Page 1

Model 151™ and 111™ ENVIRONMENTAL SPEAKER SYSTEM

Transducer: Cabinet:

1-4.5" (11.4 cm) full-range, Black or white high-impact molded

environmental driver polypropylene

Nominal Impedance: Speaker Dimensions:

4 Ohms 6.1"H x 9.1"W x 5.9" D

IEC Power Rating: Shipping Weight

Min: 10 Watts Per Channel 4.0 lbs. (1.8 kg) Per Speaker

Max: 40 Watts Per Channel

©

200 Bose Corporation

SPECIFICATIONS

(15.4 H x 23.0 W x 15.0 D cm)

Service Manual

Page 2

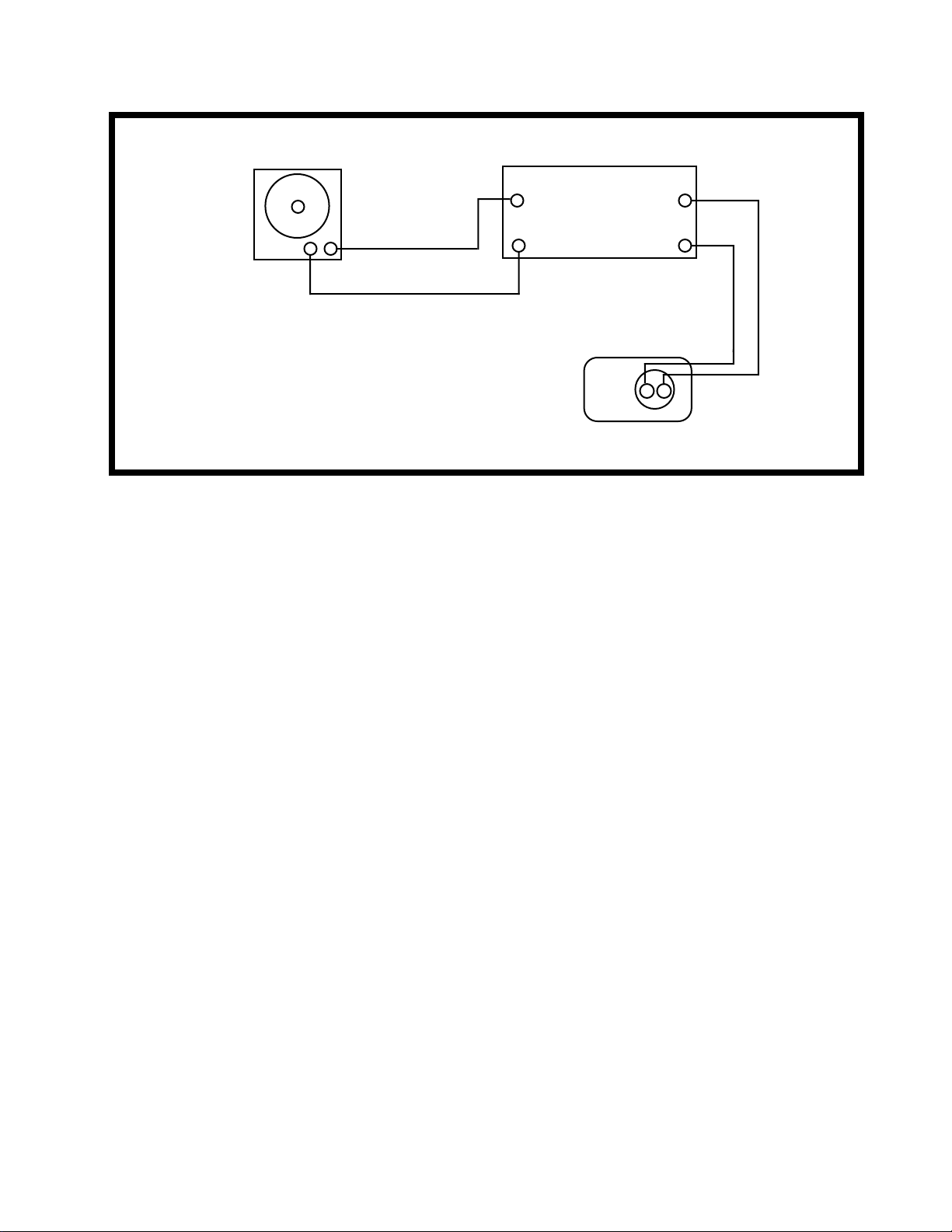

Test Procedures

NOTES: In each test procedure, it is necessary to remove the grille to access the driver.

Refer to the Grille Removal procedure.

Polarities are not marked on the input terminals of the 151™ speaker. The red terminal is

the positive (+) terminal and the black terminal is the negative (-) terminal. See Figure 1.

1. Rub and Tick Test

A. Connect a sine wave oscillator to a power amplifier. Adjust the frequency of the oscillator

to 10 Hz and the amplifier output to 6 Vrms. Connect the amplifier output to the input

terminals of the 151 speaker (see Figure 1). No extraneous noises such as rubbing,

scraping or ticking should be heard.

NOTE: To distinguish between normal suspension noise and rubs or ticks, displace the

cone on the driver slightly with your fingers. If the noise can be made to go away or get

worse, it is a rub or a tick and the driver should be replaced. If the noise stays the same, it

is normal suspension noise and the driver is fine. Suspension noises will not be heard with

program material.

2. Sweep Test

A. Sweep the oscillator from 10 Hz to 3 kHz using the 6 Vrms signal. There should not be

any loud extraneous sounds. (Note: A "whooshing" noise from the port at approximately 80

Hz is acceptable). If there are any loud buzzes or distortion, replace the driver. (See

Disassembly/Assembly Procedures for instructions on replacing the driver).

NOTE: There should not be any buzzes or rattles from within the speaker cabinet. Redress

any wire or component that buzzes.

B. Reduce the amplifier output to 3 Vrms and continue sweeping from 3 kHz to 15 kHz. If

there is any buzzing or distorting,replace the driver (see Disassembly/Assembly

Procedures for instructions on replacing the driver).

1

Page 3

Audio Signal

Generator

Power Amplifier

Input Output

--

+

-

++

Speaker

-

+

Red (+)

Black (-)

Figure 1. Test Connections 151™ Speaker

3. Air Leak Test

A. Using the 6 Vrms signal,set the oscillator frequency to 10 Hz. Block the ports. For at

least 3 seconds, listen for air leaks around the driver and baffle. If there is a "whooshing"

noise around the driver, re-position the driver gasket behind the driver to make an airtight

seal. If there are similar noises around the baffle, make sure that it is securely fastened to

the speaker cabinet.

4. Phase Test

NOTE: Supply voltage should only be momentarily applied to the speaker input terminals to

avoid possible damage to the speaker.

A. Set a DC power supply to 10 volts. To ensure that the driver is connected in phase,

connect the positive lead of the supply to the positive (+) speaker input terminal and the

negative lead to the negative (-) input terminal. The driver should move outwards with the

application of the supply voltage.

2

Page 4

Disassembly/Assembly Procedures

NOTE: Refer to Figure 2 for an exploded view of the speaker assembly. Certain parts will

be referred to in these procedures. The item number which corresponds to the part will be

enclosed in parentheses-i.e.-grille (1).

1. Grille Removal

NOTE: The grille is made entirely of metal. Do not try to remove the grille by pulling on the

plastic (polypropylene) speaker enclosure.

A. Insert the tip of a scribe or nail through one of the perforations in the grille (1). Hint:

Insert at one of the corners. Carefully work the grille out of the retaining slot.

2. Grille Replacement

A. To install the grille (1), make sure that it is oriented as shown in Figure 2.

B. Align the grille to the speaker enclosure and push in lightly.

3. Driver Removal

A. Remove 3 screws (4) which secure the driver (3) to the speaker baffle (6).

B. Carefully lift the driver out of the enclosure and cut the wires as close to the driver

terminals as possible.

4. Driver Replacement

A. Strip the wires and connect to the replacement driver (3). Make sure that the red wire is

connected to the positive (+) terminal and the black wire is connected to the negative (-)

terminal of the driver. Make sure that the driver terminals are centered in the speaker

enclosure. The correct orientation is shown in Figure 2.

B. The gasket (5) must also be correctly positioned behind the driver to provide an airtight

seal. Secure the driver (3) to the baffle (6) with 3 screws (4). Repeat the driver test

procedures.

3

Page 5

5. Baffle Removal

A. Remove 6 screws (4) that hold the baffle (6) in place. (Removing the driver is not necessary).

Stick your fingers in the baffle ports and pull the baffle carefully away from the enclosure. It may

take quite a bit of force to accomplish this task.

6. Baffle Replacement

A. Align the port side of the baffle (6) to the side of the enclosure that has the input terminals (9).

The baffle will only fit one way. Secure the baffle to the enclosure with 6 screws (4). Repeat the air

leak test.

4

Page 6

Figure 2. Speaker Assembly Exploded View

5

Page 7

Figure 3. Packaging Exploded View

6

Page 8

151™ Speaker Assembly Parts List (Figure 2)

Item

Number

Description Part Number Qty.

Per

Speaker

Assy.

1 Grille -Metal, Black 179129-1 1 2

Grille -Metal, Arctic White 179129-2 1 2

2 Nameplate-Logo, Black 171292-1 1 2

Nameplate-Logo, White 171292-2 1 2

3 Driver 257948-001 1

4 Screw-

TAPP,8-11x3/4,PAN,XRC/SQ

173556-12 9

5 Gasket-Driver, 4.5" 128407 1

6 Baffle-Black 131741-01A 1

Baffle-White 131741-01B 1

7 Batting-Polyester 116082 1 1

8 Threaded Insert 123991 2

9 Connector-Terminal Strip 171295 1

See Note

10 Screw-

TAPP,6-13x.5,PAN,XREC/SQ

173555-08 2

NOTE

1. This part is not normally available from Customer Service. Approval from the Field Service Manager is

required before ordering.

2. The nameplate is not easy to replace. If you need to replace the grille, you must also order a new nameplate. Re-attach the nameplate to the grille with an appropriate adhesive (i.e.-superglue) or by using a

soldering iron. CAUTION: If you use a soldering iron, CAREFULLY melt the nameplate posts against the

grille. Do not melt down the posts too much or the nameplate will be ruined. Also, the nameplate should be

secured so that it does not vibrate.

7

Page 9

151™ Packaging Parts List (Figure 3)

Item

Number

Description Part Number Qty.

1 Owner's Manual 171297 1

2 Card-Warranty, Universal 149225 1

3 Polybag (Literature Kit) 103351 1

4 List-Warranty Service 122766 1

5 Envelope-Warranty Registration 123001 1

6 All Products Brochure 141478 1

7 Express Music Catalog 145891 1

8 Packing-Filler, Foam 124921 2

9 Polybag (Speaker) 123831 2

10 Carton 171298 N/A

See Note

Per

Carton

8

Page 10

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

Bose Corporation

The Mountain

Framingham, Massachusetts USA 01701

P/N 173445 6/93: REV.01

FOR TECHNICAL ASSISTANCE PARTS ORDERING, CALL 800-233-4008

Loading...

Loading...