Page 1

Bose® FreeSpace

®

360P Series II Environmental Speaker

Product Description

The Bose FreeSpace 360P loudspeaker is an 80-watt, full-range environmental loudspeaker with a

360° horizontal dispersion. It is designed for use with standard amplifiers in a variety of applications,

such as shopping malls, outdoor restaurants, resorts and theme parks. It offers the following features:

• An environmental 4.5" (11.4 cm) Bose driver with passive equalization, providing high reliability

and high quality sound for outdoor applications

• A multi-tap line transformer that permits selection of tap settings of 10W, 20W, 40W, or 80W at

the 70V or 100V inputs)

• Freestanding design that blends with the landscaping and permits installation either in ground or

attached to a horizontal concrete or wood surface

Service Manual

©2007 Bose Corporation

Reference Number 263872-SM

REV 02

Electronic copy only

Page 2

FS360P II Environmental Loudspeaker

Contents

Specifications ..................................................................................................................................1

Assembly Part List ..........................................................................................................................2

Packaging Part List - Pair ...............................................................................................................2

Figure 1. Assembly and Packaging View...........................................................................................2

Disassembly Procedures................................................................................................................3

Figure 2. Schematic Diagram ............................................................................................................4

Test Procedures .............................................................................................................................. 4

Specifications

Frequency Range: 70Hz to15kHz (±3dB)

FreeSpace© 360P versions: 70V/100V (10W, 20W, 40W, 80W taps)

Sensitivity: 87dB-SPL @ 1W, 1m (pink noise)

Maximum Acoustic Output: 100dB-SPL @ 1m (pink noise)

Dispersion (–6dB point, average,1-4kHz): 360° horizontal; 50° vertical

Long-Term Power Handling: 40W continuous, 80W peak

Mechanical Specifications:

Dimensions: 14.5" (36.83 cm) base diameter; 14.9" (37.85 cm) height

Weight: 14.5 lb (16.58 kg)

Input Connections: External multi-wire cable with wire nuts included

Enclosure Construction: Glass reinforced polypropylene

Mounting Points: Three (3) #10 (M4) holes in base

Warranty

The Bose® FreeSpace® 360P Series II loudspeaker is covered by a 5-year, transferable limited warranty

Proprietary Information

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF BOSE

CORPORATION WHICH IS BEING FURNISHED ONLY FOR THE PURPOSE OF

SERVICING THE IDENTIFIED BOSE PRODUCT BY AN AUTHORIZED BOSE

SERVICE CENTER OR OWNER OF THE BOSE PRODUCT, AND SHALL NOT

BE REPRODUCED OR USED FOR ANY OTHER PURPOSE.

Caution: The FreeSpace loudspeaker contains no user serviceable parts. To prevent warranty infractions, refer servicing to warranty service centers or factory service.

1

Page 3

FS360P II Environmental Loudspeaker

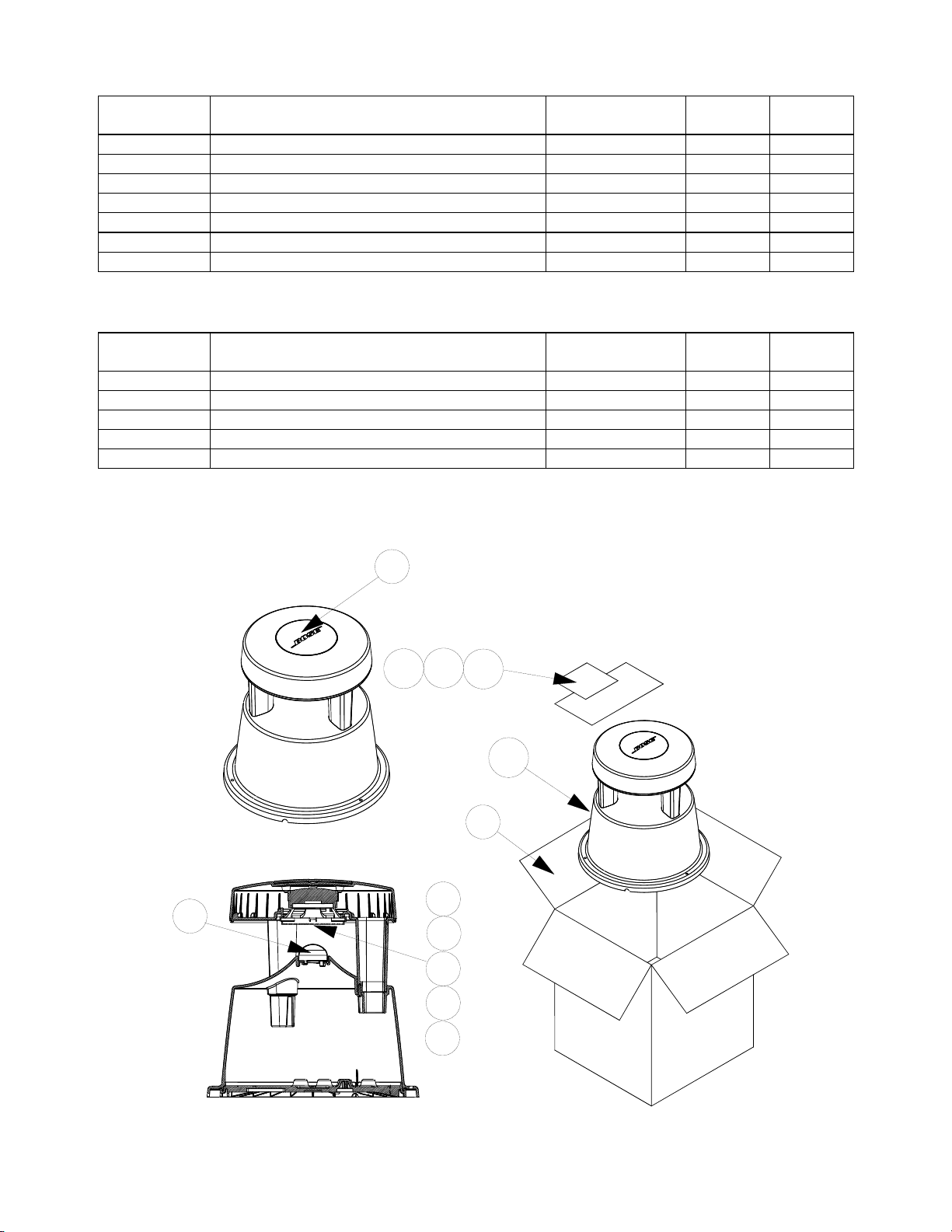

Item

Description Part Number Qty Note

Item

Description Part Number Qty Note

Assembly Part List

Number

1 DRIVER ASSY, 4. 5", EN V 289807-001 1

2 GASKET, STRIP, 2. 0X 5. 0X340.0, PSA 291132-340 1

3 DIFFUSER, FS-5 1 268607 1

4 PROTECTO R, D RI VER, TRANSIT, 4. 5 120003 1

5 LOGO CAP, GREEN 268601-1 1

6 SCREW, TF, 8-11X1.25, HEXW HD 296497-020 3 4

7 SCREW, TAPP, 8-11X. 5, PAN, XREC/SQ 296495-008 3 4

Packaging Part List - Pair

Number

8 CARTON, REG SLO TTED 270555 1

9 OWNERS GUIDE 263873 1

10 CONNECTOR, WIRENUT, 16-22AWG 188199-001 8

11 BAG, POLY, ZIP LOC K, 2 MI L, 3X5" 260556-0305 1 4

12 BAG, POLY, 13X33.5X 11.5X3 137847 2 4

Note:

1. The crossover PCB is located in the top of the unit and is not accessible for repair or replacement.

2. The transformer is located in the base of the unit and is not accessible for repair or replacment.

3

5

9

10

1

2

4

6

11

12

8

Figure 1. Assembly and Packaging View

7

2

Page 4

Driver Removal

Top Cap Removal

FS360P II Environmental Loudspeaker

Disassembly Procedures

Cut the wires close to the driver terminal.Remove three screws then lift up driver.

Remove three screws.

Lift off diffuser.

Flip unit over. Lift off top cap.

Note:

1. The crossover PCB is located in the top of the unit

and is not accessible for repair or replacement.

2. The transformer is located in the base of the unit

and is not accessible for repair or replacement.

3

Page 5

FS360P II Environmental Loudspeaker

Test Procedures

Test SetUp

70V version: Apply the positive input signal to

the red wire and the negative to the black wire.

100V version: Apply the positive input signal to

the yellow wire and the negative to the black

wire.

Connect the orange (80W) tap wire to the white

wire. After testing, return the tap setting to what

the customer had set the unit to. See schematic diagram below.

1. Phase Test

1.1 Apply 8 Vdc to the speaker input terminal.

1.2 The driver should move outward.

2. Air Leak Test

2.1 Apply a 35 Vrms, 80 Hz signal to the

speaker input terminal. (Use 50 Vrms for 100V

units)

2.2 Listen for air leaks around the driver, top

cap, and base seams. Repairs can only be

made to the driver.

3. Rub and Tick Test

3.1 Apply a 35 Vrms, 10 Hz signal to the

speaker input terminal. (Use 50 Vrms for 100V

units)

3.2. No extraneous noises such as rubbing,

scraping or ticking should be heard. To distinguish between normal suspension noise, rubs

and ticks, displace the cone of the driver with

your finger. If the sound can be made to go

away or get worse, it’s a rub or tick and the

driver should be replaced. If the noise stays

the same, it’s normal suspension noise and

will not be heard with regular program material.

4. Sweep Test

4.1 Apply a 35 Vrms, 80 Hz signal to the

speaker input terminal. (Use 50 Vrms for 100V

units). Sweep the speaker from 80 Hz to 5

kHz.

4.2 Listen for buzzes, rattles or other extraneous noises from the driver or cabinet.

L1

70V

100V

COM

COM

80W

40W

20W

10W

RED

YELLOW

BLACK

WHITE

ORANGE

GREEN

VILOT

BLUE

CONNECTOR

R1 6.2 Ohm

C1 15uF

L1 1.5mH

R2 2.7 Ohm

C2 33uF

PINK

OR

BROWN

TRANSFORMER

100V

BLACK

R1

70V

PTC

C1 R2

80W

40W 20W 10W

C2

RED

+

-

BLACK

Note: The transformer and crossover components are not accessible for repair or replacement.

Figure 2. Schematic Diagram

4

Page 6

FS360P II Environmental Loudspeaker

Date Revision

Description of Change Change

Pages

Service Manual Revision History

Level

04/03 00

04/06 00 to 01 Added RoHS part numbers This product is

03/07 02 Added driver from strip –

1

Document released at

revision 00.

removed non-rohs driver

Driven By

now built with

RoHS

compliant

parts.

ECN 37167

Affected

3

5

Page 7

Specifications and Features Subject to Change Without Notice

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 263872 REV. 03 03/07 (P)

http://serviceops.bose.com

Loading...

Loading...