Bosch SHY66C06UC/14, SHY66C02UC/14, SHY66C05UC/14, SHX46A06UC/21, SHX46A02UC/21 Installation Guide

...Page 1

Installation

LAVADO_ DE PLATO$

SHU33Ar SHU43Cr SHUS3AI SHU66Cr

SHU43Er SHU53EI SHU66Er

SHV46Cr SHV66AI

SHX33Ar SHX46Ar SHX46BI SHXS6BI

SHYS6A/$HY66C

Page 2

TABLE OF CONTENTS

INTRODUCTION ................................................... 2

TOOLS AND MATERIALS NEEDED .......................... 3

MATERIALS SUPPLIED ........................................... 4

CHOOSING LOCATION .......................................... 5

PLUMBING PREPARATION ..................................... 6

ELECTRICAL PREPARATION ................................... 7

PLACING THE DISHWASHER ................................. 8

DRAIN HOSE CONNECTION .................................. 9

HOT WATER CONNECTION .................................. 10

ELECTRICAL SUPPLY CONNECTION ...................... 11

GROUNDING INSTRUCTIONS ............................... 11

DOOR PANEL INSTALLATION ........................ 12 & 13

FINAL AD]USTMENTS .......................................... 14

BASE AND TOE PANEL .......................................... 15

TOE PANEL AND HANDLE ..................................... 16

FINAL CHECKLIST ................................................ 17

IMPORTANT: Before you begin, read these instructionscompmetely and carefully,

INSTALLER: Please leave this manual with owner for future reference,

OWNER: Save these installation instructions for local

electrical inspector's use and for future reference,

www,boschappliances,com ENGLISH =1

Page 3

THESE INSTALLATION INSTRUCTIONS ARE INTENDED

FOR USE BY QUALIFIED INSTALLERS,

Xn add(tion to these instructionsthe dishwasher shall be installed:

(n the Un(ted States, (n accordance w(th the Nat(ona) Electr(c

Code/State and Municipal codes and/or local codes,

• In Canada, in accordance with the Canadian Electric Code

C22_1 =latest edition/Provincial and Municipal codes and/or

local codes,

Please read these installation inst:ructions completely and carefully,

They will save you time and effort and help to ensure optimum dishwasher

performance,

Be sure to observe all listed

warnings and cautions. (Look for

the triangles with e×clamation marks

(ns(de,)

NEW INSTALLATION = ]:f the dishwasher (s a new insta(lation, most of the work

must be done before the dishwasher is moved into place°

REPLACEMENT - If the dishwasher is replacing another dishwasher, the

connections for the dishwasher being replaced must be checked for

compatibHi_with the new dishwasher and replaced as necessary,

INSPECT THE DTSHWkSHER

After unpacking the dishwasher and prior to insta((ation_ thoroughly inspect the

dishwasher for possible freight or cosmetic damage, Report any damage immediately,

Cosmetic defects must be reported within 5 days of installation,

NOTE: Please do not discard any bags or items that come with the

original package until after the entire installation has been completed!

= _GLTS_ www,boschapp(ia.ces,com

Page 4

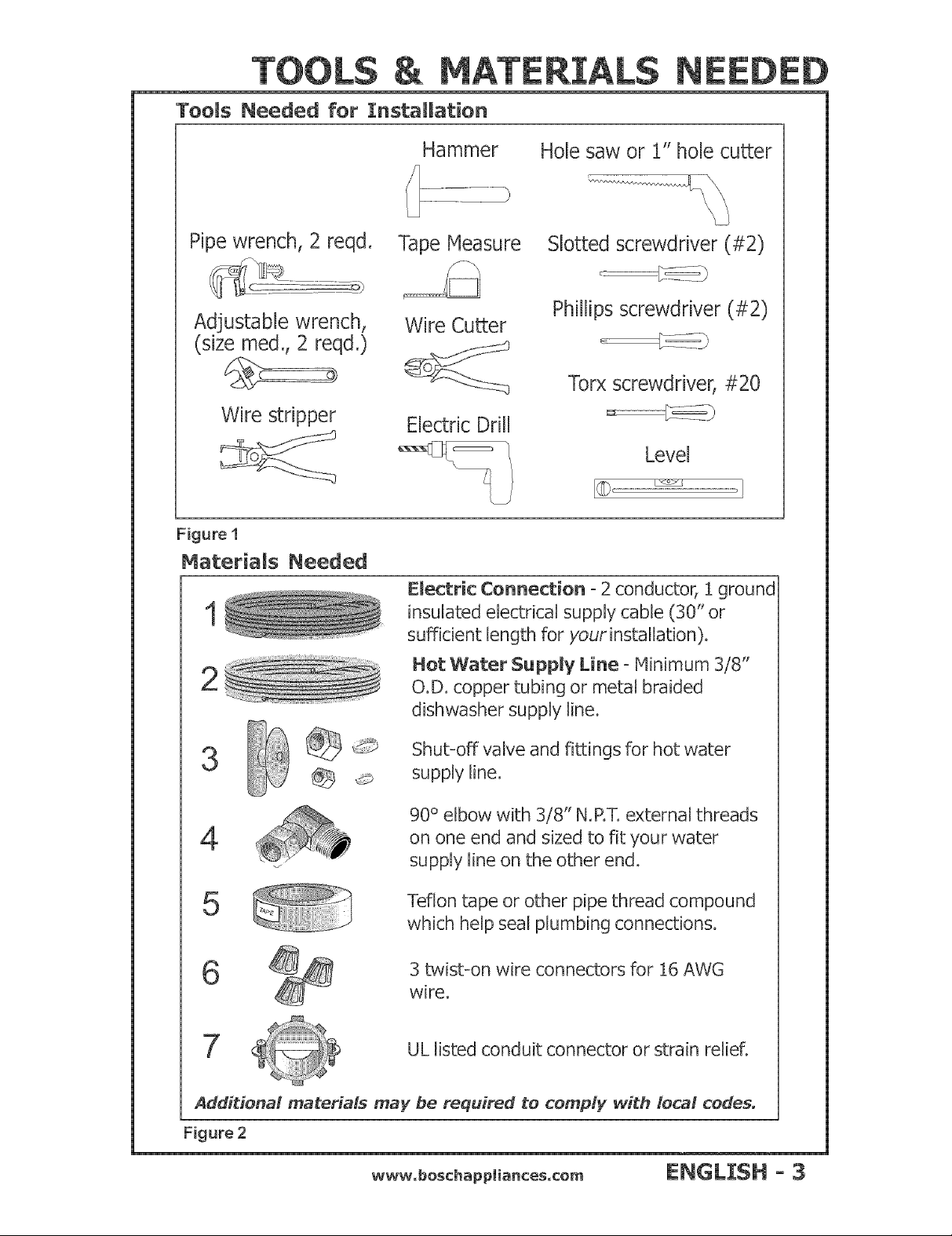

TooLs Needed for Installation

Pipe wrench, 2 reqd.

Adjustable wrench,

(size med., 2 reqd.)

Wire stripper

Figure 1

Materials Needed

1

Hammer

Tape Heasure

o)

Hole saw or 1" hole cutter

Slotted screwdriver (#2)

Phillips screwdriver (#2)

Wire Cutter

Torx screwdriver, #20

Electric Drill

Electric Connection - 2 conductor, 1 ground

insulated electrical supply cable (30" or

suffident length for your installation),

Hot Water Supply Line - Hinimum 3/8"

O.D, copper tubing or metal braided

dishwasher supply Iineo

3

4

5

6

Additional materials may be required to comply with local cedes,

Shut-off valve and fittings for hot water

supply line.

90° elbow with 3/8" N.RToexternal threads

on one end and sized to fit your water

supply line on the other end°

Teflon tape or other pipe thread compound

which help seal plumbing connectionso

3 twist-on wire connectors for 16 AWG

wireo

UL listed conduit connector or strain relief.

Figure 2

www,boschappiiances,com _N_LT_ - 3

Page 5

Accessory Parts Supplied

Accessory Parts for your model dishwasher will

come in one or more plastic bags, Check to

make sure that the parts supplied for your

model are all there, See Figure 3. If any parts

are missing contact your dealer immediately.

DISHWASHER

%NSTALLATION KIT (Clear Bag)

D, Toe Panel Screws (Smm) (2)

E. Mounting Brackets (1L & 1R)

F. Mounting Bracket Screws (2)

G. Rubber Connection Hose (1)

and Drain Hose Clamps (2)

$HY66 & $HXS6 Models

Dishwasher InstallationKit(i) and

(Green Bag) wi the following:

L. J-Box Cover (1)

M, 3-Box Screw (8ram) (1)

N. Toe Panel Screw (4x16) (2)

$HV and SH][ Models

Dishwasher InstallationKitand

Outer Door InstallationKit(Blue bag):

J. SHIiSHV Panel Installation Template

C, Cap (2 BIk)

K. Wood Screws (2)

1". Mounting Door Brackets(2 plastic)

w/Screws (4) and;

Mounting Door Brackets (2 metal)

w/Screws (4)

H. Spring Tension Screw (2)

Manual Bag

All Dishwashers come with a manual bag,

The following contents are located in every

bag:

® Use &Care Manual

® Installation Instructions

P. Tall Item Sprinkler (1)

SHY66 & SHX56 models

have an additional part:

Q, Cotton Insulation Strip (1)

Note: Pictures are not to scale. Figure 3

4- ENGLISH www.boschappiiances.com

Page 6

THBEIN AW ON

INSTRUCTIONS

INTENDEDFORU_ BY

QU_EDINSTALLE_ 1

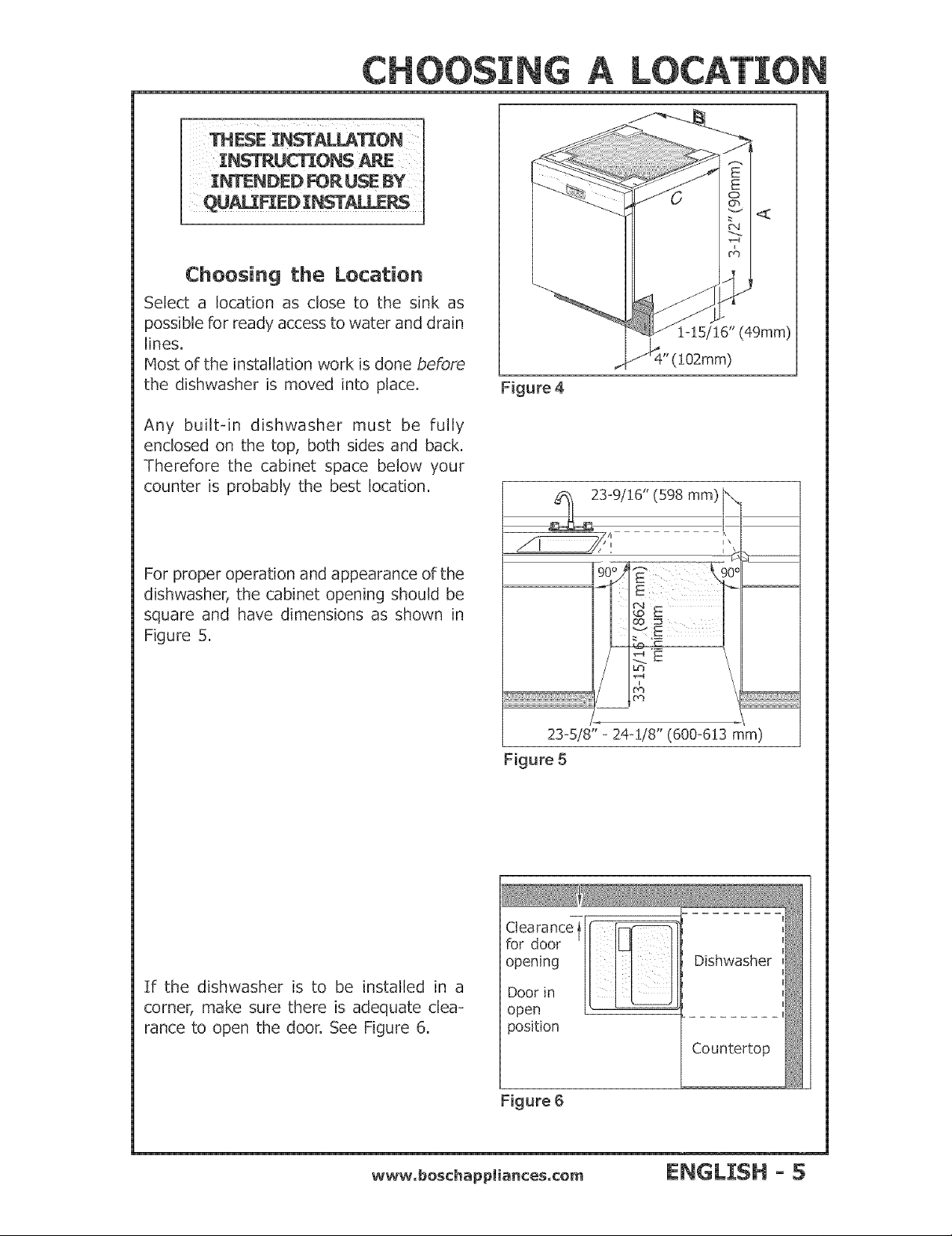

Choosing the Location

Select a locationas close to the sink as

possibleforready accesstowater and drain

lines.

Most of the installation work is done before

the dishwasher is moved into place.

Any built-in dishwasher must be fully

enclosed on the top, both sides and back.

Therefore the cabinet space below your

counter is probably the best location.

For proper operation and appearance of the

dishwasher, the cabinet opening should be

square and have dimensions as shown in

Figure 5.

(49ram)

Figure 4

23-9/16" (598 mm) "_

/F /S'I _'

If the dishwasher is to be installed in a

corner, make sure there is adequate clea-

rance to open the door. See Figure 6.

....j

23-5/8" - 24-1/8" (600-613 cam)

Figure 5

Clearance-

Dishwasher

o0on,o /11 I

oDpOrnin L

)osition

Countertop

Figure 6

www,boschappliances,com FNGL]:SH - 5

Page 7

G

INSTRUCTIONSAPE U

%NTENBED FORUSE BY I

QU_FIED INSTNJLE_

]

Drain Hose

The dishwasher comes with a seven (7)

foot drain hose.

A 1.25" access hole must be made to

allow the drain hose to be run to the

drain connection location.

Hot Water Supply

The hot water line to the dishwasher

must provide between 5 - 120 psi (0.3-

8.27 bars) water pressure.

The hot water heater should be set to

deliver 140°F (60°C) water

temperature to the dishwasher.1

A 3/8" minimum O.D. copper tubing

inlet line is recommended.

All solder connections must be made

before water line is connected to the

dishwasher's inlet water valve. Do not

solder within 6 inches (IS2.4 ram)

of the dishwasher's inlet water

valve,

• Drill a 1" (25.4 mm) diameter access

hole in the cabinet for the water supply

line (Figure 9A).

Run the line to the approximate fill

valve location, as shown in Figure 9A,

To protect against possible rupture of

the fill valve, water lines leading to

the dishwasher, as well as water lines

in the dishwasher MUST be protected

against freezing. If the valve or water

line freezes, flooding may occur. Such

ruptures are not covered by the

warranty.

If no air gap isused and the drain

line is run into a sink or disposer,

the drain line must be elevated to

a point higher than the highest

water ieveJ of the sink to prevent

back siphoning into the

dishwasher,

NOTE: If connection to an air gap is

required by local code, air gap kits are

available from local plumbing sources.

Install the air gap according to the

manufacturer's instructions.

It is recommended that a shut-off valve (not

supplied) be installed in the hot water

supply line in a readily accessible location,

see Figure 9.

Hot water

line Electrical supply cable

Figure 7

1. In order to reduce running time, Bosch recommends 140 ° F water inlet

temperature. Your dishwasher will perform equally as well at 120 ° F water

temperature, but the run time will be extended,

6- ENGLISH www,boschappliances,com

Page 8

Electricam SuppNy

The customer has the responsibility to

ensure that the dishwasher installation is

in compliance with all national and local

electrical codes and ordinances. The

dishwasher shall be installed by a qualified

electrician and properly grounded. The

electrical supply for which the dishwasher

is designed is 120\/, 60 Hz, AC, connected

to a dishwasher-dedicated electrical circuit

with a fuse or breaker rated for ::[5 amps.

If the dishwasher is connected with a food

disposer, a 20 amp (and no higher) fuse or

drcuitbreaker may be used. No other

appliances or outlets should be connected

to the dishwasher supply circuit. Electrical

supply conductors shall be copper only and

shall be minimum #16 AWG. Wire

connectors proper for the size and number

of wires used to connect the dishwasher

to the supply circuit shall be used. Do not

use all-plastic wire connectors. Strip power

supply wires approximately 1/2 inch. Do not

pre-twist wire before applying wire

connector. After installing wire connectors,

gently tug wires to check the integrity of

the connector. Place all wires and

connectors into the power supply box,

and reinstall cover with the screw provided

the installation package.

Cut a :1 (25Amm) diameter hole in the

cabinet (in area of Figure 9 B). For wood

cabinets, sand the hole until smooth.

For metal cabinets, cover the edge with

a grommet.

Run flexible cable (as codes permit) from

junction through hole in cabinet. Cable

should extend 30" (762 mm) from back

wall.

I

/

Figure 8

Electrical Rating

Volts Hertz Amperes Watts

120 60 15 1,450

(max}

Table 1

Openings for electrical lines must be

installed in the marked areas as

shown in Figures 8 and 9 to avoid

interference with the dishwasher

frame or other components.

A

HWS {355mm)

21"

(533ram)

Hot water supply line Electric supply cable

Figure 9

www,boschappliances,com ENGm ISH - 7

Page 9

G

Placing the Dishwasher

The profile strips on the sides of the

dishwasher allow the dishwasher to fit into

a cabinet opening with a width of 23-5/8"

(600 mm) to 244[/8" (613 mm). Before

sliding the dishwasher into the cabinet

opening:

• Straighten the hot water supply line and

the electrical cable (see Figure 11).

• Level & Align (initial adjustments).

• Guide the drain hose carefully (avoiding

kinks in hose) as the dishwasher is slid

into the cabinet opening.

• Make final leveling adjustments (see

FINAL STEPS Section).

• To maintain the dishwasher position and

alignment, first determine which type

of mounting your dishwasher needs:

Top Mount is used for all types of

countertops that will not be damaged

by drilling.

• For a top mount, position the

brackets fiat on each of the top

corners of the dishwasher as

shown in Figure 10A.

Side Mount is used when there is a

granite, marble or other hard natural

surface counter top that could be

damaged by drilling.

• For a side mount, bend the

brackets, then position them as

shown in Figure 10B.

A, Mounting bracket

for mounting to under A

countertop

Bo Mounting bracket

bent for mounting to

side of cabinets

Figure 10

IMPORTANT

]If you wish to change the front panel of

the dishwasher this must be done before

sliding the dishwasher into place.

_Note: Additional accessory door pa-

nels can not be used with SHU 9900

models.

• Drive Mounting Screws (see Figure 3)

through the holes in the brackets. See

Figure 10A or 10B.

• Connect the drain hose, hot water

supply line and electrical connections

as described in the following sections.

Figure 11

8- ENGLTSH www.boschappliances,com

Page 10

THESE NSTALLA ON

IN U ONS J

_N_NDEDFORUSEBY I

QU_EDINSTALLE_ I

Be sure to follow your national

and local codes at all times.

Drain Hose

* Before beginning, turn off the water

supply!

The access hole for the drain hose should

be 1.25" (32 ram) diameter,

Use the hose damps and rubber

connection hose (Figure 3) to connect

the drain hose to the sink, disposer or

air gap (Figure 14).

Openings for drain lines must be

installed in the marked areas as

shown in Figures 8 and 9 to avoid

interference with the dishwasher

frame or other components.

f_ Air Gap_

in Sink

Drain Hose

with Air

Gap & Rubber

Disposer o_8__

€ k. _7L--Trap .

Figure 12

_ J

Figure 13

Failureto provide the proper drain

connection height, 20" (508mm)

above floor [eve[ with high loop or

air gap, wiJ[ resuit in improper

of the dishwasher.

Improper draining may cause

damage to the dishwasher,

www,boschappiiances,com F@GL:ISH o 9

Drain Hose

Connected

to Sink

Figure 14

Page 11

TNESE NST LA ON

INSTRU ONS I

INTENDED FORUSE BY I

QUALI_EDINSTALLE_ i

Connecting the Hot Water

$uppIv Line

Ifusing a solderjointinsteadof acom _

pression fitting, be sure to make aft

solder connections before connecting

the water line to the dishwasher.

Make sure there are no sharp bends or

kinks in the water line which might

restrict water flow.

When connecting threaded pipe use pipe

thread compound or Teflon tape to seal

the connection.

Before connecting the copper hot water

supply line to the dishwasher, it should

be flushed with hot water to clear any

foreign material.

Apply Teflon tape or other pipe sealant

to 90 ° elbow fitting and connect

directly to water inlet valve s .

Turn on the water supply to check for

leaks after making connections.

Figure 15

DO NOT SOLDER WITHIN 6 INCHES

(152.4 FIr,I) OF THE DISHWASHER'S

INLET VALVE.

TEMPERATURES REQUIRED FOR

SOLDERING WILL DAMAGE THE

VALVE!

Water inlet valve located at the bottom

left front of the dishwasher.

Openings for water lines must be

installed in the marked areas as shown

in Figures 8 and 9 to avoid

interference with the dishwasher

frame or other components.

Figure 16

10 - ENGLISH www,boschappliances,com

Page 12

INSTRU_ONS ARE

IN_NDED _RUSE BY

QU_FIED INST_JUE_

Connecting ElectricaNSupply

Be sure to follow all local and natio-

nal electrical codes and ordinances,

• Install strain relief or conduit connector

into opening on power supply box.

• Strip the insulated wires, being extremely

careful not to strip too much insulation.

• Insert and securely fasten into strain re-

lief, two-conductor supply cable with

ground.

• Twist wire connectors tightly onto the

wires, ensuring that no bare wiring is

exposed (from insulated wires).

• Press wires back into ]-box

• Securely fasten the J-box cover or toe

panel (depending on model) with

screw(s) provided from accessories

package.

ELECTRICAL SHOCK HAZARD

• DISCONNECT ELECTRICAL POWER

AT THE CIRCUIT BREAKER BOX OR

FUSE BOX BEFORE INSTALLING THE

DISHWASHER.

• ELECTRICALLY GROUND DISH-

WASHER.

• USE COPPER CONDUCTORS ONLY.

FAILURE TO FOLLOW THESE

INSTRUCTIONS COULD RESULT IN

SERIOUS INJURY OR DEATH.

Correct Connection in 3unction Box

Black to Black

White

Junction box /ocated at the bottom

right front of the dishwasher base.

Grounding Znstructions

This appliance must be connected to a

grounded metal permanent wiring system;

or an equipment grounding conductor

must be run with the circuit conductors

and connected to the equipment grounding

terminal or lead on the dishwasher. The

dishwasher must be properly grounded

before operating. Make sure that the

dishwasher is connected to a suitable

ground in compliance with the NATIONAL

ELECTRICAL CODE, in the United States,

or the CANADIAN ELECTRIC CODE C22.1-

latest edition, in Canada as well as any pro-

vincial/state or municipal or local codes that

apply.

Relief

Figure i 7

IncorrectConnection in 3unction Box

Figure i8

www,boschappliances,com ENG LISH - 11

Page 13

Accessory Panel Installation SHU Modets

If you have an SHU model and have ordered an accessory panel kit it must be installed

prior to sliding the dishwasher into place. Dimensions of panel size that may be used is

shown in Figure 19.

Panel Installation, SHV Models

If you have an SHV model, a fully integrated model, you will have additional mounting

hardware and a folded template sheet with installation instructions comprised of

pictograms.

Refer to the folded template sheet for information on how to mount the panel. Please

note that one side of the template shows how to mount a one piece panel and the other

side of the template shows how to mount a two piece panel. Be sure of what type

installation you want before proceeding with the installation.

Refer to Figure 20 and Table 3 for guidelines on custom door panel selections.

After deciding if the extension pieces will be used or not refer to the pictograms printed

on the template for proper method of mounting your custom door.

Panel Installation, SHI Hodels

If you have an SHI model, an integrated model, you will have additional mounting

hardware and a folded template sheet with installation instructions comprised of

pictograms. In North America the stainless steel models of the integrated series (SHI

series), have a control panel that is 5-5/16" (135 mm) tall. The stainless steel model

comes with two extension pieces, referred to as the standard and long extension piece

in Table 2: the standard piece is used for drawer heights up to 6" (152mm); the long

extension piece is used for drawer heights greater than 6" (152mm) but 6-7/16" (164mm)

or less. These stainless steel extension pieces are not installed in the control panel. In

the stainless steel models, the two extension pieces are shipped loose and must be

inserted as shown in pictogram 5 on the template sheet.

The purpose of the extension piece is to allow the increase of the control panel height to

try to match the horizontal drawer line of the cabinets. If your drawers are taller than the

"C" dimension shown on Table 2, it is recommended that the extension either be slid in

as far as it will go, or removed and the door made to fit directly below the control panel.

12 - ENGLISH www,boschappliances,com

Page 14

SEE FOLDED PANEL INSTALLATION

TEMPLATE SHEET FOR STEP BY STEP

INSTRUC_ONS ON HOW TO INSTALL

YOUR DISHWASHER PANEL(S),

Figure 19

IMPORTANT

Do NOT DrillComp(etely through

your custom door panel.

MODEL

STANDARD LONG

SHI66C05UC

11/16=5/16" 1 1/8 - 11/16"

Table 2

MODEL D

SHV N/A

20 11/16 - 25

SHI

(526-635 ram)

Table 3

EXTENSION "A"

MAX -MIFf

(18-8mm) (29 - 18ram)

27 3/16" =30 5/16"

(690 - 770 ram)

27 3/16" =30 5/16"

(690 - 770 ram)

"B"

5/16 (13!

mm)

E* F

"C"

MAX -MIN

6 7/16 =5 5/8

(164 - 143 ram)

23 3/16 -23 3/8

(589 - 594 ram)

c

A

Figure 20

Z) E

.............. y

Figure 21

*Note; Do not exceed 30 5/16" (770mm)

for the overall front panel length.

www,boschappiiances,com ENGLISH- 13

Page 15

Door Tension Adjustment

(only in $HI and SHV models)

After installation of the dishwasher, open

and close the door several times to make

sure that it does so with ease, If the door

closes too quickly or if the door falls open,

the spring tension needs to be adjusted.

To Adjust the Spring Tension

Obtain Spring Tension Screws (2) out

of the SHIiSHV parts bag (see Figure

3).

Insert the screws in the right and left

sides and adjust spring tension as shown

(see Figure 22).

Leveling the Dishwasher

Raising the Rear

The rear leveling leg is adjusted by turning

the center screw at the front of the

dishwasher.

Raising the Front

The front leveling legs are adjusted by

rotating the leveling legs on the front left

and right sides of the dishwasher.

Figure 22

[Torx T 20 i

Use a screwdriver and tap the end lightly

with a hammer to turn the legs (see

Figure 23).

JVete: If additional height is needed:

Shims may be added under the leveler feet.

Figure 23

1.4 - ENGLTSH www.boschappliances.conl

Page 16

$HY66 _ $H×56 Series Base and Toe Panel Installation

Steps

Installation Parts

@

SHY66 & SHX56 Base Part

@

Base Part Screws

@

SHY66 & SHX56 Toe Panel

@

SHU Toe Panel Screws

@

SHY66 & SHX56 Installation Kit

(Refer to "Materials Supplied" section)

Junction Box Cover and Screw

Remember to carefully check, the "Materials

Supplied" section against the Installation Kit

bag and contents.

D[sassemb[v Steps

• Pull Toe Panel off (Figure 25).

• Loosen Screws

LOW TORQUE, USE HAND TOOL

ONLY.

Remove Base Part by pulling it out

and downward.

After instaHationr water and electrical

lines are connected and the unit leveled,

assemble the base part (see below)o

Assemb[v Steps

Place ]-Box Cover on ]-Box, insert

and tighten screw (Figure 26).

Drop screws inside holes in base part.

Slip Base Part under and up front

bottom panel of dishwasher. Tighten

Base Part Screws - LOW TORQUE,

USE HAND TOOL ONLY.

Slip Cotton Insulation Strip under

unit, between the bottom of Base

Part and the floor.

Figure 24

Figure 25

Figure 28

Junction Box Cover is required

for any insl:atiat:ion application

www.boschappliances,com F@GL:ISH- 15

Page 17

R_u_ar Toe Pane_

Installation (for models

other than $HY66 & $HX56)

• Obtain Toe Panel Screws from the

Dishwasher Installation Kit bag (see

Figure 3).

Insert screws through the Toe Panel.

With a Torx screwdriver, fasten screws Figure28

and toe panel into dishwasher base.

16 - ENGLISH www,boschappliances,com

Page 18

C

Final Checklist

[] Check Electrical Requirements.

[] Be sure you have correct electrical supply and recommended grounding method.

[] Turn on the hot water shut-off valve and electrical supply. Incoming water

temperature should be 120°F-140°F (49°C-60°C).

[] Operate the dishwasher through one cycle and check for plumbing leaks.

If the dishwasher does not operate properly, refer to the SELF- HELP, CUSTOMER

SERVICE and WARRANI_f sections in the Use and Care Manuat.

Customer Service :Information

]:f service becomes necessary, contact your dealer or installer or an authorized service center. Do

not attempt to repair the appliance yourself. Any work performed by unauthorized personnel may

void the warranty. If problem persists, take the following steps (in the order listed below) until the

problem is corrected to your satisfaction.

Contact your installer or the Bosch Authorized Service Contractor in your area.

2o

E-mail us from the Customer Service section of our web site, www.boschappliances.com,

3.

Write to us at the address below:

BSH Home Appliances, Corp.

5551 McFadden Avenue

Hantington Beach, CA 92649

4. Call us at: 1-800/944o2904.

Please be sure to include (if writing), or have available (if calling), the following information:

Model Number

Serial Number

Date of Original Purchase

Date Problem Originated

Explanation of Problem

Also, if writing, please be sure to include a daytime phone number.

(You will find the model number and serial number information on the label located on the right-hand

side of the inner door of the dishwasher).

LEAVEINSTALLA_ON INSTRUCTIONS AND

USE& CARE MANUAL WITH OWNER,

www,boschappliances,com FNGLISH- :[7

Page 19

18 - ENGLISH _.boschapp_ia.ces.com

Loading...

Loading...