Installation Instructions

DS422i and DS426i Dual Beam Photoelectric

Intrusion Detection Systems

1.0 Specifications

• Range: Indoors Outdoors

DS422i 300 ft. (90 m) 100 ft. (30 m)

DS426i 600 ft. (180 m) 200 ft. (60 m)

• Dimensions (HxWxD): 6.75 in. x 3.25 in. x 3.5 in.

171 mm x 82 mm x 87 mm

• Voltage: 12 to 28 VDC. Non-Polarized.

• Current: Transmitter Receiver

DS422i 15 mA 25 mA

DS426i 30 mA 25 m A

• Standby: Intended for connection to DC power

supplies capable of supplying power if

primary power fails.

• Relay: Alarm activated Form “C” with dry

contacts rated at 0.5 amps max. @

30 VAC and DC.

• Tamper: Normally Closed with cover in place.

• Pointability: The optical module can be adjusted

±90° horizontally or ±24° vertically.

• Temperature: -13°F to +130°F (-25°C to +55°C).

• Trigger Response Time:50 to 700 milliseconds, selectable.

2.0 Installation Considerations

• Stay within the listed maximum range.

• Install the system with a clear line-of-sight between the transmitter

and receiver. If installed outdoors, make sure trees, weeds, plants,

etc. will not interfere with the beams.

• Use care when installing near reflective surfaces (i.e. glossy walls

or floors). Care should be taken during alignment to ensure beams

are line-of-sight aimed and are not reflecting off surfaces.

• Do not install the units where they may be immersed in water or

subject to corrosive liquids or sprays.

• Do not install the receivers where they will be facing an intense

source of light (e.g. a rising or setting sun). If the sun can not be

avoided, mount the receiver slightly higher than the transmitter. Aim

the receiver down at the transmitter.

• Do not install the receivers where sunlight could be reflected directly

into the receiver optics.

• Do not install either unit on movable surfaces or surfaces subject to

strong vibrations.

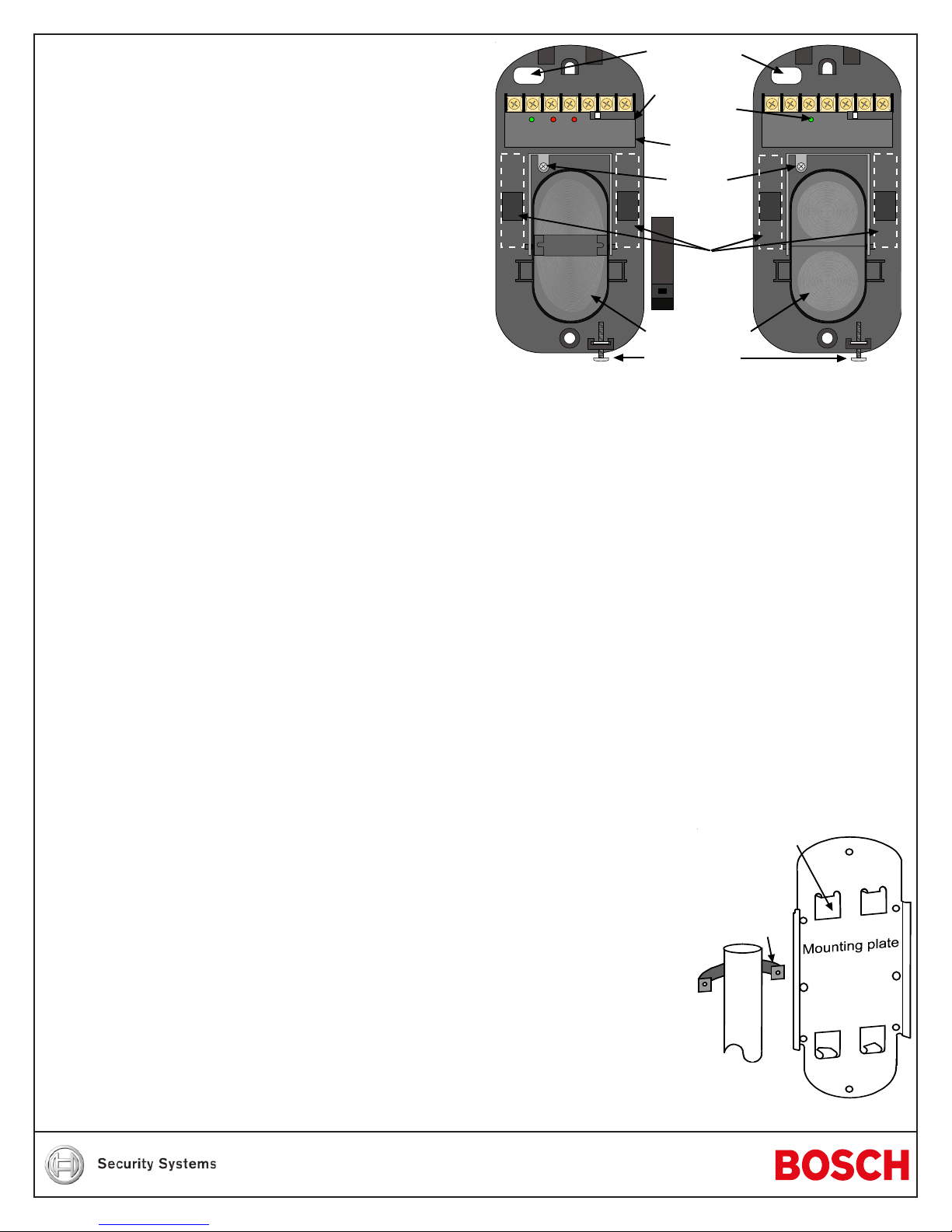

Wire Entrance

Response

Adjustment

Power LED

LEVEL ALARMGOOD

ACTIVE INFRARED SENSOR

Alignment

Voltage

POWER

ACTIVE INFRARED SENSOR

Jacks

Vertical

Fine Tuning

Screw

Alignment

Tool

Note:

Tool

may be in

any of four

positions

Optical Module

Receiver

Cover Screws

Transmitter

Figure A - Location of the system’s major items.

• Place the provided template onto the mounting surface and mark

the holes for its two mounting screws (supplied).

NOTE: Be sure all wiring is unpowered before routing.

• Route wiring (for wire size see Section 4.0) through the transmitter’s

wire entrance, leaving enough to properly wire the transmitter.

• Mount the transmitter to the mounting surface. Firmly tighten the

screws.

• Repeat this complete mounting procedure for the receiver. Be sure

to mount the receiver in direct line-of-sight with the transmitter.

3.2 Pole Mounting

NOTE: The recommended mounting height is 3 feet (1 m). However,

mounting height will change depending on the anticipated

intruder catch area.

NOTE: Use optional MB series poles or equivalent.

• Choose the appropriate mounting location. Install the poles with a

clear line-of-sight between the transmitter and receiver.

• Remove the transmitter’s cover by loosening the Cover Screw (see

Figure A).

• Firmly attach a mounting plate and U-clamp to the pole (see Figure

B) with the screws supplied. Make sure they are line-of-sight aimed

so the transmitter and receiver will be aligned.

Wiring Entrance

3.0 Mounting

3.1 Surface Mounting

NOTE: The recommended mounting height is 3 feet (1 m). However,

mounting height will change depending on the anticipated

intruder catch area.

• Choose the appropriate mounting locations. They should be rigid

and provide a clear line-of-sight between the transmitter and receiver.

• Remove the transmitter’s cover by loosening the cover mounting

screw (see Figure A).

U-clamp

Figure B - Pole assembly

NOTE: Be sure all wiring is unpowered before routing.

12 5634 7

)

• Route wiring (for wire size see Section 4.0) through the mounting

plate wire entrance (see Figure B), leaving enough to properly wire

the transmitter.

• Route the wiring through the transmitter’s wire entrance.

• Slide the transmitter onto the mounting plate. Tighten with the

mounting plate-to-unit screws.

• Repeat this complete mounting procedure for the receiver. Be sure

to mount the receiver in direct-line-of sight with the transmitter.

4.0 Wiring

Only apply power after all connections have been made

and inspected.

• Use the following chart (Figure C) to determine the minimum gauge

wire needed per length of wire run between the power source and

the last unit on the run. The chart is based on one system (one

transmitter and one receiver) connected to the same wire run from

the power source.

If more than one system is added to the run, the maximum length

per gauge decreases and is determined by dividing the length found

in the chart by the number of systems on the run.

DS422i Wiring Chart

SIZE

24 AWG(0.6mm)

22 AWG(0.8mm)

20 AWG(1.0mm)

18 AWG(1.2mm)

12 VDC

920 ft. (280m)

1,640 ft . (5 00m)

2,560 ft . (7 80m)

3,675 ft. (1120m)

24 VDC

790 ft. (240m)

1,440 ft. (440m)

2,300 ft. (700m)

3,280 ft. (1000m

5.0 Setup and Alignment

NOTE: Precise, correct alignment is a critical process for these

systems to operate effectively.

• Apply power to the units.

• Check the transmitter. The Power LED (see Figure A) should be

on. If the lamp is not on, the unit is not receiving power.

• Locate the Alignment Tool (see Figure A) on either the Transmitter

or Receiver.

• Slide the Alignment tool up and out of its holder (see Figure F) and

slide it onto the Alignment Mount on whichever side of the

Transmitter is most convenient for sighting through the viewfinder.

T

AR

NS

I

M

TT

ER

S

E

N

S

OR

LOT.

1

2

3

DS426i Wiring Chart

SIZE

24 AWG(0.6mm)

22 AWG(0.8mm)

20 AWG(1.0mm)

18 AWG(1.2mm)

• Wire the receiver and transmitter terminal strips (see Figures D and

E).

12 VDC

820 ft. (250m)

1,410 ft. (430m)

2,230 ft. (680m)

3,215 ft. (980m)

1,250 ft. (380m)

2,000 ft . (6 10m)

2,850 ft . (8 70m)

Figure C - Wire chart

24 VDC

690 ft. (210m)

12 5634 7

+

POWER ALARM TAMPER

Figure D - Receiver Wiring

+

POWER

TAMPER

Figure E - Transmitter Wiring

4

Figure F - Positioning the Alignment Tool

• From the side of the unit, look into the viewing port at the mirror.

The view in the mirror is what is in line-of-sight of the optical module.

NOTE: Alignment may be made easier with the use of an alignment

light (see Section 8.0).

• Rotate the optical module until the

image of the other unit is centered

in the mirror (see Figure G). If

initially aimed too high or low, adjust

the Vertical Fine Tuning screw (see

Figure A) until the unit is centered.

• Repeat this complete alignment sequence for the receiver’s optical

module.

• When properly aligned the Receiver’s green GOOD LED should be

lit.

6.0 Fine-tune Alignment

Meter readings are very important in providing maximum trip-safety

margins (see Figure H). A 20,000 Ohm/volt (or greater) DC VOM is

recommended.

When fine-tuning the transmitter and receiver, maximum meter

readings occur at the transmitted beam’s center, which is also the

receiver’s line-of-sight. A reduction in the system’s effectiveness will

occur if the units are not properly aligned and fine-tuned.

Figure G - Image in mirror

Page 2 © 2004 Bosch Security Systems DS422i/426i Installation Instructions

7.1 Alarm response time

SETTING

RESPONSE

TIME (ms)

RESPONSE

SPEED

CATCH

EXAMPLE

1

50±25% 23 ft./s (7 m / s) runni ng

2

210±25% 4 ft./s (1.2 m/s) jogging

3

380±25% 2.3 ft./s (0.7 m/s) quick walk

4

540±25% 1.6 ft./s (0.5 m/s) walking

5

700±25% 1 ft./s (0.3 m/s) slow walk

The system’s sensitivity to alarms is manually adjusted by the

RESPONSE TIME Control on the receiver (see Figure L1 and Table

Receiver's Line-of-Sight

L2).

Response Time

Transmitted Beam

Transmitted Beam strength is

strongest along this path

Transmitted Beam weakens

farther from its center

Control

-

+

R

E

E

C

I

ER

V

LEVEL

Figure L1 - Response Time Control

2

1

RESPONSE

3

TIME

4

5

Figure H - Beam Strength Area

• Set the meter to read 3 to 5 VDC.

• Fine peak the transmitter. Connect the meter to the receiver’s test

terminals (see Figure J).

-

+

R

E

E

C

I

V

ER

LEVEL

3

2

1

RESPONSE

TIME

4

5

Table L2 - Response Settings

NOTE: Observe the Polarity

due to DC voltage.

A setting near 1 will alarm if a person runs through the beam while a

setting near 5 will alarm for objects moving very slowly through the

beam. The setting should be adjusted lower where birds, debris,

etc., may interrupt the beam path. Be careful not to adjust the setting

too low, or it will not trigger an alarm.

NOTE: In order to comply with the requirements in UL 639, Intrusion

Figure J - Meter connection

• Rotate the transmitter’s optical module very slightly to the right and

left until a maximum meter reading has been achieved. If you cannot

obtain a reading greater than 2.3 VDC, the Transmitter and Receiver

must be realigned using the procedure in section 5.0.

NOTE: To aid in fine-tuning the system, the red LEVEL LED gets

brighter as the units get fine-tuned and the green GOOD

LED will be on when the meter readings reach a peak.

• Adjust the transmitter’s Vertical Fine Tuning screw slightly until

maximum meter readings have again been achieved.

• With the transmitter’s optical module fine-tuned, repeat this exact

process with the receiver.

7.0 Final Check

• Walk through the beams after the desired setting has been chosen.

• Walk through the beams in several locations between the units

• The system should alarm

• Replace the covers.

NOTE: If a tamper circuit

Detection Units, an object passing through the beams at a

speed of 8.8 feet per second (2.7 m/s) must trigger an alarm.

Be sure the system alarms at the desired pace.

(see Figure M).

during each crossing of the

beam. If not, re-check

alignment or trigger

response time.

Figure M - Walk testing the

system

has been installed, it should be tested now by lifting up the

• Completely block the upper beam on the transmitter. Neither the

ALARM LED nor the LEVEL LED should come on. If either does

come on, the beams are incorrectly aligned (see Figure K) and

should be re-aligned.

• Secure the covers by tightening each cover mounting screw.

8.0 Other Information

appropriate covers.

8.1 Alignment Lights

Alignment may be made easier by using a flashing high intensity

light placed in front of the units. This makes a very distinct target

when looking at the other unit through the viewing port. A

recommended light source is model AL402.

8.2 Maintenance

At least once a year the front covers should be cleaned. Use a clean

cloth and a common window cleaner.

On a daily basis, the end user should walk through the beams before

• Completely block the lower beam of the transmitter. Again, neither

the ALARM LED nor the LEVEL LED should come on.

• If necessary, re-align and fine-tune each unit.

DS422i/426i Installation Instructions © 2004 Bosch Security Systems Page 3

Figure K - Mis-aligned beams

arming. This will verify operation.

9.0 Application Tips

R

1

2

T

R

1

2

R

2

3

1

R

1

2

When using photoelectric detectors for motion detection, there are a

few installation techniques that will make the system more versatile.

9.1 Beam Stacking

Beam stacking gives a wall

of protection by stacking

several units at different

heights and providing an

T1

R

alarm activation on the

blockage of only one pair of

S

beams (see Figure N for the

correct set-up technique).

Note that the system is

installed with alternating

transmitters and receivers at

R2

D

T

each end. This eliminates the

possibility of a receiver being

covered by more than one

Figure N - Beam stack method

transmitter.

The maximum spacing between receivers (S) can be calculated by

dividing the distance between the transmitter and its receivers (D) by

20.

Therefore, if the distance between a transmitter and receiver is 100

ft. (30 m), the maximum spacing between receivers would be 100 ft.

(30 m) ÷ 20, or 5 ft. (1.5 m)

S = D/20 S = 100 ft. (30 m)/20 S = 5 ft. (1.5 m)

A potential problem when installing systems in a beam stack is “Near

Field Reflection.” Near field reflection is caused when a reflective

object is placed in the line-of-sight of the detectors and causes the

transmitted signal to be reflected to the wrong receiver (see Figure

P).

9.2 Perimeter Protection

When protecting the interior of an installation, a good technique is to

mount the units at 90° angles around the coverage area (see Figure

R).

R4

T1

3

T4

T2

R

T

R2

Figure R- Perimeter protection

Note that the beams are mounted so they cross each other. This way,

an intruder can not enter the area by walking between the units.

When installing multiple transmitters and receivers, test with all the

receivers powered-up, but with only one transmitter powered-up at a

time. A transmitter should set up only its receiver.

Receivers physically too close to a different system’s transmitters

may be set up even if the transmitter is not pointed at them (see

Figure T).

T1

2

R

T

Figure P - Near field reflection

It may be desirable to have more than two sets of beams to create

taller stacks. This can be accomplished by adding receivers as shown

in Figure Q). Note that the beam from each transmitter is covering

two receivers.

1

R

3R

4

Figure Q - Multi-system stack

© 2004 Bosch Security Systems

130 Perinton Parkway, Fairport, New York, USA 14450-9199

Customer Service: (800) 289-0096; Technical Support: (888) 886-6189

T

Figure T - Close proximity field problem

If a receiver is being set up by the wrong transmitter, the signals can

usually be eliminated by masking the sides of the transmitter and

receiver. Use electrician’s tape or duct tape inside each enclosure’s

window.

When installing these systems, remember that the infrared signal may

reflect off objects (e.g. glossy walls or floors) in the coverage area and

still set up the receiver.

A thorough walk test performed at several different points within the

coverage area will catch this problem. Re-aligning the units should

solve this problem.

The only way to insure proper continual protection is to perform

regular walk tests of the desired coverage area.

03/04

DS422i/DS426i Installation Instructions

P/N: 44974D Page 4

Loading...

Loading...