Page 1

Model 1600VI and 1800VI Professional

Stereo Power Amplifiers

®

®

©

1998 Bose Corporation

Service Manual

Part Number 199747 Rev. 00

Page 2

CONTENTS

Safety Information............................................................................................................................ 4

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 4

1800VI Specifications................................................................................................................... 5-6

1600VI Specifications................................................................................................................... 7-8

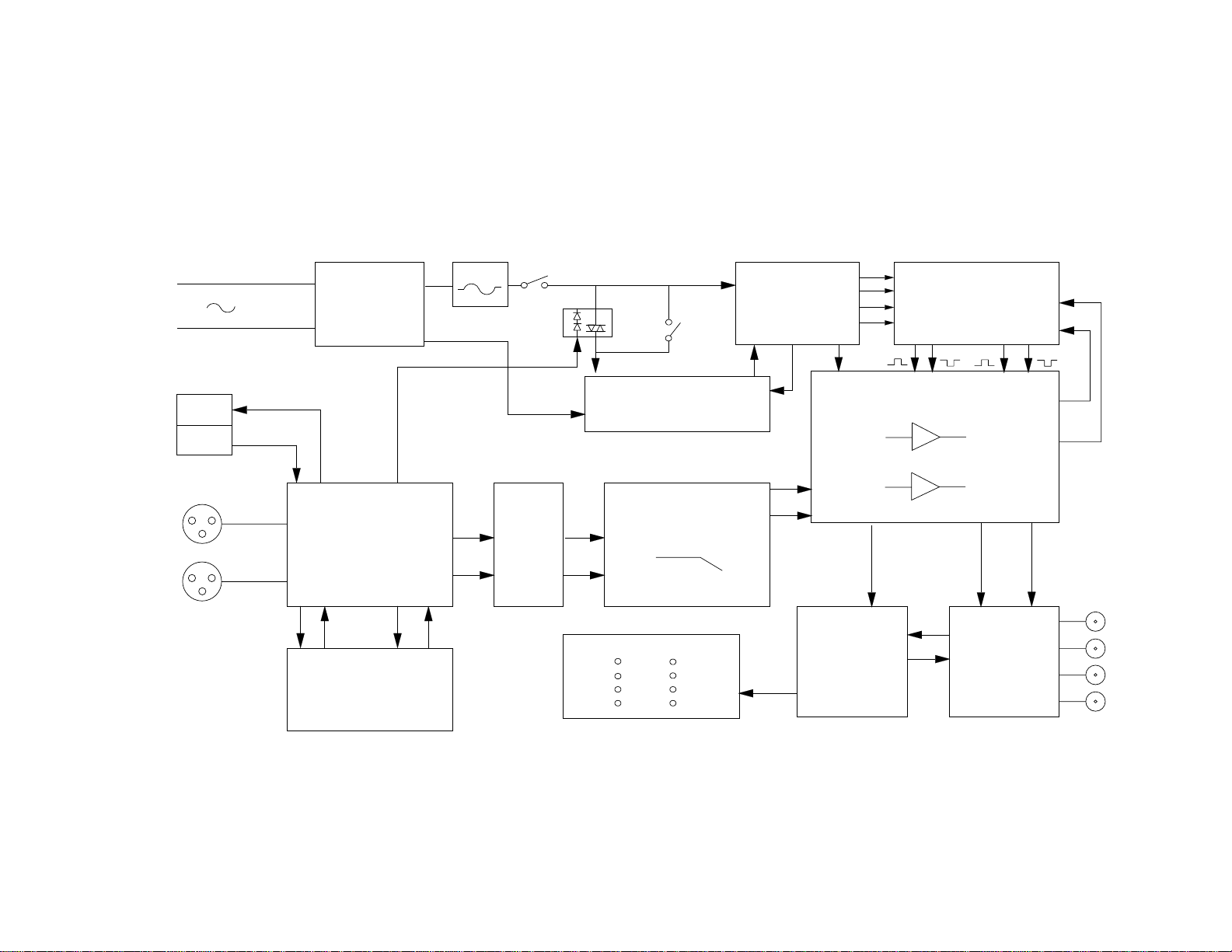

Figure 1. 1600VI and 1800VI Block Diagram .................................................................................. 9

Theory of Operation.................................................................................................................. 10-18

Disassembly/Assembly Procedures ....................................................................................... 19-30

Figure 2. Cover Removal Screw Location Side View..................................................................... 19

Figure 3. Cover Attaching Hardware.............................................................................................. 20

Figure 4. Rear View - Attaching Hardware..................................................................................... 20

Figure 5. 240V Configuration ......................................................................................................... 21

Figure 6. 1600VI and 1800VI Amplifier Assembly ......................................................................... 21

Figure 7. Bottom Mounted Components ........................................................................................ 22

Figure 8. Side View - Bottom Mounted Components ..................................................................... 27

Figure 9. Heatsink Bridge............................................................................................................... 27

Figure 10. Input Module Screw Location........................................................................................ 29

Test Procedures ........................................................................................................................ 31-33

Figure 11. EQ Card Placement ...................................................................................................... 31

Frequency Response Test Table .................................................................................................. 32

Part List Notes................................................................................................................................ 34

Main Part List............................................................................................................................. 35-37

Figure 12. Amplifier Test Setup Diagram ....................................................................................... 31

Figure 13. Front Panel Views, 100V and 120V Variation, 240V Variation...................................... 37

Figure 14. Back Panel View ........................................................................................................... 37

Figure 15. Cross Section View....................................................................................................... 38

Figure 16. 1600VI and 1800VI Amplifier T op View ........................................................................ 39

Figure 17. 1600VI and 1800VI, Amplifier Assembly Removed View ............................................. 40

Electrical Part List..................................................................................................................... 41-54

Packing List .................................................................................................................................... 55

Figure 18. 1600VI and 1800VI Amplifiers Packing Diagram ......................................................... 55

Wiring Diagrams........................................................................................................................ 56-57

Figure 19. 1600VI and 1800VI Wiring Diagram............................................................................. 56

Figure 20. 1600VI and 1800VI 240V Wiring Diagram ................................................................... 57

IC Pinout Diagrams ................................................................................................................... 58-59

2

Page 3

CAUTION: The Bose® 1600VI and 1800VI Professional

Stereo Power Amplifiers contain no user-serviceable

parts. To prevent warranty infractions, refer servicing

to warranty service centers or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

3

Page 4

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics or by special notes on the parts list. Use only replacement parts that have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer. Use the

following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

1492 (71). With the unit AC switch first in the ON position and then in OFF position, measure

from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the

unit (antennas, handle bracket, metal cabinet, screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer an electrical return path to the chassis. Any

current measured must not exceed 0.5 milliamp. Reverse the unit power cord plug in the outlet

and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a

jumper wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3)

Measure the resistance with an ohmmeter between the jumpered AC plug and each exposed

metallic cabinet part on the unit. When the exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2 Megohms. When there is no return path to

the chassis, the reading must be "infinite". If it is not within the limits specified, there is the

possibility of a shock hazard, and the unit must be repaired and rechecked before it is returned

to the customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

4

Page 5

1800VI SPECIFICATIONS

Size: 3.5"H (2U) x 19"W x 13.25"D

89mm x 483mm x 337mm

Weight: Net: 33 lbs. (15 kg)

Shipping weight: 39 lbs. (17.7 kg)

Display: 7 LED indicators per channel

1 green - READY, 5 yellow - SIGNAL,

1 red - CLIP/PROTECT

Operating Temperature: 0° to 50° C, up to 85% RH

Performance Specifications

Continuous Average Output Power,

both channels driven: 450 Watts per channel into 8 Ohms from

20 Hz to 20 kHz, with no more than 0.2% THD

600 Watts per channel into 4 Ohms from

20 Hz to 20 kHz, with no more than 0.2% THD

Bridged Mono Operation: 1400 Watts into 8 Ohms from 20 Hz to 20 kHz,

with no more than 0.2% THD

Voltage Output: 60 V line voltage per channel into 8 Ohms

49 V line voltage per channel into 4 Ohms

Dynamic Headroom: 1.0 dB nominal

Power Bandwidth: 5 Hz to 40 kHz (+0, -3 dB)

Frequency Response: 20 Hz to 20 kHz (±0.75 dB)

Channel Separation: > 65 dB @ 1 kHz; > 55 dB @ 10 kHz

Damping Factor: > 170

Input Impedance: 25k Ohms unbalanced, each leg to ground,

50k Ohms balanced

*Sensitivity: High: .775 Vrms for rated power into 4 Ohms @

1 kHz, 57 mVrms for 1W into 4 Ohms @ 1 kHz

Low: 1.5 Vrms for rated power into 4 Ohms @ 1 kHz,

116 mVrms for 1W into 4 Ohms @ 1 kHz

*Gain: High: 36.0 dB (±0.5 dB)

Low: 30.3 dB (±0.5 dB)

*The amplifier sensitivity is set to 0.775V rms for rated output. To reduce the sensitivity by 6 dB to

1.5V rms, remove JP100 (CH1) and JP200 (CH2), located on the main amplifier board.

5

Page 6

1800VI SPECIFICATIONS

Input Overload: +18 dBu

IM Distortion: < 0.1%

THD: @ 0.775 V Sensitivity, < 0.2%

@ 1.5 V Sensitivity, < 0.1%

Signal-to-Noise Ratio: > 100 dB, A-weighted, referenced to rated

power into 4 Ohms (high gain)

> 78 dBW, A-weighted, referenced to 1 W into

4 Ohms (high gain)

Slew Rate: 10 V/µS (bandwidth limited)

40 V/µS (RFI filtering removed)

®

CMRR: > 80 dB @ 1 kHz (without Bose

> 60 dB from 20 Hz - 20 kHz (without Bose

input module)

input module)

Power Consumption: 55 W at idle

800 W with musical program

1500 W at full power into 8 Ohms (continuous)

2400 W at full power into 4 Ohms (continuous)

Power Requirements: 120 VAC/50-60 Hz (USA and Canada)

230 VAC/50-60 Hz (Europe/UK)

240 VAC/50-60 Hz (Australia)

100 VAC/50-60 Hz (Japan)

Fusing: 15 Amp Slo-Blo (125 V/60 Hz)

8 Amp Slo-Blo (230 V/50 Hz)

6

Page 7

1600VI SPECIFICATIONS

Size: 3.5"H (2U) x 19"W x 13.25"D

89mm x 483mm x 337mm

Weight: Net: 30 lbs. (13.6 kg)

Shipping weight: 36 lbs. (16.3 kg)

Display: 7 LED indicators per channel

1 green - READY, 5 yellow - SIGNAL,

1 red - CLIP/PROTECT

Operating Temperature: 0° to 50° C, up to 85% RH

Performance Specifications

Continuous Average Output Power,

both channels driven: 240 Watts per channel into 8 Ohms from

20 Hz to 20 kHz, with no more than 0.2% THD

325 Watts per channel into 4 Ohms from

20 Hz to 20 kHz, with no more than 0.2% THD

Bridged Mono Operation: 700 Watts into 8 Ohms at 1 kHz, with no

more than 0.2% THD

Voltage Output: 43.8 V line voltage per channel into 8 Ohms

36.0 V line voltage per channel into 4 Ohms

Dynamic Headroom: 2.0 dB nominal

Power Bandwidth: 5 Hz to 40 kHz (+0, -3 dB)

Frequency Response: 20 Hz to 20 kHz (±0.75 dB)

Channel Separation: > 65 dB @ 1 kHz; > 55 dB @ 10 kHz

Input Impedance: 25k Ohms unbalanced, each leg to ground,

50k Ohms balanced

*Sensitivity: High: 0.775 Vrms for rated power into 4 Ohms,

83 mVrms for 1 W into 4 Ohms

Low: 1.5 Vrms for rated power into 4 Ohms,

160 mVrms for 1 W into 4 Ohms @ 1 kHz

*Gain: High: 33.3 dB (±0.5 dB)

Low: 27.6 dB (±0.5 dB)

*The amplifier sensitivity is set to 0.775V rms for rated output. To reduce the sensitivity by 6 dB to

1.5V rms, remove JP100 (CH1) and JP200 (CH2), located on the main amplifier board.

7

Page 8

1600VI SPECIFICATIONS

Input Overload: +18 dBu

IM Distortion: < 0.1%

THD: @ 0.775 V Sensitivity, < 0.2%

@ 1.5 V Sensitivity, < 0.1%

Signal-to-Noise Ratio: > 100 dB, A-weighted, referenced to rated

power into 4 Ohms (high gain)

> 78 dBW, A-weighted, referenced to 1 W into

4 Ohms (high gain)

Slew Rate: 40 V/µS (bandwidth limited)

®

CMRR: > 80 dB @ 1 kHz (without Bose

> 60 dB from 20 Hz - 20 kHz (without Bose

input module)

Power Consumption: 45 W at idle

500 W with musical program

1000 W at full power into 8 Ohms (continuous)

1550 W at full power into 4 Ohms (continuous)

input module)

Power Requirements: 120 VAC/50-60 Hz (USA and Canada)

230 VAC/50-60 Hz (Europe/UK)

240 VAC/50-60 Hz (Australia)

100 VAC/50-60 Hz (Japan)

Fusing: 10 Amp Slo-Blo (125V/60Hz)

7 Amp Slo-Blo (230V/50Hz)

8

Page 9

H

Figure 1. 1600VI and 1800VI Block Diagram

AC

N

Sequence

Send

Rcv

Line

Filter

Fuse

Sequence

(230V)

Only

On/Off

Standby

Regulation (not used

with 1600VI)

Phase Control

Power Supplies

Commutation

Control

(Class H)

Amplifier

CH 2

CH 1

CH 1

9

CH 2

Sequence

CH 1

Input

CH 2

CH 1 CH 2

Control

Input

Module

Level

Control

Lowpass

Filter

Display

Temperature

Sense

CH 1 CH 2

OUT OUT

Output

Relays

CH 1

OUT

Protection

®

Bose

EQ Card(s)

Display

Drive

Fan Drive

CH 2

OUT

Page 10

THEORY OF OPERATION

1. General

The Bose® Model 1600VI and 1800VI Professional Stereo Power Amplifiers are two-channel,

installed/portable amplifiers made for professional sound applications. The 1600VI is rated at

240 Watts into 8 Ohms and 325 Watts into 4 Ohms. In the bridged-mono setting it can deliver

700 Watts. The 1800VI is rated at 450 Watts into 8 Ohms and 600 Watts into 4 Ohms. In the

bridged-mono setting it can deliver 1400 Watts.

The protection circuits designed into the amplifiers will protect them from unexpected faults,

excessive temperature, continuous current limiting and shorted outputs.

The balanced inputs use high quality, high common-mode rejection differential amplifiers for

exceptional hum and noise rejection.

Through the use of equalization cards the amplifier can provide active equalization for Bose

402™, 502®A, 502B, 802®, Model 25/32, Model 8, Model 1B and FreeSpace® 360 professional

loudspeakers. These cards fit into the J6, Channel 1 and J7, Channel 2 connectors located on

the Input Module motherboard or the Bose ACM-1 Amplifier Control Module.

Additional Features are as follows:

• Two input connectors per channel allow 1/4" TRS, XLR, or quick connect terminal block

connection

• Two input connectors for each channel are wired in parallel

• Accepts balanced or unbalanced lines

• Independent CH 1 and CH 2 Level Controls with 11 detented positions

• Level Control Defeat Switch

• Dual Mono Mode for combining the power of both channels into a single higher powered

channel

• Sequencer connection for sequentially powering-up multiple amplifiers to limit instantaneous

in-rush current

• Bi-Amp/Full Range configurable

• Internally configurable for Parallel Mono mode for single channel low impedance operation

• Internally configurable for 0.775V or 1.5V rms input sensitivity

• Internally configurable input polarity of XLR connectors

• Class H dual-rail power supply

• Additional protection circuitry includes Clipping Eliminator, AC Lines Fuse

• Power Connected/Standby Indicator

• 7 LED display per channel, including power ready and Clip/Protect indicators

• Two-speed fan cooled

2. Circuit Descriptions

This section discusses the theory of operation of the 1600VI and 1800VI Amplifiers.

For a better understanding of the circuitry involved, refer to the schematics included with this

manual. Component pin designation is notated as follows: U1-7 means U1 at pin 7.

Unless otherwise noted, this discussion centers around the CH 1 circuitry.

The CH 2 circuitry is essentially identical.

10

Page 11

THEORY OF OPERATION

2.1 Input Module

Note: Some amplifiers will be equipped with the Bose® ACM-1 Amplifier Control Module in

place of the Bose Input Module. This module retains all of the capabilities of the Bose Input

Module, except sequence (see section 2.8), and includes the ability to control and monitor the

amplifier over a control network. Refer to the ACM-1 Amplifier Control Module service manual,

part number 199746 for more information.

The Input Module consists of signal input connections, mode switching, optional equalization,

and power sequencing circuitry. The module operates from +15V and -15V, supplied by the

host amplifier through J2-2 and J2-1 respectively.

The signal inputs are designed for balanced connection, though unbalanced inputs can be

configured by proper input wiring. Channel 1 (CH1) line-level inputs are made via P4 and J4,

Channel 2 (CH2) input connections are made via P1 and J5. P4 and P1 allow for the insertion

of either male XLR or phone plugs. The phone plug terminations are: tip positive (+), ring

negative (-), and sleeve ground. The XLR connections pins 2 and 3 are user configurable. As

shipped, jumper blocks JB2 and JB1 have jumpers between pins 2 to 3 and 5 to 6. This jumper

configuration assigns XLR pin 2 to positive (+) and pin 3 to negative (-), pin 1 is ground in all

configurations. If the jumpers are placed across JB1/JB2 pins 1 to 2 and 4 to 5 the XLR pin

assignment becomes pin 2 negative (-), and pin 3 positive (+). The Euro-block terminal block

connectors J4 and J5 assignments are: pin 1 positive (+), pin 2 negative (-), and pin 3 ground.

The CH1 input signal is applied to ICs U1, and the CH2 signal to U2. U1 and U2 are unity gain

(0 dB) differential amplifiers (SSM2141). These inputs are protected against RFI (Radio

Frequency Interference) and ESD (Electro-Static Discharge). The signals are then routed to

the A inputs of op-amp/switch ICs (BA3128) U4 (CH1) and U3 (CH2) and to EQ card

connectors J6-4 and J7-4 respectively. The switch’s B inputs are driven by the output of the EQ

cards via J6-5 and J7-5.

The input module detects the presence of EQ cards via J7-6 and J6-6. Without the card

installed these pins are pulled high (+15V) which keeps both CH1 and CH2 sections of dual

LED D23 extinguished. This logic high signal is also applied to the control pins of the switch

ICs which selects the A (unequalized) input. When an EQ is plugged into J7 and/or J6 pin 6 the

EQ is detected and pulls the control pin low (+7.5V), turning on the corresponding LED(s) and

switching the IC to the B input which selects the output of the EQ card.

On some EQ cards the equalization can be modified for either full range “FULL BANDWIDTH”

or bi-amplified “HF ONLY” operation. The equalization mode switch SW2 selects either FULL

BANDWIDTH or HF ONLY modes of the EQ cards installed. These control signals are sent to

the EQ cards via J6-7, 8 and J7-7, 8.

The selected signals from U4 and U3 are buffered by U7B and U7A which are wired to P2 and

P3. These phone connectors provide balanced, buffered, equalized outputs (if an EQ card is

installed) to drive additional amplifiers or other equipment. This allows external equipment to

provide equalized signals without the need for additional equalization. The pin assignment for

these connectors are the same as for the input phone connectors P1B and P4B. The output

circuitry is also protected from RFI and EMI.

The amplifier can be operated in four different output modes: normal (two independent channels) dual mono (one input channel, two separate channels), bridged mono, or parallel mono.

These modes are selected via SW1 and control the operation of op-amp/switching ICs U6 and

U5. Parallel mono operation requires internal modifications to the amplifier, contact the local

Bose Pro Product dealer for information on parallel mono operation.

11

Page 12

THEORY OF OPERATION

When SW1 is set to the NORMAL mode, CH1 and CH2 operate independently. In this mode a

logic high is applied to the control pins of U6 and U5. This routes the outputs of U4 and U3 to

their respective channels in the amplifier via J1-20 and J1-16.

In DUAL MONO mode both amplifier channels are driven by the signal applied to the CH2

input. U6-1 is driven high (+15V) and U5-1 is driven low (+7.5V), selecting CH2 to drive both

channels of the amplifier.

In BRIDGED MONO operation the CH2 signal is routed directly from the equalizer switch U3 to

the amplifier inputs. U5 control pin 1 is driven low (+7.5V) selecting the inverting input of the

op-amp switching IC signal. This inverting signal is then sent to the B input of U6 whose

control signal at pin 1 is driven low selecting the B input. This routes the inverted signal to the

CH1 input of the amplifier.

For information on sequence operation see Section 2.8, Sequence Send/Receive.

2.2 Power Amplifier Circuitry

The 1600VI and 1800VI amplifiers use a conventional class AB push-pull power amplifier

circuit, with a commutated two-stage (dual-rail, class H) power supply. U100A-1 is the input

stage, providing differential inputs for input and feedback connections as well as most of the

open-loop voltage gain of the circuit. Local and global negative feedback from the output stage

via R109, R113, R111/ R112 and R129 sets the closed-loop gain at 33.3 dB for the 1600VI and

36.0 dB for the 1800VI. Removing jumper JP100 disconnects R111 from the circuit and sets

the closed-loop gain at 27.6 dB for the 1600VI and 30.3 dB for the 1800VI. The factory default

settings are 33.3 dB for the 1600VI gain and 36.0 dB for the 1800VI gain. The output of

U100A-1 drives Q100 and Q101, operating as common emitters that level-shift the drive signal

and couple it to the pre-driver amplifiers Q102 and Q103. Q102 and Q103 provide additional

voltage gain, and when combined with the voltage gain of the input op-amp is sufficient to

swing the input signal between the +90V/1600VI and +106V/1800VI power supply rails. Q104

and Q122 are connected as an NPN-PNP conjugate pair and used as a VBE multiplier for bias

control. Q104 is thermally connected to the output transistors and together with Q122 provides

bias stabilization over a wide temperature range. R124 allows the bias current to be adjusted

to its optimum value.

The predrivers Q102 and Q103 provide the base current to the drivers Q108 and Q109.

These drive the output transistors; Q110, Q112, Q114, Q116, Q118 and Q120 for the positive

half-cycle, and Q111, Q113, Q115, Q117, Q119 and Q121 for the negative half-cycle.

Note: Output transistors Q112, 118, 212 and 218, along with the corresponding channel 2

output transistors Q113, 119, 213, 219, are not used in the 1600VI amplifier.

Q105 operates as a V-I limiter, sensing the voltage drop across emitter resistor R148 (Q106

across R149 for the negative side), and reducing the drive signal to the output stage under

overload conditions (see Section 3.1 Over-Current Protection for more information). From the

Amplifier Board, the signal passes to the Output Board via E100 (E200 for CH 2). R100, L100,

R110 and C100 on the Output PCB comprise the output pole circuit for amplifier stabilization.

12

Page 13

THEORY OF OPERATION

2.3 Output Relays

Note: Refer to the Output PCB schematic for the following.

Relay K100 is used to connect the output signal to the Speaker Output Binding Posts through

J1. The CH1 and CH2 (K100 and K200) output relays are energized independantly of each

other. In CH1, immediately after the power switch is turned on, +6 Vdc is applied to terminal 2

of D105 (ready LED) on the display board via the voltage divider formed by R112/R113. Terminal 1 of D105 is connected to pin 6 of K100 via J3-8 and J6-5 on the I/O board. A small amount

of current is drawn through R102 and the relay coil, which is enough to illuminate the red LED

portion of D105 but not enough to activate the relay. In the meantime, C13 begins to charge

through R26 on the I/O board, which delays turning on Q2 and Q3 by a few seconds.

When Q3 turns on, VLF+ is applied to pin 6 of K100 which activates the relay. VLF+ is also

applied to terminal 1 of D105, which reverse biases the red LED and D107, and forward biases

the green LED, drawing current from ground through R112.

2.4 Magnetic Field Power Supply

When the power switch is OFF (S1 across E1 and E2) and the linecord is connected to an AC

voltage, D1 illuminates (Standby LED). When the power switch is turned ON (S1 across E2

and E3), the LED goes off and gate voltage is applied to triac Q1, which turns it on and energizes the transformer primary winding.

The secondary winding of the power transformer has two taps that supply the two pairs of DC

supply voltages, ±90 Vdc and ±45 Vdc for the 1600VI and ±106 Vdc and ±53 Vdc for the

1800VI, each having its own bridge rectifier and filter capacitors. The ±15 Vdc is tapped from

the ±53 Vdc for the 1800VI and the ±45 Vdc for the 1600VI through R6 and R8, and regulated

by Q2, Q3 and zener diodes D3 and D6. The ±15 Vdc supply powers the op-amps and smallsignal transistors.

Note: Refer to the Regulator Board schematic diagram for the following.

The Regulator Board is not used on the 1600VI.

In the 1800VI, the triac Q1 drives the primary of the magnetic field power transformer by

operating as a phase controlled switch; its gate signal depends on the signal supplied to

opto-isolator U3 located on the regulator board. U4B provides steering for the photodiac in U3,

allowing the triac to fire on both alternations of the power line. U2 on the Regulator Board

provides AC to DC conversion, with the AC line voltage providing the input to the converter

through limit resistors R3 and R4, and the 12.5 Vdc output determined by feedback resistor

R6. This voltage provides the positive supply for U4, DC reference for comparators U4C and

U4D, and the current through opto-isolator U1 which sets the voltage for the voltage-to-current

converter U4A. Note that U4 (MC3405) is a dual op-amp and dual-voltage comparator in a

singe package (U4A/U4B are op-amps and U4C/U4D are open collector comparators).

2.5 Start-up Sequence (1800VI only)

When the power switch is OFF (S1 across E1 and E2) and the linecord is connected to an AC

voltage, D1 illuminates (STANDBY LED). When the power switch is turned ON (S1 across E2

and E3), the LED goes off and AC HI is supplied to the Regulator Board.

13

Page 14

THEORY OF OPERATION

D2 and D3 on the Regulator Board provide overvoltage protection to U4. U4B-14 is a full-wave

rectifier that outputs positive pulses to comparator U4C. The reference voltage is set at 0.7Vdc

by R10 at pin 3. Where pin 2 crosses the threshold, the output of U4C-1 goes open and C6

begins to charge through R21 and U4A-8.

U4A is a voltage-to-current converter (Howland current pump), whose output current is

determined by the voltage at the junction of R12 and R13. As the voltage increases, the

charging current to C6 increases.

The voltage on C6 is connected to comparator U4D-6. The reference voltage is set at 0.7Vdc

by R22 at pin 5. When pin 6 crosses the threshold, the output of U4D-7 goes open and base

current is supplied to Q1 through R14. Q1 turns on, and current flows through the LED portion

of U3, illuminating it and turning on the diac. This applies voltage to the gate of triac Q1 on the

Power Supply Board which fires it and allows it to conduct current through the primary side of

the power transformer.

When the output of U4B-14 drops below the threshold voltage of U4C-3, U4C-1 goes low and

C6 discharges rapidly through it. When the voltage on C6 drops below the threshold voltage of

U4D-5, U4D-7 goes low and Q1 and U3 turn off, removing the gate voltage to the triac

momentarily interrupting the current through the primary side of the transformer.

The triac is switched on and off every half-cycle of the 60Hz AC line. Thus, the triac switches

the AC line current off at a rate twice the line frequency, at the instant the line current crosses

the zero axis. The triac will then remain off for a number of degrees of the sinusoid, before

switching on again. The phase angle at which the triac switches on is the “firing angle” of the

triac. This produces enough voltage to the primary of the power transformer to allow the

secondary regulator stage to begin to operate.

2.6 Power Supply Regulation (1800VI only)

The firing angle of the triac controls the voltage on the primary of the transformer, and is

determined by the conduction of the optocoupler U3 on the Regulator Board.

As the conduction of the optocoupler increases, so does the conduction angle of the triac. The

photodiac conduction of the optocoupler is controlled by the current through the LED portion of

the optocoupler, the amount of current through the LED is equal to the amount of current

through transistor Q1. When the LED in U3 is fully ON, the triac conducts earliest in the AC

cycle: the power supply is operating at maximum output. The LED current is supplied by

voltage regulator U2 on the Regulator PCB. U5A differential amplifier senses the secondary

supply voltages through R37 and R38. The output voltage at U5A-1 increases at the rate

determined by R30 and C8 (slow start-up). The idle secondary voltages are set by R36 on the

Regulator Board .

2.7 Load Regulation (1800VI only)

When the amplifier is driven at high power into a load, the high DC supplies (rail voltages) will

begin to “sag”. Differential amplifier U5A-1 senses this and increases the LED current to

optocoupler U1. This action increases the phototransistor conduction, which increases the

output current of U4-8, increasing the charging rate on C6. This ultimately increases the triac

conduction which increases the primary voltage, which increases the secondary voltages, thus

providing steady, regulated DC supplies for the amplifier stage.

14

Page 15

THEORY OF OPERATION

The -15Vdc supplied to U5A-4 is backed up with a voltage divider off the -106Vdc supply (R26/

R27). Without this, if the -15Vdc supply should fail for some reason, the output of U5A-1 would

go high, drawing maximum current through the LED in U1 and latching the triac into full conduction. To prevent this, D8 will become forward biased and supply negative DC to U5A-4,

keeping it operating normally. Note that if the +15Vdc supply should fail, the output of U5A-1

would go negative, turning off the triac.

2.8 Sequence Send/Receive

The amplifier can be powered up while the power switch is in the OFF position by applying a

DC control voltage of +7V to +15V to the Sequence RCV terminal. Q3 on the Input Module

Board will turn on and carry the control voltage through to the SND terminal, which is connected to the next amplifier in the sequential chain. Q1 also turns on which turns on Q2,

providing enough current to pass through the LED portion of optocoupler U1 on the Power

Supply Board to illuminate it and turn on the diac. This provides a gate voltage to fire triac Q1,

which powers up the primary circuit. Once the secondary voltages are up, the +15Vdc supply

keeps the Receive circuit operating.

2.9 Commutators

Under idle or small-signal conditions, the low-rail voltage is applied to the collectors of the

output transistors through D13 and D19 on the Power Supply Board. The output of the amplifier is connected to the Power Supply Board via J1-10/J2-10. The signal is half-wave rectified

by D7 and D14, sending the positive half of the signal to comparator U2A-1 and the negative

half to comparator U2B-7. When the signal level exceeds the threshold of the comparator, Q4

(positive) or Q10 (negative) turns on. Current can now flow from ground through Q8 which acts

as a current source for Q6. Q6 or Q11 turn on providing gate drive to the power FET Q9 (positive) or Q14 (negative). When the FETs turn on, the high-rail voltage is connected to the collectors of the output transistors. D13 and D19 become reversed biased and switch off the low-rail

voltage from the circuit. Zener diodes D11 and D18 provide gate protection to the FETs.

Q7 and Q12 speed up the turn off time of the FETs.

This two-stage approach minimizes the voltage across each of the output devices which also

minimizes the power dissipation required. Without this approach, the output transistors would

be required to support the entire power supply voltage under small-signal conditions and the

“unused” portion of the power supply voltage would be turned into heat.

2.10 Display Circuit

In addition to the READY LEDs discussed in section 2.3 (Output Relays), the Display Board

contains five SIGNAL LEDs and one CLIP/PROTECT LED per channel.

The clipping indicators are driven by transistors Q100 (CH1), and Q200 (CH2) located on the

Display Board. The signal for the clipping indicators initially comes from U100A-1 and U100B-7

on the Amplifier Board. This is the same signal that operates the anti-clipping opto-isolator on

the I/O Board. D30 on the I/O Board half-wave rectifies the positive-going portion of the signal

and drives comparator U9B which is a switch. C9 and R62 establish the time constant of the

clipping indicator. D23 rectifies the negative-going portion and also drives comparator U9B.

When clipping occurs, U9B-7 changes from positive to negative, which forward biases D100

on the Display Board and turns on Q100. Q100 supplies current for clipping LED D104,

causing it to illuminate.

15

Page 16

THEORY OF OPERATION

The output signal is sensed at the speaker output via the I/O Board (J2-3 Output Board to J6-3

I/O Board to J3-6 I/O Board to J1-6 Display Board). D22 half-wave rectifies the signal and

provides a DC voltage proportional to the amplifier’s output to drive the signal display circuit.

C2 and R19 determine the response characteristics of the display.

The signal driver circuit comprised of U1-U4 is basically a ladder comparator driving LEDs,

with a twist. Assume that the signal at U2A-3 is zero volts (ignore R24 and D23 for now). R13

and R14 are a voltage divider that establishes a reference voltage for the comparators (four

per channel). The comparators compare this reference voltage against the voltages established by the tapped voltage divider made up of R22, R20, R15 and R25. The CH1 LEDs are in

the following sequence (lowest to highest): D105 (red/ green), D13 (amber), D15 (amber), D14

(amber), D12 (amber), D11 (amber), and D104 (red).

With the input at zero volts, all of the comparator outputs are at -12V, except for U2B-7 which

is high. None of the signal LEDs have any voltage across them, all are extinguished. As the

input signal rises, it crosses in sequence at the thresholds established at each of the four

comparators. First U2A-1 fires; its output goes high and D13 illuminates. Next U1B-7 fires, its

output goes high, D13 extinguishes (no net voltage across it) and D15 illuminates. Finally U1A1 fires, D15 extinguishes, and (this is the twist) D23/R24 supply current to the bottom of the

R15, R20, R22 and R25 voltage divider, which inverts the relationship of the comparators to

each other.

When U1A-1 fires, the current through R24 reverses the sequence of the voltages that establish the thresholds for the three comparators. This allows the same comparators to perform

double-duty. The new thresholds leave U1A-1 high, U2B-7 low, U2A-1 and U1B-7 low and D14

on. D11 and D12 are off. As the input signal rises further, U1B-7 fires, extinguishing D14 and

illuminating D12. Next U2A-1 fires, extinguishing D12 and illuminating D11. Finally U2B-7 fires,

extinguishing D11. The last LED is the clipping indicator, D104.

3.0 Protection Circuitry

Protection functions are provided that will deactivate the output relays. Protection is provided

for the following fault conditions:

3.1 Over-Current Protection

The amplifiers are protected from short-term excess current through the output stage by

electronic current limiters. When the current through the output transistors becomes excessive,

the voltage drop across the emitter resistors R148 and R149 bias the current limiter transistors

Q105 and Q106 on, which shunt the drive current via D106 and D107. R139, D102, R140 and

D103 determine the V-I limits.

When the current-limiters turn on, the voltage at voltage divider R127/R128 becomes less

positive, providing base current for Q1 on the I/O Board through R38. When Q1 turns on two

things happen; current flows through U3 (LED/LDR module) via D31 which attenuates the

input signal, removing the high current condition as well as providing base current to Q5

through D1 which turns off Q2 and Q3, causing the relay to disengage. C13 provides a time

delay to prevent the relay from disengaging during momentary program peaks. When the relay

disengages, it causes the red LED in D105 (READY LED) to illuminate and also turns on Q100

and D104 (CLIP/PROTECT LED).

16

Page 17

THEORY OF OPERATION

3.2 Clipping Eliminator Circuit

This circuit is controlled by the LED/LDR opto-isolator U3, located on the I/O Board. The LED

portion of this component is driven from a bridge rectifier (D4) that gets its input signal from

U100A-1 on the Amplifier Board. Under normal conditions (undistorted amplifier output) there

is almost no signal at this point. If the amplifier is driven into clipping, the signal level at

U100A-1 rises rapidly because the feedback signal no longer represents the input signal.

Once this occurs, the LED in U3 illuminates, reducing the resistance of the LDR portion which

in turn reduces the input signal. The clipping-eliminator circuit is activated by switch S2B on

the I/O Board. When the switch is off, the signal driving the bridge rectifier is shorted to ground.

3.3 DC Offset

DC offset is sensed by the comparator amplifier U2A on the I/O Board. If a DC component

should appear at the output, it is sensed through either D6 or D7, depending on its polarity.

The output of U2A-1 will switch from -14Vdc to +14Vdc, which turns on Q5 via D8. This deactivates the relay, turns the READY LED red, and turns on the CLIP/PROTECT LED.

In addition, the output of U2A-1 is conveyed to the Regulator Board via D15, J100-10 to

Regulator Board J1-12 and D9. The positive voltage on U5A-2 causes the output of U5A-1 to

become less positive, shutting off the conduction current through optocoupler U1, which shuts

off the triac and primary current.

Note: The Regulator PCB is not used in the 1600VI amplifier.

3.4 Overheated Output Transistors

A thermistor (RT100) is positioned near the amplifier PCB's heatsink. As the negative coefficient thermistor heats up, the voltage on comparator U2B-6 located on the I/O PCB drops.

When it crosses the reference voltage set up by voltage divider R42/R43, U2B-7 goes positive.

This forward biases D17, turning on Q5, which deactivates relay K100. As the heatsink temperature cools, the thermistor will cool until the voltage at U2B-6 once again crosses the

reference voltage at U2B-5, allowing the relay to reactivate.

3.4 Fan Speed Control

The fan operates at low speed when the amplifier is first turned on. The voltage at the

thermistor is connected to the Fan Drive circuit on the Output Board via D16 (on the I/O Board)

and J6-4/J2-4. As the heatsink temperature increases, the voltage at U1A-3 on the Output

Board decreases until it crosses the threshold set by voltage divider R4 and R6. When this

occurs, the output of U1A-1 toggles low, which turns on Q1. Q1 shorts across R1 and applies

the full VF+ voltage to the fan, kicking it into high speed.

3.5 Major Faults

The slo-blo line fuse protects the unit from further damage when a major fault such as a

shorted output transistor or a secondary power supply fault occurs. If the unit is run at or near

its rated power, the fuse will eventually blow. The rated line fuse allows the unit to be operated

without interruption for all musical applications.

17

Page 18

THEORY OF OPERATION

4.0 Operating Modes

The Bose® 1600VI and 1800VI amplifiers are capable of being configured to operate in several

different modes in order to allow greater flexibility in use.

4.1 Bridged Mono/Dual Mono Switching

The Stereo/Mono Switch (S1) on the Input Board is a three-position switch used to select

Normal Stereo, Bridged Mono or Dual Mono operation. In the Bridged Mono position, it connects CH 1 in parallel with the CH 2 input, but inverts the signal to CH 1. The CH 1 input

connection becomes disabled. The speaker output signals are identical except CH 1 is 180

degrees out of phase. In this way, a single speaker can be connected between the two “+”

speaker terminals and receive twice the voltage as a single channel. When connected in this

way, each channel “sees” one-half the impedance of the speaker that is connected between

them. If an 8 ohm speaker is used, each channel will see a 4 ohm load. The result is twice the

rated power (per channel) into twice the rated impedance.

Note: Each channel can still be independently controlled with its own level control so it is

important that both level controls be set to the same position for a balanced output.

When S1 is switched to the Dual Mono position, CH 1 is connected in parallel with the CH 2

input, but in phase. The CH 1 input connection becomes disabled. This allows both channels

to be driven with the same signal without the use of special patch cords. Each channel can still

be independently controlled with its own level control.

4.2 Parallel Mono

To operate in Parallel Mono mode, leave S1 in the Normal Stereo position. Removing jumpers

JP201 and JP203 will disconnect the CH 2 predrivers from the output stage. Installing jumpers

JP102, JP104, JP202 and JP204 will connect the CH 1 predrivers to the CH 2 output stage. In

this way, both channels will operate at exactly the same level, and will be controlled by the

CH 1 level control.

In addition, removing JP1 will prevent the CH 2 clip LED from activating, and installing a 16 ga.

jumper wire between WL100 and WL200 on the Output Board will tie both amplifier outputs

together before the relays.

When operating in parallel mono, either of the speaker output terminals (CH 1 or CH 2) can be

used since they both have exactly the same signal present. When a speaker is connected to

the output terminals it can be driven with twice the current capacity of a single channel. The

result is twice the rated power (per channel) into half the rated impedance.

18

Page 19

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: It's advisable to mark or note wiring

configuration before any disassembly

begins. For more information refer to the

Wiring Diagrams Figures 19 and 20.

Note: Refer to Figures 2, 3 and 4 for the

following procedures.

1. Cover Removal

1.1 Use a phillips-head screwdriver to

remove seven screws (3) from the back

and sides of the chassis cover (1) and the

two longer screws that are located in the

center behind the rack-mount brackets.

See Figure 2.

1.2 Lift the back of the cover up, while

moving it forward (front panel) from the

chassis (2). The front lip of the cover is

hinged on the two front angle pieces of the

chassis.

Note: Refer to Figure 6 for the following

procedures.

3. Display Board Removal

3.1 Remove the cover (1) using

procedure 1.

3.2 Remove the connectors from

transformer (4) terminals 6-11. This will

give you access to the screw on the

display board (5) which is next to the

transformer.

3.3 Remove two screws (20) on the solder

side of the display board with a phillipshead screwdriver.

3.4 Move the board back from the chassis

front panel and disconnect the wiring

harness from the display board J1

connector.

2. Cover Replacement

2.1 Align the cover (1) so its front angle fits

over the chassis.

2.2 Secure the cover to the chassis by

tightening seven screws (3) and the two

longer screws located in the center behind

the rack-mount brackets with a phillipshead screwdriver. See Figure 2.

Remove these screws

front

3.5 Lift the board out from the chassis.

4. Display Board Replacement

4.1 Connect the wiring harness from the

I/O board (6) to the display board (5)

J1 connector.

4.2 Secure the display board to the chassis

standoffs by tightening two screws (20)

with a phillips-head screwdriver.

rear

Side View

Do not remove

these screws

Figure 2. Cover Removal Screw Location Side View

19

Page 20

1

Cover

Qty 3

3

20

Qty 3

Input

Module

3

3

17

FOR BRIDGED

OPERATIONS

CONSULT

OWNERS MANUAL

Attaches Heatsink

Brackets, Item 22

FOR BRIDGED

OPERATIONS

CONSULT

OWNERS MANUAL

3

BOSE CORPORATION, FRAMINGHAM, MA 01701-9168 MADE IN U.S.A.

1800 SERIES V PROFESSIONAL AMPLIFIER

BOSE CORPORATION, FRAMINGHAM, MA 01701-9168 MADE IN U.S.A.

LICENSED UNDER U.S. PAT. NO. 4,484,150

Figure 3. Cover Attaching Hardware

1800 SERIES V PROFESSIONAL AMPLIFIER

LICENSED UNDER U.S. PAT. NO. 4,484,150

BRIDGED

D.O.M.

CAUTION

WARNING

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

AVIS

1400 W 8

700 W 4 700 W 4

- CH 2 + + CH 1 SPEAKER OUTPUTS

CLASS 1 WIRING SHALL BE USED

100V

50-60Hz

1800 W

AC

2

Chassis

Qty 3

3

Attaches

I/O Board

D.O.M.

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK

DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR MOISTURE.

CAUTION

11

WARNING

AVIS

3

BRIDGED

1400 W 8

700 W 4 700 W 4

- CH 2 + + CH 1 SPEAKER OUTPUTS

CLASS 1 WIRING SHALL BE USED

Attaches

11

I/O Board

100V

50-60Hz

1800 W

Attaches Heatsink

3

Brackets, Item 22

AC

2

Chassis

3

Qty 2

3

Attaches Input

Module

Fan Exhaust Slot

3

Qty 2

Attaches Lower

Fan Shield

Figure 4. Rear View - Attaching Hardware

Attaches

11

Output Board

36

Page 21

Sequence Switch

Figure 5. 240V

Configuration

9

LOAD

LINE

53

Power Switch

10

240V Line Filter

20

Display Board

Wiring Harness

Nylon Clamp

Anchors C4-C7

Capacitors

Power Supply

Board

21

Cover

Attaches Transistors

to Heatsink, Item 18

Amplifier

Board

J1

I/O Board

100V and 120V

Configuration

LINE

LOAD

48

32

Fuse Holder

Front Panel

Hinge

Qty 2

20

Nylon

Standoff

Power Switch

9

Board

10

Line Filter

Qty 2

44

8

Regulator Board

Nylon Standoff

Power Supply Board Terminals

WL1-WL3 and WL5-WL7

Output Board

16

Terminals WL1, WL2,

WL100, WL101,

WL200 and WL201

Qty 6

3

31

Qty 2

45

Qty 2

R101

R102

J1

50

7

Qty 2

47

6

7

8

9

10

11

4

Transformer

A

35

2

1

5

3

4

A

Display Board

5

1

29

Qty 28

Large Ribbon Cable

15

Shield Over

Q214 and Q216

19

I/O Board

J3 Connector

6

I/O Board J100

and J200 Connectors

Figure 6. 1600VI and 1800VI Amplifier Assembly

21

Page 22

12

Qty 2

FL1

10

Qty 2

12

LOAD

Qty 2

11

E1

16

43

Output Board

J2 Connector

Qty 4

14

P1

31

Output Board

J1

F1

33

34

32

2

9

11

LINE

14

13

Qty 4

4

Binding Post

Terminal Plug

24

25

2

1

5

3

Wht

Red

7

Vio

Black

8

Gray

Black

9

Blu

T1

Yellow

6

Red

10

4

Brn

Yellow

11

26

Lower

Shield

12

13

Cable

Ribbon

I/O Board

28

27

Upper

Shield

23

B1

Fan

Input Module

J1 Connector

Qty 4

405137

Qty 2

Part of

I/O Board

I/O Board

2-Pin

Harness

Connector

41

37

Qty 4

Figure 7. Bottom Mounted Components

22

17

42

Qty 2

Input Module

Assembly

Page 23

DISASSEMBLY/ASSEMBLY PROCEDURES

4.3 Connect the power supply cables back

to transformer (4) terminals 6-11.

4.4 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 3, 4 and 6 for the

following procedures.

5. Regulator Board Removal

Note: The regulator board is not used in

the 1600VI amplifier.

5.1 Remove the cover (1) using

procedure 1.

5.2 Note the wiring configuration and

disconnect cables WL1-WL3 and WL5-WL7

from the power supply board (7) terminals.

This will allow easier access to the regulator board (8). These terminals are located

directly over the regulator board in the

1800VI.

6.2 Carefully line up the holes of the

regulator board with the nylon standoffs

mounted on the power supply board.

Snap three corners of the board onto each

nylon standoff.

6.3 Replace the transformer (4) using

procedure 12. Refer to Figures 7 and16 for

correct wire locations.

6.4 Connect the cables from the line cord

(31) (for 240V, line cord and ground) to the

line filters terminals (10).

6.5 Connect the cables to power supply

board (7) terminals WL1-WL3 and WL5WL7. These terminals are directly over the

regulator board.

6.6 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 5 and 6 for the

following procedures.

5.3 Disconnect the cables from the

terminals of the line filter (10) that are

next to the regulator board.

5.4 Remove the transformer (4) using

procedure 11. This will allow easier access

to the standoffs that secure the regulator to

the power supply board.

5.5 Unsnap the regulator board from the

nylon standoffs mounted on the power

supply board. This will also disengage the

regulator board from the power supply

J1 connector.

6. Regulator Board Replacement

6.1 Line up and insert the pins of the

regulator board (8) J1 connector (solder

side) into the power supply (7)

J1 connector.

7. Power or Sequence Switch Removal

7.1 Remove the cover (1) using

procedure 1.

7.2 Unsolder the three tabs that secure the

power switch board (9) to the switch.

7.3 Push the switch through the chassis (2)

front panel.

8. Power or Sequence Switch

Replacement

8.1 Push the switch into the chassis (2)

front panel.

8.2 Solder the power switch board (9) to

the switch terminals. For 100V and 120V

units, make sure the LED is lined up with

the panel hole labeled "Standby". For 240V

units, make sure the board's LED is aligned

underneath the "ON" position icon.

23

8.3 Replace the cover (1) using

procedure 2.

Page 24

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to Figures 5, 6 and 7 for the

following procedures.

9. Line Filter Removal

9.1 Remove the cover (1) using

procedure 1.

9.2 Make a note of the wiring configuration

of the line filter (10) and disconnect the

wires.

9.3 Using a phillips-head screwdriver and a

5/16 wrench, remove the two screws (11)

and locknuts (12) that attach the line filter

to the chassis (2). The screws are driven

from the bottom of the chassis.

9.4 Remove the line filter from the

chassis.

10. Line Filter Replacement

11.3 Place the chassis (2) on its side.

11.4 While holding the transformer with one

hand, use a phillips-head screwdriver to

remove four screws (13) and washers (14)

from the bottom of the chassis.

11.5 Remove the transformer from the

chassis.

12. Transformer Replacement

12.1 Place the chassis (2) on its side. Align

the transformer (4) in the chassis so that

the six terminal side of the transformer is

next to the large capacitors of the power

supply board (7).

12.2 While holding the transformer with one

hand, use a phillips-head screwdriver to

tighten four screws (13) and washers (14)

from the bottom of the chassis.

10.1 Align the line filter (10) to the

chassis (2). Refer to Figures 16 and 17.

10.2 Secure the line filter to the chassis

using the two screws (11) and locknuts (12)

removed in procedure 9.3. The screws are

driven from the bottom of the chassis.

10.3 Connect the cables from the line

cord (31) and power supply to the

terminals of the line filter. Refer to the

Wiring Diagrams Figures 19 and 20.

10.4 Replace the cover using procedure 2.

Note: Refer to Figure 7 for the following

procedures.

11. Transformer Removal

11.1 Remove the cover (1) using

procedure 1.

12.3 Return the cables to their designated

terminals on the transformer. Refer to the

Wiring Diagrams, Figures 19 and 20 for

proper hookup.

12.4 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 6 and 7 for the

following procedures.

13. Amplifier Board Removal

13.1 Remove the cover (1) using

procedure 1.

13.2 Disconnect the two ribbon cables

connected to the I/O board (6), J101 and

J201, from the amplifier board (15).

13.3 Disconnect the large ribbon cable

JP200 from the power supply board (7).

11.2 Make a note of the wiring configuration

and disconnect all of the connectors

attached to the transformer (4) terminals.

13.4 Make a note of the wiring configuration and disconnect the cables connected

to terminals WL1, WL2, WL100, WL101,

WL200 and WL201 on the output

board (16).

24

Page 25

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Some cables are bundled together.

Cut any wire wraps when necessary.

13.5 Note the locations of RT100, RT200,

Q104 and Q204 at the corners of the

amplifier board and their placement against

the heatsink.

13.6 Remove one screw (29) and washer

from each of the twenty-eight transistors

that attaches the amplifier board to the

heatsink (18).

Note: Make a note of the location and

alignment of the shield over Q214 and

Q216.

13.7 Lift the amplifier board from the

heatsink.

14. Amplifier Board Replacement

14.1 Place the amplifier board (15) onto

the heatsink (18). Align the board so that

the large ribbon cable is facing the power

supply board (7). Be sure that RT100,

RT200, Q104 and Q204 are aligned

properly against the heatsink and that they

have sufficient heatsink compound

between the component and the heatsink.

14.2 Secure the amplifier board to the

heatsink by tightening one screw (29) and

washer to each of the power transistors.

Torque the screws to 5.7 inch-pounds.

Note: Make sure the shield (19) is attached to Q214 and Q216 transistors.

Refer to Figure 6 for shield alignment.

14.5 Connect the amplifier and power

supply board (7) cables to the output board

(16) WL1, WL2, WL100, WL101, WL200

and WL201 terminals. Refer to Wiring

Diagram Figure 19.

14.6 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 7, 8 and 9 for the

following procedures.

15. Output Board Removal

15.1 Remove the cover (1) using

procedure 1.

15.2 Disconnect the display board (5)

wiring harness from the I/O board (6) J3

connector.

15.3 Disconnect the amplifier board (15)

two ribbon cables from the I/O board

J100 and J200 connectors.

15.4 Make a note of the wiring configuration

and disconnect the cables connected to the

output board (16) WL1, WL2, WL100,

WL200 and WL201 terminals.

15.5 If necessary, unsolder the red and

white wires from the I/O board E10 and E11

terminals. They are located near the

amplifier board transistor shield (19).

15.6 Make a note of the wiring configuration

and disconnect the cables from the power

supply WL1-WL8 terminals. WL8 is located

near the large power supply capacitors.

14.3 Connect the two ribbon cables J101

and J201 to I/O board (6) connectors, J100

and J200).

14.4 Connect the large ribbon cable

(JP200) to the power supply board (7)

connector J2.

15.7 Make a note of the wiring configuration

and disconnect all of the cables connected

to the transformer.

15.8 Using a phillips-head screwdriver,

remove one screw from the nylon clamp

(21) that fastens the power supply

capacitors (7) C4-C7 to the chassis (2).

25

Page 26

DISASSEMBLY/ASSEMBLY PROCEDURES

15.9 Using a phillips-head screwdriver,

remove four screws (29) from the two

brackets (22) that secure the heatsink (18)

to the inside of the chassis back panel.

15.10 To release the heatsink base from

the bottom of the chassis, use a phillipshead screwdriver to remove four screws (3)

from the chassis bottom panel. Move the

entire heatsink away from the output board.

15.11 Disconnect the fan (23) from the

output board J3 connector.

15.12 Disconnect the I/O board ribbon

cable from the output board J2 connector.

15.13 Use a phillips-head screwdriver to

remove two screws (11) that fasten the

output board to the bottom of the chassis.

15.14 Use a phillips-head screwdriver to

remove two screws (11) on the back panel

that attach to the two brackets on the

output board. They are located underneath

the red and black binding posts.

15.15 Use a wrench to remove four nuts

from the binding posts (items 24 or 25).

Release the wires from the posts.

15.16 Lift the output board out of the

chassis.

16. Output Board Replacement

16.1 Place the output board (16) into the

chassis (2). Align the board so the two

brackets on the board face the back panel

of the chassis.

16.4 Connect the output board black wires

to the binding posts (items 24 or 25) by

tightening four nuts with a wrench. Refer to

Figure 19 for the proper wiring.

16.5 Connect the I/O board (6) ribbon cable

to the output board J2 connector.

16.6 Connect the fan (23) connector to the

output board J3 connector.

16.7 Return the heatsink (18) to it's location. Use a phillips-head screwdriver to

tighten four screws (29) to the two brackets

(22) that fasten the heatsink to the chassis

back panel.

16.8 Secure the heatsink to the bottom of

the chassis by tightening four screws (3)

with a phillips-head screwdriver. The

screws are driven from the bottom of the

chassis.

16.9 Secure the power supply (7) large

capacitors to the inside of the chassis by

tightening one screw (20) into the nylon

clamp that wraps around one of the

capacitors.

Note: Refer to wiring diagrams Figures 19

and 20 for the following procedures.

16.10 Connect the cables from the

amplifier (15) and power supply board to

the output board WL1, WL2, WL100,

WL200 and WL201 terminals.

16.11 Connect the amplifier board ribbon

cables to the I/O Board J100 and J200

connectors.

16.2 Secure the output board to the bottom

of the chassis by tightening two screws (11)

with a phillips-head screwdriver.

16.3 Use a phillips-head screwdriver to

tighten two screws (11) into the output

board brackets. The screws are driven

from the outside of the back panel.

16.12 Connect the display board (5) wiring

harness to the I/O board J3 connector.

16.13 Solder the red and white wires from

the 2-pin harness connector to the I/O

board E10 and E11 terminals. They are

located near the amplifier board transistor

shield (19).

26

Page 27

DISASSEMBLY/ASSEMBLY PROCEDURES

16.14 Connect the cables from the line

filter (10) power or sequence switch board

(9) and fuse holder (32) to the power

supply WL1-WL8 terminals.

16.15 Connect all the cables connected to

the transformer.

16.16 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 6, 8 and 9 for the

following procedures.

17. Power Supply Board Removal

17.1 Remove the cover (1) using

procedure 1.

17.2 Remove the transformer (4) using

procedure 11.

Attach Bridge

to Heatsink

30

Power Supply Board

Heatsink

Bridge

Heatsink, Amplifier

39

Figure 9. Heatsink Bridge

17.3 Disconnect the amplifier board (15)

ribbon cable from the power supply (7)

J2 connector.

17.4 Make a note of the wiring configuration and disconnect the wiring from power

supply terminals WL1-WL8.

18

Chassis

Attaches

Shields

to Fan

Connector

Bracket

Shield

Bracket

13

14

30

52

38

Attaches

Transformer

Attaches Power Supply

Board to Heatsink

Attaches Heatsink

to Chassis

Attaches Fan

Shield to

Chassis

2

Qty 4

Qty 4

3

Qty 4

3

Qty 2

12

51

AIR FLOW

Qty 2

Front

21

Nylon Clamp

Attaches

Nylon Clamp

18

Heatsink

35

Insulation

Attaches

29

Bracket to

Qty 4

Heatsink

17.5 Make a note of the wiring configuration and disconnect all of the wires connected to terminals E5-E17 of the power

supply board.

17.6 Use a phillips-head screwdriver to

remove one screw from the nylon clamp

(21) that secures the power supply large

capacitors to the chassis.

17.7 Remove two screws (30) from the

heatsink bridge with a phillips-head

screwdriver. Refer to Figure 9.

17.8 Disconnect the regulator board (8)

from the power supply using procedure 5.

Note: The regulator board is not used in

the 1600VI amplifier.

17.9 Remove four screws (30), one from

each corner of the power supply board with

a phillips-head screwdriver.

Heatsink Bracket

Qty 2

22

Back

Figure 8. Side View - Bottom Mounted

Components

17.10 Lift the power supply board from the

chassis.

27

Page 28

DISASSEMBLY/ASSEMBLY PROCEDURES

18. Power Supply Board Replacement

18.1 Attach the power supply board (7) to

the heatsink (18) by tightening four screws

(30) into each corner of the board. Use a

phillips-head screwdriver. Refer to Figure 7.

18.2 Seat the regulator board into the

power supply board, see Procedure 6.

18.3 Secure the power supply heatsink

bridge to the heatsink by tightening two

screws (30) with a phillips-head

screwdriver.

18.4 Secure the power supply large

capacitors to the chassis by tightening one

screw into the nylon clamp (21). See

Figure 8.

18.5 Connect all wiring to the power supply

WL1-WL8 terminals.

18.6 Connect all wires attached to the

power supply terminals E5-E17.

The screws are located over the fan

exhaust slot.

19.4 Release the lower shield from the

bottom of the chassis by removing two

screws (3) with a phillips-head screwdriver.

19.5 Disconnect the fan cable (J1) from the

output board (16) J3 connector.

19.6 Lift out the fan and shield. To disassemble the fan from the shields, (upper

(27) and lower (26)) use a phillips-head

screwdriver and 5/16" wrench to remove

four screws (28) and locknuts (12).

20. Fan Replacement

20.1 Place the fan (23) label-side down

onto the lower shield (26). The fan is

seated flush on one side of the lower shield

and a 1/2" space on the other side. Align

the fan so that the red and black wires are

on the side of the shield with the 1/2"

space.

18.7 Connect the amplifier board ribbon

cable to the power supply J2 connector.

18.8 Replace the transformer (4) using

procedure 12.

18.9 Replace the cover (1) using

procedure 2.

Note: Refer to Figures 6 and 7 for the

following procedures.

19. Fan Removal

19.1 Remove the cover (1) using

procedure 1.

19.2 Use procedure 15, Steps 15.2-15.12

to move the heatsink (18), with the amplifier, power supply and regulator boards

attached, to allow access to the fan (23).

20.2 Place the upper shield (27) on the

back of the fan. Use a phillips-head screwdriver and 5/16" wrench to tighten four

screws (28) and locknuts (12).

20.3 Secure the fan and shield to the

chassis back panel by tightening two

screws (3) with a phillips-head screwdriver.

The screws are located over the fan

exhaust slot.

20.4 Secure the lower shield to the bottom

of the chassis by tightening two screws (3)

with a phillips-head screwdriver.

20.5 Connect the fan cable into the output

board (16) J3 connector (Pin 1 is red,

Pin 2 is black).

20.6 Use procedure 16, Steps 16.4-16.15

to install the heatsink (18) and cabling.

19.3 Release the fan and shield (26) from

the chassis back panel by removing two

screws (3) with a phillips-head screwdriver.

20.7 Replace the cover (1) using

procedure 2.

28

Page 29

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to Figure 6 for the following

procedures.

21. I/O Board Removal

21.1 Use Procedure 15, Steps 15.1-15.12

to remove the chassis cover (1), disconnect

cabling, and to move the heatsink (18),

which will allow access to the I/O board (6).

21.2 Disconnect the I/O board ribbon cable

from the output board (16) J2 connector.

21.3 To release the I/O board from the

chassis back panel, use a phillips-head

screwdriver to remove four screws (11)

from the board standoffs.

21.4 If necessary, unsolder the cables from

the I/O board E1-E9 terminals.

21.5 Lift the I/O board from the chassis.

22. I/O Board Replacement

22.1 Place the I/O board (6) into the

chassis (2) with the component side of

the board facing the back panel.

22.2 Solder the cables from the display (5)

and power supply board (7) to the I/O

board E1-E9 terminals if they were

unsoldered in Procedure 21.4. Refer to the

wiring diagrams Figures 19 and 20 for

proper connection.

22.3 Connect the I/O board ribbon cable to

the output board (16) J2 connector.

Note: Refer to Figures 4, 10 and 11 for the

following procedures.

23. Input Module Removal

23.1 Use a phillips-head screwdriver to

remove two screws (3) from the input

module (17) connector panel.

23.2 Pull the input module out of the

chassis (2).

23.3 Disconnect the I/O board (6) ribbon

cable from the input module J1 connector.

23.4 Once the input module is out of the

amplifier chassis the equalization cards can

be accessed.

24. Input Module Replacement

24.1 Slide the input module (17) into its

slot far enough so you can connect the I/O

board (6) ribbon cable into the input

module J1 connector.

24.2 Slide the input module into the

chassis slot until the input module J2

connector is completely seated into the

I/O board two-pin harness connector.

The input module should be flush with the

chassis back panel.

24.3 Secure the input module to the

amplifier chassis by tightening two screws

(3) with a phillips-head screwdriver.

22.4 Attach the I/O board to the chassis

back panel by tightening four screws (11)

with a phillips-head screwdriver. The

screws are driven from the outside of the

back panel.

22.5 Use Procedure 16, Steps 16.4-16.15

to install the heatsink (18) and cables.

22.6 Replace the cover (1) using

procedure 2.

Figure 10. Input Module Screw Location

29

Page 30

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: The Bose

®

ACM-1 Amplifier Control

Module is used in place of the standard

Input Module to allow control and monitoring of the amplifier by use of a control

network. It uses the same types of audio

input connectors as the standard Input

Module, as well as EQ outputs and sequence control. It will accommodate one

Bose EQ card for each channel. Refer to

the ACM-1 Amplifier Control Module service

manual part number 199746 for more

information.

Note: Refer to Figures 4, 10 and 11 for the

following procedures.

25. Bose ACM-1 Amplifier Control

Module Removal

25.1 Use a phillips-head screwdriver to

remove two screws (3) from the Bose

ACM-1 module (17) connector panel.

25.2 Pull the ACM-1 module out of the

chassis (2).

25.3 Disconnect the I/O board (6) ribbon

cable from the ACM-1 module J1

connector.

25.4 Disconnect the ACM-1 ribbon cable

from J2 on the amplifier I/O board.

25.5 Once the ACM-1 module is out of the

amplifier chassis the equalization cards can

be accessed.

26. Bose ACM-1 Amplifier Control

Module Replacement

26.1 Slide the ACM-1 module (17) into its

slot far enough so you can connect the

amplifier I/O board (6) ribbon cable into the

ACM-1 module J1 connector. Pin 1 is to the

right as you face the rear of the amplifier.

This corresponds to the red stripe on the

ribbon cable.

26.2 Connect the ACM-1 ribbon cable to J2

located on the amplifier I/O board.

This jack is located on the top right side of

the opening in the rear of the amplifier for

the ACM-1 module. Pin 1 is to the right.

This corresponds to the red stripe on the

ribbon cable.

26.2 Slide the ACM-1 module into the

chassis slot until the input module J2

connector is completely seated into the

I/O board two-pin harness connector.

The ACM-1 module should be flush with

the chassis back panel.

26.3 Secure the ACM-1 module to the

amplifier chassis by tightening two screws

(3) with a phillips-head screwdriver.

Note: Bose Equalizer PCBs can be

installed into both the standard Input

Module and the ACM-1 Amplifier Control

Module to allow active equalization of Bose

loudspeakers as used in various installations. For more information, refer to the

Equalizer PCB Assemblies service manual

part number 181812-S2 for the 402™,

502®A, 502B, 802®, 3202®, 4402®, 9702

and LT II loudspeakers, and service

manual part number 181812-S5 for the

Model 8 and Model 25/32 loudspeakers.

Note: Refer to Figure 11 for the following

procedures.

27. Equalizer PCB Installation and

Removal

27.1 Remove the Input Module or ACM-1,

as applicable, using procedure 23 or 25.

27.2 Located on the motherboard for the

module, you will see two jacks labelled J6

and J7. J6 corresponds to channel 1 of the

amplifier, and J7 corresponds to channel 2.

27.3 Plug the EQ card into the desired

channel. Be sure that it is firmly seated into

the connector. If you are removing an EQ

card, grip it firmly and gently pull it straight

out of the connector located on the module.

27.4 Replace the module using procedure

24 or 26, as applicable.

®

30

Page 31

TEST PROCEDURES

Inputs Outputs

Audio Signal

Generator

Loads

Amplifier

rear panel

Input Module

dB Meter

Figure 11. EQ Card Placement

Test Setup Parameters:

1. In order to test these amplifiers at full

power, you will need at least one 4Ω, 500W

load and one 8Ω, 500W load.

Only if you are connected to a Bose control

network using the required Bose software

will you be able to pass audio through an

amplifier with a Bose ACM-1 Amplifier

Control Module installed. Refer to the

ACM-1 service manual part number

199746 for more information.

Figure 12. Amplifier Test Setup Diagram

2. Set up the amplifier under test as shown

in the Test Setup Diagram, Figure 12.

3. For the following tests it is recommended

that you apply balanced signals for all input

levels. If you do not have the ability to

provide balanced signal inputs, you may

use a single-ended input signal. Be sure to

connect the negative leg of the wiring to

ground for proper gain levels.

4. You will need input cables with either

XLR, TRS, or the 3-pin connectors (Bose

®

part number 182769) in order to be able to

apply an input signal to the amplifier. Refer

to section 2.1 of the Theory of Operation for

the wiring scheme.

5. The input levels shall be the actual level

as measured at the input jack, not the

signal generator open circuit level.

6. If you have an amplifier with the Bose

ACM-1 Amplifier Control Module installed,

you will need to replace it with a standard

Input Module in order to be able to test it.

1. Gain Test

1.1 Apply a 41 mVrms, 1 kHz signal to the

input of the amplifier channel under test.

1.2 Reference a dB meter to the input level.

1.3 Measure the output level for the

channel under test. For the 1600VI amplifier, it should be +27.6 dB ± 0.5 dB for low

sensitivity units, and +33.3 dB ± 0.5 for

high sensitivity units. For the 1800VI

amplifier, it should be +30.3 dB ± 0.5 dB for

low sensitivity units, and +36.0 dB ± 0.5 for

high sensitivity units.

2. Frequency Response Test

2.1 Apply a 16 mVrms, 1 kHz signal to the

amplifier channel under test.

2.2 Reference a dB meter to the output

level. This is the reference level.

2.3 Measure the frequency response. It

should be 0.0 dB ± 0.75 dB from 20 Hz to

20 kHz.

31

Page 32

TEST PROCEDURES

3. Distortion Level

3.1 Apply a 1.5 Vrms, 1 kHz signal for low

sensitivity units, or a 775 mVrms, 1 kHz

signal for high sensitivity units, to the

amplifier channel under test.