Bosch Worcester Danesmoor Utility Regular ErP+ 12/18, Worcester Danesmoor Utility System ErP+ 18/25, Worcester Danesmoor Utility Regular ErP+ 18/25, Worcester Danesmoor Utility Regular ErP+ 25/32, Worcester Danesmoor Utility System ErP+ 12/18 Installation, Commissioning And Servicing Instruction Manual

...

UK

Installation, Commissioning and Servicing instruction manual

Floor Standing oil-fired Condensing Boiler Conventional Flue & Room Sealed Flue

Greenstar Danesmoor Utility Regular

ErP+

& Utility System

ErP+

12/18, 18/25, & 25/32

For fully pumped open vent or sealed central heating systems and domestic hot water cylinders

These appliances are for use with Kerosene (Class C2) only.

6 720 821 720 (2018/04)

6720809436-00.1Wo

Contents

Contents

1 Key to symbols and safety instructions . . . . . . . . . . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Complying with the building regulations . . . . . . . . . . . . . 5

3 Appliance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Energy efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Layout and components - 18/25 System appliance shown

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.5 Layout and components - 18/25 Regular appliance shown

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Pre-Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Cleaning primary systems . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.1 Before cleaning the system: . . . . . . . . . . . . . . . . . . . . . 11

4.1.2 Flushing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.3 Appliance drain points . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.4 Appliance vent points . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.5 Inhibitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.6 Artificially softened water . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Mains supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Oil supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3.1 Single pipe gravity feed system: . . . . . . . . . . . . . . . . . . 12

4.3.2 Double pipe sub-gravity feed system: . . . . . . . . . . . . . 13

4.3.3 Single pipe suction lift with de-aerator: . . . . . . . . . . . . 13

4.3.4 Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3.5 Boiler isolation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Water systems and pipework . . . . . . . . . . . . . . . . . . . . 14

4.5 Condensate discharge . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5.1 Condensate pipe work . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5.2 Internal connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.3 External connections . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Pressure relief pipework . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7 Boiler locations and clearances . . . . . . . . . . . . . . . . . . 18

4.8 Flue terminal positions . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.9 Flue options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9.1 Conventional flue (CF) . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.9.2 Room sealed flue options . . . . . . . . . . . . . . . . . . . . . . . 22

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1 Unpacking the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Pipework positions and flue opening . . . . . . . . . . . . . . 24

5.3 Boiler installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4 Flue installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4.1 Flue damper installation . . . . . . . . . . . . . . . . . . . . . . . . 27

5.4.2 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.5 Combustion chamber (18/25 Regular shown) . . . . . . 28

5.6 Pipework connections . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.7 Oil burner and pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.8 Refitting components . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.9 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Pre-Commissioning checks - 18/25 Regular shown . . . 37

6.2 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.3 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4 Starting the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.1 Single pipe gravity feed system: . . . . . . . . . . . . . . . . . . 38

6.4.2 Double pipe sub-gravity feed systems and single pipe

suction lift with de-aerator: . . . . . . . . . . . . . . . . . . . . . . 38

6.4.3 Pump adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4.4 Burner head setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.4.5 Boiler lockout indicator on: . . . . . . . . . . . . . . . . . . . . . . 40

6.4.6 Combustion checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.4.7 Central heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5 Finishing commissioning . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5.1 Hand over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.5.2 Appliance guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7 Service and Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Inspection and service - 18/25 Regular shown . . . . . . . 44

7.2 Pre-service checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Service requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.4 Sealed system only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.5 Clean the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.6 Oil burner nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.7 Pump filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.8 External oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.9 Combustion chamber - 18/25 Regular shown . . . . . . . 46

7.10 Oil supply system and tank . . . . . . . . . . . . . . . . . . . . . . . 47

7.11 Clean the boiler - Manifold access . . . . . . . . . . . . . . . . . 47

7.12 Re-commissioning the burner . . . . . . . . . . . . . . . . . . . . 47

7.13 After service hand over . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.14 Spares . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8 Fault finding and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.1 Burner functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2 Heating and hot water . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8.3 Boiler function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.4 Logic for the 535 SE/LD RDB control box . . . . . . . . . . . 52

8.5 Riello control box 12/18 model . . . . . . . . . . . . . . . . . . . 53

8.5.3 Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.5.4 Flame sensing photocell 12/18 models . . . . . . . . . . . . 55

8.5.5 Flame sensing photocell 18/25 and 25/32 models . . . 55

8.6 Oil supply vacuum testing . . . . . . . . . . . . . . . . . . . . . . . . 55

8.7 Air pressure switch and flue overheat reset . . . . . . . . . 55

8.8 Air pressure h switch connections . . . . . . . . . . . . . . . . . 55

8.9 Oil appliance commissioning checklist . . . . . . . . . . . . . 56

8.10 Service interval record . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)2

1 Key to symbols and safety instructions

1

Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identified by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be used in this document:

• NOTICE indicates a situation that could result in damage to property

or equipment.

• CAUTION indicates a situation that could result in minor to medium

injury.

• WARNING indicates a situation that could result in severe injury or

death.

• DANGER indicates a situation that will result in severe injury or

death.

Important information

This symbol indicates important information where

there is no risk to people or property.

Additional symbols

Symbol Meaning

a numbered step in an action sequence

a step in an action sequence

a reference to a related part in the document or to other

related documents

a reference number to identify or refer to a part or item

List entries, first and second levels

• A single component/item

• A component/list, made up of multiple parts/items.

– Sub component or sublist of main component/list.

–etc.

Abbreviations used in this manual

ØDiameter

CH Central Heating

DHW Domestic Hot Water

DCW Domestic Cold water

TRV Thermostatic Radiator Valve

IP Ingress Protection

CF Conventional Flue

RS Room sealed

N/A Not Allowed

SEDBUK Seasonal Efficiency of Domestic Boilers in the UK

OFTEC Oil Firing Technical Association for the Petroleum Industry

WRAS Water Regulations Advisory Scheme

IET Institute of Engineering and Technology

LABC Local Authority Building Control Body

DWTA Domestic Water Treatment Association

Read these instructions before starting any installation

These instructions are applicable to the Worcester appliance model(s)

stated on the front cove of this manual only and must not be used with

any other make or model of appliance.

The instructions apply in the UK and Eire only and must be followed

except for any statutory obligation.

This appliance must be installed by a competent person, failure to install

correctly could lead to prosecution.

a list entry

a list entry (second level)

Table 1 Symbols

Examples of additional symbols used

A numbered step in an action sequence

A sequence of numbered steps or actions carried out in a specific order

to complete a task.

1. First action

2. Second action

3. Third action

etc.

A step in an action sequence

A sequence of defined actions or steps carried out in order to complete

a task.

▶Action

▶Next action

▶etc

A reference to a related part in the document or to other related

documents.

To refer the reader to a specific figure/table/section within the manual.

e.g. figure 1.

A reference number to identify or refer to a part or item.

In a related figure, items or parts identified by a sequential number.

1.2 General safety instructions

These installation instructions are intended for heating engineers,

plumbers, and electricians.

▶ Read any installation instructions (boiler, heating controls, etc.)

carefully before starting the installation.

▶ Observe the safety instructions and warnings.

▶ Observe national and regional regulations, technical rules and

guidelines.

▶ Record all work carried out.

Oil fumes or leaks from the appliance

If you smell oil fumes, observe the following rules.

▶ Extinguish any naked flames

▶ Isolate the electrical supply

▶ Isolate the fuel supply to the boiler

▶ Open windows and doors

▶ Rectify the fault

Health and safety

The appliance contains no asbestos and no substances have been used

in the construction process that contravene the COSHH Regulations

(Control of Substances Hazardous to Health Regulations 1988). Where

applicable, the CE mark indicates compliance with relative EU

Directives.

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 3

Key to symbols and safety instructions

Combustible and corrosive materials

Do not store or use any combustible materials (paper, thinners, paints

etc.) inside or within the vicinity of the appliance.

The combustion air must be kept clear of chemically aggressive

substances which can corrode the appliance and invalidate any

warranty.

Handling instructions and guidelines

It is advised that more than one person is involved in the transfer of the

packaged appliance from the van to the point of installation.

It is advised that no attempt should be made to move the packaged

appliance without the use of a suitable truck.

At all times the correct method for handling heavy objects should be

strictly observed.

▶ Lift only a manageable weight, or ask for help.

▶ When lifting, bend the knees, and keep the back straight and feet

apart.

▶ Do not lift and twist at the same time.

▶ Lift and carry items close to the body.

▶ Wear protective clothing and gloves to protect from any sharp edges.

Intended use

This boiler must only be used as a heat appliance in a heating system for

domestic purposes.

Any other use is considered inappropriate. Any damage that results from

such use is excluded from liability.

Appliance operation

This appliance can be used by children aged from 8 years

and above and persons with reduced physical, sensory or

mental capabilities or lack of experience and knowledge, if

they have been given supervision or instruction concerning

the use of the appliance, in a safe way, and understand the

hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall not be made by

children without supervision.

Installation, commissioning and servicing

Installation, commissioning and servicing must only be carried out by a

competent registered engineer.

▶ Only use original spares.

▶ Advise the user to have the system regularly serviced by a

competent, qualified engineer (such as OFTEC registered personnel)

using approved spares, to help maintain the economy, safety and

reliability of the appliance.

Fitting and Modification

Fitting the appliance and any controls to the appliance may only be

carried out by a competent engineer in accordance with these

instructions and the relevant Installation Regulations.

Flue systems must not be modified in any way other than as described in

the fitting instructions.

Any misuse or unauthorised modifications to the appliance, flue or

associated components and systems could invalidate the warranty. The

manufacturer accepts no liability arising from any such actions,

excluding statutory rights.

Electrical work

Electrical work must only be carried out by a qualified electrician.

▶ Before starting electrical work:

– Isolate the mains electrical supply and secure against

unintentional re-connection.

– Check for zero potential.

▶ Also observe connection diagrams of other system components.

Handover to the user

When handing over, instruct the user how to operate the heating system

and inform him about its operating conditions.

▶ Explain how to operate the heating system and draw the user's

attention to any safety-relevant action.

▶ Explain that modifications and repairs must only be carried out by an

authorised contractor.

▶ Advise the user to have the system serviced annually by a competent,

OFTEC registered engineer.

▶ Leave the installation instructions with the completed

commissioning form and the operating instructions with the user or

at the gas meter.

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)4

2 Installation regulations

2.1 Complying with the building regulations

This heating appliance forms part of the controlled services for the

building. It is law that all controlled services for buildings must comply

with building regulations. You must be able to satisfy your Local

Authority Building Control Body (LABC) that the work carried out

concerning the installation and commissioning of this heating appliance

has been carried out to a satisfactory standard.

OFTEC operate a competent persons scheme and registered installers

are able to certify that their work complies with building regulations.

Under the scheme;

• OFTEC must be informed about every installation.

• OFTEC will issue a building regulations compliance certificate to the

householder and will notify the LABC.

OFTEC provide controlled document forms CD10 and CD11 for use

during installation and commissioning respectively.

Other organisations operate self-certification schemes e.g. NAPIT and

BESCA Ltd. and it may be possible for installers who are members of

these organisations to self certify their work.

Alternatively you must submit a building control notice to the LABC

before installing any boiler. The LABC will then arrange regular

inspection visits during the work to ensure that the installation complies

with the regulations.

Installation

Failure to install appliances correctly could lead to prosecution.

The appliance should be installed by a competent person. The person

installing the appliance should be aware of the Health and Safety at Work

Act and take appropriate action to ensure that the regulations are

adhered to. In order to give optimum efficiency and trouble free

operation the appliance must be commissioned by a qualified OFTEC

engineer.

The compliance with a British Standard does not, in itself, confer

immunity from legal obligations. In particular the installation of this

appliance must be in accordance with the relevant requirements of the

following British Standards and regulations in respect of the safe

installation of equipment:

BS 5410: part 1: Code of practice for Oil Fired Boilers.

BS 799: part 5: Specification for Oil Storage Tanks.

BS 7593: Code of Practice for treatment of water in domestic

hot water central heating systems.

BS 5449: part 1: Specification for forced circulation hot water central

heating for domestic premises.

BS 5955: part 8: Specification for the installation of thermoplastic

pipes and associated fittings for use in domestic hot

and cold water services and heating systems.

BS 7291: Thermoplastic pipes and associated fittings for hot

and cold water for domestic purposes and heating

installations in buildings.

BS 7074: part 1: Application, selection and installation of expansion

vessels and ancillary equipment for sealed water

systems.

BS 1254-2: Copper and copper alloys plumbing fittings part 2:

Fittings with compression ends for use with copper

tubes.

BS 7671: IET Wiring Regulations, current edition.

BS 1362: Specification for general purpose fuse links for

domestic and similar purposes.

Installation regulations

The Building Regulations Part G, Part J and L1 England and Wales; Part

F, Part G and Part J Section III Scotland; Part L and Part F Northern

Ireland.

Local water company bye-laws.

The Control of Pollution (Oil) Regulations.

OFTEC Standards.

Where no specific instruction is given, reference should be made to the

relevant codes of practice.

Installations in Eire (Republic of Ireland)

The Installation must be performed by a competent and suitably trained

person in accordance with the following Eire regulations.

Current Building Regulations - Republic of Ireland

ETCI rules for electrical installation

For further guidance see:

OFTEC Technical book three - Regional requirements: Republic of

Ireland

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 5

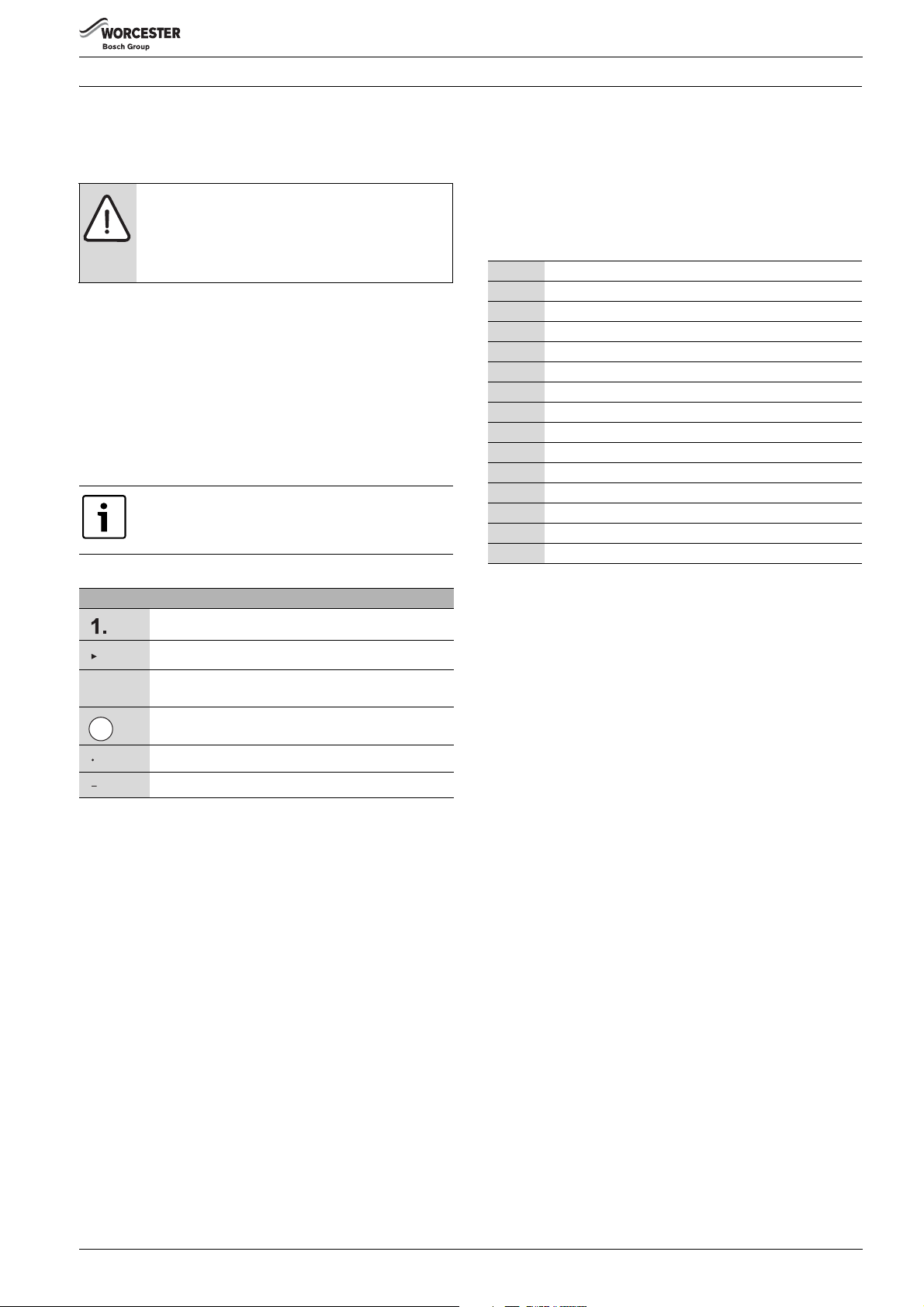

Appliance information

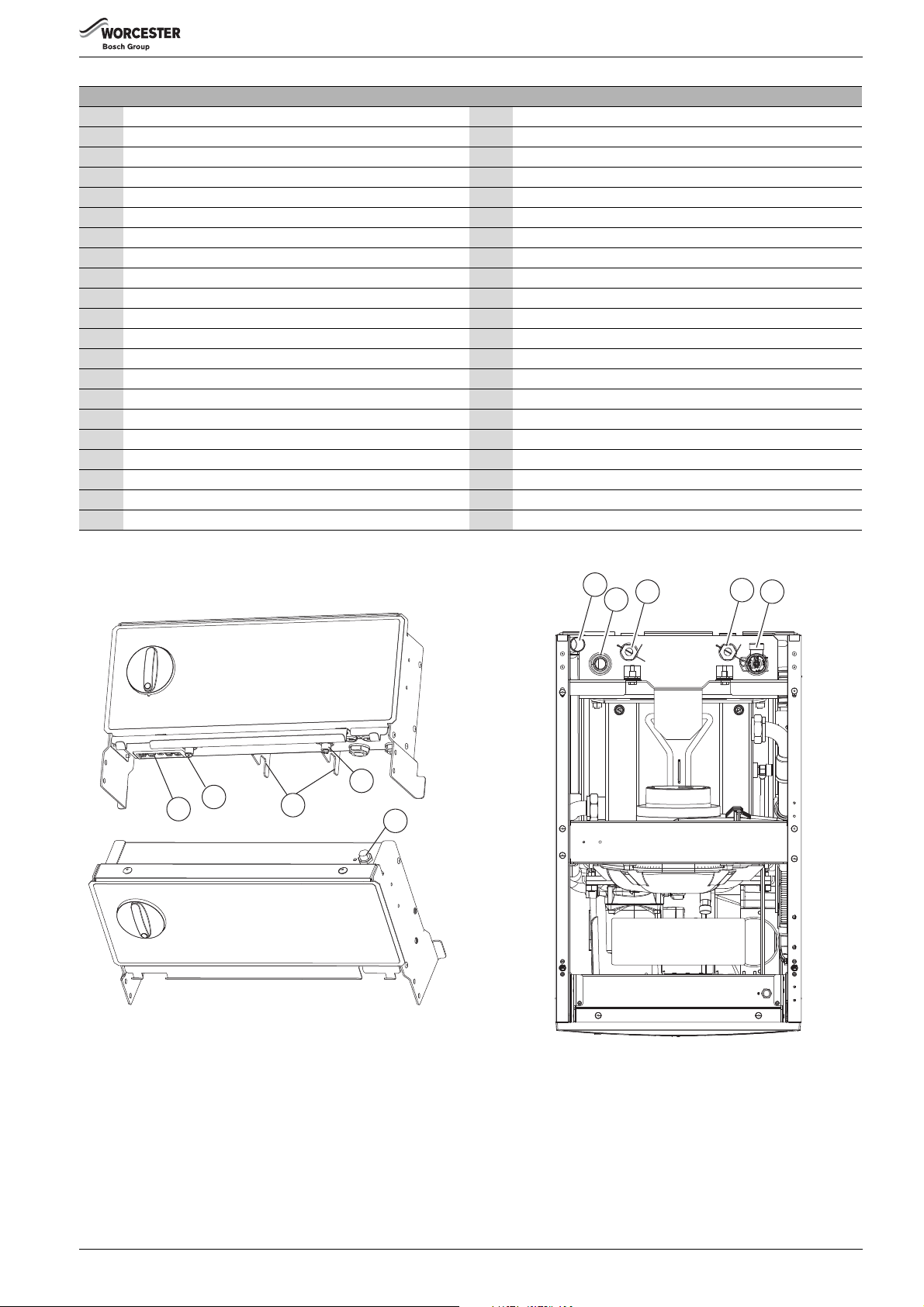

6720821720 - 05.1Wo

D

600mm

370mm

855mm

B

C

A

E

3 Appliance information

3.1 General information

Standard package:

A - Floor standing oil fired condensing boiler

B - Literature pack:

• Greenstar Danesmoor Installation, Commissioning and Servicing

instruction manual

• User Instructions

• Fascia information card

• Guarantee registration card

C - BSP plug, one inch (Regular only)

D - ErP label

E - Flue damper

3.2 Technical data

Description Units 12/18 18/25 25/32

Central heating

Central heat output (max) kW 18 25 32

Primary water capacity (total) litres 20 21 22

Maximum static head metres 30 30 30

Minimum static head metres 111

Water side resistance (20°C

difference)

Maximum available pump head

(20°C difference) Utility System

Maximum permissible sealed

system operating pressure in

accordance with WRAS

guidelines

Flue

Exit flue gas mass flow kg/hr 29 40 51

Pipework connections

Fuel line (compression) mm 10 10 10

Flow Utility BSP 1” 1” 1”

Flow Utility System mm 22 22 28

Utility flow and optional vent/air

vent

Return mm 22 22 28

Condensate (Polypropylene) mm 21.5 21.5 21.5

PRV outlet - Utility System mm 15 15 15

Electrical

Electrical power supply voltage ac ..V 230 230 230

Frequency Hz 50 50 50

Thermostats

Boiler flow temperature range

(cut in/cut out)

Control thermostat differential °C 555

Boiler high limit thermostat set

point

Boiler manual reset overheat

thermostat set point

Flue manual reset overheat

thermostat set point

General data

Maximum hearth temperature °C <100 <100 <100

SEDBUK 2009 % 91.1 90.9 90.7

SEDBUK 2005 % 93.2 93.0 92.8

Appliance protection rating IP 20 20 20

Weight (excluding packaging)

Utility Regular

Weight (excluding packaging)

Utility System

mbar 20 30 56

mH2 O 5.2 4.3 4.1

bar 2.5 2.5 2.5

BSP 111

°C 55/81 55/81 55/81

°C 95 95 95

°C 105 105 105

°C 110 110 110

kg 104 108 115

kg 112 112 122

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)6

Appliance information

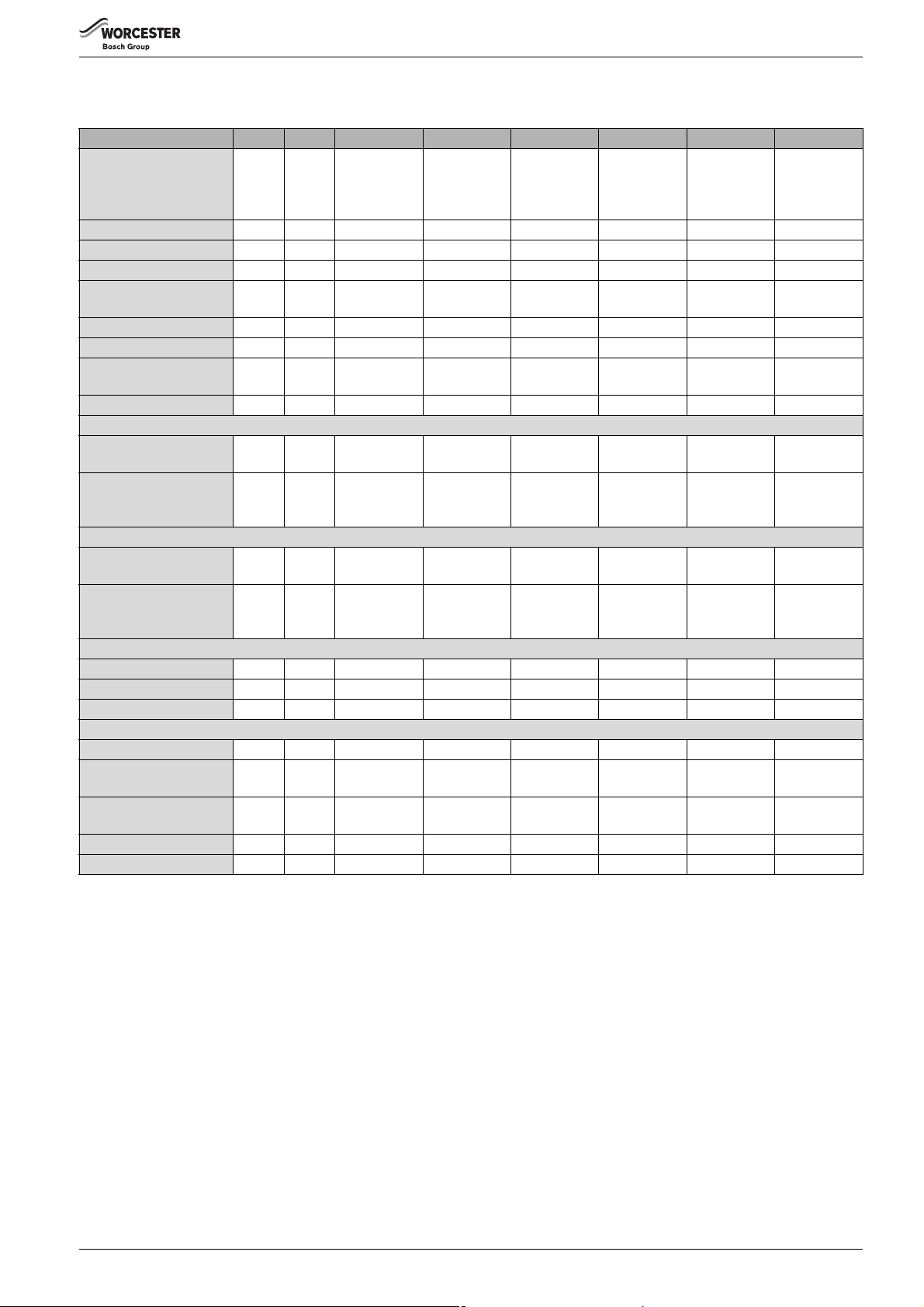

3.3 Energy efficiency

The following product data satisfy the requirements of the EU Regulations No. 811/2013 and No. 812/2013 supplementing Directive 2010/30/EU.

Product data Symbol Unit 7731600147 7731600151 7731600155 7731600148 7731600152 7731600156

ErP+

Danesmoor

Utility

Regular

18/25

Product type – – Danesmoor

Utility

Regular

12/18

Condensing boiler – – Yes Yes Yes Yes Yes Yes

Low temperature boiler – – No No No No No No

B1 boiler – – No No No No No No

Cogeneration space heater

– – No No No No No No

(CHP)

Combination heater – – No No No No No No

Rated heat output P

Seasonal space heating

η

kW 18 25 32 18 25 32

rated

% 909091909091

s

energy efficiency

Energy efficiency class––AAAAAA

Useful heat output

At rated heat output and

high temperature regime

At 30 % of rated heat output

and low temperature regime

2)

P

1)

P

kW 18.2 25.6 32.3 18.2 25.6 32.3

4

kW 5.7 8.0 10.1 5.7 8.0 10.1

1

Useful efficiency

At rated heat output and

high temperature regime

At 30 % of rated heat output

and low temperature regime

2)

η

1)

η

% 92.6 92.5 92.4 92.6 92.5 92.4

4

% 96.8 96.5 96.4 96.8 96.5 96.3

1

Auxiliary electricity consumption

At full load el

At part load el

In standby mode P

kW 0.158 0.152 0.147 0.158 0.152 0.147

max

kW 0.055 0.054 0.050 0.055 0.054 0.050

min

kW000000

SB

Other items

Standby heat loss P

Ignition burner power

P

kW 0.174 0.121 0.171 0.174 0.121 0.171

stby

kW------

ign

consumption

Emissions of nitrogen

NOx mg/kWh 110 103 109 110 103 109

oxides

Annual energy consumption Q

Sound power level, indoors L

kWh------

HE

dB(A)575654555655

WA

Table 2 Product data for energy consumption

1) High-temperature regime means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

2) Low temperature means for condensing boilers 30 °C, for low-temperature boilers 37 °C and for other heaters 50 °C return temperature (at heater inlet).

ErP+

Danesmoor

Utility

ErP+

Regular

25/32

Danesmoor

Utility

ErP+

System

12/18

Danesmoor

Utility

ErP+

System

18/25

Danesmoor

Utility

ErP+

System

25/32

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 7

Appliance information

27

26

28

30

29

31

1

2

3

4

6

5

7

8

9

10

11

12

13

14

16

17

18

19

20

21

22

23

24

15

25

32

34

33

6720821720-01.1Wo

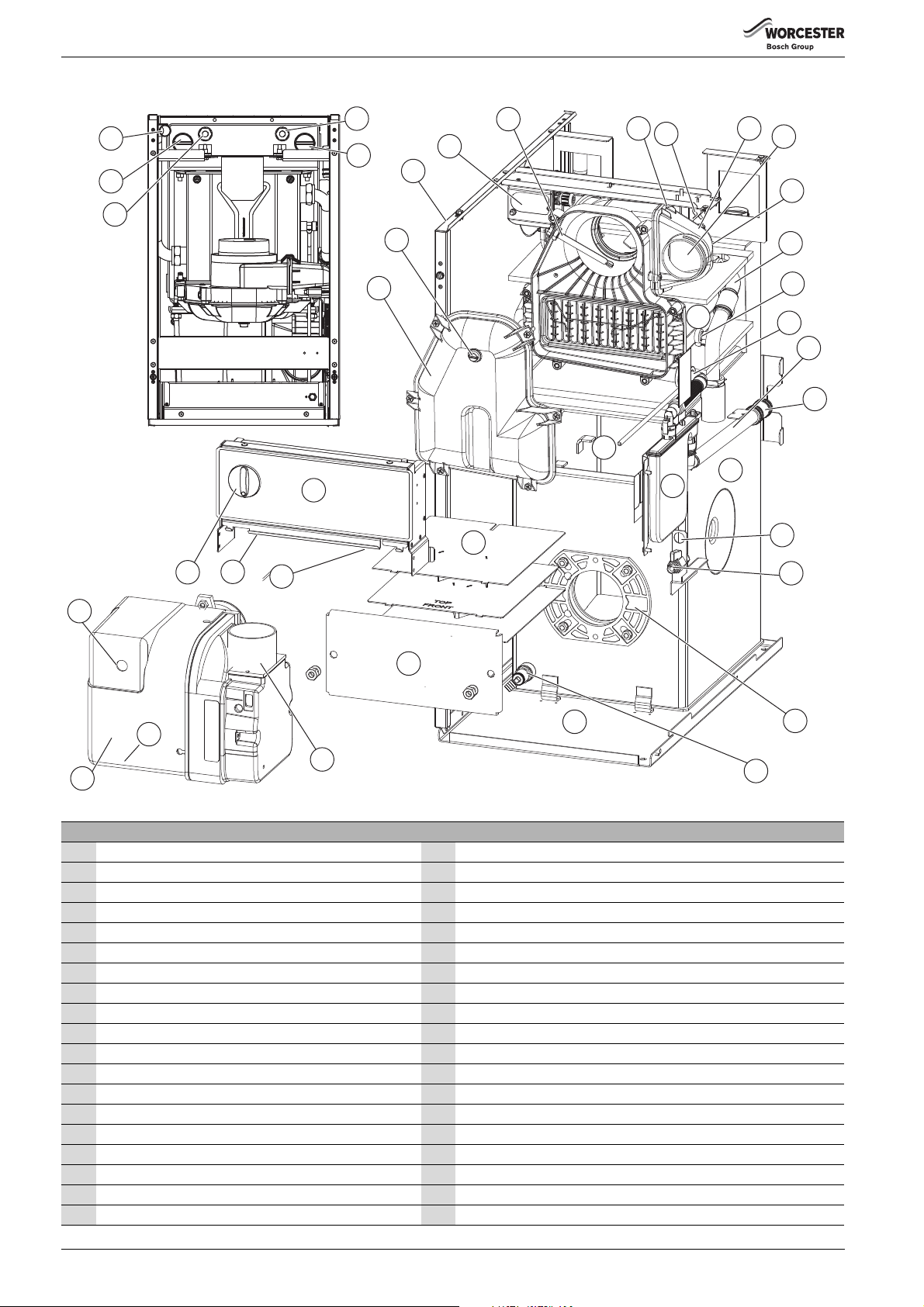

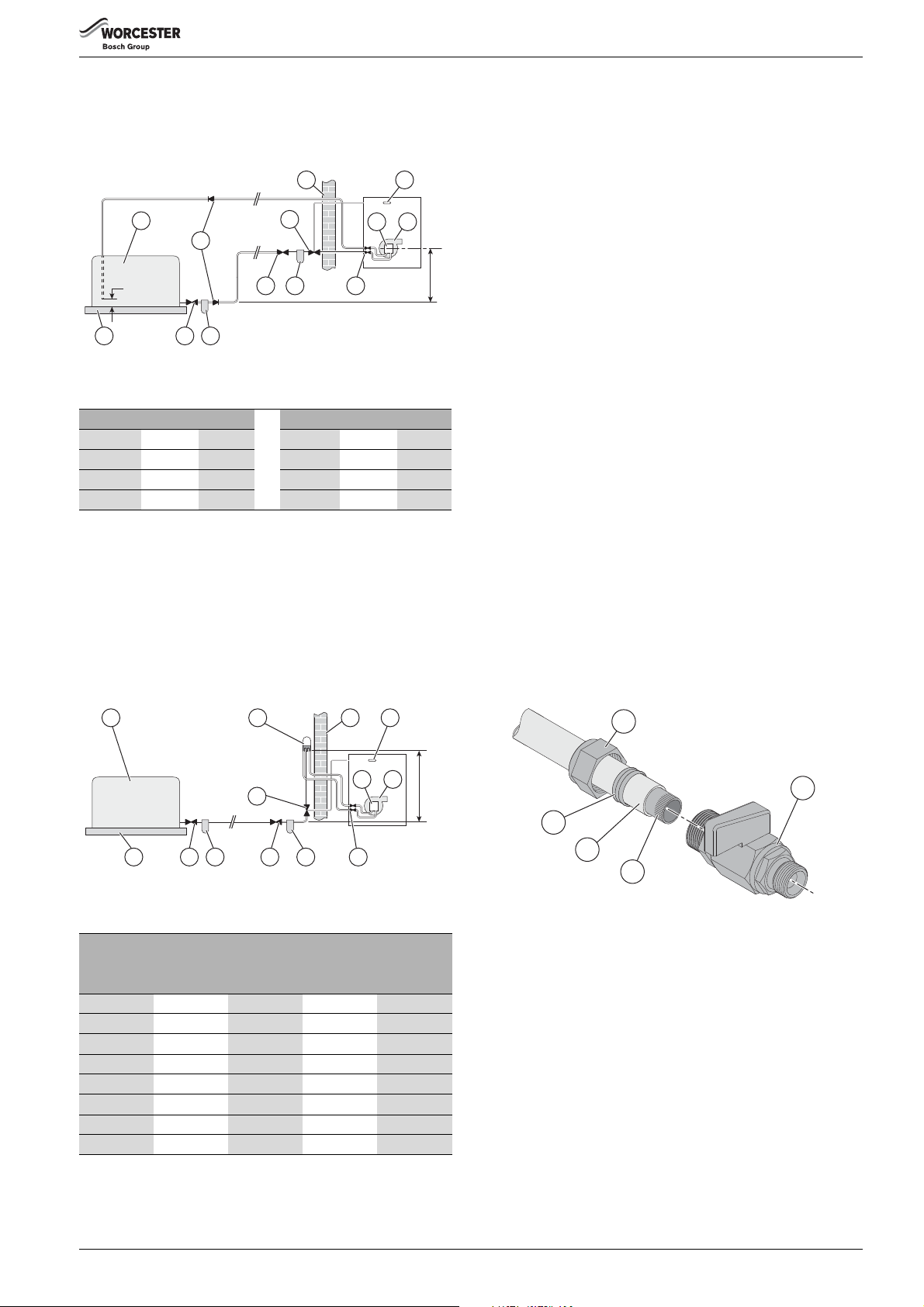

3.4 Layout and components - 18/25 System appliance shown

Fig. 1 System appliance shown

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)8

Appliance information

35

36

37

38

39

6720

821720-03.1Wo

3

41

40

2

1

FRONT

6720821720-04.1Wo

Figure 1 does not include the top, front, left, and right hand side panel

1 Return connection 21 Oil pump (behind plastic cover)

2 Flow connection 22 Burner control box (behind plastic cover)

3 Pressure relief valve 23 Riello RDB burner

4 Air inlet casing 24 Lock out reset button (on the front of the burner control box)

5 Secondary heat exchanger 25 Expansion vessel

6 Secondary heat exchanger baffles 26 Control box assembly

7 Baffle retaining clip 27 Temperature control knob

8 Secondary Heat exchange drain point 28 Flue manifold access cover

9 Condensate discharge 29 Combustion chamber access door (primary baffle inside)

10 Condensate trap 30 Flue gas sampling point

11 Optional oil return position 31 System pressure gauge

12 Oil isolating valve 32 Flue overheat thermostat phial

13 Primary heat exchanger 33 Flue manifold

14 Pump drain point 34 Air pressure switch

15 Burner mount plate 35 Burner lead connector socket

16 Base plate and oil drip tray 36 Flue thermostat reset

17 Circulating pump 37 Expansion vessel retaining bracket

18 Primary heat exchanger drain point 38 High limit thermostat reset

19 Burner air intake 39 Auto reset thermostat

20 Burner motor (behind plastic cover) 40 Control & manual reset overheat thermostat phial

41 Auto-reset high-limit thermostat phial

Table 3 Appliance component details

Fig. 2 Control panel thermostat detail Fig. 3 Top view connections

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 9

Appliance information

26

27

28

25

2

1

3

4

6

7

8

22

23

20

21

30

31

18

16

17

15

14

12

11

10

9

24

19

13

32

33

34

5

6720821720-02.1Wo

37

36

35

38

39

29

3.5 Layout and components - 18/25 Regular appliance shown

Fig. 4 18/25 Regular appliance shown

1 Control box assembly 20 Oil isolating valve

2 Flue manifold access cover 21 Optional oil return position

3Flue gas sampling point 22 Burner mounting plate

4 Casing side panel 23 Primary heat exchanger drain

5 Air pressure switch 24 Base plate and oil drip tray

6 Flue overheat thermostat phial 25 Burner air intake - connected by flexible duct [10] to air inlet casing [9]

7 Power cable clip 26 Burner motor - behind plastic cover

8 Fire valve sensor clip 27 Oil pump - behind plastic cover

9 Air inlet casing 28 Lockout reset button (on front of burner control box)

10 Flexible air duct (connecting to air intake [25]on burner) 29 Combustion chamber access door

11 Secondary heat exchanger bleed point (one on either side) 30 One piece baffle arrangement

12 Secondary heat exchanger 31 Combustion chamber

13 Heat exchanger flow pipe 32 Boiler overheat reset button

14 Secondary heat exchanger drain 33 Flue overheat reset button

15 Condensate outlet 34 Temperature control knob

16 Condensate trap 35 Return

17 Condensate drain pipe 36 Flow/Optional combined feed and vent

18 Flexible condensate drain pipe connection 37 Control & manual reset overheat thermostat phial

19 Primary heat exchanger 38 Auto-reset high-limit thermostat phial

Figure 4 does not include the top, front, and right hand side panel.

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)10

4 Pre-Installation

6720813284-21.1Wo

1

Pre-Installation

4.1 Cleaning primary systems

DANGER: Danger to life through electric shock!

▶ Before carrying out any work on electrical

components, isolate them from the power supply

(230 V AC) (fuse, circuit breaker) and secure against

unintentional reconnection.

NOTICE: Risk of damage to appliance or accessories!

▶ All the following pre-installation sections must be

read and requirements met before starting the

appliance or flue installations.

NOTICE: Risk of damage to system or appliance!

Debris from the system can damage the appliance and

reduce efficiency. Failure to comply with the guidelines

for the use of water treatment with the appliance will

invalidate the appliance guarantee and contravene the

Building Regulations.

▶ It is a requirement of the Building Services

Compliance Guide which is a second tier document

to the Building Regulations to flush and inhibit the

primary water system in accordance with BS 7593.

▶It is recommended that you fit a primary water

cleanser to the system. Worcester recommends

fitting a filter that will help remove both magnetite

and non-magnetic debris.

4.1.1 Before cleaning the system:

▶ Ensure that the system and pipe work is in good working order.

▶ Where possible keep the existing appliance/circulating pump in

place when flushing the system.

Follow the guidance of BS7593:

Treatment of water in domestic hot water central heating and also the

flushing guidelines below.

4.1.2 Flushing the system

▶ Fill the system with cold water and check for leaks.

▶ Open vented systems only:

– Turn off the water to the system header tank.

▶ Open all drain cocks and drain the system.

– See figure 5 for appliance drain points.

▶ Close drain cocks and add a suitable flushing agent at the correct

strength for the system conditions in accordance with the

manufacturer‘s instructions.

▶ Circulate the flushing agent before the boiler is fired up.

▶ Run the boiler/system at normal operating temperature as directed

by the manufacturer of the flushing agent.

▶ Drain and thoroughly flush the system to remove the flushing agent

and debris.

▶ It may be necessary to use a power flushing machine to aid the

cleansing procedure in some circumstances.

▶ Close the drain cocks and manual air vents.

▶ Add a suitable inhibitor to the system in accordance with the

manufacturers instructions.

▶ Open vented systems only:

– Turn on the water to the system header tank and allow the system

to fill.

▶ Sealed systems only:

– Fill the system to between 1 and 1.5 bar via a WRAS approved

filling loop.

▶ Vent any air from the boiler and system.

– See figure 6 for appliance manual vent points.

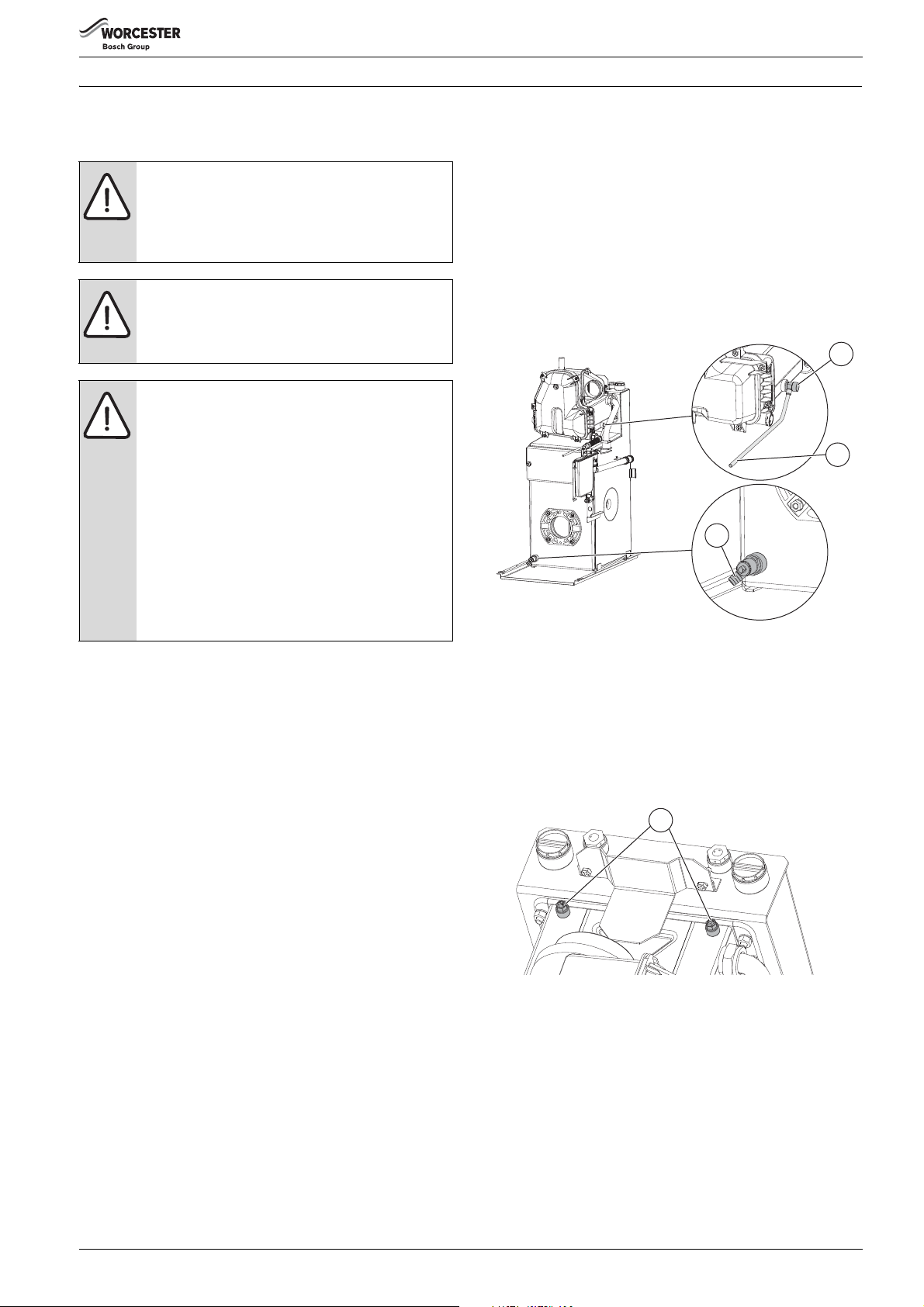

4.1.3 Appliance drain points

▶ The appliance can be drained via the primary heat exchanger point

[3]:

– There is an additional drain point on the secondary heat

exchanger [1].

1

2

3

6720813284-20.1Wo

Fig. 5 Appliance drain points

[1] Secondary heat exchanger drain point.

[2] Secondary heat exchanger drain hose.

[3] Primary heat exchanger drain point.

4.1.4 Appliance vent points

There are two vent points at the top of the secondary heat exchanger.

Only one may be in use, the other may be obscured by side fluing.

▶ Use a radiator key or suitable screwdriver to open the vent point.

Fig. 6 Manual vent points

[1] Manual vent points (each side of the secondary heat exchanger).

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 11

Pre-Installation

6720813284-08.2Wo

1

2

3 4

300mm

Min.

4m Max.

6 8

53

109

13

7

4.1.5 Inhibitor

Add a suitable inhibitor or combined inhibitor/anti-freeze, if the system

is exposed to freezing conditions, to the heating system in accordance

with the DWTA code of practice and manufacturer‘s guidelines.

The inhibitor or combined inhibitor/anti-freeze must not

cause damage to the materials within the boiler (mild

steel, stainless steel, copper and brass) and any other

materials/components within the system.

▶ The concentration level of inhibitor in the system

should be checked every 12 months or sooner if

system content is lost.

WARNING: Sealing agents

▶ In cases where all attempts to find a system micro

leak have failed, Worcester, Bosch Group supports

the use of Fernox F4 leak sealer.

Water treatment products

Suitable water treatment products can be obtain from the following

manufacturers:

ADEY 01242 546717

www.adey.com

FERNOX 0870 601 5000

www.fernox.com

SENTINEL 0800 389 4670

www.sentinel-solutions.net

4.1.6 Artificially softened water

It is possible to have an ion exchange water softener fitted to the cold

water system of the property. However, the boiler requires an untreated

cold water connection taken from the mains supply, before the water

softener, to the primary water filling point of the heating system.

Alternatively there are water softening/treatment devices that do not

adjust or alter the pH levels of the water. With these devices it may not

be necessary to provide an untreated water by-pass to the primary water

filling point of the heat system.

NOTICE:

▶ Salt based, softened water must not be used to fill

the central heating system.

4.3 Oil supply

NOTICE: Contaminated oil supplies can damage the

appliance.

Failure to ensure that the oil supply is clear of

contaminants may invalidate the appliance warranty.

▶ Ensure the oil supply is free of contaminates and

measures are taken to prevent contamination of the

appliance.

• This appliance is suitable for Kerosene (Class C2) only, no other

fuel must be used.

• Plastic or steel tanks should be installed to BS 5410.

A steel tank should conform to BS 799: part 5 and have a slope of

1:24 away from the outlet with a sludge cock at the lower end.

• Do not use galvanised steel tanks or pipework for the oil system.

• Do not use soldered joints on the oil supply pipework.

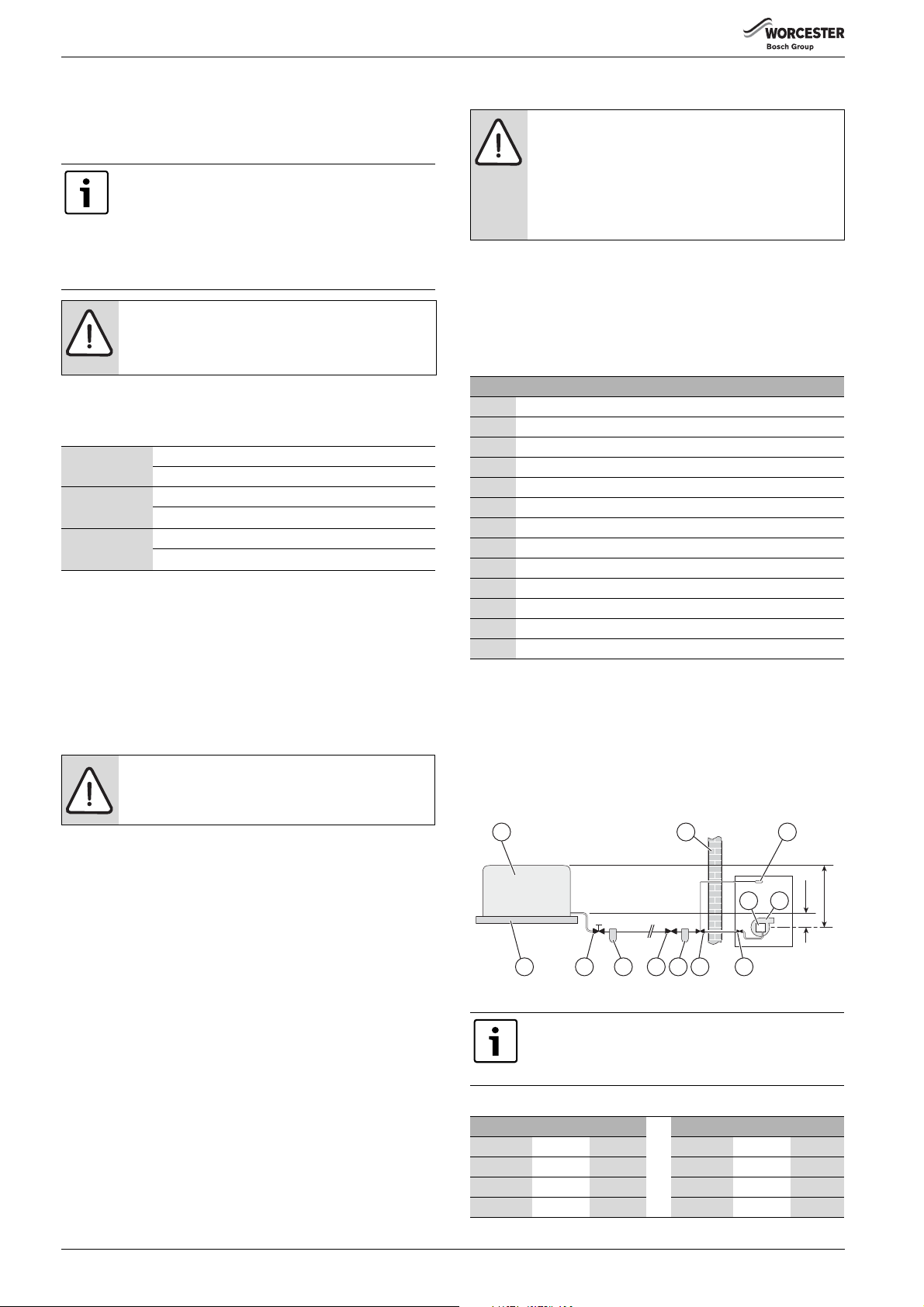

Key to Oil supply illustrations, figures 7, 8 & 9

1OIl storage tank

2 Full base (plastic tank)

3 Isolating valve

4 Oil strainer and water separator

5 Fire valve to BS 5410

6External wall

7 Oil filter (70μm max filtration size)

8 Fire valve sensor

9Oil pump

10 Oil burner

11 Non-return valve

12 De-aerator

13 Appliance isolation valves

Table 4 Key to oil supply feed system

4.3.1 Single pipe gravity feed system:

The oil storage tank [1] must be positioned so that the oil level does not

exceed 4 metres above the level of the burner oil pump [9] and in

addition the oil level must be at least 300mm above the oil pump [9].

Where the maximum oil level in the oil storage tank exceeds 4 metres, a

head breaking device must be installed between the tank [1] and the

burner oil pump [9].

4.2 Mains supply

4.2.1 Electrical supply

• Supply: 230V - 50 Hz

• Cable: PVC insulated 0.75 mm2 (24 x 0.2mm) temperature rated to

90°C.

• External 5A fuse to BS1362.

• The appliance must be earthed.

• This appliance must not be connected to a three phase supply.

• Wiring must comply with the latest IET wiring regulations.

• It must be possible to isolate the appliance from the electrical supply

with at least a 3mm contact separation in both poles supplying the

appliance.

• Wiring between the appliance and the electrical supply must comply

with IET wiring regulations and any local regulations that may apply

for fixed wiring to a stationary appliance.

• Any additional components that are connected to the boiler with

mains electrical supply must not have a separate supply.

Fig. 7 Single pipe feed

All dimensions are in metres unless otherwise stated.

The maximum pipe run figures are based on using

copper pipe with an inside diameter of 2mm less than

the outside diameter.

Maximum pipe run for single pipe gravity fed system

Head (m) 10mmØ 12mmØ Head (m) 10mmØ 12mmØ

0.5 12 30 2.5 62 100

1.0 25 69 3.0 74 100

1.5 37 91 3.5 87 100

2.0 49 100 4.0 99 100

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)12

Pre-Installation

3.5m Max.

150mm

6720813284-09.2Wo

1

2

3 4

73

6 8

5

11

109

13

6720813284-10.2Wo

2

4

3.5m Max.

1 6

12

5

33

7

109

8

13

6720813288-03.1Wo

1

5

4

3

2

4.3.2 Double pipe sub-gravity feed system:

Maximum suction height 3.5 metres. Non-return valves must be fitted to

the inlet and return oil line between the oil pump [9] and oil storage tank

[1].

Fig. 8 Double pipe feed

Maximum pipe run for double pipe sub-gravity fed system

Head (m) 10mmØ 12mmØ Head (m) 10mmØ 12mmØ

050100 2.0 26 66

0.5 44 100 2.5 20 50

1.0 38 95 3.0 14 37

1.5 32 80 3.5 8 22

4.3.3 Single pipe suction lift with de-aerator:

Maximum suction height 3.5 metres. The oil tank [1] must be positioned

below the oil pump [9]. Create an inlet and return loop between the deaerator [12] and oil pump [9].

A non-return valve must be incorporated within the de-aerator or fitted

to the oil line between the oil storage tank [1] and the de-aerator [12].

A top feed oil tank fitted with a de-aerator using an internal non-return

valve should have any non-return valves fitted in the base of the tank to

the suction line removed to assist purging air from the oil line.

4.3.4 Pipework

▶ Refer to the oil supply sections Single pipe gravity feed

system: 4.3.1, Double pipe sub-gravity feed system: 4.3.2 & Single

pipe suction lift with de-aerator: 4.3.3 for oil supply pipework

configurations.

Oil supply pipework considerations:

• Lay the oil supply pipe as straight and level as possible to avoid air

pockets and unnecessary friction losses.

– Route away from the boiler access door or other hot surfaces.

• Install a manual isolating valve to the oil supply pipe, as close to the

oil storage tank as possible.

• Fit an oil strainer and water separator to the oil supply pipe, near the

oil storage tank.

– Fit an additional oil filter (70 μm max filtration size) close to the

boiler, but not inside the boiler casing.

• Fit a fire valve in accordance with BS 5410.

– The fire valve should be fitted externally to the building with the

fire valve sensor located within the appliance case.

– A fire valve with a shut off temperature of 85°C or higher must be

fitted to avoid the possibility of nuisance shut offs.

– A capillary type valve provides a neat and simple installation.

Alternatively, a fusible link or electrical system may be used.

• Under no circumstances should a combination isolating/fire valve be

used as the sole fire protection device.

4.3.5 Boiler isolation valve

▶ Use copper pipe of the correct diameter according to the information

shown in oil supply sections 4.3.1, 4.3.2 & 4.3.3.

– If using soft copper pipe (R220) with a compression fitting, an

insert must be used to prevent the pipe from collapsing or

distorting when the fitting is tightened.

▶ Slide nut [1] and olive [5] onto the oil supply pipe [4].

▶ Slide insert [3] into the pipe.

▶ Offer the pipe to the fitting [2] and tighten the nut [1].

Fig. 9 De-aerator feed

Maximum pipe run for single pipe suction lift with de-aerator

FUEL FLOW RATE

2.5kg/h 5kg/h 10kg/h 10kg/h

Head (m) 8mmØ 8mmØ 8mmØ 10mmØ

010055 26 100

0.5 95 45 23 100

1.0 80 40 20 90

1.5 70 35 17 75

2.0 60 30 14 65

2.5 45 25 11 50

3.0 35 15 8 35

[NOTE:] The table and illustration above is a guide only and does not in

Greenstar Danesmoor Utility

3.5 25 10 5 20

any way override the de-aerator manufacturer’s instructions

ErP+

and Utility System

Fig. 10 Isolation valve bracket removed for clarity

▶ Use flexible hoses to connect from the boiler isolation valve/s to the

oil pump.

ErP+

- 6 720 821 720 (2018/04) 13

Pre-Installation

6720808218-07.1Wo

4.4 Water systems and pipework

NOTICE:

▶ The boiler should not be allowed to operate with a

return temperature of less than 30°C when the

system is up to operating temperature.

Primary system plastic pipework:

• Any plastic pipework used for the CH system must have a polymeric

barrier, complying with BS 7921 and installed to BS 5955 with

1000mm (minimum) length of copper or steel pipe connected to the

boiler.

• Plastic pipework used for underfloor heating must be correctly

controlled with a thermostatic blending valve limiting the

temperature of the circuits to approximately 50°C with 1000mm

(minimum) length of copper or steel pipe connected to the boiler,

and a 20K differential must be maintained at the appliance.

Primary system/connections/valves:

• Do not use galvanised pipes or radiators.

• All system connections, taps and mixing valves must be capable of

sustaining a pressure of 3 bar.

• Radiator valves should conform to BS 2767:10.

• All other valves should conform to BS 1010.

• An automatic bypass valve must be connected between the heating

flow and return where TRVs are used on all radiators, fitted to give at

least a 3 metre circuit when activated.

• Drain cocks are required at all the lowest points on the system.

• Air vents are required at all high points on the system.

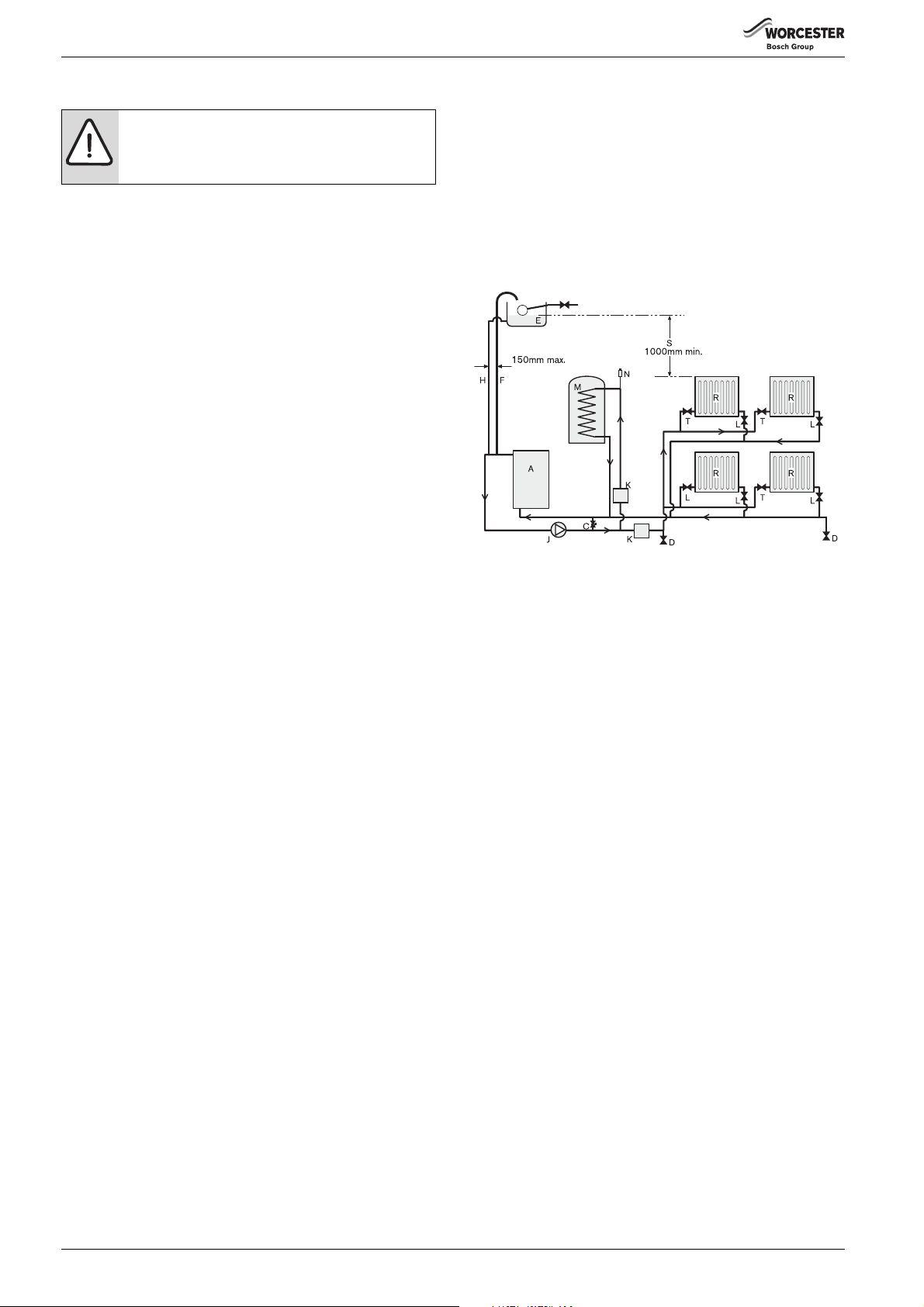

Open vent primary system (Regular only)

• The open vent pipe (F) and feed and expansion pipe (H) must rise

continuously from the appliance.

• The feed and expansion cistern (E) must be positioned to provide a

static head (S) of at least 1 metre above the highest point in the

heating system to the water level in the feed and expansion cistern.

• Ensure adequate space is left in the expansion cistern for expansion

of the system water.

• No valve shall be fitted in the open vent pipe (F) or the feed and

expansion pipe (H).

• The open vent pipe (F) must be at least 22mmØ.

Fig. 11 Regular boiler, open vent layout

[A] Regular appliance

[A1] System appliance

[B] Expansion vessel*

[C] Automatic bypass valve

[D] Drain cock

[E] Feed and expansion cistern

[F] Open vent 22mmØ min.

[G] Pressure gauge*

[H] Feed and expansion 15mmØ min.

[J] Circulating pump*

[K] Zone valves

[K1] Three port valve

[L] Lockshield valve

[M] Hot water cylinder

[N] Automatic air vent

[P] Pressure relief valve*

[P1] Pressure relief discharge*

[R] Radiators

[T] Thermostatic radiator valve TRV

[U] To filling system

[NOTE] * Components included in the System boiler

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)14

Pre-Installation

6720808218-109.1Wo

K1

P1

A1

SYSTEM FILL

SV SV

Test point

Temporary hose

Hose union

CV

CV

Heating

return

Mains

supply

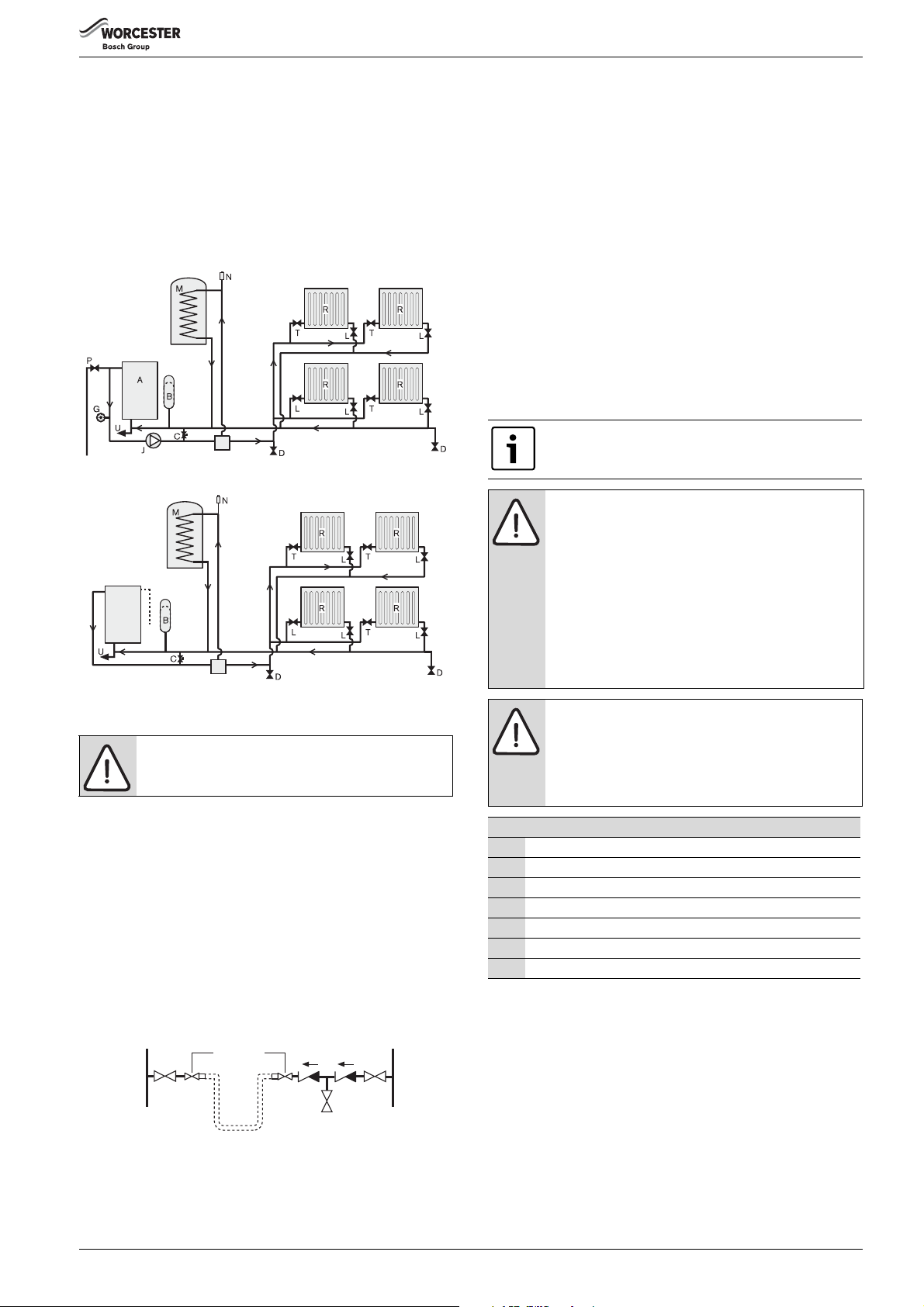

Fully pumped sealed primary system:

• A pressure relief valve (P), spring loaded safety valve set to operate

at 3bar, must be fitted to the heating flow pipe as close as possible to

the boiler or onto one of the boiler top 1” BSP outlets.

• An expansion vessel (B) must be fitted to the heating return pipe as

close as possible to the boiler and pressurised for the system volume

according to the instructions supplied with the vessel.

• A pressure gauge (G), 3 bar minimum, must be fitted to the heating

flow pipe or one of the boiler 1” BSP outlets.

• An automatic air vent (N) must be fitted.

K1

6720808218-08.1Wo

Fig. 12 Regular boiler, system layout

Fig. 13 System boiler system layout

Filling primary sealed systems

NOTICE: FILLING THE SYSTEM

▶ The system must not be filled with salt based

softened water.

• Where the system volume is more than 180 litres at 0.5 bar or

exceeds 2.65 bar at maximum heating temperature an extra

expansion vessel (B) must be fitted as close as possible to the

appliance in the central heating return.

• Pressurise the extra expansion vessel (B) to the same figure as the

expansion vessel built into the appliance (system boilers).

• Filling the system must comply with one of the methods shown in the

figure below.

• The filling point must be at low level and must never be a permanent

connection to the mains water supply.

• Filling loops must be WRAS approved.

4.5 Condensate discharge

For correct installation and trouble free operation of the appliance the

following advice should be followed:

1. All condensate pipework must ‘fall’ from the appliance by a minimum

of 3 degrees (52mm per metre) to ensure adequate condensate

flow.

2. The pipework route must allow air to be supplied back to the

appliance for correct operation of the condensate trap.

3. Connection to a rainwater down pipe must include an air break.

Also:

• Keep external pipework as short as possible and not exceed 3 metres

length.

• External pipework should be increased to a minimum diameter of

32mm and ideally be insulated.

• Minimise the number of bends and connectors.

• Remove burrs after cutting pipe.

• Remove surplus solvent from the interior of the pipe.

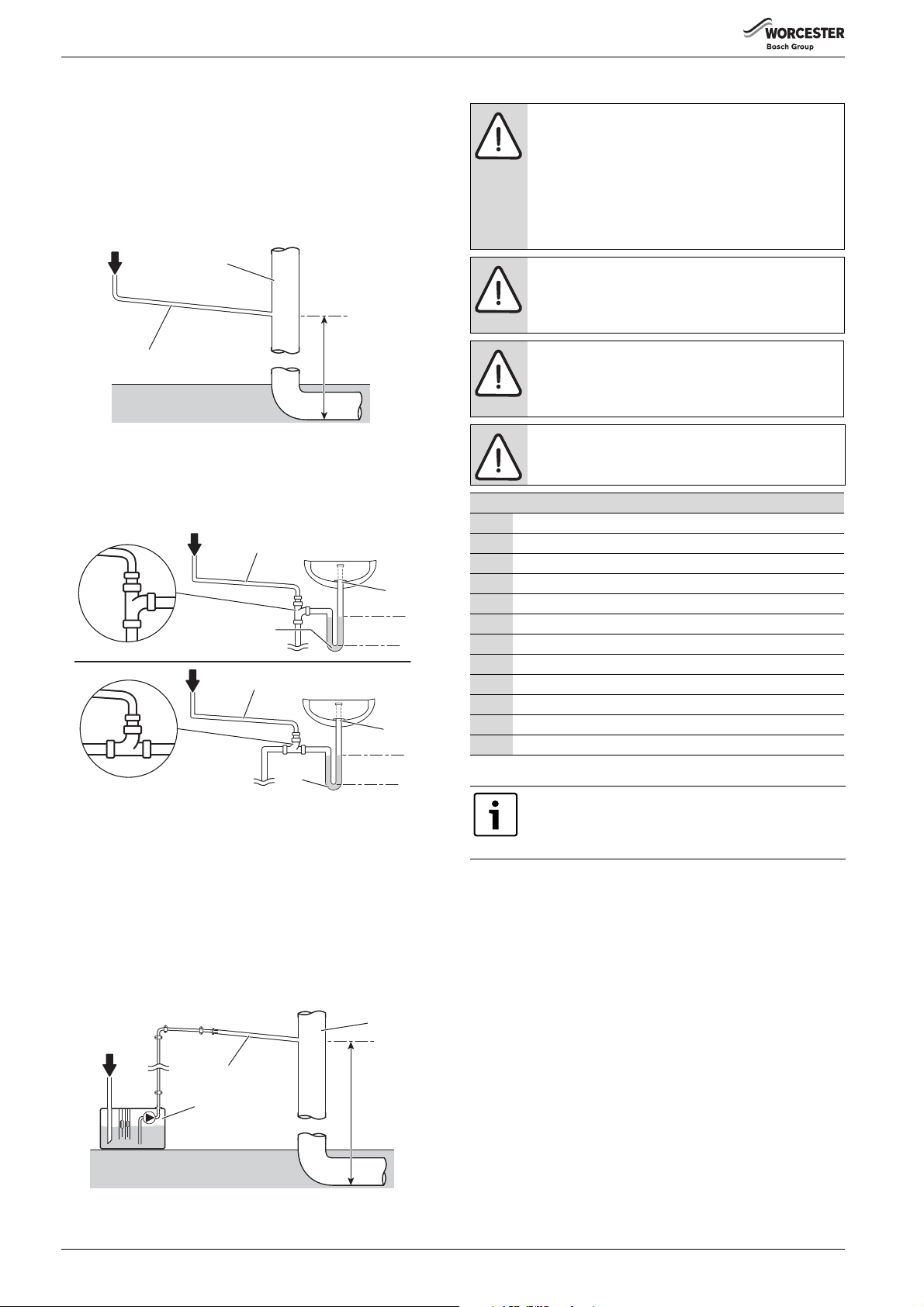

4.5.1 Condensate pipe work

Follow HHIC guidance and recommendations for

condensate disposal

NOTICE:

▶ Where a new or replacement boiler is being installed,

access to an internal “gravity discharge” point should

be one of the factors considered in determining

boiler location.

▶ The condensate pipe must be nominally

21.5mm Ø plastic pipe.

▶ The condensate pipe work must fall at least 52mm

per metre towards the outlet and should take the

shortest practicable route.

▶ Ensure there are no blockages in the pipe run.

NOTICE: Unheated internal areas.

The condensate discharge may freeze in areas during

prolonged cold temperatures.

▶ Internal pipe runs in unheated areas such as lofts,

basements and garages should be treated as external

runs.

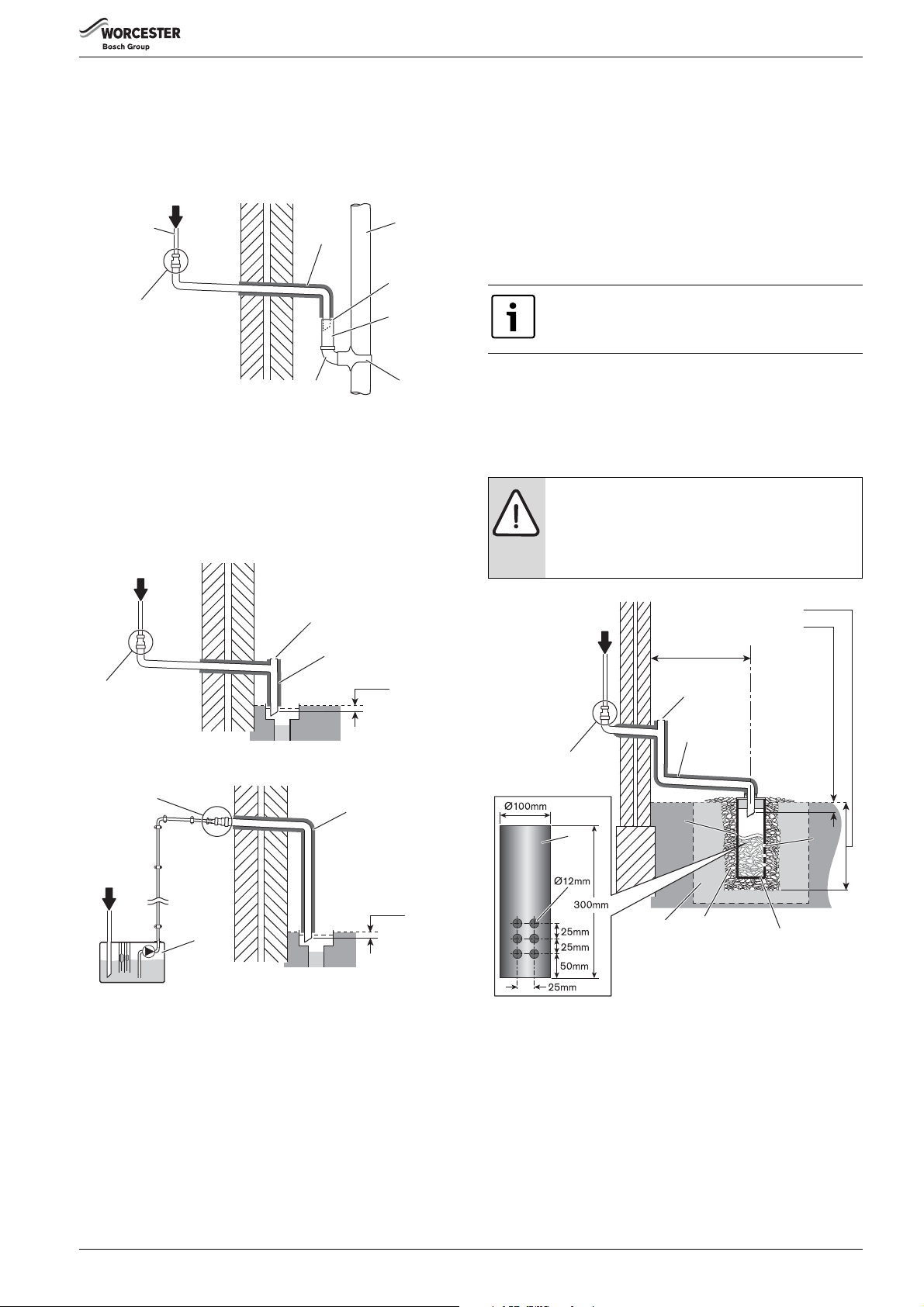

Key to condensate illustrations, figures 12, 13, 14 & 15

1 Condensate discharge from boiler

2 Soil and vent stack

3 Minimum 450mm and up to three storeys

4 Visible air break at plug hole

5 Sink or basin with integrated overflow

6 75mm sink waste trap

7 Condensate pump

Table 5 Key to Internal condensate disposal methods

Fig. 14

[SV] Stop valve

[CV] Check valve

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04) 15

Pre-Installation

6720644744-06.4Wo

21.5mm Ø

1

3

2

4.5.2 Internal connections

In order to minimise risk of freezing during prolonged cold spells, the

following methods of installing condensate drainage pipe should be

adopted, in order of priority.

Wherever possible, the condensate drainage pipe should be routed and

terminated so that the condensate drains away from the boiler under

gravity to a suitable internal foul water discharge point such as an

internal soil and vent stack. A suitable permanent connection to the foul

waste pipe should be used.

Fig. 15 Disposal to soil vent stack

Alternatively if the first option is not possible an internal kitchen,

bathroom or washing machine waste pipe etc. can be used.

Ensure that the condensate drain pipe is connected “down stream” of

the waste trap.

1

21.5mm Ø

6

1

21.5mm Ø

6

Fig. 16 Disposal to a waste pipe

CONDENSATE PUMP

Where “gravity discharge” to an internal termination is not physically

possible, or where very long internal runs would be required to reach a

suitable discharge point, condensate should be removed using a

proprietary condensate pump, of a specification recommended by the

boiler or condensate pump manufacturer.

The pump outlet pipe should discharge to a suitable internal foul water

discharge point such as an internal soil and vent stack or if not possible

to internal kitchen, bathroom or washing machine waste pipe etc. A

suitable permanent connection to the foul waste pipe should be used.

1

21.5mm Ø

7

Fig. 17 Condensate pump disposal

75mm

min.

75mm

min.

2

3

4.5.3 External connections

NOTICE: Rainwater or external drain disposal

Untreated condensate must not be allowed to flow into

streams or rivers

▶ A rainwater down pipe or an external drain shall only

be used for condensate disposal if the down pipe or

external drain is connected to a combined foul and

rainwater system

▶ Refer to BS 6798 for more information

NOTICE: Grey water systems

Contamination of recovered water

▶ Condensate disposal shall not be allowed into a grey

water recovery system that is intended for re-use

NOTICE: Freezing conditions

▶ Pipe work length should be kept to a minimum and the

route as vertical as possible.

▶ When required, use only weather proof insulation.

NOTICE: Condensate waste

▶ Care should be taken when siting a soak-away to

avoid obstructing existing services.

Continued - Key to condensate illustrations, figures 13,14, 15 & 16

8 Pipe work transition

9 Insulate and increase pipe size

10 External rain water pipe into foul water

5

11 External air break

12 Air gap

13 PVCu strap-on fitting

14 43mm 90 male/female bend

15 100mm Ø minimum plastic pipe

16 Drainage holes

17 Limestone chippings

5

18 Bottom of sealed tube

19 Increase size of soak-away with lime chippings if in clay soil

Table 6 Key to external condensate disposal methods

6720819188-03.3Wo

Condensate drainage pipe can be run above or below

ground. If the pipe work is run under ground, care must

be taken to ensure that the pipe work “fall” towards the

disposal point is maintained

If no other discharge method is possible then the use of an externally run

condensate drainage pipe terminating at a suitable foul water discharge

point, or purpose-built soak away, may be considered. If this method is

chosen then the following measures should be adopted:

▶ The external run be kept as short as possible and not exceed 3

metres.

▶ The pipe should be run internally as far as possible before going

externally and the pipe diameter should be increased to 32mm

before it passes through the wall to the exterior. The pipe should be

insulated using suitable waterproof and weather resistant insulation,

if not using a CondenseSure siphon.

▶ The external pipe should take the shortest and least exposed route to

the discharge point, and should "fall" as steeply as possible away

from the boiler, with no horizontal runs in which condensate might

stand.

▶ The use of fittings, elbows etc. should be kept to a minimum and any

internal “burrs” on cut pipe work should be removed so that the

internal pipe section is as smooth as possible.

6720819188-12.2Wo

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)16

Pre-Installation

6720810188-05.5

21.5mm Ø

9

10

11

12

13

14

8

1

6720644744-10.4Wo

9

25mm min.

1

11

8

6720644744-12.4Wo

9

25mm min.

8

1

7

6720821683-30.1Wo

500mm min.

25mm min.

400mm min.

9

16

18

17

19

15

15

16

1

8

11

Unsuitable for clay soil types

FITTING AN EXTERNAL AIR BREAK

• Refer to figure 18 when a rain water down pipe is used to dispose of

condensate.

• An air break must be installed in the 43mm pipe work, between the

boiler condensate outlet and the drainpipe, outside the property, to

avoid flooding during adverse weather conditions.

Fig. 18 Disposal into a rainwater down pipe

Where the pipe terminates over an open drain or gully, the pipe should

terminate below the grating level, but above water level, in order to

minimise “wind chill” at the open end.

The use of a drain cover (such as those used to prevent blockage by

leaves) may offer further protection from wind chill.

Pipe drainage will be improved if the end is cut at 45° as opposed to a

straight cut.

CONDENSATE SOAK AWAY

• The condensate soak away must be sited at least 500mm away from

building footings.

• The condensate drainage pipe may be run above or below the ground

to the soak away. The examples shown on this page run above

ground.

• The soak away must use a 100mm Ø plastic tube with two rows of

three 12mm holes on 25mm centres and 50mm from the bottom of

the tube. The holes must face away from the house.

• The tube must be surrounded by at least 100mm of limestone

chippings to a depth of 400mm.

Minimum hole size for the condensate soak away must be

400mm deep by 300mmØ .

In situations where there are likely to be extremes of temperature or

exposure, the use of a proprietary trace-heating system for external pipe

work, incorporating an external frost thermostat, should be considered.

If such a system is used, the requirement to use 32mm pipe does not

apply. However, all other guidance above and the instructions for the

trace heating system, should be closely followed.

NOTICE: Unheated internal areas.

▶ Internal pipe runs in unheated areas such as lofts,

basements and garages should be treated as external

runs and consideration should be given to using a

CondenseSure siphon.

Fig. 19 External disposal

Fig. 20 Condensate pump to external disposal

Greenstar Danesmoor Utility

ErP+

and Utility System

Fig. 21 To a soakaway

ErP+

- 6 720 821 720 (2018/04) 17

Pre-Installation

1

2

3

4

2

3

4

1

2

6720646608-123.1Wo

4.6 Pressure relief pipework

• The pressure relief discharge pipe (1) should be at least 15 mm

diameter copper pipe and run downwards away from the boiler and

discharge away from any electrical or other hazard, preferably to an

external drain or soakaway.

• Pipe (3) should be finished with a partial bend, near the outlet to face

the external wall (as shown) to help prevent freezing.

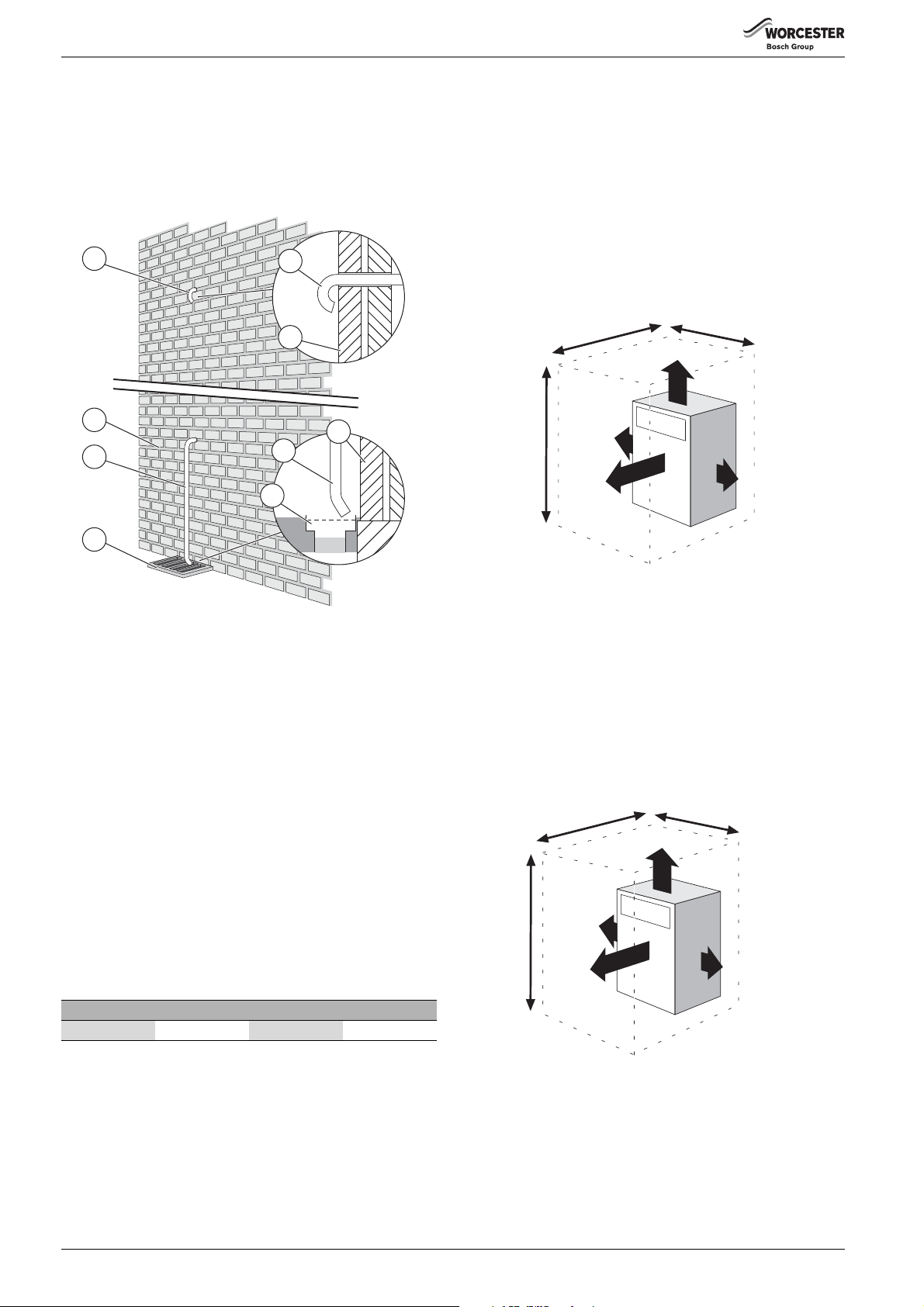

Room sealed balanced flue models (RS)

The appliance does not require a separate vent for combustion air.

Installation in cupboards or compartments require permanent vents for

cooling purposes, one at high level and one at low level, either direct to

outside air or to a room.

Both vents must pass to the same room or be on the same wall to the

outside air.

The minimum air vent free area is given in the table opposite.

Installation clearances

Figure 23 shows the minimum space recommended to install the boiler

only.

1200mm

570mm

300mm

100mm

1155mm

100mm

600mm

6720808218-16.1Wo

Fig. 23 Installation clearances

Fig. 22 Pressure relief pipe work

[2] Outside wall

[1, 3] PRV discharge pipe

[4] External drain

Service clearances

Figure 24shows the minimum space required to carry out an annual

service.

* Remove the flue 'knock-out' panel sections if this clearance is less than

75mm.

4.7 Boiler locations and clearances

This boiler is only suitable for installing internally within a property at a

suitable location onto a fixed rigid surface of the same size as the boiler

and capable of supporting the boiler weight.

The boiler must be installed on a flat level surface to ensure condensate

The appliance is suitable for an under worktop installation providing that

the worktop above the boiler (min 10mm clearance) is removable for

maintenance and repair and the front of the boiler is not enclosed.

** Due to changes to BS 5410 and modern building design, these figures

no longer incorporate the adventitious ventilation allowance.

does not enter the primary heat exchanger.

The boiler is not suitable for external installation unless a suitable

enclosure is provided.

1200mm

380mm

10 m m

Roof space installations must fully conform to BS 5410 part 1 section

4.6.9.

Open flue model (CF)

In order to ensure clean and efficient combustion an adequate supply of

air must be delivered to the combustion chamber.

To provide sufficient air a suitable inlet must be provided into the room

or space in which the boiler is situated.

5mm*

865mm

5mm*

600mm

Output 12/18 18/25 25/32

2

Size cm

An air brick or other form of continuous air supply may have to be built

into the installation in order to ensure an adequate supply of air.

99 138 165

6720808218-17.1Wo

Fig. 24 Service clearances

If the appliance is to be installed in a confined space or compartment two

air vents are required, one at high level and one at low level.

The minimum free area of each vent is shown opposite and depends

whether the air is taken from another room or from outside the building.

Where the air is taken from another room that room must contain an air

inlet as described above.

Greenstar Danesmoor Utility

ErP+

and Utility System

ErP+

- 6 720 821 720 (2018/04)18

Loading...

Loading...