Page 1

YOUR LIFE. OUR INSPIRATION.

Power

On/Off

Delay

Start

Hours

Top

Rack

Only

Cancel

Drain

Power

Scrub

Plus

Scrub

Wash

Regular

Wash

Delicate/

Econo

Quick

Wash

Rinse

& Hold

Refill

Rinse

Agent

Cycle Countdown

Dishwasher Installation Instructions

Instructions d’installation du lave-vaisselle

Instrucciones de instalación para lavadora de platos

Use and Care Manual located on reverse side

Tourner le guide pour les instructions d’utilisation et d’entretien

Voltee el manual para encontrar las instrucciones de uso y cuidado

9000060333 (8503)

Page 2

Page 3

Table of Contents / Important Instructions

Table of Contents

IMPORTANT INSTRUCTIONS ................................ 1

Tools Needed ........................................................... 2

Materials Needed .....................................................2

Materials Supplied ...................................................3

Enclosure Preparation ............................................. 4

Electrical Preparation .............................................. 5

Plumbing Preparation ........................................... 6-7

Dishwasher Preparation ........................................ 7-8

Door Panel Installation .............................................9

Important Safety Instructions

WARNING

To avoid possible injury or property damage,

OBSERVE ALL WARNINGS AND CAUTIONS.

These instructions are intended for use by

qualified installers only.

The dishwasher must be installed by a qualified

service technician.

• In addition to these instructions, the dishwasher

shall be installed to meet all electrical and

plumbing codes and ordinances (both national and

local).

Read these installation instructions completely

and follow them carefully. They will save you time

and effort and help to ensure safety and optimum

dishwasher performance.

CAUTION

If the dishwasher is installed in a location that

experiences freezing temperatures (e.g., in a

holiday home), you must drain all the water

from the dishwasher’s interior. Water system

ruptures that occur as a result of freezing are

not covered by warranty.

Placing the Dishwasher ......................................... 10

Securing the Dishwasher ....................................... 10

Drain Hose Connection .......................................... 11

Hot Water Connection ............................................12

Electrical Connection........................................ 13-14

Door Tension Adjustment ....................................... 14

Base and Toe Panel .......................................... 14-15

Final Instructions ................................................... 15

Customer Service .................................................. 16

IMPORTANT

• The dishwasher drain hose must be installed

with a portion of it at least 20” (508mm) off the

cabinet floor; otherwise the dishwasher may not

drain properly.

• This dishwasher is intended for residential use

only, and should not be used in commercial food

service establishments.

• NEW INSTALLATION - If the dishwasher is a

new installation, most of the work must be done

before the dishwasher is moved into place.

• REPLACEMENT - If the dishwasher is replacing

another dishwasher, check the existing

dishwasher connections for compatibility with

the new dishwasher, and replace parts as

necessary.

Inspect the Dishwasher

After unpacking the dishwasher and prior to

installation, thoroughly inspect the dishwasher for

possible freight or cosmetic damage. Report any

damage immediately. Cosmetic defects must be

reported within 5 days of installation.

NOTE: Do not discard any bags or items that come

with the original package until after the entire

installation has been completed.

1

Page 4

TOOLS NEEDED

Tools and Materials Needed

Hammer Hole Saw

Tape Measure

Wire Cutter

Slot Screwdriver

Wire Stripper

Phillips Screwdriver

Drill

MATERIALS NEEDED

(Additional materials may be required to comply with local codes.)

Pipe Wrench

Adjustable Wrench

Torx Screwdriver

Level

Electrical Supply Cable - Minimum #14 AWG, 2 conductor, 1 ground, insulated copper

conductors rated 75°C or higher.

Hot Water Supply Line - Minimum 3/8” O.D. copper tubing or metal braided dishwasher

supply line.

Shut-off valve and fittings appropriate for hot water supply line (copper tubing/

compression fitting, or braided hose).

90° elbow with 3/8” N.P.T. male threads on one leg, and sized to fit your water supply

line (copper tubing/compression fitting, or braided hose) on the other leg.

Teflon tape or other pipe thread compound to seal plumbing connections.

UL listed conduit connector or strain relief.

2

Page 5

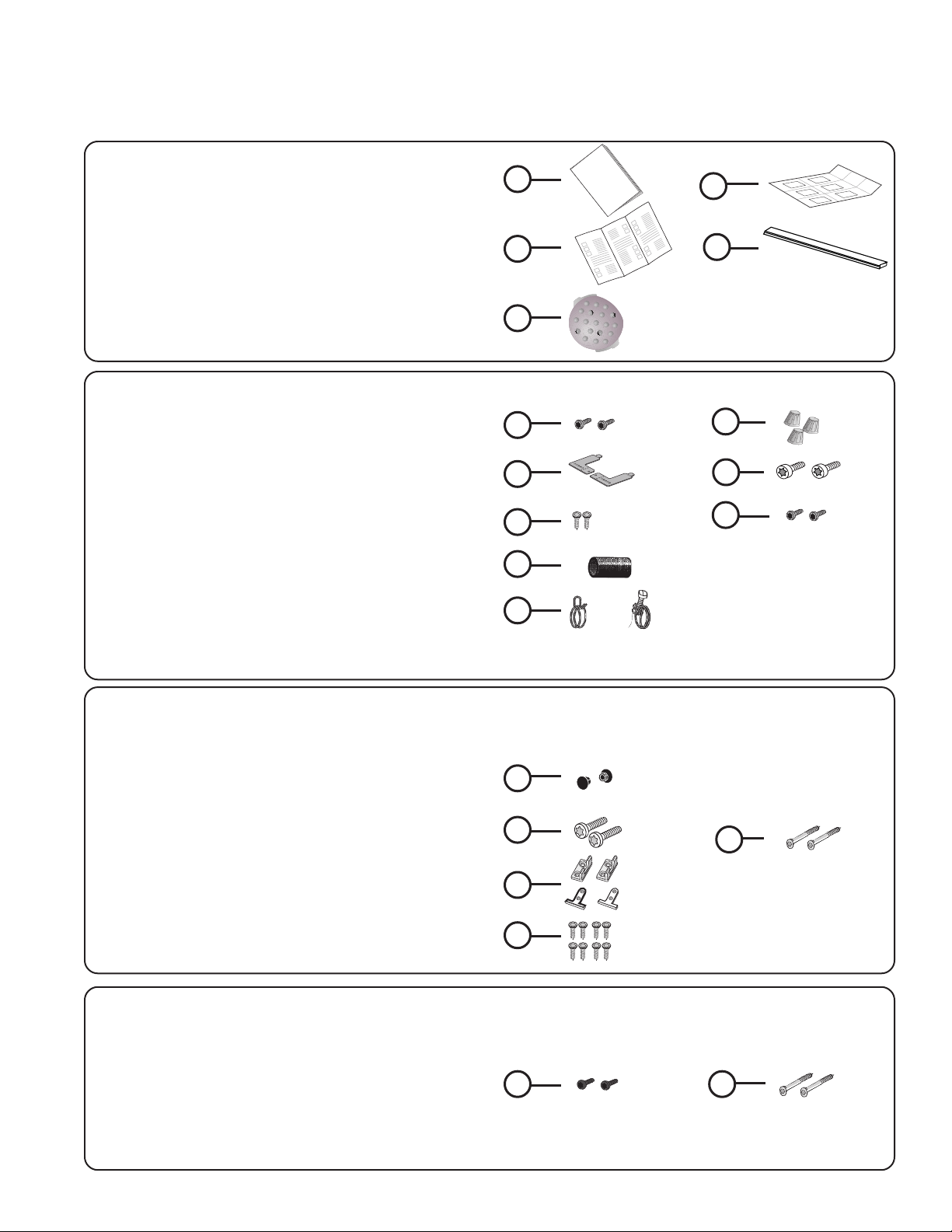

Materials Supplied

MATERIALS SUPPLIED

Accessory Parts Supplied

Accessory parts for your dishwasher come in one or more plastic bags that are outlined below.

NOTE: Make sure you save all the bags until you have completed your installation.

Manual Set Bag

A Manual Set Bag is provided with each dishwasher

and includes:

A Use & Care Instructions and Installation

Instructions (both manuals may be included

in a single “flip-style” book

B Quick Reference Guide (select models)

C Extra Tall Item Sprinkler

D SHI and SHV Installation Template (SHI and SHV

models only)

E White Cotton Insulation Strip (SHY66 and

SHX99A models only)

Dishwasher Installation Kit

A Dishwasher Installation Kit is provided with each

dishwasher and includes:

F Toe Panel Screws (2 black machine screws)

G Counter Top Mounting Brackets (2 “L” shaped

metal brackets)

H Mounting Bracket Screws (2 silver wood screws)

I Rubber Drain Hose Adaptor (1 black rubber tube)

J Hose Clamps ( 1 silver spring clamp to use to

attach the rubber adaptor to the Drain Hose and 1

gold screw clamp to attach the rubber adaptor to

the plumbing)

K Wire Nuts (3 for electrical connection)

L Electrical Junction Box Screws (2 silver

machine screws)

M Leg Leveler Locking Screws (2 gold coarse

threaded screws)

A

B

C

F

G

H

I

J

D

E

K

L

M

SHI/SHV Door Panel Installation Kit

A Door Panel Installation Kit is provided with select

dishwashers that use a custom wood door panel and

includes:

N Plastic Caps (2)

O Spring Tension Screws (2 larger silver machine

screws used to adjust the door springs to accommodate doors of different weights)

P Door Mounting Brackets (2 gold metal brackets

and 2 white plastic brackets used to mount the

custom door)

Q Door Mounting Bracket Screws (8 silver wood

screws)

R Door Mounting Screws (2 long silver screws used

to attach the door)

Toe Panel Installation Kit

A Toe Panel Installation Kit is provided with select

dishwashers (SHY66C/SHX99A) that use a special toe

panel and includes:

S Toe Panel Screws (2 black screws used to attach

the metal Toe Panel)

T Black Plastic Base Access Panel Screws (2 long

silver screws used to attach the Black plastic

Base Access Panel to the dishwasher.

N

O

P

Q

S T

R

3

Page 6

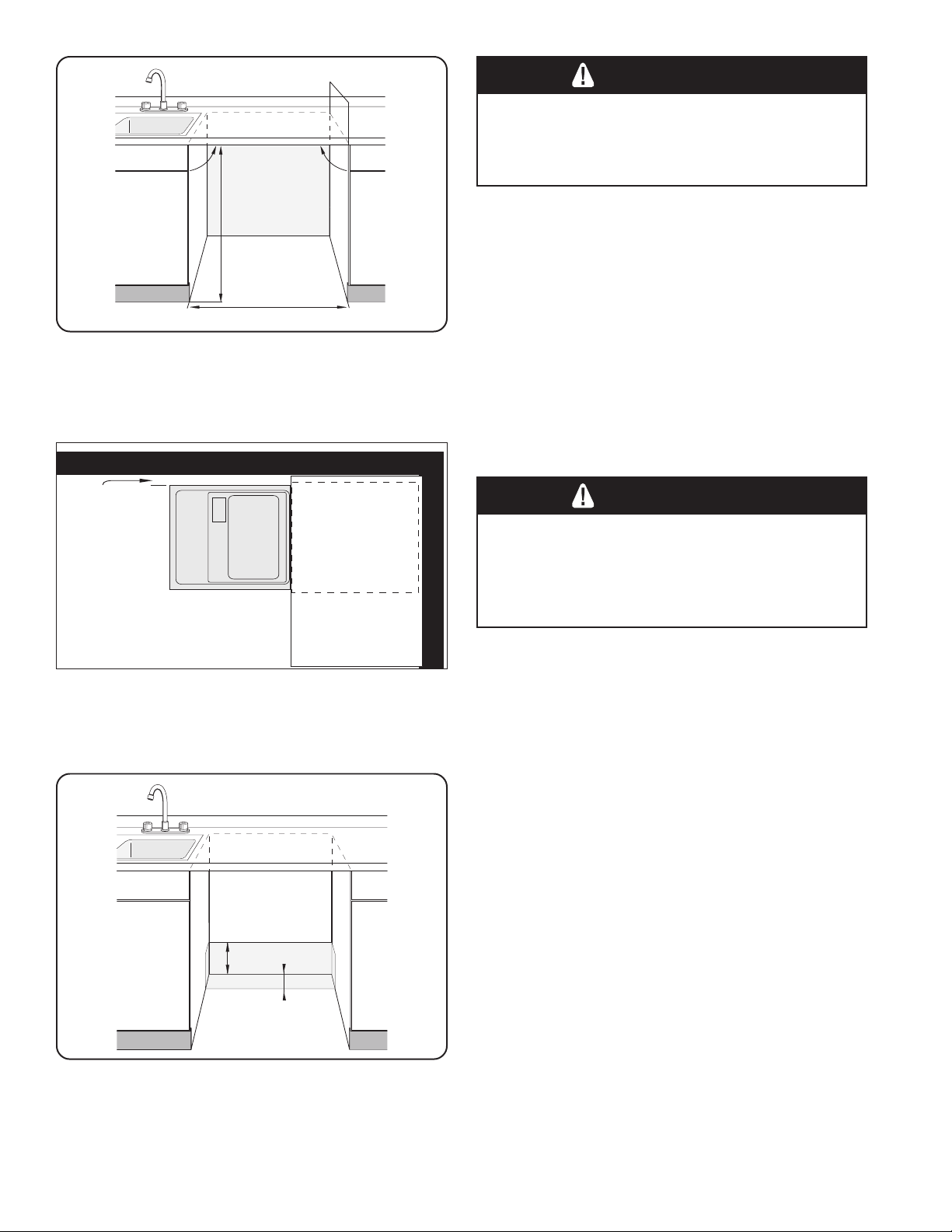

Enclosure Preparation

Check

clearance

between

dishwasher

door and wall

34"

(864mm)

minimum

23-5/8" – 24-1/4" (600–616 mm)

Figure 1

Countertop

23-9/16"

(598mm)

90 90

WARNING

Electrical Shock Hazard

To avoid electrical shock, make sure the water

supply and electrical supply are shut off before

installation or service.

ENCLOSURE PREPARATION

NOTE: This dishwasher is designed to be enclosed on the

top and both sides by standard residential kitchen

cabinetry.

Select a location as close to the sink as possible for

easy access to water supply and drain lines.

For proper dishwasher operation and appearance, ensure

that the enclosure is square and has the dimensions

shown in Figure 1.

If the dishwasher is to be installed in a corner, make sure

that there is adequate clearance to open the door. See

Figure 2.

WARNING

Electrical Shock/Fire Hazard

To avoid electric shock or fire, do not allow the

electrical and water supply lines to touch.

Separate channels are provided under the

dishwasher (see page 10).

Figure 2

3-1/2"

(89mm)

Figure 3

1-5/16"

(33mm)

If the enclosure requires openings for the electrical supply

cable, hot water supply line, and dishwasher drain hose,

place them within the dimensions shown by the shaded

area of Figure 3 to avoid interference with the dishwasher

frame or other components. Make the openings for the

electrical supply cable and hot water supply line 1”

(25.4mm) diameter. Make the opening for the dishwasher

drain hose 1-1/4” (32mm) diameter. If the openings are

made through wood, sand them smooth. If the openings

are made through metal, make them large enough to

accommodate grommets or other protective sheaths with

inside diameters of 1” (25.4mm) for the electrical supply

cable and the hot water supply line, and 1-1/4” (32mm) for

the dishwasher drain hose.

4

Page 7

(762mm)

3/8" - 1/2"

( 8mm - 13mm)

3" - 4"

( 75mm - 100mm)

21"

(533mm)

30"

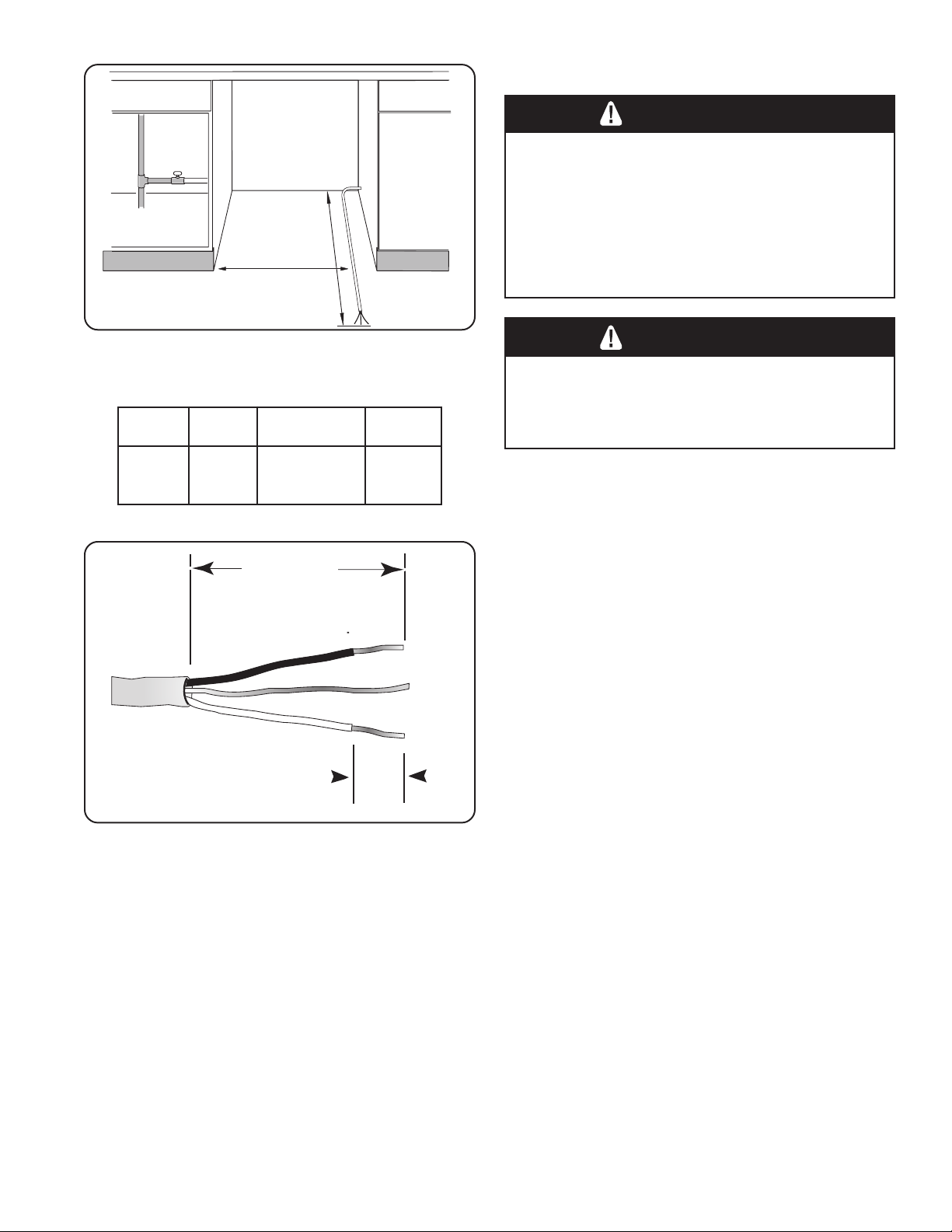

Electrical Preparation

ELECTRICAL PREPARATION

WARNING

Electrical Shock Hazard

To avoid electrical shock, do not work on an

energized circuit. Doing so could result in serious

injury or death. Only qualified electricians should

perform electrical work. Do not attempt any work

on the dishwasher electric supply circuit until you

are certain the circuit is

de-energized.

Figure 4

Dishwasher Electrical Rating

stloVztreHserepmAsttaW

0210651

Figure 5

WARNING

Fire Hazard

To avoid a fire hazard, make sure electrical work

is properly installed. Only qualified electricians

should perform electrical work.

054,1

)xam(

Electrical Supply

The customer has the responsibility of ensuring that the

dishwasher electrical installation is in compliance with all

national and local electrical codes and ordinances. The

dishwasher is designed for an electrical supply of 120V,

60 Hz, AC, connected to a dishwasher-dedicated,

properly grounded electrical circuit with a fuse or breaker

rated for 15 amps. Electrical supply conductors shall be a

minimum #14 AWG copper wire rated at 75°C or higher.

Regardless of where the electrical supply cable enters the

enclosure (following the guidelines on page 8), position

the cable 21” (533mm) from the enclosure’s left side, as

shown in Figure 4. Extend the cable 30” (762mm) from

the enclosure’s back, as shown in Figure 4.

Remove 3” - 4” (75mm - 100mm) of the cable’s outer

casing, as shown in Figure 5, then remove 3/8” - 1/2”

(9 - 13mm) of insulation from each wire, as shown in

Figure 5.

5

Page 8

14"

(355mm)

Shut off

Valve

Hot Water

Supply

Line

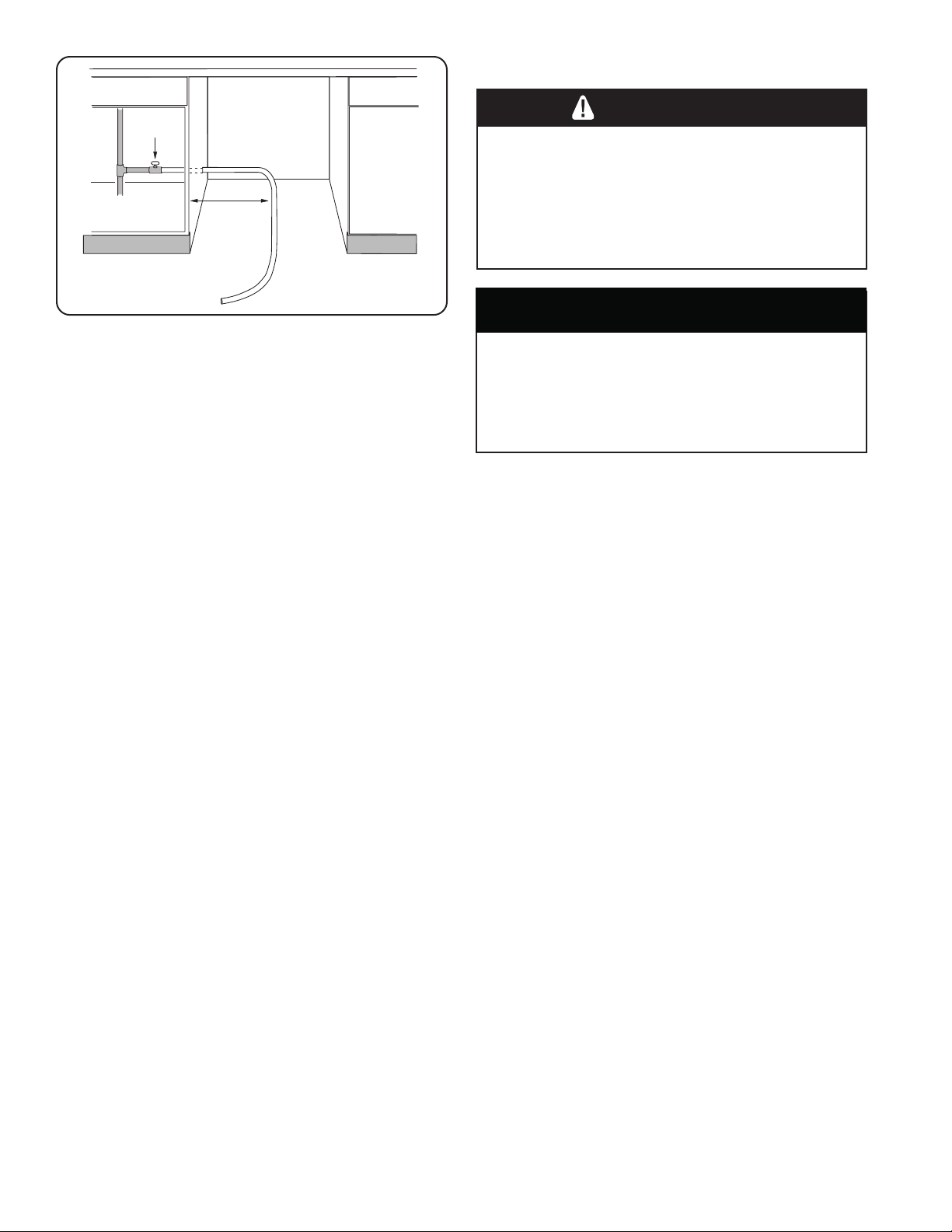

Plumbing Preparation

PLUMBING PREPARATION

To avoid being scalded, do not perform any work

on a charged hot water line. Serious injury could

result. Only qualified plumbers should perform

plumbing work. Do not attempt any work on the

dishwasher hot water supply plumbing until you

are certain the hot water supply is shut off.

WARNING

Scald Hazard

Figure 6

CAUTION

Temperatures required for soldering and sweating

will damage the dishwasher’s base and water inlet

valve. If plumbing lines are to be soldered or

sweated, keep the heat source at least 6 inches

(152.4 mm) away from the dishwasher’s base and

water inlet valve.

Hot Water Supply

The hot water heater should be set to deliver

approximately 120° F (49° C) water to the dishwasher.

Water that is too hot can cause some detergents to lose

effectiveness. Lower water temperatures will increase run

times. The hot water supply pressure must be between

15 - 145 psi (1 - 10 bars).

Hot Water Supply Plumbing

Install an easily accessible shut-off valve (not supplied) in

the hot water supply line, as shown in Figure 6. All solder

connections must be made before the water line is

connected to the dishwasher’s water inlet valve. Water

may also be supplied to the dishwasher by using a

braided hose line. Check with your local plumbing supply

sources for the proper hose and 90° elbow fitting.

6

NOTE: Regardless of where the hot water supply line

enters the enclosure, position the line 14” (355mm) from

the enclosure’s left side, as shown in Figure 6.

NOTE: Decide whether braided hose or copper tubing will

be used for the hot water supply plumbing, and purchase

the correct type of hot water supply shut-off valve, 90°

elbow, and necessary fittings for the hot water supply

plumbing.

Page 9

Plumbing Preparation/ Dishwasher Preparation

Y-branch

Tailpiece

Figure 7

Air Gap

Figure 8

PLUMBING PREPARATION (continued)

Drain Plumbing

Under Sink Drain Connection

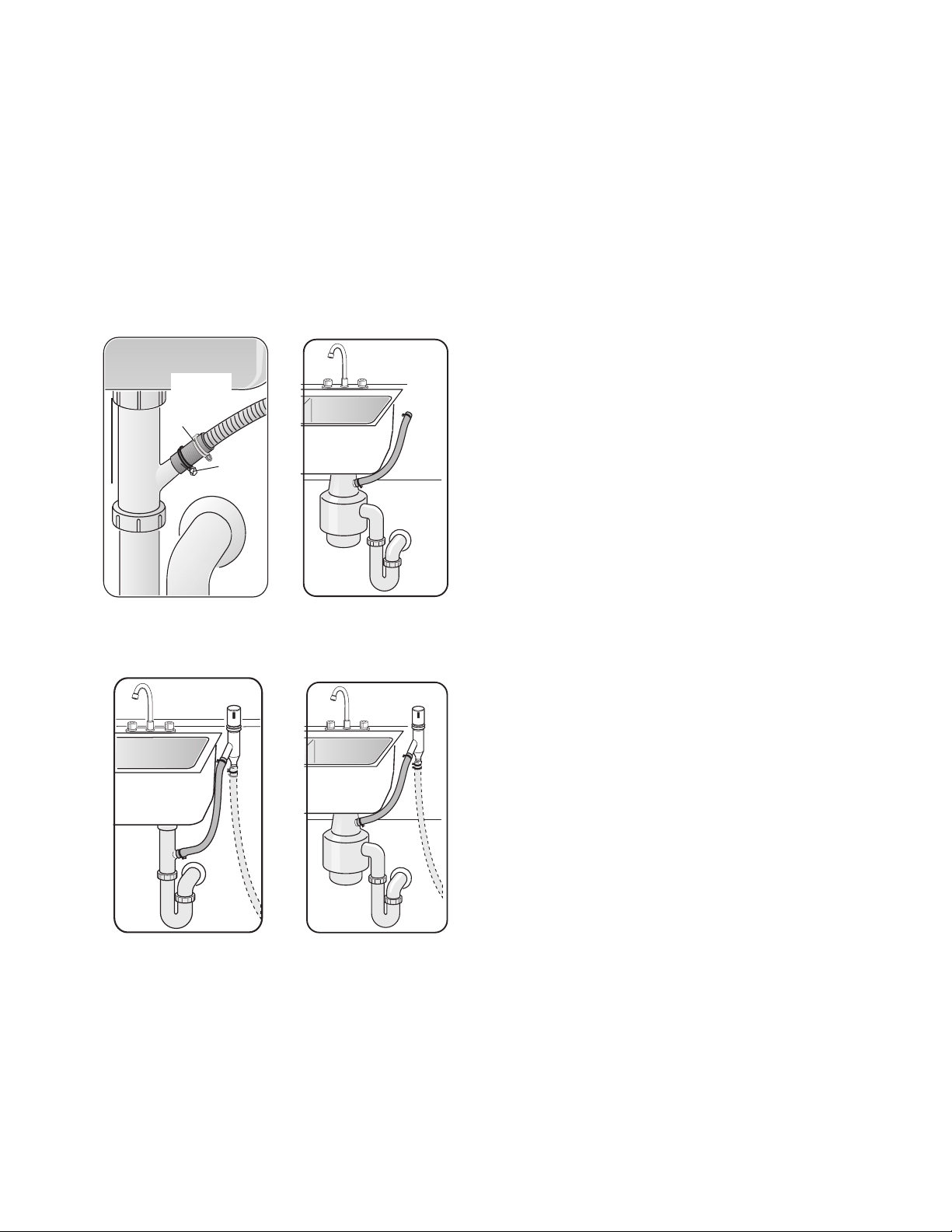

If the dishwasher is to drain either directly into the

household drain plumbing or through an air gap, install a

y-branch tailpiece under the sink as shown in Figure 7.

Installing an Air Gap

If local ordinances require an air gap, as shown in

Figure 8, install it according to the manufacturer’s

instructions.

Disposer

Make sure to remove the disposer’s dishwasher drain

connection plug before connecting the dishwasher drain

hose. See Figure 9.

DISHWASHER PREPARATION

Dishwasher preparation involves four tasks:

• Installing the Mounting Brackets

• Removing the Toe Panel

• Installing the 90° elbow fitting

• Junction Box Preparation

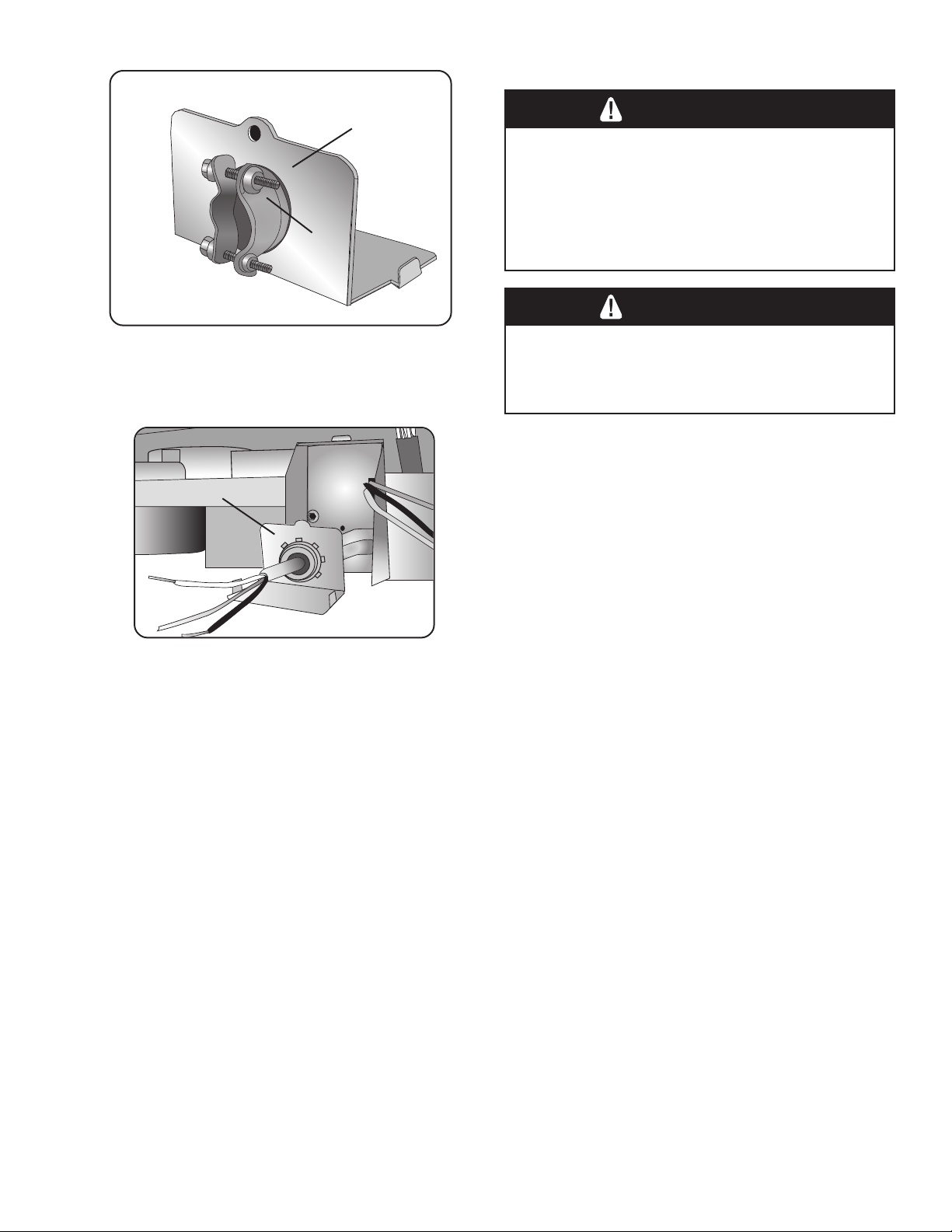

Installing the Countertop Mounting Brackets

Remove

plug

Figure 9

Top Mount

Side Mount

CAUTION

Before installing the supplied countertop mounting

brackets, decide which method of securing the

dishwasher into its enclosure will be used. Once

the mounting brackets are installed on the dishwasher, removing them is difficult and will damage

the mounting brackets and the dishwasher.

The dishwasher can be secured into its enclosure in two

ways:

1 Top Mount is used for countertops made of wood or

other materials that can easily drilled. Orient the

mounting brackets as shown in Figure 10, and

position the two small tabs on the mounting brackets

over the two slots on the dishwasher’s front corners.

Push the mounting brackets down firmly to insert the

tabs into the slots.

2 Side Mount is used for countertops made of marble,

granite, or other very hard materials that cannot be

easily drilled. Bend the mounting brackets along the

small holes and in the same direction as the two small

tabs. Orient the mounting brackets as shown in Figure

10, and position the two small tabs on the mounting

brackets over the two slots on the dishwasher’s front

corners. Push the mounting brackets down firmly to

insert the tabs into the slots.

Figure 10

WARNING

Tip Over Hazard

To avoid a tip over hazard, do not use the

dishwasher until it is completely installed. When

opening the door on an uninstalled dishwasher,

carefully open the door while supporting the rear

of the unit. Failure to follow this warning can

result in serious injury.

7

Page 10

Figure 11

Toe

Plastic Base

Access Panel

Dishwasher Preparation

DISHWASHER PREPARATION (continued)

Removing the Toe Panel

Regular Toe Panel

The toe panel is loosely attached with tape. Remove the

tape and pull the toe panel away from the dishwasher. Set

the toe panel aside. It will be reinstalled later.

SHY66C and SHX99A Plastic Base Access Panel and

Toe Panel

The plastic base access panel (select models SHY66C/

SHX99A only) and toe panel are in place on the

dishwasher, but are not attached. Remove the toe panel

first, as shown in Figure 11, then remove the plastic

base access panel, as shown in Figure 11.

Installing the 90° Elbow Fitting

NOTE: The 90° elbow fitting is not supplied with the

dishwasher, and must be purchased separately. If the

dishwasher’s hot water supply line is to be copper tubing,

make certain the elbow has a compression fitting.

Apply Teflon tape or other pipe sealant when required.

Orient the hot water supply connection leg of the elbow

toward the channel opening in the dishwasher base. See

Figure 12.

Figure 12

Junction Box Preparation

1 Remove junction box cover (see Figure 13) by lifting

the junction box cover up and off.

2 Remove the strain relief plate by removing the screw

at the back of the junction box, as shown in Figure

14 and sliding the strain relief plate out.

3 Set the junction box cover, strain relief plate, and

screw aside. They will be reinstalled later.

Remove

Screw

Junction

Box

Cover

Figure 13

X

Figure 14

8

Page 11

25”

(636 mm)

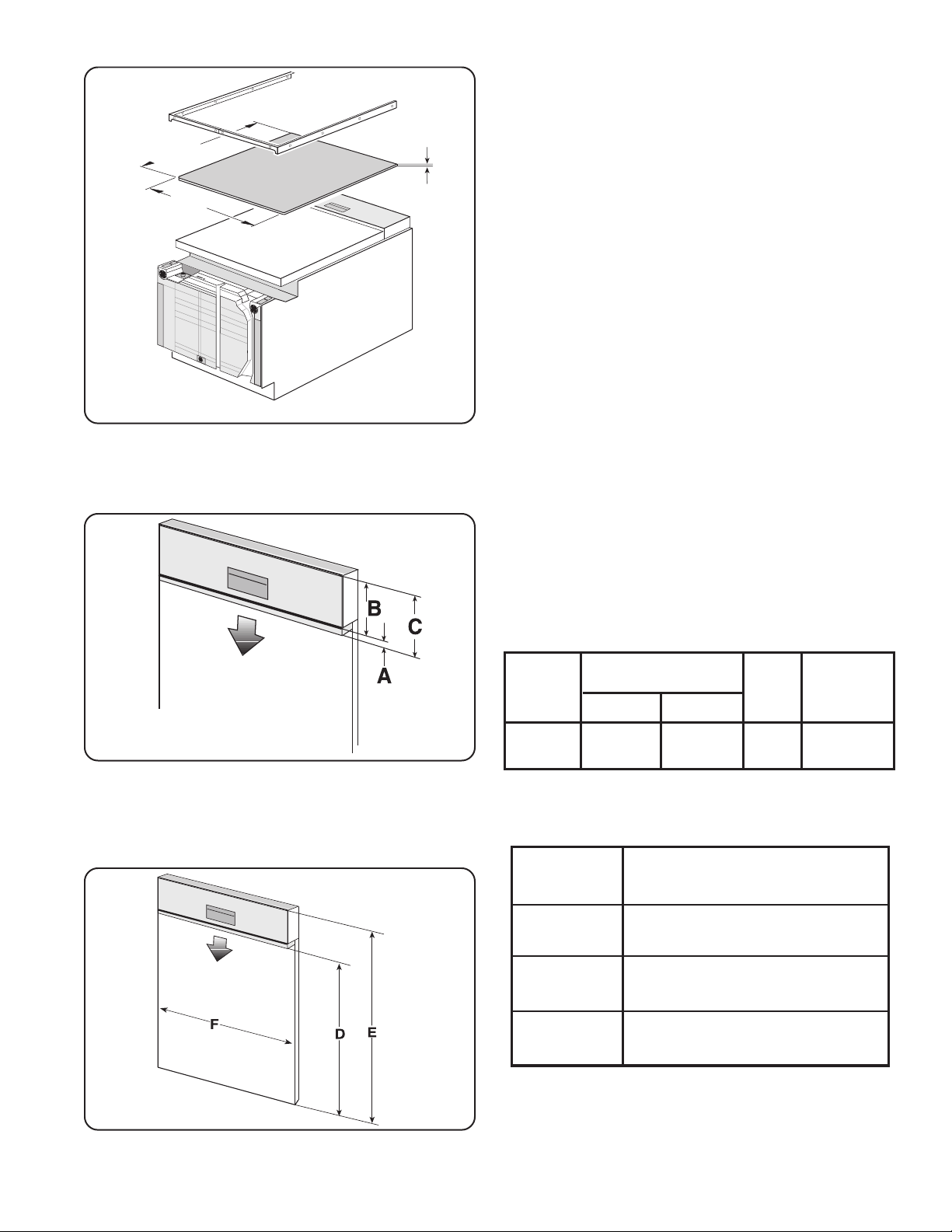

Door Panel Installation

1/4” max.

(6 mm)

DOOR PANEL INSTALLATION

SHU Models - Accessory Panel Installation

If you have an SHU model and have ordered an accessory panel kit, install the panel prior to sliding the dishwasher into place. The panel dimensions are shown in

Figure 15.

23-1/16”

(586 mm)

Figure 15

SHI Models - Panel Installation

SHI models come with additional mounting hardware and

a template sheet with installation instructions. The stainless steel models of the SHI series also come with two

extension pieces. The extension pieces are used to

match the control panel height (Figure 16, “B” dimension)

to the horizontal drawer line of the cabinets, and must be

installed as shown in on the template sheet. The standard

piece is used for drawer heights up to 6” (152mm); the

long piece is used for drawer heights greater than 6”

(152mm) but 6-7/16” (164mm) or less. If your drawers are

taller than 6-7/16”, you can either slide the extension

piece in as far as it will go, or remove it and fit the door

panel directly below the control panel.

SHI/SHV Models - Panel Installation

SHV models come with additional mounting hardware and

a template sheet that will show you how to mount the

panel. One side of the template shows how to mount a

one piece panel; the other side shows how to mount a two

piece panel. Decide which type of installation you want

before proceeding with the installation.

Figure 16

Fig. 16

Dimension

SHI Only

Fig. 17

Dimension

D (SHI)

E

(SHI & SHV)

F

(SHI & SHV)

Extension “A”

Max. - Min.

Standard

5/16 - 11/16”

(8-18mm)

Long

11/16 - 1 1/8”

(18 - 29mm)

Panel Dimension

20 11/16” - 25”

(526mm - 635mm)

27 3/16” - 30 5/16”

(690mm - 770mm)

23 3/16” - 23 3/8”

(589mm - 594mm)

“B” “C”

Max.-Min.

5 5/16”

(135mm)

5 5/8 - 6 7/16”

(143 - 164mm)

Figure 17

9

Page 12

14"

(355mm)

21"

(533mm)

Figure 18

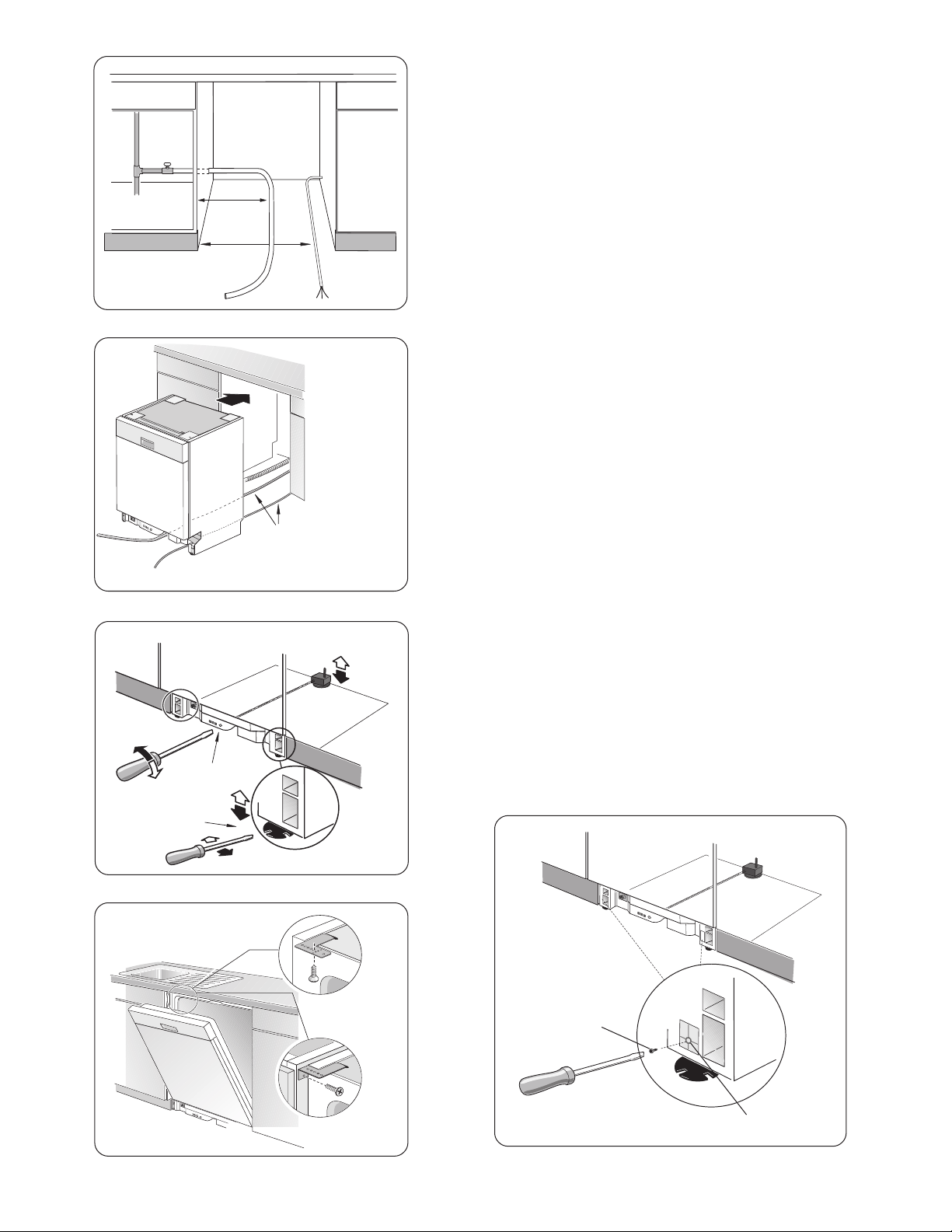

Placing the Dishwasher/ Securing the Dishwasher

PLACING THE DISHWASHER

1 Straighten and position the hot water supply line and

the electrical supply cable as shown in Figure 18 so

that they will align with their channels under the

dishwasher base.

2 Position the dishwasher close enough to the enclosure

so that you can run the dishwasher drain hose to the

under sink drain connection. Make certain that the hot

water supply line and the electrical supply cable are in

their channels under the dishwasher base, as shown in

Figure 19.

3 Slide the dishwasher into the opening making sure that

the hot water supply line and the electrical supply

cable stay in their proper channels.

4 Make sure the dishwasher is level. Adjust the rear

leveler by turning the center screw at the front of the

dishwasher, as shown in Figure 20a. Turning the screw

clockwise raises the rear of the dishwasher. Adjust the

front levelers by turning them with a screwdriver, as

shown in Figure 20b. Turning the levelers to the right

raises the dishwasher. If additional height is needed,

shims may be added under the leveler feet.

Figure 19

a

b

Figure 20

Top Mount

Hot Water Supply Line

and Electrical Supply

Cable Position in

Channels

SECURING THE DISHWASHER

1 Drive the mounting screws through the holes in the

mounting brackets as shown in Figure 21 for Top

Mount or Side Mount.

2 After the unit is installed in the enclosure, leveled and

secured, lock the two front leg levelers in place by

driving the enclosed leg leveler locking screws into

each screw boss located in front of the levelers. See

Figure 22.

3 Tighten screws until they are flush with the surface of

the bosses.

10

Figure 21

Side Mount

Leg

Leveler

Locking

Screw

Screw

Boss

Figure 22

Page 13

Silver

Spring

Clamp

Gold

Screw

Clamp

Drain Hose Connection

Installation of the Rubber Drain Hose

Adaptor

1 Obtain the Rubber Drain Hose Adaptor and the two

hose clamps from the Dishwasher Installation Kit.

2 On one outside end of the Rubber Drain Hose Adapter

is a raised groove. Insert the drain hose into the end

without the raised groove. Be sure to fully insert the

drain hose.

3 Secure the connection with the Silver Spring Clamp.

4 Use the Gold Screw Clamp to attach the Rubber Drain

Hose Adaptor to the house plumbing.

Connecting the Drain Hose to the

Household Plumbing

The dishwasher drain hose may be connected to the drain

plumbing in one of four ways:

1 Directly to the under-sink dishwasher drain connection,

as shown in Figure 23.

2 Directly to a disposer dishwasher drain connection, as

shown in Figure 24.

3 To the under-sink dishwasher drain connection through

an air gap, as shown in Figure 25.

4 To a disposer dishwasher drain connection through an

air gap, as shown on Figure 26.

Figure 23 Figure 24

Figure 25 Figure 26

Information on installing air gaps and disposers can be

found in the Plumbing Preparation section of this

manual.

NOTE: If the dishwasher drain hose is to be connected to

a disposer dishwasher drain connection, remove the plug

from the disposer’s dishwasher drain connection.

Use the supplied Rubber Drain Hose Adaptor and Drain

Hose Clamps to connect the dishwasher drain hose to the

plumbing drain connection. Use the spring clamp to

secure the Rubber Drain Hose Adaptor to the dishwasher

drain hose. Use the screw clamp to secure the Rubber

Drain Hose Adaptor to the plumbing drain connection.

The dishwasher drain hose must have one place along its

length that is securely attached 20 inches above the

cabinet floor.

11

Page 14

Hot Water Connection

HOT WATER CONNECTION

To avoid being scalded, do not perform any work

on a charged hot water line. Serious injury could

result. Only qualified plumbers should perform

plumbing work. Do not attempt any work on the

dishwasher hot water supply plumbing until you

are certain the hot water supply is shut off.

NOTE: Make certain that the correct 90° elbow fitting (not

supplied) for the hot water supply line has been purchased and installed on the dishwasher as described in

the Dishwasher Preparation section of this manual.

The hot water supply line may be connected to the

dishwasher in one of two ways:

1 With braided hose.

2 With copper tubing.

Braided Dishwasher Supply Hose

After connections are made turn on the hot water supply

to check for leaks.

NOTE: Braided dishwasher supply hoses can also be

used to extend pre-existing dishwasher water supply

lines.

WARNING

Scald Hazard

Copper Tubing

CAUTION

Temperatures required for soldering and sweating

will damage the dishwasher’s water inlet valve. If

plumbing lines are to be soldered or sweated,

keep the heat source at least 6 inches (152.4 mm)

away from the dishwasher’s water inlet valve.

• If using a solder joint instead of a compression fitting,

be sure to make all solder connections before

connecting the water line to the dishwasher.

• Make certain there are no sharp bends or kinks in the

water line that might restrict water flow.

• Be sure to use pipe thread compound or Teflon tape to

seal the connection when required.

• Before connecting the copper hot water supply line to

the dishwasher, flush it with hot water to clear any

foreign material.

• Turn on the water supply to check for leaks after

making connections.

NOTE: Do not use pipe sealant on compression fittings.

12

Page 15

Electrical Connection

ELECTRICAL CONNECTION

Figure 27

Strain Relief Plate

Figure 28

Strain

Relief

Plate

Strain Relief

(not supplied)

WARNING

Electrical Shock Hazard

To avoid electrical shock, do not work on an

energized circuit. Doing so could result in serious

injury or death. Only qualified electricians should

perform electrical work. Do not attempt any work

on the dishwasher electric supply circuit until you

are certain the circuit is de-energized.

WARNING

Fire Hazard

To avoid a fire hazard, make sure electrical work

is properly installed. Only qualified electricians

should perform electrical work.

Grounding Instructions

The dishwasher must be properly grounded before

operating. This appliance must be connected to a

grounded metal permanent wiring system, or an

equipment grounding conductor must be run with the

circuit conductors and connected to the equipment

grounding terminal or lead on the dishwasher. Make sure

that the dishwasher is connected to a suitable ground in

compliance with all local codes or, in the absence of a

local code, with the NATIONAL ELECTRICAL CODE in

the United States or the CANADIAN ELECTRIC CODE

C22.1- latest edition in Canada as well as any provincial/

state or municipal or local codes that apply.

1 Retrieve the strain relief plate, and install a strain relief

(not supplied) into the opening on the strain relief plate.

NOTE: Orient the strain relief as shown in Figure 27.

2 Pass the electrical supply cable through the strain

relief, as shown in Figure 28. Leave 3 - 4 inches of

insulated wire extending through the strain relief plate.

3 Tighten the strain relief screws.

4 Slide the strain relief plate into the junction box, and

secure it to the junction box with the supplied screw.

13

Page 16

Electrical Connection/ Door Tension Adjustment/ Base and Toe Panel

ELECTRICAL CONNECTION (continued)

WARNING

Fire Hazard

To avoid a fire hazard, make sure there are no

loose electrical connections. Make sure all

1/8”

3mm

Figure 29

electrical connections are properly made.

• Do not pre-twist the wires before connecting them

with wire nuts.

• Extend the dishwasher’s stranded wires 1/8” (3mm)

beyond the power supply cable’s solid wires, as

shown in Figure 29.

5 Using the supplied wire nuts, connect the electrical

supply wires to the dishwasher’s wires, black to black,

white to white, and green or bare. Make certain that

the insulated wires show no bare wire from the

bottoms of the wire nuts. Gently tug the wires to make

certain they are securely connected.

6 Press the wires into the junction box. Make certain

that the wire nuts do not loosen.

7 Place the cover on the junction box and secure it to

the junction box with the supplied screw.

Figure 30

Figure 31

DOOR TENSION ADJUSTMENT (only on SHI

and SHV models with custom door panels)

After the dishwasher and custom door panel are installed,

open and close the door several times to make sure that

it does so with ease. If the door closes too quickly, the

spring tension needs to be adjusted.

To Adjust the Spring Tension:

1 Obtain the provided Spring Tension Screws from the

SHI/SHV Door Panel Installation Kit.

2 Insert the screws as shown in Figure 30. Turning the

screw clockwise increases the spring tension.

TOE PANEL INSTALLATION

Regular Toe Panel Installation

Use the toe panel screws from the Dishwasher Installation Kit and a Torx screwdriver to install the toe panel as

shown in Figure 31.

14

Page 17

Base and Toe Panel/ Final Instructions

BASE AND TOE PANEL (Continued)

Plastic Base Access Panel and Toe Panel Installation

(SHY66C & SHX99A models only)

1 Place the Plastic Base Access Panel under and up the

front bottom panel of the dishwasher, as shown in

c

d

Figure 32

a

b

Figure 32a.

2 Insert the Plastic Base Access Panel screws into the

Plastic Base Access Panel, as shown in Figure 32b.

Tighten the Plastic Base Access Panel Screws.

3 Place the Cotton Insulation Strip under the unit,

between the bottom of the Plastic Base Access Panel

and the floor, as shown in Figure 32c.

4 Attach the Toe Panel to the Plastic Base Access Panel

using the Toe Panel Screws included in the Toe Panel

Installation Kit. See Figure 32d.

NOTE: You will not use the normal Toe Panel Screws

included in the Dishwasher Installation Kit on these

models.

FINAL INSTRUCTIONS

WARNING

In some conditions, Hydrogen gas can form in a

hot water system that has not been used for

weeks. Hydrogen gas is explosive. Before filling

a dishwasher from a system that has been off for

weeks, run the water from a nearby faucet in a

well ventilated area until there is no sound or

evidence of gas.

1 Energize the dishwasher power supply circuit.

2 Consult the Dishwasher Use and Care Manual, and run

the dishwasher through one complete cycle. If the

dishwasher does not operate properly, refer to the SelfHelp section of the Use and Care Manual. If the

dishwasher still does not operate properly, refer to the

Customer Service Section of the Use and Care

Manual.

15

Page 18

Customer Service

CUSTOMER SERVICE

Your Bosch dishwasher requires no special care other than that described in the Care and Cleaning section of the Use

and Care Manual. If you are having a problem with your dishwasher, before calling for service please refer to the SelfHelp section of the Use and Care Manual. If service is necessary, contact your dealer or installer or an authorized

service center. Do not attempt to repair the appliance yourself. Any work performed by unauthorized personnel may void

the warranty.

If you are having a problem with your Bosch dishwasher and are not pleased with the service you have received, please

take the following steps (in the order listed below) until the problem is corrected to your satisfaction.

1. Contact your installer or the Bosch Authorized Service Contractor in your area.

2. E-mail us from the customer service section of our website, www.boschappliances.com.

3. Write us at:

BSH Home Appliances, Corp.

5551 McFadden Avenue

Huntington Beach, CA 92649

4. Call us at 1-800-944-2904.

Please be sure to include (if you are writing), or have available (if you are calling), the following information:

• Model number

• Serial number

• Date of original purchase

• Date the problem originated

• Explanation of the problem

Also, if you are writing, please include a daytime phone number where you can be reached. You will find the model and

serial number information on the label located on the right-hand side of the inner door of your dishwasher, see Figure 1.

It will look similar to this:

Please make a copy of your invoice and keep it with this manual.

16

Page 19

Table des Matières / Instrucciones Importantes

Table des Matières

INSTRUCTIONS IMPORTANTES ................................1

Outils nécessaires ...................................................... 2

Matériaux nécessaires ............................................... 2

Matériaux fournis ........................................................3

Mise en oeuvre ...........................................................4

Préparation électrique .................................................5

Préparation de la plomberie ..................................... 6-7

Préparation du lave-vaisselle................................... 7-8

Installation panneau de porte ..................................... 9

Instructions de sécurité importantes

AVERTISSEMENT

Pour éviter tout dommage à la propriété et

blessures, OBSERVER TOUS LES

AVERTISSE-MENTS. Ces instructions sont

destinées à un installateur qualifié seulement.

Le lave-vaisselle doit être installé par un technicien

qualifié seulement.

• En plus de ces instructions, l’appareil doit être

installé conformément aux codes et règlements

électriques et de plomberie (nationaux ou locaux).

Lire entièrement ces instructions d’installation et

les observer. Elles permettront d’économiser temps

et argent et assureront un rendement sécuritaire et

optimal du lave-vaisselle.

ATTENTION

Si le lave-vaisselle est installé dans un endroit

où il y a du gel (ex. : comme dans un chalet), il

faut drainer l’eau de l’intérieur de l’appareil.

Des ruptures du système d’eau survenants à

cause du gel ne sont pas couverts par la

garantie.

Emplacement ........................................................... 10

Fixation du lave-vaisselle ......................................... 10

Connexion du tuyau de vidange ............................... 11

Connexion eau chaude ............................................. 12

Connexion électrique ........................................... 13-14

Réglage tension de la porte ...................................... 14

Base et Panneau inférieur ................................... 14-15

Instructions finales ................................................... 15

Service à la clientèle ................................................ 16

IMPORTANT

• Le tuyau de vidange du lave-vaisselle doit être

installé avec une portion à au moins 20 po (508

mm) au-dessus du plancher de l’armoire,

autrement l’appareil peut ne pas se vidanger

adéquatement.

• Le lave-vaisselle est destiné à un usage

résidentiel seulement, et ne doivent pas être

utilisés de façon commerciale.

• NOUVELLE INSTALLATION - Si le lave-vaisselle

est une nouvelle installation, la plupart du travail

doit être effectué avant l’installation de l’appareil.

• REMPLACEMENT - Si le lave-vaisselle en

remplace un autre, vérifier les connexions

existantes relativement à la compatibilité et

remplacer toutes pièces nécessaires.

Vérification du lave-vaisselle

Après avoir déballé le lave-vaisselle et avant

l’installation, vérifier entièrement l’appareil afin de voir

s’il présente des dommages esthétiques ou autres.

Rapporter tout dommage immédiatement. Les défauts

esthétiques doivent être rapportés dans un délai de 5

jours suivant l’installation.

REMARQUE : Ne pas jeter les sacs ou les pièces

fournis avec l’emballage d’origine tant que

l’installation n’est pas complétée.

1

Page 20

OUTILS NÉCESSAIRES

Outils et Matériaux Nécessaires

Marteau

Ruban à

mesurer

Coupe-fil

Scie-cloche

Tournevis à

fente

Dégaine-fil Niceau

Clé à tuyau

Tournevis Phillips

Perceuse

MATÉRIAUX NÉCESSAIRES

(D’autres matériaux peuvent être requis pour être conformes aux codes locaux.)

Clé réglable

Tournevis à

pointe

Câble d’alimentation électrique - Minimum n° 14 AWG, 2 conducteurs, 1 mise à la terre,

conducteur en cuivre isolé coté 75 °C ou plus.

Tuyau de canalisation en eau chaude - Tuyau en cuivre, minimum 3/8 po O.D. ou canalisation

en métal bridé.

Soupape d’arrêt et raccords appropriés pour canalisation en eau chaude (tuyau en cuivre/raccord

à compression ou tuyau bridé).

Coude 90° avec filets mâles 3/8 po N.P.T. sur un pied, dont la dimension s’ajuste à la canalisation

en eau (tuyau en cuivre/raccord à compression ou tuyau bridé) sur l’autre pied.

Ruban Teflon ou produit pour filet de tuyau afin de sceller les connexions de plomberie.

Connecteur de conduit listé UL ou soupape de sécurité.

2

Page 21

Matériaux Fournis

MATÉRIAUX FOURNIS

Pièces accessoires fournies

Les pièces pour le lave-vaisselle sans dans un ou plusieurs sacs, comme décrit ci-dessous.

REMARQUE : s’assurer d’avoir tous les sacs pour finaliser l’installation.

Sac avec guides

Ce sac comprend ce qui suit :

A Instructions d’utilisation et d’entretien et

instructions d’installation (pouvant être comprises

dans un seul guide)

B Guide de références rapides (certains modèles)

C Gicleur pour grands articles

D Gabarit d’installation SHI et SHV (ces modèles

seulement)

E Bande isolante en coton blanc (SHY66 et SHX99

seulement)

Nécessaire d’installation du lave-vaisselle

Ce nécessaire comprend ce qui suit :

F Vis pour panneau du bas (2 vis usinées noires)

G Fixations de plan de travail (2 « L » en métal)

H Vis de fixation (2 vis à bois argent)

I Adaptateur de tuyau de drain en caoutchouc (1

tuyau en caoutchouc noir)

J Pinces à tuyau (1 pince à ressort argent pour

utiliser avec adaptateur en caoutchouc vers tuyau

de drain et 1 pince à vis dorée pour fixer

l’adaptateur en caoutchouc à la plomberie)

K Serre-fils (3 pour connexions électriques)

L Vis de boîte de jonction (2 vis usinées argent)

M Vis de verrouillage de pied niveleur (2 vis à gros

filets dorées)

A

B

C

F

G

H

I

J

D

E

K

L

M

Nécessaire d’installation du panneau de porte

SHI/SHV

Ce nécessaire est fourni avec certains modèles

utilisant un panneau de porte en bois sur mesure et

comprend ce qui suit :

N Capuchons en plastique (2)

O Vis de tension à ressort (2 vis usinées larges

argent utilisées pour régler les ressorts de porte

accommodant les différents poids de porte)

P Fixations de porte (2 en métal doré et 2 en

plastique blanc utilisées pour installer la porte sur

mesure)

Q Vis de fixation de porte (8 vis à bois dorées)

R Vis de fixation de porte (2 longues vis argent

utilisées pour fixer la porte)

Nécessaire d’installation du panneau du bas

Ce nécessaire est fourni avec certains modèles

(SHY66C/SHX99A) et comprend :

S Vis de panneau du bas (2 vis noires utilisée pour

fixer le panneau du bas en métal)

T Vis de panneau d’accès de base en plastique noir

(2 longues vis argent pour fixer panneau d’accès

de base en plastique au lave-vaisselle)

N

O

P

Q

S T

R

3

Page 22

23-9/16 po

(598mm)

90 90

Mise en Oeuvre

AVERTISSEMENT

Risque de choc électrique

Pour éviter les chocs électrique, s’assurer que la

canalisation d’eau et l’électricité sont mises hors

circuit avant l’installation ou le service.

Vérifier le

dégagement

entre la porte

du lavevaisselle et le

mur

34 po

(864mm)

minimum

23-5/8 po – 24-1/4 po (600–616

Figure 1

Plan de travail

MISE EN OEUVRE

REMARQUE : Ce lave-vaisselle est conçus pour être

encastrés sur le dessus et les côtés par un comptoir de

cuisine résidentiel standard.

Choisir un emplacement le plus près de l’évier possible

pour un accès aisé à l’alimentation en eau et aux

canalisations de vidange.

Pour une allure et un rendement approprié, s’assurer que

l’ouverture est d’équerre et a les dimensions données à la

figure 1.

Si l’appareil est installé dans un coin, s’assurer qu’un

dégagement adéquat est prévu pour l’ouverture de la

porte, comme à la figure 2.

AVERTISSEMENT

Risque de choc électrique ou d’incendie

Pour éviter tout choc électrique ou incendie, ne

pas laisser l’électricité et la canalisation d’eau

entrer en contact. Séparer les chemins comme il

est fourni sous l’appareil (page 10).

Figure 2

3-1/2 po

(89mm)

Figure 3

1-5/16 po

(33mm)

Si l’espace requiert des ouvertures pour le câble

d’alimentation, la canali-sation d’eau chaude et le tuyau

de vidange du lave-vaisselle, les placer selon les

dimensions indiquées à la figure 3 pour éviter toute

inferférence avec le cadre du lave-vaisselle et autres

composants. Faire les ouvertures pour le câble

d’alimentation et la canalisation d’eau chaude 1 po (25,4

mm) de diamètre. Celle pour le tuyau de vidange de 1 1/4

po (32 mm) de diamètre. Si les ouvertures sont dans le

bois, poncer pour adoucir; si dans le métal, faire

l’ouverture suffisamment large pour accomoder les

passe-fils dans le diamètre intérieur de 1 po (25,4 mm)

pour le câble d’alimentation et la canalisation en eau

chaude et 1 1/4 po (32 mm) pour le tuyau de vidange du

lave-vaisselle.

4

Page 23

30po

3/8po - 1/2po

( 8mm - 13mm)

3po - 4po

( 75mm - 100mm)

(762mm)

21po

(533mm)

Figure 4

Cote électrique du lave-vaisselle

stloVztreHserèpmAsttaW

0210651

054,1

)xam(

Électricité

ÉLECTRICITÉ

AVERTISSEMENT

Risque de choc électrique

Pour éviter tout choc électrique, ne pas travailler

avec un circuit sous tension. Ceci peut causer des

blessures sérieures ou la mort. Seul un électri-cien

qualifié peut effectuer ce travail. Ne pas ten-ter de

travailler sur le circuit électrique de l’appa-reil tant

que le circuit n’est pas mis hors circuit.

AVERTISSEMENT

Risque d’incendie

Pour éviter tout risque d’incendie, s’assurer que

l’électricité est adéquatement installée. Seul un

électri-cien qualifié peut effectuer ce travail.

Alimentation électrique

Il incombe au client de s’assurer que l’installation

électrique est conforme aux codes et règlements

électriques. Le lave-vaisselle est conçu pour une

alimentation électrique de 120V, 60 Hz, c.a., branché sur

un circuit électrique séparé adéquatement mis à la terre

avec un fusible ou un coupe-circut coté pour 15 ampères.

Les conducteurs d’alimentation électrique doivent être un

fil minimum de n° 14 AWG en cuivre coté à 75 °C ou plus.

Figure 5

Quelque soit l’endoit où entre le câble d’alimentation

électrique dans l’ouverture (suivre les directives à la page

8), positionner le câble à 21 po (533 mm) depuis le côté

gauche de l’ouverture, comme à la figure 4. Tirer le câble

à 30 po (762 mm) depuis l’arrière, comme à la figure 4.

Retirer de 3 à 4 po (75 à 100 mm) de la gaine extérieure

du câble, comme à la figure 5, pis enlever de 3/8 à 1/2 po

(9 à 13 mm) d’isolant de chaque fil, comme à la figure 5.

5

Page 24

14 po

(355mm)

Shut off

Valve

Hot

Water

Supply

Line

Plomberie

PLOMBERIE

Soupape

d’arrêt

Canalisation

d’eau chaude

Figure 6

AVERTISSEMENT

Risque de brûlure

Pour éviter les brûlures, ne pas effectuer le travail

sur une canalisation d’eau chaude pleine. Seul un

plombier peut effectuer ce travail. Ne pas tenter de

travailler sur la plomberie d’eau chaude tant que

l’alimentation en eau chaude n’est pas fermée.

ATTENTION

Les températures requises pour la soudure

endommageront la base du lave-vaisselle et la

soupape d’entrée d’eau. S’il doit y avoir des

soudures, éloigner la source de chaleur d’au

moins 6 po (152,4 mm) de la base du lave-vaisselle

et de la soupape d’entrée d’eau.

Alimentation en eau chaude

Le chauffe-eau

environ 120° F (49° C) pour le lave-vaisselle. Une eau trop

chaude peut faire réduire l’efficacité du détergent. En

baissant la température de l’eau, cela peut augmenter la

durée de fonctionnement. La pression d’alimentation en

eau chaude doit être entre 15 à 145 ln/po

devrait être réglé pour donner une eau à

2

(1 à 10 barres).

Tuyau d’alimentation en eau chaude

Installer une soupape d’arrêt acces-sible (non fournie) sur

la canalisation en eau chaude, comme à la figure 6.

Une soudure doit être faite avant que la canalisation en

eau soit branchée sur la soupape d’entrée d’eau du lavevaisselle. L’eau peut être fournie à l’appareil à l’aide d’une

canalisation bridée. Vérifier auprès des quincaillerie

concernant les tuyaux appropriés et les coudes 90°.

REMARQUE : Quel que soit l’endroit où entre la

canalisation en eau chaude (voir directives page 8),

positionner la canalisation à 14 po (355 mm) depuis le

côté gauche de l’endroit, comme à la figure 6.

REMARQUE : Décider si des tuyaux bridés ou en cuivre

seront utilisés pour la canalisation en eau chaude et

acheter la soupape d’arrêt d’alimen-tation en eau chaude,

coude 90°, et raccords nécessaires pour la plom-berie

d’alimentation en eau chaude.

6

Page 25

Plomberie / Préparatio du Lave-Vaiselle

About en

Y

Figure 7

Enlever

la fiche

Intervalle

d’air

Figure 8

PLOMBERIE (suite)

Tuyau de vidange

Connexion de drain sous l’évier

Si l’appareil doit se vider directement sur le drain de la

maison ou par un espace d’air, installer un about en Y

sous l’évier comme à la figure 7.

Installation de l’espace d’air

Si les codes locaux requièrent un espace d’air comme à

la figure 8, l’installer selon les directives du fabricant.

Broyeur à déchets

S’assurer d’enlever la fiche de connexion du drain de

lave-vaisselle du broyeur avant de brancher le tuyau de

drain du lave-vaisselle, figure 9.

PRÉPARATION DU LAVE-VAISSELLE

La préparation implique ce qui suit :

• Installation des fixations

• Retrait du panneau inférieur

• Installation du raccord de coude 90°

• Préparation de la boîte de jonction

Installation des fixations de plan de travail

ATTENTION

Avant d’installer les fixations de plan de travail, il

faut décider de la façon de fixer le lave-vaisselle.

Une fois les fixations en place, elles sont difficiles

à enlever. Cela peut endommager les fixations et le

lave-vaisselle.

Sur le dessus

Figure 10

Figure 9

Sur le côté

L’appareil peut être mis en place de façon sécuritaire de 2

manières :

1 Sur le dessus est utilisé pour les comptoirs fabriqués

en bois ou autres matériaux pouvant être facilement

percés. Orienter la fixation comme à la figure 10 et

positionner les 2 petites languettes sur la fixation sur

les deux fentes des coins avant du lave-vaisselle.

Pousser fermement sur les fixation pour insérer les

languettes dans les fentes.

2 Sur le côté est utilisé pour les comptoirs en marbre,

granite ou autre matériaux très durs ne pouvant être

percés. Plier la fixation le long des petits points et

dans la même direction que les deux petites

languettes. Orienter les fixations comme à la figure 10

et 2 petites languettes sur la fixation sur les deux

fentes des coins avant du lave-vaisselle. Pousser

fermement sur les fixation pour insérer les languettes

dans les fentes.

AVERTISSEMENT

Risque de basculer

Pour éviter que l’appareil bascule, ne pas l’utiliser

tant qu’il n’est pas entièrement installé. Si l’on

ouvre la porte du lave-vaisselle non installé, ouvrir

lentement tout en supportant l’arrière de l’appareil.

Sinon, il peut en résulter des blessures sérieuses.

7

Page 26

Toe

Plastic Base

Access Panel

Panneau

de base

Figure 11

Préparatio du Lave-Vaiselle

PRÉPARATION DU LAVE-VAISSELLE

(suite)

Retrait du panneau inférieur

Panneau inférieur ordinaire

Le panneau inférieur est fixé de façon lâche avec du

Panneau

d’accès

en plastique

ruban. Retirer le ruban et retirer le panneau du lavevaisselle. Mettre de côté. Il doit être réinstaller.

Base en plastique, SHY66C et SHX99A et panneau de

base

Le panneau d’accès de la base en plastique (certains

modèles SHY66C/SHX99A seulement) et panneau de

base sont en place, mais non fixés. Enlever le panneau

de base d’abord, figure 11, puis le panneau d’accès en

plastique, figure 11.

Installation du raccord de coude 90°

REMARQUE : Le raccord de coude 90° n’est pas fourni

avec l’appareil et doit être acheté séparément. Si la

canalisa-tion en eau chaude du lave-vaisselle est en

cuivre, s’assurer que le coude est doté d’un raccord à

compression.

Appliquer du ruban Teflon ou du scellant pour tuyaux sur

toutes les connexions filetées lorsque requis.

Orienter le pied de connexion d’alimentation en eau

chaude du coude vers l’ouverture du canal à la base du

lave-vaisselle. Voir la figure 12.

Le

couvercle

de boîte de

jonction

Préparation de la boîte de jonction

1 Retirer le couvercle de la boîte de jonction, figure 13,

en soulevant le couvercle et en l’enlevant.

2 Retirer la plaque de réducteur de tension en enlevant

la vis à l’arrière de la boîte de jonction, comme à la

figure 14 et en faisant glisser la plaque vers

l’extérieur.

3 Mettre le couvercle, la plaque et le vis de côté. Ils

seront utilisés ultérieurement.

Figure 12

Enlever la vis

X

Figure 13

Figure 14

8

Page 27

25 po

(636 mm)

Installation Panneau de Porte

INSTALLATION PANNEAU DE PORTE

Modèles SHU - Installation du panneau accessoire

Si l’on possède un modèle SHU et a commandé un

1/4 po max.

(6 mm)

nécessaire de pan-neau, installer le panneau avant

d’insérer le lave-vaisselle en place. Les dimensions de

panneau sont données à la figure 15.

23-1/16 po

(586 mm)

Figure 15

Modèles SHI - Installation de panneau

Ces modèles sont dotés de fixations additionnelles et

d’un gabarit avec les instructions d’installation. Les

modèles en acier inoxydable sont munis de 2 rallonges

qui sont utilisées pour correspondre à la hauteur du

panneau de contrôle (figure 16, dimension “B” ) à la ligne

horizontale du tiroir, et doit être installé comme illustré sur

le gabarit. La pièce standard est utilisée pour un tiroir

jusqu’à 6 po (152 mm) de haut ; la pièce longue est pour

les tiroir de 6 po (152 mm) de haut mais de 6 7/16 po

(164 mm) ou moins. Si le tiroir est plus haut que 6 7/16po,

l’on peut faire glisser la rallonge le plus loin possible ou

l’enlever et ajuster le panneau de porte directement en

dessous du panneau de contrôle.

Modèles SHI/SHV - Installation du panneau

Les modèles SHV sont dotés de fixations additionnelles

et d’un gabarit indiquant comment monter le panneau. Un

côté du gabarit montre l’installation du panneau une pièce

; et l’autre celle du panneau deux pièces. Décider quelle

méthode sera utilisée avant l’installation.

Figure 16

Fig. 16

Dimension

SHI seul.

Rallonge “A”

Max. - Min.

Standard

5/16 -11/16po

(8-18mm)

Fig. 17

Dimension

D (SHI)

E

(SHI & SHV)

F

(SHI & SHV)

Long

11/16 -1 1/8 po

(18 - 29mm)

Dimension panneau

20 11/16 - 25 po

(526 mm - 635 mm)

27 3/16 - 30 5/16 po

(690 mm - 770 mm)

23 3/16 - 23 3/8 po

(589 mm - 594 mm)

5 5/16 po

(135mm)

“B”

“C”

Max.-Min.

5 5/8-6 7/16 po

(143 - 164mm)

Figure 17

9

Page 28

Emplacement du Lave-Vaiselle/ Mise en Place Sécuritaire

14 po

(355mm)

21 po

(533mm)

Figure 18

EMPLACEMENT DU LAVE-VAISSELLE

1 Placer et positionner les canalisa-tions en eau chaude

et électrique comme à la figure 18 pour qu’elles

s’alignent avec les rainures sous la base du lavevaisselle.

2 Positionner le lave-vaisselle assez près de l’ouverture

pour acheminer le tuyau de vidange à la connexion du

drain d’évier. S’assurer que la canali-sation en eau

haude et le câble électri-que sont dans leurs rainures

sous la base de l’appareil comme à la figure 19.

3 Faire glisser l’appareil dans l’ouverture en s’assurant

que la canalisation d’eau chaude et le câble d’alimentation électrique soient dans leurs chemins respectifs.

4 S’assurer que l’appareil est de niveau. Régler le pied

niveleur arrière en tournant la vis centrale devant le

lave-vaisselle comme à la figure 20a. Tourner dans le

sens horaire pour élever l’arrière de l’appareil. Régler

les pieds niveleurs avant avec un tournevis comme à

la figure 20b. Tourner vers la droite pour soulever. Si

une hauteur additionnelle est nécessaire, il faudra

peut-être des cales sous le pied niveleur.

Figure 19

a

b

Figure 20

Sur le

dessus

Canalisation

d’alimentation en eau

chaude et câble

d’alimentation

électrique

positionnés dans les

ouvertures

MISE EN PLACE SÉCURITAIRE

1 Insérer les vis de fixation dans les trous des fixations,

comme à la figure 21 pour l’installation sur le dessus

ou sur le côté.

2 Une fois l’appareil installé dans l’ouverture, mettre de

niveau et fixer, verrouiller les deux pieds niveleurs

avant en vissant les vis des verrouillage dans chaque

vis située devant les pieds niveleurs, figure 22.

3 Serrer les vis jusqu’à ce qu’elles soient à égalité de la

surface.

Vis de

verrouillage

du pied

niveleur

10

Figure 21

Sur le côté

Bloc de fixation de la vis

Figure 22

Page 29

Connexion du Tuyau Vindange

Installation de l’adaptateur du tuyau de

drain en caoutchouc

1 Prendre l’adaptateur de tuyau de drain en caoutchouc

et les 2 pinces à tuyau du nécessaire d’installation.

2 Sur une extrémité extérieure de l’adaptateur, il y a des

rainures en relief. Insérer le tuyau de drain sur

l’extrémité sans les rainures en relief. S’assurer de

bien insérer le tuyau de drain.

3 Maintenir la connexion avec la pince à ressort

argentée.

4 Utiliser la pince à ressort dorée pour attacher

l’adaptateur de tuyau de drain en caoutchouc sur la

plomberie de la résidence.

Pince à

ressort

argentée

Figure 23

Figure 25

Pince

à vis

dorée

Figure 24

Figure 26

Connexion du tuyau de drain sur la

plomberie résidentielle

Le tuyau de vidange du lave-vaisselle peut être branché

sur la tuyau de vidange de 4 façons :

1 Directement sous la connexion de vidange de l’évier,

figure 23.

2 Directement sur la connexion de vidange d’un broyeur,

figure 24.

3 Sur la connexion de vidange de l’évier par un espace

d’air, figure 25.

4 Sur la connexion de vidange d’un broyeur par un

espace d’air, figure 26.

L’information sur l’installation d’espace d’air et de

broyeurs est donnée dans la section plomberie de ce

guide.

REMARQUE : si le tuyau de drain du lave-vaisselle doit

être branché sur une connexion de drain de broyeur,

retirer la fiche de la connexion du drain de lave-vaisselle

du broyeur.

Utiiser l’adaptateur de tuyau de drain en caoutchouc et

les pinces à tuyau pour brancher le tuyau de drain du

lave-vaisselle sur la connexion de drain de plomberie.

Utiliser la pince à ressort pour maintenir l’adaptateur sur

le tuyau de drain du lave-vaisselle. Utiliser la pince à

ressort pour maintenir l’adaptateur de tuyau de drain en

caoutchouc sur la connexion du drain de plomberie.

Le tuyau de drain du lave-vaisselle doit avoir au moins un

endroit fixé en place à 20 po au-dessus du plancher de

l’armoire.

11

Page 30

Connexion eau Chaude

CONNEXION EAU CHAUDE

Pour éviter les brûlures, ne pas effectuer le travail

sur une canalisation d’eau chaude pleine. Seul un

plombier peut effectuer ce travail. Ne pas tenter de

travailler sur la plomberie d’eau chaude tant que

l’alimentation en eau chaude n’est pas fermée.

REMARQUE : S’assurer que le raccord de coude 90°

approprié (non fourni) pour la canalisation en eau chaude

a été acheté et installé sur le lave-vaisselle tel qu’il est

décrit à la section Préparation du lave-vaisselle dans ce

guide.

La canalisation en eau chaude peut être branchée sur le

lave-vaisselle d’une de deux façons :

1 avec tuyau bridé

2 avec tuyau en cuivre

Tuyau d’alimentation tressé du lave-vaisselle

Une fois les connexions effectuées, ouvrir l’alimentation

en eau chaude et vérifier les fuites.

REMARQUE : les tuyaux tressés peuvent aussi être

utilisés pour allonger les canalisations d’alimentation en

eau déjà existantes.

AVERTISSEMENT

Risque de brûlure

Tuyau en cuivre

ATTENTION

Les températures requises pour la soudure

endommageront la base du lave-vaisselle et la

soupape d’entrée d’eau. S’il doit y avoir des

soudures, éloigner la source de chaleur d’au

moins 6 po (152,4 mm) de la base du lave-vaisselle

et de la soupape d’entrée d’eau.

• Si l’on utilise un joint de soudure au lieu d’un raccord à

compression, s’assurer que toutes les connexions

soudées sont faites avant de brancher la canalisation

d’eau sur l’appareil.

• S’assurer de ne pas plier ni coincer la canalisation

d’eau, cela peut restreindre le débit d’eau.

• S’assurer d’utiliser un composant pour filets de tuyau

ou du ruban Teflon pour sceller les connexions lorsque

requis.

• Avant de brancher la canalisation en eau chaude en

cuivre sur le lave-vaisselle, le vidanger avec de l’eau

chaude pour enlever tout objet étranger.

• Ouvrir l’alimentation en eau chaude et vérifier s’il y a

des fuites.

12

REMARQUE : Ne pas utiliser de scellant à tuyau sur les

raccords de compression.

Page 31

plaque de

réducteur de

tension

réducteur de

tension (non

fourni)

Figure 27

Figure 28

Plaque de

réducteur de

tension

Connexion Électrique

CONNEXION ÉLECTRIQUE

AVERTISSEMENT

Risque de choc électrique

Ne pas travailler avec un circuit sous tension. Ceci

peut causer des blessures sérieures ou la mort.

Seul un électricien qualifié peut effectuer ce travail.

Ne pas ten-ter de travailler sur le circuit électrique

de l’appa-reil tant que le circuit n’est pas mis hors

circuit.

AVERTISSEMENT

Risque d’incendie

Pour éviter tout risque d’incendie, s’assurer que

l’électricité est adéquatement installée. Seul un

électri-cien qualifié peut effectuer ce travail.

Instructions de mise à la terre

Le lave-vaisselle doit être mis à la terre de façon

appropriée avant le fonctionnement. Cet appareil doit être

branché sur une système de câblage permanent en métal

mis à la terre ou un conducteur de mise à la terre

d’équipement doit fonctionner avec les conducteurs de

circuit et branché sur la borne de mise à la terre de

l’appareil ou sur le fil du lave-vaissel-le. S’assurer que le

lave-vaisselle est branché sur une mise à la terre adéquate conformément à tous les codes locaux ou, en

l’absence de ceux-ci, avec le Code national d’électricité

aux É.-U. ou le code canadien d’électricité, C22.1 dernière édition, au Canada ainsi qu’aux codes

provinciaux ou municipaux applicables.

1 Retirer la plaque de réducteur de tension et installer un

réducteur de tension (non fourni) sur l’ouverture de la

plaque de réducteur de tension. REMARQUE : Orienter

le réducteur de tension comme à la figure 27.

2 Passer le câble d’alimentation par le réducteur de

tension, figure 28. Laisser 3 à 4 po de fil isolé sortir

de la plaque de réducteur de tension.

3 Serrer les vis du réducteur de tension.

4 Faire glisser la plaque de réducteur de tension dans la

boîte de jonction, et fixer à la boîte de jonction avec la

vis fournie.

13

Page 32

Connexion Électrique / Derniers Réglades / Base et Panneau inférieur

CONNEXION ÉLECTRIQUE (suite)

AVERTISSEMENT

Risque d’incendie

Pour éviter un risque d’incendie, s’assurer que les

1/8po

3mm

Figure 29

connexions électriques ne sont pas lâches et

qu’elles sont adéquatement faites.

• Étirer les fils du lave-vaisselle de 1/8 po (3mm) loin

des fils solides du câble d’alimentation, comme à la

figure 29.

• Ne pas tordre les fils d’alimentation électrique avant

de les brancher avec les écrous à fils.

5 Utiliser les écrous à fils fournis, brancher les fils

d’alimentation électrique sur les fils du lave-vaisselle,

noir sur noir, blanc sur blanc, et le vert ou dénudé.

S’assurer que les fils isolés ne montrent pas de fils

dénudés depuis le bas des écrous à fils. S’assurer que

les fils sont branchés de façon sécuritaire.

6 Presser les fils dans la boîte de jonction. S’assurer

que les écrous à fils ne sont pas lâches.

7 Placer le couvercle sur la boîte de jonction et le

maintenir en place avec la vis fournies.

Figure 30

DERNIERS RÉGLAGES

Réglage de la tension de la porte (seulement

sur les modèles SHI et SHV avec panneau

de porte sur mesure)

Une fois le lave-vaisselle et la porte sur mesure installés,

ouvrir et fermer la porte quelques fois pour s’assurer

qu’elle le fait aisément. Si elle referme trop rapidement, le

ressort de tension doit être réglé.

Pour régler la tension du ressort :

1 Prendre les vis de tension à ressort fournies du sac

de pièce pour SHI/SHV.

2 Insérer les vis comme à la figure 30. Tourner dans le

sens horaire pour augmenter la tension.

BASE ET PANNEAU INFÉRIEUR

Installation du panneau inférieur ordinaire

Utiliser les vis de panneau du nécessaire d’installation du

lave-vaisselle et un tournevis Torx pour installer le

panneau comme à la figure 31.

14

Figure 31

Page 33

Base et Panneau inférieur / Instrucciones Finales

BASE ET PANNEAU INFÉIEUR (Suite)

Installation du panneau d’accès en plastique et du

panneau de base(SHY66C et SHX99A seulement)

1 Placer le panneau d’accès en plastique sous et vers le

haut du panneau avant, comme à la figure 32a.

c

d

a

b

2 Insérer les vis du panneau en plastique dans le

panneau en plastique comme à la figure 32b. Serrer

les vis du panneau d’accès en plastique.

3 Placer la bande isolante en coton sous l’appareil, entre

le bas du panneau d’accès en plastique et le plancher,

comme à la figure 32c.

4 Fixer le panneau de base sur le panneau d’accès en

plastique à l’aide des vis fournies dans le nécessaire

d’installation. Voir figure 32d.

Figure 32

REMARQUE : il ne faut pas utiliser les vis de panneau de

base normales comprises dans le nécessaire sur ces

modèles.

INSTRUCTIONS FINALES

AVERTISSEMENT

Dans certains cas, de l’hydrogène peut se

former dans un système d’eau chaude non

utilisé pendant quelques semaines. Ce gaz est

explosif. Avant d’actionner un lave-vaisselle non

utilisé depuis longtemps, faire couler l’eau au

robinet dans un endroit bien aéré tant qu’il n’y a

plus de bruit d’eau ou évidence de gaz.

1 Activer le circuit d’alimentation au lave-vaisselle.

2 Consulter le guide d’utilisation et d’entretien du lave-

vaisselle et effectuer un cycle complet. Si le lavevaisselle ne fonctionne pas adéquatement, consulter la

section guide de dépannage du guide d’utilisation et

d’entretien. S’il ne fonctionne toujours pas, consulter la

section sur le service à la clientèle du même guide.

15

Page 34

Service à la clientèle

SERVICE À LA CLIENTÈLE

Le lave-vaisselle Bosch ne requiert aucun entretien spécial autre que celui décrit dans la section Nettoyage et entretien

du guide d’utilisation et d’entretien. Si l’on a des problèmes avec l’appareil, avant d’effectuer un appel de service,

consulter le guide de dépannage du guide d’utilisation et d’entretien. Si un service est nécessaire, communiquer avec le

marchand, l’installateur ou le centre de service. Ne pas tenter de réparer l’appareil. Tout travail effectué par une personne

non autorisée peut annuler la garantie.

Si l’on a des problèmes avec le lave-vaisselle Bosch et que l’on n’est pas satisfait du service reçu, prendre les mesures

ci-dessous (dans l’ordre indiqué ci-dessous) jusqu’à ce que le problème soit corrigé.

1. Communiquer avec l’installateur ou le centre de service autorisé Bosch dans la région.

2. Envoyer un courriel depuis la section service à la clientèle sur notre site web www.boschappliances.com.

3. Nous écrire :

BSH Home Appliances, Corp.

5551 McFadden Avenue

Huntington Beach, CA 92649

4. Téléphoner au 1-800-944-2904.

S’assurer d’inclure (si l’on écrit), ou d’avoir à la portée (si l’on téléphone), l’information suivante :

• Numéro de modèle

• Numéro de série

• Date d’achat d’origine

• Date du début du problème

• Explication du problème

De plus, si l’on écrit, inclure un numéro de téléphone pendant le jour où l’on peut être rejoint.

Les numéros de modèle et de série sont situés sur la plaque signalétique placée du côté droit de l’intérieur de la porte

du lave-vaisselle. Voir figure 1. Cela ressemble à ceci :

Faire une photocopie de la facture et la conserver avec ce guide.

16

Page 35

Tabla de Materias / Instrucciones Importantes

Tabla de Materias

INSTRUCCIONES IMPORTANTES .................................... 1

Herramienta Necesaria ............................................... 2

Materiales Necesarios ................................................ 2

Materiales Provistos ................................................... 3

Preparación del Gabinete ........................................... 4

Preparación - Sistema Eléctrico ................................. 5

Preparación - Plomería ............................................ 6-7

Preparación de la Lavadora ..................................... 7-8

Instalación -Panel de la Puerta................................... 9

INSTRUCCIONES MUY IMPORTANTES

ADVERTENCIA

OBSERVE TODAS LAS ADVERTENCIAS Y

PRECAUCIONES para evitar posibles lesiones y

daños a la propiedad. Estas instrucciones son

para el uso exclusivo de instaladores calificados.

La lavadora debe ser instalada por un técnico de

servicio calificado.

• Además de estas instrucciones, se debe instalar la

lavadora para cumplir con todos los códigos y

regulaciones eléctricas e hidráulicas (nacionales y

locales).

Lea completamente estas instrucciones de

instalación y cumpla con ellas cuidadosamente.

Guiándose por ellas, usted ahorrará tiempo y empeño,

reducirá los riesgos y asegurará un desempeño

óptimo de su lavadora de platos.

CUIDADO

Si se instala la lavadora en un lugar donde

hay temperaturas bajo cero (e.g., en una casa

vacacional), usted debe drenar toda el agua

desde el interior de la lavavadora. La garantía

no cubre roturas del sistema hidráulico como

resultado de temperaturas de congelamiento.

Como Situar la Lavadora .......................................... 10

Como Afirmar la Lavadora ........................................ 10

Conexión - Manguera de Desagüe ............................ 11

Conexión de Agua Caliente ...................................... 12

Conexión Eléctrica .............................................. 13-14

Ajustar la Tensión de la Puerta ................................. 14

Base y Panel de Pie ............................................ 14-15

Instrucciones Finales ............................................... 15

Servicio al Cliente .................................................... 15

IMPORTANTE

• La manguera de desagüe debe instalarse con una

sección por lo menos a una distancia de 20” (51

cm) del piso del gabinete, de lo contrario la

lavadora podría fallar en evacuar el agua

adecuadamente.

• El uso intencionado para esta lavadoras de platos

es en el ambiente residencial y no para usarse en

los establecimientos comerciales de servicios

alimenticios.

• INSTALACIÓN NUEVA - si se instala una lavadora

en el sitio por primera vez, la mayoría del trabajo

se realiza antes de acomodar la lavadora en su

sitio.

• REEMPLAZO - Si esta lavadora reemplaza otra

instalada anteriormente, inspeccione las

conexiones presentes para averiguar si se prestan

para la nueva y cambie piezas como lo sea

necesario.

Inspeccionar la Lavadora de Platos

Después de desempacar la lavadora y antes de

instalarla, inspeccione minuciosamente la lavadora

para averiguar de daños cosméticos y los que

suceden durante el envío. Infórmenos

inmediatamente de cualquier daño. Los daños

cosméticos deben reportarse dentro de 5 días de la

instalación.

NOTA: No bote ninguna bolsa o artículos de

embalaje hasta que termine con la instalación.

1

Page 36

HERRAMIENTAS NECESARIAS

Herramientas y Materiales Necesarios

Martillo

Cinta de Medir

Alicates

Pelacables

Sierra de Punta

Destornillador

de Ranura

Cortaalambres

Llave para Tubería

Destornillador de

Estrella

Taladro

Eléctrico

MATERIALES NECESARIOS

(Podría necesitar otros materiales para cumplir con los códigos municipales)

Llave Ajustable

Destornillador

tipo Torx

Nivel

Cable de Alimentación Eléctrica - Mínimo no. 14 AWG, 2 conductores, 1 de puesta a tierra,

conductores de cobre aislados clasificados para 75°C o mayor.

Tubo de Alimentación de Agua - Mínimo 3/8” diámetro exterior, tubo de cobre o manguera

con alambre trenzado para alimentar lavadoras de platos.

Válvula de cierre y los accesorios adecuados para acoplarla a la alimentación de agua

caliente (tubo de cobre con accesorios sujetadores de compresión o manguera con alambre

trenzado).

0

Acoplador acodado de 90

con rosca exterior macho de 3/8” N.P.T. en una extremidad, y en

la otra extremidad del tamaño adecuado para poder conectarlo a la alimentación de agua

(tubo de cobre/accesorios sujetadores de compresión o manguera con alambre trenzado).

Cinta de teflón u otro sello de acoplamiento roscado para las conexiones de agua.

Conector de Conducto o Alivio de Presión aprobados por UL [

Underwriters Laboratory

].

2

Page 37

Materiales Provistos

MATERIALES PROVISTOS

Accesorios que Proporcionamos

Las piezas de accesorios para su lavadora vienen en una o más bolsas de plástico que se describen abajo.

NOTA: Asegúrese de guardar todas las bolsas hasta haber terminado la instalación.

Bolsa de juego manual

Cada lavadora viene con una bolsa de juego manual que

incluye:

A Manual de uso y cuidado e instrucciones de

instalación (ambos manuales pueden estar incluidos

en un libreto)

B Guía de referencia rápida (modelos selectos)

C Aspersor para piezas muy altas

D Plantilla de instalación SHI y SHV (solamente modelos

SHI y SHV)

E Tira de aislamiento de algodón blanco (solamente

modelos SHY66 SHX99A)

Kit de instalación de la lavadora

Cada lavadora viene con un kit de instalación que incluye:

F Tornillos del panel de pie (2 tornillos negros)

G Soportes de montaje en la cubierta (2 soportes

metálicos en forma de una “L”)

H Tornillos del soporte de montaje (2 tornillos plateados

para madera)

I Adaptador de hule para la manguera de desagüe (1

tubo negro de hule)

J Abrazaderas de manguera (1 abrazadera de resorte

plateada para fijar el adaptador de hule a la manguera

de desagüe y 1 abrazadera de tornillo dorada para

fijar el adaptador de hule a la tubería de agua)

K Conectores de alambre (3 para conexión eléctrica)

L Tornillos de la caja de conexiones eléctricas (2

tornillos plateados)

M Tornillos de bloqueo de las patas niveladoras (2

tornillos roscados dorados)

A

B

C

F

G

H

I

J

D

E

K

L

M

Kit de instalación de paneles de puertas para SHI/SHV

Se proporciona un kit de instalación de paneles de puertas

para lavadoras selectas que utilizan un panel de puerta

personalizado de madera e incluye:

N Tapas de plástico (2)

O Tornillos de tensión de resorte (2 tornillos plateados

grandes que se usan para ajustar los resortes de las

puertas para acomodar puertas de diferentes pesos)

P Soportes de montaje de puerta (2 soportes metálicos

dorados y 2 soportes de plástico blanco que se usan

para fijar la puerta personalizada)

Q Tornillos del soporte de montaje de puerta (8 tornillos

plateados para madera)

R Tornillos de montaje de puerta (2 tornillos plateados

largos que se usan para fijar la puerta)

Kit de instalación del panel de pie

Algunas lavadoras selectas (SHY66C/SHX99A) que

utilizan un panel de pie especial vienen con un kit de

instalación del panel de pie que incluye:

S Tornillos del panel de pie (2 tornillos negros que se

usan para fijar el panel metálico de pie)

T Tornillos del panel de plástico negro de acceso inferior

(2 tornillos plateados largos que se usan para fijar el

panel de plástico negro de acceso inferior a la

lavadora).

N

O

P

Q

S T

R

3

Page 38

23-9/16"

(598mm)

90 90