Bosch Wallscanner D-tect 150 Operating/safety Instructions Manual

O

PE

N

O

P

E

N

S

t

a

r

t

S

e

t

u

p

W

a

l

l

sc

a

nn

e

r

D-

t

ec

t

1

5

0

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

Wallscanner

D-tect™150

For English Version Version française Versión en español

See page 6 Voir page 17 Ver la página 29

1-877-BOSCH99 (1-877-267-2499) www.boschtools.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

-2-

P

r

o

f

e

s

s

i

o

n

a

l

D

-

T

E

C

T

1

5

0

P

r

o

f

e

s

s

i

o

n

a

l

D

-

T

E

C

T

1

5

0

P

r

o

f

e

s

s

i

o

n

a

l

D

-

T

E

C

T

1

5

0

P

r

o

f

e

s

s

i

o

n

a

l

D

-

T

E

C

T

1

5

0

D

-

T

E

C

T

1

50

S

E

NSO

R

OP

E

N

OP

E

N

S

t

a

r

t

S

e

t

up

W

a

l

l

s

c

a

n

n

e

r

D

-

t

e

c

t

1

5

0

2

1

6

7

8

9

3

4

5

14

13

15

1618

17

11

10

12

3

0

8

2

8

C

2

D-

t

ec

t

1

5

0

3

6

01

K

1

0

01

3

4

x

A

A

1

.

5

M

a

d

e

i

n

G

e

r

m

an

y

T

hi

s

d

e

vi

c

e

c

o

m

p

l

i

e

s

w

i

t

h

P

a

r

t

1

5

o

f

th

e

F

C

C

R

ul

e

s

.

O

p

e

r

a

t

i

o

n

i

s

s

u

b

j

e

ct

t

o

th

e

f

o

l

lo

w

i

ng

t

w

o

c

o

n

d

i

t

i

o

n

s

:

1

.

)

T

his

de

v

i

c

e

m

ay

n

o

t

c

a

use

h

a

r

m

f

ul

i

n

t

e

r

f

e

r

en

ce,

a

nd

2

.

)

T

h

i

s

d

ev

i

c

e

m

u

s

t

a

c

c

e

p

t

a

n

y

i

n

t

e

r

f

er

en

c

e

re

c

e

i

v

e

d

,

i

n

cl

u

d

ing

i

n

t

er

f

e

re

n

c

e

t

ha

t

m

a

y

cau

s

e

un

d

es

i

r

e

d

o

p

e

r

a

t

i

o

n

.

F

C

C

I

D

:

T

X

T

-

DTE

C

T

1

5

0

A

I

C

-

I

D

:

9

0

9

H

-

DT

E

C

T1

5

0

A

R

o

b

e

r

t

B

o

sc

h

T

o

o

l

C

o

r

p.

M

o

u

n

t

P

r

o

spe

c

t

,

I

L

-3-

Concrete

Prev Next

Sensor

N

S

1.5 cm

6

4

2

0 cm

6

4

2

88

0 cm

Concrete

e

Sensor

3.5 cm

O

P

E

N

S

t

a

r

t

S

e

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

O

P

E

N

S

ta

r

t

S

e

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

OPEN

St

a

rt

S

e

tu

p

OPEN

Start

Setup

O

P

E

N

St

a

rt

Set

u

p

OPEN

Start

Setup

OP

EN

Sta

rt

Setu

p

OPEN

Start

Setup

Concrete

e

Sensor

3.5 cm

Concrete

Prev Next

6

4

2

0 cm

6

4

2

88

0 cm

Sensor

N

S

3.5 cm

l

m

j

e

f

d

a

b

n

c

h

e

i

g

k

f

g

A

C

B

-4-

Drywall

Prev. Next

Sensor

Metal

?

0.5 cm

6

4

2

0 cm

6

4

2

88

0 cm

Concrete

Prev. Next

Sensor

?

N

S

4.0 cm

6

4

2

0 cm

6

4

2

88

0 cm

Deep concrete

Prev. Next

Sensor

?

N

S

8.8 cm

15

12

9

6

3

0 cm

15

12

9

6

3

0 cm

D

F

E

-5-

O

P

E

N

S

t

a

r

t

S

e

t

u

p

OP

E

N

S

t

a

r

t

Se

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

OPE

N

S

t

a

r

t

Se

t

u

p

O

P

E

N

S

t

a

r

t

S

e

t

u

p

OP

E

N

S

t

a

r

t

Se

t

u

p

Concrete

Prev. Next

Sensor

?

N

S

?

?

0.0 cm

6

4

2

0 cm

6

4

2

88

0 cm

Concrete

Prev. Next

Sensor

?

N

S

2.0 cm

6

4

2

0 cm

6

4

2

88

0 cm

G

I

H

-6-

Read all instructions. Failure to follow all instructions listed below may result in electric

shock, fire and/or serious injury.

SAVE THESE INSTRUCTIONS

The detector’s ability to detect objects is affected by the proximity of other equipment

that produce strong magnetic or electromagnetic fields, and by moisture, metallic

building materials, foil-laminated insulation materials and/or conductive wallpaper.

The detector’s ability to detect wood substructures (studs) is also affected by inconsistency on the

thickness of the surface material, such as plaster and lath.

It is possible that there may be metal, wood or wiring or something else, such as plastic pipes, beneath

the scanned surface that is not detected.

The detector alone should not be relied on exclusively to locate items below the

scanned surface. Use other information sources to help locate items before penetrating

the surface. Such additional sources include construction plans, visible points of entry of pipes and

wiring into walls, such as in a basement, and standard 16” and 24” stud spacing practices.

Before penetrating a surface (such as with a drill, router, saw or nail), always shut off

the electrical power, gas and water supplies. Cutting, drilling, etc… into these items

when operational can result in personal injury.

For technological reasons, the measuring tool cannot ensure 100 % certainty. To

rule out hazards, safeguard yourself each time before drilling, sawing or routing

in walls, ceilings or floors by means of other information sources, such as building plans,

pictures from the construction phase, etc. Environmental influences, such as humidity or closeness

to electrical devices, can influence the accuracy of the measuring tool. Surface quality and condition of

the walls (e. g., moisture, metallic building materials, conductive wallpaper, insulation materials, tiles)

as well as the amount, type, size and position of the objects can lead to faulty measuring results.

FCC Statement

Warning: Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class B Digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

– Consult the dealer or an experienced radio TV technician for help.

General Safety Rules

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Section 15.525 Coordination requirements.

(a) UWB imaging systems require coordination through the FCC before the equipment may be used.

The operator shall comply with any constraints on equipment usage resulting from this coordination.

(b) The users of UWB imaging devices shall supply operational areas to the FCC Office of Engineering

and Technology, which shall coordinate this information with the Federal Government through the

National Telecommunications and Information Administration. The information provided by the UWB

operator shall include the name, address and other pertinent contact information of the user, the desired

geographical area(s) of operation, and the FCC ID number and other nomenclature of the UWB device.

If the imaging device is intended to be used for mobile applications, the geographical area(s) of operation

may be the state(s) or county(ies) in which the equipment will be operated. The operator of an imaging

system used for fixed operation shall supply a specific geographical location or the address at which the

equipment will be

operated. This material shall be submitted to the following address:

Frequency Coordination Branch, OET

Federal Communications Commission

445 12th Street, SW

Washington, D.C. 20554

Attn: UWB Coordination

(c) The manufacturers, or their authorized sales agents, must inform purchasers and users of their

systems of the requirement to undertake detailed coordination of operational areas with the FCC prior

to the equipment being operated.

(d) Users of authorized, coordinated UWB systems may transfer them to other qualified users and to

different locations upon coordination of change of ownership or location to the FCC and coordination

with existing authorized operations.

(e) The FCC/NTIA coordination report shall identify those geographical areas within which the operation

of an imaging system requires additional coordination or within which the operation of an imaging

system is prohibited. If additional coordination is required for operation within specific geographical

areas, a local coordination contact will be provided. Except for operation within these designated areas,

once the information requested on the UWB imaging system is submitted to the FCC no additional

coordination with the FCC is required provided the reported areas of operation do not change. If the

area of operation changes, updated information shall be submitted to the FCC following the procedure

in paragraph (b) of this section.

(f) The coordination of routine UWB operations shall not take longer than 15 business days from the

receipt of the coordination request by NTIA. Special temporary operations may be handled with an

expedited turn-around time when circumstances warrant. The operation of UWB systems in emergency

situations involving the safety of life or property may occur without coordination provided a notification

procedure, similar to that contained in Section 2.405(a) through (e) of this chapter, is followed by the

UWB equipment user.

For Canadian Customers only

This In-wall Radar Imaging Device shall be operated where the device is directed at the wall and in

contact with or within 20 cm of the wall surface. This In-wall Radar Imaging Device shall be operated

only by law enforcement agencies, scientific research institutes, commercial mining companies,

construction companies, and emergency rescue or firefighting organizations.

-7-

WARNING: Batteries can explode or leak, and can

cause injury or fire. To reduce this risk:

ALWAYS follow all instructions and warnings on

the battery label and package.

DO NOT short any battery terminals.

DO NOT charge alkaline batteries.

DO NOT mix old and new batteries. Replace all of

them at the same time with new batteries of the

same brand and type.

DO NOT mix battery chemistries.

DISPOSE of batteries per local code.

DO NOT dispose of batteries in fire.

KEEP batteries out of reach of children.

REMOVE batteries if the device will not be used for

several months.

Electrical Safety Procedures

Environment Protection

Recycle raw materials & batteries instead of disposing of waste. The unit, accessories, packaging & used

batteries should be sorted for environmentally friendly recycling in accordance with the latest regulations.

-8-

INTENDED USE

The detection tool is intended for the detection of

metals (ferrous and non-ferrous metals, such as

pipes, metal studs and rebar), wood studs, plastic

pipes (>1” in diameter) and joists, and “live”

wires/conductors in walls, ceilings and floors.

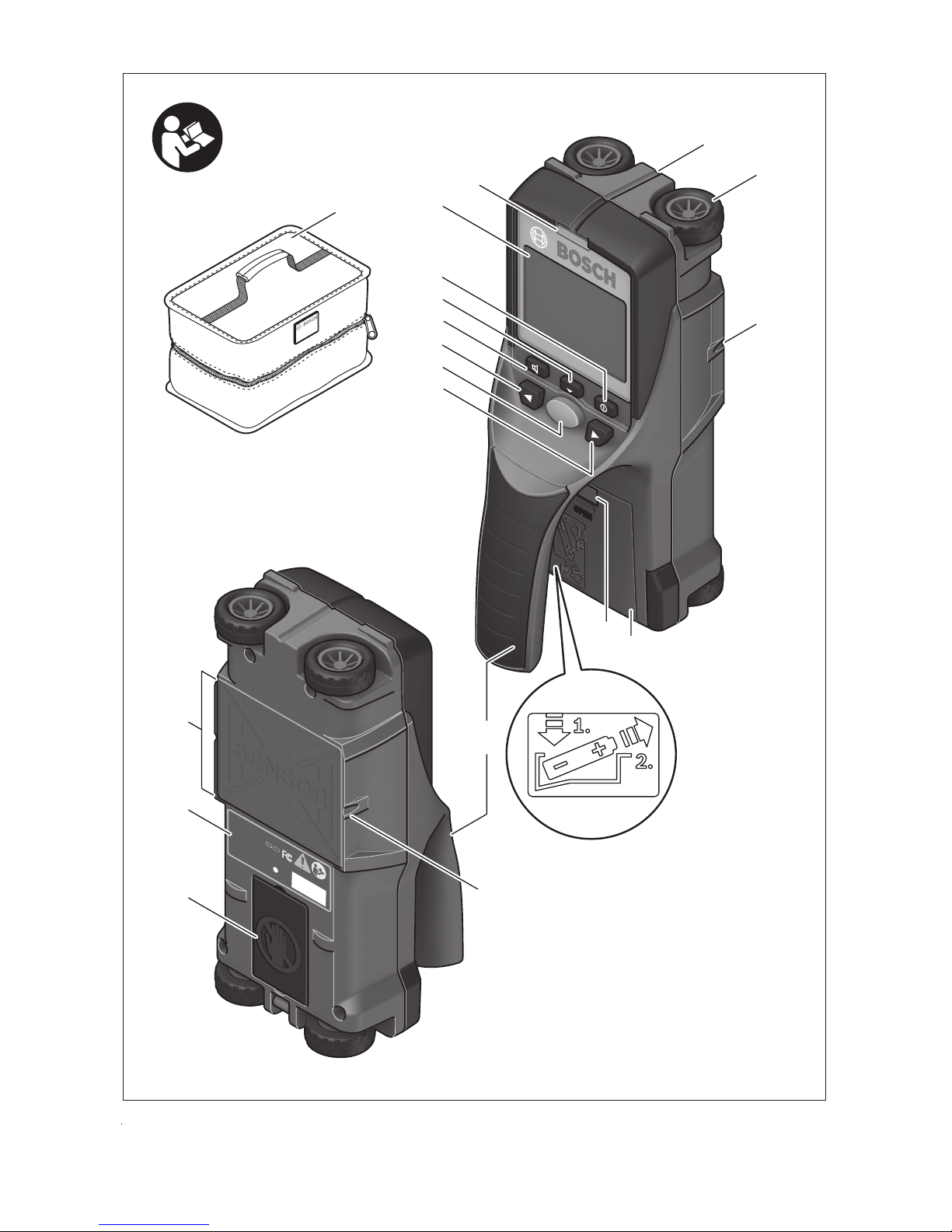

PRODUCT FEATURES

The numbering of the product features shown

refers to the illustration of the detection tool on the

graphic page.

1 Marking guide, top

2 Wheel

3 Marking guide, left and right

4 Battery lid

5 Latch of battery lid

6 Handle

7 Maintenance cover

8 Serial number

9 Sensor area

10 Selection button, right

11 Start button

12 Selection button, left

13 Audio signal button

14 Setup button

15 On/Off button

16 Display

17 LED

18 Protective soft case

The accessories illustrated or described are not

included as standard delivery.

DISPLAY ELEMENTS

a Audio signal indicator

b Battery indicator

c Sensor-range indicator

d Area already detected

e Measuring scale for object depth

f Area not yet detected

g Outer edges, to be marked left and right via

marking guide 3

h Mode indicator

i Gray: Found object outside of the

sensor range

j Black: Found object within the sensor range

k Center line, corresponds with the marking

guide

1

l Object depth indicator

m Object material indicator

n “Live” wire indicator

Optimal operation of the detection tool is possible only when the operating instructions and information are

read completely, and the instructions contained therein are strictly followed.

Functional Description

Setup

Start

-9-

Wallscanner D-tect™150

Technical Data

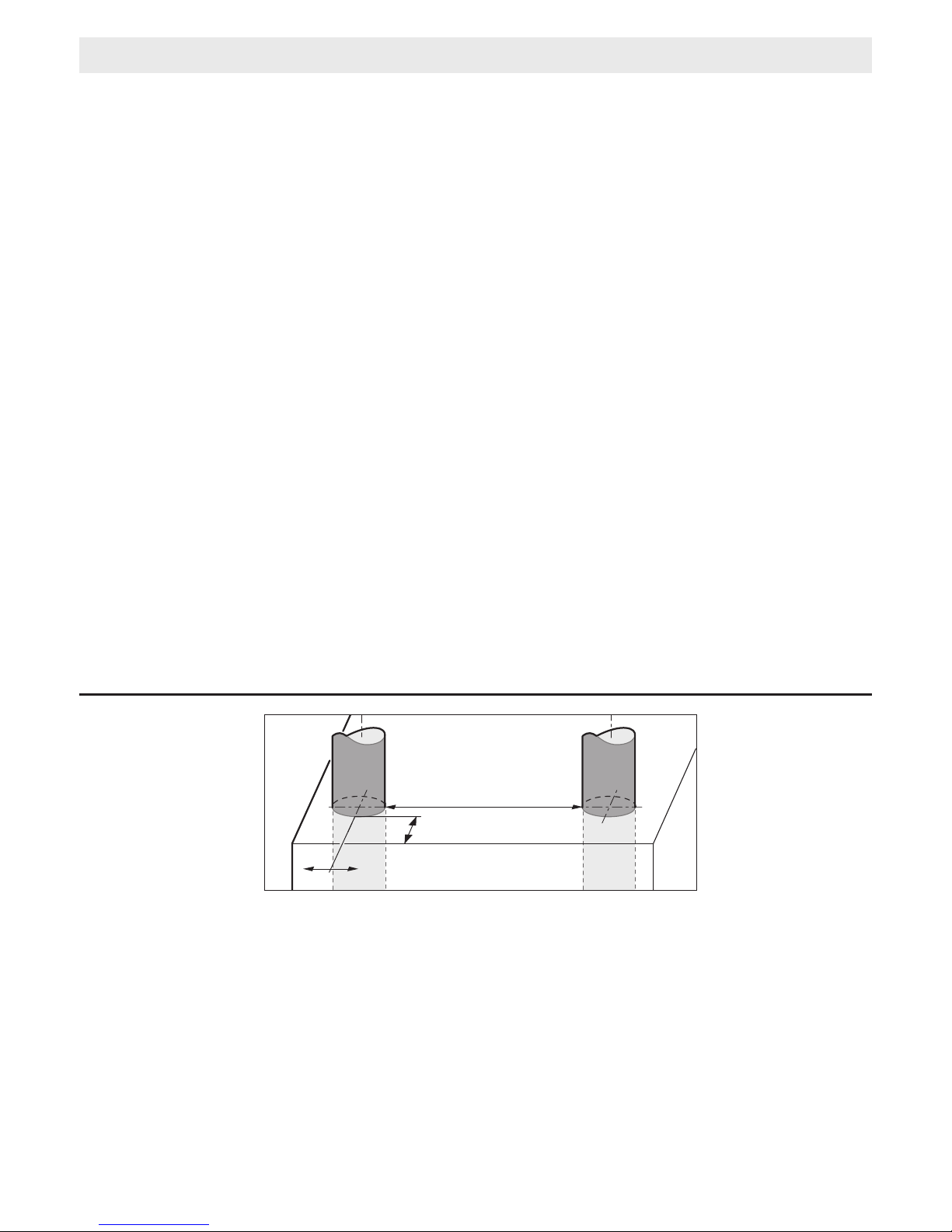

1) Depending on size and type of object as well as

material and condition of the base material.

In terms of accuracy, the measuring result

can be inferior in case of unfavorable surface

quality of the base material.

2) See graphic

Please observe the article number on the type plate

of your detection tool. The trade names of the

individual detection tools may vary.

The detection tool can be clearly identified with the

serial number 8 on the type plate.

Article number

Dimensions

Measuring accuracy to the object

center a

2)

Accuracy of the displayed object depth b

2)

– in dry concrete

– in wet concrete

Minimum distance between two neighboring

objects c

2)

Operating temperature

Storage temperature

Batteries

Battery service life, approx.

–Batteries (Alkali-manganese)

Weight according to EPTA-Procedure 01/2003

Protection class

3 601 K10 013

8 21/32” x 3 13/16 x 4 23/32”

(220 x 97 x 120 mm)

±3/16 in (±5 mm

1)

)

±3/16 in (±5 mm

1)

)

±3/8 in (±10 mm

1)

)

1 7/32 in (4cm

1)

)

+14°F … + 122°F

C

(– 10 °C ... +50 °C)

– 4 °F ... +158 °F

(–20 °C ... +70 °C)

4 x 1.5 V AA (LR06)

5 Hours

1.5lb (0.7 kg)

IP 54 (dust and splash water protected)

c

b

a

-10-

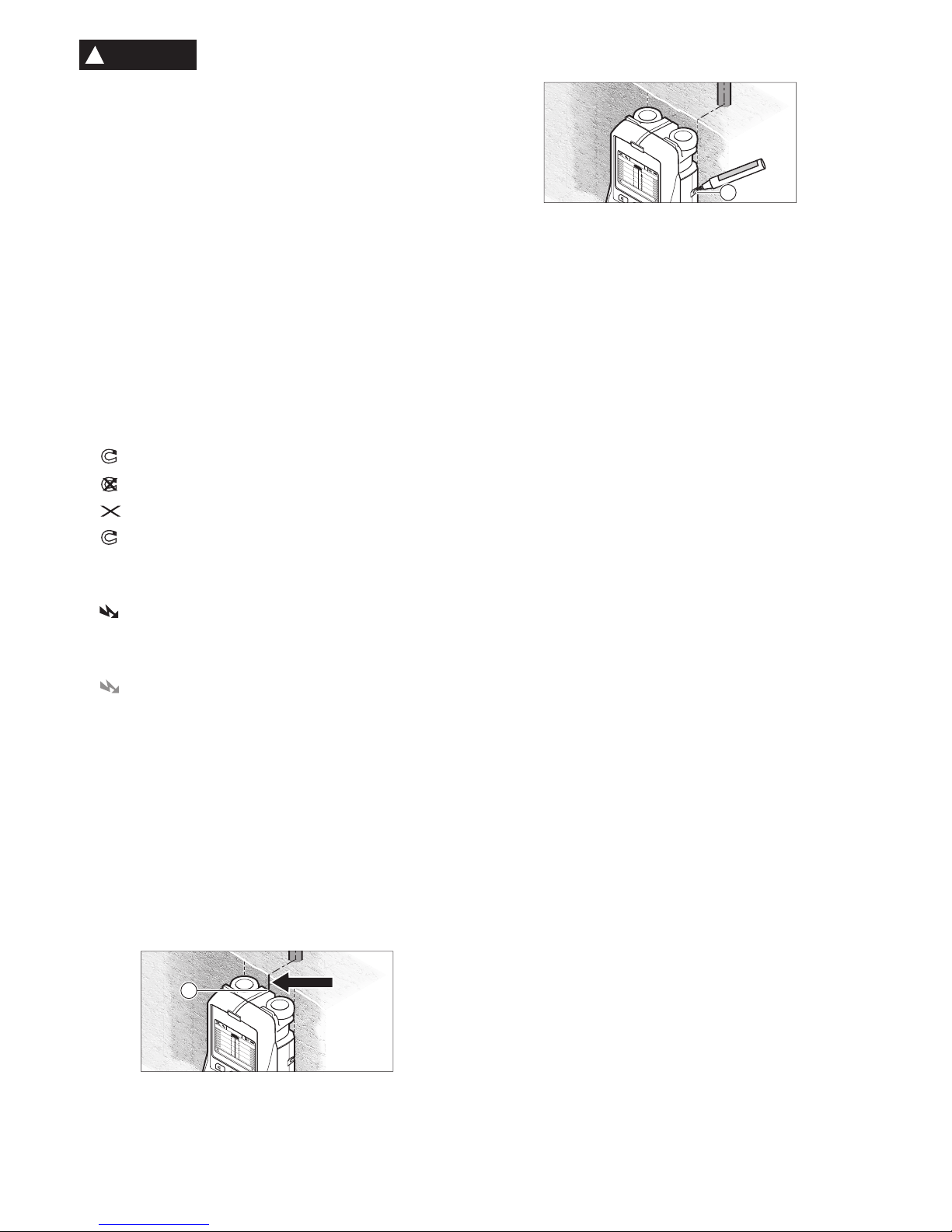

Inserting/Replacing the Battery

To open the battery lid 4, press the latch 5 in the

direction of the arrow and remove the battery lid.

Insert the batteries. When inserting, pay attention

to the correct polarity according to the

representation on the inside of the battery

compartment.

The battery indicator b in the upper status line on

the display 16 indicates the charge condition of

the batteries.

Note: Pay attention to the changing battery

symbol so that the batteries are replaced in time.

When the “Please change batteries” warning

indication is shown on the display 16, the settings

are saved and the detection tool switches off

automatically. Measurements are no longer

possible. Change the batteries.

To remove the batteries, press on the back of a

battery as indicated in the figure on the battery lid

(1). The front end of the battery is released from

the battery compartment (2), so that the battery

can easily be removed.

Always replace all batteries at the same time. Do

not use different brands or types of batteries

together.

• Remove the batteries from the detection

tool when not using it for extended periods.

When storing for long periods of time, the

batteries can corrode and discharge themselves.

Preparation

INITIAL OPERATION

• Protect the detection tool against moisture

and direct sunlight.

• If the detection tool was subject to an extreme

temperature change, allow it to adjust to the

ambient temperature before switching on.

In case of extreme temperature or variations in

temperature, the accuracy of the detection tool

and the display can be impaired.

• Do not attach any stickers or labels to the

sensor area 9 on the back of the detection

tool. Metal nameplates can affect the detection

results.

• Use or operation of transmitting systems,

such as WLAN, UMTS, radar, transmitter

antenna or microwaves in the close proximity

can influence the detection function.

Switching On and Off

• Before switching the detection tool on, make

sure that the sensor area 9 is not moist.

If required, dry the detection tool using a soft

cloth.

Switching On

– To switch on the detection tool, press the

On/Off button 15 or the start button 11.

– LED 17 lights up green and the start display is

indicated on display 16.

– When no measurement is carried out and no

button is pressed for 5 minutes, the detection

tool switches off automatically. This “Cut-off

time” can be changed in the “Settings” menu

(see “Cut-off Time”, page 12).

Switching Off

– To switch the detection tool off, press the On/Off

button 15.

– When switching off the detection tool, all

settings are retained in the menus.

Switching the Audio Signal On/Off

The audio signal can be switched on/off with the

audio signal button 13. The “Tone signal” can be

changed in the “Settings” submenu (see “Tone

Signals”, page 12).

Operation

Please change batteries

-11-

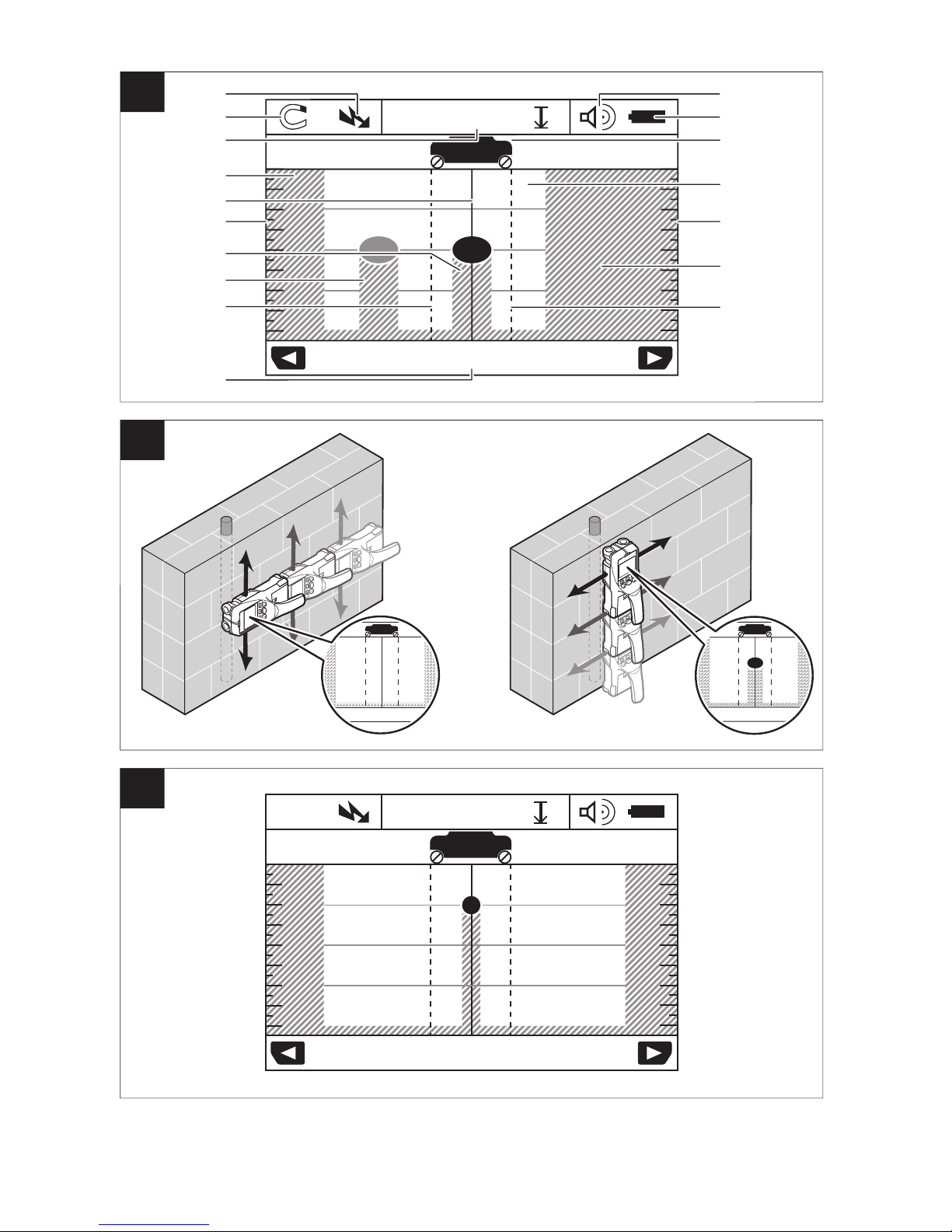

METHOD OF OPERATION

(SEE FIGURE B)

The detection tool checks the

base material of sensor area 9 in

measurement direction A to the

displayed measuring depth.

Measurement is possible only

during movement of the detection

tool in the direction of travel B and

for a measuring distance of at

least 4” 10 cm. Move the

detection tool in a straight line

with light pressure over the wall

so that the wheels remain in firm contact with

the wall. The object depth and, if possible, the

object material, are indicated on the display.

Optimal results are achieved when the measured

distance is at least 15 3/4” (40 cm) and the

detection tool is moved slowly over the entire

location. This method of operation ensures reliable

detection of outer object edges that run transverse

to the detection tool’s movement direction.

Always move crossways over the area to be

checked.

If several objects are located one over the other in

the wall, the object that is indicated in the display

is the one nearest to the surface.

The representation of the material types of

detected objects in the display 16 can deviate from

the actual object material types. This applies

particularly for very thin objects, which are

represented thicker in the display. Large cylindrical

objects (e.g. plastic or water pipes) can appear in

the display smaller than they actually are.

Detectable Objects

– Plastic pipes (e.g. water-filled plastic pipes, as

used in floor/wall-heating systems, with at least

3/4” in diameter; empty pipes with at least 1” in

diameter)

– Electrical wiring (independent of whether

carrying voltage or not)

– Three-phase wiring (e.g. to the stove)

– Low-voltage wiring (e.g. for door bell,

telephone)

– Metal pipes, bars, studs of any type (e.g. steel,

copper, aluminium)

– Reinforcing steel

– Wooden studs

– Hollow spaces

Measurements possible

– In concrete/reinforced concrete

– In brickwork (bricks, porous concrete, foam

concrete, aerated concrete, lime-sand brick)

– In light construction walls

– Under surfaces such as stucco, tiles, wallpaper,

hardwood flooring, carpet

– Behind wood, drywall

Special Measuring Cases

Based on the measuring priniciple, unfavorable

conditions can influence the measuring result, for

example:

– Multi-layered walls

– Empty plastic pipes and wood studs in hollow

spaces and light construction walls

– Objects running inclined in walls

– Moist walls

– Metal surfaces

– Hollow spaces in a wall; these can be indicated

as objects.

– Closeness to equipment that generates a

strong magnetic or electromagnetic field, e.g.

radio stations or generators.

MEASURING PROCEDURE

Switch the detection tool on. The “standard start

display” appears on display 16.

Position the detection tool against the wall and

move it over the wall in the direction of travel (see

“Operation Instructions”, page 13). Measured

results are indicated on display 16 after a

minimum measuring distance of 4” (10 cm). To

ensure correct measurement results, move the

detection tool slowly and completely over the

assumed object in the wall.

If the detection tool is lifted away from the wall

during a measurement or not operated (moving

the device or pressing a button) for more than 2

minutes, the last measured result remains on the

display. “Hold” appears on the sensor-range

indicator c. When the detection tool is placed

against the wall again, moved on or when the start

button 11 is pressed, the new measurement will

start.

When LED 17 lights up red, an object is in the

sensor range. When LED 17 lights up green, no

object is in the sensor range. When LED 17

flashes, “live” wires / conductors are in the

sensor range.

S

E

NS

O

S

E

NS

R

A

B

B

9

Sensor

Concrete

txeNverP

Move

6

4

2

0 cm

6

4

2

88

0 cm

-12-

Before drilling, sawing or routing

into a wall, protect yourself

against hazards by using other information

sources. As the measuring results can be influenced

through ambient conditions or the wall material, there

may be a hazard even though the indicator does not

indicate an object in the sensor range (no audio

signal or beep and the illuminated ring 17 lit green).

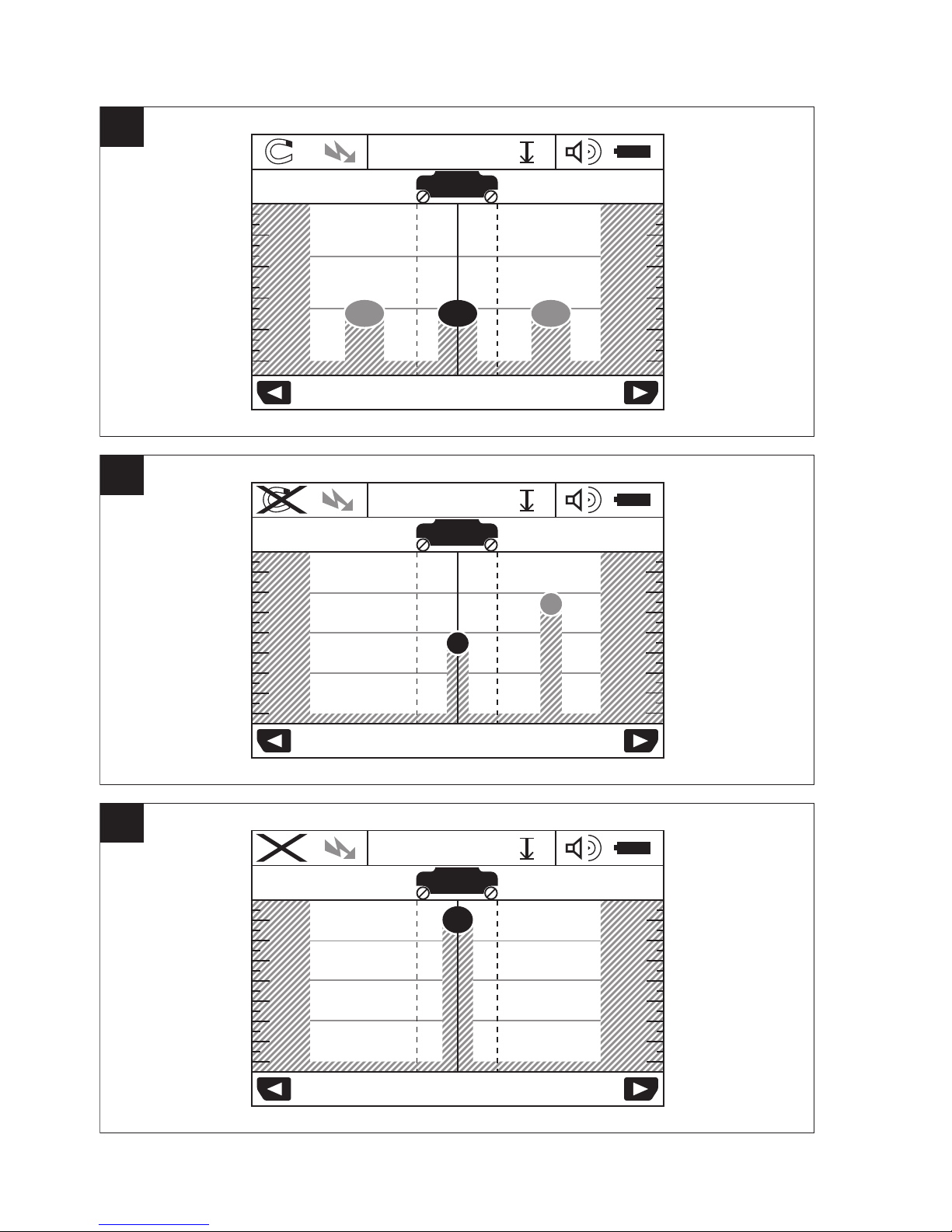

Display Elements (see figure A)

If an object is under the sensor area, it will appear

in the sensor range c of the display. Identification

of material type depends on size and depth of

object. The object depth l to the upper edge of the

found object found is indicated in the status line.

Note: Both the indication of the object depth l as

well as the material type m refer to the object

pictured black in the sensor area.

The indication of the object material m can

represent the following characteristics:

– Magnetic, e.g. reinforcing steel

– Non-magnetic, but metal, e.g. copper pipe

– Non-metal, e.g. wood or plastic

– Material type unknown

The indication of “live” wires n can represent the

following characteristics:

– “Live”

Note: For “live” wire/conductors, no further

characteristic is displayed.

– Not definite whether “live” or voltage free

Note: Three-phase wiring are possibly not

detected as “live” conductors.

Object Detection

To detect objects, moving over the measuring path

once may be enough.

When no object is found, repeat the motion

perpendicular to the initial measuring direction

(see “Operation Instructions”, page 13).

For precise detection and marking of an object,

move the detection tool back over the

measuring path.

When an object is indicated directly below the

center line k in display 16, as in the example, mark

it roughly with the top marking guide 1. This mark

will only be precise when the object is positioned

exactly vertical in the wall, as the sensor range is

located somewhat below the top marking guide.

For exact marking of the object on the wall, move

the detection tool left or right until the found object

is positioned below one of the outer edges. When

the found object is indicated directly below the

dashed righthand line g in display 16, mark it with

the right marking aid 3.

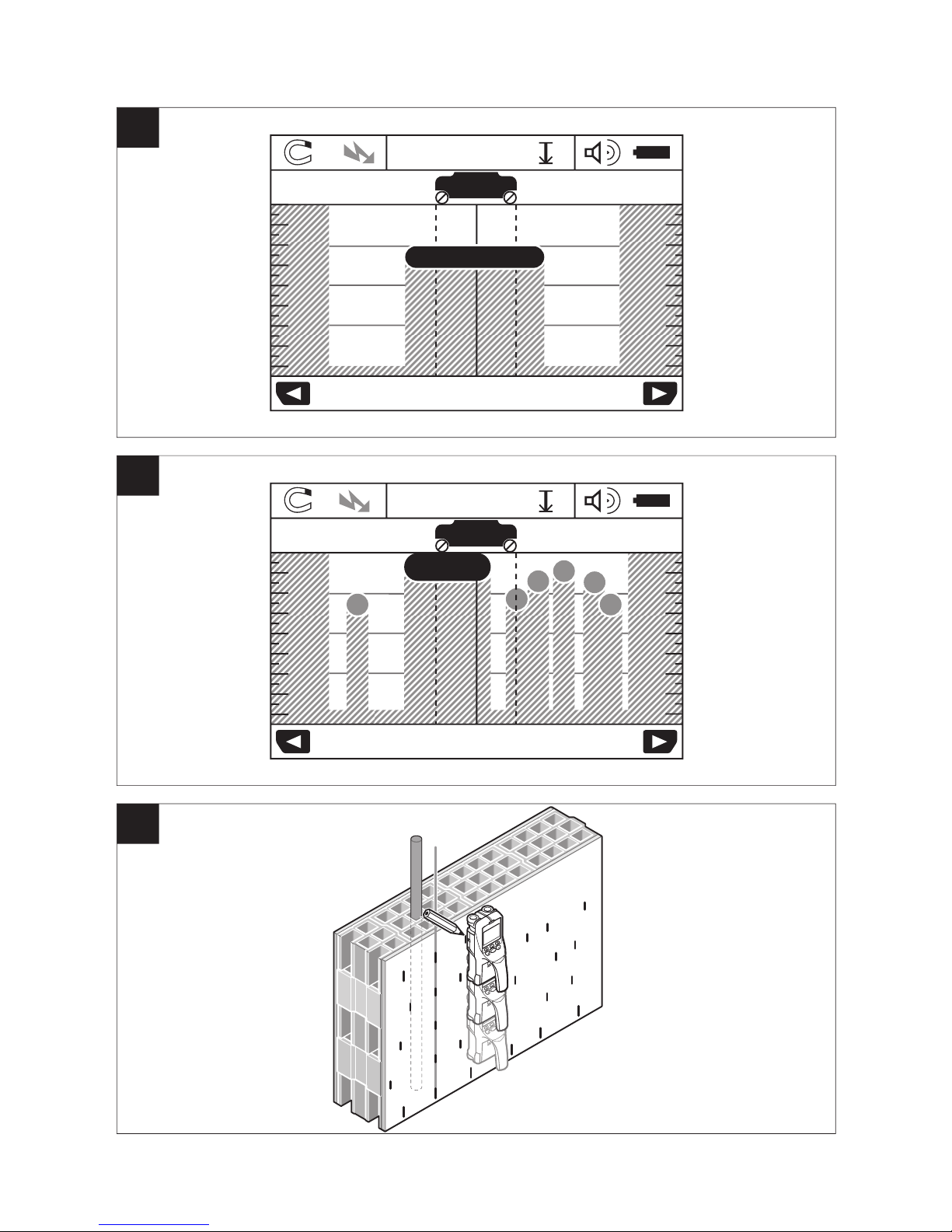

The direction of an object found in a wall can be

determined by carrying out several offset

measurements one after another (see figure I and

“Examples for Measuring Results”, page 13). Mark

and connect the respective measuring points.

By pressing the start button 11, the display of the

objects found can be deleted at any time and a

new measurement started.

CHANGING THE

OPERATING MODES

Changing between different operating modes is

possible with selection buttons 10 and 12.

– Briefly press selection button 10 to select the

next operating mode.

– Briefly press selection button 12 to select the

previous operating mode.

By selecting the operating modes, you can adapt

the detection tool to different wall materials. The

current setting is always shown in the operatingmode indication h of the display.

Concrete

“Concrete” is suitable for most applications in

brickwork or concrete. Plastic and metal objects

as well as electrical wiring are displayed. Hollow

spaces in brickwork or empty plastic pipes with a

diameter of less than 1” may not be displayed. The

maximum measuring depth is 3-1/8”.

Wet Concrete

The operating mode “ Wet Concrete” is

particularly suitable for applications in wet

reinforced concrete. Reinforcing steel, plastic and

metal pipes, as well as electrical wiring are

displayed. Differentiating between “live” and

voltage-free conductors is not possible. The

maximum detection depth is 2-3/8”.

Please note that concrete requires several months

to dry completely.

Deep Concrete

The operating mode “Deep Concrete ” is

particularly suitable for detecting objects

embedded deep in reinforced concrete.

Reinforcing steel, plastic and metal pipes, as well

as electrical wiring are displayed. The maximum

N

S

N

S

Metal

N

S

?

?

?

C

o

n

c

r

e

t

e

P

r

e

v

N

e

x

t

S

en

s

o

r

N

S

1

.

5

cm

6

4

2

0 c

m

6

4

2

8

8

0 c

m

1

C

o

n

c

r

e

t

e

P

r

e

v

N

e

x

t

S

e

n

s

o

r

N

S

1

.

5

c

m

6

4

2

0

cm

6

4

2

8

8

0

c

m

3

!

WARNING

-13-

detecting depth is 6”.

When too many objects are displayed, it may be

possible that you are moving directly alongside a

reinforcement rod. In this case, place the detection

tool a few inches aside and try again.

In-floor heating

The operating mode “In-floor heating” is

particularly suitable for detecting metal, metalcomposite and water-filled plastic pipes, as well as

for electrical wiring. Empty plastic pipes are not

displayed. The maximum measuring depth is

3-

1/8”.

Drywall

The operating mode “Drywall” is suitable for

finding wooden beams, metal framing and

electrical wiring in drywalls (wood, gypsum board,

drywall, etc.). Filled plastic pipes and wooden

studs are displayed identically. Empty plastic pipes

are not detected. The maximum measuring depth

is

3-1/8”

.

Metal

The operating mode “Metal” is suitable for

detecting metal objects and “live” wires / conductors when other operating modes in different wall

situations do not provide satisfactory results. In such

cases, the detection results will be more extensive,

yet less precise.

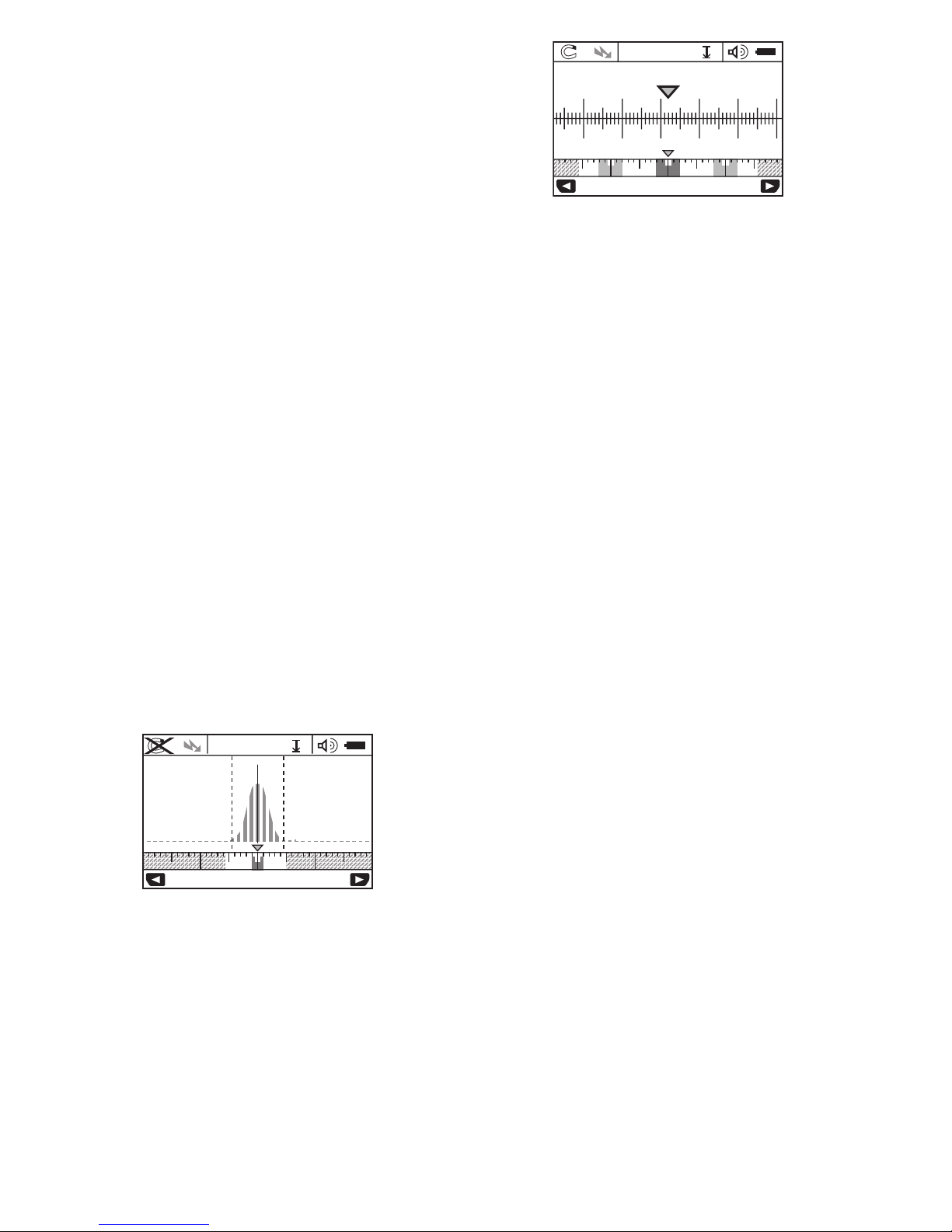

Signal View Mode

The operating mode “Signal view” is suitable for

all materials. The signal strength at the

corresponding detection position is displayed. This

mode is particularly suitable for better evaluation

of complicated material structures based on the

characteristic of the signal.

The object depth and the material types (as far as

possible) are displayed. The maximum measuring

depth is 6”.

• The signal strength shown on the main

display is not directly related to the object

depth.

CHANGING THE DISPLAY MODES

Note: Changing the display modes is possible in

any operating mode.

To switch from the standard start display to rule

mode, press and hold selection button 10 or 12.

In the example, ruler mode shows the same

situation as in figure D: Three steel bars equally

apart. In rule mode, the clearance between the

detected object centers can be determined.

The measuring distance covered from the starting

point (in the example 20.1 cm) is displayed under

the indication of the object depth l.

The three objects are displayed as rectangles in

the small ruler above the operating-mode

indication h.

Note: Both the indication of the object depth l as

well as the material type m refer to the object

pictured black in the sensor area.

To return to the standard start display, briefly press

selection button 10 or 12.

Note: Only the display is reset, not the measuring

mode!

“SETTINGS” MENU

To access the “Settings” menu, press the setup

button 14.

To exit the menu, press the start button 11. The

current settings are saved. The standard start

display for the measuring process is activated.

Navigating in the Menu

Press the setup button 14 to scroll down.

Press the selection buttons 10 and 12 to select the

values:

– Selection button 10 will select the right-hand or

next value.

– Selection button 12 will select the left-hand or

previous value.

Language

In the “Language” menu, you can change the

language of the menu navigation. The default

setting is English.

Cut-off Time

In the “Cut-off time” menu, you can set automatic

shut off time when no measurements are taken or

settings are carried out. The default setting is “5

min”.

Unit Mode

In the “unit mode” menu you can change a

measuring mode to fractional inch, decimal inch or

centimeters.

N

S

3020cm10cm0 cmcm

?

Signal view

txeN.verP

4,0 cm

4030cm20cm10cmcm

?

N

S

20 19 18 21 22 23

Deep Concrete

txeN.verP

2

0.1 cm

8.8 cm

Loading...

Loading...