Bosch Rexroth A7VO 63 User Manual

Axial piston variable pump

A7VO Series 63

RE 92202

Edition: 02.2015

Replaces: 05.2012

▶ Sizes 28 to 160

▶ Nominal pressure 350bar

▶ Maximum pressure 400bar

▶ Open circuit

Characteristics

▶ Variable pump with axial tapered piston rotary group of

bent-axis design, for hydrostatic drives in open circuit

▶ For use in mobile and stationary applications

▶ Flow is proportional to the drive speed and displace-

ment.

▶ The flow can be steplessly changed by adjusting the

bent axis.

▶ Wide selection of control devices

▶ Compact, robust pump with a long service life

Contents

Ordering code 2

Hydraulic fluids 4

Shaft seal ring 5

Flow direction 5

Operating pressure range 6

Technical data 7

LR – Power controller without power override 9

LA1 – Power controller with hydraulically

proportional power override 13

DR – Pressure controller 15

HD – Proportional hydraulic control 18

EP – Proportional electric control 20

Dimensions, size 28 21

Dimensions, size 55 24

Dimensions, size 80 28

Dimensions, size 107 32

Dimensions, size 160 36

Connector for solenoids 40

Installation instructions 41

Project planning notes 42

Safety instructions 42

RE 92202/02.2015, Bosch Rexroth AG

2 A7VO Series 63 | Axial piston variable pump

Ordering code

Ordering code

01 02 03 04 05 06 07 08 09 10 11 12 13

A7V O / 63 – V B 01

Axial piston unit

01 Bent-axis design, variable, nominal pressure 350 bar, maximum pressure 400 bar

Operating mode

02 Pump, open circuit

Size (NG)

03

Geometric displacement V

For sizes 250, 355 and 500, see data sheet 92203

Control device 28 55 80 107 160

04 Power controller without power override ● ● ● ● ●

with pressure cut-off ● ● ● ● ●

with stroke limiter negative control

with pressure cut-off and stroke limiter negative control

with pressure cut-off and load sensing – ● ● ● ● LRDS

Power controller with hydraulically proportional power override

(only available for clockwise rotation and with port plate 02)

with load sensing – ● ● – – LA1S

with load sensing and hydraulically proportional LS-override – ● ● – – LA1S5

Pressure controller ● ● ● ● ●

remotely controlled ● ● ● ● ●

with load sensing – ● ● ● ●

Proportional control hydraulic Positive control

with pressure cut-off, remotely controlled Positive control

Proportional control electrical

(cm3), see “Technical data” on page 7

g

Positive control

Δp = 25 bar

Δp = 25 bar

Δp = 10 bar

Δp = 10 bar

U = 24 V

28 55 80 107 160

– ● ● ● ●

– ● ● ● ●

● ● ● ● ●

● ● ● ● ●

● ● ● ● ● EP2

A7V

O

LR

LRD

LRH

LRDH1

DR

DRG

DRS

HD1

HD1G

Series

05 Series 6, index 3

Direction of rotation

06 Viewed on drive shaft clockwise ●

counter-clockwise ●

Sealing material

07 FKM (fluoroelastomer)

Drive shaft

08 Splined shaft DIN 5480 ●

Parallel keyed shaft according to DIN 6885 ●

Mounting flange

09 ISO 3019-2; 4-hole

Port plate for working lines

10 SAE flange ports A and S at rear (metric fastening thread)

SAE flange ports A and S at side (available for power controllers LA1S and LA1S5 only, metric fastening thread)

● = Available – = Not available = Preferred program

63

28 to 160

R

L

V

28 to 160

Z

P

B

01

02

Bosch Rexroth AG, RE 92202/02.2015

Axial piston variable pump | A7VO Series 63

Ordering code

01 02 03 04 05 06 07 08 09 10 11 12 13

A7V O / 63 – V B 01

Connector for solenoids1) (see page 40)

11 Without connector (without solenoid, with hydraulic control only; without code)

DEUTSCH molded connector, 2-pin – without suppressor diode P

Standard / special version

12 Standard version (without code)

Special version

● = Available – = Not available = Preferred program

Notes

▶ Note the project planning notes on page42!

▶ Preservation:

– Up to 12 months as standard

– Up to 24 months long-term

(state in plain text when ordering)

3

-S

1) Connectors for other electric components may differ

RE 92202/02.2015, Bosch Rexroth AG

4 A7VO Series 63 | Axial piston variable pump

Hydraulic fluids

Hydraulic fluids

The A7VO variable pump is designed for operation with HLP

mineral oil according to DIN 51524.

Application instructions and requirements for hydraulic

fluids should be taken from the following data sheets

before the start of project planning:

▶ 90220: Hydraulic fluids based on mineral oils and

related hydrocarbons

▶ 90221: Environmentally acceptable hydraulic fluids

▶ 90222: Fire-resistant, water-free hydraulic fluids

(HFDR/HFDU)

▶ 90223: Fire-resistant, water-containing hydraulic fluids

(HFC, HFB, HFAE, HFAS)

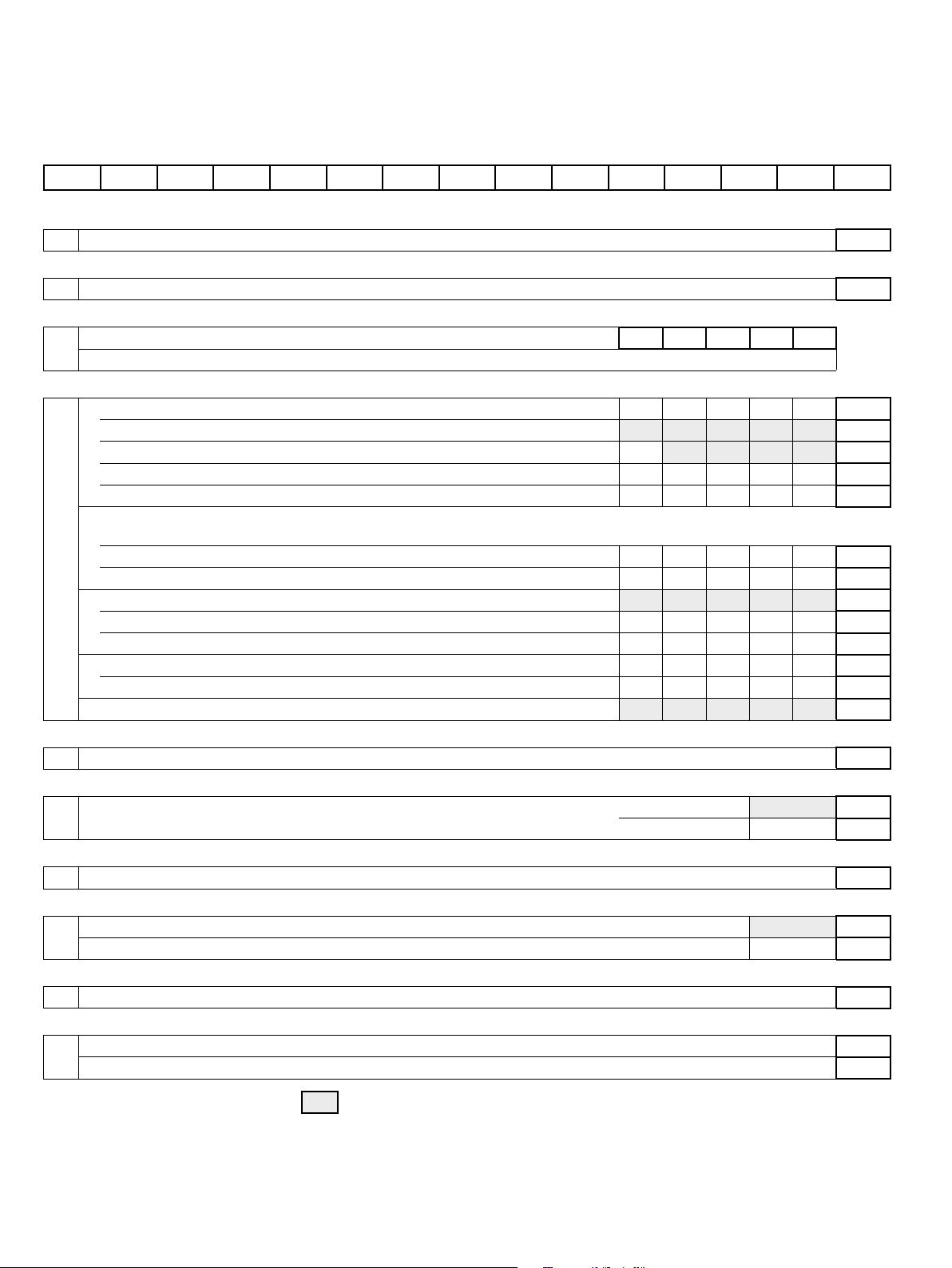

Viscosity and temperature of hydraulic fluids

Viscosity Temperature Comment

Cold start

Permissible temperature difference

Warm-up phase

Continuous operation

Short-term operation

ν

≤1600mm2/s θSt≥-40°C t≤3min, n≤1000rpm, without load p≤50 bar

max

ΔT≤25K

2

ν<1600 to 400mm

ν=400 to 10mm

ν

=36 to 16mm2/s

opt

≥7mm2/s t<3min, p<0.3×p

ν

min

/s θ=-40°C to -25°C at p≤0.7×p

2

/s

θ=-25°C to +103°C

Details regarding the selection of hydraulic fluid

The hydraulic fluid should be selected such that the

operating viscosity in the operating temperature range is

within the optimum range (ν

, see selection diagram).

opt

Note

At no point of the component may the temperature be

higher than 115 °C. The temperature difference specified in

the table is to be taken into account when determining the

viscosity in the bearing.

If it is not possible to maintain the conditions above due to

extreme operating parameters, we recommend flushing the

case at port U.

between axial piston unit and hydraulic fluid in the system

, n≤0.5×n

nom

This corresponds, for example on the VG46, to a temperature

range of +5°C to +85 °C (see selection diagram)

measured at port R

Note the permissible temperature range of the shaft seal

(ΔT=approx.12K between the bearing/shaft seal and port R

Range of optimum operating viscosity and efficiency

1/R2

nom

and t≤15min

nom

1/R2

)

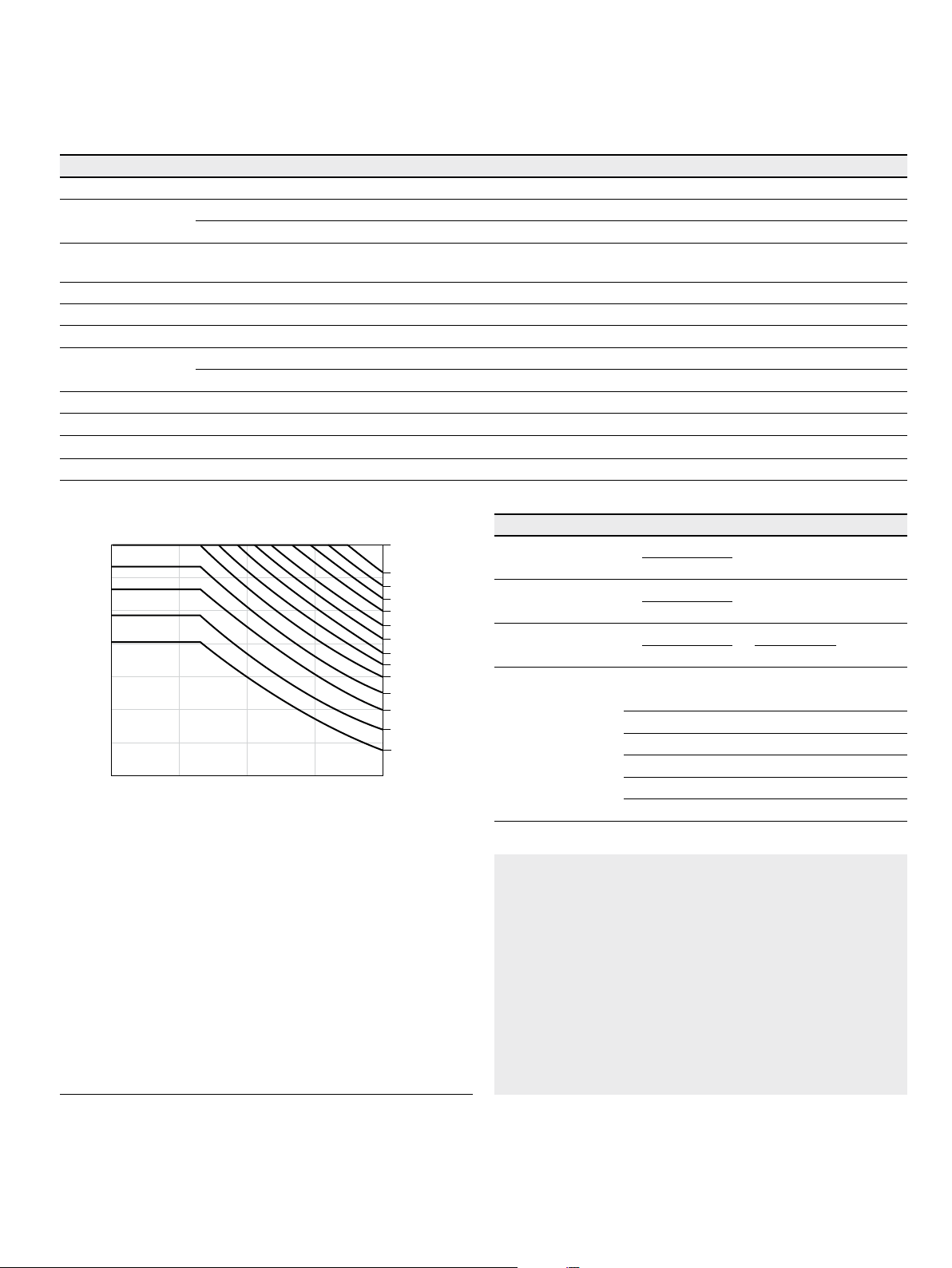

▼ Selection diagram

Maximum permissible viscosity for cold start

Range of optimum operating viscosity v

Optimum efficiency

Minimum permissible viscosity for short-term operation

Minimum permissible temperature for cold start

opt

1600

1000

600

400

200

100

Continuous operation

Warm-up phase

VG 100

VG 22

60

40

36

20

16

10

7

-40 -25 -10 10 30 50 90 11570

VG 68

VG 46

VG 32

0

Temperature θ [°C]

/s]

2

Viscosity v [mm

Bosch Rexroth AG, RE 92202/02.2015

Axial piston variable pump | A7VO Series 63

Shaft seal ring

5

Filtration of the hydraulic fluid

Finer filtration improves the cleanliness level of the hydraulic fluid, which in turn increases the service life of the axial

piston unit.

A cleanliness level of at least 20/18/15 is to be maintained

according to ISO 4406.

At very high hydraulic fluid temperatures (90°C to maximum 103°C, measured at portR

) a cleanliness level is

1/R2

necessary of at least 19/17/14 according to ISO 4406.

Leakage

The case interior is connected to the suction chamber. A

separate case drain line from the case to the reservoir is

therefore not required (both R ports are plugged).

Exception: For versions with pressure controller or pressure

cut-off, a drain line is needed to relieve port T

to the

1

reservoir.

Shaft seal ring

Permissible pressure loading

The service life of the shaft seal is influenced by the speed

of the axial piston unit and the leakage pressure in the

housing (case pressure). Momentary pressure spikes

(t<0.1s) up to 10bar are allowed. The service life of the

shaft seal decreases with increasing frequency of pressure

spikes and increasing mean differential pressure.

The case pressure must be equal to or higher than the

ambient pressure.

5

NG28

4

NG55

3

2

1

Differential pressure ∆p [bar]

NG107

NG160

NG80

0

20000 4000 6000

Rotational speed n [rpm]

The FKM shaft seal ring may be used for leakage

temperatures from -25°C to +115°C. For application cases

below -25 °C, an NBR shaft seal is required (permissible

temperature range: -40 °Cto+90°C).

Flow direction

Direction of rotation, viewed on drive shaft

clockwise counter-clockwise

S to B S to A

RE 92202/02.2015, Bosch Rexroth AG

6 A7VO Series 63 | Axial piston variable pump

Operating pressure range

Operating pressure range

Pressure at working port A or B (high-pressure side) Definition

Nominal pressure p

Maximum pressure p

nom

max

Single operating period 10s

Total operating period 300 h

Minimum pressure (high-pressure side) 10 bar absolute Minimum pressure on high-pressure side (A or B) required to

Rate of pressure change R

Amax

Pressure at suction port S (Inlet)

Minimum pressure p

Maximum pressure p

Smin

Smax

350 bar absolute The nominal pressure corresponds to the maximum design

pressure.

400 bar absolute The maximum pressure corresponds the maximum operating

pressure within the single operating period. The sum of the single

operating periods must not exceed the total operating period.

prevent damage to the axial piston unit.

16000bar/s Maximum permissible rate of pressure build-up and reduction

during a pressure change over the entire pressure range.

0.8 bar absolute

2bar absolute

Minimum pressure at suction port S (inlet) that is required to avoid

damage to the axial piston unit. The minimum required pressure is

dependent on the speed and displacement of the axial piston unit

(see diagram on page 7).

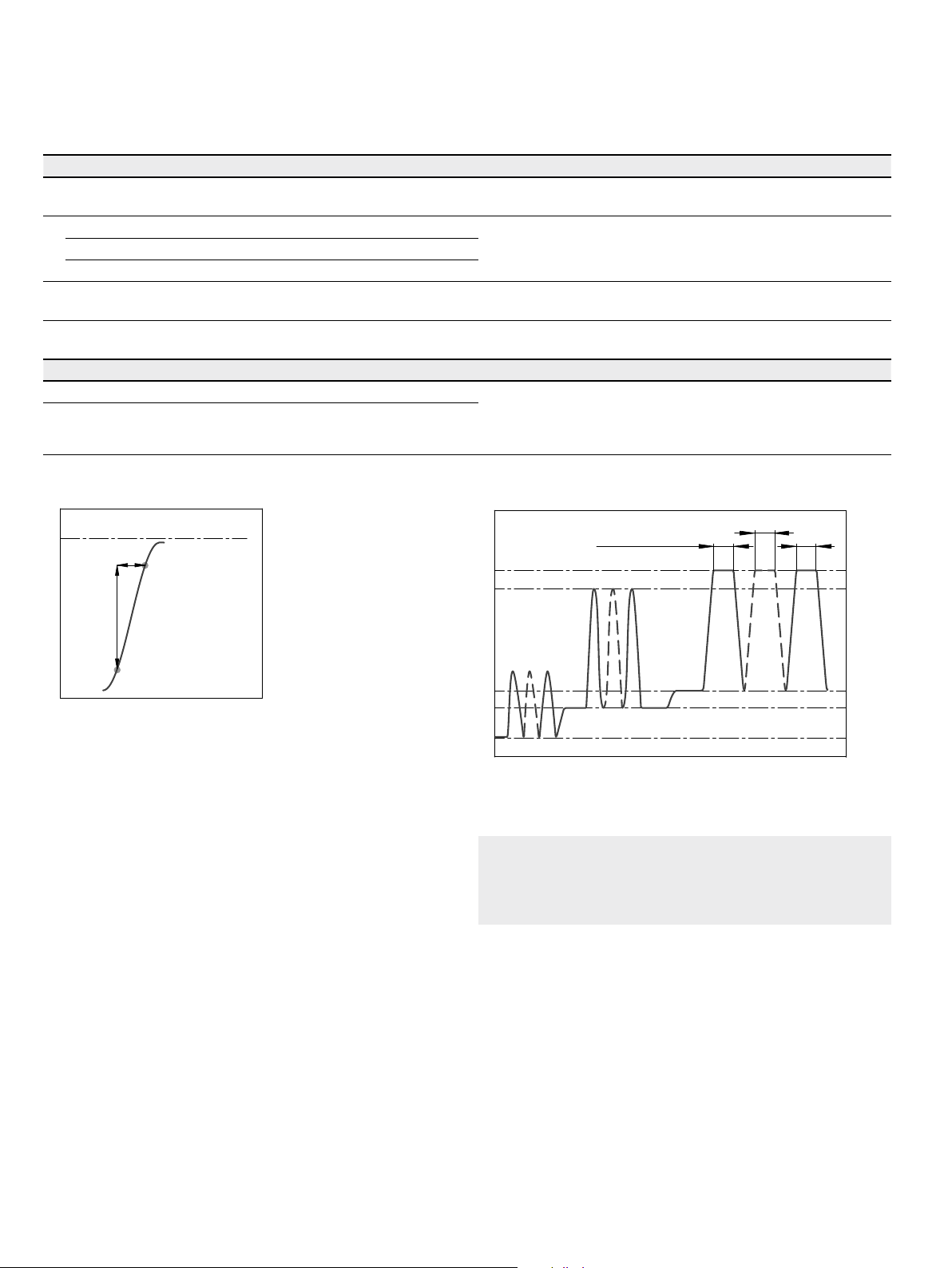

▼ Rate of pressure change R

p

nom

∆t

∆p

Pressure p

Time t

Amax

▼ Pressure definition

t

Single operating period

Maximum pressure p

Nominal pressure p

max

nom

2

t

1

t

n

Pressure p

Minimum pressure (high pressure side)

Time t

Total operating period = t1 + t2 + ... + t

n

Note

Operating pressure range valid when using hydraulic

fluids based on mineral oils. Values for other hydraulic

fluids, please contact us.

Bosch Rexroth AG, RE 92202/02.2015

Axial piston variable pump | A7VO Series 63

Technical data

Technical data

Size NG 28 55 80 107 160

Displacement, geometric, per revolution

Maximum rotational

1)

speed

At V

At V

g max

< 0.74 × V

g

Maximum rotational

2)

speed

Flow

Power

Torque

Rotary stiffness

At V

At V

At V

V

V

and n

g max

g max

g max

to Vg /2 c

g max

/2 to 0 (interpolated) c

g

nom

, n

and Δp=350bar P

nom

and Δp = 350 bar T

Moment of inertia rotary group

Maximum angular acceleration

Case volume

Weight (approx.)

g max

V

n

n

n

q

J

α

V

m

g max

nom

max1

max2

v

min

max

GR

3

cm

28.1 54.8 80 107 160

rpm 3150 2500 2240 2150 1900

rpm 4250 3400 3000 2900 2560

rpm 4750 3750 3350 3200 2850

l/min 89 137 179 230 304

kW 52 80 105 134 177

Nm 156 305 446 596 891

kNm/rad 5 10 16 21 36

kNm/rad 16 32 49 67 104

kgm² 0.0042 0.0042 0.0080 0.0127 0.0253

rad/s² 35900 31600 24200 19200 15300

l 0.5 0.75 1.2 1.5 2.4

kg 17 25

40 49 71

7

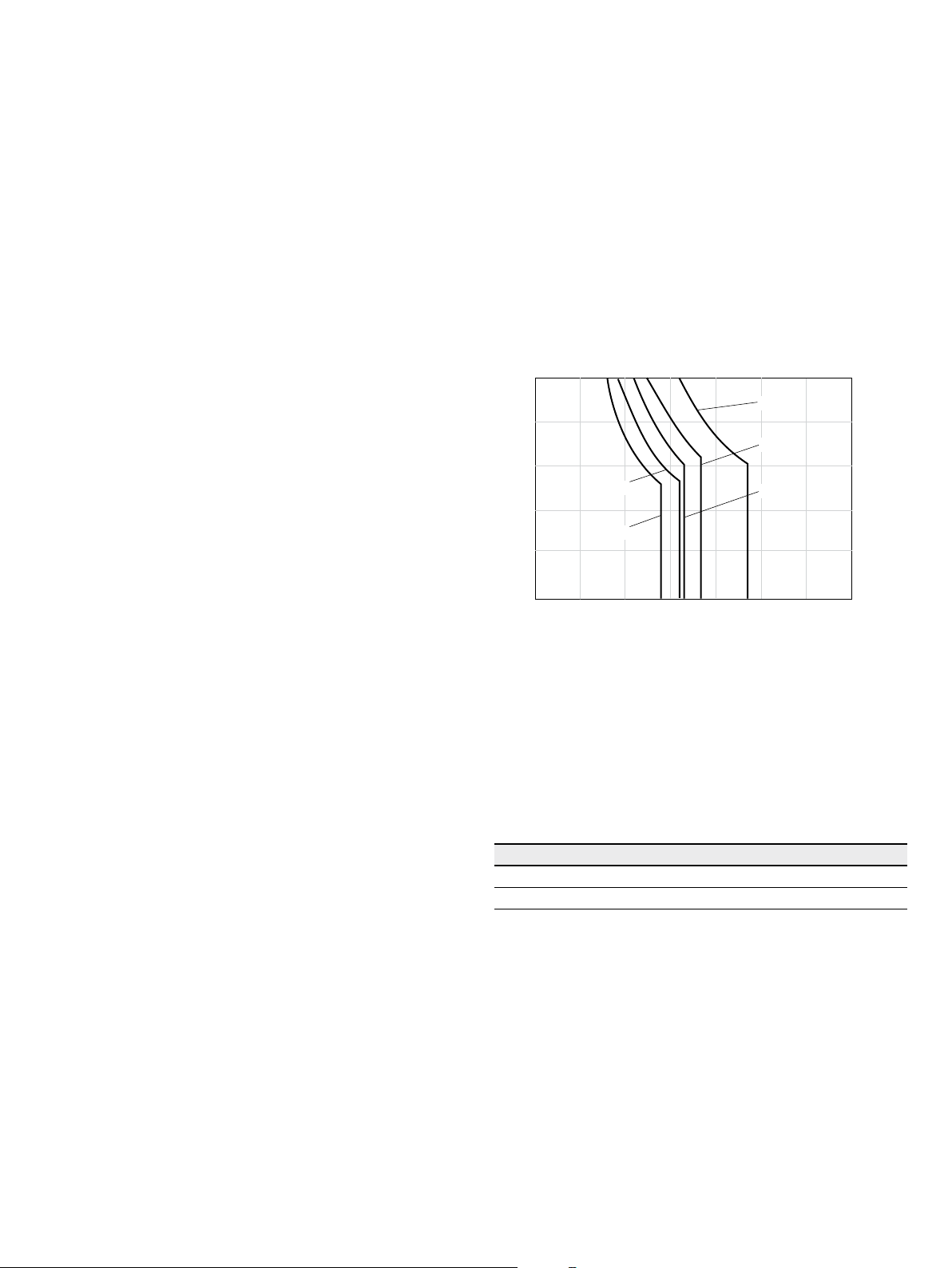

▼ Maximum permissible speed (limit speed)

Speed n / n

1.5

1.4

1.3

nom

1.2

1.1

1.0

2.3

2.0

1.9

1.8

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.9

0.8

0.6 0.7 0.8 0.9 1.0

Displacement Vg / V

1) The values are valid:

‒ At absolute pressure p

= 1bar at suction port S

abs

‒ For the optimal viscosity range of ν

g max

=36 to 16 mm2/s

opt

0.8

‒ For hydraulic fluid based on mineral oils.

2) Maximum rotational speed (speed limit) for increased inlet

pressure p

at suction port S and Vg < V

abs

, see diagram.

g max

Determining operating characteristics

× n × η

V

g

1000

× Δp

V

g

60000

v

[l/min]

[Nm]

mh

q

× Δp

v

=

600 × η

[kW]

t

abs

Flow

Torque

Power

q

T

P

v

=

=

=

20 × π × η

2 π × T × n

Key

V

Inlet pressure p

g

Δp

n

η

v

η

mh

η

t

= Displacement per revolution [cm3]

= Differential pressure [bar]

= Rotational speed [rpm]

= Volumetric efficiency

= Mechanical-hydraulic efficiency

=

Total efficiency (η

= ηv × ηmh)

t

Notes

▶ Theoretical values, without efficiency and tolerances;

values rounded

▶ Operation above the maximum values or below the

minimum values may result in a loss of function, a

reduced service life or in the destruction of the axial

piston unit. Other permissible limit values, such as

speed variation, reduced angular acceleration as a

function of the frequency and the permissible angular

acceleration at start (lower than the maximum angular

acceleration) can be found in data sheet 90261.

RE 92202/02.2015, Bosch Rexroth AG

8 A7VO Series 63 | Axial piston variable pump

Technical data

Permissible radial and axial forces of the drive shaft

Size NG 28 55 80 107 160

Drive shaft Ø mm 25 30 35 40 45

Maximum radial force

at distance a (from shaft

collar)

Maximum torque at F

Maximum differential pressure at V

F

qmax

Maximum axial force at

standstill or pressurefree operation

Permissible axial force per bar operating pressure

1)

q max

F

q

a

and

g max

+

F

ax

–

F

q max

a mm 14.0 17.5 20.0 22.5 25.0

T

q max

Δp

q max

+F

axmax

−F

axmax

+F

axperm

N 6436 7581 10266

Nm 179 281 444 681 1019

bar 400 322 349 400 400

N 0 0 0 0 0

N 315 500 710 900 11250

/bar

N/bar

4.6 7.5 9.6 11.3 15.1

13758

18278

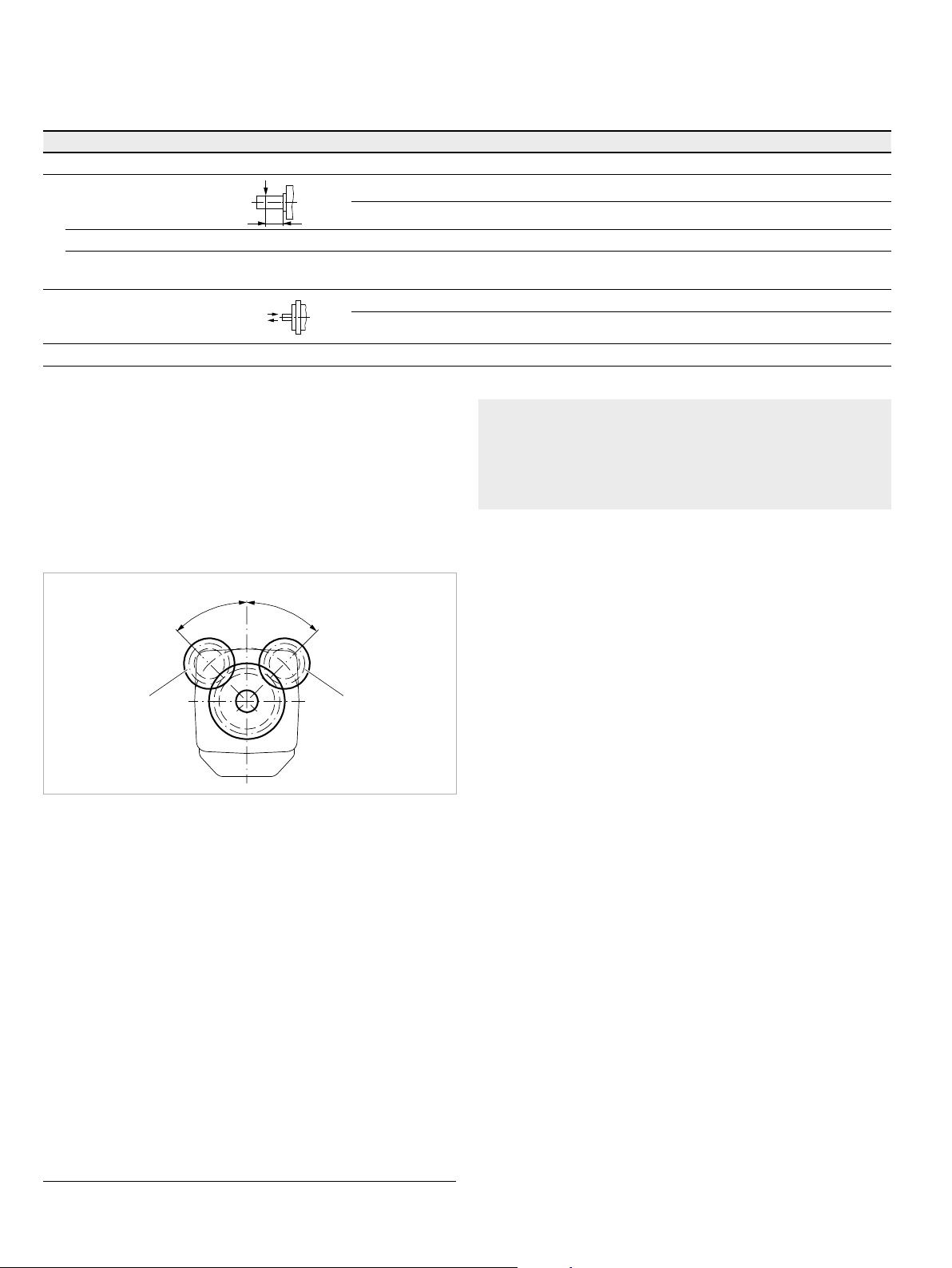

Effect of radialforce Fq on the service life of bearings

By selecting a suitable direction of radial force F

, the load

q

on the bearings, caused by the internal rotary group forces

can be reduced, thus optimizing the service life of the

bearings. Recommended position of mating gear is dependent on direction of rotation. Example:

▼ Gear drive

φ

°

5

4

=

t

p

o

φ

1 “Clockwise” rotation, pressure at port B

2 “Counter-clockwise” rotation, pressure at port A

o

p

t

=

4

5

°

21

Note

▶ The permissible axial force in direction −F

is to be

ax

avoided, because thereby the bearing life is reduced.

▶ Special requirements apply in the case of belt drives.

Please contact us.

1) With intermittent operation

Bosch Rexroth AG, RE 92202/02.2015

Axial piston variable pump | A7VO Series 63

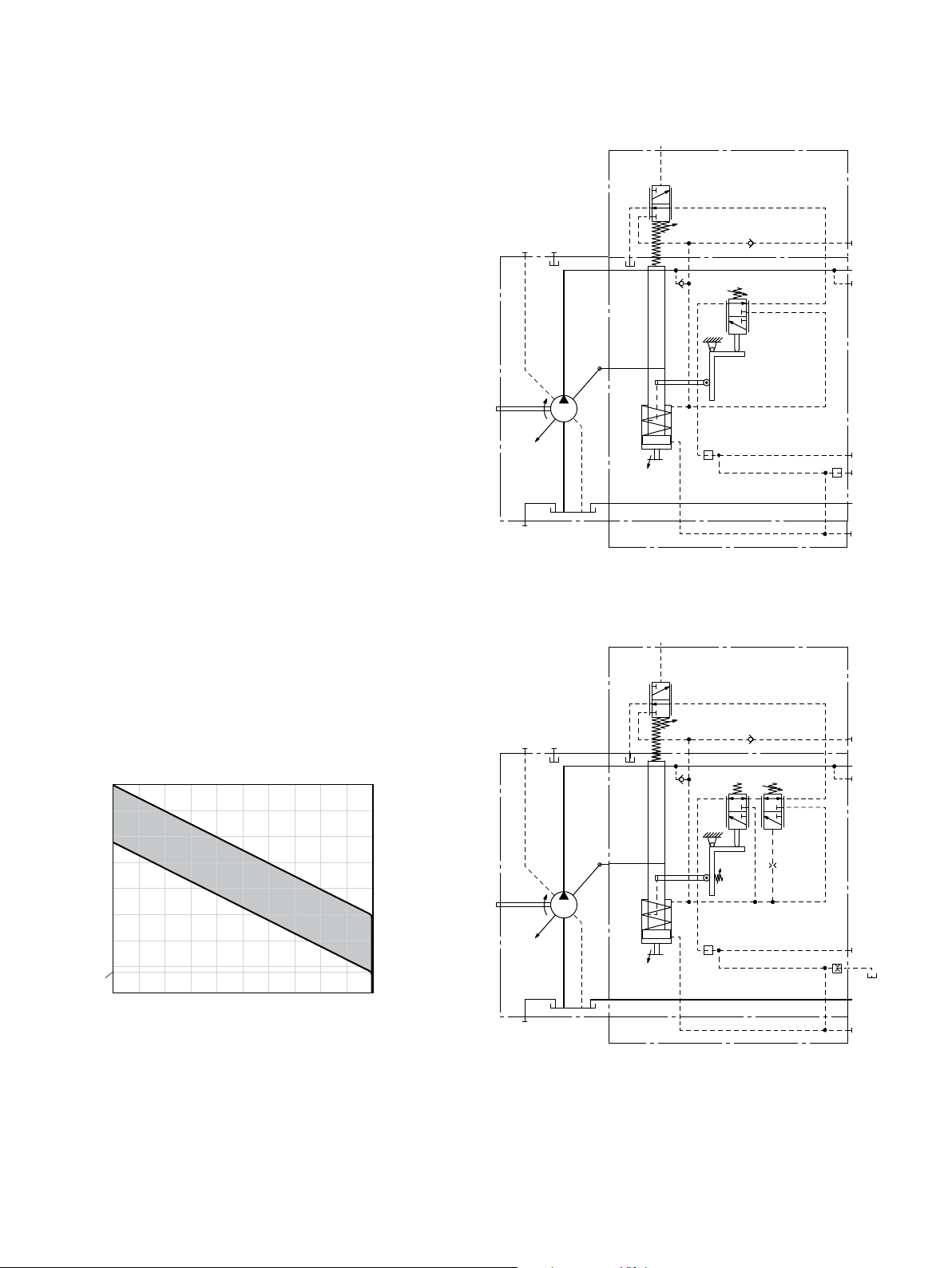

LR – Power controller without power override

LR – Power controller without power override

9

The power controller regulates the displacement of the

pump depending on the operating pressure so that a given

drive power is not exceeded at constant drive speed.

The precise control with a hyperbolic control characteristic,

provides an optimum utilization of available power.

The operating pressure acts on a rocker via a measuring

spool which moves with the control. An externally adjustable spring force counteracts this, it determines the power

setting.

If the operating pressure exceeds the set spring force, the

control valve is actuated by the rocker and the pump swivels back from the initial position V

gmax

toward V

gmin

. When

doing this, the lever length at the rocker shortens and the

operating pressure may rise in the same proportion as the

displacement reduces without the drive power being

exceeded (p

=displacement).

V

g

×Vg=constant; pB=operating pressure;

B

When depressurized, the pump is swiveled to its initial

position to V

by a return spring.

g max

The hydraulic output power (characteristic LR) is influenced by the efficiency of the pump.

▶ Beginning of control, setting range 50 to 220bar

When ordering, state in plain text:

▶ Drive power P [kW]

▶ Drive speed n [rpm]

▶ Maximum flow q

v max

[l/min]

Please contact us if you need a power diagram.

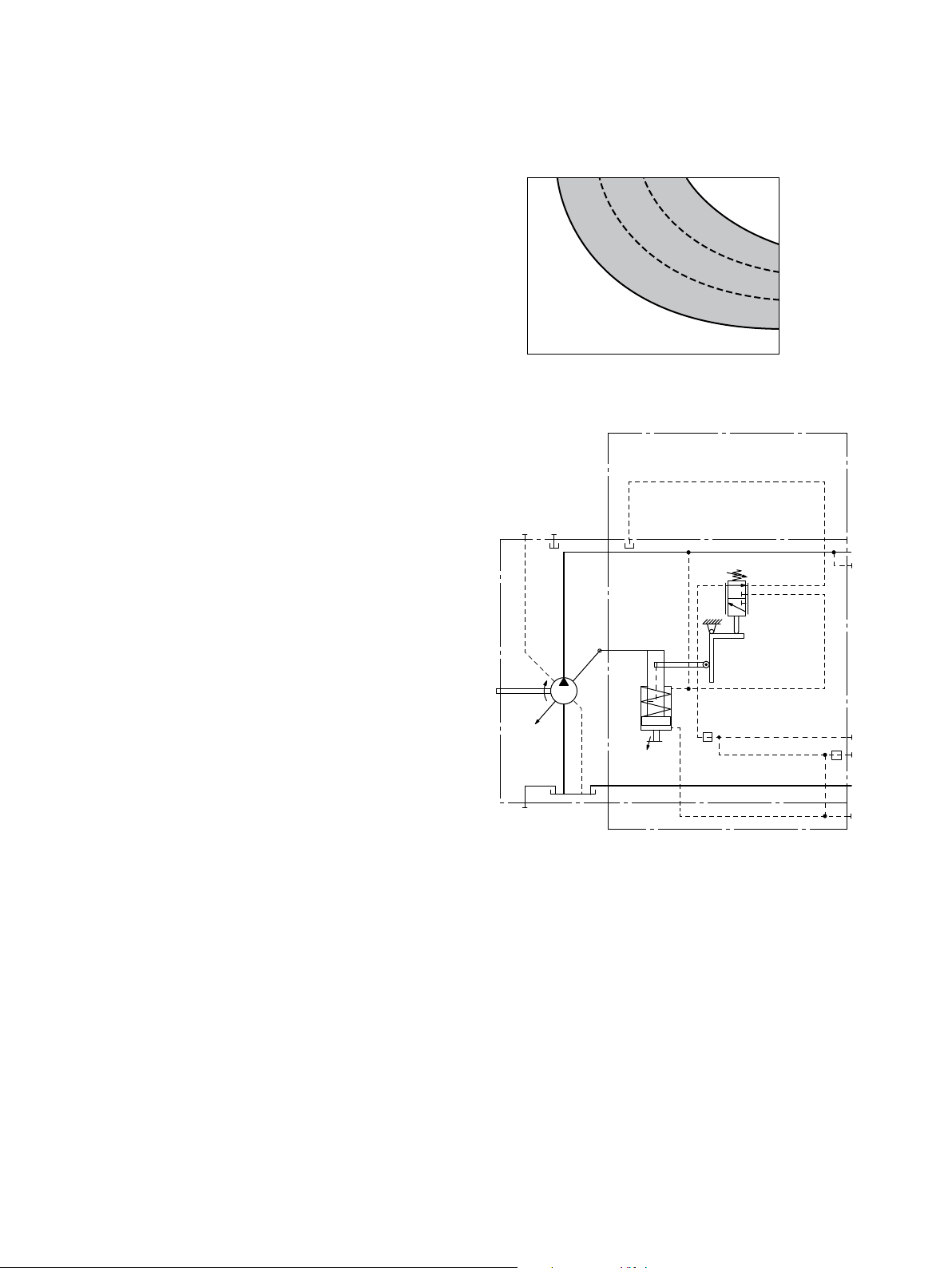

▼ Characteristic curve LR

[bar]

B

Operating pressure p

V

displacement V

g min

▼ Schematic LR

U

R

1

V

g min

V

g max

R

2

g max

220 bar

50 bar

B(A)

A

1

X

3

T

1

S

M

1

RE 92202/02.2015, Bosch Rexroth AG

10 A7VO Series 63 | Axial piston variable pump

LR – Power controller without power override

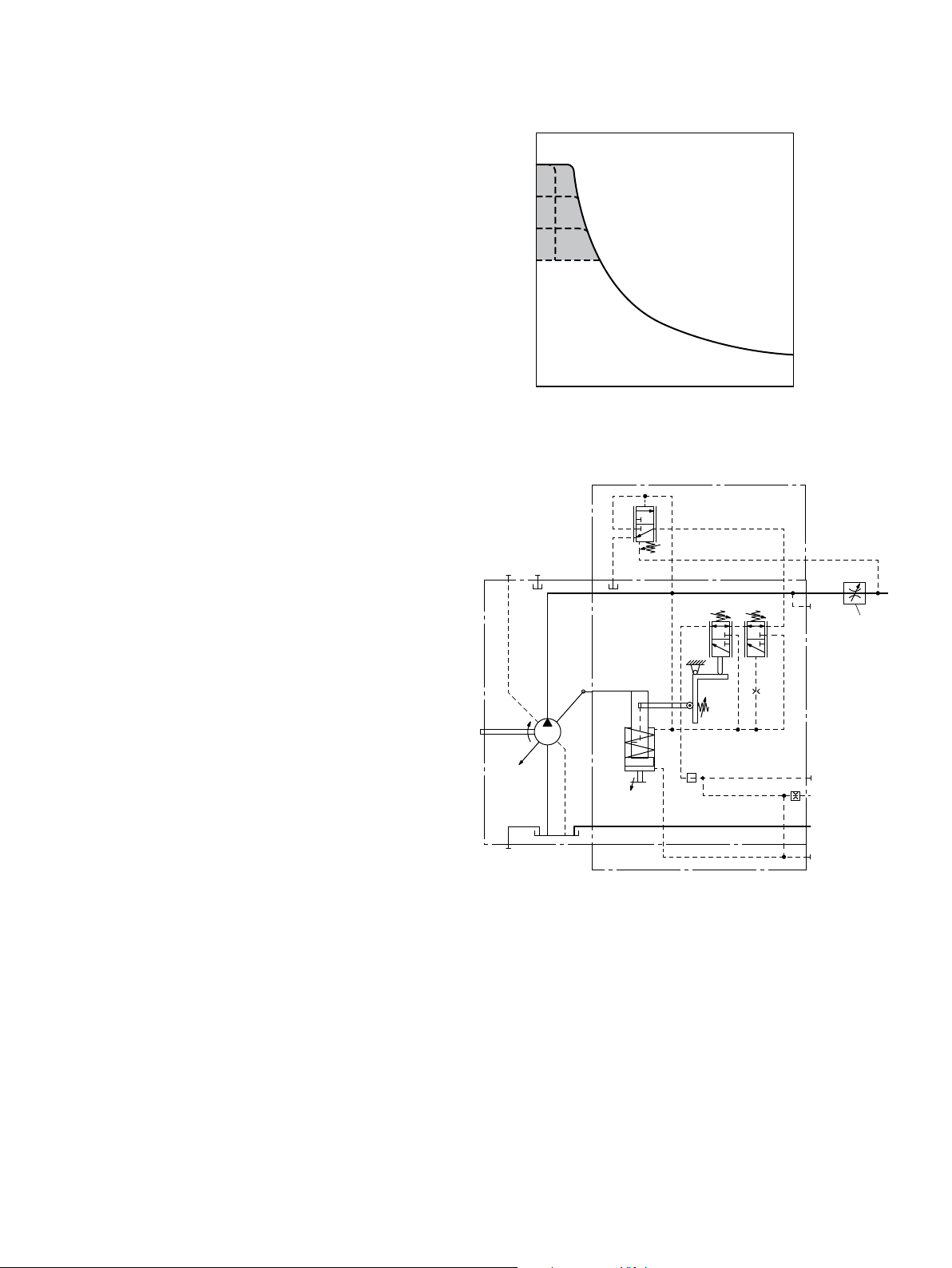

LRD – Power controller with pressure cut-off

The pressure cut-off is a pressure control which adjusts the

displacement of the pump back to V

after reaching the

g min

set pressure command value.

This function overrides the power controller, i.e. the power

control function is executed below the pressure command

value.

Pressure cut-off is preset to a pressure command value at

the factory.

▶ Setting range 200 to 350 bar

When ordering, state the setting in plain text.

Notes

▶ The pressure setting of the pressure cut-off must be at

least a factor of 5 higher than the beginning of control

of power control.

Example:

– Beginning of control of the power controller: 50bar

– Minimum setting of pressure cut-off:

5×50=250bar

Higher settings of the pressure cut-off are always

possible.

▶ For versions with pressure cut-off, a drain line is

needed from port T

When port T

1

to the reservoir.

1

is plugged and t

≤50°C, this results

tank

in a permissible pressure cut-off of≤2 min.

▶ Any pressure-relief valve included in the system to limit

the maximum pressure must have its start of opening

at least 20 bar above the pressure cut-off setting.

▼ Characteristic curve LRD

max

350

[bar]

B

200

min

Operating pressure p

V

displacement V

g min

▼ Schematic LRD

U

R

1

V

g min

V

g max

g max

B(A)

A

1

X

3

Bosch Rexroth AG, RE 92202/02.2015

T

1

S

R

2

M

1

Axial piston variable pump | A7VO Series 63

LR – Power controller without power override

11

LR… – Power controller with stroke limiter

Due to the hydraulic stroke limiter, it is possible to change

or limit the displacement of the pump continuously across

the entire control range. The displacement is set proportionally using the pilot pressure p

applied to port X1

St

(maximum of 40 bar).

The power control overrides the hydraulic stroke limiter, i.e.

below the power characteristic (hyperbolic characteristic),

the displacement is controlled in dependence on the pilot

pressure. If the set flow or operating pressure exceeds the

power control characteristic, the power control overrides

and reduces the displacement along the hyperbolic characteristic.

A control pressure of 40bar is needed to swivel the pump

from its initial position V

gmax

to V

gmin

.

The necessary control power is taken from the operating

pressure or the external control pressure applied to port Y

3

To ensure that the stroke limiter functions at a low operating pressure of <40bar, port Y

must be supplied with an

3

external control pressure of about 40bar.

LRH1 – Hydraulic stroke limiter (negative control)

▶ Control from V

gmax

to V

gmin

As the pilot pressure increases, the pump swivels to a

smaller displacement.

▶ Start of control (at V

) can be set to 4to15bar

gmax

When ordering, state the start of control in plain text.

▶ Initial position without pilot signal (pilot pressure): V

gmax

▼ Schematic LRH1

U

.

R

2

▼ Schematic LRDH1

X

1

Y

R

1

3

B(A)

A

1

V

g min

V

g max

X

3

T

1

S

M

1

X

1

▼ Characteristic curve LRH1

control pressure increase (V

40

35

30

[bar]

St

25

20

15

10

Pilot pressure p

5

4

0 0.6 0.8 1.00.40.2

Displacement Vg/V

gmax

–V

g max

) Δp=25bar

gmin

Y

U

R

1

3

B(A)

A

1

V

g min

V

g max

X

3

T

1

S

R

2

M

1

RE 92202/02.2015, Bosch Rexroth AG

12 A7VO Series 63 | Axial piston variable pump

LR – Power controller without power override

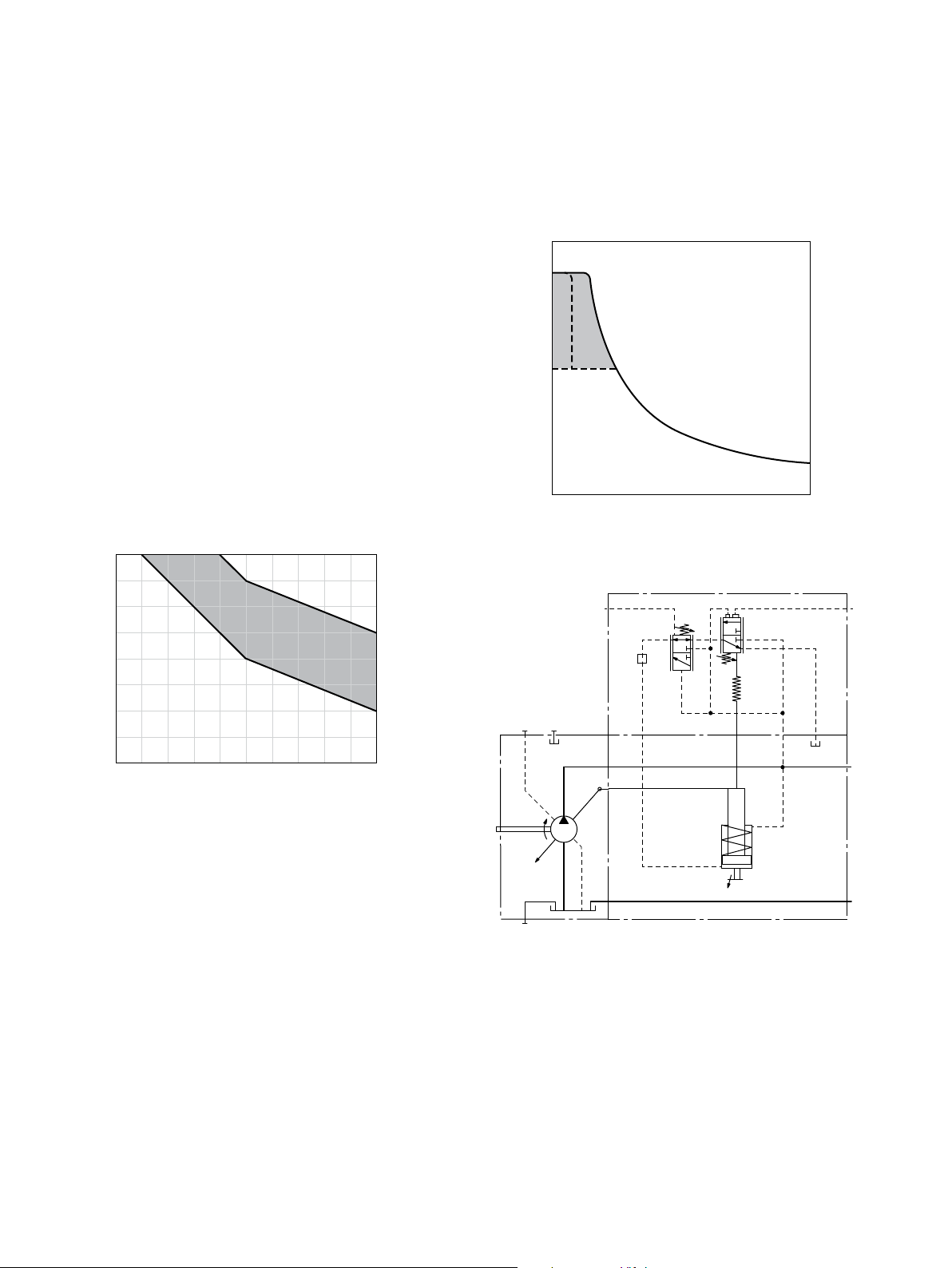

LRDS – Power control with pressure cut-off and load

sensing

The load sensing controller works as a load-pressure controlled flow controller and adjusts the displacement of the

pump to the volume required by the consumer. The flow of

the pump is then dependent on the cross section of the

external measuring orifice (1), which is located between

the pump and the consumer. Below the power curve and

the setting of the pressure cut-off and within the control

range of the pump, the flow is independent of the load

pressure.

The measuring orifice is usually a separately located load

sensing directional valve (control block). The position of

the directional valve spool determines the opening crosssection of the measuring orifice and thus the flow of the

pump.

The load sensing controller compares pressure before and

after the orifice and keeps the pressure drop (differential

pressure Δp) across the orifice – and therefore the

flow – constant.

If the differential pressure ∆p at the measuring orifice rises,

the pump is swiveled back (toward V

). If the differential

g min

pressure Δp drops, the pump is swiveled out (toward

) until equilibrium at the measuring orifice is restored.

V

gmax

Δp

measuring orifice

=p

pump

–p

consumer

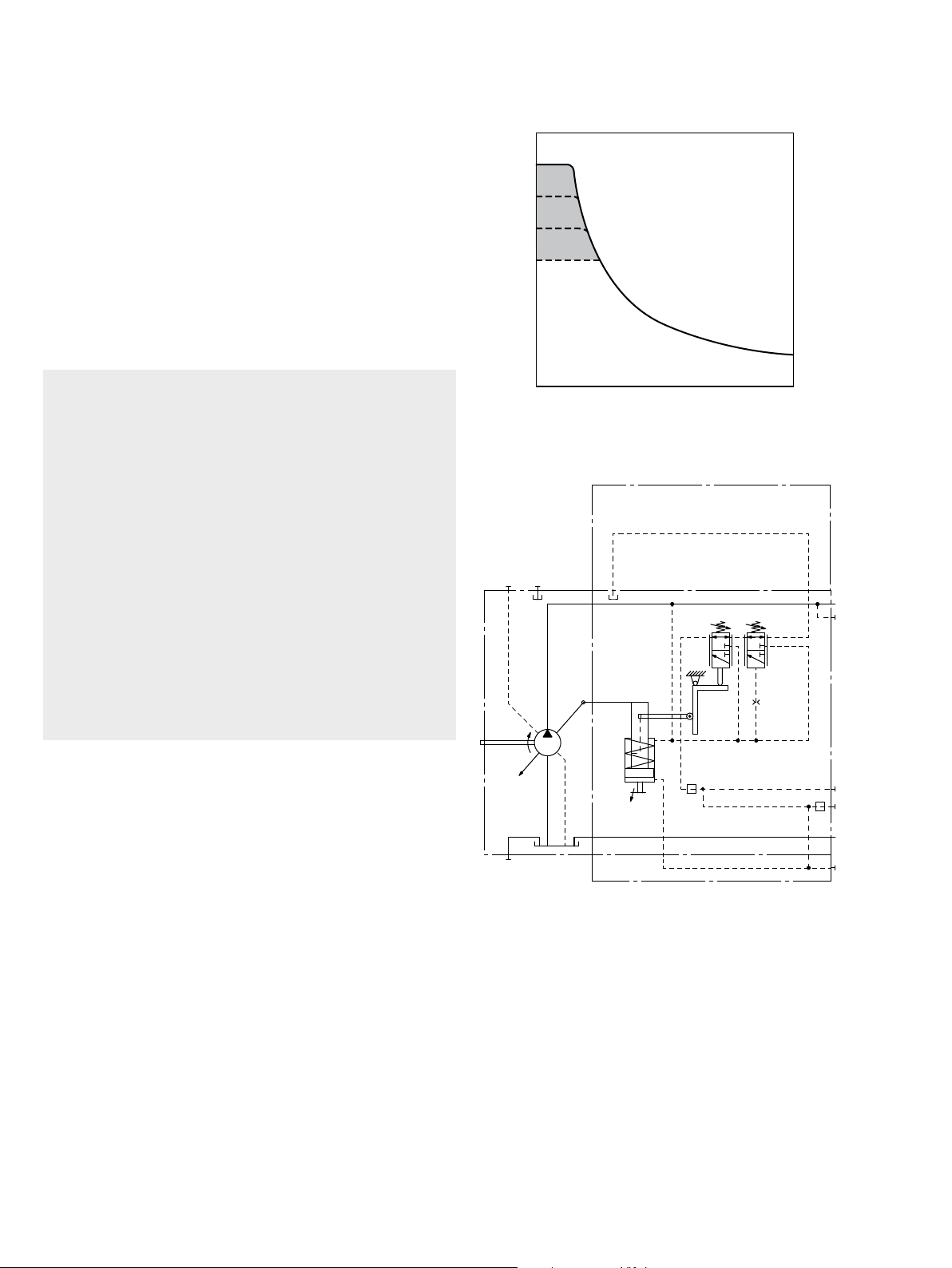

▼ Characteristic curve LRDS

max

350

[bar]

B

200

min

Operating pressure p

V

displacement V

g min

▼ Schematic LRDS

U

R

1

g max

X

4

B(A)

A

1

1

▶ Setting range for Δp 14to25bar

▶ Default setting 18bar

When ordering, state the setting in plain text.

The stand-by pressure in zero-stroke mode (metering orifice

closed) is slightly higher than the Δp setting.

In an LUDV system, the pressure cut-off is integrated in the

flow sharing control block (LUDV).

V

g min

V

g max

R

2

X

3

T

1

S

M

1

The measuring orifice (control block) (1) is not included in

the scope of delivery.

Bosch Rexroth AG, RE 92202/02.2015

Axial piston variable pump | A7VO Series 63

LA1 – Power controller with hydraulically proportional power override

LA1 – Power controller with hydraulically proportional power override

13

The power controller regulates the displacement of the

pump depending on the operating pressure so that a given

drive power is not exceeded at constant drive speed.

The hyperbolic power curve is approximated with two

measuring springs. The operating pressure acts on the measurement area of a differential piston against the measuring

springs and an externally adjustable spring force which

determines the power setting.

If the sum of the hydraulic forces exceeds the forces of the

springs, the control oil is fed to the stroking piston, which

swivels the pump back to reduce the flow.

In a depressurized state, the pump is swiveled to its initial

position to V

By connecting an external pilot pressure at port X

by a return spring.

g max

, it is

3

possible to override the power control proportionally.

Increasing pilot pressure=reduced power.

▼ Characteristic curve LA1

400

350

[bar]

300

A

250

200

150

100

Operating pressure p

50

0

0 0.2 0.4 0.6 0.8 1.0

V

displacement V

g min

Setting range

Beginning of control

g max

LA1S – Power controller with load sensing

For description of load sensing, see page12.

▼ Characteristic curve LA1S

max

350

[bar]

B

200

min

Operating pressure p

V

displacement V

g min

▼ Schematic LA1S

X

4

U

R

1

g max

X

3

A

V

The hydraulic output power (characteristic curve) is

affected by the efficiency.

V

g min

g max

When ordering, state in plain text:

▶ Drive power P [kW]

▶ Drive speed n [rpm]

▶ Maximum volume flow q

V max

[l/min]

R

2

S

Please contact us if you need a power diagram.

RE 92202/02.2015, Bosch Rexroth AG

Loading...

Loading...