Bosch Rexroth A2FM Instruction Manual

RE 91001-01-X-B2/01.2016, Bosch Rexroth AG

Details on explosion protection

▶ Field of application according to ATEX 94/9/EC

▶ Gas: II 2G ck IIB Tx in accordance with

DINEN13463‑1:2009, DINEN13463‑5:2011

Features

▶ Fixed motor with axial tapered piston rotary group of

bent‑axis design, for hydrostatic drives in open and

closed circuits.

▶ For use in mobile and stationary applications

▶ The output speed depends on the flow of the pump and

the displacement of the motor

▶ The output torque increases with the pressure differen‑

tial between the high‑pressure side and the low‑pres‑

sure side.

▶ Finely graduated sizes permit far‑reaching adaptation to

the drive concerned

▶ High power density

▶ Small dimensions

▶ High total efficiency

▶ Good starting efficiency

▶ Economical design

▶ One‑piece tapered piston with piston rings for sealing

▶ Series 61

▶ Sizes 10 to 180

▶ Nominal pressure 400bar

▶ Maximum pressure 450 bar

▶ Open and closed circuits

Axial piston fixed motor A2FM

for explosive areas

II 2G ck IIB Tx

Part II of instruction manual

according to ATEX directive

94/9/EC data sheet

RE 91001-01-X-B2

Edition: 01.2016

Replaces: 04.2009

Ordering code 2

Hydraulic fluids 3

Shaft seal 5

Flow direction 5

Speed range 5

Working pressure range 6

Technical data 7

Dimensions, sizes 10, 12, 16 10

Dimensions, sizes 23, 28, 32 12

Dimensions size 45 14

Dimensions sizes 56, 63 16

Dimensions sizes 80, 90 18

Dimensions sizes 107, 125 20

Dimensions sizes 160, 180 22

Counterbalance valve BVD 24

Installation instructions 27

Project planning notes 29

Safety instructions 29

Contents

Bosch Rexroth AG, RE 91001-01-X-B2/01.2016

2 A2FM for explosive areas | Axial piston fixed motor

Ordering code

1) Fastening thread or threaded ports, metric

2)

Threaded connections at the sides sealed with threaded plugs

3) Indicate ordering code for counterholding valve BVD separately as

per data sheet 95522.

Note the restrictions described on page 24.

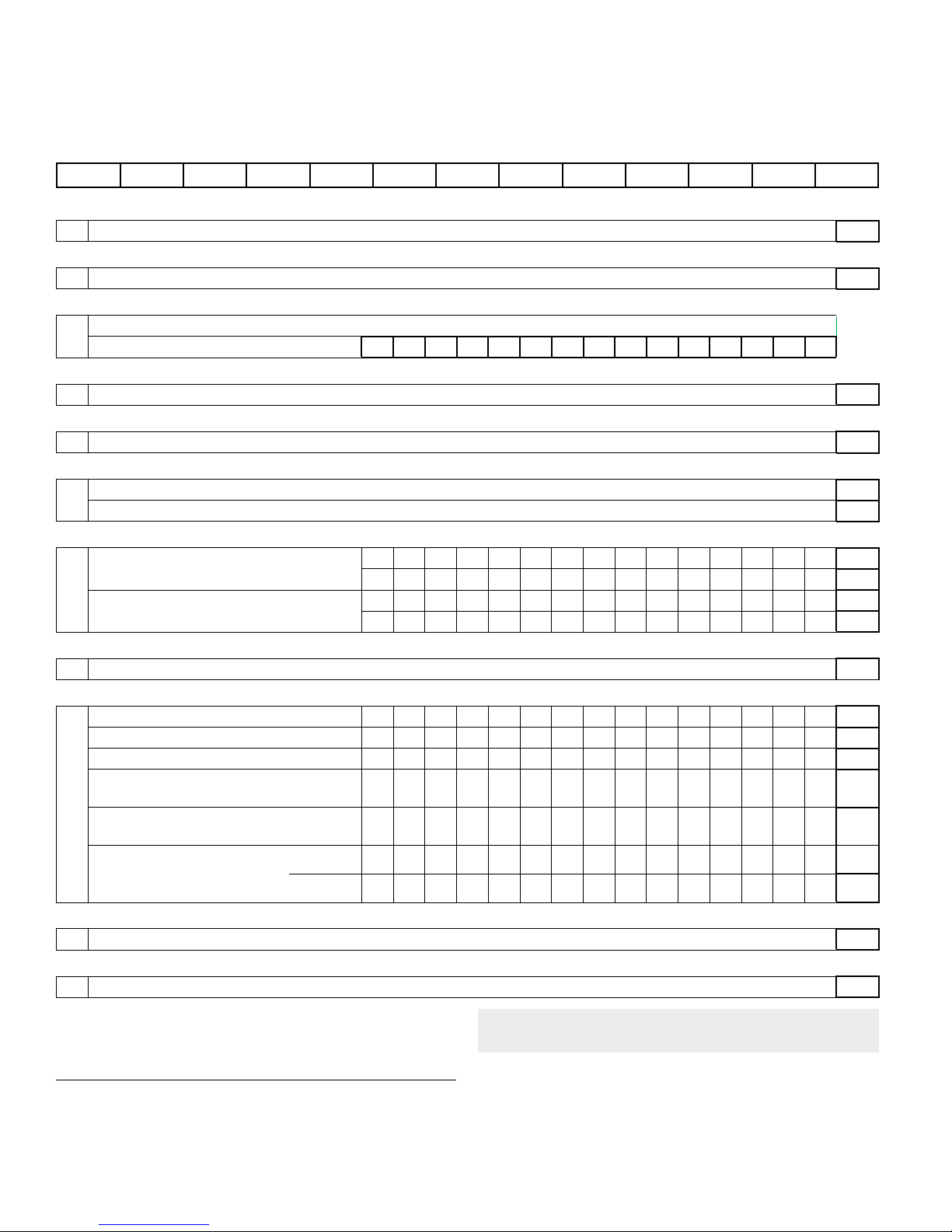

Ordering code

01 02 03 04 05 06 07 08 09 10 11

A2F M / 61 W – B J

Axial piston unit

01 Bent‑axis design, fixed, , nominal pressure 400 bar, maximum pressure 450 bar

A2F

Operating mode

02 Motor (plug‑in motor A2FE, see data sheet 91008‑01‑X‑B2) M

Size (NG)

03 Geometric displacement, see Technical data on page 7

10 12 16 23 28 32 45 56 63 80 90 107 125 160 180

Series

04 Series 6, index 1

61

Direction of rotation

05 Viewed from drive shaft, bidirectional

W

Sealing material ATEX version

06 ATEX device category 3G (normal level of safety), shaft seal ring made of FKM (fluor‑caoutchouc)

A

ATEX device category 2G (normal level of safety), shaft seal ring made of FKM (fluor‑caoutchouc)

R

Drive shaft 10 12 16 23 28 32 45 56 63 80 90 107 125 160 180

07 Splined shaft DIN 5480

● ● ● ● ● ● – ● ● ● ● ● ● ● ● A

● ● – ● ● – ● ● – ● – ● – ● – Z

Parallel keyed shaft, DIN 6885

● ● ● ● ● ● – ● ● ● ● ● ● ● ● B

● ● – ● ● – ● ● – ● – ● – ● – P

Mounting flange

08 ISO 3019‑2; 4‑hole

B

Port plate for working lines

1)

10 12 16 23 28 32 45 56 63 80 90 107 125 160 180

09 SAE flange ports A and B at rear

– – – ● ● ● ● ● ● ● ● ● ● ● ● 010

SAE flange ports A and B at side, opposite

– – – ● ● ● ● ● ● ● ● ● ● ● ● 020

Threaded ports A and B, at side, opposite

● ● ● ● ● ● – – – – – – – – – 030

Threaded connections A and B at side

and rear

2)

● ● ● ● ● ● ● ● ● – – – – – – 040

SAE flange ports A and B at bottom (same

side)

– – – – ● ● ● ● ● ● ● ● ● ● ● 100

Port plate with 1‑stage pressure‑

relief valves for mounting a coun‑

terbalance valve

3)

BVD20 – – – – – – – – – – – ● ● – – 178

BVD20/25 – – – – ● ● ● ● ● ● ● ● ● ● ● 188

Rotary group

10 Version J

J

Special version

11 Special version

-S

●

= Available

–

= Not available Note

Note the project planning notes on page29.

RE 91001-01-X-B2/01.2016, Bosch Rexroth AG

Axial piston fixed motor | A2FM for explosive areas

Hydraulic fluids

3

Features of the ATEX version

With the ATEX version of the A2FM axial piston fixed motor,

a restriction of the technical data must to be taken into

account.

External distinguishing feature compared to the standard

motor is the grounding connection, which is marked by a

socket‑head screw on the mounting flange. Observe the

instruction manual.

Note

Potential equalization: The motor must be grounded via the

grounding connection (to be provided by the customer).

For grounding points, see the instruction manual (Part I,

91001‑01‑X‑B1) chapter 7.5 “Connecting potential

equalization“.

Temperature classes according to EN 13463-1

Depending on the two temperature classes T3 and T4, the

maximum permissible speed and temperature restrictions

must be taken into account (see table “Viscosity and tem‑

perature of the hydraulic fluid” and “Technical data”).

Hydraulic fluids

The fixed motor A2FM is designed for operation with HLP

mineral oil according to DIN 51524.

Application instructions and requirements for hydraulic

fluids should be taken from the following data sheets

before the start of project planning:

▶ 90220: Hydraulic fluids based on mineral oils and

related hydrocarbons

The fixed motor A2FM for explosive areas is only approved

for mineral oils.

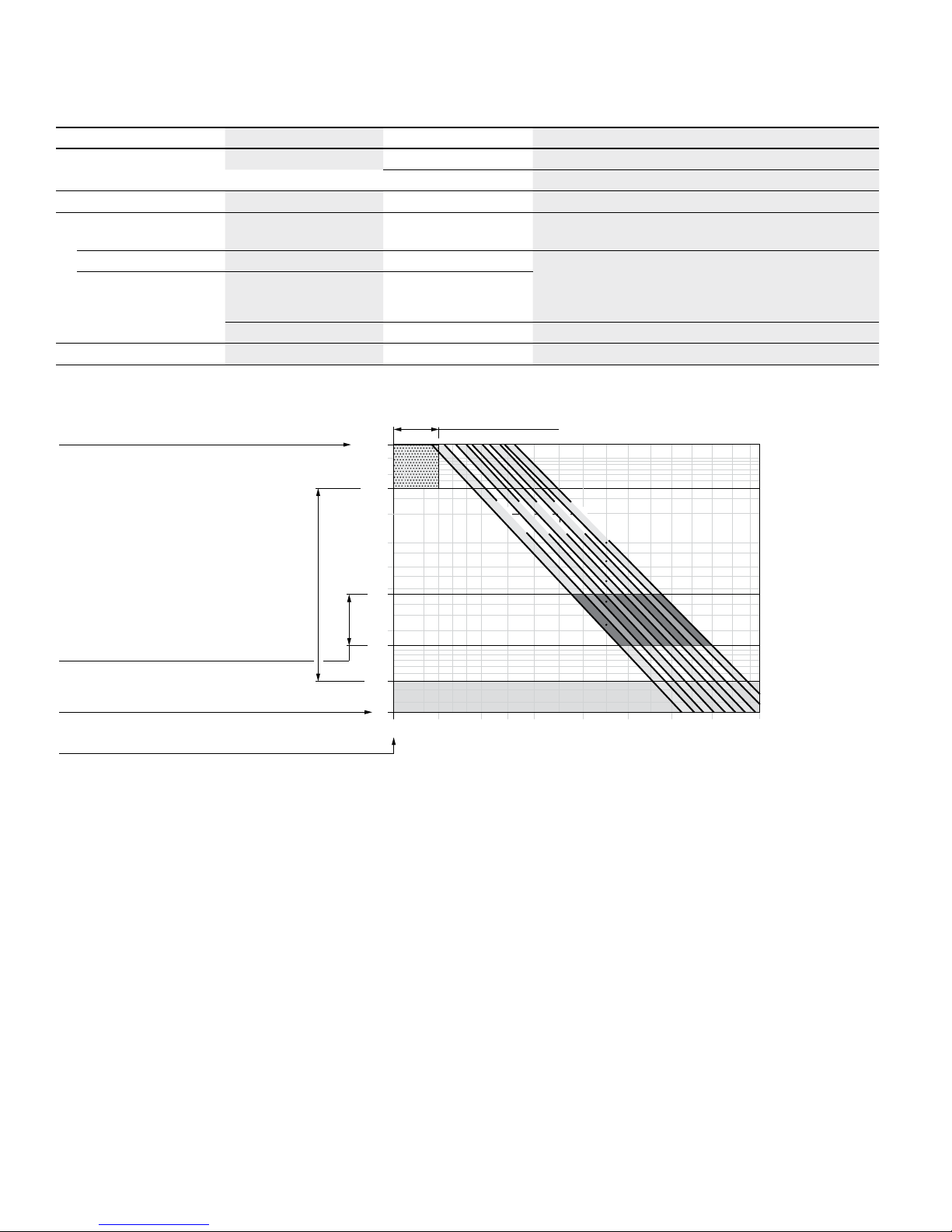

Notes on selection of hydraulic fluid

The hydraulic fluid should be selected such that the operat‑

ing viscosity in the operating temperature range is within

the optimum range (ν

opt

see selection diagram).

The ignition temperature of the hydraulic fluid must be

greater than 250°C.

Note

At no point of the component may the temperature be

higher than 90°C. The temperature difference specified in

the table is to be taken into account when determining the

viscosity in the bearing.

If it is not possible to maintain the conditions above due to

extreme operating parameters, we recommend flushing the

case at port T

1/T2

.

Project planning note

The maximum leakage temperature and case pressure must

not be exceeded. For this purpose, constant monitoring by

means of appropriate sensors in the system is necessary.

Bosch Rexroth AG, RE 91001-01-X-B2/01.2016

4 A2FM for explosive areas | Axial piston fixed motor

Hydraulic fluids

Viscosity and temperature of hydraulic fluids

Viscosity Temperature Comment

Cold start

ν

max

≤1600mm2/s θSt≥−40°C t≤3min, n≤1000rpm, without load p≤50 bar

Permissible temperature difference

ΔT≤25K

between axial piston unit and hydraulic fluid in the system

Warm‑up phase

ν<1600 to 400mm

2

/s θ=−40°C to −25°C at p≤0.7×p

nom

, n≤0.5×n

nom

and t≤15min

Continuous operation

ν=400 to 10mm

2

/s

this corresponds, for VG46 for example, to a temperature

range of +5 °C to +85 °C (see selection diagram)

Temperature class T3

θ=−25°C to +90°C

measured at port T

observe permissible temperature range of the shaft seal

ring (ΔT=approx.12K between bearing/shaft seal and

port T)

Temperature class T4

θ=−25°C to +70°C

ν

opt

=36 to 16mm2/s

Range of optimum operating viscosity and efficiency

Short‑term operation

ν

min

≥7mm2/s t<3min, p<0.3×p

nom

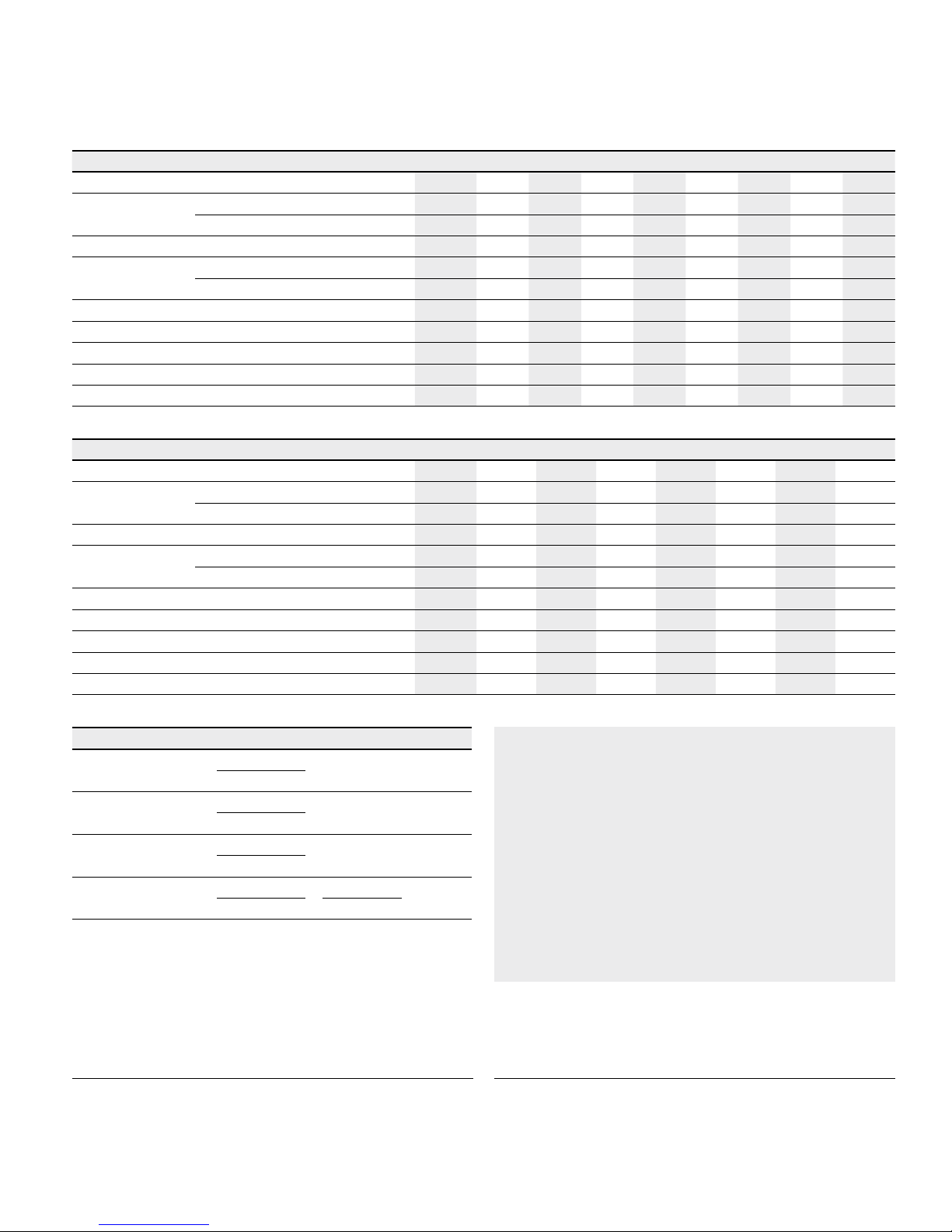

▼ Selection diagram

-40 -25 -10 10 30 50 90 11570

0

7

10

40

60

20

100

200

400

600

1000

1600

VG 22

VG 32

VG 46

VG 68

VG 100

16

36

Optimum operating viscosity range v

opt

Optimum efficiency

Maximum permissible viscosity for cold start

Minimum permissible viscosity for short‑term operation

Temperature θ [°C]

Viscosity ν [mm

2

/s]

Continuous operation

Warm‑up phase

Minimum permissible temperature for cold start

Filtration of the hydraulic fluid

Finer filtration improves the cleanliness level of the hydraulic

fluid, which increases the service life of the axial piston unit.

A cleanliness level of at least 19/17/14 is to be maintained

according to ISO4406.

RE 91001-01-X-B2/01.2016, Bosch Rexroth AG

Axial piston fixed motor | A2FM for explosive areas

Shaft seal

5

Shaft seal

Permissible pressure loading

The service life of the shaft seal is influenced by the speed

of the axial piston unit and the case drain pressure.

Themean differential pressure of 2bar between the case

and the ambient pressure may not be enduringly exceeded

at normal operating temperature. Momentary (t<0.1s)

pressure peaks of up to 10bar are allowed. The service life

of the shaft seal decreases with increasing frequency of

pressure peaks and increasing mean differential pressure.

The case pressure must be equal to or higher than the

ambient pressure.

These values are valid for ambient pressure p

abs

=1bar.

The FKM shaft seal ring may be used for leakage tempera‑

tures from ‑25°C to +90°C.

Flow direction

Direction of rotation, viewed on drive shaft

clockwise counter‑clockwise

A to B B to A

Speed range

No limit to minimum speed n

min

. If uniformity of motion

isrequired, speed n

min

must not be less than 50 rpm.

Forthe maximum speed, see Technical data on page7.

Bosch Rexroth AG, RE 91001-01-X-B2/01.2016

6 A2FM for explosive areas | Axial piston fixed motor

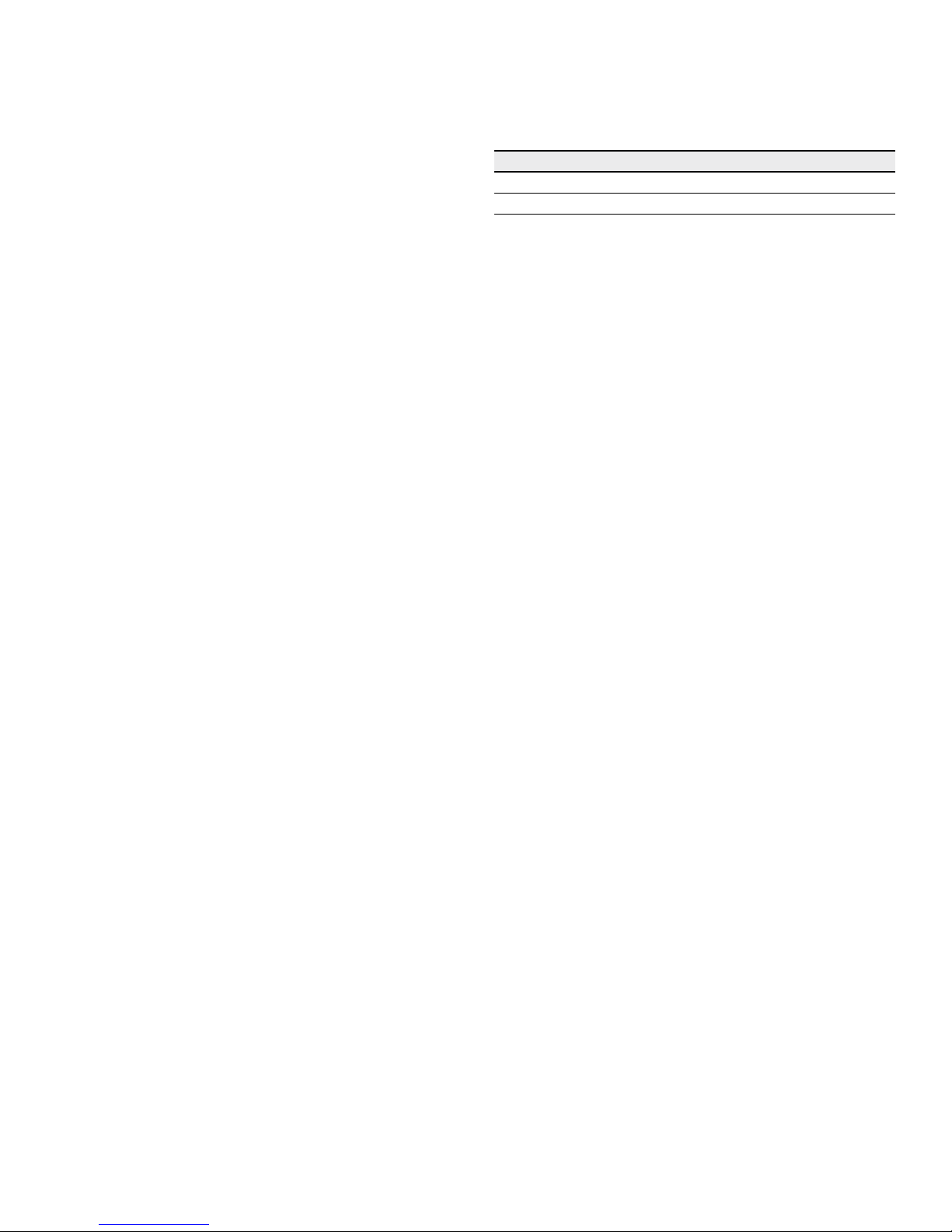

Working pressure range

Working pressure range

Pressure at the working line ports A or B Definition

Nominal pressure p

nom

400bar absolute The nominal pressure corresponds to the maximum design pressure.

Maximum pressure p

max

450bar absolute The maximum pressure corresponds to the maximum working pressure with‑

in the single operating period. The sum of the single operating periods must

not exceed the total operating period.

Single operating period 10s

Total operating period 300h

Minimum pressure (high‑pressure side) 25bar absolute Minimum pressure at the high‑pressure side (A or B) required to prevent

damage to the axial piston unit.

Minimum pressure – pump operating

mode (inlet)

See characteristic To prevent damage to the axial piston motor in pump mode (change of high‑

pressure side with unchanged direction of rotation, e.g. when braking),

aminimum pressure must be guaranteed at the working port (inlet).

Theminimum pressure depends on the rotational speed and displacement

of the axial piston unit.

Total pressure p

Su

(pressure A + pressure B)

700bar The summation pressure is the sum of the pressures at both work ports

(A and B).

Rate of pressure change R

Amax

Maximum permissible rate of pressure build‑up and reduction during

a pressure change across the entire pressure range.

with built‑in pressure relief valve 9000bar/s

without pressure relief valve 16000bar/s

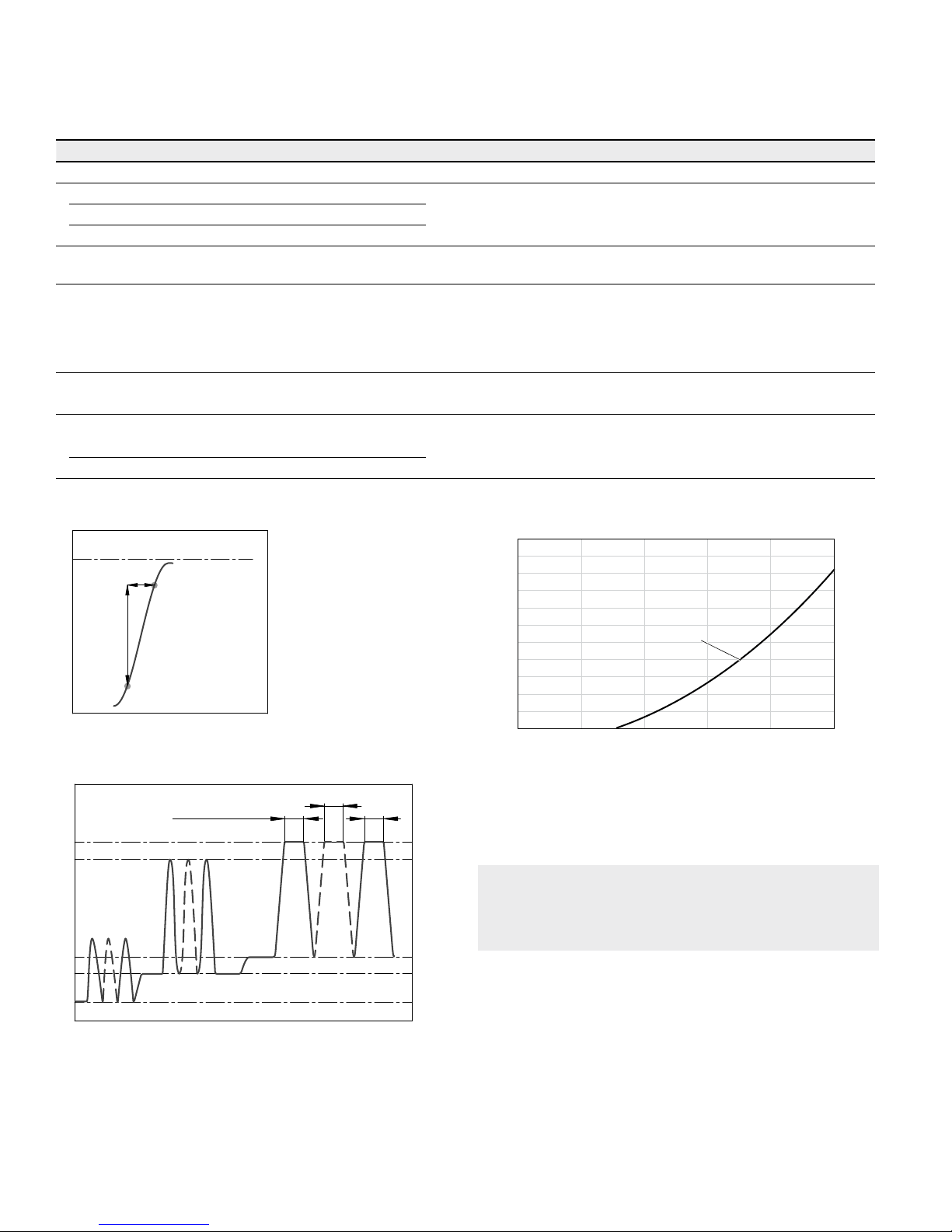

▼ Rate of pressure change R

Amax

p

nom

∆t

∆p

Time t

Pressure p

▼ Pressure definition

t

1

t

2

t

n

Single operating

period

Pressure p

Minimum pressure (high‑pressure side)

Maximum pressure p

max

Nominal pressure p

nom

Time t

Total operating period = t1 + t2 + … + t

n

▼ Minimum pressure – pump operating mode (inlet)

Inlet pressure p

abs

[bar]

Rotational speed n / n

nom

1.00.80.60.4

0.2

0

1

2

4

6

8

10

12

V

g

This diagram is only valid for the optimum viscosity range

of ν

opt

=36 to 16mm2/s.

Please contact us if these conditions cannot be satisfied.

Note

Working pressure range valid when using hydraulic fluids

based on mineral oils. Values for other hydraulic fluids,

please contact us.

RE 91001-01-X-B2/01.2016, Bosch Rexroth AG

Axial piston fixed motor | A2FM for explosive areas

Technical data

7

Technical data

Size NG 10 12 16 23 28 32 45 56

Displacement geometric, per revolution

V

g

cm

3

10.3 12 16 22.9 28.1 32 45.6 56.1

Speed maximum

1)

Temperature class T3

n

max

rpm 8000 8000 8000 6300 6300 6300 5600 5000

Temperature class T4

n

max

rpm 4000 4000 4000 3150 3150 3150 2800 2500

Inlet flow

2)

q

v max

l/min 82 96 128 144 177 202 255 281

Torque

3)

at Δp = 350bar T

Nm 57 67 89 128 157 178 254 313

at Δp = 400bar T

Nm 66 76 102 146 179 204 290 357

Rotary stiffness

c

min

kNm/rad 0.92 1.25 1.59 2.56 2.93 3.12 4.18 5.94

Moment of inertia for rotary group

J

TW

kgm

2

0.0004 0.0004 0.0004 0.0012 0.0012 0.0012 0.0024 0.0042

Maximum angular acceleration

α

rad/s² 5000 5000 5000 6500 6500 6500 14600 7500

Case volume

V

l 0.17 0.17 0.17 0.20 0.20 0.20 0.33 0.45

Weight approx.

m

kg 5.4 5.4 5.4 9.5 9.5 9.5 13.5 18

Size NG 63 80 90 107 125 160 180

Displacement geometric, per revolution

V

g

cm

3

63 80.4 90 106.7 125 160.4 180

Speed maximum

1)

Temperature class T3

n

max

rpm 5000 4500 4500 4000 4000 3600 3600

Temperature class T4

n

max

rpm 2500 2250 2250 2000 2000 1800 1800

Inlet flow

2)

q

v max

l/min 315 362 405 427 500 577 648

Torque

3)

at Δp = 350bar T

Nm 351 448 501 594 696 893 1003

at Δp = 400bar T

Nm 401 512 573 679 796 1021 1146

Rotary stiffness

c

min

kNm/rad 6.25 8.73 9.14 11.2 11.9 17.4 18.2

Moment of inertia for rotary group

J

TW

kgm

2

0.0042 0.0072 0.0072 0.0116 0.0116 0.0220 0.0220

Maximum angular acceleration

α

rad/s² 7500 6000 6000 4500 4500 3500 3500

Case volume

V

l 0.45 0.55 0.55 0.8 0.8 1.1 1.1

Weight approx.

m

kg 18 23 23 32 32 45 45

Determining the operating characteristics

Inlet flow

q

v

=

V

g

× n

[l/min]

1000 × η

v

Rotational

speed

n

=

q

v

× 1000 × η

v

[rpm]

V

g

Torque

T

=

V

g

× Δp × η

hm

[Nm]

20 × π

Power

P

=

2 π × T × n

=

q

v

× Δp × η

t

[kW]

60000 600

Key

V

g

Displacement per revolution [cm3]

Δp

Differential pressure [bar]

n

Rotational speed [rpm]

η

v

Volumetric efficiency

η

hm

Hydraulic‑mechanical efficiency

η

t

Total efficiency (ηt = ηv × ηhm)

Note

▶ Theoretical values, without efficiency and tolerances;

values rounded.

▶ Operation above the maximum values or below the

minimum values may result in a loss of function,

areduced service life or in the destruction of the axial

piston unit. Other permissible limit values, such as

speed variation, reduced angular acceleration as a

function of the frequency and the permissible angular

acceleration at start (lower than the maximum angular

acceleration) can be found in data sheet 90261.

1) The valid values (observing the maximum permissible flow):

– for the optimum viscosity range from ν

opt

= 36 to 16 mm2/s

– with hydraulic fluid on the basis of mineral oil

2) Observe limitation of inlet flow due to counterbalance valve (see

page 24).

3)

Torque without radial force, with radial force

see page 8.

Bosch Rexroth AG, RE 91001-01-X-B2/01.2016

8 A2FM for explosive areas | Axial piston fixed motor

Technical data

Permissible radial and axial forces of the drive shafts

Size NG 10 10 12 12 16 23 23 28 28

Drive shaft Ø mm 20 25 20 25 25 25 30 25 30

Maximum radial force

1)

at distance a

(from shaft collar)

a

F

q

F

q max

kN 3.0 3.2 3.0 3.2 3.2 5.7 5.4 5.7 5.4

a mm 16 16 16 16 16 16 16 16 16

Maximum torque at F

q max

T

max

Nm 66 66 76 76 102 146 146 179 179

Maximum differential pressure at V

g max

and F

q max

Δp

max

bar 400 400 400 400 400 400 400 400 400

Maximum axial force at

standstill or pressure‑

free operation

–

+

F

ax

+F

axmax

N 0 0 0 0 0 0 0 0 0

−F

axmax

N 320 320 320 320 320 500 500 500 500

Permissible axial force per bar working pressure

+F

axperm

/bar

N/bar 3.0 3.0 3.0 3.0 3.0 5.2 5.2 5.2 5.2

Size NG 32 45 56 56

2)

56 63 80 80

2)

80

Drive shaft Ø mm 30 30 30 30 35 35 35 35 40

Maximum radial force

1)

at distance a

(from shaft collar)

a

F

q

F

q max

N 5.4 7.6 9.5 7.8 9.1 9.1 11.6 11.1 11.4

a mm 16 18 18 18 18 18 20 20 20

Maximum torque at F

q max

T

max

Nm 204 290 357 294 357 401 512 488 512

Maximum differential pressure at V

g max

and F

q max

Δp

max

bar 400 400 400 330 400 400 400 380 400

Maximum axial force at

standstill or pressure‑

free operation

–

+

F

ax

+F

axmax

N 0 0 0 0 0 0 0 0 0

−F

axmax

N 500 630 800 800 800 800 1000 1000 1000

Permissible axial force per bar working pressure

+F

axperm

/bar

N/bar 5.2 7.0 8.7 8.7 8.7 8.7 10.6 10.6 10.6

Size NG 90 107 107 125 160 160 180

Drive shaft Ø mm 40 40 45 45 45 50 50

Maximum radial force

1)

at distance a (from

shaft collar)

a

F

q

F

q max

kN 11.4 13.6 14.1 14.1 18.1 18.3 18.3

a mm 20 20 20 20 25 25 25

Maximum torque at F

q max

T

max

Nm 573 679 679 796 1021 1021 1146

Maximum differential pressureat V

g max

and F

q max

p

nom perm.

bar 400 400 400 400 400 400 400

Maximum axial force at

standstill or pressure‑

free operation

–

+

F

ax

+F

axmax

N 0 0 0 0 0 0 0

−F

axmax

N 1000 1250 1250 1250 1600 1600 1600

Permissible axial force per bar working pressure

+F

axperm

/bar

N/bar 10.6 12.9 12.9 12.9 16.7 16.7 16.7

1) With intermittent operation

2)

Restricted technical data only for splined shaft

RE 91001-01-X-B2/01.2016, Bosch Rexroth AG

Axial piston fixed motor | A2FM for explosive areas

Technical data

9

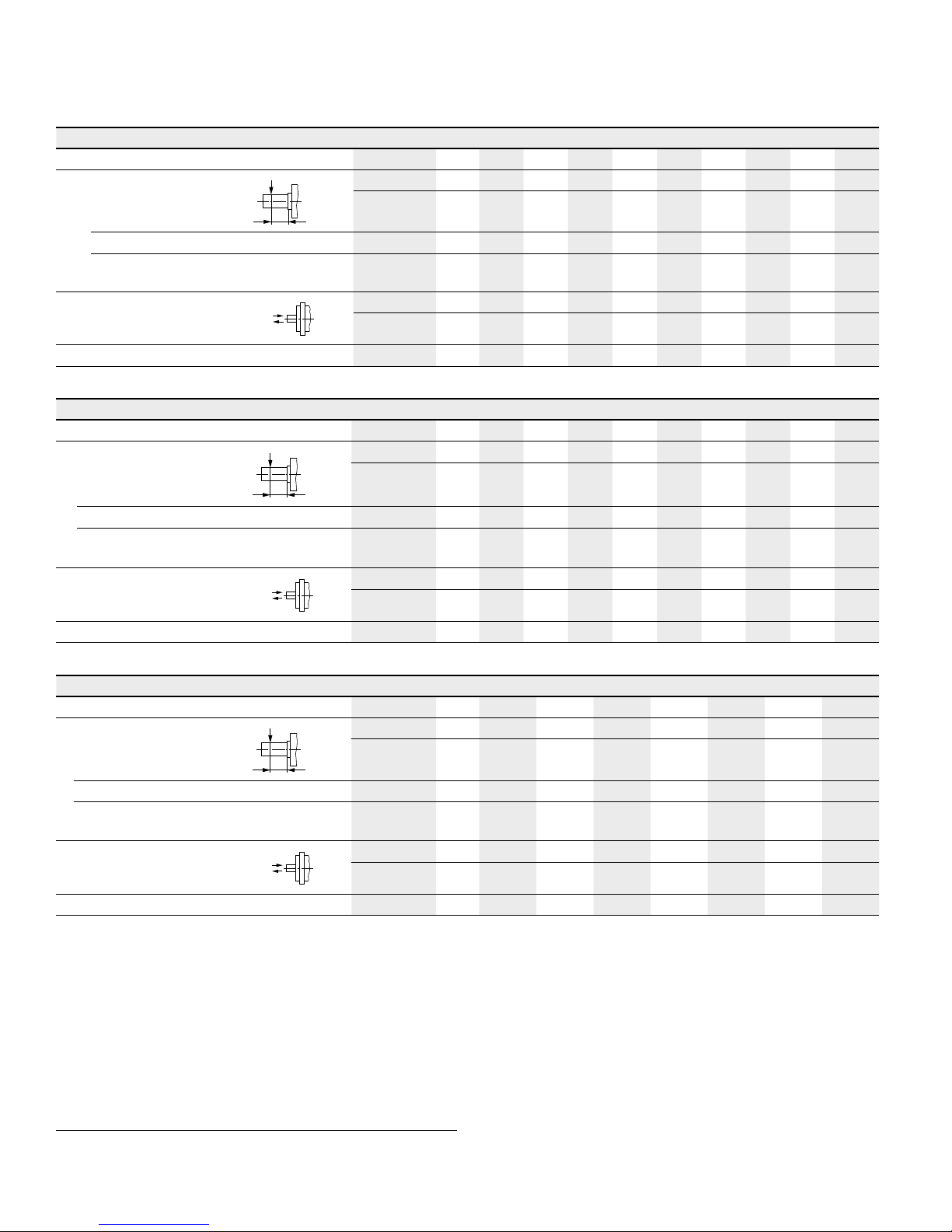

Effect of radial force F

q

on the service life of bearings

By selecting a suitable direction of radial force F

q

, the load

on the bearings, caused by the internal rotary group forces

can be reduced, thus optimizing the service life of the

bearings. Recommended position of mating gear is depen‑

dent on direction of rotation. Examples:

Gear output drive V-belt output

NG

φ

opt

φ

opt

10 to 180 ±70°

±45°

Note

▶ The permissible axial force in direction −F

ax

is to be

avoided as the lifetime of the bearing is reduced.

▶ Special requirements apply in the case of belt drives.

Please contact us.

▼ Toothed gear output drive

2

3

1

A B

φ

opt

φ

opt

1 “Counter‑clockwise” rotation. Pressure at port B

2 “Clockwise

” rotation, Pressure at port A

3 Bidirectional direction of rotation

Loading...

Loading...