Page 1

Installation and Operating Instructions

Gas Instantaneous Water Heater

Safety instructions:

If you smell gas:

- Do not operate any electrical switches.

6 720 607 526 ZA (05.02) JS

- Do not telephone from inside the danger area.

- Turn off the gas cock.

- Open windows and ventilate room.

- From outside, call the gas company and your approved

installer.

Do not use or store easily combustible materials in the vicinity

of the appliance.

W11..P...

W14..P...

W18..P...

With piezo ignition and double safety

system consisting of flue gas monitor and

heat exchanger temperature sensor.

Installation and servicing of the appliance may only be

carried out by an approved technician.

The appliance should be regularly serviced in order to ensure

that it remains in perfect and safe working order.

If there is a risk of freezing, the appliance must be switched

off and drained. If the appliance has not been drained during

a cold spell, when it is switched on again check that it

produces hot water. If problems occur, contact your installer.

Page 2

page page

W 11 P

23

31

S…

W 14 P

23

31

S…

W 18 P

23

31

S…

1. Technical Characteristics and Dimensions ............... 2

1.1 General description ..........................................................2

1.2 Explanation of model code ..............................................2

1.3 Accessories ........................................................................ 2

1.4 Dimensions ......................................................................... 3

1.5 Appliance design ............................................................... 3

1.6 Technical characteristics ................................................. 4

2. Preconditions for installation ........................................... 5

2.1 Regulations .........................................................................5

2.2 Location .............................................................................. 5

2.3 Fixing the appliance.......................................................... 5

2.4 Water connection ............................................................. 5

Index

2.5 Gas connection ................................................................. 5

2.6 Flue....................................................................................... 5

2.7 Comissioning ...................................................................... 5

3. Operation and maintenance ............................................. 6

3.1 Function .............................................................................. 6

3.2 Water temperature control .............................................. 6

3.3 Appliance adjustments ..................................................... 6

3.4 Maintenance ...................................................................... 6

3.5 Flue gas safety device ..................................................... 6

3.6 Converting to a different gas type ................................6

3.7 Troubleshooting ................................................................. 7

4. Operation .................................................................................. 8

1. Technical Characteristics and Dimensions

1.1 General Description

This water heater is fitted with a piezo system.

Guaranteed safety provided by:

- Gas-tight ionisation detector that prevents escape of gas

if there is no flame.

- Flue gas safety device that switches off the appliance if

the flue is not functioning properly.

- Temperature limiter which protects the heat exchanger

against overheating.

Heat exchanger has no tin/lead lining.

Automatic water valve made of glass-fibre reinforced

polyamide, 100% recyclable.

Automatic control of water flow maintains constant flow rate

even with fluctuating supply pressure.

Gas valve with adjustable output via a slide control.

1.2 Explanation of Model Code

W Gas instantaneous water heater

11 Flow rate (l/min)

P Piezo ignition

23 Natural gas type H

31 LPG (butane/propane)

S... Country code

1.3 Accessories (Included with Appliance)

- Sleeves and hooks for wall-mounting

2 6 720 607 526

Page 3

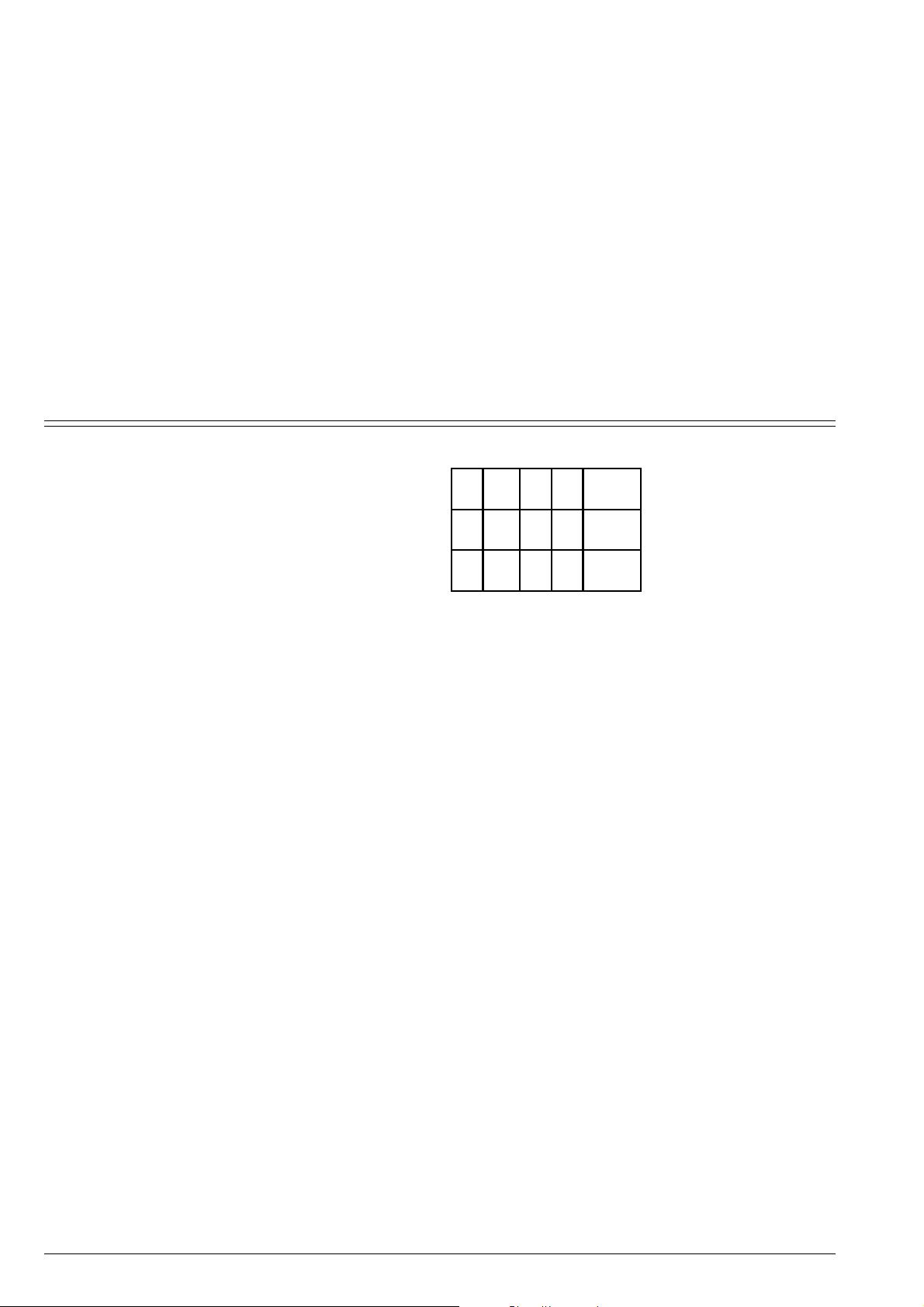

1.4 Dimensions

Dimensions

A B C D E F G H (Ø)

(mm) Natural Gas LPG

W11..P...

310 580 228 112,5 463 60 25

W14..P...

350 655 228 132,5 510 95 30

W18..P...

425 655 334 132,5 540 65 30

1/2"

1. Front cover

2. Hole for fixing to wall

3. Observation window

4. Temperature control

5. Output control

6. Gas connection

7. Exhaust pipe union

8. Draught diverter with flue gas

monitor

9. Heat exchanger

10. Automatic gas valve

11. Piezo

12. Water valve

1.5 Appliance design

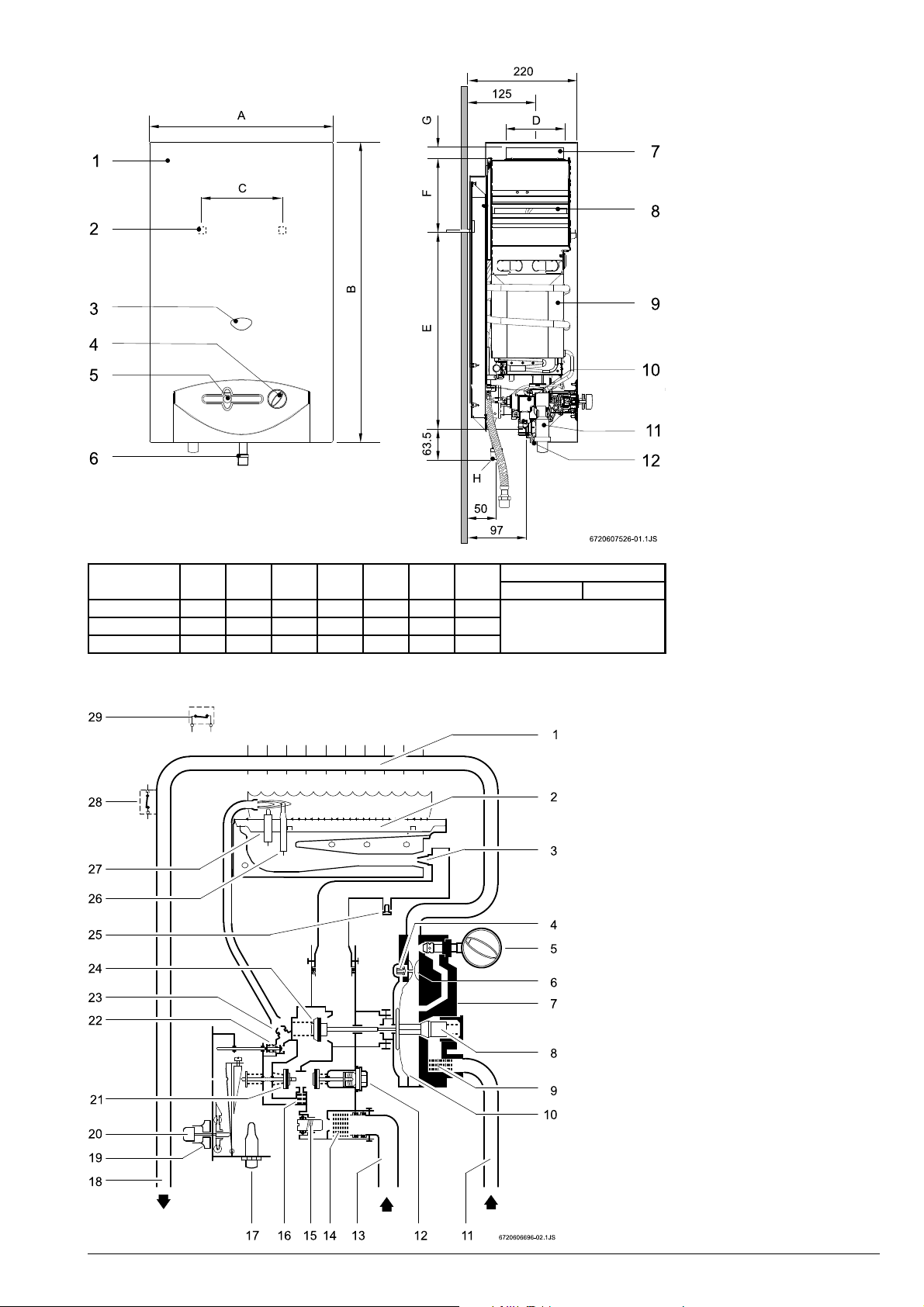

Fig. 2

1. Heat exchanger

2. Main burner

3. Injector

4. Slow ignition valve

5. Temperature control

6. Venturi

7. Water valve

8. Water throttle

9. Water filter

10. Membrane

11. Cold water pipe

12. Magnetic valve

13. Gas supply pipe

14. Gas filter

15. Regulating screw

16. Pilot filter

17. Piezo

18. Hot water pipe

19. Output control

20. Igniter button

21. Main gas valve

22. Gas valve for pilot burner

23. Pilot burner injector

24. Gas valve

25. Jet pressure testing point

26. Thermocouple

27. Igniter electrode

28. Temperature limiter

29. Flue gas safety device

Fig. 3

36 720 607 526

Page 4

1.6 Technical characteristics

Technical Data Symbol Unit W11 W14 W18

Rated max. heat output

P

n

Btu/h 65570 80595 104165

Rated min. heat output

P

min

Btu/h 31420 40300 52082

Output (modulation range) Btu/h 31420 - 65570 40300 - 80595 52082 - 104165

Rated max. heat input

Q

n

Btu/h 74450 92210 117825

Rated min. heat input

Q

min

Btu/h 36200 46105 58912

Supply pressure:

Natural gas mbar (kPa) 20 (2.0) 20 (2.0) 20 (2.0)

LPG (butane/propane) mbar (kPa) 28 (2.8) 28 (2.8) 28 (2.8)

Consumption:

Natural gas

m3/h

2.2 2.77 3.5

LPG (butane/propane) kg/h 1.75 2.2 2.79

Number of injectors 12 14 18

Max. water pressure**

p

w

psi 170 170 170

Temperature control at maximum setting

Temperature increase °C 50.0 50.0 50.0

Flow rate l/min 5.5 7 8.8

Min. operating pressure

p

wmin

psi 2.0 2.0 3.0

Temperature control at minimum setting

Temperature increase °C 25 25 25

Flow rate l/min 11 14 17.6

Draught requirement mbar 0.015 0.015 0.015

Flow rate g/s 13 17 22

Temperature °C 160 170 180

Output and heat

demand

Gas supply

specifications *

Water system specifications

Flue

specifications

***

* Hi 15°C - 1013 mbar - dry : Natural gas 34.2 MJ/m3 (9.5 kWh/m3)

LPG: Butane 45.7 MJ/kg (12.7 kWh/kg) Propane 46.4 MJ/kg (12.9 kWh/kg)

** This figure must not be exceeded taking account of water expansion

*** At maximum rated heat output

4 6 720 607 526

Page 5

2. Preconditions for installation

The appliance can only be sold in the countries mentioned

in the type plate.

2.1 Regulations

Any local by-laws and regulations pertaining to installation

and use of gas-heated appliances must be observed. Please

refer to the laws that should be attended in South Africa.

2.2 Location

The appliance should be sited in a well ventilated room where

it will not be exposed to temperatures below freezing.

To prevent corrosion, the combustion air must not contain

any corrosive substances. Substances classed as corrosionpromoting include halogenated hydrocarbons such as are

found in solvents, paints, adhesives, aerosol propellants and

various household cleaners. Appropriate measures should

be taken where necessary.

With the exception of the flue pipe, the surface temperature

of the appliance is below 85 °C. No special safety measures

are therefore necessary.

Site appliance as shown in Fig. 4.

Always site appliance in a location not exposed to

temperatures below freezing. If this is not possible, the

appliance must be switched off and drained whenever there

is a risk of freezing.

Danger: the appliances are designed to prevent flame reflow.

In case you suspect anything unusual in the appliance

operation, please shut down gas and water cocks, and call

an approved technician to check the local conditions.

To prevent flame reflow in outdoor installations please make

sure that a wind/rain protection is fitted.

To prevent flame reflow in indoor installations please make

sure that a wind/rain protection is fitted at the end of the

secondary flue.

Select pipe diameter to suit output of instantaneous water

heater being installed.

Fit gas service cock as close to appliance as possible.

Caution: This is a low pressure gas appliance. A SA certified

2.8 kPa low pressure regulator must be fitted.

2.6 Flue

It is absolutely essential that all instantaneous water heaters

are connected to a suitably dimensioned flue pipe by means

of a gas-tight connection.

The flue pipe should be made of galvanised iron, aluminium,

stainless steel or fibre concrete. Fit as shown in Fig. 4.

A flexible or rigid pipe should be used, fit it inside the flue

socket. The external diameter of the pipe should be slightly

smaller than the dimension specified in the appliances

dimensions table.

wind/rain

protection

2.3 Fixing the appliance

Remove the temperature control and the output control.

Remove the outer case by sliding it forwards and then lifting

upwards.

Fix the appliance using the sleeves and hooks supplied so

that it is vertical.

Never allow the appliance to rest against water or gas

pipes.

2.4 Water connection

It is advisable to drain the appliance before installing it as

any dirt or grit inside it could reduce the water flow rate and,

in extreme cases, could completely clog up the appliance.

Mark hot water and cold water pipes so as to prevent

confusion.

Connect pipe to automatic water valve using the connecting

kit supplied.

To prevent problems caused by sudden pressure fluctuations

in the water supply, it is advisable to fit a non-return valve to

the water outlet.

2.5 Gas connection

Take care to ensure dirt is not allowed to enter gas inlet.

Make sure that the type of gas specified on the appliance

type plate is the same as that supplied by the gas authorities.

Fig. 4

2.7 Commissioning

Turn on the gas and water cocks and check all connections

for leaks.

Check flue gas safety device good functioning, proceed as

explained in section 3.5.

56 720 607 526

Page 6

3. Operation and maintenance

Sealed parts must not be interfered with.

3.1 Function

This water heater is fitted with piezo ignition that provides

for easy commissioning.

In first place it must dislocate the output control of the off

position to the ignition position (see fig. 5).

Press in the slide control knob and subsequently press the

piezo button. Release the slide control after about 15

seconds, if the pilot flame does not stay alight, repeat the

operation.

Ignition may not be successful due to the presence of air

inside the gas supply pipe, especially if first connected or

after long inactive periods. In this case, keep the output

control knob fully depressed until the gas pipe has been

totally purged.

Slide the gas control slide fully to the right to obtain maximum

output. Sliding the gas control slide to the left reduces the

output.

In order to optimise energy consumption, adjust the output

control to supply the minimum output required.

After following these procedures, ignition of the main burner

will automatically take place whenever you turn on a hot

water tap, since the pilot burner is permanently alight.

When you want to switch off the heater, move the slide

control to the far left. After a few seconds the pilot flame

will go out.

If there is a risk of freezing, switch off the appliance and

drain the appliance.

Danger: the area in front of the burner can reach very high

temperatures, and there is a risk of burning on contact.

3.2 Water temperature control

The water temperature control is used to adjust the water

flow rate, and thereby the water temperature, to the desired

setting.

Turning the control clockwise reduces the water flow rate

and increases the temperature; turning the control anticlockwise increases the water flow rate and reduces the

temperature.

If the temperature is set only as high as required, energy

consumption is reduced and the likelihood of scale deposits

in the heat exchanger minimised.

3.3 Appliance adjustments

All instantaneous water heaters are factory-adjusted and

require no further adjustment.*

Water heaters that use LPG (liquefied petroleum gas, i.e.

butane/propane) are set to the operating pressure stated

on the identification plate (2,8 kPa).

Natural gas appliances are set to a Wobbe Index of 15 kWh/

m3 and a supply pressure of 2.0 kPa.

* Sealed components must not be tampered with.

The overhaul should involve thoroughly cleaning the heat

exchanger, burner, pilot burner and automatic water valve

filter.

If necessary, the inside of the heat exchanger and the

connecting pipes should be descaled.

Check the gas and water valves for leaks and carry out a

complete function check.

If components need to be replaced, use only genuine Bosch

spare parts.

3.5 Flue gas safety device

The recommition must be done from a qualified technician

only.

The flue gas safety device must not under any circumstances

be switched off, simulated or replaced by any other

component.

Operation and safety precautions

The flue gas safety device checks the effectiveness of flue

gas extraction by the flue. If it is inadequate, the appliance

switches off automatically so that the combustion fumes do

not escape into the room in which the appliance has been

installed. The flue gas safety device resets after a coolingdown period.

If the appliance shuts down while in operation, ventilate the

room. Wait about 10 minutes then restart the appliance. If

the problem recurs, call an engineer. The user must never

make any modifications to the appliance.

Maintenance

If faults occur on the flue gas safety device, proceed as

follows:

- Undo flue gas safety device fixing screw.

- Undo magnetic unit connector

- Remove thermocouple.

Replace damaged component with new one and refit using

the reverse of the procedure set out in the table above.

Function check*

Flue gas safety device function check:

- Disconnect flue pipe

- Replace with pipe (about 50 cm long) with sealed end

- Fit pipe vertically

- Start up appliance at rated output and set temperature

control to maximum temperature.

Under those conditions, the appliance should shut down

after two minutes. Remove temporary pipe and reconnect

flue pipe.

* This work may only be carried out by an approved engineer.

3.6 Converting to a different gas type

Use only the genuine Bosch conversion kit. Conversion

may only be carried out by an approved technician.

3.4 Maintenance

The appliance should only be serviced by an approved

engineer.

A complete overhaul should be carried out after two years.

6 6 720 607 526

Page 7

3.7 Troubleshooting

Problem Cause Solution

Pilot flame stay alight. Blocked pilot burner. Clean.*

Several atempts required to turn pilot

flame on.

Yellow pilot flame.

Flame goes out while appliance is in

operation.

Flue gas safety device has tripped Ventilate room. Wait 10 minutes then restart

appliance. If problem recurs, call an approved

technician.

Temperature limiter has tripped. Wait 10 minutes then restart appliance. If

problem recurs, call an approved technician.

Water not hot enough. Check output selector position and regulate

according with needs.

Water not hot enough, weak flame. Gas supply dynamic pressure too low. Check gas cylinder governor and replace if

incompatible or damaged. *

Check whether gas cylinder (butane) is

freezing when appliance is in operation and resite in warmer location if necessary.

Reduced water flow rate. Inadequate inlet flow rate. Check and adjust.

Dirt in water service cock or mixer unit. Check and clean.

Automatic water valve clogged. Clean filter.*

Heat exchanger clogged (scale). Clean and descale as necessary.*

Installation, servicing and repairs may only be carried out by an approved engineer.

The following table illustrates only a few solutions to straightforward problems.

The operations marked with “*” may only be carried out by an approved technician

76 720 607 526

Page 8

4. Operation

Turn on all gas and water taps

Purge air from pipes

Ignition:

Release the slide control knob

after approximately 15 seconds

Press the piezo igniter

Output Control:

output decrease output increase

Depress slide control knob

and hold it in

Repeat these steps if the flame does not stay alight

Temperature adjustment

Turning control anti-clockwise

increases water flow rate and

reduces water temperature

Switching off:

Turning control clockwise

reduces water flow rate and

increases water temperature

Move slide control to the far left

Fig. 5

Loading...

Loading...