Page 1

Contents

Safety Information ............................................................................................................................3

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................4

Supplement Description ...................................................................................................................4

Theory of Operation ..................................................................................................................... 5-6

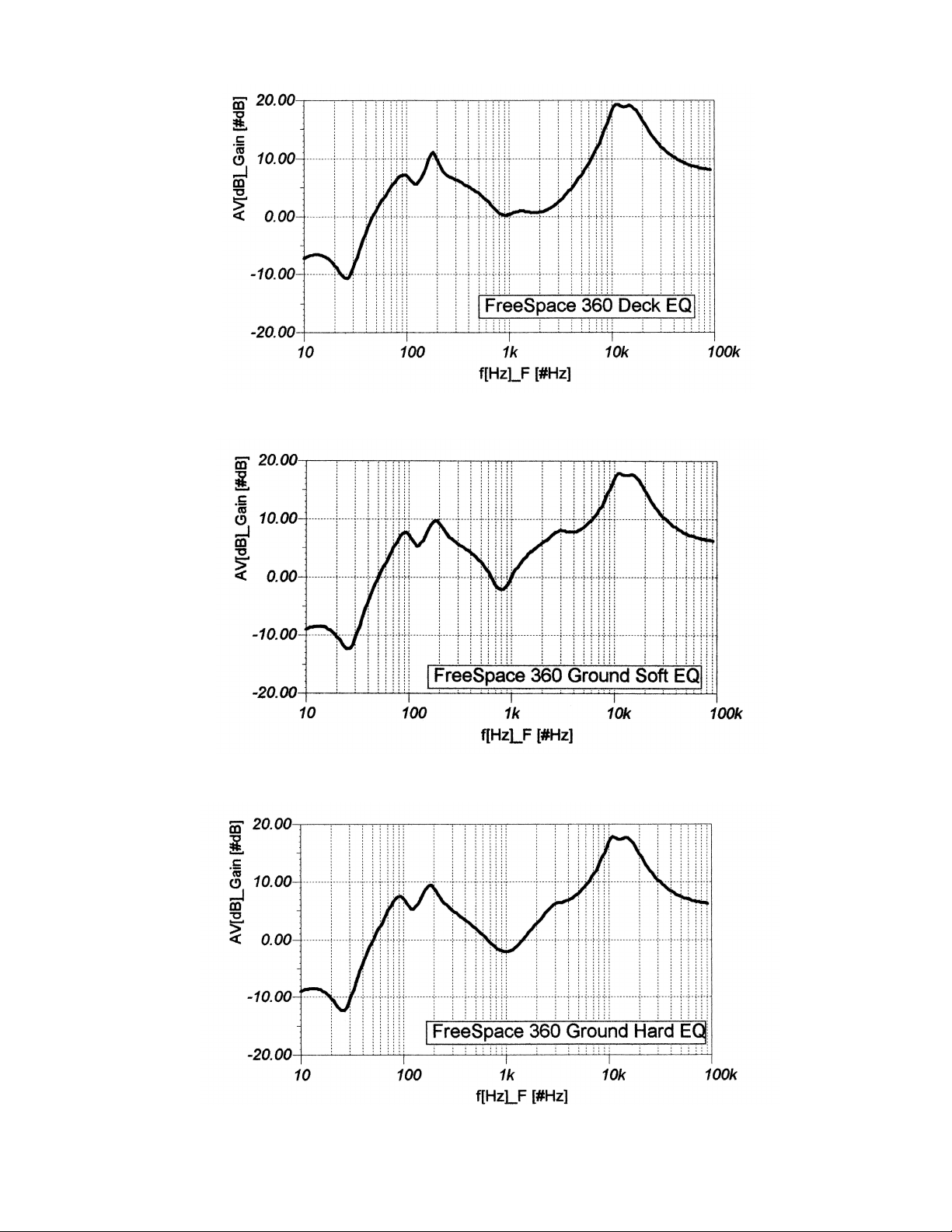

Equalizer Card Curve Diagrams ...................................................................................................... 7

Figure 1. FreeSpace® 360 Surface EQ Curve ..................................................................................7

Figure 2. FreeSpace 360 In-Ground Soft Ground EQ Curve ............................................................ 7

Figure 3. FreeSpace 360 In-Ground Hard Ground EQ Curve ..........................................................7

Disassembly/Assembly Procedures ...............................................................................................8

Figure 4. Screw Location .................................................................................................................. 8

Figure 5. EQ Card Placement ...........................................................................................................8

Test Set up Procedures ....................................................................................................................9

Test Procedures ........................................................................................................................ 10-17

Part List Notes .................................................................................................................................18

EQ Card PCB Part Numbers and Product Codes........................................................................ 18

402® Series I Electrical Part List .............................................................................................. 19-20

402 Series II Electrical Part List .............................................................................................. 21-22

®

802

Series II Electrical Part List ............................................................................................ 23-24

802 Series III Electrical Part List ............................................................................................. 25-26

502®A Electrical Part List ......................................................................................................... 27-28

502B Electrical Part List ........................................................................................................... 29-30

502BEX Electrical Part List ...................................................................................................... 31-32

Model 1B Electrical Part List .................................................................................................... 33-35

Model 8 Electrical Part List ...................................................................................................... 36-37

Model 25/32 Electrical Part List................................................................................................ 38-39

Freespace 360 In Ground Electrical Part List......................................................................... 40-42

FreeSpace 360 Surface Electrical Part List ............................................................................ 43-44

Panaray® 3202® II Electrical Part List ..................................................................................... 45-47

Panaray 4402® II Electrical Part List ....................................................................................... 48-50

Panaray 9702® II Electrical Part List ....................................................................................... 51-53

Panaray LT II Electrical Part List............................................................................................. 54-55

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 2

Contents (continued)

Packaging Part List .........................................................................................................................56

Figure 6. Packaging Exploded View ................................................................................................56

Figure 7. Bottom Side PCB Part Number 184844 ........................................................................... 57

Figure 8. Top Side PCB Part Number 184844 .................................................................................57

Figure 9. Bottom Side PCB Part Number 178860 ........................................................................... 58

Figure 10. Top Side PCB Part Number 178860...............................................................................58

Figure 11. Bottom Side PCB Part Number 190675 ......................................................................... 59

Figure 12. Top Side PCB Part Number 190675...............................................................................59

Figure 13. Bottom Side PCB Part Number 183071 ......................................................................... 60

Figure 14. Top Side PCB Part Number 183071...............................................................................60

Figure 15. 402

Figure 16. 402 Series II Schematic Diagram .................................................................................. 62

Figure 17. 802

Figure 18. 802 Series III Schematic Diagram.................................................................................64

Figure 19. 502®A Schematic Diagram.............................................................................................65

Figure 20. 502B Schematic Diagram ..............................................................................................66

Figure 21. 502BEX Schematic Diagram ......................................................................................... 67

Figure 22. Model 1B Schematic Diagram........................................................................................68

Figure 23. Model 8 Schematic Diagram ..........................................................................................69

Figure 24. Model 25/32 Schematic Diagram ...................................................................................70

Figure 25. FreeSpace® 360 Surface Schematic Diagram ...............................................................71

Figure 26. FreeSpace 360 In Ground Schematic Diagram ............................................................. 72

Figure 27. Panaray® 3202® LT II Schematic Diagram ..................................................................... 73

Figure 28. Panaray 4402® LT II Schematic Diagram ....................................................................... 74

Figure 29. Panaray 9702® LT II Schematic Diagram ....................................................................... 75

Figure 30. Panaray LT II Schematic Diagram .................................................................................76

®

Series I Schematic Diagram .................................................................................61

®

Series II Schematic Diagram ................................................................................ 63

CAUTION: THE EQ PCB ASSEMBLIES CONTAIN NO USER-SERVICEABLE PARTS. TO

PREVENT WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY SERVICE

STATIONS OR FACTORY SERVICE.

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Refer to Paragraph 84 of UL 1270. Use the following checks to

perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 “Leakage Current for Appliances” and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position, then in the

OFF position, measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliamp. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZ ARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO

THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug. (2) Turn on the

power switch of the unit. (3) Measure the resistance with an ohmmeter be-

tween the jumpered AC plug and each exposed metallic cabinet part on the

unit. When the exposed metallic part has a return path to the chassis, the

reading should be between 1 and 5.2 Megohms. When there is no return path

to the chassis, the reading must be “infinite”. If it is not within the limits specified,

there is the possibility of a shock hazard, and the unit must be repaired and re checked before it is returned to the customer.

3

Page 4

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing, or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

SUPPLEMENT DESCRIPTION

This supplement should be used along with either the 1800V service manual part number

181812 or the 1600 VI/1800 VI service manual part number 199747. The disassembly/assembly procedures, and packing part list should be used along with the information in this manual.

The test procedures were included in this manual for your convenience.

This supplement replaces the following supplements: 181812-S2, 181812-S3, 181812-S6

and 181812-S7.

4

Page 5

THEORY OF OPERATION

These Equalizer cards are designed to be installed into the AmPlus™ 50 and 100 amplifiers

and the Bose® 1600 Series VI and 1800 Series V/VI amplifiers. The EQ cards included in this

service manual are as follows; 402

III, Model 1B, Model 8, Model 25/32, Panaray

FreeSpace® 360 Surface and In Ground.

The FreeSpace 360 loudspeaker requires equalization, and this equalization is a function of the

installation. There are two variants of the card that implement EQ curves for these

installation situations:

• In Ground (when the FreeSpace 360 loudspeaker is mounted in the ground).

The appropriate EQ curve for soft or hard ground is selected with a slide switch on the card.

When S1 is in the SOFT position, the Soft Ground EQ is used; when S1 is in the HARD

position, the Hard Ground EQ is used.

• In the Surface variant, S1 is omitted and jumpered to the SURFACE position.

Note: Refer to the FreeSpace 360 Surface or In-Ground schematic diagrams, as appropriate,

for the following explanation. The designators inside the brackets "[ ]" are the schematic grid

coordinates which are provided in order to make it easier to locate components on the

schematic sheet indicated in the description. Components shown on the schematic as

OPT (optional) are not used in that particular configuration. Also refer to the EQ curves on

page 7 of this manual for an overview of the frequency response of each of the 360 applications.

The input signal is applied to these cards at JP1 pin 4. The first section at the input, U2-B [D7],

combines a first order high-pass filter with one section of a parametric cut filter. The parametric

is set for -15dB at 27 Hz and provides a steep slope below about 80 Hz The equalization is

segmented, with one block (U2 and U1), all sections [D1-8] dedicated to bass region equalization. Following the output of this section, U2-A [D1], the signal is presented to two parallel

equalization paths, one comprised of U3 [B4-7], U4-B [C3], and dedicated to EQ for mounting in

soft ground of the FreeSpace 360 loudspeaker. The other path, comprised of U5 [B4-7],

U4-A [B3] provides equalization for the FreeSpace 360 loudspeaker in hard ground installations. In the case of the FreeSpace Surface EQ card, the bottom leg of the equalizer card is not

used.

The operation of all three equalizers is similar. Considering the bass equalizer, we see U2-B's

[D7] output passed through R8 [D7] and into the non-inverting input of U2-A [D2]. This input is

extended as a bus to which EQ sections Bass 1 [D6] and Bass 2 [D5] are connected. These

will introduce dips into the audio response to provide bass cut as required. Sections Bass 3

[D4] and Bass 4 [D3] are connected to a bus extended from the inverting input of U2-A [D2]

and provide bass boost. See Figures 1,2 and 3 for the EQ curves for the various equalizer

cards.

Each of the EQ sections utilizes a gyrator-connected op-amp in conjunction with a series

capacitance to simulate an LCR series tuned circuit. The values of the capacitors and resistors

are chosen to implement EQ dips and/or peaks at the appropriate frequency, amplitude and Q

to realize the desired EQ curves. On the In-Ground EQ card, S1 [B2] selects either the HARD

or the SOFT mount EQ curve.

The output signal is taken from JP1 pin 5, and returns to the amplifier. The equalizer cards are

sensed by the amplifiers as follows. In the AmPlus 50 and 100 amplifiers, Pin 12 of J1 [B2] is

grounded and is sensed by the dynamic EQ circuit on sheet 2 of the AmPlus 50 and 100

schematic diagrams. In the 1600/1800 amplifiers, the input module detects the presence of EQ

cards via J7-6 and J6-6. Without the card installed these pins are pulled high (+15V). This logic

high signal is also applied to the control pins of the switch ICs which selects the A

(unequalized) input. When an EQ is plugged into J7 and/or J6 pin 6, the EQ is detected and

pulls the control pin low (+7.5V), turning on the corresponding LED(s) and switching the IC to

the B input which will then select the output of the EQ card to be passed on to the amplifier.

®

series I and II, 502®A, 502B, 502BEX, 802® series II and

®

LT series II 3202®, 4402®, 9702®, and

5

Page 6

THEORY OF OPERATION

The Model 1B EQ card is intended for use in the AmPlus™ 50 and 100 amplifiers as well as the

1800 V, 1600 and 1800 VI professional amplifiers. It accepts a full range (50 Hz to 16 kHz)

signal, equalizes it, and passes a full range signal back to the main amplifier signal path.

®

Refer to the FreeSpace

information.

Note: The designators inside the brackets “[ ]” are the schematic grid coordinates which are

provided in order to make it easier to locate components on the schematic sheet indicated in

the description.

The equalization is segmented, with one block (U2 and U1, all sections [D1-8]) dedicated to

bass region equalization for the Model 1B Bass module. Following the output of this section,

U2A [D1], the signal is presented to two parallel equalization paths, one comprised of U3 [B47], U4A [4-7], U4B [C3], and dedicated to EQ for surface mounted Bose

satellite speakers (Model 25 and 32). The other path, comprised of U5 [B4-7], U4A [B3] provides equalization for Bose Model 8 flush-mount satellite speakers.

The operation of all three equalizers is similar. Considering the bass equalizer, we see U2B’s

[D7] output passed through R8 [D7] and the non-inverting input of U2A [D2]. This input is

extended as a bus to which EQ sections bass 1 [D6] and Bass 2 [D5] are connected. These

will introduce dips into the audio response. Section Bass 3 [D4] is connected to a potentiometer

straddling U2A non-inverting and inverting inputs. When the wiper is moved toward the noninverting input, the section introduces a dip; when moved toward the inverting input, a peak.

Model 1B EQ card schematic diagram, sheet 1 of 1 for the following

®

FreeSpace System

Each of the EQ sections utilizes a gyrator-connected op amp in conjunction with a series

capacitor to simulate an LCR series tuned circuit. The values of the capacitors and resistors

are chosen to implement EQ curves. Each EQ section has optional steering resistors that

could allow other curves to be implemented in the future with the same card. There are also

some spare sections not currently used.

S1 [B2] selects either the FLUSH or the SURFACE mount EQ curve, while potentiometer R33

[D1] provides a boost/cut range of adjustment of the 90 Hz bass region.

6

Page 7

EQUALIZER CARD CURVE DIAGRAMS

Figure 1. FreeSpace® 360 Surface EQ Curve

Figure 2. FreeSpace 360 In-Ground Soft Ground EQ Curve

Figure 3. FreeSpace 360 In-Ground Hard Ground EQ Curve

7

Page 8

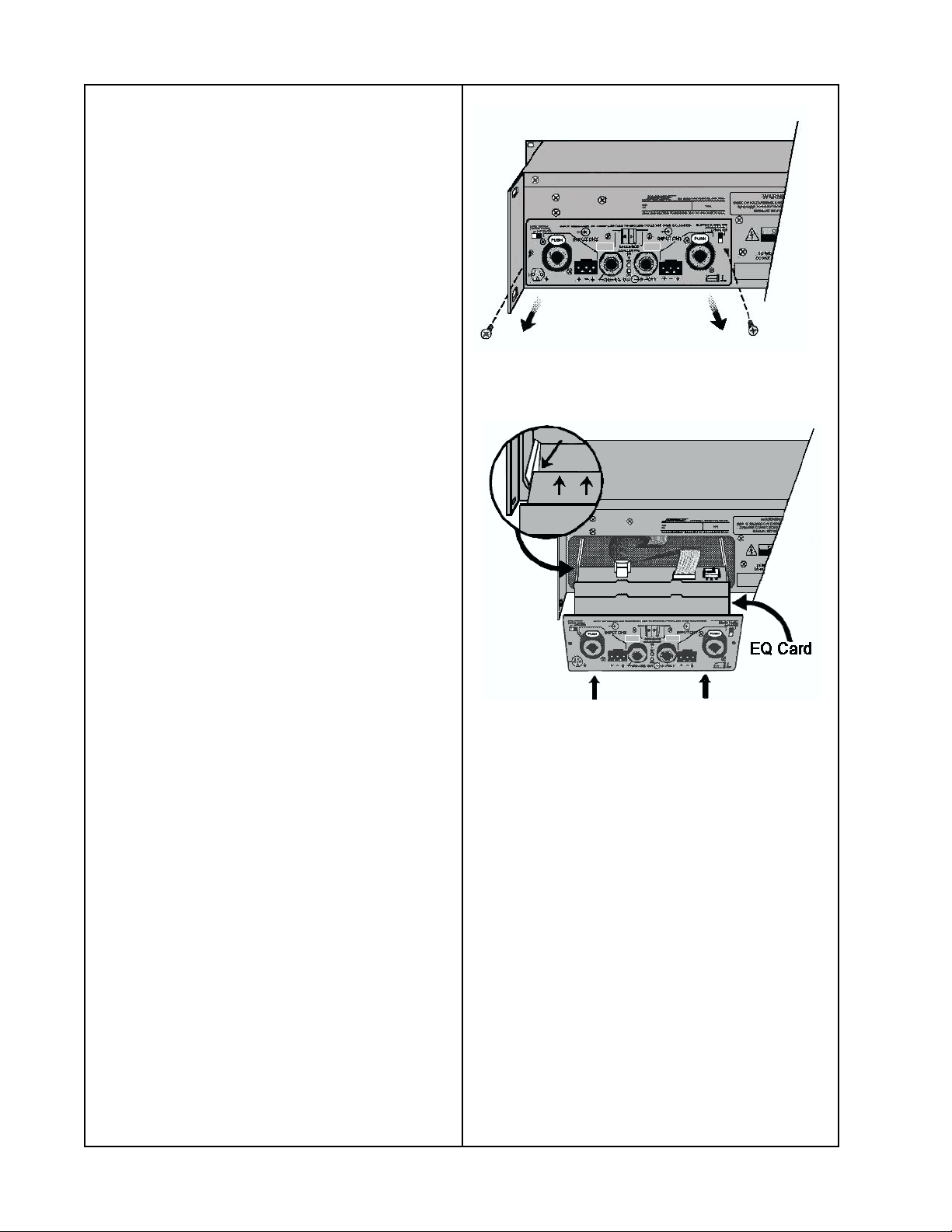

DISASSEMBLY/ASSEMBLY PROCEDURES

1. Input Panel Removal

1.1 Remove the two screws (see figure 4)

holding the panel assembly to the chassis.

1.2 Slide the input panel assembly out of

the chassis to access the EQ cards.

2. Input Panel Replacement

2.1 Slide the input panel assembly back into

the chassis (see figure 5. for proper alignment).

2.2 Secure the input panel to the chassis

using the two screws that had been removed in procedure 1.1.

3. EQ Card Placement

Figure 4. Screw Location

Note: Refer to figure 5. for EQ Card place-

ment.

3.1 Perform procedure 1.

3.2 Place the EQ card into the channel 1 or

2 connector. The connector can be inserted

in only one direction.

3.3 Perform procedure 2.

Figure 5. EQ Card Placement

8

Page 9

TEST SET UP PROCEDURES

1. Install the equalizer card under test into one of the equalizer card jacks located on the input

module of the Bose® 1600 or 1800 series amplifier. Refer to the disassembly/assembly procedures on the previous page.

2. On the amplifier input module, place switch SW1 to the NORM position. Place switch S2 to

the FULL BANDWIDTH position.

3. The input voltage shall be the actual input voltage present at the input, not the open circuit

generator input.

9

Page 10

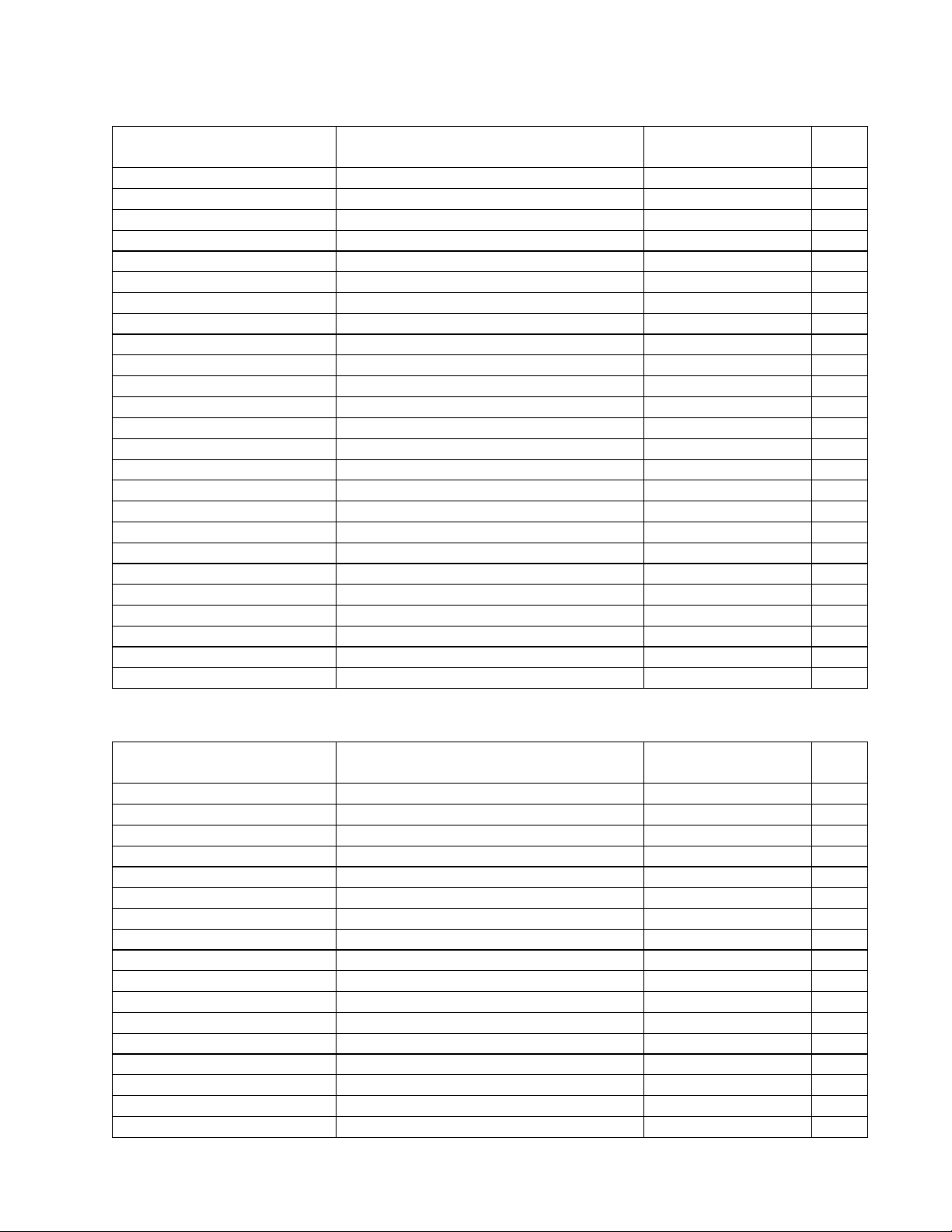

TEST PROCEDURES

1. Panaray

4402®, 9702®,LT Frequency Response Test

1.1 Apply a 100 mVrms, 700 Hz signal to

the input jack of the amplifier channel under

test.

1.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

1.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

1.4 Turn on the amplifier and measure the

response according to the gain chart listed

below.

1.5 Reference a dB meter to the output after

step 1.4 and measure the response of the

EQ card according to the corresponding

chart on this page.

3202 II

4402 II

9702 II

LT II

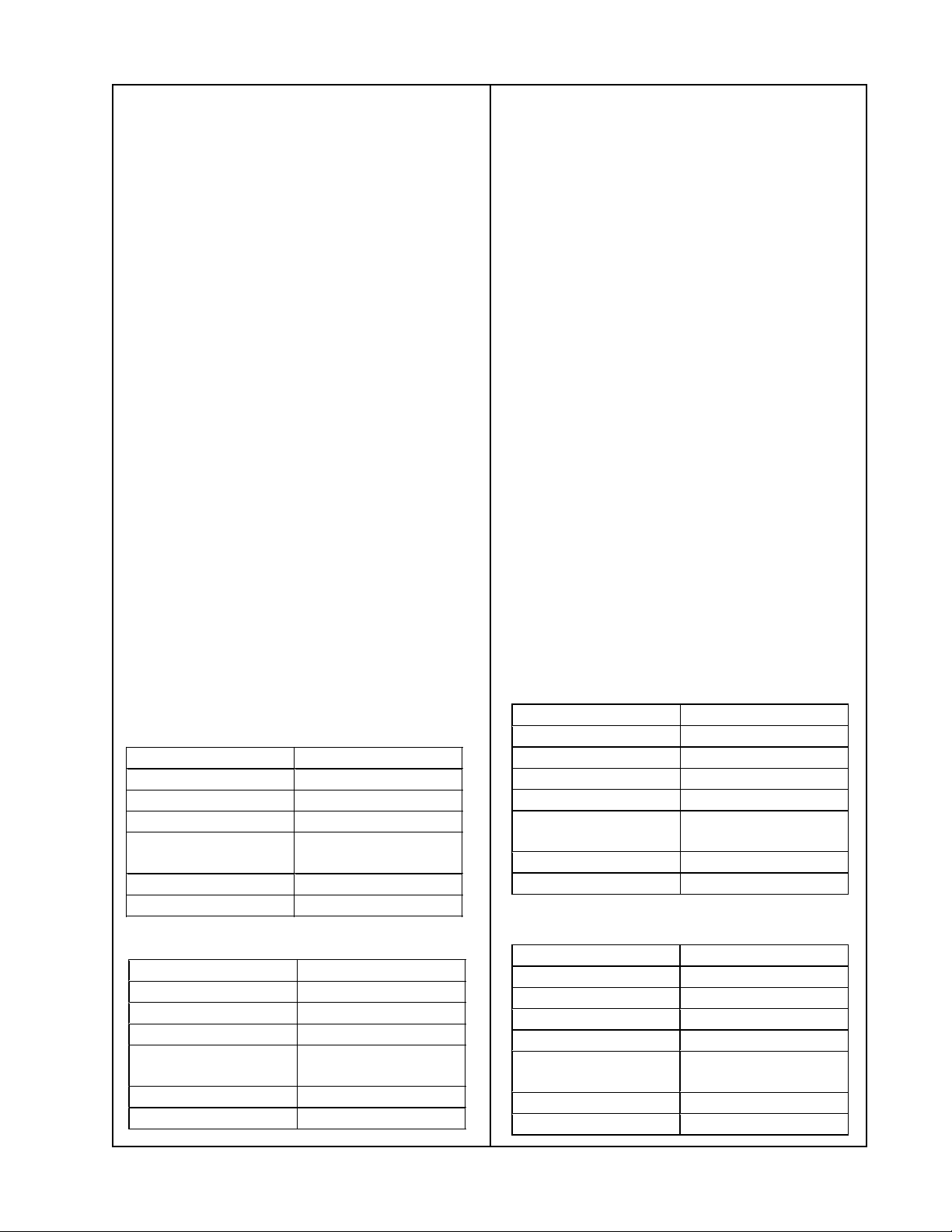

3202 II EQ Frequency Response

®

Series II EQ PCB 3202®,

EQ Gain Response

+7.0 dB ± 1.0 dB

+5.0 dB ± 1.0 dB

+2.6 dB ± 1.0 dB

+2.7 dB ± 1.0 dB

4402 II EQ Frequency Response

Frequency Output Level

50 Hz -27.4 dB ± 3 dB

150 Hz -2.2 dB ± 1.5 dB

250 Hz 1.7 dB ± 1.5 dB

500 Hz -0.9 dB ± 1.5 dB

700 Hz 0 dB

Reference

1 kHz 1.3 dB ± 1.5 dB

2 kHz -0.3 dB ± 1 dB

3 kHz 0.6 dB ± 1 dB

7 kHz -1.5 dB ± 1.5 dB

13 kHz 0 dB ± 1.5 dB

30 kHz -26 dB ± 3 dB

9702 II EQ Frequency Response

Frequency Output Level

50 Hz -23 dB ± 3 dB

100 Hz -2.4 dB ± 1.5 dB

180 Hz +5.2 dB ± 2 dB

550 Hz -1.5 dB ± 1 dB

700 Hz 0 dB

Reference

1.1 kHz +2.3 dB ± 1 dB

1.8 kHz +3.8 dB ± 1 dB

3 kHz +4.8 dB ± 1 dB

6.5 kHz +4.5 dB ± 1.5 dB

11.5 kHz +3.8 dB ± 1.5 dB

30 kHz -22 dB ± 3 dB

Frequency Output Level

50 Hz -27 dB ± 3 dB

100 Hz -6.0 dB ± 1.5 dB

200 Hz 3.0 dB ± 1.5 dB

400 Hz -1.5 dB ± 1 dB

700 Hz 0 dB

Reference

900 Hz 0.5 dB ± 1 dB

3,250 Hz -6.5 dB ± 1.5 dB

6.4 kHz -6.5 dB ± 1.5 dB

13 kHz -4.3 dB ± 1.5 dB

30 kHz -27 dB ± 3 dB

LT II System EQ Frequency Response

Frequency Output Level

40 Hz -31.7 dB ±3 dB

100 Hz -1.9 dB ±1 dB

190 Hz 7.0 dB ±2dB

300 Hz 2.5 dB ±1 dB

700 Hz 0 dB

Reference

2 kHz -0.4 dB ±1 dB

4 kHz -2.0 dB ±2 dB

10 kHz -30.7 dB ±3 dB

10

Page 11

TEST PROCEDURES

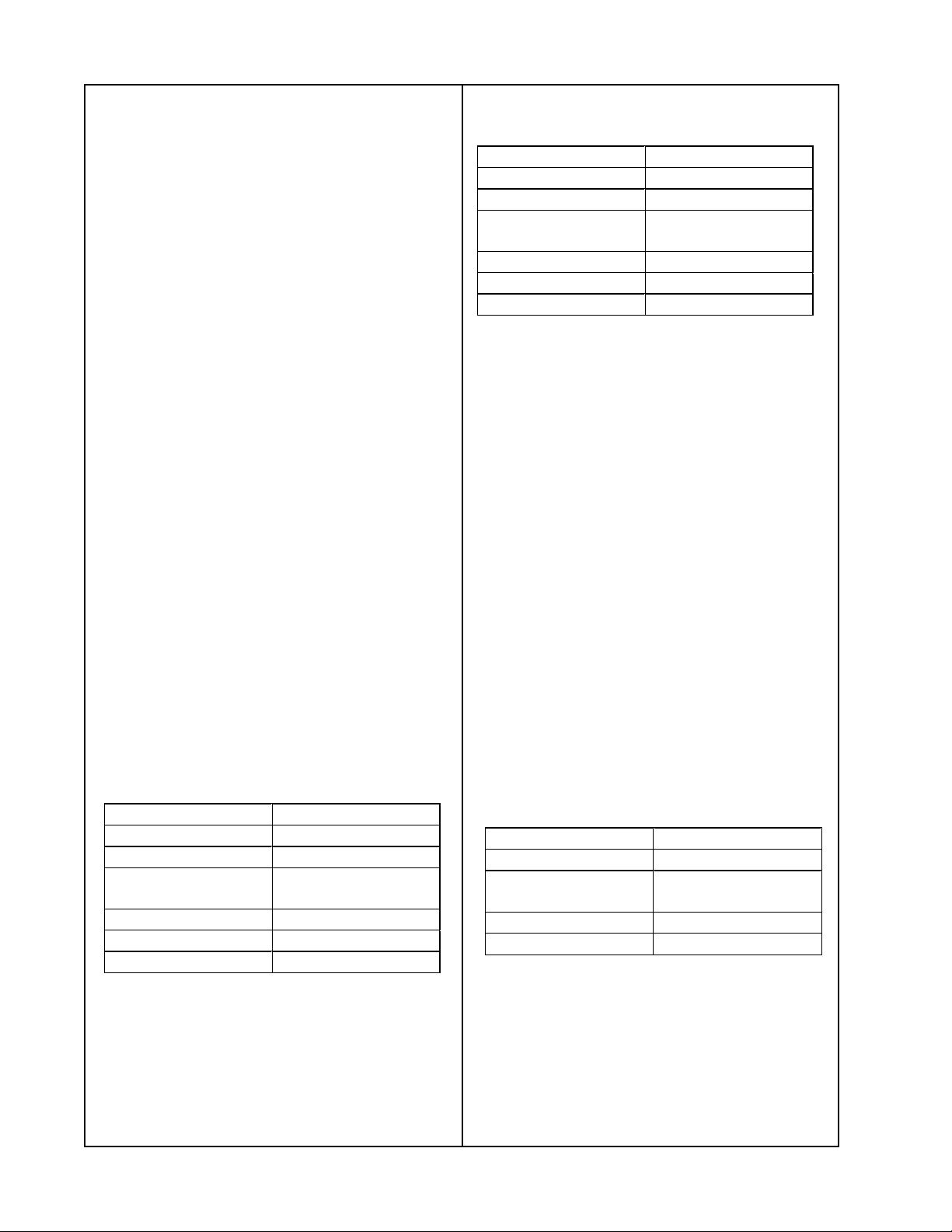

2. 402® EQ PCB Frequency Response Test

2.1 Apply a 100 mVrms, 850 Hz signal to

the input jack of the amplifier channel under

test.

2.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

2.3 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the full range position.

Insert the EQ card.

2.4 Turn on the amplifier and measure the

gain. There should be a - 3.4 dB ± 1.0 dB

change in gain at the output.

2.5 Reference a dB meter and measure

the response of the EQ card according to

the 402 EQ Full Range Response chart.

3. 402 II EQ PCB Frequency Response Test

3.1 Apply a 100 mVrms, 850 Hz signal to

the input jack of the amplifier channel under

test.

3.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

3.3 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the full range position. Insert

the EQ card.

3.4 Turn on the amplifier and measure the gain.

There should be a - 4.2 dB ± 1.0 dB change in

gain at the output.

3.5 Reference a dB meter and measure

the response of the EQ card according to the

402 II EQ Full Range Response chart.

2.6 Shut off the amplifier. Open the input panel

and switch (S2) to the high frequency position.

2.7 Measure the response according to

the 402 EQ High Frequency Response chart.

402 EQ Full Range Frequency Response

Frequency Output Level

60 Hz -3.7 dB ± 1.5 dB

105 Hz +8.5 dB ± 1.5 dB

220 Hz +3.5 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.8 dB ± 1.5 dB

14.5 kHz +13.3 dB ± 1.5 dB

402 EQ High Frequency Response

Frequency Output Level

60 Hz -16.4 dB ± 1.5 dB

105 Hz -5.2 dB ± 1.5 dB

220 Hz +2.8 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.8 dB ± 1.5 dB

14.5 kHz +13.3 dB ± 1.5 dB

3.6 Shut off the amplifier. Open the input panel

and switch (S2) to the high frequency position.

3.7 Measure the response according to the

402 II EQ High Frequency Response chart.

402 II EQ Full Range Frequency Response

Frequency Output Level

60 Hz +3.2 dB ± 1.5 dB

90 Hz +10.0 dB ± 1.5 dB

220 Hz +7.3 dB ± 1.5 dB

600 Hz -2.4 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.6 dB ± 1.5 dB

13.5 kHz +15.5 dB ± 1.5 dB

402 II EQ High Frequency Response

Frequency Output Level

60 Hz -13.0 dB ± 1.5 dB

90 Hz -5.6 dB ± 1.5 dB

220 Hz +6.8 dB ± 1.5 dB

600 Hz -2.4 dB ± 1.5 dB

850 Hz 0 dB

Reference

4 kHz +5.6 dB ± 1.5 dB

13.5 kHz +15.5 dB ± 1.5 dB

11

Page 12

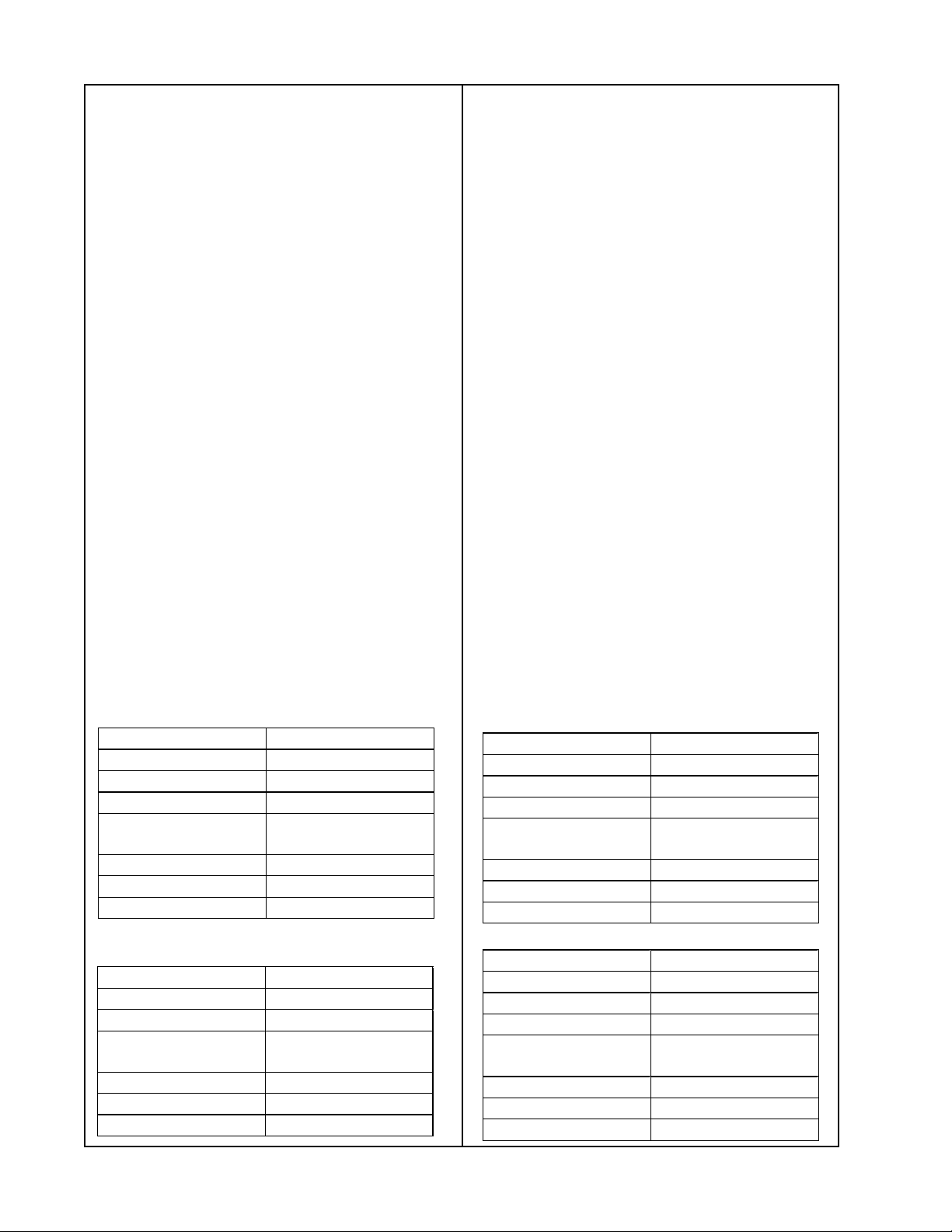

TEST PROCEDURES

®

4. 502

Test

502A EQ Full Range Frequency Response

A EQ PCB Frequency Response

4.1 Apply a 100 mVrms, 600 Hz signal to

the input jack of the amplifier channel under

test.

4.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

4.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

4.4 Turn on the amplifier and measure the

gain. There should be a +2.5 dB ± 1.0 dB

change in gain at the output.

4.5 Reference a dB meter and measure

the response of the EQ card according to

the 502A Full Range Response chart.

4.6 Shut off the amplifier. Open the input

panel and switch (S2) to the high frequency

position.

4.7 Measure the response according to

the 502A High Frequency Response chart.

502A EQ High Frequency Response

Frequency Output Level

40 Hz -28.5 dB ± 2.0 dB

140 Hz +2.9 dB ± 1.5 dB

600 Hz 0 dB

Reference

2.2 kHz +3.5 dB ± 1.5 dB

5 kHz +12.5 dB ± 1.5 dB

15 k Hz +19.0 dB ± 1.5 dB

5. 502B EQ PCB Frequency Response Test

5.1 Apply a 100 mVrms, 80 Hz signal to the

input jack of the amplifier channel under test.

5.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

5.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

5.4 Turn on the amplifier and measure the

gain. There should be an +8.5 dB ± 1.0 dB

change in gain at the output.

5.5 Reference a dB meter and measure

the response of the EQ card according to

the 502B EQ Response chart.

Frequency Output Level

40 Hz -24.5 dB ± 2.0 dB

140 Hz +4.3 dB ± 1.5 dB

600 Hz 0 dB

Reference

2,2 kHz +3.5 dB ± 1.5 dB

5 kHz +12.5 dB ± 1.5 dB

15 kHz +18.4 dB ± 1.5 dB

502B EQ PCB Frequency Response

Frequency Output Level

40 Hz -5.8 dB ± 2.0 dB

80 Hz 0 dB

Reference

100 Hz +1.3 dB ± 1.0 dB

300 Hz -17.5 dB ± 2.0 dB

12

Page 13

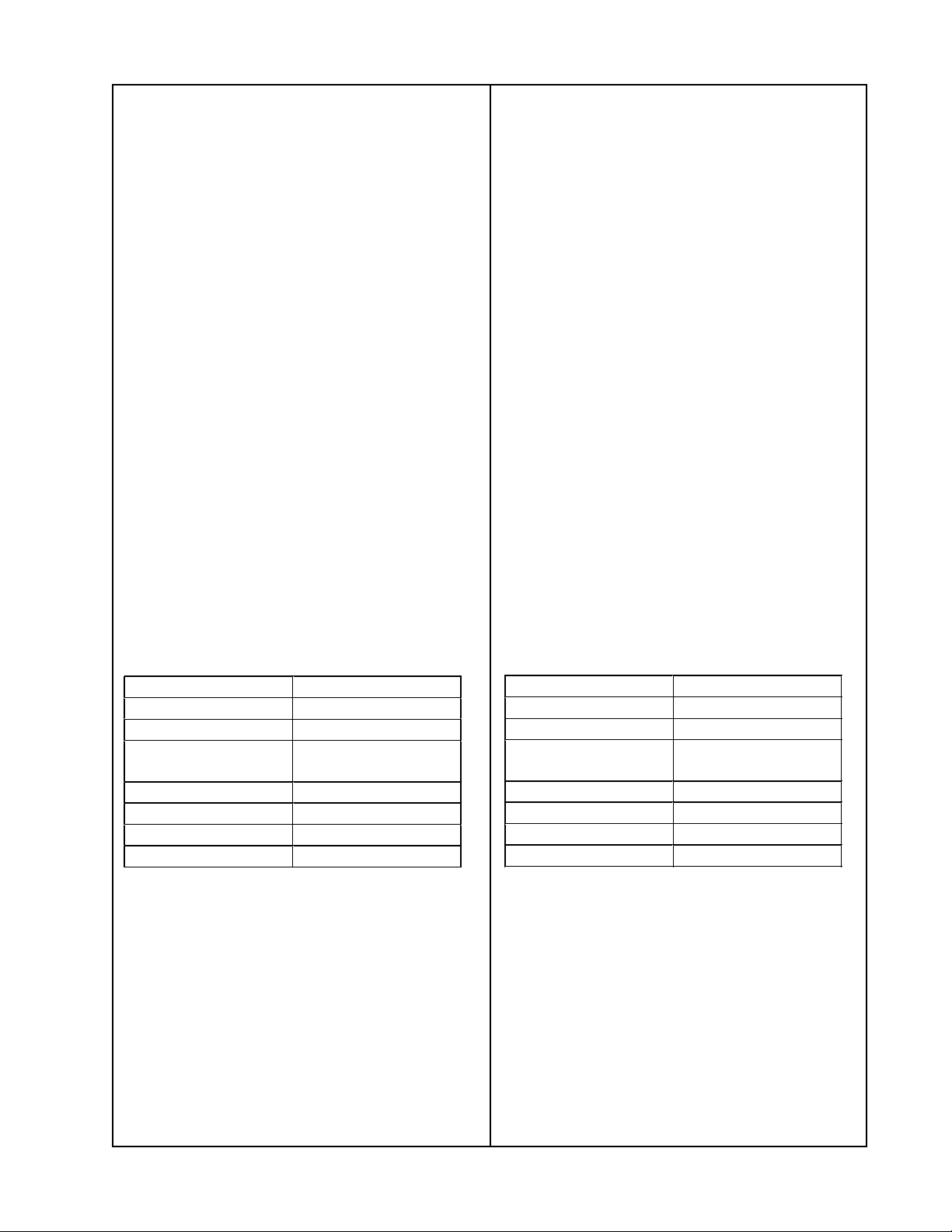

TEST PROCEDURES

®

6. 502

Test

502BEX EQ PCB Frequency Response

BEX EQ PCB Frequency Response

6.1 Apply a 200 mVrms, 100 Hz signal to

the input jack of the amplifier channel under

test.

6.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

6.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

6.4 Turn on the amplifier and measure the

gain. There should be an +4.2 dB ± 1.0 dB

change in gain at the output.

6.5 Reference a dB meter and measure

the response of the EQ card according to

the 502B EQ Response chart.

7.4 Place the switch (S1) on the Model 1B

EQ PCB to the FLUSH position. Rotate the

pot R33 fully CW.

7.5 Turn on the amplifier and measure the

gain. There should be an +2.8 dB ± 1.0 dB

change in gain at the output.

7.6 Reference a dB meter and measure

the response of the EQ card according to

the Model 1B Flush EQ Response chart.

Model 1B EQ PCB Flush Frequency

Response

Frequency Output Level

60 Hz +4.25 dB ± 1.5 dB

100 Hz +3.3 dB ± 1.5 dB

200 Hz +0.5 dB ± 1.5 dB

500 Hz +5.25 dB ± 1.5 dB

1 kHz 0 dB

Reference

2 kHz -1.0 dB ± 1.5 dB

8 kHz +7.75 dB ± 1.5 dB

10 kHz +9.5 dB ± 2.5 dB

Frequency Output Level

30 Hz -15.2 dB ± 2.0 dB

55 Hz +2.3 dB ± 1.4 dB

100 Hz 0 dB

Reference

160 Hz - 6.8 dB ± 1.0 dB

240 Hz -0.8 dB ± 1.2 dB

500 Hz -11.6 dB ± 2.0 dB

7. Model 1B EQ PCB Flush Frequency

Response Test

7.1 Apply a 200 mVrms, 100 Hz signal to

the input jack of the amplifier channel under

test.

7.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

7.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

7.7 Shut off the amplifier and place the

switch (S1) on the Model 1B EQ PCB to the

SURFACE position.

7.8 Replace the input card into the amplifier

and turn the amplifier on.

7.9 Reference a dB meter and measure

the response of the EQ card according to

the Model 1B EQ Surface Frequency

Response chart.

Model 1B EQ Surface Frequency

Response

Frequency Output Level

200 Hz +0.5 dB ± 1.5 dB

500 Hz +0.6 dB ± 1.5 dB

1 kHz 0 dB

Reference

2 kHz -1.3 dB ± 1.5 dB

8 kHz +7.6 dB ± 1.5 dB

10 kHz +7.8 dB ± 2.5 dB

13

Page 14

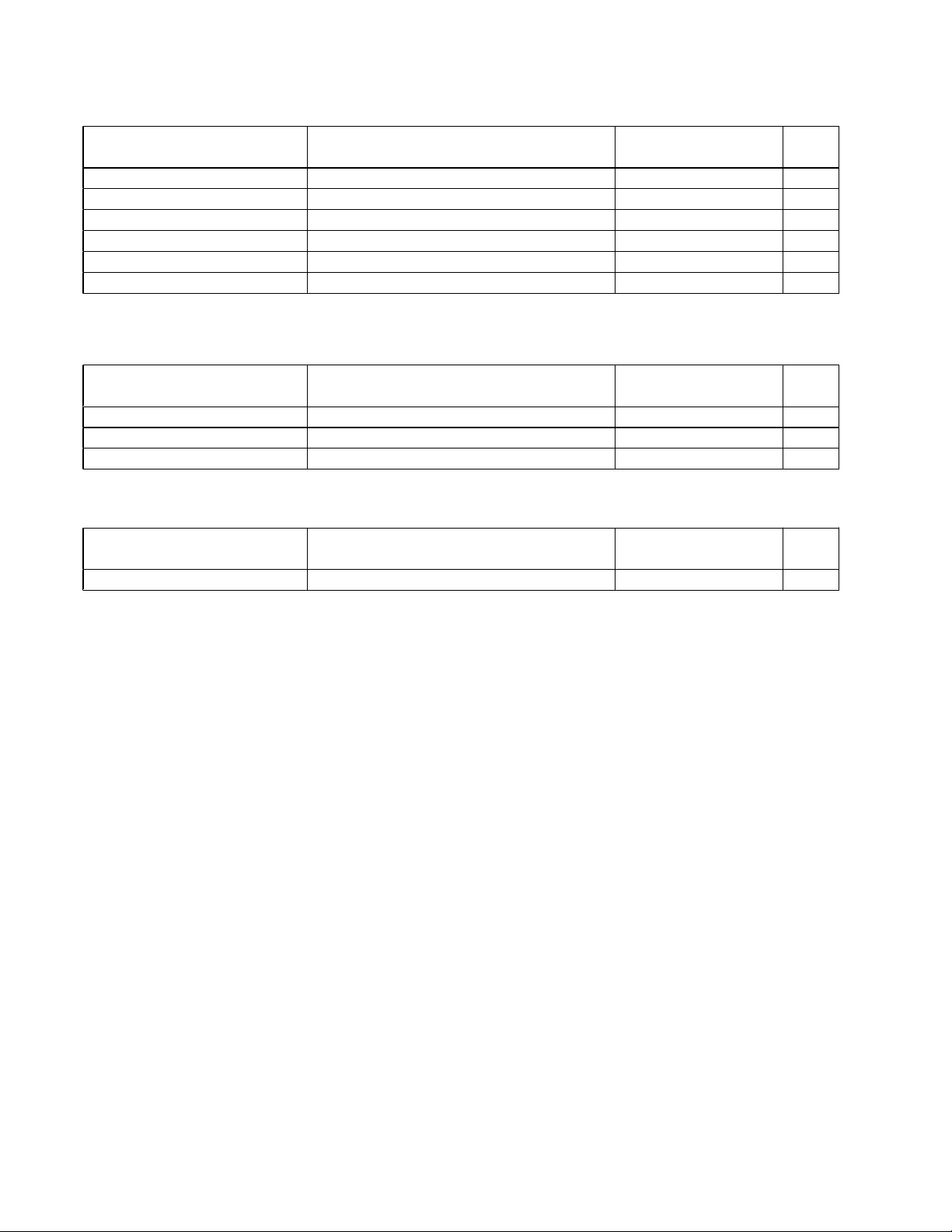

TEST PROCEDURES

8. 802

®

EQ PCB Frequency Response Test

8.1 Apply a 100 mVrms, 700 Hz signal to the

input jack of the amplifier channel under test.

8.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

8.3 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the full range position. Insert

the EQ card.

8.4 Turn on the amplifier and measure the

gain. There should be a +1. 7 dB ± 1.0 dB

change in gain at the output.

8.5 Reference a dB meter and measure the

response of the EQ card according to the 802

Full Range Response chart on this page.

8.6 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the high frequency position.

8.7 Measure the response according to the

802 EQ High Frequency Response.

802 EQ PCB Full Range Frequency

Response

Frequency Output Level

40 Hz +8.0 dB ± 1.5 dB

55 Hz +13.5 dB ± 1.5 dB

140 Hz +6.6 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +2.1 dB ± 1.5 dB

6 kHz +9.6 dB ± 1.5 dB

14.5 kHz +16.7 dB ± 1.5 dB

802 EQ PCB High Frequency Response

Frequency Output Level

40 Hz -21.0 dB ± 1.5 dB

60 Hz -11.5 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +2.1 dB ± 1.5 dB

6 kHz +9.6 dB ± 1.5 dB

14.5 kHz +16.7 dB ± 1.5 dB

9. 802 III EQ PCB Frequency Response Test

9.1 Apply a 100 mVrms, 700 Hz signal to the

input jack of the amplifier channel under

test.

9.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

9.3 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the full range position. Insert

the EQ card.

9.4 Turn on the amplifier and measure the gain.

There should be a +1. 7 dB ± 1.0 dB change

in gain at the output.

9.5 Reference a dB meter and measure

the response of the EQ card according to the

802 III Full Range Response chart.

9.6 Shut off the amplifier. Open the input panel

and switch the high frequency/full range

switch (S2) to the high frequency position.

9.7 Measure the response according to

the 802 III EQ High Frequency Response.

802 III EQ PCB Full Range Frequency

Response

Frequency Output Level

40 Hz +1.9 dB ± 1.5 dB

70 Hz +13.5 dB ± 1.5 dB

140 Hz +7.5 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +1.8 dB ± 1.5 dB

6 kHz +6.9 dB ± 1.5 dB

13 kHz +13.8 dB ± 1.5 dB

802 III EQ PCB High Frequency Response

Frequency Output Level

40 Hz -24.9 dB ± 1.5 dB

70 Hz -10.6 dB ± 1.5 dB

140 Hz +5.2 dB ± 1.5 dB

700 Hz 0 dB

Reference

2.5 kHz +1.9 dB ± 1.5 dB

6 kHz +7.0 dB ± 1.5 dB

13 kHz +13.9 dB ± 1.5 dB

14

Page 15

TEST PROCEDURES

10. Model 8 EQ PCB Frequency Response

Test

10.1 Apply a 100 mVrms, 1 kHz signal to

the input jack of the amplifier channel under

test.

10.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

10.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

10.4 Turn on the amplifier and measure the

gain. There should be a -3.5 dB ± 1.0 dB

change in gain at the output.

10.5 Reference a dB meter and measure

the response of the EQ card according to

the Model 8 Full Range Response chart

below.

11. Model 25/32 EQ PCB Frequency

Response Test

11.1 Apply a 100 mVrms, 1 kHz signal to

the input jack of the amplifier channel under

test.

11.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed..

11.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Insert the EQ card.

11.4 Turn on the amplifier and measure the

gain. There should be a -4.8 dB ± 1.0 dB

change in gain at the output.

11.5 Reference a dB meter and measure

the response of the EQ card according to

the Model 25/32 Full Range Response.

Model 8 Frequency Response

Frequency Output Level

95 Hz +11.3 dB ± 1.5 dB

250 Hz +4.5 dB ± 1.5 dB

1 kHz 0 dB

Reference

2 kHz +3.0 dB ± 1.5 dB

4 kHz +7.0 dB ± 1.5 dB

8 kHz +10.5 dB ± 1.5 dB

12.5 kHz +11.75 dB ± 2.5 dB

Model 25/32 Frequency Response

Frequency Output Level

95 Hz +12.3 dB ± 1.5 dB

250 Hz +4.4 dB ± 1.5 dB

1 kHz 0 dB

Reference

2 kHz +1.7 dB ± 1.5 dB

4 kHz +7.6 dB ± 1.5 dB

8 kHz +12.0 dB ± 1.5 dB

12.5 kHz +15.0 dB ± 2.5 dB

15

Page 16

TEST PROCEDURES

12. FreeSpace® 360 In Soft Ground

Frequency Response Test

12.1 Apply a 100 mVrms, 1 kHz signal to

the input jack of the amplifier channel under

test.

12.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

12.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

Switch the switch on the EQ card to the

SOFT position and insert the EQ card.

12.4 Turn on the amplifier and measure the

gain. There should be a 0.0 ± 1.0 dB

change in gain at the output.

12.5 Reference a dB meter and measure

the response of the EQ card according to

the In Soft Ground Frequency Response

chart.

In Soft Ground Frequency Response

Frequency Output Level

30 Hz -10.3 dB ± 1.5 dB

180 Hz +9.5 dB ± 1.5 dB

190 Hz +7.8 dB ± 1.5 dB

1 kHz 0 dB

Reference

3 kHz +8.1 dB ± 1.0 dB

4 kHz +7.8 dB ± 1.0 dB

10 kHz +16.4 dB ± 2.5 dB

13.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

NOTE: Switch the switch (S1) on the EQ

card to the HARD position and insert the

EQ card.

13.4 Turn on the amplifier and measure the

gain. There should be a -2.1 ± 1.0 dB

change in gain at the output.

13.5 Reference a dB meter and measure

the response according to the In Hard

Ground Frequency Response chart.

In Hard Ground Frequency Response

Frequency Output Level

30 Hz -8.3 dB ± 1.5 dB

90 Hz +9.8 dB ± 1.5 dB

180 Hz +11.2 dB ± 1.0 dB

800 Hz +0.8 dB ± 1.0 dB

1 kHz 0 dB

Reference

3 kHz +8.1 dB ± 1.0 dB

4 kHz +8.7 dB ± 1.0 dB

10 kHz +18.2 dB ± 2.5 dB

13. FreeSpace 360 In Hard Ground

Frequency Response Test.

13.1 Apply a 100 mVrms, 1 kHz signal to

the input jack of the amplifier channel under

test.

13.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

16

Page 17

TEST PROCEDURES

14. FreeSpace® 360 Surface EQ PCB

Frequency Response Test.

14.1 Apply a 100 mVrms, 1 kHz signal to

the input jack of the amplifier channel under

test.

14.2 Adjust the amplifier volume controls to

maximum and reference a dB meter to the

output. No EQ card installed.

14.3 Shut off the amplifier. Open the input

panel and switch the high frequency/full

range switch (S2) to the full range position.

NOTE: Switch the switch (S1) on the EQ

card to the SOFT position and insert the

EQ card.

14.4 Turn on the amplifier and measure the

gain. There should be a +1.0 ± 1.0 dB

change in gain at the output.

14.5 Reference a dB meter and measure

the response of the EQ card according to

the Surface Frequency Response chart.

15. Distortion Test

15.1 Apply a signal from the chart below to

the input jack of the amplifier channel under

test.

15.2 Measure the distortion level at the

output of the amplifier. It should be £ 0.1%

THD.

Product Input Level Frequency

402

402

II

802

II

802

III

502A

502B 700 mVrms 80 Hz

502BEX 4.5 Vrms 100 Hz

M 1B 750 mVrms 1 kHz

M 8 750 mVrms 1 kHz

M 25/32 750 mVrms 1 kHz

3202

4402

9702

1.4 Vrms 850 Hz

1.4 Vrms 850 Hz

750 mVrms 700 Hz

750 mVrms 700 Hz

730 mVrms 600 Hz

II

II

II

4 Vrms 320 Hz

4 Vrms 320 Hz

4 Vrms 320 Hz

360 Surface Frequency Response

Frequency Output Level

30 Hz -8.8 dB ± 1.5 dB

90 Hz +7.2 dB ± 1.5 dB

180 Hz +11.0 dB ± 1.5 dB

900 Hz +0.2 dB ± 1.5 dB

1 kHz 0 dB

Reference

2 kHz +0.4 dB ± 1.5 dB

5 kHz +6.7 dB ± 1.0 dB

10 kHz +17.9 dB ± 2.5 dB

17

Page 18

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This connector is used on the 502®B EQ PCB only.

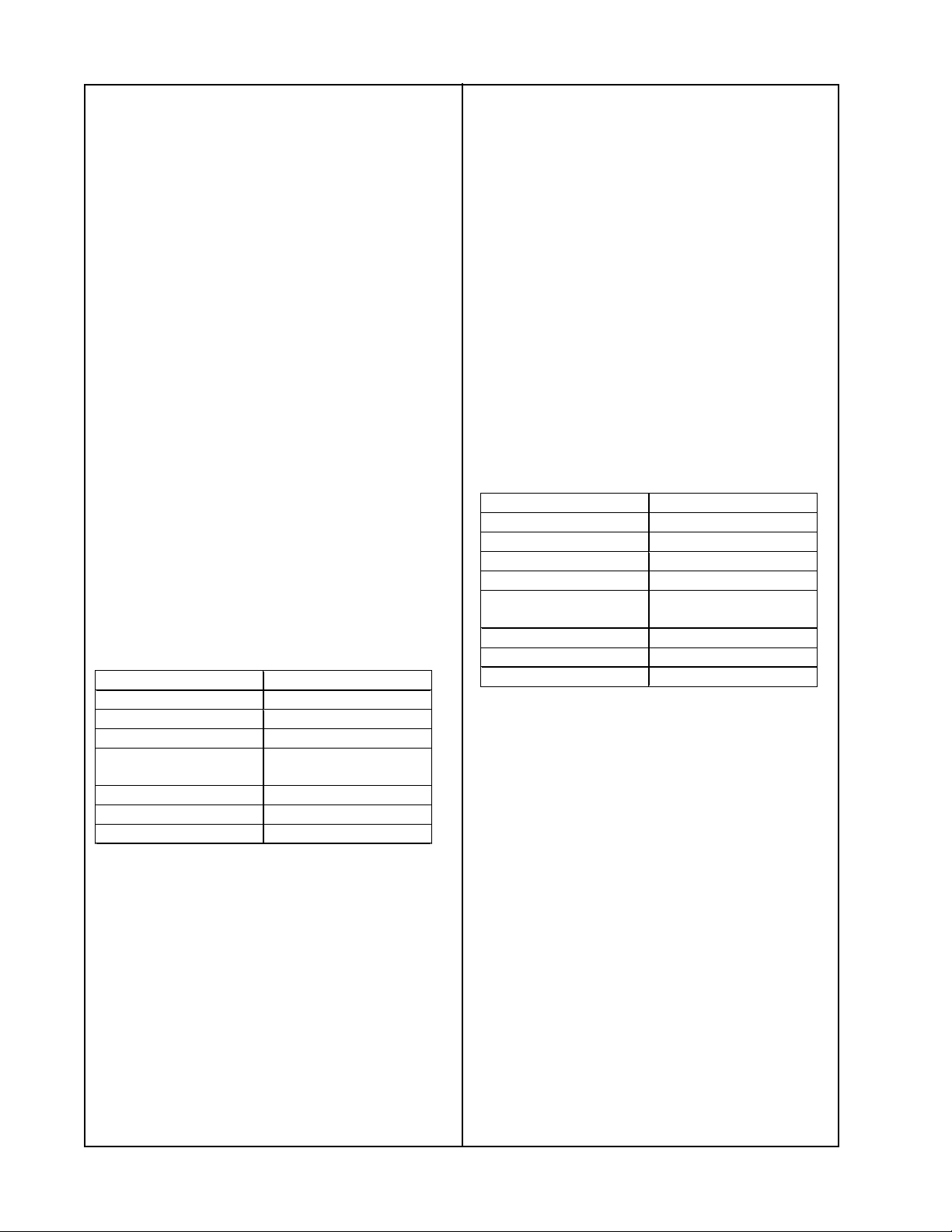

EQ CARD PCB

PART NUMBERS AND PRODUCT CODES

PCB Part Number Description Product Code

177333

258111

177356

258115

177342 502A EQ Card 009082

177349 502B EQ Card 009081

191921 502BEX EQ Card 019551

183111-001

183123-001

183105-001

183117-001

190670-001E Model 1B EQ Card 019509

184825 Model 8 EQ Card 015134

183744 Model 32 EQ Card 011687

198379-0011E

198383-0011E FreeSpace 360 In-ground 021844

Panaray

Panaray 4402 II EQ Card

Panaray 9702 II EQ Card

402 EQ Card

402 II EQ Card

II EQ Card

802

802 III EQ Card

3302 II EQ Card

Panaray LT II EQ Card

FreeSpace

360 Surface

009083

026677

009080

026679

011502

011504

017929

018485

021845

18

Page 19

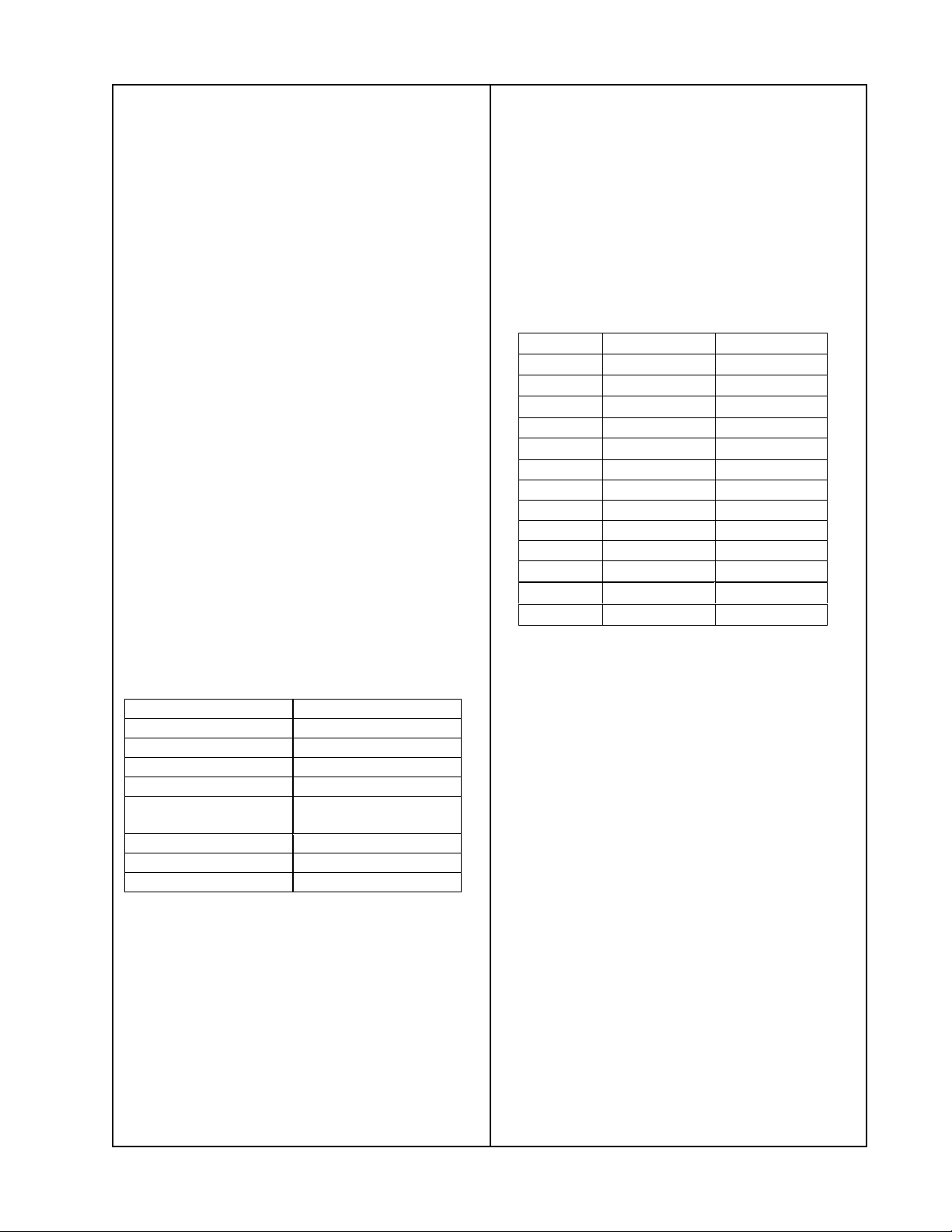

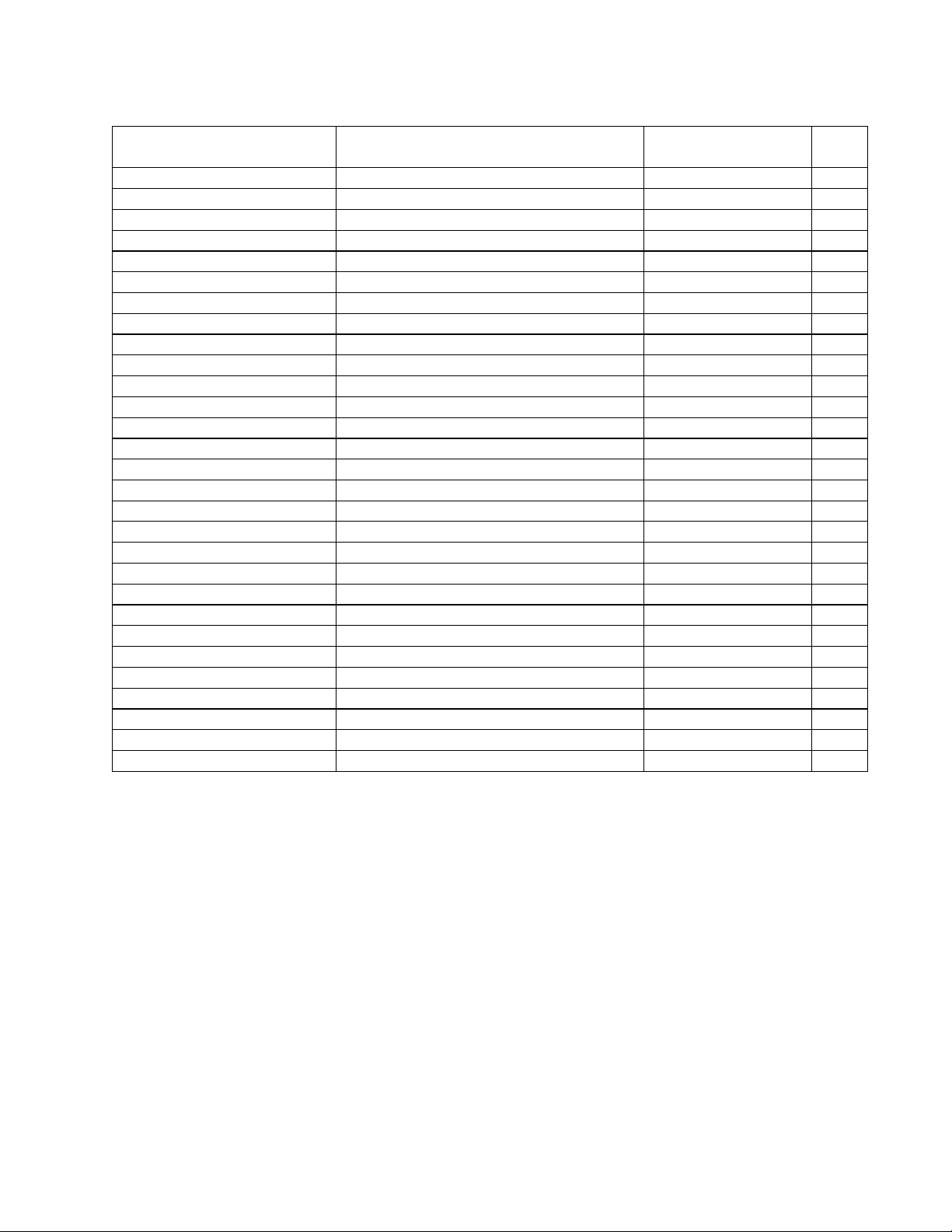

402® SERIES I ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 10.0K, 1206, 1/8W, 1% 124894-1002

R2 10.0K, 1206, 1/8W, 1% 124894-1002

R3 3.92K, 1206, 1/8W, 1% 124894-3921

R4 3.92K, 1206, 1/8W, 1% 124894-3921

R5 8.25K, 1206, 1/8W, 1% 124894-8251

R6 1.82K, 1206, 1/8W, 1% 124894-1821

R7 1.82K, 1206, 1/8W, 1% 124894-1821

R11 100K, 1206, 1/8W, 1% 124894-1003

R13 JUMPER, CHIP 124896

R14 3.92K, 1206, 1/8W, 1% 124894-3921

R17 5.11K, 1206, 1/8W, 1% 124894-5111

R19 JUMPER, CHIP 124896

R20 JUMPER, CHIP 124896

R21 JUMPER, CHIP 124896

R27 JUMPER, CHIP 124896

R30 86.6K, 1206, 1/8W, 1% 124894-8662

R31 21.5K, 1206, 1/8W, 1% 124894-2152

R32 78.7K, 1206, 1/8W, 1% 124894-7872

R33 6.49K, 1206, 1/8W, 1% 124894-6491

R34 JUMPER, CHIP 124896

R35 JUMPER, CHIP 124896

R36 JUMPER, CHIP 124896

R37 47.0K, 1206, 1/8W, 5% 124895-4735

R38 47.0K, 1206, 1/8W, 5% 124895-4735

R39 JUMPER, CHIP 124896

Description Part

Number

Note

Capacitors

Reference

Designator

C2 .1uF, BOX, 85, 50V, 5% 137127-104

C3 27uF, BOX, 85, 50V, 5% 137127-274

C4 .0047uF, BOX, 85, 100V, 5% 137127-472

C5 680pF, CER, 10%, 50V 137269-681

C6 .0022uF, BOX, 85, 100V, 5% 137127-222

C7 .047uF, BOX, 85, 63V, 5% 137127-473

C8 .047uF, BOX, 85, 63V, 5% 137127-473

C17 .068uF, BOX, 85, 63V, 5% 137127-683

C19 .068uF, BOX, 85, 63V, 5% 137127-683

C20 .022uF, BOX, 85, 100V, 5% 137127-223

C22 .022uF, BOX, 85, 100V, 5% 137127-223

C24 10000pF, CHIP, 5% 124959-103

C26 10000pF, CHIP, 5% 124959-103

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Note

19

Page 20

402® SERIES I ELECTRICAL PART LIST

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Integrated circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

20

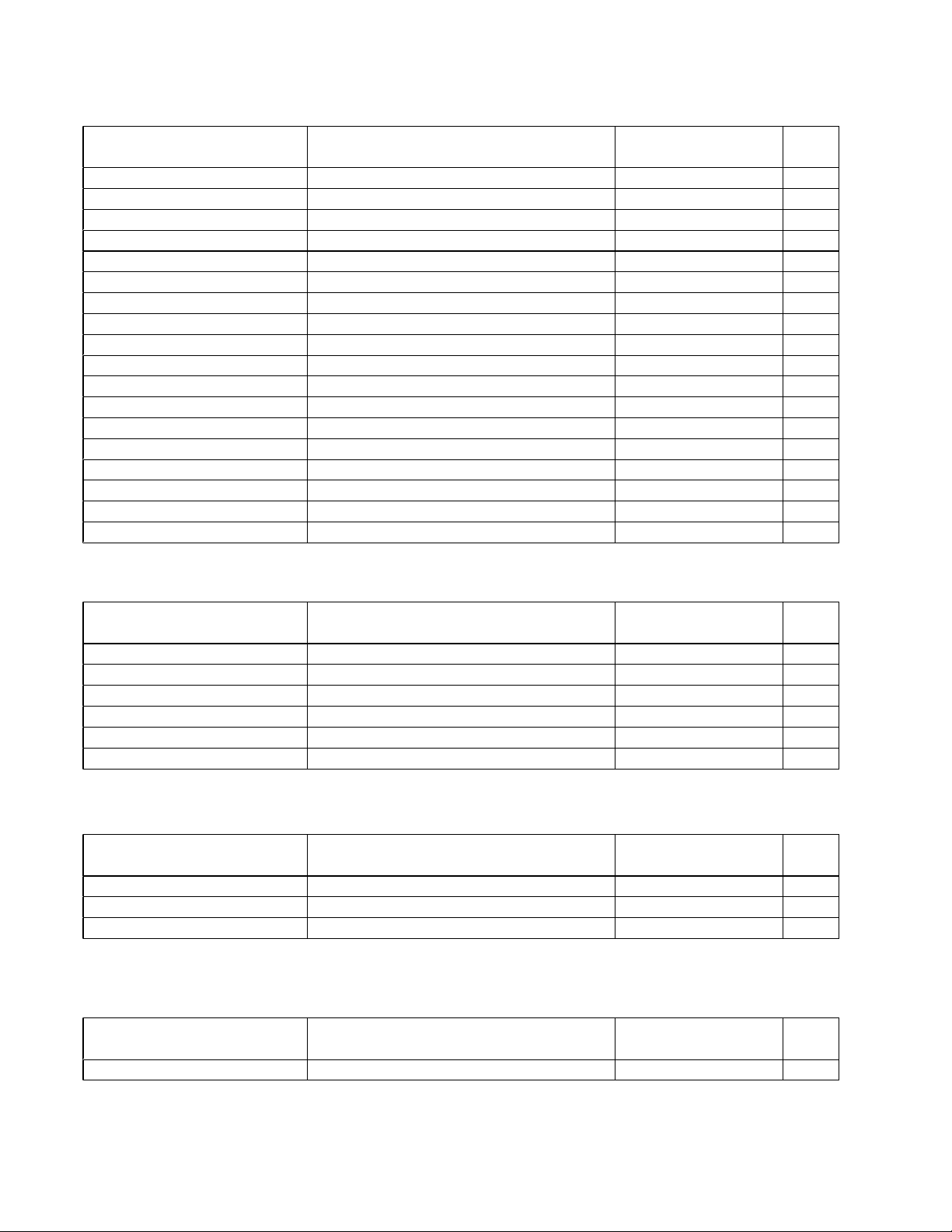

Page 21

402® SERIES II ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 10.0K, 1206, 1/8W, 1% 124894-1001

R2 1.00K, 1206, 1/8W, 1% 124894-1001

R3 2.21K, 1206, 1/8W, 1% 124894-2211

R4 1.47K, 1206, 1/8W, 1% 124894-1471

R5 JUMPER, CHIP 124896

R8 182K, 1206, 1/8W, 1% 124894-1823

R9 3.83K, 1206, 1/8W, 1% 124894-3831

R10 25.5K, 1206, 1/8W, 1% 124894-2552

R12 5.76K, 1206, 1/8W, 1% 124894-5761

R13 1.00K, 1206, 1/8W, 1% 124894-1001

R14 2.00K, 1206, 1/8W, 1% 124894-2001

R17 10.0K, 1206, 1/8W, 1% 124894-1002

R19 JUMPER, CHIP 124896

R20 JUMPER, CHIP 124896

R21 30.1K, 1206, 1/8W, 1% 124894-3012

R22 JUMPER, CHIP 124896

R23 5.76K, 1206, 1/8W, 1% 124894-5761

R24 2.00K, 1206, 1/8W, 1% 124894-2001

R26 3.01K, 1206, 1/8W, 1% 124894-3011

R27 634 OHM, 1206, 1/8W, 1% 124894-6340

R30 75.0K, 1206, 1/8W, 1% 124894-7502

R31 21.5K, 1206, 1/8W, 1% 124894-2152

R32 78.7K, 1206, 1/8W, 1% 124894-7872

R33 7.15K, 1206, 1/8W, 1% 124894-7151

R35 JUMPER, CHIP 124896

R36 JUMPER, CHIP 124896

R37 47.5K, 1206, 1/8W, 1% 124894-4752

R38 47.5K, 1206, 1/8W, 1% 124894-4752

R39 JUMPER, CHIP 124896

Description Part

Number

Note

21

Page 22

402® SERIES II ELECTRICAL PART LIST

Capacitors

Reference

Designator

C3 .0022uF, BOX, 85, 100V, 5% 137127-222

C5 .0018uF, BOX, 85, 100V, 5% 137127-182

C8 .082uF, BOX, 85, 50V, 5% 137127-823

C10 .01uF, BOX, 85, 100V, 5% 137127-103

C14 .022uF, BOX, 85, 100V, 5% 137127-223

C15 .068uF, BOX, 85, 63V, 5% 137127-683

C16 .047uF, BOX, 85, 63V, 5% 137127-473

C17 .082uF, BOX, 85, 50V, 5% 137127-823

C19 .082uF, BOX, 85, 50V, 5% 137127-823

C20 .022uF, BOX, 85, 100V, 5% 137127-223

C22 .022uF, BOX, 85, 100V, 5% 137127-223

C23 .027uF, BOX, 85, 63V, 5% 137127-273

C24 10000pF, CHIP, 5% 124959-103

C26 10000pF, CHIP, 5% 124959-103

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Diodes

Note

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

22

Page 23

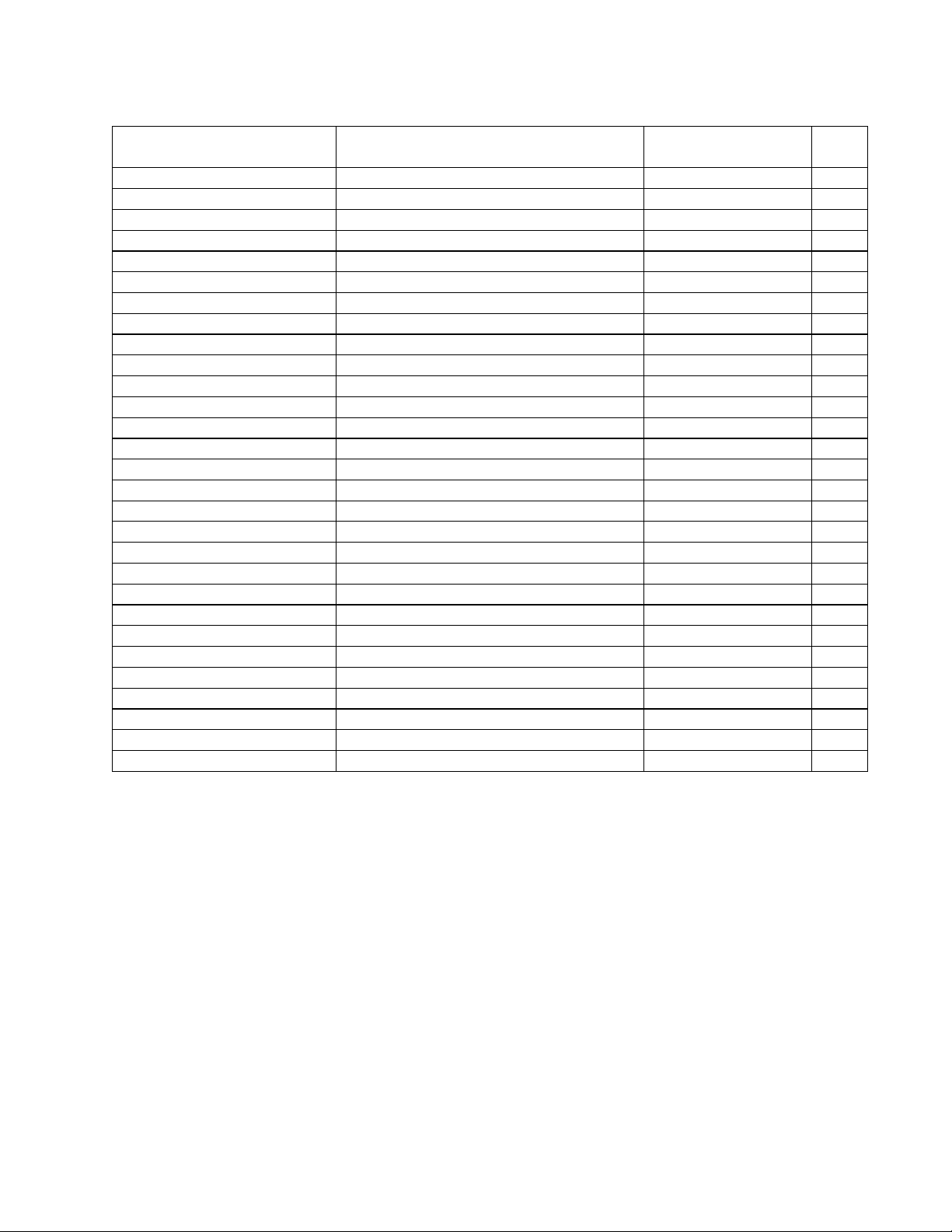

802® SERIES II ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 3.32K, 1206, 1/8W, 1% 124894-3321

R2 1.00K, 1206, 1/8W, 1% 124894-1001

R3 1.27K, 1206, 1/8W, 1% 124894-1271

R4 1.27K, 1206, 1/8W, 1% 124894-1271

R5 JUMPER, CHIP 124896

R8 9.09K, 1206, 1/8W, 1% 124894-9091

R9 6.81K, 1206, 1/8W, 1% 124894-6811

R10 3.01K, 1206, 1/8W, 1% 124894-3011

R12 9.09K, 1206, 1/8W, 1% 124894-9091

R13 5.62K, 1206, 1/8W, 1% 124894-5621

R14 54.9K, 1206, 1/8W, 1% 124894-5492

R15 61.9K, 1206, 1/8W, 1% 124894-6192

R16 2.49K, 1206, 1/8W, 1% 124894-2491

R19 JUMPER, CHIP 124896

R20 JUMPER, CHIP 124896

R22 JUMPER, CHIP 124896

R26 16.5K, 1206, 1/8W, 1% 124894-1652

R27 20.0K, 1206, 1/8W, 1% 124894-2002

R29 1.74K, 1206, 1/8W, 1% 124894-1741

R30 93.1K, 1206, 1/8W, 1% 124894-9312

R31 2.00K, 1206, 1/8W, 1% 124894-2001

R32 34.8K, 1206, 1/8W, 1% 124894-3482

R33 6.34K, 1206, 1/8W, 1% 124894-6341

R37 47.5K, 1206, 1/8W, 1% 124894-4752

R38 47.5K, 1206, 1/8W, 1% 124894-4752

R39 JUMPER, CHIP 124896

R40 JUMPER, CHIP 124896

R41 JUMPER, CHIP 124896

R44 JUMPER, CHIP 124896

Description Part

Number

Note

23

Page 24

802® SERIES II ELECTRICAL PART LIST

Capacitors

Reference

Designator

C3 .0068uF, BOX, 85, 100V, 5% 137127-682

C5 .0027uF, BOX, 85, 100V, 5% 137127-272

C8 .12uF, BOX, 85, 50V, 5% 137127-124

C10 .033uF, BOX, 85, 63V, 5% 137127-333

C11 .0082uF, BOX, 85, 100V, 5% 137127-822

C12 .0056uF, BOX, 85, 100V, 5% 137127-562

C16 .1uF, BOX, 85, 50V, 5% 137127-104

C18 .1uF, BOX, 85, 50V, 5% 137127-104

C19 .1uF, BOX, 85, 50V, 5% 137127-104

C20 .47uF, BOX, 85, 50V, 5% 137127-474

C21 .15uF, BOX, 85, 50V, 5% 137127-154

C22 .15uF, BOX, 85, 50V, 5% 137127-154

C23 .033uF, BOX, 85, 63V, 5% 137127-333

C24 10000pF, CHIP, 5% 124959-103

C26 10000pF, CHIP, 5% 124959-103

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Note

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059OP, AMP, QUAD 144008

U2 NJM2059OP, AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

24

Page 25

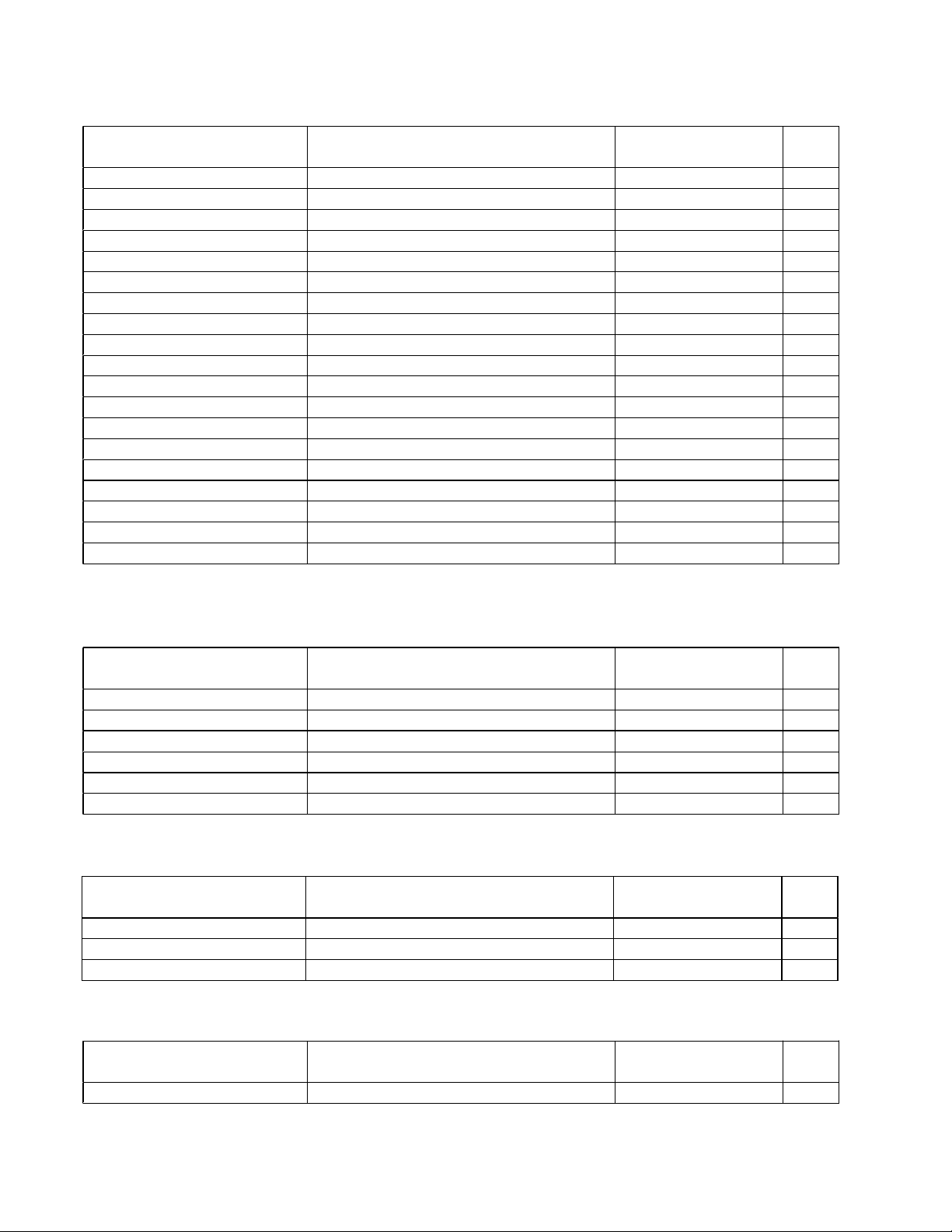

802® SERIES III ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 3.32K, 1206, 1/8W, 1% 124894-3321

R2 1.00K, 1206, 1/8W, 1% 124894-1001

R3 1.27K, 1206, 1/8W, 1% 124894-1271

R4 1.27K, 1206, 1/8W, 1% 124894-1271

R5 JUMPER, CHIP 124896

R8 9.09K, 1206, 1/8W, 1% 124894-9091

R9 6.81K, 1206, 1/8W, 1% 124894-6811

R10 3.01K, 1206, 1/8W, 1% 124894-3311

R12 9.09K, 1206, 1/8W, 1% 124894-9091

R13 5.62K, 1206, 1/8W, 1% 124894-5621

R14 54.9K, 1206, 1/8W, 1% 124894-5492

R15 61.9K, 1206, 1/8W, 1% 124894-6192

R16 2.49K, 1206, 1/8W, 1% 124894-2491

R19 JUMPER, CHIP 124896

R20 JUMPER, CHIP 124896

R22 JUMPER, CHIP 124896

R26 16.5K, 1206, 1/8W, 1% 124894-1652

R27 20.0K, 1206, 1/8W, 1% 124894-2002

R29 1.74K, 1206, 1/8W, 1% 124894-1741

R30 93.1K, 1206, 1/8W, 1% 124894-9312

R31 2.00K, 1206, 1/8W, 1% 124894-2001

R32 34.8K, 1206, 1/8W, 1% 124894-3482

R33 6.34K, 1206, 1/8W, 1% 124894-6341

R37 47.5K, 1206, 1/8W, 1% 124894-4752

R38 47.5K, 1206, 1/8W, 1% 124894-4752

R39 JUMPER, CHIP 124896

R40 JUMPER, CHIP 124896

R41 JUMPER, CHIP 124896

R44 JUMPER, CHIP 124896

Description Part

Number

Note

25

Page 26

802® SERIES III ELECTRICAL PART LIST

Capacitors

Reference

Designator

C3 .0068uF, BOX, 85, 100V, 5% 137127-682

C5 .0027uF, BOX, 85, 100V, 5% 137127-272

C8 .12uF, BOX, 85, 50V, 5% 137127-124

C10 .033uF, BOX, 85, 63V, 5% 137127-333

C11 .0082uF, BOX, 85, 100V, 5% 137127-822

C12 .0056uF, BOX, 85, 100V, 5% 137127-562

C16 .1uF, BOX, 85, 50V, 5% 137127-104

C18 .1uF, BOX, 85, 50V, 5% 137127-104

C19 .1uF, BOX, 85, 50V, 5% 137127-104

C20 .47uF, BOX, 85, 50V, 5% 137127-474

C21 .15uF, BOX, 85, 50V, 5% 137127-154

C22 .15uF, BOX, 85, 50V, 5% 137127-154

C23 .033uF, BOX, 85, 63V, 5% 137127-333

C24 10000pF, CHIP, 5% 124959-103

C26 10000pF, CHIP, 5% 124959-103

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Note

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

26

Page 27

502®A ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 3.65K, 1206, 1/8W, 1% 124894-3651

R2 2.00K, 1206, 1/8W, 1% 124894-2001

R3 4.02K, 1206, 1/8W, 1% 124894-4021

R4 4.02K, 1206, 1/8W, 1% 124894-4021

R5 JUMPER, CHIP 124896

R8 30.1K, 1206, 1/8W, 1% 124894-3012

R11 49.9K, 1206, 1/8W, 1% 124894-4992

R12 2.32K, 1206, 1/8W, 1% 124894-2321

R13 2.00K, 1206, 1/8W, 1% 124894-2001

R14 13.0K, 1206, 1/8W, 1% 124894-1302

R15 20.0K, 1206, 1/8W, 1% 124894-2002

R16 1.33K, 1206, 1/8W, 1% 124894-1331

R17 100K, 1206, 1/8W, 1% 124894-1003

R18 3.16K, 1206, 1/8W, 1% 124894-3161

R19 511 OHM, 1206, 1/8W, 1% 124894-5110

R20 JUMPER, CHIP 124896

R21 18.2K, 1206, 1/8W, 1% 124894-1822

R22 274 OHM, 1206, 1/8W, 1% 124894-2740

R23 8.66K, 1206, 1/8W, 1% 124894-8661

R24 6.34K, 1206, 1/8W, 1% 124894-6341

R25 274 OHM, 1206, 1/8W, 1% 124894-2740

R26 1.91K, 1206, 1/8W, 1% 124894-1911

R27 2.21K, 1206, 1/8W, 1% 124894-2211

R28 2.43K, 1206, 1/8W, 1% 124894-2431

R29 2.00K, 1206, 1/8W, 1% 124894-2001

R30 43.2K, 1206, 1/8W, 1% 124894-4322

R31 3.01K, 1206, 1/8W, 1% 124894-3011

R32 41.2K, 1206, 1/8W, 1% 124894-4122

R33 3.92K, 1206, 1/8W, 1% 124894-3921

R37 47.0K, 1206, 1/8W, 5% 124895-4735

R38 47.0K, 1206, 1/8W, 5% 124895-4735

R39 JUMPER, CHIP 124896

Description Part

Number

Note

27

Page 28

502®A ELECTRICAL PART LIST

Capacitors

Reference

Designator

C2 100pF, CER, 10%, 50V 137269-101

C3 .01uF, BOX, 85, 100V, 5% 137127-103

C5 680pF, CER, 10%, 50V 137269-681

C8 .0047uF, BOX, 85, 100V, 5% 137127-472

C10 .0047uF, BOX, 85, 100V, 5% 137127-472

C11 .01uF, BOX, 85, 100V, 5% 137127-103

C12 .01uF, BOX, 85, 100V, 5% 137127-103

C14 .1uF, BOX, 85, 50V, 5% 137127-104

C15 .1uF, BOX, 85, 50V, 5% 137127-104

C16 100pF, CER, 10%, 50V 137269-101

C17 .47uF, BOX, 85, 50V, 5% 137127-474

C18 .1uF, BOX, 85, 50V, 5% 137127-104

C19 .1uF, BOX, 85, 50V, 5% 137127-104

C20 .47uF, BOX, 85, 50V, 5% 137127-474

C21 .1uF, BOX, 85, 50V, 5% 137127-104

C22 .1uF, BOX, 85, 50V, 5% 137127-104

C23 .01uF, BOX, 85, 100V, 5% 137127-103

C24 10000pF, CHIP, 5% 124959-103

C25 .047uF, BOX, 85, 63V, 5% 137127-473

C26 10000pF, CHIP, 5% 124959-103

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Note

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN,HEADER, 12 PIN 149538

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

28

Page 29

502®B ELECTRICAL PART LIST

Resistors

Reference

Designator

R35 6.81K, 1206, 1/8W, 1% 124894-6811

R36 4.75K, 1206, 1/8W, 1% 124894-4751

R37 15.4K, 1206, 1/8W, 1% 124894-1542

R38 4.75K, 1206, 1/8W, 1% 124894-4751

R39 JUMPER, CHIP 124896

R40 5.11K, 1206, 1/8W, 1% 124894-5111

R41 221K, 1206, 1/8W, 1% 124894-2213

R42 1.10K, 1206, 1/8W, 1% 124894-1101

R43 49.9K, 1206, 1/8W, 1% 124894-4992

R44 221K, 1206, 1/8W, 1% 124894-2213

R45 68.1K, 1206, 1/8W, 1% 124894-6812

R46 6.98K, 1206, 1/8W, 1% 124894-6981

R47 1.00K, 1206, 1/8W, 1% 124894-1001

R48 4.32K, 1206, 1/8W, 1% 124894-4321

R49 5.49K, 1206, 1/8W, 1% 124894-5491

R50 14.0K, 1206, 1/8W, 1% 124894-1402

R51 14.0K, 1206, 1/8W, 1% 124894-1402

R52 6.81K, 1206, 1/8W, 1% 124894-6811

Description Part

Number

Capacitors

Note

Reference

Designator

C26 100pF, CER, 10%, 50V 137269-101

C27 100pF, CER, 10%, 50V 137269-101

C28 .47uF, BOX, 85, 50V, 5% 137127-474

C29 .22uF, BOX, 85, 50V, 5% 137127-224

C30 .22uF, BOX, 85, 50V, 5% 137127-224

C31 .1uF, BOX, 85, 50V, 5% 137127-104

C32 .1uF, BOX, 85, 50V, 5% 137127-104

C34 .22uF, BOX, 85, 50V, 5% 137127-224

C35 .022uF, BOX, 85, 100V, 5% 137127-223

C36 .18uF, BOX, 85, 50V, 5% 137127-184

C52 10000pF, CHIP ,5% 124959-103

C53 10000pF, CHIP ,5% 124959-103

C54 10000pF, CHIP ,5% 124959-103

C55 10000pF, CHIP ,5% 124959-103

Description Part

Number

Note

29

Page 30

502®B ELECTRICAL PART LIST

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D7 1N4148, 52MM AXIAL 121501

D8 1N4148, 52MM AXIAL 121501

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

J2 CONN, HEADER, 2 POS, MALE 134739-02

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

30

Page 31

502®BEX ELECTRICAL PART LIST

Resistors

Reference

Designator

R35 6.81K, 1206, 1/8W, 1% 124894-6811

R36 4.75K, 1206, 1/8W, 1% 124894-4751

R37 4.75K, 1206, 1/8W, 1% 124894-4751

R38 4.75K, 1206, 1/8W, 1% 124894-4751

R39 4.75K, 1206, 1/8W, 1% 124894-4751

R40 5.11K, 1206, 1/8W, 1% 124894-5111

R41 221K, 1206, 1/8W, 1% 124894-2213

R42 1.10K, 1206, 1/8W, 1% 124894-1101

R43 100K, 1206, 1/8W, 1% 124894-1003

R45 33.2K, 1206, 1/8W, 1% 124894-3322

R46 1.02K, 1206, 1/8W, 1% 124894-1021

R47 JUMPER, CHIP 124896

R49 4.87K, 1206, 1/8W, 1% 124894-4871

R50 4.87K, 1206, 1/8W, 1% 124894-4871

R51 4.87K, 1206, 1/8W, 1% 124894-4871

R52 6.81K, 1206, 1/8W, 1% 124894-6811

Reference

Designator

C26 100pF, CER, 10%, 50V 137269-101

C27 100pF, CER, 10%, 50V 137269-101

C28 .27uF, BOX, 85, 50V, 5% 137127-274

C29 .22uF, BOX, 85, 50V, 5% 137127-224

C30 .22uF, BOX, 85, 50V, 5% 137127-224

C31 .1uF, BOX, 85, 50V, 5% 137127-104

C32 .1uF, BOX, 85, 50V, 5% 137127-104

C34 .15uF, BOX, 85, 50V, 5% 137127-154

C35 .022uF, BOX, 85, 100V, 5% 137127-223

C36 .39uF, BOX, 85, 50V, 5% 137127-394

C52 10000pF, CHIP, 5% 124959-103

C53 10000pF, CHIP, 5% 124959-103

C54 10000pF, CHIP, 5% 124959-103

C55 10000pF, CHIP, 5% 124959-103

Description Part

Number

Capacitors

Description Part

Number

Note

Note

31

Page 32

502®BEX ELECTRICAL PART LIST

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D7 1N4148, 52MM AXIAL 121501

D8 1N4148, 52MM AXIAL 121501

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

J2 CONN, HEADER, 2 POS, MALE 134739-02

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

32

Page 33

MODEL 1B ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 JUMPER, CHIP 133627

R2 JUMPER, CHIP 133627

R3 20.0K, CHIP, 0805, 1% 133625-2002

R5 JUMPER, CHIP 133627

R8 24.9K, CHIP, 0805, 1% 133625-2492

R9 30.1K, CHIP, 0805, 1% 133625-3012

R10 30.1K, CHIP, 0805, 1% 133625-3012

R13 32.4K, CHIP, 0805, 1% 133625-3242

R14 32.4K, CHIP, 0805, 1% 133625-3242

R15 6.81K, CHIP, 0805, 1% 133625-6811

R16 6.81K, CHIP, 0805, 1% 133625-6811

R18 JUMPER, CHIP 133627

R19 JUMPER, CHIP 133627

R20 JUMPER, CHIP 133627

R21 24.9K, CHIP, 0805, 1% 133625-2492

R26 JUMPER, CHIP 133627

R30 JUMPER, CHIP 133627

R50 20.0K, CHIP, 0805, 1% 133625-2002

R51 16.9K, 0805, 1/10W, 1% 133625-1692

R52 16.9K, 0805, 1/10W, 1% 133625-1692

R53 JUMPER, CHIP 133627

R55 JUMPER, CHIP 133627

R56 JUMPER, CHIP 133627

R57 3.32K, CHIP, 0805, 1/10W, 1% 133625-3321

R58 3.32K, CHIP, 0805, 1/10W, 1% 133625-3321

R61 16.9K, 0805, 1/10W, 1% 133625-1692

R62 16.9K, 0805, 1/10W, 1% 133625-1692

R63 20.0K, CHIP, 0805, 1% 133625-2002

R64 JUMPER, CHIP 133627

R80 20.0K, CHIP, 0805, 1% 133625-2002

R81 20.0K, CHIP, 0805, 1% 133625-2002

R82 20.0K, CHIP, 0805, 1% 133625-2002

R84 JUMPER, CHIP 133627

R85 JUMPER, CHIP 133627

R86 JUMPER, CHIP 133627

R87 3.9K, CHIP, 0805, 1/10W, 5% 133626-3925

R88 3.9K, CHIP, 0805, 1/10W, 5% 133626-3925

R91 JUMPER, CHIP 133627

R92 JUMPER, CHIP 133627

R93 20.0K, CHIP, 0805, 1% 133625-2002

R94 100 OHM, CHIP, 0805, 1% 133625-1000

Description Part

Number

Note

33

Page 34

MODEL 1B ELECTRICAL PART LIST

Capacitors

Reference

Designator

C2 .22uF, BOX, 85, 50V, 5% 137127-224

C5 .01uF, BOX, 85, 100V, 5% 137127-103

C6 .47uF, BOX, 85, 50V, 5% 137127-474

C7 .18uF, BOX, 85, 50V, 5% 137127-184

C8 .0033uF, BOX, 85, 100V, 5% 137127-332

C9 .15uF, BOX, 85, 50V, 5% 137127-154

C10 .012uF, BOX, 85, 100V, 5% 137127-123

C11 .33uF, BOX, 85, 50V, 5% 137127-334

C12 .47uF, BOX, 85, 50V, 5% 137127-474

C13 .12uF, BOX, 85, 50V, 5% 137127-124

C17 68pF, 0805, COG, 50V, 5% 133622-680

C50 .0047uF, BOX, 85, 100V, 5% 137127-472

C51 .039uF, BOX, 85, 63V, 5% 137127-393

C52 .0033uF, BOX, 85, 100V, 5% 137127-332

C56 .0015uF, BOX, 85, 100V, 5% 137127-152

C57 015uF, BOX, 85, 100V, 5% 137127-153

C58 330pF, DISC, SL, 50V, 10% 137269-331

C59 .0068uF, BOX, 85, 100V, 5% 137127-682

C60 .056uF, BOX, 85, 63V, 5% 137127-563

C61 .0047uF, BOX, 85, 100V, 5% 137127-472

C62 68pF, 0805, COG, 50V, 5% 133622-680

C80 .0047uF, BOX, 85, 100V, 5% 137127-472

C81 .027uF, BOX, 85, 63V, 5% 137127-273

C86 .0015uF, BOX, 85, 100V, 5% 137127-152

C87 .012uF, BOX, 85, 100V, 5% 137127-123

C88 .0015uF, BOX, 85, 100V, 5% 137127-152

C92 68pF, 0805, COG, 50V, 5% 133622-680

C98 .1uF, 1206, Z5U, 50V, 20% 124958-1041

C99 1.1uF, 1206, Z5U, 50V, 20% 124958-1041

C100 .022uF, 0805, X7R, 50V, 10% 133623-223

C101 .022uF, 0805, X7R, 50V, 10% 133623-223

C102 .022uF, 0805, X7R, 50V, 10% 133623-223

C103 .022uF, 0805, X7R, 50V, 10% 133623-223

C104 .022uF, 0805, X7R, 50V, 10% 133623-223

C105 .022uF, 0805, X7R, 50V, 10% 133623-223

C106 .022uF, 0805, X7R, 50V, 10% 133623-223

C107 .022uF, 0805, X7R, 50V, 10% 133623-223

C108 .022uF, 0805, X7R, 50V, 10% 133623-223

C109 .022uF, 0805, X7R, 50V, 10% 133623-223

Description Part

Number

Note

34

Page 35

MODEL 1B ELECTRICAL PART LIST

Diodes

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP QUAD, SOIC-14 187472

U2 NJM4559, OP AMP DUAL, SOIC-8 187473

U3 NJM2059, OP AMP QUAD, SOIC-14 187472

U4 NJM4559, OP AMP DUAL, SOIC-8 187473

U5 NJM2059, OP AMP QUAD, SOIC-14 187472

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

S1 SWITCH, SPDT, VERTICAL, SLIDE 187481

R33 50K, 90 DEG, ROTARY, LINEAR 188673-050

Description Part

Number

Integrated Circuits

Description Part

Number

Miscellaneous

Description Part

Number

Note

Note

Note

35

Page 36

MODEL 8 ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 20.0K, 1206, 1/8W, 1% 124894-2002

R2 14.0K, 1206, 1/8W, 1% 124894-1402

R3 4.12K, 1206, 1/8W, 1% 124894-4121

R5 887 OHM, 1206, 1/8W, 1% 124894-8870

R9 11.5K, 1206, 1/8W, 1% 124894-1152

R11 110K, 1206, 1/8W, 1% 124894-1103

R12 100K, 1206, 1/8W, 1% 124894-1003

R13 4.12K, 1206, 1/8W, 1% 124894-4121

R14 16.5K, 1206, 1/8W, 1% 124894-1652

R16 4.99K, 1206, 1/8W, 1% 124894-4991

R17 7.15K, 1206, 1/8W, 1% 124894-7151

R18 6.19K, 1206, 1/8W, 1% 124894-6191

R19 10.0K, 1206, 1/8W, 1% 124894-1002

R20 4.99K, 1206, 1/8W, 1% 124894-4991

R22 7.15K, 1206, 1/8W, 1% 124894-7151

R25 887 OHM, 1206, 1/8W, 1% 124894-8870

R26 6.19K, 1206, 1/8W, 1% 124894-6191

R27 15.0K, 1206, 1/8W, 1% 124894-1502

R31 21.5K, 1206, 1/8W, 1% 124894-2152

R32 78.7K, 1206, 1/8W, 1% 124894-7872

R35 JUMPER, CHIP 124896

R36 JUMPER, CHIP 124896

R37 47.0K, 1206, 1/8W, 5% 124895-4735

R38 47.0K, 1206, 1/8W, 5% 124895-4735

R40 JUMPER, CHIP 124896

R41 JUMPER, CHIP 124896

R42 JUMPER, CHIP 124896

R43 JUMPER, CHIP 124896

R44 JUMPER, CHIP 124896

R45 JUMPER, CHIP 124896

Description Part

Number

Note

36

Page 37

MODEL 8 ELECTRICAL PART LIST

Capacitors

Reference

Designator

C2 .047uF, BOX, 85, 63V, 5% 137127-473

C3 .33uF, BOX, 85, 50V, 5% 137127-334

C6 .0033uF, BOX, 85, 100V, 5% 137127-332

C8 .047uF, BOX, 85, 63V, 5% 137127-473

C10 .047uF, BOX, 85, 63V, 5% 137127-473

C11 .033uF, BOX, 85, 63V, 5% 137127-333

C12 .0056uF, BOX, 85, 100V, 5% 137127-562

C20 .022uF, BOX, 85, 100V, 5% 137127-223

C22 .022uF, BOX, 85, 100V, 5% 137127-223

C24 10000pF, CHIP, 5% 124959-103

C25 .0027uF, BOX, 85, 100V, 5% 137127-272

C26 10000pF, CHIP, 5% 124959-103

C27 .0022uF, BOX, 85, 100V, 5% 137127-222

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Description Part

Number

Diodes

Note

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Integrated Circuits

Description Part

Number

Connectors

Description Part

Number

Note

Note

Note

37

Page 38

MODEL 25/32 ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 20.0K, 1206, 1/8W, 1% 124894-2002

R2 10.0K, 1206, 1/8W, 1% 124894-1002

R3 22.1K, 1206, 1/8W, 1% 124894-2212

R5 8.25K, 1206, 1/8W, 1% 124894-8251

R9 11.5K, 1206, 1/8W, 1% 124894-1152

R11 110K, 1206, 1/8W, 1% 124894-1103

R12 150K, 1206, 1/8W, 1% 124894-1503

R13 4.99K, 1206, 1/8W, 1% 124894-4991

R14 22.1K, 1206, 1/8W, 1% 124894-2212

R16 10.0K, 1206, 1/8W, 1% 124894-1002

R17 10.0K, 1206, 1/8W, 1% 124894-1002

R18 4.75K, 1206, 1/8W, 1% 124894-4751

R19 4.75K, 1206, 1/8W, 1% 124894-4751

R20 4.99K, 1206, 1/8W, 1% 124894-4991

R22 3.92K, 1206, 1/8W, 1% 124894-3921

R25 JUMPER, CHIP 124896

R26 6.19K, 1206, 1/8W, 1% 124894-6191

R27 8.25K, 1206, 1/8W, 1% 124894-8251

R31 21.5K, 1206, 1/8W, 1% 124894-2152

R32 78.7K, 1206, 1/8W, 1% 124894-7872

R35 JUMPER, CHIP 124896

R36 JUMPER, CHIP 124896

R37 47.0K, 1206, 1/8W, 5% 124895-4735

R38 47.0K, 1206, 1/8W, 5% 124895-4735

R40 JUMPER, CHIP 124896

R41 JUMPER, CHIP 124896

R42 JUMPER, CHIP 124896

R43 JUMPER, CHIP 124896

R44 JUMPER, CHIP 124896

R45 JUMPER, CHIP 124896

Description Part

Number

Note

38

Page 39

MODEL 25/32 ELECTRICAL PART LIST

Capacitors

Reference

Designator

C2 .068uF, BOX, 85, 63V, 5% 137127-683

C3 .27uF, BOX, 85, 50V, 5% 137127-274

C8 .047uF, BOX, 85, 63V, 5% 137127-473

C10 .056uF, BOX, 85, 63V, 5% 137127-563

C11 .0056uF, BOX, 85, 100V, 5% 137127-562

C12 .0056uF, BOX, 85, 100V, 5% 137127-562

C20 .022uF, BOX, 85, 100V, 5% 137127-223

C22 .022uF, BOX, 85, 100V, 5% 137127-223

C24 10000pF, CHIP,5% 124959-103

C25 .0027uF, BOX, 85, 100V, 5% 137127-272

C26 10000pF, CHIP, 5% 124959-103

C27 .0027uF, BOX, 85, 100V, 5% 137127-272

C48 10000pF, CHIP, 5% 124959-103

C49 10000pF, CHIP, 5% 124959-103

C50 10000pF, CHIP, 5% 124959-103

C51 10000pF, CHIP, 5% 124959-103

Reference

Designator

D1 1N4148, 52MM AXIAL 121501

D2 1N4148, 52MM AXIAL 121501

D3 1N4148, 52MM AXIAL 121501

D4 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

D5 1N4148, 52MM AXIAL 121501

D6 1N4746, ZEN, 18V, 1W, 5% 116995-4746A

Description Part

Number

Diodes

Description Part

Number

Note

Note

Integrated Circuits

Reference

Designator

U1 NJM2059, OP AMP, QUAD 144008

U2 NJM2059, OP AMP, QUAD 144008

U3 BA3128N, SWITCH, ACTIVE, SIP-8 177292

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

Description Part

Number

Connectors

Description Part

Number

39

Note

Note

Page 40

FREESPACE® 360 IN GROUND ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 2.00K, CHIP, 0805, 1/10W, 1% 133625-2001

R2 JUMPER, CHIP 133627

R3 18.2K, CHIP, 0805, 1/10W, 1% 133625-1822

R4 2.21K, CHIP, 0805, 1/10W, 1% 133625-2211

R5 JUMPER, CHIP 133627

R8 200K, CHIP, 0805, 1/10W, 1% 133625-2003

R9 392K, CHIP, 0805, 1/10W, 1% 133625-3923

R10 392K, CHIP, 0805, 1/10W, 1% 133625-3923

R12 JUMPER, CHIP 133627

R13 28.7K, CHIP ,0805, 1/10W, 1% 133625-2872

R14 28.7K, CHIP, 0805, 1/10W, 1% 133625-2872

R15 127K, CHIP, 0805, 1/10W, 1% 133625-1273

R16 127K, CHIP, 0805, 1/10W, 1% 133625-1273

R17 JUMPER, CHIP 133627

R18 JUMPER, CHIP 133627

R19 169K, CHIP, 0805, 1/10W, 1% 133625-1693

R20 169K, CHIP, 0805, 1/10W, 1% 133625-1693

R21 200K, CHIP, 0805, 1/10W, 1% 133625-2003

R24 JUMPER, CHIP 133627

R26 JUMPER, CHIP 133627

R28 JUMPER, CHIP 133627

R30 JUMPER, CHIP 133627

R50 24.9K, CHIP, 0805, 1/10W, 1% 133625-2492

R51 8.25K, CHIP, 0805, 1/10W, 1% 133625-8251

R52 8.25K, CHIP, 0805, 1/10W, 1% 133625-8251

R55 47.5K, CHIP, 0805, 1/10W, 1% 133625-4752

R56 47.5K, CHIP, 0805, 1/10W, 1% 133625-4752

R57 6.81K, CHIP, 0805, 1/10W, 1% 133625-6811

R58 6.81K, CHIP, 0805, 1/10W, 1% 133625-6811

R59 JUMPER, CHIP 133627

R61 4.87K, CHIP, 0805, 1/10W, 1% 133625-4871

R62 4.87K, CHIP, 0805, 1/10W, 1% 133625-4871

R63 24.9K, CHIP, 0805, 1/10W, 1% 133625-2492

R64 JUMPER, CHIP 133627

R80 24.9K, CHIP, 0805, 1/10W, 1% 133625-2492

R81 8.25K, CHIP, 0805, 1/10W, 1% 133625-8251

R82 8.25K, CHIP, 0805, 1/10W, 1% 133625-8251

R83 JUMPER, CHIP 133627

R85 66.5K, CHIP, 0805, 1/10W, 1% 133625-6652

R86 66.5K, CHIP, 0805, 1/10W, 1% 133625-6652

R87 6.81K, CHIP, 0805, 1/10W, 1% 133625-6811

R88 6.81K, CHIP, 0805, 1/10W, 1% 133625-6811

R89 JUMPER, CHIP 133627

R91 4.87K, CHIP, 0805, 1/10W, 1% 133625-4871

R92 4.87K, CHIP, 0805, 1/10W, 1% 133625-4871

R93 24.9K, CHIP, 0805, 1/10W, 1% 133625-2492

R94 100 OHM, CHIP, 0805, 1/10W, 1% 133625-1000

Description Part

Number

Note

40

Page 41

FREESPACE® 360 IN GROUND ELECTRICAL PART LIST

Capacitors

Reference

Designator

C2 .22uF, BOX, 85, 50V, 5% 137127-224

C5 390pF, MONO, COG, 50V, 5% 140564-391

C6 .018uF, BOX, 85, 100V, 5% 137127-183

C7 .0068uF, BOX, 85, 100V, 5% 137127-682

C8 .047uF, BOX, 85, 63V, 5% 137127-473

C9 .47uF, BOX, 85, 50V, 5% 137127-474

C10 .47uF, BOX, 85, 50V, 5% 137127-474

C11 .0015uF, BOX, 85, 100V, 5% 137127-152

C12 .015uF, BOX, 85, 100V, 5% 137127-153

C13 .022uF, BOX, 85, 100V, 5% 137127-223

C14 .0027uF, BOX, 85, 100V, 5% 137127-272

C15 .033uF, BOX, 85, 63V, 5% 137127-333

C16 .01uF, BOX, 85, 100V, 5% 137127-103

C17 18pF, 0805, 50V, 5% 133622-180

C50 .0056uF, BOX, 85, 100V, 5% 137127-562

C51 .033uF, BOX, 85, 63V, 5% 137127-333

C52 .068uF, BOX, 85, 63V, 5% 137127-683

C53 270pF, MONO, COG, 50V, 5% 140564-271

C54 .0039uF, BOX, 85, 100V, 5% 137127-392

C55 390pF, MONO, COG, 50V, 5% 140564-391

C56 330pF, MONO, COG, 50V, 5% 140564-331

C57 .0068uF, BOX, 85, 100V, 5% 137127-682

C58 .0056uF, BOX, 85, 100V, 5% 137127-562

C59 560pF, MONO, COG, 50V, 5% 140564-561

C60 .0047uF, BOX, 85, 100V, 5% 137127-472

C61 .0033uF, BOX, 85, 100V, 5% 137127-332

C62 68pF, 0805, COG, 50V, 5% 133622-680

C80 .0082uF, BOX, 85, 100V, 5% 137127-822

C81 .022uF, BOX, 85, 100V, 5% 137127-223

C82 .022uF, BOX, 85, 100V, 5% 137127-223

C83 220pF, MONO, 5% 140564-221

C84 .0022uF, BOX, 85, 100V, 5% 137127-222

C85 820pF, MONO, COG, 50V, 5% 140564-821

C86 330pF, MONO, COG, 50V, 5% 140564-331

C87 .0068uF, BOX, 85, 100V, 5% 137127-682

C88 .0056uF, BOX, 85, 100V, 5% 137127-562

C89 560pF, MONO, COG, 50V, 5% 140564-561

C90 .0047uF, BOX, 85, 100V, 5% 137127-472

C91 .0033uF, BOX, 85, 100V, 5% 137127-332

C92 68pF, 0805, COG, 50V, 5% 133622-680

C98 .1uF, 1206, Z5U, 50V, 20% 124958-1041

C99 .1uF, 1206, Z5U, 50V, 20% 124958-1041

C100 .022uF, 0805, X7R, 50V, 10% 133623-223

C101 .022uF, 0805, X7R, 50V, 10% 133623-223

C102 .022uF, 0805, X7R, 50V, 10% 133623-223

C103 .022uF, 0805, X7R, 50V, 10% 133623-223

Description Part

Number

Note

41

Page 42

FREESPACE® 360 IN GROUND ELECTRICAL PART LIST

Capacitors (continued)

Reference

Designator

C104 .022uF, 0805, X7R, 50V, 10% 133623-223

C105 .022uF, 0805, X7R, 50V, 10% 133623-223

C106 .022uF, 0805, X7R, 50V, 10% 133623-223

C107 .022uF, 0805, X7R, 50V, 10% 133623-223

C108 .022uF, 0805, X7R, 50V, 10% 133623-223

C109 .022uF, 0805, X7R, 50V, 10% 133623-223

Reference

Designator

U1 NJM2059, OP AMP, QUAD, SOIC-14 187472

U2 NJM4559, OP AMP, DUAL, SOIC-8 187473

U3 NJM2059, OP AMP, QUAD, SOIC-14 187472

U4 NJM4559, OP AMP, DUAL, SOIC-8 187473

U5 NJM2059, OP AMP, QUAD, SOIC-14 187472

Reference

Designator

J1 CONN, HEADER, 12 PIN 149538

S1 SWITCH, SPDT, VERTICAL, SLIDE 187481

Description Part

Number

Integrated Circuits

Description Part

Number

Miscellaneous

Description Part

Number

Note

Note

Note

42

Page 43

FREESPACE® 360 SURFACE ELECTRICAL PART LIST

Resistors

Reference

Designator

R1 2.00K, CHIP, 0805, 1% 133625-2001

R2 JUMPER, CHIP 133627

R3 18.2K, CHIP, 0805, 1% 133625-1822

R4 1.50K, 0805, 1/10W, 1% 133625-1501

R5 JUMPER, CHIP 133627

R8 200K, 0805, 1/10W, 1% 133625-2003

R9 392K, 0805, 1/10W, 1% 133625-3923

R10 392K, 0805, 1/10W, 1% 133625-3923

R12 JUMPER, CHIP 133627

R13 28.7K, 0805, 1/10W, 1% 133625-2872

R14 28.7K, 0805, 1/10W, 1% 133625-2872

R15 127K, 0805, 1/10W, 1% 133625-1273

R16 127K, 0805, 1/10W, 1% 133625-1273

R17 JUMPER, CHIP 133627

R18 JUMPER, CHIP 133627

R19 392K, 0805, 1/10W, 1% 133625-3923

R20 392K, 0805, 1/10W, 1% 133625-3923