BOSE 102 Schematic

102 COMMERCIAL SOUND SYSTEM

©2009 Bose Corporation

Service Manual

Reference Number 130105-SM Rev . 04

Electronic Copy Only

CONTENTS

Electrostatic Discharge Sensitive (ESDS) Device Handling.........................................................3

Safety Information................................................................................................................................4

Specifications.......................................................................................................................................5

Disassembly/Assembly Procedures ............................................................................................. 6-9

102® Flush-Mount Loudspeaker........................................................................................................6

Figure 1. 102 Flush-Mount Grille Removal.............................................................................................6

Figure 2. 102 Flush-Mount Driver Replacement....................................................................................6

102 Surface-Mount Loudspeaker......................................................................................................7

Figure 3. 102 Surface-Mount Driver Removal/Replacement................................................................7

Figure 4. 102 Surface-Mount Baffle Assembly ......................................................................................8

102 System Controller Procedures................................................................................................8-9

Figure 5. 102 System Controller Exploded View ..................................................................................10

Figure 6. 102 System Controller Block Diagram ................................................................................11

T est Procedures ......................................................................................................................... 12-15

Figure 7. Test Connections for 102F or 102S Loudspeaker................................................................12

102 Loudspeaker T est Signals.........................................................................................................12

102 System Controller Test Procedures ...................................................................................... 13

102 System Controller Initial Switch Positions..............................................................................13

102 System Controller Frequency Response................................................................................14

102 System Controller T est Procedures...................................................................................14-15

102 System Controller V oice Channel Response..........................................................................15

102 Loudspeaker Driver Wiring ......................................................................................................16

Figure 8. 102 Loudspeaker Schematic Diagram (Passive Units).......................................................16

Figure 9. 102 Loudspeaker Schematic Diagram (Transformer Units)................................................16

Figure 10. Tap Selection Switch Wiring (Transformer Units)..............................................................16

T ap Selection Switch Wiring............................................................................................................16

102 Flush-Mount Loudspeaker Parts List (Per Figure 10) ......................................................... 17

102 Flush-Mount Loudspeaker Installation Hardware ................................................................ 17

102 Loudspeaker Exploded Views ................................................................................................ 18

Figure 1 1a. 102 Flush-Mount Non-RoHS Loudspeaker Exploded View ............................................ ..18

Figure 1 1b. 102 Flush-Mount RoHS Loudspeaker Exploded View ......................................................18

102 Surface-Mount Loudspeaker Parts List (Per Figures 11 & 12) ........................................... 19

102 Surface-Mount Loudspeaker Installation Hardware ............................................................ 19

Figure 12. 102 Surface-Mount Loudspeaker Exploded View ...............................................................20

Figure 13. 102 Surface-Mount Loudspeaker ..................................................................................... 21

102 System Controller Parts Lists ............................................................................................ 22-25

102 System Controller Packing List .............................................................................................. 25

102 Loudspeaker Packing Diagrams ........................................................................................ 26-27

Figure 14. 102 Flush-Mount Loudspeaker Packing Diagram..............................................................26

Figure 15. 102 Surface-Mount Loudspeaker Packing Diagram...........................................................27

Service Manual Revision History .....................................................................................................28

2

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing, or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly grounded.

Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble

wrap, or plastic trays.

CAUTION: THE 102® SYSTEM CONTROLLER CONTAINS

NO USER-SERVICEABLE PARTS. TO PREVENT

WARRANTY INFRACTIONS, REFER SERVICING TO

WARRANTY SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE® CORPORATION WHICH IS BEING FURNISHED ONLY

FOR THE PURPOSE OF SERVICING THE IDENTIFIED BOSE

PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR

OWNER OF THE BOSE PRODUCT, AND SHALL NOT BE

REPRODUCED OR USED FOR ANY OTHER PURPOSE.

3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the ! symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check

(1) With the unit completely reassembled, plug the AC line cord directly

into a 120V AC outlet. Do not use an isolation transformer during

this test. Use a leakage current tester or a metering system that

complies with American National Standards Institute (ANSI) C101.1

"Leakage Current for Appliances" and Underwriters Laboratories (UL) 1492 (71).

(2) With the unit AC switch first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the unit (antennas, handle bracket, metal cabinet,

screwheads, metallic overlays, control shafts, etc.), especially any

exposed metal parts that offer an electrical return path to the chassis.

(3) Any current measured must not exceed 0.5 milliamp.

(4) Reverse the unit power cord plug in the outlet and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check

(1) Unplug the power supply and connect a jumper wire between the two

prongs of the plug.

(2) Turn on the power switch of the unit.

(3) Measure the resistance with an ohmmeter between the jumpered AC plug

and each exposed metallic cabinet part on the unit. When the exposed

metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 megohms. When there is no return path to the chassis,

the reading must be "infinite". If it is not within the limits specified, there is

the possibility of a shock hazard, and the unit must be repaired and

rechecked before it is returned to the customer.

4

SPECIFICATIONS

102® System Controller:

Input Level: Music - 100mV or 1V selectable

Voice - Mic or line, selectable, variable

(AGC calibration)

Output Level: 1V nominal

Input Impedance: Music - 2k ohms, balanced, differential

Voice - 600 ohms, balanced, differential

Bass Cut Switch: 6 dB

Distortion: Less than 0.1% THD

CMRR: Greater than 40 dB, all inputs

AGC: Attack level - variable

Attack time - < 5 ms

Release time - 200 ms

Mute: Mute level - -30 dB ( with defeat switch on ch. B)

Attack time - < 5 ms

Release time - 2 seconds

Accessories: 4 rack-mount screws, supplied

Dimensions: 1 3/4" H x 18 31/32" W x 4 1/4" D

(44 mm x 482 mm x 107 mm)

102 Flush-Mount and 102 Surface-Mount Loudspeakers:

Frequency Response: 80 Hz - 18 kHz, ± 3 dB

Distortion: <1% @ 10% rated power input

Driver: Single, 4 1/2" Helical Voice Coil

Enclosure: Dual port, bass reflex type

Volume: 200 cubic inches

Port Resonance: 80Hz

Sensitivity: 95 dB SPL, 1W, 1m @ 1 kHz

Weight: 5 lbs. (2.3 kg)

Temperature: Minimum - 0° C

Maximum - 60° C

Humidity: Minimum - 0 %

Maximum - 98 %

5

DISASSEMBLY/ASSEMBLY PROCEDURES

102® Flush-Mount Loudspeaker

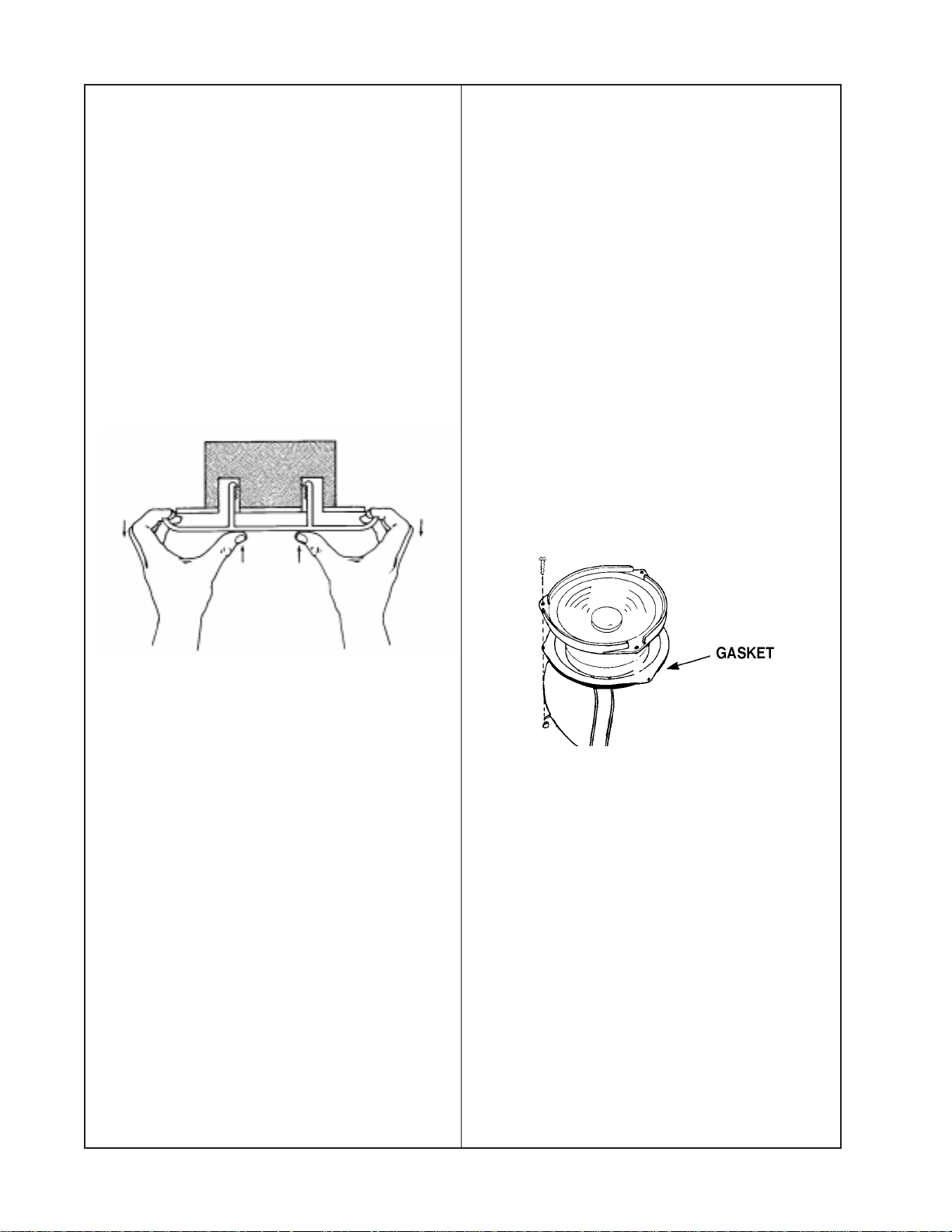

1. Grille Removal

1.1 The optional Bose® grille is held in

place via a tooth/groove-type design.

To remove the grille, grasp the edges of the

grille with your fingers and place your

thumbs toward the center of the grille.

1.2 As you press inward with your thumbs,

pull outward with your fingers. This will

release the teeth from the grooves, allowing the grille to be removed from the loudspeaker enclosure. (See Figure 1)

3.2 Carefully lift the driver out of the enclosure and cut the wires as close to the driver

terminals as possible.

4. Driver Replacement

4.1 Strip the wires and connect them to

the replacement driver. Make sure that

the red wire is connected to the

positive (+) terminal and the black wire

is connected to the negative (-) terminal

of the driver.

4.2 Align the driver and gasket to the

enclosure. Make certain the gasket is

correctly positioned to provide an airtight

seal.

4.3 Secure the driver to the enclosure with

the three screws. Do not overtighten.

(See Figure 2)

Figure 1. 102 Flush-Mount Grille Removal

2. Grille Replacement

2.1 Align the legs on the grille with the

openings in the speaker enclosure.

2.2 Press the grille upward so that the

teeth on the grille legs engage the teeth in

the speaker enclosure.

2.3 Push the grille upward until the

grille is flush with the mounting surface.

3. Driver Removal

3.1 Using a flat-blade screwdriver or a 1/4"

socket, remove the three screws holding

the driver in place.

Figure 2. 102 Flush-Mount Driver

Replacement

6

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: The following procedures are for the

transformered units only. The passive

versions do not have a tap selection switch,

transformer, or capacitor within the enclosure.

5. Wiring-Well Cover:

(Transformer and Capacitor Access)

5.1 To remove the wiring-well cover

located in the back of the enclosure, use a

flat-blade screwdriver or a 1/4" socket to

loosen the two screws that hold the metal

cover in place.

5.2 Swing the cover free to gain access to

the transformer and capacitor.

6. Front plate removal

(Access to tap selection switch)

6.1 Using a flat-blade screwdriver or a 1/4"

socket, remove the two screws that hold

the plastic front plate in position.

6.2 Lift the plate out to gain access to the

tap selection switch and wiring.

102® Surface-Mount Loudspeaker

1. Grille Removal

2.2 Fit the grille to two adjacent corners of

the enclosure.

2.3 Gently apply pressure to the two

remaining corners to fit the grille into the

enclosure.

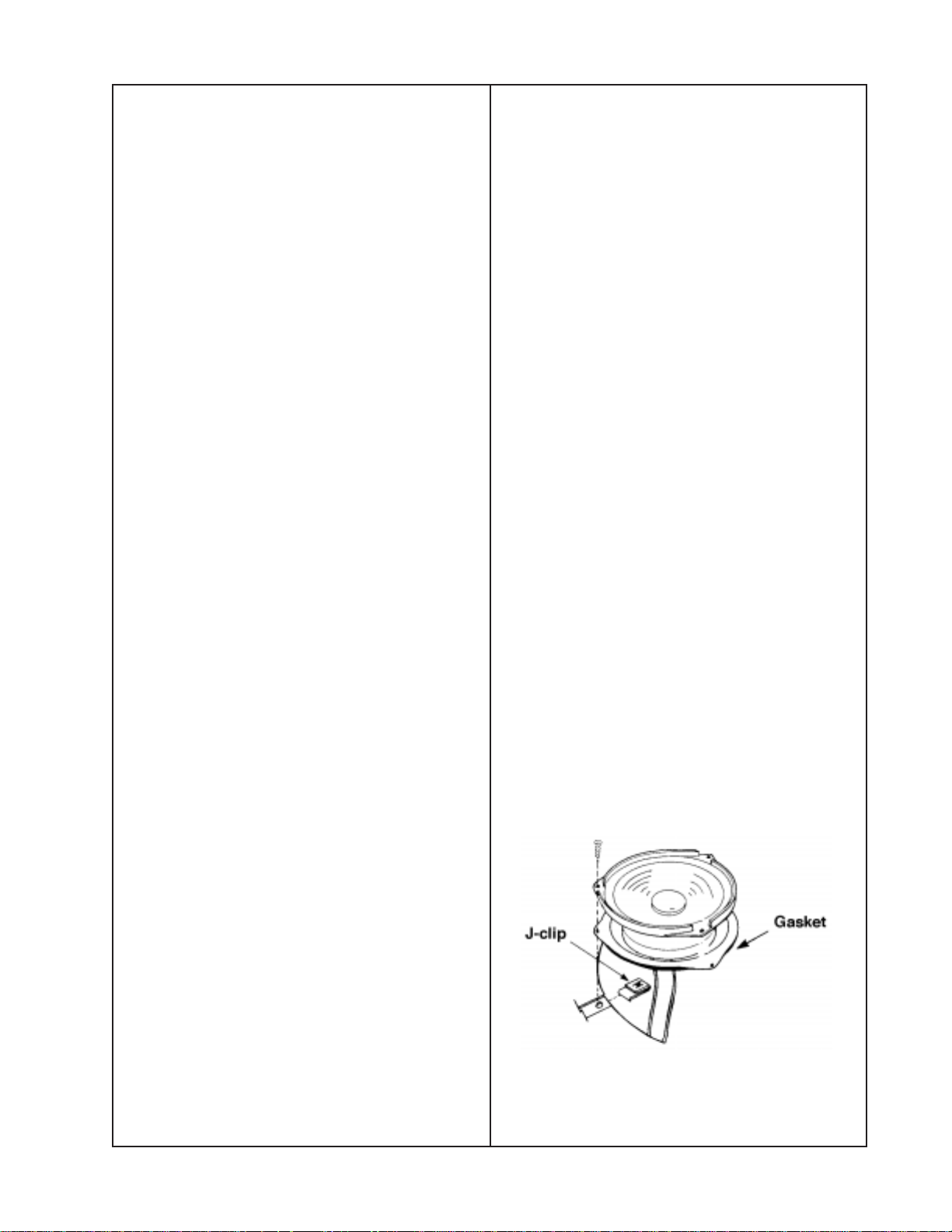

3. Driver Removal

3.1 Using a cross-head screwdriver,

remove the three screws that hold the

driver in place.

3.2 Carefully lift the driver out of the

enclosure and cut the wires as close

to the driver terminals as possible.

4. Driver Replacement

4.1 Strip the wires and connect them

to the replacement driver.

Note: Make certain that the red wire is

connected to the positive (+) terminal and

the black wire is connected to the

negative (-) terminal of the driver.

4.2 Align the driver and gasket to the

J-clips. Make sure the gasket is correctly

positioned behind the driver to provide an

airtight seal.

1.1 To remove the grille, take a small

flat-blade screwdriver or scribe and grasp

the edge of the grille at one of the corners.

1.2 Gently work the grille out of the retaining slot.

Note: There is no grille frame exposed.

You must grasp the grille on the metal

portion of the grille and not on the polystyrene, which is part of the speaker

enclosure.

2. Grille Replacement

2.1 To install the grille, first be sure that

the Bose® logo is facing the same way as

the print on the back of the enclosure.

4.3 Secure the driver to the J-clips with

the three screws. Do not overtighten.

(See Figure 3)

Figure 3. 102 Surface-Mount Driver

Replacement

7

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: The following procedures are for the

transformered units only. The passive

versions do not have a tap selection switch

or transformer within the enclosure.

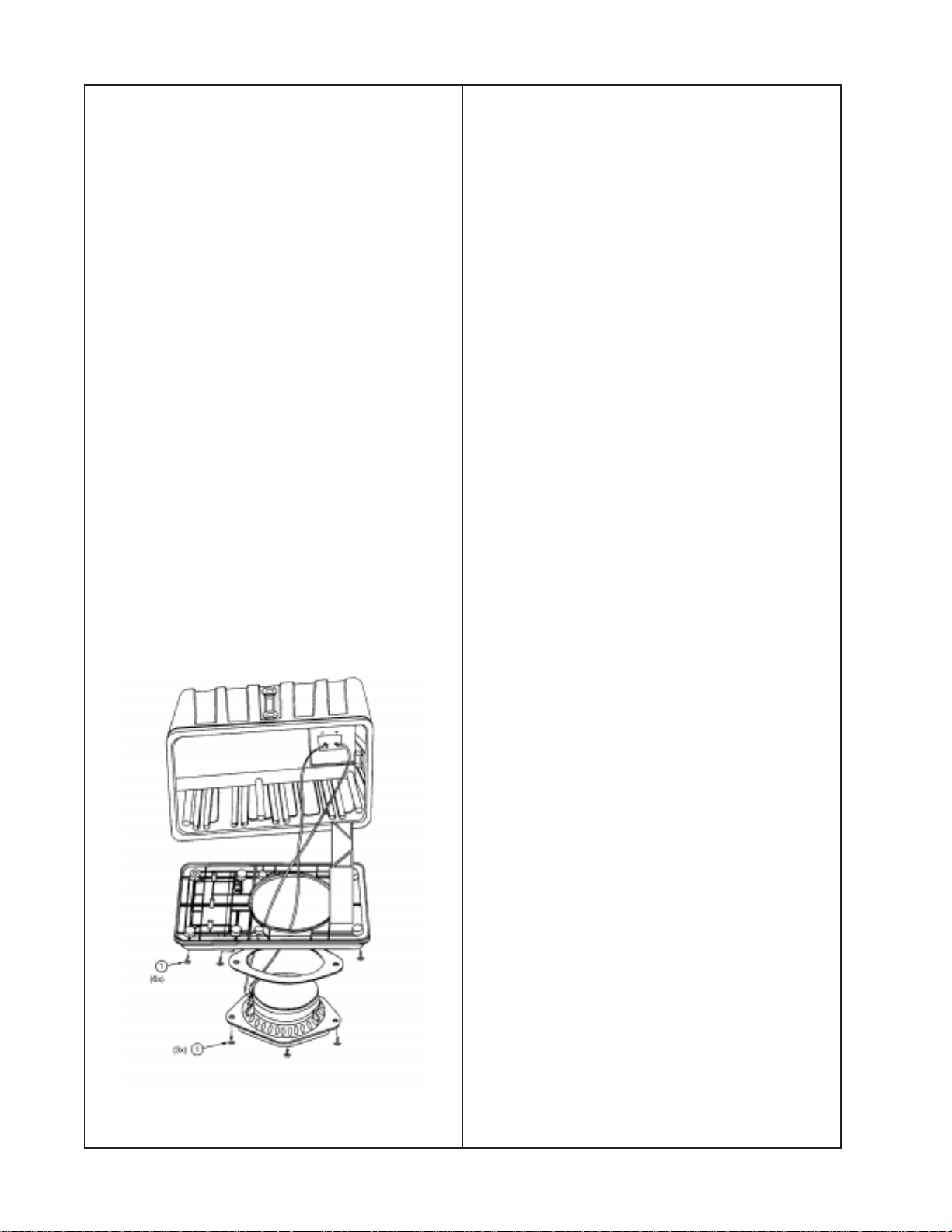

5. Baffle Removal

102

System Controller Procedures

1. Top Cover Removal

Note: Refer to Figure 5, 102 System

Controller Exploded View.

5.1 Remove the six screws (1) that hold

the baffle in place. Do not remove the

three screws holding the driver in place.

(See Figure 4)

5.2 Pry the baffle away from the enclosure

body. This can be accomplished by inserting the hook portion of a scribe or your

fingers into the ports and using this as a

grasping area to pry the two sections apart.

This will expose the tap selection switch

and transformer.

6. Baffle Replacement

6.1 Align the port side of the baffle to the

side of the enclosure that has the input

terminals.

6.2 Secure the baffle with the six screws.

1.1 Using a cross-tip screwdriver, remove

the six screws (1) securing the top cover,

(2) of the unit. There is one located on top,

two on the sides, and three on the back

panel.

1.2 Slide the top cover toward the rear of

the unit until it clears the ribs on the front

panel (3), then lift it straight off.

2. Top Cover Replacement

2.1 Align the top cover (2) with the rear

panel, and slide it down and forward until it

is in place against the front panel (3).

2.2 Secure the top cover using the six

screws (1) removed in procedure 1.1.

3. Front Panel Removal

3.1 Remove the top cover (2) using

procedures 1.1 and 1.2.

Figure 4. 102® Surface-Mount Baffle Assembly

3.2 Turn the unit over, and remove the

three screws (4) that secure the front panel

(3) to the chassis (5).

3.3 Slide the front panel off of the chassis.

4. Front Panel Replacement

4.1 Slide the front panel (3) onto the

chassis (5), aligning the holes for the LEDs

and push-switch.

4.2 Secure the front panel to the chassis

using the three screws (4) removed in

procedure 3.2.

4.3 Replace the top cover (2) using

procedures 2.1 and 2.2.

8

DISASSEMBLY/ASSEMBLY PROCEDURES

5. Main Circuit Board Removal

5.1 Remove the top cover (2) using

procedures 1.1 and 1.2.

5.2 Unplug the four cables from the con-

nectors on the circuit board (6) at JE02,

JE01, JE51, and JG01.

Note: You must first lift the tab on the

connector to release the wire.

5.3 Remove the front panel (3) using

procedures 3.1 through 3.3.

5.4 Remove the five screws (7) that

secure the circuit board to the chassis (5).

5.5 Slide the circuit board forward out

of the chassis.

6. Main Circuit Board Replacement

6.1 Align the circuit board (6) with the tabs

located on the chassis (5).

6.2 Replace the front panel (3) using

procedures 4.1 through 4.3.

6.3 Plug the four cables removed in

procedure 5.2 back into their respective

connectors.

6.4 Replace the top cover (2) using

procedures 2.1 and 2.2.

9

Loading...

Loading...