Bosch SSB1000 SA, SSB800 SA, SSB1000 TL User Manual

WARNING:

Improper installation, set-up, modication, operation or maintenance of

the heating system can cause personal injury and property damage.

Follow these instructions precisely.

If you require assistance or further information, contact a trained and

certied installer.

WARNING:

The operating instructions are part of the technical documents that

must be handed over to the owner or operator of the heating system.

Explain to the owner or operator how to use the heating system using

the operating instructions. Make sure that they are familiar with all

required information for the safe and proper operation of the heating

system.

These instructions are available in English and French.

Please keep these instructions for future reference.

BUDERUS SSB BOILER

CONTROL SYSTEM MANUAL

SSB800 SA | SSB1000 SA | SSB1000 TL

Installation and Service Instructions for Contractors

6720892984 (2019/02) US

2 |

Contents

1 Key to symbols and safety instructions .............. 4

1.1 Key to symbols ..................................4

1.2 Safety instructions ...............................4

1.3 General warning .................................4

STAND-ALONE BOILER (Burners Cascade) - SYSTEM

2

ARCHITECTURE

2.1 General........................................6

2.2 905TS Control Systemn ...........................6

2.2.1 Modbus connection 905PB and 905TS ...............6

2.2.2 Setpoints on touch screen .........................7

2.3 2 Burners Cascade with Touchscreen and Building

2.4 Dipswitch setting for 2 Burners Cascade ..............8

2.5 Additional device specifications .....................8

BURNERS cascade ...........................9

3

3.1 Burner cascade communication setup ................9

3.2 Setting the burner address (Rev. 4.0.905.15250)........9

3.2.1 E2prom address selection through e2prom setting ......9

3.2.2 E2prom address selection through dip-switch input......9

3.2.3 Communication with LabVision PC software ..........10

3.3 Cascade – Heating only (Rev. 4.0.905.15250).........10

3.3.1 Cascade – domestic hot water .....................12

3.3.2 Cascade – DHW priority (Rev. 3.0.0.12377) ..........12

3.3.3 Limitation of the MAX power for DHW (Rev.

3.3.4 Cascade – start/stop sequence (Rev. 3.0.0.12315) .....13

3.3.5 Cascade – power balance mode (Rev. 4.0.905.15906) ..15

3.3.6 Cascade – burner rotation (Rev. 4.0.905.x) . . . . . . . . . . .17

3.3.7 Cascade – error handling .........................17

Service display .............................18

4

4.1 General.......................................18

4.1.1 Introduction....................................18

4.1.2 General information .............................18

4.1.3 Display functions ...............................18

4.1.4 Display icons ..................................18

4.2 Screens ......................................19

4.2.1 Splash screen (Rev 1.1.0.13425)...................19

4.2.2 Entering the menu ..............................19

4.2.3 Protected menu items ...........................19

4.2.4 DAir Sequence .................................20

4.2.5 Language settings ..............................20

4.3 Menu Structure.................................22

Main control ...............................26

5

5.1 Ignition cycle (Rev 3.0.0.0)........................26

5.2 Control functions ...............................26

5.2.1 Demand for central heating (Rev 3.0.0.0) ............26

5.2.2 Demand for Domestic Hot Water (Rev 3.0.0.0) ........31

............................. 6

Management System (BMS) .......................7

4.0.905.16570) .................................12

5.3 Safety and system function .......................34

5.3.1 Flame detection (Rev 3.0.0.0) .....................34

5.3.2 Ionization jumper (Rev 3.0.0.0) ....................34

5.3.3 Flame recovery (Rev 3.0.0.0)......................34

5.3.4 Overheat detection (safety limit) (Rev 3.0.0.0).........34

5.3.5 Sensor availability (Rev 3.0.0.0)....................34

5.3.6 Pump start every 24 hours (Rev 3.0.0.0) .............35

5.3.7 Frost protection (Rev 3.0.0.0)......................35

5.3.8 Flue temperature protection (Rev 3.0.0.0) ............36

5.3.9 Input configuration 900MN (Rev 4.0.905.16712) .......36

5.3.10 Output configuration 900MN (Rev 4.0.905.16712) .....36

5.3.11 Heat exchanger protection: max differential (Rev 3.0.0.0) 37

5.3.12 Appliance selection (Rev 3.0.0.0)...................37

5.3.13 Anti-legionella protection (Rev 3.0.0.0) ..............37

5.3.14 De-Air sequence (Rev 3.0.0.0).....................38

5.3.15 Low water cut off (Rev 3.0.0.0).....................39

5.3.16 Heat exchanger protection (Rev 3.0.0.0) .............39

Boiler cascade..............................41

6

6.1 Extended 4x2 boiler/burner cascade with Touch Screen

and Building Management System (BMS) ............41

6.2 Compensation for secondary manifold temperature on

single boiler ...................................42

6.3 Set Switches for all cascade boards ................42

6.3.1 Power off all the boards ..........................42

6.3.2 Set AL Power switch S1 and Dip switch for 905MN

Managing of Boiler X ............................42

6.3.3 Set AL Power switch S1 and Dip switch for 905MN

Dependent boards ..............................42

6.4 Set the Modules and Boiler Cascade Settings ........42

6.4.1 Cascade of Modules: Set the address for all the

modules Boards ...............................42

6.4.2 Cascade of Modules: Set Number of expected Modules

(to do only in the managing of Modules) .............42

6.4.3 Cascade of Boilers: Set Boiler Address for all the

Managing boards ...............................42

6.4.4 Cascade of Boilers: Set Number of expected Boiler (to

do only in the managing of Boiler) ..................42

System test................................43

7

7.1 System test (Rev 3.0.0.0).........................43

7.1.1 System test for cascade burners with air-damper

functionality ...................................43

7.2 Physical high limit test mode. (100°C +/- 5°C).........43

7.2.1 Starting the test ................................43

7.2.2 Running the test ................................43

7.2.3 Stopping the test ...............................44

7.2.4 Monitoring of attempts ...........................44

7.2.5 Limitations ....................................44

7.3 LWCO Error evaluated at Boiler level................44

7.4 System test in cascades with air damper ............44

Service reminder ............................45

8

8.1 Service Reminder...............................45

6720892984 (2019/02) US SSB

8.1.1 Service Reminder...............................45

8.1.2 Service Overdue logging .........................45

8.1.3 Service Reminder implementations .................45

8.1.4 Resetting the Service Reminder....................45

8.1.5 Menu’s and Parameters ..........................45

| 3

Appendix A - Connection diagram

Appendix B - Maximum load on outputs

Appendix C - System parameters

Appendix D - Control System Technical Specifications

Appendix E - NTC sensor curve selection (Rev 3.0.0.0)

Appendix F - 5 Error table (Rev. 4.0.905.17114)

Appendix G - PID: Proportional-Integral-Derivative controller

Appendix H - Cascade parameter

Appendix I - Connector description for 905mn1x (120vac version)

Appendix J - PB Connectors Description

Appendix K - Modbus

............................67

....................46

.................48

.....................49

.......54

.......55

.............55

...59

.....................62

. . . . . . . . . . . . . . . .65

63

Appendix L - Safety timing

Appendix M - Building Management System (BMS) Registers

Specifications

.........................73

..............................75

SSB 6720892984 (2019/02) US

4 | Key to symbols and safety instructions

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

Warnings in this document are identied by a warning

triangle printed against a grey background.

Keywords at the start of a warning indicate the type and

seriousness of the ensuing risk if measures to prevent the

risk are not taken.

The following keywords are dened and can be used in this document:

DANGER

•

result in death or serious injury.

WARNING

•

could result in death or serious injury.

CAUTION

•

could result in minor to moderate injury.

NOTICE

•

Important information

1.2 Safety instructions

Observe these instructions for your safety.

The burner and control must be correctly installed and adjusted to ensure

safe and economical operation of the gas boiler.

Read this installation and maintenance manual carefully and note the

details on the boiler nameplate before placing the boiler in operation.

Risk of fatal injury from explosion of ammable gases

If you smell gas there is a danger of explosion.

► Never work on gas lines unless you are licensed contractor / gas tter.

► Make sure that a licensed contractor / gas tter installs the boiler,

connects gas and vent, places the boiler in operation, connects the

electrical power, and maintains and repairs the boiler.

► No open ame! No smoking! Do not use lighters.

► Prevent spark formation. Do not operate electrical switches, including

telephones, plugs or door bells.

► Close main gas valve.

► Open doors and windows.

► Warn other occupants of the building, but do not use door bells.

► Call gas company from outside the building.

► If gas can be heard escaping, leave the building immediately, prevent

other people from entering, notify police and re departments from

outside the building

Risk to life from electrical shock.

► Disconnect the power supply to the boiler heating system before

conducting any work on it, e.g. turn off the heating system emergency

switch outside the boiler room.

► It is not sufcient just to turn off the control.

► Do not carry out electrical work unless you are qualied for this type

of work.

► Before servicing disconnect electrical power and lock out to prevent

indicates a hazardous situation which, if not avoided, will

indicates a hazardous situation which, if not avoided,

indicates a hazardous situation which, if not avoided,

is used to address practices not related to personal injury.

This symbol indicates important information where there is

no risk to people or property.

accidental reconnection.

► Observe and follow the local, state and federal installation regulations.

Risk of fatal injury from ue gas poisoning

Insufcient ventilation or combustion air availability may cause dangerous

ue gas leaks or formation.

► Make sure that inlets and outlets are not reduced in size or closed.

► If faults are not corrected immediately, the boiler must not be operated

until all faults have been corrected.

► Inform the system operator and/or owner of the fault and the danger

in writing.

When working on the ue gas venting equipment or vent damper leakage

of ue gases may endanger the lives of people.

► Carefully observe proper operation of the vent damper. Do not start up

the boiler unless the vent damper is operating properly.

► Use only original parts when replacing parts.

► When replacing the vent damper, install the new one in the specied

position.

Risk to life by poisoning by spillage of ue gases

► If the blocked vent switch trips frequently the fault must be corrected

and proper operation of the blocked vent switch test must be

conducted.

Risk to life by poisoning by leakage of ue gases

► Make sure that the boiler is not equipped with a thermally controlled

ue gas vent damper after the open draft hood.

Risk of fatal injury from neglecting your own safety in case of

emergency, such as with a re

► Never put yourself at risk. Your own safety must always take priority.

Fire danger due to ammable materials or liquids

► Make sure that there are no ammable materials or liquids in the

immediate vicinity of the boiler.

► Maintain a minimum distance of 15 inches from the boiler.

Installation and maintenance

► Observe all current standards and guidelines applicable to the

installation and operation of the boiler heating system as applicable in

your state or local jurisdiction.

► Clean and service the boiler system once a year. Check that the

complete heating system operates correctly.

► Immediately correct all faults to prevent system damage.

► Only use original Bosch spare parts. Losses caused by the use of

parts not supplied by Bosch are excluded from the Bosch warranty.

1.3 General warning

The installation must conform to the requirements of the authority having

jurisdiction or, in the absence of such requirements, to the latest edition

of the National Fuel Gas Code, ANSI Z223.1./NFPA 54. In Canada,

installation must be in accordance with the requirements of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

Where required by local, state and federal regulations, the system must

comply with the American Society of Mechanical Engineers Safety Code

for Controls and Safety Devices for Automatically Fired Boilers (ASME

CSD-1).

The hot water distribution system must comply with all applicable codes

and regulations. When replacing an existing boiler, it is important to check

the condition of the entire hot water distribution system to ensure safe

operation.

Valves external to the boiler must be tted with T-handles and condensate

piping must be installed in accordance with the State Plumbing Code.

6720892984 (2019/02) US SSB

NOTICE:

► This boiler must be installed by a licensed contractor/ gas tter.

Failure to do so shall void the product warranty.

► The boiler is intended only for the use for which it was specically

designed and built. Bosch is hereby excluded from any liability for

damages caused to persons, animals or property resulting from

installation errors, improper adjustment, maintenance or use.

► In order to ensure safety and correct operation, the installation shall

always take place in full compliance with the applicable codes and

following with the instructions provided by the manufacturer, and must

always be carried out by a licensed contractor / gas tter only.

► The equipment must be installed in appropriate place and in

combination with appropriate systems as specied by code.

► The unit may be exposed to temperatures between 5 deg F (-15°C)

and 150 deg F (65°C) in its original packaging. Do not expose the

unit to weather without the protection of the original packaging until

the boiler has been properly installed. Until then there is no frost

protection for the boiler.

► After removing the packaging check the integrity and completeness of

delivery and in case of non-compliance, contact your dealer.

► If there is a water loss, disconnect the boiler from the main power

supply, close the water supply and immediately call technical

assistance or installer/local contractor.

► Periodically check that the condensate drain is free from obstruction.

► Periodically check the system pressure. System pressure should be

checked when the system is in standby mode and no call for heat is

present.

► Maintenance is mandatory and shall be carried out at least once a

year.

► This manual shall be read carefully, in order to install and operate the

boiler appropriately, and safely.

► Boiler installations, settings and service should only be performed by

experienced licensed contractor / gas tter. End Users should only

make adjustments with the assistance of a licensed contractor / gas

tter.

► Any maintenance operation or service before disconnecting the boiler

from the main power supply is forbidden.

► Do not remove or modify safety equipment.

► Do not pull or twist the electrical wires, from the boiler, even if the

device is disconnected from the main power supply.

► Do not obstruct or reduce the ventilation openings.

► Do not install the unit outdoors.

► Do not leave any combustibles or containers of ammable substances

in the room where the boiler is installed.

► Keep packing material out of reach of children as it can be potentially

dangerous. It must be disposed of as required by law.

► The opening of metal casing of the device and removing of the cover

are prohibited to the end user. Any service on the boiler must be

carried out by authorized personal.

► It’s prohibited to dispose the product as domestic waste. The

separate disposal of a household appliance avoids possible negative

consequences for the environment and human health deriving from

inappropriate disposal and allows to recover the materials it is made

of in order to achieve signicant savings in energy and resources.

Key to symbols and safety instructions | 5

SSB 6720892984 (2019/02) US

6 | STAND-ALONE BOILER (Burners Cascade) - SYSTEM ARCHITECTURE

2 STAND-ALONE BOILER (Burners Cascade) - SYSTEM ARCHITECTURE

2.1 General

The 900 series burner controls are designed to function as a standalone control unit for intermittent operation on heating appliances with a premix

(modulating) burner and a pneumatic air-gas system.

This specication is suitable for the following version:

PN: 900MN 900MN type for Commercial units

2.2 905TS Control Systemn

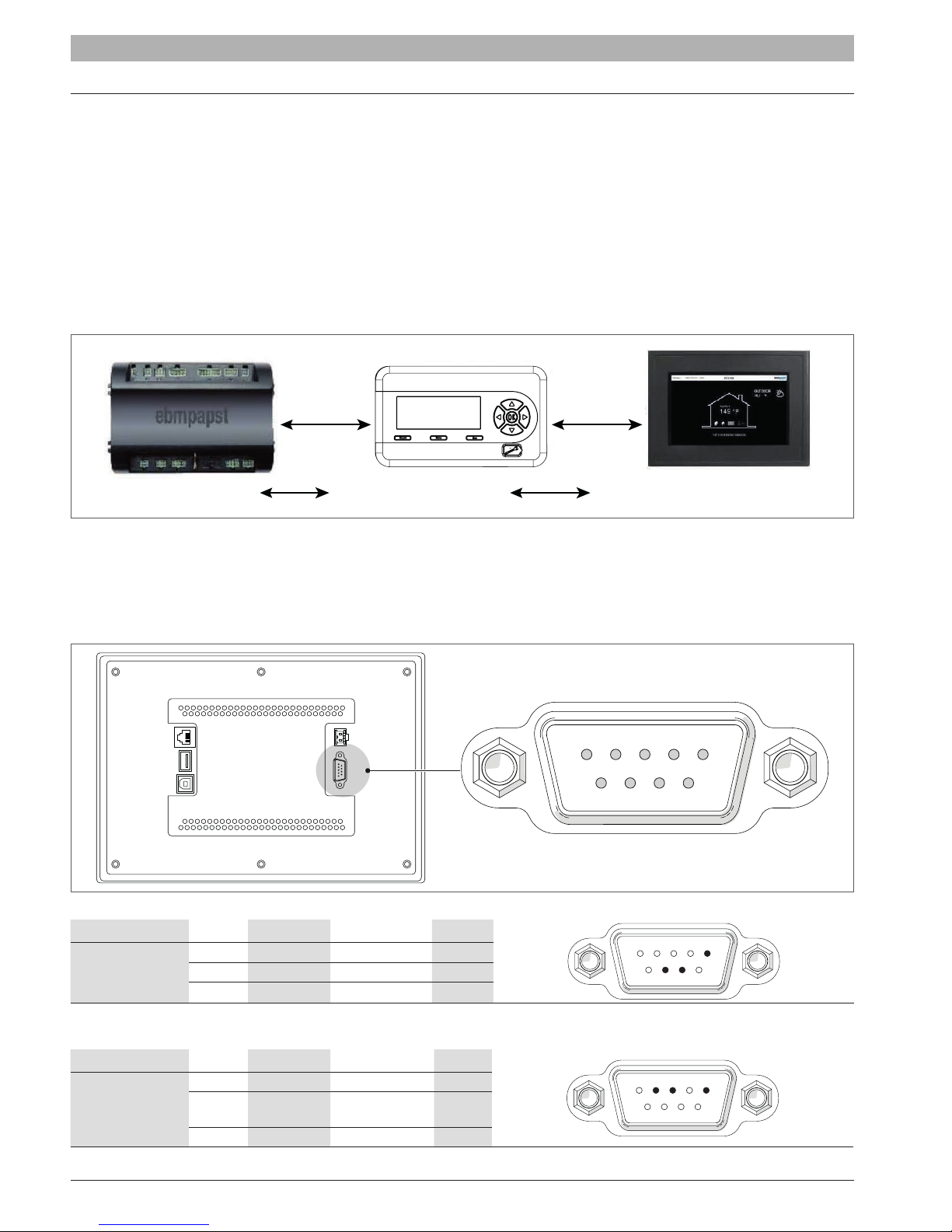

The following scheme shows the communication protocols the 905 Modules use to communicate with each other:

AL-BUS MODBUS

905MN control (J6)

905PB Display (J25)

905TS Touch Screen (COM2)

2.2.1 Modbus connection 905PB and 905TS

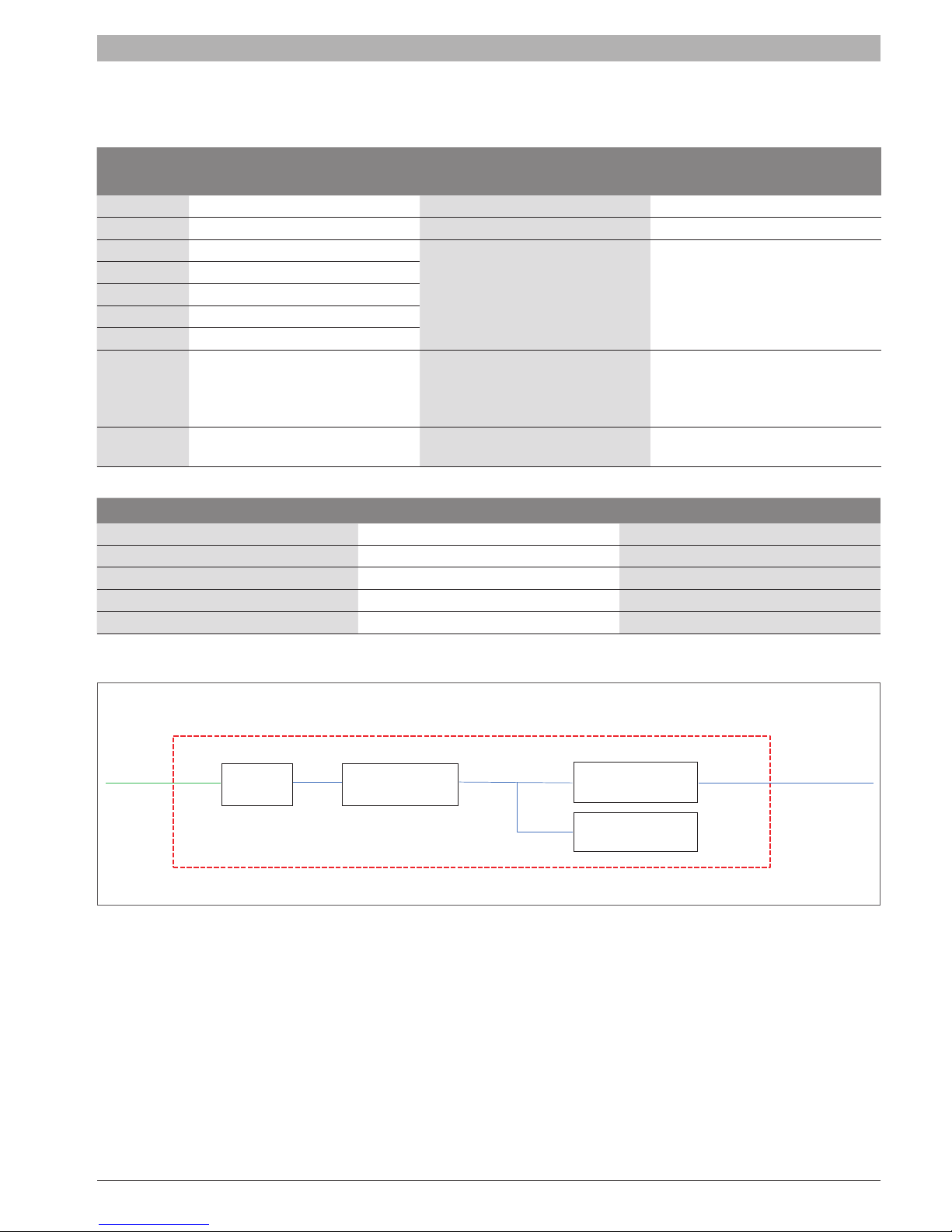

The 905TS has a port on the backside called ‘COM’, which is used to communicate with the 905PB display by MODBUS. The following illustration shows

the location of the COM port (backside 905TS) and pin-numbering:

LANUSB1USB2

+ -

24VDC

COM

1 2 3 4 5

6 7 8 9

Primary connection to 905PB:

Communication Pin Function Connect to

COM2

(Master)

5 GND 905 PB (J25-1)

7 RS 485 + 905 PB (J25-3)

8 RS 485 - 905 PB (J25-2)

1 2 3 4 5

6 7 8 9

Optional secondary interface:

Communication Pin Function Connect to

2 RS 232 RXD External Adapter RS 485

COM1

(Slave)

3 RS 232 TXD External Adapter RS 485

5 GND

6720892984 (2019/02) US SSB

1 2 3 4 5

6 7 8 9

STAND-ALONE BOILER (Burners Cascade) - SYSTEM ARCHITECTURE | 7

2.2.2 Setpoints on touch screen

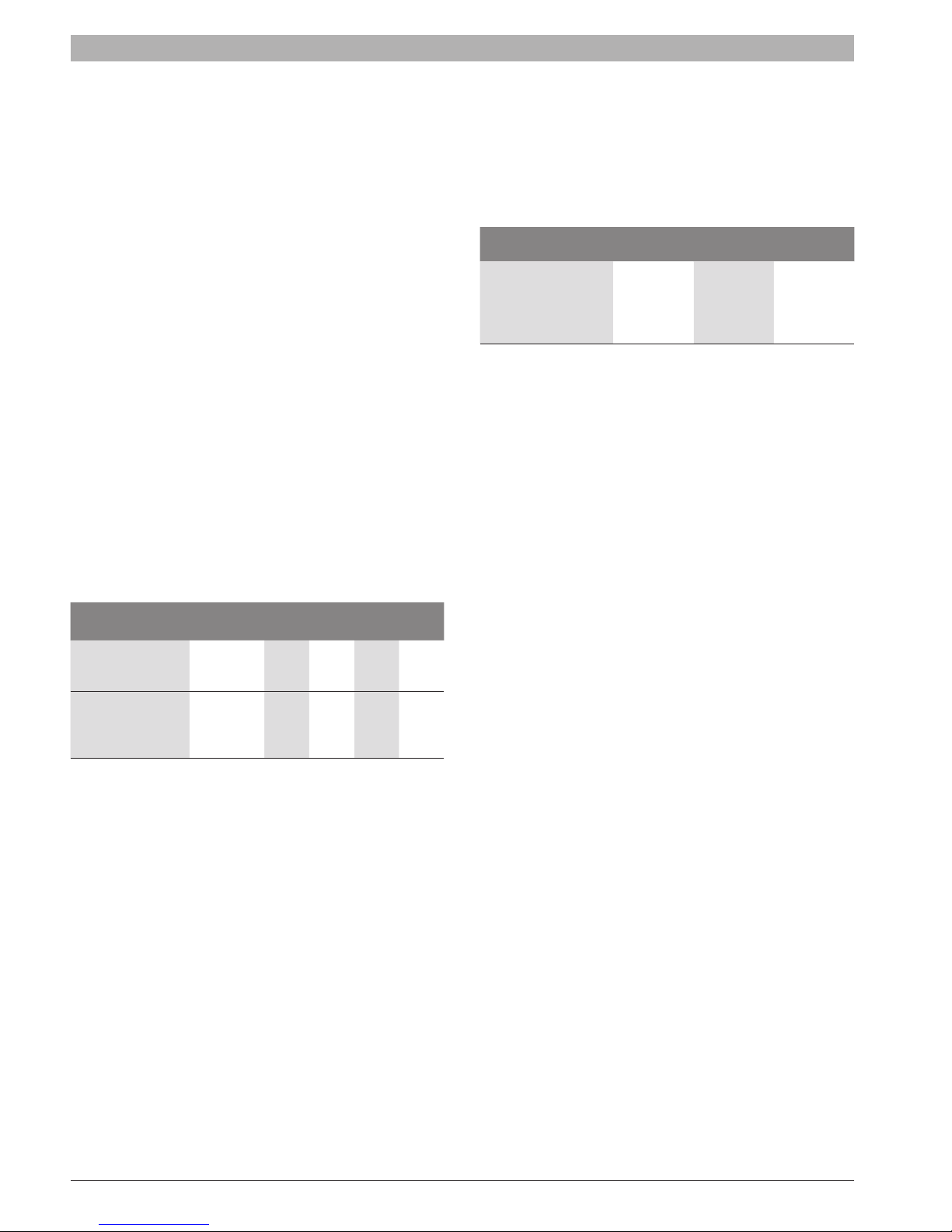

The following table describes the setpoints that are shown on ver 2.d or higher:

CH mode

Cascade screen – System setpoint

Cascade system supply setpoint

Boiler screen – Boiler Setpoint Cascade

boiler supply setpoint

Module screen – Module Setpoint

Burner supply setpoint

No demand CH Mode X setpoint Frost Protection Setpoint Frost Protection setpoint

Frost CH Mode X setpoint Frost Protection Setpoint Frost Protection setpoint

0 Parameter CH setpoint

1 Calculated outdoor setpoint

2 Calculated outdoor setpoint

3 Calculated outdoor setpoint

Cascade system supply setpoint

+

increase calculated by the boiler cascade

controller

Cascade boiler supply setpoint

+

increase calculated by the burner/module

cascade controller

4 0-10V input setpoint

Cascade boiler supply setpoint

Emergency

Cascade

See above Cascade System Emergency Setpoint

increase calculated by the burner/module

+

cascade controller

Emergency

Boiler

See above Boiler Emergency Setpoint Boiler Emergency Setpoint

The following table describes how the setpoint is limited in a cascade system:

E2_Ch_Max_Setpoint 90°C / 194°F = Absolute maximum setpoint

Controller maximum setpoint = 90°C / 194°F E2_CH_Reset_Curve_Boiler_Maximum

CH Control range

Controller minimum setpoint = 30°C / 86°F E2_CH_Reset_Curve_Boiler_Minimum

E2_Ch_Min_Setpoint 20°C / 68°F = Absolute minimum setpoint

2.3 2 Burners Cascade with Touchscreen and Building Management System (BMS)

Single boiler containing up to 2 modules/burners

BMS bus

RS485

RS232

Touch Screen

Module / burner 1

Module / burner 2

Cascade bus

SSB 6720892984 (2019/02) US

8 | STAND-ALONE BOILER (Burners Cascade) - SYSTEM ARCHITECTURE

1

ON DIP

2 3 4 5 6 7 8

1

ON DIP

2 3 4 5 6 7 8

1

ON DIP

2 3 4 5 6 7 8

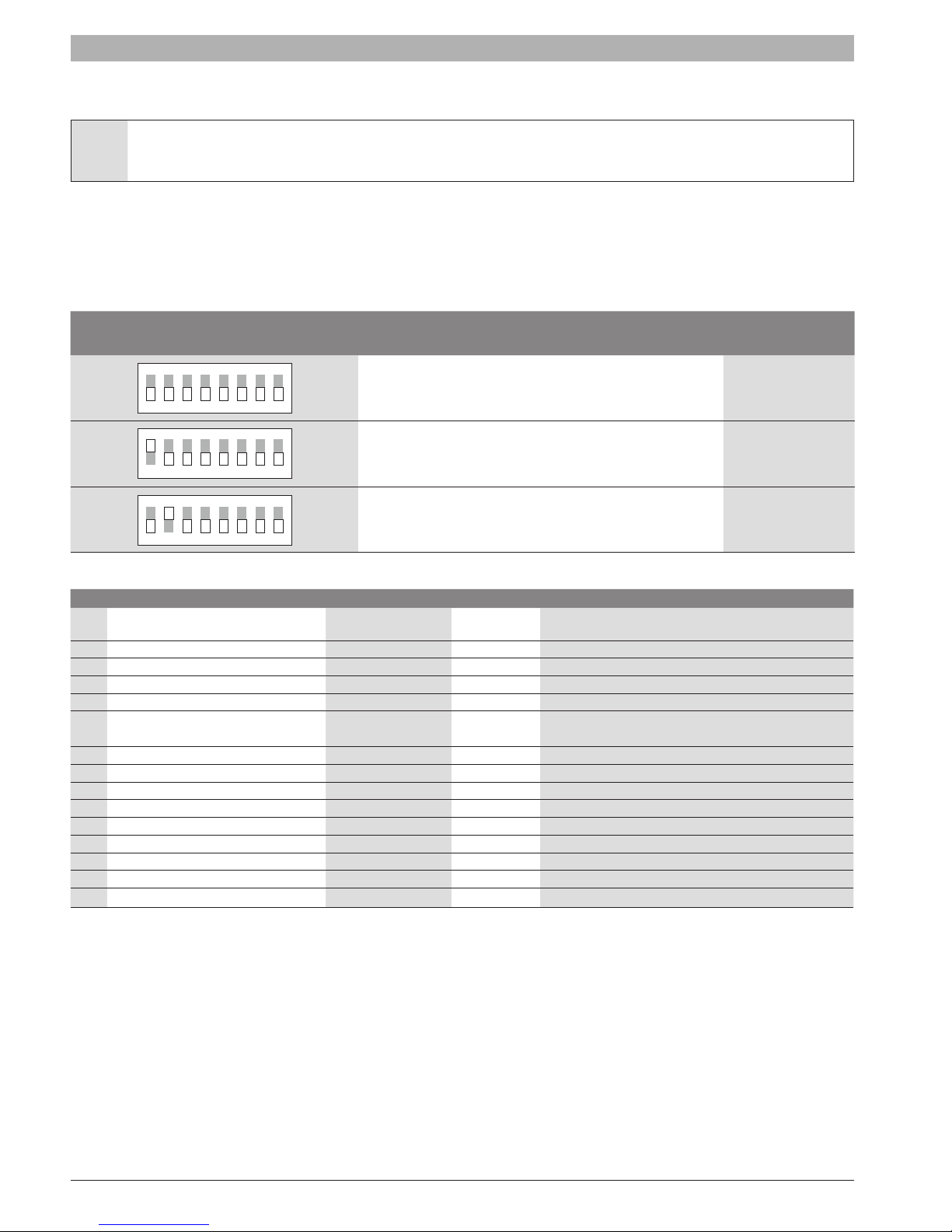

2.4 Dipswitch setting for 2 Burners Cascade

Power switch S1 should only be activated on the managing boiler. Activating more than one switch on the cascade bus may damage the

controller!

For a single burner the address is:

Stand-Alone: All dip-switches OFF.

2 burner cascade addressing:

Group 1 (1-2): All dip-switches OFF, the selected burner number ON.

Dip-switch setting Burner Operation

LabVision

Device Address

ON DIP

Standalone burner 100

1

2 3 4 5 6 7 8

ON DIP

1st burner (managing) 100

1

2 3 4 5 6 7 8

ON DIP

2nd burner (depending) 101

1

2 3 4 5 6 7 8

2.5 Additional device specications

No. Type Brand Congure Article description

1 Flow Sensor Huba Control

2 Water Pressure switch Huba Control Relative pressure switch type 620/625

3 Gas Pressure switches (min.–max) Krom Schroder Gas and air, ¼” NPT, DG 50NT and DG 50HT

5 Sensor Taco Customer Only LWCO probe, no controller, 3/8” P8S-1

6 Burner Customer 150 kW ~ 511BTU/hr

7 Fan ebm-papst

8 Unit Return Temp. Sensor Tasseron Inside NTC sensor - TSD00AE (10k@25°C / 77°F, 3%)

9 Unit Flow Temp. Sensor Tasseron NTC sensor - TSD00AE (10k@25°C / 77°F, 3%)

10 Unit Flue Temp. Sensor Tasseron Inside NTC sensor - TSD20D1 (10k@25°C / 77°F, 3%)

11 System Temp. Sensor Tasseron Inside NTC sensor - TSK10D2 (10k@25°C / 77°F, 3%)

12 Outdoor Temp. Sensor Tasseron Inside NTC sensor - TSRD110-R (10k@25°C / 77°F, 3%)

13 Safety Temp. Sensor Term-o-disc TS18-12491, 100°C / 212°F

14 Unit Flue Pressure Switch Krom Schroder DL4ET-1 330 - 350Pa

15 Unit Condensate Pressure Switch Krom Schroder DL4ET-1 330 - 350Pa

16 Gas valve ebm-papst GB-GD 057 D01 S00

Huba DN25. Flow sensor for liquid media type 200. Flow

range 0,5 … 150 l/min

NRG137 (120VAC PWM)

NRG137/2400-3633-010304-115

6720892984 (2019/02) US SSB

3 BURNERS cascade

1

ON DIP

2 3 4 5 6 7 8

1

ON DIP

2 3 4 5 6 7 8

1

ON DIP

2 3 4 5 6 7 8

3.1 Burner cascade communication setup

In order for the system to work for cascade the communication busses

must be parallel linked together. The managing burner uses the AL-bus

connection on J6 1-8 for burner cascade. The depending burner must be

connected to the managing burner on the J8 AL-bus connection.

It is important that the power on the J8 AL-bus connection on all

depending burners is switched to the OFF position. Also all burners in the

cascade system must have a unique address selected.

Demand: 0-10V / OpenTherm / On-Off

T outside

Boiler sensor

90xMN -

–

–

90xMN D1

J6

Boiler manager

90xMN –

J8

3.2 Setting the burner address (Rev. 4.0.905.15250)

The managing burner of the cascade system is connected to the AL-bus

connection on J6 1-8. This connection also provides the power for the

communication bus. The depending burners are all parallel connected to

the managing burner communication bus.

Since the bus power is provided by the managing burner on J6 1-8,

switch S1 must be set in the OFF position on all controls.

J11

D2

J8

ONOFF

BURNERS cascade | 9

3.2.1 E2prom address selection through e2prom setting

When the Dip-switch conguration is set to disabled the burner address is

selected with an e2prom parameter. This setting can be changed using a

computer with LabVision PC software.

Burner

address

Burner Operation

Function of

sensor input

J5 (7-15)

0 (default) Standalone burner No function 100

1

2

3

4

1st boiler

(Managing)

2nd boiler

(dependent)

3rd boiler

(dependent)

4th boiler

(dependent)

System sensor 100

No function 101

No function 102

No function 103

$ $ $

8

8th boiler

(dependent)

No function 107

3.2.2 E2prom address selection through dip-switch input

When the Dip-switch conguration is set to Cascade burner address

the burner address is selected with the dip-switch input. The switches

are numbered 1 to 8. When an invalid dip-switch setting is selected the

burner address will be set to a standalone burner. When the Dip-switch

conguration is set to Cascade burner address the E2prom parameter is

not used.

Dip-switch setting

ON DIP

Burner

Operation

Standalone burner 100

1

2 3 4 5 6 7 8

ON DIP

1st burner

1

2 3 4 5 6 7 8

(managing)

LabVision Device

Address

LabVision

Device

Address

100

The burner address can be set through an e2prom setting or the

Dip-Switch input available on the control. Which option is used can be

set with the Dip-switch conguration parameter on the Labvision PC

software. Each burner must be congured with its own unique address.

SSB 6720892984 (2019/02) US

ON DIP

1

2 3 4 5 6 7 8

2nd burner

(depending)

101

10 | BURNERS cascade

3.2.3 Communication with LabVision PC software

There are two options for communication with the LabVision PC software.

The 850US Device (Argus-to-USB) can either be parallel connected to

the cascade communication bus or separately to the J8 connection on the

leading burner.

When the 850US Device (Argus-to-USB) is connected to the J8

connection, switch S1 has to be set in the ON position. This powers

the communication bus to allow communication with the Labvision PC

software.

NOTE: there is less information available when connected to the J8

connection on the leading burner. Only the information known by

the leading burner can be shown in the Labvision PC software.

3.3 Cascade – Heating only (Rev. 4.0.905.15250)

Managing burner

When a burner is set as Managing (Address = 1), the controller of this

burner will drive the cascade. The CH mode of this managing burner

applies to all other burners. It is only required to set the CH mode on the

managing burner.

• The outdoor temperature sensor connected to the managing burner

will be the outdoor sensor for the cascade operation

• The system sensor (

will be the control sensor for the cascade supply temperature.

• The (modulating) thermostat connected to the managing burner will

be the CH heat demand input for the cascade system.

Based on the system temperature

Cascade_Setpoint

setpoint, to achieve the requested

The managing burner provides the calculated setpoint to all dependent

burners. The modulating power of the dependent burners is PID

controlled based on the calculated setpoint and dependent burner supply

temperature.

T_System

the managing burner calculates a required burner

) connected to the managing burner

(T_System)

Cascade_Setpoint

and the requested

.

Cascade CH setpoint adaption

When the system temperature is not high enough the setpoint for all

burners will be adjusted.

The boiler setpoint will be increased when the system temperature

drops below

Cascade_Setpoint temperature

This is determined as following:

A PID-control loop over the system temperature

T_System)

the PID controller is between

Up_Limit)

Limit)

calculated boiler setpoint will be limited at

default 80°C (176°F)).

When the system temperature is above cascade setpoint, the calculated

boiler setpoint will be decreased with a step dened by parameter

Slew_Rate_Step_Down

In case the system temperature is below cascade setpoint the calculated

boiler setpoint will be increased with a step dened by parameter

Slew_Rate_Step_Up

The PID calculation does not start immediately but after a certain delay

period to stabilize the system rst.

The delay period is

(settable), for example 60 minutes.

Cascade_Setpoint

and decreased when it rises above

.

(Cascade_Setpoint /

calculates the adjustment of the boiler setpoint. The range of

(Cascade_Setpoint + Max_Range_

and

(Cascade_Setpoint – Min_Range_Down_

. This offset is added to the

Cascade_Setpoint

and then this

CH_Max_Setpoint

(default 1°C (1,8°F)).

(default 1°C (1,8°F)).

Start_PID_Modulation_Delay_Factor

(by

PID_

PID_

6720892984 (2019/02) US SSB

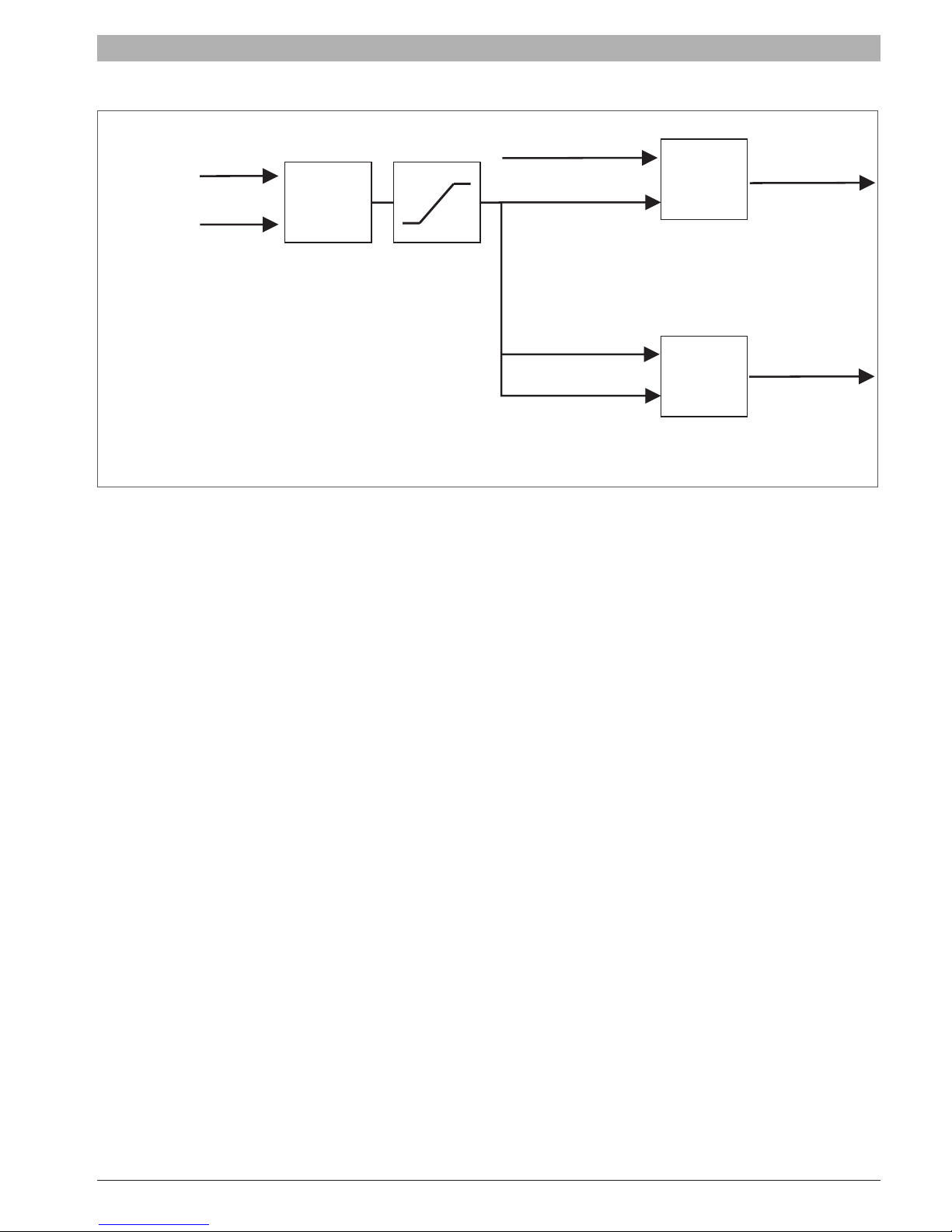

The following diagram shows how the setpoint to the dependents is determined:

BURNERS cascade | 11

T_System

Cascade setpoint

PID slew rate

The changes of the PID output can be limited with the

avoid big setpoint changes to the burners. The slew rate is set in °C/100ms.

For example when the

change a maximum of 1,0°C every 100ms.

The slew rate can be set in steps of 0,1°C/100ms. When set to 0,0°C/100ms the limitation is disabled.

PID_Max_Slew_Rate_Up

PID

System Loop

Offset Setpoint

Calculation

PID_Slew_Rate_Step_Up and PID_Slew_Rate_Step_Down

and

PID_Max_Slew_Rate_Down

T_Supply sensor

Calculated boiler setpoint

T_Supply sensor

Calculated boiler setpoint

are set to 1,0°C/100ms it means the calculated setpoint can

PID

Dependent 1 boiler

PID loop

PID

Dependent 2 boiler

PID loop

(factory settable) setting to

Burner Power

Burner Power

Dependent Burner

The CH mode for the cascade is dened by the setting of the managing burner. CH mode settings on dependents are ignored.

In case a burner is set as dependent (Address = 2-8/16) the setpoint is always provided by the managing burner.

The modulating power of the ALL burners is PID controlled by the burner itself by comparing the calculated setpoint from the managing burner and

T_Supply

The burner of the managing burner itself will be controlled in the cascade system as it would as it was a dependent burner.

Only the pumps and sensor inputs are used.

Burner power

Cascade operation with power modes is designed to work best in cascade systems with equal burners/burners having the same power output.

.

SSB 6720892984 (2019/02) US

12 | BURNERS cascade

3.3.1 Cascade – domestic hot water

Settings

In the installer DHW menu of the managing burner control the

Mode

should be set.

DHW_

Available DHW modes in cascade are mode 1 or 2.

Dependent Burner

In case a burner is set as dependent (Address = 2-8/16) the DHW

setpoint is always provided by the managing burner, the internal control of

the setpoint functions are disabled.

3.3.2 Cascade – DHW priority (Rev. 3.0.0.12377)

Three possible level of DHW and CH heating priority are congurable:

• DHW Priority - BOTH [0]: When both CH and DHW demand have

to be served the priority it is given to the DHW demand for a given

interval (indicated with parameter

DHW_Max_Priority_Timer

).As

soon as the interval has expired the priority switches to CH demand.

The interval time will be reloaded and priority will switch again after

the interval is over.

• DHW Priority - CH [1]: The priority is permanently given to CH

Demand.

• DHW Priority - DHW [2]: The priority is permanently given to DHW

Demand.

• DHW/CH Parallel[3]: The priority us permanently given to DHW

Demand. But Under the following condition the CH pump can started:

Setpoint_CH

< SystemTemp.

3.3.3 Limitation of the MAX power for DHW (Rev. 4.0.905.16570)

When demand change from CH to DHW all burners in the boiler stop

and start DHW demand with a limit amount of burner. The parameter

Max_Active_Dep_DHW

indicates the number of burners available for

N_

DHW. This number will be always be limited in the control to the amount

of burners that is available in the cascade.

Relevant variables

Specic Parameters Level

(Default)

Value

Range

N_Max_Active_Dep_

DHW

Max amount of active burners

per boiler for serve DHW

demand

2: Installer 1 0..16

Relevant variables

Specic Parameters Level

DHW Priority

Both, CH or DHW priority,

Parallel

2: Installer 2 0..3

DHW Max Priority

Timer

[min]

Interval time for switching

the priority

2: Installer 60 1..60

(Default) Value Range

6720892984 (2019/02) US SSB

BURNERS cascade | 13

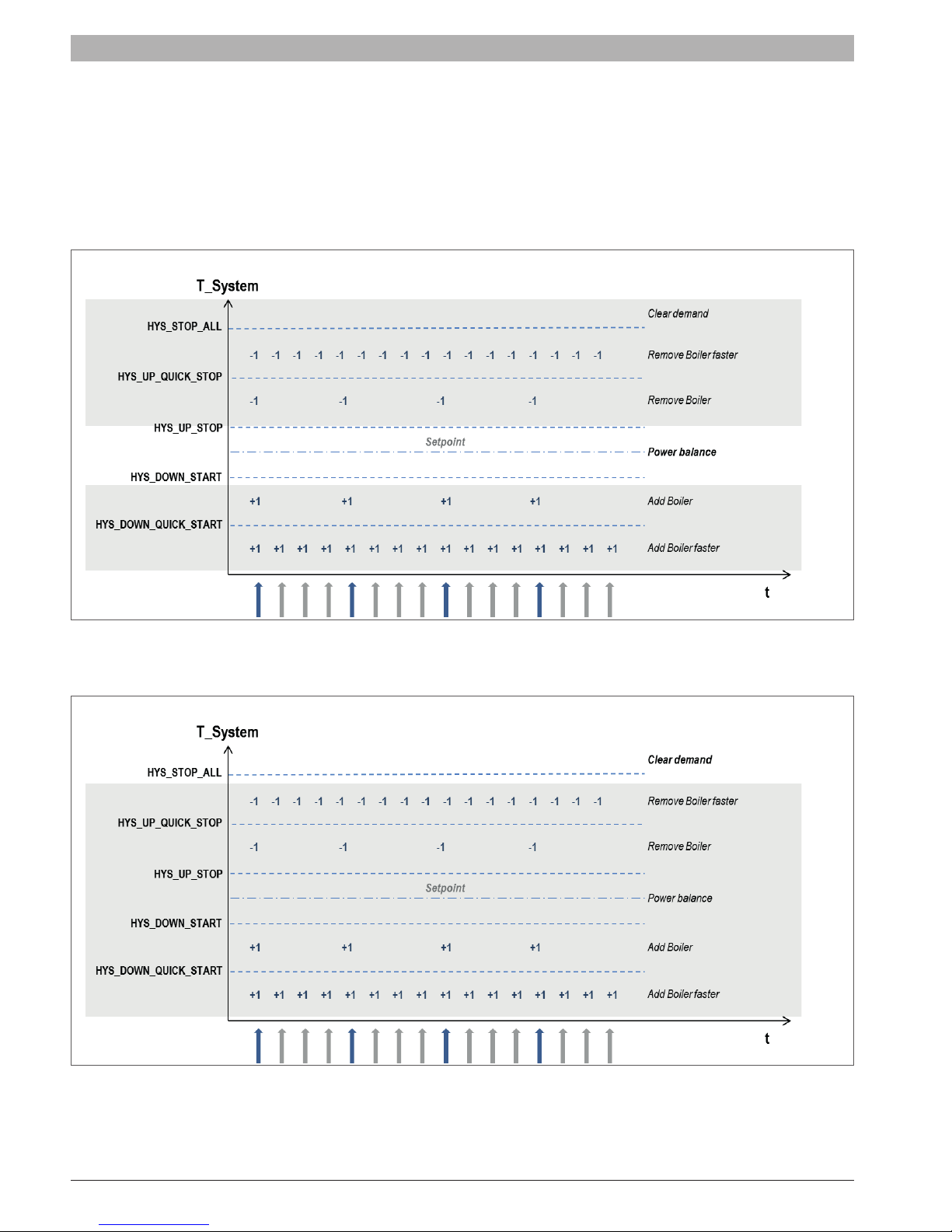

3.3.4 Cascade – start/stop sequence (Rev. 3.0.0.12315)

The managing burner sends the calculated

Calculated_Setpoint

dependent burners will start or stop using different algorithms.

If a CH or DHW demand request is present, the next dependent burner is always called to ensure that the general (on board) pump of at least one

dependent is always running especially in the case where

In the latter case the Frost protection setpoint is sent to the dependent burner.

Quick Starting and Stopping Burners

When there is a big difference between the

quicker.

and

T_Supply

Cascade_Setpoint

. Depending on the temperature difference between

T_System

and the

to the dependent burners. The power of the burners is PID controlled based on the

T_System

is much higher than the setpoint.

Cascade_Setpoint

the call for a start or stop of the next or last depending is done

T_Header and Header_Setpoint

(CH or DHW) the

• Quick Starting Burners: If the

intervals of

• Quick Stopping Burners: If the

intervals of

Starting and Stopping Burners

With a small difference between

Quick_Start_Interval

Quick_Stop_Interval

T_System

T_Syste

m is

, for example 30 sec.

T_System

is

, for example 30 sec.

and the

Hyst_Down_Quick_Start

Hyst_Up_Quick_Stop

Cascade_Setpoint

the call for a start or stop of the next or last Dependant burner is executed.

degrees below the

degrees above the

Cascade_Setpoint

Cascade_Setpoint

the burners are started at

, the burners are stopped at

SSB 6720892984 (2019/02) US

14 | BURNERS cascade

• Starting Burners: If the

Interval, for example 3 min.

• Stopping Burners: If the

Interval

Power balance

When the

See “3.3.5 Cascade – power balance mode (Rev. 4.0.905.15906)” pag. 15.

, for example 3 min.

T_System

T_System

is

Hyst_Down_Start

T_System is Hyst_Up _Sto

is between

Hyst_Down_Start

degrees below the

p degrees above the

and

Hyst_Up_Stop

Cascade_Setpoint

Cascade_Setpoint

a power balance algorithm can be activated.

the burners are started at intervals of Start_

, the burners are stopped at intervals of

Stop_

Stop all dependent

All the dependents are stopped as soon as the

The following graph shows when all the burners are stopped:

T_System

is far greater than

Cascade_Setpoint

.

6720892984 (2019/02) US SSB

Relevant variables

Specic Parameters Level

(Default)

Value

Settable

°C °F °C °F

Delay_ Period_Start_Next_

Burner

[min]

Start Delay Time

Delay_ Period_Stop_Last_

Burner

[min]

Stop Delay Time

Quick_Delay_ Period_

Start_Next_Burner

Quick Start Interval

[sec]

Quick_Delay_ Period_

Stop_Last_Burner

Quick Stop Interval

[sec]

2: Installer

2: Installer

2: Installer

2: Installer

3

(min)

3

(min)

30

(sec)

30

(sec)

1..15

1..15

5..300

5..300

Hyst_Down_Start_Burner

[°C/°F]

Start Burner Diff

2: Installer 5 9 0..20 0..36

Hyst_Up_Stop_Burner

[°C/°F]

Stop Burner Diff

Hyst_Up_Stop_All

Stop Burner Diff

[°C/°F]

2: Installer 5 9 0..20 0..36

2: Installer 30 54 30 54

Hyst_Down_Quick_Start

[°C/°F]

Start Burner Diff in short time

Hyst_Up_Quick_Stop

Stop Burner Diff in short time

2: Installer 10 18 0..20 0..36

[°C/°F]

2: Installer 10 18 0..20 0..36

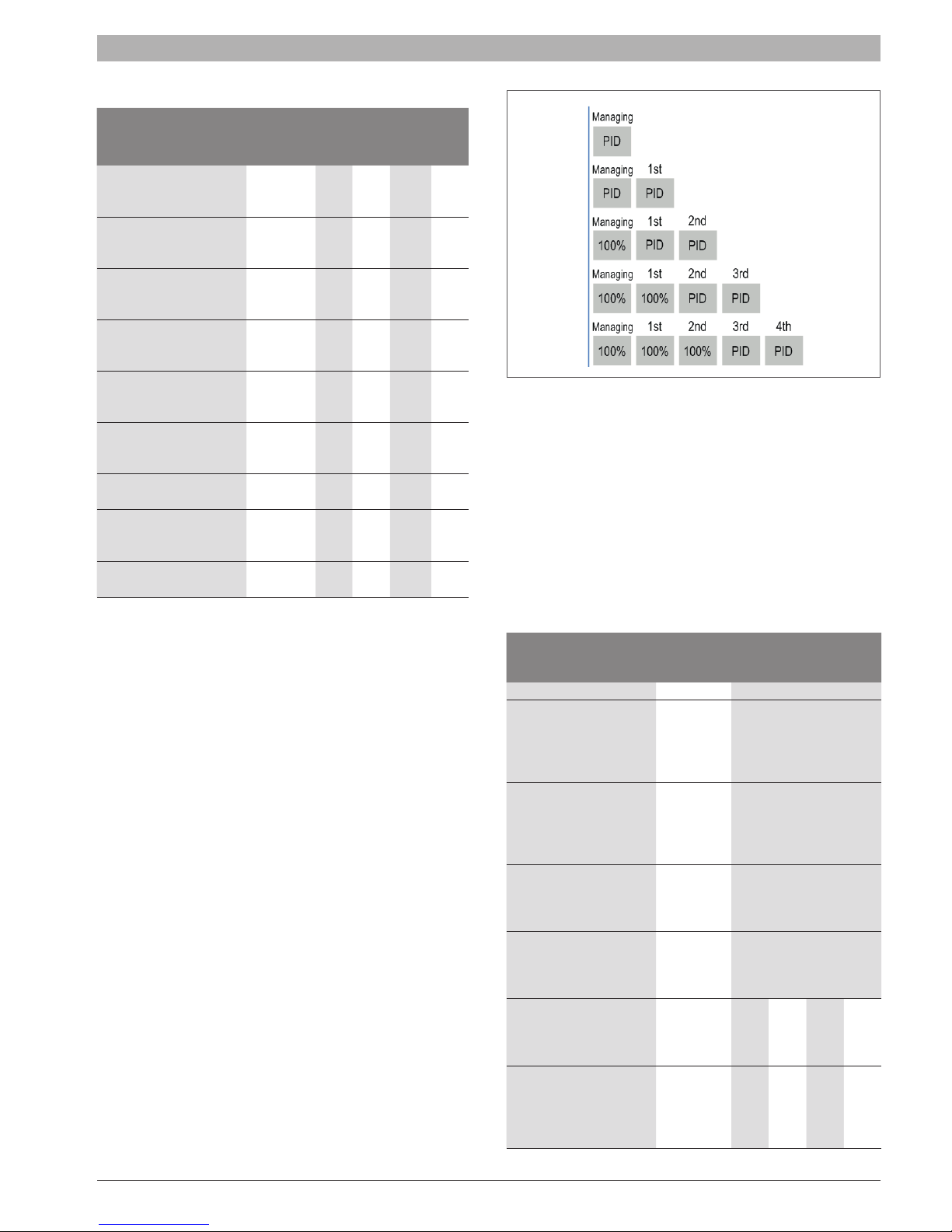

3.3.5 Cascade – power balance mode (Rev. 4.0.905.15906)

Two different power control modes can be selected to operate the

cascade system.

• Power mode 0:

Power control disabled, each burner modulates based on the system

setpoint.

• Power mode 1:

Power control algorithm to have a minimum amount of boilers/burners

active.

• Power mode 2:

Power control algorithm to have a maximum amount of boilers/

burners active.

• Power mode 3:

Power control algorithm to have a balanced amount of boilers/burners

active.

3.3.5.1 Power mode 1 - Minimum burners on (Rev. 4.0.905.15906)

Power Mode 1 guarantees to have as minimum as possible dependent

ON in order to reach the

T_System

.

The modulation of most boilers/burners is forced to 100%, and the last 2

boilers/burners are PID controlled by the setpoint (

from the managing burner in relation to the system temperature (

System

).

Cascade_Setpoint

T_

The last 2 boilers/burners are modulating to make sure that the power

can be adapted to the system temperature without continuous cycling of

the last burner(s).

Below is a picture that shows an example with 4 boilers/burners.

BURNERS cascade | 15

Burner Startup

The next burner is started under the following conditions:

• At least one PID controlled depending is operating at a power [%] >

Start_Rate_Next_Burner

The managing burner forces another burner to 100% power and waits

for 3 min. (

Delay_Period_Start_Next_Dependent

before another burner can be started.

Burner shut down

The last started burner will be stopped under the following conditions:

• All PID controlled depending in burn state Power [%] <

Last_Burner

[%]. The managing burner releases another burner

for PID control and waits for 3 min.(

Dependent

, settable) before another burner can be stopped.

Relevant variables

Specic Parameters Level

Power_Mode 2: Installer 3 0..3

Start_Rate_Next_Burner

Threshold rate before start the

next Burner. Condition: at least 1

depending in burn state power [%] >

Start_Rate_Next_Burner [%]

Stop_Rate_Last_Burner

Threshold rate before start the next

Burner. Condition: all depending in

burn state Power [%] < Stop_Rate_

Next_Burner [%]

Delay_ Period_Start_Next_

Burner

[min]

When the timeout is over the last

dependent can be started

Delay_ Period_Stop_Last_

)

[min]

Burner

When the timeout is over the last

Burner can be stopped

Hyst_Up_Stop_Burner

Hysterese to stop Burner. Condition:

T_System above Header_Setpoint

plus Hyst_Up_Stop_ Burner

Hyst_ Down_Start_Burner

[sec]

Hysterese to stop Burner. Condition:

T_System below Header_Setpoint

plus Hyst_Up_Stop_Burner

[%].

Delay_Period_Stop_Next_

(Default)

Value

°C °F °C °F

[%]

2: Installer 80 1..100

[%]

2: Installer 25 1..100

2: Installer 3 1..15

2: Installer 3 1..15

2: Installer 5 9 0..20 0..36

2: Installer 5 9 0..20 0..36

, settable)

Stop_Rate_

Range

SSB 6720892984 (2019/02) US

16 | BURNERS cascade

3.3.5.2 Power mode 2 – Maximum burners on (Rev. 4.0.905.15906)

Power mode 2 is designed to have as many depending burners on

as possible. When the average burner power of the active depending

burners is above a set minimum power, another burner is started.

Burner startup

The next burner is started under the following conditions:

• When the average burner power of all depending burners is over the

set minimum burner power + hysteresis.

− Sum of burner power of all depending [%] >

power

[%] * (depending in burn + 1) +

power_hysteresis

.

minimum_

minimum_

Burner shut down

The last started burner will be stopped under the following conditions:

• When the average burner power of all depending burners is under the

set minimum burner power.

− Sum of burner power of all depending [%] <

power

[%] * depending in burn.

minimum_

Relevant variables

Specic Parameters Level

(Default)

Value

Range

Power_Mode 2: Installer 3 0..3

Minimum_Power

Minimum average burner power

setting

[%]

2: Installer 20 1..100

Minimum_Power_

Hysteresis

Hysteresis for the minimum average

burner power setting

[%]

2: Installer 40 1..100

3.3.5.3 Power mode 3 – Balanced burners on (Rev. 4.0.905.15906)

Power mode 3 is designed to have a balanced water ow in systems with

a header/manifold.

Burner startup

The next burner is started under the following conditions:

• When the average burner power of all depending burners is over the

set start rate for the next burner.

− Sum of burner power of all depending [%] >

Next_Burner

[%] * depending in burn.

Start_Rate_

Burner shut down

The last started burner will be stopped under the following conditions:

• When the average burner power of all depending burners is under the

set stop rate for the next burner.

− Sum of burner power of all depending [%] <

Next_Burner

[%] * depending in burn.

Stop_Rate_

Relevant variables

Specic Parameters Level

(Default)

Value

Range

°C °F °C °F

Power_Mode 2: Installer 3 0..3

Start_Rate_Next_Burner

Threshold rate before start the

next Burner. Condition: at least 1

depending in burn state power [%] >

Start_Rate_Next_Burner [%]

Stop_Rate_Last_Burner

Threshold rate before start the next

Burner. Condition: all depending in

burn state Power [%] < Stop_Rate_

Next_Burner [%]

[%]

2: Installer 80 1..100

[%]

2: Installer 25 1..100

Delay_ Period_Start_Next_

Burner

[min]

When the timeout is over the last

dependent can be started

2: Installer 3 1..15

Delay_ Period_Stop_Last_

[min]

Burner

When the timeout is over the last

Burner can be stopped

2: Installer 3 1..15

Hyst_Up_Stop_Burner

Hysterese to stop Burner. Condition:

T_System above Header_Setpoint

plus Hyst_Up_Stop_ Burner

2: Installer 5 9 0..20 0..36

Hyst_ Down_Start_Burner

[sec]

Hysterese to stop Burner. Condition:

T_System below Header_Setpoint

plus Hyst_Up_Stop_Burner

2: Installer 5 9 0..20 0..36

6720892984 (2019/02) US SSB

BURNERS cascade | 17

3.3.6 Cascade – burner rotation (Rev. 4.0.905.x)

The burner rotation function can change the start/stop sequence for the

cascade burners.

The parameter

after which the sequence is updated.

When

disabled.

When the parameter

the burner rotation days left will be initialized to the new

Rotation_Interval

When for example

is as following (x is the last burner):

Days Start/Stop sequence

Day 0-5 1-2-3-4-5..x

Day 5-10 2-3-4-5..x-1

Day 10-15 3-4-5..x-1-2

Day 15-20 4-5..x-1-2-3

Day 20-25 5..x-1-2-3-4

With parameter

that is rst to start in the sequence is selected.

When the burners are rotated the parameter

Start

is automatically updated to the next depending.

When burner rotation is disabled the parameter

To_Start

When the

control will clear all demand of the cascade control. After this it will

start cascade demand generation with the new selection for

Depending_To_Start

Relevant variables

Specic Parameters Level

Burner_Rotation_Interval 2: Installer 5

First_Depending_To_Start 2: Installer 1 1..8/16

Burner_Rotation_Interval

Burner_Rotation_Interval

Burner_Rotation_Interval

setting.

Burner_Rotation_Interval

First_Depending_To_Start

is reset to 0.

First_Depending_To_Start

.

sets the number of days

is set to 0 burner rotation is

is updated

Burner_

= 5 the start sequence

the current depending

First_Depending_To_

First_Depending_

is manually changed the

First_

(Default)

Value

Range

0..30

0 = Disable

3.3.7 Cascade – error handling

3.3.7.1 Emergency mode

Open / Shorted boiler or system sensor

When the setting “

the control can go into emergency mode when the system sensor status

is not ok. When the system sensor is open or shorted the control goes

into the emergency mode.

The managing burner display may show that the system is in emergency

mode.

In emergency mode the system setpoint is set to the

Emergency_Setpoint

When an emergency heat demand is generated all burners are allowed to

start burning on this setpoint.

Loss of cascade communication (Rev. 3.0.0.14038)

The leading board is aware of how many dependents should be present

in the system. This value is stored in the e2prom. When powering on the

system the leading burner has to detect all depending burners within 60

seconds.

When not all dependent burners are detected the control will show the

CC_LOSS_COMMUNICATION

When the communication with any of the depending burners is lost during

operation the control will show the

CC_LOSS_COMMUNICATION

CC_LOSS_COMMUNICATION

The

not block the control.

3.3.7.2 Managing burner error (Rev. 3.0.0.11748)

When the managing burner is in error mode this burner is not used

anymore for the cascade system.

However depending on the error code, the pumps connected by the

managing burner still can be active for the cascade system. When the

managing unit is reset from lockout state, the cascade controllers are

re-initialized.

Permit_Burner_Emergency_Mode

(settable via installer menu).

warning.

warning after 60 seconds.

warning is purely informative and will

” is enabled

Cascade_

SSB 6720892984 (2019/02) US

18 | Service display

4 Service display

4.1 General

4.1.1 Introduction

The 900PB Display is an advanced graphical user interface for

applications such as HMI for heating appliances.

It can be used in combination with other epHS controls and

communicates with these controls via the AL-BUS connection.

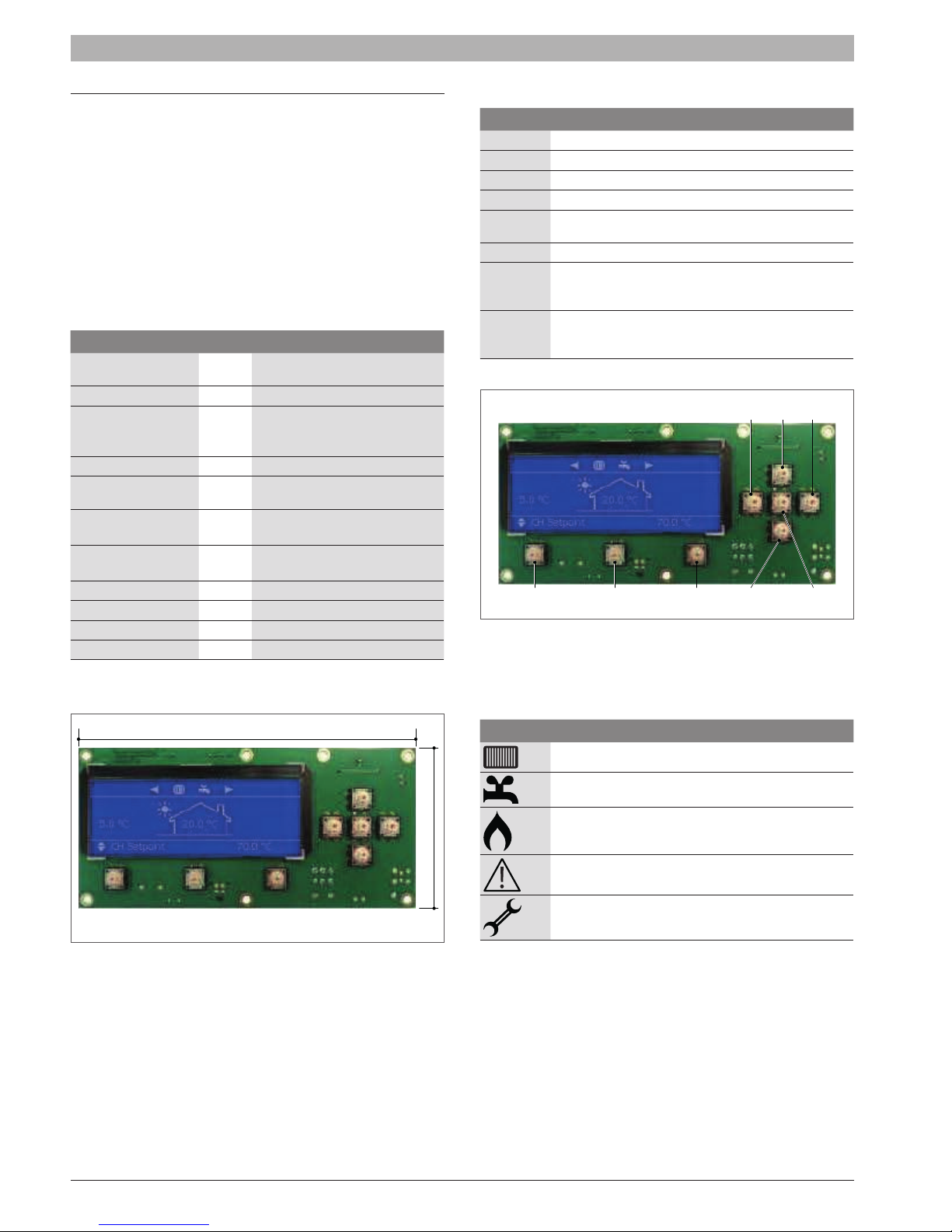

This manual is applicable for layout versions:

• 900PB06_3R

4.1.2 General information

Dimensions PCB

L × W

× H

Operating temperature 0°C to +50°C (32°F to 122°F)

Connections

LCD mode 255 x 80 Dot graphic

Module dimensions

W × H

× T

Viewing area W × H

Active area W × H

Dot size W × H 0.34 x 0.37

Dot pitch W × H 0.37 x 0.40

LCD display mode TN/Blue/Negative/Transective

Viewing direction 12 O’clock

900PB06_3R:

900PB0X_3R: 178x85x13mm

(7,01”x3,35”x0,51”)

See “Appendix J - PB Connectors

Description” pag. 65

121,4x47,6x5,0mm

(4,78”x1,87”x0,2”)

106,4 x 39,0mm

(4,19”x1,54”)

95,0 x 32,0mm

(3,74”x1,26”)

4.1.3 Display functions

Button Function

RESET Reset Lockout error

MENU Enter the main menu

ESC Return to the Status overview

LEFT Return to previous menu item or Status overview

RIGHT

Enter a menu item or conrm selection in Status overview

(when directly setting Actual setpoint or DHW setpoint)

ENTER Conrm a setting or enter a menu item

Directly select Actual setpoint of DHW setpoint in the

UP

Status overview, push RIGHT to conrm and use UP or

DOWN to adjust value

Directly select Actual setpoint of DHW setpoint in the

DOWN

Status overview, push RIGHT to conrm and use UP or

DOWN to adjust value

RIGHTLEFT

UP

RESET MENU ESC DOWN

ENTER

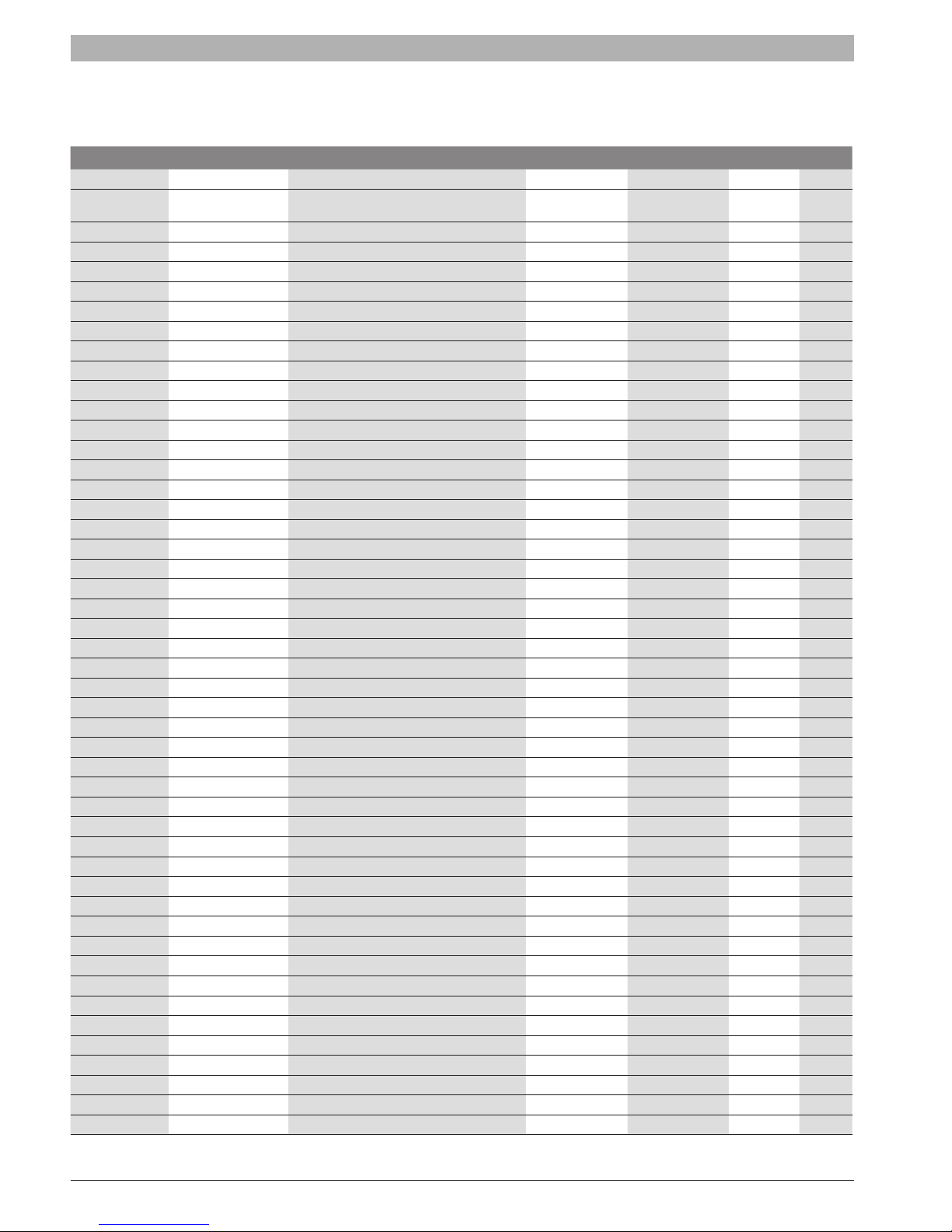

4.1.4 Display icons

The following table gives a short description of the icons that can be

visible on the main screen during operating:

178

1 = 1 mm

85

Icon Description

Central Heating demand

Domestic Hot Water demand

Indicates that the appliance burner is ON

Cascade Emergency Mode active

Error notication

6720892984 (2019/02) US SSB

Service display | 19

4.2 Screens

4.2.1 Splash screen (Rev 1.1.0.13425)

Heating System B.V.

This screen is active during power up and will remain active until

communication with the Main Control (the AL-BUS) has been established.

Standard no default start-up screen is installed, only the text “initializing”

will appear (for certain projects a ‘Settings parameter is available to select

a customized splash screen).

After communication has been established the following Status overview

appears:

10.0°C

4.2.2 Entering the menu

Enter the menu by pressing the MENU button once. The header in the

screen shows you are inside the main menu.

While scrolling through the menu you will see that the selected menu item

is shown in a white rectangle.

Menu

Heating

Sanitary Water

Information

Settings

Enter a menu item by pressing ENTER or RIGHT.

The header shows your location inside the menu, as seen in the following

image on the next page:

Heating

CH Setpoint

Climatic Compensation

Actual Setpoint

Set Actual setpoint/DHW setpoint directly via the Status overview

When CH is active, you can adjust the Actual setpoint directly on the

bottom of the Status overview.

When DHW is active, you can adjust the DHW setpoint directly on the

bottom of the Status overview.

This means that when CH is active, you cannot set the DHW setpoint

directly via the Status overview.

When DHW is active, you also cannot set the Actual setpoint (CH

setpoint) directly via the Status overview.

Press UP/DOWN to select the mode, then press ENTER/RIGHT to

conrm the mode and the Actual/DHW setpoint becomes directly settable.

Use UP/DOWN to increase/decrease the setpoint.

Press ENTER/RIGHT to conrm your alteration or press BACK/LEFT to

cancel.

A setpoint is only visible on the main screen when no error or alert is

active. In case of an active error or alert, the bottom right part of the PB

screen is used to display the error or alert text.

Disable the DHW Service (only for Storage appliance with 850MN)

It is possible to disable the DHW service by keeping pressing ENTER for

5 seconds.

The display will then show the string “Standby” on the Status overview.

The request for demand will be ignored in the following cases:

• DHW REQUEST demand

• STORAGE COLD demand

• PRE HEAT demand

• TAP FLOW demand

Press the ENTER button again for 5 seconds in order to re-enable the

DHW service.

50.0°C

If you are inside the menu (or a menu item) and want to return directly to

the Status overview press MENU/ESC.

If you want to go back one step in the menu press BACK/LEFT.

4.2.3 Protected menu items

Some menu items are protected and only accessible via a password*.

The following password screen will then appear:

Password

0 * * *

Enter the password with the following steps:

1 Use the UP/DOWN button to adjust the rst number

2 Press ENTER or RIGHT to conrm and to go to the following number.

3 Enter 0300.

SSB 6720892984 (2019/02) US

20 | Service display

Repeat this action for all numbers to enter the password.

During this action, if you want to return to the previous screen, just press

MENU or ESC to cancel.

After the password is entered in correctly, the menu item will become

available.

The following menu items require a password*:

(Sub) Menu item Location inside menu

Climatic Compensation via ‘Heating > Climatic compensation’

Boiler via ‘Settings > Boiler’

* Passwords for different user levels are always customer specic and will

be provided by epHS to the appliance manufacturer only (due to safety

reasons).

4.2.4 DAir Sequence

The “De-Air” sequence is a safety function that starts at every power ON

and is used to remove the air from the heater-exchanger.

The DAir sequence does not start after a general reset (like the locking

error reset or 24 hours reset)

The display will show the following string during DAir sequence:

• “Dair Running”

• “Dair Error Water Pressure”

The DAir sequence can be canceled by the user by pressing the OK

button for over 5 seconds.

Press ESC to go back in the menu and return to the Status Indication

screen.

No matter what language you set, the menu icons will always remain

universal.

4.2.5.2 Set the display language from Chinese back to English

First, make sure you the Status Indication screen is displayed, which

looks as following:

12 09

16.5°C

生活热水温度设定

If this is not the case, press the ESC button a couple of times until you

return to this screen.

The following steps describe how to set the display from Chinese back to

English:

[1] Press the MENU button once to enter the main Menu (菜单)

[2] Select “Settings” (设置) and press the ENTER button to access this

menu:

49.0°C

4.2.5 Language settings

The 900PB display has a number of different language options, such as

English, French, Chinese and Italian.

Paragraph 4.2.5.1 describes how to set the display language (and

characters) to Chinese.

Paragraph 4.2.5.2 describes how to set the language back from Chinese

to English (or any other language).

4.2.5.1 Set the display language to Chinese

Please follow the next steps, which describe how to set the display

language to Chinese:

[1] From the Status Overview, press the MENU button once

[2] Select “Settings” and press the ENTER button

[3] Select “General Settings” and press the ENTER button

[4] Select “Language” and press the ENTER button

[5] Select the Chinese language (中文) and press ENTER

After the Step 5 the text and menu items will automatically be displayed

in Chinese:

基本设置

语言

单位类型

日期时间

Aα

其他设置

菜单

供暖

生活热水

Info

设置

[3] Select “General Settings” (基本设置) and press the ENTER button:

设置

基本设置

锅炉设置

[4] Select “Language” (语言) and press the ENTER button:

基本设置

语言

单位类型

日期时间

Aα

其他设置

6720892984 (2019/02) US SSB

[5] Select the desired language (“English“) and press ENTER to

conrm: (For setting the display to French: select “Français”, for

Italian select “Italiano”)

语言

English

Français

中文

Italiano

Once you have set the English language, the screen will display its

information in English again:

General setting

Language

Unit Type

Date & Time

Aα

Other Setting

Service display | 21

Press ESC to go back in the menu and return to the Status Indication

screen.

SSB 6720892984 (2019/02) US

22 | Service display

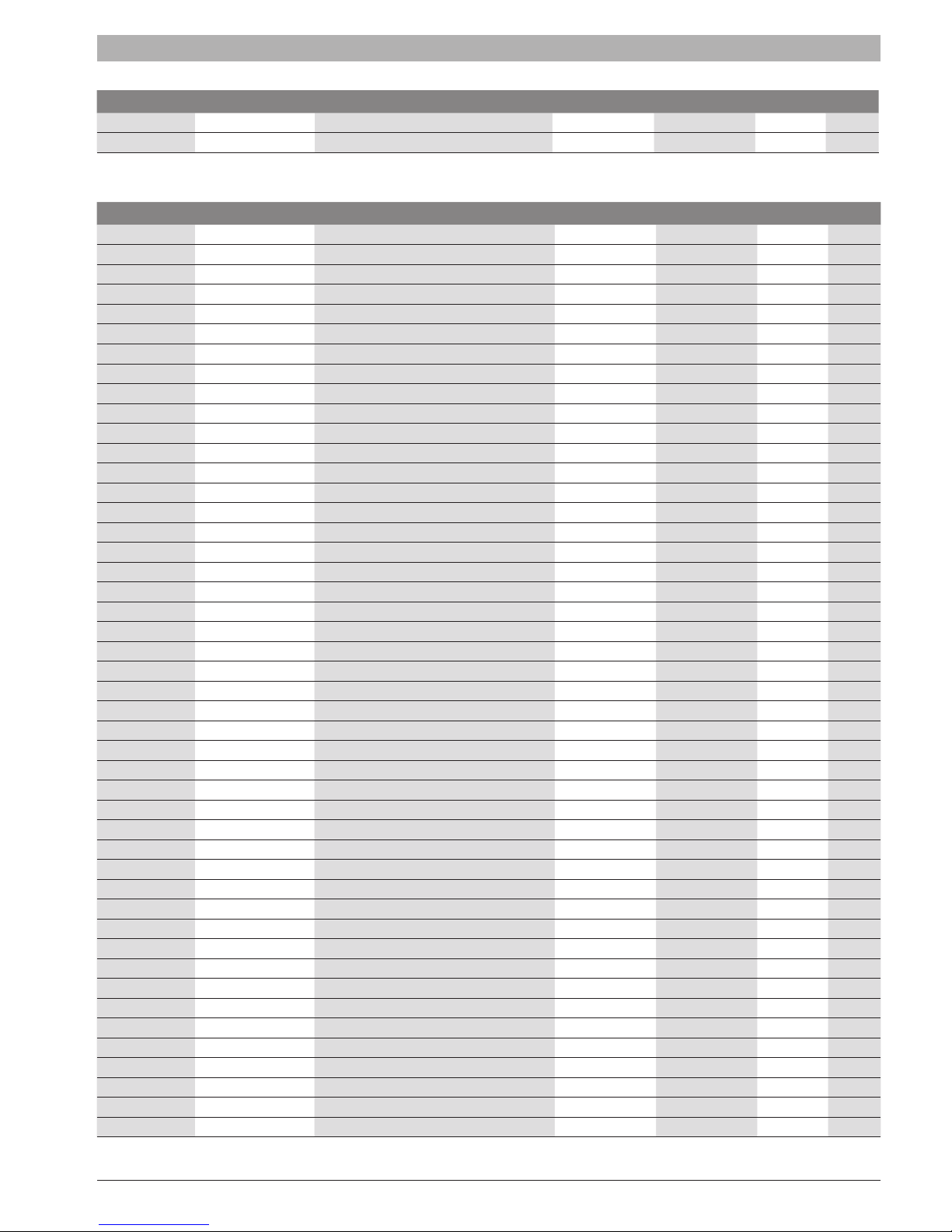

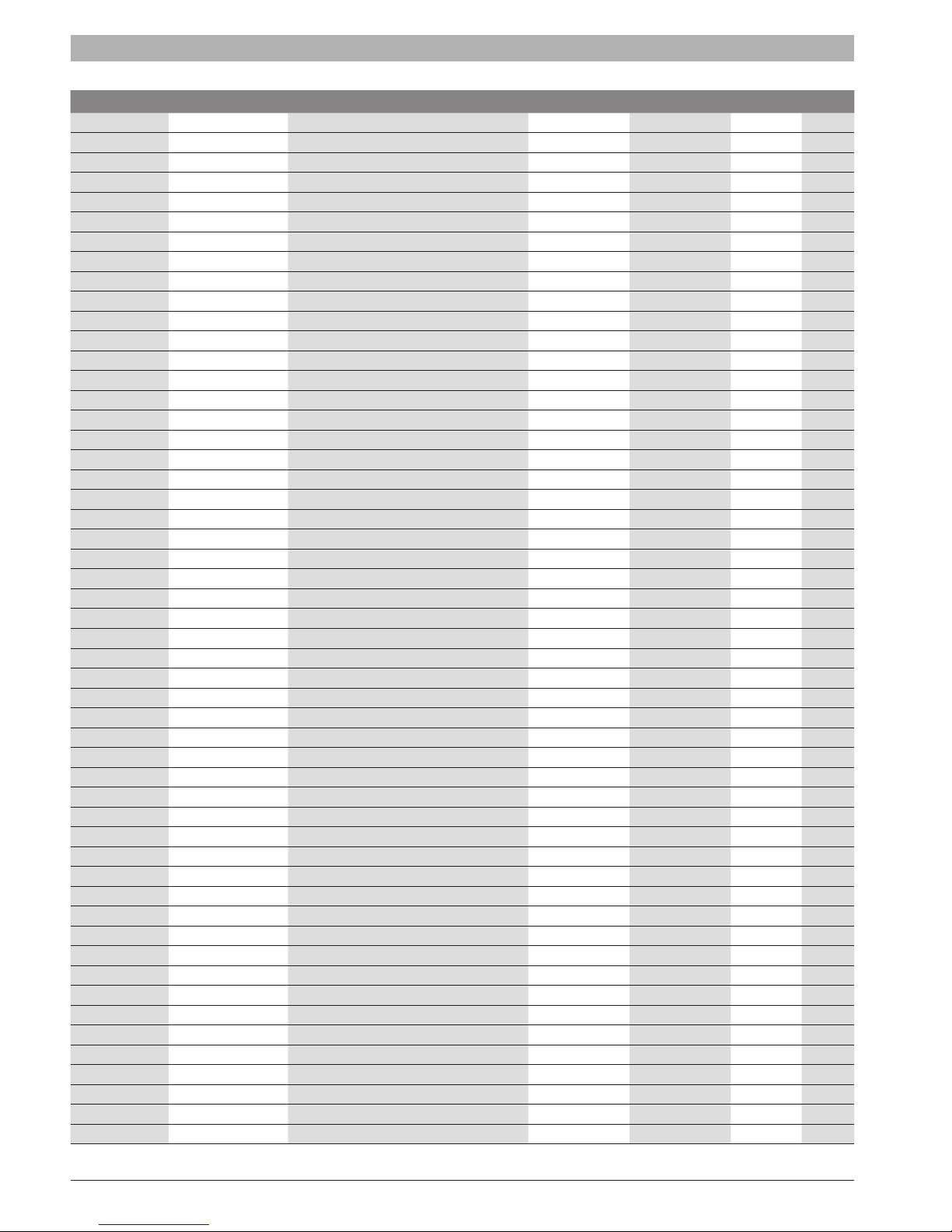

4.3 Menu Structure

Below is a schematic overview of the menu structure of 900MN control.

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

Central Heating CH Setpoint CH Setpoint

Climatic

Compensation

Setpoint_Max

Setpoint_Min

Outdoor_Max

Outdoor_Min

WW_Shutdown

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

1: User •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

Sanitary Water DHW Setpoint

Information Boiler DHW Temp

DCW Temp

Fan Power

Flow Temp

Flow 2 Temp

Flue Temp

Flue 2 Temp

Outside Temp

Return Temp

System Temp

0 – 10V Input

Flow Rate

RT Input

Water Pressure

Ionization

Burner State 1: User •

Error No.

Actual setpoint

Settings General Language English 1: User

Italian 1: User

Unit type Metric

Imperial

Date/Time Date

Time

System information Display

Boiler

Solar

Zone

Device group

Modbus Address

Boiler (1) CH Mode

(2) Mod Pump Mode

(3) CH Setpoint

(*) Calc. Setp. Offset

(4) CH Pump Overrun

(5) General Pump Overrun

(6) Flue Temp ABS Limit

(7) CH Hyst

°C/°F

°C/°F

°C/°F

RPM

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

V

l|min.

Open/Closed

bar/psi

uA

#

°C/°F

°C, Bar, etc.

°F, PSI, etc.

dd-mm-year

00:00

[####] *

[####] *

[####] *

[####] *

###MN

0-255

0-6

0-4

°C/°F

°C/°F

Sec.

Sec.

°C/°F

°C/°F

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User •

1: User

1: User

1: User

1: User

1: User •

1: User •

1: User

1: User

1: User •

1: User

2:Installer •

2:Installer

1: User •

2:Installer •

2:Installer

2:Installer •

3:Factory •

2:Installer •

6720892984 (2019/02) US SSB

Service display | 23

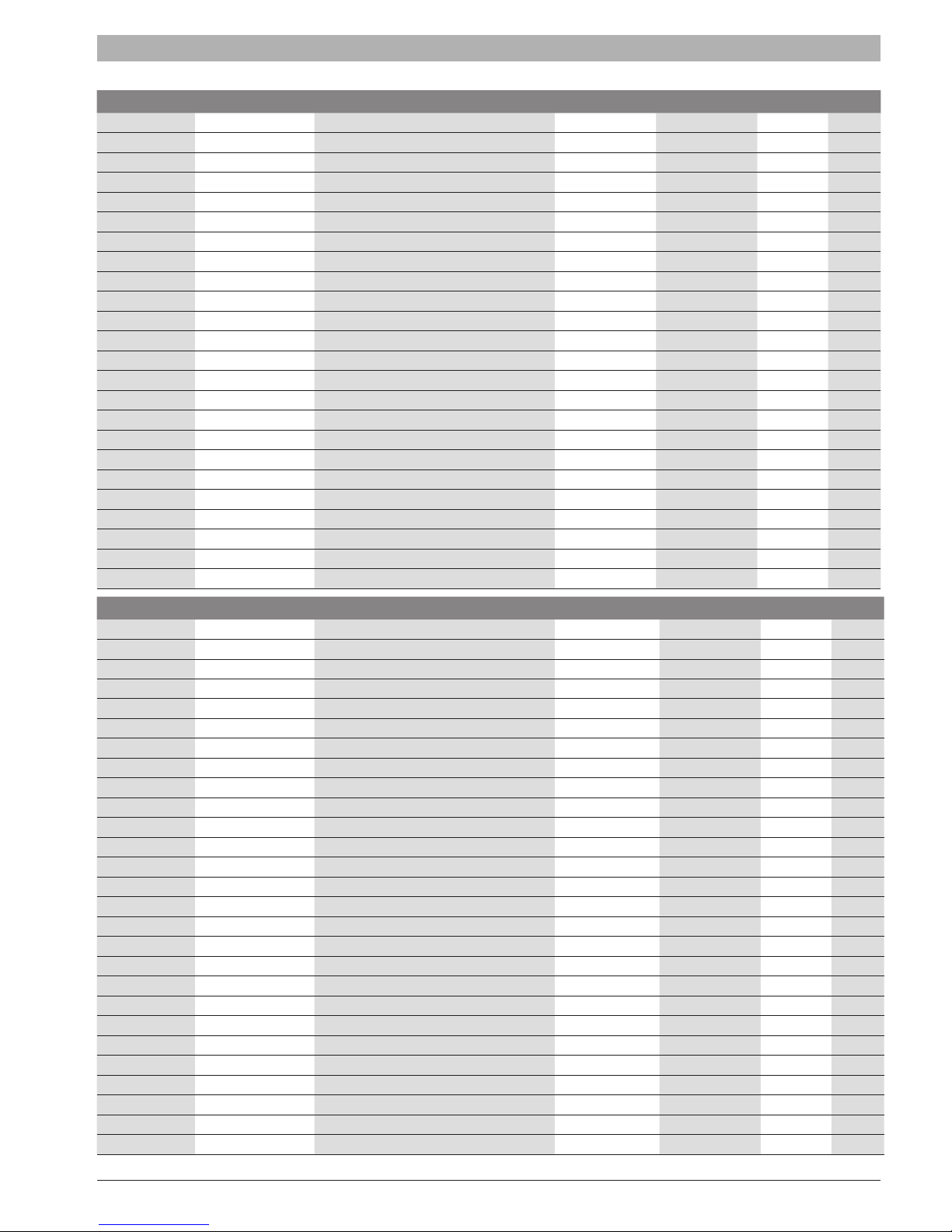

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

(7) CH Hyst Up

(*) CH Hyst Down

* Checksum software version

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

(8) Flue Gas Diff

(9) Anti Cycle Period

(10) Anti Cycle T Diff

(11) Ramp Delay Step Mod

(12) Hx Diff Delta Tmin

(13) Hx Diff Max Wait Time

(14) P CH Max

(15) P CH Min

(16) CH PID P 3: Factory •

(17) CH PID I 3: Factory •

(18) CH PID D 3: Factory •

(19) High CH Setpoint

(20) Outdoor Temp For Hi Setp

(21) Low CH Setpoint

(22) Outdoor Temp For Lo Setp

(23) CH Setpoint Min.

(24) CH Setpoint Max.

(25) Warm Weather Shutdown

(26) Boost Temp. Incr.

(27) Boost Time Delay

(28) Night Setback Temp.

(29) Weather Setpoint

(30) HydroAir CH Hyst Down

(31) HydroAir CH Hyst Up

(32) HydroAir CH PID P 3: Factory

(33) HydroAir CH PID I 3: Factory

(34) HydroAir CH PID D 3: Factory

(35) DHW Mode

(*) P DHW Max

(*) P DHW Min

(36) DHW Storage Hyst Dn

(37) DHW Storage Hyst Up

(38) DHW Store Supply Extra

(39) DHW Store Supp Hyst Dn

(40) DHW Store Supp Hyst Up

(41) DHW Store Hold Warm

(42) DHW Priority

(43) DHW Max Priority Time

(44) Post Pump DHW Time

(45) DHW Store PID P 3: Factory •

(46) DHW Store PID I 3: Factory •

(47) DHW Store PID D 3: Factory •

(48) DHW Setpoint

(49) DHW Hysterese Down

(50) DHW Hysterese Up

(51) DHW Instant PID P 3: Factory •

°C/°F

°C/°F

°C/°F

Sec.

°C/°F

On/Off

°C/°F

Sec.

%

%

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

Min.

°C/°F

°C/°F

°C/°F

°C/°F

0-5

%

%

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

0-2

Min.

Sec.

°C/°F

°C/°F

°C/°F

2:Installer •

2:Installer •

3: Factory

2: Installer •

2: Installer •

2: Installer

3: Factory •

3: Factory •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer

3: Factory

3: Factory

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

2: Installer •

3: Factory •

3: Factory •

3: Factory •

2: Installer •

2: Installer •

2: Installer •

1: User •

3: Factory •

3: Factory •

SSB 6720892984 (2019/02) US

24 | Service display

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

(52) DHW Instant PID I 3: Factory •

(53) DHW Instant PID D 3:Factory •

(54) Tap Detect DHW Drop

(55) Tap Detect Hyst Dn

(56) TapFlow Max Time

(57) Tap Det Hold Active Time

(58) Tap Det Stop Diff SupRet

(59) Tap Det Stop Diff RetDhw

(60) Flow Rate Start

(61) Flow Rate Lo Temp Pwr

(62) Flow Rate Hi Temp Pwr

(63) DHW On Off Period

(64) PH Mode

(65) PH Eco Setpoint

(66) PH Hold Time

(67) PH After Tap Hold Time

(68) After Tap Hold Time

(69) PreHeat Hyst Down

(70) PreHeat Hyst Up

(71) PreHeat Delay Time

(72) Permit EmergencyMode

(73) Boiler Address

(74) Cas Emergency Setpoint

(75) Delay Per Start Next Dep

(76) Delay Per Stop Next Dep

(*) Delay Per Quick Start Next Dep

(*) Delay Per Quick Start Next Dep

(77) Hyst Down Start Boiler

(78) Hyst Up Stop Boiler

(*) Hyst Down Quick Start Boiler

(*) Hyst Up Quick Stop Boiler

(*) Hyst Up Stop All Boilers

(79) Max Setp Offset Down

(80) Max Setp Offset Up

(81) Start Mod Delay Fact

(82) Next Boiler Start Rate

(83) Next Boiler Stop Rate

(84) Boiler Rotation Interval

(*) Boiler First to Start 2:Installer •

(85) DHW Boiler Assign

(86) Casc PID P 3:Factory •

(87) Casc PID I 3:Factory •

(88) Casc PID Slew Rate 3:Factory

(*) Casc PID Slew Rate Up 3:Factory •

(*) Casc PID Slew Rate Down 3:Factory •

(89) Frost Protection

(90) Frost Protection Setpoint

(91) DHW Max Setpoint

(92) Fan Speed Maximum

(93) Fan Speed Minimum

(94) Fan Speed Ignition

(95) Gas Type

°C/°F

°C/°F

Sec.

Sec.

°C/°F

°C/°F

l/min / gpm

l/min / gpm

l/min / gpm

Sec.

Comfort, Eco

°C/°F

Sec.

Sec.

Sec.

°C/°F

°C/°F

Sec.

Yes/No

0-16

°C/°F

Sec.

Sec.

Sec.

Sec.

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

°C/°F

Min.

%

%

Days

0-16

On/Off

°C/°F

°C/°F

RPM

RPM

RPM

0-4

3:Factory

3:Factory

3:Factory

3:Factory

3:Factory

3:Factory

3:Factory •

3:Factory •

3:Factory •

3:Factory •

1:User •

3:Factory •

3:Factory

3:Factory •

3:Factory •

3:Factory •

3:Factory •

3:Factory •

1:User •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer

2:Installer

2:Installer

2:Installer

2:Installer •

2:Installer •

2:Installer •

3:Factory

6720892984 (2019/02) US SSB

Service display | 25

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

(*) Prog. Input 1.

(*) Prog. Input 2.

(*) Prog. Input 3.

(*) Prog. Input 5.

(*) Prog. Input 6.

(*) Prog. Input 7.

(*) Prog. Input RT.

(*) Prog. Output 1.

(*) Prog. Output 2.

(*) Prog. Output 3.

(*) Flow Sensor 2:Installer •

(*) Flow Scaling Factor

(*) Min Pressure

(*) Pressure Fill Hyst.

(*) Service Reminder

(*) Service Status

(*) Mod. Pump dT

(*) Mod. Pump Start Time

(*) Mod. Pump Type 2:Installer •

(*) Mod. Pump Mode 2:Installer •

(*) Mod. Pump Min Pwr

(*) Appliance Type

(*) Min Flow 2:Installer •

(*) Nominal Flow 2:Installer •

0-4

0-2

0-2

0-2

0-3

0-4

0-1

0-5

0-3

0-2

RMP/l

bar/psi

bar/psi

Days

On/Off/Reset

°C/°F

Sec.

%

0-4

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

2:Installer •

Main menu Menu item Submenu / Parameter Sub item Value / Unit User level 900MN

Test mode

Test Status OFF

Power FAN MAX 1:User •

Fan Speed O RPM

OFF

CH MAX 1:User •

O RPM

OFF

LOW 1:User •

O RPM

OFF

IGNIT 1:User •

O RPM

OFF

HIGH 1:User •

O RPM

OFF

OFF 1:User •

O RPM

OFF

LWCO1 1:User •

O RPM

OFF

LWCO2 1:User •

O RPM

OFF

MAX TEMP 1:User •

O RPM

SSB 6720892984 (2019/02) US

26 | Main control

5 Main control

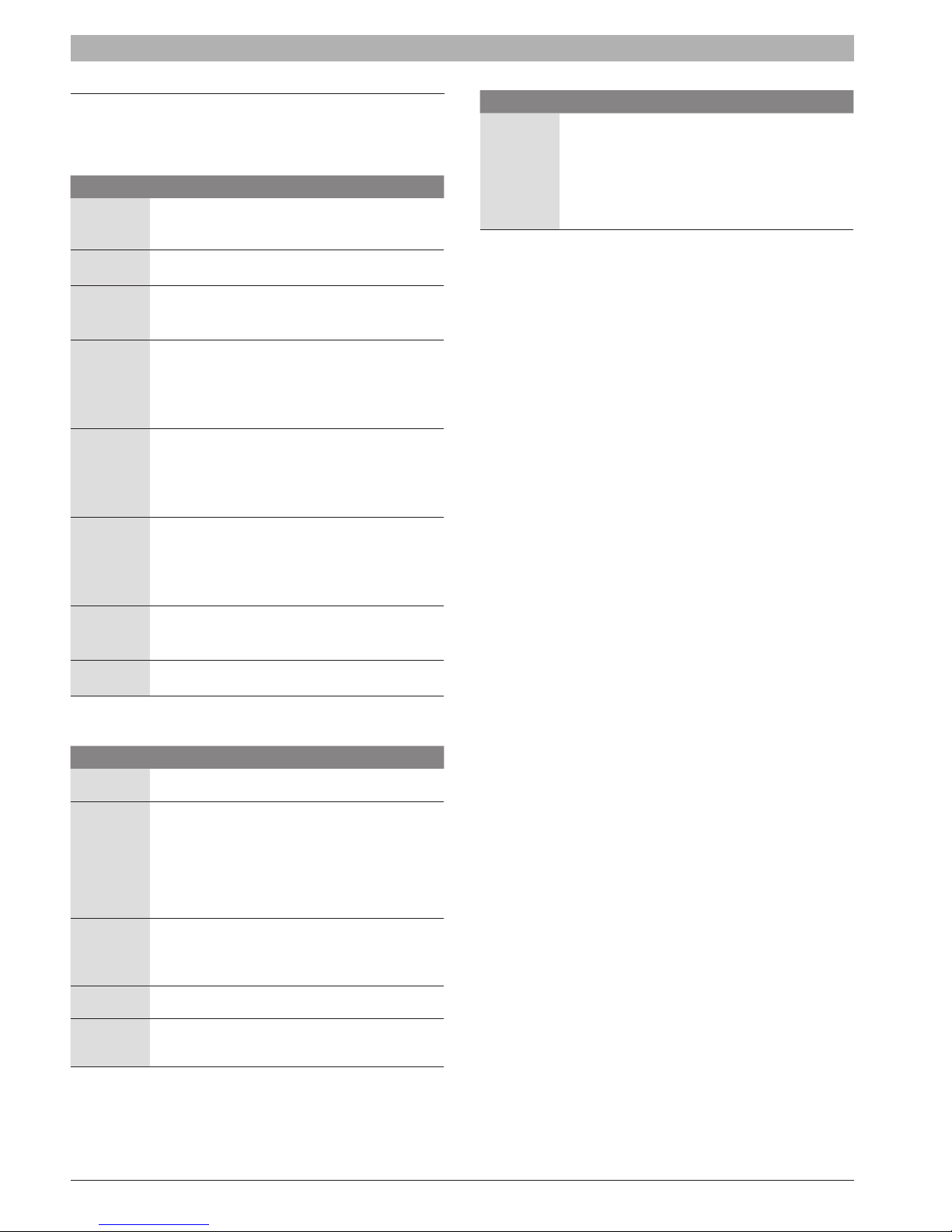

5.1 Ignition cycle (Rev 3.0.0.0)

The table below shows the states of the burner ignition cycle.

Control state Actions

Fan is not running

Pre purge 0

Pre purge 1

Pre ignit

Ignit

Flame

proving

Burn

Post purge 0

Post purge 1

When an air pressure switch (APS) is enabled the APS

position is checked.

Fan starts at ignition speed

When an APS is enabled the APS position is checked

Fan stays at ignition speed

Igniter is started

When a LPG tank is selected, the tank valve is opened

Fan stays at ignition speed

The gas valve is opened

Igniter stays on

When a LPG tank is selected, the tank valve stays

opened

Fan stays at ignition speed

The gas valve stays opened

The igniter is stopped

When a LPG tank is selected, the tank valve stays

opened

The fan is modulating

The gas valve stays opened

When a LPG tank is selected, the tank valve stays

opened

When an APS is enabled the APS position is checked

The fan is set at ignition speed

The gas valve is closed

When a LPG tank is selected, the tank valve is closed

Fan stays at ignition speed

When an APS is enabled the APS position is checked

The fan speed is continuously monitored. The following

conditions for the fan speed are checked.

Fan

supervision

• The actual fan speed must be within 300rpm of the

target fan speed

• When in the burn state both the actual and target

fan speeds are above 4200rpm, the check on the

300rpm range is not performed.

5.2 Control functions

Dependent on the required functions of the appliance and connected

sensors and components, several operation modes for Central Heating

(CH) and Domestic Hot Water (DHW) can be selected.

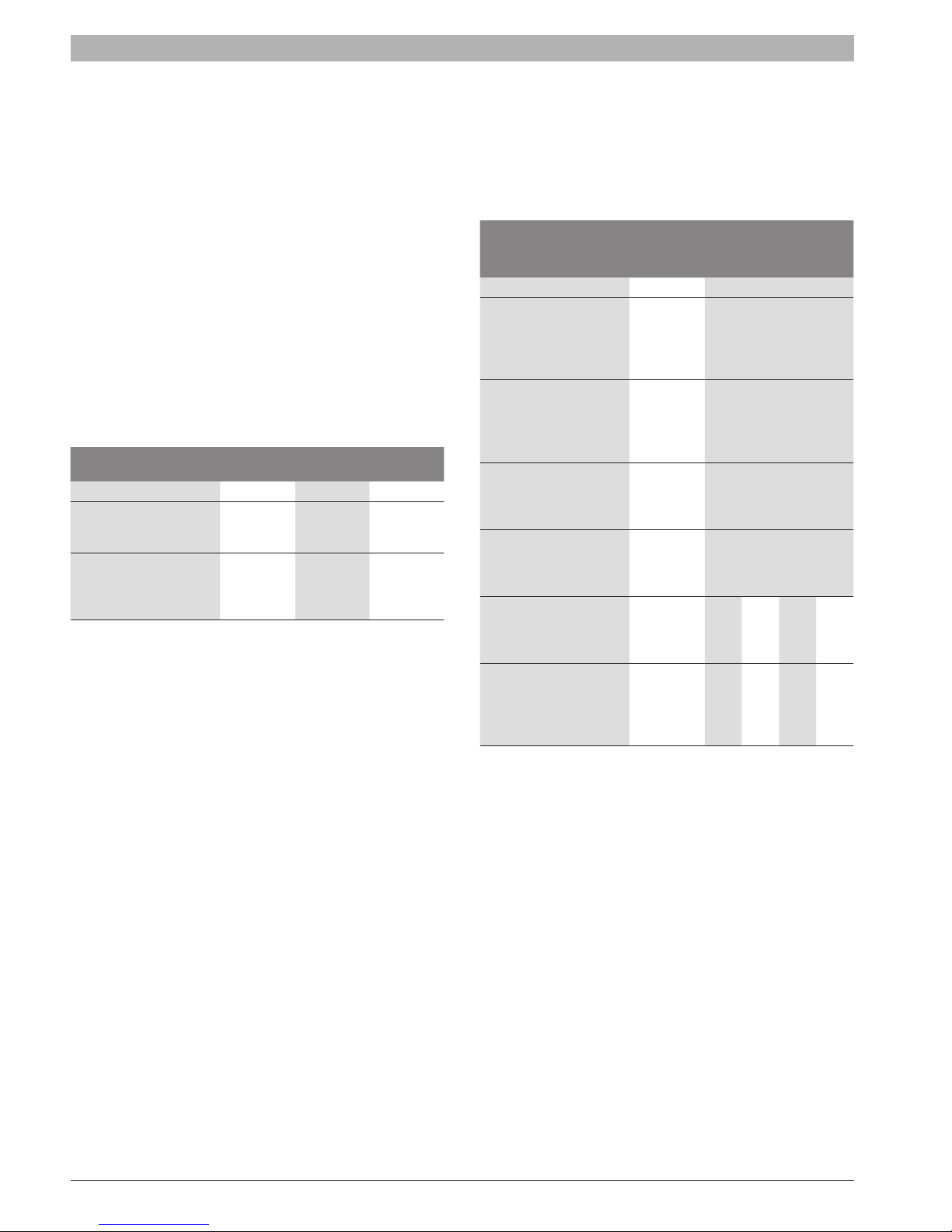

5.2.1 Demand for central heating (Rev 3.0.0.0)

5.2.1.1 CH Mode 0 - Central Heating demand

For this mode the CH mode should be set to 0 and no outdoor sensor is

needed.

If the room thermostat closes, the pump is switched ON. When the supply

temperature drops

(settable via the menu) the burner is switched ON. The power for the

burner is PID regulated between

the PID parameters for Central Heating (Also see chapter “Appendix G PID: Proportional-Integral-Derivative controller” pag. 59).

If the supply temperature reaches a temperature

above the

However, if

maximum setpoint the burner switches OFF at the maximum setpoint.

If the room thermostat opens the burner is switched OFF (if this was

not already happening) and the CH and general pumps run ON for

CH_Post_Pump_Time

CH_Hysterese_Down below the CH_Setpoint

T_Supply

and the

CH_Setpoint

CH_Hysterese_Up

CH_Setpoint

CH_Setpoint + CH_Hysterese_Up

the burner is switched OFF.

is greater than

.

using

During the ignition cycle there are multiple safety checks active.

False ame

detection

Re-ignition

Flame

establishing

time

Flame out too

late

Flame loss

If ame is detected at the end of the pre-spark period

(

Pre ignit

If at the end of the safety period no ame is detected

the control will go to post-purge to remove the unburned

gas. After this a re-ignition attempt is started following

the same cycle.

The number of re-ignition attempts is limited to

Ignit_Trials

Sparking stops in the

for ionization detection.

The Flame proving state takes

) a lockout error occurs

after which a lockout occurs.

Flame proving

SAFETY_PERIOD -

state to allow

IGNIT_PERIOD.

If at the end of the Post purge 0 state the ame is still

detected a lockout follows.

When a ame is lost during a burn cycle the control will

restart the burner. The number of restarts is limited by

the

max_ame_trials

setting.

Max_

Anti-cycling time

(This function is also applicable to all other CH modes)

When the burner is switched OFF because the supply temperature

CH_Setpoint + CH_Hysterese_Up

reaches

period of time (

is allowed to be switched ON again.

This function is to prevent fast switching ON and OFF of the burner.

However, when during the anti-cycle wait time the differential between

setpoint and supply temperature gets greater than

anti-cycle

Maximum CH power

(This function is also applicable to all other CH modes)

The maximum burner power during CH operation can be limited with

parameter

Minimum CH power

(This function is also applicable to all other CH and DHW modes)

• The minimum burner power during operation can be limited with

parameter

Anti_Cycle_Period

will be aborted and the burner is allowed to start.

P_CH_Max

.

P_CH_Min

.

¨ 180 sec. settable) before it

, the control will wait a

Anti_Cycle_T_Diff,

6720892984 (2019/02) US SSB

Loading...

Loading...