Bosch SSB255, SSB399, SSB512 Installation And Service Manual

WARNING:

Improper installation, set-up, modication, operation or maintenance of

the heating system can cause personal injury and property damage.

Follow these instructions precisely.

If you require assistance or further information, contact a licensed

contractor / gas tter.

WARNING:

The operating instructions are part of the technical documents that

must be handed over to the owner or operator of the heating system.

Explain to the owner or operator how to use the heating system using

the operating instructions. Make sure that they are familiar with all

required information for the safe and proper operation of the heating

system.

NOTICE:

In Massachusetts, this appliance must be installed by a licensed

plumber or gas tter.

These instructions are available in English and French.

Please keep these instructions for future reference.

Gas Condensing Stainless Steel Boiler

BUDERUS SSB BOILER

SSB255 | SSB399 | SSB512

Installation and Service Instructions for Contractors

6720818454 (2016/02) US

2 |

Contents

1 Key to symbols and safety instructions ..............3

1.1 Key to symbols..................................3

1.2 Safety instructions ...............................3

1.3 General warning.................................3

Product description ..........................4

2

2.1 Introduction.....................................4

2.2 Scope of delivery ................................4

2.3 Proper use .....................................5

2.4 Environmental responsibility / disposal ...............5

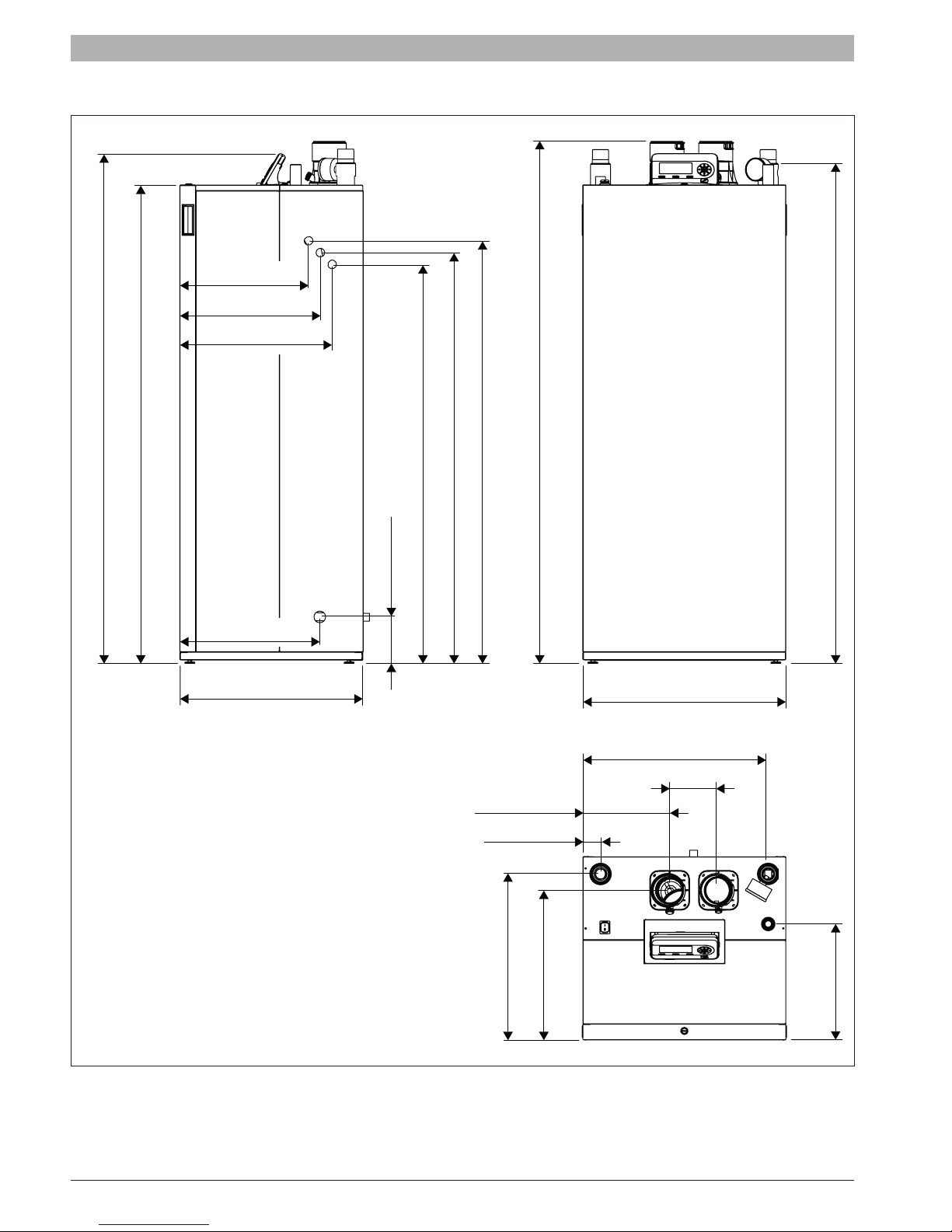

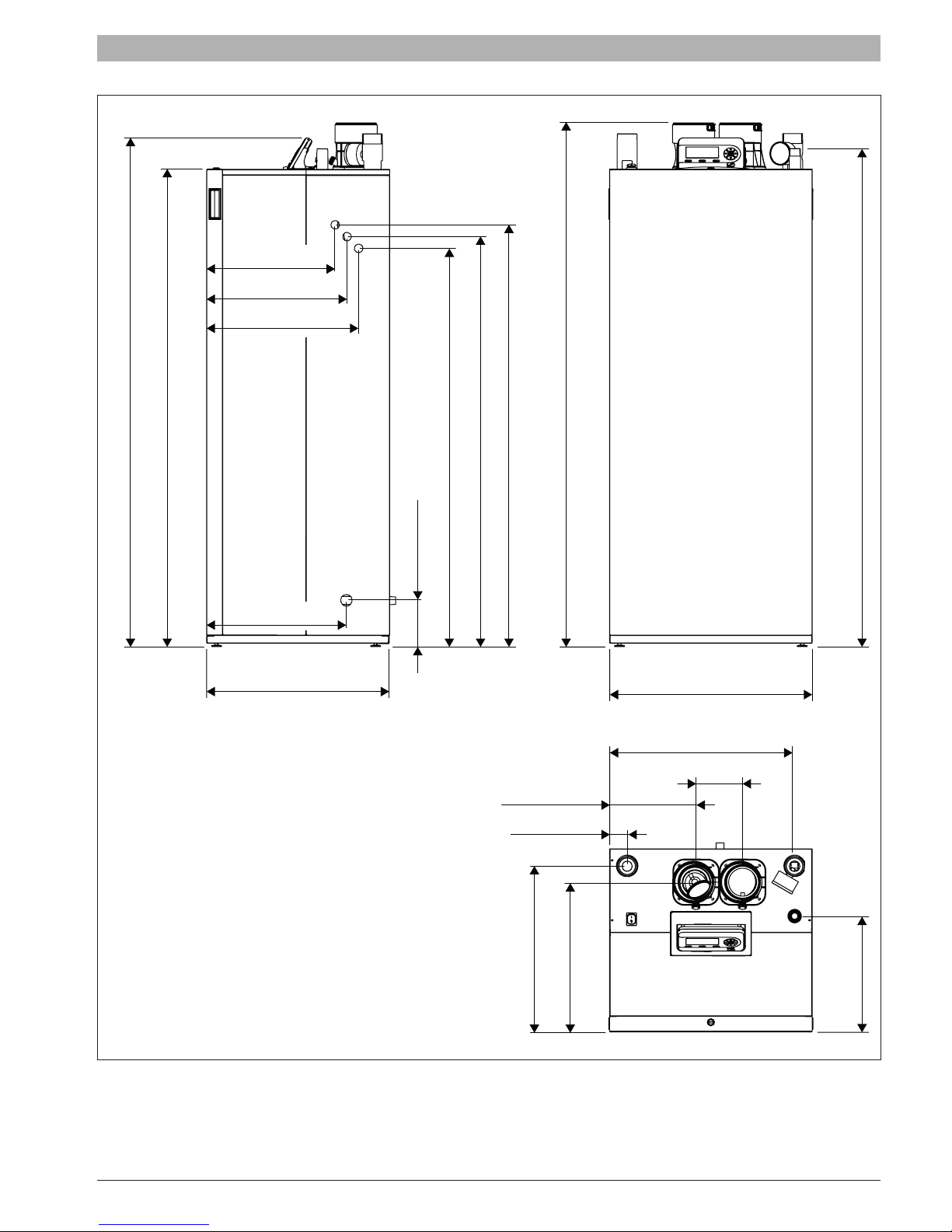

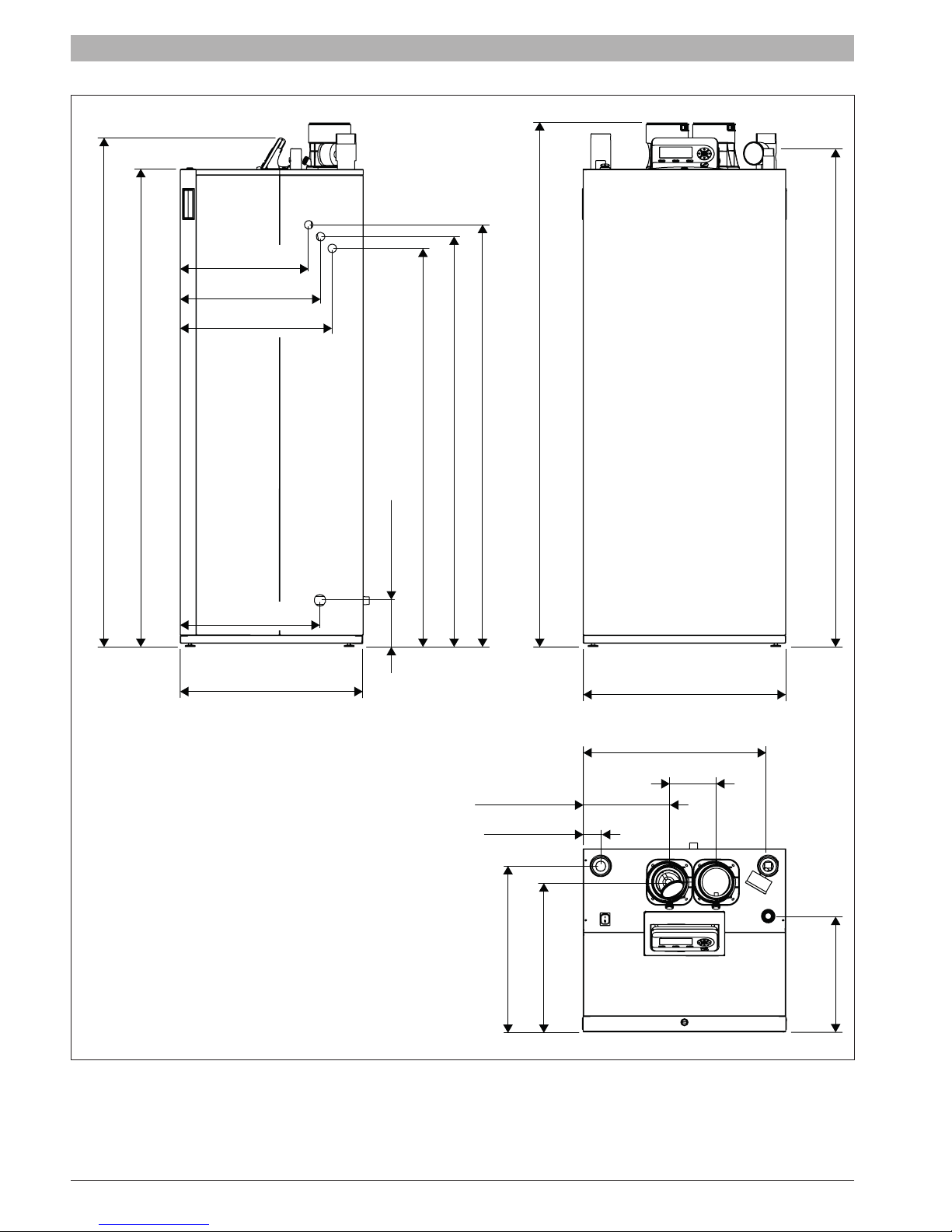

2.5 Dimensions and Connections.......................6

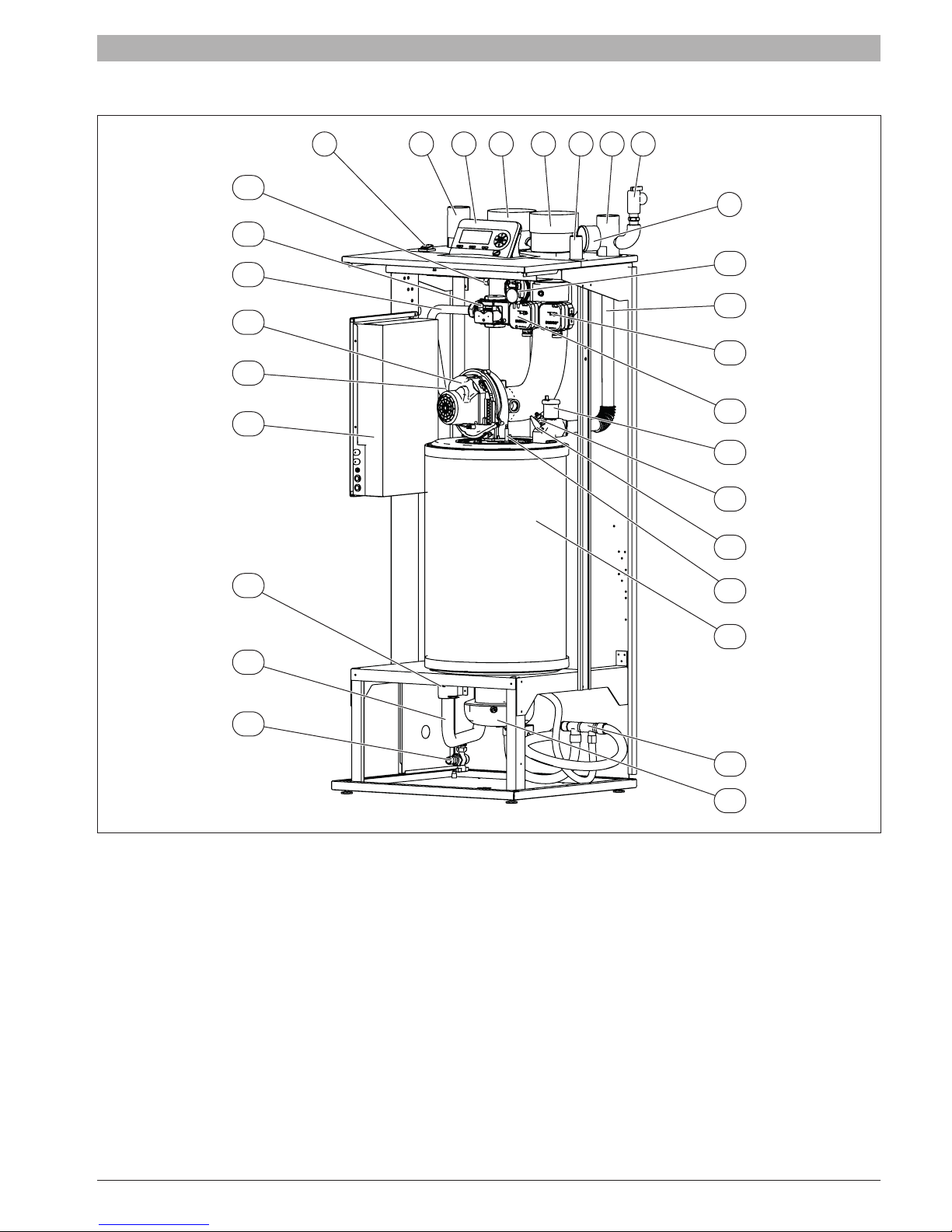

2.6 Main components................................9

2.7 Technical data .................................10

2.8 Efficiency Curves ...............................11

Regulations ...............................13

3

3.1 Compliance with standards and regulations...........13

3.2 Operating limits of the boiler.......................13

3.3 Additional regulations for installation in Massachusetts ..13

4.7.5 Approved examples of horizontal and vertical venting

installation ....................................29

4.7.6 Multiple boiler ..................................32

4.7.7 De-rating for altitude installation....................33

Commissioning (for single boiler application) ..........34

5

5.1 Switching the appliance ON/OFF ...................34

5.2 Setting date and time ............................34

5.3 Setting CH and DHW setpoint .....................35

5.4 Boiler information ...............................35

5.5 Parameters list .................................36

5.6 Outdoor reset ..................................36

5.7 Adjusting and setting CO

5.8 Setting frost protection ...........................40

Troubleshooting.............................40

6

6.1 Error codes are shown on the display ...............40

6.1.1 Lockout errors .................................41

6.1.2 Blocking errors .................................42

6.2 Errors not shown on display .......................44

6.3 Sensor Resistance table .........................44

limits ....................39

2

Installation ................................14

4

4.1 Packaging and product identification ................14

4.2 Installation room................................14

4.3 Water Chemistry Guidelines.......................15

4.4 Hydraulic connection ............................15

4.4.1 Low water cut off ...............................16

4.4.2 High limit safety switch ...........................16

4.4.3 Pressure relief valve (PRV) .......................16

4.4.4 Expansion tank.................................16

4.4.5 Pump ........................................17

4.4.6 Condensate removal ............................19

4.5 Electrical connection ............................19

4.5.1 Power supply cable connection ....................19

4.5.2 Access to the electrical terminal strip ................20

4.5.3 Room thermostat connection ......................20

4.5.4 Outside temperature sensor.......................20

4.5.5 Electrical wiring diagram .........................21

4.6 Gas supply piping...............................22

4.6.1 Connection of gas supply piping ...................22

4.6.2 Gas type conversion.............................22

4.7 Venting and air piping system .....................23

4.7.1 General venting and combustion air piping system .....24

4.7.2 Connecting flue gas systems ......................25

4.7.3 Installation of the exhaust and air intake system .......25

4.7.4 Vent and combustion air pipe length [For single boiler

installations] ...................................28

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

7

7.1 General.......................................45

7.2 Maintenance / inspection schedule for end user .......45

7.3 Maintenance / inspection schedule for licensed

contractor / gas fitter.............................45

7.3.1 Gas leaking inspection ...........................45

7.3.2 Check exhaust and combustion air pipe system .......45

7.3.3 Inspection of ignition electrode.....................45

7.3.4 Checking for wiring and connections ................45

7.3.5 Burner gasket inspection .........................45

Applications ...............................46

8

8.1 Multiple zone with indirect tank (pump for each zone) ...46

8.1.1 Settings ......................................47

8.2 Multiple zone with indirect tank (valve for each zone) ...48

8.2.1 Settings ......................................49

8.3 Cascade connection.............................50

8.3.1 Settings ......................................53

Commissioning log for the appliance ...............54

9

Spare parts ................................56

10

6720818454 (2016/02) US SSB

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identied by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent the

risk are not taken.

The following keywords are dened and can be used in this document:

DANGER

•

result in death or serious injury.

WARNING

•

could result in death or serious injury.

CAUTION

•

could result in minor to moderate injury.

NOTICE

•

Important information

1.2 Safety instructions

Observe these instructions for your safety.

The burner and control must be correctly installed and adjusted to ensure

safe and economical operation of the gas boiler.

Read this installation and maintenance manual carefully and note the

details on the boiler nameplate before placing the boiler in operation.

Risk of fatal injury from explosion of ammable gases

If you smell gas there is a danger of explosion.

► Never work on gas lines unless you are licensed contractor / gas tter.

► Make sure that a licensed contractor / gas tter installs the boiler,

connects gas and vent, places the boiler in operation, connects the

electrical power, and maintains and repairs the boiler.

► No open ame! No smoking! Do not use lighters.

► Prevent spark formation. Do not operate electrical switches, including

telephones, plugs or door bells.

► Close main gas valve.

► Open doors and windows.

► Warn other occupants of the building, but do not use door bells.

► Call gas company from outside the building.

► If gas can be heard escaping, leave the building immediately, prevent

other people from entering, notify police and re departments from

outside the building

Risk to life from electrical shock.

► Disconnect the power supply to the boiler heating system before

conducting any work on it, e.g. turn off the heating system emergency

switch outside the boiler room.

► It is not sufcient just to turn off the control.

► Do not carry out electrical work unless you are qualied for this type

of work.

► Before servicing disconnect electrical power and lock out to prevent

accidental reconnection.

► Observe and follow the local, state and federal installation regulations.

indicates a hazardous situation which, if not avoided, will

indicates a hazardous situation which, if not avoided,

indicates a hazardous situation which, if not avoided,

is used to address practices not related to personal injury.

This symbol indicates important information where there is

no risk to people or property.

Key to symbols and safety instructions | 3

Risk of fatal injury from ue gas poisoning

Insufcient ventilation or combustion air availability may cause dangerous

ue gas leaks or formation.

► Make sure that inlets and outlets are not reduced in size or closed.

► If faults are not corrected immediately, the boiler must not be operated

until all faults have been corrected.

► Inform the system operator and/or owner of the fault and the danger

in writing.

When working on the ue gas venting equipment or vent damper leakage

of ue gases may endanger the lives of people.

► Carefully observe proper operation of the vent damper. Do not start up

the boiler unless the vent damper is operating properly.

► Use only original parts when replacing parts.

► When replacing the vent damper, install the new one in the specied

position.

Risk to life by poisoning by spillage of ue gases

► If the blocked vent switch trips frequently the fault must be corrected

and proper operation of the blocked vent switch test must be

conducted.

Risk to life by poisoning by leakage of ue gases

► Make sure that the boiler is not equipped with a thermally controlled

ue gas vent damper after the open draft hood.

Risk of fatal injury from neglecting your own safety in case of

emergency, such as with a re

► Never put yourself at risk. Your own safety must always take priority.

Fire danger due to ammable materials or liquids

► Make sure that there are no ammable materials or liquids in the

immediate vicinity of the boiler.

► Maintain a minimum distance of 15 inches from the boiler.

Installation and maintenance

► Observe all current standards and guidelines applicable to the

installation and operation of the boiler heating system as applicable in

your state or local jurisdiction.

► Clean and service the boiler system once a year. Check that the

complete heating system operates correctly.

► Immediately correct all faults to prevent system damage.

► Only use original Bosch spare parts. Losses caused by the use of

parts not supplied by Bosch are excluded from the Bosch warranty.

1.3 General warning

The installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to the latest edition

of the National Fuel Gas Code, ANSI Z223.1./NFPA 54. In Canada,

installation must be in accordance with the requirements of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

Where required by local, state and federal regulations, the system must

comply with the American Society of Mechanical Engineers Safety Code

for Controls and Safety Devices for Automatically Fired Boilers (ASME

CSD-1).

The hot water distribution system must comply with all applicable codes

and regulations. When replacing an existing boiler, it is important to check

the condition of the entire hot water distribution system to ensure safe

operation.

In the Commonwealth of Massachusetts, this appliance must be installed

by a licensed plumber or gas tter. Valves external to the boiler must

be tted with T-handles and condensate piping must be installed in

accordance with the State Plumbing Code.

SSB 6720818454 (2016/02) US

4 | Product description

NOTICE:

► This boiler must be installed by a licensed contractor/ gas tter.

Failure to do so shall void the product warranty.

► The boiler is intended only for the use for which it was specically

designed and built. Bosch is hereby excluded from any liability for

damages caused to persons, animals or property resulting from

installation errors, improper adjustment, maintenance or use.

► In order to ensure safety and correct operation, the installation shall

always take place in full compliance with the applicable codes and

following with the instructions provided by the manufacturer, and must

always be carried out by a licensed contractor / gas tter only.

► The equipment must be installed in appropriate place and in

combination with appropriate systems as specied by code.

► The unit may be exposed to temperatures between 5 deg F (-15°C)

and 150 deg F (65°C) in its original packaging. Do not expose the

unit to weather without the protection of the original packaging until

the boiler has been properly installed. Until then there is no frost

protection for the boiler.

► After removing the packaging check the integrity and completeness of

delivery and in case of non-compliance, contact your dealer.

► If there is a water loss, disconnect the boiler from the main power

supply, close the water supply and immediately call technical

assistance or installer/local contractor.

► Periodically check that the condensate drain is free from obstruction.

► Periodically check the system pressure. System pressure should be

checked when the system is in standby mode and no call for heat is

present.

► Maintenance is mandatory and shall be carried out at least once a

year.

► This manual shall be read carefully, in order to install and operate the

boiler appropriately, and safely.

► Boiler installations, settings and service should only be performed by

experienced licensed contractor / gas tter. End Users should only

make adjustments with the assistance of a licensed contractor / gas

tter.

► Any maintenance operation or service before disconnecting the boiler

from the main power supply is forbidden.

► Do not remove or modify safety equipment.

► Do not pull or twist the electrical wires, from the boiler, even if the

device is disconnected from the main power supply.

► Do not obstruct or reduce the ventilation openings.

► Do not install the unit outdoors.

► Do not leave any combustibles or containers of ammable substances

in the room where the boiler is installed.

► Keep packing material out of reach of children as it can be potentially

dangerous. It must be disposed of as required by law.

► The opening of metal casing of the device and removing of the cover

are prohibited to the end user. Any service on the boiler must be

carried out by authorized personal.

► It’s prohibited to dispose the product as domestic waste. The

separate disposal of a household appliance avoids possible negative

consequences for the environment and human health deriving from

inappropriate disposal and allows to recover the materials it is made

of in order to achieve signicant savings in energy and resources.

2 Product description

2.1 Introduction

• The gas-red condensing SSB boilers are designed to be used in

central heating systems. Any other use is prohibited.

• This boiler can be connected to an indirect storage tank for the

production of domestic hot water.

• There are several options for venting including single pipe, two pipe

and concentric see section “4.7 Venting and air piping system” for

details.

• The quality of the system water is very important. Poor water quality

can damage heating systems and boilers due to scale formation and

corrosion (see water quality section).

• The boilers can also function directly with any hydronic emitter.

When installing the boiler and system connections, the installer must

consider the total head loss and ow rates in order to adequately size

piping and circulator pumps.

• The SSB boiler can be connected to a room thermostat.

• An outdoor air temperature sensor must also be connected to the

boiler for an outdoor reset supply temperature control for increased

fuel efciency and comfort.

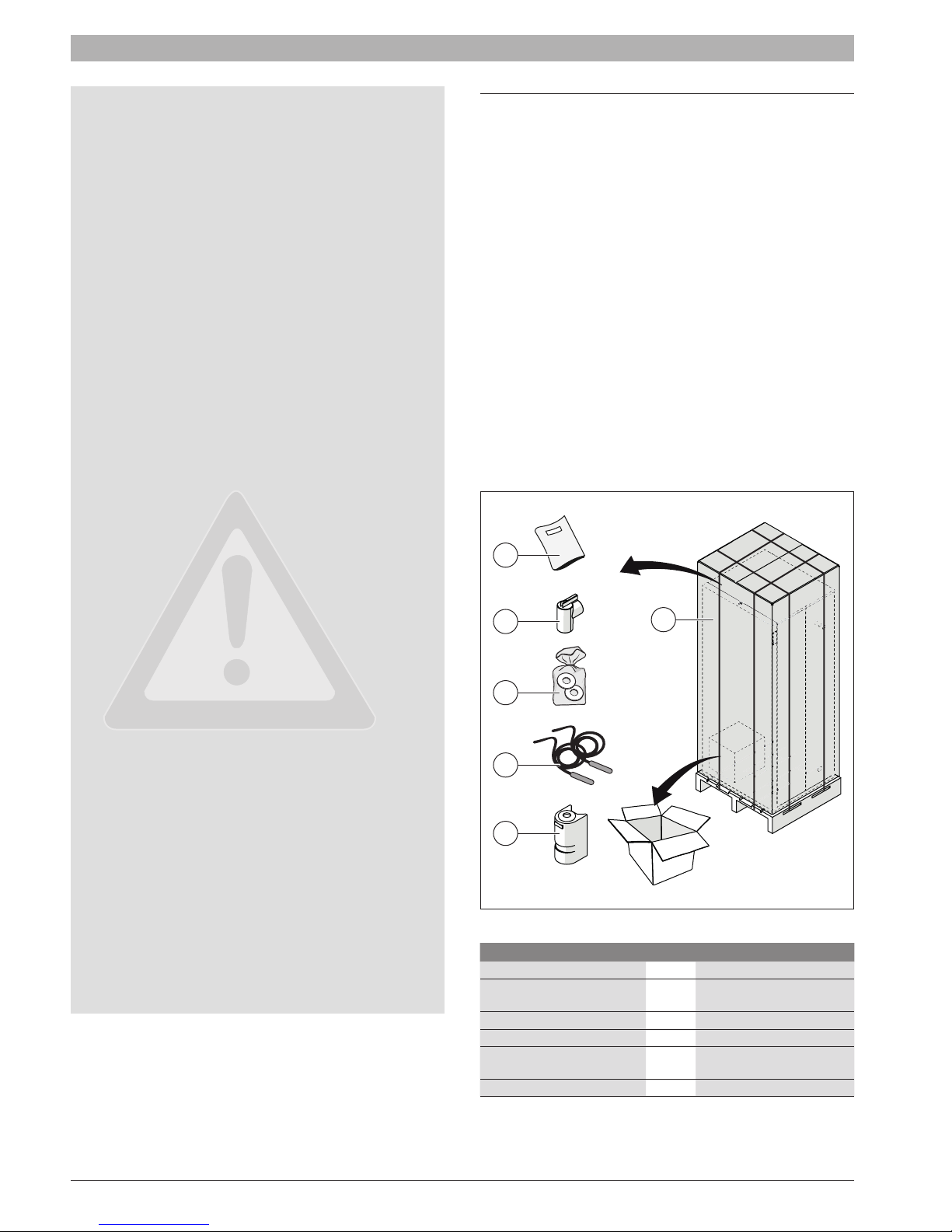

2.2 Scope of delivery

2

3

6

.5

4

6.75

1

5

6

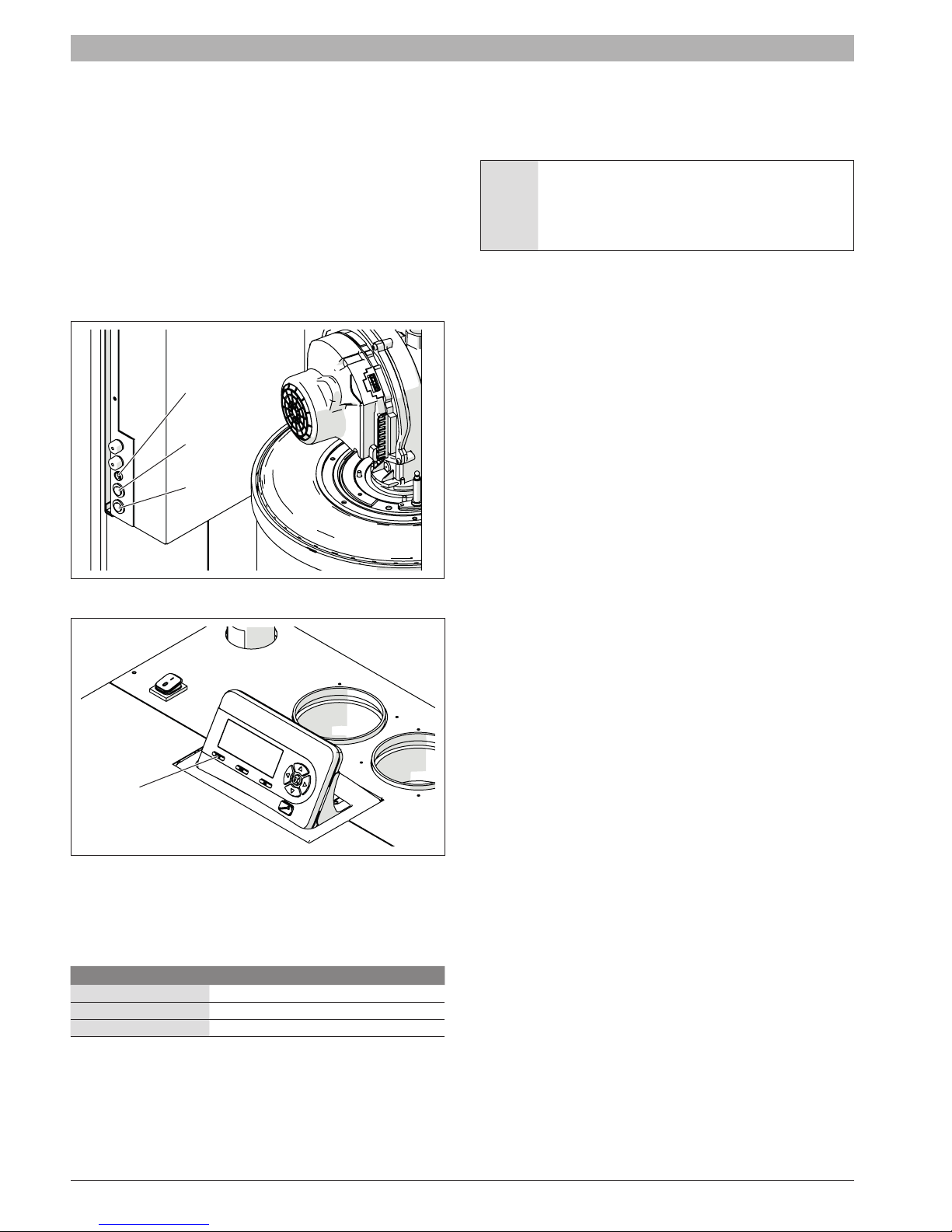

Fig. 1 Scope of delivery

Component Qty Packaging method

[1] Gas condensing boiler 1 Pallet

[2] Set of documents for

appliance

[3] Safety relief valve 1 Cardboard box on pallet

[4] LP conversion kit 1 Plastic package

[5] Universal Sensor for LLH

or DHW

[6] Outdoor sensor 1 Cardboard box on pallet

1 Plastic package

2 Cardboard box on pallet

6720818454 (2016/02) US SSB

2.3 Proper use

► The SSB Boilers are designed for large residential, commercial and

light industrial applications.

► The SSB 512 is delivered in compliance with CSD-1 Commercial

Applications.

► The appliance may only be installed in closed loop hot water central

heating systems.

► Any other purpose is considered improper use. Any resulting damage

is excluded from the manufacturer’s warranty.

► In some heating applications like pool, spa or process water heating a

heat exchanger must to be installed.

2.4 Environmental responsibility / disposal

Environmental responsibility is one of the fundamental company policies

of the Bosch Group.

We regard quality of performance, economy and environmental

responsibility as equal objectives. Environmental protection laws and

regulations are strictly adhered to.

To protect the environment, we use the best possible technology and

materials taking into account economic points of view.

Packaging

All packaging materials used are environmentally-friendly and recyclable.

Product description | 5

SSB 6720818454 (2016/02) US

6 | Product description

19 19/32” (498mm)

17 21/32” (448mm)

13 11/16” (348mm)

2.5 Dimensions and Connections

15 7/32” (386mm)

16 19/32” (422mm)

18” (457mm)

F

60 3/16” (1529mm)

56 7/16” (1434mm)

16 17/32” (420mm)

21 21/32” (550mm)

61 9/16” (1564mm)

49 27/32” (1266mm)

48 7/16” (1231mm)

47 1/32” (1195mm)

G

5 7/16” (138mm)

58 7/8” (1496mm)

23 31/32” (609mm)

21 5/8” (549mm)

5 1/2” (140mm)

10 1/16” (256mm)

2 3/32” (53mm)

B

A

DE

C

Fig. 2 SSB255 (dimension in inches [mm])

A System supply - 1” 1/2 NPT

B System return - 1” 1/2 NPT

C Gas inlet - 1” NPT

6720818454 (2016/02) US SSB

D Flue exhaust - 3” (80mm)

E Intake air - 3” (80mm)

19 19/32” (498mm)

17 21/32” (448mm)

13 11/16” (348mm)

15 7/32” (386mm)

16 19/32” (422mm)

18” (457mm)

Product description | 7

F

60 3/16” (1529mm)

56 7/16” (1434mm)

16 17/32” (420mm)

21 21/32” (550mm)

61 9/16” (1564mm)

49 27/32” (1266mm)

48 7/16” (1231mm)

47 1/32” (1195mm)

G

5 7/16” (138mm)

58 7/8” (1496mm)

23 31/32” (609mm)

21 5/8” (549mm)

5 1/2” (140mm)

10 1/16” (256mm)

2 3/32” (53mm)

B

A

DE

C

Fig. 3 SSB399 (dimension in inches [mm])

A System supply - 1” 1/2 NPT

B System return - 1” 1/2 NPT

C Gas inlet - 1” NPT

SSB 6720818454 (2016/02) US

D Flue exhaust - 4” (110mm)

E Intake air - 4” (110mm)

8 | Product description

19 19/32” (498mm)

17 21/32” (448mm)

13 11/16” (348mm)

15 7/32” (386mm)

16 19/32” (422mm)

F

18” (457mm)

60 3/16” (1529mm)

56 7/16” (1434mm)

16 17/32” (420mm)

21 21/32” (550mm)

61 9/16” (1564mm)

49 27/32” (1266mm)

48 7/16” (1231mm)

47 1/32” (1195mm)

G

5 7/16” (138mm)

58 7/8” (1496mm)

23 31/32” (609mm)

21 5/8” (549mm)

5 1/2” (140mm)

10 1/16” (256mm)

2 3/32” (53mm)

B

A

DE

C

Fig. 4 SSB512 (dimension in inches [mm])

A System supply - 2” NPT

B System return - 2” NPT

C Gas inlet - 1” NPT

6720818454 (2016/02) US SSB

D Flue exhaust - 4” (110mm)

E Intake air - 4” (110mm)

2.6 Main components

29

28

Product description | 9

1 2 3 4 65 7 8

9

27

26

25

24

23

22

10

11

12

13

14

15

16

17

18

21

Fig. 5 SSB512 (main components)

[1] Main power switch

[2] System return

[3] Removable display

[4] Flue exhaust

[5] Intake air

[6] Gas inlet

[7] System supply

[8] Pressure Relief Valve

[9] Tridicator

[10] Air pressure switch

[11] Heat exchanger supply pipe

[12] Max pressure switch [For SSB 512 Only]

[13] Min pressure switch [For SSB 512 only]. Location should be burner

side of gas valve.

[14] Automatic air vent

19

20

[15] Low water cut off probe

[16] High limit temp. safety switch

[17] Spark electrode

[18] Heat exchanger

[19] Condensate manifold

[20] Air pressure switch connection

[21] Low point drain valve

[22] Heat exchanger return pipe

[23] Return temperature probe

[24] Wiring Control Panel

[25] Main shut off gas valve

[26] Fan

[27] Gas pipe

[28] Gas valve

[29] Flue gas probe

SSB 6720818454 (2016/02) US

10 | Product description

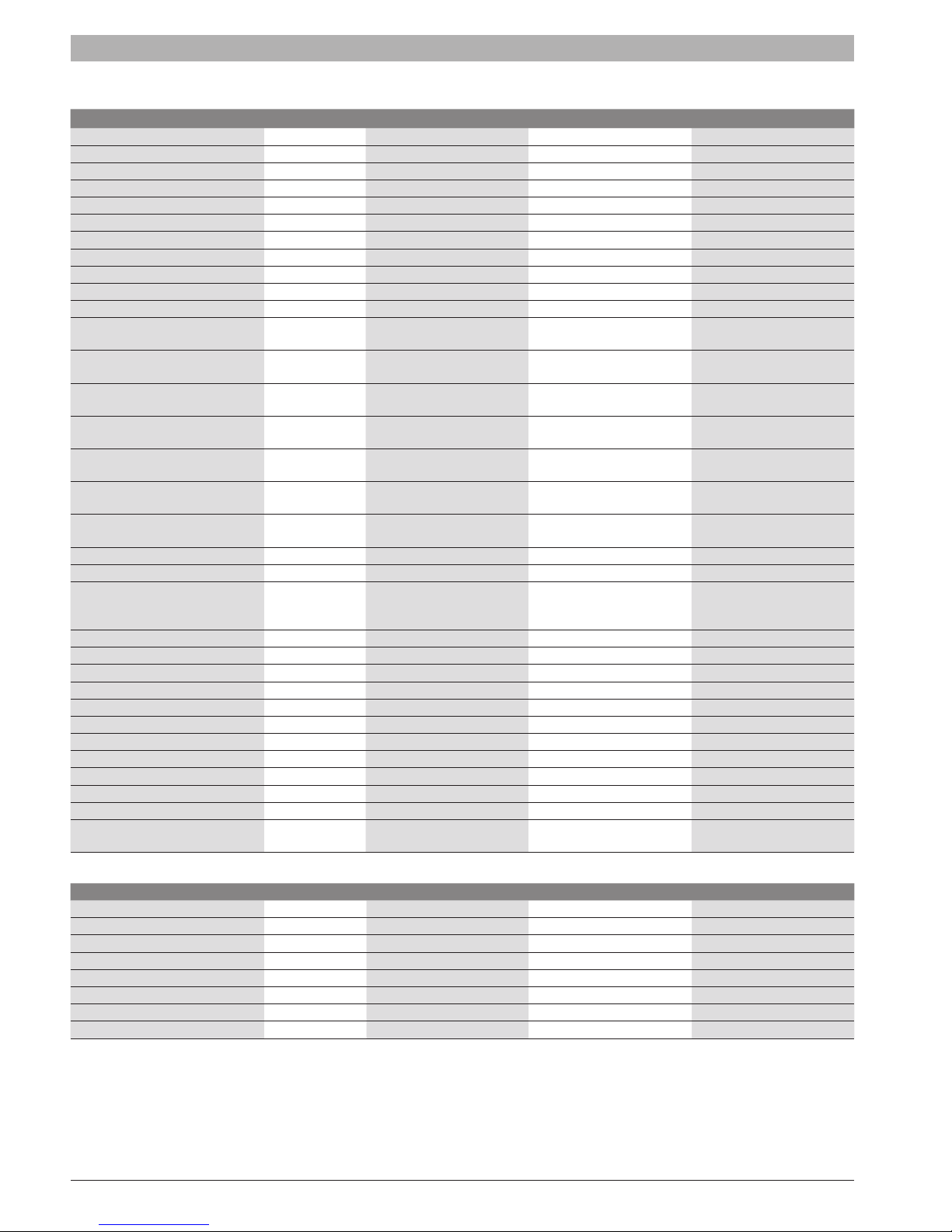

2.7 Technical data

Unit SSB255 SSB399 SSB512

Boiler Category ASME Sect.IV ASME Sect.IV ASME Sect.IV

Type of Gas Natural Gas, Propane * Natural Gas, Propane * Natural Gas, Propane *

Max input rate BTU/hr (kW) 255,900 (75) 399,000 (117) 512,000 (150)

Min input rate BTU/hr (kW) 51,180 (15) 79,800 (23.4) 102,400 (30)

Turndown Rate (%) 5:1 (20 %) 5:1 (20 %) 5:1 (20 %)

Gas Connections (NPT) Ø Inch 1” 1’’ 1’’

Max. NG Pressure Inch W.C. (mbar) 10.5 (26.15) 10.5 (26.15) 10.5 (26.15)

Min. NG Pressure Inch W.C. (mbar) 3.5 (8.72) 3.5 (8.72) 3.5 (8.72)

Max. LPG Pressure Inch W.C. (mbar) 13 (32.3) 13 (32.3) 13 (32.3)

Min. LPG Pressure Inch W.C. (mbar) 8 (19.9) 8 (19.9) 8 (19.9)

Water Connections Ø Inch 1 ½ “ 1 ½” 2’’

Max. Allowable Working Pressure

(MAWP)

Recommended water ow @ max

power (∆T 36 °F / 20 °C)

Max water ow @ max power

(∆T 27 °F / 15 °C)

Min water ow @ max power

(∆T 54 °F / 30 °C)

Min water ow @ min power

(∆T 27 °F / 15 °C)

Water Pressure Drop @

recommended water ow

Water Pressure Drop @ max water

ow

Water Volume Gallon (liter) 4.0 (15.2) 4.5 (17.0) 6.0 (23.0)

Vent/Air Intake Connections Ø Inch (Ø mm) 3 (80) 4 (100) 4 (100)

Vent Materials

Max operating temperature °F (°C) 194 (90) 194 (90) 194 (90)

Max HE allowable temperature °F (°C) 210 (98.9) 210 (98.9) 210 (98.9)

Ambient storage temperature dry °F (°C) 5 to 150 (-15 to 65) 5 to 150 (-15 to 65) 5 to 150 (-15 to 65)

Ambient functioning temperature °F (°C) 32 to 120 (0 to 49) 32 to 120 (0 to 49) 32 to 120 (0 to 49)

Ambient Relative Humidity [RH] % RH Minimum 30%, Maximum 90% Minimum 30%, Maximum 90% Minimum 30%, Maximum 90%

Surface area heat exchanger SQFT (m

Standard Listings & Approvals CSA, ASME, AHRI CSA, ASME, AHRI CSA, ASME, AHRI

Electrical Req. 120VAC/1PH/60Hz 2 FLA** 2.5 FLA** 2.5 FLA**

Noise rating dB 46 47 48

Weight (dry) lbs (kg) 198 (90) 220 (100) 242 (110)

Min. clearance to combustibles *** Inch (mm) 2” (50.8) 2” (50.8) 2” (50.8)

Dimension WxHxD

PSI (bar) 80 (5.5) 80 (5.5) 80 (5.5)

3

GPM (m

/h) 14.2 (3.2) 22.2 (5.0) 28.4 (6.5)

3

GPM (m

/h) 18.9 (4.3) 29.5 (6.7) 37.9 (8.6)

3

GPM (m

/h) 9.5 (2.2) 14.8 (3.4) 18.9 (4.3)

3

GPM (m

/h) 3.8 (0.9) 5.9 (1.3) 7.6 (1.7)

Feet Head (mbar) 3.8 (114) 8.3 (250) 21.7 (650)

Feet Head (mbar) 6.4 (190) 13.8 (410) 37.73 (1120)

CPVC, PVC, PP, PP Flex,

Stainless Steel AL29-4C

IPEX type IIA & IIB

2

) 22.0 (2.0) 27.2 (2.5) 43.0 (4.0)

Inch

(mm)

23 31/32” x 61 9/16” x 21 21/32”

(609x1564x550)

CPVC, PVC, PP, PP Flex,

Stainless Steel AL29-4C

IPEX type IIA & IIB

23 31/32” x 61 9/16” x 21 21/32”

(609x1564x550)

CPVC, PVC, PP, PP Flex,

Stainless Steel AL29-4C

IPEX type IIA & IIB

23 31/32” x 61 9/16” x 21 21/32”

(609x1564x550)

AHRI certied ratings

Unit SSB255 SSB399 SSB512

Input MBH 255 399 511.8

Heating Capacity MBH 237.0 n/a n/a

Gross Output MBH n/a 386.0 495.0

AFUE % 96 n/a n/a

Combustion Efciency % n/a 97.6 95.4

Thermal efciency % n/a 96.9 96.8

Net rating MBH 206.0 336.0 430.0

2 % 10.2 10.1 9.5

CO

(*) With conversion.

(**) FLA (Full Load Amperage) - maximum current drawn by the boiler without pumps.

(***) The 2” minimum clearance is required for all sides of the boiler. The boiler may be installed on combustible (wood) oors excluding carpets.

See Fig. 9 for minimum clearance recommendation for serviceability.

6720818454 (2016/02) US SSB

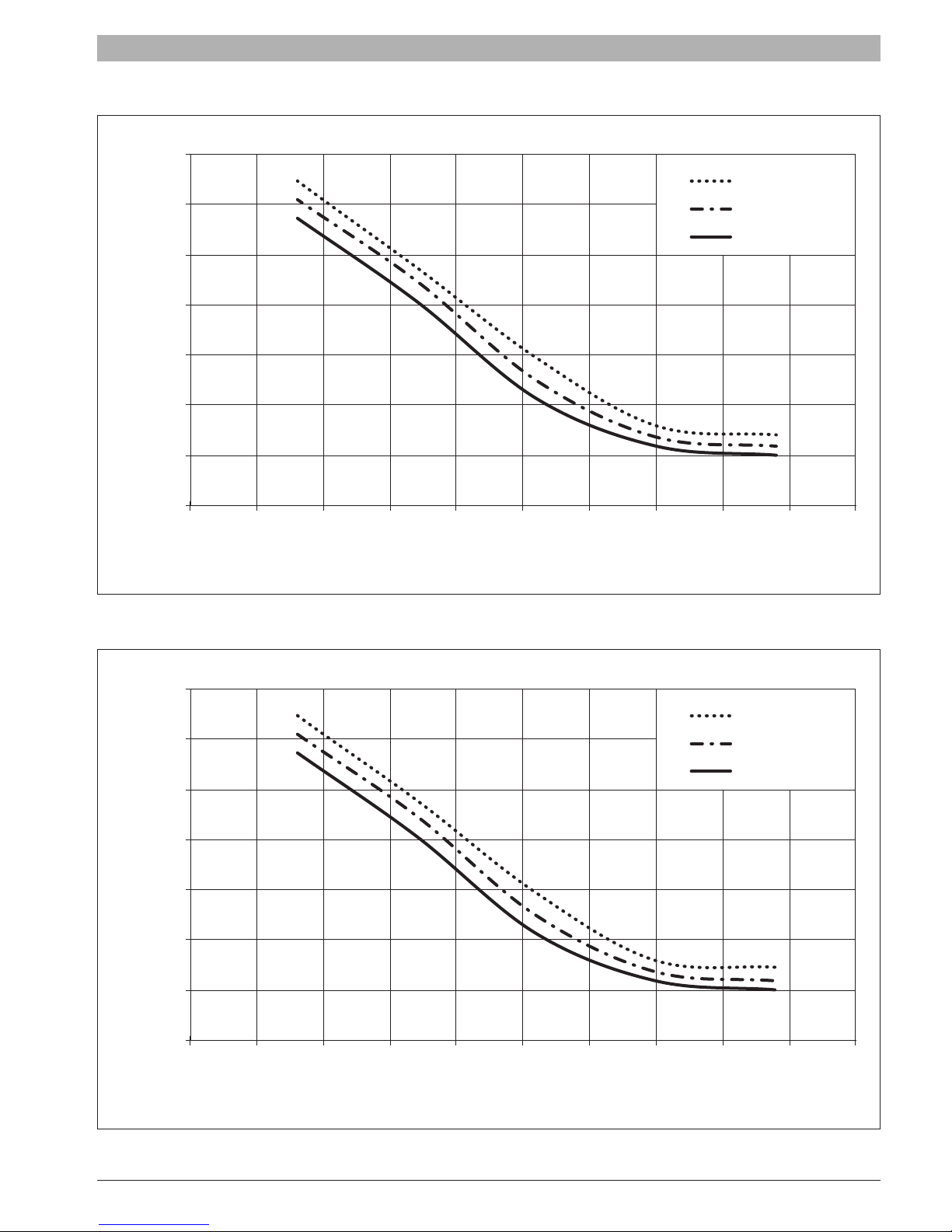

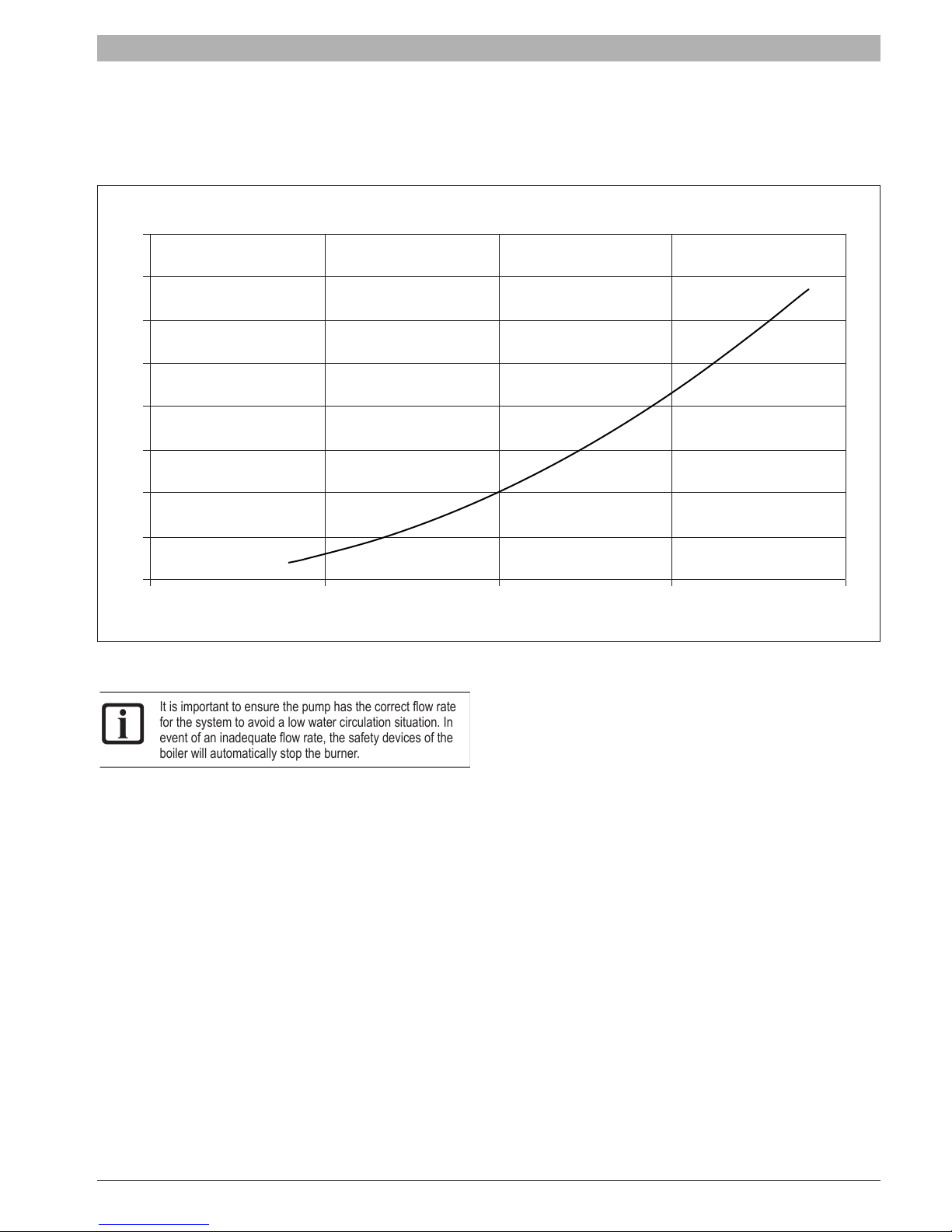

2.8 Efciency Curves

100%

98%

Product description | 11

20% input

30% input

96%

94%

92%

Thermal Efficiency

90%

88%

86%

70 80 90 100 110 120 130 140 150 160 170

Fig. 6 Thermal Efciency Curves SSB255*

* Thermal Efciency curve is for reference only as this is a residential boiler

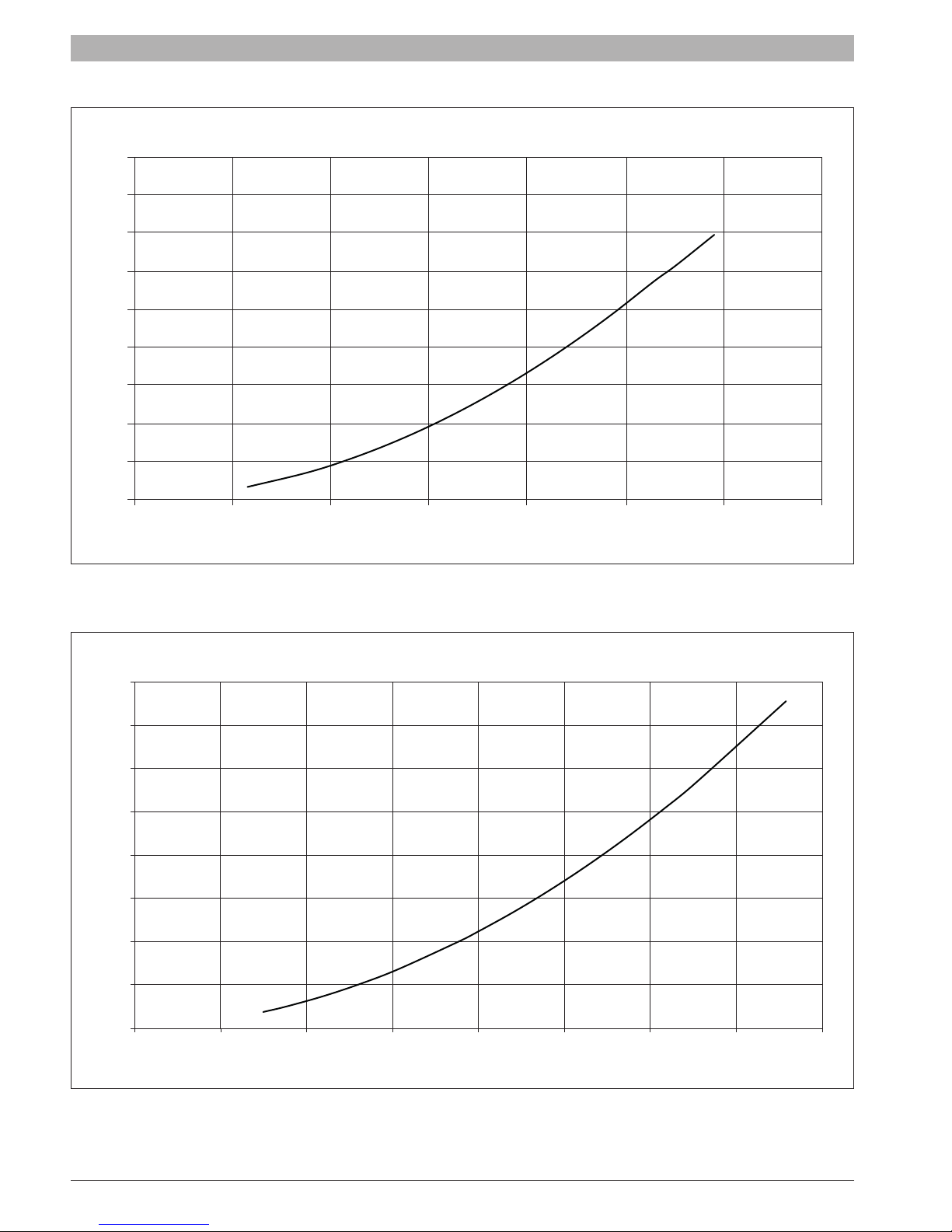

100%

100% input

Return Water Temperature (°F) @ 36 Degree Rise

98%

96%

94%

92%

Thermal Efficiency

90%

88%

86%

70 80 90 100 110 120 130 140 150 160 170

Fig. 7 Thermal Efciency Curves SSB399

20% input

30% input

100% input

Return Water Temperature (°F) @ 36 Degree Rise

SSB 6720818454 (2016/02) US

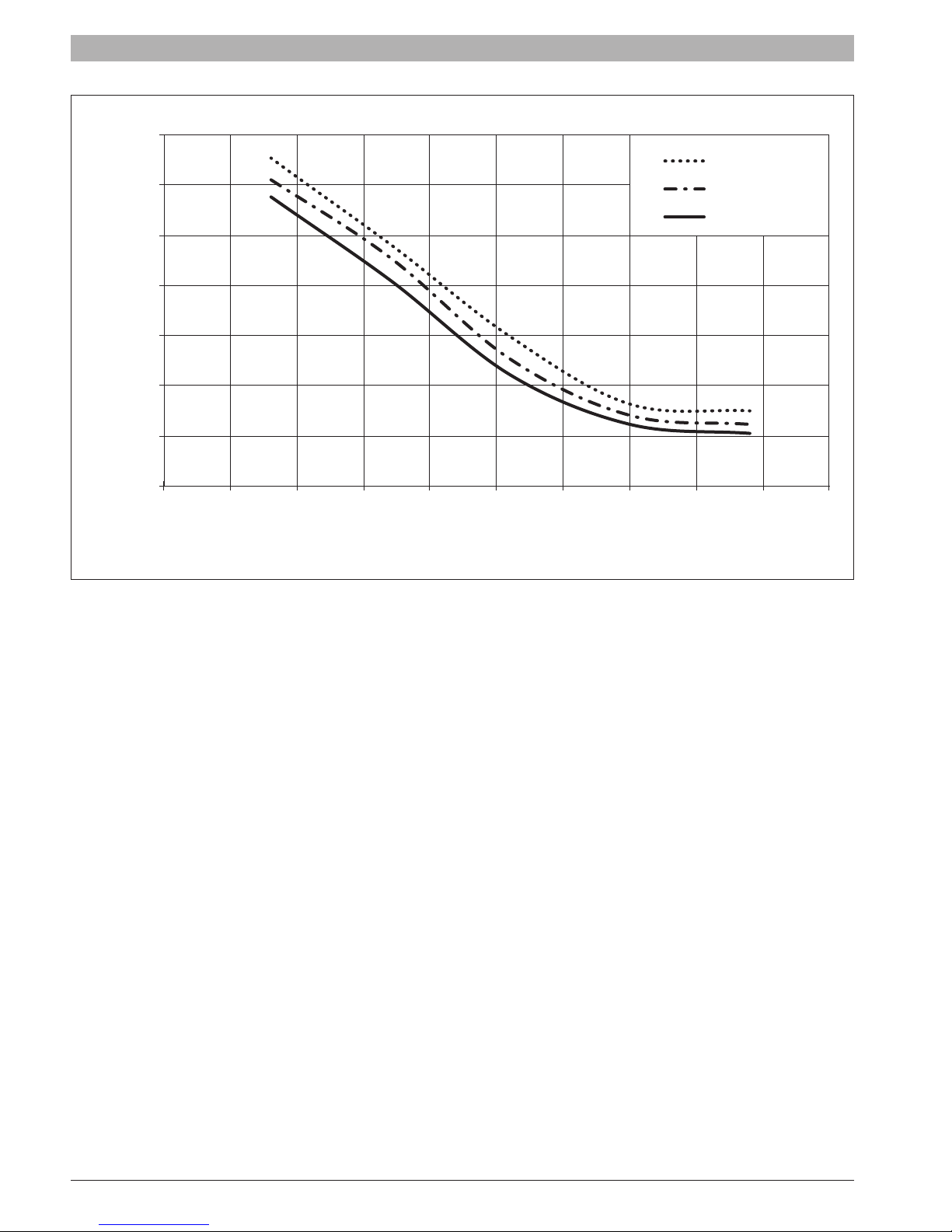

12 | Product description

100%

98%

20% input

30% input

96%

94%

92%

Thermal Efficiency

90%

88%

86%

70 80 90 100 110 120 130 140 150 160 170

Fig. 8 Thermal Efciency Curves SSB512

100% input

Return Water Temperature (°F) @ 36 Degree Rise

6720818454 (2016/02) US SSB

3 Regulations

Observe all rules, regulations, standards and guidelines

applicable to the installation and operation of this appliance

in your country.

In the Commonwealth of Massachusetts, this appliance

must be installed by a licensed plumber or gas tter. Valves

external to the boiler must be tted with T-handles and

condensate piping must be installed in accordance with the

State Plumbing Code.

3.1 Compliance with standards and regulations

The installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to the latest edition

of the National Fuel Gas Code, ANSI Z223.1./NFPA 54. In Canada,

installation must be in accordance with the requirements of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

This condensing gas boiler complies in its design and mode of operation

with the American National Standard ANSI Z21.13/CSA4.9, latest edition

for Gas Fired Low Pressure Steam and Hot Water Boilers.

Other conrmed approvals and certications are indicated by labels on

the boiler.

Where required by the authority having jurisdiction, the installation

must conform to the Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

Install CO detectors per local regulations. Boiler requires yearly

maintenance (see section “7 Maintenance”).

3.2 Operating limits of the boiler

The heat exchanger has been designed and certied in accordance with

the ASME Boiler and Pressure Vessel Code, Section IV.

The hot water distribution system must comply with all applicable codes

and regulations. When replacing an existing boiler, it is important to

check the condition of the entire hot water distribution system to ensure

safe operation. Common practice calls for inspecting an existing system

in its entirety and bringing it up to code. All pipework should be properly

cleaned and ushed.

3.3 Additional regulations for installation in

Massachusetts

(a) For all side wall horizontally vented gas fueled equipment installed in

every dwelling, building or structure used in whole or in part for residential

purposes, including those owned or operated by the Commonwealth and

where the side wall exhaust vent termination is less than seven (7) feet

[2150 mm] above nished grade in the area of the venting, including but

not limited to decks and porches, the following requirements shall be

satised:

• INSTALLATION OF CARBON MONOXIDE DETECTORS. At the

time of installation of the side wall horizontal vented gas fueled

equipment, the installing plumber or gastter shall observe that a hard

wired carbon monoxide detector with an alarm and battery backup is installed on the oor level where the gas equipment is to be

installed. In addition, the installing plumber or gastter shall observe

that a battery operated or hard wired carbon monoxide detector

with an alarm is installed on each additional level of the dwelling,

building or structure served by the side wall horizontal vented gas

fueled equipment. It shall be the responsibility of the property owner

to secure the services of qualied licensed professionals for the

installation of hard wired carbon monoxide detectors.

- In the event that the side wall horizontally vented gas fueled

equipment is installed in a crawl space or an attic, the hard wired

carbon monoxide detector with alarm and battery back-up may be

Regulations | 13

installed on the next adjacent oor level.

- In the event that the requirements of this subdivision can not be

met at the time of completion of installation, the owner shall have

a period of thirty (30) days to comply with the above requirements;

provided, however, that during said thirty (30) day period, a

battery operated carbon monoxide detector with an alarm shall be

installed.

• APPROVED CARBON MONOXIDE DETECTORS. Each carbon

monoxide detector as required in accordance with the above

provisions shall comply with NPA 720 and be ANSI/UL 2034 listed and

IAS certied.

• SIGNAGE. A metal or plastic identication plate shall be permanently

mounted to the exterior of the building at a minimum height of eight (8)

feet above grade directly in line with the exhaust vent terminal for the

horizontally vented gas fueled heating appliance or equipment. The

sign shall read, in print size no less than one-half (.) inch in size, “GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

• INSPECTION. The state or local gas inspector of the side wall

horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspections, the inspector observes carbon

monoxide detectors and signage installed in accordance with the

provisions of 248 CRM 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from 248 CRM

5.08(2)(a) 1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment Not Required

To Be Vented” in the most current edition of NFPA 54 as adopted by

the board; and

• Product Approved side wall horizontally vented gas fueled equipment

installed in a room or structure separate from the dwelling, building or

structure used in whole or in part for residential purposes.

(c) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT

VENTING SYSTEM REQUIRED. When the manufacturer of Product

Approved side wall horizontally mounted gas equipment provides a

venting system design or venting system components with the equipment,

the instructions provided by the manufacturer for the installation of the

equipment and venting shall include:

• Detailed instructions for the installation of the venting system or the

venting system components; and

• A complete parts list for the venting system design or venting system.

(d) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT

VENTING SYSTEM NOT PROVIDED. When the manufacturer of Product

Approved side wall horizontally vented gas fueled equipment does not

provide the parts for the venting of ue gases, but identies special

venting systems, the following requirements shall be satised by the

manufacturer:

• The referenced special venting systems shall be included with the

appliance or equipment installation instructions; and

• The special venting systems shall be Product Approved by the Board,

and the instructions for that system shall include a parts list and

detailed installation instructions.

(e) A copy of all instructions for all Product Approved side wall horizontally

vented gas fueled equipment, all venting instructions, all parts lists for

venting instructions, and/or venting design instructions shall remain with

the appliance or equipment at the completion of the installation.

SSB 6720818454 (2016/02) US

14 | Installation

4 Installation

4.1 Packaging and product identication

The SSB is delivered strapped to a pallet, packed and protected in a

cardboard carton.

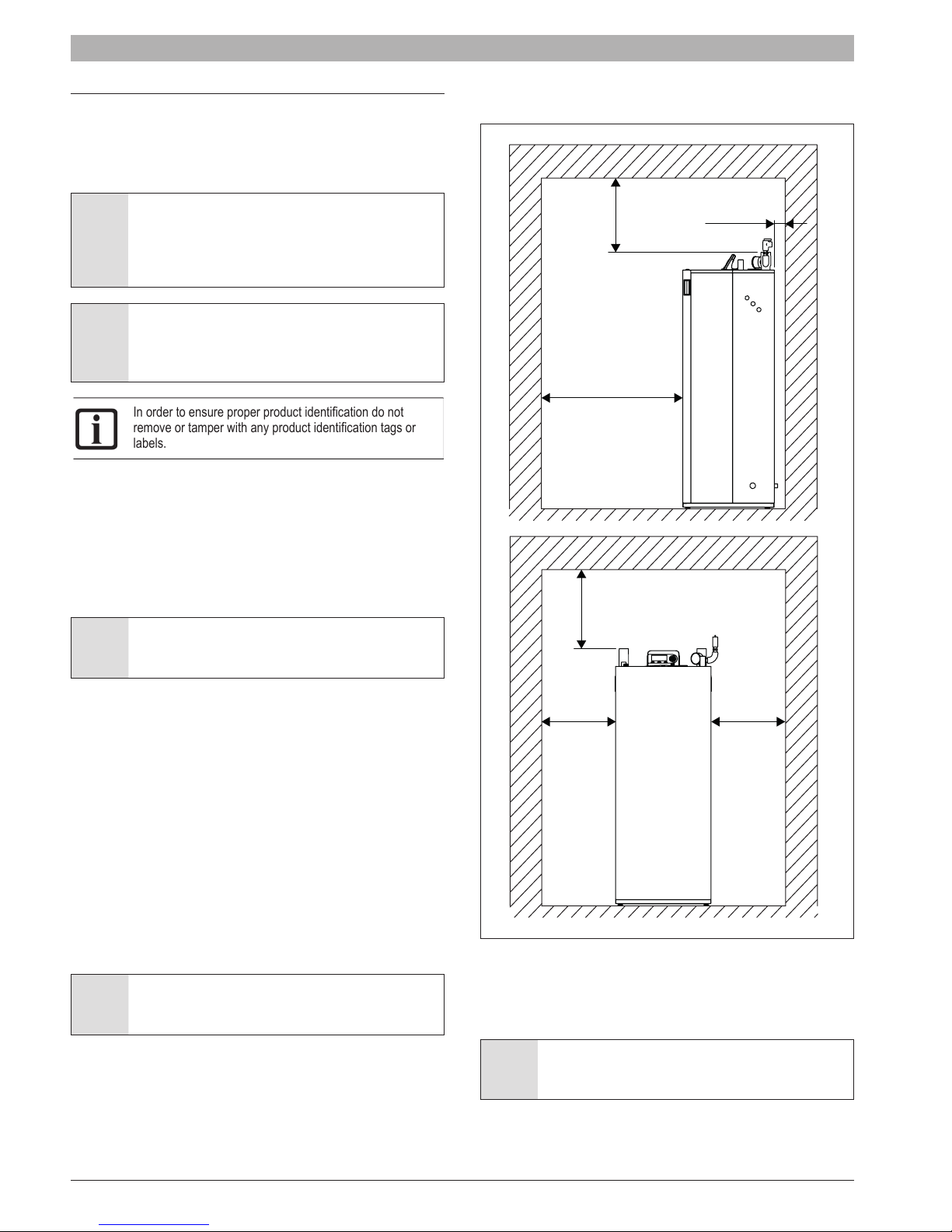

The recommended clearance for ease of installation and service are

illustrated in the following picture:

NOTICE: The packaging shows the characteristics of the

product: model, power, fuel type and version. In case of

deviation from the order, contact your local dealer.

After removing the packaging check the condition and

completeness of delivery.

WARNING: Keep the packing material out of reach of

children as it may be dangerous.

Dispose of packaging in an environmentally responsible

manner.

In order to ensure proper product identication do not

remove or tamper with any product identication tags or

labels.

4.2 Installation room

The boiler must be installed in rooms that comply with all local, state and

federal codes and laws. Before commissioning the boiler verify exhaust

ue and terminations are properly sealed and secured.

• Adequate combustion air and ventilation is required for safe and

proper installation of the boiler, regardless whether the combustion air

is taken from the outside (Direct Vent, sealed combustion) or inside

(room air for combustion).

WARNING: Insufcient ventilation of the boiler room can

lead to high air temperatures and lead to risk of personal

injury or death from ue gas poisoning!

2” (50mm)

20” (500mm)

40” (1000mm)

20” (500mm)

• Make sure that intake and exhaust openings are sufciently sized and no

reduction or closure of openings takes place. If these are not provided, do

not operate the boiler (see section “4.7.2 Connecting ue gas systems”).

• The heating units cannot be installed outdoors. NEVER place this

appliance in a location that would subject it to temperatures at or near

freezing or temperature that exceed 120°F (49°C) while in operation.

Failure to properly locate this unit can result in premature failure.

• This appliance must be installed in a location so that any water

leaking from the unit or piping connections or relief valve openings

will not cause damage to the area surrounding the unit or any lower

oors in the structure. When such locations cannot be avoided, it

is recommended that a suitable drain pan, adequately drained, be

installed under the boiler. The pan must not restrict combustion air ow.

• When installed in a room with thin ooring, resonating noises may

occur. Isolate the boiler from direct contact with the oor to minimize

noise transmission.

• Do not allow excessive dust to collect on the appliance.

WARNING: If the information in these instructions is not

followed exactly, a re or explosion may result causing

property damage, personal injury or death.

• Do not store or use gasoline or other ammable vapors and liquids in

the proximity of this or any other appliance.

• Installation and service must be performed by a qualied installer,

service agency or the gas supplier.

• Please consider the space needed for accessibility to safety and

control devices and for performing maintenance operations.

4” (100mm) 4” (100mm)

Fig. 9 Recommended minimum clearances for installation and

servicing (dimension in inches [mm])

2” (50.8 mm) clearance from combustibles is permitted, but respect the

clearance in Fig. 9 for serviceability”. The boiler can be installed on a

combustible (wood) oor excluding carpets.

NOTICE: This device is equipped with a freeze protection

function. For further information see section “5.8 Setting

frost protection”.

6720818454 (2016/02) US SSB

Installation | 15

4.3 Water Chemistry Guidelines

NOTICE: If using anti-freeze:

► Follow the boiler manufacturer’s instructions on

antifreeze concentration.

► Frost protection and inhibitor level has to be checked

annually during the regular scheduled maintenance of

the condensing boiler.

NOTICE: System damage!

► It is the installer’s responsibility to ensure that the

heating system is compatible with the boiler type and

size installed.

► pH-value of the heating water to be kept between 6.5

and 9.

To avoid any presence of oxygen in the system, it is advised to prevent as

little as possible air during installation. Usual spots where air is most likely

to seep in are: gaskets, pumps, air vents and O-rings gaskets. Using

an automatic water ll system exposes the system to fresh oxygenated

water. In commercial applications it is recommended to install a water

meter to measure the introduction of fresh water into the system.

A minimum water pressure is required for optimum performance.

Minimum water pressure required: 7.25 psi (0.5 bar).

Before and during assembly, the system must be kept free of impurities,

construction dust, sand, copper dust, grease, carbon deposits, etc., as

well as welding ux residue. In any of these instances, the old system

must be rinsed with clear water mixed with a highly concentrated rinse

agent.

For freeze protection use only propylene glycol, with scale inhibitors, with

a maximum volume [concentration] of 40% of glycol.

NOTICE: DO NOT use PVC for exhaust venting when using

anti-freeze in the primary circuit of the boiler. Use CPVC, PP

or stainless steel only!

Water hardness must fall within the following limits:

50 ppm of CaCO

► Use only untreated water to ll the system.

► Do not use TSP (tri-sodium phosphate).

► Do not use ll water treated with salt bedding type exchangers (ion

exchanger).

► Never introduce non-approved boiler treatment or similar additives.

► Only use ll water with a hardness below 7 grains.

► Filling with chlorinated water is acceptable if chlorine levels are below

100 ppm.

► Consult a local water treatment specialist for recommendations if any

of the above is outside the stated ranges.

► When using oxygen permeable PEX, the system must be separated

from the boiler by a heat exchanger.

► A correctly sized and working expansion vessel must be installed.

► Do not exceed the maximum permissible ow rate through the boiler.

► Excessive ow can cause erosion damage to the heat exchanger.

► Eliminate System Leaks:

Continuous addition of make-up water will constantly add oxygen to

the system and lead to corrosion. All system leaks must be repaired.

< (alkali strength) < 150 ppm of CaCO3.

3

In the following table are listed the chemical water specications.

Parameters Units Value

General feature - Colorless, no sediment

Dissolved Oxygen mg/l < 0,05

Total iron (Fe) mg/l < 0,3

Total copper (Cu) mg/l < 0,1

Na

2SO3

N

2H4

PO

4

Tab. 1 Water specication

mg/l < 10

mg/l < 3

mg/l < 15

4.4 Hydraulic connection

Hydraulic connection are shown in Fig. 2, Fig. 3 and Fig. 4. In the

following table are listed the pipe dimension for each model:

Model

SSB255 1-1/2” NPT male 1-1/2” NPT male

SSB399 1-1/2” NPT male 1-1/2” NPT male

SSB512 2” NPT male 2” NPT male

• Do not use cleaning uids that are not compatible with the boiler

materials, including acids (e.g. hydrochloric acid and similar ones) at

any concentration

• Introducing fresh water to the system increases the oxygen presence

and can cause corrosion of metallic components. Immediately repair

any drips or leaks in the system to avoid constant introduction of air

into the system.

• Do not use the water contained in the boiler for domestic use or as

drinking water or within swimming pools.

• Excessive uctuation in pressure changes in the system can cause

fatigue and stress on the heat exchanger. This is detrimental to the

integrity of the boiler and system components, it is mandatory to

maintain a constant operating pressure.

Ø Water supply

connection

NOTICE: Before connecting the boiler to the heating

system, ush the heating system to remove sediment, ux,

dirt, and other foreign matter. The heat exchanger may be

damaged by sediment or corrosion.

Ø Water return

connection

SSB 6720818454 (2016/02) US

16 | Installation

4.4.1 Low water cut off

A low water cut off (LWCO) is installed in the boiler, the manual reset

button is located on the front of the internal sliding wiring center.

To check the functionality of LWCO press the test button (the top button

shown in Fig. 10). The LED on the block will light and in the screen will

appear the error “MN: Low Water Cutoff Error”. At this point press the

reset button (the bottom button). The LED will turn off.

4.4.2 High limit safety switch

A high limit safety switch is installed in the boiler. To simulate a high limit

lockout at 208°F press the “MENU” and “OK” buttons simultaneously for

10 seconds. The control will display “MN: Max. Thermostat Lock Error”.

At this point press the reset button on the removable display to restart the

boiler.

LED

Test

Reset

4.4.4 Expansion tank

An expansion tank must be installed in the hydraulic system. The

expansion tank must be properly sized for the boiler and the system

volume, temperature and pressure.

WARNING: An undersized expansion tank will cause

leakage of water from the pressure relief valve and

introduce fresh water into the system. Excessive addition of

makeup water can cause corrosion of metallic components

and compromise the functionality of the boiler.

Refer to instructions provided by the manufacturer of the expansion tank

for details on its installation and sizing.

Fig. 10

Reset

Fig. 11

4.4.3 Pressure relief valve (PRV)

The boiler is supplied with a pressure relief valve (PRV). The relief

pressure for each valve for each model of the boiler is shown in the

following table:

Boiler model Relief Pressure

SSB255 30 psi (2.07 bar)

SSB399 30 psi (2.07 bar)

SSB512 75 psi (5.17 bar)

A 75psi pressure relief valve can be purchased separately and eld

installed.

The pressure relief valve (PRV) must be piped to a suitable drain to

prevent injury if the valve releases. Use a pipe of the same diameter of

the outlet of the valve

6720818454 (2016/02) US SSB

Installation | 17

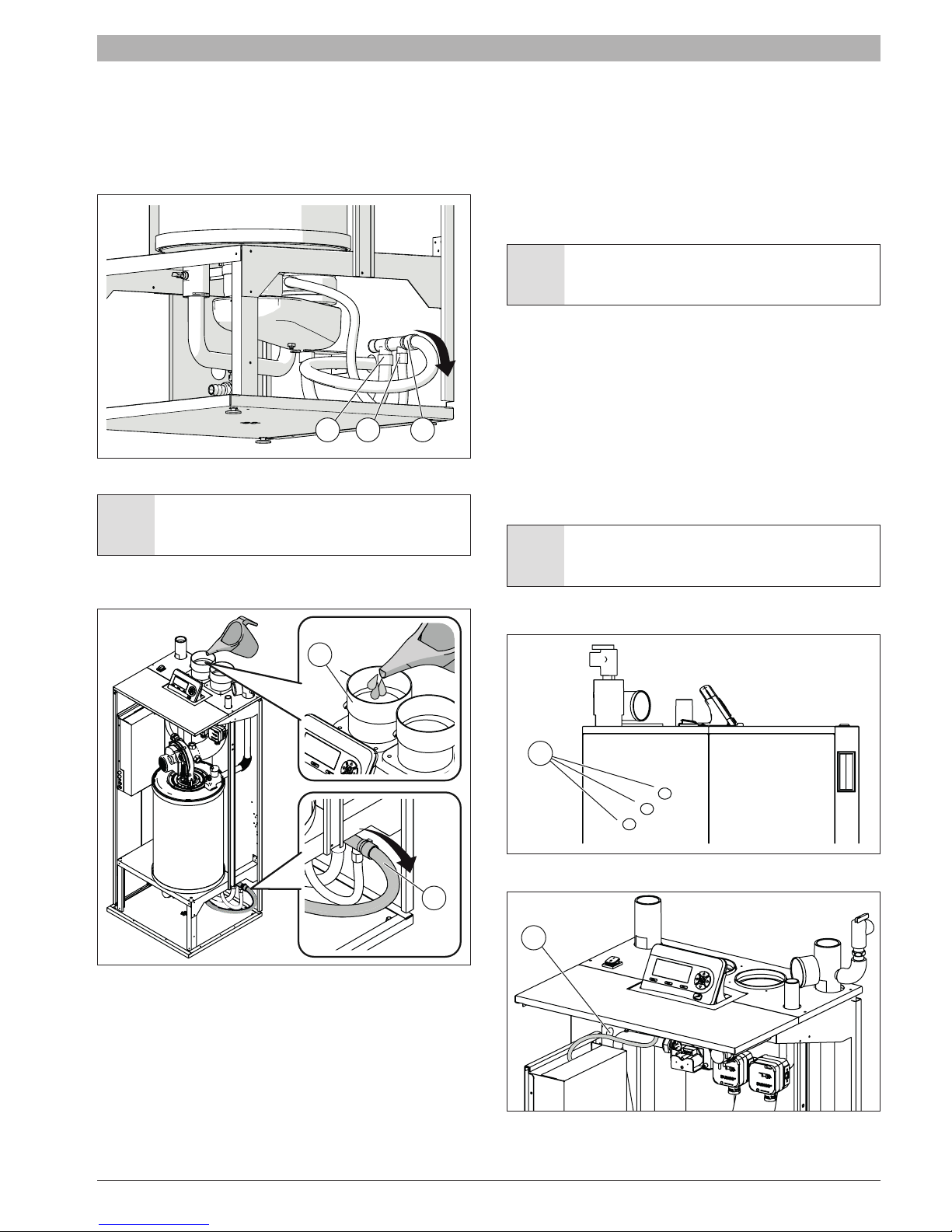

4.4.5 Pump

SSB boilers must be tted with a circulator pump. The graph in the following gure shows the pressure drop through the boiler circuit depending on the

ow rate.

SSB255

∆ p/ Feet of Head

8

7

6

5

4

3

2

1

0

0510 15 20

Fig. 12 SSB255 Pressure drop

It is important to ensure the pump has the correct ow rate

for the system to avoid a low water circulation situation. In

event of an inadequate ow rate, the safety devices of the

boiler will automatically stop the burner.

Flowrate / GPM

SSB 6720818454 (2016/02) US

18 | Installation

SSB399

∆ p/ Feet of Head

18

16

14

12

10

8

6

4

2

0

0510 15 20 25 30 35

Fig. 13 SSB399 Pressure drop

SSB512

∆ p/ Feet of Head

40

35

30

25

20

15

10

5

Flowrate / GPM

0

0510 15 20 25 30 35 40

Fig. 14 SSB512 Pressure drop

6720818454 (2016/02) US SSB

Flowrate / GPM

Installation | 19

H2O

1

H2O

2

4.4.6 Condensate removal

The condensate water produced by the boiler during its normal operation

is collected by two plastic pipes (A and B) provided with the boiler and

connected with a plastic collector inside the case. A third tube (C) collects

the condensate output from the collector [Arrow is the direction of ow of

condensate].

A B C

Fig. 15

DANGER: The condensate pipe A and B, shown in Fig. 15,

must be lled with water or combustion gases will enter the

room with a risk of an excessive level of carbon monoxide.

To ll the condensate discharge add water from the vent (1) until you see

water come out of the condensate discharge pipe (2).

stream.

• Never use copper pipes or of other material not intended for the

specic purpose, because the action of condensate will cause a rapid

deterioration.

• Check that the condensate drain pipe is adequately sloping towards

the discharge point avoiding high points, which can inhibit the ow of

condensate.

• Install the condensate pipe in such a way so as to avoid the freezing

of the liquid.

NOTICE: Verify condensate disposal / neutralization is in

accordance with local, state and federal regulations.

A condensate removal pump is required if the boiler is below the drain.

When installing a condensate pump, select one approved for use with

condensing boilers and furnaces. The pump should have an overow

switch to prevent property damage from condensate leakage.

4.5 Electrical connection

4.5.1 Power supply cable connection

To connect the boiler to the electrical supply, as required by local, state

and federal codes, provide and install a service switch (15 amp is

recommended).

The power supply cable can be inserted into the boiler using one of the

six knock out holes (A) on the sides as shown in Fig. 17.

WARNING: All the electrical wiring must be secured by

appropriate strain reliefs.

To secure the supply cable inside of the boiler use the cable clamp shown

in position B shown in Fig. 18.

A

Fig. 17

B

Fig. 16

The condensate water shall be discharged at atmospheric pressure,

i.e. by dripping into a siphon-shaped container connected to the home

sewage system or suitable drain, and shall be neutralized prior to draining

per local codes.

The boiler is equipped with three holes (in the right, left and back side) to

carry the condensate out the condensate drain tube.

Install the condensate drain tube through the appropriate hole and be

sure to pitch away from the boiler.

• Do not reduce the diameter of the condensate drain pipe down

SSB 6720818454 (2016/02) US

Fig. 18

20 | Installation

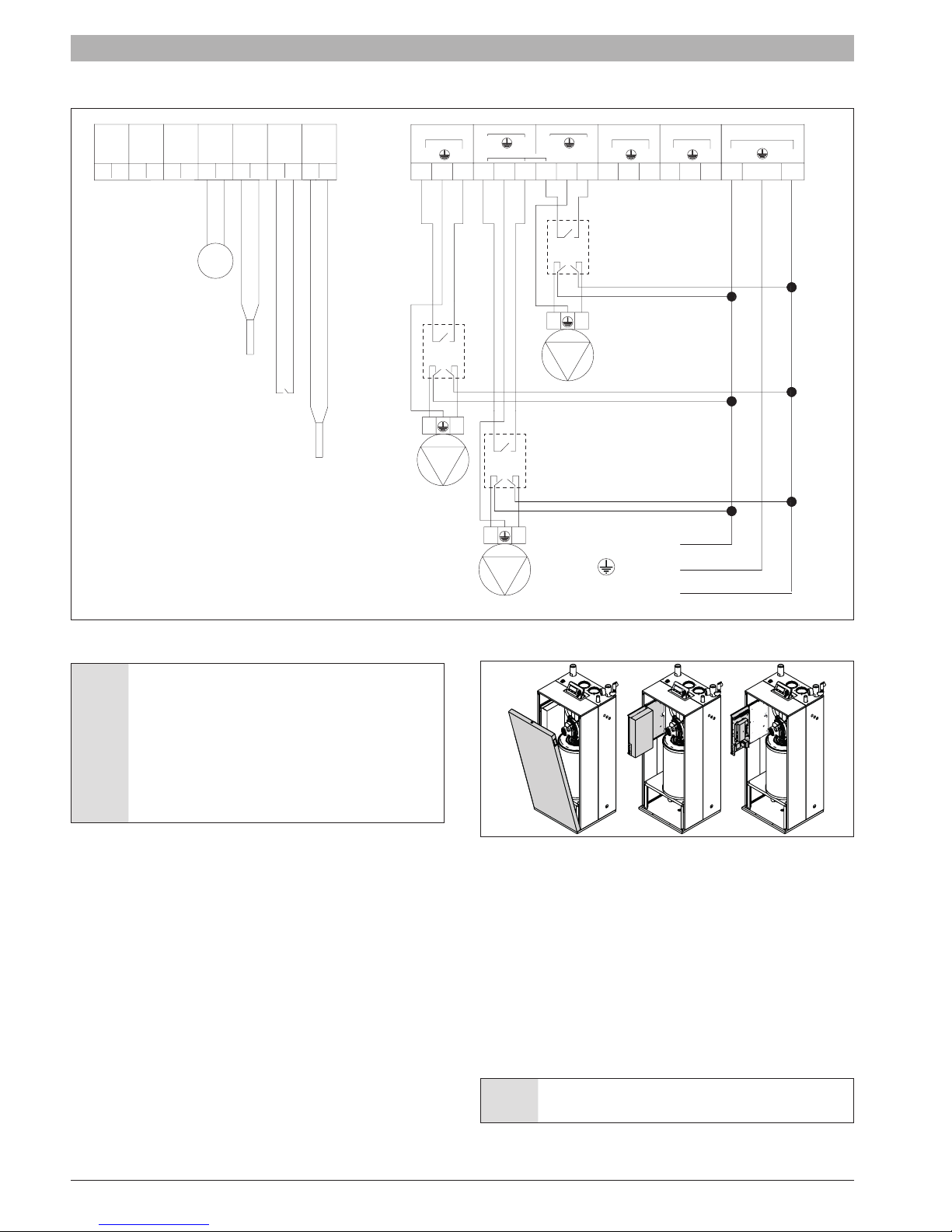

The general electrical connection is shown in the following diagram :

CASCADE

MOD

BUS

Switch

4567

Gas

LINK

123

Outdoor sensor

DHW tank sensor

or aquastat

Room thermostat

DHW Tank

Out

Door

89

Room

Thermostat

Sensor

10 11 12 13 14

Supply sensor

Supply

Sensor

Furnished

Relay (*)

and

Installed

by others

Boiler pump

System pump

Boiler

Pump

L

101102 103104 105106 107108 109

L

Pump CH

L

3 Way

N

N

Pump DHW

N

L

L

N

Relay (*)

Furnished and

Installed by others

L

N

120 V Neutral

N

L

110111 112

Alarm

N

L

113114 115

120 V Aux

Relay (*)

Furnished and

Installed by others

DHW tank pump

120 V Line

Ground

N

120 V Main in

L

116118117

(**)

N

Fig. 19

(*) NOTICE: The maximum amp load for each pump is 1 A

when 2 or 3 pumps are connected. For this reason, if the

power consumption of each pump is higher than 84 watt,

use a relay as shown in gure.

If just one pump is connected, the maximum amp load

of this single pump is 2 A. For this reason if the power

consumption of the pump is higher than 168 watt, use a

relay as shown in gure Fig. 19.

(**) NOTICE: line voltage.

4.5.2 Access to the electrical terminal strip

To have access to the internal terminal strip of the boiler follow the steps

below (see Fig. 20).

► Rotate the lock at the top on the front panel and remove the front

panel as shown.

► Slide out the electrical box and remove the two screw from the front.

► Remove the box cover to have access to the terminal strip.

Fig. 20

4.5.3 Room thermostat connection

Connect the thermostat to terminals 11 and 12 as shown in Fig. 19.

4.5.4 Outside temperature sensor

If outside temperature control is to be used, the outside probe needs

to be connected to terminals 7 and 8 as shown in Fig. 19. The outside

probe shall be installed on an outer wall, North or North/East, away from

windows, door, and ventilation grids. Never install the probe in a position

exposed to the sun.

The maximum length is 300’ (100 meter), if the cable length exceeds

32’ (10 meters) a shielded cable is required and shall be connected to

chassis ground.

6720818454 (2016/02) US SSB

NOTICE: All Sensors and low voltage wiring shall not be

routed in direct contact or near high voltage power.

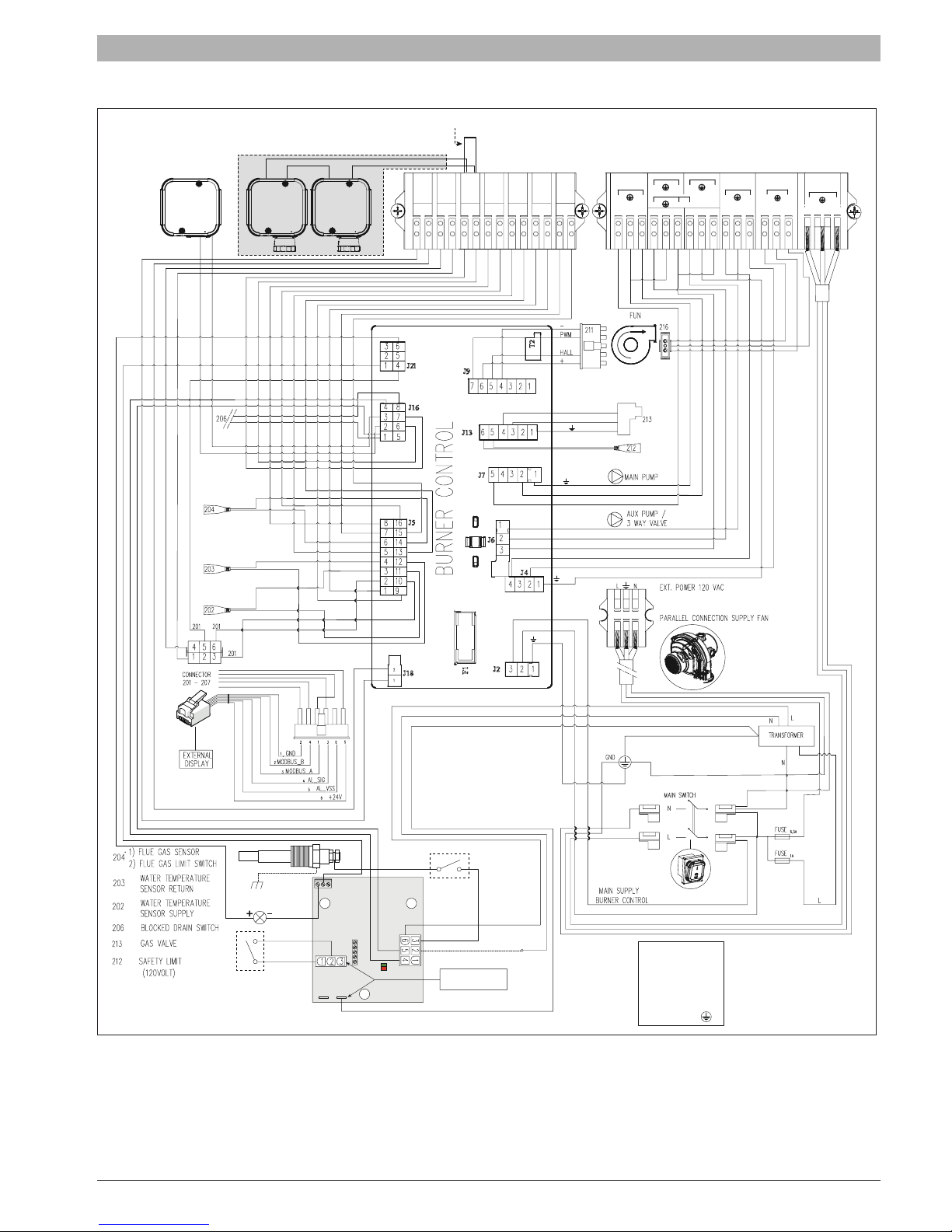

4.5.5 Electrical wiring diagram

FLUE

PRESSURE

SWITCH

PRESSURE

SWITCH

MAX

SSB512 ONLY

PRESSURE

SWITCH

MIN

SSB255 ONLY - SSB399 ONLY

CASCADE

LINK

12

MOD

BUS

34

GAS

SWITCH

OUT

DOOR

65

LOW VOLTAGE

IN / OUT

DHW

Supply

Room

Sensor

Tank

Ther-

Sensor

mostat

978

10

13

11 12

Installation | 21

HIGH VOLTAGE

OUT

PUMP CH

MAIN PUMP

14

L

103101102

PUMP DHW

NL NL

3 WAY

N

NL L

109107108

106104105

110

ALLARM

111

120 V AUX

NL

112

VOLTAGE

NL

116

115113114

HIGH

120 V

MAIN IN

L

117

N

118

w

w

blu

blu

blu

blu

blu

blu

brn

brn

brn

brn

blu

o

bl

blu

brn

blu

brn

24 V

bl

brn

blu

blu

brn

brn

brn

blu

w

brn

brn

blblugbrn

blubrn

bl

bl

blu

brn

brn

GND

bl

w

GND

w

N

GND

bl

bl

w

GND

w

bl

brn

w

113114115

L

bl w

bl

brn

w

bl

bl

w

w

bl w

24V

24V

CHASSIS

GROUND

(Via Boiler / Piping)

TEST

External Test Switch

(Normally Closed,

Opens to Test)

214

209

208

210

w

210

bl

210

209

bl

208

bl

bl

w

120V

AR1

w

w

214

208

w

209

bl

214

AR1

HIGH VOLTAGE

24 VAC HOT

PROBE

Manual Reset Switch

(Normally Closed,

Opens to Reset)

RESET

P

GND

AC COMMON

Alternate Chassis

Ground Connection

brn= CABLE BROWN

blu= CABLE BLUE

bl= CABLE BLACK

w= CABLE WHITE

o= CABLE ORANGE

g= CABLE GRAY

L= LINE

N= NEUTRAL

grn/yel = Ground

Fig. 21 Wiring diagram

SSB 6720818454 (2016/02) US

Loading...

Loading...