Page 1

Gas Cooktop

Installation Manual

NGM5056UC, NGM5656UC, NGM8056UC, NGM8656UC,

NGMP056UC, NGMP656UC

Page 2

Table of Contents

Use and care manual

Safety Definitions .......................................................... 2

IMPORTANT SAFETY INSTRUCTIONS ........................ 3

Gas Appliance Safety .......................................................... 3

Propane Gas Installation ..................................................... 4

Equipment and Usage Safety Requirements .................. 4

Appliance Handling Safety ................................................. 5

Safety Codes and Standards ............................................. 5

State of California Proposition 65 Warning: .................... 5

Electric Safety ....................................................................... 5

High Altitude Installation ..................................................... 5

Before You Begin .......................................................... 6

Tools and Parts Needed ..................................................... 6

Parts Included ....................................................................... 6

General Information ............................................................. 6

7KLV%RVFK$SSOLDQFHLVPDGHE\

%6++RPH$SSOLDQFHV&RUSRUDWLRQ

0DLQ6WUHHW6XLWH

,UYLQH&$

4XHVWLRQV"

Preparation ............................................................................ 6

Installation Procedure .................................................. 8

Prepare the Countertop ...................................................... 8

Seal the Cooktop with Foam Tape ................................... 8

Install the Cooktop ............................................................... 9

Connect Gas Supply ........................................................... 9

Connect Electrical Supply ............................................... 10

Burner Cap and Burner Base Placement ..................... 10

Install Burner Grates ......................................................... 12

Check the Installation ....................................................... 12

Service ......................................................................... 13

Before Calling Service ..................................................... 13

ZZZERVFKKRPHFRPXV

:HORRNIRUZDUGWRKHDULQJIURP\RX

Safety Definitions

9 WARNING

This indicates that death or serious injuries may

occur as a result of non-observance of this warning.

9 CAUTION

This indicates that minor or moderate injuries may

occur as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or property may occur as a result of non-compliance with this advisory.

Note: This alerts you to important information and/or tips.

2

Page 3

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY I NST RUCT I ONSREAD AND SAVE THESE INSTRUCTIONS

Gas Appliance Safety

:$51,1*,IWKHLQIRUPDWLRQLQWKHVHLQVWUXFWLRQV

LVQRWIROORZHGH[DFWO\DILUHRUH[SORVLRQPD\

UHVXOWFDXVLQJSURSHUW\GDPDJHSHUVRQDOLQMXU\

RUGHDWK

²

'RQRWVWRUHRUXVHJDVROLQHRURWKHUIODPPDEOH

YDSRUVDQGOLTXLGVLQWKHYLFLQLW\RIWKLVRUDQ\

RWKHUDSSOLDQFH

²

:+$772'2,)<2860(//*$6

'RQRWWU\WROLJKWDQ\DSSOLDQFH

'RQRWWRXFKDQ\HOHFWULFDOVZLWFK

'RQRWXVHDQ\SKRQHLQ\RXUEXLOGLQJ

,PPHGLDWHO\FDOO\RXUJDVVXSSOLHUIURPD

QHLJKERU·VSKRQH)ROORZWKHJDVVXSSOLHU·V

LQVWUXFWLRQV

,I\RXFDQQRWUHDFK\RXUJDVVXSSOLHUFDOO

WKHILUHGHSDUWPHQW

,QVWDOODWLRQDQGVHUYLFHPXVWEHSHUIRUPHG

²

E\DTXDOLILHGLQVWDOOHUVHUYLFHDJHQF\RUWKH

JDVVXSSOLHU

3

Page 4

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT: SAVE THESE INSTRUCTIONS FOR THE LOCAL ELECTRICAL INSPECTOR’S USE.

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE UNIT FOR THE OWNER.

OWNER: PLEASE RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

WARNING

When properly cared for, your new appliance has been

designed to be safe and reliable. Read all instructions

carefully before use. These precautions will reduce the

risk of burns, electric shock, fire and injury to persons.

When using kitchen appliances, basic safety precautions

must be followed including those in the following pages.

WARNING

Do not repair, replace or remove any part of the

appliance unless specifically recommended in the

manuals. Improper installation, service or maintenance

can cause injury or property damage. Refer to this

manual for guidance. All other servicing must be done by

an authorized service agency.

▯ Install a gas shutoff valve near the appliance. It must

be easily accessible in an emergency.

▯ Leak testing must be conducted by the installer

according to the instructions in this manual.

▯ The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing at pressures in excess of

1/2 psi (3.5 kPa).

▯ The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psi (3.5 kPa).

▯ The minimum supply pressure must be 1” water

column above the manifold pressure printed on the

data plate.

▯ The maximum supply pressure must not exceed 14.0

inches water column (34.9 Millibars).

▯ For Massachusetts installations:

▯ Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified

or licensed by the state, province or region where

this appliance is being installed.

▯ Shut-off valve must be a “T” handle gas cock.

▯ Flexible gas connector must be new and not longer

than 36 inches.

▯ Installer-show the owner where the gas shut-off valve

is located.

Propane Gas Installation

▯ The propane gas tank must be equipped with its own

high pressure regulator. In addition, the regulator

supplied with this unit must also be used.

▯ The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or installer must do the

conversion.

Equipment and Usage Safety Requirements

▯ The cooktop must be used in conjunction with a

suitable ventilation system.

▯ Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the

appliance. Never allow children to play with packaging

material.

▯ Never modify or alter the construction of the

appliance. For example, do not remove panels, wire

covers or screws.

▯ To eliminate the risk of burns or fire while reaching

over heated surface units, cabinet storage space

located above the surface units should be avoided. If

cabinet storage is to be provided, the risk can be

reduced by installing a hood that projects horizontally

a minimum of 5 inches beyond the bottom of the

cabinet.

▯ Verify that cabinets above the cooktop are a maximum

of 13 inches (330mm) deep.

4

Page 5

9 IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Appliance Handling Safety

CAUTION

▯ Unit is heavy and requires at least two people

or proper equipment to move.

▯ Hidden surfaces may have sharp edges. Use

caution when reaching behind or under

appliance.

Safety Codes and Standards

▯ This appliance complies with one or more of the

following standards:

ANSI Z21.1, Household Cooking Gas Appliances

▯ It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

▯ Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 or, in Canada, the

Natural Gas and Propane Installation Code, CSA

B149.1.

▯ The appliance must be electrically grounded in

accordance with local codes or, in the absence of

local codes, with the National Electrical Code ANSI/

NFPA 70 or the Canadian Electric Code, CSA C22.1-

02.

State of California Proposition 65 Warning:

WARNING

This product can expose you to chemicals including vinyl

chloride, which is known to the State of California to

cause cancer and birth defects or other reproductive

harm. For more information go to

www.P65Warnings.ca.gov.

Note: IMPORTANT SAFETY NOTICE: The California Safe

Drinking and Toxic Enforcement Act requires the

Governor of California to publish a list of substances

known to the state to cause cancer, birth defect or other

reproductive harm, and requires businesses to warn

customers of potential exposure to such substances. The

burning of gas cooking fuel and the elimination of soil

during self-cleaning can generate small amounts of

carbon monoxide. The fiberglass insulation in Self Clean

ovens gives off very small amounts of formaldehyde

during the first several cleaning cycles. California lists

formaldehyde as a potential cause of cancer. Carbon

monoxide is a potential cause of reproductive toxicity.

Exposure to these substances can be minimized by:

1.

Providing good ventilation when cooking with gas.

2.

Operating the unit according to the instructions in this manual.

Electric Safety

▯ Before you plug in an electrical cord, be sure all

controls are in the OFF position.

▯ For appliances equipped with a cord and plug, do not

cut or remove the ground prong. It must be plugged

into a matching grounding type receptacle to avoid

electrical shock. If there is any doubt as to whether the

wall receptacle is properly grounded, the customer

should have it checked by a certified electrician.

▯ This appliance should be installed in accordance with

the National Electric Code or Canadian Electrical

Code. It is required that the cooktop be installed on a

grounded, non-GFCI branch circuit.

▯ Installer-show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

▯ Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

▯ Be sure your appliance is properly installed and

grounded by a certified technician. Installation,

electrical connections and grounding must comply

with all applicable codes.

High Altitude Installation

Contact customer service for use at altitudes above

2,000 feet (610 meters).

5

Page 6

Before You Begin

( )

Tools and Parts Needed

▯ Phillips Head Screwdriver

▯ Precision Flathead Screwdriver

▯ Tape Measure

▯ Teflon Tape (Gas Rated)

▯ Adjustable Wrench or Channel Lock Pliers

Parts Included

▯ Foam Tape

▯ Mounting Brackets (4)

▯ Screws, #10-32 x 2 1/2” (63.8 mm) (4)

▯ Sheet Metal Screws, #8 x 3/8” (9.5 mm) (4)

▯ Washers (4)

▯ Burner Grates (3)

▯ Burners

▯ 30” models: (4) or (5)

▯ 36” models: (5)

▯ Burner Caps

▯ 30” models: (4) or (5)

▯ 36” models: (5)

▯ Pressure Regulator

▯ LP Gas Conversion Kit

Note: If parts are missing or damaged, call the number or write to the address listed on the inside back cover.

Preparation

Electrical Requirements

9 CAUTION

Do not use an extension cord with the gas cooktop.

This appliance requires a 60 Hz, 15 Amp, 120 VAC

connection. Plan the installation so that the power

connection is accessible from the front of the cabinet.

Gas Requirements

Supply Pressure:

▯ Natural Gas: 7 inches water column (14.9 Millibars)

▯ Propane Gas: 11 inches water column (27.4 Millibars)

The propane gas tank must be equipped with its own

high pressure regulator in addition to the pressure

regulator supplied with this unit. The cooktop is shipped

from the factory for use with natural gas. For use with LP

conversion, a certified technician or installer must do the

conversion.

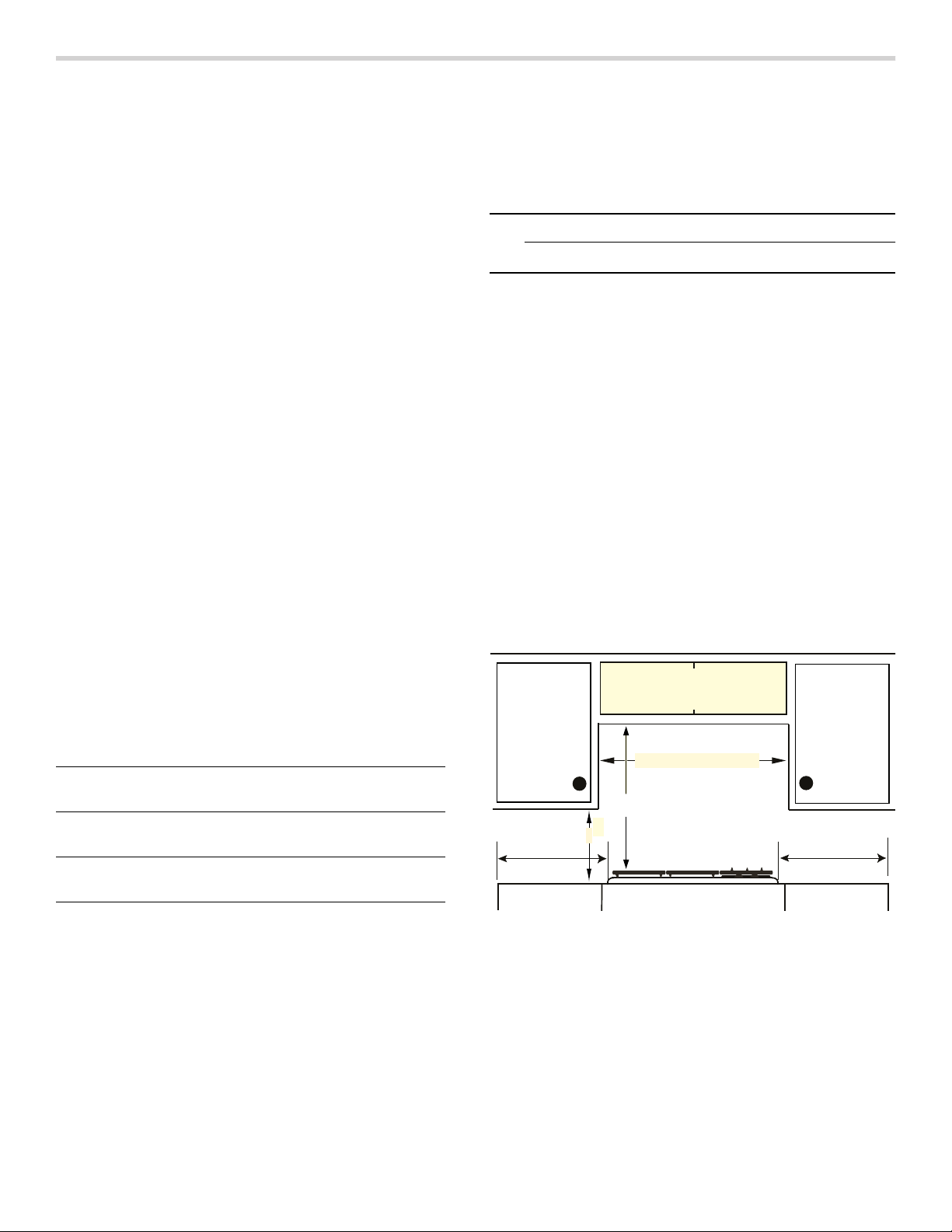

Cabinet Requirements

General Information

Overall Dimensions

30” Models 36” Models

Width (Side to Side) 31”

(788 mm)

Depth (Front to Back) 21 1/4”

(540 mm)

Height (Top to Bottom) 3 13/16”

(97 mm)

Note: These are overall dimensions NOT cutout dimensions.

37”

(940 mm)

21 1/4”

(540 mm)

3 13/16”

(97 mm)

Depth from Back Wall

Cabinet 13" (330) max.

Centered over cooktop

NGM30 - min. 30" (762)

NGM36 - min. 36" (914)

Above counter - min. 30" (762)

min. 18" (458)

Left Side

min. 12" (305)

to combustible surface

Rear wall - 2" (51mm)

Right Side

min. 12" (305)

=mm

▯ Instructions are based on standard American cabinets

36” high (91cm) x 24” deep (61cm) with a 25”

(63cm) countertop.

▯ The maximum depth of a cabinet installed above the

cooktop is 13” (33cm).

Note: All measurements given must be precisely followed. If nonstandard cabinets are used, make sure they are installed with minimum dimensions shown.

Plan the installation of the unit so that the power cord,

gas shut-off valve and gas pressure regulator are

accessible from the front of the cabinet.

6

Page 7

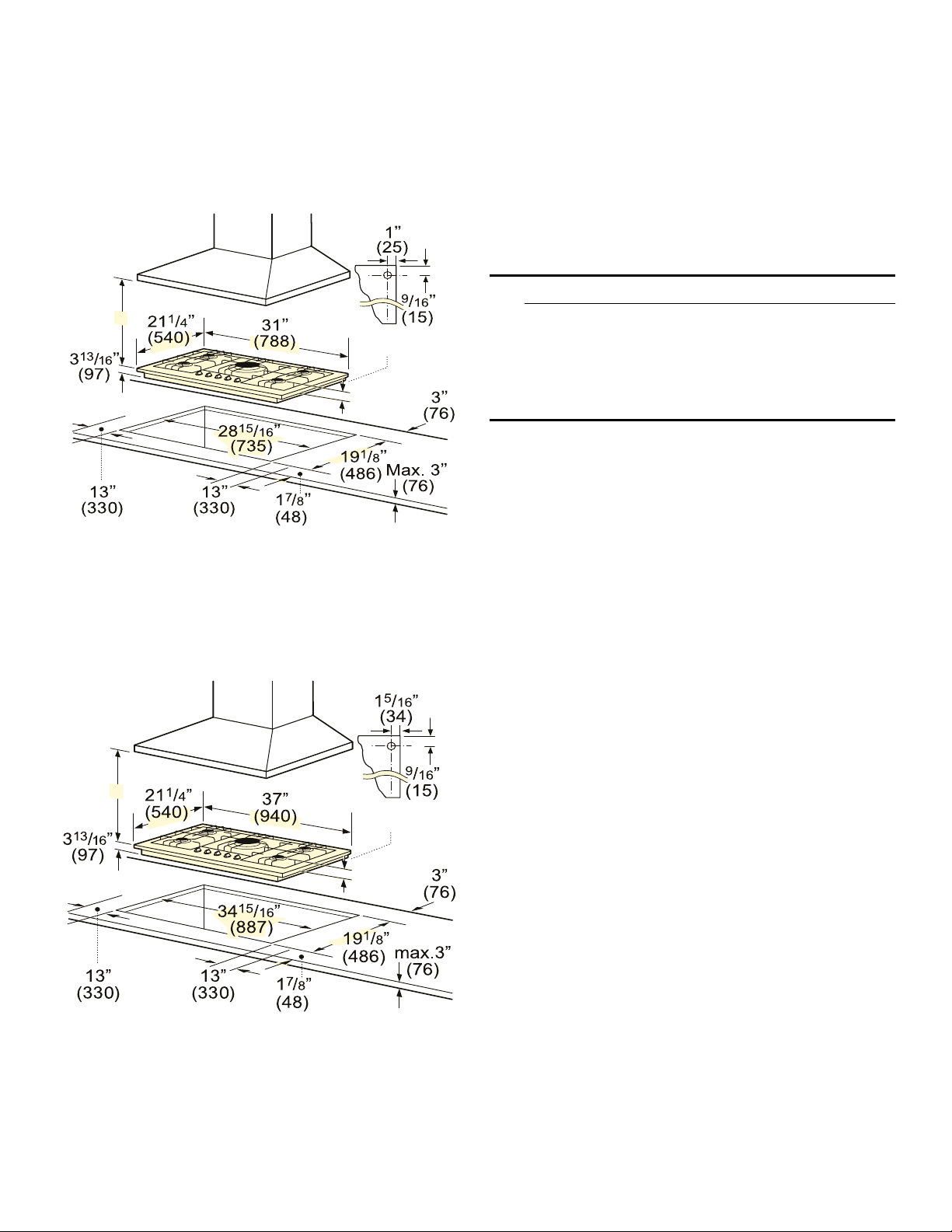

Countertop Requirements

Mounting Requirements

Note: All measurements given must be precisely

followed. If nonstandard cabinets are used, make sure

they are installed with minimum dimensions shown in

image below.

gas

connection

*

1ʎ/ʓʘ”

(37)

*Dimension from countertop to top of grates

**When installed in combination with a hood,

refer to hood manufacturer

’s requirements for installation.

( )=mm

Use the hold down brackets supplied. See “Install the

Cooktop” section for further details.

Ventilation Requirements

We strongly recommend the installation of ventilation with the appliance. The appliance must be installed according to the furnished instructions.

9 CAUTION

The appliance should not be installed with a

ventilation system that blows air downward toward

the burners. This type of ventilation system may

cause ignition and combustion problems with the

gas cooking appliance resulting in personal injury or

unintended operation.

30” Models

*Dimension from countertop to top of grates

**When installed in combination with a hood,

refer to hood manufacturer

’s requirements for installation.

gas

connection

*

1ʎ/ʓʘ”

(37)

( )=mm

36” Models

7

Page 8

Installation Procedure

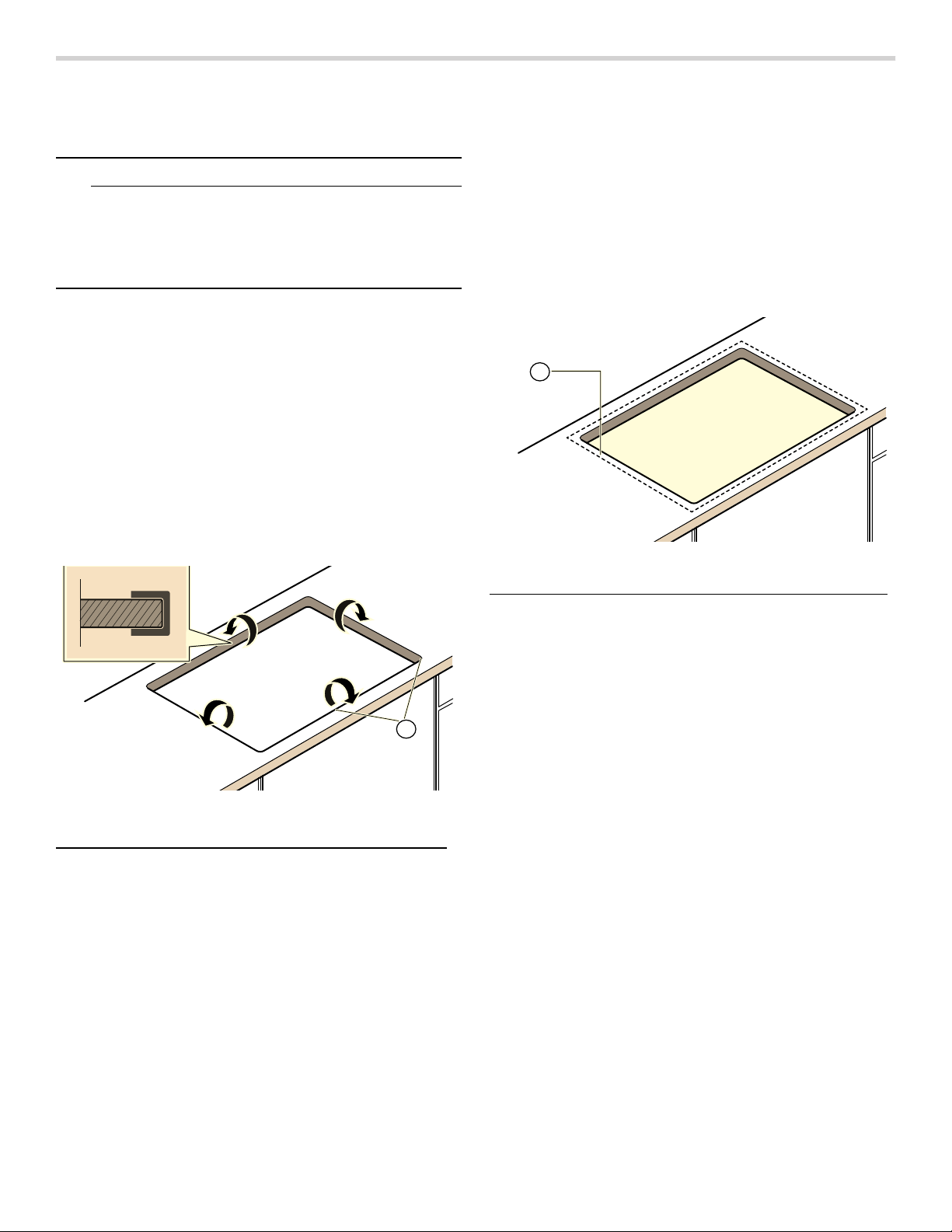

Prepare the Countertop

9 WARNING

To avoid electrical shock hazard, before installing

the cooktop, switch power off at the service panel to

prevent the power from being switched on

accidentally.

Cut out the countertop per the dimensions shown in the section “Cabinet Requirements”.

Some solid surface materials require different cutting

methods. Consult with the solid surface manufacturer for

the correct cutting method needed. Apply heat reflective

tape such as Scotch Aluminum Foil Tape #425 or #427

(not included) around the cutout so that it folds over the

top and sides. Do not wrap the tape underneath the

cooktop. Be sure the tape extends beyond the outermost

flange of the cooktop. All corners should be covered with

tape.

Seal the Cooktop with Foam Tape

Note: Failure to install the foam tape may affect burner

performance.

Apply the self adhesive foam tape in one continuous rectangle directly to the counter around the perimeter of the cutout as shown by the dotted line in the image below. The foam tape should be flush with the edge of the cutout.

$

Foam Tape Placement-Counter Cutout

A Foam Tape Placement

Solid Surface Countertops-Counter Cutout

A Heat Reflective Tape

$

8

Page 9

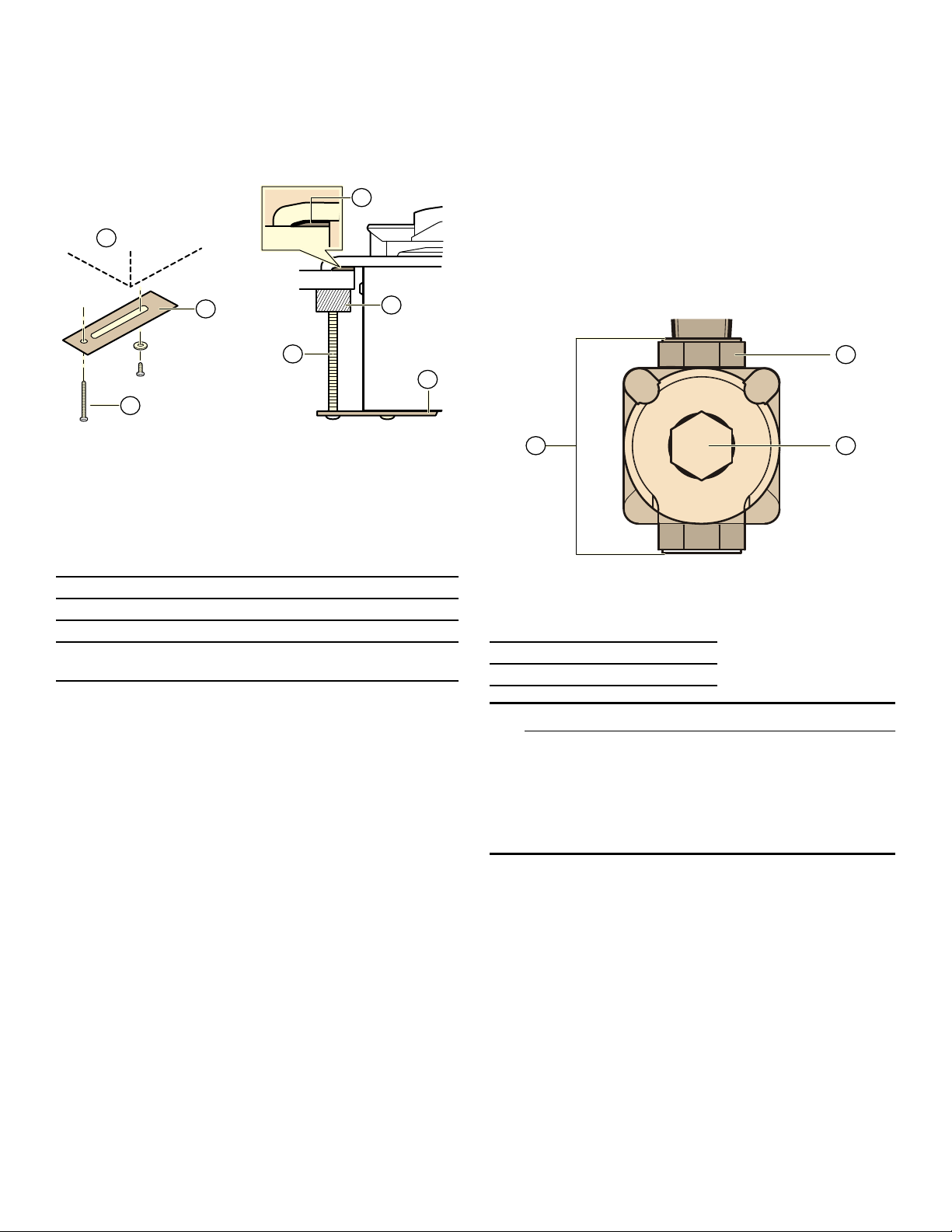

Install the Cooktop

Insert the cooktop into the cutout. Attach the clamps of the mounting brackets packaged with the cooktop. Use the washer and screws provided.

'

$

Connect Gas Supply

The gas inlet to the unit is located at the right rear of the cooktop.

Install the pressure regulator (supplied with unit) to

manifold pipe using Teflon tape on threads of manifold

pipe. Turn to hand tighten plus 1/4 turn, not exceeding 1

turn for alignment. To prevent possible damage to the

gas pressure regulator, install it after the cooktop is in its

permanent position. When the regulator is securely

installed on the manifold pipe, the conversion nut will be

easily accessible.

%

*

(

+

&

Adjust the mounting brackets to desired position and tighten screws to cooktop. Insert adjusting screw into clamp and secure cooktop to countertop.

Attaching Mounting Brackets

A Cooktop

B/H Hold Down Bracket

C/E Adjusting Screw

D Foam Tape (Seal)

G Wooden Block (to be used with solid surfacing

material)

Note: For solid surface material installations:

▯ Insert a wooden block between the end of the screw

and the bottom of the countertop.

▯ Do not overtighten adjusting screw.

▯ Trim excess aluminum tape around cooktop flange.

Tip: Install hold down bracket without the adjusting screw installed. Turn hold down brackets flush with the sides of the cutout. This will help with inserting cooktop in hard-to-reach spaces.

$

%&

Pressure Regulator

A Manifold Pipe

B Conversion Nut

C Pressure Regulator

9 WARNING

Do not attempt any adjustment of the pressure

regulator, except when converting to propane.

Adjustments could lead to leaks or cause incorrect

gas pressure to the appliance.

9

Page 10

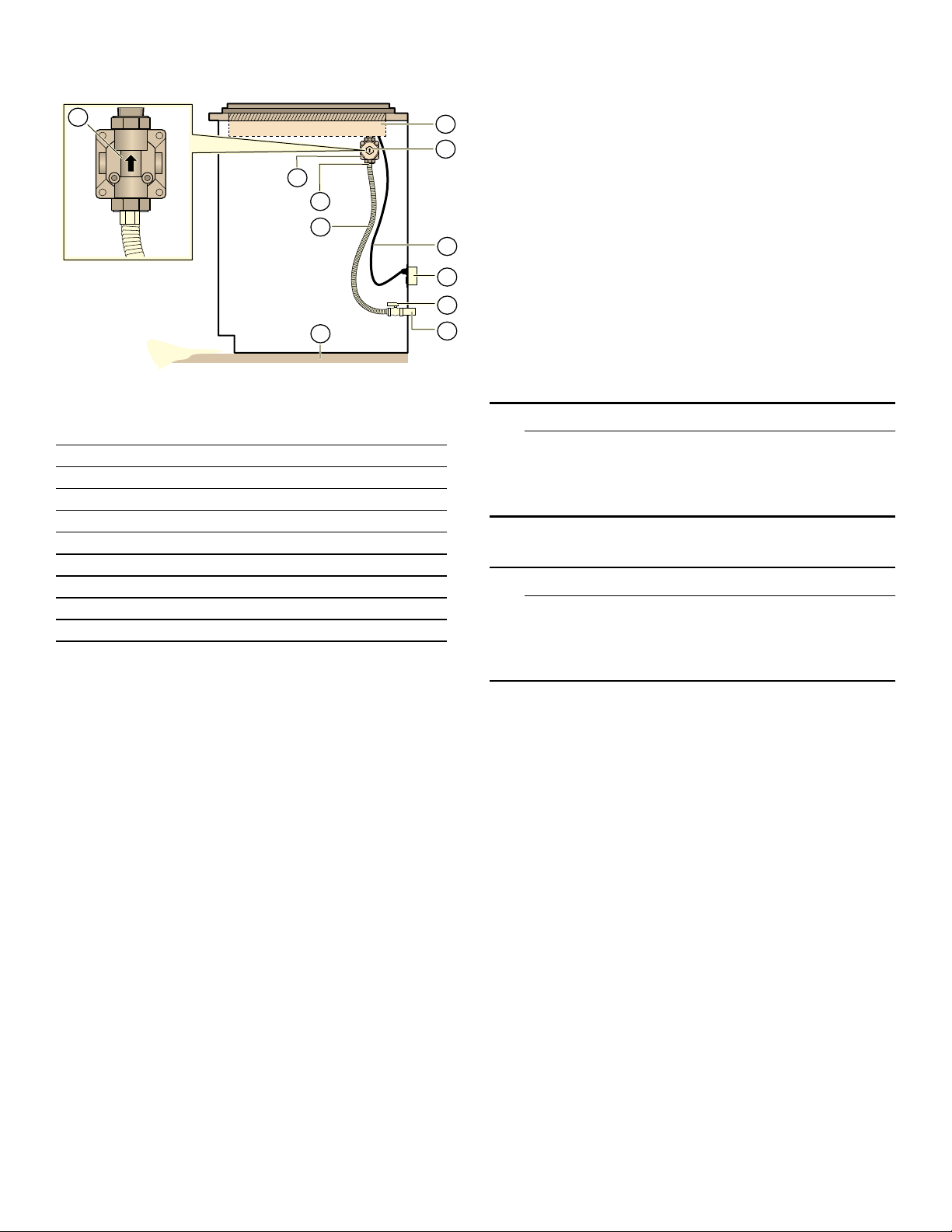

Side View Gas Cooktop Installation

Important Notes for Gas Connection:

%

$

%

&

'

(

*

Arrow on the back of

the pressure regulator

shows the direction of

gas flow.

/

+

-

.

Gas and Electrical Location

A Rough-in Cooktop Box

B Arrow on Pressure Regulator

C Pressure Regulator

D 1/2” Female Pipe Threads

E Flexible Gas Line

G Power Cord (60 inches/1,524mm)

H 120 Volt Receptacle

J Gas Cut-off Valve

K Gas Supply Line Stub-out

L Floor

Connect the gas supply line to the unit pressure regulator using a 1/2” flex gas line connector between manual shut-off valve and pressure regulator. Always use a new flex line.

Check supply line connections for leaks using a soap solution or non-corrosive leak detection fluid. Do not use a flame of any sort.

1.

Turn on gas.

2.

Apply a soap solution or non-corrosive leak detection

fluid to all joints and fittings in the gas connection

between the shut-off valve and the cooktop. Include

gas fittings and joints in the cooktop if connections

may have been disturbed during installation. Bubbles

appearing around fittings and connections indicate a

leak.

3.

If a leak appears, turn off supply line gas shut-off valve and tighten connections.

4.

Retest for leaks by turning on the supply line gas shutoff valve. When leak check is complete (no bubbles

appear), test is complete.

5.

Wipe off all soap solution or detection fluid residue.

▯ The appliance and its individual gas shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5kPa).

▯ The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psi (3.5kPa).

Connect Electrical Supply

Before connecting the 5-foot (1.5m) supply cord to a wall receptacle, make certain that gas shut-off valve and all burner controls are in OFF position.

Burner Cap and Burner Base Placement

9 WARNING

To prevent flare-ups, do not use the cooktop without

all burner caps and all burner grates properly

positioned.

9 WARNING

To prevent burns, do not touch burner caps or

grates while hot. Turn the cooktop off and allow the

burners to cool.

The burner caps must be properly placed for the cooktop to function properly. If the burner cap is not properly placed, one or more of the following problems may occur:

▯ Burner flames are too high.

▯ Flames shoot out of burners.

▯ Stainless steel discolors.

▯ Burners do not ignite.

▯ Burner flames light unevenly.

▯ Burner emits gas odor.

10

Page 11

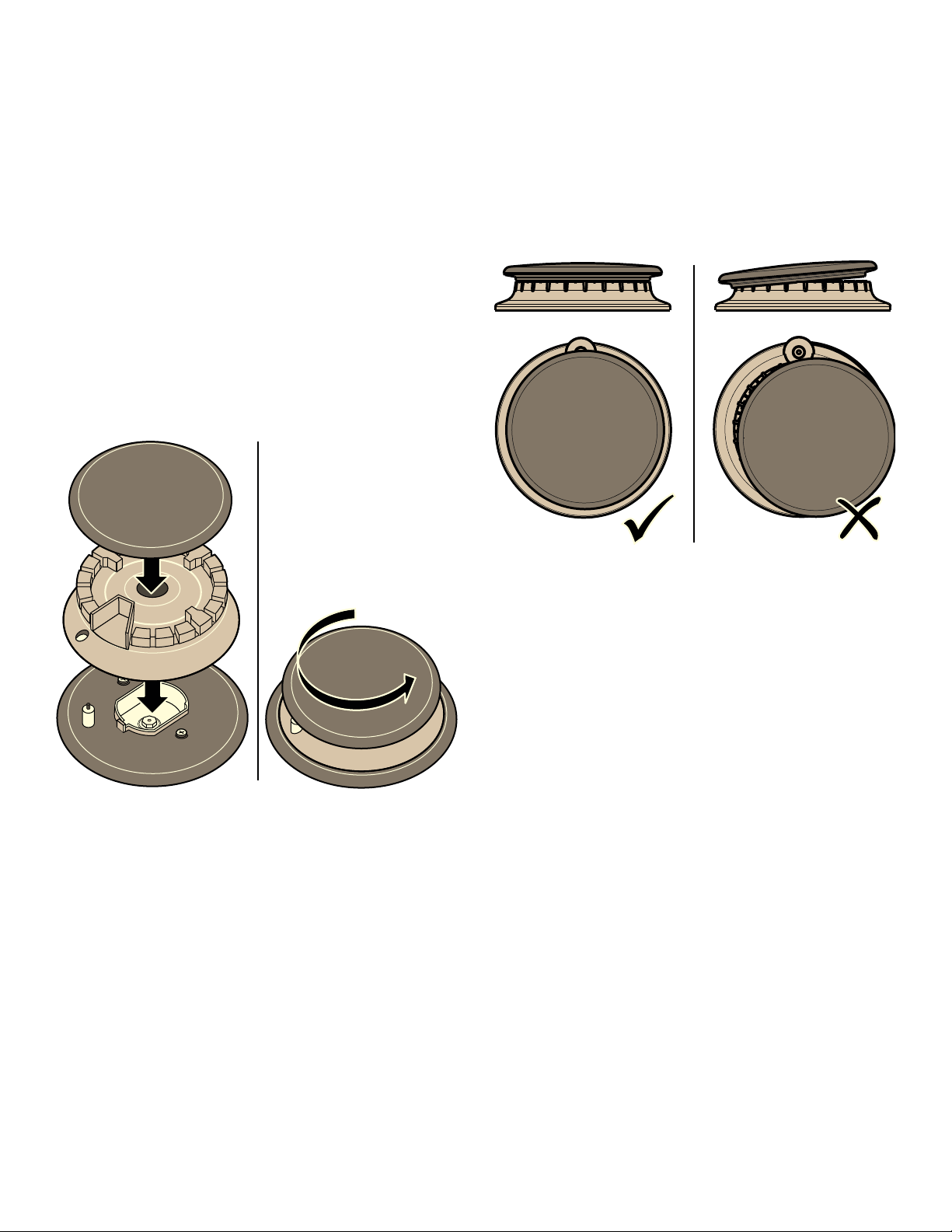

Burner Cap and Burner Base Placement

Checking Burner Cap Placement

▯ After electrical connection is complete, place each

burner base on the corresponding location on the

cooktop. One of the three bars on the burner base

should line up with the notch and prevent the base

from rotating. The small hole or cutout near the edge

should also line up with the igniter. Pay special

attention to avoid damaging the igniter during

installation of the base. See Illustration below.

▯ Once each base is located and resting evenly, place

each burner cap on its correct burner base. See

Illustration.

▯ Place burner cap gently on top of base so that the

prongs of the burner base fit snugly into the groove of

the burner cap.

▯ If the maintop is removed by a certified installer (for

example to check electrical or piping connection) the

panhead screws that were removed must be reinstalled to ensure proper functionality of burners.

1

2

▯ Check to make sure that there is no gap between the

burner cap and burner base. See illustration below for

correct and incorrect placements of the burner cap.

▯ You may gently try to move the burner cap from side

to side to check if it is properly placed. If properly

placed, the cap will click from side to side as the

prongs hit the groove ridge.

Placing Burner Caps and Bases

Checking Burner Cap Placement

11

Page 12

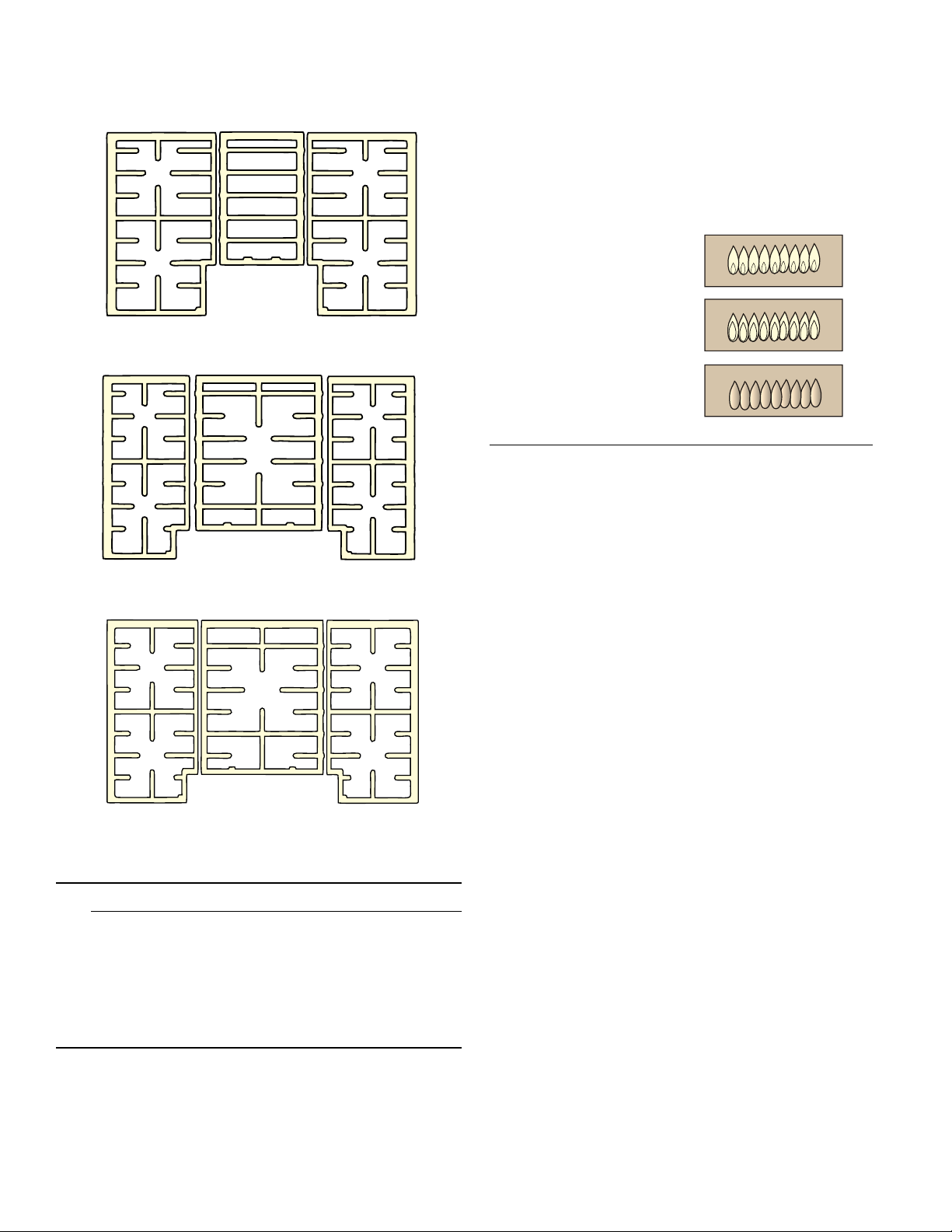

Install Burner Grates

Properly position and install each burner grate as shown in the illustration below.

30” 4 Burner

Check the Installation

Place each correct sized burner cap in its seated, notched position and check the operation of the electric igniters. Check flame characteristics. Flame should be blue with a minimal yellow tip on the outer cone of the flames.

Checking Flame Characteristics

Yellow Flames:

Further adjustment is

required.

Yellow Tips on Outer

Cones:

Normal for LP Gas

Soft Blue Flames:

Normal for Natural Gas

Note: If the flame is completely or mostly yellow, verify that the regulator is set for the correct fuel. After adjustment, retest.

30” 5 Burner

36” 5 Burner

9 WARNING

To prevent flare-ups, properly support pots and

avoid spills, all grates must be properly positioned

on the cooktop whenever the cooktop is in use.

Each of the four feet must be placed into the

corresponding dimples in the cooktop. Do not use a

grate if the rubber feet are missing or damaged.

Some yellow streaking is normal during the initial startup. Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

For replacement of rubber feet: Call Customer Support at 1-800-944-2904.

12

Page 13

Service

Before Calling Service

If the igniters do not spark or the “on” indicator lights (available in some models) do not glow, check the power source to see if a fuse has blown or if the circuit breaker has tripped.

Refer to the Statement of Limited Warranty in the Use

and Care Manual. See the Use and Care Manual for

troubleshooting information.

Product Rating Label

The rating label shows the model number and the FD number (production number/product’s unique identifier) of your cooktop. It is located on the underside of the cooktop.

$

Rating Label Location

A Rating Label

Model number and FD Number

The model number and the FD number of your appliance are found on the rating label. Make a note of these numbers in the space below to save time in the event your appliance requires service.

Model # FD #

Bosch Customer Support 800-944-2904

Keep your invoice or escrow papers for warranty

validation if service is needed.

13

Page 14

Table des Matières

Notice d’utilisation

Définitions de sécurité ................................................ 14

IMPORTANTES CONSIGNES DE SÉCURITÉ ............. 15

Utilisation sécuritaire de l'électroménager

alimenté au gaz : ............................................................... 15

Installation au gaz propane ............................................. 16

Exigences en matière de sécurité pour l'utilisation et

l'équipement ....................................................................... 16

Sécurité de manutention des appareils ........................ 17

Codes et normes de sécurité ......................................... 17

Avertissement issue de la proposition 65

de l’État de la Californie : ................................................ 17

Sécurité électrique ............................................................ 17

Installation à altitude élevée ............................................ 17

Avant de commencer .................................................. 18

Outils et pièces nécessaires ........................................... 18

Pièces incluses .................................................................. 18

Informations générales ..................................................... 18

&HWDSSDUHLOpOHFWURPpQDJHU%RVFKHVWIDEULTXpSDU

%6++RPH$SSOLDQFHV&RUSRUDWLRQ

0DLQ6WUHHW6XLWH

,UYLQH&$

Préparatifs .......................................................................... 18

Procédure d'installation ............................................. 20

Préparation du plan de travail ........................................ 20

Sceller la table de cuisson avec le ruban de

mousse ............................................................................... 20

Installation de la table de cuisson ................................. 21

Branchement du gaz ........................................................ 21

Brancher l'alimentation électrique .................................. 22

Positionnement du chapeau et de la base

du brûleur ........................................................................... 22

Installation des grilles du brûleur ................................... 24

Vérification de l'installation .............................................. 24

Dépannage ................................................................... 25

Avant d'appeler le service de dépannage ................... 25

9RXVDYH]GHVTXHVWLRQV"

ZZZERVFKKRPHFRPXV

1RXVQRXVIHURQVXQSODLVLUGHYRXVVHUYLU

Définitions de sécurité

9 AVERTISSEMENT

Ceci indique que le non-respect de cet

avertissement peut entraîner des blessures graves,

voire la mort.

9 ATTENTION

Ceci indique que le non-respect de cet

avertissement peut entraîner des blessures légères

ou de gravité moyenne.

ââ

AVIS : Ceci indique que la non-conformité à cet avis de sécurité peut entraîner des dégâts matériels ou endommager l'appareil.

Remarque : Ceci vous signale des informations et/ou indications importantes.

14

Page 15

9 IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

IMPORTANTES CONSI GNES DE SÉCURI TÉLI RE ET CONS ER VE R CES INSTRUCTIONS

Utilisation sécuritaire de l'électroménager alimenté au gaz :

$9(57,66(0(176LOHVGLUHFWLYHVQHVRQWSDV

VXLYLHVjODOHWWUHLO\DXQULVTXHGLQFHQGLHRX

GH[SORVLRQSRXYDQWHQWUDvQHUGHVGRPPDJHV

PDWpULDX[GHVEOHVVXUHVRXXQGpFqV

²

1HSDVFRQVHUYHURXXWLOLVHUGHOHVVHQFHRX

GDXWUHVOLTXLGHVRXYDSHXUVLQIODPPDEOHVj

SUR[LPLWpGHFHWDSSDUHLORXGHWRXWDXWUHDSSDUHLO

²

48()$,5(6,92863(5&(9(=81(2'(85'(*$=

1HSDVHVVD\HUGHPHWWUHXQDSSDUHLOVRXVWHQVLRQ

1HSDVWRXFKHUGLQWHUUXSWHXUGHFRXUDQWpOHFWULTXH

1HSDVXWLOLVHUGHWpOpSKRQHVGDQVOpGLILFH

&RPPXQLTXHULPPpGLDWHPHQWDYHFOHIRXUQLVVHXU

GHJD]GHSXLVODSSDUHLOWpOpSKRQLTXHGXQYRLVLQ

5HVSHFWHUOHVGLUHFWLYHVGXIRXUQLVVHXUGHJD]

6LOVDYqUHLPSRVVLEOHGHMRLQGUHOHIRXUQLVVHXUGH

JD]FRPPXQLTXHUDYHFOHVSRPSLHUV

8WLOLVHUOHVVHUYLFHVGXQLQVWDOODWHXURXGXQHDJHQFH

²

GHVHUYLFHVTXDOLILpVRXOHIRXUQLVVHXUGHJD]SRXU

SURFpGHUjOLQVWDOODWLRQHWDX[UpSDUDWLRQV

15

Page 16

9 IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

IMPORTANT : CONSERVEZ CES CONSIGNES À L'INTENTION DE L'INSPECTEUR EN ÉLECTRICITÉ.

INSTALLATEUR : PRIÈRE DE LAISSER CES CONSIGNES AVEC CET APPAREIL À L'INTENTION DU PROPRIÉTAIRE.

PROPRIÉTAIRE : PRIÈRE DE CONSERVER CES CONSIGNES POUR RÉFÉRENCE ULTÉRIEURE.

AVERTISSEMENT

Correctement entretenu, votre électroménager neuf a été

conçu pour être sécuritaire et fiable. Lisez attentivement

toutes les instructions avant l’utilisation. Ces précautions

réduiront le risque de brûlure, d'électrocution, d’incendie

et de blessures corporelles. Lorsque vous utilisez des

appareils électroménagers de cuisine, il importe de

suivre des précautions de sécurité de base, y compris

celles indiquées dans les pages suivantes.

AVERTISSEMENT

Ne pas réparer, remplacer ni retirer toute pièce de

l’électroménager à moins que cela ne soit

spécifiquement recommandé par les manuels.

L'installation, l'entretien ou une réparation inadéquat

pourrait causer des blessures ou des dégâts matériels.

Consulter ce manuel pour les directives d'utilisation.

Toute autre réparation doit être effectuée par une agence

de service d'entretien autorisé.

▯ Installer un robinet d'arrêt près de l'électroménager. Il

doit être facilement accessible en cas d'urgence.

▯ L'installateur doit procéder au test de fuites selon les

consignes fournies dans le présent manuel.

▯ L'appareil et son propre robinet d'arrêt doivent être

déconnectés de la canalisation du système

d'alimentation en gaz au cours de test aux pressions

qui dépassent 1/2 PSI (3,5 kPa).

▯ L’électroménager doit être isolé de la canalisation du

système d'alimentation en gaz en fermant son propre

robinet d'arrêt manuel pour tout test de pression à des

pressions égales ou inférieures à 1/2 PSI (3,5 kPa).

▯ La pression d'admission minimum doit être de 1 po de

colonne d'eau au-dessus de la pression d'admission

imprimée sur la plaque signalétique.

▯ La pression d'admission maximum ne doit pas

excéder 14 po de colonne d'eau (34,5 millibars).

▯ Pour les installations au Massachusetts :

▯ L'installation doit être exécutée par un entrepreneur,

un plombier ou un ajusteur d'appareils à gaz

qualifié ou autorisé par l'État, la province ou la

région d'installation de cet électroménager.

▯ Le robinet d'arrêt doit être robinet à gaz avec

poignée en T.

▯ Le connecteur à gaz souple doit être neuf et ne doit

pas dépasser 36 pouces.

▯ Installateur : prière d'indiquer au propriétaire,

l'emplacement du robinet d'arrêt.

Installation au gaz propane

▯ Le réservoir de gaz propane doit être doté de son

propre régulateur de pression élevée. De plus, le

régulateur de pression livré avec cet appareil doit

aussi être utilisé.

▯ L'électroménager est livré de l'usine prêt à utiliser avec

du gaz naturel. Il doit être converti pour usage avec

gaz propane. Un technicien ou un installateur qualifié

doit procéder à la conversion.

Exigences en matière de sécurité pour l'utilisation et l'équipement

▯ Utiliser un système de ventilation convenable avec la

table de cuisson.

▯ Retirer tout le ruban adhésif et l'emballage avant

d'utiliser l'électroménager. Jeter l'emballage après

avoir déballé l'électroménager. Ne jamais laisser les

enfants jouer avec le matériel d'emballage.

▯ Ne jamais altérer ni modifier la configuration de

l'électroménager. Par exemple, ne pas retirer les

panneaux, les couvre-fils ou les vis.

▯ Pour éliminer le risque de brûlure ou d'incendie

lorsque vous vous étirez au-dessus des surfaces

chauffantes de l'électroménager, il faut éviter d'installer

des armoires de rangement au-dessus de la surface

de l'électroménager. Si une armoire de rangement est

installé, il est possible de réduire le risque en installant

une hotte qui dépasse (horizontalement) d'au moins

5 po le bord du fond de l'armoire.

▯ Vérifier que la profondeur des armoires au-dessus de

la table de cuisson est au maximum de 13 po

(330 m).

16

Page 17

9 IMPORTANTES CONSIGNES DE SÉCURITÉ

LIRE ET CONSERVER CES INSTRUCTIONS

Sécurité de manutention des appareils

ATTENTION

▯ L’appareil est lourd et son déplacement exige

au moins deux personnes ou encore un

équipement approprié.

▯ Les surfaces cachées peuvent comporter des

arêtes vives. Redoubler de vigilance quand

vous passez la main derrière ou sous l'appareil

électroménager.

Codes et normes de sécurité

▯ Cet appareil est conforme à une ou plusieurs des

normes suivantes :

ANSI Z21.1, Appareils électroménagers pour la

cuisson à gaz

▯ Il incombe au propriétaire et à l'installateur de

déterminer si des exigences et/ou normes

additionnelles s'appliquent pour des installations

spécifiques.

▯ L’installation doit être conforme aux codes locaux ou,

en l’absence de tels codes, au National Fuel Gas

Code ANSI Z223.1/NFPA 54 ou, au Canada, au code

national CSA B149.1 d’installation du gaz naturel et

du propane.

▯ L'électroménager doit être mis à la terre en conformité

aux codes locaux, ou en l’absence de tels codes, au

National Electric Code ANSI/NFPA 70 ou, au Canada,

au code canadien de l’électricité CSA C22.1-02.

Avertissement issue de la proposition 65 de l’État de la Californie :

AVERTISSEMENT

Ce produit peut vous exposer à des produits chimiques,

comme du chlorure de vinyle, reconnus par l’État de la

Californie comme causant le cancer, des malformations

congénitales ou d’autres effets nocifs sur la

reproduction. Pour de plus amples renseignements,

consultez www.P65Warnings.ca.gov.

Remarque : AVIS DE SÉCURITÉ IMPORTANT : En application de la loi californienne concernant la salubrité de l’eau et la protection contre les substances chimiques (« California Safe Drinking Water and Toxic Enforcement Act »), le gouverneur de Californie est tenu de publier une liste reconnue par l’État de Californie comme étant cancérigènes ou pouvant causer des malformations ou présenter un danger pour la reproduction, et les entreprises sont tenues d’avertir les consommateurs des risques potentiels d’exposition à de telles substances. La combustion de gaz combustible pour la cuisson et l'élimination de résidus pendant l'autonettoyage peuvent générer de faibles quantités de monoxyde de carbone. Dans les fours équipés du Nettoyage Auto, de faibles quantités de formaldéhyde peuvent se dégager lors de l'élimination des salissures pendant les quelques premiers cycles autonettoyants. La Californie classe le formaldéhyde parmi les produits potentiellement cancérigènes. Le monoxyde de carbone est une cause possible de toxicité pour la reproduction. Il est possible de réduire l'exposition à ces substances en :

1.

assurant une bonne ventilation lors de la cuisson au gaz; et

2.

utilisant l'appareil selon les instructions de ce manuel.

Sécurité électrique

▯ Avant de brancher le cordon électrique, vérifier que

toutes les commandes sont à la position OFF (Arrêt).

▯ Pour les électroménagers dotés d'un cordon

d'alimentation avec fiche, ne pas couper ni enlever la

broche de mise à la terre. Pour éviter toute

électrocution, brancher le cordon dans une prise de

courant correspondante avec mise à la terre. En cas

de doute concernant la mise à la terre appropriée de

la prise murale, le client doit faire vérifier celle-ci par

un électricien qualifié.

▯ Cet électroménager doit être installé conformément au

Code national de l'électricité ou au Code canadien de

l'électricité. L'installation de la table de cuisson doit

être sur un circuit mis à la terre sans disjoncteur

différentiel de fuite à la terre (non-DDFT).

▯ Installateur : Indiquez au propriétaire l'emplacement

du disjoncteur ou du fusible. Identifiez sa position pour

pouvoir le retrouver facilement.

▯ Avant l'installation, couper l'alimentation au panneau

de service. Verrouiller le panneau de service pour

empêcher que l'alimentation ne soit rétablie par

accident.

▯ S'assurer que l’électroménager est correctement

installé et mis à la terre par un technicien qualifié.

L’installation, les raccordements électriques et la mise

à la terre doivent être conformes avec tous les codes

applicables.

Installation à altitude élevée

Communiquer avec le service après-vente pour une

utilisation au-dessus de 2 000 pi (610 mètres).

17

Page 18

Avant de commencer

Outils et pièces nécessaires

▯ Tournevis à tête Phillips

▯ Tournevis à lame plate de précision

▯ Ruban à mesurer

▯ Ruban de teflon (de classe Gaz)

▯ Clé réglage ou pince multiprise

Pièces incluses

▯ Ruban de mousse

▯ Supports de fixation (4)

▯ Vis, no 10-32 x 2 1/2 po (63,8 mm) (4)

▯ Vis à tôle, No 8 x 3/8 po (9,5 mm) (4)

▯ Rondelles (4)

▯ Grilles de brûleur (3)

▯ Brûleurs

▯ Modèles de 30 po : (4) ou (5)

▯ Modèles de 36 po : (5)

▯ Chapeaux de brûleur

▯ Modèles de 30 po : (4) ou (5)

▯ Modèles de 36 po : (5)

▯ Régulateur de pression

▯ Trousse de conversion au gaz de PL

Remarque : Si des pièces sont manquantes ou endommagées, composer le numéro indiqué ou écrire à l'adresse indiquée à la troisième de couverture.

Préparatifs

Exigences électriques

9 ATTENTION

Ne pas utiliser une rallonge avec la table de

cuisson.

Cet électroménager a besoin d'un raccord de 60 Hz,

15 A, 120 volts c.a. Planifier l'installation de sorte que le

raccord électrique est accessible de l'avant de l'armoire.

Exigences en matière de gaz

Pression d'admission :

▯ Gaz naturel : 7 po de colonne d'eau (14,9 millibars)

▯ Gaz propane : 11 po de colonne d'eau

(27,4 millibars)

Le réservoir de gaz propane doit être doté de son propre

régulateur de pression élevée en plus du régulateur de

pression fourni avec cet appareil. Cette table de cuisson

est livrée de l'usine prête à utiliser avec du gaz naturel.

Pour une conversion au gaz de PL, un technicien ou un

installateur qualifié doit y procéder.

Informations générales

Dimension hors tout

Modèles de

30 po

Largeur (d'un côté à

l'autre)

Profondeur (de l'avant

vers l'arrière)

Hauteur (du haut au

bas)

31 po

(788 mm)

21 1/4 po

(540 mm)

3 13/16 po

(97 mm)

Remarque : Ce sont les dimensions hors tout et NON les dimensions pour la découpe.

Modèles de

36 po

37 po

(940 mm)

21 1/4 po

(540 mm)

3 13/16 po

(97 mm)

18

Page 19

Exigences concernant les armoires

Profondeur depuis la paroi arrière

Armoire 13 po (330) max.

Centrée au-dessus

de la table de cuisson

NGM30 : min. 30 po (762)

NGM36 : min. 36 po (914)

Au-dessus du comptoir :

min. 30 po (762)

min. 18 po (458)

Côté gauche

min. 12 po (305)

de la surface inflammable

Paroi arrière : 2 po (51 mm)

Côté droit

min. 12 po (305)

( )=mm

▯ Les consignes sont fondées sur des armoires

normales (aux États-Unis) de 36 po (91 cm) de

hauteur et de 24 po (61 cm) de profondeur avec un

plan de travail à 25 po (63 cm).

▯ La profondeur maximale de l'armoire installée au-

dessus de la table de cuisson est de 13 po (33 cm).

Remarque : Il faut respecter précisément toutes les mesures fournies. Dans le cas d'armoires hors normes, s'assurer qu'elles ont les dimensions minimales d'installation indiquées.

* Distance du plan de travail à la face supérieur des grilles

** Lors d'une installation en combinaison avec une hotte, consulter

les exigences d'installation du fabricant de la hotte.

Modèles de 30 po

connexion

au gaz

*

1ʎ/ʓʘ

(37)

( )=mm

Planifier l'installation de l'appareil de sorte que le cordon

d'alimentation, le robinet d'arrêt et le régulateur de

pression du gaz sont accessibles de l'avant de l'armoire.

Exigences concernant le plan de travail

Remarque : Il faut respecter précisément toutes les

mesures fournies. Dans le cas d'armoires hors normes,

s'assurer qu'elles ont les dimensions minimales

d'installation indiquées sur l'image ci-dessous.

*

1ʎ/ʓʘ

(37)

* Distance du plan de travail à la face supérieur des grilles

** Lors d'une installation en combinaison avec une hotte, consulter

les exigences d'installation du fabricant de la hotte.

Modèles de 36 po

connexion

au gaz

( )=mm

19

Page 20

Exigences pour la fixation

Utiliser les supports de fixation fournis. Consulter la

section « Installation de la table de cuisson » pour de

plus amples renseignements.

Exigences concernant la ventilation

Nous recommandons fortement l'installation d'un système de ventilation avec l'électroménager. Il doit être installé conformément aux consignes d'installation fournies.

Procédure d'installation

Préparation du plan de travail

9 AVERTISSEMENT

Pour éviter tout danger d'électrocution avant

d'installer la table de cuisson, couper l'alimentation

au panneau de service pour éviter que l'alimentation

soit rétablie accidentellement.

Découper le plan de travail aux dimensions indiquées dans la section « Exigences concernant les armoires ».

9 ATTENTION

L'électroménager ne doit pas être installé avec un

système de ventilation qui souffle l'air vers le bas en

direction des brûleurs. Ce type de système de

ventilation peut entraîner des problèmes d'allumage

et de combustion avec l'appareil de cuisson au gaz

pouvant causer des blessures corporelles ou un

fonctionnement indésirable.

Sceller la table de cuisson avec le ruban de mousse

Remarque : Ne pas installer le ruban de mousse peut

influencer le rendement du brûleur.

Appliquer le ruban autocollant de mousse en un

rectangle ininterrompu sur le rebord de la découpe dans

le plan de travail (sur le périmètre) comme illustré par la

ligne pointillée sur l'image ci-dessous. Le ruban de

mousse doit être de niveau avec le rebord de la

découpe.

Certains matériaux demandent des méthodes de

découpe différentes. Consulter le fabricant de la surface

solide pour connaître la bonne méthode de découpe.

Appliquer du ruban réflecteur de chaleur comme du

ruban d'aluminium Scotch no 425 ou no 427 (non

compris) autour de la découpe pour qu'il se plie par

dessus la surface et les côtés. Ne pas plier le ruban sous

la table de cuisson. S'assurer que le ruban dépasse audelà du rebord externe de la collerette de la table de

cuisson. Tous les coins doivent être couverts de ruban.

$

Découpe de la surface solide du plan de travail

A Ruban réflecteur de chaleur

$

Placement du ruban de mousse sur le périmètre de la

découpe dans le plan de travail

A Placement du ruban de mousse

20

Page 21

Installation de la table de cuisson

Insérer la table de cuisson dans la découpe. Fixer les pinces du support de fixation livré avec la table de cuisson. Utiliser la rondelle et les vis fournis.

'

$

%

(

&

Régler le support de fixation à la hauteur désirée, et serrer les vis à la table de cuisson. Insérer les vis de réglage dans la pince et fixer solidement la table de cuisson au plan de travail.

*

+

Branchement du gaz

L'admission de gaz de l'appareil est située à droite, à l'arrière de la table de cuisson.

Installer le régulateur de pression (fourni avec cet

appareil) au tuyau collecteur avec du ruban teflon sur les

filets du tuyau collecteur. Serrer à la main puis tourner 1/

4 de tour de plus sans excéder 1 tour, pour l'alignement.

Pour éviter d'endommager le régulateur de pression de

gaz, l'installer après avoir mis la table de cuisson dans

sa position permanente. Une fois le régulateur

solidement installé sur le tuyau collecteur, il sera facile

d'accéder à l'écrou de conversion.

$

%&

Fixation des supports

A Table de cuisson

B/H Support de retenue

C/E Vis de réglage

D Ruban de mousse (scellé)

G Bloc de bois (à utiliser avec le matériau de la

surface solide)

Remarque : Installation sur une surface solide :

▯ Insérer un bloc de bois entre l'extrémité de la vis et le

dessous du plan de travail.

▯ Ne pas trop serrer la vis de réglage.

▯ Couper l'excès de ruban d'aluminium autour de la

collerette de la table de cuisson.

Conseil : Installer le support de retenue sans la vis de réglage. Tourner le support de retenue pour qu'il soit de niveau avec les côtés de la découpe. Cela aidera à la pose de la table des cuisson dans des espaces difficiles à atteindre.

Régulateur de pression

A Tuyau collecteur

B Écrou de conversion

C Régulateur de pression

9 AVERTISSEMENT

Ne pas essayer d'ajuster le régulateur de pression à

moins de convertir l'appareil électroménager au

propane. Les réglages peuvent entraîner des fuites

ou une mauvaise pression en direction de l'appareil

électroménager.

21

Page 22

Vue latérale de l'installation de la table de cuisson au gaz

%

$

%

&

'

(

*

La flèche au dos du

régulateur de pression

pointe dans la direction

du débit de gaz.

/

+

-

.

Emplacement du gaz et de l'électricité

A Boîtier de la robinetterie brute de la table de

cuisson

B Flèche sur le régulateur de pression

C Régulateur de pression

D Tuyau de 1/2 po à filets femelles

E Conduite de gaz souple

G Cordon d'alimentation (60 po/1 524 mm)

H Prise de 120 volts

J Robinet d'arrêt du gaz

K Embout pour la conduite d'alimentation en gaz

L Plancher

Raccorder la conduite d'alimentation en gaz au régulateur de pression de l'appareil avec un connecteur souple de gaz de 1/2 po entre le robinet d'arrêt manuel et le régulateur de pression. Toujours utiliser une conduite souple neuve.

Vérifier la présence de fuites des conduites d'alimentation au moyen d'une solution savonneuse ou d’un liquide de détection de fuites non corrosif. Ne jamais utiliser une flamme sans égard au type de flamme.

4.

Tester de nouveau la présence de fuites en ouvrant le robinet d'arrêt de l'alimentation de gaz. Quand aucune bulle n'apparaît, le test de fuite est terminé.

5.

Essuyer tout résidu de la solution savonneuse ou du liquide de détection de fuite.

Remarques importantes pour les raccords de gaz :

▯ L'appareil et son propre robinet d'arrêt doivent être

déconnectés de la canalisation du système

d'alimentation en gaz au cours de tests de pression de

ce système aux pressions qui dépassent 1/2 PSI

(3,5 kPa).

▯ L’appareil électroménager doit être isolé de la

canalisation du système d'alimentation en gaz en

fermant son propre robinet d'arrêt manuel pour tout

test de pression de la canalisation du système

d'alimentation en gaz à des pressions égales ou

inférieures à 1/2 PSI (3,5 kPa).

Brancher l'alimentation électrique

Avant de raccorder le cordon d'alimentation de 5 pi (1,5 m) à une prise murale, s'assurer que le robinet d'arrêt et toutes les commandes de brûleur sont en position fermée.

Positionnement du chapeau et de la base du brûleur

9 AVERTISSEMENT

Pour éviter des flambées, ne pas utiliser la table de

cuisson sans tous les chapeaux de brûleurs en

place et toutes les grilles de brûleur bien

positionnées.

9 AVERTISSEMENT

Pour éviter les brûlures, ne pas retirer les chapeaux

de brûleur ni les grilles quand ils sont chauds.

Éteindre la table de cuisson et laisser les brûleurs

refroidir.

1.

Ouvrir le gaz.

2.

Appliquer une solution savonneuse ou un liquide de

détection de fuites non corrosif à toutes les jonctions

et tous les raccords des conduites de gaz entre le

robinet d'arrêt et la table de cuisson. Inclure les

raccords et les jonctions de gaz de la table de cuisson

si les raccords auraient pu être déréglés au cours de

l'installation. Une bulle qui apparaît autour d'un

raccordement indique une fuite.

3.

En présence d'une fuite, couper l'alimentation en gaz en fermant le robinet d'arrêt et serrer le ou les raccords qui fuient.

22

Il faut que les chapeaux de brûleurs soient correctement positionnés pour le bon fonctionnement de la table de cuisson. Un ou plusieurs problèmes peuvent survenir si un chapeau de brûleur n’est pas bien positionné :

▯ La flamme du brûleur est trop élevée.

▯ Des flammes jaillissent des brûleurs.

▯ L’acier inoxydable se décolore.

▯ Les brûleurs ne s’allument pas.

▯ La flamme du brûleur n’est pas uniforme.

▯ Une odeur de gaz se dégage du brûleur.

Page 23

Positionnement du chapeau et de la base du brûleur

Vérification du positionnement du chapeau du brûleur

▯ Après avoir terminé le raccordement électrique,

déposer chaque base de brûleur à l’endroit

correspondant sur la table de cuisson. Une des trois

rainures sur la base du brûleur doit être alignée avec

l'encoche pour empêcher son pivotement. Le petit trou

ou la petite découpe près du rebord doit aussi être

aligné(e) avec l’allumeur. Faire très attention de ne

pas endommager l’allumeur lors de l’installation de la

base. Voir l’illustration ci-dessous.

▯ Une fois toutes les bases installées et bien appuyées,

placer les chapeaux de brûleur sur la bonne base.

Voir l’illustration.

▯ Déposer délicatement le chapeau de brûleur sur le

dessus de la base de sorte que les pattes de la base

soient bien ajustées dans la goulotte du chapeau du

brûleur.

▯ Si un installateur certifié retire la table de travail (par

exemple pour vérifier le raccordement électriques ou

des conduites), il faut réinstaller les vis à tête

cylindrique pour assurer le bon fonctionnement des

brûleurs.

1

2

▯ S’assurer qu’il n’y a aucun espace entre le chapeau et

la base du brûleur. Consulter l’illustration ci-dessous

pour voir un positionnement correct et incorrect du

chapeau du brûleur.

▯ Vous pouvez essayer délicatement de bouger le

chapeau du brûleur pour vérifier s’il est correctement

positionné. Si tel est le cas, un clic se fera entendre

lorsque les pattes du chapeau frapperont la saillie de

la goulotte.

Positionnement des chapeaux et des bases de brûleur

Vérification du positionnement du chapeau du brûleur

23

Page 24

Installation des grilles du brûleur

Positionner et installer correctement la grille de chaque brûleur comme illustré ci-dessous.

Modèle de 30 po à 4 brûleurs

Vérification de l'installation

Insérer chaque chapeau de brûleur du bon diamètre en

place sur la rainure et vérifier le fonctionnement des

allumeurs électriques. Vérifier les caractéristiques de la

flamme. La flamme doit être bleue avec une toute petite

extrémité jaune sur le cône extérieur des flammes.

Vérification des caractéristiques de la flamme

Flammes jaunes :

Réglages supplémentaires requis.

Extrémités des cônes

externes jaunes :

Normales pour un gaz de

pétrole liquéfié

Flammes bleues

douces :

Normales pour le gaz

naturel

Remarque : Si la flamme est entièrement ou presque toute jaune, vérifier si le régulateur est réglé au bon combustible. Après le réglage, procéder à un nouveau test.

Modèle de 30 po à 5 brûleurs

Modèle de 36 po à 5 brûleurs

9 AVERTISSEMENT

Pour éviter des flambées, toutes les grilles doivent

être bien positionnées sur la table de cuisson à

chaque utilisation pour bien soutenir les casseroles

et éviter les éclaboussures. Chacun des quatre

pieds doit s’appuyer dans les petites dépressions

correspondantes de la table de cuisson. Ne pas

utiliser une grille si les pieds de caoutchouc sont

manquants ou endommagés.

Au cours du démarrage initial, il est normal que la

flamme soit bigarrée de jaune. Laisser l'appareil

fonctionner de quatre à cinq minutes puis réévaluer

avant de procéder aux réglages.

Pour remplacer les pieds de caoutchouc :

Communiquer avec le Service après-vente au 1-800-944-

2904.

24

Page 25

Dépannage

Avant d'appeler le service de dépannage

Si les allumeurs ne produisent pas d'étincelles ou que les témoins ne s'allument pas (offerts sur certains modèles), vérifier la source d'alimentation électrique à la recherche d'un fusible grillé ou d'un disjoncteur actionné.

Consultez l'énoncé de garantie limitée dans le Manuel

d'utilisation et d'entretien. Consultez le Manuel

d'utilisation et d'entretien pour les renseignements de

dépannage.

Plaque signalétique du produit

La plaque signalétique comporte le numéro de modèle et le numéro FD (numéro de production/code unique d'identification) de la table de cuisson. Elle est située sur le dessous de la table de cuisson.

$

Emplacement de la plaque signalétique

A Plaque signalétique

Numéro de modèle et numéro FD

Le numéro de modèle et le numéro FD de l'électroménager figurent sur la plaque signalétique. Prendre ces numéros en note dans l'espace ci-dessous pour sauver du temps, au cas où l'électroménager aurait besoin d'être réparé.

No de modèle No FD

Service après-vente de

Bosch

Conservez votre facture ou votre contrat aux fins de

validation de garantie si jamais vous avez besoin d'une

réparation.

800-944-2904

25

Page 26

Contenido

Manual de instrucciones

Definiciones de seguridad .......................................... 26

INSTRUCCIONES DE SEGURIDAD IMPORTANTES . 27

Seguridad para aparatos de gas ................................... 27

Instalación con gas propano .......................................... 28

Requisitos de seguridad del equipo y el uso .............. 28

Seguridad de manejo del electrodoméstico ................ 29

Códigos y normas de seguridad ................................... 29

Advertencia en virtud de la Proposición 65

del estado de California: .................................................. 29

Seguridad con la electricidad ......................................... 29

Instalación a gran altitud .................................................. 29

Antes de empezar ........................................................ 30

Herramientas y piezas necesarias ................................. 30

Piezas incluidas ................................................................. 30

Información general .......................................................... 30

(VWHHOHFWURGRPpVWLFRGH%RVFKHVKHFKRSRU

%6++RPH$SSOLDQFHV&RUSRUDWLRQ

0DLQ6WUHHW6XLWH

,UYLQH&$

¢3UHJXQWDV"

Preparación ........................................................................ 30

Procedimiento de instalación .................................... 32

Preparar la cubierta .......................................................... 32

Sellar la placa de cocción con cinta de espuma ....... 32

Instalar la placa de cocción ............................................ 33

Conectar el suministro de gas ....................................... 33

Conexión de la alimentación eléctrica .......................... 34

Colocación de las tapas y las bases de

los quemadores ................................................................ 34

Colocar las rejillas de los quemadores ........................ 36

Pruebe la instalación ........................................................ 36

Servicio técnico ........................................................... 37

Antes de llamar al servicio técnico ............................... 37

ZZZERVFKKRPHFRPXV

£(VSHUDPRVRLUGHXVWHG

Definiciones de seguridad

9 ADVERTENCIA

Esto indica que pueden producirse heridas graves

o incluso la muerte si no se cumple con esta

advertencia.

9 ATENCION

Esto indica que pueden producirse heridas leves o

moderadas si no se cumple con esta advertencia.

AVISO: Esto indica que pueden producirse daños en el aparato o en los bienes si no se cumple con este aviso.

Nota: Esto alerta sobre información o sugerencias importantes.

26

Page 27

9 INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA Y CONSERVE ESTAS INSTRUCCIONES

I NSTRUCCI ONES DE SEGURI DAD IMPORTANTESLEA Y CONSERVE ESTAS INSTRUCCIONES

Seguridad para aparatos de gas

$'9(57(1&,$6LODLQIRUPDFLyQHQHVWDV

LQVWUXFFLRQHVQRVHVLJXHFRQSUHFLVLyQVH

SXHGHSURGXFLUXQLQFHQGLRRXQDH[SORVLyQ

RFDVLRQDQGRGDxRVDODSURSLHGDGOHVLRQHV

DODVSHUVRQDVRLQFOXVRODPXHUWH

²

1RDOPDFHQHQLXVHJDVROLQDXRWURVYDSRUHV\

OtTXLGRVLQIODPDEOHVHQODSUR[LPLGDGGHHVWH

DSDUDWRRFXDOTXLHURWUR

²

48e+$&(56,'(7(&7$2/25$*$6

1RWUDWHGHHQFHQGHUQLQJ~QDSDUDWR

1RWRTXHQLQJ~QLQWHUUXSWRUHOpFWULFR

1RXWLOLFHQLQJ~QWHOpIRQRHQVXHGLILFLR

/ODPHLQPHGLDWDPHQWHDVXSURYHHGRUGHJDV

GHVGHXQWHOpIRQRYHFLQR6LJDODVLQVWUXFFLRQHV

GHOSURYHHGRUGHJDV

6LQRSXHGHFRQWDFWDUDVXSURYHHGRUGHJDV

FRPXQtTXHVHFRQHOGHSDUWDPHQWRGHERPEHURV

²

/DLQVWDODFLyQ\HOVHUYLFLRGHEHQVHUOOHYDGRVD

FDERSRUXQLQVWDODGRUFDOLILFDGRDJHQFLDGH

VHUYLFLRRHOSURYHHGRUGHJDV

27

Page 28

9 INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA Y CONSERVE ESTAS INSTRUCCIONES

IMPORTANTE: CONSERVAR ESTAS INSTRUCCIONES PARA QUE LAS USE EL INSPECTOR DE ELECTRICIDAD LOCAL.

INSTALADOR: DEJAR ESTAS INSTRUCCIONES JUNTO A LA UNIDAD PARA EL PROPIETARIO.

PROPIETARIO: CONSERVAR ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

ADVERTENCIA

Su nuevo electrodoméstico ha sido diseñado para ser

seguro y confiable si recibe el cuidado adecuado. Leer

atentamente todas las instrucciones antes de usarlo.

Estas precauciones reducirán el riesgo de quemaduras,

descarga eléctrica, incendio y heridas a personas. A la

hora de utilizar electrodomésticos de cocina se deben

tomar precauciones de seguridad básicas, incluidas las

que se encuentran en las páginas siguientes.

ADVERTENCIA

No reparar, reemplazar ni retirar ninguna pieza del

aparato a menos que se recomiende específicamente en

los manuales.La instalación, el servicio técnico o el

mantenimiento incorrectos pueden causar lesiones o

daños materiales. Consultar este manual como guía.

Cualquier otra labor de mantenimiento debe de ser

efectuada por una agencia de mantenimiento autorizada.

▯ Instalar una llave de cierre de gas cerca del

electrodoméstico. Tiene que de ser de fácil acceso a

ella en caso de emergencia.

▯ El instalador debe realizar una prueba de fugas de

forma de acuerdo con las instrucciones de este

manual.

▯ El electrodoméstico y su llave de cierre individual

deben estar desconectados del sistema de tuberías

de suministro de gas durante cualquier prueba de

presión con presiones superiores a 1/2 psi (3.5 kPa).

▯ El electrodoméstico debe aislarse del sistema de

tuberías de suministro de gas cerrando su llave de

cierre individual manual durante cualquier prueba de

presión del sistema de tuberías de suministro de gas

con presiones iguales o inferiores a 1/2 psi (3.5 kPa).

▯ La presión de suministro mínima debe ser 1” de

columna de agua superior a la presión del colector,

impresa en la placa de características.

▯ La presión de suministro máxima no debe ser superior

a 14.0 pulgadas de columna de agua (34.9 milibares).

▯ Para instalaciones en Massachusetts:

▯ La instalación debe hacerla un contratista, plomero

o instalador de gas calificado o con licencia del

estado, provincia o región donde se vaya a instalar

este electrodoméstico.

▯ La llave de cierre tiene que ser una llave de gas en

T.

▯ El conector de gas flexible debe de ser nuevo y de

una longitud no superior a 36 pulgadas.

▯ Instalador: mostrar al propietario dónde está situada la

llave de cierre del gas.

Instalación con gas propano

▯ El tanque de gas propano debe estar equipado con

su propio regulador de alta presión.Además, también

se debe utilizar el regulador suministrado con esta

unidad.

▯ El electrodoméstico se envía desde la fábrica para su

uso con gas natural. Tiene que adaptarse para poder

utilizarse con gas propano. Esta adaptación tiene que

realizarla un técnico o instalador calificado.

Requisitos de seguridad del equipo y el uso

▯ La placa de cocción debe de utilizarse junto con un

sistema de ventilación adecuado.

▯ Retirar toda la cinta y el embalaje antes de usar el

electrodoméstico. Destruir el embalaje después de

desembalar el electrodoméstico. No dejar nunca que

los niños jueguen con el material de embalaje.

▯ No modificar ni alterar la estructura del

electrodoméstico. Por ejemplo, no retirar los paneles,

las cubiertas para cables ni los tornillos.

▯ Para eliminar el riesgo de sufrir quemaduras o que se

produzca un incendio al alcanzar las unidades cuya

superficie esté caliente, se deberá evitar colocar

gabinetes de almacenamiento encima de las unidades

de la superficie. Si va a haber gabinetes de

almacenamiento, el riesgo puede reducirse colocando

una campana que se proyecte horizontalmente como

mínimo 5 pulgadas más allá de la base del gabinete.

▯ Verificar que los gabinetes que se encuentren arriba

de la placa de cocción tengan, como máximo,

13 pulgadas (330 mm) de profundidad.

28

Page 29

9 INSTRUCCIONES DE SEGURIDAD IMPORTANTES

LEA Y CONSERVE ESTAS INSTRUCCIONES

Seguridad de manejo del electrodoméstico

ATENCION

▯ La unidad es pesada y se requieren al menos

dos personas o un equipo adecuado para

trasladarla.

▯ Las superficies ocultas pueden tener bordes

filosos. Proceder con cuidado al intentar

sujetar el electrodoméstico por la parte trasera

o desde abajo.

Códigos y normas de seguridad

▯ Este aparato cumple con una o varias de las

siguientes normas:

ANSI Z21.1, para electrodomésticos de cocción con

gas

▯ Es responsabilidad del propietario y del instalador

determinar si se aplican otros requisitos o normas en

instalaciones específicas.

▯ La instalación debe realizarse cumpliendo las normas

locales o, en ausencia de estas, conforme al Código

Nacional de Combustibles Gaseosos (ANSI Z223.1/

NFPA 54) o, si se lleva a cabo en Canadá, al Código

de Instalación de Gas Natural y Propano (L.P.) (CSA

B149.1).

▯ El electrodoméstico debe conectarse a tierra

conforme a la normativa local o, en ausencia de esta,

conforme al Código Eléctrico Nacional (ANSI/NFPA

70) o al Código Eléctrico de Canadá (CSA C22.1-02).

Advertencia en virtud de la Proposición 65 del estado de California:

ADVERTENCIA

Este producto puede exponerlo a sustancias químicas,

incluyendo cloruro de vinilo, que el estado de California

sabe que provocan cáncer, defectos congénitos u otro

daño reproductivo. Para obtener más información, ir a la

página web: www.P65Warnings.ca.gov.

Nota: INFORMACIÓN IMPORTANTE DE SEGURIDAD: la Ley de aplicación de líquidos potables y tóxicos exige que el gobernador de California publique una lista de sustancias conocidas que se sabe que provocan cáncer, defectos congénitos u otros daños reproductivos y exige a las empresas que adviertan a sus clientes de la exposición potencial a dichas sustancias. El proceso de quemado del combustible para cocción a gas y la eliminación de los restos durante la autolimpieza puede generar pequeñas cantidades de monóxido de carbono. El aislamiento de fibra de vidrio en los hornos de autolimpieza desprende pequeñas cantidades de formaldehído durante los primeros ciclos de limpieza. California incluye el formaldehído como una potencial causa de cáncer. El monóxido de carbono es una causa potencial de toxicidad reproductiva. Se puede reducir la exposición a estas sustancias de las siguientes formas:

1.

Garantizando una buena ventilación cuando se cocina con gas.

2.

Utilizando la unidad de forma acorde con las instrucciones de este manual.

Seguridad con la electricidad

▯ Antes de enchufar un cable eléctrico, asegurarse de

que todos los controles se encuentren en la posición

OFF (apagado).

▯ Para los electrodomésticos provistos de cable y

enchufe, no cortar ni retirar la pata de conexión a

tierra.Esta debe estar enchufada en un receptáculo

adecuado con conexión a tierra para evitar descargas

eléctricas. Si se tienen dudas acerca de si el enchufe

de la pared tiene una conexión a tierra adecuada, el

cliente debería pedirle a un electricista certificado que

lo compruebe.

▯ El electrodoméstico debe instalarse conforme al

Código Eléctrico Nacional o al Código Eléctrico de

Canadá. Es necesario que la placa de cocción se

instale con un circuito de derivación sin protección

GFCI con conexión a tierra.

▯ Instalador: mostrar al propietario la ubicación del

interruptor del circuito o del fusible. Marcarlo para

recordar más fácilmente.

▯ Antes de realizar la instalación, desconectar la

alimentación eléctrica en el panel de servicio.

Bloquear el panel de servicio para impedir que se

conecte accidentalmente la alimentación eléctrica.

▯ Asegurarse de que el aparato está correctamente

instalado y conectado a tierra por un técnico

certificado.La instalación, las conexiones eléctricas y

la conexión a tierra deben cumplir con todas las

normas correspondientes.

Instalación a gran altitud

Contactar con el Servicio de Asistencia Técnica cuando

el electrodoméstico se vaya a utilizar a una altitud

superior a 2,000 pies (610 metros).

29

Page 30

Antes de empezar

Herramientas y piezas necesarias

▯ Desarmador de cabeza Phillips

▯ Desarmador de punta plana de precisión

▯ Medida de cinta

▯ Cinta de teflón (marcada para gas)

▯ Llave ajustable o pinzas ajustables

Piezas incluidas

▯ Cinta de espuma

▯ Soportes de montaje (4)

▯ Tornillos, #10-32 x 2 1/2” (63.8 mm) (4)

▯ Tornillos para placa, #8 x 3/8” (9.5 mm) (4)

▯ Rondanas (4)

▯ Rejillas de los quemadores (3)

▯ Quemadores

▯ Modelos de 30": (4) o (5)

▯ Modelos de 36": (5)

▯ Tapas de los quemadores

▯ Modelos de 30": (4) o (5)

▯ Modelos de 36": (5)

▯ Regulador de presión

▯ Kit de conversión de Gas LP

Nota: Si faltan piezas o alguna de ellas está dañada, llamar al número o escribir a la dirección que figuran en la parte interior de la contraportada.

Preparación

Requisitos eléctricos

9 ATENCION

No utilizar un cable de extensión con la placa de

cocción de gas.

Este electrodoméstico requiere de una conexión de 120

V CA, 60 Hz, 15 A.Planificar la instalación de tal manera

que la conexión a la toma de corriente sea accesible

desde la parte frontal del gabinete.

Requisitos de gas

Presión de suministro:

▯ Gas natural: 7 pulgadas de columna de agua (14.9

milibares)

▯ Gas propano: 11 pulgadas de columna de agua (27.4

milibares)

El tanque de gas propano debe estar equipado con su

propio regulador de alta presión, además del regulador

de presión incluido con esta unidad. La placa de cocción

se envía desde la fábrica para su uso con gas natural.

Para utilizarla con gas LP, la conversión tiene que

realizarla un técnico o instalador calificado.

Información general

Medidas totales

Modelos de

30"

Ancho (lado a lado) 31”

(788 mm)

Profundidad (parte frontal-posterior)

21 1/4”

(540 mm)

Altura (de arriba abajo) 3 13/16”

(97 mm)

Nota: Estas son las medidas totales, NO las del recorte.

Modelos de

36"

37”

(940 mm)

21 1/4”

(540 mm)

3 13/16”

(97 mm)

30

Page 31

Requisitos del gabinete

Profundidad máx. del gabinete

de la pared trasera de 13" (330)

Centrado con la pared trasera

NGM30: mín. 30" (762)

NGM36: mín. 36" (914)

Encima de la placa de cocción:

mín. 30" (762) de la superficie

mín. 18" (458)

Lado izquierdo

mín. 12" (305)

combustible

de la placa de cocción:

2" (51 mm)

Lado derecho

mín. 12" (305)

( )=mm

▯ Las instrucciones se basan en gabinetes estándares

americanos de 36” (91 cm) de altura y 24” (61 cm)

de profundidad, con una cubierta de 25” (63 cm).

▯ La profundidad máxima de un gabinete instalado

encima de la placa de cocción es de 13” (33 cm).

Nota: Todas las medidas dadas deben respetarse con precisión.Si se utilizan gabinetes no estándares, asegurarse de que se instalan con las medidas mínimas mostradas.

* Medidas desde la cubierta hasta la parte superior de las rejillas

** Si el aparato se instala combinado con una campana, consultar

los requisitos de instalación del fabricante de la campana.

Modelos de 30"

*

1ʎ/ʓʘ”

(37)

conexión

de gas

( )=mm

Planificar la instalación de la unidad de tal manera que el

cable de alimentación, la llave de cierre de gas y el

regulador de presión sean accesibles desde la parte

frontal del gabinete.

Requisitos de la cubierta

Nota: Todas las medidas dadas deben respetarse con

precisión.Si se utilizan gabinetes no estándares,

asegurarse de que se instalan con las medidas mínimas

mostradas en la imagen siguiente.

*

1ʎ/ʓʘ”

(37)

* Medidas desde la cubierta hasta la parte superior de las rejillas

** Si el aparato se instala combinado con una campana, consultar

los requisitos de instalación del fabricante de la campana.

Modelos de 36"

conexión

de gas

( )=mm

31

Page 32

Requisitos de instalación

Usar las placas de sujeción suministradas. Consultar la

sección «Instalar la placa de cocción» para obtener más

información.

Requisitos para la ventilación

Recomendamos encarecidamente instalar un sistema de ventilación con el electrodoméstico. El electrodoméstico debe instalarse de acuerdo con las instrucciones facilitadas.

Procedimiento de instalación

Preparar la cubierta

9 ADVERTENCIA

Para evitar el peligro de descarga eléctrica, antes

de instalar la placa de cocción, desconectar el

suministro eléctrico en el panel de servicio para

impedir que se conecte accidentalmente.

9 ATENCION

El electrodoméstico no debe instalarse con un

sistema de ventilación que expulse aire hacia abajo,

en dirección a los quemadores.Este tipo de

ventilación podría causar problemas de ignición y

combustión en el electrodoméstico de cocción de

gas, con lo que se podrían producir lesiones o

manejo involuntario.

Sellar la placa de cocción con cinta de espuma

Nota: Si no se pone cinta de espuma, el rendimiento del

quemador podría verse afectado.

Aplicar la cinta adhesiva de espuma en un rectángulo

continuo directamente en la cubierta alrededor del

perímetro del recorte, tal y como muestra la línea

discontinua en la imagen de abajo. La cinta de espuma

debería quedar al ras del borde del recorte.

Cortar la cubierta de acuerdo a las medidas indicadas en la sección «Requisitos del gabinete».

Algunos materiales de superficies sólidas requieren

distintos métodos de corte. Consultar al fabricante de la

superficie sólida sobre el método de corte correcto.

Poner cinta termorreflectante como cinta de aluminio

Scotch #425 o #427 (no incluida) alrededor del recorte

de modo que se doble sobre la parte superior y los

laterales. No envolver la cinta por debajo de la placa de

cocción. Asegurarse de que la cinta se extienda más allá

del lateral que más sobresalga de la placa de cocción.

Todas las esquinas deberían estar cubiertas con cinta.

$

$

Colocación de la cinta de espuma: recorte de la

cubierta

A Colocación de la cinta de espuma

Corte en cubiertas de superficie sólida

A Cinta termorreflectante

32

Page 33

Instalar la placa de cocción

Insertar la placa de cocción en el recorte. Fijar las sujeciones de las placas de sujeción que vienen con la placa de cocción. Utilizar la rondana y los tornillos provistos.

'

$

Conectar el suministro de gas

La entrada de gas de la unidad está situada en la parte posterior derecha de la placa de cocción.

Instalar el regulador de presión (suministrado junto con

la unidad) en el tubo colector. Para ello, colocar cinta de

teflón en la rosca del tubo.Girar 1/4 de vuelta para

apretarlo, sin superar 1 vuelta para la alineación.Para

evitar posibles daños en el regulador de presión del gas,

instalarlo después de haber colocado la placa de

cocción en su posición final. Cuando el regulador esté

instalado firmemente en el tubo colector, será fácil

acceder a la tuerca de conversión.

%

*

(

+

&

Ajustar las placas de fijación en la posición deseada y apretar los tornillos a la placa de cocción. Insertar el tornillo de ajuste en la sujeción y fijar la placa de cocción a la cubierta.

Acoplar las placas de fijación

A Placa de cocción

B/H Placa de sujeción

C/E Tornillo de ajuste

D Cinta de espuma (sellante)

G Bloque de madera (que se usará con materiales

de superficies sólidas)

Nota: Para instalaciones en material de superficies sólidas:

▯ Insertar un bloque de madera entre el extremo del

tornillo y la parte inferior de la cubierta.

▯ No apretar demasiado el tornillo de ajuste.

▯ Recortar el exceso de cinta de aluminio en torno al

borde de la placa de cocción.

Consejo: Instalar la placa de fijación sin el tornillo de ajuste encajado.Girar las placas de sujeción para que queden enrasadas con los lados del recorte. De este modo, será más fácil insertar la placa de cocción en espacios de difícil acceso.

$

%&

Regulador de presión

A Tubo colector

B Tuerca de conversión

C Regulador de presión

9 ADVERTENCIA

No intentar realizar ningún ajuste en el regulador de