Page 1

CONTENTS

Warranty .............................................................................................................................................1

Safety Information .............................................................................................................................2

Electrostatic Discharge Sensitive (ESDS) Device Handling ....................................................... 2

Specifications.................................................................................................................................... 3

Part List Notes ..................................................................................................................................3

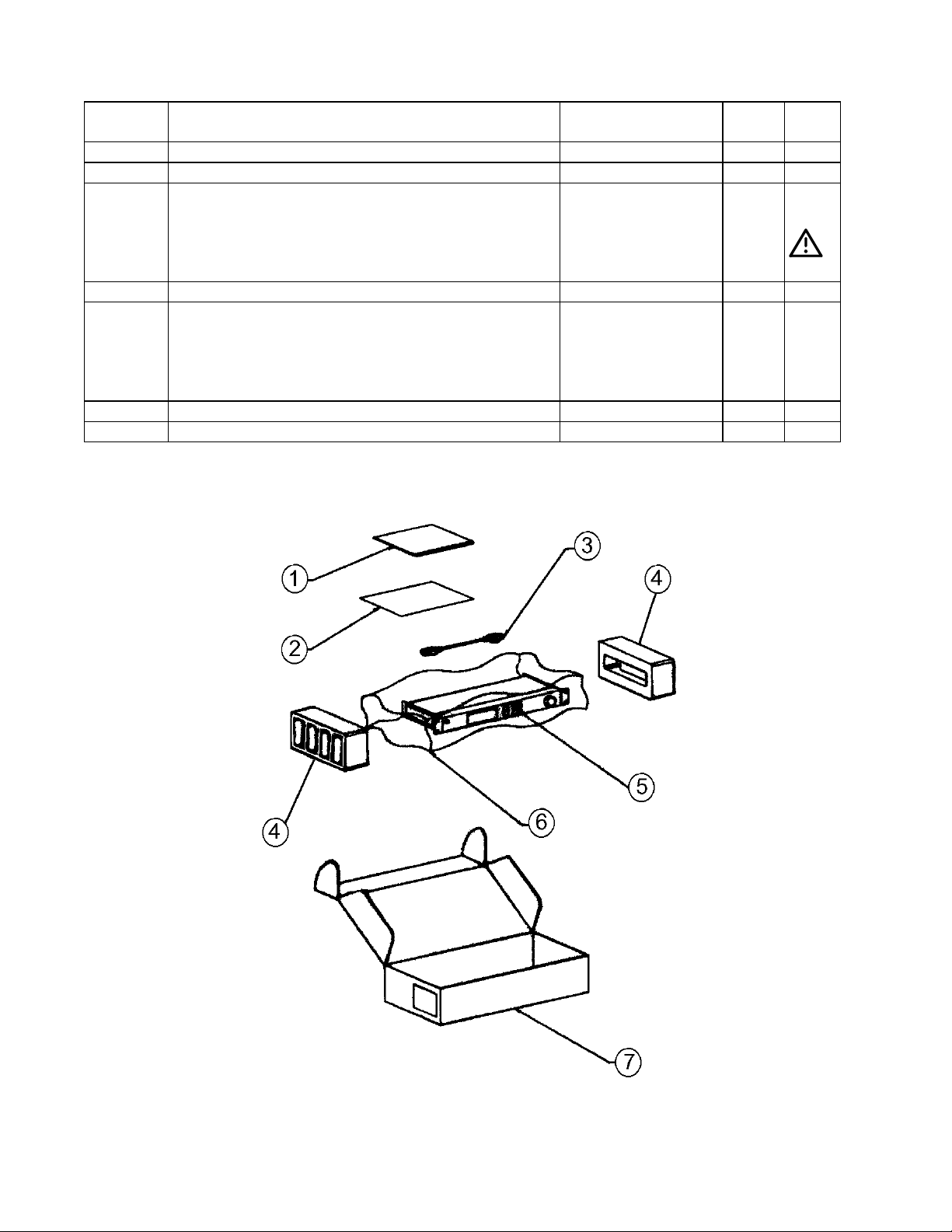

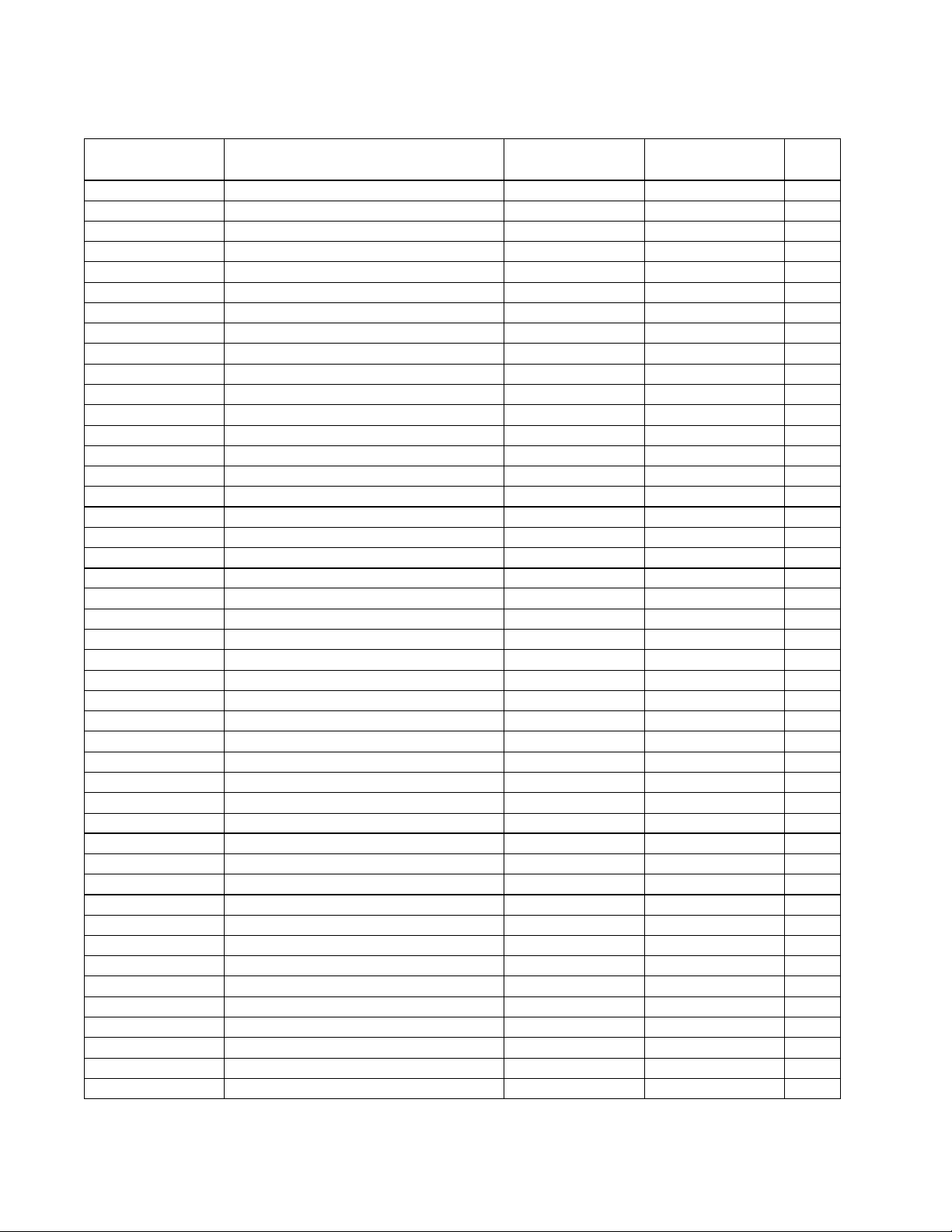

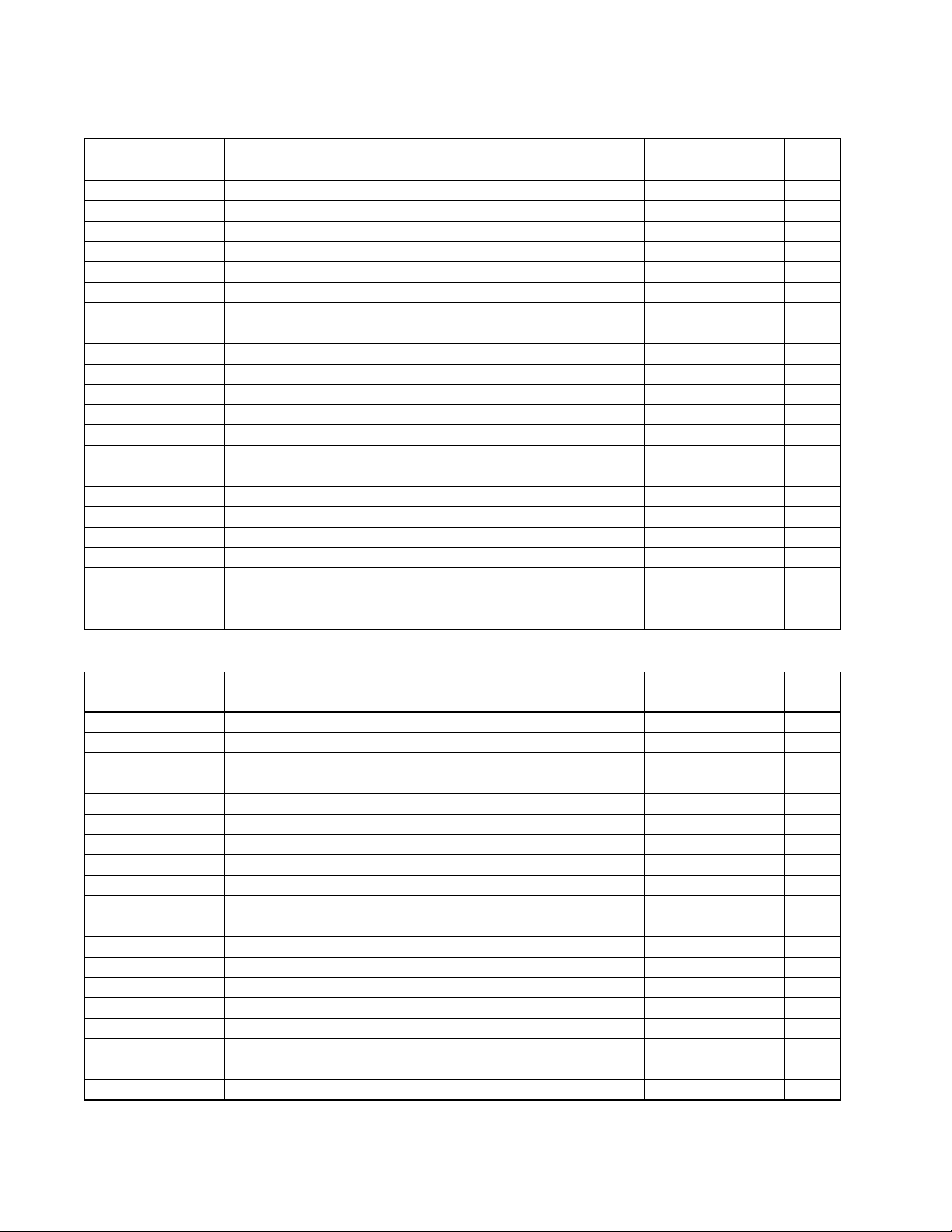

Packaging Part List ...........................................................................................................................4

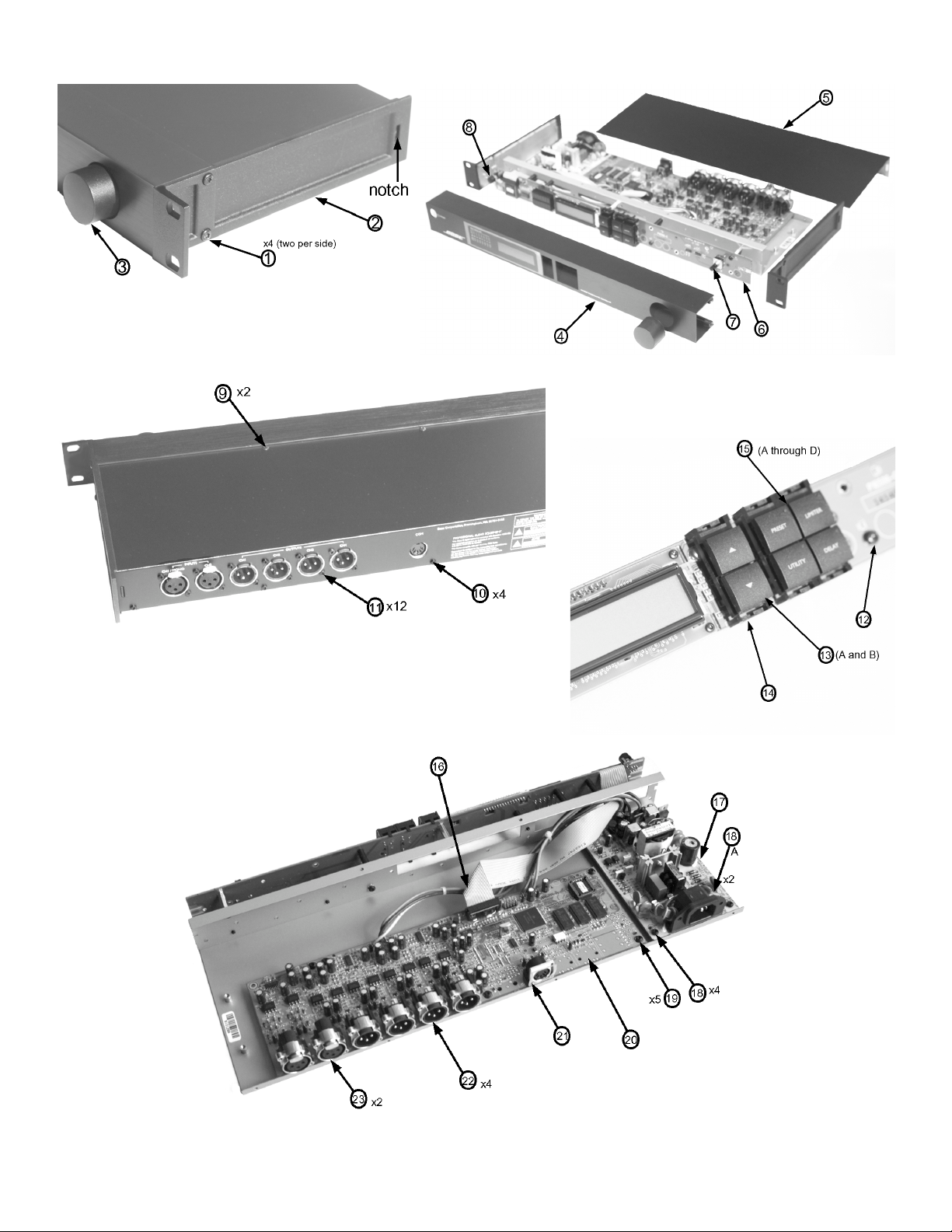

Figure 1. Packaging Exploded View ..................................................................................................4

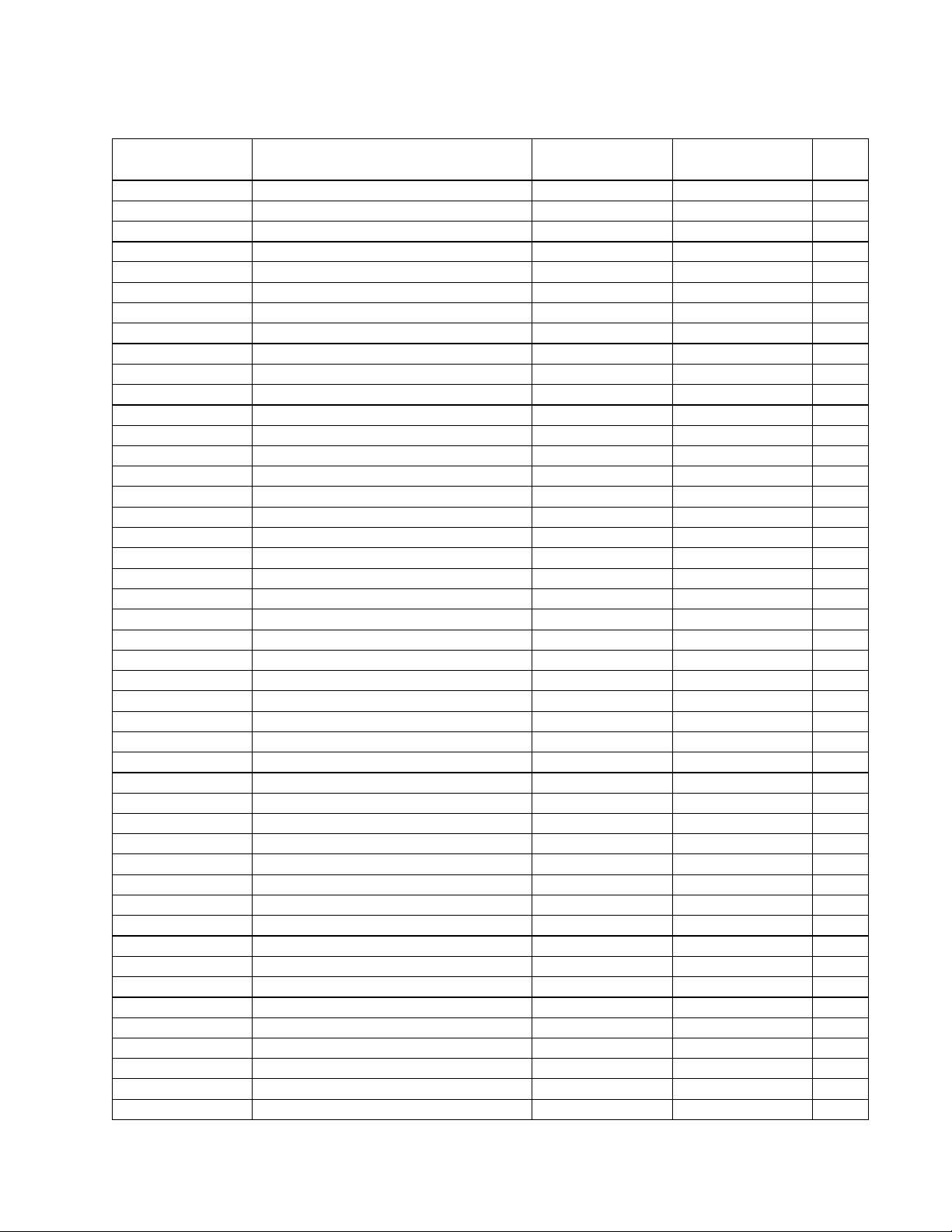

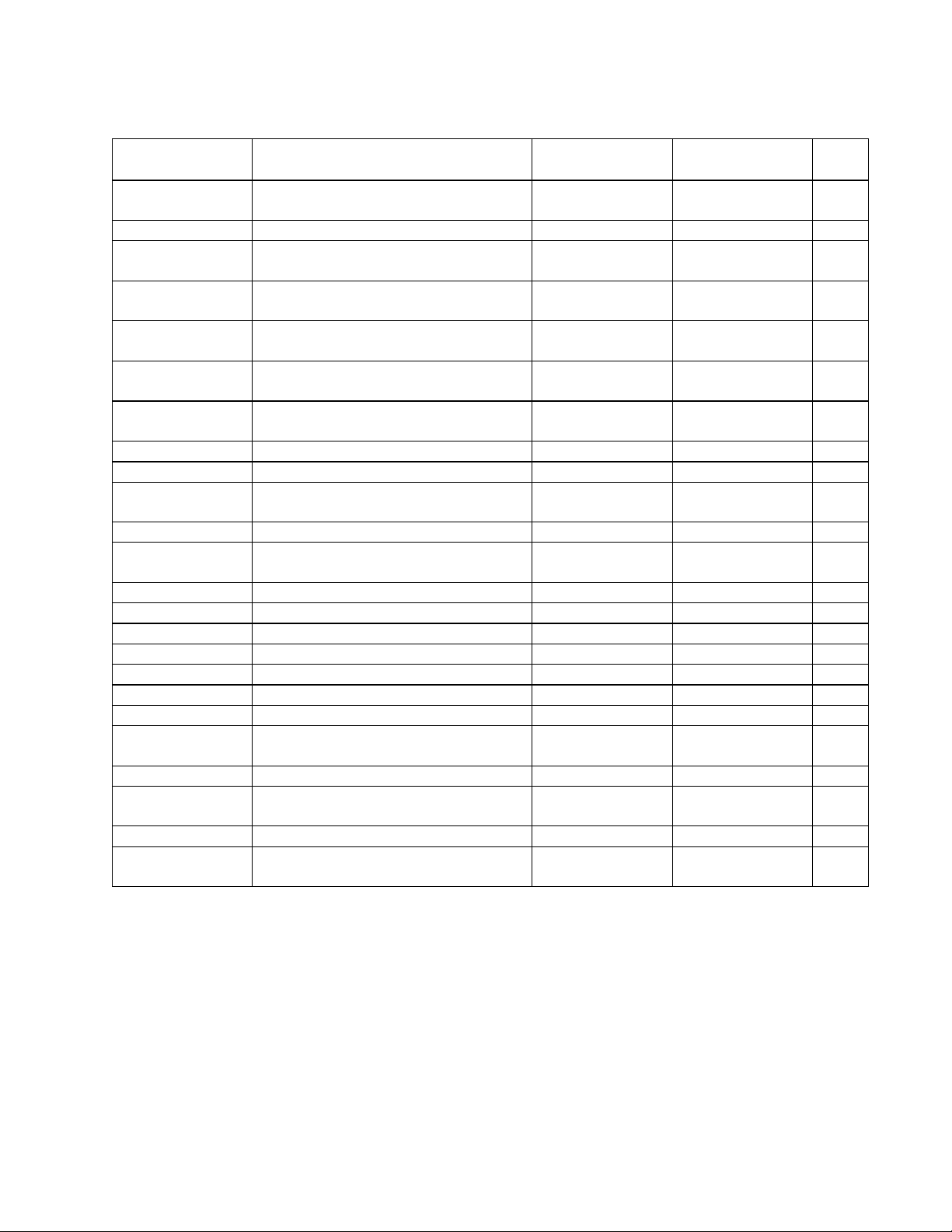

Main Part List ....................................................................................................................................5

Figure 2. Panaray

Electrical Part Lists .................................................................................................................... 7-23

Main PCB Assembly .................................................................................................................... 7-21

Display PCB Assembly .............................................................................................................. 22-23

Disassembly Procedures ...............................................................................................................24

Test Procedures ....................................................................................................................... 25-29

Appendix .................................................................................................................................... 30-59

®

Bose

Bose Professional Loudspeaker EQ Preset Lists ................................................................ 42-55

Theory of Operation ................................................................................................................. 56-59

Main PCB Overview .......................................................................................................................56

Front Panel PCB Overview ...........................................................................................................56

Power Supply .................................................................................................................................. 57

DSP Circuit ......................................................................................................................................57

Analog/Digital Audio Routing ......................................................................................................... 58

Front Panel AVR Microprocessor ..................................................................................................58

Service Manual Revision History .................................................................................................60

Professional Loudspeaker Frequency Response Curves ....................................... 30-41

Figure 3. Panaray Platform Diagram .............................................................................................. 56

Figure 4. Block Diagram ................................................................................................................. 59

®

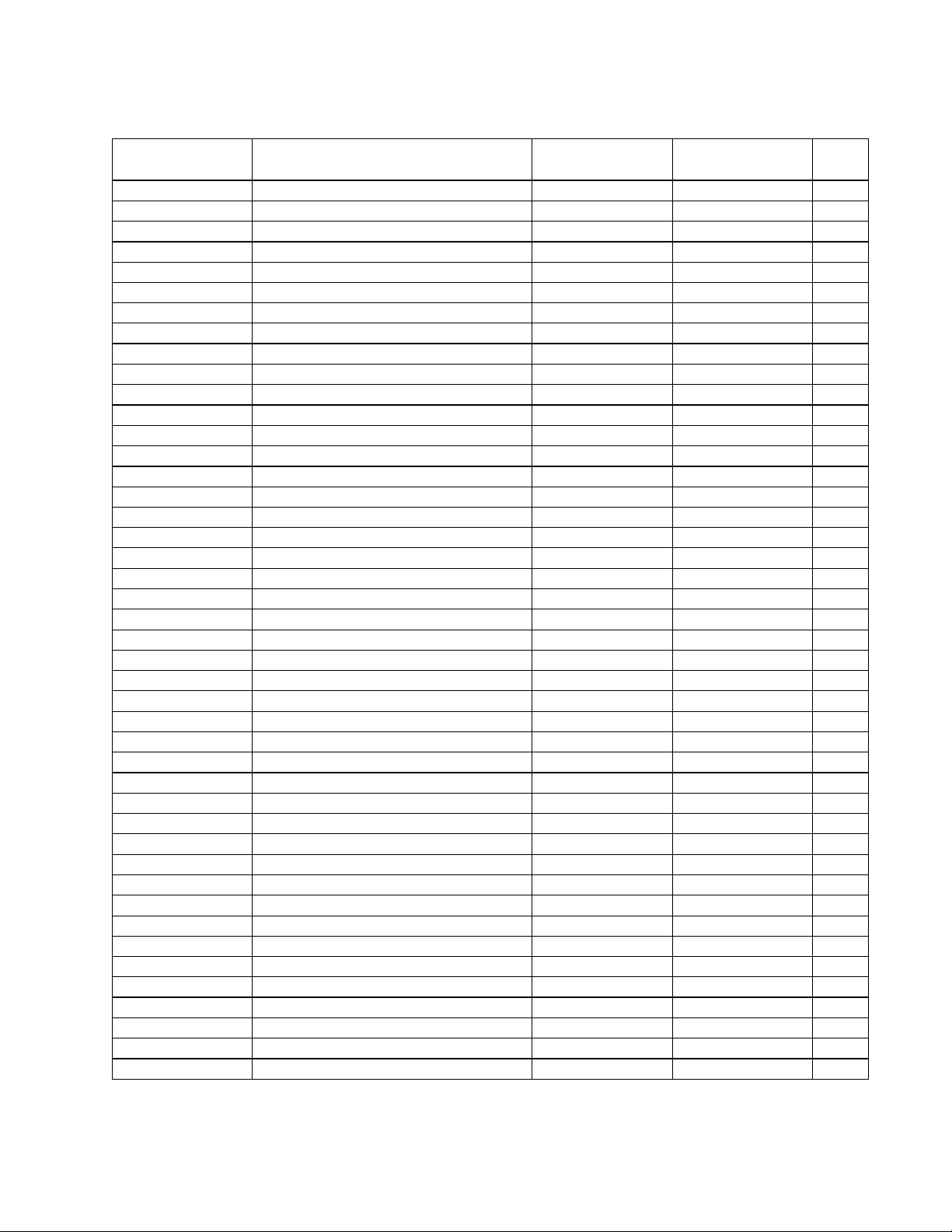

Digital Controller Exploded View ........................................................................ 6

CAUTION: The Bose Panaray Digital Controller

contains no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

WARRANTY

The Bose Panaray Digital Controller is covered by a limited 1-year transferable warranty.

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester or a metering system that complies with American National Standards Institute

(ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL) UL6500 /

UL60065 / IEC 60065 paragraph 9.1.1. With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads, metallic

overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the unit

power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products,

the resistance measured to exposed input/output connectors should be between 4 and infinite

MOhms. If it is not within the limits specified, there is the possibility of a shock hazard, and the

unit must be repaired and rechecked before it is returned to the customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing, or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble

wrap or plastic trays.

2

Page 3

SPECIFICATIONS

A

Finish:

Dimensions:

Weight:

Impedance balanced:

Input level:

Maximum output level:

Input sensitivity:

D to A conversion:

D to A delay:

Dynamic range:

THD:

nodized aluminum front

plated and painted steel chassis

19" x 1.75" x 8.2" (483 x 44 x 195 mm)

4.1 lb (1.85 kg)

21 K Ohms

Minimum:

Maximum:

@9 dB headroom: -12 dBu to +9 dBu

0 dBu

+18 dBu

+18 dBu (balanced)

24 bit, 128 x oversampling bitstream

0.63 ms @ 44.1 kHz

100 dB typically, 20 Hz to 20 kHz

<94 dB (0.002%) @ 1 kHz +20 dBu output

Frequency response:

Crosstalk:

Mains voltage:

Power consumption:

20 Hz to 20 kHz: +0/-0.5 dB

-95 dB, 20 Hz to 20 kHz

100 to 240 VAC, 50 Hz to 60 Hz

(auto switching)

15W

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

3

Page 4

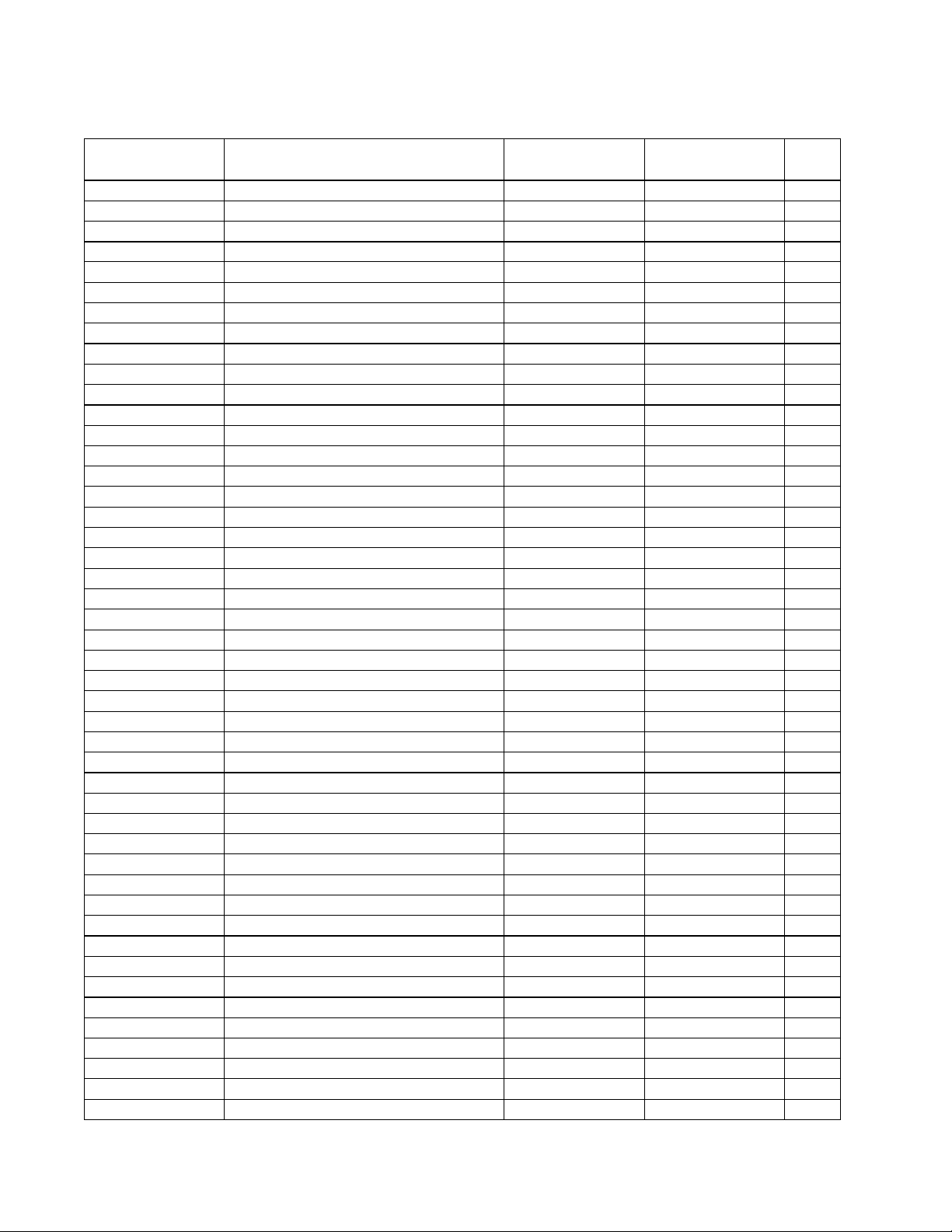

PACKAGING PART LIST

Item

Number

1 OWNER’S MANUAL 262330 1

2 SHEET, DECLARATION OF CONFORMITY 263578 1

3 POWER CORD, 120V (US/CANADA)

POWER CORD, 220V (EURO)

POWER CORD, 230V (UK/SING)

POWER CORD, 240V (AUS)

POWER CORD, 100V (JAPAN)

4 END CAP, PACKING 263651 2

5 PANARAY SYSTEM CONT, 120V (US/CAN)

PANARAY SYSTEM CONT, 220V (EURO)

PANARAY SYSTEM CONT, 230V (UK/SING)

PANARAY SYSTEM CONT, 240V (AUS)

PANARAY SYSTEM CONT, 100V (JAPAN)

6 POLYBAG 263652 1

7 CARTON 263653 1

Description Part

Number

263453-006

173352

173351

284241-006

173353

028021

028022

028023

028024

028025

Qty. Note

1 3

1

Figure 1. Packaging Exploded View

4

Page 5

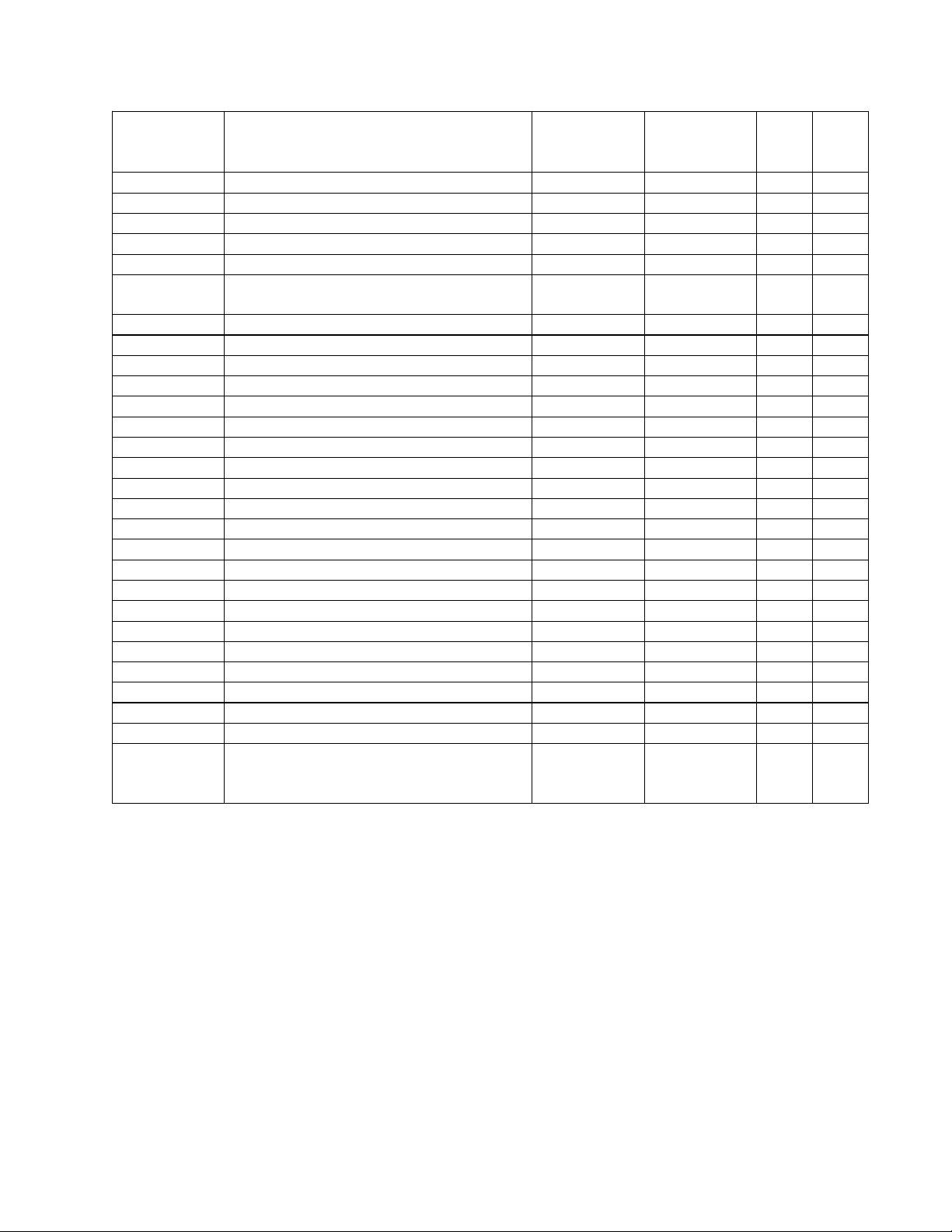

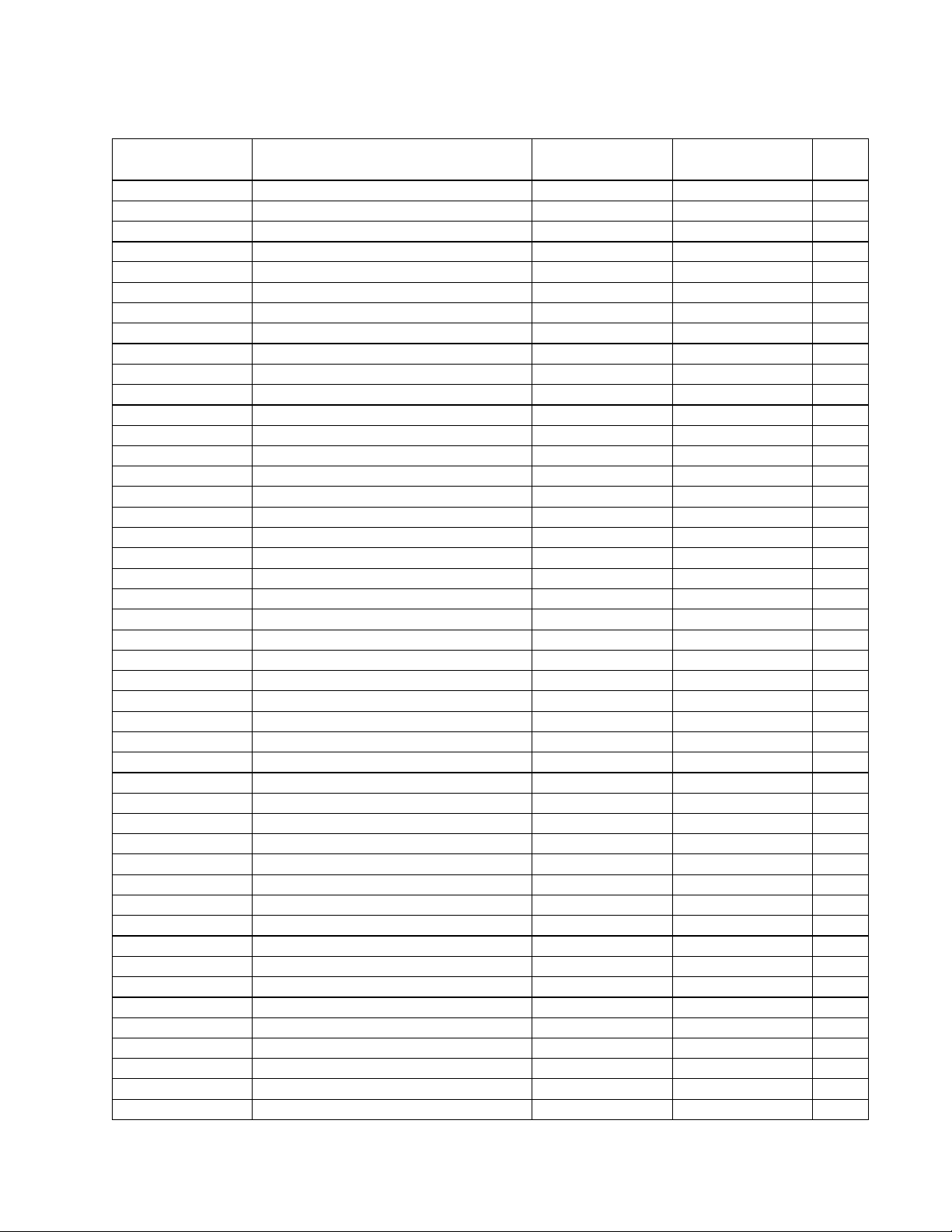

MAIN PART LIST

Refer to Figure 2

Item

Number

1 SIDE PANEL SCREWS E56200101 268902 4

2 SIDE PANEL (RACK EARS) E58100301 268901 2

3 KNOB, ROTARY SWITCH E33800402 268903 1

4 FRONT PANEL E58201001 268904 1

5 TOP COVER E58100242 268905 1

6 FRONT PANEL PCB ASSY.

(INCLUDES DISPLAY PCB ASSY)

7 ROTARY SWITCH, ENCODER E34000301 268907 1

8 KNOB, POWER SWITCH E33800501 268908 1

9 SCREWS, TOP COVER (TOP) N/A --- 2 4

10 SCREW, TOP COVER (REAR) E56300201 268909 4

11 SCREW, CONNECTOR E56300201 268910 12

12 SCREW, DISPLAY PCB N/A --- 3 4

13 BUTTON ASSY., ARROWS E33901202 268911 1

14 CONSOLE, BUTTON ASSEMBLY E33800602 268912 1

15A BUTTON ASSY., PRESET E33904062 268913 1

15B BUTTON ASSY., UNITY E33900402 268914 1

15C BUTTON ASSY., LIMITER E33904072 268915 1

15D BUTTON ASSY., DELAY E33903202 268916 1

16 HARNESS, DISPLAY PCB N/A --- 1 4

17 POWER SUPPLY PCB ASSY E50000101 268917 1

18 SCREW, AC JACK E56300401 268918 2

18A SCREW, POWER SUPPLY PCB E56300101 268919 4

19 SCREW, MAIN PCB E56300101 268920 5

20 MAIN PCB ASSY B80110050 268921 1 2

21 DIN CONNECTOR E52200101 268922 1

22 XLR CONNECTOR, MALE E52200701 268923 4

23 XLR CONNECTOR, FEMALE E52200601 268924 2

- DISPLAY PCB ASSY. (THIS IS THE

DISPLAY PCB SECTION OF THE

FRONT PANEL PCB ASSY ONLY)

Description Vendor

Part

Number

B80721001 294111 1 2

B8072001 268906 1

Number

Bose

Part

Qty. Note

5

Page 6

Figure 2. Panaray® Digital Controller Exploded View

6

Page 7

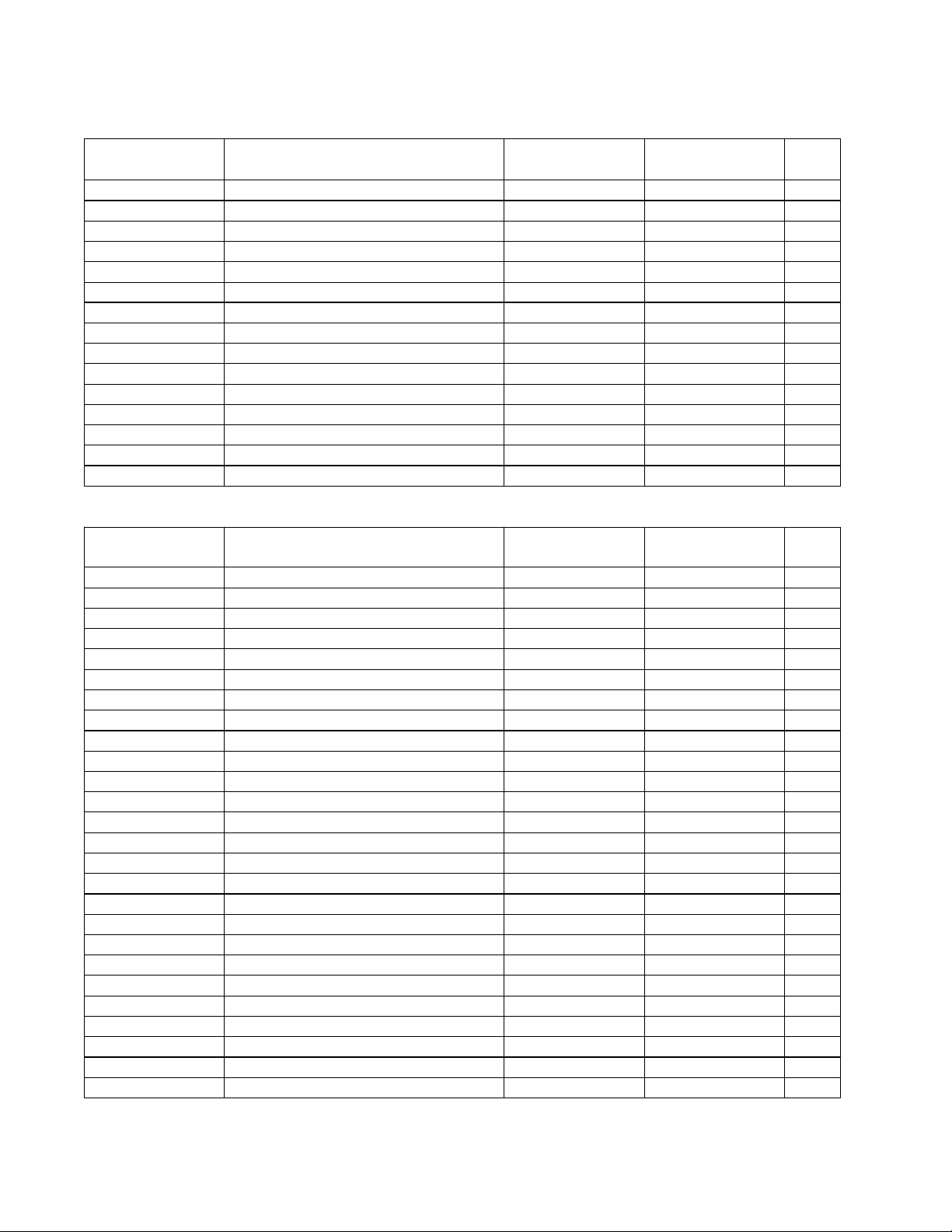

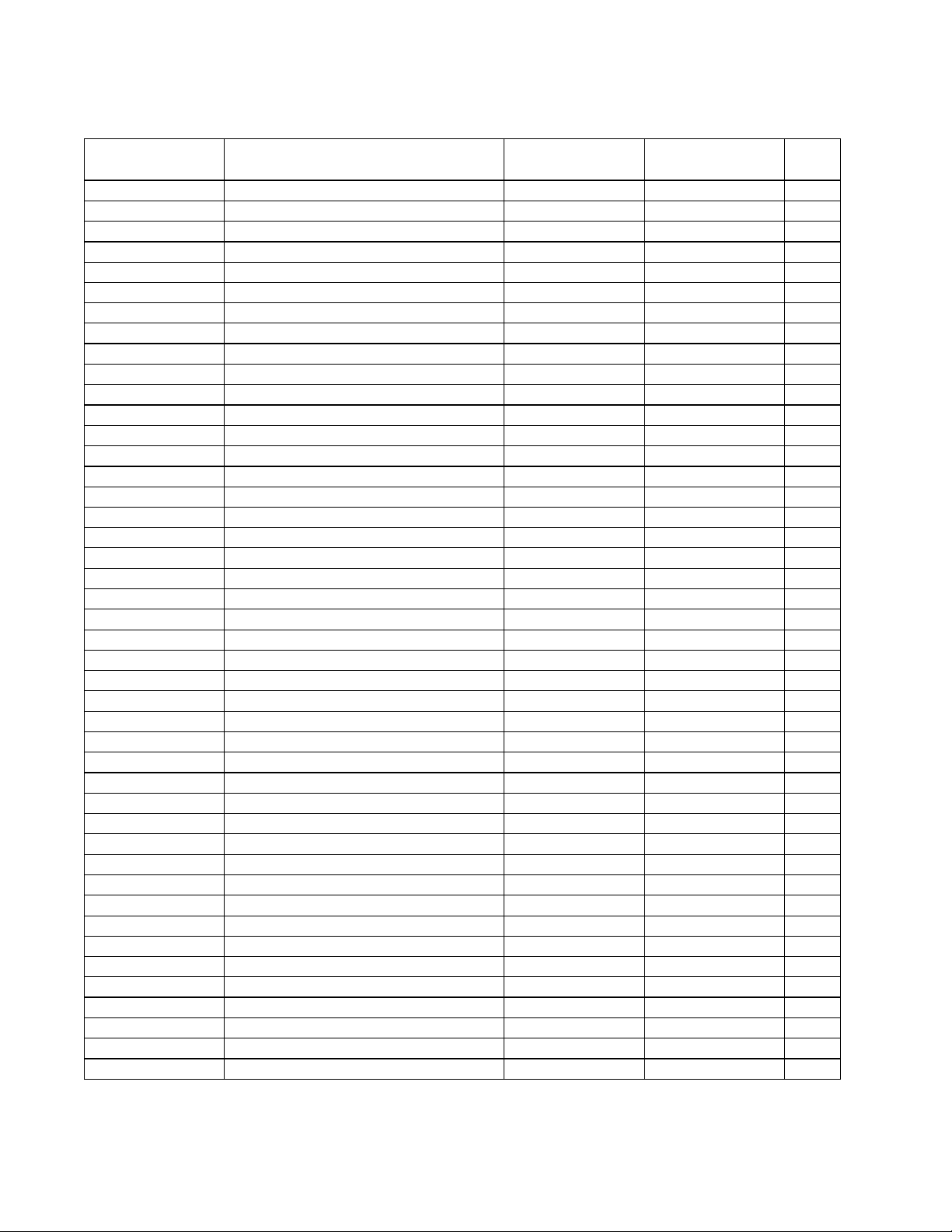

ELECTRICAL PART LIST

Main PCB Assembly

Resistors

Reference

Designator

R6 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R7 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R8 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R9 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R10 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R11 820 OHM, 0805, 1/10W, 5% E15103601 133626-8215 4

R12 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R13 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R14 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R15 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R16 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R17 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R18 2.49K, 0805, 1/10W, 1% E15400501 133625-2491 4

R19 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R20 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R21 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R22 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R23 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R24 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R25 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R26 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R27 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R28 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R29 506 OHM, 0805, 1/10W, 5% E15103501 - 4

R30 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R31 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R32 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R33 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R34 2.49K, 1206, 5% E15500201 124894-2491 4

R35 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R36 909 OHM, MET FILM, 1/4W, 1% E10400101 - 4

R37 909K, METAL FILM, 1/4W, 1% E10400201 - 4

R38 3.32K, 0805, 1/10W, 1% E15401801 133625-3321 4

R39 3.32K, 0805, 1/10W, 1% E15401801 133625-3321 4

R40 909K, METAL FILM, 1/4W, 1% E10400201 - 4

R41 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R42 499 OHM, 0805, 1/10W, 1% E15400901 133625-4990 4

R43 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R44 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R45 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R46 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R47 220 OHM, 0805, 1/10W, 5% E15100801 133625-2210 4

R48 499 OHM, 0805, 1/10W, 1% E15400901 133625-4990 4

R49 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

Description Vendor

Part Number

Part Number

Bose

Note

7

Page 8

ELECTRICAL PART LIST

Main PCB Assembly

Resistors (continued)

Reference

Designator

R50 909K, METAL FILM, 1/4W, 1% E10400201 - 4

R51 3.32K, 0805, 1/10W, 1% E15401801 133625-3321 4

R52 909K, METAL FILM, 1/4W, 1% E10400201 - 4

R53 3.32K, 0805, 1/10W, 1% E15401801 133625-3321 4

R54 909 OHM, MET FILM, 1/4W, 1% E10400101 - 4

R55 10.0K, 0805, 1/10W, 1% E15400101 133625-1002 4

R56 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R57 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R58 39K, 0805, 1/10W, 5% E15102801 - 4

R59 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R60 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R61 909 OHM, MET FILM, 1/4W, 1% E10400101 - 4

R62 909 OHM, MET FILM, 1/4W, 1% E10400101 - 4

R63 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R64 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R66 3.74K, 0805, 1% E15400801 133625-3741 4

R67 5.11K, 0805, 1% E15401101 133625-5111 4

R68 5.11K, 0805, 1% E15401101 133625-5111 4

R69 340 OHM, 0805, 1% E15400701 133625-3400 4

R70 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R71 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R72 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R73 4.99K, 0805, 1/10W, 1% E15401001 133625-4991 4

R74 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R75 3.74K, 0805, 1/10W, 1% E15400801 133625-3741 4

R76 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R78 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R79 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R80 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R81 38.3K, 1206, 1/10W, 1% E15500101 133625-3832 4

R82 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R83 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R84 38.3K, 1206, 1/10W, 1% E15500101 133625-3832 4

R85 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R86 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R87 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R88 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R89 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R90 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R91 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R92 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R93 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R94 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R95 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R96 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R97 38.3K, 0805, 1/10W, 1% E15500101 133625-3832 4

Description Vendor

Part Number

Part Number

Bose

Note

8

Page 9

ELECTRICAL PART LIST

Main PCB Assembly

Resistors (continued)

Reference

Designator

R98 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R99 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R100 4.99K, 0805, 1/10W, 1% E15401001 133625-4991 4

R101 3.74K, 0805, 1/10W, 1% E15400801 133625-3741 4

R102 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R103 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R104 38.3K, 1206, 1/10W, 1% E15500101 133625-3832 4

R105 2.49K, 0805, 1/10W, 1% E15400501 133625-2491 4

R106 1.24K, 0805, 1/10W, 1% E15400201 133625-1211 4

R107 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R108 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R109 2.49K, 0805, 1/10W, 1% E15400501 133625-2491 4

R110 1.24K, 0805, 1/10W, 1% E15400201 133625-1211 4

R111 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R112 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R113 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R114 4.7 OHM, 0805, 1/10W, 5% E15102501 133626-4R75 4

R115 62 OHM, 1/2W, 5%, LEADED E10000101 - 4

R116 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R117 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R118 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R119 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R120 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R121 1.0K, 0805, 1/10W, 5% E15100701 133626-1025 4

R122 10K, 0805, 1/10W, 5% E15100201 133625-1035 4

R123 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R124 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R125 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R126 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R127 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R128 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R129 412K, 0805, 1/10W, 1% E15401701 - 4

R130 221K, 0805, 1/10W, 1% E15401501 133625-2213 4

R131 221K, 0805, 1/10W, 1% E15401501 133625-2213 4

R132 604K, 0805, 1/10W, 1% E15401601 133625-6043 4

R133 604K, 0805, 1/10W, 1% E15401601 133625-6043 4

R134 6.8K, 0805, 1/10W, 5% E15101701 133626-6825 4

R135 6.8K, 0805, 1/10W, 5% E15101701 133626-6825 4

R136 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R137 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R138 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R139 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R140 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R141 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R142 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

R143 2.80K, 0805, 1/10W, 1% E15400601 133625-2801 4

Description Vendor

Part Number

Part Number

Bose

Note

9

Page 10

ELECTRICAL PART LIST

Main PCB Assembly

Resistors (continued)

Reference

Designator

R144 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R145 4.7 OHM, 0805, 1/10W, 5% E15102501 133626-4R75 4

R146 10K, 0805, 1/10W, 5% E15100201 133625-1035 4

R147 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R148 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R151 10M, 0805, 1/10W, 5% E15102601 133626-1065 4

R152 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R154 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R155 412K, 0805, 1/10W, 1% E15401701 - 4

R156 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R165 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R166 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R167 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R170 62 OHM, 1/2W, 5%, LEADED E10000101 - 4

R171 412K, 0805, 1/10W, 1% E15401701 - 4

R172 221K, 0805, 1/10W, 1% E15401501 133625-2213 4

R173 412K, 0805, 1/10W, 1% E15401701 - 4

R174 221K, 0805, 1/10W, 1% E15401501 133625-2213 4

R175 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R176 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R177 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R178 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R179 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R180 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R182 33 OHM, 0805, 1/10W, 5% E15103401 133626-3305 4

R184 2.49K, 1206, 5% E15500201 124894-2491 4

R185 604K, 0805, 1/10W, 1% E15401601 133625-6043 4

R186 604K, 0805, 1/10W, 1% E15401601 133625-6043 4

R187 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R191 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R192 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R193 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R195 6.8K, 0805, 1/10W, 5% E15101701 133626-6825 4

R196 6.8K, 0805, 1/10W, 5% E15101701 133626-6825 4

R197 100 OHM, 0805, 1/10W, 5% E15100101 133625-1000 4

R198 10K, 0805, 51/10W, % E15100201 133626-1035 4

R202 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R203 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R205 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R207 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R208 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R209 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R210 100K, 0805, 1/10W, 5% E15102001 133626-1045 4

R211 100K, 0805, 1/10W, 5% E15102001 133626-1045 4

R212 10M, 0805, 1/10W, 5% E15102601 133626-1065 4

R213 10M, 0805, 1/10W, 5% E15102601 133626-1065 4

Description Vendor

Part Number

Part Number

Bose

Note

10

Page 11

ELECTRICAL PART LIST

Main PCB Assembly

Resistors (continued)

Reference

Designator

R214 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R219 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R220 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R221 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R222 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R223 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R224 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R225 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R226 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R227 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R228 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R229 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R230 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R231 5.11K, 0805, 1/10W, 1% E15401101 133625-5111 4

R232 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R233 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R234 340 OHM, 0805, 1/10W, 1% E15400701 133625-3400 4

R235 8.25K, 0805, 1/10W, 1% E15401301 133625-8251 4

R236 4.99K, 0805, 1/10W, 1% E15401001 133625-4991 4

R237 3.74K, 0805, 1/10W, 1% E15400801 133625-3741 4

R238 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R239 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R240 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R241 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R242 38.3K, 0805, 1/10W, 1% E15500101 133625-3832 4

R243 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R244 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R245 38.3K, 0805, 1/10W, 1% E15500101 133625-3832 4

R246 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R247 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R248 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R249 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R250 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R251 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R252 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R253 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R254 1.50K, 0805, 1/10W, 1% E15400401 133625-1501 4

R255 4.99K, 0805, 1/10W, 5% E15500301 133625-4991 4

R256 38.3K, 0805, 1/10W, 1% E15500101 133625-3832 4

R257 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R258 2.49K, 1206, 1/4W, 5% E15500201 124894-2491 4

R259 4.99K, 0805, 1/10W, 1% E15401001 133625-4991 4

R260 3.74K, 0805, 1/10W, 1% E15400801 133625-3741 4

R261 4.99K, 1206, 1/10W, 5% E15500301 133625-4991 4

R262 38.3K, 1206, 1/10W, 1% E15500101 133625-3832 4

R263 2.49K, 0805, 1/10W, 1% E15400501 133625-2491 4

Description Vendor

Part Number

Part Number

Bose

Note

11

Page 12

ELECTRICAL PART LIST

Main PCB Assembly

Resistors (continued)

Reference

Designator

R264 1.24K, 0805, 1/10W, 1% E15400201 133625-1211 4

R265 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R266 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R267 2.49K, 0805, 1/10W, 1% E15400501 133625-2491 4

R268 1.24K, 0805, 1/10W, 1% E15400201 133625-1211 4

R269 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R270 634 OHM, 0805, 1/10W, 1% E15401201 133625-6340 4

R271 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R272 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R273 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R274 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R275 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R276 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R277 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

W1 33 OHM, 0805, 1/10W, 5% E15103401 133626-3305 4

Description Vendor

Part Number

Capacitors

Part Number

Bose

Note

Reference

Designator

C1 100nF, 0805, 10% E25301801 - 4

C2 100nF, 0805, 10% E25301801 - 4

C3 100nF, 0805, 10% E25301801 - 4

C4 100nF, 0805, 10% E25301801 - 4

C7 2.2nF, 0805, 5% E25200201 - 4

C8 470pF, 0805, 5% E25200101 133622-471 4

C8 470pF, 0805, 5% E25200101 133622-471 4

C10 470pF, 0805, 5% E25200101 133622-471 4

C11 39pF, 0805, 5% E25301601 133622-390 4

C12 39pF, 0805, 5% E25301601 133622-390 4

C14 100nF, 1206, +80/-20% E25500301 - 4

C15 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

C16 100nF, 0805, 10% E25301801 - 4

C20 220pF, 1206, % E25500201 133622-221 4

C21 220pF, 1206, % E25500201 133622-221 4

C22 470pF, 0805, 5% E25200101 133622-471 4

C23 470pF, 0805, 5% E25200101 133622-471 4

C24 47pF, 0805, 5% E25300501 133622-470 4

C25 47pF, 0805, 5% E25300501 133622-470 4

C26 2.2nF, 0805, 5% E25200201 - 4

C27 4.7nF, 0805, 5% E25301301 - 4

C28 2.2nF, 0805, 5% E25200201 - 4

C29 100nF, 1206, +80/-20% E25500301 - 4

C30 100nF, 1206, +80/-20% E25500301 - 4

C31 220pF, 1206, 5% E25500201 133622-221 4

C32 470pF, 0805, 5% E25200101 133622-471 4

Description Vendor

Part Number

Bose

Part Number

Note

12

Page 13

ELECTRICAL PART LIST

Main PCB Assembly

Capacitors (continued)

Reference

Designator

C33 47pF, 0805, 5% E25300501 133622-470 4

C34 2.2nF, 0805, 5% E25200201 - 4

C35 47pF, 0805, 5% E25300501 133622-470 4

C36 220pF, 1206, % E25500201 133622-221 4

C37 470pF, 0805, 5% E25200101 133622-471 4

C38 4.7nF, 0805, 5% E25301301 - 4

C39 2.2nF, 0805, 5% E25200201 - 4

C41 100nF, 0805, +80/-20% E25301001 - 4

C42 100nF, 0805, +80/-20% E25301001 - 4

C43 100nF, 0805, +80/-20% E25301001 - 4

C44 100nF, 0805, +80/-20% E25301001 - 4

C45 100nF, 0805, +80/-20% E25301001 - 4

C46 100nF, 0805, +80/-20% E25301001 - 4

C47 100nF, 0805, +80/-20% E25301001 - 4

C48 100nF, 0805, +80/-20% E25301001 - 4

C49 100nF, 0805, +80/-20% E25301001 - 4

C50 100nF, 0805, +80/-20% E25301001 - 4

C51 100nF, 0805, +80/-20% E25301001 - 4

C52 100nF, 0805, +80/-20% E25301001 - 4

C53 100nF, 0805, +80/-20% E25301001 - 4

C54 470pF, 0805, 5% E25200101 133622-471 4

C55 2.2nF, 0805, 5% E25200201 - 4

C56 47pF, 0805, 5% E25300501 133622-470 4

C57 27pF, 0805, 5% E25300801 133622-270 4

C58 100nF, 0805, +80/-20% E25301001 - 4

C59 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C60 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C61 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

C62 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

C63 27pF, 0805, 5% E25300801 133622-270 4

C64 47pF, 0805, 5% E25300501 133622-470 4

C65 27pF, 0805, 5% E25300801 133622-270 4

C66 27pF, 0805, 5% E25300801 133622-270 4

C67 100nF, 1206, +80/-20% E25500301 - 4

C68 100nF, 1206, +80/-20% E25500301 - 4

C69 100nF, 0805, 10% E25300701 - 4

C70 100nF, 0805, 10% E25300701 - 4

C71 100nF, 0805, 10% E25300701 - 4

C72 100nF, 0805, 10% E25300701 - 4

C73 100nF, 0805, +80/-20% E25301001 - 4

C74 100nF, 0805, 10% E25301801 - 4

C75 10nF, 0805, 5% E25300301 - 4

C76 100nF, 0805, +80/-20% E25301001 - 4

C77 100nF, 0805, +80/-20% E25301001 - 4

C78 100nF, 0805, +80/-20% E25301001 - 4

Description Vendor

Part Number

Part Number

Bose

Note

13

Page 14

ELECTRICAL PART LIST

Main PCB Assembly

Capacitors (continued)

Reference

Designator

C79 100nF, 0805, +80/-20% E25301001 - 4

C85 47pF, 1206, 5% E25500101 133622-470 4

C87 47pF, 0805, 5% E25300501 133622-470 4

C88 100nF, 1206, +80/-20% E25500301 - 4

C89 100nF, 1206, +80/-20% E25500301 - 4

C90 100nF, 1206, +80/-20% E25500301 - 4

C91 100nF, 0805, 10% E25301801 - 4

C92 100nF, 0805, +80/-20% E25301001 - 4

C93 100nF, 0805, +80/-20% E25301001 - 4

C94 100nF, 0805, +80/-20% E25301001 - 4

C95 100nF, 0805, +80/-20% E25301001 - 4

C96 100nF, 0805, +80/-20% E25301001 - 4

C97 100nF, 0805, +80/-20% E25301001 - 4

C98 100nF, 0805, +80/-20% E25301001 - 4

C99 100nF, 0805, 10% E25301801 - 4

C100 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C101 100nF, 0805, +80/-20% E25301001 - 4

C102 100nF, 0805, +80/-20% E25301001 - 4

C103 100nF, 0805, +80/-20% E25301001 - 4

C104 100nF, 0805, +80/-20% E25301001 - 4

C105 100nF, 0805, +80/-20% E25301001 - 4

C106 330nF, 0805, +80/-20% E25301101 - 4

C107 100nF, 0805, +80/-20% E25301001 - 4

C108 100nF, 0805, +80/-20% E25301001 -- 4

C109 100nF, 0805, +80/-20% E25301001 - 4

C110 100nF, 0805, +80/-20% E25301001 - 4

C111 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C112 47pF, 0805, 5% E25300501 133622-470 4

C113 47pF, 0805, 5% E25300501 133622-470 4

C114 100nF, 0805, +80/-20% E25301001 - 4

C115 47pF, 0805, 5% E25300501 133622-470 4

C116 47pF, 0805, 5% E25300501 133622-470 4

C117 47pF, 0805, 5% E25300501 133622-470 4

C118 47pF, 0805, 5% E25300501 133622-470 4

C119 47pF, 0805, 5% E25300501 133622-470 4

C120 47pF, 0805, 5% E25300501 133622-470 4

C121 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C122 1nF, 0805, 5% E25300601 - 4

C123 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C124 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C125 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C126 1nF, 0805, 5% E25300601 - 4

C127 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C128 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C129 47pF, 1206, 5% E25500101 133622-470 4

Description Vendor

Part Number

Part Number

Bose

Note

14

Page 15

ELECTRICAL PART LIST

Main PCB Assembly

Capacitors (continued)

Reference

Designator

C130 47pF, 1206, 5% E25500101 133622-470 4

C131 47pF, 1206, 5% E25500101 133622-470 4

C135 100nF, 0805, +80/-20% E25301001 - 4

C138 1nF, 0805, 5% E25300601 - 4

C139 1nF, 0805, 5% E25300601 - 4

C140 220pF, 1206, 5% E25500201 133622-221 4

C141 220pF, 1206, 5% E25500201 133622-221 4

C142 47pF, 0805, 5% E25300501 133622-470 4

C143 47pF, 0805, 5% E25300501 133622-470 4

C144 47pF, 0805, 5% E25300501 133622-470 4

C145 220pF, 1206, 5% E25500201 133622-221 4

C146 47pF, 0805, 5% E25300501 133622-470 4

C147 220pF, 1206, 5% E25500201 133622-221 4

C148 100pF, 0805, 5% E25300401 133622-102 4

C149 100pF, 0805, 5% E25300401 133622-102 4

C150 47pF, 0805, 5% E25300501 133622-470 4

C151 47pF, 0805, 5% E25300501 133622-470 4

C154 100nF, 0805, +80/-20% E25301001 - 4

C155 100nF, 0805, +80/-20% E25301001 - 4

C156 100nF, 0805, +80/-20% E25301001 - 4

C157 220pF, 1206, 5% E25500201 133622-221 4

C158 100nF, 0805, +80/-20% E25301001 - 4

C159 100nF, 0805, +80/-20% E25301001 - 4

C160 100nF, 0805, +80/-20% E25301001 - 4

C161 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C162 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C163 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C164 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C165 100nF, 0805, +80/-20% E25301001 - 4

C166 220pF, 1206, 5% E25500201 133622-221 4

C167 47pF, 0805, 5% E25300501 133622-470 4

C168 47pF, 0805, 5% E25300501 133622-470 4

C169 47pF, 0805, 5% E25300501 133622-470 4

C170 47pF, 0805, 5% E25300501 133622-470 4

C171 47pF, 0805, 5% E25300501 133622-470 4

C172 330nF, 0805, +80/-20% E25301101 - 4

C179 100nF, 0805, +80/-20% E25301001 - 4

C180 100nF, 0805, +80/-20% E25301001 - 4

C181 2.2uF, EL, 85OC, 25V, 20% E22000401 149948-2R2H 4

C182 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C183 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C187 100nF, 0805, +80/-20% E25301001 - 4

C188 100nF, 0805, +80/-20% E25301001 - 4

C189 100nF, 0805, +80/-20% E25301001 - 4

C190 100nF, 0805, +80/-20% E25301001 - 4

C191 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

Description Vendor

Part Number

Part Number

Bose

Note

15

Page 16

ELECTRICAL PART LIST

Main PCB Assembly

Capacitors (continued)

Reference

Designator

C192 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C193 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C194 47pF, 0805, 5% E25300501 133622-470 4

C195 47pF, 0805, 5% E25300501 133622-470 4

C196 47pF, 0805, 5% E25300501 133622-470 4

C197 47pF, 0805, 5% E25300501 133622-470 4

C198 100pF, 0805, 5% E25300401 133622-102 4

C199 100pF, 0805, 5% E25300401 133622-102 4

C200 100nF, 0805, +80/-20% E25301001 - 4

C201 100nF, 0805, +80/-20% E25301001 - 4

C202 220pF, 1206, 5% E25500201 133622-221 4

C203 220pF, 1206, 5% E25500201 133622-221 4

C204 100nF, 0805, +80/-20% E25301001 - 4

C205 100nF, 0805, +80/-20% E25301001 - 4

C206 100nF, 0805, +80/-20% E25301001 - 4

C207 100nF, 0805, +80/-20% E25301001 - 4

C208 100nF, 0805, +80/-20% E25301001 - 4

C209 100nF, 0805, +80/-20% E25301001 - 4

C210 100nF, 0805, +80/-20% E25301001 - 4

C211 100nF, 0805, +80/-20% E25301001 - 4

C212 2.2nF, 0805, 5% E25200201 - 4

C213 470pF, 0805, 5% E25200101 133622-471 4

C214 470pF, 0805, 5% E25200101 133622-471 4

C215 470pF, 0805, 5% E25200101 133622-471 4

C216 470pF, 0805, 5% E25200101 133622-471 4

C217 2.2nF, 0805, 5% E25200201 - 4

C218 47pF, 0805, 5% E25300501 133622-470 4

C219 27pF, 0805, 5% E25300801 133622-270 4

C220 27pF, 0805, 5% E25300801 133622-270 4

C221 47pF, 0805, 5% E25300501 133622-470 4

C222 27pF, 0805, 5% E25300801 133622-270 4

C223 27pF, 0805, 5% E25300801 133622-270 4

C224 100nF, 1206, +80/-20% E25500301 - 4

C225 100nF, 1206, +80/-20% E25500301 - 4

C226 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

C227 10uF, EL, 85OC, 25V, 20% E22000101 149948-100E 4

C228 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C229 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C230 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C231 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C232 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C233 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C234 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C235 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

Description Vendor

Part Number

Part Number

Bose

Note

16

Page 17

ELECTRICAL PART LIST

Main PCB Assembly

Capacitors (continued)

Reference

Designator

C236 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C237 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C238 100uF, EL, 85OC, 25V, 20% E22000201 149948-101E 4

C239 220uF, EL, 85OC, 25V, 20% E22000301 149948-221E 4

C240 100nF, 0805, +80/-20% E25301001 - 4

Description Vendor

Part Number

Inductors

Part Number

Bose

Note

Reference

Designator

Description Vendor

Part Number

Bose

Part Number

Note

L1 47uH, IND/IMC-1210, SMD E50200101 - 4

L4 FERRITE, CK08 E50300101 - 4

L5 FERRITE, CK08 E50300101 - 4

L6 FERRITE, CK08 E50300101 - 4

L7 FERRITE, CK08 E50300101 - 4

L8 FERRITE, CK08 E50300101 - 4

L12 FERRITE, CK08 E50300101 - 4

L13 FERRITE, CK08 E50300101 - 4

L14 FERRITE, CK08 E50300101 - 4

L15 FERRITE, CK08 E50300101 - 4

L16 FERRITE, CK08 E50300101 - 4

L17 FERRITE, CK08 E50300101 - 4

L19 FERRITE, CK08 E50300101 - 4

L20 FERRITE, CK08 E50300101 - 4

L21 FERRITE, CK08 E50300101 - 4

L22 FERRITE, CK08 E50300101 - 4

L23 FERRITE, CK08 E50300101 - 4

L24 FERRITE, CK08 E50300101 - 4

L25 FERRITE, CK08 E50300101 - 4

L26 FERRITE, CK08 E50300101 - 4

Diodes

Reference

Designator

Description Vendor

Part Number

Bose

Part Number

Note

D1 1N4148, SOD-80, SWITCHING E36000101 - 4

D2 TVS-DIODE, SOT-23 E36600101 - 4

D3 TVS-DIODE, SOT-23 E36600101 - 4

D4 TVS-DIODE, SOT-23 E36600101 - 4

D5 TVS-DIODE, SOT-23 E36600101 - 4

D6 TVS-DIODE, SOT-23 E36600101 - 4

D7 1N4148, SOD-80, SWITCHING E36000101 - 4

D8 1N4148, SOD-80, SWITCHING E36000101 - 4

D9 1N4148, SOD-80, SWITCHING E36000101 - 4

D10 1N4148, SOD-80, SWITCHING E36000101 - 4

D11 1N4148, SOD-80, SWITCHING E36000101 - 4

D12 1N4148, SOD-80, SWITCHING E36000101 - 4

D13 1N4148, SOD-80, SWITCHING E36000101 - 4

D14 1N4148, SOD-80, SWITCHING E36000101 - 4

17

Page 18

ELECTRICAL PART LIST

Main PCB Assembly

Diodes (continued)

Reference

Designator

D15 1N4148, SOD-80, SWITCHING E36000101 - 4

D16 ZENER, 4.7V, SOD-80, 400mW E36400201 135247-5230 4

D22 TVS-DIODE, SOT-23 E36600101 - 4

D23 TVS-DIODE, SOT-23 E36600101 - 4

D24 TVS-DIODE, SOT-23 E36600101 - 4

D26 1N4148, SOD-80, SWITCHING E36000101 - 4

D29 1N4148, SOD-80, SWITCHING E36000101 - 4

D30 1N4148, SOD-80, SWITCHING E36000101 - 4

D33 ZENER, 4.7V, SOD-80, 400mW E36400201 135247-5230 4

D34 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D35 ZENER, 4.7V, SOD-80, 400mW E36400201 135247-5230 4

D36 ZENER, 4.7V, SOD-80, 400mW E36400201 135247-5230 4

D37 1N4148, SOD-80, SWITCHING E36000101 - 4

D34 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D38 ZENER, 3.9V, SOD-80, 400mW E36400301 - 4

D39 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D40 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D41 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D42 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D43 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D44 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

D45 ZENER, 3.0V, SOD-80, 500mW E36400101 - 4

Description Vendor

Part Number

Transistors

Part Number

Bose

Note

Reference

Designator

Q1 BC847, NPN, SOT23-D E35100101 - 4

Q2 2SD2114, NPN, SOT23-D E35100201 - 4

Q3 BC847, NPN, SOT23-D E35100101 - 4

Q4 BC847, NPN, SOT23-D E35100101 - 4

Q5 BC857, PNP, SOT23-D E35100301 - 4

Q6 2SD2114, NPN, SOT23-D E35100201 - 4

Q7 2SD2114, NPN, SOT23-D E35100201 - 4

Q8 2SD2114, NPN, SOT23-D E35100201 - 4

Q9 BC847, NPN, SOT23-D E35100101 - 4

Q10 2SD2114, NPN, SOT23-D E35100201 - 4

Q11 2SD2114, NPN, SOT23-D E35100201 - 4

Q14 BC857, PNP, SOT23-D E35100301 - 4

Q15 BC857, PNP, SOT23-D E35100301 - 4

Q16 BC857, PNP, SOT23-D E35100301 - 4

Q17 BC857, PNP, SOT23-D E35100301 - 4

Q18 BC857, PNP, SOT23-D E35100301 - 4

Q19 BC857, PNP, SOT23-D E35100301 - 4

Q20 BC847, NPN, SOT23-D E35100101 - 4

Q21 BC847, NPN, SOT23-D E35100101 - 4

Description Vendor

Part Number

Bose

Part Number

Note

18

Page 19

ELECTRICAL PART LIST

Main PCB Assembly

Integrated Circuits

Reference

Designator

IC2 AK4524, SSOP28, 24-BIT 96KHZ

CODEC

IC3 DSP-56362, QFP\144P E49000101 - 4

IC5 SN74LV00, SO14, QUAD, 2-

INPUT NAND GATE

IC6 128KX8, SOJ32/400, HIGH

SPEED PROCESSOR

IC7 128KX8, SOJ32/400, HIGH

SPEED PROCESSOR

IC8 128KX8, SOJ32/400, HIGH

SPEED PROCESSOR

IC9 DG441, SO16, QUAD SPST

ANALOG SWITCH

IC10 5532, DIP8, OP-AMP E47000101 - 4

IC11 5532, DIP8, OP-AMP E47000101 - 4

IC12 39VF020, PLCC32R, 24-BIT

96KHZ, CODEC

IC13 5532, DIP8, OP-AMP E47000101 - 4

IC14 6N137, DIP8, HIGH SPEED TTL

LEVEL OPTOCOUPLER

IC15 5532, DIP8, OP-AMP E47000101 - 4

IC16 5532, DIP8, OP-AMP E47000101 - 4

IC18 5532, DIP8, OP-AMP E47000101 - 4

IC19 5532, DIP8, OP-AMP E47000101 - 4

IC20 5532, DIP8, OP-AMP E47000101 - 4

IC21 5532, DIP8, OP-AMP E47000101 - 4

IC24 LM78L05, TO-92, 5V, REG E42100101 - 4

IC25 74HCT4052, SO16, DUAL 4-CH

ANALOG MULTIPLEXER

IC27 5532, DIP8, OP-AMP E47000101 - 4

IC30 74HCT4052, SO16, DUAL 4-CH

ANALOG MULTIPLEXER

IC37 LM78L05, TO-92, 5V, REG E42100101 - 4

IC38 AK4524, SSOP28, 24-BIT 96KHZ

CODEC

Description Vendor

Part Number

E49100301 - 4

E45000101 - 4

E48100102 - 4

E48100102 - 4

E48100102 - 4

E39900101 - 4

E48401001 - 4

E34600101 - 4

E45000201 - 4

E45000201 - 4

E49100301 - 4

Part Number

Bose

Note

19

Page 20

ELECTRICAL PART LIST

Main PCB Assembly

Miscellaneous

Reference

Designator

J3 DIN5F, DIN CONNECTOR E52200101 - 4

J5 HDR2X10, PIN HEADER, 2x10 E52800201 - 4

J6 XLR CONNECTOR, FEMALE E52200401 - 4

J8 HDR2X5, PIN HEADER, 2x5 E52800101 - 4

J9 XLR CONNECTOR, FEMALE E52200401 - 4

J10 XLR CONNECTOR, MALE E52200501 - 4

J11 XLR CONNECTOR, MALE E52200501 - 4

J12 PLCC32_SOCKET E44800101 - 4

J16 XLR CONNECTOR, MALE E52200501 - 4

J17 XLR CONNECTOR, MALE E52200501 - 4

X2 22.5792 MHz, CRYSTAL E33000201 - 4

Description Vendor

Part Number

Part Number

Bose

Note

20

Page 21

ELECTRICAL PART LIST

Display PCB Assembly

Resistors

Reference

Designator

R1 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R2 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R3 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R4 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R5 47K, 0805, 1/10W, 5% E15101401 133626-4735 4

R6 560 OHM, 0805, 1/10W, 5% E15103501 133626-5615 4

R7 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R8 47K, 0805, 1/10W, 5% E15101401 133626-4735 4

R9 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R10 82 OHM, 0805, 1/10W, 5% E15102301 - 4

R11 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R12 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R13 3.9K, 0805, 1/10W, 5% E15101301 133626-3925 4

R14 3.9K, 0805, 1/10W, 5% E15101301 133626-3925 4

R15 560 OHM, 0805, 1/10W, 5% E15103501 133626-5615 4

R16 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R17 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R18 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R19 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R20 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R21 10K, 0805, 1/10W, 5% E15100201 133626-1035 4

R22 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R23 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R24 2.2K, 0805, 1/10W, 5% E15101101 133626-2225 4

R25 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R26 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R28 1.8K, 0805, 1/10W, 5% E15103901 133626-1825 4

R29 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R31 3.01K, 0805, 1/10W, 5% E15104001 133625-3011 4

R32 301 OHM, 0805, 1/10W, 5% E15104011 133625-3010 4

R33 2.61K, 0805, 1/10W, 5% E15104021 133625-2611 4

R35 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R37 49.9K, 0805, 1/10W, 5% E15103801 133625-4992 4

R39 0 OHM, 0805, 1/10W, 5% E15103701 133627 4

R42 10 OHM, 0805, 1/10W, 5% E15100301 133626-1005 4

R45 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R46 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R47 220 OHM, 0805, 1/10W, 5% E15100801 133626-2215 4

R57 120 OHM, 0805, 1/10W, 5% E15102201 133626-1215 4

R62 82 OHM, 0805, 1/10W, 5% E15102301 - 4

Description Vendor

Part Number

Bose®

Part Number

Note

21

Page 22

ELECTRICAL PART LIST

Display PCB Assembly

Capacitors

Reference

Designator

C1 100nF, 0805, +80/-20% E25301001 - 4

C2 100nF, 0805, +80/-20% E25301001 - 4

C3 1nF, 0805, 5% E25300601 - 4

C7 100nF, 0805, 10% E25300701 - 4

C8 39pF, 0805, 5% E25301601 133622-390 4

C10 39pF, 0805, 5% E25301601 133622-390 4

C11 100nF, 0805, +80/-20% E25301001 - 4

C15 100nF, 0805, 10% E25300701 - 4

C16 100nF, 0805, 10% E25300701 - 4

C17 100nF, 0805, 10% E25300701 - 4

C18 100nF, 0805, 10% E25300701 - 4

C20 100nF, 0805, 10% E25300701 - 4

C21 100nF, 0805, 10% E25300701 - 4

C22 100nF, 0805, 10% E25300701 - 4

C24 100nF, 0805, 10% E25300701 - 4

C24 100nF, 0805, 10% E25300701 - 4

C26 100nF, 0805, 10% E25300701 - 4

C27 100nF, 0805, 10% E25300701 - 4

C28 100nF, 0805, 10% E25300701 - 4

C33 10uF, EL, 85OC, 25V, 20% E22100201 149948-100E 4

C35 100nF, 0805, 10% E25300701 - 4

Description Vendor

Part Number

Diodes

Bose®

Part Number

Note

Reference

Designator

D1 BAT54, SOT23, SCHOTTKY E36000201 - 4

D2 BAT54, SOT23, SCHOTTKY E36000201 - 4

D3 BAT54, SOT23, SCHOTTKY E36000201 - 4

D4 BAT54, SOT23, SCHOTTKY E36000201 - 4

LD1 LED, 3MM GREEN E31700201 - 4

LD2 LED, 3MM GREEN E31700201 - 4

LD3 LED_BAR 7 SEGMENT E31700401 - 4

LD4 LED_BAR 7 SEGMENT E31700401 - 4

LD9 LED, 3MM GREEN E31700201 - 4

LD10 LED, 3MM GREEN E31700201 - 4

Reference

Designator

Q4 BC857, SOT23-D, PNP E35100301 - 4

Q5 BC857, SOT23-D, PNP E35100301 - 4

Description Vendor

Part Number

Transistors

Description Vendor

Part Number

Bose

Part Number

Bose

Part Number

Note

Note

22

Page 23

ELECTRICAL PART LIST

®

Display PCB Assembly

Integrated Circuits

Reference

Designator

Description Vendor

Part Number

Bose

Part Number

IC1 MAX809, SOT23, S PIN RESET E49100101 - 4

IC2 74HC132, SO14, QUAD 2-INPUT

E45500301 - 4

NAND GATE

IC3 74HCT574, S01420WB, OCTAL

E45500701 - 4

D-TYPE FLIP FLOP

IC4 74HC74, SO14, DUAL D FLIP

E45500201 - 4

FLOP

IC8 AT8535, PLCC-14, 8 BIT, MICRO E49000211 - 4

Miscellaneous

Note

Reference

Designator

Description Vendor

Part Number

Bose®

Part Number

Note

J1 CABLE, HDR2X10 E59700101 - 4

J2 CONNECTOR 16, HDR16 E52800301 - 4

J3 PLCC44_SOCKET E44800201 - 4

S1 SW/TACT2, TACT SWITCH E34000101 - 4

S2 SW/TACT2, TACT SWITCH E34000101 - 4

S3 SW/TACT2, TACT SWITCH E34000101 - 4

S4 SW/TACT2, TACT SWITCH E34000101 - 4

S5 SW/TACT2, TACT SWITCH E34000101 - 4

S6 SW/TACT2, TACT SWITCH E34000101 - 4

S7 ENCODER, ROTARY SWITCH E34000301 - 4

S17 POWER SWITCH E34000201 - 4

X1 4 MHZ CRYSTAL, LOW PROFILE E33000301 - 4

23

Page 24

DISASSEMBLY PROCEDURES

Note: Refer to Figure 2 for the following

procedures.

CAUTION: Before re-assembling the unit,

use compressed air to blow out any metal

shavings that may have fallen into the unit

during disassembly.

1. Side Panel Removal

1.1 Using a TX-15 Torx bit, remove the two

screws (1) located on each side of the unit.

1.2 With the front of the unit facing you, pull

the front of the side panels (2) out until the

tab at the rear of the side panel is free.

2. Front Panel Removal

2.1 Perform procedure 1.

2.2 Pull off the rotary knob (3).

2.3 Pull the front panel (4) forward slightly

and slide it off the toward either end of the

unit.

3. Top Cover Removal

3.1 Perform procedure 1.

3.2 Using a phillips-head screwdriver, re-

move the four screws (10) along the bottom

rear of the unit and the two screws (9) on the

top front of the top cover (5).

4.3 Remove the button assembly (14) with

the arrows on it.

4.4 Using a T-9 Torx bit remove the three

screws (12) that secure the front PCB (6)

to the chassis.

4.5 Gently pull the front panel PCB assembly

off of the black plastic standoffs.

4.6 Gently remove the PCB assembly while

feeding the cable assembly through the front

of the chassis.

5. Main PCB Removal

5.1 Perform procedure 3.

5.2 Remove the front panel PCB assembly’s

cable connector from the main PCB.

5.3 Using a T-9 Torx bit, remove the five

screws (19) that secure the main PCB to

the chassis.

5.4 Lift up the main PCB toward the front of

the unit. Make a note of the wiring configuration and unsolder the wires located at the

front of the PCB.

5.5 Lift out the main PCB assembly.

6. Power Supply PCB Removal

6.1 Perform procedure 3.

3.3 Remove the twelve screws (11) that

secure the XLR connectors to the rear of the

top cover.

3.4 Lift off the top cover.

4. Front Panel PCB Removal

4.1 Perform procedure 2.

4.2 Remove the connector for the front panel

PCB assembly (15) from the main PCB.

6.2 Using a T-9 Torx bit, remove the four

screws (18) that secure the corners of the

power supply PCB (17) and the two screws

(18A) that secure the AC jack to the chassis.

6.3 Lift up the PCB toward the front of the

unit. Make a note of the wiring configuration

and unsolder the wires at the front of the

PCB.

6.4 Lift out the power supply PCB.

24

Page 25

TEST PROCEDURES

Test Setup:

1. The arrow buttons navigate through the

user interface settings; Mono, Stereo, Bass

Array and separate channel operation.

2. The rotary control selects the type of

speaker EQ under test e.g. 402, 802, LT4402

etc.

3. For the following test procedures, set the

unit to Stereo setting and then use the rotary

control to select the EQ to test.

Note: The Panaray® system digital controller

has the equalized frequency responses for

all of the Bose® professional speakers

programmed into a DSP integrated circuit.

Prior to testing for frequency response,

check that the system responds to key pad

entries. Press the arrow keys to navigate

through the EQ selection settings. Rotate the

rotary pot and check that the display

changes from one type of speaker equalization to another. If these functions are working

properly then continue on to the frequency

response tests. If these functions are not

working, the unit may be defective.

Required Test Equipment:

• Audio Signal Generator

• dB Meter

1.5 Measure the frequency response of the

output using the table below.

402 EQ Full Range Frequency Response

Frequency Output Level

60 Hz -3.7 dB ± 1.5 dB

105 Hz +8.5 dB ± 1.5 dB

220 Hz +3.5 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.8 dB ± 1.5 dB

14.5 kHz +13.3 dB ± 1.5 dB

1.6 Select the 402 high frequency setting.

1.7 Apply a 100 mVrms, 850 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the output

jack of the controller.

1.8 Measure the frequency response of the

output using the table below.

402 EQ High Frequency Response

Frequency Output Level

60 Hz -16.4 dB ± 1.5 dB

105 Hz -5.2 dB ± 1.5 dB

220 Hz +2.8 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.8 dB ± 1.5 dB

14.5 kHz +13.3 dB ± 1.5 dB

1. 402

®

EQ Frequency Response Test

1.1 Select the 402 stereo setting for the

following tests.

1.2 Apply a 100 mVrms, 850 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input jack

of the controller.

1.3 Measure the gain at the output of the

channel under test. It should be -3.4 +/- 1dB.

1.4 Reference a dB meter to the output of

the controller channel under test.

2. 402 II EQ Frequency Response Test

2.1. Select the 402 II stereo setting for the

following tests.

2.2 Apply a 100 mVrms, 850 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of

the controller.

2.3 Measure the gain at the output of the

channel under test. It should be -3.4 +/- 1dB.

2.4 Reference a dB meter to the output of

the controller channel under test.

25

Page 26

TEST PROCEDURES

2.5 Measure the frequency response of the

output using the table below.

402 II EQ Full Range Frequency Response

Frequency Output Level

60 Hz +3.2 dB ± 1.5 dB

90 Hz +10.0 dB ± 1.5 dB

220 Hz +7.3 dB ± 1.5 dB

600 Hz -2.4 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.6 dB ± 1.5 dB

13.5 kHz +15.5 dB ± 1.5 dB

2.6 Select the 402 II high frequency setting.

2.7 Apply a 100 mVrms, 850 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the output

jack of the controller.

2.8 Measure the frequency response of the

output using the table below.

402 II EQ High Frequency Response

Frequency Output Level

60 Hz -13.0 dB ± 1.5 dB

90 Hz -5.6 dB ± 1.5 dB

220 Hz +6.8 dB ± 1.5 dB

600 Hz -2.4 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.6 dB ± 1.5 dB

13.5 kHz +15.5 dB ± 1.5 dB

3.5 Measure the frequency response using

the table below.

502A EQ Full Range Frequency Response

Frequency Output Level

40 Hz -24.5 dB ± 2.0 dB

140 Hz +4.3 dB ± 1.5 dB

600 Hz 0 dB

Reference

2,2 kHz +3.5 dB ± 1.5 dB

5 kHz +12.5 dB ± 1.5 dB

15 kHz +18.4 dB ± 1.5 dB

3.6 Select the 502 high frequency setting.

3.7 Apply a 100 mVrms, 600 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the output

jack of the controller.

3.8 Measure the frequency response of the

output using the table below.

502A EQ High Frequency Response

Frequency Output Level

40 Hz -28.5 dB ± 2.0 dB

140 Hz +2.9 dB ± 1.5 dB

600 Hz 0 dB

Reference

2.2 kHz +3.5 dB ± 1.5 dB

5 kHz +12.5 dB ± 1.5 dB

15 k Hz +19.0 dB ± 1.5 dB

4. 502B EQ Frequency Response Test

3. 502®A EQ Frequency Response Test

3.1 Select the 502A Stereo setting.

3.2 Apply a 100 mVrms, 600 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of the

channel under test.

3.3 Measure the gain. It should be -4.4 +/- 1

dB.

3.4 Reference a dB meter to the output of the

channel under test.

4.1 Select the 502B setting.

4.2 Apply a 200 mVrms, 80 Hz signal to

the input jack of the controller channel under

test.

4.3 Reference a dB meter to the input of the

channel under test.

4.4 Measure the gain. It should be +13.8 +/1 dB.

4.5 Reference a dB meter to the output of

the channel under test.

26

Page 27

TEST PROCEDURES

4.6 Measure the frequency response using

the table below.

502B EQ Frequency Response

Frequency Output Level

40 Hz -5.8 dB ± 2.0 dB

80 Hz 0 dB

Reference

100 Hz +1.3 dB ± 1.0 dB

300 Hz -17.5 dB ± 2.0 dB

5. 502BEX EQ Frequency Response Test

5.1 Select the 502BEX setting.

5.2 Apply a 200 mVrms, 100 Hz signal to

the input jack of the controller channel under

test.

5.3 Reference a dB meter to the input of the

channel under test.

5.4 Measure the gain. It should be +4.2 +/1 dB.

6.3 Reference a dB meter to the input of the

channel under test.

6.4 Measure the gain. It should be +1.8 +/1 dB.

6.5 Reference a dB meter to the output of

the channel under test.

6.6 Measure the frequency response of the

output using the table below.

802 II EQ Full Range Frequency Response

Frequency Output Level

40 Hz +8.0 dB ± 1.5 dB

55 Hz +13.5 dB ± 1.5 dB

140 Hz +6.6 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +2.1 dB ± 1.5 dB

6 kHz +9.6 dB ± 1.5 dB

14.5 kHz +16.7 dB ± 1.5 dB

6.7 Select the 802 high frequency setting.

5.5 Reference a dB meter to the output of

the channel under test.

5.6 Measure the frequency response using

the table below.

502®BEX EQ Frequency Response

Frequency Output Level

30 Hz -15.2 dB ± 2.0 dB

55 Hz +2.3 dB ± 1.4 dB

100 Hz 0 dB

Reference

160 Hz - 6.8 dB ± 1.0 dB

240 Hz -0.8 dB ± 1.2 dB

500 Hz -11.6 dB ± 2.0 dB

6. 802® II EQ Frequency Response Test

6.1 Select the 802 II stereo setting.

6.2 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test.

6.8 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the output of

the channel under test.

6.9 Measure the frequency response of the

output using the table below.

802 II EQ High Frequency Response

Frequency Output Level

40 Hz -21.0 dB ± 1.5 dB

60 Hz -11.5 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +2.1 dB ± 1.5 dB

6 kHz +9.6 dB ± 1.5 dB

14.5 kHz +16.7 dB ± 1.5 dB

27

Page 28

TEST PROCEDURES

7. 802 III EQ Frequency Response Test

7.1 Select the 802 III stereo setting.

7.2 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of the

channel under test.

7.3 Measure the gain. It should be +1 +/1 dB.

7.4 Reference a dB meter to the output of

the channel under test.

7.5 Measure the frequency response of the

output using the table below.

802 III EQ Full Range Frequency Response

Frequency Output Level

40 Hz +1.9 dB ± 1.5 dB

70 Hz +13.5 dB ± 1.5 dB

140 Hz +7.5 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +1.8 dB ± 1.5 dB

6 kHz +6.9 dB ± 1.5 dB

13 kHz +13.8 dB ± 1.5 dB

7.6 Select the 802® high frequency setting.

7.7 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the output jack

of the channel under test.

8. Panaray® LT3202 Series II EQ Frequency

Response Test

8.1 Select the LT3202 stereo setting.

8.2 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of

the channel under test.

8.3 Measure the gain. It should be +7 +/1 dB.

8.4 Reference a dB meter to the output of

the channel under test.

8.5 Measure the frequency response of the

output using the following table.

LT3202 Series II EQ Frequency Response

Frequency Output Level

50 Hz -27 dB ± 3 dB

100 Hz -6.0 dB ± 1.5 dB

200 Hz 3.0 dB ± 1.5 dB

400 Hz -1.5 dB ± 1 dB

700 Hz 0 dB

Reference

900 Hz 0.5 dB ± 1 dB

3,250 Hz -6.5 dB ± 1.5 dB

6.4 kHz -6.5 dB ± 1.5 dB

13 kHz -4.3 dB ± 1.5 dB

30 kHz -27 dB ± 3 dB

9. Panaray LT4402 EQ Series II Frequency

Response Test

7.8 Measure the frequency response of the

output using the table below.

802 III EQ High Frequency Response

Frequency Output Level

40 Hz -24.9 dB ± 1.5 dB

70 Hz -10.6 dB ± 1.5 dB

140 Hz +5.2 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +1.9 dB ± 1.5 dB

6 kHz +7.0 dB ± 1.5 dB

13 kHz +13.9 dB ± 1.5 dB

9.1 Select the LT4402 stereo setting.

9.2 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of

the channel under test.

9.3 Measure the gain. It should be +5 +/1 dB.

9.4 Reference a dB meter to the output of

the channel under test.

28

Page 29

TEST PROCEDURES

9.5 Measure the frequency response of the

output using the table below.

LT4402 Series II EQ Frequency Response

Frequency Output Level

50 Hz -27.4 dB ± 3 dB

150 Hz -2.2 dB ± 1.5 dB

250 Hz 1.7 dB ± 1.5 dB

500 Hz -0.9 dB ± 1.5 dB

700 Hz 0 dB

Reference

1 kHz 1.3 dB ± 1.5 dB

2 kHz -0.3 dB ± 1 dB

3 kHz 0.6 dB ± 1 dB

7 kHz -1.5 dB ± 1.5 dB

13 kHz 0 dB ± 1.5 dB

30 kHz -26 dB ± 3 dB

10. Panaray® LT9702 Series II EQ

Frequency Response Test

Frequency Output Level

50 Hz -23 dB ± 3 dB

100 Hz -2.4 dB ± 1.5 dB

180 Hz +5.2 dB ± 2 dB

550 Hz -1.5 dB ± 1 dB

700 Hz 0 dB

Reference

1.1 kHz +2.3 dB ± 1 dB

1.8 kHz +3.8 dB ± 1 dB

3 kHz +4.8 dB ± 1 dB

6.5 kHz +4.5 dB ± 1.5 dB

11.5 kHz +3.8 dB ± 1.5 dB

30 kHz -22 dB ± 3 dB

10.1 Select the LT9702 stereo setting.

10.2 Apply a 100 mVrms, 700 Hz signal to

the input jack of the controller channel under

test. Reference a dB meter to the input of the

channel under test.

10.3 Measure the gain. It should be +2.6 +/1 dB.

10.4 Reference a dB meter to the output of

the channel under test.

10.5 Measure the frequency response of the

output using the following table.

LT9702 Series II EQ Frequency Response

29

Page 30

APPENDIX

402® Series II Full Range Frequency Response Curve

402 Series II Hi Pass Frequency Response Curve

30

Page 31

APPENDIX

502®A Full Range Frequency Response Curve

502A Hi Pass Frequency Response Curve

31

Page 32

APPENDIX

502®B Frequency Response Curve

502BEX Frequency Response Curve

32

Page 33

APPENDIX

802® Series III Full Range Frequency Response Curve

802 Series III Hi Pass Frequency Response Curve

33

Page 34

APPENDIX

802® Series III Stacked Full Range Frequency Response curve

802 Series III Stacked Hi Pass Frequency Response Curve

34

Page 35

APPENDIX

Panaray® LT3202® Series II Frequency Response Curve

Panaray LT4402® Series II Frequency Response Curve

35

Page 36

APPENDIX

Panaray® LT9702® Series II Frequency Response Curve

36

Page 37

APPENDIX

Panaray® MA12 Free Field Frequency Response Curve

Panaray MA12 Hi Pass Frequency Response Curve

37

Page 38

APPENDIX

Panaray® MA12 Wall Mount Frequency Response Curve

Panaray MA12 Stacked Free Field Frequency Response Curve

38

Page 39

APPENDIX

Panaray

®

MA12 Stacked Hi Pass Frequency Response Curve

Panaray MA12 Stacked Wall Mount Frequency Response Curve

39

Page 40

APPENDIX

Panaray® MB4 100 Hz Low Pass Frequency Response Curve

Panaray MB4 160 Hz Low Pass Frequency Response Curve

40

Page 41

APPENDIX

Panaray MB4 200 Hz Low Pass Frequency Response Curve

Panaray MB4 280 Hz Low Pass Frequency Response Curve

41

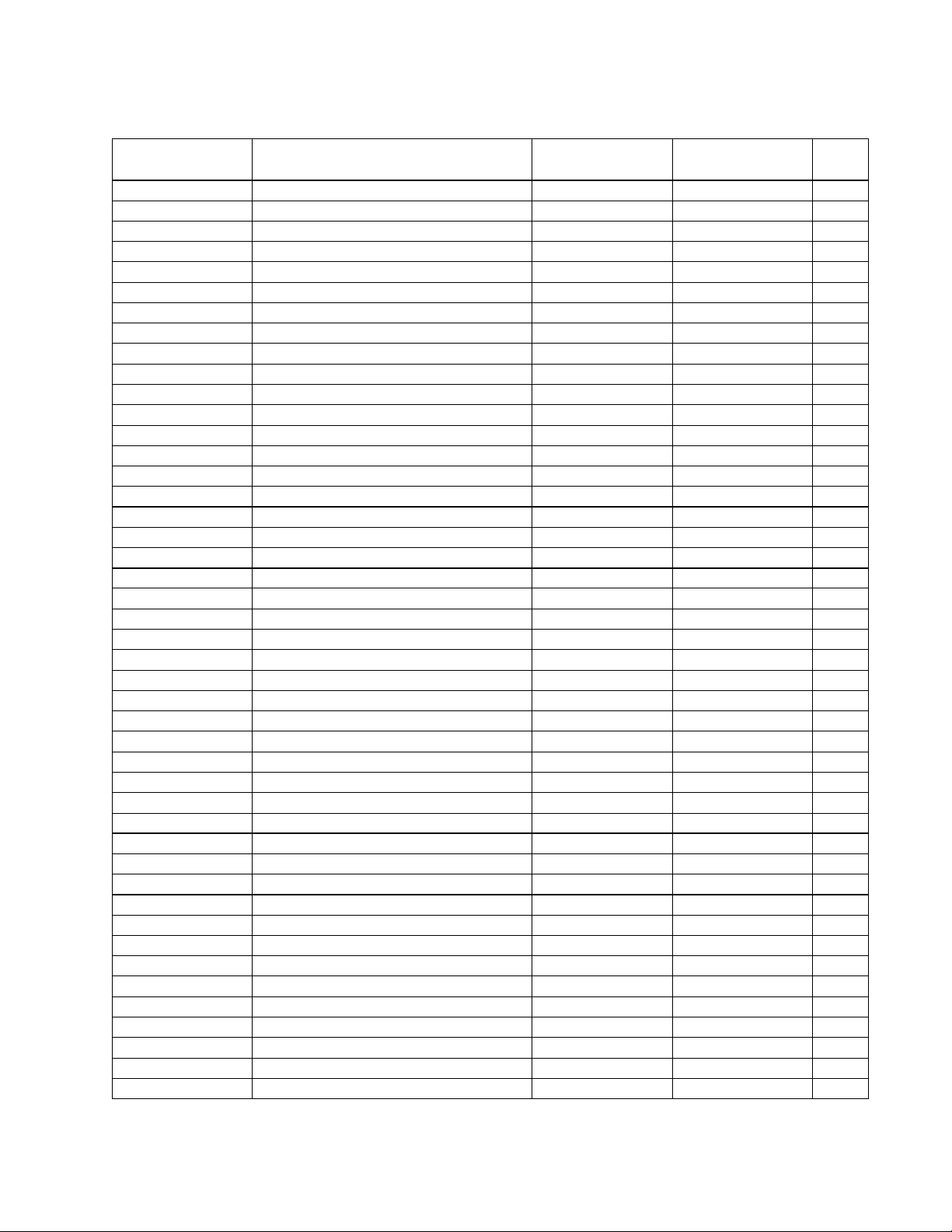

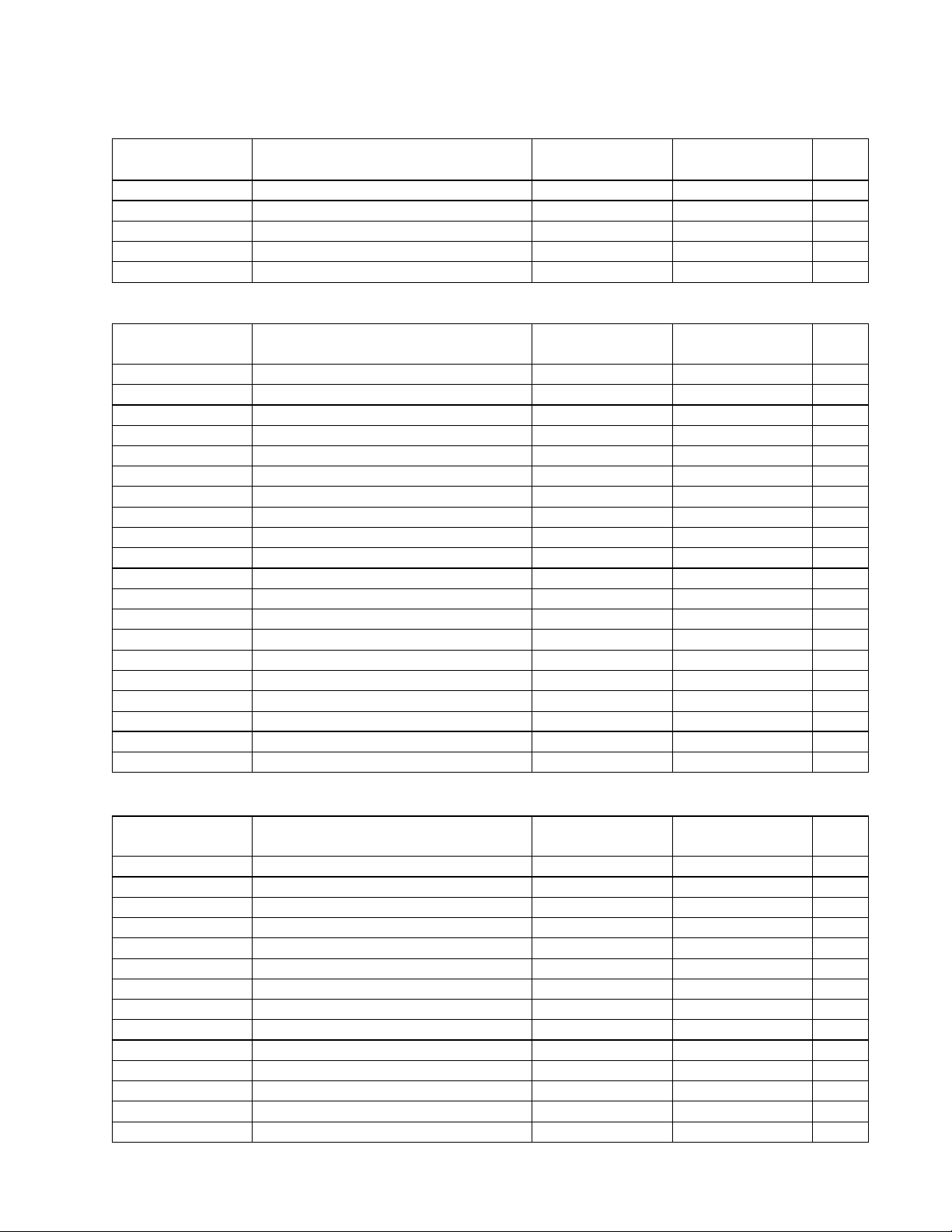

Page 42

APPENDIX

The following is a list of 180 presets that are available in the Panaray

®

system digital controller.

The presets are separated into three banks: Mono, Stereo and Bass Array. Included in this list is

the name of each preset as it appears on the Panaray controller LCD as well as a description of

the preset and the default settings for each of the four channels.

Bose® Loudspeaker EQ Preset List- Mono Bank

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

402

I

402 I+502B

402 I+MB4 402 Series I loudspeaker

402 I+AWCS 402 Series I loudspeaker

402 I HF 402 Series I loudspeaker

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

402

II

402 II+502B 402 Series II loudspeaker

402

II

+502BEX

402 II+MB4 402 Series II loudspeaker

402 II+AWCS 402 Series II loudspeaker

402 II HF 402 Series II loudspeaker

402 Series I loudspeaker full

range EQ

402 Series I loudspeaker

bi-amped with 502B

bi-amped with MB4

bi-amped with AWCS

bi-amped at 160 Hz

402 Series II loudspeaker full

range EQ

bi-amped with 502B

402 Series II loudspeaker

bi-amped with 502BEX

bi-amped with MB4

bi-amped with AWCS

bi-amped at 160 Hz

402

Mono

I

Full Range

402

Mono

I

High Freq.

Mono

402

I

High Freq.

402

Mono

I

High Freq.

402

Mono

I

High Freq.

402

II

Mono

Full Range

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402 I Mono

Full Range

402 I Mono

High Freq.

402 I Mono

High Freq.

402 I Mono

High Freq.

402 I Mono

High Freq.

402

II

Mono

Full Range

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402

II

Mono

High Freq.

402 I Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

402 I Mono

High Freq.

402

Mono

II

Full Range

502B Mono

Low

502BEX

Mono Low

MB4 Mono

Low

AWCS

Mono Low

402

II

Mono

High Freq.

402 I Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

402 I Mono

High Freq.

402 II Mono

Full Range

502B Mono

Low

502BEX

Mono Low

MB4 Mono

Low

AWCS

Mono Low

402

II

Mono

High Freq.

42

Page 43

APPENDIX

Bose® Loudspeaker EQ Preset List- Mono Bank (continued)

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

502A

502A+502B 502A loudspeaker bi-amped

502A+MB4 502A loudspeaker bi-amped

502A+AWCS 502A loudspeaker bi-amped

502A HF 502A loudspeaker bi-amped

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

802

II

802 II+502B

802 II+MB4 802 Series II loudspeaker

802 II+AWCS 802 Series II loudspeaker

802 II HF 802 Series II loudspeaker

802 II STK Stacked 802 Series

802

II

STK+502

802 II STK

+AWCS

802 II STK HF 802 Series II loudspeaker

B

502A loudspeaker full rangeEQ502A Mono

Full Range

502A Mono

with 502B

with MB4

with AWCS

Limiting is assigned to

Note:

channels 3 and 4 for

protection of the AWCS

with at 180 Hz

802 Series II loudspeaker full

range EQ

802 Series II loudspeaker

bi-amped with 502B

bi-amped with MB4

bi-amped with AWCS

Limiting is assigned to

Note:

channels 3 and 4 for

protection of the AWCS

bi-amped at 112 Hz

II

loudspeaker full range EQ

Stacked 802 Series

loudspeaker bi-amped with

502B

802 Series II loudspeaker

bi-amped with AWCS

Limiting is assigned to

Note:

channels 3 and 4 for

protection of the AWCS

bi-amped at 112 Hz

II

High Freq.

502A Mono

High Freq.

502A Mono

High Freq.

502A Mono

High Freq.

802

II

Mono

Full Range

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

Full Range

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

502A Mono

Full Range

502A Mono

High Freq.

502A Mono

High Freq.

502A Mono

High Freq.

502A Mono

High Freq.

802

II

Mono

Full Range

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

Full Range

802

II

Mono

High Freq.

802

II

Mono

High Freq.

802

II

Mono

High Freq.

502A Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

502A Mono

High Freq.

802

II

Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

802

Mono

II

High Freq.

802

II

Mono

Full Range

502B Mono

Low

AWCS

Mono Low

802

Mono

II

High Freq.

502A Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

502A Mono

High Freq.

802

II

Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

802 II Mono

High Freq.

802

II

Mono

Full Range

502B Mono

Low

AWCS

Mono Low

802 II Mono

High Freq.

43

Page 44

APPENDIX

Bose® Loudspeaker EQ Preset List- Mono Bank (continued)

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

802

III

802

+502B

III

802

+MB4 802 Series

III

802

+AWCS 802 Series

III

802

HF 802 Series

III

802

STK Stacked 802 Series

III

802

III

STK+502

802

+AWCS

802

STK+MB4

802

B

STK

III

III

STK HF 802 Series

III

802 Series

full range EQ

802 Series

bi-amped with 502B

bi-amped with MB4

bi-amped with AWCS

Note:

channels 3 and 4 for

protection of the AWCS

bi-amped at 125 Hz

loudspeaker full range EQ

Stacked 802 Series

loudspeaker bi-amped with

502B

802 Series

bi-amped with AWCS

Note:

channels 3 and 4 for

protection of the AWCS

Stacked 802 Series

loudspeaker

bi-amped with MB4

bi-amped at 125 Hz

Limiting is assigned to

Limiting is assigned to

loudspeaker

III

loudspeaker

III

loudspeaker

III

loudspeaker

III

loudspeaker

III

loudspeaker

III

loudspeaker

III

III

III

III

802

III

Mono

Full Range

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

Full Range

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

Full Range

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

Full Range

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

High Freq.

802

III

Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

802

III

Mono

High Freq.

802

III

Mono

Full Range

502B Mono

Low

AWCS

Mono Low

MB4 Mono

Low

802

III

Mono

High Freq.

802

III

Mono

Full Range

502B Mono

Low

MB4 Mono

Low

AWCS

Mono Low

802

III

Mono

High Freq.

802

III

Mono

Full Range

502B Mono

Low

AWCS

Mono Low

MB4 Mono

Low

802

III

Mono

High Freq.

44

Page 45

APPENDIX

Bose® Loudspeaker EQ Preset List- Mono Bank (continued)

LCD Display Preset Description Output Default Configuration

Mono Presets Channel 1 Channel 2 Channel 3 Channel 4

MA12 WALL MA12 loudspeaker full range

Wall mount EQ

MA12 FREE MA12 loudspeaker full range

Free field EQ

MA12+502B MA12 loudspeaker

bi-amped with 502B

MA12+MB4 MA12 loudspeaker

bi-amped with MB4

MA12 HF MA12 loudspeaker

bi-amped at 160 Hz

MA12STK

WALL

MA12STK

FREE

MA12STK+502BMA12 loudspeaker

MA12STK+MB4MA12 loudspeaker

MA12STK HF MA12 loudspeaker

MA12 loudspeaker full range

Wall mount EQ

MA12 loudspeaker full range

Free field EQ

bi-amped with 502B

bi-amped with MB4

bi-amped at 160 Hz

MA12

Mono

Full Range

MA12

Mono

Full Range

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

Full Range

MA12

Mono

Full Range

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

Full Range

MA12

Mono

Full Range

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

Full Range

MA12

Mono

Full Range

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12

Mono

High Freq.

MA12 Mono

Full Range

MA12 Mono

Full Range

502B Mono

Low