Page 1

Contents

Safety Information............................................................................................................................ 2

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 3

Supplement Description.................................................................................................................. 3

Test Procedures ............................................................................................................................... 4

Part List Notes.................................................................................................................................. 5

Electrical Part List......................................................................................................................... 6-7

PCB Layout....................................................................................................................................... 8

Figure 1. PCB SMD Bottom View .................................................................................................... 8

Figure 2. PCB Component Top View................................................................................................ 8

Figure 3. Model 8 and Model 25/32 Schematic Diagram ................................................................. 9

CAUTION: THE EQ PCB ASSEMBLIES CONTAIN NO USER-SERVICEABLE PARTS. TO

PREVENT WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY SERVICE

STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 “Leakage Current for Appliances” and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position, then in the

OFF position, measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliamp. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZ ARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO

THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug. (2) Turn on the

power switch of the unit. (3) Measure the resistance with an ohmmeter be-

tween the jumpered AC plug and each exposed metallic cabinet part on the

unit. When the exposed metallic part has a return path to the chassis, the

reading should be between 1 and 5.2 Megohms. When there is no return path

to the chassis, the reading must be “infinite”. If it is not within the limits specified,

there is the possibility of a shock hazard, and the unit must be repaired and re checked before it is returned to the customer.

2

Page 3

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing, or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

SUPPLEMENT DESCRIPTION

This supplement should be used along with the 1800V EQ PCB service manual part number

181812-S2. The disassembly/assembly procedures, and packing part list should be used along

with the information in this manual. The test procedures were included in this manual for your

convenience.

3

Page 4

TEST PROCEDURES

1. Model 8 EQ PCB Response Test

1.1 Apply a signal of 1kHz at an input level

of 100mVrms.

1.2 Adjust the amplifier volume controls to

maximum. No EQ card installed.

1.3 Reference a dB meter to the output of

the amplifier.

1.4 Shut off the amplifier and insert the EQ

card according to the assembly procedure.

1.5 Turn on the amplifier and measure the

gain. There should be a -3.5dB change in

gain at the output.

1.6 Reference a dB meter and measure

the response of the EQ card according to

the Model 8 Full Range Response chart

below.

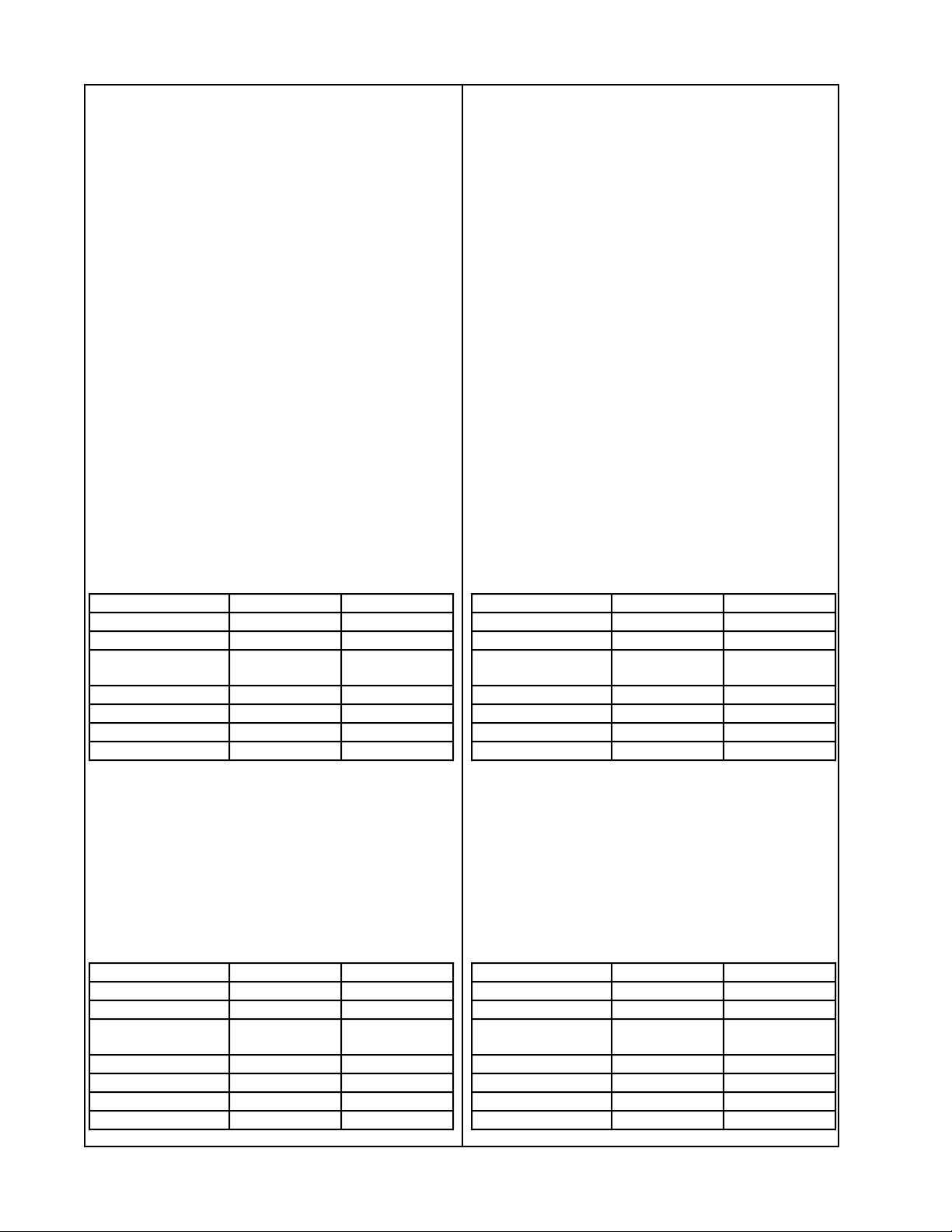

Model 8 Full Range Response Chart Model 25/32 Full Range Response Chart

Frequency Output Tolerence

95Hz +11.3dB ±1.5dB

250Hz +4.5dB ±1.5dB

1kHz 0dB

Reference

2kHz +3.0dB ±1.5dB

4kHz +7.0dB ±1.5dB

8kHz +10.5dB ±1.5dB

12.5kHz +11.75dB ±2.5dB

-

2. Model 25/32 EQ PCB Response Test

2.1 Apply a signal of 1kHz at an input level

of 100mVrms.

2.2 Adjust the amplifier volume controls to

maximum. No EQ card installed.

2.3 Reference a dB meter to the output of

the amplifier.

2.4 Shut off the amplifier and insert the EQ

card according to the assembly procedure.

2.5 Turn on the amplifier and measure the

gain. There should be a -4.8dB change in

gain at the output.

2.6 Reference a dB meter and measure

the response of the EQ card according to

the Model 25/32 Full Range Response

chart below.

Frequency Output Tolerence

95Hz +12.3dB ±1.5dB

250Hz +4.4dB ±1.5dB

1kHz 0dB

Reference

2kHz +1.7dB ±1.5dB

4kHz +7.6dB ±1.5dB

8kHz +12.0dB ±1.5dB

12.5kHz +15.0dB ±2.5dB

-

1.7 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch to the high frequency position.

1.8 Measure the response according to the

Model 25/32 High Frequency Response

chart below.

Model 8 High Freq. Response Chart

Frequency Output Tolerence

95Hz +11.3dB ±1.5dB

250Hz +4.5dB ±1.5dB

1kHz 0dB

Reference

2kHz +3.0dB ±1.5dB

4kHz +7.0dB ±1.5dB

8kHz +10.5dB ±1.5dB

12.5kHz +11.75dB ±2.5dB

-

2.7 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch to the high frequency position.

2.8 Measure the response according to the

Model 25/32 High Frequency Response

chart below.

Model 25/32 High Freq. Response Chart

Frequency Output Tolerence

95Hz +12.3dB ±1.5dB

250Hz +4.4dB ±1.5dB

1kHz 0dB

Reference

2kHz +1.7dB ±1.5dB

4kHz +7.6dB ±1.5dB

8kHz +12.0dB ±1.5dB

12.5kHz +15.0dB ±2.5dB

4

-

Page 5

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCB are listed in the Electrical Part Lists.

3. This part is critical for safety purposes. Failure to use a substitute replacement with

the same safety characteristics as the recommended replacement part might create shock, fire

and or other hazards.

4. The reference designators that are in bold print are used on the model 8 EQ PCB assembly.

5

Page 6

ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 20.0KΩ, 1206, 1/8W, 1% 124894-2002

R2, 16, 17, 19 10.0KΩ, 1206, 1/8W, 1% 124894-1002 4

R2 14.0KΩ, 1206, 1/8W, 1% 124894-1402 4

R3, 14 22.1KΩ, 1206, 1/8W, 1% 124894-2212

R3, 13 4.12KΩ, 1206, 1/8W, 1% 124894-4121 4

R5, 27 8.25KΩ, 1206, 1/8W, 1% 124894-8251

R5, 25 887Ω, 1206, 1/8W, 1% 124894-8870 4

R9 11.5KΩ, 1206, 1/8W, 1% 124894-1152

R11 110KΩ, 1206, 1/8W, 1% 124894-1103

R12 150KΩ, 1206, 1/8W, 1% 124894-1503

R12 100KΩ, 1206, 1/8W, 1% 124894-1003 4

R13, 16, 20 4.99KΩ, 1206, 1/8W, 1% 124894-4991 4

R14 16.5KΩ, 1206, 1/8W, 1% 124894-1652 4

R17, 22 7.15KΩ, 1206, 1/8W, 1% 124894-7151 4

R18, 19 4.75KΩ, 1206, 1/8W, 1% 124894-4751

R22 3.92KΩ, 1206, 1/8W, 1% 124894-3921

R25, 35, 36, 40-45 JUMPER, CHIP 124896

R26 6.19KΩ, 1206, 1/8W, 1% 124894-6191

R27 15.0KΩ, 1206, 1/8W, 1% 124894-1502 4

R31 21.5KΩ, 1206, 1/8W, 1% 124894-2152

R32 78.7KΩ, 1206, 1/8W, 1% 124894-7872

R37, 38 47.0KΩ, 1206, 1/8W, 5% 124895-4735

Description Part

Number

Note

Capacitors

Reference

Designator

C2 .068uF, BOX, 85, 63V, 5% 137127-683

C2, 8, 10 .047uF, BOX, 85, 63V, 5% 137127-473 4

C3 .27uF, BOX, 85, 50V, 5% 137127-274

C3 .33uF, BOX, 85, 50V, 5% 137127-334 4

C6 .0033uF, BOX, 85, 100V,

5%

C10 .056uF, BOX, 85, 63V, 5% 137127-563

C11 .033uF, BOX, 85, 63V, 5% 137127-333 4

C11, 12 .0056uF, BOX, 85, 100V,

5%

C20, 22 .022uF, BOX, 85, 100V,

5%

C24, 26, 48-51 10000pF, CHIP, 5% 124959-103

C25, 27 .0027uF, BOX, 85, 100V,

5%

C27 .0022uF, BOX, 85, 100V,

5%

Description Part

Number

137127-332 4

137127-562

137127-223

137127-272

137127-222 4

Note

6

Page 7

ELECTRICAL PART LIST

Diodes

Reference

Designator

D1, 2, 3, 5 1N4148, 52MM, AXIAL 121501

D4, 6 ZEN, 18V, 1W, 5%,

1N4746A

Integrated Circuits

Reference

Designator

U1, 2 IC, OP AMP, QUAD 144008

U3 IC, SWITCH, ACTIVE,

SIP-8, BA3128N

Description Part

Number

116995-4746A

Description Part

Number

177292

Note

Note

7

Page 8

PCB LAYOUT

Figure 1. PCB SMD Bottom View

Figure 2. PCB Component Top View

8

Page 9

2

R

5

4

3

1

2

34

5

6

78

A

B

C

DD

C

B

A

FRAMINGHAM, MA 01701-9168

8

7

6

1

+15V

+15V

+15V

+15V

+15V

-15V

-15V

-15V

-15V

-15V

R39

NU

R45

0

R44

0

R41

0

R40

0

C27

OPT

R42

0

R43

0

11

4

1

2

3

U1

RC4156N

D6

1N4746A

D4

1N4746A

D5

1N4148

D3

1N4148

D2

1N4148

D1

1N4148

C26

.01

C24

.01

RC4156N

14

13

12

U2

R34

N.U.

R36

0

R35

0

R38

47k

C1

N.U.

C2

.068

R1

20k

R2

OPT

C3

OPT

R3

OPT

R4

N.U.

C5

N.U.

RC4156N

8

9

10

U1

R5

OPT

C6

OPT

R6

N.U.

R7

N.U.

C4

N.U.

C7

N.U.

C8

.047

C10

OPT

11

4

1

2

3

U2

RC4156N

R11

110K

R13

OPT

R8

N.U.

C9

N.U.

R12

OPT

R10

N.U.

R9

11.5K

R16

OPT

R15

OPT

R18

OPT

C13

N.U.

R14

OPT

R19

OPT

R17

OPT

RC4156N

7

6

5

U1

C12

.0056

C11

OPT

C14

N.U.

C15

N.U.

RC4156N

8

9

10

U2

R25

OPT

R27

OPT

R21

N.U.

C16

N.U.

R26

6.19K

R23

N.U.

R24

N.U.

R20

4.99k

R22

OPT

C17

N.U.

C25

.0027

R33

N.U.

RC4156N

7

6

5

U2

6J1

5J1

2J1

3

J1

R37

47k

RC4156N

14

13

12

U1

C19

N.U.

C18

N.U.

C20

.022

1

5

4

8

673

2

U3

NJM2120

VEE

VCC

-INB

+INB

-INA

+INA

SW

OUT

R31

21.5K

7

J1

R32

78.7K

R30

N.U.

R28

N.U.

C23

N.U.

C22

.022

C21

N.U.

R29

N.U.

1J1

C48

.01

C49

.01

C50

.01

C51

.01

4J1

Model 8, and Model 25/32

EQ PCB 184844

Page 1 of 1

Service Manual 181812-S5 REV 00

Note: See the part list for the proper value of OPT components.

Figure 3. Model 8 and Model 25/32 Schematic Diagram

9

Page 10

Model 1800-V Professional Stereo Power

Amplifier EQ PCB Assemblies

1 CHANNEL 2

dBPEAK/PROTECT

PEAK/PROTECT

0

3

6

9

12

ON

5

8

3.5

12

2

20

1

40

.25

0

OFF

STANDBY

ON

T

1800 SERIES V PROFESSIONAL AMPLIFIER

5

8

3.5

12

2

20

1

40

.25

0

OFF

©

1997 Bose Corporation

Supplement

Service Manual

Part Number 181812-S5

Page 11

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

®

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 181812-S5 REV. 00 11/97 FOR TECHNICAL ASSISTANCE OR PART ORDERS, CALL 1-800-367-4008

Loading...

Loading...