Bosch WORCESTER GREENSTAR WIRING CENTRE Installation, Commissioning & Servicing Instructions

INSTALLATION COMMISSIONING & SERVICING INSTRUCTIONS

GREENSTAR WIRING CENTRE

60

0

5

4

3

2

1

I

70

0

4

max

S

off

I

I

Y0

6 720 801 106-00.1O

6 720 804 107 (2012/10) en

CONTENTS

CONTENTS

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 2

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Correct use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Additional system components . . . . . . . . . . . . . . . . . . . . 4

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.1 Connection of BUS and temperature sensor ( 24 V) . . 5

3.2.2 Connection to mains power, pump and

valves (230 V AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.3 Wiring diagrams with system examples . . . . . . . . . . . . . . 8

4 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Status indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Replacing the fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1 KEY TO SYMBOLS AND SAFETY

INSTRUCTIONS

ADDITIONAL SYMBOLS

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

• List entry

– List entry (second level)

Table 1

1.2 SAFETY INSTRUCTIONS

▶ Observe all country-specific regulations and standards during

installation and operation.

▶ Observe all instructions to ensure satisfactory operation.

▶ This product must only be installed and commissioned by a

competent person.

▶ Never install this product in wet rooms.

▶ Install and commission the boiler and other accessories according to

the relevant instructions.

▶ Risk of scalding! A mixer device must be installed if water

temperatures higher than 60 °C are set.

▶ Use this product exclusively in conjunction with the Worcester

controls accessory and boilers that comply with the intended use.

Follow the wiring diagram.

▶ The product requires different voltages.

Do not connect the low-voltage equipment to 230 V mains and vice-

versa.

▶ Before installing the product: electrically isolate the boiler and system

components. Secure against unintentional reconnection and make

sure the power supply is disconnected.

ABOUT THESE INSTRUCTIONS

These installation instructions contain important information regarding

the safe and proper installation, commissioning and maintenance of the

product.

These installation instructions are intended for competent persons who,

as a result of their training and experience, are skilled in dealing with

electrical installations and heating systems.

In these instructions the Greenstar Wiring Center will be referred as

“module”.

1.1 KEY TO SYMBOLS

WARNINGS

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTE indicates a situation that could result in damage to property or

equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or death.

IMPORTANT INFORMATION

This symbol indicates important information where

there is no risk to people or property.

2 PRODUCT DETAILS

NOTICE: Floor damage!

▶ Underfloor heating installations must include a

suitable controls package to prevent excessive flow

temperatures entering the floor.

• The module controls the pump and motorized valves in

– a mid-position (Y-plan) system

-or-

– a two-port valve (S-plan) system

-or-

– three central heating circuits only, without electronic mixing valves

-or-

– two central heating circuits without electronic mixing valves and

one domestic hot water cylinder circuit.

• The module collects

– the temperature of the DHW cylinder via the cylinder temperature

sensor supplied

– the demand signals (from room and/or frost thermostats

optionally).

6 720 804 107 (2012/10)2

PRODUCT DETAILS

i

• Pump seizure protection function:

– The connected pump is monitored and ran for a short period after

24 hours of downtime. This prevents the pump from seizing.

A maximum of three modules per system are permissible, irrespective of

the number of other BUS subscribers:

• a maximum of two modules for a total of six heating circuits without

electronic mixing valves

• a maximum of one module for two additional heating circuits without

electronic mixing valves and one cylinder charging circuit

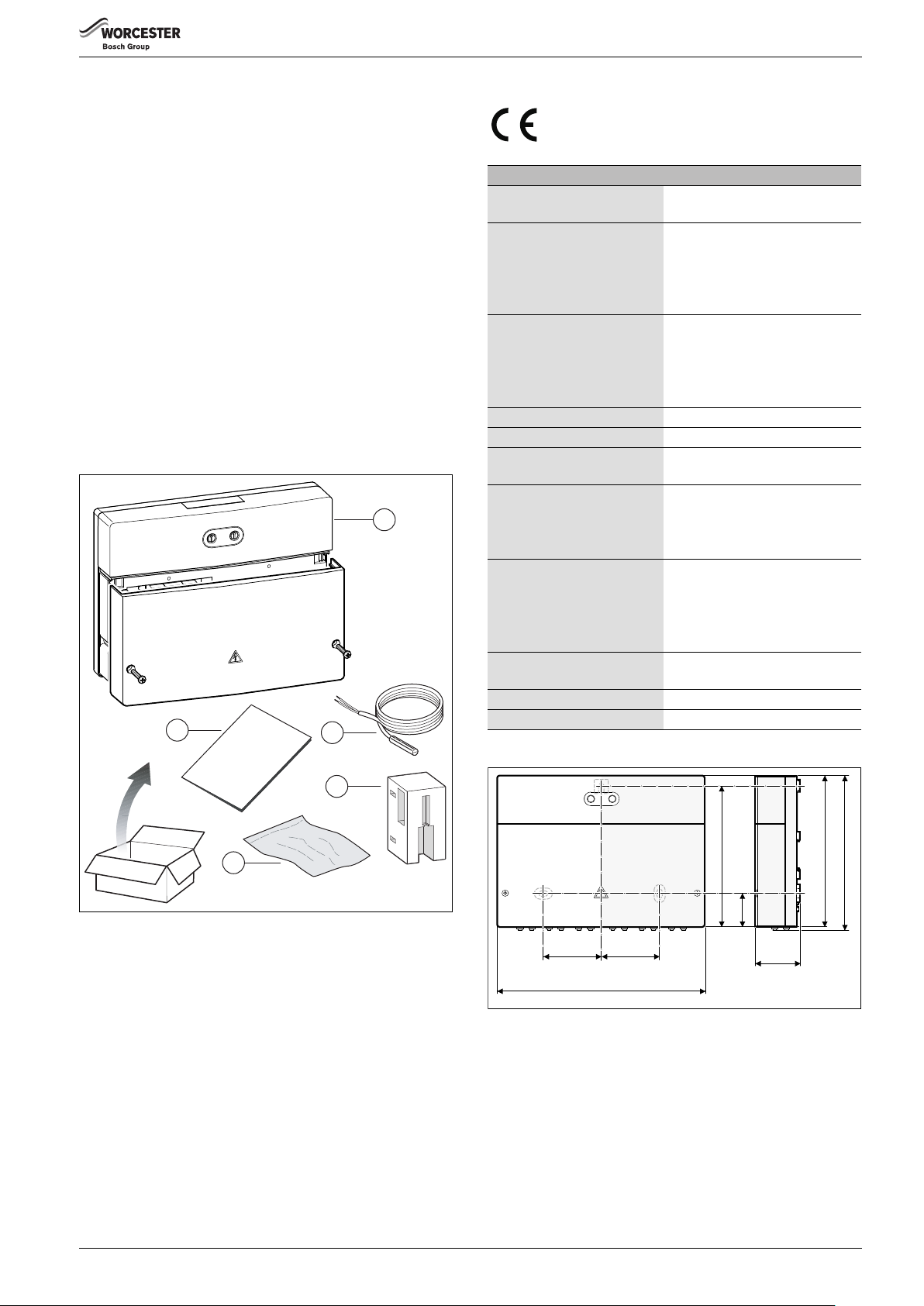

As delivered, the code switch is set to Y. The module will therefore

operate the system as a mid-position (Y-plan). S (S-plan) or other

configurations can be selected when necessary.

2.1 CORRECT USE

The module communicates via an EMS-plus interface with other EMSplus-enabled BUS subscribers such as Greenstar boilers.

▶ Only use the appliance for its intended purpose.

▶ Observe all country-specific regulations and standards during

installation and operation.

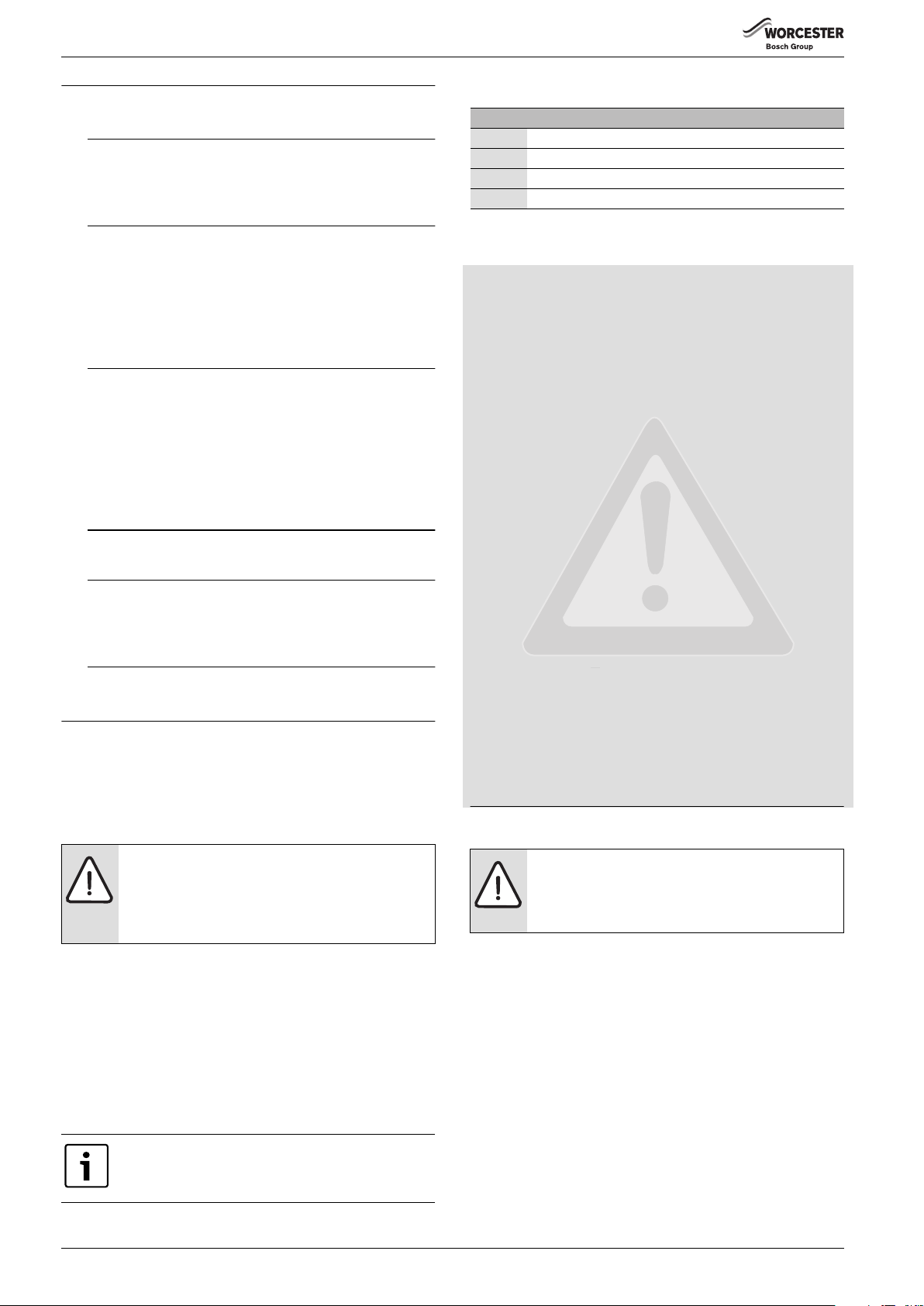

2.2 STANDARD DELIVERY

1

5

2

2.3 SPECIFICATION

Design and operation of this product conform to European

Directives and the supplementary national requirements. Its

conformity is demonstrated by the CE designation.

Technical data

Dimensions (W × H × D) 151 × 184 × 61 mm

(further dimensions fig. 2)

Maximum conductor crosssection

• Terminal 230 V

• Extra-low voltage connecting

terminal

Rated voltages

• BUS

• Module power supply

• Pump and mixer

Fuse 230 V, 5 AT

BUS interface EMS plus

Power consumption –

Standby

max. power output

• per connection (PZ1 ... PZ3)

• per connection (IZ1 ... IZ4)

Temperature sensor

measuring range

• lower fault limit

• display range

• upper fault limit

Permissible ambient

temperature

IP rating IP 44

Id. no. Type plate ( fig. 3, page 4)

Table 2 Technical data

• 2.5 mm

• 1.5 mm

• 15 V DC

• 230 V AC, 50 Hz

• 230 V AC, 50 Hz

< 1 W

• 400 W (high-efficiency pumps

• 230 V AC, max. 0.5 A

• < – 10 °C

• 0 ... 100 °C

• > 125 °C

0 ... 60 °C

2

2

(reverse-polarity-protected)

permissible; max. 40 A/s)

3

4

6 720 804 106-01.1O

Fig. 1 Scope of supply

[1] Module

[2] Cylinder temperature sensor (TC1)

[3] Cylinder temperature sensor (TC1) retaining device. To enable

satisfactory installation of the cylinder temperature sensor on hot

water cylinders without sensor pockets.

[4] Bag with installation material

[5] Installation instructions

72

Fig. 2 Dimensions

246

72

169

40,5

181

61

6 720 804 106-02.1O

184

6 720 804 107 (2012/10) 3

INSTALLATION

60

50

70

4

40

3

2

xo

ma

S

f

f

1

I

I

Y

0

I

6 720 804 106-03.1O

Fig. 3 Position of type plate

Test values for the cylinder temperature sensor (included with the

product)

°C °C

20 14772 56 3723

26 11500 62 3032

32 9043 68 2488

38 7174 74 2053

44 5730 80 1704

50 4608 86 1421

Table 3 Resistance vales of supplied cylinder temperature sensor.

2.4 CLEANING AND CARE

▶ If required, wipe the enclosure with a damp cloth. Never use

chemically aggressive or acidic cleaning agents.

2.5 ADDITIONAL SYSTEM COMPONENTS

• For a mid-position (Y-plan) system:

– Circulating pump; connection to PZ3

– Mid-position valve; connection to PZ1 and PZ2

– Room and/or frost thermostats (optional); connection to IZ3 and

IZ4

• For a two-port valve (S-plan) system:

– Circulating pump; connection to PZ3

– 2 x 2-port valves (with end switches); connection to PZ1 and IZ1

and to PZ2 and IZ2

– Room and/or frost thermostat (optional); connection to IZ3 and IZ4

• For heating circuits with separate heating pumps without electronic

mixing valves (e.g. downstream of low-loss header):

– Circulating pump; connection to PZ1...3

– Room thermostat (optional); connection to IZ1...3

• For domestic hot water cylinder charging circuit with separate

cylinder primary pump (e.g. downstream of low-loss header):

– Cylinder primary pump; connection to PZ1

– Cylinder temperature sensor; connection to TC1

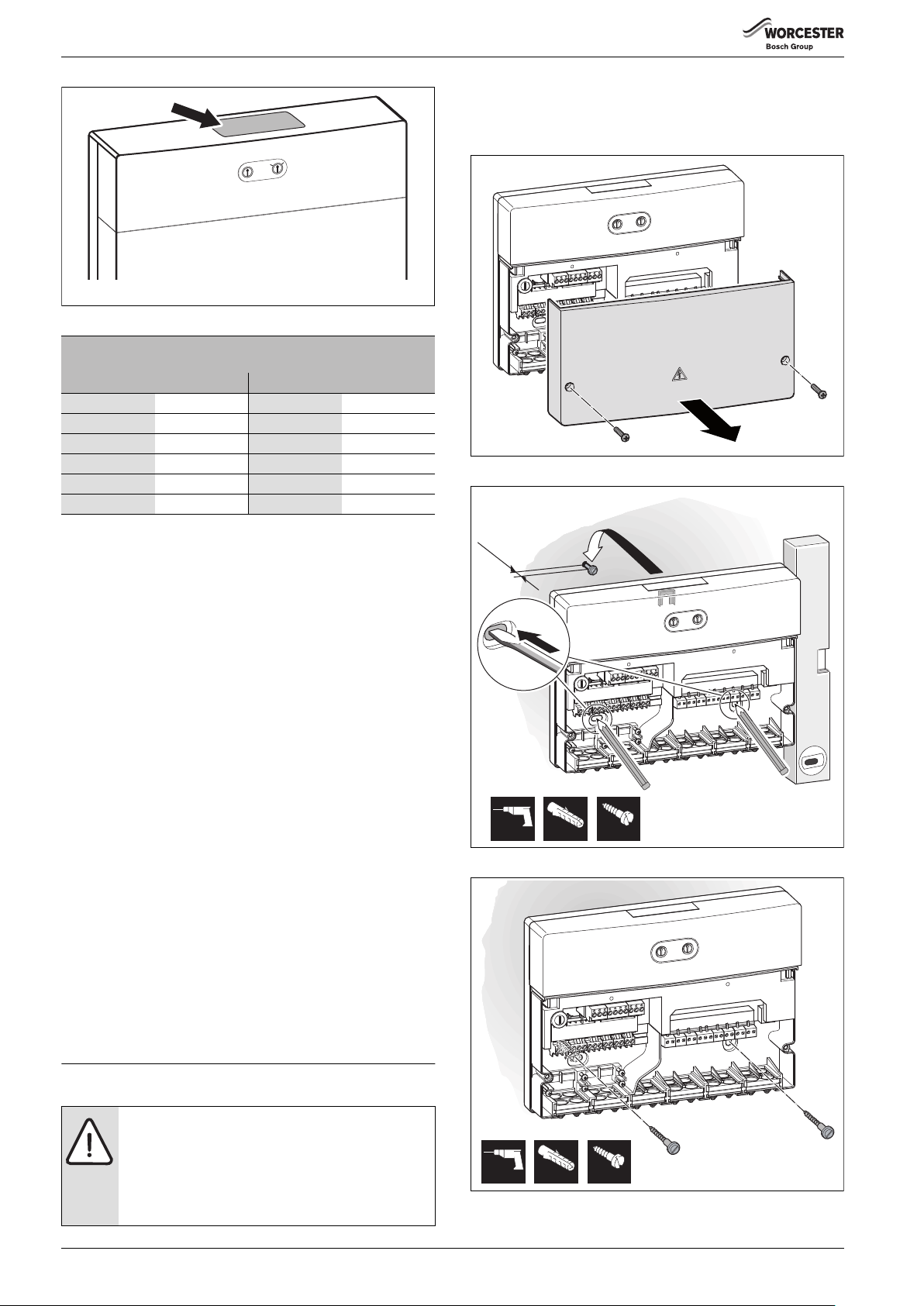

3.1 INSTALLATION

WALL MOUNTING

▶ Mount the module to a wall ( Fig. 4 to 6).

Fig. 4 Wall mounting - step 1

3.

~ 1,5

2.*

1.

4.

*

6 mm 3,5 mm6 mm

Fig. 5 Wall mounting - step 2

6 720 804 106-04.1O

4.

4.

6 720 804 106-05.1O

INSTALLATION OF ADDITIONAL SYSTEM COMPONENTS

▶ Fit additional system components according to legal requirements

and the installation instructions provided.

3 INSTALLATION

DANGER: Risk of electric shock!

▶ Prior to the installation of this product:

Isolate the boiler and system components from the

power supply (230 V AC).

▶ Before commissioning:

Fit the cover ( Fig. 19, page 8).

6 mm 3,5 mm6 mm

Fig. 6 Wall mounting - step 3

6 720 804 106-06.1o

6 720 804 107 (2012/10)4

INSTALLATION

DIN RAIL MOUNTING

▶ Mount the module to a DIN rail ( fig. 7).

6 720 804 106-07.1O

Fig. 7 DIN rail mounting

▶ Observe fig. 8 when removing the component from the DIN rail.

2.

3.2.1 CONNECTION OF BUS AND TEMPERATURE SENSOR

(24 V)

If the maximum cable length of the BUS connections

between all BUS subscribers is exceeded or if the BUS

system is realised as a ring structure, the system cannot

be commissioned.

Maximum total length of BUS connections:

• 100 m at 0.50 mm

• 300 m at 1.50 mm

2

conductor cross-section

2

conductor cross-section

▶ All LV leads must be routed separately from cables carrying mains

voltage to avoid inductive interference (minimum separation

100 mm).

▶ In the case of inductive external interference (e.g. by PV systems), use

shielded cables (e.g. LiYCY) and earth the shield on one side. Do not

connect the shield to the grounded terminal of the module, but to a

building ground terminal, e.g. a free ground terminal or a water pipe.

▶ Connect 1 pair of BUS terminals (BUS 1 and BUS 2) to the BUS

terminals of the boiler.

▶ Connect the cylinder temperature sensor supplied to the terminal

TC1.

For hot water cylinders without sensor pockets, use the

cylinder sensor retaining device to mount the cylinder

temperature sensor securely to the side of the cylinder.

Fig. 8 Removal from DIN rail

3.2 ELECTRICAL CONNECTIONS

DANGER: Risk of electric shock!

▶ Secure together the wires of every cable connected.

This can be done by stripping a short section of cable

sheath or with cable ties close to the terminals

( fig. 9).

3.

1.

6 720 804 106-08.1O

When sensor leads are extended, apply the following lead crosssections:

• Up to 20 m with 0.75 mm

• 20 m up to 100 m with 1.50 mm

2

to 1.50 mm2 conductor cross-section

2

conductor cross-section

▶ Route cables through the grommets provided and connect them as

described in chapter 3.2.3.

3.2.2 CONNECTION TO MAINS POWER, PUMP AND VALVES (230 V AC)

The connection to mains power, pump and valves may

differ depending on the system installed. The following

description is a suggestion how to carry out the electrical

connection of the module.

DANGER: Risk of electric shock!

If the heating system is wired in such a way that the

Greenstar wiring centre and boiler have separate points

of isolation ( fig. 10, page 6):

▶ Attach a warning label to each point of isolation. This

label has to advise that it is not the sole point of

isolation and it has to identify the location of the other

means of isolation.

▶ Electrically isolate the boiler and system

components. Secure against unintentional

reconnection and make sure the power supply is

disconnected.

6 720 647 922-40.1O

Fig. 9 Secure together the wires of every cable connected.

▶ Observe current regulations applicable to power connections, and

use at least cable type H05 VV-…

6 720 804 107 (2012/10) 5

Loading...

Loading...