Page 1

Instantaneous gas water heater

Models

W 325 K..T1

W 400 K..T2

· Installation

· Operation

· Maintenance

The Bosch instantaneous water heater is a high efficiency,

space saving answer to your water heating needs. All Bosch

instantaneous water heaters heat water only as required;

noenergy is lost maintaining a large voluma of water at

elevated temperatures as in tanktype storage water heaters.

Suitable for heating potable water. Certified for space heating

in combination with potable water only. Not certified for

heating only.

READ INSTRUCTIONS CAREFULLY BEFORE INSTALLING

NOTICE TO INSTALLER: Please leave this manual

with the owner or affix adjacent to appliance.

ASTRAVAN DISTRIBUTORS, LTD.

123 Charles Street

6 720 601 783 CA (03.11) AL

North Vancouver, B.C. V7H 1S1

Phone Canada: (604) 929-5488

Phone USA: (206) 860-8448

Web Site: www.astravan.com

WARNING: If the information in this manual is

not followed exactly, a fire or explosion may

result causing property damage, personal injury

or death.

−−

− Do not store or use gasoline or other flammable

−−

vapors and liquids in the vicinity of this or any other

appliance.

−−

− WHAT TO DO IF YOU SMELL GAS

−−

••

• Do not try to light any appliance.

••

••

• Do not touch any electrical switch; do not use

••

any phone in your building.

••

• Immediately call your gas supplier from a

••

neighbor’s phone. Follow the gas supplier’s

instructions.

••

• If you cannot reach your gas supplier, call the

••

fire department.

−−

− Installation and service must be performed by a

−−

qualified installer agency or the gas supplier.

Note: In case of problems please contact your salesman or installer

Page 2

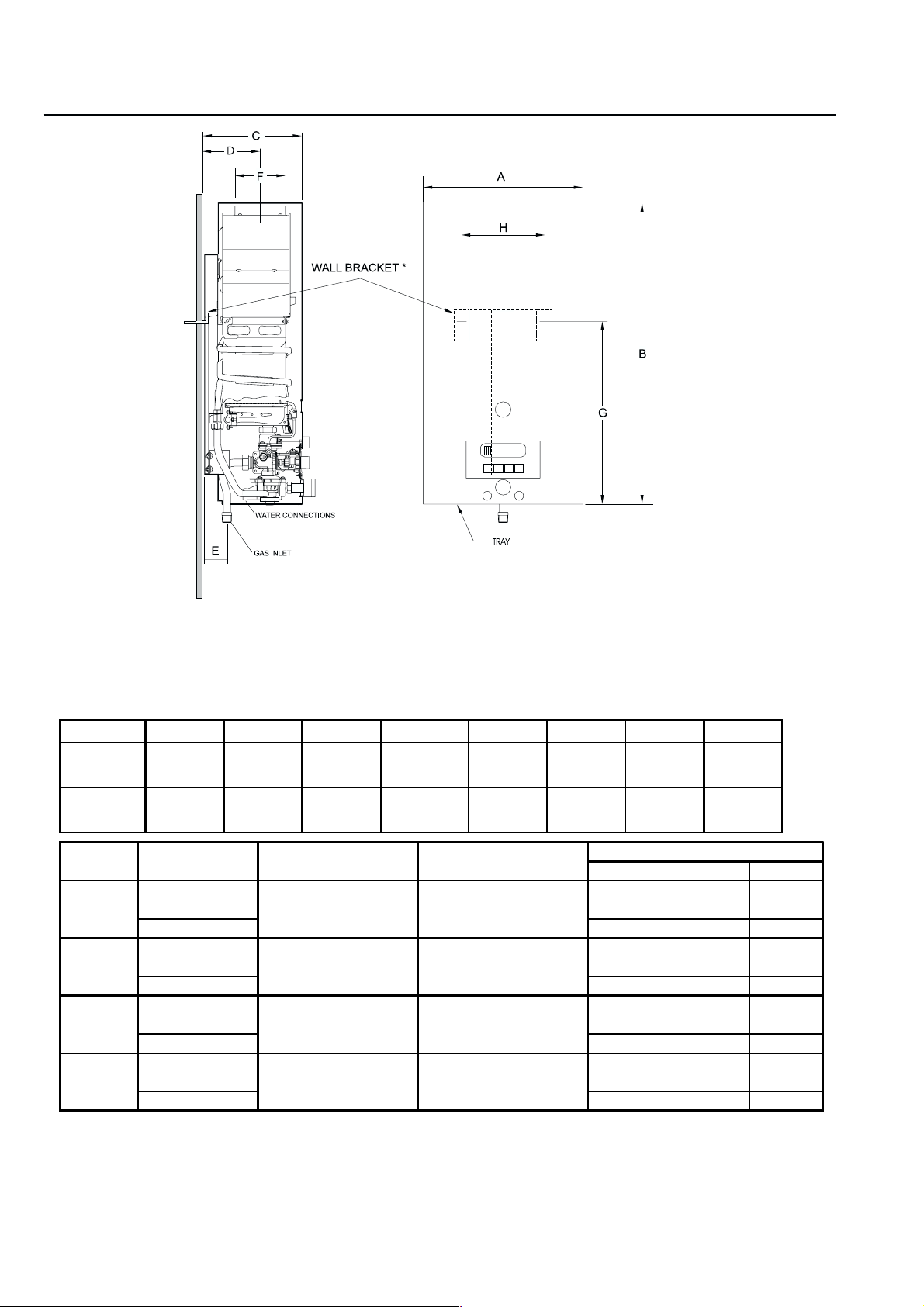

DIMENSIONS

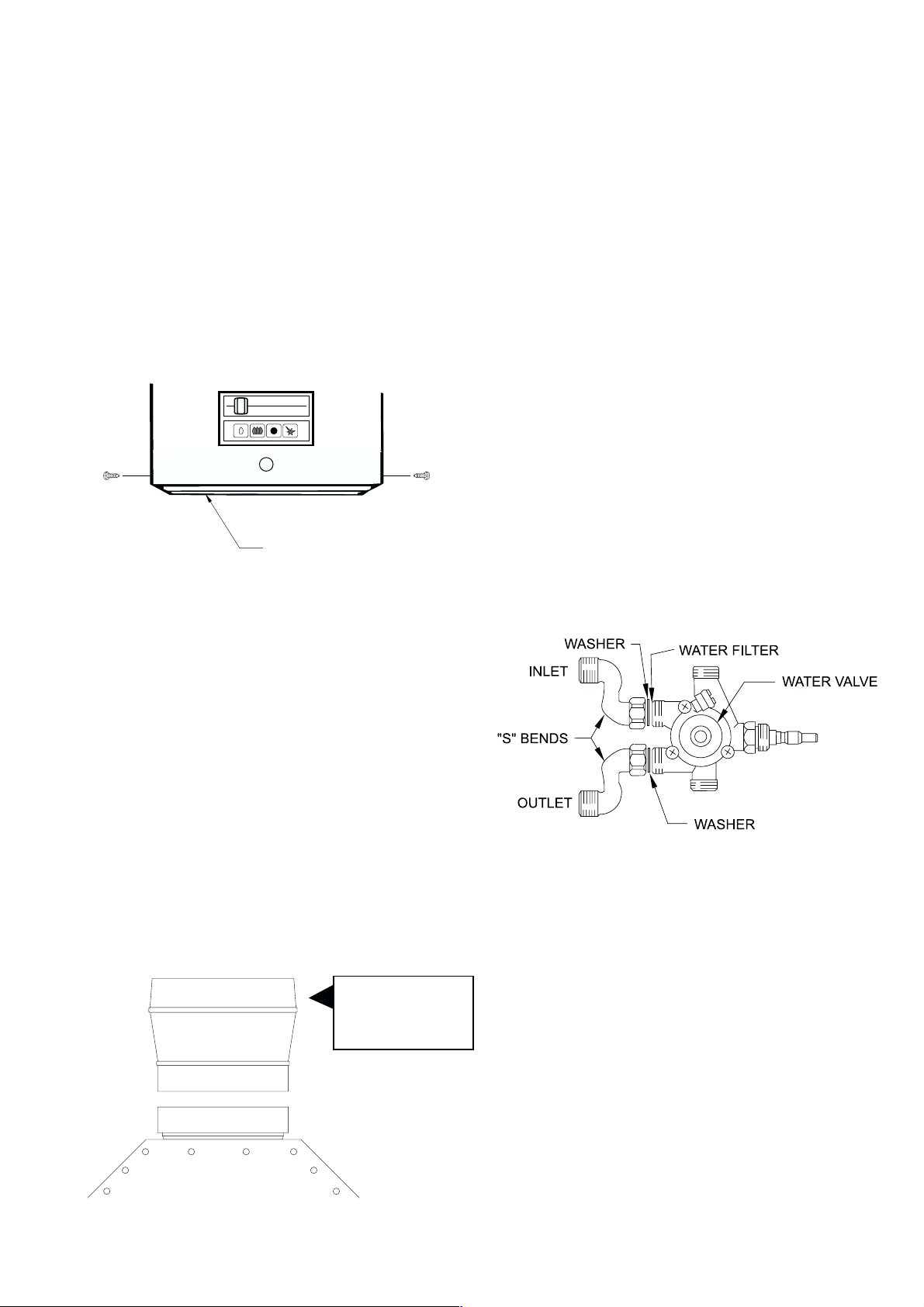

Figure 1

Maximum hydrostatic water pressure – 1.03 Mpa (150 p.s.i.)

Maximum recommend working pressure – 0.69 Mpa (100 p.s.i.)

Minimum working pressure – 0.0138 Mpa (2 p.s.i.) at 2 Litres/min. (0.5 U.S. Gallons/min) free discharge

Minimum recommended inlet water pressure for use with showers 30 p.s.i.g.

Dimensions in Milimetres (inches)

Model A B C D E F G H

W325

W400

Model Type of gas Altitude Input

W325

W325

W400

W400

400 755 250 155 85 130 410 320

17 1/4" 29 3/4" 9 3/4" 6" 3 1/4" 5" 16 1/8" 12 5/8"

440 770 250 155 85 130 410 320

17 1/4" 30 1/4" 9 3/4" 6" 3 1/4" 5" 16 1/8" 12 5/8"

Main Burner orifices

Size, mm Qt.

Natural

Propane 0.79 diam. 14

Natural

Propane 0.79 diam. 14

Natural

Propane 0.82 diam. 16

Natural

Propane 0.82 diam. 16

standard 29.30kW (100,000Btu/hr) 1.25 diam. 14

(0 - 2,000 ft.) 27.83 kW (95,000Btu/hr)

high** 26.37kW (90,000Btu/hr) 1.25 diam. 14

(2,000 - 4,500 ft.) 25.05 kW (85,000Btu/hr)

standard 34.28 kW 1.25 diam. 16

(0 - 2,000 ft.) (117,000Btu/hr)

high** 30.85 kW 1.25 diam. 16

(2,000 - 4,500 ft.) ( 105,000Btu/hr)

* The wall bracket is only required for the WR 325 K … when mounted directly to combustible construction. The WR

400 K… T2 may be mounted directly to combustible construction.

** The high altitude ratings listed are Canadian Gas Association high altitude ratings and are only valid in Canada. In the

U.S., the National Fuel Gas Code, ANSI Z223.1/NFPA 54, recommends for high altitude installations above 2,000 feet,

that the input rate be reduced 4% for each 1,000 feet above sea level. – See page 8.

2

Page 3

FORWARD

This design complies with CAN1-4.3-77 and ANS1Z21.10.3b

1994 as an instantaneous gas water heater. In addition the

unit complies with CAN1-2.17-M80 for use at high altitude,

2.000-4.500 feet above sea level.

Installation, operation and maintenance information is

provided in this manual. Installation and operation instrution

should be thoroughly reviewed before proceeding with

installation of the BOSCH instantaneous gas water heater.

The BOSCH instantaneous gas water heater is designedto

operate on natural or propane gas; however, make sure

that gas onwhich heater is to operate is to operate is the

same as specified on the heater’s model/rating plate.

In addition to these instructions, the water heater shall be

installed in accordance with CAN1-B149 Installation Code

(in Canada) or ANSI Z223-1/NFFA 54 National fuel Gas

Code (in U.S.) and/or local installation codes.

These shall be carefully folowed in all cases.

INSTALLATION INSTRUCTIONS

Note: Proper plumbling, venting, gas connections and an

adequate supply of combustion air are required for safe and

reliable operatrion. Ability equivalent to that of a licensed

tradesman in the field involved is required for installation

and/or servicing of these heaters.

AIR REQUIREMENTS

For safe operation ,sufficient air for combustion, ventilation

and dilution of flue gases must be available. An insufficient

supply of air will result in a yellow luminous burner flame,

causing carboning or sooting of the heat exchanger.

LOCATION

Before installation the BOSCH instantaneous gas water

heater consideration must be given to proper location.

Location should be as close to a chimney or gas vent as

practicable, in an area with an adequate air supply and as

centralized with the piping system as possible. The heater

should not not be located in area where it will be subject to

freezing. The heater should be located in an area where

leakage of the heater or its connections will not result in

damage to the area adjacent to the heater or to lower floors

of the structure.

In order to prevent corrosion, make sure that the combustion

air kept free of aggressive substances. Subtances that

especially contribute to corrosion are halogenated

hydrocarbons (e.g. chlorine and fluorine), which are

contained in solvents, paint, adhesives, propellant gases,

various house hold cleaners, etc. Take precautionary

measures as necessary.

If plastic pipes are used , a 1.5 m metal connection must be

provided on the cold and hot sides.

Note: When such loctions cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the water heater. The pan

must not restrict combustion air flow.

In unconfined spaces, in buildings of normal construction,

infiltration normally is adequate to provide air for combustion,

ventilation and dilution of flue gases. However, a confined

space must be provided with two permanent openings to

provide combustion and ventilation air to the appliance. Each

opening shall have a free area of one square inch per 1000

BTU/Hr* of total input rating os all appliances in the

enlosure.One opening shall be within 12 inches of the top

and one within 12 inches of the bottom of the enclosure.

* SPECIAL NOTE

When the W 400 K… T2 is installed in a confined space of

minimum size the openings described above must be

increased to a size of 1 ½ square inches per 1000 BTU/Hr.

In other words, for the W400 K..T2 installed in a minimum

sized confined space the two openings that are to be made

in the enclosure within 12 inches of the top and 12 inches

of the bottom must each have a minimum free area of, (11/

2”) x (117) = 175.5 square inches.

3

Page 4

For either confined or unconfined space in a building of

tight construction with inadequate infiltration, air must be

drawn from the outdoors or from spaces that freely

communicate the outdoors. Two permanent openings located

as indicated above are to be provided as follows:

1. When communicating with outdoor directly, or by means

of vertical ducts, each opening shall have a free area

of not less than one square inch per 4000 BTU/Hr of

total input of all appliances in the space.

2. When communicating with outdoors by means of

horizontal ducts, each opening shall have a free area of

not less than one square inch per 2000 BTU/Hr of

total input of all appliances in the space.

For detailed reqirements see

- in Canada, CAN 1-B 149 Installation Codes

- in U.S., ANSI Z223.1/NFPA 54 National Fuel Gas Code.

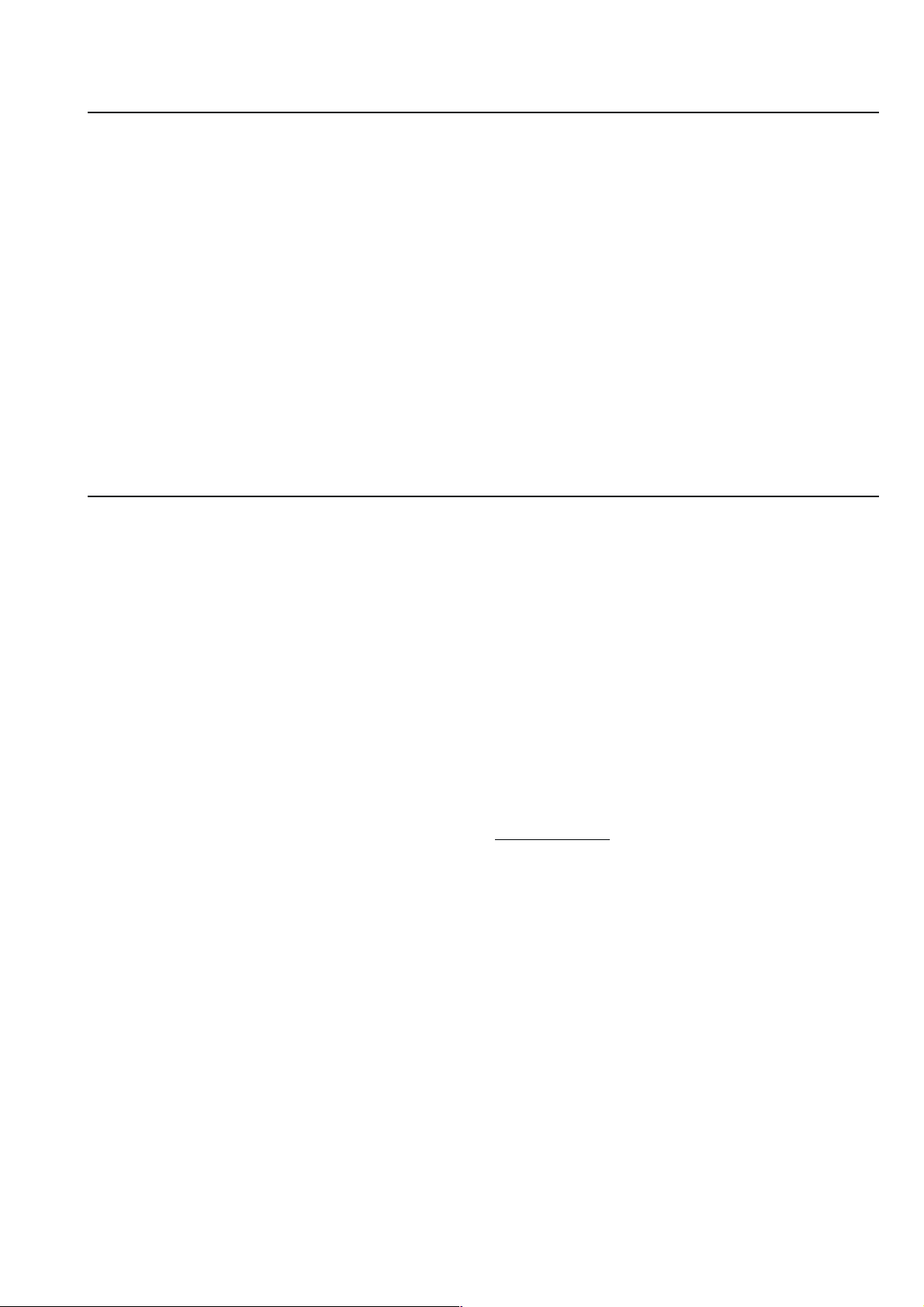

MOUTING

The W 325 K.. and W 400 K.. are design certified for

mounting to a wall. A wall bracket, see figure 1 is provided

with the W 325 K.. and must be used when the heater

mounted on a combustible wall. Heaters may not be installed

directly on a carpeted wall.

The heater, or the wall bracket, must be mounted to the wall

using appropriate anchoring materials.

WARNING

Failure to use the wall bracket with the W 325 K… when

installing the unit on combustible construction will cause

an unsafe condition and possible fire. In addition, failure to

use the wall bracket when installing the W 325 K… on

combustible construction will be in violation of A.G.A. and

C.G.A. certification of the unit.

WARNING

1. Flammable materials, gasoline, pressurized containers,

or any other items or articles that are potentially fire

hazards must never be placed on or adjacant to the

heater. The appliance area must be kept free of all

combustible materials, gasoline and other flammable

vapors and liquids.

2. Do not obstruct the flow of combuston and ventilation

air to the appliance.

CLEARENCE

In Canada

The W 325 and the W 400 are design certified for installation

on a combustible wall (for the W 325 the wall bracket

supplied with the unit must be used for mounting to

combustible construction), and for installation in an alcove

or closet with minimum clearances to 0 mm from back, 102

mm (4 inches) from sides, 305 mm (12 inches) from top and

bottom, and 102 mm (4 inches) from front. A minimum of

305 mm (12 inches) shall be allowed for maintenance of

serviceable parts.

Clearence from vent is dependant upon the clearence rating

of the venting material used; that is, type B-1 vent is approved

for 1 inch clearence, B-2 vent for 2 inch, etc.

In United States

The W 325 and the W 400 are design certified for installation

on a combustible wall (for the W 325 the wall bracket

supplied with the unit must be used for mounting to

combustible construction), and for installation in an alcove

with minimum clearences to combustible construction of 0

mm from back, 102 mm (4 inches) from sides, 305 mm (12

inches) from top and bottom. In addition, the WR 325 has

also been design certified for closet installation with minimum

clearences to combustible construction of 0 mm from back,

102 mm (4 inches ) from sides, 305 mm (12 inches) from

top and bottom, and 102 (4 inches) from front. A minimum

of 305 mm (12 inches) shall be allowed for maintenance of

serviceable parts.Clearence from vent is dependent upon

the clearence rating of the venting material used, that is,

type B-1 vent is approved for 1 inch clearence, B-2 vent for

2 inch, etc.

Note: If wall is a stud wall sheethed with plasterboard it is

recommended that support board(s), either 1 x 4’s or ½

(minimum) plywood first be attached across a pair of

studs and then heater, in the case of the W 400 K…,

or the wall bracket, in the case of the W 325 K…, be

attached to the support boards. See figure 2.

WALL STUDS

WALL

BRACKET

1” X 4” SUPPORT

Figure 2

BOARDS

Expansion and contraction of piping due to changing water

temperature in pipes imparts movement to heater which, if

mounted directly to a brittle, friable board such as

plasterboard can cause failure of mounting.

4

Page 5

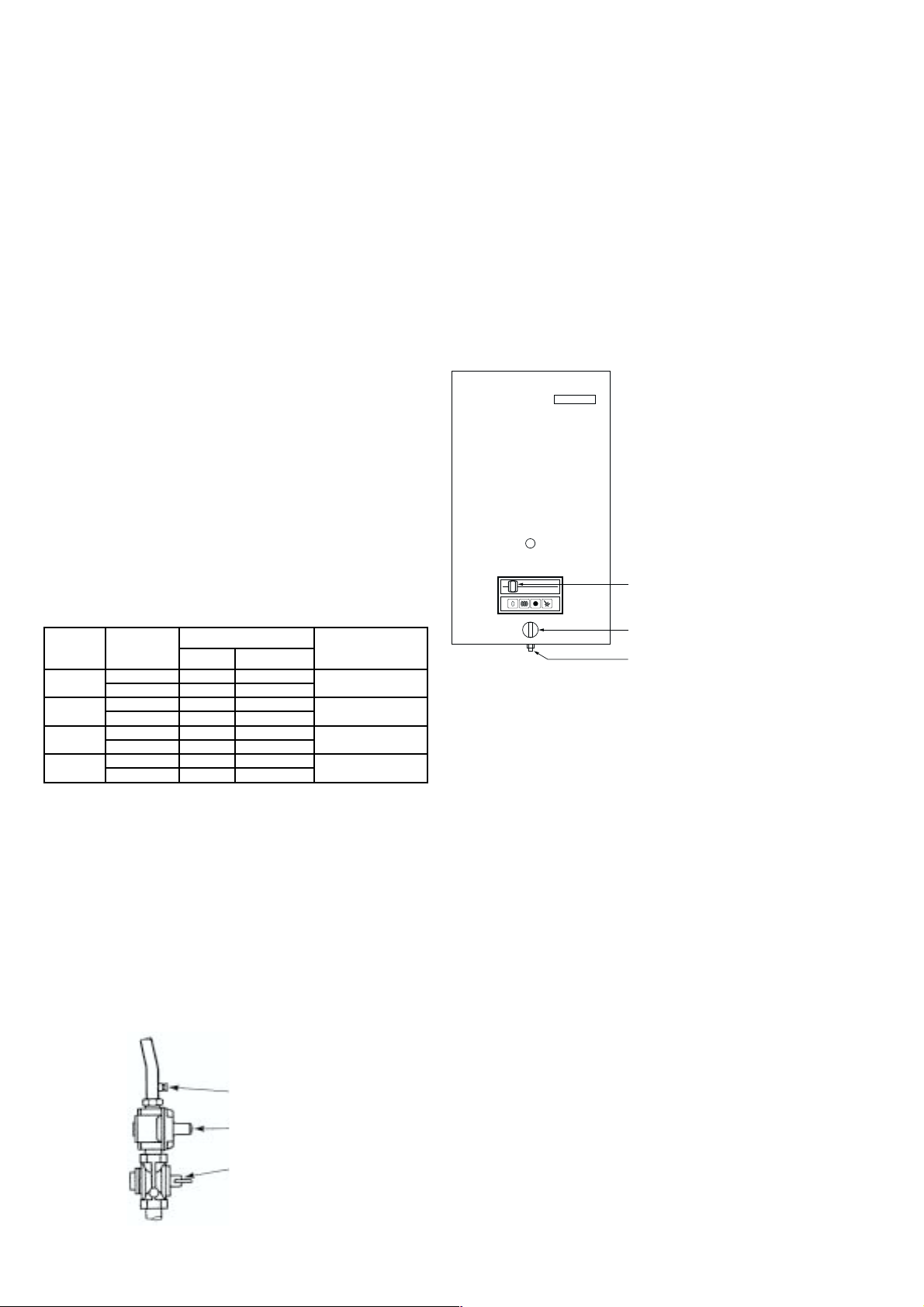

DRIP TRAY

If the water heater is being mounted above a floor of

combustible construction, the drip tray ( shipped loose in

the water heater) must be attached to the bottom of front

cover of the water heater at time of installation. The drip

tray should be attached to the front cover, using screws

provided, as shown in figure 3.

Failure to use drip tray when installing unit above a floor of

combustible construction will cause an unsafe condition and

possible fire and will be in violation of A.G.A. and C.G.A.

sertification of the unit.

DRIP TRAY

For high altitude use the adaptor must be installed as shown

in figure 4, without alternation, before connecting the six

inch flue to the unit. The adaptor must be secured to the

draft diverter outlet with a minimum of two screws.

Also, in Canada, the gas pressure regulator supplied with

the water heater is factory preset to deliver gas to the water

at the proper pressure settting for high altitude operation,

see PRESSURE REGULATION section of this manual.

WARNING

Failure to increase vent size on W 400 to six inches and/or

to assure that manifold pressure is set to proper value listed

on rating plate for applications at altitudes in range 2,000

to 4,500 ft. above sea level will cause unsafe venting,

asphyxiation, and voids C.G.A. certification.

WATER CONNECTIONS

The W series instantaneous water heatrs are provided with

two S-bend water connectors/adaptors that must be

connected to inlet and oulet and outlet connections on water

valve assembly, see figure 1 and figure 5 below.

Figure 3

VENTING

The BOSCH instantaneous water heaters have builtin draft

diverters and are designed for indoor installation only. The

draft diverter outlet must be connected to a clear,

unobstructed vent of the same size, or lerger, refer to:

- In Canada, CAN1-B149 Installation Code for detailed

requirements.

- In U.S.A., ANSI Z223.1/NFPA 54 – National Fuel Gas

Code for detailed requirements.

The flue connection for both the W 325 K… and W 400

K… is 130 mm (5 inches); however, in Canada for

installations at high altitude (2,000-4,500 ft. above see level)

a six inch (6”) flue is required for the W 400 K.

5” x 6” adaptor used

on high altitude model

W 400 only

Water valve and S-bends, top view

Figure 5

The purpose of the S-bend water connectors/adaptors is to

provide threaded water connections that meet standards

used in North America, ANSI Standard Taper Pipe Thread

(1/2” NPT). The cold water supply should be connected to

S-bend attached to inlet of water valve and hot water

connection should be made to S-bend attached to outlet of

water valve.

Figure 4

Note: A shut-off valve should be placed in the cold water

supply line to the heater to facilitate servicing the

heater.

5

Page 6

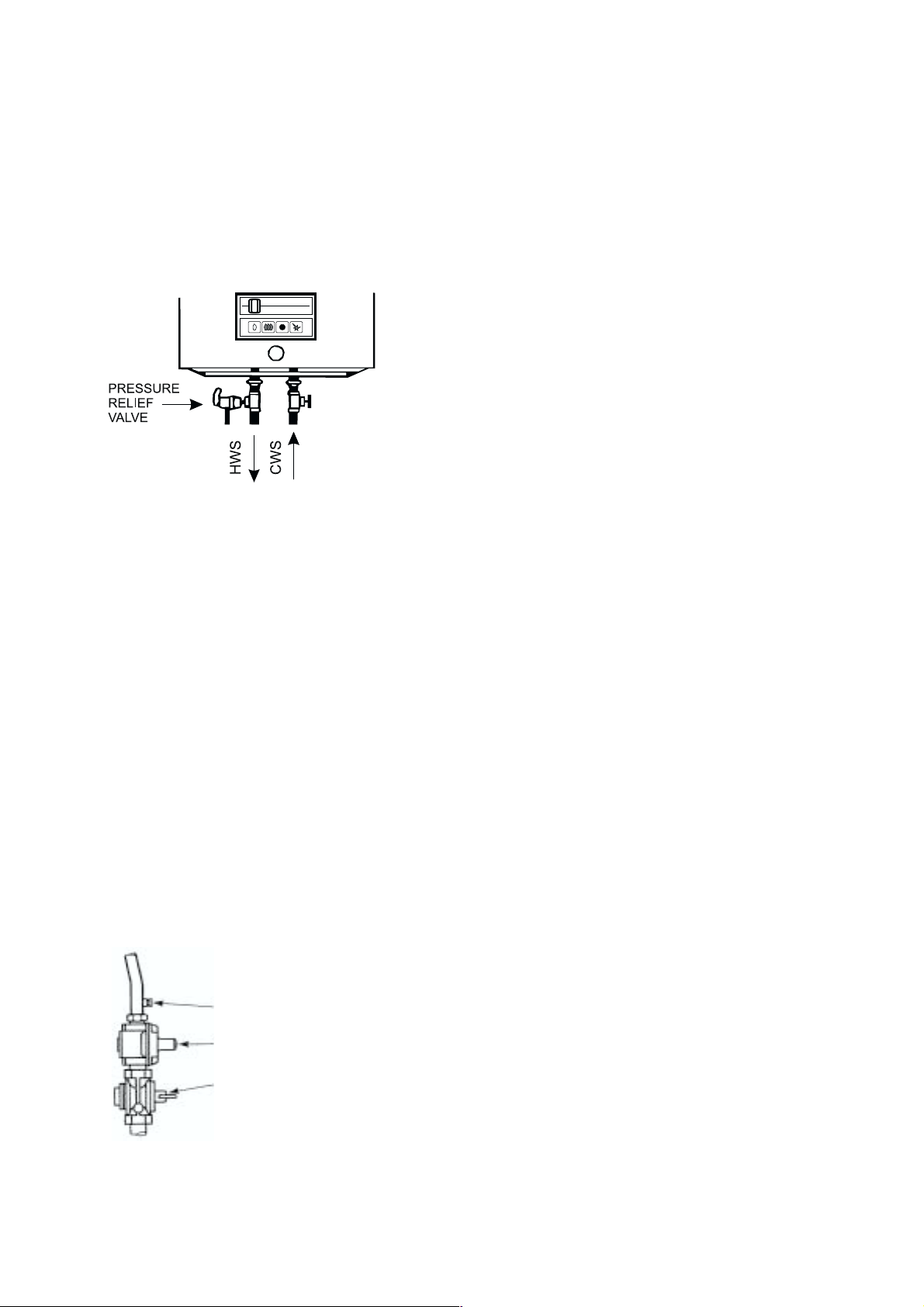

RELIEF VALVE

The listed pressure relief valve supplied must be installed

near the hot water outlet at time of installation of the heater.

No valve is to be placed between the relief valve and the

heater. A line must be connected to the relief valve to direct

discharge to a safe location. Do not install reducing coupling

or any other restriction in the discharge line must be installed

so as to allow complete drainage of the valve and the line.

See figure 6.

Figure 6

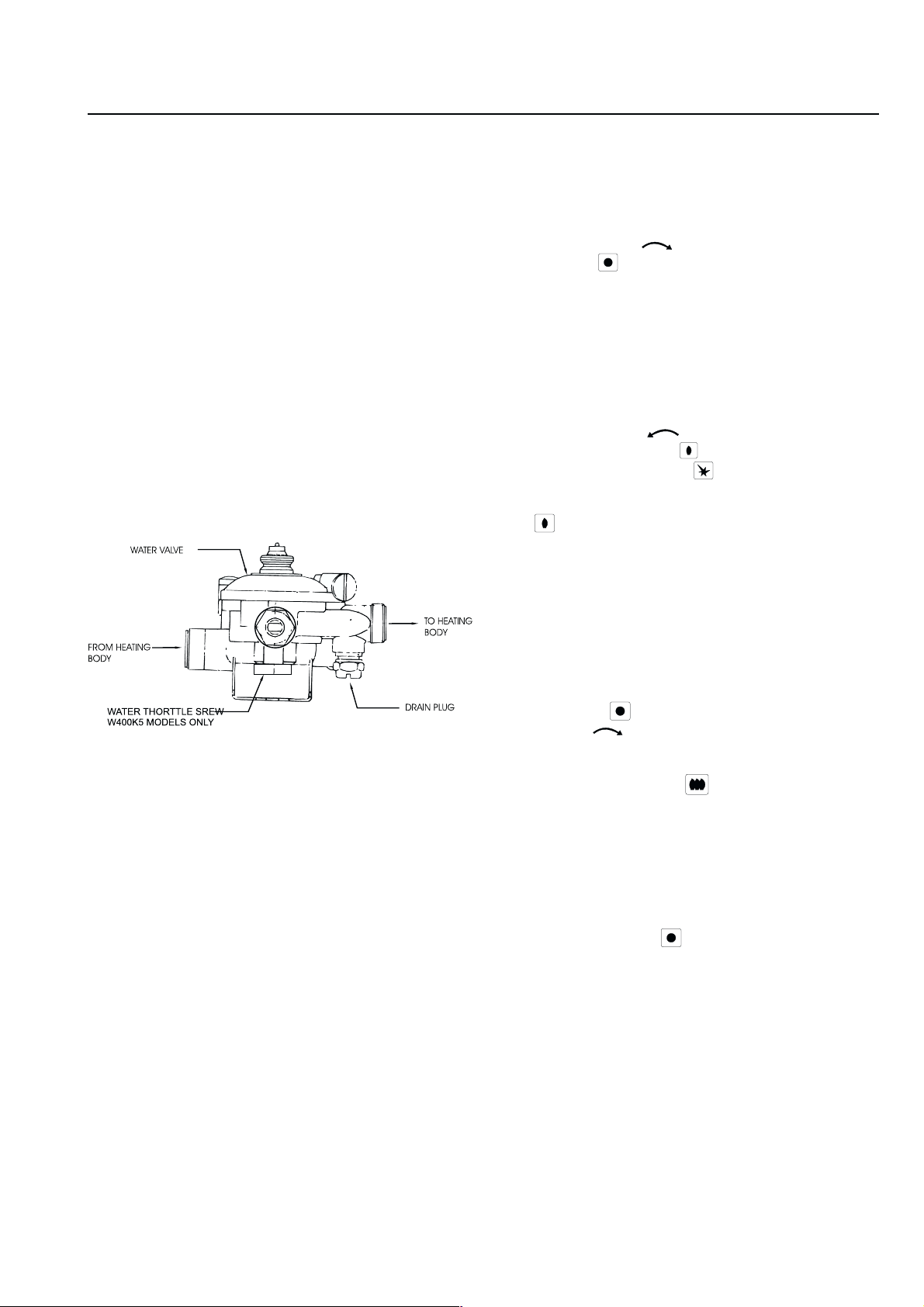

GAS CONNECTIONS

Before connecting the gas supply to the heater check

heater’s model/rating plate to make sure that gas on which

heater is to operate is the same as specified on the model/

rating plate.

The W 400 K and the W 325 K instantaneous gas water

heaters are supplied with a gas pressure regulator that must

be installed on the heater before attaching the gas supply

line, see figure 7. Failure to install the pressure regulator, or

the failure to install it in the sequence shown in figure 7 will

be of A.G.A. and C.G.A. certification of the unit.

BOSCH water heaters are shipped from the factory with

the gas pressure regulators preset for tte gas shown on the

rating plate to the correct pressure:

- in Canada, for high altitude operation;

- in U.S., for standard altitude operation unless specially

marked as a high altiude unit.

Check to make sure that the gas listed on the rating plate is

same as gas listed on the pressure regulator.

See PRESSURE REGULATION of this manual for

information regarding gas pressure settings.

Note: Before attaching the gas supply line, be sure that all

gas pipe is clean on the inside. To trap any dirt or

foreign material in the gas suplly line, a drip leg must

be incorporated in the piping. The drip leg must be

readily accessible and not subject to freezing

conditions. Install in accordance with

recommendations of serving gas supplier.

Joint compounds (pipe dope) shall be applied sparingly and

only to the male threads of pipe joints. Do not apply

compound to the first two threads. The joint compound used

must be resistant to the action of liquified petroleum gases.

Before placing water heater in operation check for gas

leakage. Soap and water solution, or other material

acceptable for this purpose, shall be used in locating gas

leaks. Matches, candles, lighters, or other ignition sources

shall not be used for this purpose.

WARNING

The heater and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressure in excess of

3,45 kPa (1/2 psig).

The water heater must be isolated from the gas supply piping

system by closing its individual manuaql shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 3.45 kPa (1/2 psig).

Figure 7

6

PRESSURE TAP

PRESSURE REGULATOR

MANUAL GAS VALVE

The water heater, including the pressure regulator and

manual valve provided with it, must not be operated at gas

supply pressures in excess of 3.45 kPa (1/2 psig). If

overpressure has occurred such as through improper testing

of the gas lines or emergency malfunction of the supply, the

gas valve and regulator must be checked for safe operation.

Make sure that the outside vent valves are protected against

blockage. These are part of the gas supply system, not the

water heater.Vent blockage may occur during ice storms.

Page 7

OPERATING INSTRUTIONS

WARNING

If the water has been damaged or exposed to fire or sooting

or if any part has been underwater do not use. Immediately

call a qualified service technician to inspect the appliance

and to replace any part of the control system and any gas

control which has been underwater and to clean the heat

exchanger assembly and water valve.

FILLING

Before proceeding with operation of the water heater make

sure that system is filled with water.

- Make sure drain is closed, see figure 8, below.

- Open a nearby hot water faucet to permit the water to

fill the heater and piping.

- Close the hot water faucet after the water flows freely

and all air has escaped from system.

- The water heater is now ready to be lit.

Figure 8

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information, first section of the

Lighting Instruction Plate on the cover.

2. The main manual gas valve must be closed (turn valve

handle clockwise ) and the gas valve OFF button

depressed . See figure 9.

3. Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow “B” in the safety information

given above on this plate. If you don’t smell gas, go to

next step.

4. The pilot burner is located behind the peephole located

in the front center of the jacket directlybelow this

instrution plate.

5. Open main manual gas valve by turning valve handle

counterclockwise .

6. Depress PILOT button and light pilot by pushing

PILOT IGNITER button . This may have to be

repeated.

7. Observe pilot flame though peephole. The PILOT button

- should be held down at least 10 seconds with

pilot burning. When the PILOT button is released the

pilot should continue to burn.

- If the PILOT button does not pop up when released

stop and immediately call your service technician or

gas supplier.

- If the pilot will not stay repeat lighting procedure steps

1 through 8.

- If the pilot will not stay lit after several tries, depress the

OFF button , turn the manual gas valve handle

clockwise to OFF position and call your service

technician or gas supplier.

SERVICE HINT

The strainer (screen) in the water valve, located in the inlet

of the water valve, may require occasional cleaning due to

foreign material in the water supply. This will restrict the

flow of may affect heater operation and prolong filling time.

To inspect the strainer close the cold water supply valve

ahead of the heater, disconnect S-bend from inlet of water

valve, and remove strainer from inlet. Clean if required,

replace strainer in inlet to water valve, reconnect S-bend

and turn on water supply.

Light the water heater in accordance with the instructions

on the Lighting and Operating Plate on the water heater.

For your convenience, the instructions are repeated below.

8. Depress the ON button . The heater will now fire

when water is drawn at arate greater than the threshold

flow rate (see manual)*.

Note: If main burner should fail to ignite make sure pilot is

burning. If not repeat lighting procedure steps 1 through 8.

TO TURN OFF GAS TO APPLIANCE

1. Depress OFF buton and close the main gas valve

by turning handle clockwise to OFF position. See figure

9.

*see Water Flow Selector section.

7

Page 8

PRESSURE REGULATION

The pressure regulator supplied with the water heater is

adjusted to operate on the gas specified on the rating plate,

and:

- in Canada, is factory preset to deliver gas at the high

altitude pressure setting listed on the rating plate and

as shown below.

- In the U.S., is factory preset to deliver gas at the standard

altitude setting listed on the rating plate and as shown

below.

The pressure setting of the gas pressure regulator should

be checked at installation to assure that the setting is correct

for the gas being used and the altitude at which the

appliance is installed. See rating plate on the unit, or the

chart below for proper settings.

In Canada, for a heater being installed at standard altitude

(o-2,000 ft. elevation) the manifold pressure should be reset

at installation to value shown on the rating plate, or chart

below, for standard altitude.

The gas pressures specified below refer to flow pressure

taken at the pressure tap in the gas inlet pipe (just above

pressure regulator), figure 9, while the heater is operating

at full input.

Appliance Regulator Pressure Setting

Model Type of Gas

W325

W325

W400

W400

natural 1.36 5.5 standard

propane 2.61 10.5 (0-2,000 ft.)

natural 1.09 4.4 high *

propane 2.11 8.5 (2,000 - 4,500 ft.)

natural 1.41 5.7 standard

propane 2.61 10.5 (0-2,000 ft.)

natural 1.14 4.6 high *

propane 2.09 8.4 (2,000 - 4,500 ft.)

*Note: The high altitude ratings listed are Canadian Gas

Association high altitude ratings for the appliances and are

only valid in Canada. In the U.S. the National Fuel Gas

Code, ANSI Z223.1/NFPA 54, recommends for high altitude

installations, above 2000 feet, that the input rate be reduced

4% for each 1,000 Feet above sea level.

Pressure

kPa Inches, W.C.

Altitude

TEMPERATURE REGULATION

I W325K and W400K Models only

For domestic purposes the water flow selector should be

turned clockwise to stop and the gas control slide slid to

right hand stop and remain in those positions.

See figure 10.

Should overheating occur or the gas supply fail to shut

off, turn off the manual gas control valve to the appliance

and have the heater checked by a qualified serviceman to

determine the reason for te malfunction.

GAS CONTROL SLIDE

WATER FLOW SELECTOR KNOB

W325K AND W400K ONLY

WATER THROTTLE SCREW

Figure 10

WATER FLOW SELECTION

With the water flow selector turned clockwise to the stop,

the heater’s water valve will regulate the flow rate through

the heater permitting a maximum flow rate of:

- 5.8 L/Min. (1.5 U.S. Gal./min.), for W325

- 6.8 L/Min. (1.8 U.S. Gal./min.), for W400

W400K5 MODEL ONLY

Your appliance dealer and/or your local gas supplier should

be consulted in regard to any high altitude installation. If

field adjustment is required it should be performed by a

qualified serciveman experienced in such work.

PRESSURE TAP

PRESSURE REGULATOR

MANUAL GAS VALVE IN OFF

POSITION

Figure 9

8

This setting permits a person at a remote location to control

the water temperature by mixing more or less cold water

with the hot water supplied by the heater.

Page 9

The water flow selector regulates the hot water output by

1

(

adjustng the flow rate of the water through the heater. Below

you will find listed the maximum that can be selected by

adjusting the water flow selector and the minimum flow rate

for main burner operation.

Also listed are the temperature rises that would be expected,

at flow rates indicated, when the heater is firing at full input.

WATER FLOW ADJUSTMENT RATE ALL

MODELS

Model

W 325

W 400

Maximum Flow Rate

(counter-clockwise to stop)

3 L/min.

3.4 U.S. Gal./min.) Temp.

Rise 25° C (45° F)

15 L/m in. (4.0

U.S. Gal./min.) Temp.

Rise 25° C (45° F)

Minimum Flow Rate

(clockwise to stop)

5.8 L/min. (1.5

U.S. Gal./min.) Temp.

Rise 55° C (100° F)

6.8 L/min. (1.8

U.S. Gal./min.) Temp.

Rise 55° C (100° F)

*Note: If flow rate through the heater is less than the minimum

flow rate shown for the heater the main burner will not fire.

The minimum flow rate is the “THERSHOLD FLOW RATE”

referred to in the lighting instructions.

II W400 K5 Models only

These models do not have a manual flow selector knob.

Flow can be regulated using the water throttle screw on the

bottom of the water control valve (see fig.8).

Because this model is usually always used for full flow

applications such as recirculation to storage, pressure

washers, boosters, etc., this water throttle screw somes from

the factory srewed in (clockwise) to maximum flow position

to give flows and temperature indicated above.

GAS CONTROL SLIDE

With the gas control slide at the right hand stop the heater

will fire at its full rated input when water is drawn at a rate

that will cause the gas valve to open fully. The gas control

slide will restrict the input down to approximately 50% of

full rated input when adjusted to the left hand stop.

HIGH TEMPERATURE LIMIT SWITCH

The BOSCH W series instantaneous gas water heaters

are equipped with a high temperature switch with a set point

of approx. 90° C ( 194° F). If the water temperature at the

point exceeds the set point the switch will open, interrupting

the safety circuit and stopping gas flow to the pilot and

main burner.

Outage as a result of high limit operation indicates that the

heater is not functioning properly. The heater should be

checked by a qualifed serviceman and reason for

malfunction corrected. To relight pilot follow instructions

provided on unit.

9

Page 10

PREVENTIVE MAINTENANCE

PILOT AND MIAN BURNER

Check pilot and main burners at least every 12 months for

proper flame characteristics.

The proper flame should envelop approximately 10 mm (3/8

inch) of tip of thermocouple.

Figure 11

If the pilot flame is too small, then the pilot burner must be

cleaned. The position of the igniter electrode should also

be checked to assure that electrode is approximately 3mm

(1/8”) from pilot, see figure 11.

The main burner should exhibit the following characteristics:

- Provide complete combustion of gas.

- Cause rapid ignition and carryover of flame across burners.

- Operate quickly during ignition, burning, and extinction.

If the main burners fail to exhibit above characteristics they

must be cleaned, either by blowing them off with compressed

air or by washing them in soap and water and rinsing.

If it proves necessary to wash the main burner assembly

the following procedure should be used:

1- Turn off the gas supply to the water heater.

2- Disconnect pilot gas tube at the gas valve and unscrew

the gas manifold assembly union nut, where the gas

manifold inlet pipe connects to the gas valve and remove

the gas assembly.

3- Wash in soap and water and then rinse.

4- Reassemble – Check for gas leaks after reassembly

and correct as required.

5- Refer to Lighting Procedure to relight the heater.

VENTING

The vent piping and finned heat exchanger should be checked

at least once a year for dust and carbon deposits, and

cleaned as necessary.

PRESSURE RELIEF VALVE

At least once a year the pressure relief valve should be

checked to insure that if it is in operating condition. Before

testing the relief valve take necessary precautions to prevent

water damage. Lift the lever on the valve several times until

the valve seats properly and operates freely. Do not check

the relief valve when hot water is being drawn and the main

burner is on. Water exiting the valve under these conditions

would be hot.

Figure 12

If the pressure relief valve on the appliance discharges this

is an indication of water pressure above the pressure rating

of the relief valve. If the pressure relief valve continually

discharges on a periodic basis contact the water supplier or

local plumbing inspector on how to correct the situation. Do

not plug the pressure relief valve.

PERIODIC REMOVAL OF LIME DEPOSITS

After 12 to 24 months of service, depending on frequency

of use and water harness, the heater should be checked for

accumulation of calcium carbonate (lime) and delimed, if

necessary. Thereafter a regular schedule, based on initial

inspection findings, should be set up to delime the heater.

10

Page 11

BOSCH INSTANTANEOUS WATER HEATERS APPROVED

FOR SPACE HEATING UNDE R CL ASS IV

When using the Bosch Models W 400-K for water heating and space heating the following requirements

shall apply :

All space heating equipment, piping and components connected to the heater shall be suitable for use

with potable water.

Toxic chemicals such as boiler treatment compounds, antifreeze etc, shall not be introduced into potable

water used for space heating.

When used for potable water this unit may not be connected to any heating system or components

previously used solely for space heating.

A temperature mixing valve must be installed where space heating temperature requirements are higher

than normal domestic supply temperatures to reduce scald hazard potential. Particular care must be

taken to select the correct type of thermal mixing valve to satisfy the installed application requirements,

i.e. If full anti-scald protection is specified then only that type of valve must be selected that is supported

by the manufacturer’s claim. Below is a typical schematic which should be used as a guide only.

Always obey the installation instructions supplied by the mixing valve supplier.

Temperature Mixing

Valve Regulator

Feed to Space

Heating Equipment

Supply to

Bosch Heaters

Return from Bosch

Heaters and

Space Heating

130°F Hot

Water Service

check

valve

Cold Water Supply to

tempering regulator

HOT WATER

STORAGE

TAN K

Note: These schematics and explanatory text should not be

used for design purposes, but only as a general guide. Actual

system design and installation must be by qualified people.

SEPARATE PUMPS REQUIRED

FOR HEATER AND CIRCULATION SYSTEM

Installations must conform to CSA B214 hydronic standard

and local code requirements.

11

Page 12

12

Page 13

Nº Description

g

g

g pip

pip

p

p

g

g

p

pply pip

g

g

p

g

g

g

g

W325 K..P..T1 W 400 K…P…T2

1Front shell 8705401525

2 Cover

4Drau

5 Heat exchan

6 Connectin

7Cold water

8 Washer 1/2"

9Tem

10 Main burner LPG 8708120469 8708120296

10 Main burner NG 8708120471 8708120298

11 Pilot burner ( 75 )

11a Filter

12 S

13 Pilot injector ( 5 ) NG

13 Pilot orifice (49) LPG

14 Pilot

15 Thermocou

16 Washer 1"

17 Throttle disc ( 7.0 ) LPG 8700100174

18 Gas valve NG 8707001890 8707011110

18 Gas valve LPG 8707001897 8707001942

19 Gas su

20 Ma

21 Washer

22 Gas filter

23 Termo connection

24 Water valve 8707002393 8707002478

25 Sealin

26 Dia

27 Slow-i

28 Settin

29 O-rin

30 Valve

31 Venturi (12) 8708205235

31 Venturi (16) 8708205248

32 Water strainer

33 water elbow fitin

ht diverter 8705505307 8705505354

er 8705406132 8705406235

e hot

e

erature limit

arking plu

as pipe

le

e

netic unit

screw 8703406204 8703406214

hragm 8700503050 8700503043

nition valve 8708503062 8708503060

screw 8703404092 8703404098

Part Number for Models

8703304011

8700705431

8700705294

8710103045

8707206017

8708105337

8700507055

8708107002

8708200005

8748200173

8710707166

8747202083

8710103060

8700705464

8747201094

8700103144

8700507051

8747202078

8700205050

8708500230

8700507059

8700705472

13

Page 14

ASTRAVAN DISTRIBUTORS, LTD.

123 Charles Street

North Vancouver, BC. V7H 1S1

Phone (Canada): (604) 929-5488

Phone (USA): (206) 860-8448

Site Internet: www.astravan.com

Page 15

Chauffe-eau à gaz instantané

Modèles

W 325 K…T1

W 400 K…T2

· Installation

· Fonctionnement

· Entretien

Le chauffe-eau instantané BOSCH est la réponse pour

haute éfficacité dans un espace restreint en satisfaisant

tout vos besoin d’eau chaude. Tous les chauffes- eaux

instantanés Bosch chauffent seulement la quantité d’eau

sur demande sans dépenser de l’énergie pour maintenir la

température élevé de l’eau dans le réservoir.

POUR VOTRE SECURITE

Si vous sentez un gaz odorant:

1. Ouvrir les fenêtres

2. Ne toucher pas à aucun contact électrique

3. Eteindre toute flamme

3. Appeler immédiatement votre fournisseur de gaz

ASTRAVAN DISTRIBUTORS, LTD.

6 720 601 783 CA (03.11) AL

123 Charles Street

North Vancouver, B.C. V7H 1S1

Téléphone (Canada): (604) 929-5488

Téléphone (USA): (206) 860-8448

Site Internet : www.astravan.com

A noter : En cas de problème contacter votre vendeur ou l’ouvrier d’installation.

Ne pas placer ou utiliser de la gasoline ou tout autres

liquide et vapeur inflammable a proximité de ce brûleur

ou d’ autres appareils.

POUR VOTRE SECURITE

Page 16

Dimensions

Figure 1

Pression maximum hydrostatique de l’eau - 0.97 MPa ( 150 lb / po ca.)

Pression maximum d’opération recommander - 0.69 MPa (100 lb / po ca)

Pression minimum d’opération - 0.05 MPa (7.3 lb/po ca) au taux de débit minimum.

Dimension en milimètre (pouces)

Modèle A B C D E F G H

W325

W400

Modèle Type de gaz Altitude Consommation

W325

W325

W400

W400

400 755 250 155 85 130 410 320

17 1/4" 29 3/4" 9 3/4" 6" 3 1/4" 5" 16 1/8" 12 5/8"

440 770 250 155 85 130 410 320

17 1/4" 30 1/4" 9 3/4" 6" 3 1/4" 5" 16 1/8" 12 5/8"

Orifices du brûleur principal

Dimension, mm Qte

Naturel

Propane 0.79 diam. 14

Naturel

Propane 0.79 diam. 14

Naturel

Propane 0.82 diam. 16

Naturel

Propane 0.82 diam. 16

normale 29.30kW (100,000Btu/hr) 1.25 diam. 14

(0 - 2,000 Pieds) 27.83 kW (95,000Btu/hr)

haute** 26.37kW (90,000Btu/hr) 1.25 diam. 14

(2,000 - 4,500 Pieds) 25.05 kW (85,000Btu/hr)

normale 34.28 kW 1.25 diam. 16

(0 - 2,000 Pieds) (117,000Btu/hr)

haute** 30.85 kW 1.25 diam. 16

(2,000 - 4,500 Pieds) ( 105,000Btu/hr)

* La console de mur est requis seulement pour le WR 325 K…quand il est installé dans une construction combustible.

Le WR 400K…T2 peut être installé directement à une construction combustible.

** Les évaluations de haute altitude dans cette liste sont les évaluations de l’évaluations de l’Association Canadien de gaz pour haute

altitude et sont utilisable seulement au Canada. Au Etats- Unis, le National Fuel Gaz Code, ANSI Z223.1-1984 recommandé pour

une installation de plus de 2,000 pieds au- dessus du niveau de la mer, que la consommation soit réduite de 4% pour chaque 1,000

pieds au- dessus du niveau de la mer. Voir page 8.

2

Page 17

AVERTISSEMENT AU LECTEUR

Les caractéristiques des chauffe- eau à gaz instantanés de

modèles W325 K et W400 K sont conformes au normes

CAN 1-4.3 et ANSI Z21-10 (dernière édition). De plus, les

modèles W325 K et W400 K répondent aux normes CAN

1-2.17 pour les applications à haute altitude, soit de 2000

à 4500 pieds au- dessus du niveau de la mer.

Le présent manuel contient les instructions d’installation de

fonctionnement et d’entretien de l’appareil. Avant de

procéder à l’installation du chauffe- eau à gaz instantané

BOSCH, il est recommandé de lire attentivement les

instructions se rapportant à l’installation et au fonctionnement

de l’appareil.

INSTRUCTION D’I NSTALLATION

A noter: Avoir la bonne plomberie, ventilation, connections

de gaz et une bonne provision d’air de combustion sont

requis pour une opération efficace et sans risque. En plus il

est très important que l’installateur soit bien qualifié dans le

métier d’installation et d’entretien de chauffe-eau à gaz.

EMPLACEMENT

Avant l’installation du chauffe- eau à gaz instantané BOSCH,

il faut prendre en considération l’endroit pour l’emplacement.

L’emplacement doit être proche d’une cheminée ou un évent

à gaz si possible et que l’endroit offre une bonne provision

d’air et centré avec le système de tuyautage. Le chauffeeau W325K ne peut pas être installé dans un endroit qui

ne sera pas endommagé en cas de fuite du chauffe- eau ou

d’un de ces raccords.

A noter : Quand tels endroits sont pas évitable on

recommande qu’un bassin d’égouttoir soit installé sous le

chauffe- eau avec un drainage adéquat. Le bassin d’égouttoir

ne doit pas empêcher la circulation d’air de combustion.

Le chauffe- eau à gaz instantané BOSCH est conçu de

sorte à pouvoir être adapté au propane ou au gaz naturel.

On doit toutefois S’ASSURER que le combustible utilisé

pour alimenter le chauffe- eau est celui qui est spécifié sur

la plaque signalétique du chauffe- eau.

En plus des instructions d’installation prévues ci- haut, les

chauffe- eau doivent être installés conformément au code

d’installation CAN/CGA- B149 (au Canada) ou à la dernière

édition du National Fuel Gas Code Z223.1 (aux États- Unis),

et/ou tout autre code d’installation local. Ces normes doivent

être respectées dans tous les cas.

REQUISITION D’AIR

Pour une opération en sûreté, il faut avoir une quantité

suffisante d’air de combustion, ventilation et une dilution

des émanations. Si la quantité d’air est insuffisante, la flamme

du brûler sera de couleur jaunâtre et produira du sédiment

de carbonne ou de la suie à l’echangeur de chaleur. Dans

les espaces libres, dans les bâtiments de construction normal,

en général il y a assez d’infiltration pour la provision d’air de

combustion, ventilation et dilution des émanations.

Toutefois, dans un espace restreint, il faut faire deux

ouvertures permanentes pour la provision d’air de

combustion et ventilation pour l’appareil. Chaque ouverture

doit avoir une superficie libre d’un pouce carré par 1000

BTU/Heure * du grand total de consommation de tous les

appareils dans l’espace restreint. Une ouverture sera à 12

pouces au dessus du sol et une autre á autre à 12 pouces

en-dessous du plafond.

3

Page 18

Soit un espace ou restreint dans un bâtiment de

construction étroite avec une infiltration insuffisante, l’air

doit être tiré de l’extérieure ou d’espaces qui communique

avec le plein air. Les deux ouvertures mentionnées ci-dessus

doivent être pourvu comme suit :

. Quand la communication est directement avec le plein

air ou par les évents verticaux, chaque ouverture doit

avoir une superficie libre pas moins qu’un pouce carré

par 4000 BTU/heure du grand total de consommation

de tous les appareils dans l’espace.

. Quand la communication est avec le plein air par les

évents horizontaux, chaque ouverture doit avoir une

superficie libre pas moins qu’un pouce carré par 2000

BTU/heure du grand total de consommation de tous les

appareils dans l’espace.

Pour les exigences détaillées voir :

- Au Canada, CAN 1-B 149 Installation Codes (codes

d’installation)

- Dans les Etats- Unis, ANSI Z 223.1-1984 National Fuel

GAS Code.

AVERTISSEMENT

Matériaux combustibles, l’essence, récipient sous pression

ou n’importe quelles articles qui sont facilement combustibles

ne doivent pas jamais être placés sur ou près d’un appareil

de chauffage. L’endroit ou l’appareil est situé ne doit pas

contenir aucun matériaux combustibles , de l’essence, ou

d’autre vapeurs et liquides combustibles.

Ne pas obstruer la circulation de l’air combustible et

ventilation pour le appareil.

MONTAGE

Le W 325K et le W 400 K sont de conceptions certifiés

pour l’installation sur un mur. La console de mur, voir figure

1, est fourni avec le W 325K et doit être utilisé pour le

montage d’un appareil de chauffage sur un mur combustible.

Les appareils de chauffage ne peuvent pas être installer

directement sur un mur couvert de tapis. L’appareil de

chauffage ou la console de mur doit être monté sur le mur

avec une plaque d’encrage.

AVERTISSEMENT

L’omission de la console de mur avec le W 325 K pour le

montage sur un mur combustible peut rendre les conditions

dangereuse avec le possibilité d’incendie. En plus, l’omission

de la console de mur pour le montage de W 325K.. sur une

construction combustible sera une infraction contre la

certification de l’appareil par l’ A.G.A et C.G.A..

Note : Si le mur est construit avec des montants couvert de

panneaux en enduit, on recommande que les planches de

support soit 1x4’s, ou ½’’(minimum) contre-plaqué support

attacher aux montants pour le montage de l’appareil de

chauffage dans le cas de W 325 K.. doit être attaché aux

planches de support. Voir figure 2.

L’expansion et contraction de la tuyauterie, du au

changement de température de l’eau dans les tuyaux,

transmet le mouvement à l’appareil de chauffage, lequel, si

il est monté à un endroit pas solide comme les panneaux en

enduit, la monture peut être fragile et tomber.

DEGAGEMENT

Le W 325 et le W 400 sont de conceptions certifié pour

l’installation sur un mur de construction combustible (pour

le W 325, la console de mur fourni avec l’appareil doit être

utilisé pour le montage sur une construction combustible)

et pour l’installation dans une alcôve ou un placard avec un

espace libre minimum à la construction combustible de 0mm

de l’arrière, 102mm (4 pouces) des côtées, 305mm (12

pouces) du haut et du bas et 102mm (4 pouces) du devant.

Un minimum de 305mm (12 pouces) doit être établi comme

espace pour l’entretien et service aux pièces de rechange.

Le dégagement pour l’éventail est selon le classement de

dégagement pour le matériel de l’éventail utiliser, c’est á

dire le type B-1 éventail est approuvez pour un espace de 1

pouce, le B-2 éventail pour 2 pouces, etc…

Figure 2

4

Page 19

L’EGOUTTOIR

Si l’appareil de chauffage est monté au-dessus du sol de la

construction combustible, l’égouttoir (fourni avec l’appareil,

détachée) doit être assemblé au bas du couvercle devant

l’appareil pendant l’installation.

L’égouttoir doit être attaché au couvercle du devant avec

les écroues fournient comme montré à la figure 3.

L’omission de l’usage de l’égouttoir quand l’appareil est

installé au-dessus du sol de construction combustibles peut

rendre les conditions dangereuse avec la possibilité

d’incendie et une infraction contre la certification de

l’appareil de A.G.A. et C.G.A..

En haute altitude l’adaptateur doit être installé comme

montré à la figure 4, sans modification, avant le montage

du conduit de six pouces à l’appareil.

L’adaptateur doit être attacher sécurement au directeur du

tirage d’air avec un minimum de deux vises.

Aussi, au Canada le régulateur de pression du gaz fournie

avec le chauffe-eau est réglé à l’avance en usine pour livrer

la bonne pression de gaz au chauffe-eau pour un fonctionnement en haute altitude, voir la section REGULATION DE

PRESSION dans ce manuel.

AVERTISSEMENT

L’omission d’agrandir la grandeur du conduit sur le W400

de six pouces et/ou s’assurer que la pression du collecteur

est mise à la valeur indiquée sur l’étiquette d’évaluation

pour les applications à haute altitude de 2.000 à 4.500

pieds au dessus du niveau de la mer peut causer une

mauvaise ventilation, l’asphyxie et annuler la certification

de C.G.A..

LES RACCORDS D’EAU

Les séries W chauffes- eaux instantanés sont fournient avec

deux S- codes raccords/adaptateurs d’eau, lesquelles doivent être connectés aux connections d’entrée et de sortie

de l’eau sur le clapet d’eau, voir figure 1 et figure 5 cidessous.

Figure 3

VENTILATION

Les chauffes- eaux instantané Bosch sont construit avec

un directeur du tirage d’air et sont conçuent pour l’usage à

l’intérieure seulement. Le directeur du tirage d’air doit être

raccordé á un évent de la même grandeur ou plus grand,

propre de tout débris, référer à :

- Au Canada, CAN 1-B149 Installation Code pour les

exigences détaillées.

- Dans les Etats- Unis, ANSI Z 223.1- 1984 National Fuel

Gas Code pour les exigences détaillées.

5” X 6” adapteur est

utilisé pour haute

altitude Modèle W 400

seulement.

CLAPET D’EAU ET S.COUDES VUE DE HAUT

Figure 5

La raison pour les S-coude raccords/adaptateurs d’eau est

de procurer des connections d’eau filetés en accordance

avec les normes de l’Amérique du Nord, ANSI standard taper

Pipe Thread (1/2’’ NPT).

L’alimentation de l’eau froide doit être raccordé au S-coude

attaché á l’entrée du clapet d’eau et la connection á l’eau

chaude doit être raccordé au S-coude attaché à la sortie

du clapet d’eau.

Figure 4

A noter: Un robinet d’arrêt doit être placé dans le tuyau

d’alimentation d’eau froide du chauffe-eau pour y faciliter

l’entretien.

5

Page 20

SOUPAPE DE SURETE

La soupape de sûreté fourni doit être installé au moment de

l’installation du chauffe-eau. Aucun autre robinet doit être

installé entre la soupape de sûreté et le chauffe-eau. Un

tuyau d’écoulement doit être raccordé à la soupape de sûreté

pour le drainage soit dirigé en lieu sûr. N’installer pas aucune

réduction mâle- femelle ou autres restrictions dans le tuyau

d’écoulement. Le tuyau d’écoulement doit être installé de

façon à faciliter un drainage complet pour la soupape de

sûreté et la tuyauterie. Voir figure 6.

Figure 6

RACCORDS DE GAZ

Avant de raccorder l’alimentation de gaz au chauffe- eau,

vérifier l’étiquette de modèle/évaluation du chauffe- eau

pour s’assurer que le gaz d’alimentation est le même

qu’indiquer sur l’étiquette de modèle/évaluation.

Le W 400K et le W 325K chauffe-eau au gaz instantané

sont munient d’un régulateur de pression à gaz qui doit être

installé au chauffe-eau avant le raccordement du tuyau

d’alimentation du gaz, voir figure 7. L’omission d’installer le

régulateur dans l’ordre montré à la figure 7 sera une infraction

contre la certification de l’appareil de l’ A.G.A. et C.G.A..

Vérifier pour être certain que le gaz indiqué sur la plaque

d’évaluation est le même que le gaz indiqué sur le régulateur

de pression. VOIR REGLEMENT DE PRESSION dans ce

manuel pour l’information concernant le réglage de pression

à gaz.

A noter: Avant de raccorder le tuyau d’alimentation de gaz

vérifier que l’intérieure du tuyau est propre. Pour se

débarrasser de la saleté et de toutes corps étrangers dans

le tuyau d’alimentation de gaz, un mamelon purgeur doit

être installé dans la tuyauterie. Le mamelon purgeur doit

être accessible et sans danger de gel. L ‘installation doit

être en accordante avec les recommandations du fournisseur

de gaz.

Le composé de l’encolleuse (le composé du filetage) doit

être appliqué avec modération et seulement au filetage mâle.

N’appliquer pas le composé au deux premier filets. Le

composé du filetage doit résister au gaz liquéfié.

Avant de mettre le chauffe-eau en opération vérifiez pour

toute fuite de gaz. Une solution d’eau et savon ou autre

matériel acceptable pour ce travail être utilisé pour localiser

les fuites de gaz. Des allumettes, bougies, allume-cigarette

ou d’autre source d’allumage sont défendent pour ce travail.

AVERTISSEMENT

Le chauffe-eau et ces robinets de fermeture doivent être

détachés du système de tuyauterie d’alimentation de gaz

pendant la vérification de ce système au- dessus de 3.45

kPa (1/2 Lb/po.ca.)

Le chauffe-eau doit être isolé du système de tuyauterie

d’alimentation de gaz par son robinet de fermeture pendant

la vérification de pression du système à une pression égal

ou moins que 3.45 kPa (1/2 Lb/po.ca.)

Les chauffes-eaux BOSCH sont expédier de l’usine avec

le régulateur de pression à gaz déjà ajusté tel qu’indiqué

sur la plaque d’évaluation :

- Au Canada, pour le fonctionnement à haute altitude.

- Au Etats- Unis, pour le fonctionnement à altitude

normale, sauf si indiqué comme un appareil de haute

altitude.

ROBINET DE PRESSION

REGULATEUR DE

PRESSION

Figure 7

Le chauffe-eau, y compris le régulateur de pression et le

robinet manuel fourni, ne doivent pas fonctionner à une

pression de gaz au-dessus de 3.45 kPa (1/2 Lb/po.ca.).

Si il y a une surpression qui se développe soit par une

mauvaise vérification de la pression de gaz ou un mauvais

fonctionnement du système d’alimentation d’urgence, le

robinet de gaz et le régulateur doivent vérifier pour un

fonctionnement en toute sécurité. Etre certain que les clapets

d’échappement à l’extérieure sont protégés contre toute

obstruction. Ils font partie du système d’alimentation de gaz

et non du chauffe-eau. L’obstruction du clapet

d’échappement peut se produire pendant les tempêtes de

neige.

6

Page 21

INSTRUCTION DE FONCTIONNEMENT

AVERTISSEMENT

Si le chauffe-eau était endommager ou exposer au feu ou à

la suie, ou que l’une de ces pièces était sous l’eau, ne pas

utiliser. Appeler immédiatement un technicien de service

qualifié pour vérifier l’appareil et pour remplacer les pièces

du système de contrôle et les pièces de contrôle à gaz qui

étaient sous l’eau et pour nettoyer l’échangeur de chaleur

et le robinet d’eau.

REMPLISSAGE

Avant de procéder au fonctionnement du chauffe-eau, il

faut s’assurer que le système est rempli d’eau.

Être certain que le bouchon de vidange est fermé, voir figure

8, ci-dessous.

- Ouvrer le robinet d’eau chaude pour permette de remplir

le chauffe-eau et la tuyauterie.

- Fermer le robinet d’eau chaude après que l’eau s’écoule

librement et que l’air est sortie du système.

- Le chauffe-eau est maintenant prêt à allumer.

LES INSTRUCTIONS D’ALLUMAGE

1. Le robinet de gaz manuel principal doit être fermé et le

boutton “OFF” du robinet de gaz abaissé et ensuite

attendre cinq minutes avant de poursuivre.

2. Ouvrir le robinet de gaz manuel et complètement

abaisser le bouton du pilot et celui de la veilleuse en

poussant le bouton d’ignition du témoin.

3. Observer la fiamme témoin à travers du trou. Le bouton

du témoin doit être retenu pour une période d’au moins

10 secondes avec le témoin allumé. Quand vous

relâchez le bouton du témoin, le témoins devrais

continuer à brûlé.

4. Abaisser complètement le bouton ON et relâcher. Le

chauffe-eau devra s’allumer quand l’eau sera tiré a un

taux plus grand que le seuil du taux de débit. (voir

manuel).

NOTE : Si le brûleur principal ne veut pas s’allumer, s’assurer

que le témoin brûle toujours. Sinon répéter les étapes de 1

à 4.

Comment fermer le chauffe-eau: Abaisser le bouton OFF

et fermer le robinet manuel principal de gaz.

* Voir la section du sélecteur de débit d’eau

Figure 8

GUIDE D’ENTRETIEN

L’épurateur dans le robinet d’eau, localisé à l’entrée du

robinet, à besoin d’être nettoyer de temps à autre à cause

de la saleté et corps étrangers qui se loge dans l’alimentation

d’eau. Ceci va ralentir le débit d’eau, déranger le

fonctionnement du chauffe-eau et prolonger le temps du

remplissage. Pour vérifier l’épurateur, fermer le robinet

d’alimentation d’eau froide au devant du chauffe- eau,

détacher le S- coude à l’entrée du robinet d’eau et enlever

l’épurateur de l’entrée. Nettoyer si nécessaire, replacer

l’épurateur à l’entrée du robinet d’eau, raccorder le S- coude

et ouvrer le tuyau d’alimentation d’eau.

Allumer le chauffe-eau en accordance avec les instructions

sur la plaque d’allumage et fonctionnement attacher au

chauffe-eau. Pour votre commodité les instructions sont

répétées ci-dessous.

POUR FERMER LE GAZ QUI ALIMENTE L’APPAREIL

Tourner le bouton du robinet de gaz vers Ia gauche endessous de la position OFF et fermer le robinet du chauffeeau

* voir la section REGULATION DE TEMPERATURE

7

Page 22

REGULATION DE PRESSION

Le régulateur fourni avec le chauffe-eau est réglé pour le

fonctionnement au gaz spécifier sur la plaque d’évaluation,

et :

- Au Canada, il est déjà ajusté pour livré le gaz à haute

altitude comme montré sur la plaque d’évaluation cidessous.

- Dans les États- Unis, il est déjà ajusté pour livré le gaz

à une altitude normale comme montré sur la plaque

d’évaluation normale comme montré sur la plaque

d’évaluation ci-dessous.

ROBINET DE PRESSION

REGULATEUR DE PRESSION

VANNE DE GAZ MANUELLE

L’ajustement de pression du régulateur de gaz doit être vérifié

à l’installation pour être sure que le réglage est exact pour

le gaz utilisé et l’altitude au quel l’appareil est installé. Voir

la plaque d’évaluation sur l’appareil ou le diagramme audessous pour le bon réglage.

Au Canada, pour un chauffe-eau installé à altitude normale

(0-2000 pieds d’élévation) la pression du collecteur doit

être réglé à l’installation à partir des valeurs de la plaque

d’évaluation ou comme montré sur le diagramme au-dessous

pour l’altitude normale. Les pressions de gaz spécifiées se

réfèrent au taux de pression pris au robinet de pression dans

le tuyau d’entrée du gaz (au-dessus du régulateur de

pression), voir figure 9, quand le chauffe-eau fonctionne à

pleine puissance.

REGLAGE DE PRESSION DU COLLECTEUR

MODEL Type de Gaz

W325

W325

W400

W400

naturel 1.36 5.5 normal

propane 2.61 10.5 (0-2,000 pieds)

naturel 1.09 4.4 haut *

propane 2.11 8.5 (2,000 - 4,500 pieds)

naturel 1.41 5.7 normal

propane 2.61 10.5 (0-2,000 pieds)

naturel 1.14 4.6 haut *

propane 2.09 8.4 (2,000 - 4,500 pieds)

Pression du Collecteur

kPa Pouces, W.C.

Altitude

Figure 9

Avis: La robinet de gaz manuel principal doit être toumé à

la position OFF, comme démontré à la figure 9, enlever le

bouchon dans le raccord du robinet de pression avant de

connecter la jauge de pression.

REGULATION DE TEMPERATURE

Pour l’usage domestique le selecteur du débit d’eau doit

être tourné le sens des aiguilles d’une montre à la position

STOP et glisser la coulisse de control de gaz vers la droite

à la position STOP et doivent demeurer à leurs position.

* A noter: Les évaluations de haute altitude dans cette liste sont les

évaluations de l’Association de gaz Canadien pour haute altitude et sont

valides seulement au Canada. Au Etats-Unis, le National Fuel Gas Code.

ANSI Z223.1 - 1984 recommande pour l’installation au-dessus de 2,000

pieds que le taux de la consommatiom soit réduit par 4% pour chaque

1,000 pieds au-dessus du niveau de la mer.

8

COULISSE DE CONTROL DE GAZ

SELECTEUR DE DEBIT D’EAU

Page 23

SELECTEUR DE DEBIT D’EAU

Avec le sélecteur de débit d’eau tourné le sens des aiguilles

d’une montre à la position STOP, le robinet d’eau du chauffèeau controllera le taux de débit à travers du chauffe-eau et

permettras un taux de débit maximum de:

- L/min. (1.5 US. gal/min.), pour W325

- L/min. (1.8 US. gal/min.), paur W400

Ce réglage permet à une personne d’un endroit éloigné de

controller la température de l’eau en mélangeant plus ou

moins d’eau froide avec l’eau chaude fournis par le chauffeeau.

Le sélecteur de débit d’eau contrôle la sortie d’eau chaude

en ajustant le taux de débit d’eau à travers le chauffe-eau.

COULISSE DE CONTROLE DU GAZ

Avec la coulisse de contrôle du gaz à la position STOP du

côté droit le chauffe-eau fonctionneras à pleine puissance

quand l’eau est tiré à une taux qui permetteras au robinet

de s’ouvrir. La coulisse de contrôle du gaz peut restreindre

la consommation à 50% approximativement du taux de

pleine puissance quand vous placez la coulisse à la position

STOP du côté gauche.

LIMITEUR DE HAUTE TEMPERATURE

Le BOSCH W séries chauffes-eaux au gaz instantanées

sont équipé avec un limiteur de haute température avec

une mise au point d’a peu près 90°C (195°F). Si la

température d’eau au point de sensibilite est à l’excès de

mise au point, le limiteur ouvreras le gaz de sûreté et arrêtera

le débit du gaz à petite flamme et au brûleur principale.

En-dessous vous trouverez les maximum et les minimum de

débit d’eau qui peuvent être sélectionné en ajustant le

sélecteur de débit d’eau. Aussi, vous trouverez les élévations

de température qui peuvent être obtenues aux taux de débit

indiqué quand le chauffe-eau fonctionne à pleine puissance.

REGLAGE A VARIATIONS DU DEBIT D’EAU

Modèle

W325

W400

Taux de débit maximum

contraire des aiguilles d'une

montre pour fermer)

13 L/min. (3.4 US. gal/min.)

élévation de temp 25°C (45°F)

15 L/min. (4.0 US. gal/min.)

élévation de temp 25°C (45°F)

Note:

1 S i le taux de débit d’eau qui passe à travers du chauffe-eau est

moins que le taux de débit minimum que celui mentionné à la

liste au-dessus le brûleur principale se fermeras.

2. Le taux de débit minimum est aussi décrit comme le taux de

débit du seuil pour le fonctionnement de la robinet à gaz.

(sens

Taux de débit minimum

des aiguilles d'une montre pour

fermer)

5.8L/min. (1.5 US. gal/min)

élévation de temp 55°C (100°F)

6.8L/min. (1.8 US. gal/min)

élévation de temp 55°C (100°F)

(sens

L’interruption de service attribuable à l’opération de haute

température limitée montre que le chauffe-eau fonctionne

mal. Le chauffe-eau doit être vérifié par un technicien de

service qualifié et le défaut corriger. Pour rallumer la petite

flamme suivez les instructions fourni sur l’appareil.

9

Page 24

L’ENTRETIEN PREVENTIF

TEMOIN ET BRULEUR PRINCIPAL

Vérifier le témoin et les brûleurs principaux au moins à chaque 12 mois pour le bon fonctionnement de la flamme.

Le témoin doit couvrir environ 10mm (3/8 pouce) sur le

bout du thermocouple.

Figure 11

Si le flamme témoin est très petite, le brûler principal doit

être nettoyé. La position de l’électrode de l’ignition doit être

vérifié aussi pour être certain que l’électrode est environ

3mm (1/8’’) de l’orifice de la flamme témoin, voir figure 11.

Le brûleur principale doit avoir les caractéristiques

suivantes :

- Provision complète de combustion de gaz.

- Fournir un allumage rapide et faire que la flamme soit

bien répartis sur le brûleur

- Rapide fonctionnement pendant l’allumage, brûlage et

l’extinction.

- Les flammes du brûleur doit être bleu et les flammes ne

doivent s’élever au-dessus des orifices du brûleur. Voir

figure 12.

S’y il faut laver le brûleur principale, suiveur les procédures

suivantes :

1. Fermer l’alimentation de gaz au chauffe-eau.

2. Détacher le tube à gaz du témoin près de la vanne de

gaz et dévisser l’écrou de coulage du collecteur qui est

connecté au robinet de gaz et détacher l’ensemble du

brûleur principal à gaz.

3. Laver dans l’eau savonneuse et rincer.

4. Faire le remontage. Vérifier pour fuite de gaz après le

remontage et faire les ajustements si nécessaire.

5. Référer aux procedures d’allumages pour allumer le

chauffe-eau.

SYSTEM D’AERATION

L’évent et l’échangeur de chaleur avec ailette doivent être

vérifié au moins une fois par année pour sédiment de

poussière de carbone et nettoyer si nécessaire.

SOUPAPE DE SURETE A PRESSION

Au moins une fois par année, le soupape de sûreté de

pression doit être vérifié pour assurer qu’elle est en bonne

condition de fonctionnement. Avant la vérification de la

soupape de sûreté, il faut prendre les précautions nécessaire

pour risque de dommage d’eau.

Levez le levier sur la soupape plusieurs fois jusqu’à la

soupape s’assoit proprement et fonctionne librement. Ne

pas vérifier la soupape pendant l’opération quand l’eau

chaude est tiré et que le brûleur principal est allumé. L’eau

de sortie de la soupape dans des conditions pareilles peut

être chaude.

Si la soupape de sûreté de pression attaché á l’appareil,

coule, ceci est une indication que la pression d’eau est audessus de l’évaluation de pression de la soupape de sûreté.

Si l’écoulement de la soupape de sûreté continue

périodiquement, appelez votre fournisseur d’eau ou

l’inspecteur de plomberie local pour corriger la situation. Ne

boucher pas la soupape de sûreté à pression.

Figure 12

Si les brûleurs principaux ne montrent pas les

caractéristiques ci-dessus, ils doivent être nettoyés soit par

air comprimé sur les orifices ou laver avec de l’eau et du

savon et rincer.

10

L’ENLEVEMENT PERIODIQUE DE SEDIMENT DE CHAUX

Après 12 à 24 mois de service, dépendant de l’usage et la

dureté de l’eau, le chauffe-eau doit être vérifié pour

l’accumulation de carbonate de calcium (chaux) et enlever

la chaux si nécessaire. Par la suite un programme régulier

basé sur la vérification initiale, doit être monté enlever la

chaux sur le chauffe-eau.

Page 25

CHAUFFE-EAU INSTANTANÉS BOSCH

HOMOLOGUÉS POUR LE CHAUFFAGE (CLASSE IV)

Lors de l’emploi d’un chauffe-eau Bosch W 400-K pour le chauffage de l’eau et le chauffage de l’espace,

les exigences suivantes sont applicables:

Tous les équipements de chauffage, tuyauteries et composants connectés à l’appareil de chauffage

doivent convenir pour l’utilisation avec de l’eau potable.

Il n’est pas permis d’introduire des compsés chimiques toxiques ( par exemple composés de traitement

de chaudière, antigel, etc.) dans l’eau potable utilisée pour le chauffage de l’espace.

Lors de l’utilisation pour le chauffage d’eau potable, cet appareil ne doit pas être connecté à un système

de chauffage ou équipement de chauffage utilisé antérieurement uniquement pour le chauffage de l’espace.

Lorsque la température utilisée pour le chauffage est plus élevée que la température normalement utilisée

pour de l’eau à usage domestique, on doit installer une vanne de mixage pour réduire les risques de

brûlure. On doit veiller particulièrement à choisir la vanne de mixage thermique de type correct pour

satisfaire le besoin de l’application spécifique; par exemple si une protection totale contre les brûlures

est spécifiée, on doit utiliser uniquement un accessoire offrant ce niveau de performance conformément

aux déclarations du fabricant. On présent cidessous - uniquement à titre de guide - un schéma typique

d’installation.

Il faudra toujours observer scrupuleusement les instructions fournies par le fournisseur de la vanne de

mixage.

Vanne de régulation/

mixage thermique

Alimentation des

équipements

de chauffage de l’espace

Alimentation

des chauffe-eau

Retour des chauffe-eau

Bosch et appareils de

chauffage

Distribution d’eau

chaude 130º F

Clapet

unidirectionnel

Arrivée d’eau froide

pour réduction de

la température

Reservoir de

stockage

d’eau chaude

NOTE: Ne pas utiliser le schéma présenté ici et le texte

d’explication comme spécifications de conception, mais

uniquement comme information générale. Seul un personnel

qualifié est habilité à concevoir un système et à le rèaliser.

DES POMPES DISTINCTES SONT NÉCESSAIRES POUR

LE CHAUFFAGE ET POUR LE SYSTÈME DE

CIRCULATION.

L’installation doit satisfaire les critères de la norme CSA

B214 (systèmes de chauffage à eau chaude) et des

règlements locaux en vigueur

11

Page 26

12

Page 27

Nº Description

u

f

1 Habillage 8705401525

2 Couvercle

4 Anti-refouleur 8705505307 8705505354

5 Corps de chauffe 8705406132 8705406235

6 Tuyauterie chaud

7 Tube arrivée eau

8Joint 1/2"

9 Limiteur de température

10 Brûleur PROP 8708120469 8708120296

10 Brûleur GN 8708120471 8708120298

11 Veilleuse ( 75 )

11a Filtre

12 Eléctrode d'allumage

13 Injecteur de veilleuse ( 5 ) GN

13 Injecteur de veilleuse (49) PROP

14 Tube veilleuse

15 Thermoélément: Sécurité veille

16 Joint 1"

17 Diaphragme ( 7.0 ) PROP 8700100174

18 Bloc gaz GN 8707001890 8707011110

18 Bloc gaz PROP 8707001897 8707001942

19 Tuyau d´arrivée gaz

20 Téte magnétique

21 Joint

22 Filtre gaz

23 Thermocâbles

24 Valve eau 8707002393 8707002478

25 Couvercle d´étanchétité 8703406204 8703406214

26 Membrane 8700503050 8700503043

27 Vanne d´allumage progressi

28 Vis de réglage 8703404092 8703404098

29 Joint torique

30 Soupape

31 Venturi (12) 8708205235

31 Venturi (16) 8708205248

32 Filtre eau

Numéro de pièce pour les modèles

W325 K..P..T1 W 400 K…P…T2

8703304011

8700705431

8700705294

8710103045

8707206017

8708105337

8700507055

8708107002

8708200005

8748200173

8710707166

8747202083

8710103060

8700705464

8747201094

8700103144

8700507051

8747202078

8708503062 8708503060

8700205050

8708500230

8700507059

13

Page 28

ASTRAVAN DISTRIBUTORS, LTD.

123 Charles Street

North Vancouver, BC. V7H 1S1

Téléphone (Canada): (604) 929-5488

Téléphone (USA): (206) 860-8448

Site Internet: www.astravan.com

Loading...

Loading...