Page 1

Instantaneous gas water heater

POWER VENTED - ELECTRONIC IGNITION

Model

WR430-3K

• installation

• operation

• maintenance

The Bosch instantaneous water heater is a high efficiency,

space saving answer to your water heating needs. All Bosch

instantaneous water heaters heat water only as required;

no energy is lost maintaining a large volume of water at

elevated temperatures as in tank-type storage water heaters.

Suitable for heating potable water only. Not approved for

space heating purposes.

READ INSTRUCTIONS CAREFULLY BEFORE INSTALLING

NOTICE TO INSTALLER: Please leave this

manual with the owner or affix adjacent to

appliance.

ASTRAVAN DISTRIBUTORS, LTD.

6 720 606 181 CA (03.11) AL

123 Charles Street

North Vancouver, B.C. V7H 1S1

Phone Canada: (604) 929-5488

Phone USA: (206) 860-8448

Web Site: www astravan.com

WARNING: If the information in this

manual is not followed exactly, a fire or

explosion may result causing property

damge, personal injury or death.

- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity of

this or any other applicance

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

- Installation and service must be performed by

a qualified installer, service agency or the gas

supplier.

Note: In case of problems please contact your salesman or installer

Page 2

BOSCH WR430-3K

NAT. GAS PROPANE

Principle of Operation:

When a hot water faucet is opened, the flow of water through

the heater causes the gas valve to open. At the same time

a microswitch is activated which sends a spark to the pilot.

The flame sensor confirms that the pilot has been lighted

and allows burners to ignite. The pilot goes out. The power

exhaust system runs as long as the burners are on. The

heat exchanger coils absorb the heat generated by the

burners and transfer heat to the water. When the hot water

faucet is shut off, the gas valve automatically closes and

the burners turn off, followed immediately by the exhaust

system. Your hot water faucet is an ignition key to turn on

the water heater, giving you control over your hot water energy

use. Every time you turn off your hot water faucet, the energy

consumption for hot water returns to zero.

FEATURES

- Power Venting with safety shutoff

- Electronic Pilot Ignition

- On/Off switch to activate system

- High Quality Materials for Long Working Life.

- Copper heating coils for endless supply of hot water.

Gas Input

max. 130 000 Btu/hr 125 000 Btu/hr

min. 28 000 Btu/hr 28 000 Btu/hr

Water Connection 1/2” Thread fitting

H x W x D 29 3/4” x 18 1/4” x 8 3/4”

Vent 4” (Category III Gas Appliance)

Max. lineal vent pipe length 15’ (4.5m)

Gas Connection 1/2” NPT thread

Shower pressure 40 Psi

Min. Water Pressure 18 Psi (no fittings attached)

Max. Water Pressure 150 Psi

Shipping Weight 50.6 LB

Net Weight 44 LB

2.5 GPM at 90° rise (32°C) (9.5 l)

5.0 GPM at 45° rise(16°C) (19.5 l)

- Burner output proportional to hot water flow demand for

maximum energy efficiency.

- Safety flame sensor at pilot burner.

- Automatic over heating protection shut-off sensor.

- Stainless steel burners with stabilized blue flame.

- Built-in corrosion resistant power venter.

- Compact space saver: mounts on a wall with two hooks.

- Easily removable one-piece cover.

- Easy one person installation.

- Adjustable water flow restrictor ensure that water flow

demand will not exceed the heating capacity of the heater.

UNPACKING THE BOSCH WR430-3K HEATER

Min. Water Flow 1/2 gal/min

120V/60Hz 1.2 Amps

LP GAS Supply Pressure inlet. min. 11”W.C.*

LP GAS regulator outlet pressure 9.9”W.C.*

Natural Gas Pressure inlet min.: 7”W.C.*

Natural Gas Regulator Pressure 5.38 W.C.**

* Inlet gas pressure must not exceed this value

** For purposes of input adjustment

ELECTRICAL 3 ft. ( 0.9 m) power cable supplied c/w CSA

3 prong plug.

This heater is packed securely. The box includes two water connection fittings, a control knob, a gas pressure regulator, a

pressure relief valve, an incandescent particle tray, two hooks for hanging the heater, this manual. Do not lose this manual

as there is a charge for replacement.

2

Page 3

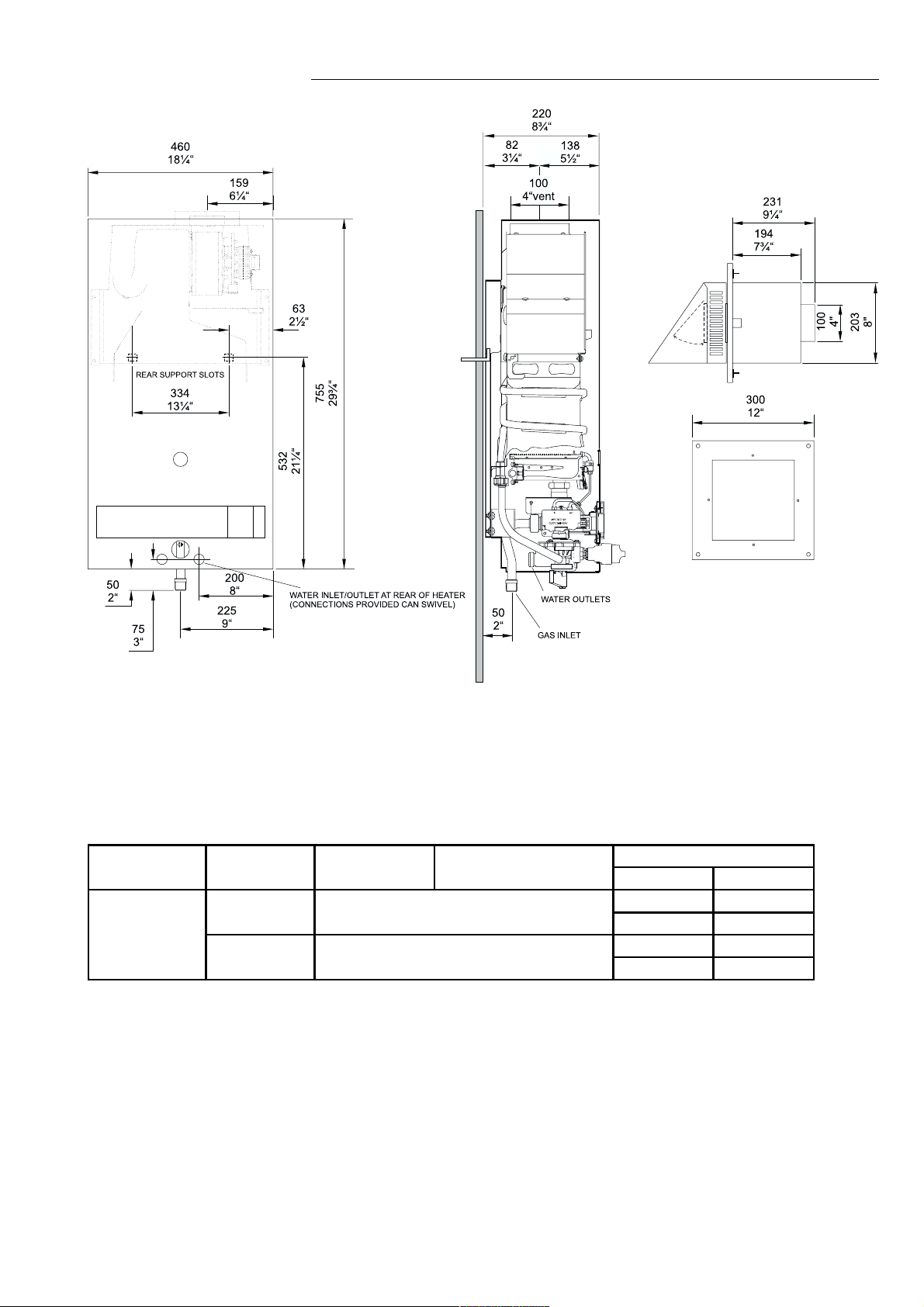

DIMENSIONS

EXTERIOR

TERMINATION

D084_089

Figure 1

Maximum Hydrostatic water pressure - 1.03 MPa (150 p.s.i.)

Maximum recommended working pressure - 0.69 MPa (100 p.s.i.)

Minimum working pressure - 0.09 MPa (13 p.s.i.) no piping attached

Reccomended pressure for showers and domestic, 0.27 MPa (40 p.s.i.)

Model Type of Gas Altitude Input

WR430-3.K.. 0.79 diam. 18

• The high altitude ratings listed are Canadian Gas Association high altitude ratings and are valid only in Canada. In the U.S., the

National Fuel Gas Code, ANSI Z223.1-1988, recommends for high altitude installations above 2,000 feet, that the input rate be

reduced 4% for each 1,000 feet above sea level. - See page 14.

natural gas

propane

0 - 2 000 ft 130 000 Btu/hr (38 kW)

2 - 4 500 ft 116 000 Btu/hr (34 kW)

0 - 2 000 ft 125 000 Btu/hr (36 kW)

2 - 4 500 ft 112 000 Btu/hr (33 kW)

Main Burner Orifices

Size, mm Qt.

1.20 diam. 18

1.20 diam. 18

0.79 diam. 18

3

Page 4

FORWARD

The design of the WR430-3K complies with CAN 1-4.3

and ANSI Z21.10 (latest edition) as an instantaneous gas

water heater. In addition, the WR400-3K also complies with

CAN 1-2.17 for use at high altitudes, 2,000 - 4,500 ft. above

sea level.

Installation, operation and maintenance instructions are

provided in this manual. Installation and operation

instructions should be thoroughly reviewed before

proceeding with installation of the BOSCH instantaneous

gas water heater.

The BOSCH instantaneous gas water heater is designed

to operate on natural or propane gas: however, make sure

that gas on which heater is to operate is the same as

specified on the heater’s model/rating plate.

In addition to these instructions, the water heater shall be

installed in accordance with CAN/CGA-B149 Installation

Code (in Canada) or Z223.1-latest edition, National Fuel

Gas Code (in U.S.A.) and/or local installation codes. These

shall be carefully followed in all cases.

INSTALLATION INSTRUCTIONS

The Bosch WR430-3K is a high efficiency fin tube heater and should not be installed and operated during construction or

building renovations if location is exposed to above normal dust levels. This can cause dust build up in the finned heat

exchanger and result in damage to heater and be a hazard to health.

Note: Proper plumbing, venting, gas connections and an

adequate supply of combustion air are required for

safe and reliable operation. Ability equivalent to that

of a licensed tradesman in the field involved is

required for installation and/or service of these water

heaters.

AIR REQUIREMENTS

For safe operation, sufficient air for combustion, ventilation

and dilution of flue gases must be available. An insufficient

supply of air will result in a yellow luminous burner flame,

causing carboning or sooting of the heat exchanger.

LOCATION

Before installing the BOSCH instantaneous gas water

heater, consideration must be given to proper location. The

location should be as close to outside vent termination as

practicable, in an area with an adequate air supply and as

centralized with the piping system as possible. The heater

should not be located in an area where it will be subject to

freezing. The heater should be located in an area where

leakage of the heater or its connections will not result in

damage to the area adjacent to the heater or to lower floors

of the structure. See venting page 5.

Note: When such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the water heater. The pan

must not restrict combustion air flow.

ELECTRICAL

A grounded switched plug receptable must be provided

immediately below the left hand corner of heater to accept

and provide power to supplied 3 ft. (0.9m) appliance cable

and plug.

In order to prevent corrosion, make sure that the combustion

air is kept free of aggressive substances. Substances that

especially contribute to corrosion are halogenated

hydrocarbons (e.g., chlorine and fluorine) which are

contaned in solvents, paint, adhesives, propellant gases,

various household cleaners, etc. Take precautionary

measures as necessary.

In unconfined spaces, in buildings of normal construction,

infiltration normally is adequate to provide air for combustion,

ventilation and dilution of flue gases. However, a confined

space must be provided with two permanent openings to

provide combustion and ventilation air to the appliance. Each

opening shall have a free area of one square inch per 1,000

Btu/Hr* of total input rating of all the appliances in the

enclosure. One opening shall be within 12 inches of the

top and one within 12 inches of the bottom of the enclosure.

* Special Note

When the WR430-3K is installed in a confined space of

minimum size the openings described above must be

increased in to a size of 1-1/2 square inches per 1,000

BTU/Hr. In other words, when installed in a minimum sized

confined space the two openings that are to be made in

the enclosure within 12 inches of the top and 12 inches of

the bottom must each have a minimum free area of, (1-1½”

- 2" x (130) = 195 square inches.

4

Page 5

For either a confined or unconfined space in a building of

tight construction with inadequate infiltration, air must be

drawn from the outdoors or from spaces that freely

communicate with the outdoors. Two permanent openings

located as indicated are to be provided as follows:

1. When communicating with outdoors directly or by

means of vertical ducts, each opening shall have a

free area of not less than one square inch per 4,000

BTU/Hr. of total input of all appliances in the space.

2. When communicating with outdoors by means of

horizontal ducts, each opening shall have a free area

of not less than one square inch per 2,000 BTU/Hr. of

total input of all appliances in the space.

For detailed requirements see:

• in Canada, CAN/CGA-B149 Installation Codes

• in U.S.A., ANSIZ223.1-latest edition, National Fuel Gas

Code.

MOUNTING

The WR430-3K is design certified for mounting to a wall.

The heater must not be installed on a carpeted wall. The

heater must be mounted to the wall using appropriate

anchoring materials.

Note: If wall is a stud wall sheathed with plasterboard it is

recommended that support board(s), either 1 x 4's

or 1/2” (minimum) plywood first be attached across

a pair of studs and then the heaters should be

attached to the support boards. See Figure 2.

Figure 2

WALL STUDS

WARNING!

1. Flammable materials, gasoline, pressurized containers,

or any other items or articles that are potentially fire

hazards must never be placed on or adjacent to the

heater. The appliance area must be kept free of all

combustible materials, gasoline and other flammable

vapors and liquids.

2. Do not obstruct the flow of combustion and ventilation

air to the appliance.

CLEARANCE

The WR430-3K is design certified for installation on a

combustible wall and for installation in an alcove or closet

with minimum clearances to combustible construction of 0

mm from back, 102 mm (4 inches) from sides, 305 mm (12

inches) from top and bottom, and 102 mm (4 inches) from

front. A minimum of 305 mm (12 inches) shall be allowed

for maintenance of serviceable parts. Clearance from vent

is dependent upon the clearance rating of the venting

material used; see venting page 6.

SUPPORT BOARD

1” X 4”

SPACE BOARD

Fig. 2 - Mounting the Heater

Expansion and contraction of piping due to changing water

temperature in the pipes imparts movement to the heater

which, if mounted directly to a brittle, friable board, such as

plasterboard, can cause failure of mounting.

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1latest edition in U.S.A. or CAN/CGA-B149 INSTALLATION CODES IN CANADA. LOCAL CODES AND/OR THE

REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION MUST BE FOLLOWED.

5

Page 6

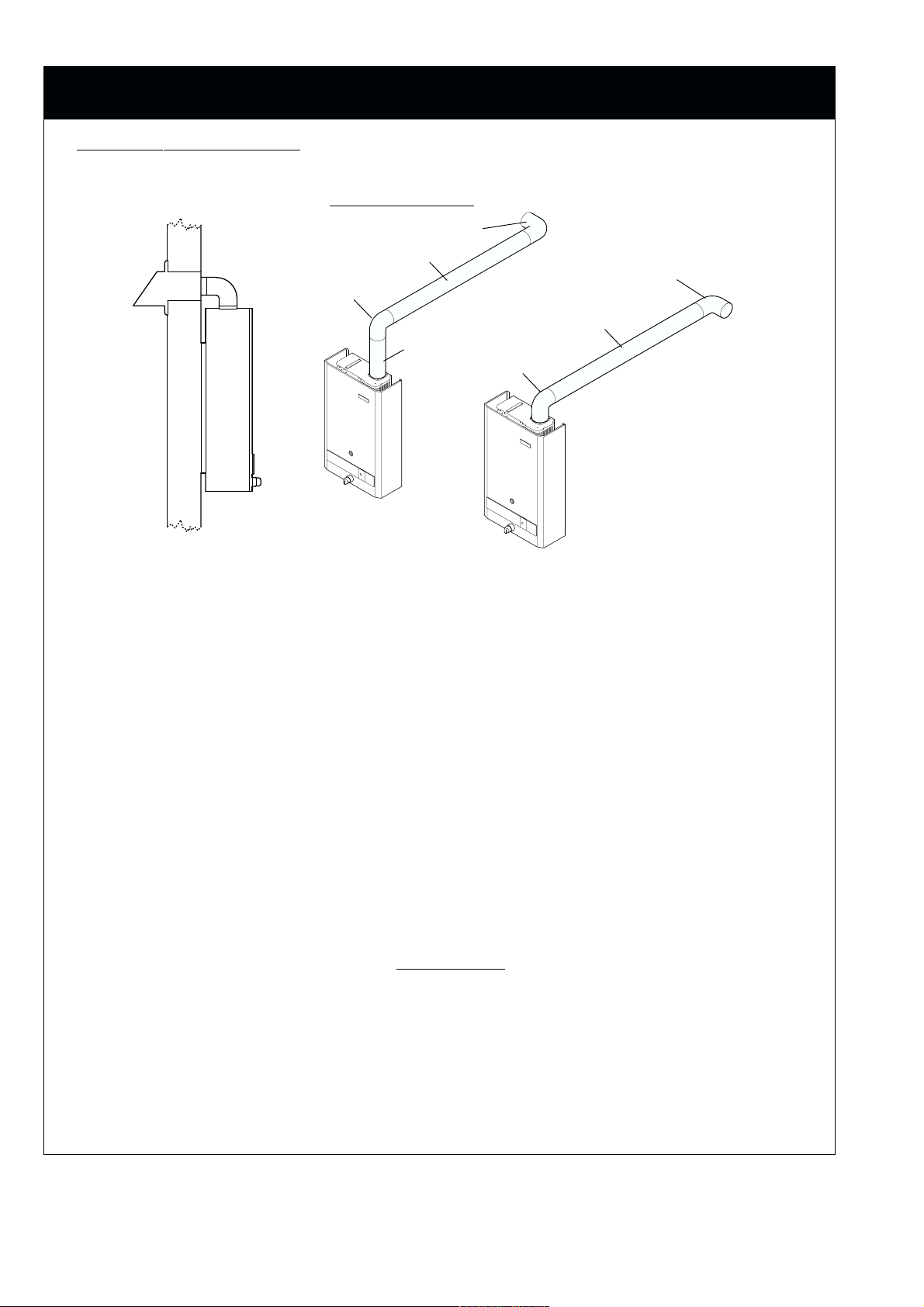

Bosch POWER VENTING SYSTEM

INTRODUCTION

Bosch power venting models are designed to overcome difficult venting problems which cannot be performed

with atmospheric venting: to meet your hot water demand load very efficiently, with an environmentally friendly

appliance which conserves energy and significantly reduces combustion emissions to atmosphere.

GENERAL INFORMATION

This Power Vent System must be installed by a *qualified installer in accordance with all applicable local gas

and electrical codes and in the absence of:

• With the current CAN1/CGA B149 installation code for gas burning appliances and the Canadian Electrical

code C22.1-M90 part 1 (for Canada).

• With the National Fuel Code and the ANSI Z223.1-LATEST and National Electrical Code ANSI/NFPA No

70-LATEST electrical code (for USA).

The Bosch warranty will be voided by, and Bosch disclaims any responsibility for the following actions:

• Use of any unapproved venting component part not manufactured or approved by Bosch in combination

with the Bosch WR430-3K unit.

• The Bosch WR430-3K must not be modified in any way when installing the Power Vent System. All

systems must be installed as per Bosch Installation Guide.

• Installation other than instructed in this manual.

CAUTION:

Bosch Power Vent System must be installed by a qualified agency in accordance with these instructions.

If improperly installed a hazardous condition such as an explosion or Carbon Monoxide poisoning

could result. Bosch will not be responsible for any and all improperly installed appliances.

*QUALIFIED INSTALLING AGENCY: Any individual, firm, corporation or company which either in person or

through a representative is engaged in and is responsible for the installation and operation of gas appliances and

draft control devices, who is experienced in such work, familiar with all precautions required, and has complied

with all the requirements of the authority having jurisdiction.

GENERAL VENTING INFORMATION

SIZING & DISTANCES:

Plan the vent system so that code clearances and manufacturer’s distances are maintained from combustible

materials, plumbing and wiring.

This unit may be directly connected to approved vent termination with a 90° elbow or located with a maximum

lineal length of 15 ft. (4.6m) including two 90° elbows from termination. All vent pipe and fittings must only be

4” (10.2cm) in diameter.

6

Page 7

Bosch POWER VENTING SYSTEM

GENERAL VENTING INFORMATION - continued

APPROVED VENTING MATERIALS:

Single wall:

As gauge listed in the current CAN1/CGA B149 installation code for gas burning appliances (for Canada),

National Fuel Code ANSI Z223.1-LATEST (for USA).

Note: Cannot be used in concealed locations.

B-Vent materials:

Straight lengths only (no elbow) may be used under following conditions

(i) Unsealed 5” B-vent may be used as a chase for sealed 4” single wall through concealed or unheated

areas.

Clearances to combustible materials for walls and partitions:

• 1” (25mm) for B-Vent.

• 3” (76mm) for single wall and uninsulated PVS-1 vent piping.

A wall thimble must be installed for internal wall applications.

All runs through unheated space or exposed to outside temperatures must be insulated to prevent condensation.

All portions of the vent system under positive pressure during operation (on the outlet side of the WR430-3K)

shall be sealed with high temperature silicone and high temperature aluminum duct tape and installed so as to

prevent leakage of flue or vent gases into building.

GENERAL CODE REQUIREMENTS

Before commencing an installation always consult with local gas and electrical codes and authorities, in the

absence must be installed:

• With the current CAN1/CGA B149 installation code for gas burning appliances and the Canadian Electrical

code C22.1-M90 part 1 (for Canada).

• With the National Fuel Code and the ANSI Z223.1-LATEST and National Electrical Code ANSI/NFPA No 70LATEST electrical code (for USA).

7

Page 8

Bosch POWER VENTING SYSTEM

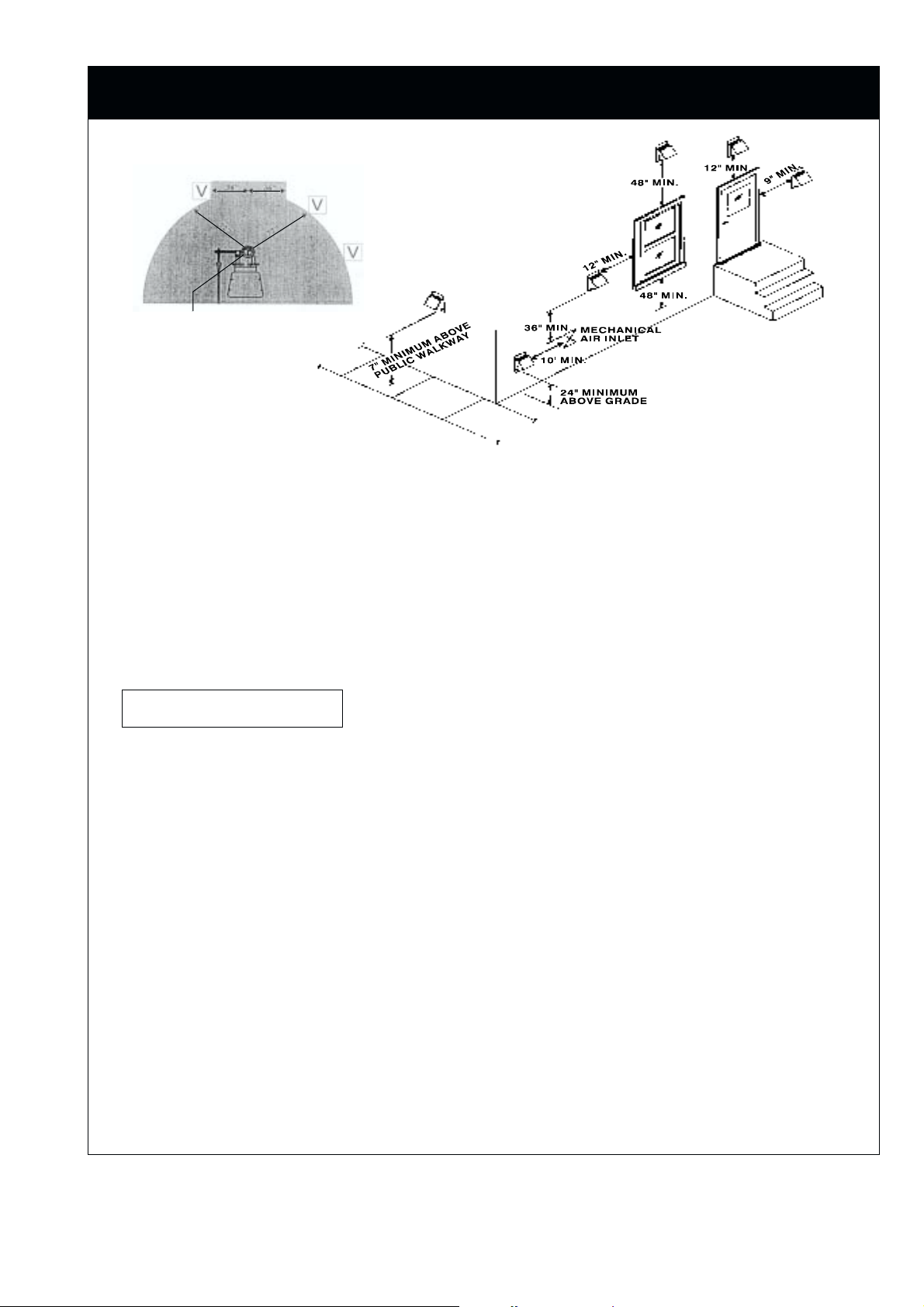

VENT TERMINAL INSTALLATION:

Before installing Bosch WR430-3K determine the location of vent system termination which may be immediately

connected with a 90° elbow or with a maximum lineal length of 15 feet including two 90° elbows. (See Fig. 1)

90° el

12 ft straight

(5.7m)

90° el

90° el

3 ft straight

(0.3m)

15 ft straight

(4.6m)

90° el

MAXIMUM LENGTH OF ALL PIPE LENGTHS

MUST NOT EXCEED 15 FT (4.6M)

Note: In cold climate areas negative air pressure such as unbalanced heating and ventilating systems can

cause reverse air flows in gas vent and chimney systems. Under extreme cold conditions this can cause

freezing and damage Bosch heat exchanger during prolonged period of times when they are not in use,

such as night time hours. Vent termination with back draft flapper is supplied in order to minimize outside

air infiltration and risk of freezing equipment.

The approved terminal shall be so arranged for flue gases to be directed in a manner which will not jeopardize

people, overheat combustible structures or enter into buildings, and that proper clearances are maintained (See

Fig. 2 )

a) The vent terminal of this Power Vent System shall not be less than 7 feet (213cm) above grade when

located in areas accessible to public walkways.

b) A vent terminal shall terminate at least 3 feet (91cm) above and a minimum of 10 feet (305cm) horizontally

from any (mechanical) air inlet.

c) The vent terminal shall not be within 6 feet (183cm) radius from a gas meter or regulator, and horizontally

it must be a minimum of 3 feet (91cm) from the centre line of such regulator.

d) The vent terminal shall be a minimum of 6 feet (182cm) from any combustion air inlet.

e) The vent terminal shall terminate from an

opening window, at least 4 feet (122cm) below or below the

opening and 12 inches (30cm) horizontally. From a door 1 foot (30cm) above and 9 inches (23cm)

horizontally.

f) The vent terminal shall not be less than 3 feet (91cm) from an adjacent building.

g) The vent terminal shall not be less than 2 feet (61cm) above grade.

8

Page 9

Bosch POWER VENTING SYSTEM

Figure 2

36”

36”

7

2

”

72”

REGULATOR VENT

ELECTRICAL WIRING:

1. The electrical contact ratings are as follows:

______ 1/10 HP at 120 VAC

______ 3 Amps (full load) at 120 VA

2. Provide switched plug receptacle to accommodate Bosch grounded plug.

3. Make certain the power source is adequate for the fan motor requirements.

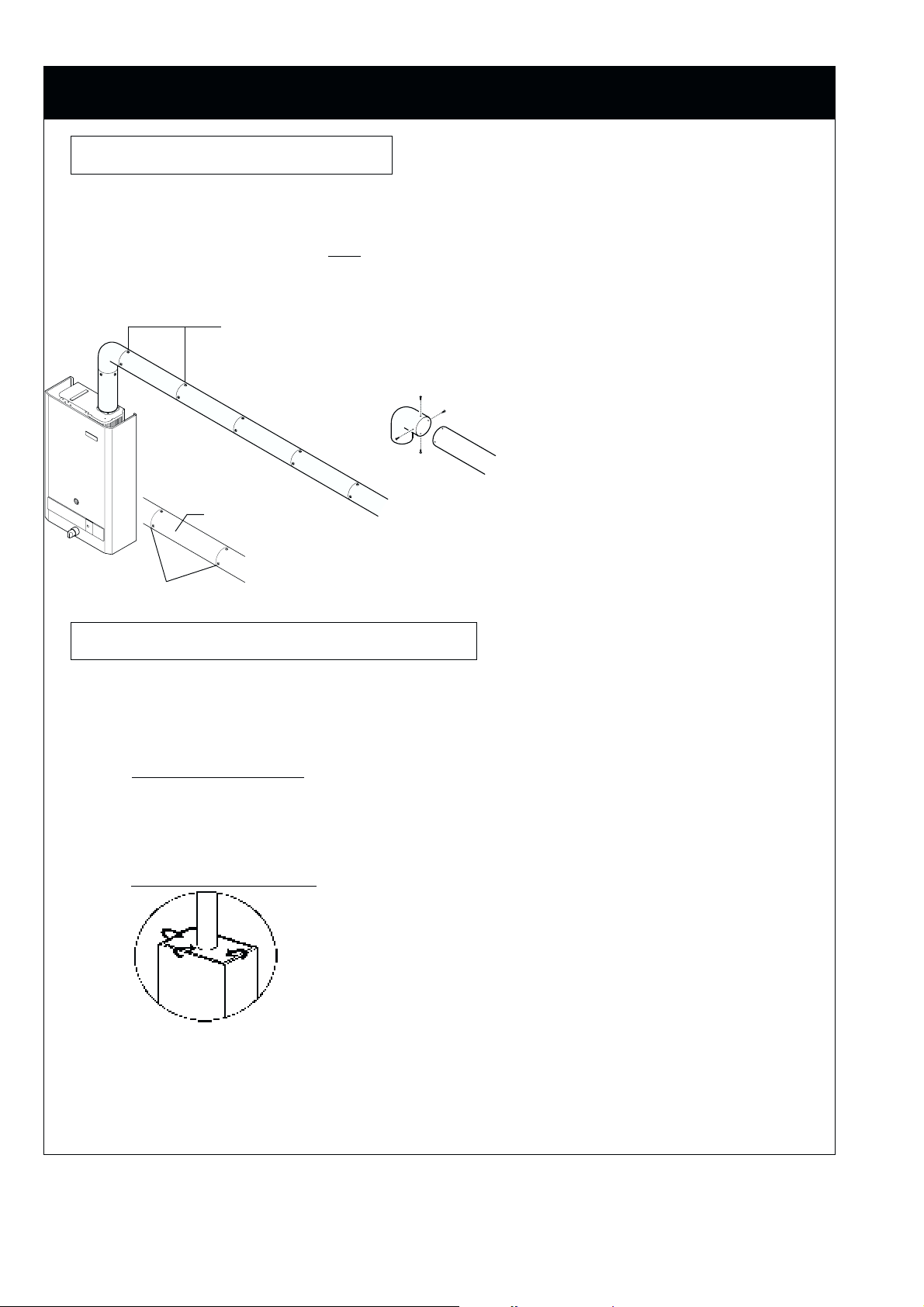

VENT INSTALLATION

1. Choose approved terminal location

2. Cut vent terminal opening through outside wall - Refer to installation instructions supplied with termination.

3. Install vent terminal by fastening from outside with 4 screws and caulking around flange edge. Check that

optional flapper moves freely if applicable.

4. Install 4” venting materials and secure all joints with a minimum of four screws for each joint. Please note that

wherever possible use continual lengths of pipe to reduce the number of joints.

5. Seal all positive vent pipe and elbow joints between Bosch unit and vent terminal with high temperature

silicone and/or hi temperature aluminum tape following manufacturer’s instructions (i.e. always push silicone

ahead of nozzle)

9

Page 10

Bosch POWER VENTING SYSTEM

VENT INSTALLATION (continued)

6. Support venting duct with plumber’s strap (supplied by installer). Solid piping need only be supported every

four feet. All horizontal pipe joints must be secured with a minimum of four screws per joint. (See Figure 3)

7. All runs through unheated spaces must be wrapped and insulated with a minimum of 1” insulation.

Figure 3

Vent support hangers (plumber's

strapping) should be 4 ft. apart on

horizontal runs.

Use 4 screws

per joint

RIGID PIPE

positive pressure

All joints must be sealed with high temperature silicone

and high temperature aluminum vent pipe tape

All clamped joints on the positive

side of the power venter are to

be sealed with high temperature

silicone.

OPERATION AND CHECKING THE DRAFT

A. Place Bosch appliance into operation. Follow lighting pilot and operating instructions on Bosch

cover.

1. Draw water continuously to activate appliance which will turn on gas burner.

2. CHECKING THE DRAFT. Operate the appliance with cover in place for a minimum of five minutes and

check for proper venting, and assure that the combustion products are venting properly, by passing a

lighted match flame or smoke taper over the top edge of the Bosch cover and towards draft hood. If the

vent is drawing properly, the smoke or match flame will be drawn over the top edge of the Bosch cover

and into the draft hood or opening. (see drawing below Checking The Draft)

CHECKING THE DRAFT

10

NOTE: If smoke is not drawn in then the combustion products are

escaping from the relief opening into the room. Under these

conditions, the equipment shall not be operated until proper

adjustments or repairs are made to provide adequate draft.

3. Check draft spill safety switch by obstructing outside vent terminal and by drawing water. Spill switch

should trip and shut off gas supply to Bosch unit. Remove outside obstruction.

4. If spill switch trips allow 5 minutes to reset.

Page 11

Bosch POWER VENTING SYSTEM

B. The Air-Flow Adjustment on the Power Venter is factory set for optimum air flow. Operating at its setting will

assure that combustion gases are safely removed to the outside.

MAINTENANCE

Points of inspection are:

1. Motor - Motor must rotate freely.

2. Fan Wheel - Wheel must be clean of dust or any other coating which inhibits rotation or air flow. Remove

all foreign material from vent system before operation.

3. Spill Switch - Verify proper spill switch operation by observing Operation Sequence and by temporarily

blocking termination outlet.

4. Check Draft - Check for flue gas spillage following steps in the Operation And Checking Draft on

page 9.

5. Vent Termination - Inspect to ensure installation and clearances have not been altered or obstructed and

that the back draft flapper (when used) movement is free and operational. Note that terminal hood is

removable for easy flapper maintenance or replacement.

Hinge

Vent termination hood

Flapper

11

Page 12

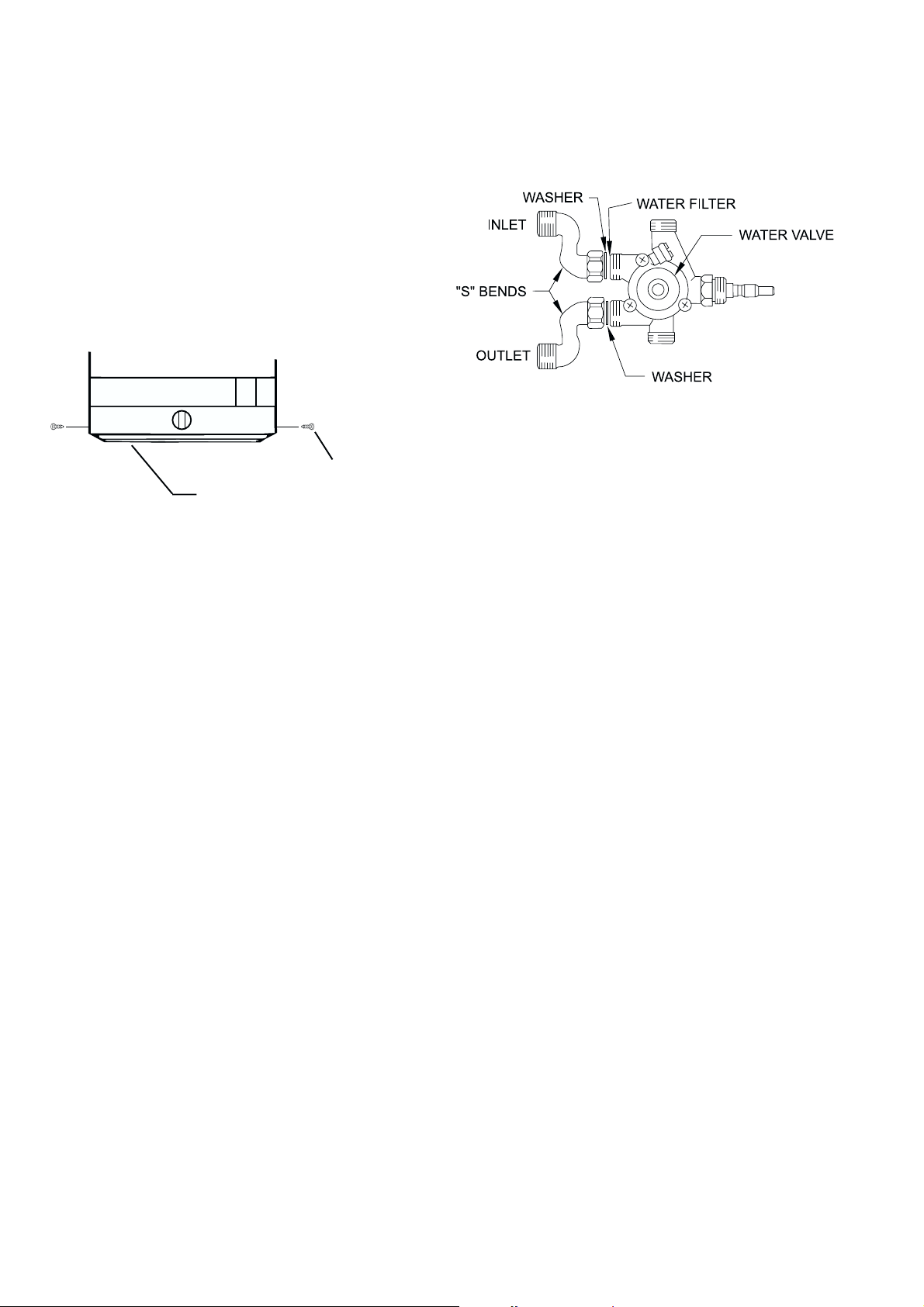

DRIP TRAY

WATER CONNECTIONS

If the water heater is being mounted above a floor of

combustible construction the drip tray (shipped loose in the

carton with the water heater) must be attached to the bottom

of the front cover of the water heater at the time of

installation. The drip tray should be attached to the front

cover, using screws provided, as shown in Figure 3.

Failure to use drip tray when installing unit above a floor of

combusible construction will cause an unsafe condition and

possible fire and will be in violation of A.G.A. and C.G.A.

certification of the unit.

Figure 3.

SCREWS

INCANDESCENT PARTICLE TRAY

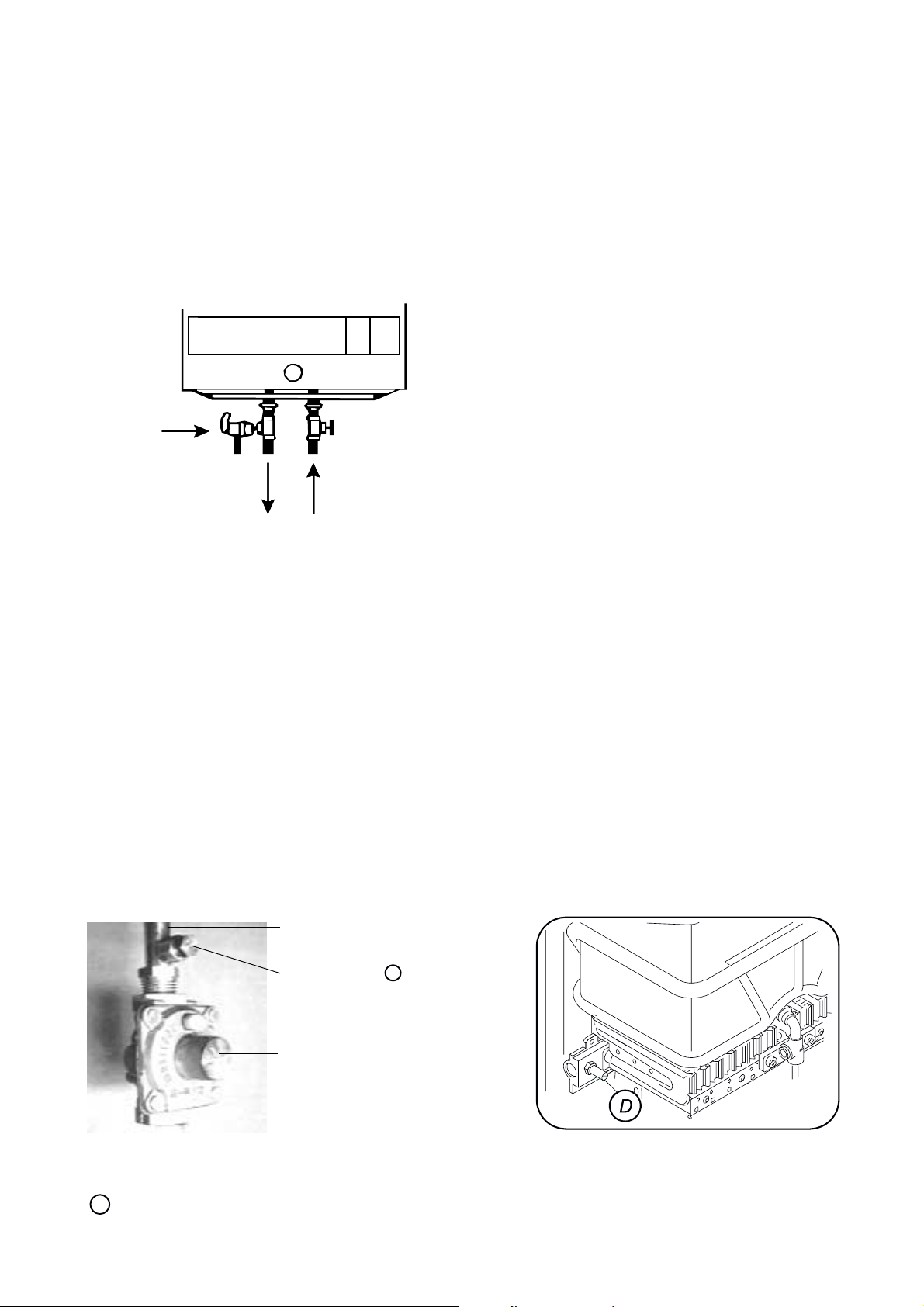

The BOSCH instantaneous water heaters are provided with

two S-bend water connectors/adaptors that must be

connected to inlet and outlet connections on water valve

assembly, see Figure 5, below.

Water valve and S-bends, top view

Figure 5.

The purpose of the S-bend water connectors/adaptors is to

provide threaded water connections that meet standards

used in North America, ANSI Standard Taper Pipe Thread

(1/2” NPT). The cold water supply should be connected to

S-bend attached to inlet of water valve and the hot water

connection should be made to S-bend attached to the outlet

of water valve.

If plastic piping is to be used, a 1.5 meter (approx. 5 feet)

length of metal piping must first be attached to both the

cold water inlet and hot water outlet of the water heater.

Note: A shut-off valve should be placed in the cold water

supply line to the heater to facilitate servicing the

heater.

12

Page 13

RELIEF VALVE

The listed pressure relief valve supplied must be installed

near the hot water outlet at time of installation of the heater.

No valve is to be placed between the relief valve and the

heater. A drain line must be connected to the relief valve to

direct discharge to a safe location. Do not install reducing

coupling or any other restriction in the discharge line. The

discharge line must be installed so as to allow complete

drainage of both the valve and the line. See figure 6.

Figure 6.

Pressure

Pressure

Relief

Relief

Valve

Valve

HWSHWS

CWSCWS

Check to make sure that the gas listed on the rating plate is

same as gas listed on the pressure regulator. See

PRESSURE REGULATION section of this manual for

information regarding gas pressure settings.

Note: Before attaching the gas supply line, be sure that all

gas pipe is clean on the inside. To trap any dirt or

foreign material in the gas supply line, a drip leg must

be incorporated in the piping. The drip leg must be

readily accessible and not subject to freezing

conditions. Install in accordance with the

recommendations of serving gas supplier.

Joint compounds (pipe dope) shall be applied sparingly and

only to the male threads of pipe joints. Do not apply

compound to the first two threads. The joint compound must

be resistant to the action of liquified petroleum gases.

Before placing water heater in operation, check for gas

leakage. Soap and water solution, or other material

acceptable for this purpose shall be used in locating gas

leaks. Matches, candles, lighters, or other ignition sources

shall not be used for this purpose.

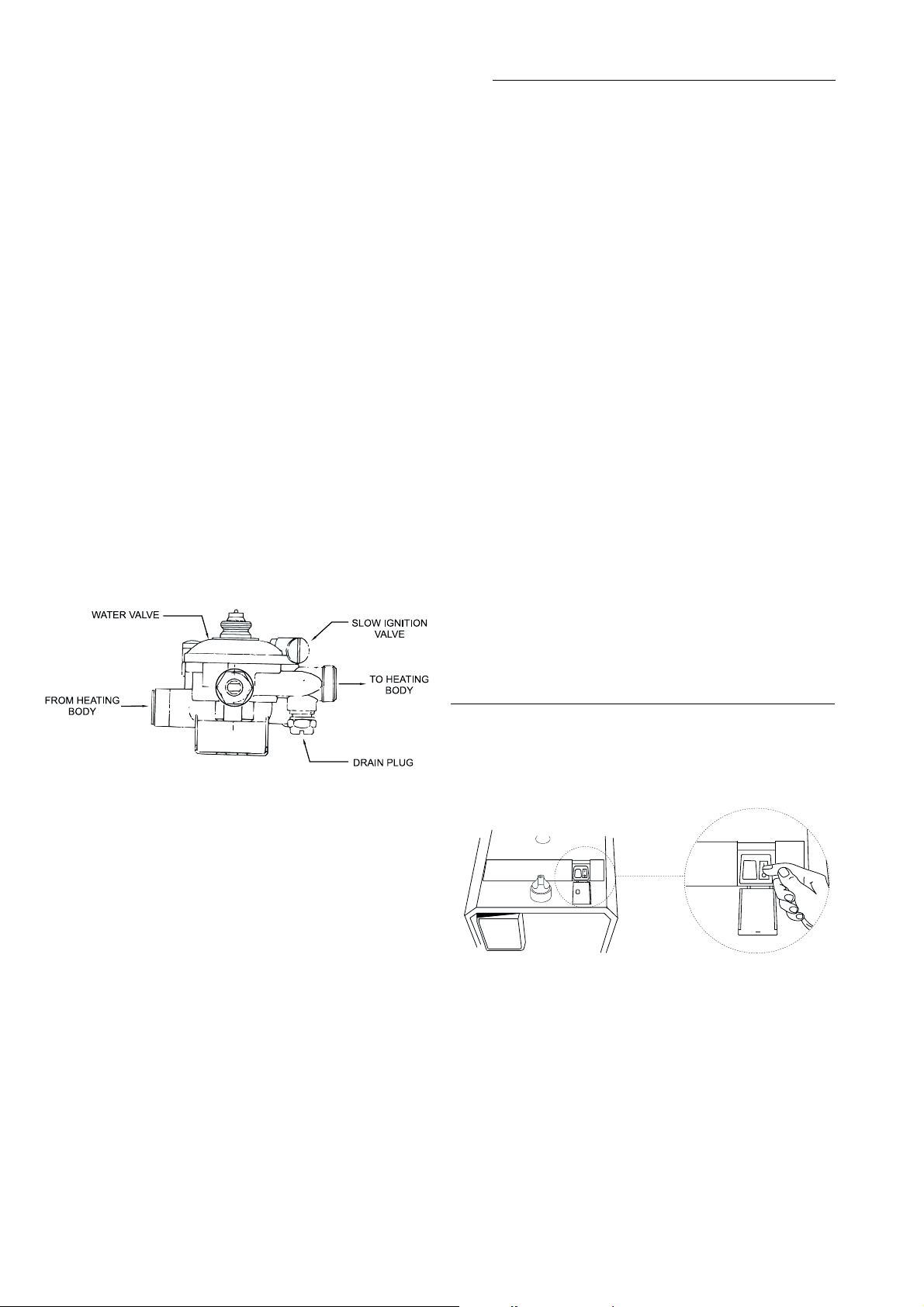

GAS CONNECTIONS

Before connecting the gas supply to the heater, check

heater’s model/rating plate to make sure that the gas on

which heater is to operate is the same as specified on the

model/rating plate.

The WR400-3.K.. instantaneous water heaters are supplied

with a gas pressure regulator that must be installed on the

heater before attaching the gas supply line. See figure 7.

Failure to install the gas pressure regulator as shown in

figure 7 will be a violation of A.G.A. and C.G.A. certification

of the unit.

BOSCH water heaters are shipped from the factory with

the gas pressure regulators preset for the gas shown on the

rating plate to the correct pressure:

• in Canada, for high altitude operation;

• in U.S.A., for standard altitude operation unless

specifically marked as a high altitude unit.

GAS INLET PIPE

PRESSURE TAP T

WARNING

The heater and its individual shutoff valves must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 3.45 kPa (1/2 psig).

The water heater, including the pressure regulator provided

with it, must not be operated at gas supply pressures in

excess of 3.45 kPa (1/2 psig). If overpressure has occurred

such as through improper testing of the gas lines or

emergency malfunction of the supply system, the gas valve

and regulator must be checked for safe operation. Make

sure that the outside vent valves are protected against

blockage. These are part of the gas supply system, not the

water heater. Vent blockage may occur during ice storms.

Figure 7(a) Gas Burner test point D for measuring burner

manifold pressure at full flow and input:

Standard Altitude: 4.58”W.C. Nat Gas, 9.11”W.C. Propane.

High Altitude: 3.73”W.C. Nat Gas, 7.27”W.C. Propane.

APPLIANCE PRESSURE

REGULATOR

Figure 7. GAS MANIFOLD PRESSURE TEST POINT

T For measuring correct regulator operating pressure.

13

Page 14

OPERATING INSTRUCTIONS

WARNING!

If the water heater has been damaged or exposed to fire or

sooting, or if any part has been underwater, do not use. If

unit has been operated during construction or alterations

and exposed to above normal dust levels the heat exchanger

should be examined and cleaned regularly. Operation with

dust obstructed fins could be a health hazard. Immediately

call a qualified service technician to inspect the appliance

and to replace any part of the control system and any gas

control which has been underwater and to clean the heat

exchanger assembly and water valve.

FILLING

Before proceeding with operation of the water heater make

sure that the system is filled with water:

• Make sure drain is closed. See figure 8, below.

• Open a nearby hot water faucet to permit the water to

fill the heater and piping.

• Close the hot water faucet after the water flows freely

and all air has escaped from the system.

The water heater is now ready to be lit.

LIGHTING AND OPERATING INSTRUCTIONS

1. STOP! Read the safety information above on this lable.

2. The gas valve must be shut off by putting the ON/OFF

switch to position “o” Wait five (5) minutes to clear out

any gas. If you small gas, STOP! Follow “B” in the safety

information above. If you do not smell gas, go to the

next step.

3. This water heater is equipped with a safety pilot burner

and an automatic ignition control system.

4. Set the ON/OFF switch (flip down cover plate on frontal

panel strip) marked I/O to the I position. In this position,

the water heater is ready to use. (See Fig. 10).

5. Turn the hot water faucet on the minimum flow rate

required to activate the heater. The automatic ignition

system first ignites the safety pilot burner which then

ignites the main burner in about 4 seconds.

6. The pilot flame will extiguish 10-30 seconds after the

burners come on. The burners will remain on until the

hot water tap is turned off.

7. Vent fan turns on and off with burner.

NOTE: On a first time initial installation, existence of air in

the gas supply line and in the water line may cause some

ignition delay. In that case, repeatedly open and close the

hot water tap in order to restart the ignition process until all

the air has been purged.

Figure 8

SERVICE HINT

The screen (strainer) in the water valve, located in the inlet

of the water valve, may require occasional cleaning due to

foreign material in the water supply. This will restrict the

flow of water and may affect heater operation and prolong

filling time. To inspect the strainer, close the cold water supply

valve ahead of the heater, disconnect the S-bend from the

inlet of the water valve and remove strainer from inlet. Clean

if required, replace strainer in inlet to the water valve,

reconnect S-bend and turn on water supply.

TO TURN OFF GAS TO APPLIANCE

Turn off the manual lever on the gas supply line to the heater

and set the ON/OFF switch to the OFF (O) position.

To operate the heater, set the ON/OFF switch to position

I. The switch is located behind the flip down cover plate

on the front panel strip.

To shut down the heater, set the ON/OFF switch to

position O.

G667_091

Figure 10

Light the water heater in accordance with the instructions

on the Lighting and Operating Plate on the water heater.

For your convenience, the instructions are repeated here:

14

Page 15

PRESSURE REGULATION

The pressure regulator supplied with the water heater is

adjusted to operate on the gas specified on the rating plate

and:

• in Canada, is factory preset to deliver gas at the high

altitude setting listed on the rating plate and as shown

below.

• in the U.S.A., is factory preset to deliver gas at the

standard altitude setting listed on the rating plate and as

shown below.

The pressure setting of the gas pressure regulator should

be checked at installation to assure that the setting is correct

for the gas being used and the altitude at which the

appliance is installed. See rating plate on the unit, Table 1,

below, for proper setting.

In Canada, for a heater being installed at standard altitude

(0-2,000 ft above sea level) the manifold pressure should

be reset at installation to the value shown on the rating

plate, or Table 1, below, for standard altitude.

REGULATOR

SUPPLY TEST

PRESSURE TAP T

Your appliance dealer and/or your local gas supplier should

be consulted in regard to any high altitude installation. If

field adjustment is required it should be performed by a

qualified serviceman experienced in such work.

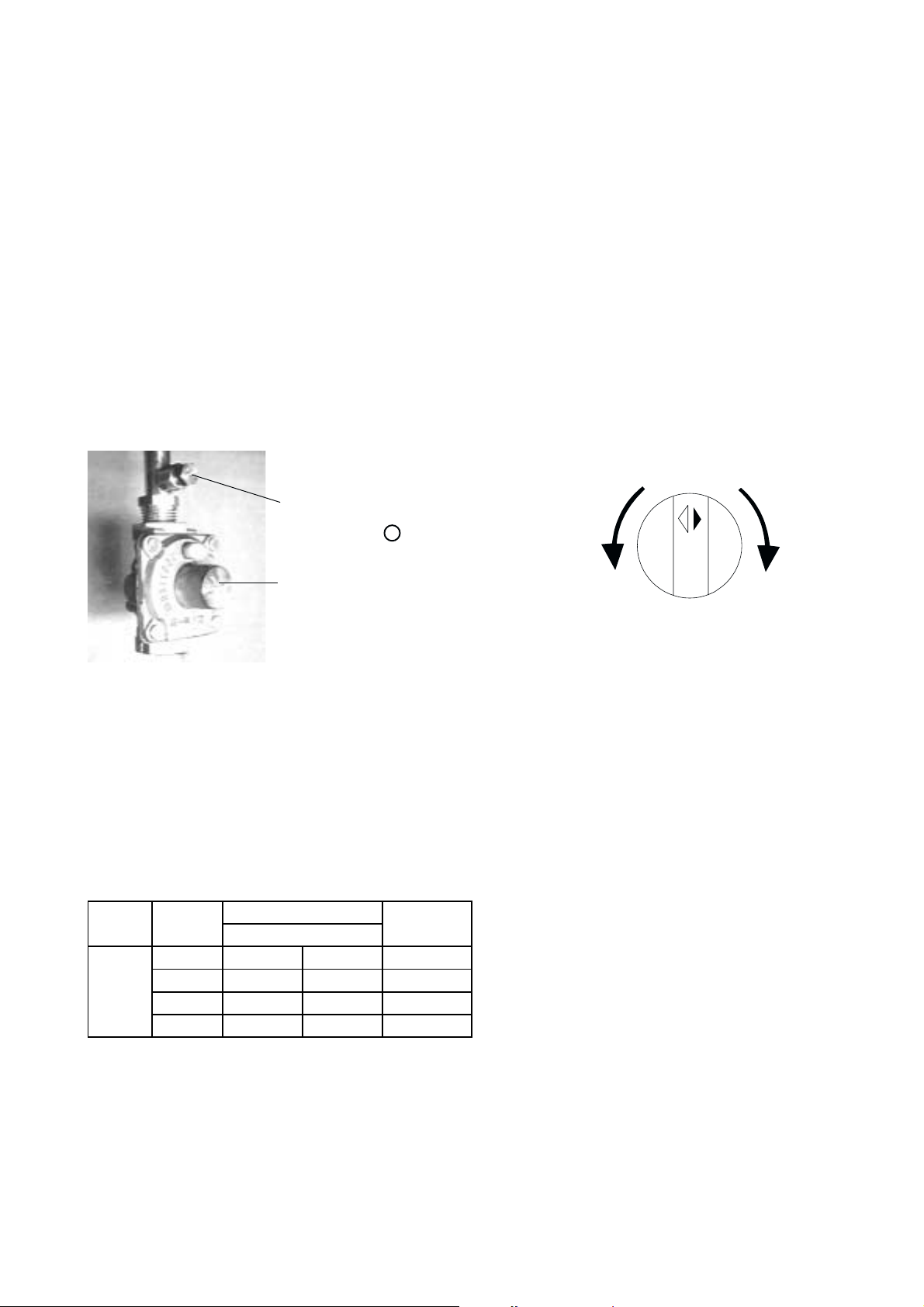

TEMPERATURE REGULATION

The BOSCH WR430-3K is equipped with a modulating

gas valve which adjusts the flow of gas to the main burner

in proportion to the water flow rate. Within its heating

capacity the WR430-3K attempts to maintain the set

temperature rise across the heater. This temperature rise

can be set in range of 25C° - to - 50C° (45F° - to - 90F°),

by means of the water flow selector. See Figure 12. When

the water flow selector is turned to the right hand stop the

water heater is set for 50C° (90F°) temperature rise; when

the water flow seletor is set to the left hand stop it is set for

25C° (45F°) temperature rise.

Temperature Adjustment Knob

Decreases temperature

and increases flow

Increases temperature

and decreases flow

ADJUSTABLE

PRESSURE REGULATOR

Figure 11

The gas pressures specified below refer to flow pressure

taken at the pressure tap in the gas inlet pipe just above the

pressure regulator, (see figure 11) while the heater is

operating at full input.

Gas pressures read at burner test point D (see fig. 7(a)

page 12.

Table 1.

Appliance Regulator Pressure Setting

Model Type of Gas

natural 1.41 5.38 standard

WR430-3K

*Note: The high altitude ratings listed are Canadian Gas Association

propane 2.61 9.9 (0-2,000 ft.)

natural 1.14 4.4 high*

propane 2.09 7.9 (2,000-4,500 ft.)

high altitude ratings for the appliances and are only valid in

Canada. In the U.S.A. the National Fuel Gas Code, ANSI 11988, recommends for high altitude installations, above 2,000

feet, that the input rate be reduced 4% for each 1,000 feet

above sea level.

Regulator Pressure Supply

kPa Inches, W.C.

Altitude

Figure 12 - Principles of Operation

Figure 12

With the water flow selector turned to its right hand stop

position (50C° rise setting) and with an inlet water

temperature of 10°C (50F°) the outlet water temperature

will be maintained at approximately 60C° (140F°) in the

water flow rate range of approximately 2 litres/min. (0.5 U.S.

gals./min.) to 9.5 litres/min. (2.5 U.S. gals./min.).

The minimum flow rate for operation, the “Threshold Flow

Rate” referred to in the lighting instructions is 2 litres/min

(0.5 U.S. gals./min.). If the water flow rate is below this level

the main burner will not fire. If the flow rate exceeds 9.5

litres/min (2.5 U.S. gals./min.) the temperature rise aross

the heater will decrease in proportion to the rate above this

temperature.

HIGH TEMPERATURE LIMIT SWITCH

The BOSCH series instantaneous gas water heaters are

equipped with a high temperature limit switch with a set

point of approximately 90°C (195°F). If the water temperature

at the sensing points exceeds the set point the switch will

open, interrupting the safety circuit and stopping gas flow

to the pilot and main burner.

Outage as the result of high limit operation indicates that

the heater is not functioning properly. The heater should be

checked by a qualified serviceman and the reason for the

malfunction is corrected.

15

Page 16

MAINTENANCE AND SERVICE

Do not enlarge the orifice.

Approximately once a year, the Bosch should be checked,

cleaned and serviced as necessary. To remove the front

cover, first remove the incandescent p article tray , then pull

off the temperature adjustment knob and unscrew and

remove the plastic collar. Pull main cover out toward you

and lift up and out. THE FOLLOWING OPERATIONS

SHOULD BE PERFORMED BY A QUALIFIED SER VICE

PERSON:

Vent System: Should be checked annually. Clean and rep air

as needed. See Preventative Maintenance Page 10.

Water Valve: The water valve on this heater should be

serviced periodically. The frequency will depend on the

mineral content of the water and conditions of use or

whenever signs of corrosion appear at the gas and water

valve joint. Check that the water inlet filter (#36 on Figure

19, page 20) is clean. Diaphragm should be replaced every

7-8 yrs. in residential applications and 3-5 yrs for commercial

applications. In acid water areas the venturi should also be

replaced at the same time (#39 on Figure 19, page 20).

Pilot Flame: The pilot flame should burn with a clean,

sharp, blue flame and should resemble the diagram in Fig.

13. If the flame is soft and yellow the pilot screen may be

dirty or the pilot burner orifice may need to be cleaned or

replaced. The pilot flame should be approximately 2 inches

long, extending past the flame sensor. If the flame is too

small, it will not reach the flame sensor and the burners

will not come on.

3mm

Correct gap between pilot

burner tip and electrode tip

Do not use any wire or sharp object to clean orifices. Natural

gas orifices are large enough that you can usually clean

them by blowing through them. To access the pilot orifice,

remove 2 screws holding pilot assembly in place. Then loosen

compression fittings to expose pilot orifice.

Heat Exchanger should be visually examined once a year

or more often in dusty areas. If fins at top show dust or

debris accumulation, remove and clean with brush and soapy

water.

Removal of the Heat Exchanger

1. Shut off the gas and water cold

supply lines to the heater and remove

the front cover.

2. Remove the drain screw from the

bottom of the water regulator and

open the hot water tap to allow the

unit to drain.

3. Remove cover and unscrew metal

retaining bar at the top front of the

heat exchanger

4. Undo water connection nuts at

heat exchanger from both sides

Estimated service time is 10 minutes to re & re, plus cleaning time

5. Tilt the heating body to the front

at the top and lift away from the

heater.

Main Burner Flames: The main burner flames should be

blue, with a more intense blue cone in the center core. Yellow

flames could be a sign of plugged or dirty burners, or a

blockage on the heat exchangers fins. If some burners have

yellow flames while others have good flames, it is likely that

dust, lint or spider webs have partially clogged the burner

venturis. To clean the burners, contact a gas service person.

Electrode

Pilot cap orifice

Pilot tube

Flame sensor

Electrode

Fig. 13 - Characteristic Pilot Flame

To clean the pilot burner and/or the pilot orifice: Turn off

the gas to the unit. Set the On/Off switch to Off ( position

0). Remove the cover of the heater. To do so, pull off the

temperature adjustment knob and unscrew and remove the

plastic collar. Pull main cover out toward you and lift up and

out. The pilot orifice should be cleaned or replaced.

Mineral Scale Build-up: In hard water areas the Bosch,

when operated at lower temperature settings, tend not to

accumulate mineral buildup. If however, the heater is used

at the higher temperature settings and the water has a high

mineral content, periodic descaling may be necessary. The

heating coil should be removed and flushed with a descaling

solution. Signs of scaling are rising outlet temperature and

knocking noises when water is flowing.

TROUBLE SHOOTING

Introduction

The Bosch WR430-3K burners are activated by a water

flow valve. Numerous water related problems can cause

this water valve to malfunction such as: Insufficient water

flow volume to activate the burners at its minimum flow

requirement; Dirt in the water flow valve causing it to

malfunction; Sediment build-up in faucet aerators, or shower

heads; Uneven pressures between cold and hot, (with single

lever faucets) Plumbing cross overs. These water flow related

problems can cause the heater to deliver less than its full

output, or to fail to ignite or to shut down completely.

Problems are stated in upper case, bold face. Most common

causes for the problems follow in order of likelihood. The

suggested solutions require that the cover be taken off. To

do this, remove incandescent particle tray, pull off the

temperature adjustment knob and unscrew and remove the

plastic collar. Pull main cover out toward you and lift up and

out.

16

Page 17

NO SPARK AT THE PILOT

1. ON/Off switch is not “On” (Position I).

The On/Off switch is located behind the flipdown cover

plate on the front panel strip. See fig. 10.

2. Water flow is not sufficient to activate heater.

Water flow rate at faucet is below minimum flow needed to

activate heater. When temperature adjustment knob is turned

all the way clockwise, the Bosch WR430-3K requires 1/2

gallon per minute flow to activate the heater. As a reference,

this is a flow which would fill a quart jar in 30 seonds. If the

temperature adjustment knob is turned fully

counterclockwise, a flow rate of 1.1 gallons/minute is required

to activate the heater.

3. Water inlet filter is clogged

Water flow is restricted, preventing needed flow to activate

heater. Clean water inlet filter screen.

4. Cross over in water lines

To confirm there is no cross-over in the plumbing, shut off

the cold water supply to the Bosch water heater and open a

not water faucet. There should not be any water flowing at

that faucet. Water running is a sign of a plumbing cross

over. Consult your plumber.

5. Microswitch needs to be adjusted or replaced.

If you do not hear a click when a tap is opened, the

microswitch needs to be adjusted. See Fig 15 for adjustment.

Replace the microswitch if the adjustment does not solve

the problem.

Fig. 15 - Microswitch Adjustment

7. Cold incoming water connection made to wrong side

of heater

Make sure cold water inlet connection is on the right side of

heater when you are facing heater.

8. Water valve parts may be dirty of components damaged

First check that venturi is free of dirt particles. Water valve

and component parts must be totally free of dirt. In hard

water areas, mineral deposits can eventually (3-5 years in

hard water areas) corrode the water valve parts to a point

where they will need replacing. Any sign of moisture at the

top of the water valve is a sign that the water valve needs to

be serviced immediately.

9. Loose connection at the ECO

Ignition sparker will not operate if the electrical circuit is

interrupted. Check that the connections to the ECO are

secure and tighten if necessary.

SPARKS APPEAR AT PILOT WHEN HOT WATER

TAP TURNED ON, BUT PILOT AND BURNERS

WILL NOT IGNITE

1. Air in the Gas Line

Normally this is a problem at time of initial installation, after

the pipes have been worked on, or after a gas supply line

has been allowed to empty. Bleed the air trapped in the gas

line by turning the hot water faucet on and off until the air

has been cleared from the line.

2. No gas to the Bosch

A. Gas cock on gas line may not be open

B. Gas regulator may be shut or damaged. Replace or unjam

the regulator. Note: The regulator furnished with the heater

is exclusively designed for low gas pressure. Excessive

pressure will lock it up. Jamming usually happens when using

propane gas if the gas pressure between the gas tank and

the water heater’s gas regulator has not been reduced. See

Page 14 for recommended correct gas pressure. To unjam a

regulator, consult your gas supplier.

Pilot does not spark with

water flow

1 Close water tap

2 Remove screw cap and

unscrew adjusting screw til

sparking starts

3 Screw in turning one and

half turns more

4 Replace screw cap

ADJUSTING

SCREW

Pilot is always sparking

without water flow

1 Close water tap

2 Screw in adjusting screw, till it

stops sparking

3 Continue to screw in turning

one and a half turns more

3. Pilot orifice or gas valve is dirty

Clogging of the pilot burner can be caused by dust in the

air or dirt in the gas. The pilot orifice or gas filter may need

to be cleaned or replace.

4. Water valve assembly needs to be checked

If the pilot orifice is clean, the water valve assembly should

be checked. The adjustment screw on the water valve microswitch may not be tight enough (Fig. 15). Remove central

cap beneath micro-switch assembly, carefully loosen the

adjustment screw until the pilot light ignites. At that point

retighten the screw one and a half turns.

5. Pilot electrovalve switch may need to be replaced (See

Fig 17).

Call your service person or call: Canada 1-800-663-8405,

U.S.A. 1.800-824-7337.

6. Electronic Control Box may need to be replaced, (See

Fig 17).

Call your service person or call: Canada 1-800-663-8405,

U.S.A. 1.800-824-7337.

17

Page 18

PILOT SPARKS CONTINUOUSLY WITH

NO WATER RUNNING

1. Microswitch needs adjustment

If no water is running, but pilot electrode continuously sparks,

the microswitch screw to the water valve needs adjustment.

See Figure 16.

PILOT LIGHTS BUT BURNERS

WILL NOT COME ON

1. Confirm water valve assembly is working properly.

2. Confirm the flame sensor is in its proper position.

3. Confirm the burner electrovalve switch is functioning

properly. Contact your service person or call:

Canada 1-800-663-8405, U.S.A. 1.800-824-7337.

4. The electrical Control Box (Fig. 16) may need to be

replaced. Contact your service person or call:

Canada 1-800-663-8405, U.S.A. 1.800-824-7337.

E864_020

Fig. 16 - Electrical wiring diagram

MAIN BURNERS GO OUT DURING HOT

WATER USE

1. Flow rate diminished below activation rate: 0.5 USGM

(2.5 l) in hot position, 1.0 USGM (5 l) in warm position

2. Unbalanced pressure in the water lines

The added restriction caused by the Bosch in the hot water

system can result in uneven pressures between the cold

and the hot. In such cases when mixing cold water at the

tap, the lower hot water pressure may be overpowered by a

much higher cold water pressure, which may cause the

Bosch burners to shut down. Make sure faucet aerators

and showerheads are free of minerals and dirt. Do not add

any flow restrictor to the shower head.

3. Check gas supply

4. ECO (overheat sensor) tripped due to overheating

5. Minimum inlet pressure on well is inadequate

Check the inlet water pressure. On a private well, raise the

minimum pressure setting to 40 psi for best performance.

Confirm that the pressure tank is not water logged.

6. Check Blower Fan. Is it operating when burner comes

on?

7. Check flapper in outside vent termination for free

movement.

18

WATER IS TOO HOT

1. Check for lime build-up. (See mineral scale p. 15)

2. Temperature Selection too high

Turn the temperature adjustment knob counter-clockwise

(to the left) to lower the maximum water temperature.

Note: This will increase the activation flow rate.

3. Inlet water temperature is too hot (as with preheated

water.)

4. Insufficient water pressure

WATER IS NOT HOT ENOUGH

1. Temperature selection too low.

Change the setting. Turn the temperature adjustment knob

clockwise (to the right).

Note: This will decrease the activation flow rate.

2. Water flow through the heater is higher than the

capacity of the Bosch to heat it.

This can be due to too high water inlet pressure (60 psi

max. for best results) or due to acid water erosion of venturi.

Check venturi (Part #39, Fig. 19 page 20).

3. Btu input is too low due to insufficient gas pressure.

It is extremely important for a tankless instantaneous water

heater to have the right size gas line to obtain the correct

gas pressure.

See specifications on page 14, table 1. Unlike storage tank

water heaters, the burners of a tankless water heater must

be very powerful to heat water instantaneously since they

do this only at the time hot water is actually being used. It is

therefore imperative that the gas pressure requirement be

met exactly. Insufficient gas pressure will directly affect the

water temperature at the time of usage. See page 14 for

correct gas pressure settings and fig. 11 for locations where

gas pressures are taken.

4. Btu input is too low due to insufficient gas supply.

Make sure your main gas line is fully opened. If using LP

gas, be sure that the size of the propane tank is adequate to

supply the required gas pressure.

5. Cold water is mixing with the hot water between the

Bosch and the outlet.

Compare water temperature at outlet of the Bosch (hold

the Bosch’s outlet pipe with your hand) and at the tap. If

these two are very different, check for mixing valve or

plumbing crossover (see “NO SPARK AT THE PILOT”

paragraph #4). Where automatic “anti-scald” valves are

required by code, lower the temperature setting on the Bosch

as much as possible and balance the pressure between

cold and hot water after the Bosch.

Page 19

6. Parts in water flow valve are corroded so that the

gas passage is not fully opening.

Contact your service person or call:

Canada 1-800-663-8405, U.S.A. 1-800-824-7337.

2. Cold water is mixing with the hot water between the

Bosch and the outlet.

See 4 under “NO SPARK AT THE PILOT”.

HOT WATER TEMPERATURE

FLUCTUATES

1. Unbalanced pressure in waterlines.

The added restriction caused by the Bosch in the hot water

system can result in uneven pressures between the cold

and the hot. In such cases when mixing cold water at the

tap, the lower hot water pressure may be overpowered by a

much higher cold water pressure, which may cause the

Bosch burners to shut down. Make sure faucet aerators or

shower heads are free of minerals. Do not add any flow

restrictor to the shower head.

Fig. 17 - Diagram of WR430-3K

3. Inlet water pressure is erratic due to inadequate supply

water pressure or saturated pressure tank on well

system.

Check the inlet water pressure. On a private well, raise

minimum pressure setting to 40 psi. Confirm that the

pressure tank is not water logged.

4. Gas pressure is too low.

See page 14 for correct specifications.

14

See fig 7(a) on

page 12

3

1. Heat exchanger

2. Pilot assembly

3. Burner manifold gas

pressure test nipple

4. Main gas burner

5. Pilot gas tubing

6. Gas valve

7. Electronic control box

8. Power cord

9. on/off switch

10. Temperature

adjustment selector

11. Microswitch

12. Gas inlet gas pressure

test nipple

13. Electric box

14. Exhaust Fan

2

5

6

13

7

8

11

1

4

9

10

See table 1 on

page 14

12

19

Page 20

Fig. 18

INTERIOR COMPONENTS DIAGRAM

AND PARTS LIST WR430

1 Front Cover 8 705 421 255

2 Bosch Decal 8 701 103 050

3 Plastic lower snap-on 8 705 506 451

4 Temperature adjustment knob complete 8 702 000 219

5 Temperature adjustment knob 8 702 000 111

6 Exhaust fan assembly 8 707 204 023

7 Draft diverter 8 705 505 451

8 Fan protection 8 701 302 164

9 Flue gas safety device 8 707 206 185

10 Heat Exchanger 8 705 406 235

11 Hot water pipe 8 700 705 556

12 Washer 8 710 103 045

13 Overheat sensor (ECO) 8 707 206 040

14 Cold water pipe 8 700 705 294

15 Main burner assembly 8 708 120 298 NG

8 708 120 296 LP

16 Washer for burner assembly 8 710 103 060

17 Throttle disc 8 700 100 189 LP only

18 Gas Valve 8 707 011 811 NG

8 707 011 812 LP

19 Diaphragm switch 8 708 504 021 NG

8 708 504 049 LP

20 Main solenoid valve 8 708 501 250

21 Pilot solenoid valve 8 708 501 249

22 O-ring 8 700 205 120

23 Electrode ignition group 8 718 107 067

24 Pilot burner assembly 8 708 105 337 NG

8 708 105 491 LP

25 Pilot orifice 8 708 200 069 NG

8 708 200 312 LP

26 Pilot gas tube 8 700 707 349

27 Washer 8 700 103 173

28 Electronic control box 8 707 207 011

29 Electric control box 8 707 101 021

30 On/Off switch 8 707 200 014

31 Microswitch 8 707 200 007

32 Water valve 8 707 002 534

33 Water valve repair kit 8 703 406 178

34 Slow ignition valve 8 708 503 063

35 Diaphragm 8 700 503 053

36 Water inlet filter 8 700 507 045

37 Selector screw 8 708 500 251

38 Volumetric water governor 8 707 402 015

39 Venturi 8 708 205 249

40 Cover complete 8 705 500 076

20

Page 21

Fig. 19 - INTERIOR COMPONENTS DIAGRAM AND PARTS LIST

21

Page 22

22

Page 23

23

Page 24

ASTRAVAN DISTRIBUTORS, LTD.

123 Charles Street

North Vancouver, B.C. V7H 1S1

Phone Canada: (604) 929-5488

Phone USA: (206) 860-8448

Web Site: www astravan.com

Page 25

Chauffe-eau instantané, à gaz

VENTILATEUR D'EXTRACTION - ALLUMAGE ÉLECTRONIQUE

Modèle

WR430-3K

• installation

• utilisation

• entretien

Le chauffe-eau instantané Bosch est un appareil très

efficace et peu encombrant destiné au chauffage de l'eau.

Un chauffe-eau instantané Bosch ne chauffe de l'eau que

sur demande; et il n'y a aucune perte d'énergie imputable

au maintien d'un volume d'eau important à une température

élevée comme dans le cas d'un chauffe-eau à accumulation.

LIRE ATTENTIVEMENT LES INSTRUCTIONS AVANT L'INSTALLATION

AVIS À L'INSTALLATEUR : Remettre ce

manuel au propriétaire, ou laisser le manuel

près du chauffe-eau.

ASTRAVAN DISTRIBUTORS, LTD.

6 720 606 181 CA (03.11) AL

123 Charles Street

North Vancouver, B.C. V7H 1S1

Téléphone (Canada) : (604) 929-5488

Téléphone (USA) : (206) 860-8448

Site Internet : www astravan.com

AVERTISSEMENT : Si les instructions de ce manuel

ne sont pas scrupuleusement observées, il pourra

exister un risque d'incendie ou d'explosion

susceptible de provoquer des dommages

matériels et/ou des blessures graves ou

mortelles.

- Ne pas remiser ou utiliser de l'essence ou un autre

produit inflammable liquide ou gazeux au voisinage

de cet appareil ou de tout autre appareil ménager

- QUE FAIRE SI UNE ODEUR DE GAZ EST

PERCEPTIBLE?

• Ne mettre en marche aucun appareil.

• Ne toucher aucun commutateur électrique; ne

pas utiliser un téléphone dans le bâtiment.

• Contacter immédiatement le fournisseur de gaz

à partir du téléphone d'un voisin. Exécuter les

instructions communiquées par le fournisseur de

gaz.

• S'il n'est pas possible de joindre le fournisseur de

gaz, contacter les pompiers.

- Tout travail d'installation ou d'entretien doit être

exécuté par un technicien qualifié ou un membre

du personnel d'une agence d'entretien ou du

fournisseur de gaz.

Note : En cas de problème, contacter le fournisseur ou l'installateur du produit

Page 26

BOSCH WR430-3K

GAZ NAT PROPANE

Principe de fonctionnement :

Lors de l'ouverture d'un robinet, la circulation de l'eau à travers le

chauffe-eau provoque l'ouverture de la vanne d'arrivée de gaz;

simultanément la manœuvre d'un micro-contacteur provoque la

génération d'étincelles pour l'allumage de la flamme de veille. Un

détecteur de flamme détermine que la flamme de veille est allumée et

permet ensuite l'allumage du brûleur. Ensuite la flamme de veille

s'éteint. Le ventilateur d'extraction fonctionne aussi longtemps que

le brûleur est allumé. Le serpentin de l'échangeur de chaleur absorbe

la chaleur générée par le brûleur et la transfère à l'eau. Lors de la

fermeture du robinet de puisage, la vanne d'arrivée de gaz se ferme

automatiquement et le brûleur s'éteint; le ventilateur d'extraction

s'arrête immédiatement après. Le robinet de puisage d'eau tient lieu

d'organe de commande de l'allumage du brûleur du chauffe-eau; on

contrôle ainsi totalement la consommation d'eau chaude et d'énergie.

Dès qu'on referme le robinet de puisage d'eau chaude, ceci met fin

à la consommation d'énergie du chauffe-eau.

CARACTÉRISTIQUES

- Ventilateur d'extraction, avec circuit d'arrêt de sécurité

- Allumage électronique, avec flamme de veille

- Fonctionnement commandé par un commutateur marche/arrêt

- Matériaux de haute qualité - grande longévité.

- Échangeur de chaleur à serpentin de cuivre - source d'eau chaude

durable.

- Débit thermique du brûleur proportionnel au débit d'eau efficacité énergétique maximale.

- Brûleur de veille avec détecteur de flamme - sécurité.

- Protection contre un chauffage excessif par circuit de détection/

arrêt automatique.

Débit thermique

max. 130 000 Btu/h 125 000 Btu/h

min. 28 000 Btu/h 28 000 Btu/h

Raccordement eau : raccord fileté ½ po

H x L x P 29 ¾ po x 18 ¼ po x 8 ¾ po

Bouche de décharge de 4 po (appareil à gaz catégorie III)

Longueur effective max. du conduit de décharge 15 pi (4,5 m)

Raccordement gaz : raccord fileté ½ po NPT

Pression pour douche : 40 lb/po²

Pression d'eau mini : 18 lb/po² (aucun accessoire installé)

Pression d'eau maxi : 150 lb/po²

Poids pour expédition : 50,6 lb

Poids net : 44 lb

Débit pour augmentation de température de 90 °F (32 °C) : 9,5 L/

2,5 GPM

Débit pour augmentation de température de 45 °F (16 °C) : 19,5 L/

5,0 GPM

Débit d'eau minimum : ½ gal/min

120 V/60 Hz , 1,2 A

Propane - pression mini à l'entrée 11 po (col. d'eau)*

Propane - pression sortie détendeur 9,9 po (col. d'eau)*

- Brûleur d'acier inoxydable; flamme bleue stabilisée.

- Ventilateur d'extraction incorporé, résistant à la corrosion.

- Appareil peu encombrant : installation sur un mur avec deux

crochets.

- Capot monopièce à dépose facile.

- Installation facile par une personne seule.

- Dispositif réglable de restriction du débit d'eau - la demande

n'excédera pas la capacité thermique du chauffe-eau.

Gaz naturel - pression mini à l'entrée 7 po (col. d'eau)*

Gaz naturel - pression sortie détendeur 5,38 po (col. d'eau)**

* La pression d'arrivée de gaz ne doit pas dépasser cette valeur

** Pour réglage de la pression à l'entrée

Câble d'alimentation électrique fourni - 3 pi (0,9 m), avec fiche CSA

à 3 broches.

DÉBALLAGE DU CHAUFFE-EAU BOSCH WR430-3K

Ce chauffe-eau a été soigneusement emballé. On trouve dans l'emballage deux raccords de connexion (eau), un bouton

de commande, un détendeur, une soupape de surpression, un plateau de récupération des particules incandescentes,

deux crochets de suspension, et le présent manuel. Veiller à ne pas égarer ce manuel; un éventuel remplacement sera

facturé.

2

Page 27

DIMENSIONS

BOUCHE DE

DÉCHARGE À

L’ E X T É R I E U R ,

AVEC CLAPET

D084_089

Figure 1

Pression d'eau maximum - 1,03 MPa (150 lb/po²)

Pression de service maximum - 0,69 MPa (100 lb/po²)

Pression de service minimum - 0,09 MPa (13 lb/po²) sans tuyauterie installée

Pression recommandée pour applications usuelles et douche - 0,27 MPa (40 lb/po²)

Modèle Type of Gaz Altitude Débit thermique

Gicleur principal

Dia., mm Qt.

WR430-3.K.. 0.79 18

gaz naturel

propane

• Les valeurs de débit thermique indiquées pour une altitude élevée correspondent aux critères de l'Association canadienne du gaz;

elles ne sont valides qu'au Canada. Aux É.-U. la norme ANSI Z223.1-1988 (National Fuel Gas Code) recommande une réduction

des valeurs de débit thermique de 4 % pour chaque palier de 1000 pieds au-delà de 2000 pieds au-dessus du niveau de la mer.

Voir page 14.

0 - 2 000 pi 130 000 Btu/hr (38 kW)

2 - 4 500 pi 116 000 Btu/hr (34 kW)

0 - 2 000 pi 125 000 Btu/hr (36 kW)

2 - 4 500 pi 112 000 Btu/hr (33 kW)

1.20 18

1.20 18

0.79 18

3

Page 28

INTRODUCTION

La conception du chauffe-eau WR430-3K en permet la classification

comme "chauffe-eau instantané à gaz" selon les critères des normes

CAN 1-4.3 et ANSI Z21.10 (édition la plus récente). De plus le

chauffe-eau WR400-3K satisfait également les critères de la norme

CAN 1-2,17 pour l'utilisation à une altitude de 2000 - 4500 pi audessus du niveau de la mer.

Ce manuel contient les instructions d'installation, utilisation et

entretien de l'appareil. Étudier attentivement les instructions

d'utilisation avant d'entreprendre l'installation de ce chauffe-eau

instantané BOSCH.

Le chauffe-eau instantané BOSCH est conçu pour être alimenté au

gaz naturel ou au propane; cependant on doit vérifier que le type

de gaz disponible est celui qui est spécifié sur la plaque signalétique

de l'appareil.

En plus des présentes instructions, l'installation du chauffe-eau

doit satisfaire les critères de l'édition la plus récente du code

d'installation CAN/CGA-B149 (au Canada) ou de la norme Z223.1

(National Fuel Gas Code - aux É.-U.) et/ou des codes locaux

applicables. Les prescriptions des codes et normes applicables

devront être scrupuleusement respectées.

INSTRUCTIONS D'INSTALLATION

Le chauffe-eau Bosch WR430-3K comporte un échangeur de chaleur à tube/ailettes de haute efficacité; on ne devrait pas l'installer ou le

faire fonctionner durant une période de construction ou de rénovation d'un bâtiment, si l'emplacement d'installation est exposé à une

quantité de poussière supérieure à la normale; ceci pourrait provoquer une accumulation de poussière sur l'échangeur de chaleur, qui

pourrait endommager l'appareil et susciter des risques pour la santé.

Note : Le fonctionnement fiable et en sécurité de l'appareil nécessite

une source adéquate d'air de combustion et une réalisation

correcte des circuits et canalisations (eau, gaz, conduit

d'évacuation). Les travaux d'installation et/ou entretien du

chauffe-eau nécessitent des aptitudes et connaissances

équivalentes à celles qui sont exigées des techniciens

professionnels dans chaque spécialité concernée.

DEMANDE D'AIR

Une quantité d'air suffisante doit être disponible pour la combustion

du gaz et pour l'aération du local, et pour la dilution des gaz de

combustion. Une carence d'air suscitera l'établissement d'une

flamme jaune lumineuse sur le brûleur, et l'accumulation de suie sur

l'échangeur de chaleur.

LIEU D'INSTALLATION

Veiller à choisir un emplacement d'installation convenable pour le

chauffe-eau instantané à gaz BOSCH. L'emplacement d'installation

doit être aussi proche que possible de la bouche de décharge à

l'extérieur et aussi proche que possible des tuyauteries

d'alimentation, et il doit disposer d'une source adéquate d'air de

combustion. Ne pas installer le chauffe-eau en un lieu où il pourrait

être exposé au gel. Il est prudent que le chauffe-eau soit installé en

un endroit où une éventuelle fuite d'eau ne fera pas subir de

dommages aux locaux adjacents ou des étages inférieurs du

bâtiment. Voir Extraction des gaz de combustion, à la page 5.

Note : Si l'emplacement d'installation ne peut satisfaire ces critères,

on recommande d'installer sur le chauffe-eau un plateau de

récupération adéquatement relié à une canalisation

d'évacuation. Le plateau utilisé ne doit pas entraver la

circulation d'air de combustion.

ALIMENTATION ÉLECTRIQUE

On doit disposer d'une prise de courant reliée à la terre et contrôlée

par un interrupteur, au-dessous de l'angle inférieur gauche du

chauffe-eau, pour le branchement du cordon d'alimentation fourni

de

3 pi (0,9 m).

Pour éviter la corrosion, veiller à ce que l'air de combustion soit

exempt de substances agressives, en particulier les hydrocarbures

halogénés (composés contenant par exemple du chlore ou du

fluor) qui peuvent entrer dans la composition de divers produits

comme solvant, peinture, adhésif, flacon d'aérosol, produits de

nettoyage ménager, etc. Appliquer les précautions nécessaires.

Dans un espace non confiné d'un bâtiment de construction normale,

l'infiltration d'air est normalement suffisante pour que le chauffe-eau

dispose de la quantité adéquate d'air de combustion, ventilation et

dilution. Cependant si le chauffe-eau est installé dans un espace

confiné (par exemple un placard), il sera nécessaire d'établir deux

ouvertures permanentes pour l'alimentation de l'appareil en air de

combustion et de ventilation. Chaque ouverture doit offrir un espace

de passage libre de 1 po² par 1000 Btu/h* de débit thermique,

pour l'ensemble des appareils installés dans l'espace confiné

considéré. L'une des ouvertures doit être placée à moins de 12 po

du sommet et l'autre à moins de 12 po du fond.

* Note spéciale

Si le chauffe-eau WR430-3K doit être installé dans un espace

confiné de taille minimum, la taille des ouvertures d'entrée d'air

spécifiée ci-dessus doit être de 1,5 po² par 1000 BTU/h de débit

thermique. En d'autres mots, pour l'installation du chauffe-eau dans

un espace confiné de taille minimum, chacune des deux ouvertures

d'aération de l'espace confiné placées à moins de 12 po du sommet

et à moins de 12 po du fond doit offrir une surface de passage d'air

d'au moins 1,5 po² x 130 = 195 po².

4

Page 29

Pour un chauffe-eau installé dans espace confiné ou non confiné

dans un bâtiment relativement étanche, avec infiltration d'air

insuffisante, on doit prélever l'air d'alimentation du chauffe-eau à

l'extérieur ou dans un espace qui communique librement avec

l'extérieur. On doit donc prévoir deux ouvertures permanentes aux

positions indiquées, comme suit :

MONTAGE

La conception du chauffe-eau WR430-3K est homologuée pour

l'installation sur un mur. Le chauffe-eau ne doit pas être installé sur

un mur garni d'une moquette murale; le chauffe-eau doit être fixé sur

le mur au moyen d'accessoires d'ancrage appropriés.

1. Communication avec l'extérieur, directement ou par des

conduits verticaux. Chaque ouverture d'alimentation doit offrir

une surface de passage d'au moins 1 po² par 4000 BTU/h

de capacité thermique totale pour l'ensemble des appareils

installés dans l'espace concerné.

2. Communication avec l'extérieur par des conduits

horizontaux. Chaque ouverture d'alimentation doit offrir une

surface de passage d'au moins 1 po² par 2000 BTU/h de

capacité thermique totale pour l'ensemble des appareils

installés dans l'espace concerné.

Pour le détail des prescriptions, consulter les normes suivantes

(dernière édition) :

• Au Canada, code d'installation CAN/CGA-B149

• Aux É.-U., norme ANSIZ223.1 (National Fuel Gas Code).

AVERTISSEMENT!

1. Ne jamais placer sur le chauffe-eau ou à proximité un récipient

pressurisé ou récipient contenant de l'essence ou un autre

produit inflammable, ou tout autre article constituant un risque

d'incendie. On doit maintenir le voisinage de l'appareil

totalement exempt de produits combustibles, essence et

autres produits inflammables liquides ou gazeux.

2. Ne pas entraver l'arrivée d'air de combustion et de ventilation à

l'appareil.

DÉGAGEMENTS DE SÉPARATION

La conception du chauffe-eau WR430-3K est homologuée pour

l'installation sur un mur de matériaux combustibles ou dans une

alcôve ou un placard, si les valeurs suivantes sont respectées pour

les dégagements de séparation entre le chauffe-eau et les matériaux

combustibles : 0 mm à l'arrière, 102 mm (4 po) sur les côtés, 305

mm (12 po) au sommet et au-dessous, et 102 mm (4 po) à l'avant.

On doit également établir un espace libre d'au moins 305 mm (12

po) pour les interventions d'entretien ou changement de pièces. La

valeur du dégagement de séparation à respecter autour du conduit

d'évacuation des gaz de combustion dépendra du matériau et des

caractéristiques du conduit d'évacuation utilisé; voir la page 6.

Note : Si le mur est constitué d'une ossature garnie de panneaux

de gypse, on recommande de fixer d'abord sur les poteaux

d'ossature des traverses de bois de 1 po x 4 po ou de

contreplaqué d'au moins ½ po, et de fixer ensuite le chauffeeau sur ces supports de bois. Voir la figure 2.

Figure 2

POTEAUX DU

COLOMBAGE

TRAVERSE DE

SUPPORT

TRAVERSE

D'ESPACEMENT 1

PO X 4 PO

Fig. 2 - Montage du chauffe-eau

Les phénomènes de dilatation/contraction des tuyauteries sous

l'effet des variations de la température de l'eau provoquent des

mouvements du chauffe-eau; si celui-ci est fixé directement sur un

matériau fragile ou friable, comme un panneau de gypse, la solidité

de la fixation se dégradera.

L'INSTALLATION DU CHAUFFE-EAU DOIT SATISFAIRE LES CRITÈRES DE L'ÉDITION LA PLUS RÉCENTE DU

CODE D'INSTALLATION CAN/CGA-B149 (AU CANADA) OU DE LA NORME Z223.1 (NATIONAL FUEL GAS CODE

- AUX É.-U.) ET/OU LES PRESCRIPTIONS DE L'AUTORITÉ RÉGLEMENTAIRE COMPÉTENTE.

5

Page 30

CIRCUIT DE DÉCHARGE ET VENTILATEUR D'EXTRACTION Bosch

INTRODUCTION

La conception d'un chauffe-eau Bosch avec ventilateur d'extraction permet de résoudre certaines difficultés qui sont

insurmontables dans le cas d'un système à décharge naturelle vers l'atmosphère; on peut ainsi satisfaire efficacement la

demande d'eau chaude avec un appareil non polluant qui minimise la consommation d'énergie et les rejets de gaz de combustion

à l'atmosphère.

INFORMATION GÉNÉRALE

Le circuit de décharge avec ventilateur d'extraction doit être installé par un *technicien qualifié, dans le respect des prescriptions

de tous les codes applicables régissant les installations d'équipements à gaz et électriques; en l'absence de tels codes, il

conviendra de respecter les prescriptions de l'édition la plus récente des normes suivantes :

• Norme CAN1/CGA B149 (Code d'installation des appareils à combustion de gaz), et Code canadien de l'électricité

C22.1-M90 partie 1, pour le Canada.

• Norme ANSI Z223.1 (National Fuel Code) et norme ANSI/NFPA No 70 (National Electrical Code), pour les É.-U.

Les actions suivantes rendront la garantie Bosch invalide, et Bosch rejette toute responsabilité à cet égard :

• Utilisation de tout composant de circuit d'évacuation non homologué et non fabriqué ou approuvé par Bosch, en

conjonction avec le chauffe-eau Bosch WR430-3K.

• Modification quelconque du chauffe-eau Bosch WR430-3K lors de l'installation du circuit de décharge avec ventilateur

d'extraction. Chaque système doit être installé conformément aux instructions du guide d'installation Bosch.

• Installation réalisée non conformément aux instructions de ce manuel.

MISE EN GARDE :

Le circuit de décharge Bosch avec ventilateur d'extraction doit être installé par une personne qualifiée en conformité

avec les présentes instructions.

Toute installation incorrecte peut susciter l'établissement d'une situation dangereuse, comme risque d'explosion

ou d'empoisonnement par le monoxyde de carbone. Bosch décline toute responsabilité en rapport avec un

appareil incorrectement installé.

*PERSONNEL D'INSTALLATION QUALIFIÉ : Technicien indépendant ou personnel d'une firme ou entreprise qui entreprend

des travaux d'installation et mise en service d'appareils à gaz et dispositifs de contrôle du tirage ou d'extraction d'air, qui justifie

d'une expérience adéquate dans ces travaux, qui a une parfaite connaissance des précautions à observer, et dont le travail

d'installation satisfait les critères de l'autorité réglementaire compétente.

INFORMATION GÉNÉRALE SUR LE CIRCUIT DE DÉCHARGE

DIMENSIONS ET DISTANCES :

Planifier l'installation du circuit de décharge en veillant au respect des dégagements de séparation stipulés par le code

applicable ou par le fabricant, pour la séparation entre les composants du circuit et matériaux combustibles, câblage électrique

et canalisations de plomberie.

Cet appareil doit être directement relié à une bouche de décharge homologuée au moyen d'un coude à 90°, ou au moyen d'un

circuit de décharge de moins de 15 pi (4,6 m) (longueur effective); le circuit d'évacuation ne doit pas incorporer plus de deux

coudes à 90°. Utiliser pour le circuit d'évacuation

uniquement des produits et raccords de diamètre de 4 po (10,2 cm).

6

Page 31

CIRCUIT DE DÉCHARGE ET VENTILATEUR D'EXTRACTION Bosch

INFORMATION GÉNÉRALE SUR LE CIRCUIT DE DÉCHARGE - suite

MATÉRIAUX APPROUVÉS POUR LE CIRCUIT DE DÉCHARGE :

Paroi simple :

Matériau d'épaisseur mentionnée dans l'édition la plus récente de la norme CAN1/CGA B149 (Code d'installation des

appareils à gaz) pour le Canada, ou norme ANSI Z223.1 (National Fuel Code) pour les É.-U.

Note : On ne peut utiliser ces composants dans un espace dissimulé.

Matériaux "B-vent" :

Dans les conditions ci-dessous, on ne peut utiliser que des sections de conduit droites (sans coude)

(i) Section de conduit "B-vent" de 5 po non scellé, utilisée comme gaine de passage d'un conduit scellé de 4 po à paroi

simple, à travers un espace dissimulé ou non chauffé.