Bosch Worcester 240 Combi OF Installation And Servicing Instructions

....--~~~ORCESTER-----.

BOSCH

240

WALL

MOUNTED

COMBINATION

MAINS

Combi OF

FED

INSTALLATION AND

SERVICING

BOILER

DOMESTIC

FOR

HOT

CENTRAL

WATER

HEATING

AND

INSTRUCTIONS

IMPORTANT:

THESE

INSTRUCTIONS

To

THIS

THESE

GC

NUMBER

BOILER

Automatic Modulating Control

Domestic

Maximum 24.0 kW (82,000 Btu/

APPUANCE

INSTRUCTIONS

ARE

Hot

Minimum

TO

BE

LEFT

47

311

OUTPUT

Water and Central Heating

9.2 kW

(31

,400

IS

FOR

USE

APPLY

WITH

IN

THE

09

Btu/h)

WITH

THE

USER

h)

NATURAL

UK

ONLY

OR

AT

GAS

THE

ONLY

GAS

METER

Contents

1. Installation Requirements

2.

3.

4.

5.

6.

7.

8.

9.

General

Technical

Siting

Siting

Air

Sealed

Open

Domestic

Information

Data

the Appliance

the

Flue

Supply

....

System

Vent Primary

Hot

...................

Terminal

...................................................................

..........................................................

Water

....

.....

....................................

.......

........

...

..................................

......

...........

.....

..................

......................................................

..........................

Water

System

......

...............

.......................................

1. Installation Regulations

1.1

Gas

Safety (Installation and

All

gas appliances must

accordance

with

the above regulations.

ances correctly could lead to prosecution.

The

1.2

overrid

1.3

fer

of

ments

amended, current

tions,

the

Electridty

(

the

BS

b

BS

BS

tic

BS

in

BS

input not exceeding

BS

t

ions

1

standards, t

other relevant

manufacturers notes must not

ing

statutory obligations.

The

compliance

immunity

this

appliance must

of

the

Building

local

relevant

6798:1987

oilers

of

5449

:19

Water

at

rated input not exceeding 60

90

with a British

from

legal

be

Gas

Safety

(Install

lEE

Wiring

Standards (

Company. Health

Work

Regulat

recommendations

Specifi

cati

Central Heating

5546:1990 Installation of gas hot water supplies

purposes.

5440:1:1990

put not exceedi

Flues

ng

60

and

kW:

5440:2:1989 Flues and

60kW: Air

6891

:1988 Installation

up

to

28

mm

(R

1 ).

.4

To

ensure that the installation

he

system and components should conform to any

Br

itish Standards

in the instructions.

Use)

Regulations 1984

be

installed

by

a competent person

Failure

be

Standard does

obligations.

in

accordance

In

particular the installation

with

ati

on

and

Use)

Regulations,

local

ScotlandXConsolidation)

and Safety Document No. 635

ions

).

!t

should

be

of

the f

ollowing British

on

for

installati

on

of gas

kW.

for Domestic Premises.

Ven

tilati

on

for

gas appliances

Flues

.

Ventilation

for

gas appliances

Supply.

of low

pressure gas pipework installa·

will

perform to the highest

in

addition

..

.....

.............

.........

......

.........

...............

to

install appli·

taken,in any

not.

of

itself.

the

relevant

Regulations

Building

and

byelaws

in

accordance w

Standards.

fired

hot water

for

to

those mentioned

Page

2

Page

2

Page

4

Page

5

Page

6

Page

6

Page

7

Page

8

Page

8

way

,as

con

require

1984 as

Regula·

ith

domes·

of

rated

of

rated

in

of

10.

Electrical

11

. Installation

12. Commissioning ...........................................

13.

Instructions

14

. Inspection and Servidng

15

. Replacement

16

. Short Parts List

17

. Operational

18.

Fault

An

optional

Operating

2.5 ELECTRICAL SUPPlY

Mains supply:

Internal fuses:

2.6

GAS

The

·

boiler requires 2.

and supply pipes must be capable

gas in addition

·

served.

lengths and the allowance to be made for fittings.

BS6891 for

The

meter

mbar (B

The

complete installation,

ed

for

soundness and purged.

3

2.9

8.7

18.G 12.0 9.4

Note:

Each

fitting

length

of

length to

ie: Elbow

.................

Finding ....................

facia

Switch

240V

T2A

SUPPLY

to

The

table below gi

...

.......

................

to

the

of

Parts

...

...............

Flow

Diagram ...

.................

....

...................

User

...........................................

..........

...........

....

.....

.....................

................

..........................

...........................

..........................

...................

..........................................

mounted programmer instead

.

-,

50

Hz,

150 watts. External fuse

(F1)

and

T315mA (F2).

82

m'

/h (96.8

the demand

ves

ft

' /hr)

of

supplying this quantity

from any other appliances being

an ind

icati

on

further information.

gov

ernor should deliver a dynamic pressure

in wg.)

at the appliance.

TOTAL

GAS

SUPPLY

Gas

Discharge Rate

used in the gas

straight p

give

= 0.5 metres,

ipe

the total

including

LENGTH

PIPE

6 9

- -

5.8

line

which

length

Tee

= 0.5 metres,

the gas meter, must

Refer

to

BS

OF

(metres)

(m3

/h)

4.6

from

the meter

must be

added

.

6891

90° Bend

........

...................

..............

.........

...

...................

of

of

gas.

of

limiting

.

is

equivalent to a

to

the straight

........

Page 10

......

Page 1 3

Page 1 5

...

..

Page 16

........

.. Page 17

Page 19

..... Page 25

Page 26

Page

the standard

The

gas meter

gas pipe

Refer

of

be

test·

Pipe

Diamet

er

(mm)

15

22

28

pipe

= 0.3 metres.

28

3A.

of

to

20

2. General Information

2.1

This

appliance is

The

2.2

output

heating load

2.3

2.4

A

A

Fully

ho

An

A

appliance controls are set to provide a maximum

for

the domestic hot water

of

The

appliance has a permanent

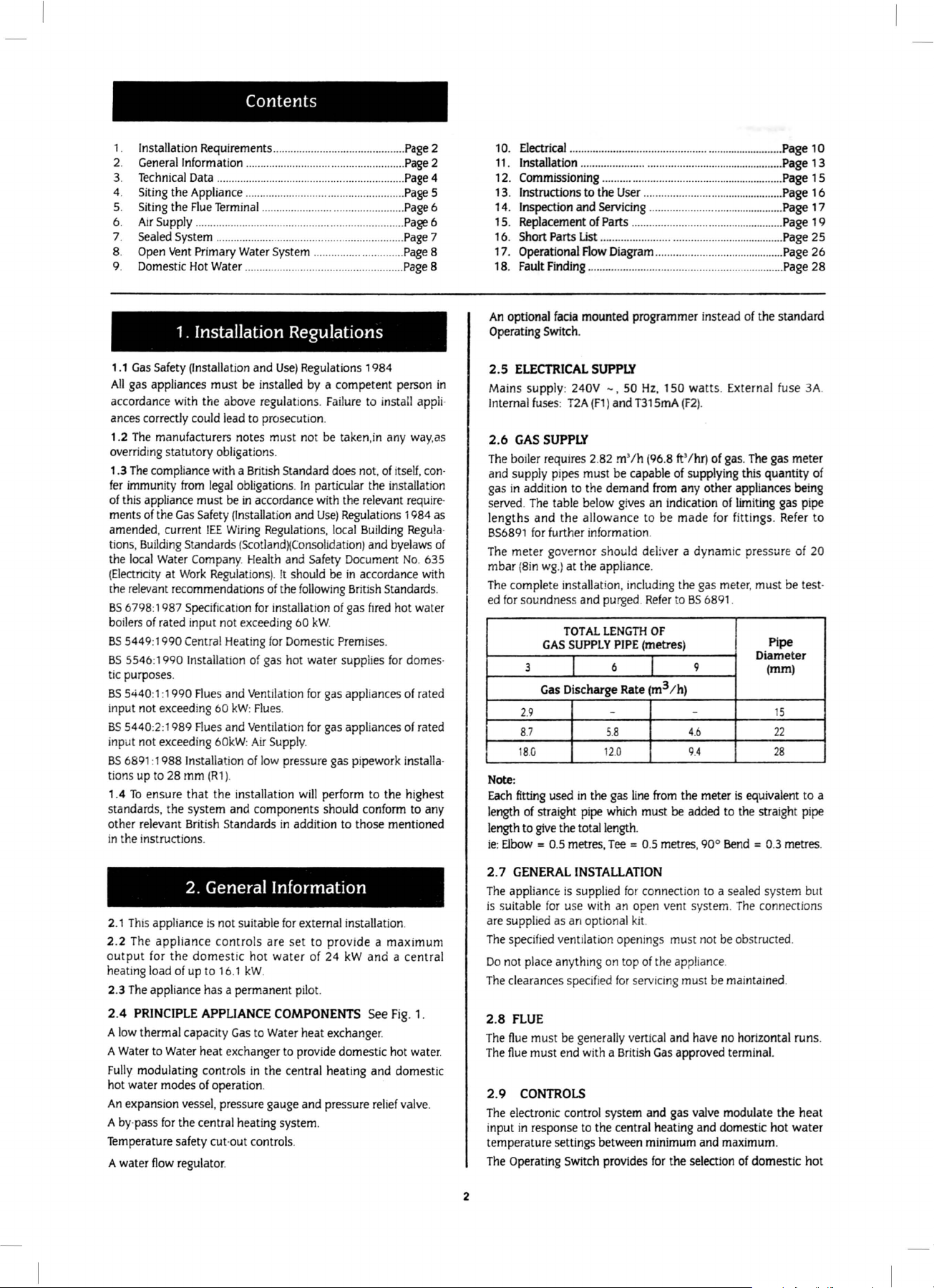

PRINCIPLE APPLIANCE COMPONENTS See

low

thermal capacity

Water

to

Water

modulating controls

t water modes

expansion vessel, pressure gauge and pressure

by

·pass

for

Temperature safety

A water

flow

not

suitable

up

to 16.1 kW.

Gas

heat exchanger

in

of

operation.

the central heati

cut·out controls.

regulator.

for

external installation.

of

pilot.

to

Water

heat exchanger.

to

provide domest

the central heating and domes

ng

system.

24

kW

and a central

Fig

. 1.

ic

hot

water.

tic

relief

valve

.

2. 7 GENERAL INSTALLATION

The

appliance:

is

suitable

are suppl

The

spec

Do

not

The

clearances specified

2.8

FLUE

The

flue must

The

flue

2.9 CONTROLS

T

he

electronic control system and gas

in

input

is

supplied

for

use

with

an

ied

as an option

ified

ventilation openings must

pla

ce anything

al

on

for

be

generally

must end

response to t

with a British

he

central heati

for

connec

open vent system.

kit.

top

of

the appliance.

servici

verti

cal

Gas

temperature settings between minimum and

The

Operating

2

Switch

provides

for

tion

to a sea

led

The

not

be obst

ng

must

be

maintai

and have

approved

the selecti

no

horizontal runs.

terminal.

valve

modulate the heat

ng

and domestic hot water

max

imum.

on

of

domestic hot

system but

connections

ructed.

ned

.

Fig.

1. Appliance

Waterflow

manifold

L_

Central hearing

by

·

pass adj

uster

t__

- -

..

--

water

only

(WATER)

(HEATING & WATER)

A

fac

ia mounted programmer

remote mounted

prog

Automat

-

water

ic

Central heati

Cen

flow diagram.

air

vent

- ----

---,--

-Oomestoe

-ng

retu

tral heati

ng

flow

Gas

heat

Boile

Mains

rn

to

Water

exchanger

r

Water

v

alve

-:

Pr

essure

cold water

div

erter

I

I

reli

ef val

ve

hot

wate

r out

in

or central heating and domestic hot water

or

OFF

.

is

ava

ilable as an optional extra. A

rammer may be connected

to

ance.

The

integral

fac

ia displays indicate the status

prov

ision

for

There is

thermostat and/ or a

The

electronic controls prevent rapid

the connection

frost

thermostat.

of

the appliance.

of

a mains voltage

cycling

of

the appliance

the central heating mode.

2.1

0

SYSTEM

NOTES

WARNING

Check that no dirt is left

as

this could cause

the heating system and the cold water

the gas supply before

The

water pipe connections throughout a sealed system must

be capable

of

sustaining a pressure

Radiator valves must conform

(10): 1972

The

relief

.

valve

discharge must be directed

trical components or where

A drain

cock

to

BS

in

either the

damage

finally

it

2879 must

gas

and water pipework

to the appliance. Thoroughly flush

mains supply. Purge

connecting the appliance

of

upto 3 bar.

to

the requirements

away

from

would

cause a hazard to the

be

fitted

to

the lowest point

system.

For

circu

it design purposes

of the informati

on given

it

is

important that due note

in

Table

3 relating

to

the available

pump head.

the appli-

room

..

of

BS2767

any

elec

user.

of

is

taken

the

in

2.11

Hot

be

suitable

SHOWERS,

and

cold

BIDETS,

taps and

for

operating at a mains pressure of up

TAPS

mixing

AND

MIXING

valves used

VALVES

in

the system must

to

1 0 bar.

Thermostatically controlled or pressure equalising shower

valves

will guard against the

ature.

Hot

and

cold

mains

fed

rim

flushing

With

taps

ously and the

Flow

avoid

vidual outlets.

Systems

2.12

The

appliance must not be operated

The

appliance must not be operated wi

bidet subject

all

mains

fed

systems the

will vary with the number

cold

water mai

balancing

using

an excessive reduction

For

further information contact Worcester Heat

Ltd

.

SAFETY

CONSIDERATIONS

flow

of

water at too

higb

water can be supplied direct to an

to

local

Water

Company requirements.

flow

ns

'Ball-o-Fix'

in

of water

of

outlets operated simultane-

supply pressure

type valves

flow

in

from

the individual

to

the property.

is

recommended

or

even

starvation

a waterless condit

th

the boiler inner casing

a temper-

I

to

ion

over-

to

indi

.

-

cover removed.

Work

must not

and electricity supplies

Checks

made into

be

carried out

must be made

walls

and partitions

on

the appliance without the gas

being

switched

to

ensure that the ventilation openings

off

.

are

of

the correct size and

are

not

obstructed.

2.13

OPERATION

Domestic Hot Water:

will

light

at its maximum setting and then automatically adjust

With

a demand

for

hot water the burner

its output to maintain the temperature rise of the delivered

water.

When

hot water

extinguish.

The

pump

dissipate the residual heat

Central Heating:

at its

mum

minimum

output.

setting and gradually increase

The

adjusted to maintain the temperature

can reduce down to a minimum of

With

output

is

no

will

continue

from

a demand

of

the appliance

longer required, the burner

to

run

for

a short period

the appliance.

for

heating the burner

to

is

then automatically

of

the system.

?.2

kW.

If

will

give

the

The

output

the system

will

light

maxi

to

-

no

longer requires even the minimum output to maintain the

room

desired

will

continue

ance.

The

utes

before re-lighting

temperature the burner

to

run

to

dissipate the residual heat

appliance

will

remain

to

automatically meet the system

off

for a fixed

will

extinguish.

from

period

The

of

the

two

require-

pump

appli

min

-

-

ments.

Domestic Hot Water

supply

demand

heat

for

domestic hot water at a tap or shower

the central heating requirement

hot water demand.

burner

will

extinguish and the appliance

tral heating state and its normal mode

will

continue

ance

as

necessary.

to

and

Central Heating:

The

· appliance

will

to the central heating system as required. A

will

override

for

the period

When

hot water

is

run to dissipate the residual heat

of

the domestic

no

longer required the

will

return to the

of

operation.

The

from

cen

pump

the appli·

-

-

3

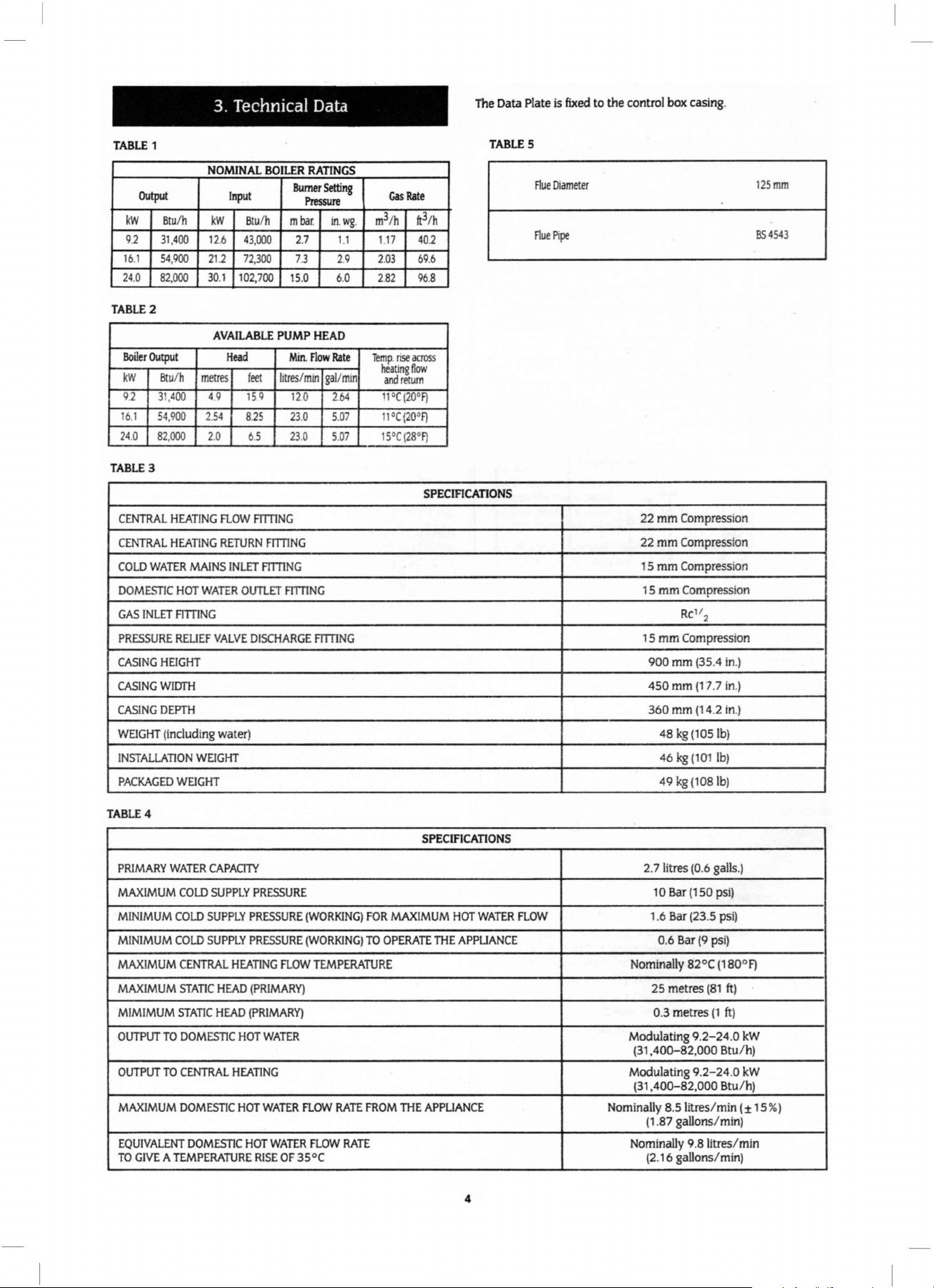

TABLE

The

3. Technical Data

1

Data Plate is

TABLE

fixed

to

the control box casing.

5

OUtput

kW

9.2 31,

16

.1

24

.0

TABLE2

Boiler

Output

kW

9.2 31,

16

.1 54,9

24

.0

TABLE

3

CENTRAL

CENTRAL

COLD

WATER

DOMESTIC

GAS

INLET

PRESSURE

CASING

CASING

CASING

WEIGHT

INSTALLATI

PACKAGED

NOMINAL

Btu/h

54,900

82,000

Btu

82,000

HEIGHT

WIDTH

DEPTH

(including water) 48

kW

400 12.6

212

30

AVAILABLE PUMP HEAD

/h

metres

400

4.9

00 2.54

2.0 6.5

HEATING

HEATING

MAINS

HOT

WATER

FrrnNG

RELIEF

VALVE

ON WEIGHT

WEIGHT

.1

FLOW

RETURN

Input

Btu

/h

43,000

72,300

102,700

Head

feet

15

Q

8.

25

FriTING

INLET

FrrnNG

OUTLET

DISCHARGE

BOILER

RATINGS

Burner

Setting

Pressure

mbar. in.wg. m3/h

2.7

1.1

73

2.9 2.

.0

Flow

FriTING

6.0

Rate

gal/min

2.

64

15

Min.

litres/min

120

23.0 5.07

23.0 5.07

FmiNG

FmiNG

Gas

1.17

03

2.

82

Temp

heating

and

11

11

•c

15

Rate

3

/h

tt

40.2

69

.6

96

.8

.

rise

across

flow

return

•c

(

20"FJ

(20"FJ

°C {28

°F)

SPECIFICATIONS

Flue Diameter

Flue

Pipe

22

22

15

15

15

900

450

360

mm

Compression

mm

Compression

mm

Compression

mm

Compression

Rc

mm

Compression

mm

mm

mm

kg

(10Sib)

46

kg

(101

49

kg

(1

1'2

(35.4 in.)

(17

.7 in.)

(14.2 in.)

lb)

08 lb)

125mm

BS

4543

TABLE4

PRIMARY

MAXIMUM

MINIMUM

MINIMUM

MAXIMUM

MAXIMUM

MIMIMUM

OUTPUT

OUTPUT

MAXIMUM

EQUIVALENT

TO

WATER

COLD

COLD

COLD

CENTRAL

STATIC

STATIC

TO

DOMESTIC

TO

CENTRAL

DOMESTIC

GIVE A TEMPERATURE

DOMESTIC

CAPACITY

SUPPLY

SUPPLY

PRESSURE

SUPPLY

PRESSURE

HEATING

HEAD

(PRIMARY)

HEAD

(PRIMARY)

HOT

HEATING

HOT

HOT

PRESSURE

(WORKING)

(WORKING)

FLOW

WATER

WATER

FLOW

WATER FLOW

RISE

OF

35°C (2.16 gallons

FOR

TO

OPERATE

TEMPERATURE

RATE

FROM

RATE

SPECIFICATIONS

MAXIMUM

THE

THE

APPLIANCE

HOT

WATER

APPLIANCE

4

FLOW

2. 7 litres (0.6 galls.)

1 0 Bar

(1

50 psi)

1.6 Bar (23.5 psi)

0.6 Bar

(9

Nominally 82°C (180°F)

25 metres (

0.3 metres

Modulating 9.

(31

,40Q-82,000 Btu

Modulating 9.2

(31

,400-82,000 Btu

Nominally 8.51itres

(1

.87 gallons/min)

Nominally 9.

8litres

psi)

81

(1

2-24

-24

/min

/min)

ft)

ft)

.0 kW

/h)

.0 kW

/h)

(±

/min

15%)

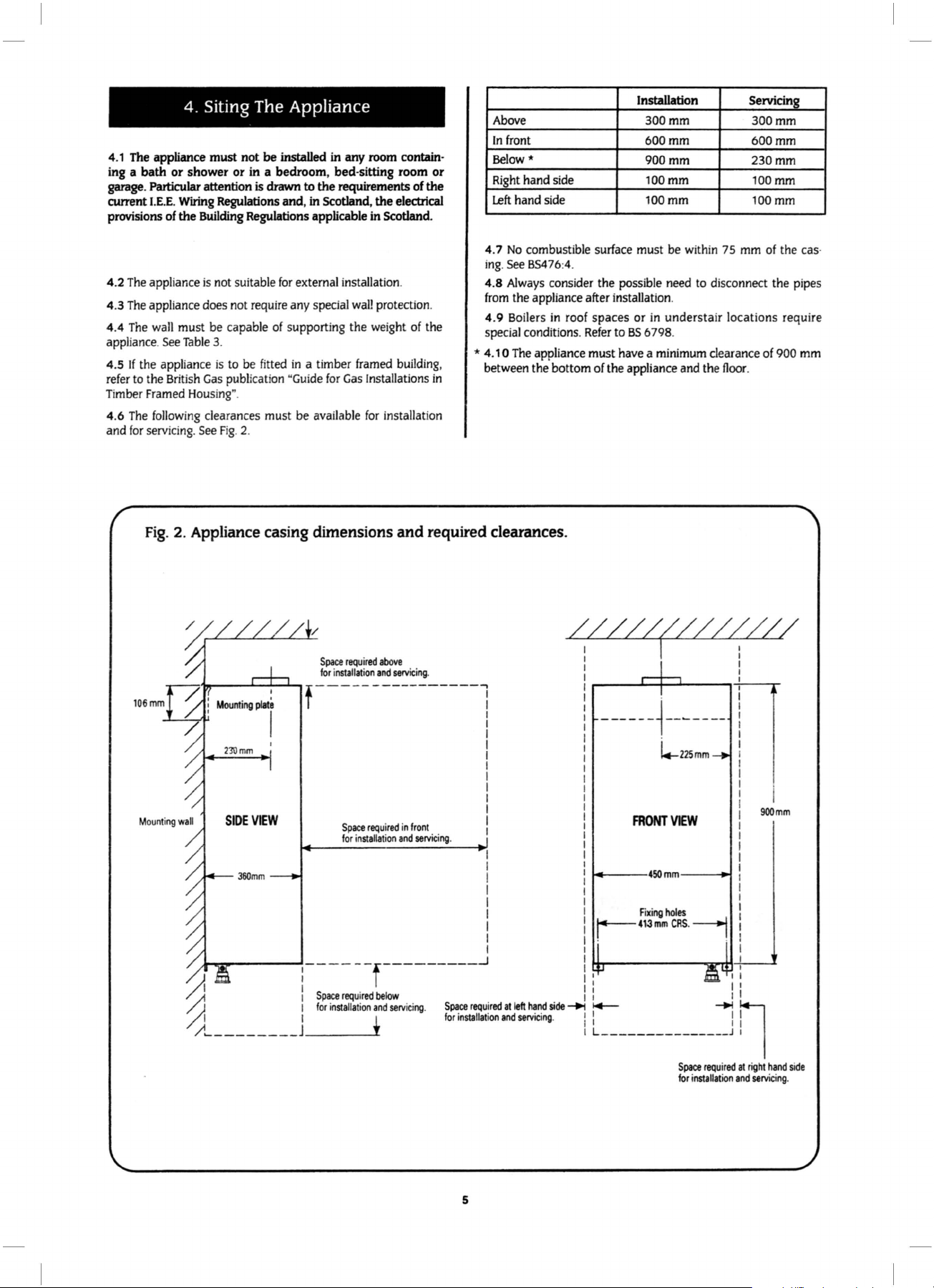

4. Siting The Appliance

4.1 The appliance

ing a

bath

garage. Particular attention is drawn to

current

I.E.E.

provisions of

The

appliance

4.2

The

appliance does not require any special

4.3

The

4.4

appliance. See

4.5

refer to the British

Timber Framed Housing".

4.6

and

wall must be capable of supporting the weight of the

If

the appliance

The

following clearances must be available

for

servicing. See Fig. 2.

must

not

be installed

or

shower

Wiring Regulations and,

the

Table

or

in a

bedroom,

Building Regulations applicable

is

not suitable

3.

is

to be fitted

Gas

publication "Guide

for

external installation.

in

in

any room contain-

bed-sitting

the

requirements of

in

Scotland,

wall

a timber framed building,

for

Gas

room

the

electrical

in

Scotland.

protection.

Installations

for

installation

or

the

in

Installation

Above

In

front

Below*

Right hand side

Left

hand side

4.7

No

combustible surface must be within 75 mm of the cas·

ing

. See BS476:4.

4.8 Always consider the possible need to disconnect the pipes

from the appliance after installation.

4.9 Boilers in roof

special conditions.

* 4.

10

The appliance must have a minimum clearance of 900 mm

between the bottom

spaces

Refer

ofthe

300mm

600mm

900mm

100mm 100mm

100mm 100mm

or

in

understair

to

BS

6798.

appliance and the floor.

Servicing

300mm

600mm

230mm

locations require

Fig.

106mm

2.

Appliance casing dimensions

Space

required

for installalion

f-----

SlOE

VIEW

Space

for installation

:----

~

/).

/)~

____

____

I

Space

required

1

for

installation

j t

and

required clearances.

above

and

servicing

.

-----------~

I

I

I

I

I

I

I

I

I

I

required

in

and

front

servicing

I

I

.

I

I

I

I

I

I

I

I

Space

,,,

...

I

_j

required

, • • M

at

left

hand

..

,......

__ f _________

below

and

serv

icing.

////~/////J/~

I I

I I

I I

I :

I

I

I

I

------~-

I

I

I

I

I

I

I

I

I

I

I

FRONT

~-----4~mm----~

~413mm

I

1 I

side

-+1

I+-

. i

L_

______________

-

~----

~225mm

VIEW

Fixing

holes

CAS.___,

~--~

I

II

-+1

j ! I

900mm

il

Space

required

at

right

hand

for

installa

tion

and

5

servicing

side

.

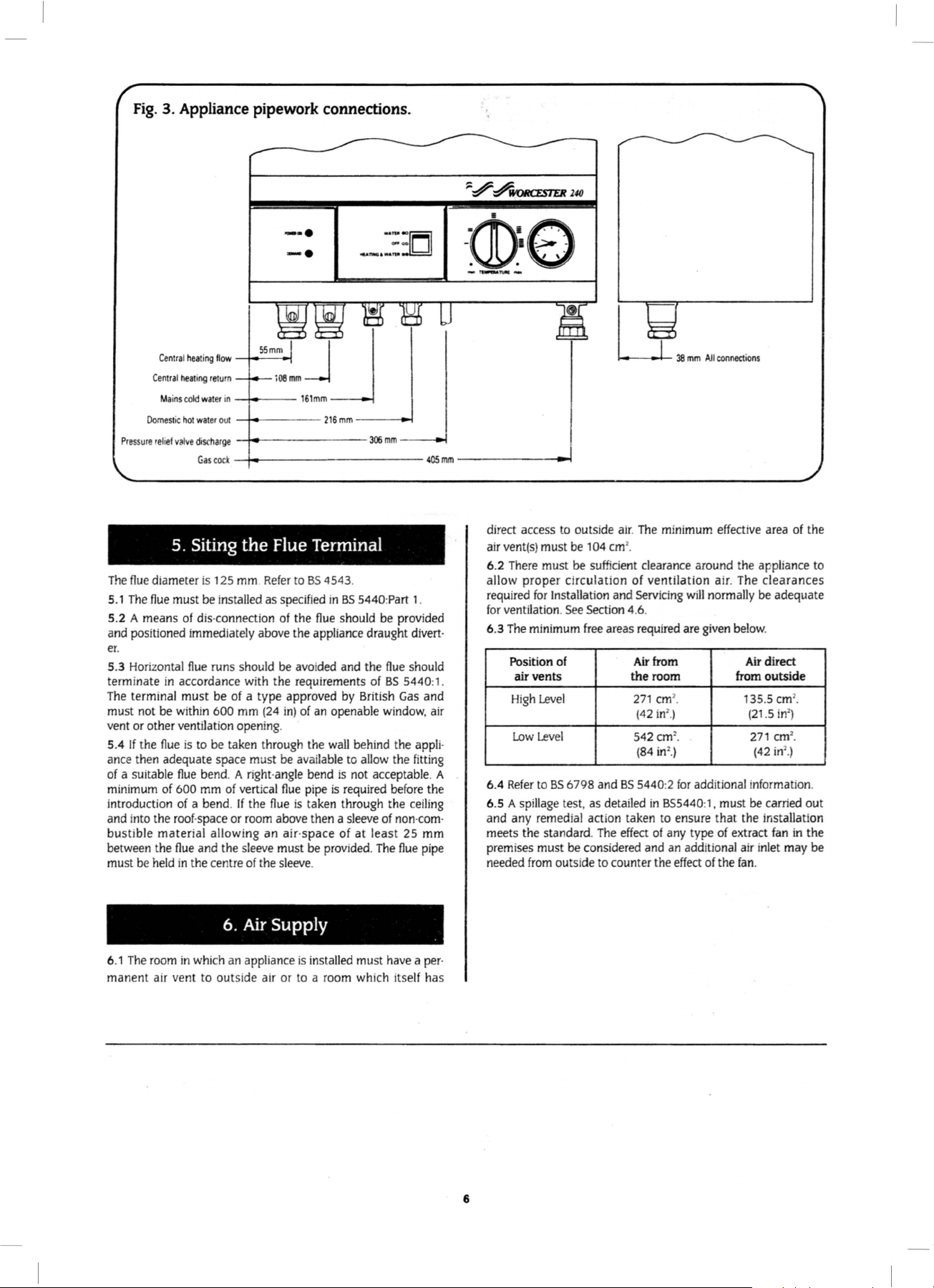

Fig.

3. Appliance pipework connections.

-·

·

-·

"'

"":

__

,_::D

rr-;J

tt\·r:!\

-w·o

_,....,..YI.III_

Central heating

Central

hearing

return

Mains

cold

water

Domest

ic

hot

water

Pressure

relief

valve

discharge

Gas

cock

5. Siting

The

flue

diameter

The

5.1

5.2 A means

and positioned immediately above the appliance draught divert·

er

5.3

terminate

The

must not be

vent

5.4

ance t

of

minimum

introduction

and i

bustible material allowing an air-space of at least 25

between the

must

flue

.

Horizontal

terminal must be

or

other ventilation opening.

If

the

hen

a suitable

nto

the

be

held

is

125

must

be

of

dis

-connection

flue

runs should be

in

accordance with the requirements

within

600

flue

is

to

be taken through the

adequate space must

flue

bend. A right·

of

600

mm

of

a bend.

roof

·space

flue

and the

in the centre

55

flow

in --114--

out

--

-1--

----

-1--

-------

-

1--

-----------

mm

the

mm

Refer

installed as

of

a type approved

mm

(24

of

verti

cal

If

the

flue

or

room

sleeve

of

the

Jj

i

08

mm

161mm

216

mm

-----<

306

Flue Terminal

to

BS

4543.

specified

of

in)

be

angle

flue

above then a

must

sleeve

in

BS

5440:

the

flue

should

avoided

available

is

and the

by British

of

an

openable

wall

behind the

to

allow

bend

is

not

pipe

is

required

taken through the

sleeve

be

provided.

.

of

acceptable. A

~

mm

--

Part

be

provided

flue

BS

5440

Gas

window.

the

before

of

non·com

The

flue

~

405mm

1.

should

:1.

and

air

appli·

fitting

the

ceiling

mm

pipe

------

·

-~

direct access

air

vent(s)

6.2

There

allow proper circulation

required

for

ventilation.

6.3

The

Position

air vents the room

High

Low

6.4

Refer

6.5 A

and any remedial acti

meets the standard.

premises must

needed

must

must

for

Installat

minimum

Level

Level

to

BS

spillage

from

to

outside air.

be

104

cm

be

sufficient

ion

and

See

Section

free

areas

of

6798 and

test, as detailed

on

The

be

considered and

outside

to

counter the

The

minimum

2

.

clearance around the appliance

of

ventilation air.

Servicing

4.6.

required

Air

from

2

271

cm

2

(42

in

.)

2

542

cm

2

(

84

in

.)

BS

5440:2

in

855440:1, must

taken

to

effect

of

any

an

effect

effective

The

will

normally

are g

iven

below

Air direct

from

of

of

extract

the

fan

135

(21

271

(42

be

.

•

•

for

additional information.

ensure that the installation

type

additional air

area

of the

clearances

be

adequate

.

outside

2

.5

cm

.

2

.5 in

)

2

cm

•

2

in

.)

carried out

fan

in the

inlet

may be

to

6.1

The

manent

room

air

in

vent

6.

which

an

to

outside air or

Air

Supply

appliance

is

installed must

to a room

have a per

which itse

·

lf has

6

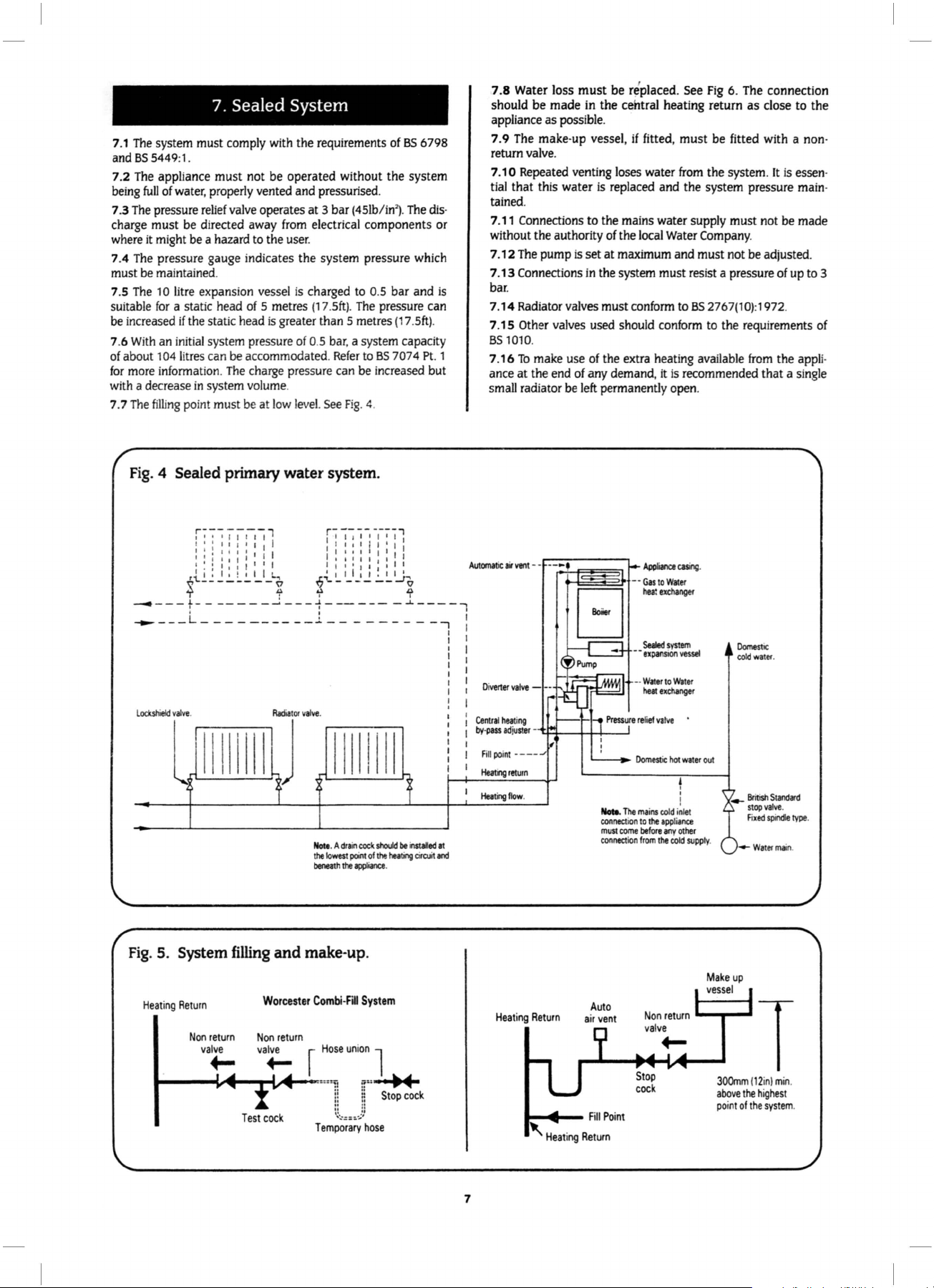

7. Sealed System

7.1

The

system must comply with the requirements of

BS

5449:

and

7.2 The appliance

being

7.3 The pressure relief valve operates

1.

must

not be operated without the system

full

of

water, properly vented and pressurised.

at

3 bar (45lb/in"). The discharge must be directed away from electrical components or

where it might be a hazard to the user.

7.4 The pressure gauge indicates the system pressure which

must be maintained.

7.5

The

10 litre expansion vessel

suitable

be increased

7.6

of

for

with a decrease

7.7

for

a static head

if

the static head

With

an initial system pressure of 0.5 bar, a system capacity

of

about 104litres can be accommodated.

more information.

The

filling

Fig.

4 Sealed primary water system.

The

charge pressure can be increased but

in

system volume.

point must be at

is

charged to 0.5 bar and

5 metres

is

(17.5ft)

greater than 5 metres

Refer

low

level.

See

Fig. 4.

. The pressure can

to

BS

BS

6798

(17

.Sft)

.

7074 Pt . 1

7.8 Water loss

be

should

must

be

r~placed

.

See

Fig

6. The connection

made in the central heating return

as

close to

the

appliance as possible.

7.9 The make-up vessel,

must be

fitted with a non-

if

fitted,

return valve.

7.

10

Repeated venting loses water from the system. it

tial

that

this water is replaced and the system pressure main-

is

essen·

tained.

Connections

7.11

without the authority of the local Water

7.1 2 The pump

Connections

7.13

is

bar.

7.14

Radiator valves must conform to

7.1

5 Other valves used should conform to the requirements of

BS

1010.

7.

16

To

make use

ance

at

the end of any demand,

to

the mains water supply must not be made

Company.

is

set

at

maximum and must not be adjusted.

in

the system must resist a pressure of up to 3

BS

2767(10):1972.

of

the extra heating available

it

is

recommended

from

that

the appli-

a single

small radiator be left permanently open.

L

ocl<shield

valve

.

l

11111

Fig.

5. System filling

Heating

Return

Non

valve

1-----t..•-

111

return

....

...

Test

Radiator

valve

J

and

Worcester

Non

return

va~

-t..•-"":=:

cock

.

I II I Ill I

Note

. A

dtm

the

beneath

make-up.

Combi-Fill

~

Temporary

c:oc:1t

lowest

point

the

appliance

Hose

union

zr,

!l

II

·:~==•.]

should

of

the

heating

.

System

l

::u

I 1

i~

Stop

II

:

hose

be

~

~

cock

installed

cir

cuit

at

and

Central

heating

by-pass adj

Fill poi

Heamg

Heating

Heating

uster

-

~+----l-+--+----J

nt

----

return

flow

.

Return

....

....,..__

'

Heating

Auto

air

vent

FiiiPoint

Return

Nola

.

The

connection

must

come

connection

Suled

system

--expansion

-·

Water

to Wat

heat

excltlnger

mains

cold inlet

to

the

appliance

before

any

from

the

other

cold

vessel

er

I

I

'

l

supply

._

.

JOOmm (12

above

point

Domestic

cold

water

British

Standard

stop

valve

Fi

xed

spindle

-Wat

er

inl

the highest

of

the

system

.

mai

min

.

type.

n.

.

.

7

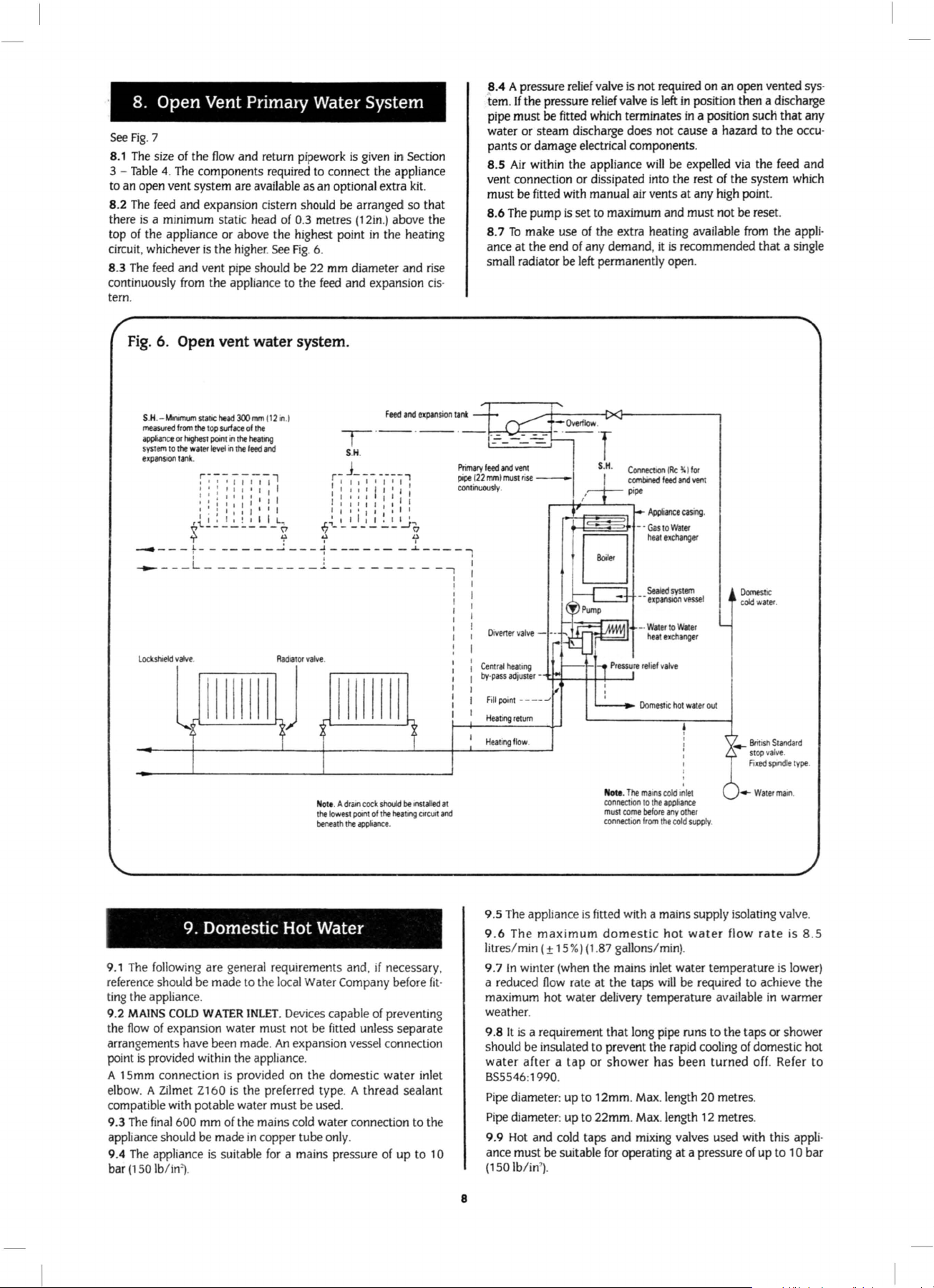

8. Open Vent Primary Water System

See

Fig

. 7

8.1

The

size of the

Thble

3 -

4.

to an open vent system are available as an optional extra

8.2

The

feed and expansion cistern should be arranged

there

is

a minimum static head of 0.3 metres (12in.) above the

top of the appliance

circuit, whichever

8.3 The feed and vent pipe should be 22 mm diameter

continuously

tern.

Fig.

6. Open vent water system.

S.H

.-

Mnmum

me85Uied

appliance

system

expansiOn

-----

- - -t----- - -

- -

flow

and return pipework

The

components required to connect the appliance

or

above the highest point

is

the higher. See Fig. 6.

from

the appliance to the feed and expansion cis·

statiC

hud

300

mm

112111

from

the

top

or

to

--L-_________

surface

t.ghest

point

in

the

wat

tank

.

,tl. I'!

\'

'T

0 I

the

er

level

in

the

;~-;--;jj1-1jl

l " " I • I I I : I I :

I I I I I I I I I I

I

I:

I I I I I I I J I I I I I I I I I

I

::

I I I I I I I :I I I I I I I I :

-

----

.1

of

the

heattng

feed

ill1d

I I

I

~

---~

• I I

_;

- - -~ -

is

given

in

-r

·- ·- ·- ·

S.H.

j

r----

.!.,

~---------'~

I I

----,

II

::I

II

I'

-----

.:.

__ ----

in

the heating

Feed

: : I I

I

I'

I I .

Section

kit.

so

that

and

rise

and

expansion

tank

Primary

pipel22mmlmustrise-

I

...

contiooously

-~ ----...,

-

---,

I

I

8.4 A pressure relief valve is not required on an open vented sys·

tern.

If

the

pressure relief valve

pipe must

be fitted which terminates

water or steam discharge does not cause a hazard to the

is

left

in

position then a discharge

in

a position such

that

any

occu·

pants or damage electrical components.

8.5 Air w

it

hin the appliance

will

be expelled via the feed

and

vent connection or dissipated into the rest of the system which

must be fitted with manual air vents

8.6 The pump

8. 7

To

ance

at

is set to maximum and must not be reset.

make use of the extra heating available from the appli·

the end of any demand,

at

any high point.

it

is

recommended

that

a single

small radiator be left permanently open .

-

Overflow

.

:-_-:_-==:

feed

ill1d

.

vent

-·- ·r

S.H.

Domest

cold

water

ic

.

lockstoeld

v...,•

l

.

tlll

Radllltor

llll

valvt.

J

llllllll

Nott

. A

dr0111

the

poont

cock

appliance

the lowest

beneath

9. Domestic Hot Water

9.1 The following are gen er

reference should be made to the local Water

ti

ng the appliance.

9.2

MAINS

COLD

WATER

flow

the

of expansion water must not be fitted unless separate

arrangements have been made.

is

provided within the appliance.

point

A 15mm connection is provided on the domestic

elbow. A

Zilmet Z160 is the preferred type. A thread

compatible with potable water must be used.

9.3

The

final

600 mm of the mains cold water connection to the

appliance should be made

9.4

The

appliance is suitable

bar (150 lb/in").

al

requirements and,

Company before

INLET

. Devices capable of preventing

An

expansion vessel connection

in

copper tube only.

for

a mains pressure of up to 1 0

should

be

of

the

heat

.

if

necessary,

water

sealant

InStalled

tng

c1r

inlet

cut

-·

Water

to

Wate

eat exchanger

'

cold 1nle1

the

appfta

nce

any

other

the

cold

supply.

r

._. Brinsn Standard

stop

valve

.

Fixed

spindle

type

....

Waterma

111

.

.

at

ill1d

Central heaung

by-pass adju

ste

F

ill

point -----'

Heating

return

Heat

ing flow

r -

~±--t+-1----'

,

.

Nota

connection

must

connection

.

The

come

h

ma.ns

to

before

from

9.5 The appliance is fitted with a mains supply isolating valve.

9.6

The

maximum

litres/min ( ± 15

9.7

In

winter (when the mains inlet water temperature is lower)

fit

·

a reduced

flow

maximum hot water delivery temperature available

domestic

%)

(1

.87 gallons/min).

rate at the taps

hot

water

flow

rate

will

be required to achieve the

in

is 8 .5

warmer

weather.

It

is

9.8

a requirement

that

long pipe runs

to

the taps

or

shower

should be insulated to prevent the rapid cooling of domestic hot

water

after a tap

or

shower

has

been

turned

off. Refer

to

BS5546:1990.

Pipe diameter: up

Pipe

diameter: up to

9.9 Hot and cold taps

ance must be suitable

(150

lb/in

').

to

12mm. Max. length 20 metres.

22mm

. Max. length 12 metres.

and

mixing valves used with this appli·

for

operating at a pressure of

up

to 1 0

bar

8

9.1 0

No

anti·syphonage arrangements are necessary except

some loose head showers.

See

also Section 9.12 following.

for

9.11 Thermostatically controlled or pressure equalising shower

will

valves

guard against the

flow

of water

at

too high a temper·

ature.

9.

12

The

head of a loose head shower must not

(1

in)

25mm

sion

an

anti·syphonage device at the po int of the

above the top edge of the bath to prevent its immer·

in

bath water. Alternatively the shower must be fitted with

fall

flexible

doser

than

hose con·

nections.

9.

13

The

supply of hot and cold mains water direct to a bidet is

permitted, (subject to local Water

vided that the bidet is of the over-rim flushing type.

Company requirements), pro-

The

outlet(s)

should be shroucded and unable to have any temporary hand

No

held spray attached.

anti-syphonage arrangements are nee·

essary.

9.14

As the maximum temperature of the Water to Water heat

is

exchanger is limited by the control drcuit, there

need for

water

treatment

to prevent scale accumulation .

normally no

In

exceptional drcumstances a device to prevent scale formation

can be fitted.

Installation of a scale inhibitor assembly should be

dance with the requirements of the local Water Company.

isolating valve should be fitted

to

allow servidng. The water

in

accor·

An

hardness can be determined using a standard test paper or by

reference to the local Water

Company.

9

1

0.

Electrical

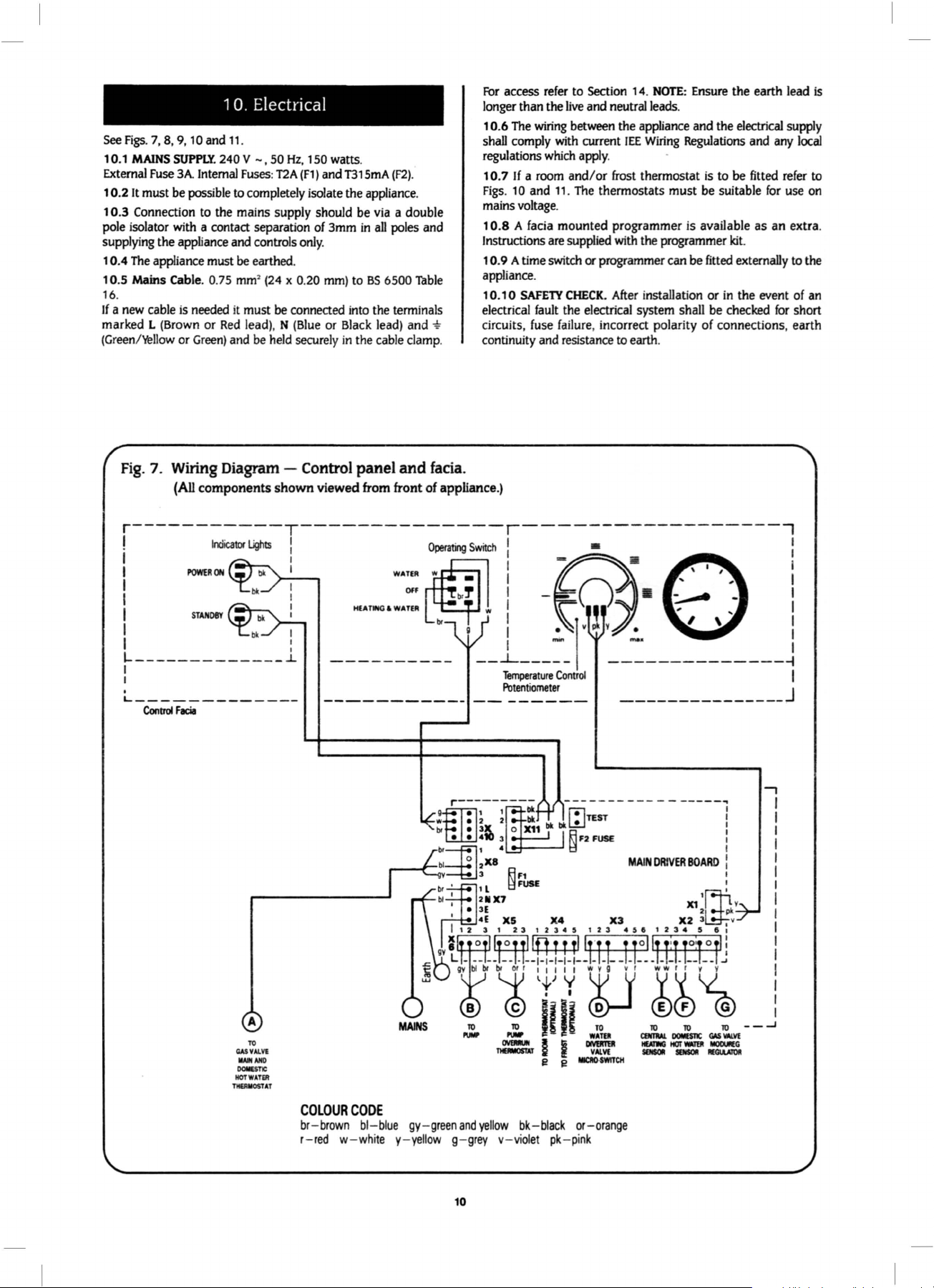

See

Figs. 7,

8, 9,

10

and 11.

1

0.1

MAINS

External

1 0.2

1

Fuse

It

must

0.3 Connection

pole isolator

SUPPlY

3A

be

with

240 V - ,

Internal

possible

to

the mains supply should be

50

Fuses: T2A

to

completely isolate the appliance.

a contact separation

supplying the appliance and controls

1 0.4

The

appliance must

10.5 Mains Cable. 0.

16

.

If a new

marked L

(Green/'rellow

cable

is

needed it must

(Brown

or

Green)

Fig.

7. Wiring Diagram - Control

(All

be

earthed.

75 mm•

or

Red

lead), N

and

be

components

(24

x 0.

be

held

shown

Hz,

150

watts.

(F1)

and

of

T315mA

3mm

in

via

all

(F2)

poles

.

a double

and

only.

20

mm)

to

BS

6500

Thble

connected

(Blue

securely

into

the terminals

or

Black

lead) and -t

in

the

cable

clamp.

panel

and

facia.

viewed from front of appliance.)

For

access

refer

to Section 14.

longer than the

0.6

The

1

shall

comply

regulations

1

0. 7

If a room

Figs.

10

mains

voltage

0.8 A

1

Instructions

1 0. 9 A time

live

and neutral leads.

wiring

between the appliance and the

with

current

which

apply

and/

or frost thermostat

and 11.

The

thermostats must be suitable

.

facia

mounted programmer

are

supplied

switch

or

programmer can be

appliance.

1 0.10

SAFETY

electrical

circuits,

CHECK.

fault

the electrical system shall

fuse

failure

, incorrect polarity of connections, earth

continuity and resistance

NOTE: Ensure

lEE

Wiring

.

with

the programmer kit.

After

installation or

to

earth.

the earth lead

electrical

Regulations

is

and

to be fitted

any

refer

for

is

available as an extra.

fitted

externally

in

the event of

be

checked

for

supply

local

use

on

to

the

an

short

is

to

A

TO

CASVAI.Vl

IIAII

AIIO

OOIIESTlC

HOT

WATER

TltEAIIOST

AT

COLOUR

br-brown blr-red w-whi

CODE

blue gy-

te y-yellow g-grey

green

and

10

yellow

bk-black

v- vi

olet pk- pi

...,

or-orange

nk

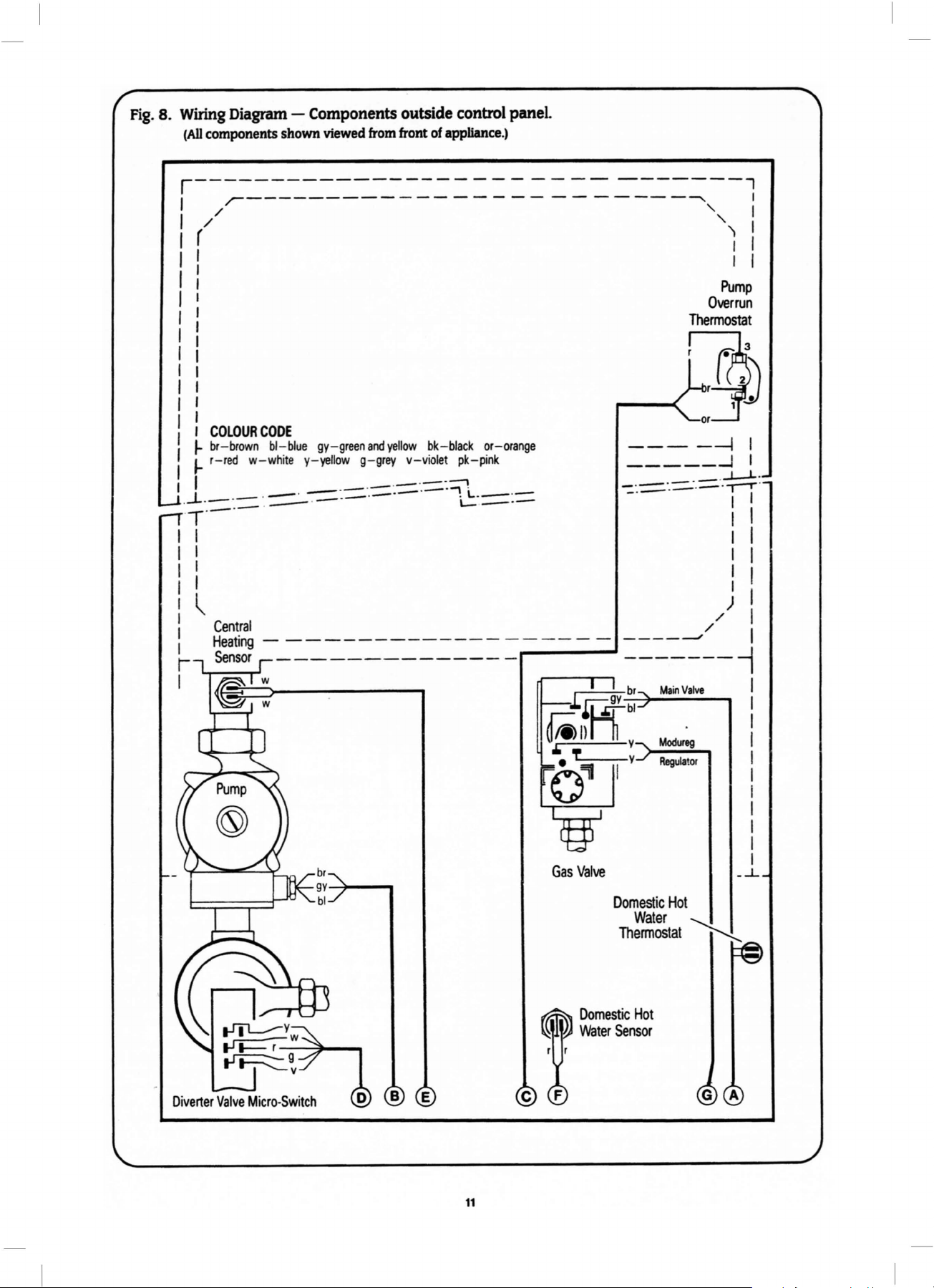

Fig.

8. Wiring Diagram - Components outside control

(All

components shown viewed

from

front

of

panel

appliance.)

r-------------

,r------------

/ ' I

/ ' I

-------

-------

----

-------l

-----~

r i 1

l I I

I

I

I

I

I

I

I

I

I

I

I

COLOUR

~

br-brown bl-blue

J-

r-red w-white y-yellow g-grey

I ·- ·- ·- ·.

I · - .

-~-

-

'T ·- ·- ·

CODE

--

-----·--

·

.---

gy-green

· - ·

and

-·-

I I

I I

I I

I I

I

~

I

I

I

I

-------------

I

br

gy~--..

bl

yellow

bk-black

v-violet pk-pink

-::::

·.=;!

.

L-.

L.--

or-orange

·-

----

----

Gas

Valve

-----1

_____

-=·.-::::.·.::=:

-----//

-------

Main

Modureg

Regulator

Domestic

Water

Thermostat

Overrun

Thermostat

_ .

.- -

Valve

Hot

'-...!...

1

Pump

_J

...J...-1...

Tj

I I

I I

I I

I I

I I

/)

-i

-

1

~

I

I

.

·

I

I

I

I

I

I

I

I

I

I

I

I

I

...J...

Diverter

Valve

Micro-Switch

11

Domestic

Water

Sensor

Hot

Loading...

Loading...