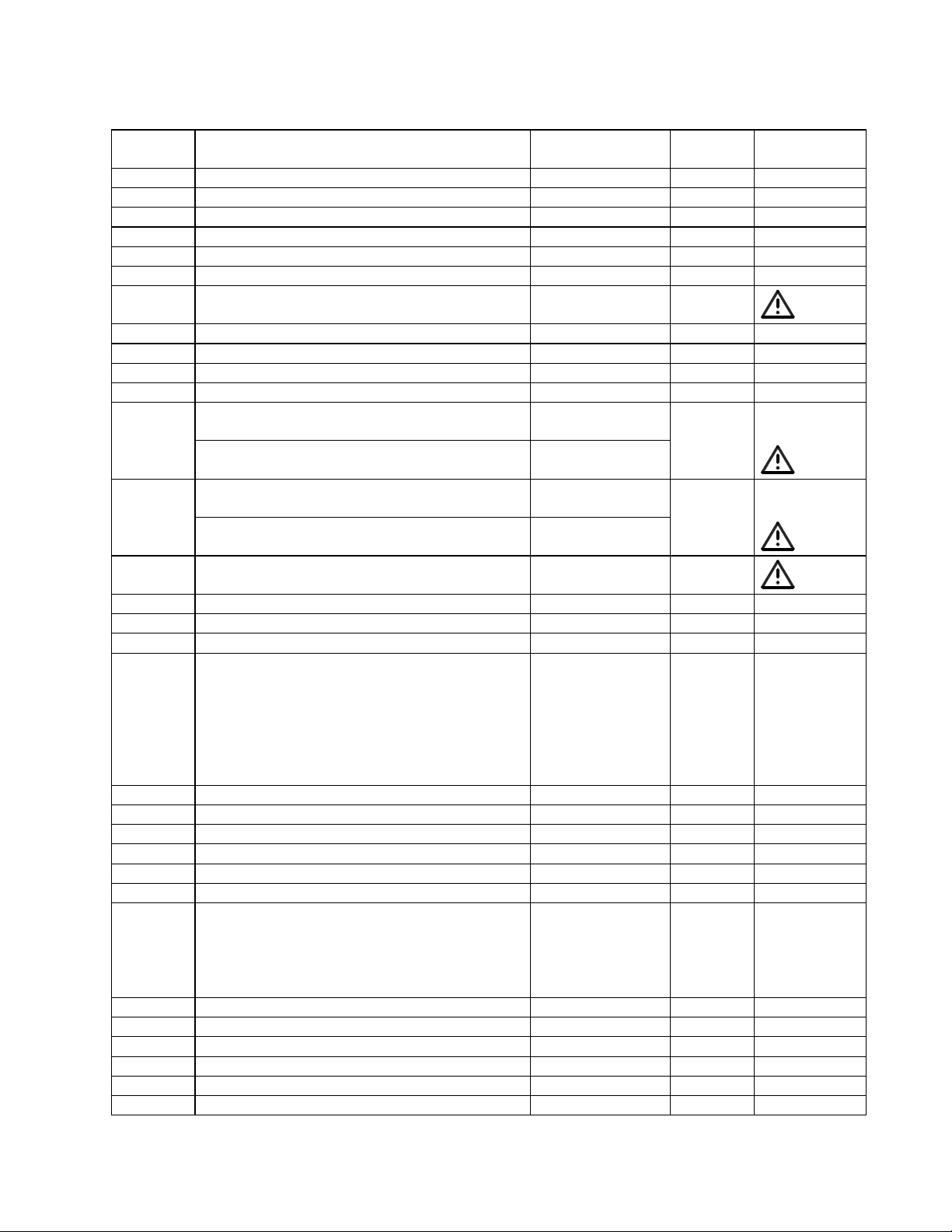

PACKAGING PART LIST

Item

Description Part Number Qty. Note

Item

Description Part Number Qty. Note

FreeSp ace® E4 Series II Business Music System (see Figure 1)

Number

1 FS INSTALLER CD FOR E4 V2.000 279435-2000 1

2 BAG, POLY, 14.38 x 9.87 x 2mil 103351 1

3 FS E4 SERIES II OWNERS GUIDE 279145-001 1

4 FS E4 SERIES II QUICK START GUIDE 279146-001 1

5 LINE CORD, 120V, 16 AW G, DET, US/CA

LINE CORD, 240V, DETACHABLE, UK/SING

LINE CORD, 230V, DETACHABLE, EURO

LINE CORD, 100V, DETACHABLE, JAPAN

LINE CORD, 240V, DETACHABLE, AUS

6 FS E4 ACCESSORY KIT, ALL VERSIO N S 260549 1

7 BAG, POLY, HDPE 13.5 x 35 x 9.5 x 1mil 114522 1

8 PACKING, FOAM, PU, 16 X 4 X 1 268755 4

9 PACKING, FOAM, EPS 262031 2

10 CARTON, RSC, E4 SERIES II 279496-001 1

Accessory Kit Part List (not shown)

263453-006

173351

173352

173353

284241-006

1 3

Number

- CARTON, D-C, 266856 1

- CONNECTOR, HDR, 5.08MM SP, WEID, 2P 260621-02 5

- CONNECTOR, PLUG-IN 172930-02 7

- CONNECTOR, PLUG IN, 3 POS, MALE, BLK 172930-03 2

- CONNECTOR, PLUG-IN, 4P 172930-04 4

- FEET, CHASSIS 187478 4

- LABEL, VOLTAGE SELECT 170206 1

- BAG, POLY, ZI P LOCK, 2 MIL, 3X5" 260556-0305 5

1

2

3

4

REF

92x

8

5

7

6

4x

10

Figure 1. FreeSpace E4 Series II System Packaging View

12

Page 13

Item

Description Part Number Qty. Note

MAIN PART LIST

FreeSp ace® E4 Series II Business Music System (see Figure 2)

Number

1 SCREW, 6-32x.312, TAPP, FLAT, XREC 198422-005 10

2 COVER, CHASSIS 259122 1

3 FAN, DC, 80 X 80 X 25, 24V, 35 CFM 260576-2435 1

4 NUT, HEX, 6-32, KEPS 100413-3 5

5 NUT, HEX, 5/16-18 103236-3118 1

6 WASHER, LOC K, S PRING, HELICL, 5/16 196095-14 1

7 XFMR, PWR, TOROID, DUALSHIELD;

8 CHASSIS, WELDMENT 279473 1

9 INLET ASSY, AC, W/CAPS, SU RG 260575-1 1

10 SCREW PLATE, IEC CONNEC TOR 260560-1 1

11 VOL SEL, INSERT, 100/ 120/220/240 260578-4801 1

12 FUSE, 3AG, SLO-BLO, 6.30 AMP

FUSE, 5 X 20MM, SLO-BLO, 3.15A

13 FUSE DRAWER, 1P, G R EY, 6.3 X 32MM

FUSE DRAWER, 1P, BLK, 5 X 20MM

14 SWITCH, AC POWER, DPST, 16A, 250V 260600 1 3

15 SCREW, TAPP, #4-40 x . 5, PAN, XREC 170284-08 2

16 SCREW, JACK, RS-23 2 PO R T 260564 2

17 SCREW, 6-32, MACH, F LAT, XREC 190623-004 10

18

A

B

C

D

E

19 SCREW, 6-32, PH, INT, S EM 181248-004 9

20 SUPPORT, PCB, POST, MINI, 1.5" 260594-24 4

21 HARNESS, 20P, DS P / MI C SE NS 260511-1 1

22 HARNESS, 16P, DSP / R EM O U T 260512-1 1

23 HARNESS, 16P, DS P / U SER INT 260513-1 1

24 HARNESS, 34P, PS / PA / DSP 260514-1 1

25 AMP MODULE ASSY, FS 4400

26 STANDOFF, HEX , THD, 6-32, .25 X 2.50 260584-625040 3

27 HARNESS ASSY , XFMR / PS 260610 2

28 NUT, STND HEX, WASHER 100413-2 3

29 HEATSINK, ALUMINUM, PS / PA - 1

- CLIP, CABLE, ADHESIVE BACKED 191437 1

- ADAPTER KIT, F S 440 0 AMP MODULE 311963 1

279678-001 1 3

includes cup washer and rubber pad

260593-35 1 3

(100/110V UNITS)

177311-03150

(230/240V UNITS)

260579-17 1 3

(100/110V UNITS)

260579-06

(230/240V UNITS)

PCB ASSY, E4 SERIES II, DSP / UI

CONSISTS O F:

AUTOVOLUME PC B

WALLPLATE SEN SE PC B

DSP/UI PCB

LED PCB

FLASH MEMORY PCB

(Must be used with the adapter kit be low .

Refer to service bulletin 278977-B2,

located in the back of this manual for

more information.)

278979-001 1

301391 1

13

Page 14

1 10x

2

3

20

4x

A

18

21

B

22

C

19

2x

Note: Flash Memory PCB,

18E, is not shown.

10x

17

18

24

29

25

283x

3x

19

26 3x

272x

23

18

18

4x

19

45x

5

6

7

D

8

2x

Figure 2. FreeSpace

4

9

14

15162x

®

E4 Series II Business Music System Exploded View

12

13

10

11

14

Page 15

MAIN PART LIST

Item

Description Part Number Qty. Note

E4 Series II Power Supply / Power Amplifier PCB Module (see Figure 3)

Number

1 INSULATOR, CER, AL OX, TO 247 260607 8

2 HEATSINK, AL, 4.84 X 3.4" 259112 1

3 SCREW, 6-32, PH, INT, SEM 181248-008 4

4 CLIP, MAX, HEAT XFER, AAVID, #23 260601-23 8

5 SUPPORT, PCB, POST, MINI, 9/16" 260594-09 3

- SOCKET, .100 SP X 8.5MM, 1 X 11 260652 - A11F 4

- FUSE CLIP, 5MM 178548 12 3

4

8x

8x

3

4x

2

1

Lower Amp PCB

Upper Amp PCB

(channels 1 and 2)

5

3x

(channels 3 and 4)

Figure 3. E4 Series II Power Supply / Power Amplifier PCB Module

15

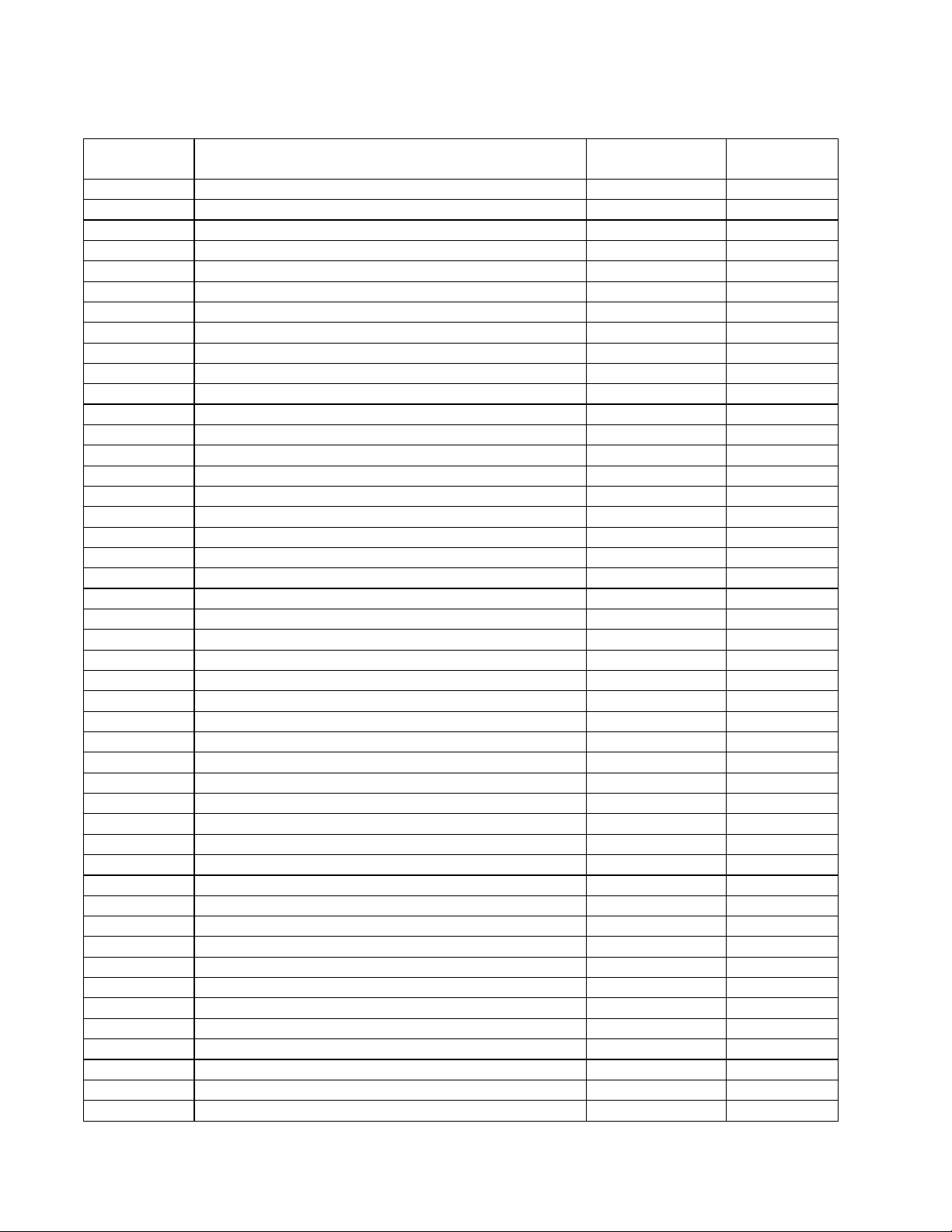

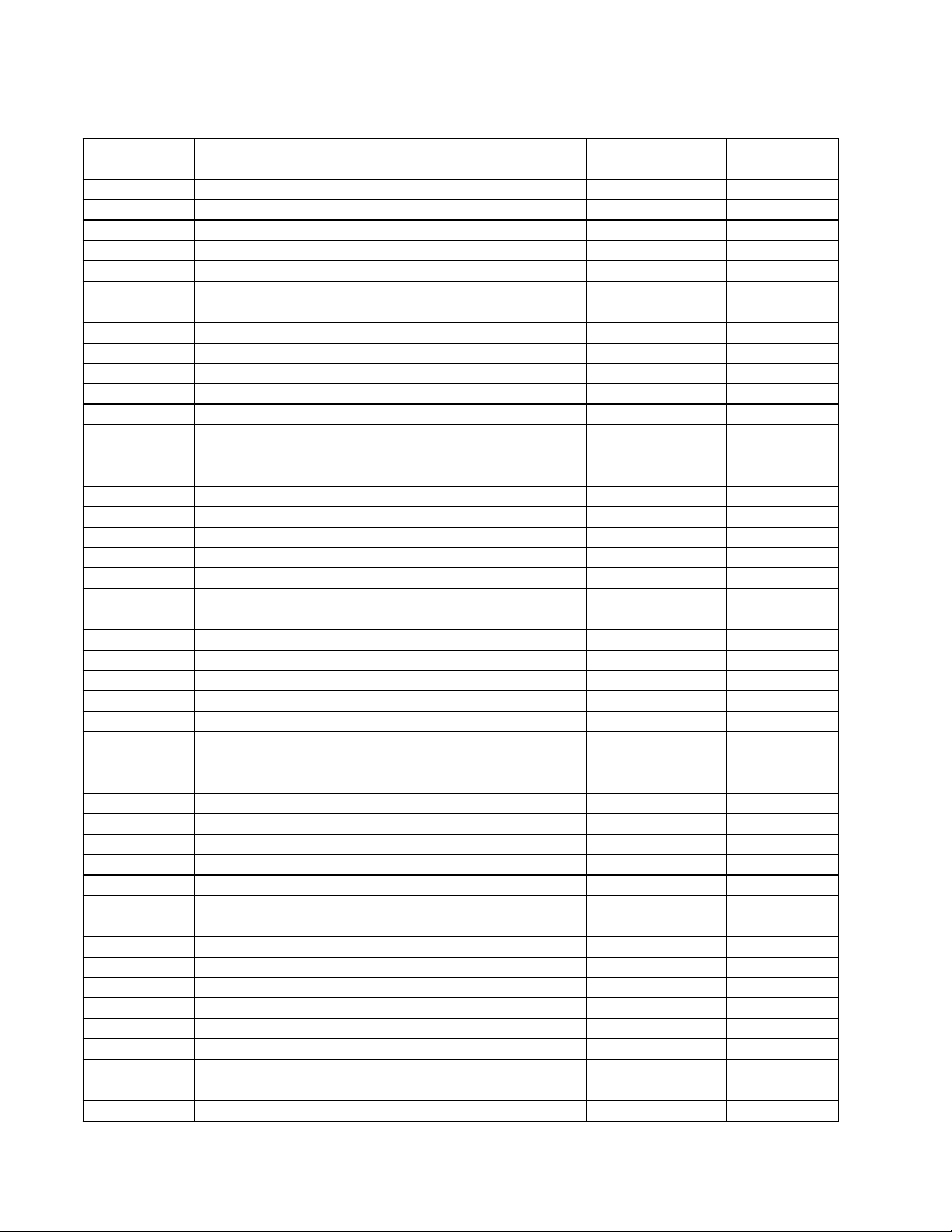

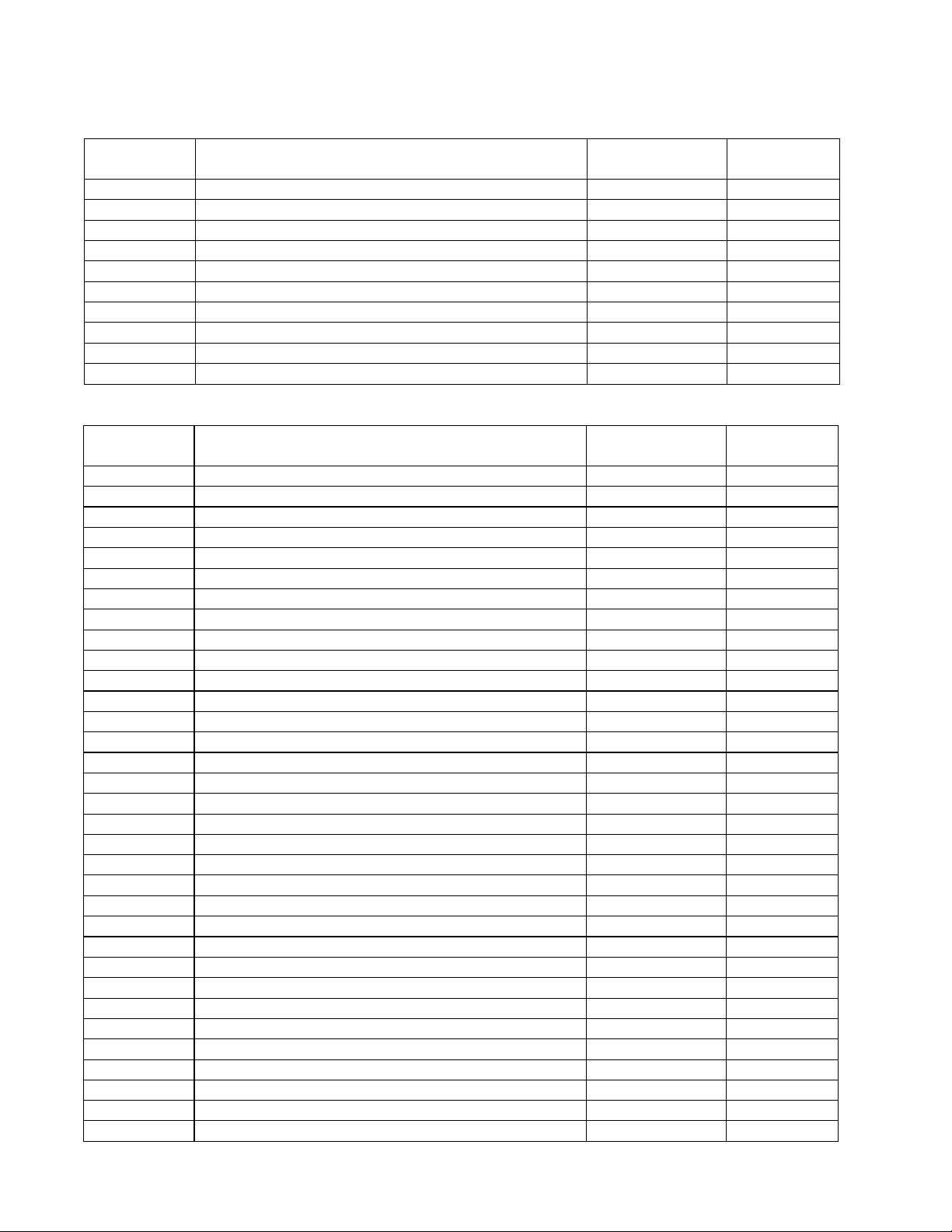

Page 16

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors

Designator

R101 1.10K, 0805, 1/10W, 1% 133625-1101 4

R102 10.0K, 0805, 1/10W, 1% 133625-1002 4

R107 10 OHM, 2512, 1W, 5% 181895-10R0 4

R108 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R109 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R110 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R111 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R112 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R113 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R114 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R115 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R116 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R117 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R118 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R119 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R120 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R121 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R122 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R123 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R124 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R125 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R126 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R127 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R128 1.10K, 0805, 1/10W, 1% 133625-1101 4

R131 10.0K, 0805, 1/10W, 1% 133625-1002 4

R132 33 OHM, 2512, 1W, 5% 181895-33R0 4

R133 10.0K, 0805, 1/10W, 1% 133625-1002 4

R134 10.0K, 0805, 1/10W, 1% 133625-1002 4

R135 10.0K, 0805, 1/10W, 1% 133625-1002 4

R136 100K, 0805, 1/10W, 1% 133625-1003 4

R137 22.1 OHM, 0805, 1/10W, 1% 133625-22R1 4

R138 22.1 OHM, 0805, 1/10W, 1% 133625-22R1 4

R139 JUMPER, CHIP, 0805 133627 4

R140 JUMPER, CHIP, 0805 133627 4

R201 1.10K, 0805, 1/10W, 1% 133625-1101 4

R202 JUMPER, CHIP, 0805 133627 4

R203 1.00K, 0805, 1/10W, 1% 133625-1001 4

R205 2.00K, 0805, 1/10W, 1% 133625-2001 4

R206 10.0K, 0805, 1/10W, 1% 133625-1002 4

R208 13.7K, 0805, 1/10W, 1% 133625-1372 4

R213 220 OHM, 2512, 1W, 5% 181895-2200 4

R214 1.10K, 0805, 1/10W, 1% 133625-1101 4

R215 1.00K, 0805, 1/10W, 1% 133625-1001 4

R216 2.00K, 0805, 1/10W, 1% 133625-2001 4

R217 10.0K, 0805, 1/10W, 1% 133625-1002 4

R219 13.7K, 0805, 1/10W, 1% 133625-1372 4

16

Page 17

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R220 JUMPER, CHIP, 0805 133627 4

R226 20.0K, 0805, 1/10W, 1% 133625-2002 4

R227 22.1K, FILM, 0805, 1% 133625-2212 4

R228 30.1K, 0805, 1/10W, 1% 133625-3012 4

R229 49.9K, 0805, 1/10W, 1% 133625-4992 4

R230 10.0K, 0805, 1/10W, 1% 133625-1002 4

R231 11.0K, 0805, 1/10W, 1% 133625-1102 4

R232 43.2K, 0805, 1/10W, 1% 133625-4322 4

R234 49.9K, 0805, 1/10W, 1% 133625-4992 4

R235 15.0K, 0805, 1/10W, 1% 133625-1502 4

R236 15.0K, 0805, 1/10W, 1% 133625-1502 4

R237 22.1K, FILM, 0805, 1% 133625-2212 4

R240 1.10K, 0805, 1/10W, 1% 133625-1101 4

R241 9.09K, 0805, 1/10W, 1% 133625-9091 4

R242 20.0K, 0805, 1/10W, 1% 133625-2002 4

R243 22.1K, FILM, 0805, 1% 133625-2212 4

R244 30.1K, 0805, 1/10W, 1% 133625-3012 4

R245 49.9K, 0805, 1/10W, 1% 133625-4992 4

R246 10.0K, 0805, 1/10W, 1% 133625-1002 4

R247 11.0K, 0805, 1/10W, 1% 133625-1102 4

R248 43.2K, 0805, 1/10W, 1% 133625-4322 4

R250 49.9K, 0805, 1/10W, 1% 133625-4992 4

R251 15.0K, 0805, 1/10W, 1% 133625-1502 4

R252 15.0K, 0805, 1/10W, 1% 133625-1502 4

R253 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R256 1.10K, 0805, 1/10W, 1% 133625-1101 4

R257 9.09K, 0805, 1/10W, 1% 133625-9091 4

R258 1.10K, 0805, 1/10W, 1% 133625-1101 4

R259 JUMPER, CHIP, 0805 133627 4

R260 1.00K, 0805, 1/10W, 1% 133625-1001 4

R262 2.00K, 0805, 1/10W, 1% 133625-2001 4

R263 10.0K, 0805, 1/10W, 1% 133625-1002 4

R265 13.7K, 0805, 1/10W, 1% 133625-1372 4

R270 1.10K, 0805, 1/10W, 1% 133625-1101 4

R271 JUMPER, CHIP, 0805 133627 4

R272 1.00K, 0805, 1/10W, 1% 133625-1001 4

R274 2.00K, 0805, 1/10W, 1% 133625-2001 4

R275 10.0K, 0805, 1/10W, 1% 133625-1002 4

R277 13.7K, 0805, 1/10W, 1% 133625-1372 4

R282 20.0K, 0805, 1/10W, 1% 133625-2002 4

R283 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R284 30.1K, 0805, 1/10W, 1% 133625-3012 4

R285 49.9K, 0805, 1/10W, 1% 133625-4992 4

R286 10.0K, 0805, 1/10W, 1% 133625-1002 4

R287 11.0K, 0805, 1/10W, 1% 133625-1102 4

R288 43.2K, 0805, 1/10W, 1% 133625-4322 4

17

Page 18

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R290 49.9K, 0805, 1/10W, 1% 133625-4992 4

R291 15.0K, 0805, 1/10W, 1% 133625-1502 4

R292 15.0K, 0805, 1/10W, 1% 133625-1502 4

R293 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R296 1.10K, 0805, 1/10W, 1% 133625-1101 4

R297 9.09K, 0805, 1/10W, 1% 133625-9091 4

R298 20.0K, 0805, 1/10W, 1% 133625-2002 4

R299 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R300 30.1K, 0805, 1/10W, 1% 133625-3012 4

R301 49.9K, 0805, 1/10W, 1% 133625-4992 4

R302 10.0K, 0805, 1/10W, 1% 133625-1002 4

R303 11.0K, 0805, 1/10W, 1% 133625-1102 4

R304 43.2K, 0805, 1/10W, 1% 133625-4322 4

R306 49.9K, 0805, 1/10W, 1% 133625-4992 4

R307 15.0K, 0805, 1/10W, 1% 133625-1502 4

R308 15.0K, 0805, 1/10W, 1% 133625-1502 4

R309 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R312 1.10K, 0805, 1/10W, 1% 133625-1101 4

R313 9.09K, 0805, 1/10W, 1% 133625-9091 4

R314 100K, 0805, 1/10W, 1% 133625-1003 4

R315 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R316 100K, 0805, 1/10W, 1% 133625-1003 4

R317 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R318 100K, 0805, 1/10W, 1% 133625-1003 4

R319 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R320 100K, 0805, 1/10W, 1% 133625-1003 4

R321 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R322 33 OHM, 2512, 1W, 5% 181895-33R0 4

R323 33 OHM, 2512, 1W, 5% 181895-33R0 4

R324 100K, 0805, 1/10W, 1% 133625-1003 4

R325 100K, 0805, 1/10W, 1% 133625-1003 4

R326 100K, 0805, 1/10W, 1% 133625-1003 4

R327 100K, 0805, 1/10W, 1% 133625-1003 4

R328 JUMPER, CHIP, 0805 133627 4

R329 JUMPER, CHIP, 0805 133627 4

R330 JUMPER, CHIP, 0805 133627 4

R331 JUMPER, CHIP, 0805 133627 4

R332 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R333 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R401 200 OHM, 0805, 1/10W, 1% 133625-2000 4

R402 16 OHM, 2512, 1W, 5% 181895-16R0 4

R403 200 OHM, 0805, 1/10W, 1% 133625-2000 4

R404 402 OHM, 0805, 1/10W, 1% 133625-4020 4

R429 10.0K, 0805, 1/10W, 1% 133625-1002 4

R430 1.00K, 0805, 1/10W, 1% 133625-1001 4

R501 18.2K, 0805, 1/10W, 1% 133625-1822 4

18

Page 19

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R502 182 OHM, 3ES, 0805, 1/10W, 1% 133625-1820 4

R503 5.11K, 0805, 1/10W, 1% 133625-5111 4

R504 7.87K, 0805, 1/10W, 1% 133625-7871 4

R505 1.27K, 0805, 1/10W, 1% 133625-1271 4

R506 5.49K, 0805, 1/10W, 1% 133625-5491 4

R507 2.00K, 0805, 1/10W, 1% 133625-2001 4

R508 2.00K, 0805, 1/10W, 1% 133625-2001 4

R509 182 OHM, 3ES, 0805, 1/10W, 1% 133625-1820 4

R510 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R511 7.87K, 0805, 1/10W, 1% 133625-7871 4

R513 100K, 0805, 1/10W, 1% 133625-1003 4

R514 5.11K, 0805, 1/10W, 1% 133625-5111 4

R515 18.2K, 0805, 1/10W, 1% 133625-1822 4

R516 18.2K, 0805, 1/10W, 1% 133625-1822 4

R517 10.0 OHM, 0805, 1/10W, 1% 133625-10R0 4

R518 182 OHM, 3ES, 0805, 1/10W, 1% 133625-1820 4

R519 5.11K, 0805, 1/10W, 1% 133625-5111 4

R520 7.87K, 0805, 1/10W, 1% 133625-7871 4

R521 1.27K, 0805, 1/10W, 1% 133625-1271 4

R522 5.49K, 0805, 1/10W, 1% 133625-5491 4

R523 2.00K, 0805, 1/10W, 1% 133625-2001 4

R524 2.00K, 0805, 1/10W, 1% 133625-2001 4

R525 182 OHM, 3ES, 0805, 1/10W, 1% 133625-1820 4

R526 7.87K, 0805, 1/10W, 1% 133625-7871 4

R528 100K, 0805, 1/10W, 1% 133625-1003 4

R529 5.11K, 0805, 1/10W, 1% 133625-5111 4

R530 18.2K, 0805, 1/10W, 1% 133625-1822 4

R531 18.2K, 0805, 1/10W, 1% 133625-1822 4

R532 5.11K, 0805, 1/10W, 1% 133625-5111 4

R533 7.87K, 0805, 1/10W, 1% 133625-7871 4

R534 5.11K, 0805, 1/10W, 1% 133625-5111 4

R537 2.00K, 0805, 1/10W, 1% 133625-2001 4

R538 2.00K, 0805, 1/10W, 1% 133625-2001 4

R539 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R540 7.87K, 0805, 1/10W, 1% 133625-7871 4

R541 5.11K, 0805, 1/10W, 1% 133625-5111 4

R544 5.11K, 0805, 1/10W, 1% 133625-5111 4

R545 18.2K, 0805, 1/10W, 1% 133625-1822 4

R546 18.2K, 0805, 1/10W, 1% 133625-1822 4

R547 10.0 OHMS, 0805, 1/10W, 1% 133625-10R0 4

R548 5.11K, 0805, 1/10W, 1% 133625-5111 4

R549 7.87K, 0805, 1/10W, 1% 133625-7871 4

R550 5.11K, 0805, 1/10W, 1% 133625-5111 4

R553 2.00K, 0805, 1/10W, 1% 133625-2001 4

R554 2.00K, 0805, 1/10W, 1% 133625-2001 4

R555 7.87K, 0805, 1/10W, 1% 133625-7871 4

19

Page 20

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R556 5.11K, 0805, 1/10W, 1% 133625-5111 4

R557 5.11K, 0805, 1/10W, 1% 133625-5111 4

R558 18.2K, 0805, 1/10W, 1% 133625-1822 4

R561 4.75K, 0805, 1/10W, 1% 133625-4751 4

R562 5.90K, 0805, 1/10W, 1% 133625-5901 4

R563 1.10K, 0805, 1/10W, 1% 133625-1101 4

R566 100K, 0805, 1/10W, 1% 133625-1003 4

R568 25.5K, 0805, 1/10W, 1% 133625-2552 4

R571 100K, 0805, 1/10W, 1% 133625-1003 4

R572 10.0K, 0805, 1/10W, 1% 133625-1002 4

R573 25.5K, 0805, 1/10W, 1% 133625-2552 4

R575 100K, 0805, 1/10W, 1% 133625-1003 4

R576 10.0K, 0805, 1/10W, 1% 133625-1002 4

R577 25.5K, 0805, 1/10W, 1% 133625-2552 4

R579 100K, 0805, 1/10W, 1% 133625-1003 4

R580 10.0K, 0805, 1/10W, 1% 133625-1002 4

R581 1.91K, 0805, 1/10W, 1% 133625-1911 4

R582 25.5K, 0805, 1/10W, 1% 133625-2552 4

R583 10.0K, 0805, 1/10W, 1% 133625-1002 4

R584 47.5K, 0805, 1/10W, 1% 133625-4752 4

R585 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R586 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R587 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R588 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R589 10.0K, 0805, 1/10W, 1% 133625-1002 4

R590 26.7K, 0805, 1/10W, 1% 133625-2672 4

R591 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R592 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R593 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R594 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R599 10.0K, 0805, 1/10W, 1% 133625-1002 4

R600 10.0K, 0805, 1/10W, 1% 133625-1002 4

R601 10.0K, 0805, 1/10W, 1% 133625-1002 4

R603 49.9 OHM, 0805, 1/10W, 1% 133625-49R9 4

R604 49.9 OHM, 0805, 1/10W, 1% 133625-49R9 4

R605 10.0K, 0805, 1/10W, 1% 133625-1002 4

R608 10.0K, 0805, 1/10W, 1% 133625-1002 4

R609 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R610 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R611 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R612 10.0K, 0805, 1/10W, 1% 133625-1002 4

R614 10.0K, 0805, 1/10W, 1% 133625-1002 4

R615 1.00K, 0805, 1/10W, 1% 133625-1001 4

R619 1.00K, 0805, 1/10W, 1% 133625-1001 4

R623 1.00K, 0805, 1/10W, 1% 133625-1001 4

R624 1.0M, 0805, 1/10W, 1% 133625-1004 4

20

Page 21

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R625 1.0M, 0805, 1/10W, 1% 133625-1004 4

R626 1.0M, 0805, 1/10W, 1% 133625-1004 4

R627 1.0M, 0805, 1/10W, 1% 133625-1004 4

R628 1.00K, 0805, 1/10W, 1% 133625-1001 4

R631 1.00K, 0805, 1/10W, 1% 133625-1001 4

R632 1.00K, 0805, 1/10W, 1% 133625-1001 4

R635 10.0K, 0805, 1/10W, 1% 133625-1002 4

R636 1.10K, 0805, 1/10W, 1% 133625-1101 4

R637 1.00K, 0805, 1/10W, 1% 133625-1001 4

R638 681 OHM, 0805, 1/10W, 1% 133625-6810 4

R640 681 OHM, 0805, 1/10W, 1% 133625-6810 4

R641 1.0M, 0805, 1/10W, 1% 133625-1004 4

R642 1.10K, 0805, 1/10W, 1% 133625-1101 4

R643 1.00K, 0805, 1/10W, 1% 133625-1001 4

R647 1.10K, 0805, 1/10W, 1% 133625-1101 4

R648 1.00K, 0805, 1/10W, 1% 133625-1001 4

R649 681 OHM, 0805, 1/10W, 1% 133625-6810 4

R651 681 OHM, 0805, 1/10W, 1% 133625-6810 4

R652 1.0M, 0805, 1/10W, 1% 133625-1004 4

R653 1.10K, 0805, 1/10W, 1% 133625-1101 4

R654 1.00K, 0805, 1/10W, 1% 133625-1001 4

R658 22.6K, 0805, 1/10W, 1% 133625-2262 4

R659 22.6K, 0805, 1/10W, 1% 133625-2262 4

R660 5.49K, 0805, 1/10W, 1% 133625-5491 4

R661 5.49K, 0805, 1/10W, 1% 133625-5491 4

R662 1.62K, 0805, 1/10W, 1% 133625-1621 4

R663 1.62K, 0805, 1/10W, 1% 133625-1621 4

R664 499 OHM, 0805, 1/10W, 1% 133625-4990 4

R665 499 OHM, 0805, 1/10W, 1% 133625-4990 4

R666 150 OHM, 0805, 1/10W, 1% 133625-1500 4

R667 150 OHM, 0805, 1/10W, 1% 133625-1500 4

R668 49.9 OHM, 0805, 1/10W, 1% 133625-49R9 4

R669 49.9 OHM, 0805, 1/10W, 1% 133625-49R9 4

R670 499 OHM, 0805, 1/10W, 1% 133625-4990 4

R671 5.49K, 0805, 1/10W, 1% 133625-5491 4

R672 4.12K, 0805, 1/10W, 1% 133625-4121 4

R673 16 OHM, 2512, 1W, 5% 181895-16R0 4

R674 2.2 OHM, 2512, 1W, 5% 181895-2R2 4

R675 16 OHM, 2512, 1W, 5% 181895-16R0 4

R677 10 OHM, 2512, 1W, 5% 181895-10R0 4

R678 10 OHM, 2512, 1W, 5% 181895-10R0 4

R679 10 OHM, 2512, 1W, 5% 181895-10R0 4

R680 10.0K, 0805, 1/10W, 1% 133625-1002 4

R681 2.00K, 0805, 1/10W, 1% 133625-2001 4

R682 562 OHM, 0805, 1/10W, 1% 133625-5620 4

R683 2.00K, 0805, 1/10W, 1% 133625-2001 4

21

Page 22

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R684 100K, 0805, 1/10W, 1% 133625-1003 4

R685 100K, 0805, 1/10W, 1% 133625-1003 4

R686 100K, 0805, 1/10W, 1% 133625-1003 4

R687 2.00K, 0805, 1/10W, 1% 133625-2001 4

R688 5.49K, 0805, 1/10W, 1% 133625-5491 4

R689 2.49K, 0805, 1/10W, 1% 133625-2491 4

R690 3.09K, 0805, 1/10W, 1% 133625-3091 4

R691 1.10K, 0805, 1/10W, 1% 133625-1101 4

R692 1.10K, 0805, 1/10W, 1% 133625-1101 4

R693 1.10K, 0805, 1/10W, 1% 133625-1101 4

R694 1.10K, 0805, 1/10W, 1% 133625-1101 4

R698 1.10K, 0805, 1/10W, 1% 133625-1101 4

R699 5.49K, 0805, 1/10W, 1% 133625-5491 4

R700 33.2K, 0805, 1/10W, 1% 133625-3322 4

R701 9.09K, 0805, 1/10W, 1% 133625-9091 4

R702 15.0K, 0805, 1/10W, 1% 133625-1502 4

R703 20.0K, 0805, 1/10W, 1% 133625-2002 4

R704 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R705 30.1K, 0805, 1/10W, 1% 133625-3012 4

R706 49.9K, 0805, 1/10W, 1% 133625-4992 4

R707 10.0K, 0805, 1/10W, 1% 133625-1002 4

R708 43.2K, 0805, 1/10W, 1% 133625-4322 4

R709 11.0K, 0805, 1/10W, 1% 133625-1102 4

R710 49.9K, 0805, 1/10W, 1% 133625-4992 4

R711 15.0K, 0805, 1/10W, 1% 133625-1502 4

R712 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R715 20.0K, 0805, 1/10W, 1% 133625-2002 4

R716 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R717 30.1K, 0805, 1/10W, 1% 133625-3012 4

R718 49.9K, 0805, 1/10W, 1% 133625-4992 4

R719 10.0K, 0805, 1/10W, 1% 133625-1002 4

R720 43.2K, 0805, 1/10W, 1% 133625-4322 4

R721 11.0K, 0805, 1/10W, 1% 133625-1102 4

R722 49.9K, 0805, 1/10W, 1% 133625-4992 4

R723 15.0K, 0805, 1/10W, 1% 133625-1502 4

R724 15.0K, 0805, 1/10W, 1% 133625-1502 4

R725 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R728 33.2K, 0805, 1/10W, 1% 133625-3322 4

R729 9.09K, 0805, 1/10W, 1% 133625-9091 4

R730 20.0K, 0805, 1/10W, 1% 133625-2002 4

R731 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R732 30.1K, 0805, 1/10W, 1% 133625-3012 4

R733 49.9K, 0805, 1/10W, 1% 133625-4992 4

R734 10.0K, 0805, 1/10W, 1% 133625-1002 4

R735 43.2K, 0805, 1/10W, 1% 133625-4322 4

R736 11.0K, 0805, 1/10W, 1% 133625-1102 4

22

Page 23

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R737 49.9K, 0805, 1/10W, 1% 133625-4992 4

R738 15.0K, 0805, 1/10W, 1% 133625-1502 4

R739 15.0K, 0805, 1/10W, 1% 133625-1502 4

R740 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R743 33.2K, 0805, 1/10W, 1% 133625-3322 4

R744 9.09K, 0805, 1/10W, 1% 133625-9091 4

R745 20.0K, 0805, 1/10W, 1% 133625-2002 4

R746 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R747 30.1K, 0805, 1/10W, 1% 133625-3012 4

R748 49.9K, 0805, 1/10W, 1% 133625-4992 4

R749 10.0K, 0805, 1/10W, 1% 133625-1002 4

R750 43.2K, 0805, 1/10W, 1% 133625-4322 4

R751 11.0K, 0805, 1/10W, 1% 133625-1102 4

R752 49.9K, 0805, 1/10W, 1% 133625-4992 4

R753 15.0K, 0805, 1/10W, 1% 133625-1502 4

R754 15.0K, 0805, 1/10W, 1% 133625-1502 4

R755 22.1K, FILM, 0805, 1/10W, 1% 133625-2212 4

R758 33.2K, 0805, 1/10W, 1% 133625-3322 4

R759 9.09K, 0805, 1/10W, 1% 133625-9091 4

R760 10.0K, 0805, 1/10W, 1% 133625-1002 4

R761 1.10K, 0805, 1/10W, 1% 133625-1101 4

R762 24.9K, 0805, 1/10W, 1% 133625-2492 4

R763 4.99K, 0805, 1/10W, 1% 133625-4991 4

R764 3.09K, 0805, 1/10W, 1% 133625-3091 4

R765 2.00K, 0805, 1/10W, 1% 133625-2001 4

R766 2.00K, 0805, 1/10W, 1% 133625-2001 4

R771 JUMPER, CHIP, 0805 133627 4

R772 JUMPER, CHIP, 0805 133627 4

R773 JUMPER, CHIP, 0805 133627 4

R774 JUMPER, CHIP, 0805 133627 4

R778 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R779 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R780 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R781 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R782 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R783 1.10K, 0805, 1/10W, 1% 133625-1101 4

R784 1.10K, 0805, 1/10W, 1% 133625-1101 4

R785 3.09K, 0805, 1/10W, 1% 133625-3091 4

R786 20.0K, 0805, 1/10W, 1% 133625-2002 4

R787 1.10K, 0805, 1/10W, 1% 133625-1101 4

R788 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R789 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R790 JUMPER, CHIP, 0805 133627 4

R791 JUMPER, CHIP, 0805 133627 4

R792 100 OHM, 0805, 1/10W, 1% 133625-1000 4

R793 267 OHM, 0805, 1/10W, 1% 133625-2670 4

23

Page 24

Reference

Description Part Number Note

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Resistors (continued)

Designator

R794 10.0K, 0805, 1/10W, 1% 133625-1002 4

RP400 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP401 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP402 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP403 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP404 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP405 4 X 10K ARRAY, SMT, .125W, 5% 195577-1034 4

RP406 8 X 100 OHM ARRAY, SMT, 1/8W, 5% 195577-1018 4

RP407 8 X 100 OHM ARRAY, SMT, 1/8W, 5% 195577-1018 4

RP408 8 X 100 OHM ARRAY, SMT, 1/8W, 5% 195577-1018 4

Designator

C101 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C102 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C103 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C104 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C105 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C106 10uF, EL, 85C, 25V, 20% 177902-100E 4

C107 10uF, EL, 85C, 25V, 20% 177902-100E 4

C108 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C109 .33uF, 0805, X7RSM, 16V, 5% 196995-334 4

C110 .33uF, 0805, X7RSM, 16V, 5% 196995-334 4

C111 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C112 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C113 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C115 10pF, 0805, COG, 50V, 5% 133622-100 4

C116 10pF, 0805, COG, 50V, 5% 133622-100 4

C201 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C203 1000pF, 0805, COG, 50V, 5% 133622-102 4

C204 100pF, 0805, COG, 50V, 5% 133622-101 4

C205 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C206 33pF, 0805, COG, 50V, 5% 133622-330 4

C208 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C209 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C210 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C211 100pF, 0805, COG, 50V, 5% 133622-101 4

C212 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C213 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C214 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C215 33pF, 0805, COG, 50V, 5% 133622-330 4

C218 1000pF, 0805, COG, 50V, 5% 133622-102 4

C220 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C222 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C223 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C224 3300pF, 0805, X7R, 50V, 10% 133623-332 4

Capacitors

24

Page 25

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C225 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C226 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C228 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C229 1500pF, 0805, COG, 50V, 5% 133622-152 4

C231 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C232 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C233 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C234 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C235 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C236 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C237 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C238 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C239 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C240 1500pF, 0805, COG, 50V, 5% 133622-152 4

C241 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C243 1000pF, 0805, COG, 50V, 5% 133622-102 4

C244 100pF, 0805, COG, 50V, 5% 133622-101 4

C245 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C246 33pF, 0805, COG, 50V, 5% 133622-330 4

C248 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C250 1000pF, 0805, COG, 50V, 5% 133622-102 4

C251 100pF, 0805, COG, 50V, 5% 133622-101 4

C252 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C253 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C254 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C255 33pF, 0805, COG, 50V, 5% 133622-330 4

C258 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C260 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C261 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C262 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C263 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C264 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C266 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C267 1500pF, 0805, COG, 50V, 5% 133622-152 4

C269 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C270 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C271 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C272 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C273 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C274 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C275 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C276 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C277 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C278 1500pF, 0805, COG, 50V, 5% 133622-152 4

C279 10uF, EL, 85C, 25V, 20% 177902-100E 4

C280 10uF, EL, 85C, 25V, 20% 177902-100E 4

25

Page 26

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C281 10uF, EL, 85C, 25V, 20% 177902-100E 4

C282 10uF, EL, 85C, 25V, 20% 177902-100E 4

C283 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C284 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C285 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C286 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C287 33pF, 0805, COG, 50V, 5% 133622-330 4

C288 33pF, 0805, COG, 50V, 5% 133622-330 4

C289 33pF, 0805, COG, 50V, 5% 133622-330 4

C290 33pF, 0805, COG, 50V, 5% 133622-330 4

C291 1000pF, 0805, COG, 50V, 5% 133622-102 4

C292 1000pF, 0805, COG, 50V, 5% 133622-102 4

C293 1000pF, 0805, COG, 50V, 5% 133622-102 4

C294 1000pF, 0805, COG, 50V, 5% 133622-102 4

C295 100pF, 0805, COG, 50V, 5% 133622-101 4

C296 100pF, 0805, COG, 50V, 5% 133622-101 4

C401 1000pF, 0805, COG, 50V, 5% 133622-102 4

C402 1000pF, 0805, COG, 50V, 5% 133622-102 4

C403 10uF, EL, 85C, 25V, 20% 177902-100E 4

C404 10uF, EL, 85C, 25V, 20% 177902-100E 4

C405 1000pF, 0805, COG, 50V, 5% 133622-102 4

C406 1000pF, 0805, COG, 50V, 5% 133622-102 4

C407 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C408 10uF, EL, 85C, 25V, 20% 177902-100E 4

C409 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C410 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C411 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C412 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C413 1000pF, 0805, COG, 50V, 5% 133622-102 4

C414 1000pF, 0805, COG, 50V, 5% 133622-102 4

C415 1000pF, 0805, COG, 50V, 5% 133622-102 4

C416 1000pF, 0805, COG, 50V, 5% 133622-102 4

C417 1000pF, 0805, COG, 50V, 5% 133622-102 4

C501 68pF, 0805, COG, 50V, 5% 133622-680 4

C503 2200pF, 0805, COG, 50V, 5% 133622-222 4

C504 470pF, 0805, COG, 50V, 5% 133622-471 4

C505 68pF, 0805, COG, 50V, 5% 133622-680 4

C506 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C507 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C508 10uF, EL, 85C, 25V, 20% 177902-100E 4

C509 68pF, 0805, COG, 50V, 5% 133622-680 4

C510 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C511 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C513 2200pF, 0805, COG, 50V, 5% 133622-222 4

C514 470pF, 0805, COG, 50V, 5% 133622-471 4

C515 68pF, 0805, COG, 50V, 5% 133622-680 4

26

Page 27

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C516 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C517 4.7MFD, EL, 85C, 25V, 20% 177902-4R7E 4

C518 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C519 68pF, 0805, COG, 50V, 5% 133622-680 4

C521 2200pF, 0805, COG, 50V, 5% 133622-222 4

C522 470pF, 0805, COG, 50V, 5% 133622-471 4

C523 68pF, 0805, COG, 50V, 5% 133622-680 4

C525 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C526 10uF, EL, 85C, 25V, 20% 177902-100E 4

C527 68pF, 0805, COG, 50V, 5% 133622-680 4

C528 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C529 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C531 470pF, 0805, COG, 50V, 5% 133622-471 4

C532 2200pF, 0805, COG, 50V, 5% 133622-222 4

C533 68pF, 0805, COG, 50V, 5% 133622-680 4

C534 4.7MFD, EL, 85C, 25V, 20% 177902-4R7E 4

C535 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C537 10uF, EL, 85C, 25V, 20% 177902-100E 4

C538 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C539 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C541 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C542 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C545 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C547 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C548 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C551 1000pF, 0805, COG, 50V, 5% 133622-102 4

C552 6800pF, 0805, X7R, 10% 133623-682 4

C553 1000pF, 0805, COG, 50V, 5% 133622-102 4

C554 10uF, EL, 85C, 25V, 20% 177902-100E 4

C555 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C556 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C557 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C558 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C559 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C560 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C561 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C562 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C563 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C564 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C565 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C566 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C567 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C568 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C569 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C570 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C572 .1uF, 0805, X7R, 25V, 10% 181264-104 4

27

Page 28

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C573 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C575 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C576 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C577 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C578 33pF, 0805, COG, 50V, 5% 133622-330 4

C579 33pF, 0805, COG, 50V, 5% 133622-330 4

C580 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C581 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C582 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C583 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C584 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C585 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C586 4700pF, 0805, X7R, 50V, 10% 133623-472 4

C587 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C588 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C591 1000pF, 0805, COG, 50V, 5% 133622-102 4

C592 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C593 100pF, 0805, COG, 50V, 5% 133622-101 4

C595 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C597 1000pF, 0805, COG, 50V, 5% 133622-102 4

C598 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C599 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C601 1000pF, 0805, COG, 50V, 5% 133622-102 4

C602 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C603 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C604 100pF, 0805, COG, 50V, 5% 133622-101 4

C607 1000pF, 0805, COG, 50V, 5% 133622-102 4

C609 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C612 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C613 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C614 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C617 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C618 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C619 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C622 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C623 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C624 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C625 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C626 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C627 2200pF, 0805, COG, 50V, 5% 133622-222 4

C628 100pF, 0805, COG, 50V, 5% 133622-101 4

C629 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C630 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C631 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C632 1000pF, 0805, COG, 50V, 5% 133622-102 4

C633 2200pF, 0805, COG, 50V, 5% 133622-222 4

28

Page 29

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C634 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C635 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C636 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C637 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C638 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C639 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C640 2200pF, 0805, COG, 50V, 5% 133622-222 4

C641 100pF, 0805, COG, 50V, 5% 133622-101 4

C642 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C643 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C644 330MF, EL, SMD, 6.0MM, 25V, 20% 258166-331E 4

C645 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C646 2200pF, 0805, COG, 50V, 5% 133622-222 4

C647 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C648 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C649 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C650 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C651 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C652 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C653 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C654 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C655 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C656 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C657 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C658 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C659 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C660 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C661 33pF, 0805, COG, 50V, 5% 133622-330 4

C662 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C663 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C664 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C665 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C666 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C667 22uF, EL, 85C, 16V, 20% 177902-220C 4

C668 10uF, EL, 85C, 25V, 20% 177902-100E 4

C669 10uF, EL, 85V, 25V, 20% 177902-100E 4

C670 10uF, EL, 85C, 25V, 20% 177902-100E 4

C671 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C672 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C673 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C674 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C675 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C676 10uF, EL, 85C, 25V, 20% 177902-100E 4

C677 10uF, EL, 85C, 25V, 20% 177902-100E 4

C678 .47uF, 0805, X7R, 15V, 5% 196995-474 4

C679 .1uF, 0805, X7R, 25V, 10% 181264-104 4

29

Page 30

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C680 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C681 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C682 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C683 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C684 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C685 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C686 10uF, EL, 85C, 25V, 20% 177902-100E 4

C687 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C688 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C689 .33uF, 0805, X7RSM, 16V, 5% 196995-334 4

C690 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C691 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C692 10uF, EL, 85C, 25V, 20% 177902-100E 4

C693 10uF, EL, 85C, 25V, 20% 177902-100E 4

C694 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C695 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C696 10uF, EL, 85C, 25V, 20% 177902-100E 4

C697 4.7MFD, EL, 85C, 25V, 20% 177902-4R7E 4

C698 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C699 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C700 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C701 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C702 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C703 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C704 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C705 1500pF, 0805, COG, 50V, 5% 133622-152 4

C706 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C707 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C708 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C709 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C710 1500pF, 0805, COG, 50V, 5% 133622-152 4

C711 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C712 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C713 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C714 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C715 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C716 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C717 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C718 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C719 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C720 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C721 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C722 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C723 1500pF, 0805, COG, 50V, 5% 133622-152 4

C724 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C725 .1uF, 0805, X7R, 25V, 10% 181264-104 4

30

Page 31

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Capacitors (continued)

Designator

C726 100uF, EL, SMD, 105C, 25V, 20% 255071-101E 4

C727 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C728 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C729 3300pF, 0805, X7R, 50V, 10% 133623-332 4

C730 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C731 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C732 1500pF, 0805, COG, 50V, 5% 133622-152 4

C733 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C734 10uF, EL, 85C, 25V, 20% 177902-100E 4

C735 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C736 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C737 2.2uF, EL, SMD, 85C, 35V, 20% 177902-2R2V 4

C738 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C739 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C740 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C741 .01uF, 0805, X7R, 50V, 10% 133623-103 4

C742 33pF, 0805, COG, 50V, 5% 133622-330 4

C743 33pF, 0805, COG, 50V, 5% 133622-330 4

C744 33pF, 0805, COG, 50V, 5% 133622-330 4

C745 33pF, 0805, COG, 50V, 5% 133622-330 4

C746 33pF, 0805, COG, 50V, 5% 133622-330 4

C747 .1uF, 0805, X7R, 25V, 10% 181264-104 4

C748 .33uF, X7RSM, 16V, 5%, 0805 196995-334 4

C749 1000pF, 0805, COG, 50V, 5% 133622-102 4

C750 1000pF, 0805, COG, 50V, 5% 133622-102 4

C751 100pF, 0805, COG, 50V, 5% 133622-101 4

C752 100pF, 0805, COG, 50V, 5% 133622-101 4

C753 100pF, 0805, COG, 50V, 5% 133622-101 4

C754 100pF, 0805, COG, 50V, 5% 133622-101 4

C755 2200pF, 0805, COG, 50V, 5% 133622-222 4

C756 2200pF, 0805, COG, 50V, 5% 133622-222 4

C757 2200pF, 0805, COG, 50V, 5% 133622-222 4

C758 2200pF, 0805, COG, 50V, 5% 133622-222 4

C759 .33uF, 0805, X7RSM, 16V, 5% 196995-334 4

31

Page 32

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Diodes

Designator

D102 SOD123, 1N4148W 257662 4

D103 SMT, S1A 178380-1 4

D104 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D105 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D106 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D107 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D108 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D109 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D110 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D111 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D112 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D113 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D114 LED, RGY, VERT, RECT, PCB MT 260616-001 4

D201 BAV99, SOT23 147239 4

D203 SMT, S1A 178380-1 4

D204 BAV99, SOT23 147239 4

D206 BAV99, SOT23 147239 4

D207 BAV99, SOT23 147239 4

D208 BAV99, SOT23 147239 4

D210 BAV99, SOT23 147239 4

D212 BAV99, SOT23 147239 4

D213 BAV99, SOT23 147239 4

D214 SMT, S1A 178380-1 4

D215 SMT, S1A 178380-1 4

D401 SMT, S1A 178380-1 4

D501 BAV99, SOT23 147239 4

D502 BAV99, SOT23 147239 4

D503 BAV99, SOT23 147239 4

D504 BAV99, SOT23 147239 4

D505 BAV99, SOT23 147239 4

D506 BAV99, SOT23 147239 4

D507 BAV99, SOT23 147239 4

D508 BAV99, SOT23 147239 4

D521 BAV99, SOT23 147239 4

D522 BAV99, SOT23 147239 4

D523 BAV99, SOT23 147239 4

D524 BAV99, SOT23 147239 4

D525 BAV99, SOT23 147239 4

D526 BAV99, SOT23 147239 4

D527 BAV99, SOT23 147239 4

D528 BAV99, SOT23 147239 4

D529 SMT, S1A 178380-1 4

D530 SMT, S1A 178380-1 4

D531 SMT, S1A 178380-1 4

D532 SMT, S1A 178380-1 4

D533 SMT, S1A 178380-1 4

32

Page 33

ELECTRICAL PART LIST

Reference

Description Part Number Note

Reference

Description Part Number Note

Reference

Description Part Number Note

Digital Signal Processor / User Interface PCB Assembly

Diodes (continued)

Designator

D534 SHOTTKY, BAT42W, SOD-123 196984- 002 4

D535 SOD123, 1N4148W 257662 4

D536 BAV99, SOT23 147239 4

D537 BAV99, SOT23 147239 4

D538 BAV99, SOT23 147239 4

D539 BAV99, SOT23 147239 4

D540 SOD123, 1N4148W 257662 4

D541 BAV99, SOT23 147239 4

D542 BAV99, SOT23 147239 4

D543 BAV99, SOT23 147239 4

D544 BAV99, SOT23 147239 4

D545 BAV99, SOT23 147239 4

D546 BAV99, SOT23 147239 4

D547 BAV99, SOT23 147239 4

D548 BAV99, SOT23 147239 4

Transistors

Designator

Q501 PNP, SOT, MMBT3906 148596 4

Q502 PNP, SOT, MMBT3906 148596 4

Q503 NPN, SOT, MMBT3904 146819 4

Designator

U101 SCHMIT TRIG, INV, 74HC14, SO14 260624 4

U102 SHIFT REG W/LTCH, 8 BIT, 74HC595 258171 4

U103 SHIFT REG W/LTCH, 8 BIT, 74HC595 258171 4

U104 SHIFT REG W/LTCH, 8 BIT, 74HC595 258171 4

U105 VOLT REG, SMD, POS, SOT89, +5V 258167-05 4

U106 USB, SER INT, PDIUSBD11, SOIC16 260644 4

U107 VREG, POS, D2PAK, LD1086, 3.3V 260638-33 4

U108 OSCILLATOR, SMD, SG636, 12.0000 MHZ 260618-120000 4

U202 OP AMP DUAL, SOIC-8, NJM4559 187473 4

U203 VOL CTL, ST, TC9412AF, SOIC24 196350 4

U204 VOLT REG, SMD, POS, SOT89, +8V 258167-08 4

U206 OP AMP DUAL, SOIC-8, NJM4559 187473 4

U207 OP AMP QUAD, SOIC-14, NJM2059 187472 4

U208 OP AMP QUAD, SOIC-14, NJM2059 187472 4

U210 OP AMP DUAL, SOIC-8, NJM4559 187473 4

U211 VOL CTL, ST, TC9412AF, SOIC24 196350 4

U213 OP AMP DUAL, SOIC-8, NJM4559 187473 4

U214 OP AMP QUAD, SOIC-14, NJM2059 187472 4

U215 OP AMP QUAD, SOIC-14, NJM2059 187472 4

U216 VOLT REG, SMD, POS, SOT89, +15V 258167-15 4

U217 VOLT REG, NEG, 7915, SOT89 260688-15 4

Integrated Circuits

33

Page 34

Reference

Description Part Number Note

ELECTRICAL PART LIST

Digital Signal Processor / User Interface PCB Assembly

Integrated Circuits (continued)

Designator

U401 VOLT REG, SMD, POS, SOT89, +5V 258167-05 4

U402 SHIFT REG W/LTCH, 8 BT, 74HC595 258171 4

U403 SHIFT REG W/LTCH, 8 BT, 74HC595 258171 4

U404 SHIFT REG, 8 BIT, 74HC166, SOIC 260657-1 4

U405 SHIFT REG, 8 BIT, 74HC166, SOIC 260657-1 4

U406 SHIFT REG, 8 BIT, 74HC166, SOIC 260657-1 4

U501 OPAMP, DUAL, NJM4560, DMP-8 260655-2 4

U503 CODEC, AUDIO, AK4528, VSOP-28 260654 4

U504 OP AMP, DUAL, NJM4560, DMP-8 260655-2 4

U505 OP AMP, DUAL, NJM4560, DMP-8 260655-2 4

U507 CODEC, AUDIO, AK4528, VSOP-28 260654 4

U509 OP AMP SWITCH, SOIC-8, NJM2120 187474 4

U510 OP AMP SWITCH, SOIC-8, NJM2120 187474 4

U511 OP AMP SWITCH, SOIC-8, NJM2120 187474 4

U512 OP AMP SWITCH, SOIC-8, NJM2120 187474 4

U513 RAM, 128K X 8, IDT71V124, SO32-3 260653-3 4

U514 RAM, 128K X 8, IDT71V124, SO32-3 260653-3 4

U515 RAM, 128K X 8, IDT71V124, SO32-3 260653-3 4

U516 EPROM, UNPROG, OTP, 128x8, AT27CV010A 260545-90JC 4

U517 DSP, TQFP-144, DSP56362 260650 4

U518 RAM, STAT 32K X 8, CY7C199 260649 4

U519 LATCH, D, OCT, 74ACT573, SOIC20 260629 4

U520 MICRO, 80C251, PLCC-44 260648 4

U521 2 INPUT NOR GATE X 4, 74HC02 260645 4

U522 OR GATE, QUAD, 74HC32, SOIC14 260591-1 4

U523 REAL TIME CLOCK, RTC8564, VSOJ20 260565-1 4

U524 TRANSCVR, RS232, MAX202E, SO16 260553-202S 4

U525 DUAL FLIP FLOP, 74HC74, SOIC14 260647 4

U526 COUNTER, 8 BIT, 74HC590, SOIC16 260646 4

U527 OSCILLATOR, SMD, SG636, 22.5792 MHZ 260618-225792 4

U529 RCVR, AUD DIFF, INA134, SOIC8 260559-1 4

U530 OP AMP, DUAL, NJM4565MA 258127 4

U531 VOL CTL, ST, TC9412AF, SOIC24 196350 4

U532 RCVR, AUD DIFF, INA134, SOIC8 260559-1 4

U535 MULTIPLEXER, ANALOG, ADG409, SO16 260590-1 4

U536 VOLT REG, LOW DROPOUT, TL751L12 260661-12 4

U537 AMP, LOW PWR, INA129, SMD, SOIC8 260558-1 4

U538 OP AMP, DUAL, SOIC-8, NJM4559 187473 4

U539 VOLT REG, LOW DROPOUT, TL751L12 260661-12 4

U540 AMP, LOW PWR, INA129, SMD, SOIC8 260558-1 4

U541 ANALOG SWITCH, SOIC 16, ADG452 258168 4

U542 ANALOG SWITCH, SOIC 16, ADG452 258168 4

U543 ANALOG SWITCH, SOIC 16, ADG452 258168 4

U544 MICROCONTROLLER, 8-BIT, PIC16F874, QFP 260662 4

U545 SHFT REG W/LTCH, 8 BIT, 74HC595 258171 4

U546 SHFT REG W/LTCH, 8 BIT, 74HC595 258171 4

34

Page 35

ELECTRICAL PART LIST

Reference

Description Part Number Note

Reference

Description Part Number Note

Digital Signal Processor / User Interface PCB Assembly

Integrated Circuits (continued)

Designator

U547 VOLT REG, POS, D2PAK, LD1086, 5.0V 260638-50 4

U548 VOLT REG, POS, D2PAK, 7815, 15V 260689-15 4

U549 VOLT REG, NEG, D2PAK, 7915, -15 260687-15 4

U550 VOLT REG, POS, D2PAK, LD1086, 3.3V 260638-33 4

U551 VOLT REG, SMD, POS, SOT89, +5V 258167-05 4

U552 VOLT SUPVSR, TL7705, SOIC8 260640 4

U553 BUFFER, OCT, 74HC541, SOIC20 260566-1 4

U700 OP AMP, DUAL, SOIC-8, NJM4559 187473 4

U701 EPROM, PGMD, 39SF020 279467-001 4

U702 OP AMP, QUAD, SOIC-14, NJM2059 187472 4

U703 OP AMP, QUAD, SOIC-14, NJM2059 187472 4

U704 OP AMP, QUAD, SOIC-14, NJM2059 187472 4

U705 OP AMP, QUAD, SOIC-14, NJM2059 187472 4

U706 OP AMP, DUAL, SOIC-8, NJM4559 187473 4

Miscellaneous

Designator

B1 BATT , COIN, 3V, 23 X 2.5MM, BR2325 260597 4

BKT1 SCREW TERM, PCB HORIZ, 6-32 187504 4

BKT2 SCREW TERM, PCB HORIZ, 6-32 187504 4

BKT3 SCREW TERM, PCB HORIZ, 6-32 187504 4

BKT4 SCREW TERM, PCB HORIZ, 6-32 187504 4

BKT5 SCREW TERM, PCB HORIZ, 6-32 187504 4

BKT6 SCREW TERM, PCB HORIZ, 6-32 187504 4

J101 CONN, X2 ROW, .1SP, RT ANG, 16 PIN 260615-16 4

J201 CONN, RT ANG, 2 POS, BLK 177291-02 4

J202 CONN, RT ANG, 2 POS, BLK 177291-02 4

J203 CONN, RT ANG, 2 POS, BLK 177291-02 4

J204 CONN, RT ANG, 2 POS, BLK 177291-02 4

J205 CONN, DUAL ROW, .1SP, 20 PIN, AU 260681-20 4

J206 CONN, D-SUB, RT ANG, PC MT, FEM, 9 CT 260637 4

J401 CONN, RT ANG, 4 POS 177291-04 4

J402 CONN, RT ANG, 2 POS, BLK 177291-02 4

J403 CONN, RT ANG, 2 POS, BLK 177291-02 4

J404 CONN, DUAL ROW, .1SP, 16 PIN, AU 260681-16 4

J502 CONN, X2 ROW, .1SP, STR, 40 PIN 260614-40 4

J503 CONN, RT ANG, 4 POS 177291-04 4

J508 CONN, RT ANG, 4 POS 177291-04 4

J509 CONN, RTANG, 3 POS, BLK 177291-03 4

J510 CONN, DUAL ROW, .1SP, 16 PIN, AU 260681-16 4

J511 CONN, DUAL ROW, .1SP, 20 PIN, AU 260681-20 4

J512 CONN, DUAL ROW, .1SP, 16 PIN, AU 260681-16 4

J701 HEADER, RT ANG, W/LATCH, 40 PIN 260557-40 4

JH501 CONN, DUAL ROW, .1SP, 34 PIN, AU 260681-34 4

JP501 CONN, HEADER, 6 PIN, .1SP, .25 SQ 260683-06 4

35

Page 36

ELECTRICAL PART LIST

Reference

Description Part Number Note

Digital Signal Processor / User Interface PCB Assembly

Miscellaneous (continued)

Designator

JR101 CONN, USB, B TYPE, PCB MT, THRU HOL 260623 4

JR401 JACK, MODULAR, DUAL RJ45, PCB MT 260625 4

JR402 JACK, MODULAR, DUAL RJ45, PCB MT 260625 4

P501 HEADER, MALE, X2, VERT, .1SP, 14 PIN 260636-14 4

SW101 SWITCH, SPST, 12MM, PCB MT, W/CAP 260580-CB 4

W/U516 SOCKET, SURFACE MOUNT, PLCC, 32P 252356-32 4

W/U701 SOCKET, SURFACE MOUNT, PLCC, 32P 252356-32 4

W1B1 HOLDER, BATT, PC MOUNT, 23MM 260596-23 4

Y501 CRYSTAL, SMD, HCM49, 11.0592 MHZ 260619-110592 4

- CONN, PHONO, QUAD 199839 4

36

Page 37

Reference

Description Part Number Note

ELECTRICAL PART LIST

E4 Series II Power Supply / Power Amplifier PCB Assembly

Resistors

Designator

R1 220 OHM, 2512, 1W, 5% 181895-2200 4

R2 2.00K, 0805, 1/10W, 1% 133625-2001 4

R3 4.99K, 0805, 1/10W, 1% 133625-4991 4

R4 4.99K, 0805, 1/10W, 1% 133625-4991 4

R5 4.99K, 0805, 1/10W, 1% 133625-4991 4

R6 10 OHM, 2512, 1W, 5% 181895-10R0 4

R7 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R8 1K, 2512, 1W, 5% 181895-1001 4

R9 4.70K, 1206, 1/8W, 5% 124895 -4725 4

R10 1.2M, 1206, 1/4W, 5% 124895-1255 4

R11 1.2M, 1206, 1/4W, 5% 124895-1255 4

R12 4.70K, 1206, 1/8 W, 5% 124895-4725 4

R13 5.1 OHM, 2512, 1W, 5% 181895-5R10 4

R14 5.1 OHM, 2512, 1W, 5% 181895-5R10 4

R15 49.9K, 0805, 1/10 W, 1% 133625-4992 4

R16 4.70K, 1206, 1/8 W, 5% 124895-4725 4

R17 301 OHM, 0805, 1/10W, 1% 133625-3010 4

R18 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R19 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R20 2.00K, 0805, 1/10 W, 1% 133625-2001 4

R21 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R22 200K, 1206, 1/4W, 1% 260585-2003 4

R23 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R24 1.00K, 0805, 1/10 W, 1% 133625-1001 4

R25 2.00K, 0805, 1/10 W, 1% 133625-2001 4

R26 4.99K, 0805, 1/10 W, 1% 133625-4991 4

R27 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R28 10.0K, 0805, 1/10 W, 1% 133625-1002 4

R29 4.99K, 0805, 1/10 W, 1% 133625-4991 4

R30 4.99K, 0805, 1/10 W, 1% 133625-4991 4

R31 1.00K, 0805, 1/10 W, 1% 133625-1001 4

R32 1.00K, 0805, 1/10 W, 1% 133625-1001 4

R33 33 OHM, 2512, 1W, 5% 181895-33R0 4

R34 33 OHM, 2512, 1W, 5% 181895-33R0 4

R35 10 OHM, 2512, 1W, 5% 181895-10R0 4

R36 34.8K, 0805, 1/10 W, 1% 133625-3482 4

R37 34.8K, 0805, 1/10 W, 1% 133625-3482 4

R38 4.99K, 0805, 1/10 W, 1% 133625-4991 4

R39 20.0K, 0805, 1/10 W, 1% 133625-2002 4

R40 20.0K, 0805, 1/10 W, 1% 133625-2002 4

R41 20.0K, 0805, 1/10 W, 1% 133625-2002 4

R42 20.0K, 0805, 1/10 W, 1% 133625-2002 4

R43 4.99K, 0805, 1/10 W, 1% 133625-4991 4