Bosch W 135 K..B, W 275 1 K.B., W 400-1K..B, W 350 1 K.B. Installation, Servicing And User Instructions Manual

Page 1

For your safety

If you smell gas:

- Turn off gas isolating valve;

- Open windows to increase air circulation;

- Do not operate any electrical switches;

- Do not use the telephone on the premises;

- Call an authorised technician or the local gas authority

immediately.

Installation and servicing should only be performed

by authorised personnel.

Regular maintenance is recommended to ensure correct

and safe performance.

Do not store or use inflammable liquids or materials near

the appliance.

If the appliance is installed in a position likely to be affected

by frost, isolate gas and water supplies, remove batteries

and drain. If problems occur call an authorised technician

immediately.

The installer should explain to the customer how the

appliance functions and how to operate it. A copy of these

instructions must be made available to him.

W 135 K.B..

W 275 - 1 K.B..

W 350 - 1 K.B..

W 400 - 1 K.B..

Gas Fired Instantaneous

Water Heaters

Installation, Servicing and User Instructions

With electronic ignition and

ionisation probe safety

system

6 720 605 351 PT 1999.11

Page 2

2

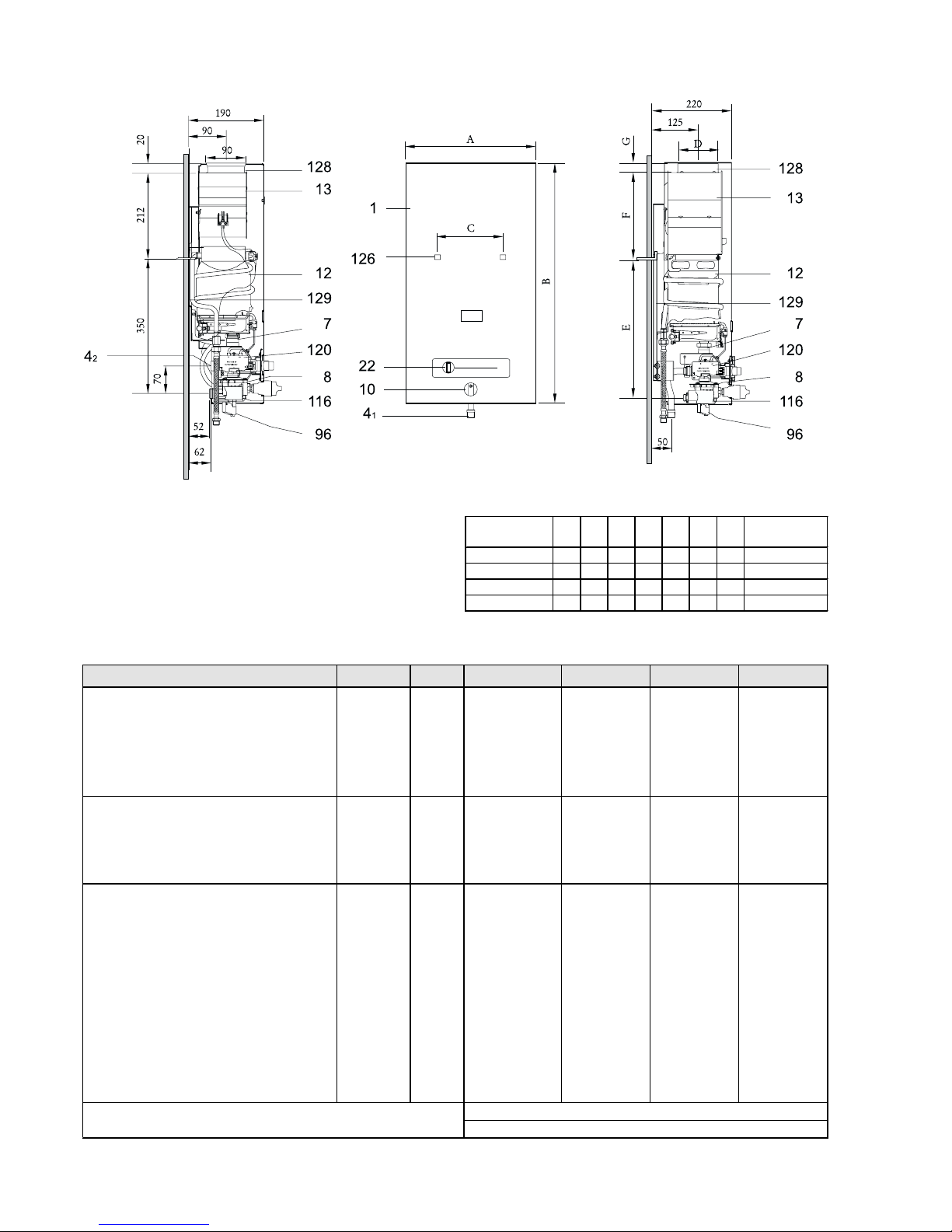

1.1 Dimensions

1 - Front cover

41 - Gas inlet

42 - Gas inlet (W135... Ø 3/4")

7 - Gas valve assembly

8 - Water valve assembly

10 - Temperature selector

12 - Heat exchanger

13 - Chimney with draught

diverter

Fig. 1

D663_014

22 - Output slide control

120 - Ignition unit

116 - Battery box

96 - Micro-switch

126 - Position of back

panel mounting slots

128 - Flue pipe connection

129 - Back panel

1.2 Technical Data

1. Main Features and Technical Data

*Hi 15°C - 1013 mbar - dry: Butane = 45.72 MJ/kg (12,7kWh/kg) - Propane = 46.44 MJ/kg (12,9 kWh/kg)

** Even with the effects of water dilation, the water pressure in the appliance shall not exceed this value.

W 135 K..B

W 275/350/400 K..B

Dimensions

(mm)

ABCDEFG

W 135 K..B..

270 610 138 ---- ---- ---- ---- ø3/4"

W 275-1K..B..

360 680 228 110 423 227 25 ø3/4"

W 350-1K..B.. 400 755 228 132 460 233 30 ø3/4"

W 400-1K..B..

460 755 334 132 512 182 30 ø3/4"

Gas connection

Ø

Appliance Ratings Symbols Units W 135..B W 275-1..B W 350-1..B W 400-1..B

Nominal useful output

P

n

kW 9.4 19.2 24.4 27,9

Minimum useful input (based on net c.v.)

P

min

kW 4.7 9.6 12.2 14

Manual useful output range kW 4.7-9.4 9.6-19.2 12.2-24.4 14-27.9

Nominal heat input

Q

n

kW 11.2 21.8 27.9 32.1

Minimum heat input

Q

min

kW 5.6 10.9 14 16.1

Gas inlet pressure

LP gas (Butane/Propane)* - 3+ G30/31 mbar 28/37 28/37 28/37 28/37

Gas consumption

LP gases - (Butane/ Propane)* kg/h 0.85 1.7 2.2 2.5

Water data **

Maximum inlet water pres sure

p

w

bar 12 12 12 12

Water flow selector

right

Min. water flow l/min. 2.5 5 5.9 7.3

Temperature rise °C55 555555

Min. inlet water pressure

p

wmin

bar 0.15 0.15 0.2 0.2

Water flow selector

left

Min. water flow l/min 5.4 11 14 16

Temperature rise °C25 252525

Min. inlet water pressure bar 0.6 0.5 0.8 1.2

CATEGORY

II

2H3+

TYPE

B

11BS

Page 3

3

2. Installation Requirements

Gas Safety (Installation and Use) Regulations:

October 1994

All gas appliances must be installed by a competent person

in accordance with the above regulations. Failure to install

appliances correctly could lead to prosecution.

2.1 Location

The appliance should be installed in a frost-free, wellventilated room and connected to a flue.

2.2 Water Connection

It is advisable to flush all water pipes before installing your

gas appliance, purging them of sand and other particles

which could later affect the heater's performance.

Make sure the water valve is fitted with a water filter.

Regular cleaning of the water filter should be carried out.

Identify and mark cold (right) and hot water (left) pipes to

avoid wrong connections.

Connect water pipes to appliance using correct fittings.

2.3 Gas Connection

Make sure that your water heater model is compatible with

the type of gas supplied.

A gas isolating valve must be provided near the appliance.

Verify the gas supply pressure - compare with the values in

chapter "Technical Data", pt. 1.2.

2.4 Flue Pipe Connection

The appliance must be connected to a flue pipe, no smaller

than the appliance outlet, ensuring a good seal.

The flue pipe can be made of galvanised steel, aluminium

or stainless steel.

2.5 Air supply

The room in which an appliance is installed must have a

permanent air vent to outside air or to a room which itself

has direct access to outside air. The minimum effective

area of the air vent(s) must be 23cm2 (W135), 72cm

2

(W275), 99cm2 (W350) or 118cm2 (W400).

Installations in cupboards or compartments require

permanent vents for cooling purposes, one at high level

and one at low level, either direct to outside air or to a

room. Both vents must pass to the same room or be on

the same wall to outside air.

There must be sufficient clearence around the appliance

to allow proper circulation of ventilation air. The minimum

clearances required are 50 mm for the sides and 150 mm

above the appliances front cover.

The minimum free areas required are given below.

After this procedure, whenever a hot water outlet is opened,

automatic ignition will take place by lighting the pilot burner

first, and the main burner about four seconds later. After

some seconds the flame of the pilot burner will die out.

This saves a considerable amount of energy, since the

pilot burner only remains alight during the time it takes to

light the main burner, not as in conventional systems where

it burns permanently.

The gas slide control allows for output variation according

to one's needs. The further to the right you position the

slide the greater the output, but also the greater the

consumption of gas.

In order to optimise energy consumption, adjust slide

position to supply the minimum output required.

When starting up the appliance, the existence of air inside

the gas supply pipework may cause some ignition

difficulties. In that case, open and close the hot water tap

repeatedly to re-start the ignition process, until complete

air purge is obtained.

Fig. 3

Decrease

output

Increase

output

Move slide control

to the right

Fig. 2

additional air inlet may be needed from outside to counter

the effect of the fan.

2.6 Installation

Open gas and water isolating valves and check the

soundness of all connections. Take the two 1,5V batteries

supplied with the appliance and place them correctly in

the battery box (fig. 2).

Refer to BS 6798 and BS 5440:2 for additional information.

A spillage test, as detailed in BS 5440:1, must be carried

out and any remedial action taken to ensure that the

installation meets the standard. The effect of any type of

extract fan in the premises must be considered and an

3. Operating and Servicing

3.1 Operating the Water Heater

The appliance is equipped with automatic electronic

ignition, making it easy to ignite the pilot burner.

Start off by moving the output slide control from the off to

the ignition position.

W135 W275 W350 W400 W135 W275 W350 W400

HIGH LEVEL

(cm

2

)

100.8 196.2 251.1 288.9 50.4 98.1 125.6 144.5

LOW LEVEL

(cm

2

)

201.6 392.4 502.2 577.8 100.8 196.2 251.1 288.9

POSITION OF

AIR VENTS

AIR FROM

THE ROOM

AIR DIRECT

FROM OUTSIDE

Page 4

* To be handled by authorised personnel only.

3.4 Fault Finding

The following table outlines some common problems and their solutions.

3.2 Flue gas safety device

The appliance is equipped with a flue gas safety device. If

the burner extinguishes while in operation, it is likely that

the flue gas safety device has activated. Ventilate the room

and reignite the appliance 10 minutes later. If it happens

again, please contact a professional installer.

The servicing of the flue gas safety device must always

be undertaken by a Corgi registered technician. The flue

gas safety device can never be put out of operation.

3.3 Servicing

Servicing is only to be performed by a Corgi registered

technician. It is recommended that the appliance is fully

serviced every year.

The heat exchanger, main burner, pilot burner and water

valve filter must be thoroughly cleaned.

If necessary, the heat exchanger and connecting pipes

should be de-scaled, and subsequently the soundness of

the water and gas valves checked. A complete check on

all the functions should be carried out.

If some parts have to be replaced, use only original spare

parts supplied by the manufacturer.

Problem Possi ble Cause Solutio n

Appliance does not ignite. Misplaced or worn out batteries. Check position and replace if

necessary.

Slow and difficult ignition of pilot

burner.

Worn out batteries. Replace

Burner extinguishes while in

operation.

Flue gas safety device activated. Ventilate the room and re-ignite the

appliance some minutes later. If it

happens again, contact a Corgi

registered technician.

Insufficient water temperature. Wrong output selected. Check position of water temperature

selector and adjust according to your

output needs.

Insufficient water temperature,

short flame.

Insufficient gas pressure. Check if gas container freezes while in

use. If so, place it in a warmer location.

Check if gas inlet governor is of

appropriate type, and is in good

working condition. Replace if

necessary.*

Dirty/damaged gas filter or burner. Clean gas filter and burner.*

Pilot burner doesn’tsparkwith

water flow.

Unadjusted micro-switch screw. Turn the water off.*

Remove cover cap from lower part of

micro-switch and turn the screw off

until the sparking begins, then turn

further 1 and 1/2 turns.

Insufficient water flow. Insufficient water pressure. Check and adjust.

Dirty taps or mixers. Check and clean.

Blocked water valve. Clean the filter.*

Blocked heating body (scale). Clean and de-scale.*

Loading...

Loading...