Bosch WT 11 AM1 E Installation And User Instructions Manual

Installation and Users Instructions

Gas water heaters

WT 11 AM1 E

6 720 607 800 (2016/02) GB

Read installation manual prior to installation of this unit!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation room must fulfill the ventilation requirements!

Installation by an authorised person only!

6 720 607 800 (2016/02)

2 | Table of contents

Table of contents

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety Instructions . . . . . . . . . . . . . . . . . . . . 3

2 Appliance specifications . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Declaration of conformity with relevant EEC

regulations . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Technical Identification code . . . . . . . . . . . . 4

2.3 Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Special Accessories . . . . . . . . . . . . . . . . . . . 4

2.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Electrical layout . . . . . . . . . . . . . . . . . . . . . . . 6

2.8 Operational instructions . . . . . . . . . . . . . . . . 6

2.9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . 7

2.10 Product data on energy consumption . . . . . 8

3 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Before operating the appliance . . . . . . . . . . 9

3.2 Connect and disconnect the appliance . . . . 9

3.3 Regulation of water temperature . . . . . . . 10

3.4 Breakdown indication . . . . . . . . . . . . . . . . 10

3.5 Purge appliance . . . . . . . . . . . . . . . . . . . . . 10

4 Flue accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Flue Accessories . . . . . . . . . . . . . . . . . . . . 11

4.1.1 Vertical flue . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.2 Fitting the restrictor plate . . . . . . . . . . . . . 11

4.1.3 Horizontal flue . . . . . . . . . . . . . . . . . . . . . . 13

4.1.4 Fitting the restrictor plate . . . . . . . . . . . . . 13

5 Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Important . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Selection of location for installation . . . . . 15

6.3 Minimum distances . . . . . . . . . . . . . . . . . . 16

6.4 Installation of support bar . . . . . . . . . . . . . 16

6.5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.6 Water connection . . . . . . . . . . . . . . . . . . . 17

6.7 Gas connection . . . . . . . . . . . . . . . . . . . . . 17

6.8 Inlet/exhaust pipe installation . . . . . . . . . 17

7 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . 18

7.1 Connection . . . . . . . . . . . . . . . . . . . . . . . . 18

7.2 Power cable . . . . . . . . . . . . . . . . . . . . . . . . 18

8 Gas regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8.1 Factory regulations . . . . . . . . . . . . . . . . . . 18

8.2 Pressure regulation . . . . . . . . . . . . . . . . . . 19

8.3 Changing gas type . . . . . . . . . . . . . . . . . . . 20

9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.1 Periodic maintenance tasks . . . . . . . . . . . 21

9.2 Startup after maintenance . . . . . . . . . . . . 21

9.3 Changing fuses (control box) . . . . . . . . . . 21

9.4 Temperature range selection . . . . . . . . . . 21

10 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

11 Environmental protection . . . . . . . . . . . . . . . . . . . 23

6 720 607 800 (2016/02)

Key to symbols and safety instructions | 3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 Safety Instructions

If there is a smell of gas:

▶ Close the gas valve.

▶ Open windows.

▶ Do not connect any electrical apparatus.

▶ Extinguish any naked flames.

▶ Phone the gas company or an authorized technician from a

safe distance.

If there is a smell of burnt gases:

▶ Disconnect the appliance.

▶ Open doors and windows.

▶ Inform an installation company.

Fitting, modifications

▶ The fitting and modification of the installation of the

appliance must be carried out only by an authorized

technician.

▶ The pipes carrying burnt gases must not be modified.

▶ Do not close or reduce air circulation holes.

Maintenance

▶ The user must maintain and periodically service the

appliance.

▶ The user is responsible for the safety and environmental

compatibility of the installation.

▶ The appliance should be serviced annually.

▶ Only original spare parts should be used.

Explosive and inflammable materials

▶ Inflammable materials (paper, solvents, ink, etc.) should

not be stored near the appliance.

Combustion air and ambient air

▶ To avoid corrosion, combustion air and ambient air should

be free of aggressive substances (for example halogenated

hydrocarbons containing chlorine and fluoride

composites).

Client information

▶ Inform the client about the function and operation of the

appliance.

▶ Caution clients against performing modifications or repairs

themselves.

Safety of electrical appliances for

domestic use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

prevent hazards from occurring when using

electrical appliances:

“This appliance can be used by children of 8

years and older, as well as by people with

reduced physical, sensory or mental

capabilities or lacking in experience and

knowledge, if they are supervised and have

been given instruction in the safe use of the

Warnings in this document are identified by

a warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

6 720 607 800 (2016/02)

4 | Appliance specifications

appliance and understand the resulting

dangers. Children must not play with the

appliance. Cleaning and user maintenance

must not be performed by children without

supervision.”

“If the power cable is damaged, it must be

replaced by the manufacturer, its customer

service department or a similarly qualified

person, so that risks are avoided.”

2 Appliance specifications

2.1 Declaration of conformity with relevant EEC

regulations

This appliance fulfills European directive requirements 2009/

142/EEC, 92/42/EEC, 2006/95/EEC, 2004/336/EEC and

corresponds to the specifications described in the

corresponding EEC certificate of proof.

2.2 Technical Identification code

[W] Gas water heater

[T] Thermostatic

[11] Capacity (l/min)

[A] Room sealed

[M] Forced exhaust

[1] Multi-point, normal pressure

[E] Electrical Ignition

[31] GPL number indicator

2.3 Appendices

• Gas water heater

• Fitting elements

• Set of flow-restrictor plates

• Documentation

• Gas accessory ¾ " - ½ "

2.4 Description

• Wall mounted appliance

•GPL burner

• Electronic ignition

• Water flow regulator

• Heat sensors to monitor temperature of water entering and

leaving appliance

• Safety Mechanisms

– Verification of flame by ionization

– Differential pressostat fan control

– Security temperature regulator

• Electrical connection: 230 V, 50 Hz

2.5 Special Accessories

• Conversion kit to adapt natural gas to butane/propane and

vice-versa.

• Exhaust accessories

Model Country Category

WT 11 PT, ES, GB, IT, CH, HR II

2H3+

DE II

2E3B/P

NL II

2L3B/P

FR, LU II

2E+3+

BE I

2E+

I

3+

Type B32, C

12x

, C

32x

, C42, C52, C62, C

82x

Table 2

W T 11 A M1 E31

Table 3

6 720 607 800 (2016/02)

Appliance specifications | 5

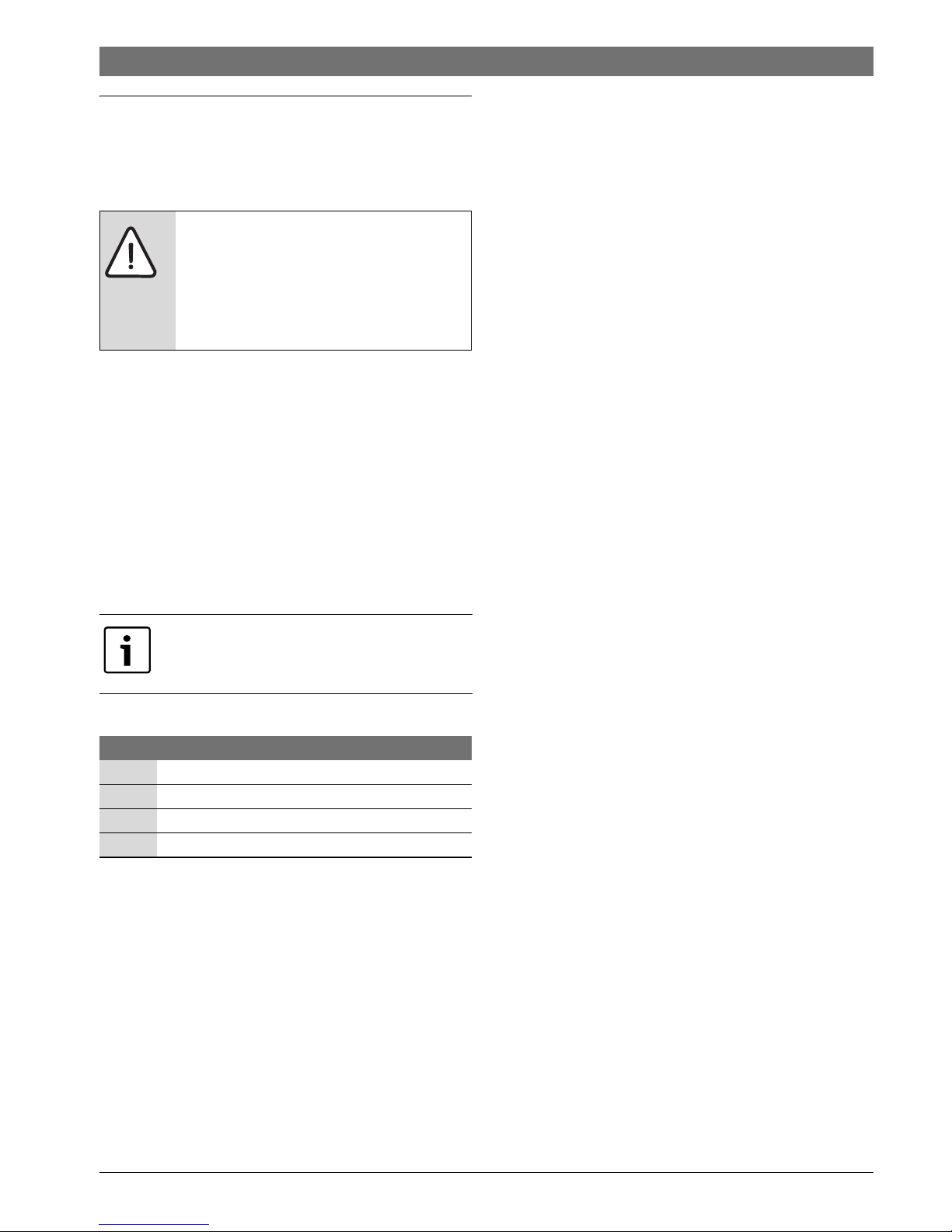

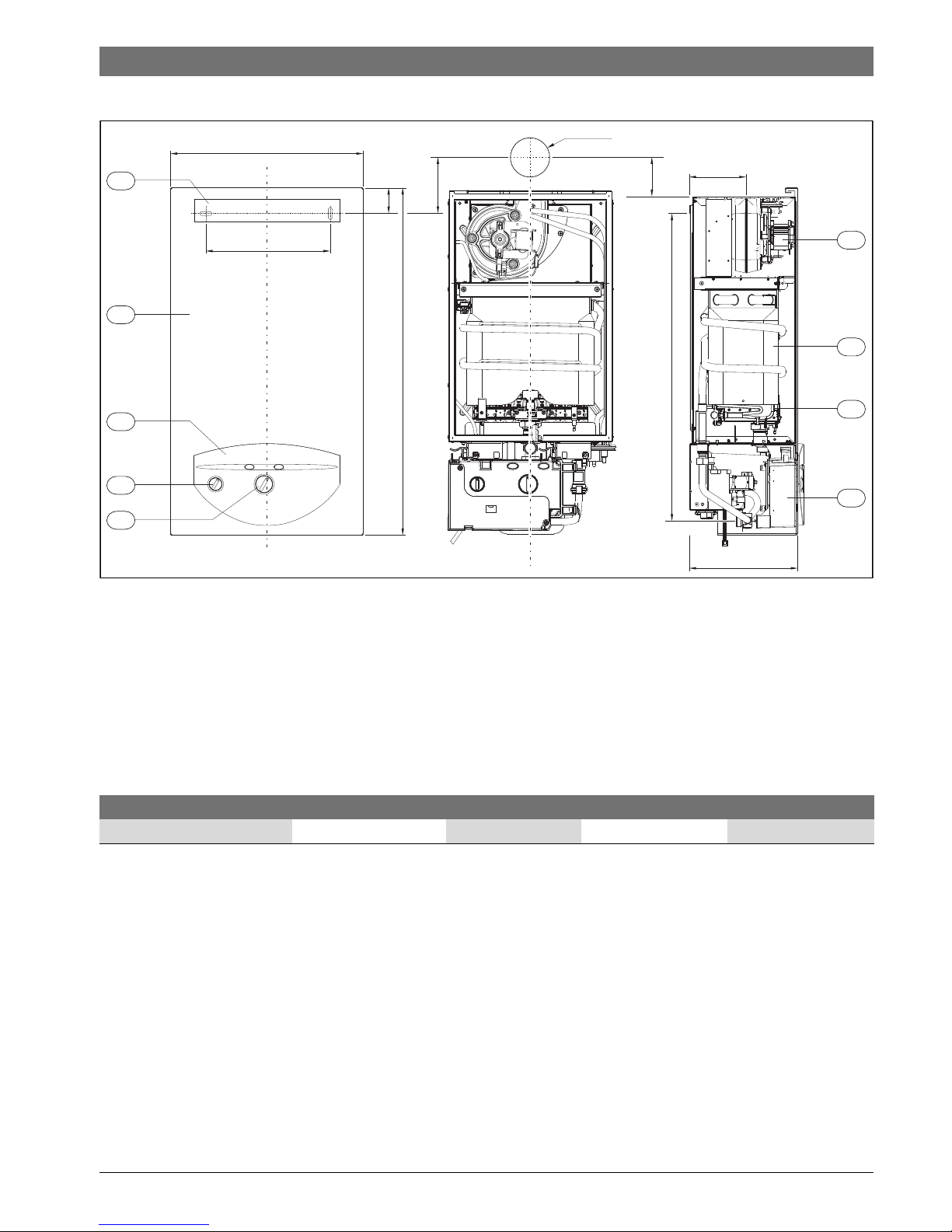

2.6 Dimensions

Fig. 1

[1] Front cover

[2] Mirror

[3] On/off switch

[4] Fan

[5] Heat exchanger

[6] Burner

[7] Control box

[8] Temperature selector

[9] Fixing bracket

1

4

5

6

7

3

8

2

A

B

D

C

6720607298-04.2Av

9

65

90

Ø115

134

230

114

A B C D

WT11 340 670 220 65

Table 4 Dimensions

6 720 607 800 (2016/02)

6 | Appliance specifications

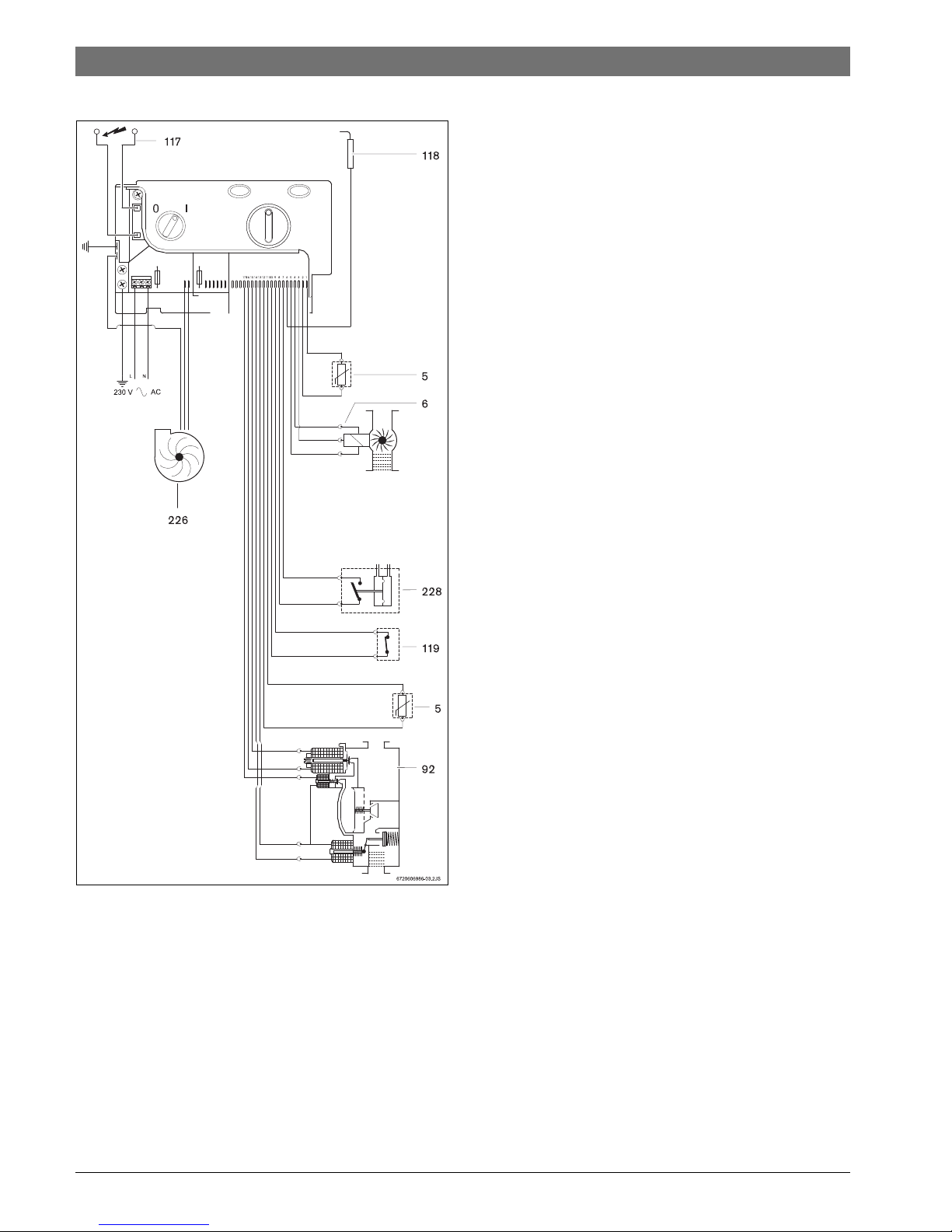

2.7 Electrical layout

Fig. 2 Electrical layout

[5] Heat sensor

[6] Water flow sensor

[92] Gas valve

[117] Ignition electrode

[118] Ionization electrode

[119] Temperature limiter

[226] Fan

[228] Differential pressostat

2.8 Operational instructions

Hot water

Open the gas and water valves and ensure that all joints are

hermetic.

Place the main switch (Fig. 3, [3]) in the operating position

(chapter 3.2), so that the appliance is quickly ready for use.

When a hot tap is opened, the water flow sensor should be in

(Fig. 2, [6]) send a signal to the control unit. This signal

initiates the following:

•The fan starts working

• Simultaneously, sparks are produced and the gas valve

(Fig. 2, [92]) opens.

•The burner lights

• The ionization electrode (Fig. 2, [118]) controls the state

of the flame

• The water temperature is controlled automatically by the

sensors/controllers according to the temperature selected

Security cut-off when safety period is surpassed

If a flame is not achieved within the stipulated security period

(15 sec), a security cut-off will occur.

The presence of air in the gas inlet pipe (when the appliance is

used after long periods of inactivity for example) may delay

ignition.

In this case, if the attempts to ignite go on too long, the security

mechanisms prevent operation.

Security cut-off due to excessive water heating

The control unit detects the heating temperature via a NTC

resistor located in the hot water exit tube and the temperature

limiter located in the heat exchanger. If it detects an excessive

temperature it provokes a security cut-off.

Security cut-off due to deficient exhaust conditions

(pressostat)

The pressostat detects pressure differences outside the fan

and effects a security cut-off when it detects deficient exhaust

conditions.

Restarting after security cut-off

To restart the appliance following a security cut-off:

▶ Press the reset button.

6 720 607 800 (2016/02)

Appliance specifications | 7

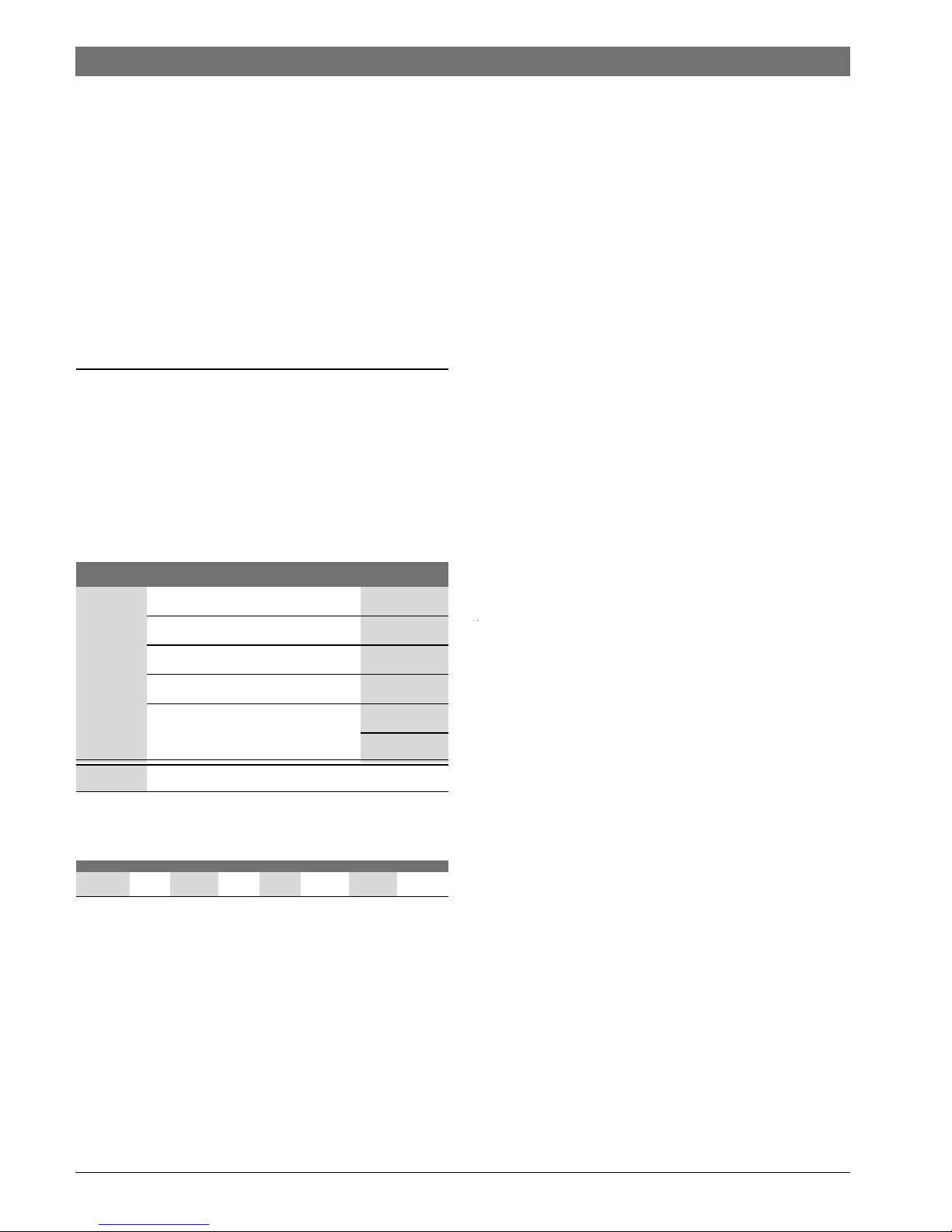

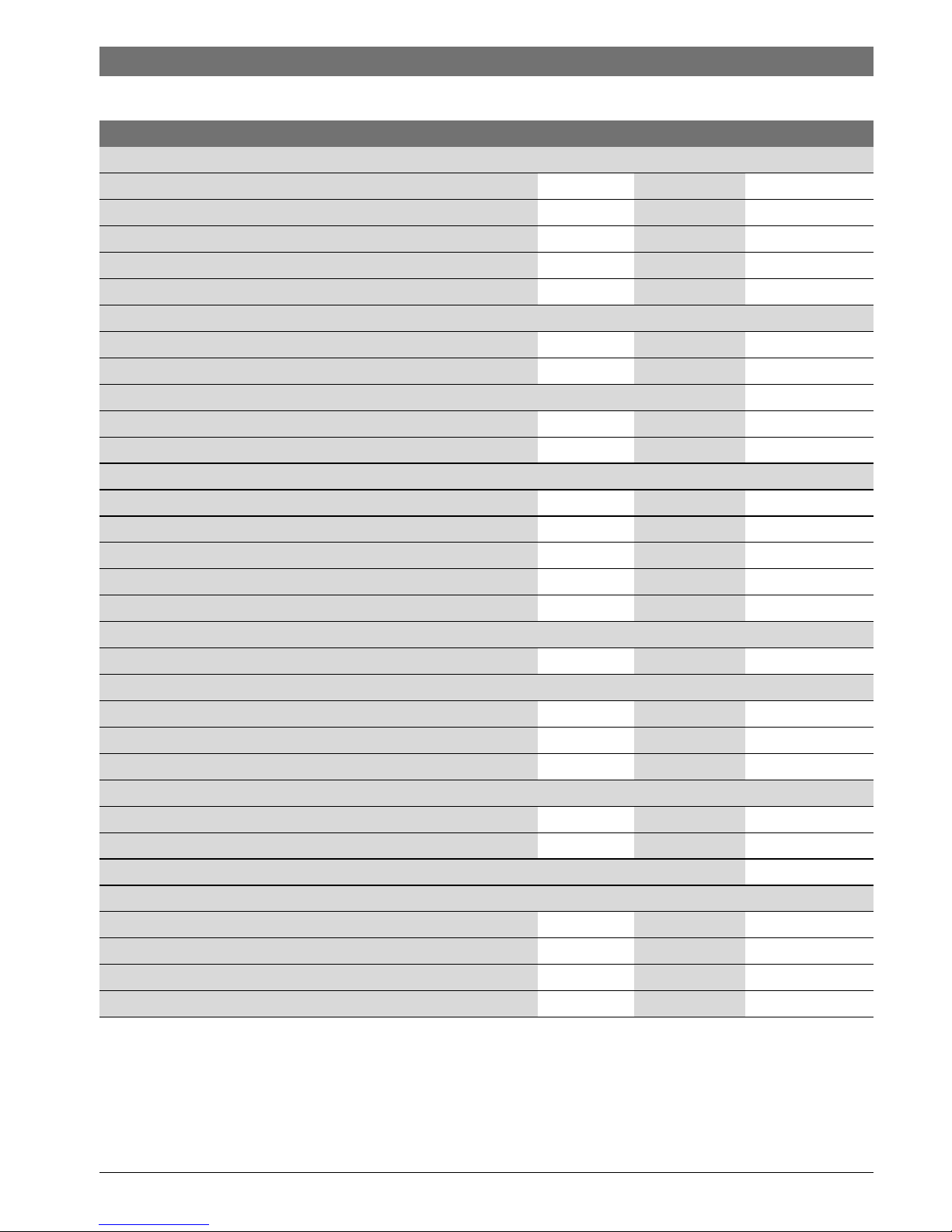

2.9 Technical data

Technical characteristics Symbols Units WT11

Power

1)

1) GPL: Butane 45.65 MJ/kg (12.7 kWh/kg) – Propane 46.34 MJ/kg (12.9 kWh/kg)

Usable power Pn kW 19,3

Minimum usable power Pmin kW 7

Regulatory field 7 - 19,3

Nominal power Qn kW 21,8

Minimum nominal power Qmin kW 9

Gas data

Inlet pressure

G.P.L. (Butane/Propane) G30/G31 mbar 28-30/37

Consumption*

G.P.L. (Butane/Propane) G30/G31 kg/h 1,9

Gas connection 3/4”

Water data

Maximum admissible pressure

2)

2) In order to account for the dilation effect of water, it should not exceed this value.

pw bar 12

Minimum working pressure pwmin bar 0,3

Startup flow l/min 3,2

Flow corresponding to a temperature rise of 25 °C l/min 11

Water connection 3/4”

Smoke circuit

Combustion gas flow

3)

3) For nominal calorific power

kg/h 50

Temperature of gases at extractor grill

Using maximum possible drive compression (4 m) °C 170

Using minimum drive compression (0,37 m) °C 220

Flue socket dia. mm Ø60/100

Electrical circuit

Tension (50 HZ) V 230

Maximum power limit W65

Type of protection IPX4D

General Data

Weight (excluding packaging) kg 20

Height mm 670

Width mm 340

Depth mm 220

Table 5

6 720 607 800 (2016/02)

8 | Appliance specifications

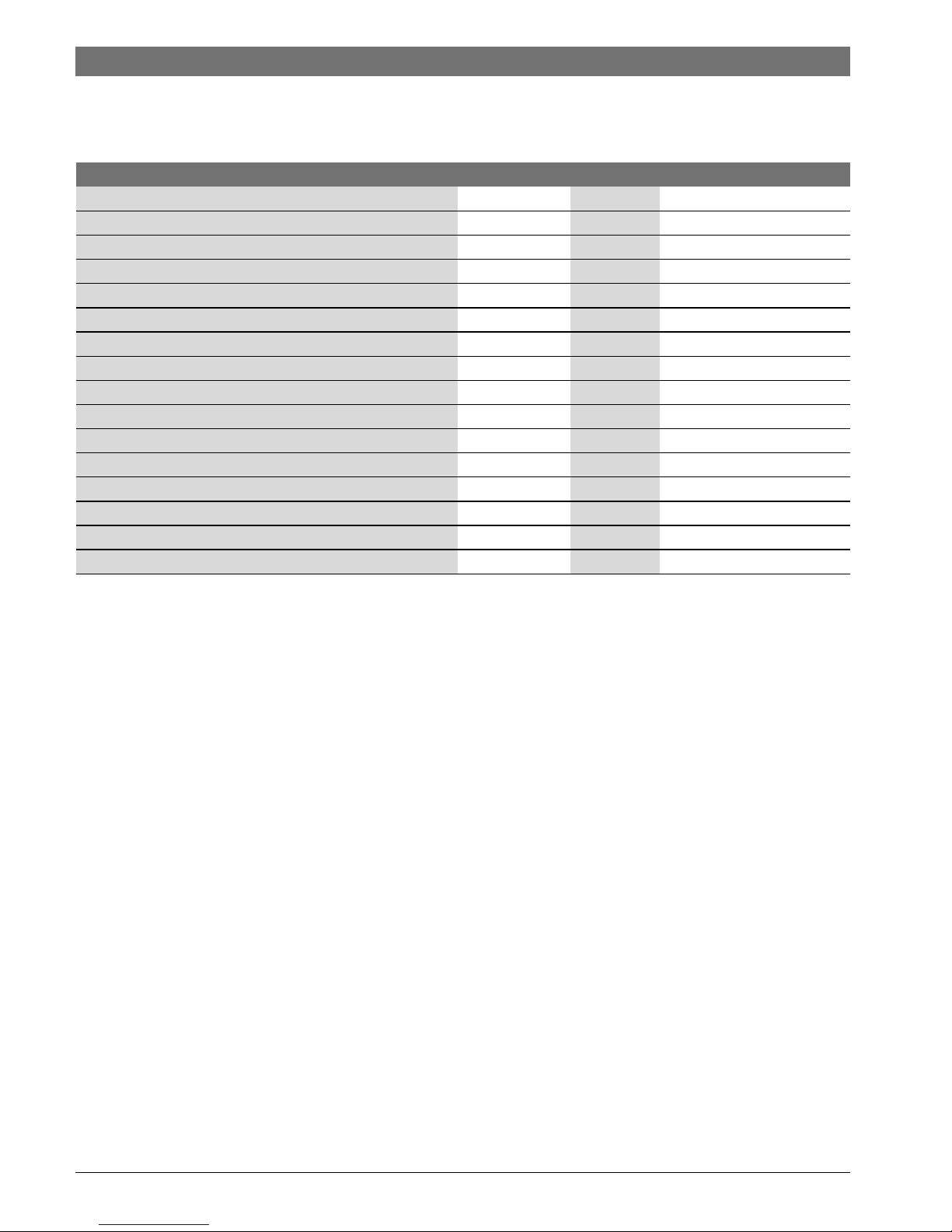

2.10 Product data on energy consumption

The following product data complies with the requirements of EU Regulations 811/2013, 812/2013, 813/2013 and 814/2013

as supplement to the Directive 2010/30/EU.

Product data Symbol Unit 7701411040

Product type – – WT 11 AM1 E 31

Emissions of nitrogen oxides NO

x

mg/kWh 171

Sound power level, indoors L

WA

dB(A) 54

Declared load profile – –S

Other load profiles – –M

Water heating energy efficiency class – –A

Water heating energy efficiency

wh

%54

Water heating energy efficiency (other load profiles)

wh

%63

Annual electricity consumption AEC kWh 27

Annual electricity consumption (other load profiles) AEC kWh 35

Daily electricity consumption (average climate conditions) Q

elec

kWh 0,125

Annual fuel consumption AFC GJ 3

Annual fuel consumption (other load profiles) AFC GJ 7

Daily fuel consumption Q

fuel

kWh 3,978

Smart control enabled? – –No

Thermostat temperature (factory setting) T

set

°C –

Table 6 Product data on energy consumption

6 720 607 800 (2016/02)

Use | 9

3Use

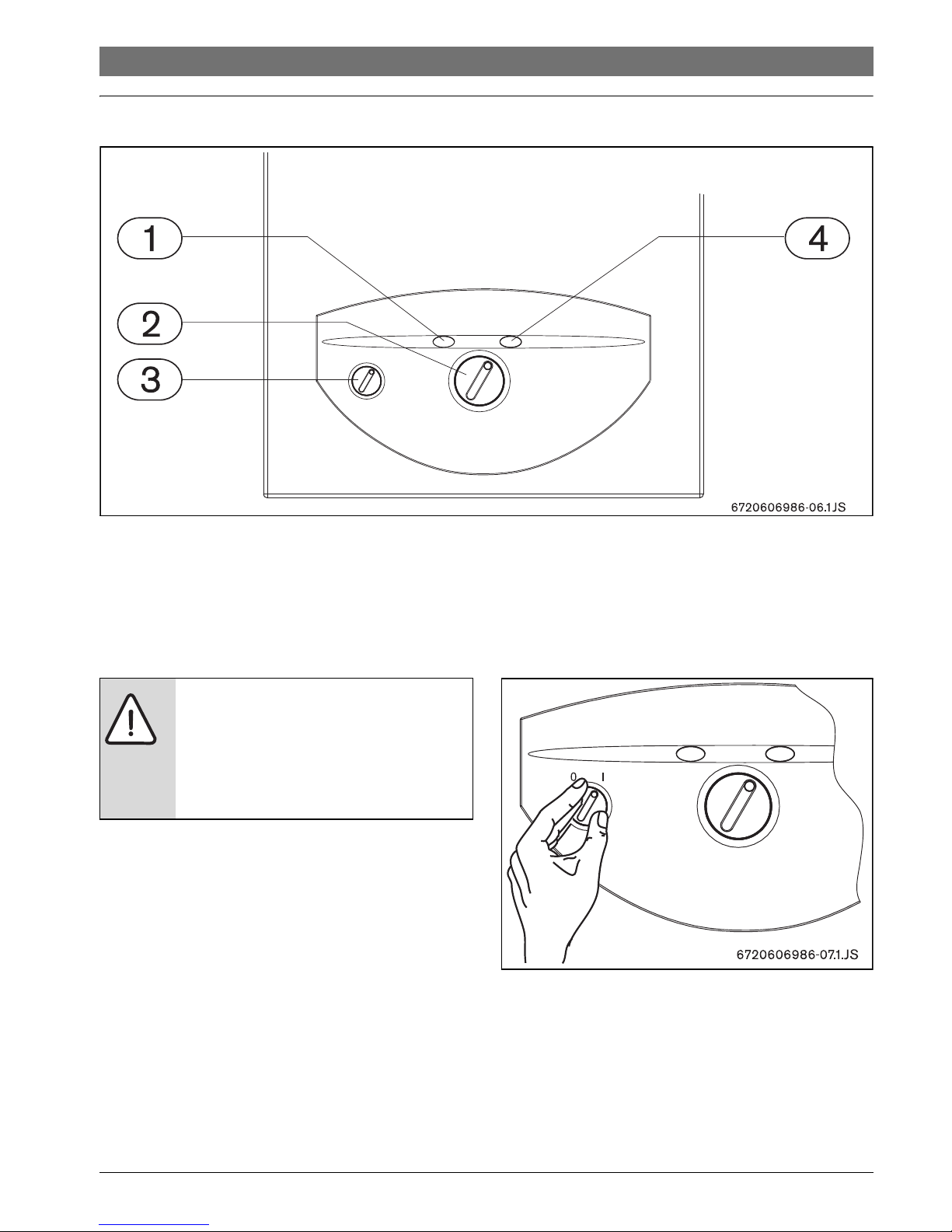

Fig. 3

[1] Reset button

[2] Temperature selector

[3] Main switch

[4] Burner state key

3.1 Before operating the appliance

▶ Ensure that the type of gas specified on the characteristics

panel is the same as that provided on the site.

▶ Open the gas valve.

▶ Open the water valve.

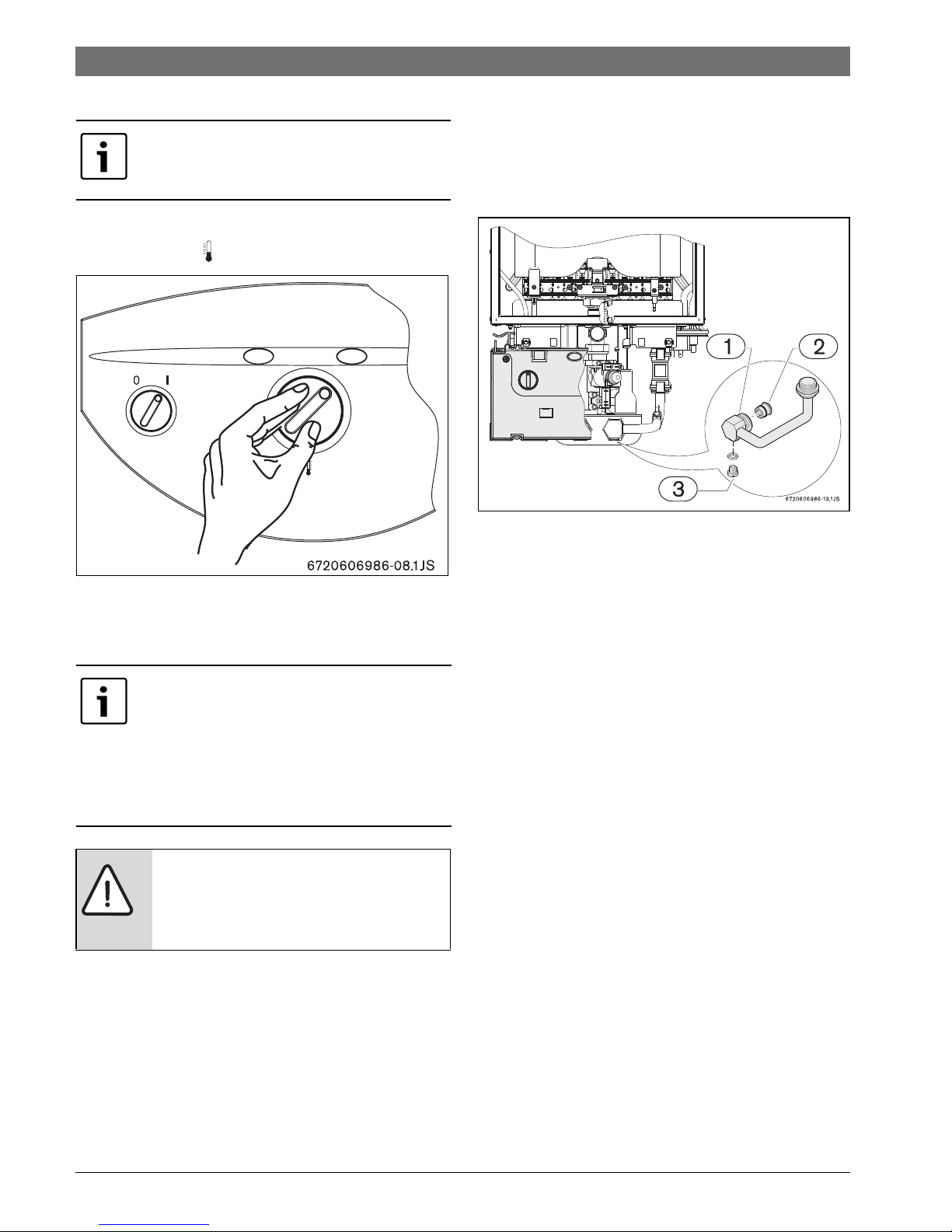

3.2 Connect and disconnect the appliance

Connect

▶ Turn the main switch to position I.

The panel shows the temperature to which the water will be

heated.

Fig. 4

Disconnect

▶ Turn the main switch to position 0.

CAUTION:

▶ The initial startup of the heater must be

realized by a qualified technician, who

will provide the client with all the

information necessary for its correct

usage.

6 720 607 800 (2016/02)

10 | Use

3.3 Regulation of water temperature

To regulate the emitted water temperature:

▶ turn the selector , to the desired value.

Fig. 5

▶ When the desired value has been selected, open the hot

water tap.

3.4 Breakdown indication

The appliance incorporates a breakdown indication system.

Anomalies are detected by the red light on the reset button

(Fig. 3, [1]). The appliance can only be restarted once the

fault has been repaired and the reset button pressed.

To identify the fault consult chapter 10 in this manual.

3.5 Purge appliance

If there is a risk of freezing, proceed as follows:

▶ Loosen the purge screw (Fig. 6) located on the water inlet

pipe.

▶ Empty the appliance of all water.

Fig. 6 Purge screw

The temperature value on the regulator

corresponds to the emission temperature.

If the temperature selected is superior to that

permitted by the power of the appliance, the

water may not achieve the desired

temperature. In this case, the exit flow should

be adjusted:

▶ Close the hot water tap until the desired

value is acquired.

CAUTION:

▶ The area in front of the burner can reach

very high temperatures, and there is a

risk of burning on contact.

6 720 607 800 (2016/02)

Flue accessories | 11

4Flue accessories

4.1 Flue Accessories

Flue pipes have an internal diameter of 60 mm and external

diameter of 100 mm.

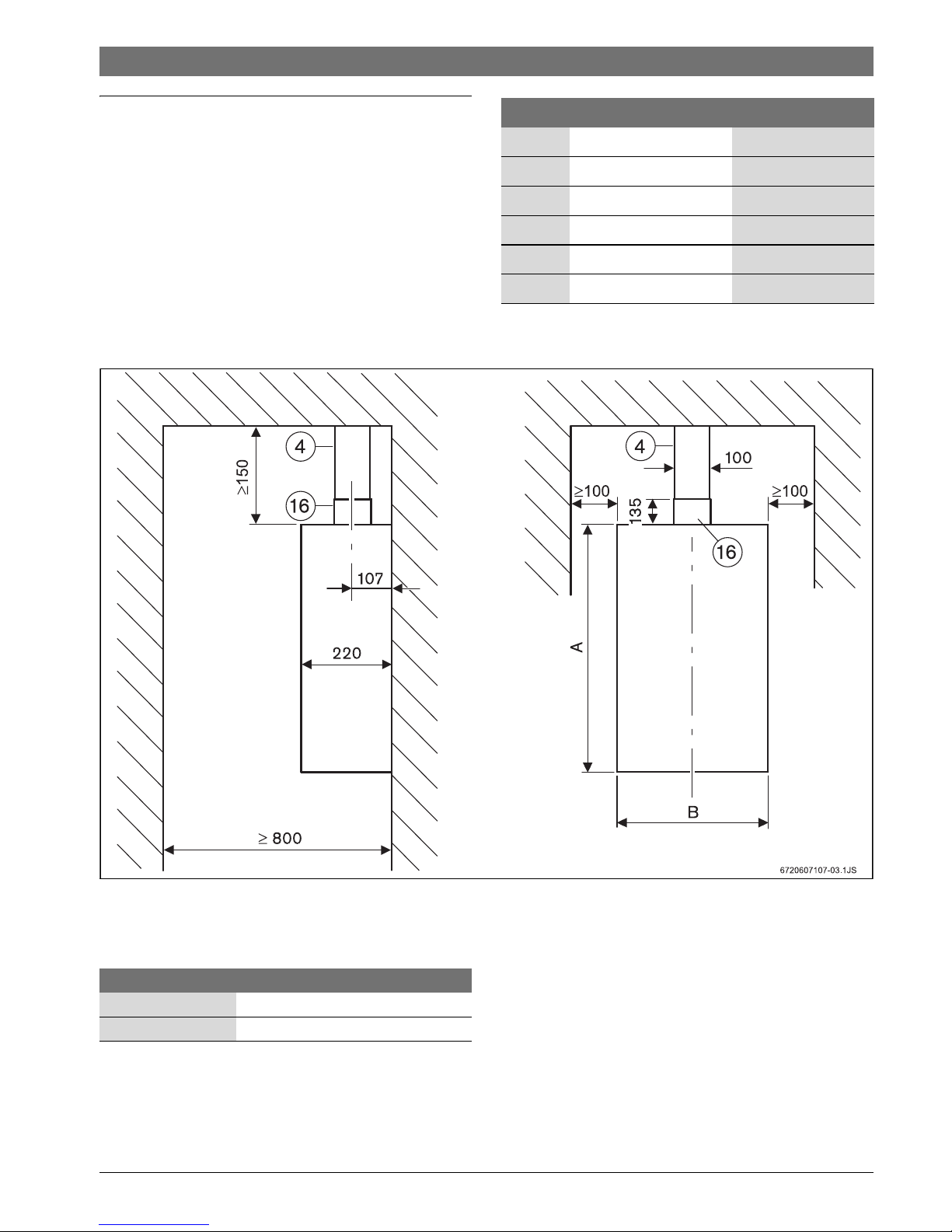

4.1.1 Vertical flue

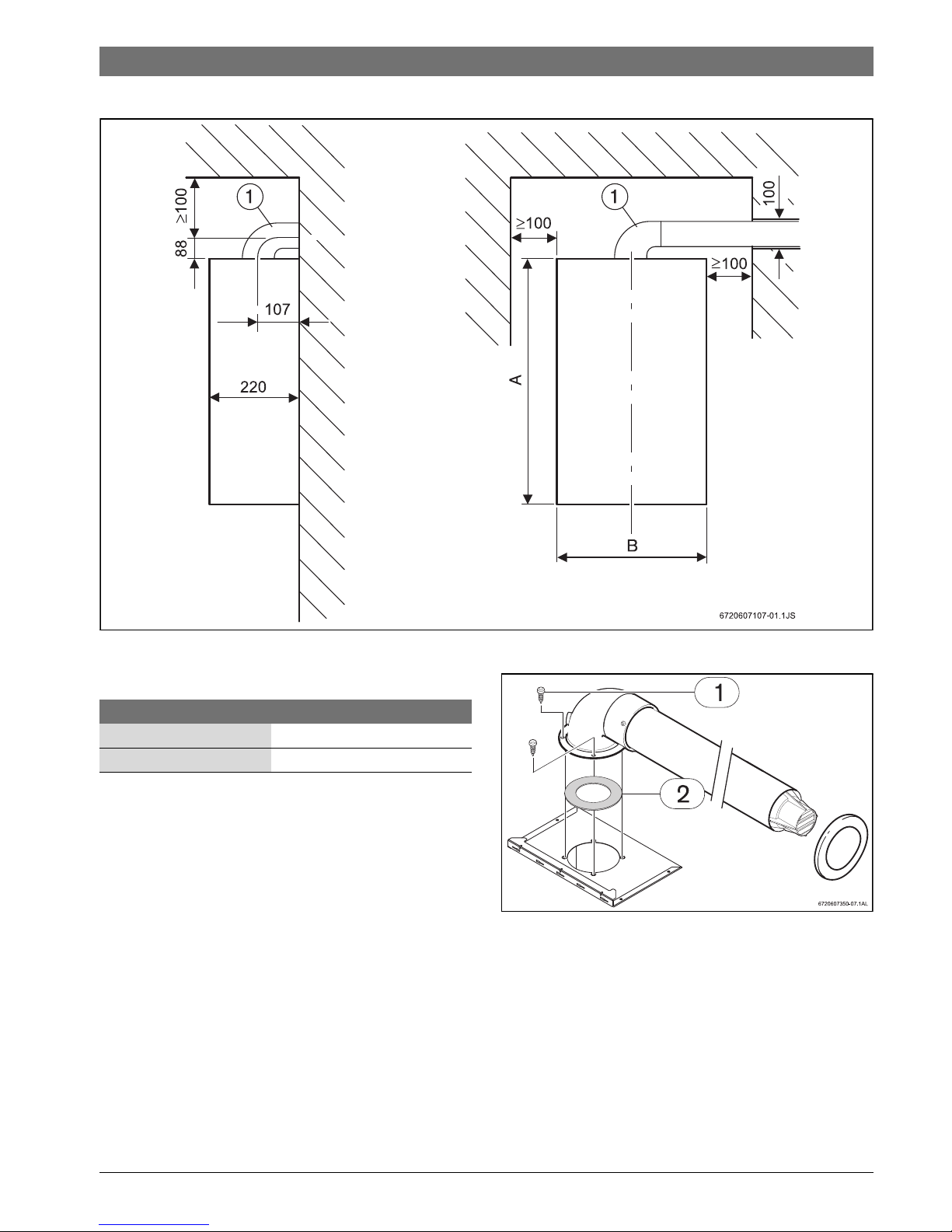

Fig. 7 Recommended clearance (mm)

[4] AZ 396

[16] Adapter concentric Ø 60/100mm

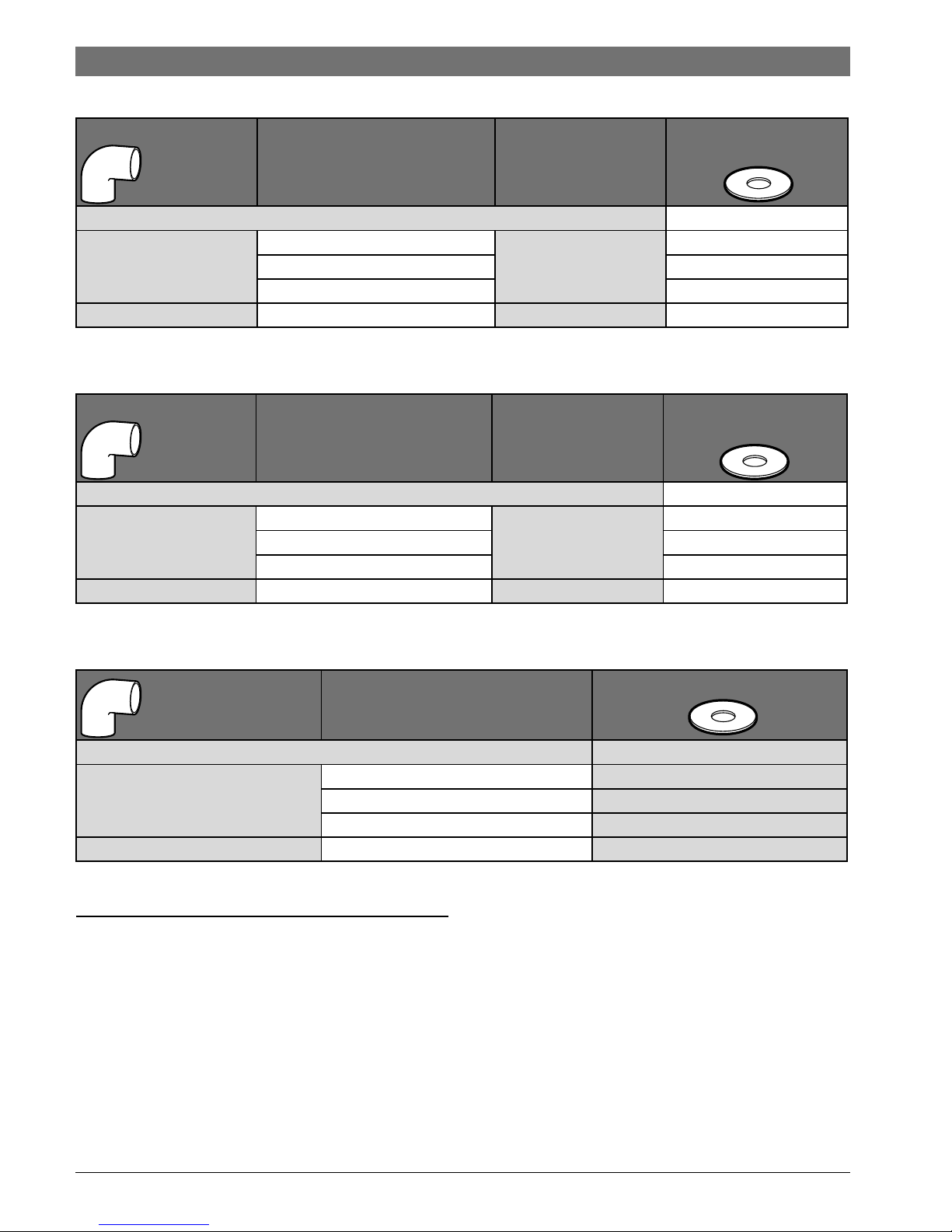

4.1.2 Fitting the restrictor plate

Depending on flue exhaust and installations conditions, a

restrictor plate may need to be fitted (Fig. 8) under the

accessory (table 11 and 12).

In order to assure a good appliance functioning, correct

restrictor plates should be used.

Type Description TTNR

AZ388 Horizontal set 7 716 050 063

--- Flue pipe 350 mm 7 736 995 059

--- Flue pipe 750 mm 7 736 995 063

--- Elbow 45° 7 736 995 071

--- Elbow 90° 7 736 995 079

AZ396 Vertical set 7 716 050 071

Table 7 Flue accessories Ø60-100mm

WT11

A 670

B 340

Table 8

6 720 607 800 (2016/02)

12 | Flue accessories

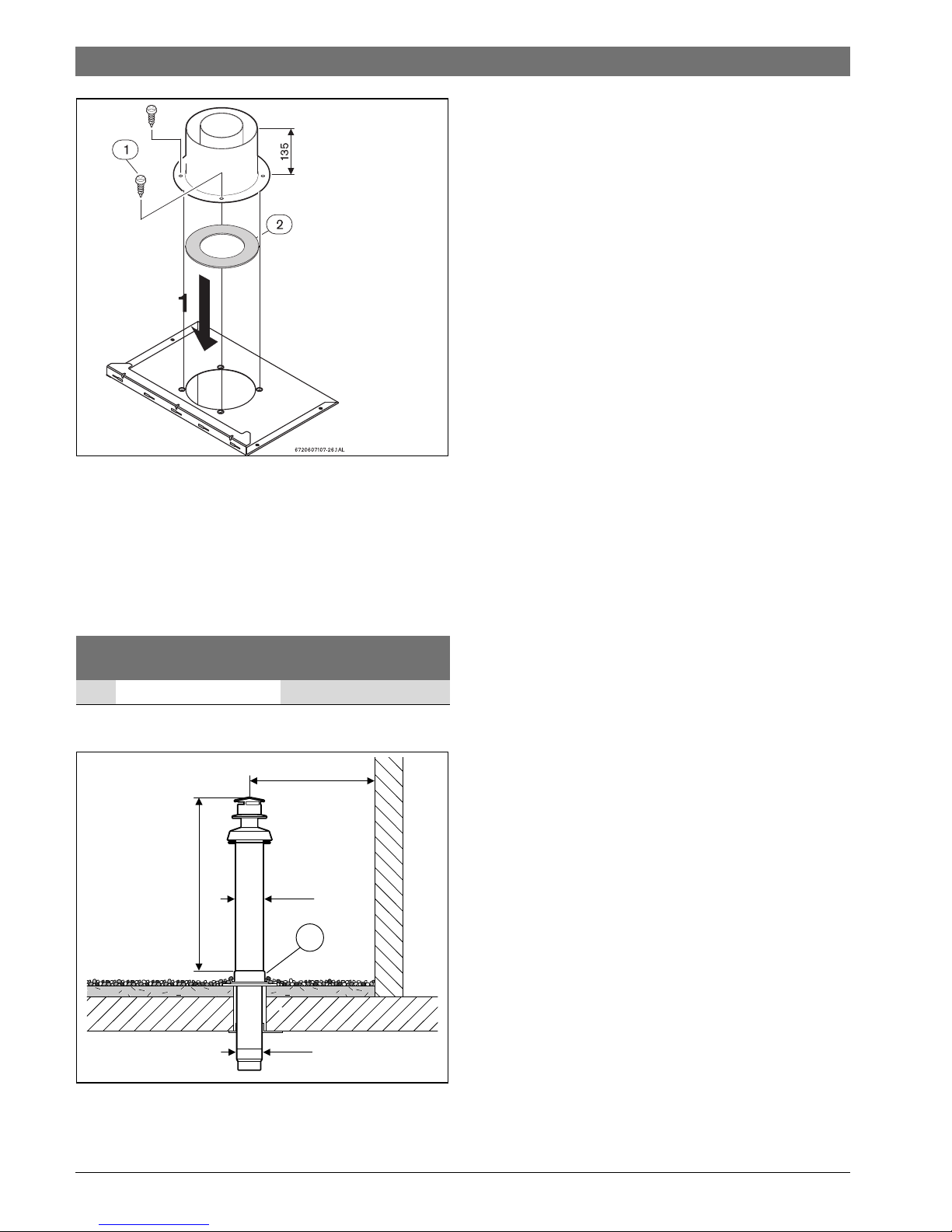

Fig. 8 Restrictor plate

▶ Loosen accessory fixing screws (Fig. 11, [1]).

▶ Place restrictor plate (Fig. 11, [2]) between the

accessory and the appliance.

▶ Reassemble the accessory in the appliance using the 4

screws (Fig. 11, [1]).

Security distance, flat roof

Fig. 9 Recommended clearance (mm)

inflammable material

no

inflammable material

X 1500 500

Table 9

Ø134

Ø125

X

865

6 702 604 882-02.

17

6 720 607 800 (2016/02)

Flue accessories | 13

4.1.3 Horizontal flue

Fig. 10 Recommended clearance (mm)

[1] AZ 388

4.1.4 Fitting the restrictor plate

Depending on flue exhaust and installations conditions, a

restrictor plate may need to be fitted (Fig. 11) under the

accessory (table 11 and 12).

In order to assure a good appliance functioning, correct

restrictor plates should be used.

Fig. 11 Restrictor plate

▶ Loosen accessory fixing screws (Fig. 11, [1]).

▶ Place restrictor plate (Fig. 11, [2]) between the accessory

and the appliance.

▶ Reassemble the accessory in the appliance using the 4

screws (Fig. 11, [1]).

WT11

A 670

B 340

Table 10

6 720 607 800 (2016/02)

14 | Regulation

Flue configuration C

12

- horizontal, with accessory AZ388 and 7736995083

Flue configuration C32 - vertical, with accessory AZ396

Flue configuration C52 - max. length for 80/80: 6 m

5Regulation

The currently applicable country standards must be observed.

L

[mm]

L

max

[mm]

WT.11

1 x 90° 1500 4000 Ø 78

1500 - 2500 Ø 78

2500 - 4000 Ø 78

2 x 90° 2000 2000 Ø 86

Table 11

L

[mm]

L

max

[mm]

WT.11

0 x 90° 1850 3850 Ø 76

1850 - 2850 Ø 76

2850 - 3850 Ø 76

2 x 90° 2850 2850 Ø 76

Table 12

L [mm]

WT11

0 x 90° 1850 Ø 76

1850 - 2850

Ø 76

2850 - 6000

Ø 76

2 x 90° 4000 Ø 76

Table 13

90°

90°

90°

6 720 607 800 (2016/02)

Installation | 15

6 Installation

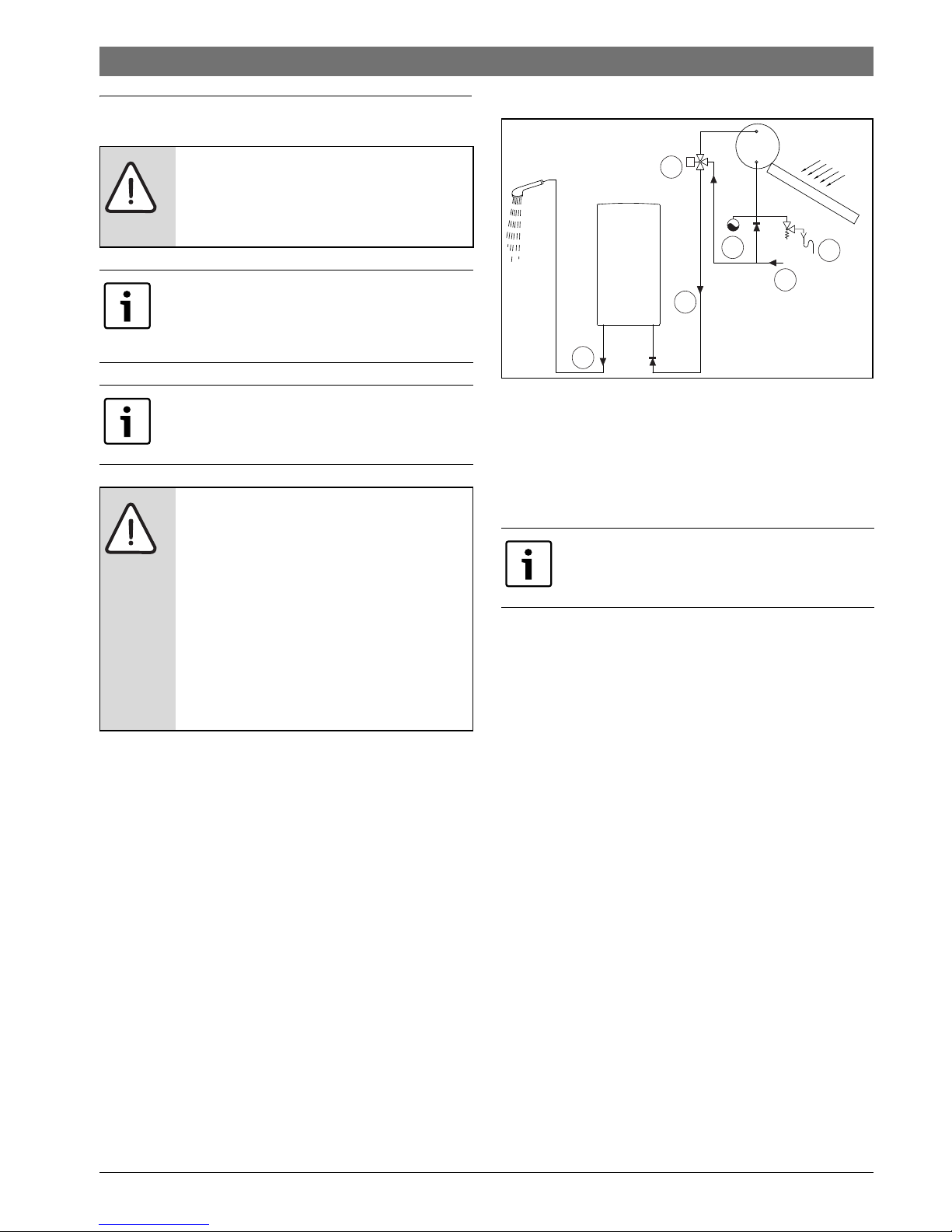

Solar installations

Fig. 12 Solar installation

[1] Cold water

[2] Hot water

[3] Thermostatic valve

[4] Expansion vessel

[5] Safety unit

6.1 Important

▶ Before installation, consult the gas company and current

legislation regarding gas appliance and site ventilation.

▶ Install a gas shut-off tap as close to the appliance as

possible.

▶ After connection to the gas main, the appliance should be

carefully cleaned and tested for leaks; To avoid damage

from excess pressure in the automatic gas regulator, this

should be carried out with the gas valve shut.

▶ Ensure that the appliance installed is suitable for the type

of gas provided.

▶ Ensure that the flow and pressures for the regulator

installed are those indicated for the consumption of the

appliance (see technical data in table 5).

6.2 Selection of location for installation

Considerations relevant to location

▶ Fulfil requirements specific to each country.

▶ The heater must not installed above a source of heat.

▶ Respect the minimum installation measurements indicated

in Fig. 13.

DANGER: Explosion

▶ Always turn off the gas cock before

carrying out any work on components

which carry gas.

Installation, electrical connection, gas

installation, connection of inlet and exhaust

pipes and initial startup must be realized

exclusively by authorized personnel.

The heater can only be used in the countries

indicated on the appliance type plate.

CAUTION: Assure that inlet water into the

appliance does not exceed 60 °C, for

example when used as a backup for solar

installations.

▶ A 3-way valve or thermostatic valve

(adjusted to values lower than 60 °C)

must be installed before the appliance if

inlet water temperature exceeds this

limit.

▶ Assure that the installation contains an

expansion vessel.

For outlet temperature greater then 45 °C we

recommend the use of a descaling system.

2

2

1

3

6720608999-11.6V

T

5

4

Loading...

Loading...