Bosch SHE99C05UC/38, SHX33A02UC/38, SHX46L15UC/36, SHX46L15UC/38, SHX46L15UC/35 Installation Guide

...Page 1

ishwasher installation instructions

English/French/Spanish

f

important Safety instructions

IMPORTANT

The dishwasher drain hose must be installed

To avoid possible injury or property damage,

OBSERVE ALL WARNINGS AND CAUTIONS.

These instructions are intended for use by

qualified installers only.

The dishwasher must be installed by a qualified

service technician or installer.

In addition to these instructions, the dishwasher

shall be installed to meet all electrical and

plumbing codes and ordinances (both national

and local).

Read these installation instructions completely

and follow them carefully. They will save you time

and effort and help to ensure safety and optimum

dishwasher performance,

if the dishwasher is installed in a location

that experiences freezing temperatures (e.g.,

in a holiday home), you must drain all the

water from the dishwasher's interior. Water

system ruptures that occur as a result of

freezing are NOT COVERED BY WARRANTY.

with a portion of it at least 20" (508mm) off the

cabinet floor; otherwise the dishwasher may not

drain properly.

This dishwasher is intended for residential use

only, and should not be used in commercial

food service establishments.

NEW INSTALLATION - If the dishwasher is a

new installation, most of the work must be done

before the dishwasher is moved into place.

REPLACEMENT - If the dishwasher is

replacing another dishwasher, check

the existing dishwasher connections for

compatibility with the new dishwasher, and

replace parts as necessary.

This appliance has been found to be in

compliance with CAN/CSA-C22.2 No. 167/UL

749. It is the responsibility of the owner and the

installer to determine if additional requirements

and standards apply in specific installations.

Inspect the Dishwasher

After unpacking the dishwasher and prior to

installation, thoroughly inspect the dishwasher for

possible freight or cosmetic damage. Report any

damage immediately. Cosmetic defects must be

reported within 30 days of installation.

NOTE: Do not discard any bags or items that

come with the original package until after the entire

installation has been completed.

\ J

9000121319REV B ° 01/06

1

Page 2

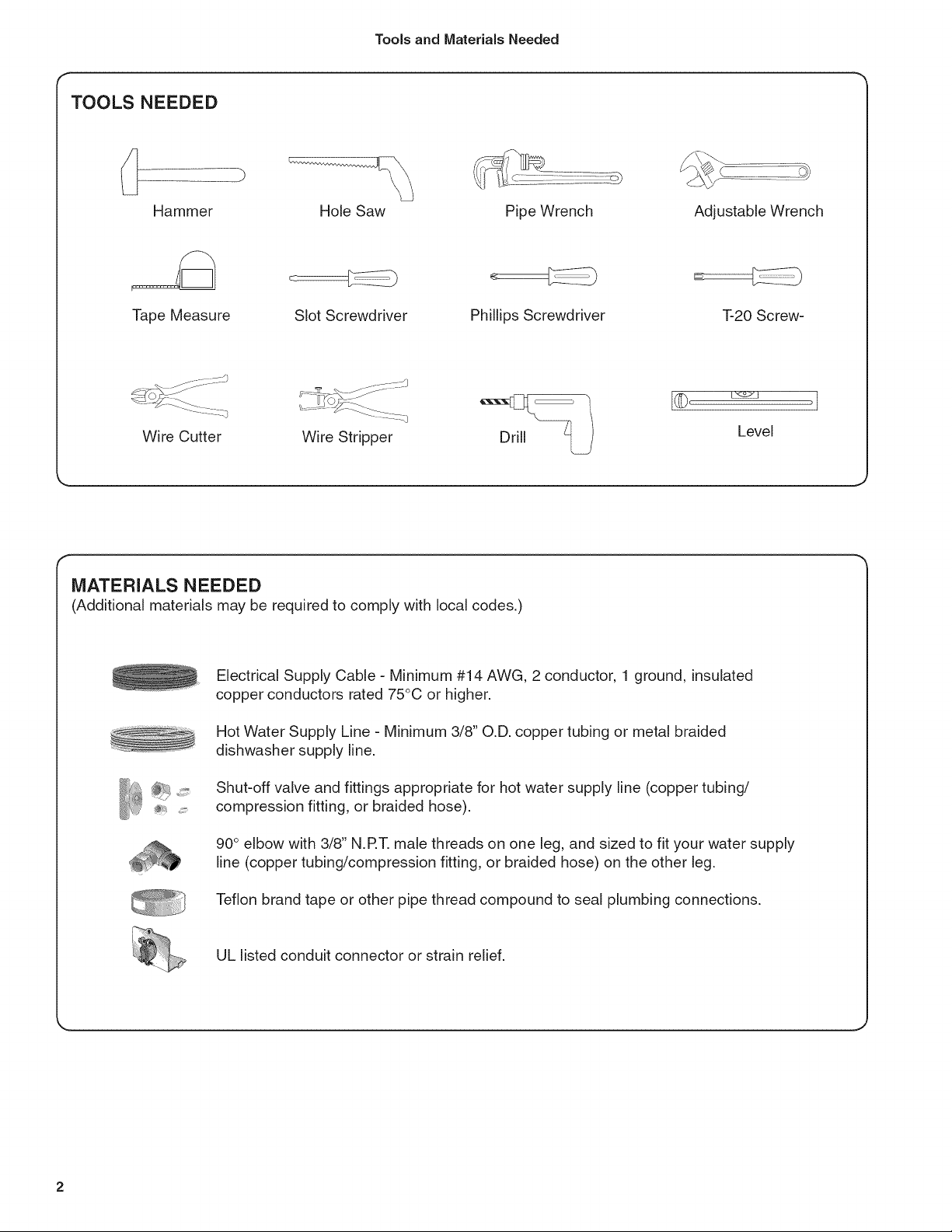

TOOLS NEEDED

Tools and Materials Needed

(..

Hammer

Tape Measure

Hole Saw

Slot Screwdriver

Phillips Screwdriver

Wire Cutter Wire Stripper

MATERIALS NEEDED

(Additional materials may be required to comply with local codes.)

Pipe Wrench

Adjustable Wrench

T-20 Screw-

Level

Electrical Supply Cable - Minimum #14 AWG, 2 conductor, 1 ground, insulated

copper conductors rated 75°C or higher.

Hot Water Supply Line - Minimum 3/8" O.D. copper tubing or metal braided

dishwasher supply line.

,..z

Shut-off valve and fittings appropriate for hot water supply line (copper tubing/

compression fitting, or braided hose).

90° elbow with 3/8" N.RT. male threads on one leg, and sized to fit your water supply

line (copper tubing/compression fitting, or braided hose) on the other leg.

Teflon brand tape or other pipe thread compound to seal plumbing connections.

UL listed conduit connector or strain relief.

2

Page 3

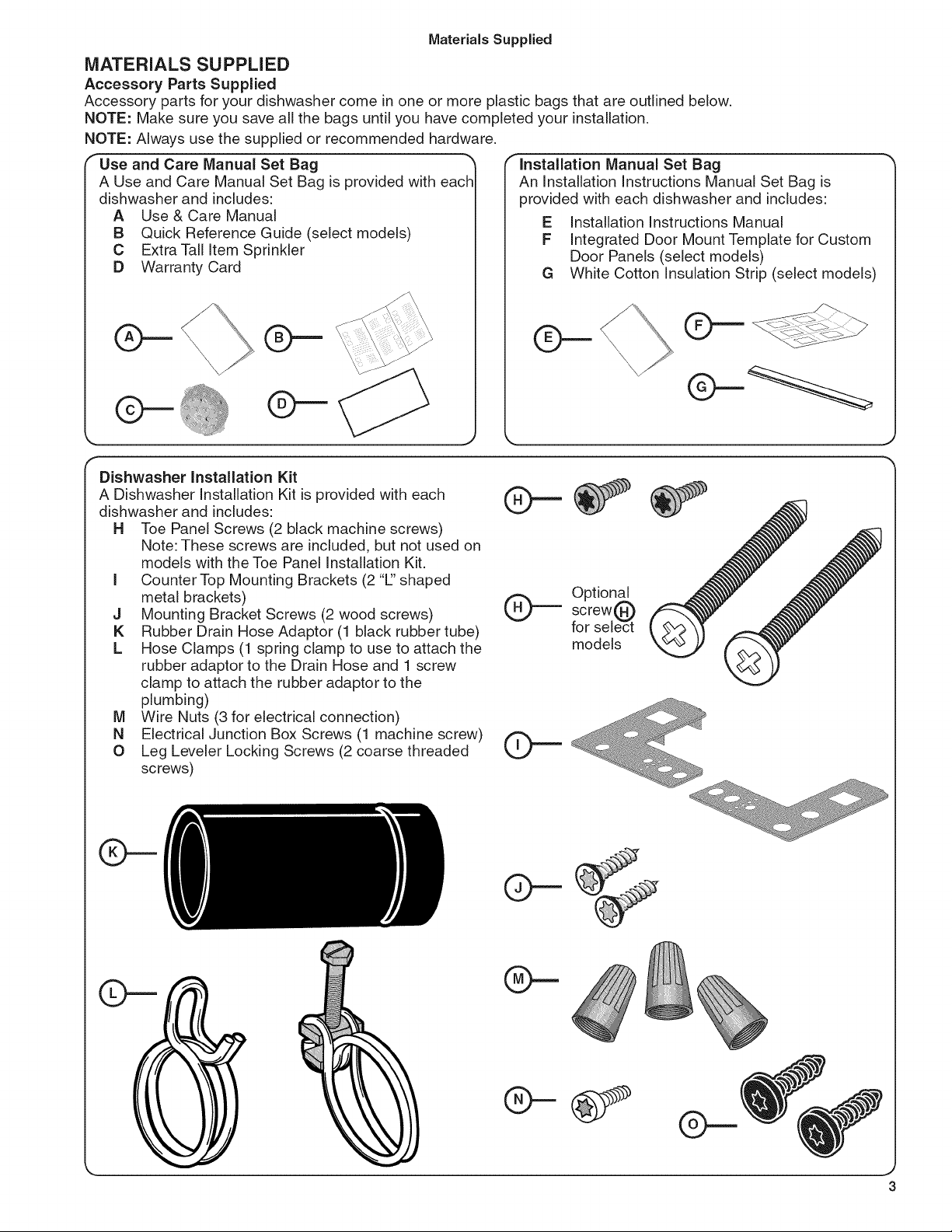

IVlaterialsSupplied

MATERIALS SUPPLIED

Accessory Parts Supplied

Accessory parts for your dishwasher come in one or more plastic bags that are outlined below.

NOTE: Make sure you save all the bags until you have completed your installation.

NOTE: Always use the supplied or recommended hardware.

r Use and Care Manual Set Bag "

A Use and Care Manual Set Bag is provided with each

dishwasher and includes:

A Use & Care Manual E

B Quick Reference Guide (select models) F

C ExtraTall item Sprinkler

D Warranty Card

Dishwasher Installation Kit

A Dishwasher Installation Kit is provided with each

dishwasher and includes:

H Toe Panel Screws (2 black machine screws)

Note: These screws are included, but not used on

models with the Toe Panel Installation Kit.

I Counter Top Mounting Brackets (2 '1" shaped

metal brackets)

J Mounting Bracket Screws (2 wood screws)

K Rubber Drain Hose Adaptor (1 black rubber tube)

L Hose Clamps (1 spring clamp to use to attach the

rubber adaptor to the Drain Hose and 1 screw

clamp to attach the rubber adaptor to the

plumbing)

M Wire Nuts (3 for electrical connection)

N Electrical Junction Box Screws (1 machine screw)

0 Leg Leveler Locking Screws (2 coarse threaded

screws)

Installation Manual Set Bag

An installation instructions Manual Set Bag is

provided with each dishwasher and includes:

Installation Instructions Manual

Integrated Door Mount Template for Custom

Door Panels (select models)

G

White Cotton Insulation Strip (select models)

Optional

(_-" screw(_

for select

models

3

Page 4

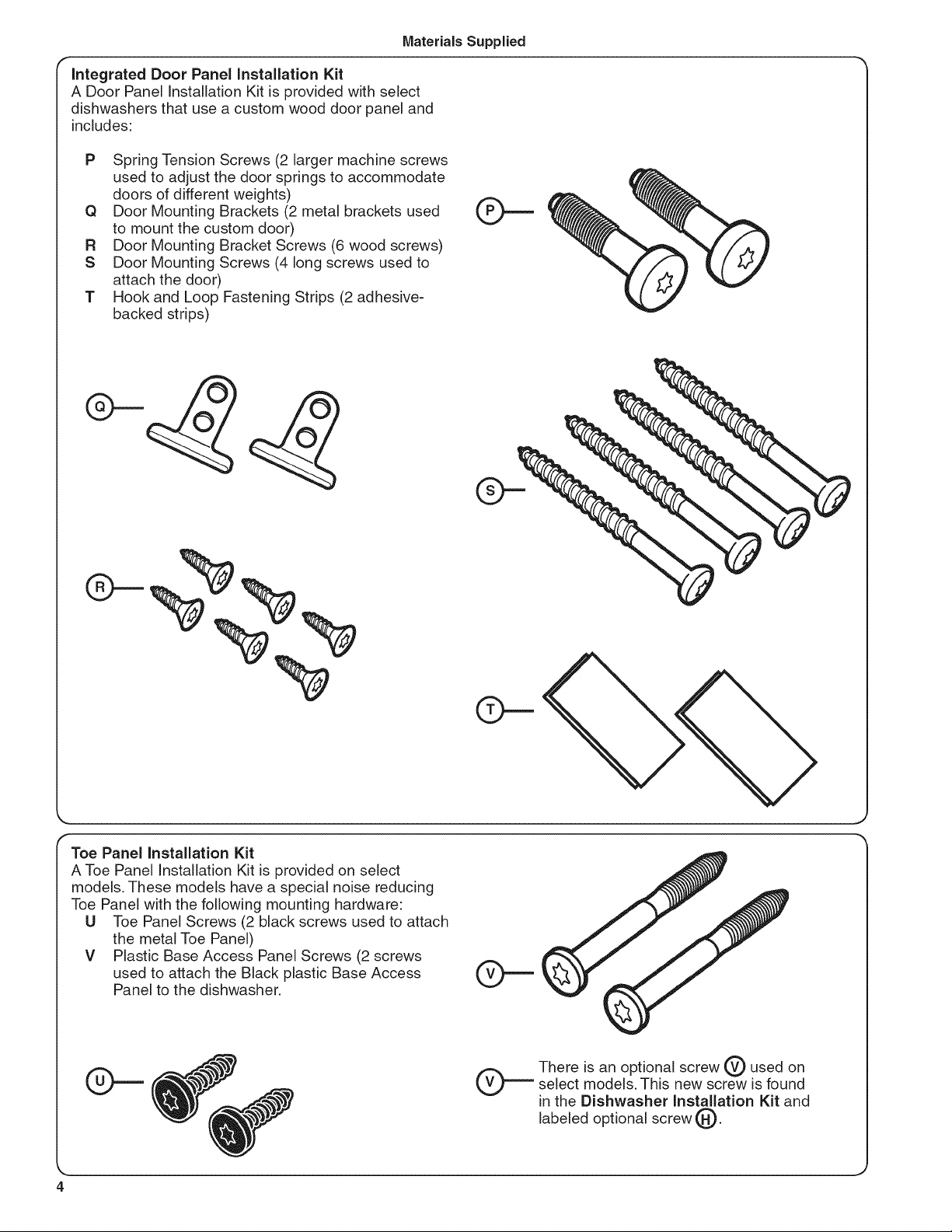

Materials Supplied

integrated Door Panel Installation Kit

A Door Panel Installation Kit is provided with select

dishwashers that use a custom wood door panel and

includes:

P Spring Tension Screws (2 larger machine screws

used to adjust the door springs to accommodate

doors of different weights)

Q Door Mounting Brackets (2 metal brackets used

to mount the custom door)

R Door Mounting Bracket Screws (6 wood screws)

S Door Mounting Screws (4 long screws used to

attach the door)

T Hook and Loop Fastening Strips (2 adhesive-

backed strips)

f

Toe Panel Installation Kit

A Toe Panel Installation Kit is provided on select

models. These models have a special noise reducing

Toe Panel with the following mounting hardware:

U Toe Panel Screws (2 black screws used to attach

the metal Toe Panel)

V Plastic Base Access Panel Screws (2 screws

used to attach the Black plastic Base Access

Panel to the dishwasher,

4

There is an optional screw (_) used on

(_)_ select models. This new screw is found

in the Dishwasher installation Kit and

labeled optional screw (_.

Page 5

/I

90 _ )0

I

I

34"

(864rnm)

minimum

/

23-5/8" - 24-1/4" (600-616 mm)

Figure 1

23-9/I 6"

(598mm)

Enclosure Pre

A

)aration

Avoid Scalding or Electrical Shock Hazard

Make sure the water supply and electrical supply

are shut off before installation or service.

ENCLOSURE PREPARATION

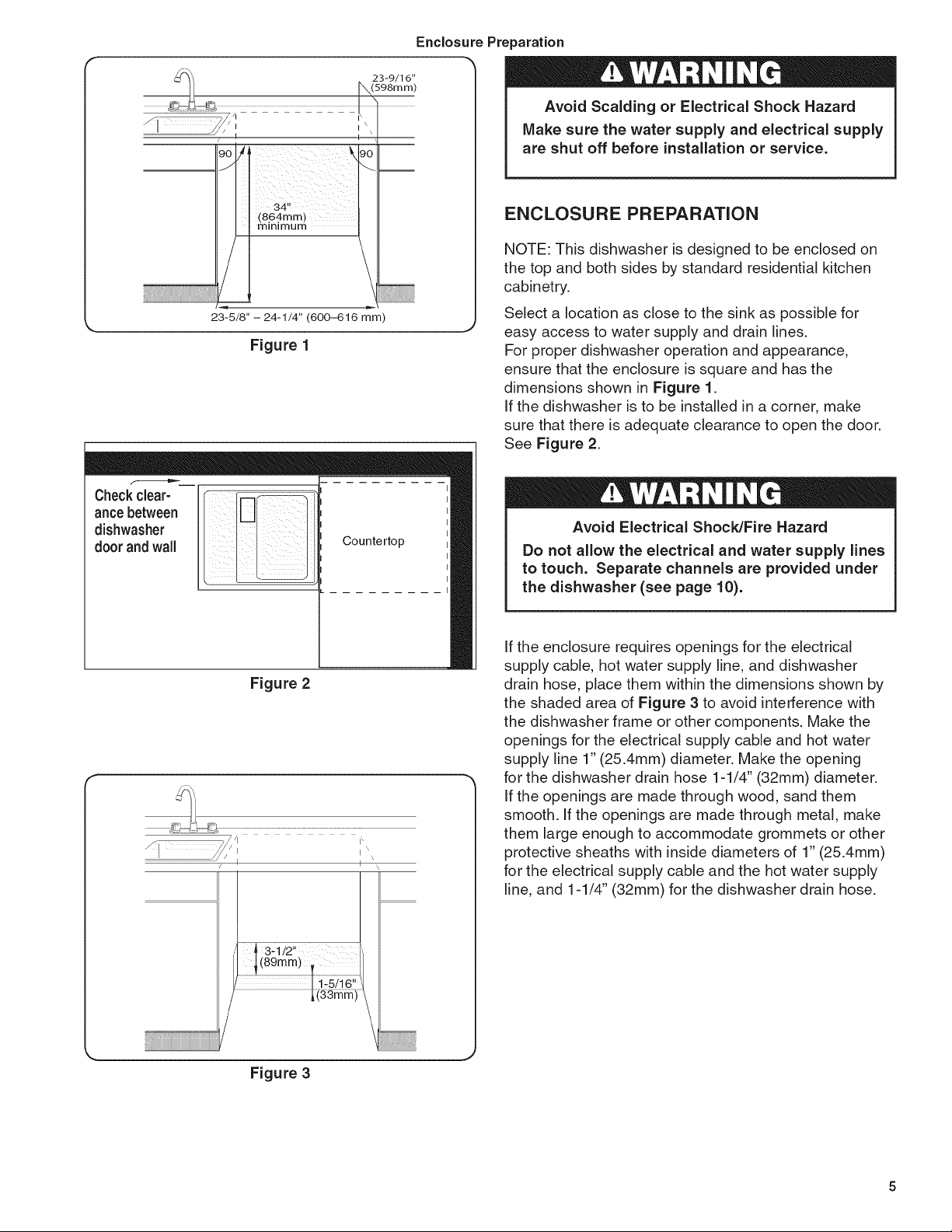

NOTE: This dishwasher is designed to be enclosed on

the top and both sides by standard residential kitchen

cabinetry.

Select a location as close to the sink as possible for

easy access to water supply and drain lines.

For proper dishwasher operation and appearance,

ensure that the enclosure is square and has the

dimensions shown in Figure 1.

If the dishwasher is to be installed in a corner, make

sure that there is adequate clearance to open the door.

See Figure 2.

ance between I

dishwasher / Countertop

door and wall I

Figure 2

E I I I

_/I I"

, 3-1/2"

Avoid Electrical Shock/Fire Hazard

Do not allow the electrical and water supply lines

to touch. Separate channels are provided under

the dishwasher (see page 10).

If the enclosure requires openings for the electrical

supply cable, hot water supply line, and dishwasher

drain hose, place them within the dimensions shown by

the shaded area of Figure 3 to avoid interference with

the dishwasher frame or other components. Make the

openings for the electrical supply cable and hot water

supply line 1" (25.4mm) diameter. Make the opening

for the dishwasher drain hose 1-1/4" (32mm) diameter.

If the openings are made through wood, sand them

smooth. If the openings are made through metal, make

them large enough to accommodate grommets or other

protective sheaths with inside diameters of 1" (25.4mm)

for the electrical supply cable and the hot water supply

line, and 1-1/4" (32mm) for the dishwasher drain hose.

Figure 3

J

Page 6

(762mm)

21 "

(533mm)

30" i

Electrical Preparation

. ELECTRICAL PREPARATION

Avoid E(ectrica( Shock Hazard

Do not work on an energized circuit. Doing

so could result in serious injury or death.

Only qualified electricians should perform

electrical work. Do not attempt any work on the

dishwasher electric supply circuit until you are

certain the circuit is de=energized.

Figure 4

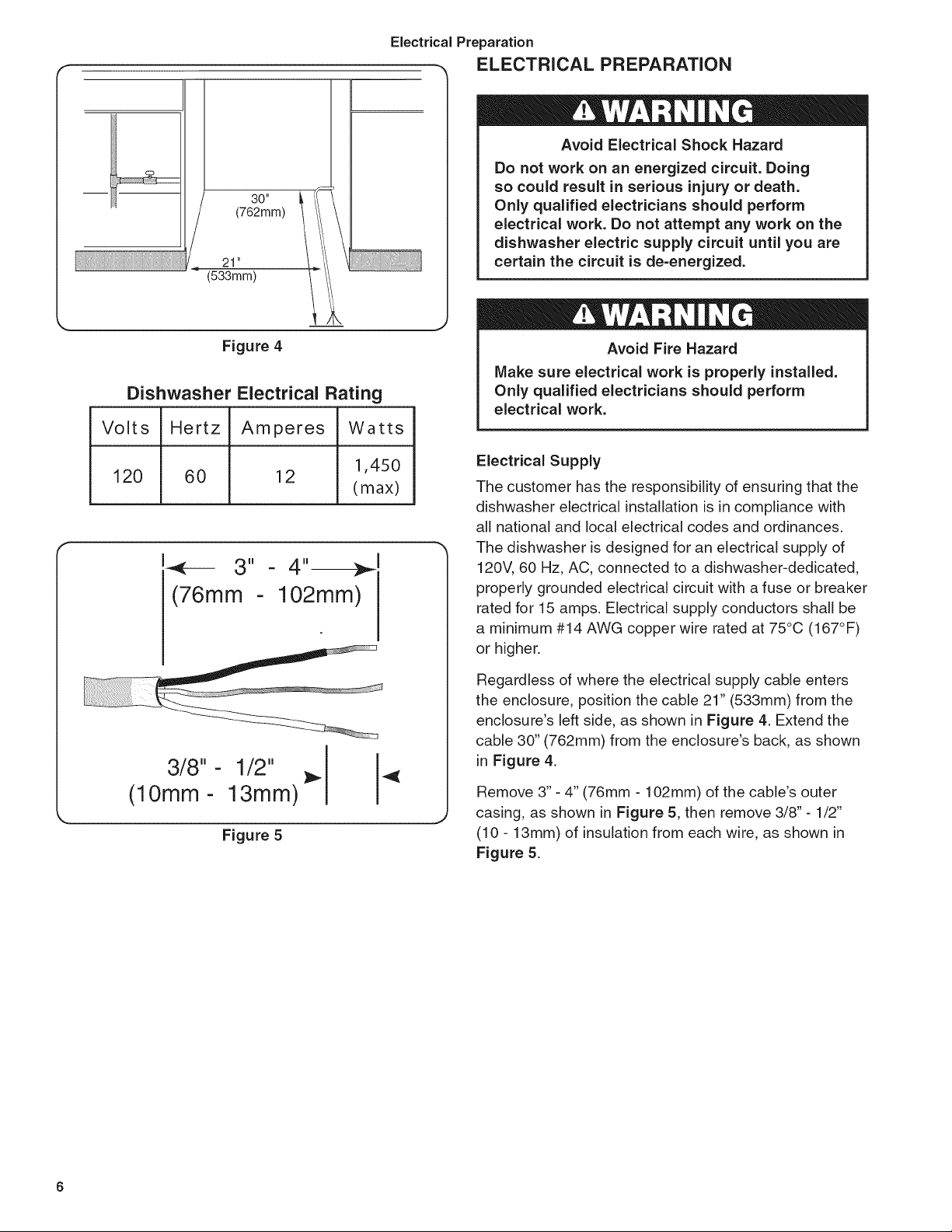

Dishwasher Electrical Rating

Volts Hertz Amperes Watts

120 60 12

1,450

(max)

3/8"- 1/2"

(10mm - 13mm)

Figure 5

Avoid Fire Hazard

Make sure electrical work is properly instal(ed.

Only qualified electricians should perform

electrical work.

Electrical Supply

The customer has the responsibility of ensuring that the

dishwasher electrical instal(ation is in compliance with

al( national and (ocal electrical codes and ordinances.

The dishwasher is designed for an electrical supply of

120V, 60 Hz, AC, connected to a dishwasher-dedicated,

properly grounded electrical circuit with a fuse or breaker

rated for 15 amps. Electrical supply conductors shal( be

a minimum #14 AWG copper wire rated at 75°C (167°F)

or higher.

Regardless of where the electrical supply cable enters

the enclosure, position the cable 21" (533mm) from the

enclosure's left side, as shown in Figure 4. Extend the

cable 30" (762mm) from the enclosure's back, as shown

in Figure 4.

Remove 3" - 4" (76mm - 102mm) of the cable's outer

casing, as shown in Figure 5, then remove 3/8"- 1/2"

(10 - 13mm) of insulation from each wire, as shown in

Figure 5.

6

Page 7

Plumbing Preparation

PLUMBING PREPARATION

Avoid Scald Hazard

Do not perform any work on a charged hot water

line. Serious injury could result. Only qualified

plumbers should perform plumbing work. Do not

attempt any work on the dishwasher hot water

14

supply plumbing until you are certain the hot

water supply is shut off.

Figure 6

Temperatures required for soldering and

sweating will damage the dishwasher's base

and water inlet valve. If plumbing lines are to

be soldered or sweated, keep the heat source

at least 6 inches (152.4 ram) away from the

dishwasher's base and water inlet valve.

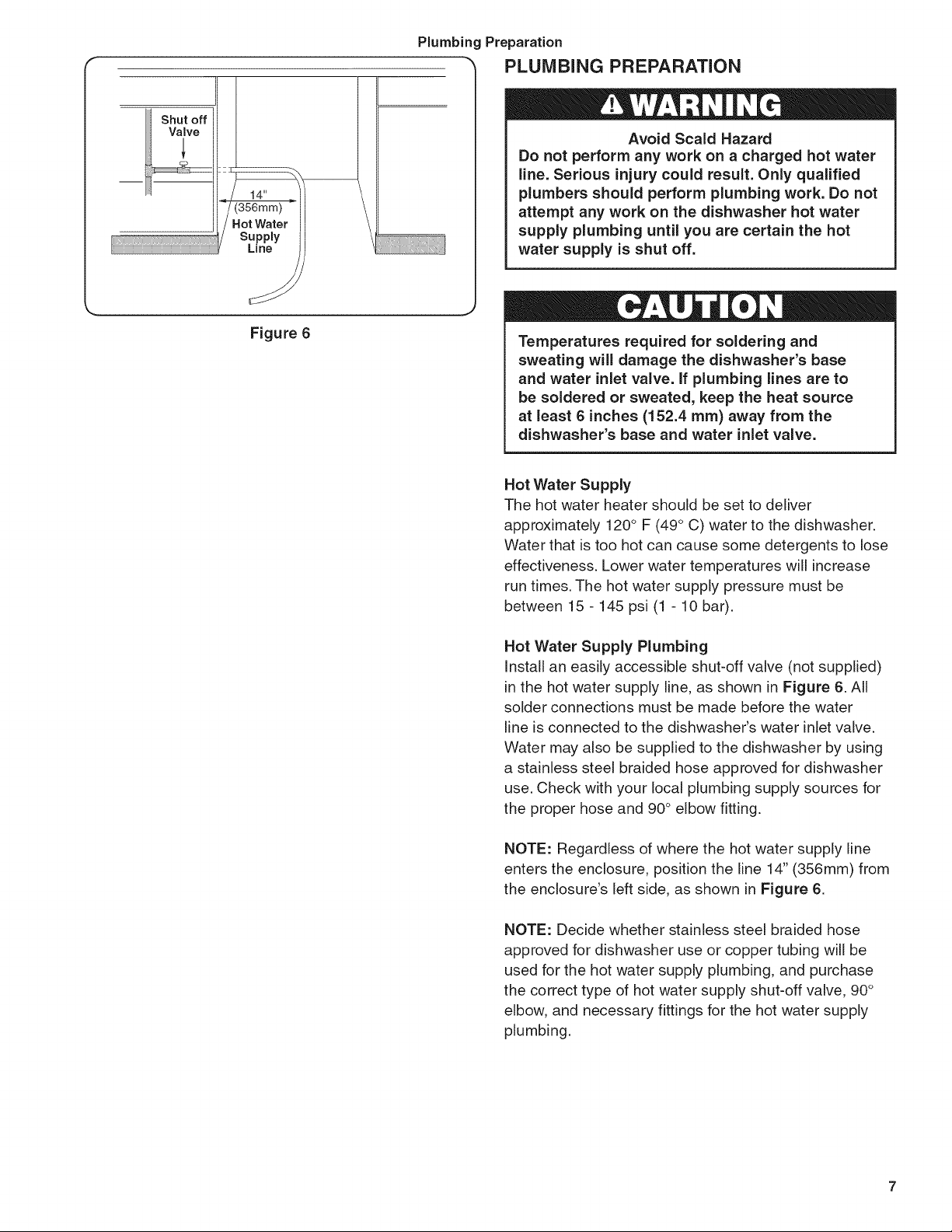

Hot Water Supply

The hot water heater should be set to deliver

approximately 120° F (49 ° C) water to the dishwasher.

Water that is too hot can cause some detergents to lose

effectiveness. Lower water temperatures will increase

run times. The hot water supply pressure must be

between 15 - 145 psi (1 - 10 bar).

Hot Water Supply Plumbing

Install an easily accessible shut-off valve (not supplied)

in the hot water supply line, as shown in Figure 6. All

solder connections must be made before the water

line is connected to the dishwasher's water inlet valve.

Water may also be supplied to the dishwasher by using

a stainless steel braided hose approved for dishwasher

use. Check with your local plumbing supply sources for

the proper hose and 90° elbow fitting.

NOTE: Regardless of where the hot water supply line

enters the enclosure, position the line 14" (356mm) from

the enclosure's left side, as shown in Figure 6.

NOTE: Decide whether stainless steel braided hose

approved for dishwasher use or copper tubing will be

used for the hot water supply plumbing, and purchase

the correct type of hot water supply shut-off valve, 90°

elbow, and necessary fittings for the hot water supply

plumbing.

Page 8

Y-branch

_ Tailpiece

Plumbing Preparation/Dishwasher Preparation

Air_ PLUMBING PREPARATION (continued)

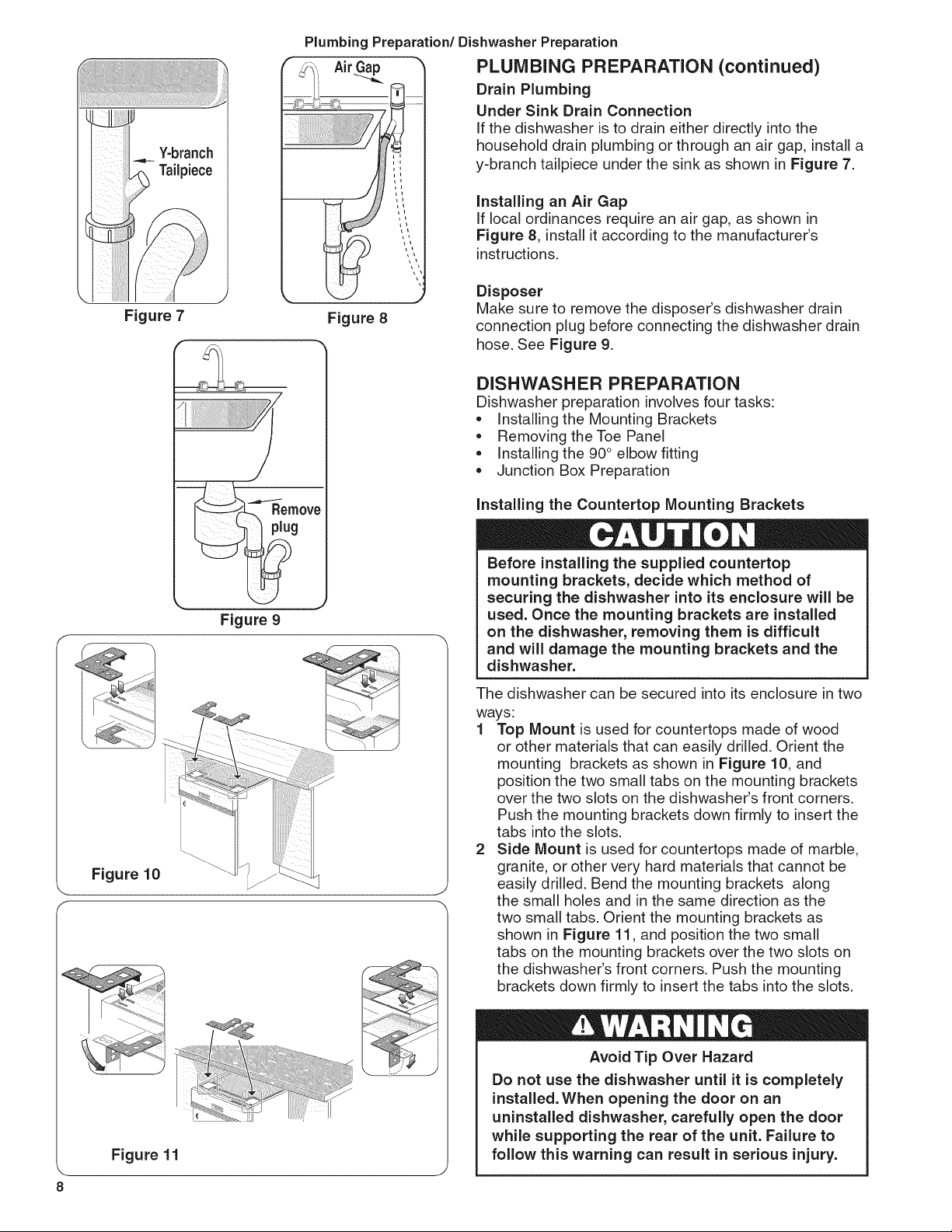

Drain Plumbing

Under Sink Drain Connection

If the dishwasher is to drain either directly into the

household drain plumbing or through an air gap, install a

y-branch tailpiece under the sink as shown in Figure 7.

Installing an Air Gap

if local ordinances require an air gap, as shown in

Figure 8, install it according to the manufacturer's

instructions.

I I 2

Figure 7

Figure 10

___eugm°ve

Figure 9

Figure 8

J

Disposer

Make sure to remove the disposer's dishwasher drain

connection plug before connecting the dishwasher drain

hose. See Figure 9.

DISHWASHER PREPARATION

Dishwasher preparation involves four tasks:

Installing the Mounting Brackets

Removing the Toe Panel

Installing the 90 ° elbow fitting

Junction Box Preparation

Installing the Countertop Mounting Brackets

Before installing the supplied countertop

mounting brackets, decide which method of

securing the dishwasher into its enclosure will be

used. Once the mounting brackets are installed

on the dishwasher, removing them is difficult

and will damage the mounting brackets and the

dishwasher.

The dishwasher can be secured into its enclosure in two

ways:

1 Top Mount is used for countertops made of wood

or other materials that can easily drilled. Orient the

mounting brackets as shown in Figure 10, and

position the two small tabs on the mounting brackets

over the two slots on the dishwasher's front corners.

Push the mounting brackets down firmly to insert the

tabs into the slots.

2 Side Mount is used for countertops made of marble,

granite, or other very hard materials that cannot be

easily drilled. Bend the mounting brackets along

the small holes and in the same direction as the

two small tabs. Orient the mounting brackets as

shown in Figure 11, and position the two small

tabs on the mounting brackets over the two slots on

the dishwasher's front corners. Push the mounting

brackets down firmly to insert the tabs into the slots.

Avoid Tip Over Hazard

Do not use the dishwasher until it is completely

installed. When opening the door on an

uninstalled dishwasher, carefully open the door

while supporting the rear of the unit. Failure to

\

Figure 11

8

follow this warning can result in serious injury.

Page 9

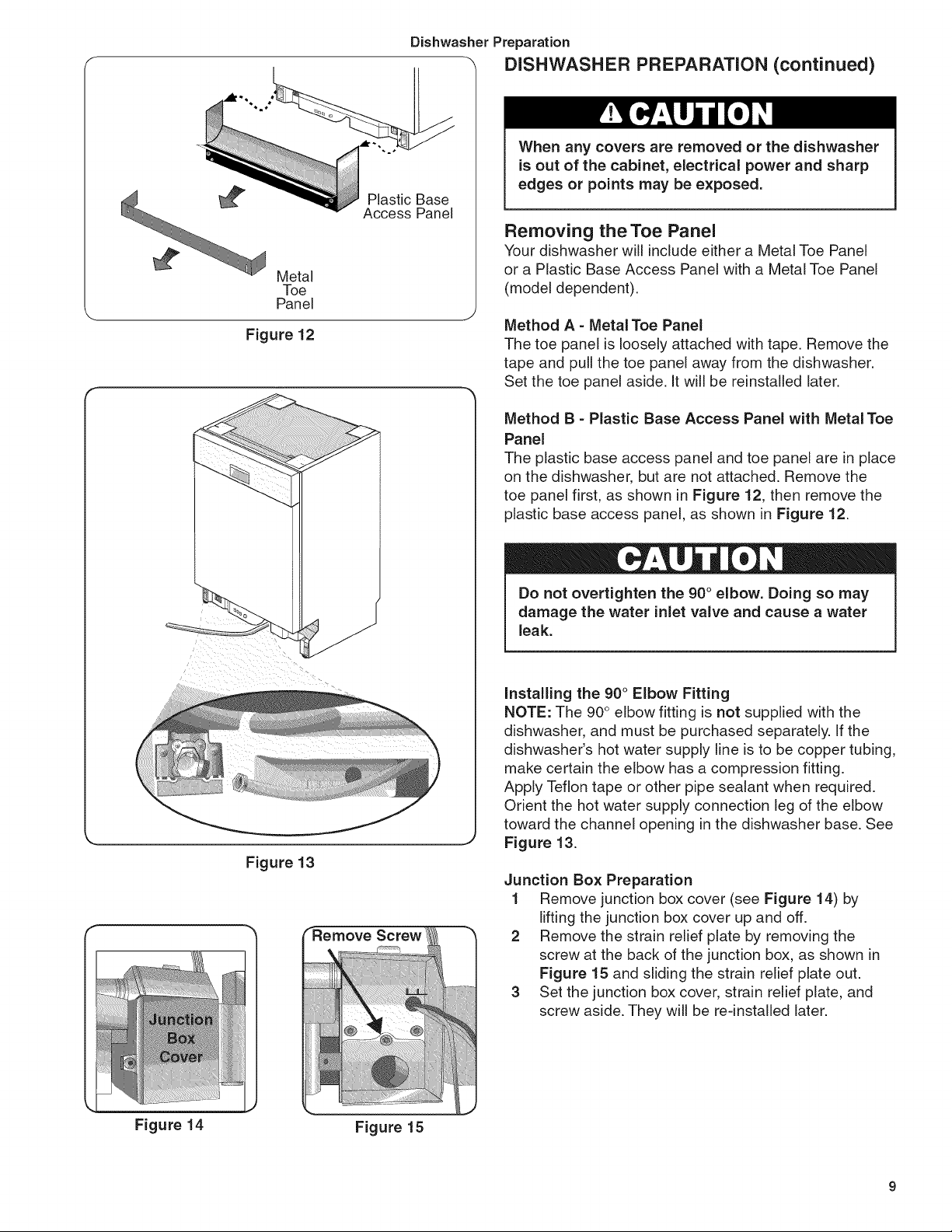

Metal

Toe

Panel

Figure 12

Dishwasher Preparation

Access Panel

Plastic Base

DISHWASHER PREPARATION (continued)

When any covers are removed or the dishwasher

is out of the cabinet, electrical power and sharp

edges or points may be exposed.

Removing the Toe Panel

Your dishwasher will include either a Metal Toe Panel

or a Plastic Base Access Panel with a Metal Toe Panel

(model dependent),

Method A - Metal Toe Panel

The toe panel is loosely attached with tape. Remove the

tape and pull the toe panel away from the dishwasher.

Set the toe panel aside. It will be reinstalled later.

Method B - Plastic Base Access Panel with Metal Toe

Panel

The plastic base access panel and toe panel are in place

on the dishwasher, but are not attached. Remove the

toe panel first, as shown in Figure 12, then remove the

plastic base access panel, as shown in Figure 12.

Figure 13

Do not overtighten the 90 ° elbow. Doing so may

damage the water inlet valve and cause a water

leak.

Installing the 90 ° Elbow Fitting

NOTE: The 90° elbow fitting is not supplied with the

dishwasher, and must be purchased separately. If the

dishwasher's hot water supply line is to be copper tubing,

make certain the elbow has a compression fitting.

Apply Teflon tape or other pipe sealant when required.

Orient the hot water supply connection leg of the elbow

toward the channel opening in the dishwasher base. See

Figure 13.

Junction Box Preparation

1 Remove junction box cover (see Figure 14) by

lifting the junction box cover up and off.

2 Remove the strain relief plate by removing the

screw at the back of the junction box, as shown in

Figure 15 and sliding the strain relief plate out.

3 Set the junction box cover, strain relief plate, and

screw aside. They will be re-installed later.

Figure 14 Figure 15

Page 10

Door Panel Installation

" DOOR PANEL INSTALLATION

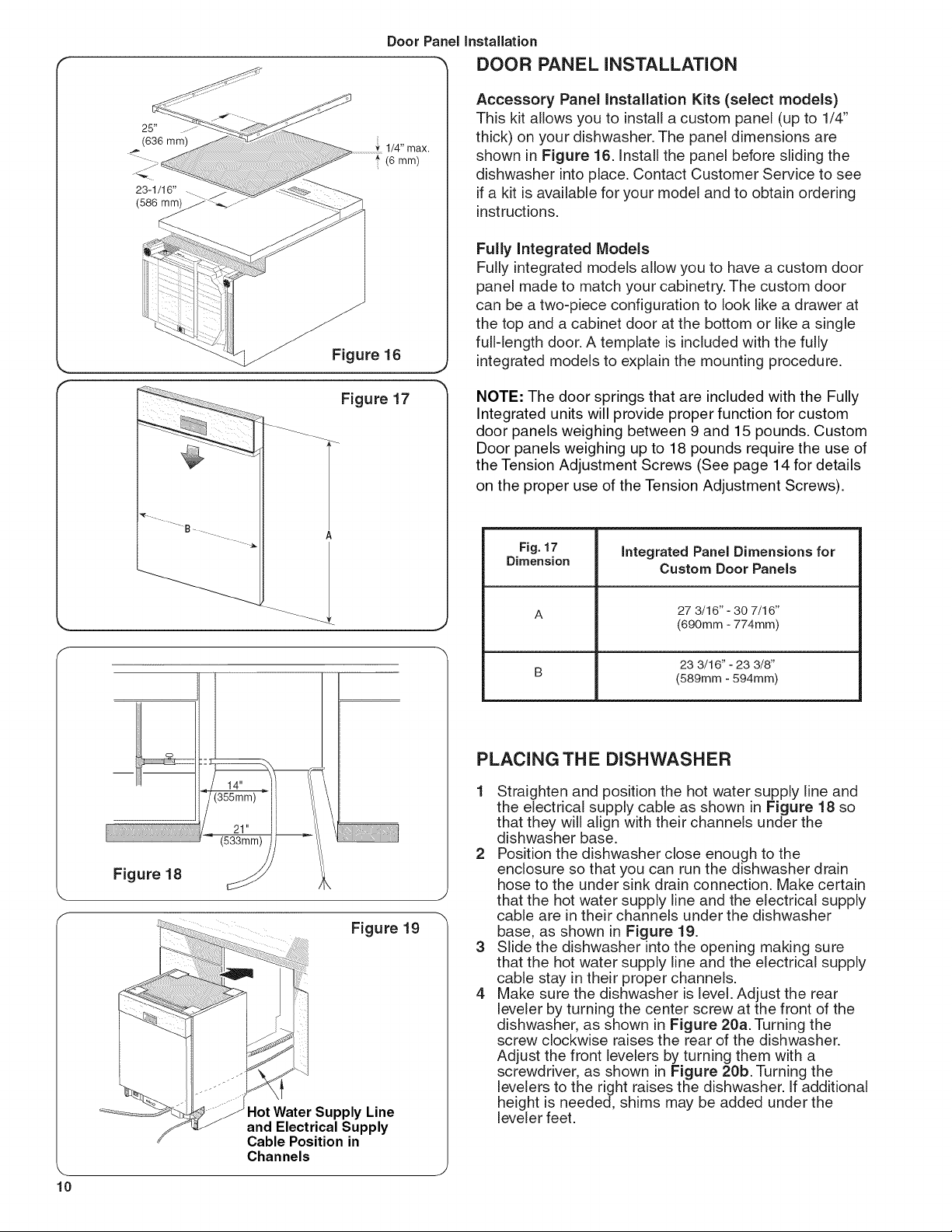

Accessory Panel Installation Kits (select models)

25"

(636 mm)

p

1/4" max.

(6rnrn)

23-1/16"

(586 mm)

Figure 16

f

Figure 17

This kit allows you to install a custom panel (up to 1/4"

thick) on your dishwasher. The panel dimensions are

shown in Figure 16. Install the panel before sliding the

dishwasher into place. Contact Customer Service to see

if a kit is available for your model and to obtain ordering

instructions.

Fully Integrated Models

Fully integrated models allow you to have a custom door

panel made to match your cabinetry. The custom door

can be a two-piece configuration to look like a drawer at

the top and a cabinet door at the bottom or like a single

full-length door. A template is included with the fully

integrated models to explain the mounting procedure.

NOTE: The door springs that are included with the Fully

Integrated units will provide proper function for custom

door panels weighing between 9 and 15 pounds. Custom

Door panels weighing up to 18 pounds require the use of

the Tension Adjustment Screws (See page 14 for details

on the proper use of the Tension Adjustment Screws).

Figure 18

A

Figure 19

Hot Water Supply Line

and Electrical Supply

Cable Position in

Channels

Integrated Panel Dimensions for

Custom Door Panels

27 3/16" - 30 7/16"

(690mm - 774mm)

23 3/16" - 23 3/8"

B (589mm - 594mm)

PLACING THE DISHWASHER

1 Straighten and position the hot water supply line and

the electrical supply cable as shown in Figure 18 so

that they will align with their channels under the

dishwasher base.

2 Position the dishwasher close enough to the

enclosure so that you can run the dishwasher drain

hose to the under sink drain connection. Make certain

that the hot water supply line and the electrical supply

cable are in their channels under the dishwasher

base, as shown in Figure 19.

3 Slide the dishwasher into the opening making sure

that the hot water supply line and the electrical supply

cable stay in their proper channels.

4 Make sure the dishwasher is level. Adjust the rear

leveler by turning the center screw at the front of the

dishwasher, as shown in Figure 20a. Turning the

screw clockwise raises the rear of the dishwasher.

Adjust the front levelers by turning them with a

screwdriver, as shown in Figure 20b. Turning the

levelers to the right raises the dishwasher. If additional

height is needed, shims may be added under the

leveler feet.

10

Page 11

Figure 20

Placing the Dishwasher/Securing the Dishwasher

SECURING THE DISHWASHER

1 Drive the mounting screw's through the holes in the

_ mounting brackets as shown in Figure 21 for Top or

/

/ secured, lock the two front leg levelers in place by

Side Mount.

2 After the unit is installed in the enclosure, leveled and

driving the enclosed leg leveler locking screws into

each screw boss located in front of the levelers. See

Figure 22.

3 Tighten screws until they are flush with the surface of

the bosses.

f

TopMount

Figure 21

Figure 22

SideMount

J

installation of the Rubber Drain Hose

Adaptor

1 Obtain the Rubber Drain Hose Adaptor and the two

hose clamps from the Dishwasher Installation Kit (do

not substitute).

2 On one outside end of the Rubber Drain Hose

Adapter is a raised rib. insert the dishwasher drain

hose intothe end without the raised rib (see Figure

23). Be sure to fully insert the drain hose.

3 Secure the connection with the Spring Clamp (see

Figure 24).

4 Use the Screw Clamp to attach the Rubber Drain

Hose Adaptor to the house plumbing (see Figure 24).

J

Leg

Leveler

Locking

Screw

Screw

Boss

Rubber Drain Hose Adaptor

Raised Rib (cross section) Dishwasher

/

Connects to house- _/ '_

hold plumbing insert until drain

hose locks in place

Figure 23

Spring

Clamp

Figure 24

11

Page 12

Drain Hose Connection/Hot Water Connection

Non-Metallic Tie

Figure 25

Figure 26

Figure 27 Figure 28

Air Vent Hose

i

MIN.

20"

Connecting the Drain Hose to the

Household Plumbing

The dishwasher drain hose may be connected to the

drain plumbing in one of four ways:

1 Directly to the undersink dishwasher drain

connection, as shown in Figure 25.

2 Directly to a disposer dishwasher drain connection,

as shown in Figure 26.

3 To the undersink dishwasher drain connection

through an air gap, as shown in Figure 27.

4 To a disposer dishwasher drain connection through

an air gap, as shown on Figure 28.

Information on installing air gaps and disposers can

be found in the Plumbing Preparation section of this

manual.

iMPORTANT NOTES:

If the dishwasher drain hose is to be connected to

a disposer dishwasher drain connection, remove

the plug from the disposer's dishwasher drain

connection.

The dishwasher drain hose must have one place

along its length that is securely attached 20 inches

above the cabinet floor.

The drain hose length can be extended if necessary.

The maximum length of the drain hose, including the

hose leading to the air gap, is 150 inches.

The hose shown in Figure 29 is an air vent. The end

of this hose should be left in the dishwasher base.

Do not make any connections to this hose.

HOT WATER CONNECTION

12

Do not make any

connections to this hose

Figure 29

Avoid Scald Hazard

Do not perform any work on a charged hot water

line. Serious injury could result. Only qualified

plumbers should perform plumbing work. Do not

attempt any work on the dishwasher hot water

supply plumbing until you are certain the hot

water supply is shut off.

NOTE: Make certain that the correct 90° elbow fitting

(not supplied) for the hot water supply line has been

purchased and installed on the dishwasher as described

in the Dishwasher Preparation section of this manual.

The hot water supply line may be connected to the

dishwasher in one of two ways:

1 With braided hose,

2 With copper tubing.

Stainless Steel Braided Hose Approved for

Dishwasher Use.

After connections are made turn on the hot water supply

to check for leaks.

NOTE: Braided dishwasher supply hoses can also be

used to extend pre-existing dishwasher water supply

lines.

Page 13

Hot Water Connection/Electrical Connection

Copper Tubing

Temperatures required for soldering and sweating

will damage the dishwasher's water inlet valve.

if plumbing lines are to be soldered or sweated,

keep the heat source at least 6 inches (152.4 ram)

away from the dishwasher's water inlet valve.

If using a solder joint instead of a compression fitting,

be sure to make all solder connections before

connecting the water line to the dishwasher.

Make certain there are no sharp bends or kinks in the

water line that might restrict water flow.

Be sure to use pipe thread compound or Teflon brand

tape to seal the connection when required.

Before connecting the copper hot water supply line

to the dishwasher, flush it with hot water to clear any

foreign material.

Turn on the water supply to check for leaks after

making connections.

NOTE: Do not use pipe sealant on compression fittings.

ELECTRICAL CONNECTION

Figure 30

Figure 31

Strain

Relief

Strain Relief

Casing

Avoid Electrical Shock Hazard

Do not work on an energized circuit. Doing so

could result in serious injury or death. Only

qualified electricians should perform electrical

work. Do not attempt any work on the dishwasher

electric supply circuit until you are certain the

circuit is de=energized.

Avoid Fire Hazard

Make sure electrical work is properly installed.

Only qualified electricians should perform

electrical work.

Grounding Instructions

The dishwasher must be properly grounded before

operating. This appliance must be connected to a

grounded metal permanent wiring system, or an

equipment grounding conductor must be run with the

circuit conductors and connected to the equipment

grounding terminal or lead on the dishwasher. Make sure

that the dishwasher is connected to a suitable ground in

compliance with all local codes or, in the absence of a

local code, with the NATIONAL ELECTRICAL CODE in

the United States or the CANADIAN ELECTRIC CODE

C22.1-1atest edition in Canada as well as any provincial/

state or municipal or local codes that apply.

1 Retrieve the strain relief plate, and install a strain

relief (not supplied) into the opening on the strain

relief plate. NOTE: Orient the strain relief as shown in

Figure 30.

2 Pass the electrical supply cable through the strain

relief, as shown in Figure 31. Make sure the outer

wire casing extends about 1/2" (13mm) through the

strain relief.

3 Tighten the strain relief screws.

4 Slide the strain relief plate into the junction box, and

secure it to the junction box with the supplied screw.

13

Page 14

Electrical Connection/Door Tension Adjustment/Base and Toe Panel

. ELECTRICAL CONNECTION (continued)

Avoid Fire Hazard

Make sure there are no loose electrical

connections. Make sure all electrical connections

are properly made.

= Do not pre-twist the wires before connecting them

with wire nuts.

Extend the dishwasher's stranded wires 1/8"

Figure 32

(3mm) beyond the power supply cable's solid

wires, as shown in Figure 32.

5 Using the supplied wire nuts, connect the electrical

supply wires to the dishwasher's wires, black to

black, white to white, and green or bare. Make certain

that the insulated wires show no bare wire from the

bottoms of the wire nuts. Gently tug the wires to make

certain they are securely connected.

6 Press the wires into the junction box as shown in

Figure 33. Make certain that the wire nuts do not

loosen.

7 Place the cover on the junction box and secure it to

the junction box with the supplied screw.

Figure 33

4-

Figure 34

_i iii

ill _iii ii

iiii iii_

DOOR TENSION ADJUSTMENT (only on

fulJy integrated models with custom

door panels)

After the dishwasher and custom door panel are

installed, open and close the door several times to make

sure that it does so with ease. If the door falls open too

quickly, the spring tension needs to be adjusted.

To Adjust the Spring Tension:

1 Obtain the provided Spring Tension Screws from the

Integrated Door Panel Installation Kit.

2 Insert the screws as shown in Figure 34. Turning the

screw clockwise increases the spring tension.

TOE PANEL iNSTALLATiON

Method A =Regular Toe Panel Installation

Use the toe panel screws from the Dishwasher

Installation Kit to install the toe panel as shown in Figure

35,

14

Figure 35

Page 15

Figure 36

Baseand Toe Panel/Final instructions

-, BASE AND TOE PANEL (Continued)

Method B - Plastic Base Access Panel and Toe Panel

Installation (select models)

1 Place the Plastic Base Access Panel under and up

the front bottom panel of the dishwasher, as shown in

Figure 36a.

2 Insert the Plastic Base Access Panel screws into the

Plastic Base Access Panel, as shown in Figure 36b.

Tighten the Plastic Base Access Panel Screws.

3 Place the Cotton Insulation Strip under the unit,

between the bottom of the Plastic Base Access Panel

and the floor, as shown in Figure 36c.

4 Attach the Metal Toe Panel to the Plastic Base

Access Panel using the Toe Panel Screws included in

the Toe Panel Installation Kit. See Figure 36d.

NOTE: You will not use the normal Toe Panel Screws

included in the Dishwasher Installation Kit on these

models.

in some conditions, Hydrogen gas can form in

a hot water system that has not been used for

weeks. Hydrogen gas is explosive. Before filling

a dishwasher from a system that has been off

for weeks, run the water from a nearby faucet in

a well ventilated area until there is no sound or

evidence of gas.

FINAL iNSTRUCTiONS

1 Energize the dishwasher power supply circuit.

2 Consult the Dishwasher Use and Care Manual, and

run the dishwasher through one complete cycle. If

the dishwasher does not operate properly, refer to

the Self-Help section of the Use and Care Manual. If

the dishwasher still does not operate properly, refer

to the Customer Service Section of the Use and Care

Manual.

15

Page 16

Customer Service

Customer Service

Your dishwasher requires no special care other

than that described in the Care and Maintenance

section of the Use and Care Manual. If you are

having a problem with your dishwasher, before

calling for service please refer to the Self Help

section in the Use and Care Manual. If service

is necessary, contact your dealer or installer or

an authorized service center. Do not attempt to

repair the appliance yourself. Any work performed

by unauthorized personnel may void the warranty.

Removing any cover or pulling the

dishwasher from the cabinet can expose

hot water connections, electrical power and

sharp edges or points.

If you are having a problem with your dishwasher

and are not pleased with the service you have

received, please take the following steps (in the

order listed below) until the problem is corrected

to you r satisfaction:

.

Call us at the Customer Service phone

number listed on the label located on the

right edge of the dishwasher door as shown

in Figure 37.

Please be sure to include (if you are writing), or

have available (if you are calling), the following

information:

,, Model number

,, Serial number

,, Date of original purchase

,, Date the problem originated

,, Explanation of the problem

Also, if you are writing, please include a daytime

phone number where you can be reached.

Please make a copy of your invoice and keep it

with this manual. The customer must show proof

of purchase to obtain warranty service.

1. Contact your installer or the Authorized

Service Contractor in your area.

2. E-mail us. See your Use and Care Manual

for instructions.

3. Write us at the address below:

BSH Home Appliances, Corp.

5551 McFadden Avenue

Huntington Beach, CA 92649

Figure 37

Customer Service Phone Number

Model and Serial Number Label

, "_ I ++r+-- r_:r+-+n+n_ ;+x_ _J',_ir._F F¢r/_mI_ ."DrB-I-_'. I

'"' _LH,I*¢ p:l: n _'1_'[ n" .1 ....... I_'-] E-'_ "-

\

Serial Number Model Number

,,4

16

© BSH Home Appliances Corporation 2005 • Litho U.S.A. 07/04

Page 17

Tabla de IVlaterias / Instrucciones Irnportantes

Instrucciones De Instalacibn Del Lavavajillas

IngleslFrancesiEspa£=ol

INSTRUCCIONES MUY IMPORTANTES

OBSERVE TODAS LAS ADVERTENCIAS Y PRE-

CAUCIONES para evitar posibles lesiones y

dahos a la propiedad. Estas instrucciones son

para el uso e×clusivo de instaladores calificados.

La lavadora debe ser instalada por un tecnico de

servicio o instalador calificado.

• Adem&s de estas instrucciones, se debe instalar

la lavadora para cumplir con todos los c6digos y

regulaciones electricas e hidraulicas (nacionales y

locales).

Lea completamente estas instrucciones de

instalacibn y cumpla con elias cuidadosamente.

Gui_ndose por elias, usted ahorrar_ tiempo y

empeSo, reducir& los riesgos y asegurar& un

desempe_o 6ptimo de su lavadora de platos.

Si se instala la lavadora en un lugar donde

hay temperaturas bajo cero (e.g., en una casa

vacacional), usted debe drenar toda el agua

desde el interior de la lavavadora.

LA GARANTiA NO CUBRE roturas del siste-

ma hidr_ulico como resultado de temperatu=

ras de congelamiento.

IMPORTANTE

• La manguera de desagee debe instalarse con

una secci6n por Io menos a una distancia de

20" (51 cm) del piso del gabinete, de Io contrario

la lavadora podria fallar en evacuar el agua

adecuadamente.

• El uso intencionado para esta lavadoras de platos

es en el ambiente residencial y no para usarse

en los establecimientos comerciales de servicios

alimenticios.

• INSTALACION NUEVA - si se instala una lava-

dora en el sitio por primera vez, la mayoria del

trabajo se realiza antes de acomodar la lavadora

en su sitio.

• REEMPLAZO - Siesta lavadora reemplaza

otra instalada anteriormente, inspeccione las

conexiones presentes para averiguar si se

prestan para la nueva y cambie piezas como Io

sea necesario.

• Este aparato cumple con la norma CAN/CSA-

C22.2 No. 167/UL 749. Es la responsabilidad del

propietario y del instalador determinar si aplican

requerimientos y normas adicionales en instala-

ciones especificas.

Inspeccionar la Lavadora de Platos

Despu_s de desempacar la lavadora y antes

de instalarla, inspeccione minuciosamente la

lavadora para averiguar de da_os cosm_ticos y

los que suceden durante el envio. Inf6rmenos

inmediatamente de cualquier da_o. Los da_os

cosm_ticos deben reportarse dentro de 30 dias de

la instalaci6n.

NOTA: No bote ninguna bolsa o articulos de

embalaje hasta que termine con la instalaci6n.

9000121319 REV B " 01/06

,J

1

Page 18

HERRAIVllENTAS NECESARIAS

Herramientas y IVlaterialesNecesarios

Martillo Sierra de Punta

Cinta de Medir

Destornillador Destornillador de Destornillador

Llave para Llave Ajustable

de Ranura Estrella tipo T-20

Alicates

Pelacables El_ctrico _-J

MATERIALES NECESARIOS

(Podria necesitar otros materiales para cumplir con los c6digos municipales)

Nivel

Cable de Alimentaci6n El_ctrica - M[nimo no. 14 AWG, 2 conductores, 1 de puesta a tierra,

conductores de cobre aislados clasificados para 75°C o mayor.

Tubo de Alimentaci6n de Agua - Minimo 3/8" di&metro exterior, tubo de cobre o manguera

con alambre trenzado para alimentar lavadoras de platos.

V&lvula de cierre y los accesorios adecuados para acoplarla a la alimentaci6n de agua

caliente (tubo de cobre con accesorios sujetadores de compresi6n o manguera con

:,o

alambre trenzado).

Acoplador acodado de 90ocon rosca exterior macho de 3/8" N.ET. en una extremidad, yen

la otra extremidad del tamafio adecuado para poder conectarlo a la alimentaci6n de agua

(tubo de cobre/accesorios sujetadores de compresi6n o manguera con alambre trenzado).

Cinta de la marca de f&brica del Teflon u otto sello de acoplamiento roscado para las

conexiones de agua.

Conector de Conducto o Alivio de Presi6n aprobados por UL [Underwriters Laboratory].

2

Page 19

MaterialesProvistos

iViATERIALES PROVISTOS

Accesorios que Proporcionamos

Las piezas de accesorios para su lavadora vienen en una o mas bolsas de pl_stico que se describen abajo.

NOTA: AsegQrese de guardar todas las bolsas hasta haber terminado la instalaci6n.

NOTA: Siempre utilice las piezas y herramientas incluidas o recomendadas.

f

Bolsa con juego del manual de uso y cuidado

Cada lavavajillas viene con un juego del manual de uso y

cuidado en una bolsa que incluye:

A Manual de usoycuidado

B Guia de referencia rapida (modelos selectos)

C Aspersor para piezas muy altas

D Tarjeta de la garantia

%, =4

Kit de instalaci6n de la lavadora

Cada lavadora viene con un kit de instalaci6n que incluye:

H Tornillos del panel de pie (2 tornillos negros)

Nota: Se incluyen estos tornillos, pero no se utilizan en

los modelos que incluyen el kit de instalaci6n del panel

de pie.

I Soportes de montaje en la cubierta (2 soportes metali-

cos en forma de una '1")

J Tornillos del soporte de montaje (2 tornillos para

madera)

K Adaptador de hule para la manguera de desag0e (1

tubo negro de hule)

L Abrazaderas de manguera (1 abrazadera de resorte

para fijar el adaptador de hule a la manguera de de-

sagQe y 1 abrazadera de tornillo para fijar el adaptador

de hule a la tuberia de agua)

M Conectores de alambre (3 para conexi6n el6ctrica)

N Tornillos de la caja de conexiones el_ctricas (1 tornillo)

O Tornillos de bloqueo de las patas niveladoras (2 tornil-

los gruesos, roscados)

* Bolsa con juego del manual de instalaci6n

Cada lavavajillas viene con un juego del manual de

instrucciones de instalaci6n en una bolsa que incluye:

E Instrucciones de instalaci6n

F Plantilla de montaje de puertas integradas para

paneles personalizados de puertas (modelos

selectos)

G Tira de aislamiento de algod6n blanco (modelos

selectos)

_ cional

tornillo(_

para

seleccionar

modelo

J

3

Page 20

Materiales Provistos

Kit de instalaci6n para paneles de puertas integradas

Se proporciona un kit de instalaci6n de paneles de puertas

para lavadoras selectas que utilizan un panel de puerta

personalizado de madera e incluye:

P Tomillos de tensi6n de resorte (2 tornillos grandes que

se usan para ajustar los resortes de las puertas para

acomodar puertas de diferentes pesos)

Q Soportes de montaje de puerta (2 soportes met_.licos

que se usan para fijar la puerta personalizada)

R Tomillos del soporte de montaje de puerta (6 tornillos

para madera)

S Tornillos de montaje de puerta (4 tornillos largos que se

usan para fijar la puerta)

T Tiras sujetadoras de gancho y lazo (2 tiras adhesivas)

Kit de instalaci6n del panel de pie

Un kit de instalaci6n del panel del dedo del pie se

proporciona en los selectos modelos. Estos modelos tienen

un ruido especial el reducir del panel del dedo del pie con el

hardware de montaje siguiente:

U Tornillos del panel de pie (2 tornillos negros que se usan

para fijar el panel met&lico de pie)

V Tornillos del panel de pl&stico de acceso inferior (2 tornil-

los que se usan para fijar el panel de pl&stico negro de

acceso inferior a la lavadora).

Nota: No se utitiza el tornitlo _H) en unidades que

tienen este kit.

4

(9--

Alli ser uno opcional tornillo(_ used en

(_"_ seleccionar modelo. Este nuevo tornillo

ser encontrar en lavaplatos instalaci6n

kit y etiquetar opcional tornillo(_).

,.)

Page 21

Reviseel

espacio libre

entrela puerta

de la lavadora

y la pared

9o/,

34" x IL/

(864mm)

minimum

23-5/8" - 24-1/4" (600-616 mm)

Ilustraci6n 1

Superficie

del

Contador

Preparaci6n del Gabinete

23-9/16"

(598mm)

Evite el riesgo de escaldadura y de

descarga el_ctrica

AsegQrese de apagar el suministro de agua y

la alimentaci6n el_ctrica antes de realizar la

instalaci6n o de dar el servicio.

PREPARACION DEL GABINETE

NOTA: Se diseffaron esta lavadora con la intenci6n de

encajarlas y asi cubrir la cara superior y ambos lados

con armarios convencionales para cocinas residenciales.

Escoja un sitio tan cerca del fregador como sea posible

para obtener un acceso f&cil a la fuente de agua y alas

cafferias de evacuaci6n.

Para realizar una operaci6n adecuada y presentar una

buena apariencia, cuide de que el gabinete est_ en

cuadro y que tenga las dimensiones que muestra la

Ilustraci6n 1.

Si instala la lavadora en un rinc6n, cuide de que la

puerta tenga bastante espacio libre para abrirla, tal

como indica en la Ilustraci6n 2.

Evite el riesgo de descarga ei_ctrica/fuego

No permita que se toquen las Ifneas el_ctricas

con las lineas de suministro de agua.

Ilustraci6n 2

ii i\\

Iiustraci6n 3

Si el gabinete requiere perforaciones para el cable

el_ctrico, el tubo de agua caliente y para la manguera

de desagee, sitQe _stos dentro de las dimensiones

sombreadas en la Ilustraci6n 3 para evitar que interfieren

con la armadura de la lavadora u otto componente. Las

perforaciones para el cable el_ctrico y el tubo de agua

caliente se hacen con un di&metro de 1" (2.5 cm). La

perforaci6n para la manguera de desagee se hace con

un di&metro de 1-1/4" (3+ cm). Despu_s de cortar la

madera lije las orillas hasta que queden lisas. Aumente

las dimensiones de las perforaciones a trav_s de metal

para poder acomodar algt3n ojal u otro tipo de arandela

protectora con un di&metro interior de 1" (2.5 cm) para el

cable el_ctrico y el tubo de agua caliente, y de 1-1/4" (3+

cm) para la manguera de desagee.

Page 22

30" 1

(762mm)

21"

(533mm)

Ilustraci6n 4

Preparaci6n=Sistema El_ctrico

PREPARACION - SISTEMA ELE_CTRICO

Evite el riesgo de descarga el_ctrica

No trabaje con un circuito activado. S61o

el_ctricos calificados deben realizar los trabajos

el_ctricos. No trate de realizar ningQn trabajo en

el circuito el_ctrico de la lavavadora hasta que

est_ seguro que el circuito est_ desactivado.

Evite el riesgo de fuego

Aseg_rese de instalar correctamente las

conexiones el_ctricas. S61o el_ctricos calificados

deben realizar los trabajos el_ctricos.

Corriente Electrica Nominal de la Lavadora

Voltios Hertzios

120 60

Amperios

12

Vatios

1,4.50

(max)

3"

(76mm

Alimentacibn El_ctrica

Le toca al cliente la responsabilidad de asegurarse

de que la instalaci6n del sistema el_ctrico para la

lavadora cumpla con todos los c6digos y ordenanzas

nacionales y municipales. La lavadora se disefi6 para

una fuente el_ctrica de 120V, 60 Hz, AC, conectada a

un circuito dedicado exclusivamente a la lavadora y con

puesta a tierra apropiada que cuenta con un fusible o

cortacircuitos de corriente nominal a 15 amperios. Los

conductores de electricidad deberAn tener cables de

cobre con un mfnimo de #14 AWG clasificados para

75°C (167°F) o mayor.

No obstante el sitio donde el cable de alimentaci6n

el_ctrica entra al gabinete, sitQe el cable a 21" (53 cm)

del lado izquierdo del gabinete, tal como indica en la

Ilustraci6n 4. Corra 30" (76 cm) del cable por la parte

trasera del gabinete, tal como indica en la Ilustraci6n 4.

Elimine de 3" a 4" (de 7.5 cm a 10 cm) del recubrimiento

protector exterior del cable, tal como indica en la

Ilustraci6n 5. Despu_s desforre de 3/8" a 1/2" (de 1 cm a

1.5 cm) de aislamiento de cada cable, tal como indica en

la Ilustraci6n 5.

3/8"- 1/2"

(10mm - 13mm)

J

Ilustraci6n 5

6

Page 23

v_lvula

___de cierre 14__" _--

alirnentaci6n

de agua //

cal_

Preparaci6n - SisternaPIorneria

PREPARACION DEL SISTEIVlA DE

PLOIVlERiA

Evite el riesgo de escaldadura

No realice ning_n trabajo en una Ifnea cargada

de agua caliente. No trate de realizar ningOn

tipo de trabajo en la Ifnea de suministro de agua

caliente a la lavadora hasta quedar seguro que el

suministro de agua caliente est_ apagado.

llustraci6n 6

Las temperaturas que se requieren para soldar y

condensar dahar_n la base y la v_ivula de entrada

de agua de la lavadora. Cuando se deben soldar

las Ifneas hidr_ulicas, mantenga la fuente de calor

a una distancia de al menos 6 pulgadas (152.4

ram) de la base y la vblvula de entrada de agua de

la lavadora.

Alimentaci6n de Agua Caliente

El calentador de agua se debe fijar a una temperatura

de 120° F (49° C). Por la razon es que agua demasiado

caliente puede causar que algunos detergente pierdan

efectividad y que con temperaturas bajas el cyclo de

lavado es mas largo. La presi6n de la alimentaciSn de

agua caliente debe registrar entre 15 y 145 psi (de 1 a

10 bar).

Sistema de Alimentacibn de Agua Caliente

En el tubo de alimentaci6n de agua caliente instale una

v_lvula de cierre (algo que no proporcionamos) de modo

que su acceso sea f&cil, tal como indica en la Ilustraci6n

6. Se deben terminar todas las conexiones soldadas

antes de conectar el tubo de agua a la v&lvula de entrada

de agua a la lavadora. Tambi_n se puede suministrar

agua a la lavavajilla por medio de una manguera

trenzada de acero inoxidable que esta aprobada para el

uso con lavavajillas. Consulte con sus proveedores de

piezas de plomeria para obtener los accesorios para las

caSerias y los acopladores acodados de 90°.

NOTA: No obstante el sitio donde el tubo de agua

caliente entre en el gabinete, sitQe el tubo a 14" (356

mm) del lado izquierdo del gabinete, tal como indica en

la IlustraciSn 6.

NOTA: Decida si o no va a usar una manguera trenzada

de acero inoxidable aprobada para tuberia de cobre o el

uso con lavavajillas para conectar el suministro de agua

caliente y compre el tipo correcto de la v&lvula de cierre

para el suministro de agua caliente, codo de 90° y las

conexiones necesarias para la conexi6n del suministro

de agua caliente.

Page 24

Tubode

. I ii i_ t 4t

llustraci6n 7

desag_Je

enY

Preparaci6n - Sistema PIomeda / Preparaci6n de la Lavadora

PREPARACION DEL SISTEIVIA DE

PLOMERiA (continUa)

Sistema de Evacuaci6n

Conexi6n del desag_e debajo del fregador

Si tiene la intenci6n de que la lavadora evac_e directa-

mente en el sistema de desagQe de la vivienda o a

traves de un dispositivo de ventilaci6n [air gap], instale

un tubo de desagQe en Y debajo del fregador, tal como

indica en la llustraci6n 7.

Instalacibn del Dispositivo de Ventilaci6n

Si las ordenanzas municipales requieren ventilaci6n,

tal como indica en la Ilustraci6n 8, instale el dispositivo

conforme a las instrucciones del fabricante.

Eliminador de Basura

Aseg_rese de quitar el tap6n de la conexi6n del desagQe

Ilustraci6n 8 a la lavavajillas del eliminador de basura. Yea Ilustraci6n

9,

PREPARACION DE LA LAVADORA

Se elaboran cuatro tareas en la preparaci6n de la

lavadora:

• Instalar los Soportes de Montaje

• Desmontar el Panel de Pie

• Instalar el Acoplador Acodado de 90°

• Preparar la Caja de Conexiones

llustraci6n 10

Ilustraci6n 9

Antes de instalar los soportes de montaje en la

cubierta que se incluyen, decida cubl m_todo va a

usar para fijar la lavadora en su espacio. Una vez

que se instalaron los soportes de montaje en la

lavadora, es dificil quitarlos y el intento de hacerlo

dahara los soportes de la lavadora.

Instalar los soportes de montaje en la cubierta

Se puede afirmar la lavadora en su gabinete por

medio de dos mdtodos:

1 El Montaje Superior se utiliza cuando el contador

tiene una superficie de madera u otro material f&cil de

perforar. Acomode los soportes de montaje tal como

indica en la Ilustraci6n 10 y sit0e la dos leng0etas

pequeSas de modo que cubran las dos ranuras

en los rincones delanteros de la lavadora. Oprima

firmemente hacia abajo los soportes de montaje

hasta introducir las leng0etas en sus ranuras.

2 El Montaje Lateral se utiliza para las superficies

de contador hechas de m&rmol, granito u otro

material muy duro que no se perfora f&cilmente.

Doble los soportes de montaje en linea con los

hoyos pequeSos yen la misma direcci6n como las

dos lengQetas pequeSas. Acomode los soportes de

J

montaje tal como indica en la Ilustraci6n 11 y sit0e

las dos lengQetas pequeSas encima de los soportes

de montaje sobre las dos ranuras en los rincones

delanteros de la lavadora. Oprima firmemente hacia

abajo los soportes de montaje para poder introducir

las lengQetas en las ranuras.

Evite el riesgo de volcadura

No use la lavavajillas hasta que est_ instalada

completamente. Cuando abra la puerta de una

lavadora no instalada, h_galo con mucho cuidado

\

Ilustraci6n 11

soportando la parte trasera del aparato. En caso

contrario usted puede sufrir lesiones serias.

8

Page 25

llustraci6n 12

Preparacibn de la Lavadora

" Preparacion de la Lavadora (continUa)

Cada vez que alguien quita alguna tapa o jala

la lavavajillas fuera del gabinete, conexiones

de corriente el_ctrica y bordes o puntas filosas

pueden quedar expuestas.

QUITAR EL PANEL DE PIE

Su lavavajillas incluye ya sea un panel de pie met&lico o

un panel de acceso bAsico de plAstico con panel de pie

metAlico (depende del modelo).

J

M_todo A - Panel de pie met_lico

El panel de pie est& ligeramente sujetado con cinta

adhesiva. Quite la cinta y separe el panel de pie de la

lavadora. Ponga el panel al lado. Usted Io reinstalar&

m&s tarde.

M_todo B - Panel de acceso b_sico de pl_stico con

panel de pie met_lico

El panel de pl&stico de acceso inferior (modelos selectos

y el panel de pie est&n en su posici6n en la lavadora,

pero no estan instalados. Quite el panel de pie primero,

como se indica en la Ilustraci6n 12, luego quite el panel

de pl&stico de acceso inferior, como se indica en la

Ilustraci6n 12.

Ilustraci6n 13

Ilustraci6n 14 Ilustraci6n 15

No apriete el codo de 90° demasiado. De Io

contrario se puede dahar la v_lvula de entrada de

agua y causar una fuga de agua.

COMO INSTALAR EL ACOPLADOR ACODADO DE 90°

NOTA: No se proporciona el acoplador acodado de 90 °

con la lavadora y por consiguiente se debe comprar

separadamente. Si usted decide usar tuberia de

cobre para alimentar el agua caliente, cuide de que

el acoplador cuente con un accesorio sujetador de

compresi6n.

Selle todas las conexiones roscadas con cinta de tefl6n o

compuesto sellador de rosca cuando sea necesario. See

Figure 13.

Oriente la otra extremidad que se conectar& a la

alimentaci6n de agua caliente hacia la apertura del canal

en la base de la lavadora.

Preparacibn de la Caja de Conexiones

1 Quite la tapadera de la caja de conexiones, la

Ilustraci6n 14, levantando y jalando la cubierta hacia

arriba.

2 Quite la placa de alivio de presi6n por medio de

extraer el tornillo de la parte trasera de la caja de

conexiones, como muestra en la Ilustraci6n 15, y

deslizar la placa de alivio de presi6n hacia afuera.

3 Ponga a un lado la tapadera de la caja de conexiones,

la placa de alivio de presi6n y el tornillo. Usted los

reinstalar& m&s tarde.

9

Page 26

Instalaci6n=Panelde la Puerta / Como Situar y Afirmar la Lavadora

25" _ 1/4" max.

(636 mm) nm) _,

< t

23-1/16"

(586 mm)

Ilustraci6n 16

,: q

Ilustraci6n 17

INSTALACION - PANEL DE LA PUERTA

Kits de accesorios para instalar paneles (modelos

selectos)

Este kit le permite instalar un panel personalizado (hasta

1/4" de grueso) en su lavavajillas. La Figura 16 muestra

las dimensiones del panel. Instale el panel antes de

deslizar la lavavajillas en su lugar. Contacte al servicio

al cliente para vet si existe un kit para su modelo y para

obtener instrucciones sobre c6mo hacer su pedido.

Modelos totalmente integrados

Los modelos totalmente integrados le permiten mandar

a hacer un panel de puerta totalmente personalizado

para hacer juego con sus gabinetes. La puerta

personalizada puede set una configuraci6n de dos

puertas para verse como un caj6n en la parte superior y

una puerta de gabinete en la parte inferior o como una

sola puerta. Se incluye una plantilla con los modelos

totalmente integrados para explicar el procedimiento de

montaje.

Ilustraci6n 18

Ilustraci6n 19

-- Ilus. 17 --

Dimensiones

A

B 23 3/16" - 23 3/8"

Dimensiones de paneles integrados para

paneles de puertas personalizadas

27 3/16" - 30 7/16"

(de 690 mm a 774 mm)

(de 589 mm a 594 mm)

COMO SITUAR LA LAVADORA

1 Enderece y acomode el tubo de alimentaci6n de

agua caliente y el cable de alimentaci6n el6ctrica

como muestra la Ilustraci6n 18 de modo que queden

en linea con sus propios canales en la base de la

lavadora.

2 Acomode la lavadora tan cerca del gabinete como

para poder conectar la manguera de desagQe de

la lavadora a la conexi6n de evacuaci6n debajo del

fregador. AsegQrese de que el tubo de agua caliente

y el cable el6ctrico est6n puestos en sus canales

respectivos bajo la base de la lavadora, tal como

indican en la Ilustraci6n 19.

3 Empuje la lavadora al espacio libre y aseg_rese que

la I[nea de suministro de agua caliente y el cable

de alimentaci6n el6ctrica queden en sus canales

apropiados.

10

LaIineadesuministr0de

aguacalienteyel cablede

alimentaci6nelectricasec010can

en10scanales.

Page 27

Conexi6n - Manguera de Desag_Je / Conexi6n de Agua Caliente

llustraci6n 20

b

Montajeen

superficie

Montajelateral

4

Asegt3rese de nivelar la lavadora. Ajuste el nivelador

trasero pot medio de darle vuelta al tornillo del centro

en la cara frontal de la lavadora, tal como indica en

la Ilustraci6n 20a. La parte trasera de la lavadora se

eleva a medida que se gire el tornillo en el sentido del

reloj. Ajuste los niveladores de frente por medio de

darles vuelta con un destornillador, tal como indica en

la Ilustraci6n 20b. La lavadora se eleva a medida que

los niveladores giran hacia la derecha. Si la lavadora

debe elevarse at3n m&s, introduzca calces debajo de

los pies de los niveladores.

COMO AFIRMAR LA LAVADORA

J

1 Atornille los tornillos de fijaci6n a traves de los

orificios en los soportes de montaje como se muestra

en la FJgura 21 para un montaje en superficie o para

un montaje lateral.

2 Despues de instalar la unidad en la abertura, nivelar

y fijarla, bloquee las dos paras delanteras de nive-

laci6n atornillando los dos tornillos fijadores de las

paras de nivelaci6n en cada recept&culo de tornillo

que se encuentran en el frente de las paras. Vea la

Ilustraci6n 22.

3 Apriete los tornillos hasta que queden al ras con la

superficie de los receptAculos.

f

Reborde

elevado

Jlustraci6n 21

Tornillofijador

dela patade

nivelaci6n

llustraci6n 22

\

Adaptador de hule para Ja

manguera de drenaje (corte Manguera de

Receptaculo

de tornillo

J

drenaje de Ja

rsal) lavavajillas

INSTALACION DEL ADAPTADOR DE HULE PARA LA

MANGUERA DE DRENAJE

1 Saque el adaptador de hule para la manguera de

drenaje y las dos abrazaderas de manguera del kit de

JnstalacJ6nde la lavavajillas (no los sustituye).

2 En un extremo exterior del adaptador de hule para

la manguera de drenaje se encuentra un reborde

elevado. Inserte la manguera de drenaje de la

lavavajillas en el extremo sin eJreborde elevado (vea

la FJgura 23). AsegQrese de Jnsertar la manguera de

drenaje completamente.

3 Asegure la conexi6n con la abrazadera de resorte

(vea Figura 24).

4 Use la abrazadera de tornillo para fijar el adaptador

de hule para la manguera de drenaje a la tuber[a de

drenaje de la casa (vea FJgura 24).

Reborde

elevado en la

parte exterior

del adaptador

de hule para

la manguera

de drenaje

Abrazadera

de tornillo

tuberJa de drenaje Inserte hasta que la man-

de lacasa guera de drenaje quede

bioqueada en su Jugar

Figure 23

Figure 24

J

11

Page 28

Cone×i6n de Agua Caliente

llustraci6n 25 llustraci6n 26

Ilustracion 27

Ilustraci6n 28

Manguera de

purga de aire

Conectar la manguera de desagiJe a la tu-

berfa de agua

La manguera de desagee puede conectarse segen uno

de cuatro m_todos:

1 Directamente a la conexi6n de evacuaci6n debajo del

fraegador, como muestra la Ilustraci6n 25.

2 Directamente a la conexi6n de evacuaci6n para

MIN. lavadoras de platos en un eliminador de basura, como

20" muestra la Ilustraci6n 26.

3 A la conexi6n de evacuaci6n debajo del fregador y a

trav_s de un dispositivo de ventilaci6n, como muestra

la Ilustraci6n 27.

4 A la conexi6n de evacuaci6n para lavadoras de

platos en un eliminador de basura y a trav_s de un

dispositivo de ventilaci6n, como muestra la Ilustraci6n

28.

Se puede averiguar informaci6n referente a la

-,, instalaci6n de dispositivos de ventilaci6n y de

eliminadores de basura en la secci6n Preparaci6n -

Plomerfa de este manual.

NOTAS IIVIPORTANTES:

Si se va a conectar la manguera de desagOe de la la-

vadora a la conexi6n de desagOe de una trituradora de

alimentos, quite el tap6n de la conexi6n de desagee

de la trituradora.

La manguera de desagee de la lavadora debe tener

un lugar a Io largo de su Iongitud, que quede fijado al

menos 20" (508mm) arriba del piso del gabinete.

Se puede extender la Iongitud de la manguera de

drenaje si es necesario. La m_xima Iongitud de

la manguera de drenaje, incluyendo la manguera

conduciendo al espacio de aire, es 150 pulgadas (381

era).

La manguera que aparece en la Figura 29 es una

abertura de ventilaci6n. Se debe dejar el extremo de

esta manguera en la base de la lavavajiNas. No haga

ningQn tipo de conexi6n a esta manguera.

CONEXION DE AGUA CALIENTE

12

No haga ningun tipo de

conexi6n a esta manguera

Ilustraci6n 29

Evite el riesgo de escaldadura

No realice ningen trabajo en una Ifnea cargada

de agua caliente. No trate de realizar ning_n

tipo de trabajo en la Ifnea de suministro de agua

caliente a la lavadora hasta quedar seguro que el

suministro de agua caliente est_ apagado.

NOTA: AsegQrese de que se instal6 el acoplador acoda-

do de 90° (algo que no proporcionamos) adecuado para

el tubo de aNmentaci6n de agua caliente a la lavadora tal

como descrito en la secci6n Preparaci6n de la Lavadora

en este manual.

Se puede conectar el tubo de agua caliente a la lava-

dora segQn uno de estos dos metodos:

J

1 Con una manguera con alambre trenzado

2 Con tuberfa de cobre

Manguera trenzada de acero inoxidable aprobada para

el uso con lavavajillas

Despu_s de realizar las conexiones, prenda el

suministro de agua caliente y revise si tiene fugas.

NOTA: Se pueden utilizar las mangueras trenzadas de

suministro de la lavadora para extender las Ifneas pre-

existentes de suministro de agua a la lavadora.

Page 29

Conexi6n de Agua Caliente / Conexi6n El_ctrica

Tubo de Cobre

Las ternperaturas que se requieren para soldar y

condensar da_ar_n la v_lvula de entrada de agua

de la lavadora. Cuando se deban soldar las Ifneas

hidr_ulicas, mantenga la fuente de calor a una

distancia de al menos 6 pulgadas (152.4 ram) de la

v_lvula de entrada de agua de la lavadora.

• Si decide usar acopladores soldados mas bien que los de

compresi6n, elabore todas las conexiones soldadas antes

de conectar la fuente de agua a la lavadora.

• Cuide de que el tubo de agua no este doblado o torcido de

modo que impide la corriente de agua.

• AsegOrese de usar un compuesto para rosca de tubo

o cinta de la marca de fabrica del Teflon para sellar la

conexi6n cuando sea necesario.

• Antes de conectar el tubo de cobre para el agua caliente

a la lavadora, enju&guelo con agua caliente para eliminar

cualquier material ajeno.

• Abra lafuente de agua para revisar la presencia de fugas

despu_s de realizar todas las conexiones.

NOTA: No use sellador para tubos en conexiones de presi6n.

CONEXION ELI_CTRICA

La placa de

llustraci6n 30

llustraci6n 31

alivio de

pres,on

del cable

Evite el riesgo de descarga el_ctrica

No trabaje con un circuito activado. S61o el_ctricos

calificados deben realizar los trabajos el_ctricos. No

trate de realizar ningen trabajo en el circuito el_ctrico

de la lavavadora hasta que est_ seguro que el circuito

est_ desactivado.

Evite el riesgo de fuego

Asegerese de instalar correctamente las conexiones

el_ctricas. S61o el_ctricos calificados deben realizar

los trabajos el_ctricos.

Instrucciones para la Puesta a Tierra

La lavadora debe estar propiamente puesta a tierra antes

de hacerla funcionar. La maquina debe estar conectada a

un sistema de cableo permanente puesto a tierra con un

dispositivo metalico. O de otro modo, se conecta el conductor

de tierra junto con los conductores del circuito a la borna de

puesta a tierra del equipo en la lavadora. Cuide de que la

lavadora est_ conectada a una puesta a tierra conforme a

todos los c6digos municipales o, en caso de que no exista un

c6digo local, seg0n Io que estipula el c6digo nacional el_ctrico

[NATIONAL ELECTRICAL CODE] en los Estados Unidos o

el c6digo canadiense [CANADIAN ELECTRIC CODE] C22.1-

la eltima edici6n en Canad& adem&s de cualquier c6digo

provincial/estatal, municipal o local pertinente.

1 Recoja la placa de alivio de presi6n e instale un

dispositivo de alivio de presi6n [strain reliel7 (algo que no

proporcionamos) en la apertura de la misma placa.

NOTA: Acomode el alivio de presi6n tal como indica en la

Ilustraci6n 30.

2 Corra el cable de alimentaci6n el_ctrica a trav_s del alivio de

presi6n, como muestra la Ilustraci6n 31. AsegOrese que el

revestimiento exterior del cable pase cerca de 1/2" (13mm) a

trav_s del prensacable.

3 Apriete los tornillos del alivio de presi6n.

4 Acomode la placa de alivio de presi6n por medio de

deslizarla hacia adentro de la caja de conexiones, y sujete la

placa con los tornillos que incluimos.

13

Page 30

Conexi6n El_ctrica/ Ajuste de Tensi6n de la Puerta / Basey Panel de Pie

. CONEXI6N ELI_CTRICA (continUa)

Evite el riesgo de fuego

Asegerese que no haya ninguna cone×i6n

el_ctrica suelta. Aseg_rese que se hicieron todas

las conexiones el_ctricas correctamente.

• No tuerzo los cables de alimentaci6n el_ctrica

cuando con los conecta con los capuchones de

Ilustraci6n 32

Ilustraci6n 33

rosca.

• Extendia los cables de conductores trenzados en

la lavadora que miden 1/8" (3 mm) fuera del cable

de alimentaci6n el_ctrica con conductores s61idos

(o enterizos), como muestra la Ilustraci6n 32.

5 Utilice los capuchones de rosca que proporcionamos

para conectar los cables de alimentaci6n el_ctrica

a los cables de la lavadora, negro con negro,

blanco con blanco y verde o desforrado al verde o

al desforrado. Cuide de que no se pueda ver cable

desforrado en las conexiones con capuchones.

Ligeramente jale los cables para asegurarse de que

est_n fuertemente conectados.

6 Meta los cables a presi6n a la caja de conexiones

como se muestra en la Figura 33. AsegQrese que los

conectores de alambre no est_n flojos.

7 Acomode la tapadera en la caja de conexiones y

suj_tela con el tornillo que proporcionamos.

Ilustraci6n 34

AJUSTE DE TENSION DE LA PUERTA

(solamente en los modelos integradas con

paneles de puertas personalizados)

Despues de instalar la lavadora y el panel de la puerta

personalizado, abra y cierre la puerta varias veces para

asegurar su buen funcionamiento. Si se abre la puerta

muy rapidamente, es necesario ajustar la tensi6n del

resorte.

Cbmo Ajustar la Tensibn del Resorte:

10btenga los tornillos de resorte de tensi6n de la

bolsa de piezas para los modelos integradas.

2 Introduzca los tornillos como muestra la Ilustraci6n

34. Dele vuelta al tornillo en el sentido del reloj para

aumentar la tensi6n del resorte.

Instalaci6n del panel de pie

M_todo A - Instalaci6n del Panel de Pie

Use los tornillos del panel de pie incluidos en el Juego

de Instalaci6n de la Lavadora para instalar el panel de

pie, como muestra la Nustraci6n 35.

14

Ilustraci6n 35

Page 31

Ilustraci6n 36

BaseyPaneldePie/ Instrucciones Finales

-- BASE Y PANEL DE PiE (ContinUa)

M_tado B =Instalacion del panel de pl_stico de

acceso inferior y del panel de pie (selectos modelos)

1 Coloque el panel de pID.stico de acceso inferior

debajo y hacia arriba del panel inferior delantero de la

lavadora como se indica en Ilustraci6n 36a.

2 Inserte los tornillos del panel de plastico de acceso

inferior en el panel de pID.stico como se indica en

Nustraci6n 36b. Apriete los tornillos del panel de

pID.stico de acceso inferior.

3 Coloque la tira de aislamiento de algod6n debajo

de la unidad, entre la base del panel de plD.stico de

acceso inferior y el piso como se indica en Ilustraci6n

36c.

4 Fije el panel de pie al panel de plastico de acceso

inferior utilizando los tornillos para el panel de pie que

se incluyen con el kit de instalaci6n del panel de pie.

Vea la Ilustraci6n 36d.

NOTA: En estos modelos usted no va a utilizar los

tornillos normales para el panel de pie que se incluyen

en el kit de instalaci6n de la lavadora.

INSTRUCCIONES FINALES

En algunas condiciones, se puede format gas

hidr6geno en un sistema de agua caliente que no

se ha utilizado durante sernanas. El gas hidr6g=

eno es explosivo. Antes de Ilenar una lavadora de

un sisterna que no se ha utilizado pot sernanas,

abra una Ilave de agua cerca de la lavadora en un

_rea bien ventilada basra que se deja de oir algen

sonido o basra que no haya ninguna evidencia de

la presencia de gas.

1

Energice el circuito de alimentaci6n electrica a la

lavadora.

2

Consulte el Manual de Uso y Cuidado de la Lavadora

de Platos y corra la lavadora por todo un ciclo

completo. Si la lavadora no funciona adecuadamente,

consulte la secci6n Autoayuda del Manual de Uso

y Cuidado. Si todavfa no funciona debidamente,

consulte la secci6n Servicio al Cliente del Manual de

Uso y Cuidado.

15

Page 32

Servicio ai cliente

Su lavavajillas no requiere atenci6n especial diferente

del que se describe en la secci6n de cuidado y

mantenimiento del manual de uso y cuidado. Si tiene

alg0n problema con su lavavajilla, consulte la secci6n

de autoayuda en el manual de uso y cuidado antes de

Ilamarnos y solicitar ayuda. Si se necesita servicio,

p6ngase en contacto con su distribuidor o instalador

o con un centro de servicio autorizado. No trate

de reparar el aparato usted mismo. Todo trabajo

realizado por personas no autorizadas puede invalidar

la garantia.

r, l [o llJI ,Io]

Quitar alguna tapa o jalar la lavavajillas fuera

del gabinete puede exponer conexiones de

agua caliente, de corriente el_ctrica o bordes

o puntas filosas.

Si usted tiene alg0n problema con su lavavajillas y

no esta contento con el servicio que haya recibido,

tome los siguientes pasos por favor (en el orden

listado abajo) hasta corregir el problema a su entera

satisfacci6n:

1. Contacte a su instalador o al contratista de

servicio autorizado en su Area.

2. Mandenos un correo electr6nico. Consulte su

manual de uso y cuidado para las instrucciones.

3. Escribanos a la siguiente direcci6n:

BSH Home Appliances, Corp.

5551 McFadden Avenue

Huntington Beach, CA 92649

, Llamenos al nQmero de telefono del servicio al

cliente que aparece en la etiqueta en el borde

derecho de la puerta de la lavavajillas como se

muestra en la Figura 37.

AsegOrese por favor de incluir (si esta escribiendo)

o tener a la mano (si esta hablando) la siguiente

informaci6n:

• NOmero de modelo

NOmero de serie

Fecha de la compra original

Fecha cuando se origin6 el problema

Explicaci6n del problema

Usted podra encontrar la informaci6n sobre el n0mero

de modelo y el nQmero de serie en la placa (etiqueta)

que se encuentra en la orilla derecha de la puerta de

la lavavajillas tal como se muestra en la Figura 37.

Ademas, si nos escribe, favor de incluir un nQmero

telef6nico donde Io podamos Iocalizar durante el dia.

Por favor saque una copia de su factura y guardela

junto con este manual. El cliente debe mostrar un

comprobante de compra para obtener el servicio de

garantia.

16

Figura 37

N0mero de telefono del servicio al cliente

Placa/Etiqueta con el N0mero de

Modelo y el NOmero de Serie

NOmero de Serie NOmero de Modelo

© BSH Home Appliances Corporation 2005 • Litho U.S.A. 07/04

Loading...

Loading...