Bosch WORCESTER GREENSTAR 25CDi GC, WORCESTER GREENSTAR 37CDi, WORCESTER GREENSTAR 30CDi, WORCESTER GREENSTAR 25CDi, WORCESTER GREENSTAR 42CDi Instruction Manual

GREENSTAR CDi

WALL

HUNG

RSF GAS-FIRED

CONDENSING

COMBINATION BOILER

FOR SEALED CENTRAL HEATING SYSTEMS AND MAINS FED DOMESTIC HOT WATER

IS

THE APPLIANCE

NATURAL GAS OR

NATURAL

LIQUID PETROLEUM GAS:

GAS:

WORCESTER

WORCESTER GREENSTAR 30CDi

WORCESTER GREENSTAR 37CDi

WORCESTER GREENSTAR 42CDi

WORCESTER GREENSTAR 25CDi

WORCESTER GREENSTAR 30CDi

WORCESTER GREENSTAR 37CDi

WORCESTER GREENSTAR 42CDi

FOR USE WITH

L.P.G.

(Cat

II

2H3P TYPE C13 & C33)

GREENSTAR 25CDi

INSTRUCTION

INSTALLATION,

&SERVICING

COMMISSIONING

GC

NUMBER 47-311-92

GC

NUMBER 47-311-93

GC

NUMBER 47-406-08

GC

NUMBER 47-406-10

GC

NUMBER 47-311-96

GC

NUMBER 47-311-97

GC

NUMBER 47-406- 09

GC

NUMBER 47-406-11

MANUAL

(}enchmarf)

CONTACT INFORMATION

INSTALLATION & SERVICING INSTRUCTIONS

WORCESTER

TECHNICAL: 08705 266241

SERVICE: 08457

SPARES: 01905 752571

LITERATURE: 01905 752556

TRAINING: 01905 752526

SALES: 01905 752640

WEBSITE:

WATER TREATMENT:

OX 01799 550811

FERN

www.fernox.com

SENTINEL

www.betzdearborn.com/sentinel

TERMINAL GUARD:

FLUE

TOWER FLUE COMPONENTS

VALE

RISE

TONBRIDGE

TN9 1TB

BOSCH:

256206

www.worcester-bosch.co.uk

0151

420

9595

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE STARTING INSTALLATION.

THESE

MODEL(S)

USED WITH ANY OTHER MAKE

THE INSTRUCTIONS APPLY

STATUTORY OBLIGATION.

THIS APPLIANCE MUST BE INSTALLED

CORRECTLY

IF YOU ARE

DISTANCE LEARNING

BOSCH.

PLEASE LEAVE

BENCHMARK

(EIRE ONLY) WITH THE USER OR

ING.

ABBREVIATIONS USED

INSTRUCTIONS

STATED

COULD

IN

ANY DOUBT CONTACT WORCESTER

LOG

ARE

APPLICABLE

ON THE FRONT COVER OF THIS MANUAL ONLY AND MUST NOT BE

OR

MODEL

IN

THE UK ONLY AND MUST BE FOLLOWED EXCEPT FOR ANY

LEAD

TO

PROSECUTION.

AND TRAINING

THESE

INSTRUCTIONS,

BOOK OR A CERTIFICATE CONFIRMING COMPLIANCE WITH IS

AT

THE

IN

THIS MANUAL:

TO THE

OF APPLIANCE.

BY

A COMPETENT PERSON. FAILURE

COURSES

THE

GAS

WORCESTER

BOSCH

ARE AVAILABLE FROM

USER

GUIDE

METER AFTER INSTALLATION OR SERVIC-

BOSCH

TECHNICAL HELPLINE.

AND

THE

APPLIANCE

TO

INSTALL

WORCESTER

COMPLETED

813

0 Diameter

NG

LPG Liquid Petroleum Gas

CH

DHW

IP Ingress Protection

SEDBUK

Natural Gas

Central Heating

Domestic Hot Water

Seasonal Efficiency of Domestic Boilers

in

the United Kingdom

STORE THE APPLIANCE IN A DRY AREA

PRIOR

TO

INSTALLATION.

LIFTING AND CARRYING PRECAUTIONS:

• Lift only a manageable weight, or ask for

help.

When lifting the boiler, bend the knees,

•

and keep the back straight and feet apart.

• Do not lift and twist at the same time.

• Lift and carry the boiler close to the body

• Wear protective clothing and gloves to

protect from

any

sharp edges

SYMBOLS USED IN

Domestic hot water

Central heating

•

Cold water

Electricity supply

supply

Gas

THIS

main

MANUAL:

supply

Time

clock C H only

Programmer/timer

Room

thermostat

Wait time period

INSTALLATION &

SERVICING INSTRUCTIONS

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

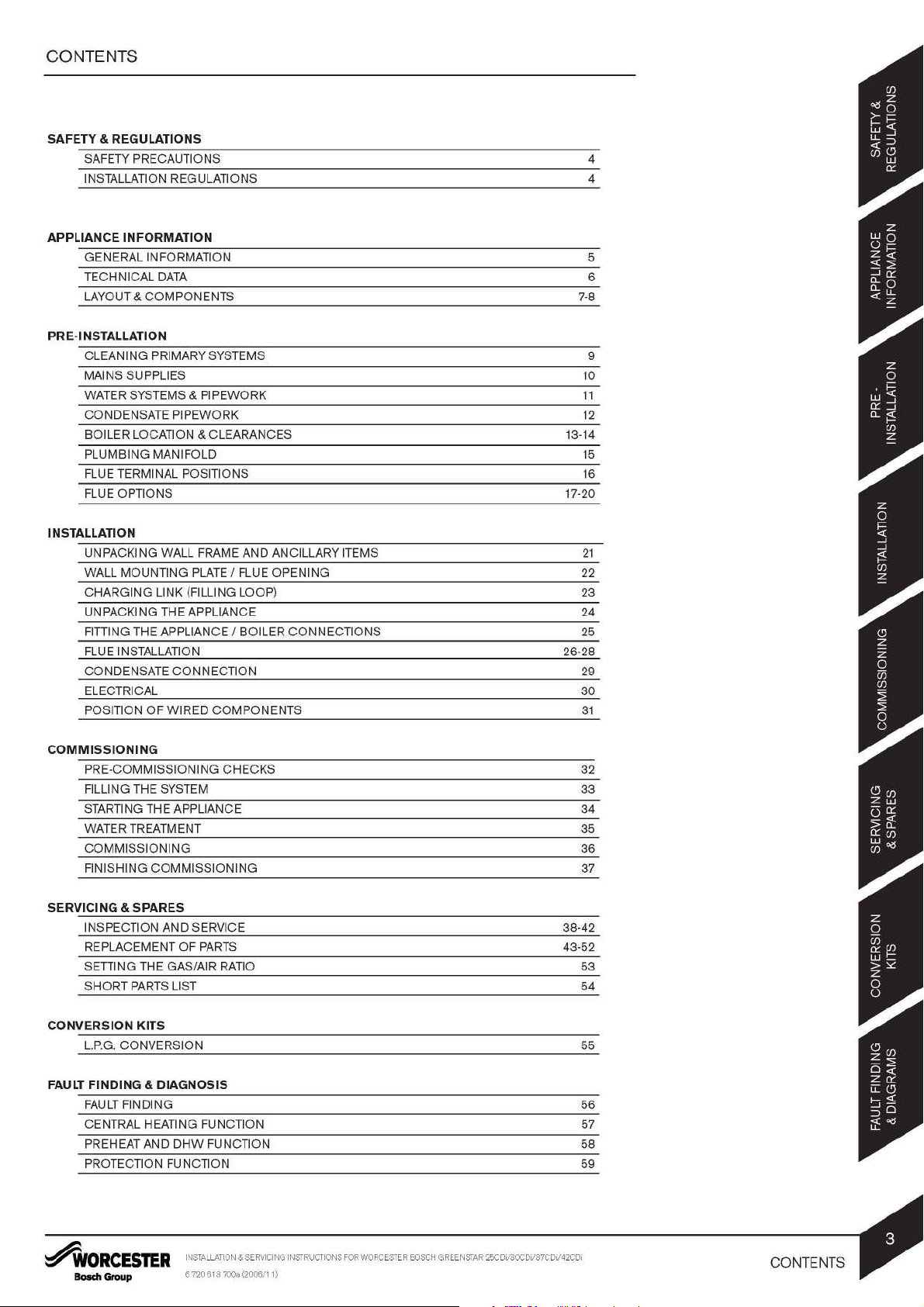

CONTENTS

SAFETY & REGULATIONS

SAFETY PRECAUTIONS

INSTALLATION REGULATIONS

APPLIANCE INFORMATION

GENERAL INFORMATION

TECHNICAL

LAYOUT & COMPONENTS

PRE-INSTALLATION

CLEANING PRIMARY SYSTEMS

MAINS SUPPLIES

WATER SYSTEMS & PIPEWORK

CONDENSATE PIPEWORK

BOILER LOCATION & CLEARANCES

PLUMBING MANIFOLD

FLUE TERMINAL POSITIONS

FLUE OPTIONS

DATA

4

4

5

6

7-8

9

10

11

12

13-14

15

16

17-20

INSTALLATION

UNPACKING WALL FRAME AND ANCILLARY ITEMS

PLATE

WALL MOUNTING

CHARGING

UNPACKING THE APPLIANCE

FITTING THE APPLIANCE I BOILER

FLUE INSTALLATION

CONDENSATE CONNECTION

ELECTRICAL

POSITION OF WIRED COMPONENTS

LINK (FILLING LOOP)

I FLUE OPENING

CONNECTIONS

COMMISSIONING

PRE-COMMISSIONING

FILLING THE SYSTEM

STARTING THE APPLIANCE

WATER TREATMENT

COMMISSIONING

FINISHING

COMMISSIONING

CHECKS

SERVICING & SPARES

INSPECTION AND SERVICE

REPLACEMENT OF

SETTING THE GAS/AIR

SHORT

PARTS

PARTS

RATIO

LIST

21

22

23

24

25

26-28

29

30

31

32

33

34

35

36

37

38-42

43-52

53

54

CONVERSION KITS

L.P.G.

CONVERSION

FAULT

FINDING & DIAGNOSIS

FAULT

FINDING

CENTRAL HEATING FUNCTION

PREHEAT AND

PROTECTION FUNCTION

DHW

~ORCESTER

Bosch

Group

FUNCTION

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDci42CDI

55

56

57

58

59

CONTENTS

SAFETY PRECAUTIONS

IF YOU SMELL GAS:

X DON'T

X DON'T TURN

V'

V'

V'

V'

V'

(/Jenc!Jmorl()

A Benchmark Log

including

commissioned and serviced according to the manufacturer's instructions.

HEALTH &

COMBUSTIBLE

FITTING & MODIFICATIONS

SERVICING

SMOKE

DO PUT

DO

OPEN

DO KEEP

DO TURN

TELEPHONE

their CORGI registration number

IMPORTANT: The completed Benchmark Checklist will be required

warranty

ELECTRICAL

OUT

NAKED

DOORS

PEOPLE

OFF

THE

Book

work

OR

STRIKE

MATCHES

SWITCHES

FLAMES

AND

WINDOWS

AWAY

FROM

THE

CONTROL

NATIONAL

is provided by the manufacturer for the installer

and may be required by the local Building Control Inspector.

VALVE AT

GAS

ON OR

OFF

THE

AREA

AFFECTED

THE

METER

EMERGENCY

to

confirm that the boiler has been installed,

SERVICE

ON

0800111999

to

complete

in

SAFETY

The

appliance

construction process that contravene the

Hazardous

Do not store or use any combustible materials (paper, thinners, paints etc.) inside or

within the vicinity

Chemically

chlorine or fluorine

Fitting the appliance and any controls

competent

Regulations 1998.

Flue systems must

instructions.

associated components and systems could invalidate the warranty. The manufacturer

accepts

Advise

engineer (such as British

to

help maintain the economy, safety and reliability

IMPORTANT-

Benchmark section after each service.

contains

to

Health Regulations 1988).

AND

of

aggressive

engineer

Any

no liability arising from any such actions, excluding statutory rights.

the

user

no

asbestos

and

no

COSHH

CORROSIVE MATERIALS

the appliance.

substances,

compounds

in

accordance

not

be modified

misuse

to

have

Gas

or

the

such as

can corrode the appliance and invalidate any warranty.

to

the appliance may only be carried out

with

the

in

any way other than as described

unauthorised

system

or

CORGI

modifications

serviced

registered personnel) using approved spares,

substances

Regulations (Control

halogenated

Gas

annually

of

hydrocarbons

Safety

to

by a competent, qualified

the appliance.

have

been

(Installation

the

appliance,

The service engineer must complete the Service Record

the event

used

of

Substances

containing

and

in

the fitting

of

in

Use)

flue

in

any

the

by

the

or

INSTALLATION REGULATIONS

Gas

Safety

(Installation

All

gas

appliances

competent person

regulations. Failure to install appliances correctly

could lead

The

with,

Regulations,

Regulations,

(Consolidation), Building Regulations (Northern

Ireland), local

Document

Regulations

requirements.

British Standards:

The

including:

BS7074:1

water

BS6891 : Installation

pipework up to 28mm

BS5546

domestic purposes

EN:12828:

BS5440:1

ances of rated heating not exceeding

Flues

BS5440:2

ances of rated heating not exceeding

Air

BS7593

water central heating systems

a

BS

input up to

Where no specific instruction is given, reference

should be made to the relevant British Standard

codes

L.P.G.

An

a room or internal space below ground level unless

one side of the building

Timber framed buildings:

Where the boiler

building the guidelines laid down

1 and

Buildings" should be adhered to.

to prosecution.

appliance must be installed

and

comply

IE E Regulations,

Building

water

635

1989)

relevant British Standards should be followed,

:Code

supply

: Installation of gas hot water supplies for

Central heating for domestic premises

: Flues and ventilation for gas appli-

: Flues and ventilation for gas appli-

Supply

: Treatment

6798 : Installation of gas fired boilers of rated

70kW

(net)

of

Practice.

Installation:

appliance using

is

IGE

"Gas

& Use)

Regulations:

must

be

installed

in

accordance with the above

in

to, the

current:

Standards

by-laws, Health &

(The

Electricity

and

any

of practice for domestic and hot

of

low

pressure

(R1)

of

water

in

L.P.G.

must not be installed

is

open to the ground.

to be fitted to a timber framed

in

Installations

in

Timber Frame

accordance

Gas

Safety

Building

(Scotland)

Safety

at

Work

other

local

70kW

(net) :

70kW

(net) :

domestic

BS5440:

by

gas

hot

Part

a

in

SAFETY PRECAUTIONS

& INSTALLATION REGULATIONS

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

Potable water:

components

domestic

WRAS.

co;

(2006/11)

compounds

water system must be

~ORCESTER

All seals, joints and

and solder) and

the secondary

approved by

CHwater:

Artificially softened water must not be used to

fill the central heating system.

25CDI/30CDI/37CDI/42

613

700a

6 720

(including flux

used as

Bosch

Group

part

of

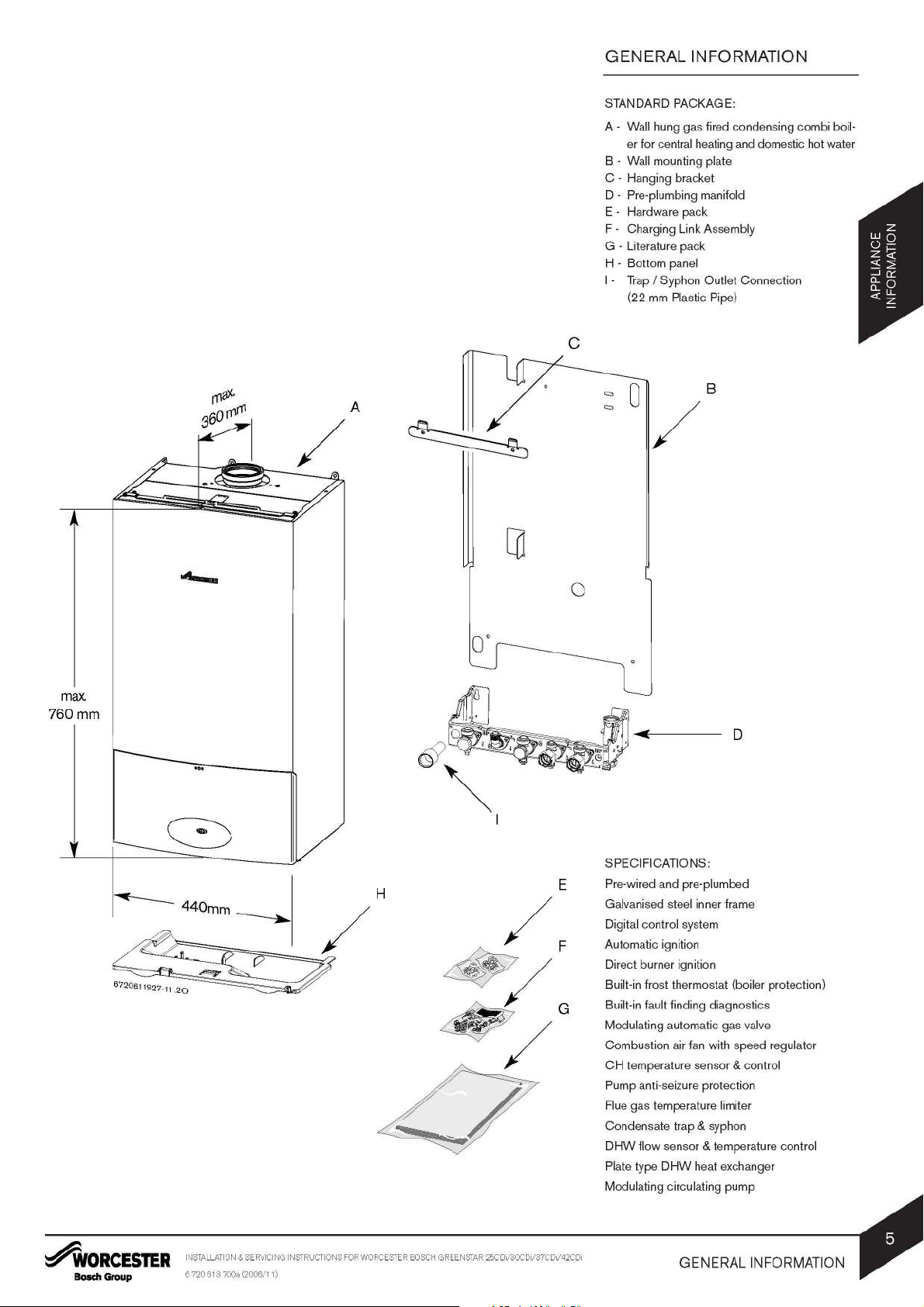

GENERAL INFORMATION

Bottom

(22 mm

PACKAGE:

gas

pack

pack

panel

Plastic Pipe)

STANDARD

A-

Wall hung

er for central heating and domestic hot water

Wall mounting plate

B -

C

- Hanging bracket

D - Pre-plumbing manifold

E - Hardware

F-

Charging Link Assembly

G - Literature

H -

I

- Trap I Syphon Outlet Connection

c

/

fired condensing combi boil-

B

max.

760mm

H

0

0

D

69~

I

SPECIFICATIONS:

Pre-wired and pre-plumbed

Galvanised steel inner frame

Digital control system

Automatic ignition

Direct burner ignition

Built-in frost thermostat (boiler protection)

Built-in fault finding diagnostics

Modulating automatic gas valve

Combustion air fan with speed regulator

CH

temperature sensor & control

Pump

anti-seizure protection

gas

Flue

Condensate trap & syphon

DHW

Plate

Modulating circulating

temperature limiter

flow

sensor & temperature control

type

DHW

heat exchanger

pump

~ORCESTER

Bosch

Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDc!42CD'

GENERAL INFORMATION

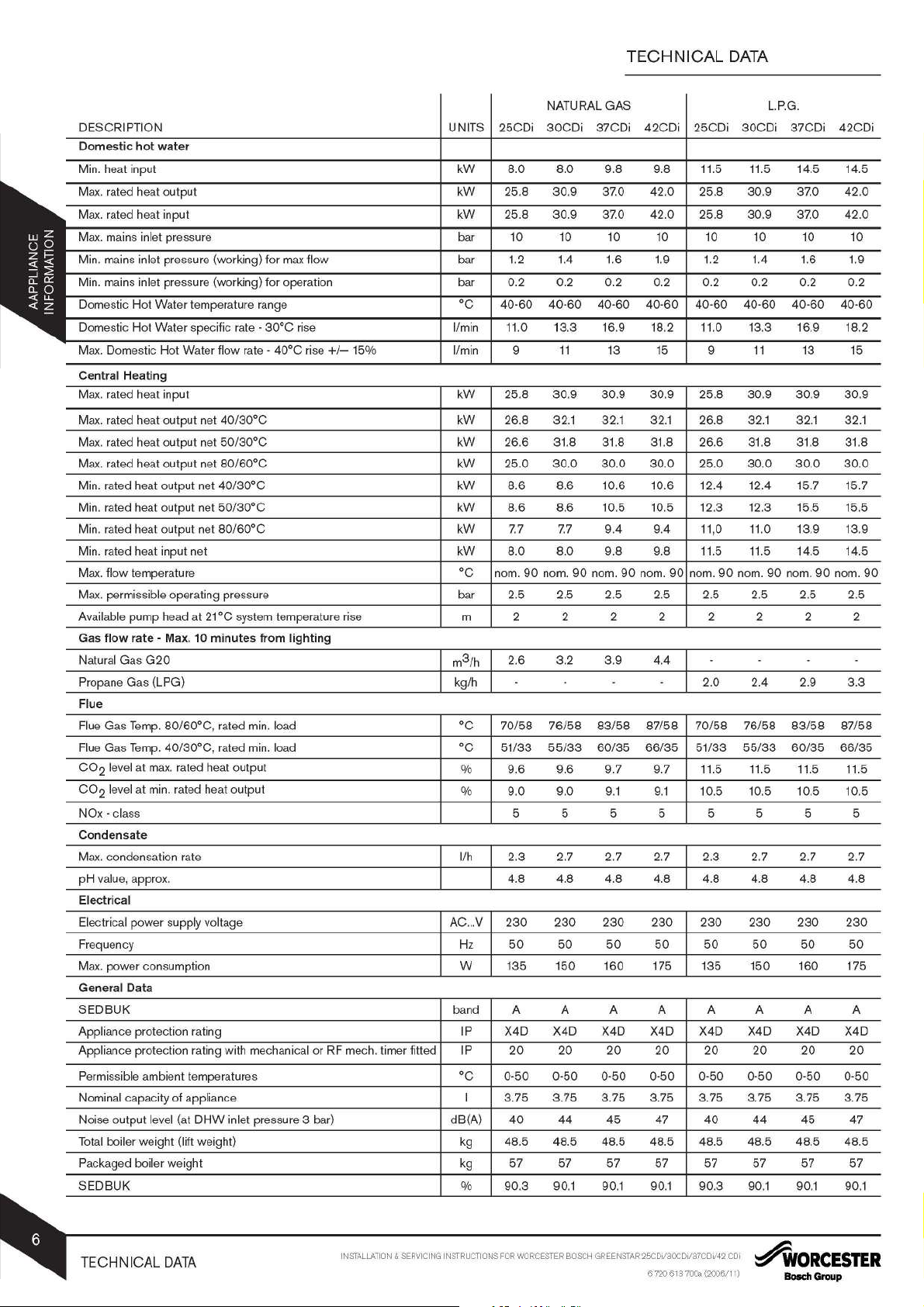

TECHNICAL

NATURAL GAS L.P.G.

DESCRIPTION UNITS 25CDi

Central Heating

Max.

rated heat input

Max.

rated heat output net

Max.

rated heat output net

Max.

rated heat output net

Min. rated heat output net

Min. rated heat output net

Min. rated heat output net

Min. rated heat input net

Max.

flow temperature

Max.

permissible operating pressure bar 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Available pump head at

flow

rate-

Gas

Natural Gas

Propane Gas (LPG)

Flue

Flue

Gas

Flue

Gas

C02

level at

C02

level at

NOx-

class

Condensate

Max.

condensation rate 2.3 2.7 2.7 2.7 2.3 2.7 2.7 2.7

pH

value, approx. 4.8 4.8 4.8 4.8 4.8 4.8 4.8 4.8

Electrical

Electrical

Frequency

Max.

power consumption w 135 150 160 175 135 150 160 175

General Data

SEDBUK

Appliance protection rating IP X4D X4D X4D X4D X4D X4D X4D X4D

Appliance protection rating with mechanical or

Permissible

Nominal

Noise output

Total

boiler weight (lift weight)

Packaged boiler weight

SEDBUK

Max.

G20

Temp.

80/60°C,

Temp.

40/30°C,

max.

min.

rated heat output

power supply voltage

ambient temperatures

capacity of appliance I 3.75 3.75 3.75 3.75 3.75 3.75 3.75 3.75

level (at

40/30°C

50/30°C

80/60°C

40/30°C

50/30°C

80/60°C

21

•c

system temperature rise m 2 2 2 2 2 2 2 2

10

minutes

rated min. load

rated min. load

rated heat output

DHW

inlet pressure 3 bar)

from

lighting

RF

mech. timer fitted IP 20 20 20 20 20 20 20 20

kW

kW

kW

kW

kW

kW

kW

kW

•c

nom.

•c

70/58

•c

51/33

% 9.6 9.6 9.7 9.7

% 9.0 9.0

AC

..

.V

Hz

band A A A A A A A A

•c

dB(A)

kg

kg

% 90.3

30CDi

25.8 30.9 30.9 30.9 25.8 30.9 30.9 30.9

26.8 32.1

26.6 31.8 31.8 31.8 26.6 31.8 31.8 31.8

25.0

8.6 8.6 10.6 10.6 12.4 12.4 15.7 15.7

8.6 8.6 10.5 10.5 12.3 12.3 15.5 15.5

7.7 7.7

8.0 8.0 9.8 9.8

90

nom.

2.6 3.2 3.9 4.4

76/58

55/33

5 5 5 5 5 5 5 5

230

50 50

0-50 0-50 0-50 0-50 0-50 0-50 0-50 0-50

40 44

48.5 48.5 48.5 48.5 48.5 48.5 48.5 48.5

57 57 57 57 57 57 57 57

37CDi 42CDi 25CDi

32.1

30.0

90.1

30.0 30.0 25.0 30.0

9.4 9.4

90

nom.

90

83/58

60/35

9.1 9.1

230

230 230 230 230 230 230

50

45 47

90.1 90.1

32.1

nom.

90

87/58

66/35

50 50

DATA

30CDi

26.8

11,0 11.0

11.5 11.5

nom.

90

nom.

2.0

70/58 76/58

51/33

55/33

11.5 11.5 11.5 11.5

10.5 10.5 10.5 10.5

40 44

90.3

37CDi 42CDi

32.1 32.1 32.1

30.0 30.0

13.9 13.9

14.5 14.5

90

nom.

90

nom.

2.4 2.9 3.3

83/58

60/35

50

90.1 90.1 90.1

50

45 47

87/58

66/35

50

90

TECHNICAL

DATA

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

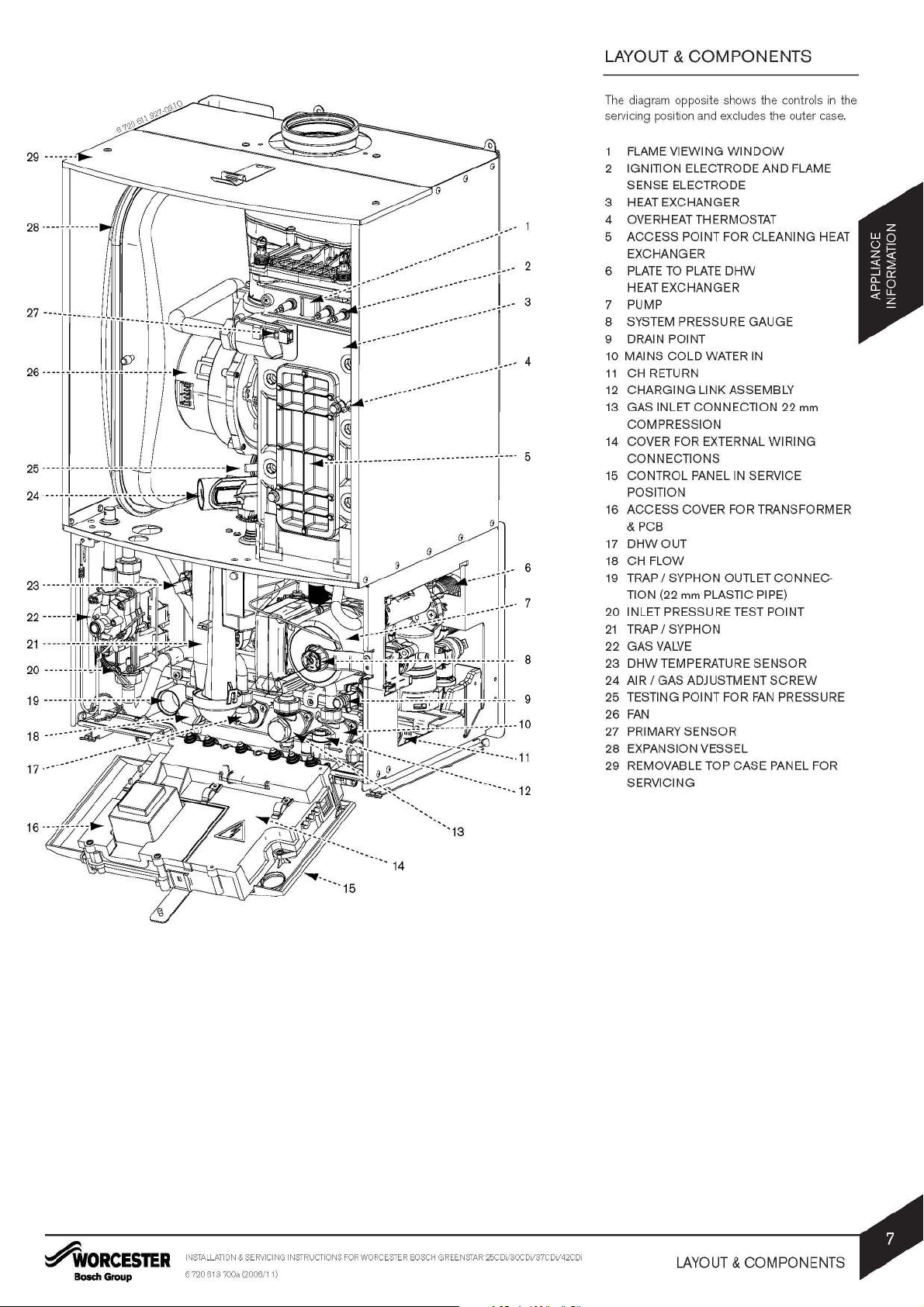

LAYOUT &

The

diagram opposite shows the controls

servicing position

COMPONENTS

and

excludes the outer

in

case.

the

28

·---------

27

------------

---

---

---

---

---

................

-- 3

. 5

12

FLAME VIEWING

2 IGNITION ELECTRODE AND FLAME

SENSE ELECTRODE

WINDOW

3 HEAT EXCHANGER

4 OVERHEAT THERMOSTAT

5 ACCESS POINT FOR CLEANING HEAT

2

EXCHANGER

6

PLATE

TO

HEAT EXCHANGER

7 PUMP

PLATE

DHW

8 SYSTEM PRESSURE GAUGE

9 DRAIN POINT

10

MAINS

COLD

WATER

4

6

7

8

11

CH

RETURN

12

CHARGING

13

GAS INLET CONNECTION 22

COMPRESSION

14

COVER FOR EXTERNAL

CONNECTIONS

15

CONTROL PANEL

POSITION

16

ACCESS COVER FOR TRANSFORMER

&PCB

17

DHWOUT

18

CH

FLOW

19

TRAP I SYPHON OUTLET

TION (22

20 INLET PRESSURE TEST POINT

21

TRAP I SYPHON

22 GAS

23

DHW

24 AIR I GAS ADJUSTMENT

25 TESTING POINT FOR

FAN

26

27

PRIMARY

28 EXPANSION VESSEL

29 REMOVABLE TOP CASE PANEL FOR

SERVICING

LINK ASSEMBLY

mm

PLASTIC PIPE)

VALVE

TEMPERATURE

SENSOR

IN

IN

SERVICE

SENSOR

FAN

mm

WIRING

CONNEC·

SCREW

PRESSURE

16 ·-

---

........

14

~ORCESTER

Bosch

Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDci42CDI

LAYOUT &

COMPONENTS

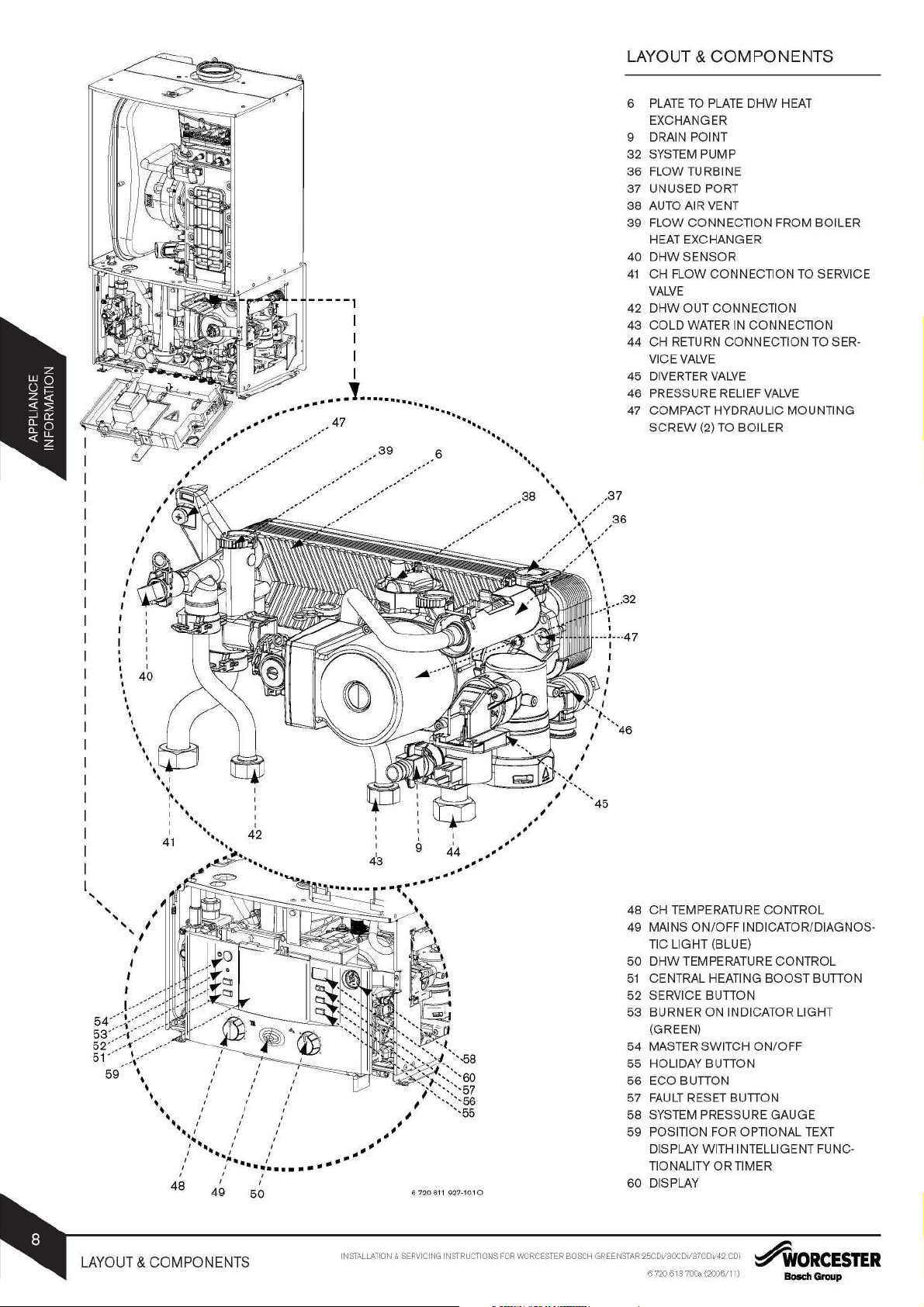

LAYOUT & COMPONENTS

PLATE

TO

PLATE

DHW

6

EXCHANGER

DRAIN POINT

9

32 SYSTEM PUMP

36

FLOW TURBINE

37 UNUSED PORT

38

AUTO AIR VENT

39 FLOW CONNECTION FROM BOILER

HEAT EXCHANGER

DHW

40

41

SENSOR

CH FLOW CONNECTION

VALVE

42

DHW

OUT CONNECTION

43 COLD WATER

IN

44 CH RETURN CONNECTION

VALVE

VICE

45 DIVERTER

VALVE

46 PRESSURE RELIEF

47

COMPACT HYDRAULIC MOUNTING

SCREW

I

I

I

I

I

I

I

I

I

I

I

',,1

I

I 45

41

I

I

42

I

I

••

•••

•'

•'

I

•'

1'-,

I

I

I

',,

I

I

---•---47

I

I

I

I

I

I

I

''46

I

(2)

TO

HEAT

TO

CONNECTION

VALVE

BOILER

SERVICE

TO

SER-

'

'

',

' I

'I

;

I

I

t

LAYOUT & COMPONENTS

6720611927-10.10

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

CH TEMPERATURE CONTROL

48

MAINS

49

ON/OFF

TIC LIGHT

DHW

50

51

TEMPERATURE CONTROL

CENTRAL HEATING

INDICATOR/DIAGNOS-

(BLUE)

BOOST

BUTTON

52 SERVICE BUTTON

53 BURNER ON INDICATOR LIGHT

(GREEN)

MASTER SWITCH

54

ON/OFF

55 HOLIDAY BUTTON

56 ECO BUTTON

57

FAULT

RESET BUTTON

58 SYSTEM PRESSURE GAUGE

59

POSITION FOR OPTIONAL

TEXT

DISPLAY WITH INTELLIGENT FUNC-

TIONALITY OR TIMER

60 DISPLAY

25CDI/30CDI/37CDI/42

6 720

613

700a

co;

(2006/11)

~ORCESTER

Bosch

Group

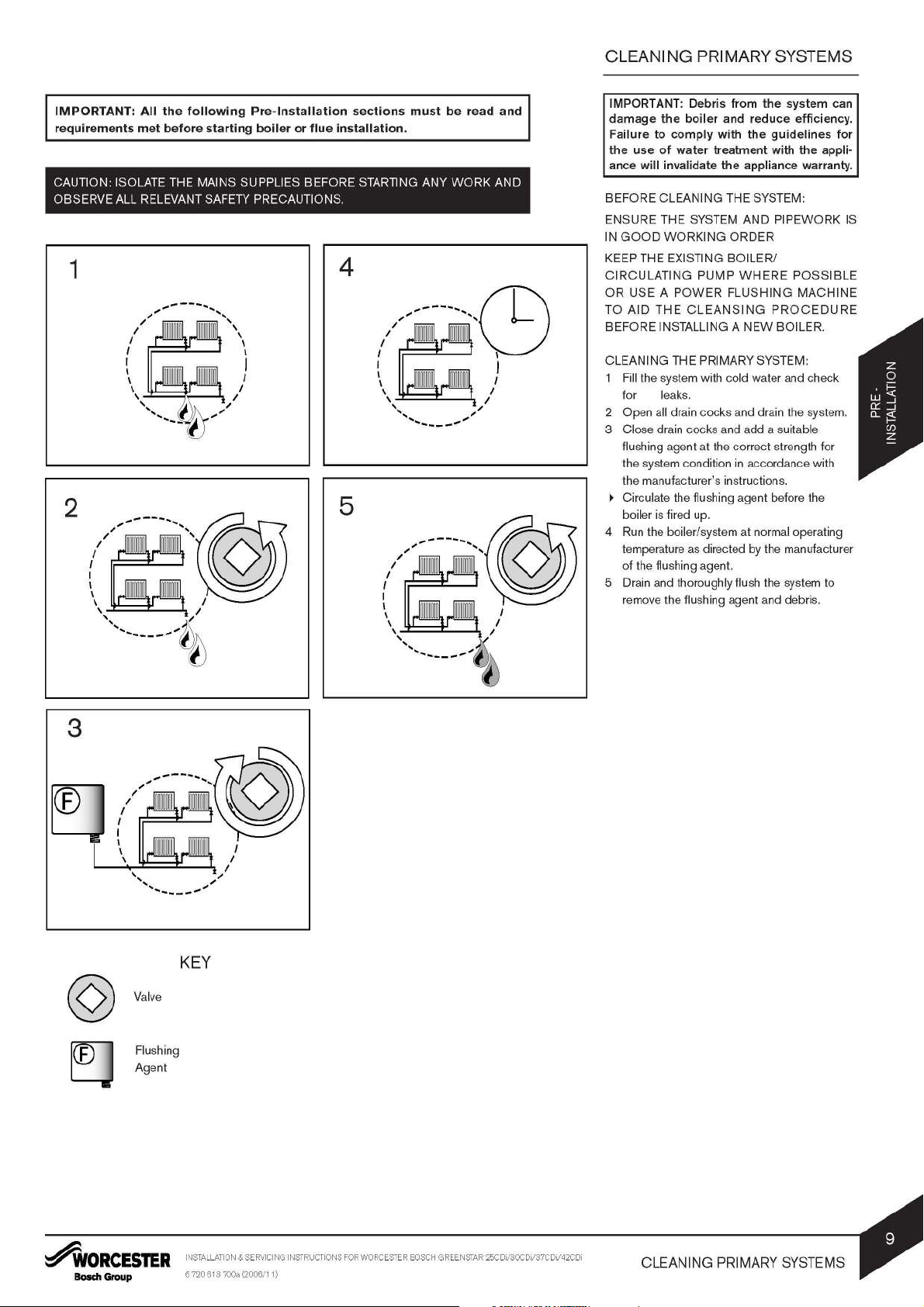

IMPORTANT:

requirements

CAUTION: ISOLATE

OBSERVE ALL RELEVANT SAFETY PRECAUTIONS.

All

met

the

following

before

THE

MAINS SUPPLIES BEFORE STARTING ANY WORK AND

starting

Pre-Installation

boiler

or

flue

1

2

sections

installation.

4

5

must

be

read

and

CLEANING PRIMARY SYSTEMS

the

IMPORTANT: Debris from

damage

Failure to

the

ance will invalidate the appliance warranty.

BEFORE CLEANING THE SYSTEM:

ENSURE

IN

KEEP

CIRCULATING PUMP

OR USE

TO

BEFORE INSTALLING A NEW BOILER.

CLEANING THE PRIMARY SYSTEM:

2 Open

3

~

4

5

the

boiler and reduce efficiency.

comply

use

of

THE

GOOD

WORKING ORDER

THE EXISTING BOILER/

A POWER FLUSHING MACHINE

AID

THE

Fill

the

system with cold water

for

leaks.

all

drain cocks

Close drain cocks

agent at

flushing

the

system condition

the

manufacturer's instructions.

Circulate

boiler

is

fired

Run

the

boiler/system at

temperature

of

the

flushing agent.

Drain

and

remove

the flushing agent and debris.

with

water treatment with the appli-

SYSTEM

WHERE

CLEANSING

and

and

the

correct strength for

in

the

flushing agent before

up.

as

directed

thoroughly flush

system can

the

guidelines

AND PIPEWORK

POSSIBLE

PROCEDURE

and

check

drain

the

system.

add a suitable

accordance with

the

normal

operating

by

the

manufacturer

the

system to

for

IS

3

@

~

KEY

Valve

Flushing

Agent

~ORCESTER

Bosch Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDci42CD•

CLEANING PRIMARY SYSTEMS

f

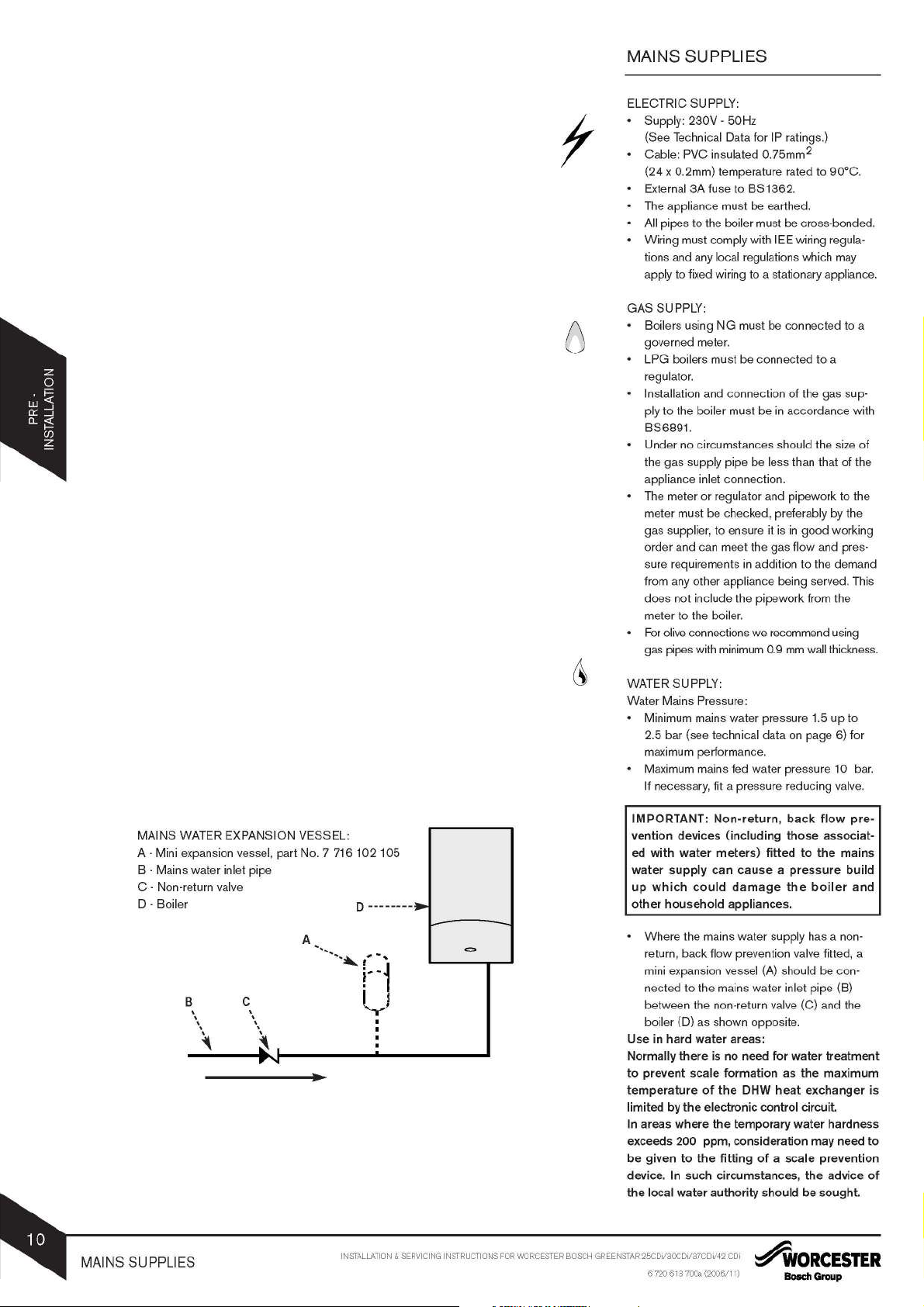

MAINS SUPPLIES

ELECTRIC SUPPLY:

230V-

Supply:

(See Technical Data for IP ratings.)

Cable: PVC insulated

(24 x 0.2mm) temperature rated to

External

The

appliance must

• All pipes to the boiler must be cross-bonded.

Wiring must comply with lEE wiring regula-

tions and

apply to fixed wiring to a stationary appliance.

GAS SUPPLY:

Boilers using

governed meter.

LPG boilers must be connected to a

regulator.

Installation

ply

to the boiler must be

BS6891.

Under no circumstances should the size

the gas supply pipe be less than that of the

appliance inlet connection.

The

meter or regulator and pipework to the

meter must be checked,

gas

supplier, to ensure it

order and can meet the gas

sure requirements

from any other

does not

meter to the

For

olive

gas pipes with

50Hz

0.

75mm2

90°C.

3A

fuse to BS1362.

be

earthed.

any

local regulations which

NG

must

be

connected to a

and connection of the gas sup-

in

accordance with

preferably

is

in

in

addition to the demand

appliance being served. This

include the pipework from the

boiler.

connections we recommend using

minimum

0.9

mm

may

by

the

good working

flow and pres-

wall thickness.

of

MAINS WATER EXPANSION VESSEL:

A-

Mini expansion vessel, part

B - Mains water

C-

Non-return valve

D-

Boiler

inlet pipe

B

\

\

c

\

\

\

\

No.7

716

\

\

~

'

,.."'

102 105

--------•

D

=

-

SUPPLY:

WATER

Water Mains Pressure:

Minimum mains water pressure

2.5 bar (see

maximum performance.

Maximum mains fed water pressure

If necessary, fit a pressure reducing valve.

IMPORTANT:

vention

ed

with

water

up

which

other

household

Where the mains water supply has a non-

return, back flow prevention valve fitted, a

mini expansion

nected to the mains water inlet pipe (B)

between the non-return

boiler (D) as shown opposite.

Use in hard

Normally there is no need for water

to

prevent

temperature

limited by

In areas where

exceeds

be

given

device. In such circumstances,

the

local water authority should

technical data

Non-return,

devices

supply

200 ppm, consideration may need

(including

water

meters)

can

cause a pressure

could

damage

appliances.

(A)

vessel

water

areas:

scale

formation

of

the

DHW

the

electronic control circuit.

the

temporary water hardness

to

the

fitting

of a scale

1.5

on

page

back

those

fitted

to

the

the

boiler

should be con-

valve (C) and the

as

the

heat

exchanger

the

be

up to

6)

for

10

bar.

flow

pre-

associat-

mains

build

and

treatment

maximum

is

to

prevention

advice

of

sought.

MAINS SUPPLIES

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

WATER SYSTEMS &

PIPEWORK

PLASTIC

• Any plastic

CONNECTIONS/VALVES:

• All system connections, taps and mixing

• All other valves should conform

• An automatic bypass may be required,

• A drain

• An air vent is required at the highest point

PIPEWORK:

pipework

barrier with

copper

Plastic

must be correctly controlled with a thermo-

static blending valve limiting the temperature

of

the circuits to approx.

The

valve

from corrosion).

valves must be capable

sure up

Radiator

BS2767:10.

On

ing systems where a radiator previously did

not exist, each radiator

TRV, except the one fitted

a

room/area as the room thermostat.

On boiler only replacement jobs, it is recom-

mended, (but not mandatory,)

each radiator.

for energy conservation purposes,

mend

each radiator.

(downstream

tain the minimum flow-rate through the appli-

ance.

on the system.

on the system.

600

or steel pipe

pipework

pipework

must be

to

3 bar.

valves should conform

new

installations, or extensions to exist-

to

the customer that a TRV is fitted

cock

must have a polymeric

mm

(minimum) length

connected

used for underfloor heating

50°C.

from the boiler

in

copper

It is, however, a requirement,

of

the pump),

is required at the lowest point

to

or steel (protected

of

sustaining a pres-

should be fitted with

in

in

of

to

the boiler.

the blending

to

to

BS

1010.

the same

to

fit a TRV on

to

recom-

order to main-

to

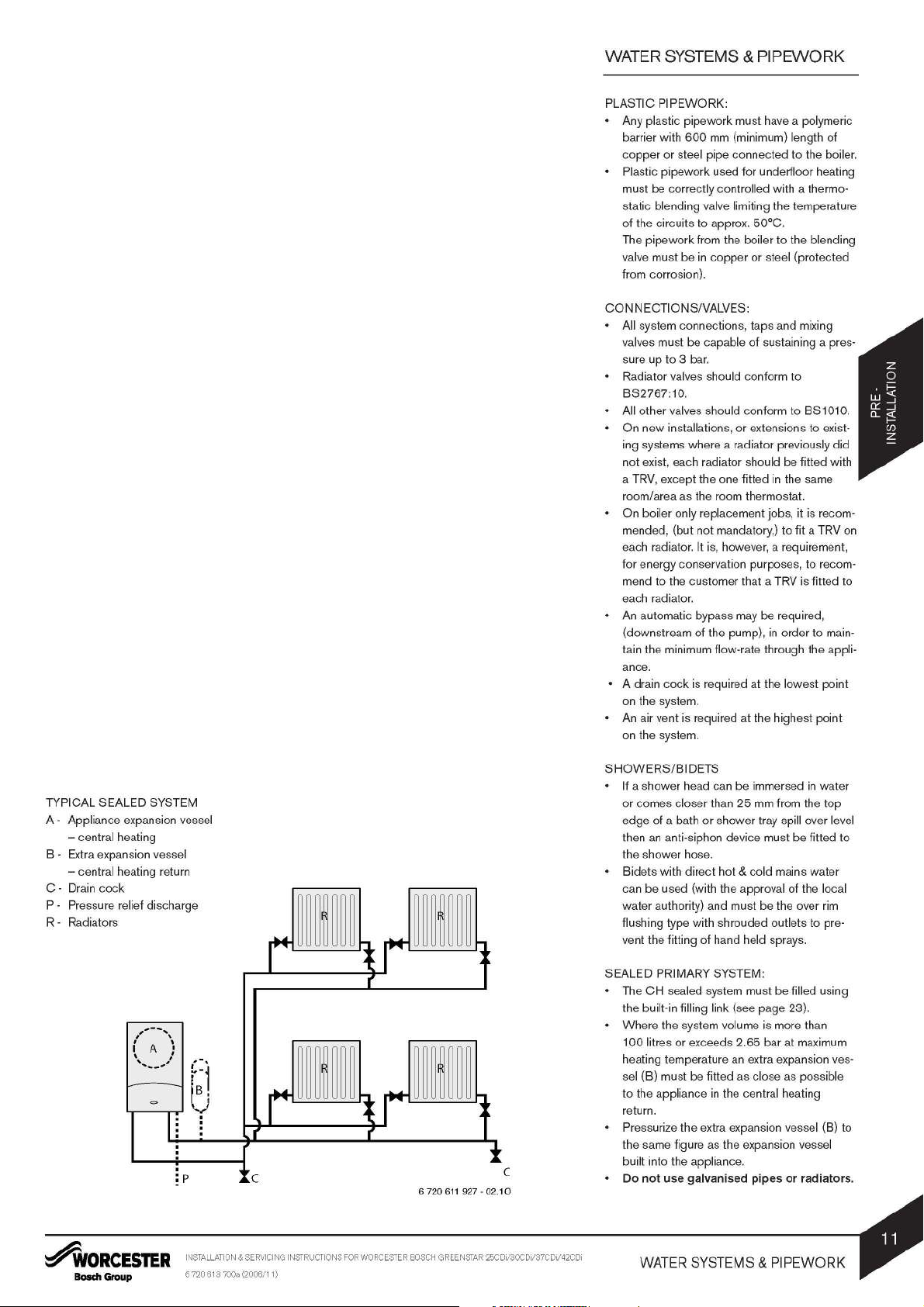

TYPICAL

A-

B-

C-

p-

R-

SEALED

Appliance expansion vessel

- central heating

Extra expansion

- central heating return

cock

Drain

Pressure relief discharge

Radiators

SYSTEM

vessel

,,--,

, '

, '

I A I

\.

...

__

...

SHOWERS/BIDETS

If a shower head can be immersed

or

comes

closer than

edge

of

a bath

an

anti-siphon device must be fitted

then

the shower hose.

Bidets with

can be used (with the

water authority) and must be the over rim

flushing type with shrouded outlets to pre-

~ ~ ~~

~ ~

[

,l

c

6

720

611

927-02.10

vent the fitting

SEALED

The

the built-in filling link (see page 23).

Where

100

heating temperature

sel

to

the appliance

return.

Pressurize the extra expansion vessel (B) to

the same figure as the expansion

built

Do

direct

PRIMARY SYSTEM:

CH

sealed system must be filled using

the system volume is more than

litres or exceeds 2.65 bar at maximum

(B) must be fitted as close as possible

into the appliance.

not

use

galvanised

25

mm from the

or

shower tray spill over level

hot & cold mains water

approval

of

hand held sprays.

an

extra expansion ves-

in

the central heating

pipes

in

of

the local

vessel

or

radiators.

water

top

to

~ORCESTER

Bosch

Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDci42CD•

WATER

SYSTEMS

& PIPEWORK

3

5

r1

----------

~1

lnvectlb

G

-

..............

25mm

m1n.

-- H

400mm

m1n.

..

r

: /

~1 ~·~---f--

m

"·------K

-------J

'•

CONDENSATE PIPEWORK

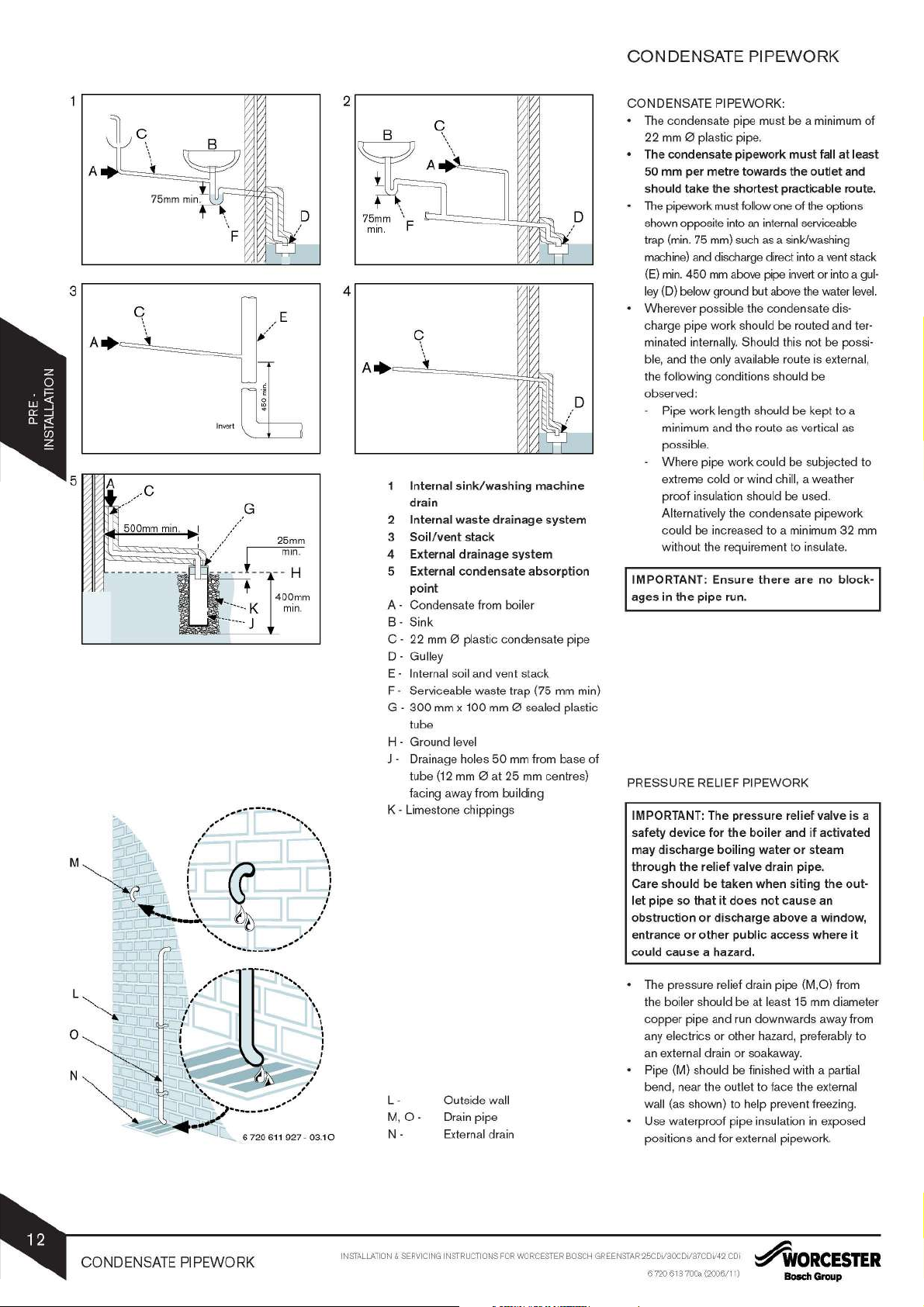

CONDENSATE PIPEWORK:

The

condensate pipe must be a minimum of

22

mm

0 plastic pipe.

The condensate

50

mm

per

take

should

The

pipework must follow

shown opposite into

trap

(min.

machine)

(E)

min.

450

ley

(D)

4

'I

'I

'I

'I

'I/~

'I

D

A+

~

~

'I

'I

:

~'

sink/washing

Internal

drain

2 Internal

3

4 External

5 External

A - Condensate from boiler

B-

C-

DE - Internal soil and vent stack

F

- Serviceable waste trap (75

G-

H - Ground level

waste

Soil/vent

point

Sink

22

Gulley

300

tube

stack

drainage

condensate

mm

0 plastic condensate pipe

mm

x 100

J - Drainage holes

tube

(12

mm

0 at 25

facing away from

K - Limestone chippings

"~\,

\

\

\

L-

M,O-

N-

Outside wall

Drain pipe

External drain

machine

drainage

system

absorption

mm

0 sealed plastic

50

mm

from base of

mm

building

system

mm

min)

centres)

IMPORTANT:

ages

PRESSURE RELIEF PIPEWORK

IMPORTANT:

safety

may

through

Care

let

obstruction

entrance

could

below ground but above

Wherever possible the condensate dis-

charge pipe work should

minated internally. Should this not be possi-

ble,

and the only available route is external,

the following conditions should be

observed:

Pipe work length should be kept to a

minimum and the route as

possible.

Where pipe work could be subjected to

extreme

proof

Alternatively the condensate pipework

could

without the requirement to insulate.

in

the

device

discharge

the

should

pipe

so

or

cause

The

pressure relief drain pipe (M,O) from

boiler should be at least

the

copper pipe and

electrics or other hazard, preferably to

any

an

external drain or soakaway.

Pipe (M) should

bend, near the outlet to face the external

(as shown) to help prevent freezing.

wall

Use waterproof pipe

positions and for

pipework

metre

towards

the

shortest

75

mm)

such

and

discharge direct into a vent stack

mm

above pipe

cold or wind chill, a weather

insulation should be used.

be

increased to a minimum

Ensure

pipe

run.

pressure

The

for

the

boiling

relief

valve

be

taken

that

it

does

or

discharge

other

public

a hazard.

run

be

external pipework.

must

fall

the

outlet

practicable route.

one

of

the

an

internal

serviceable

as

a sink/washing

invert

or into a

the

water

be

routed and ter-

vertical as

there

are

no

relief

valve is a

boiler

and

if

activated

water

or

steam

drain

pipe.

when

siting

the

not

cause

an

above

a window,

access

where

15

mm

downwards away from

finished with a partial

insulation

in

exposed

at

least

and

options

level.

32

block-

out-

it

diameter

gul-

mm

CONDENSATE PIPEWORK

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

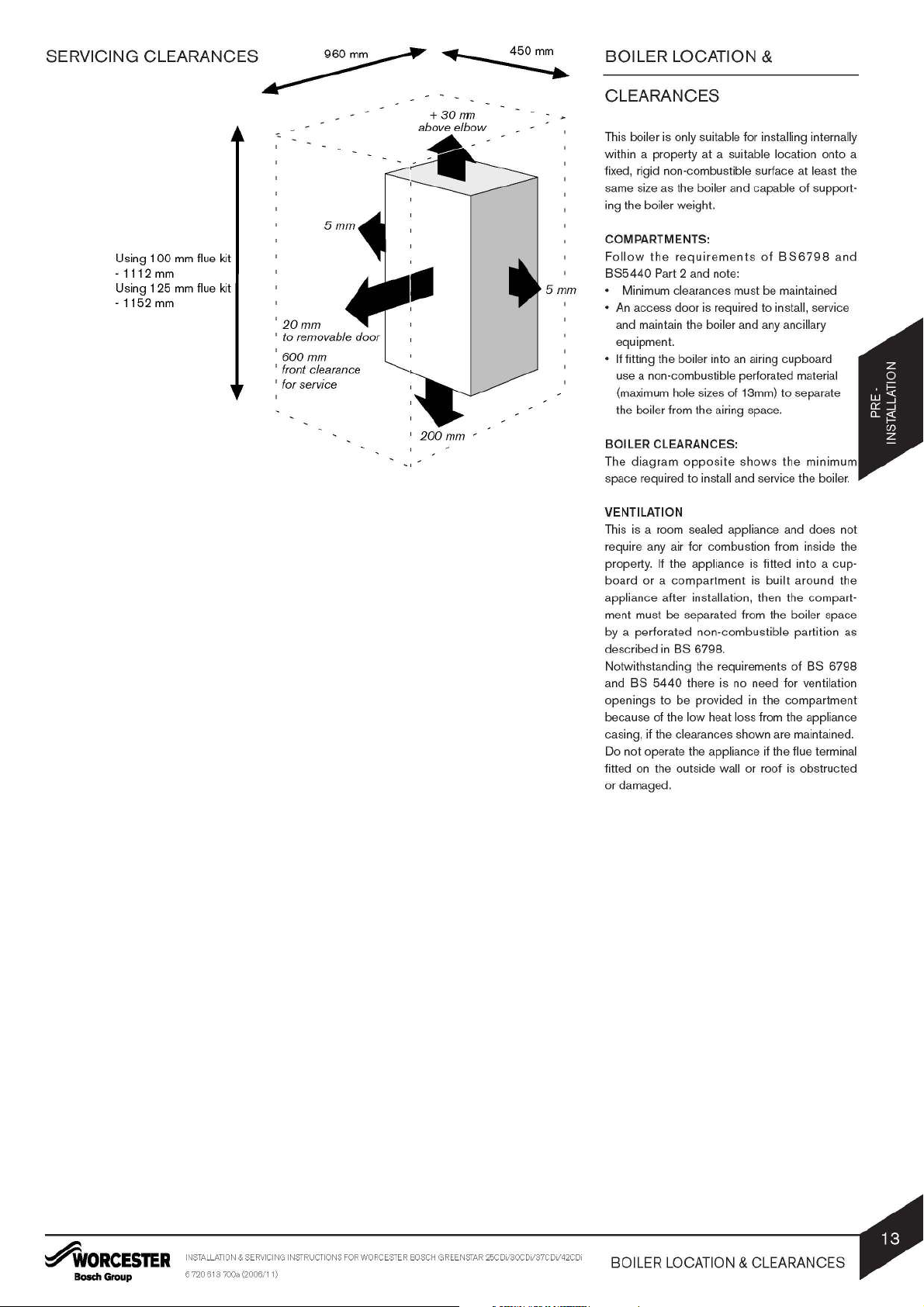

SERVICING

Using 1

-1112

Using 1 25 mm

-1152

CLEARANCES

00

mm

mm

mm flue kit

flue kit

~-

'20mm

'

to

removable door

600mm

'

front

for

'

clearance

service

-

+30mn

above elbow

'

200

mm '

5mm

BOILER LOCATION &

CLEARANCES

This boiler is only suitable for installing internally

within a

fixed, rigid

same size as the

ing the

property

boiler weight.

COMPARTMENTS:

Follow

the

BS5440

Minimum

access

• An

and maintain the

equipment.

• If fitting the boiler into

use a non-combustible perforated material

(maximum hole sizes

the boiler from the airing space.

BOILER CLEARANCES:

The

diagram

space required

at a suitable location

non-combustible surface at least the

boiler

and

capable

requirements

Part 2 and note:

clearances must

door

is required to install, service

boiler and any ancillary

opposite

to

install and service the boiler.

an

of

shows

of

be

airing

13mm)

onto

of

support-

BS6798

maintained

cupboard

to

separate

the

m1n1mu

and

a

VENTILATION

This is a room sealed appliance and

require any air for

property.

board

appliance

ment must be separated from the boiler

by a

described

Notwithstanding

and

openings

because

casing, if the clearances

Do

fitted on the outside wall

or

If the

or a compartment

perforated

BS

5440

to

of

not

operate the appliance if the flue terminal

damaged.

combustion

appliance

after installation, then the

non-combustible

in

BS

6798.

the requirements

there is

be

provided

the

low

is

is

no

need for ventilation

in

heat loss from the appliance

shown

or

roof is

does

from inside the

fitted

into a cup-

built

around

compart-

partition

of

BS

the

compartment

are maintained.

obstructed

not

the

space

as

6798

~ORCESTER

Bosch

Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDci42CD•

BOILER LOCATION & CLEARANCES

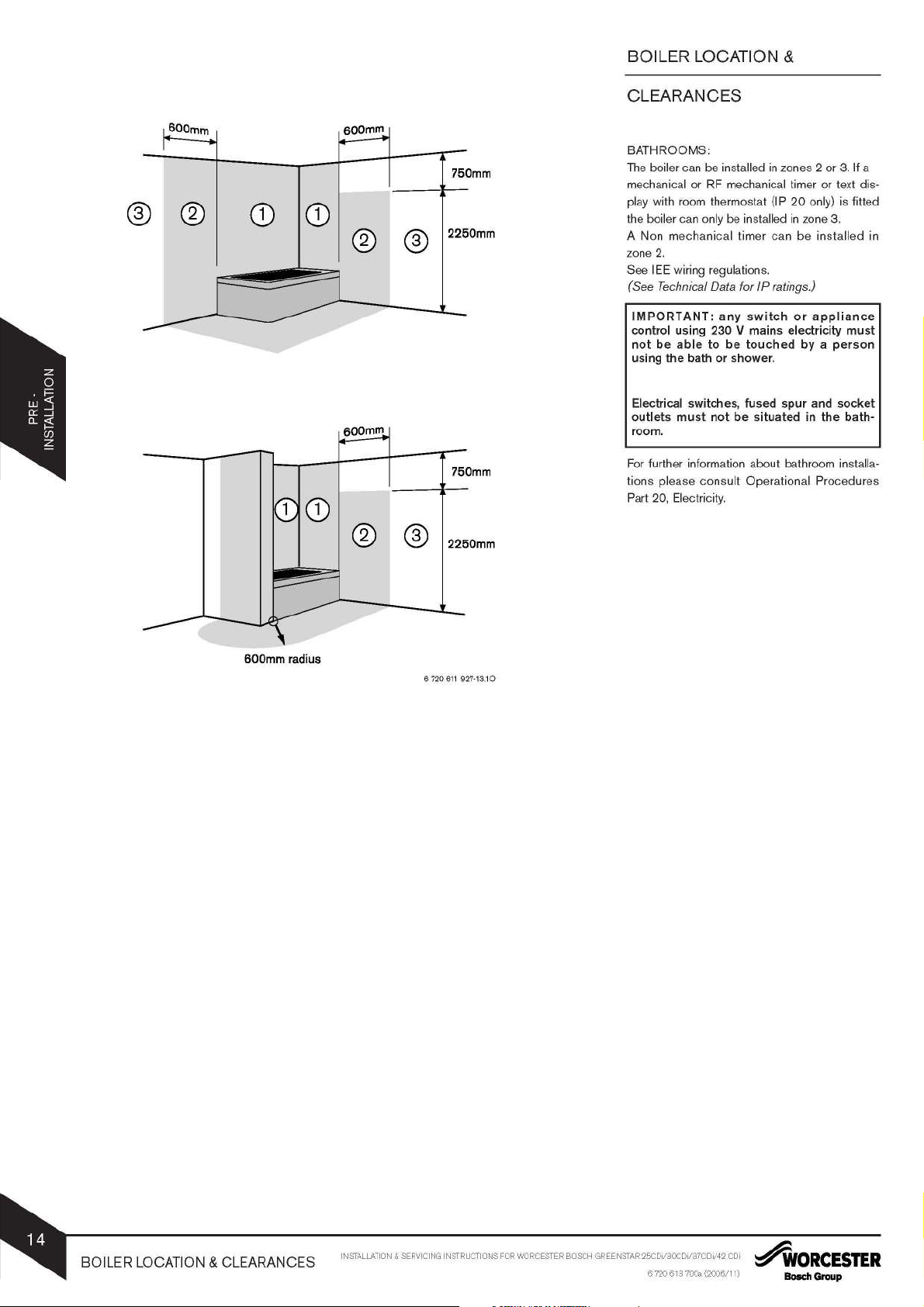

®

@

CD

aoomm

CD

@

®

750mm

2250mm

BOILER LOCATION &

CLEARANCES

BATHROOMS:

The

boiler can be installed

mechanical or

play with room thermostat (IP 20 only)

boiler can only be installed

the

A Non mechanical timer can be installed in

zone

2.

See lEE wiring regulations.

(See Technical Data for

RF

in

zones 2 or

mechanical timer or text dis-

in

IP

ratings.}

zone

3.

If a

is

fitted

3.

600mm

radius

aoomm

@

®

6720611927-13.10

750mm

2250mm

IMPORTANT:

control using 230 V mains electricity

not

be

using

the

Electrical switches, fused

outlets

room.

For

further information about bathroom installa-

lions please consult Operational Procedures

20, Electricity.

Part

able

bath

must

any

to

or

not

switch

be

touched

shower.

be

situated

or

appliance

by a person

spur

and

in

the

must

socket

bath-

BOILER LOCATION & CLEARANCES

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

c;J!:_

DHW

Out (alternative from above appliance)

15

mm

PLUMBING MANIFOLD

CH

Flow

•

(alternative

from above

appliance)

mm

22

l U Gas Supply (alternative from above appliance) 22

:~

c..~

H

c:;J!:_

~-

1

I

I

I

I

I

I

Mains Water

•

In

(alternative from above appliance)

CH

Return (alternative from above appliance) 22

mm

15

mm

mm

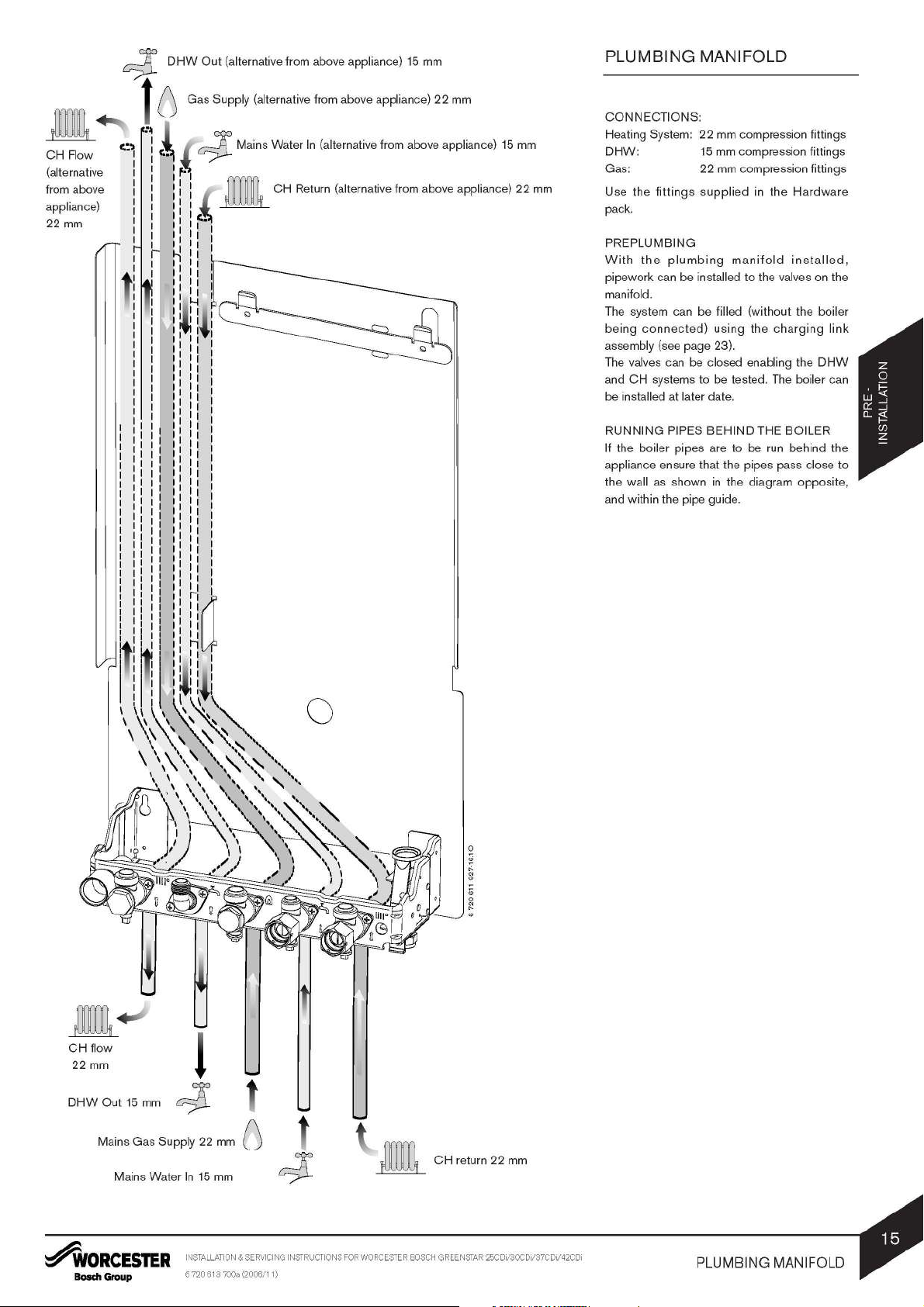

CONNECTIONS:

Heating System: 22

DHW:

Gas: 22

Use the

pack.

PREPLUMBING

With

pipework can be installed to the valves

manifold.

The

being

assembly

The

and

be

RUNNING PIPES

If

appliance ensure that the pipes pass close to

the

and within the pipe guide.

fittings

the

plumbing

system can be filled (without the boiler

connected)

(see page 23).

valves can be closed enabling the

CH

systems to be tested.

installed

the boiler pipes are to be

wall

at

as

15

supplied

later date.

shown

mm

compression fittings

mm

compression fittings

mm

compression fittings

in

the Hardware

manifold

using the

BEHIND

in

the diagram opposite,

installed,

charging

The

boiler can

THE BOILER

run

behind the

on

link

DHW

the

CH

flow

mm

22

DHW

Out

15

mm

Mains Gas Supply 22

Mains Water

~ORCESTER

Bosch

Group

mm

In

15

mm

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

•

BOSCH

CH

return 22

GREENSTAR

mm

25CDV30CDV37CDci42CDI

PLUMBING MANIFOLD

FLUE TERMINAL POSITIONS

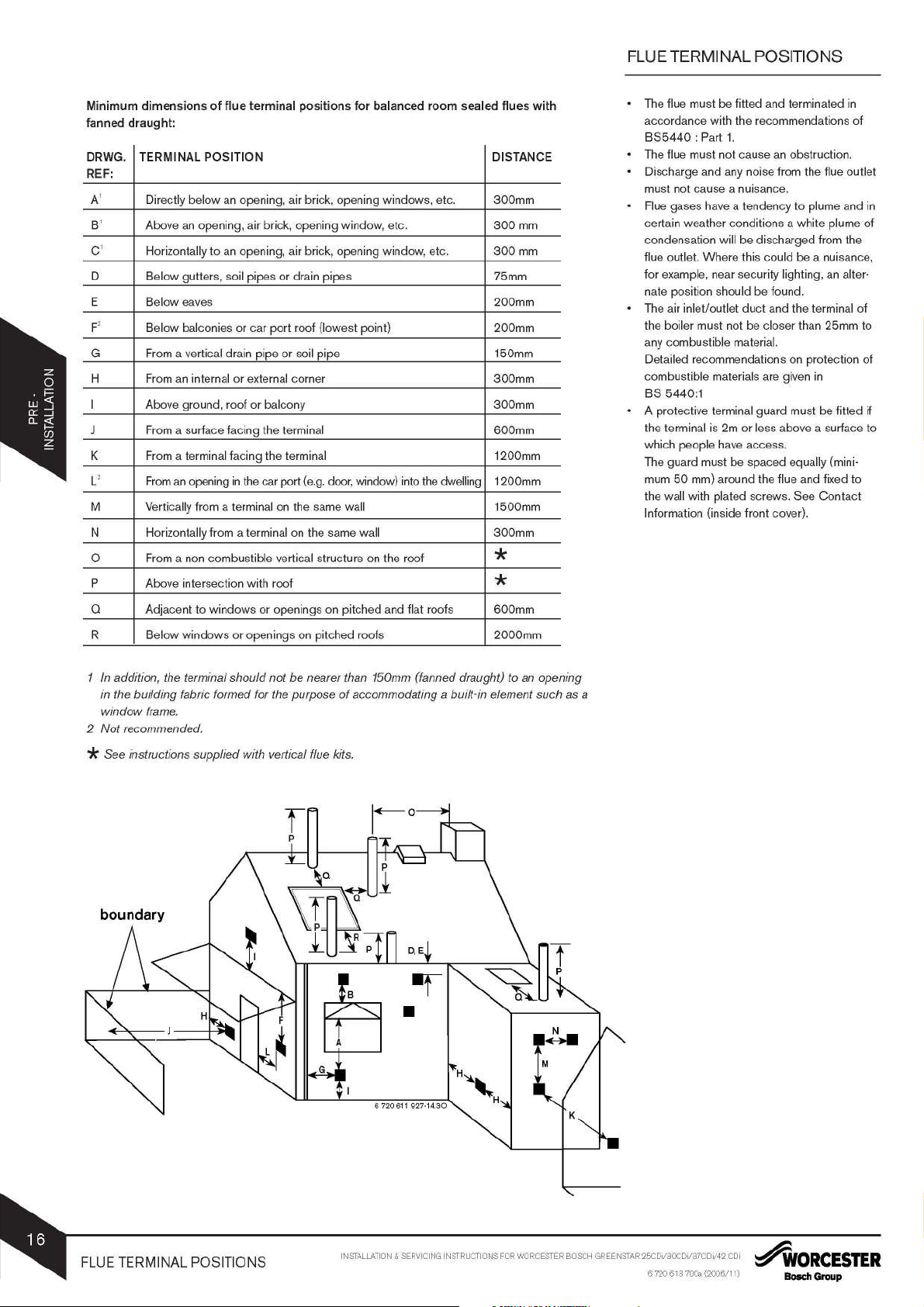

Minimum

fanned

DRWG.

REF:

A'

B'

C'

D

E

F2

dimensions

draught:

TERMINAL

Directly

Above

Horizontally

Below

Below

Below

of

flue

terminal

POSITION

below

an

opening, air brick, opening

an

opening, air brick, opening window, etc.

to

an

opening, air brick, opening window, etc.

gutters, soil pipes or drain pipes 75mm

eaves

balconies or car

positions

port

roof (lowest point)

for

balanced

windows,

room

etc.

sealed

flues

DISTANCE

300mm

300mm

300mm

200mm

200mm

G From a vertical drain pipe or soil pipe 150mm

an

H From

I Above ground, roof or balcony

internal or external corner

J From a surface facing the terminal

K From a terminal facing the terminal

L2

From

an

opening

in

the car port

(e.g.

door, window) into the dwelling

M Vertically from a terminal on the same wall

N Horizontally from a terminal on the same wall

300mm

300mm

600mm

1200mm

1200mm

1500mm

300mm

0 From a non combustible vertical structure on the roof

p

Above intersection with roof

0 Adjacent to

R

Below

windows

windows

or openings on pitched and flat roofs

or openings on pitched roofs

*

*

600mm

2000mm

with

The flue must be fitted and terminated

accordance with the recommendations

BS5440

The flue must not cause

Discharge and any noise from the

must not cause a nuisance.

Flue gases have a tendency

certain weather conditions a white plume

condensation will be discharged from the

flue outlet.

for

nate position should be found.

The air

the boiler must not be closer than

any

Detailed

combustible materials are given

BS

• A protective terminal guard must be fitted if

the terminal is 2m or less above a surface to

which

The guard must be spaced

mum

the

Information (inside front cover).

: Part

1.

an

obstruction.

to

Where

this could be a nuisance,

example, near security lighting,

inlet/outlet

combustible material.

recommendations on protection

5440:1

people have access.

50

mm) around the flue and fixed to

wall with plated screws. See

duct

and the terminal

equally (mini-

in

of

flue outlet

plume and

an

alter-

25mm

in

Contact

of

in

of

to

of

In

addition, the terminal should not

in

the building

window

frame.

fabric

formed

2 Not recommended.

See

instructions supplied with vertical

*

be

for

the purpose

nearer than 150mm (fanned draught}

of

accommodating a built-in element

flue

kits.

to

an

opening

such

as a

FLUE TERMINAL POSITIONS

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

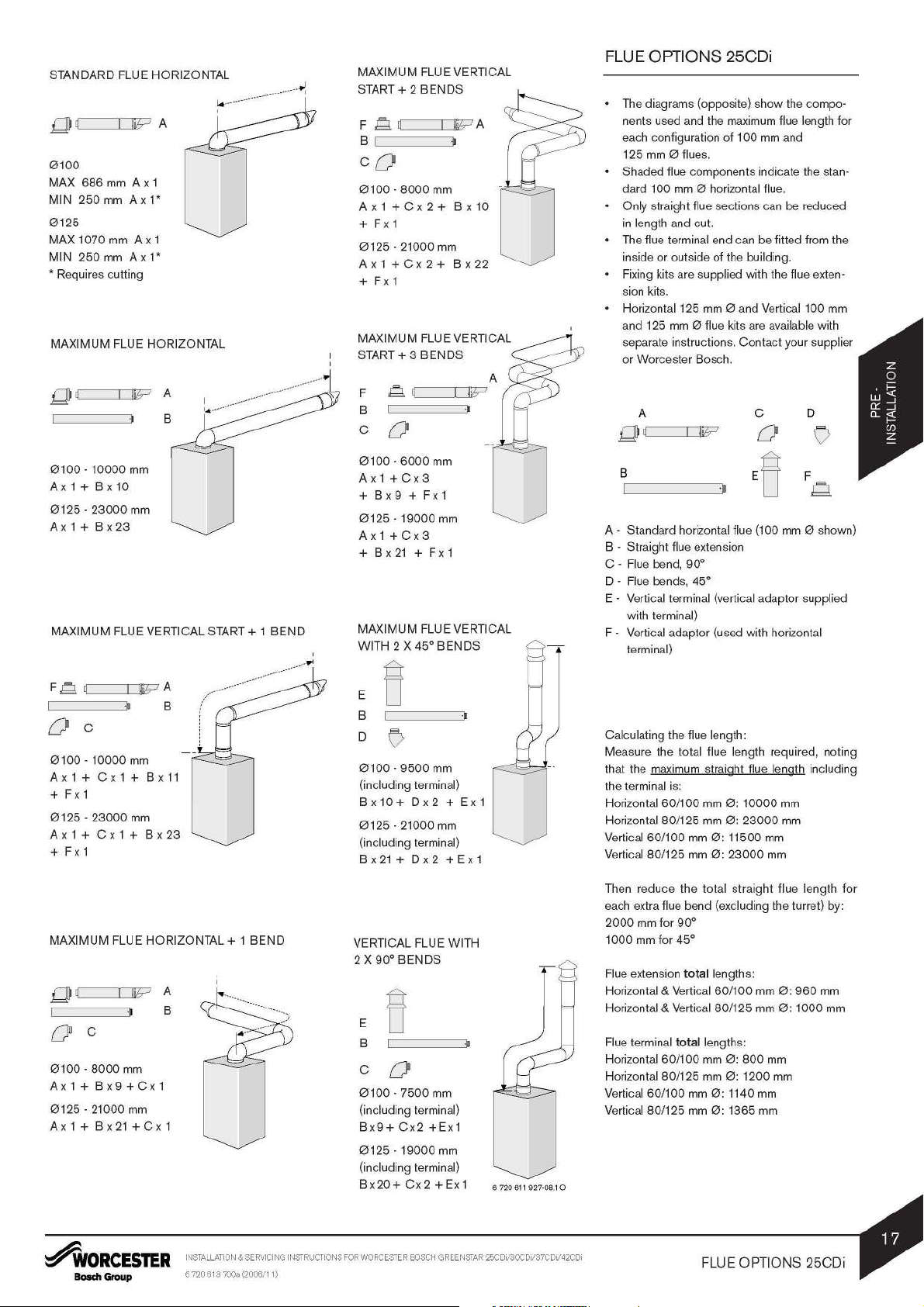

STANDARD FLUE HORIZONTAL

0100

MAX 686

MIN 250

0125

MAX 1070

MIN 250

* Requires cutting

MAXIMUM FLUE HORIZONTAL

0100-

Ax1+Bx10

0125-

Ax

MAXIMUM FLUE VERTICAL START+ 1 BEND

mm

mm

mm

mm

10000

23000

1 + B x 23

Ax

Ax

Ax

Ax

mm

mm

1

1*

1

1*

--------~

MAXIMUM FLUE VERTICAL

START+

F

B

bi

L__

2 BENDS

0'----,

___

1 ' lu:z?' A

___..

co

0100-8000

A X 1 + c X 2 + B X

+

Fx

0125-

A X 1 + c X 2 + B X 22

+

Fx

MAXIMUM FLUE VERTICAL

START+ 3 BENDS

F

B

c 0

0100-6000

Ax1+Cx3

+Bxg+Fx1

0125-

Ax1+Cx3

+ B X

MAXIMUM FLUE VERTICAL

WITH 2 X 45°

1

21000

1

1gooo

21

mm

10

mm

mm

mm

+ F X 1

BENDS

FLUE

OPTIONS 25CDi

The

diagrams (opposite) show the components used and the

each configuration of

125

mm

0 flues.

• Shaded flue

dard 100

• Only

in

•

The

inside or outside of the

Fixing kits are supplied with the flue exten-

sion kits.

Horizontal125

and 125

separate instructions. Contact your

or Worcester Bosch.

mm

straight flue sections can be reduced

length and cut.

flue terminal end can be fitted from the

mm

A c D

QH

B

A-

Standard horizontal flue

B - Straight

C-

D E - Vertical terminal (vertical adaptor supplied

F-

flue extension

Flue

bend,

Flue

bends, 45°

with terminal)

Vertical adaptor (used with horizontal

terminal)

maximum

components indicate the stan-

0 horizontal flue.

mm

0 and Vertical100

0 flue kits

lb--l

i

goo

flue length for

mm

and

100

building.

are

available with

0

ED

(100

mm

supplier

v

F

fd_

0 shown)

mm

0 c

0100-

10000

mm

Ax1+Cx1+Bx11

+

Fx

1

0125-

23000

mm

A X 1 + c X 1 + B X 23

Fx

1

+

MAXIMUM FLUE

HORIZONTAL+

0 c

0100-

8000

mm

Ax1 + Bxg+Cx1

0125-

21000

mm

A X 1 + B X

21

+ c X 1

1 BEND

E

B

D V

0100-

g500

mm

(including terminal)

Bx10+Dx2+Ex1

0125-

21000

mm

(including terminal)

21

+ D X 2 + E X 1

B X

VERTICAL FLUE WITH

2 X

goo

BENDS

E

B

c

0

0100-

7500

mm

(including terminal)

Bxg+

Cx2

+Ex1

0125-

1gooo

mm

(including terminal)

Bx20+

Cx2

+Ex1

Calculating

Measure the total flue length required, noting

that the maximum straight flue length including

the terminal is:

Horizontal 60/100

Horizontal80/125

Vertical60/100

Vertical 80/125

Then reduce the total straight flue length for

each extra

2000

1000

Flue

Horizontal & Vertical 60/100

Horizontal & Vertical 80/125

Flue

Horizontal 60/100

Horizontal80/125

Vertical60/100

Vertical 80/125

6

720

611

927-08.1 0

the flue length:

mm

0:

10000

mm

0:

23000

mm

0:

11500

mm

mm

0:

23000

mm

flue bend (excluding the turret) by:

mm

for

goo

mm

for 45°

extension total lengths:

mm

mm

terminal total lengths:

mm

0:

800

mm

mm

0:

1200

mm

0:

1140

mm

mm

0:

1365

mm

mm

mm

0:

0:

mm

g5o

1000

mm

mm

~ORCESTER

Bosch

Group

INSTALLATION & SERVICING

6

720

613

700a

(2006/11)

INSTRUCTIONS

FOR

WORCESTER

BOSCH

GREENSTAR

25CDV30CDV37CDc!42CD•

FLUE

OPTIONS 25CDi

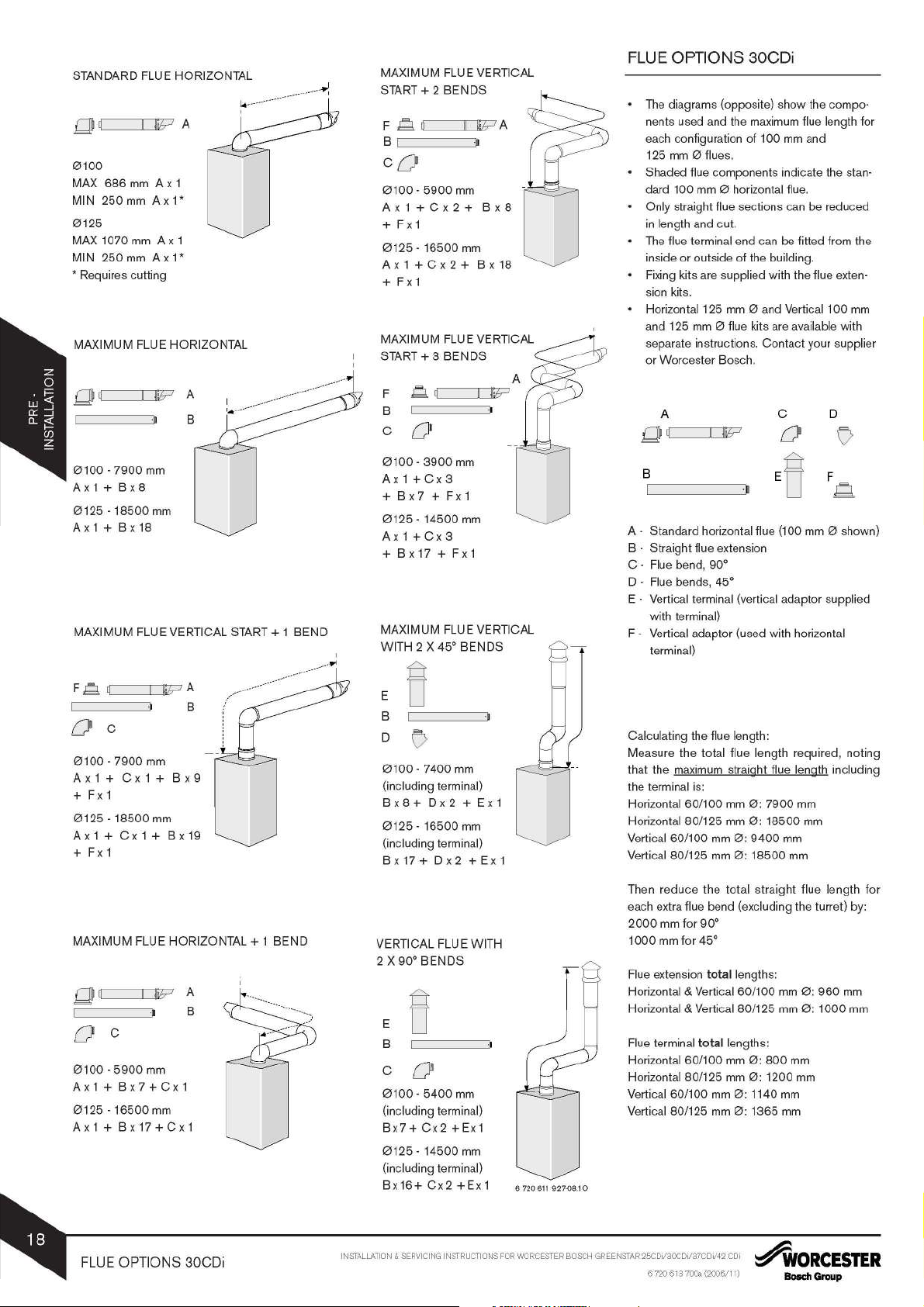

STANDARD FLUE HORIZONTAL

mm

mm

mm

mm

7goo

18500

18

Ax

Ax

Ax

mm

mm

PA

Ax

1

1*

1

1*

Q H I

0100

MAX

686

MIN 250

0125

MAX 1070

MIN 250

* Requires cutting

MAXIMUM FLUE HORIZONTAL

0100-

Ax1+Bx8

0125A X 1 + B X

MAXIMUM FLUE VERTICAL START+ 1 BEND

_____

,.,

MAXIMUM FLUE VERTICAL

.bi

~---~

2 BENDS

d II

START+

F

B

co

0100-

5goo

Ax1+Cx2+

+

Fx

1

0125-

16500

A X 1 + c X 2 + B X

+

Fx

1

MAXIMUM FLUE VERTICAL

START+ 3 BENDS

F

B

c 0

0100-

3goo

Ax1+Cx3

+Bx7+Fx1

0125-

14500

Ax1+Cx3

+Bx17+Fx1

MAXIMUM FLUE VERTICAL

WITH 2 X 45° BENDS

I

mm

mm

mm

mm

iPA

Bx8

18

FLUE

OPTIONS 30CDi

The

diagrams (opposite) show the components used and the maximum flue length for

each configuration of

mm

0 flues.

125

• Shaded flue

dard 100

Only

in

length and cut.

•

The

inside or outside of the building.

Fixing

sion kits.

Horizontal 125

and 125

separate instructions. Contact your

or Worcester Bosch.

A c D

components indicate the stan-

mm

straight flue sections can be reduced

flue terminal end can

kits

are

mm

_QH

B

A - Standard horizontal flue

B - Straight flue extension

C -

Flue

bend,

goo

D -

Flue

bends, 45°

E - Vertical terminal (vertical adaptor supplied

with terminal)

F-

Vertical adaptor (used with horizontal

terminal)

100

mm

and

0 horizontal flue.

be

fitted from the

supplied with the flue exten-

mm

0 and Vertical 100

0 flue kits

IP

are

available with

0

EB

(1

00

mm

supplier

v

F

Q

0 shown)

mm

0 c

0100-

7goo

mm

Ax1+Cx1+Bxg

+

Fx

1

0125-

18500

mm

Ax1+Cx1+Bx1g

+

Fx

1

MAXIMUM FLUE

bJ

Oc_

_

_JL_

_uc

iP A

0 c

0100-

5goo

mm

Ax1 + Bx7+Cx1

0125-

16500

mm

Ax1 + Bx17+Cx1

HORIZONTAL+

B

1 BEND

E

B

B

D V

0100-

7400

mm

(including terminal)

Bx8+Dx2+Ex1

0125-

16500

mm

(including terminal)

Bx17+

VERTICAL FLUE WITH

2 X

E

B

goo

BENDS

B

Dx2

+Ex1

c 0

0100-5400

(including terminal)

Bx7+

0125(including terminal)

Bx16+

Cx2

14500

Cx2

mm

+Ex1

mm

+Ex1

Calculating

Measure the total flue length required, noting

that the

the terminal is:

Horizontal 60/100

Horizontal 80/125

Vertical 60/100

Vertical 80/125

Then reduce the total straight flue length for

each extra flue bend (excluding the turret)

2000

1000

Flue

Horizontal

Horizontal & Vertical 80/125

Flue

Horizontal 60/100

Horizontal 80/125

Vertical 60/100

Vertical 80/125

6

720

611

927-08.1 0

the flue length:

maximum

mm

mm

extension total lengths:

terminal total lengths:

straight flue length including

mm

0:

7goo

mm

0:

18500

mm

0:

g400

mm

0:

18500

for

goo

for 45°

& Vertical 60/100

mm

0:

800

mm

0:

1200

mm

0:

1140

mm

0:

1365

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

0:

0:

g5o

1000

by:

mm

mm

FLUE

OPTIONS 30CDi

INSTALLATION & SERVICING INSTRUCTIONS

FOR

WORCESTER BOSCH GREENSTAR

25CDI/30CDI/37CDI/42

6 720

613

700a

(2006/11)

co;

~ORCESTER

Bosch

Group

Loading...

Loading...