Bosch NGM8654UC/01, NGM8054UC/03, NGM8054UC/01, NGM5664UC/01, NGM5654UC/01 Installation Guide

...Page 1

Gas Cooktops

Models: NGM

Page 2

Table of Contents

Safety ...................................... 1

IMPORTANT SAFETY INSTRUCTIONS .............................. 1

Installation .................................. 2

Before You Begin ............................................... 2

Tools and Parts Needed ...................................................... 2

Parts Included .............................................................. 2

General Information .......................................................... 3

Preparation ................................................................ 3

Installation Procedure ........................................... 4

Prepare the Countertop ....................................................... 4

Seal the Cooktop with Foam Tape .............................................. 4

Install the Cooktop ........................................................... 5

Connect Gas Supply ......................................................... 5

Connect Electrical Supply ..................................................... 6

Burner Cap Placement ....................................................... 6

Final Check ................................................................ 8

Service ..................................... 8

Before Calling Service ........................................... 8

Product Data Plate ........................................................... 8

This Bosch Appliance is made by

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions?

1-800-944-2904

www.boschappliances.com

We look forward to hearing from you!

Page 3

Safety

IMPORTANT SAFETY

INSTRUCTIONS

READ AN D SAVE TH ESE

INSTRUCTIONS

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE

APPLIANCE AFTER INSTALLATION IS COMPLETE.

IMPORTANT: SAVE FOR THE LOCAL INSPECTOR'S

USE.

Important Safety Instructions

WARNING:

Do not repair or replace any part of the appliance unless

specifically recommended in the manuals. Improper

installation, service or maintenance can cause injury or

property damage. Refer to this manual for guidance. All

other servicing should be done by a qualified technician.

Gas Appliance Safety

WARNING:

If the information in this manual is not followed exactly, a

fire or explosion may result causing property damage,

)ersonal injury or death.

• Leak testing must be conducted by the installer

according to the instructions in this manual.

• The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing at pressures in excess of ½ psi

(3.5 kPa).

• The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than ½

psi (3.5 kPa)

• The minimum supply pressure must be 1"water

column above the manifold pressure printed on the

data plate.

• The maximum supply pressure must not exceed 14.0

inches water column (34.9Millibars).

• For Massachusetts installations:

• Installation must be performed by a qualified or

licensed contractor, plumber or gas fitter qualified

or licensed by the state, province or region where

this appliance is being installed.

• Shut-off valve must be a "T" handle gas cock.

• Flexible gas connector must be new and not longer

than 36 inches.

Installer - show the owner where the gas shut-off valve

is located.

Propane Gas Installation

-- Do not store or use combustible materials,

gasoline or other flammable vapors and liquids

in the vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

• If you cannot reach your gas supplier, call

the fire department.

-- Installation and service must be performed by a

qualified installer, authorized service agency or

the gas supplier.

• Install a gas shutoff valve near the appliance. It must

be easily accessible in an emergency.

• The propane gas tank must be equipped with its own

high pressure regulator. In addition, the regulator

supplied with this unit must also be used.

• The appliance is shipped from the factory for use with

natural gas. It must be converted for use with propane.

A qualified technician or installer must do the

conversion.

Equipment and Usage Safety Requirements

The cooktop must be used in conjunction with a

suitable ventilation system.

Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the

appliance. Never allow children to play with packaging

material.

Never modify or alter the construction of the appliance.

For example, do not remove panels, wire covers or

screws.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

English 1

Page 4

storageistobeprovided,theriskcanbereducedby

installingahoodthatprojectshorizontallyaminimum

of5inchesbeyondthebottomofthecabinet.

Verifythatcabinetsabovethecooktopareamaximum

of13"(330mm)deep.

codes, with the National Electrical Code ANSI/NFPA

70, latest edition. (In Canada, installation must be in

accordance with the CAN 1-B 149.1 and .2 Installation

Codes for Gas Burning Appliances and/or local

codes).

Appliance Handling Safety

• Unit is heavy and requires at least two people or proper

equipment to move.

• Hidden surfaces may have sharp edges. Use caution

when reaching behind or under appliance.

Safety Codes and Standards

• This appliance complies with one or more of the

following Standards:

• UL 858, The Standard for the Safety of

Household Electric Ranges

• UL 923, The Standard for the Safety of

Microwave Cooking Appliances

• UL 507, The Standard for the Safety of Electric

Fans

• ANSI Z21.1, The American National Standard

for Household Cooking Gas Appliances

• CAN/CSA-C22.2 No. 113-M1984 Fans and

Ventilators

• CAN/CSA-C22.2 No. 61-M89 Household

Cooking Ranges

• It is the responsibility of the owner and the installer to

determine if additional requirements and/or standards

apply to specific installations.

• Installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas

Code, ANSI Z223. I/NFPA 54.

• The appliance must be electrically grounded in

accordance with local codes or, in the absence of local

Electric Safety

• Before you plug in an electrical cord, be sure all

controls are in the OFF position.

• For appliances equipped with a cord and plug, do not

cut or remove the ground prong. It must be plugged

into a matching grounding type receptacle to avoid

electrical shock. If there is any doubt as to whether the

wall receptacle is properly grounded, the customer

should have it checked by a qualified electrician.

• This appliance should be installed in accordance with

the National Electric Code or Canadian Electrical

Code. It is required that the cooktop be installed on a

grounded, non-GFCI branch circuit.

• Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

• Important - Save these instructions for the local

electrical inspector's use.

• Before installing, turn power OFF at the service panel.

Lock service panel to prevent power from being turned

ON accidentally.

• Be sure your appliance is properly installed and

grounded by a qualified technician. Installation,

electrical connections and grounding must comply with

all applicable codes.

High Altitude Installation

Contact service for use at altitudes above 2000 feet.

Installation

Before You Begin

Tools and Parts Needed

1. Phillips Head Screwdriver

2. Drill with 114" (6.5mm) bit

3. Tape Measure

4. Teflon Tape (Gas Rated)

Parts Included

1. Foam tape

English 2

2. Hold down brackets (4)

3. Screws, #10-32 x 2 1/2" (63.8mm) (4)

4. Sheet Metal Screws, #8 x 318" (9.5mm) (4)

5. Washers (4)

6. Burner Grates (3)

7. Burner Caps

36" models: (5)

30" models: (4) or (5)

8. Pressure Regulator

If parts are missing or damaged, call the number or write to

the address listed inside the back cover.

Page 5

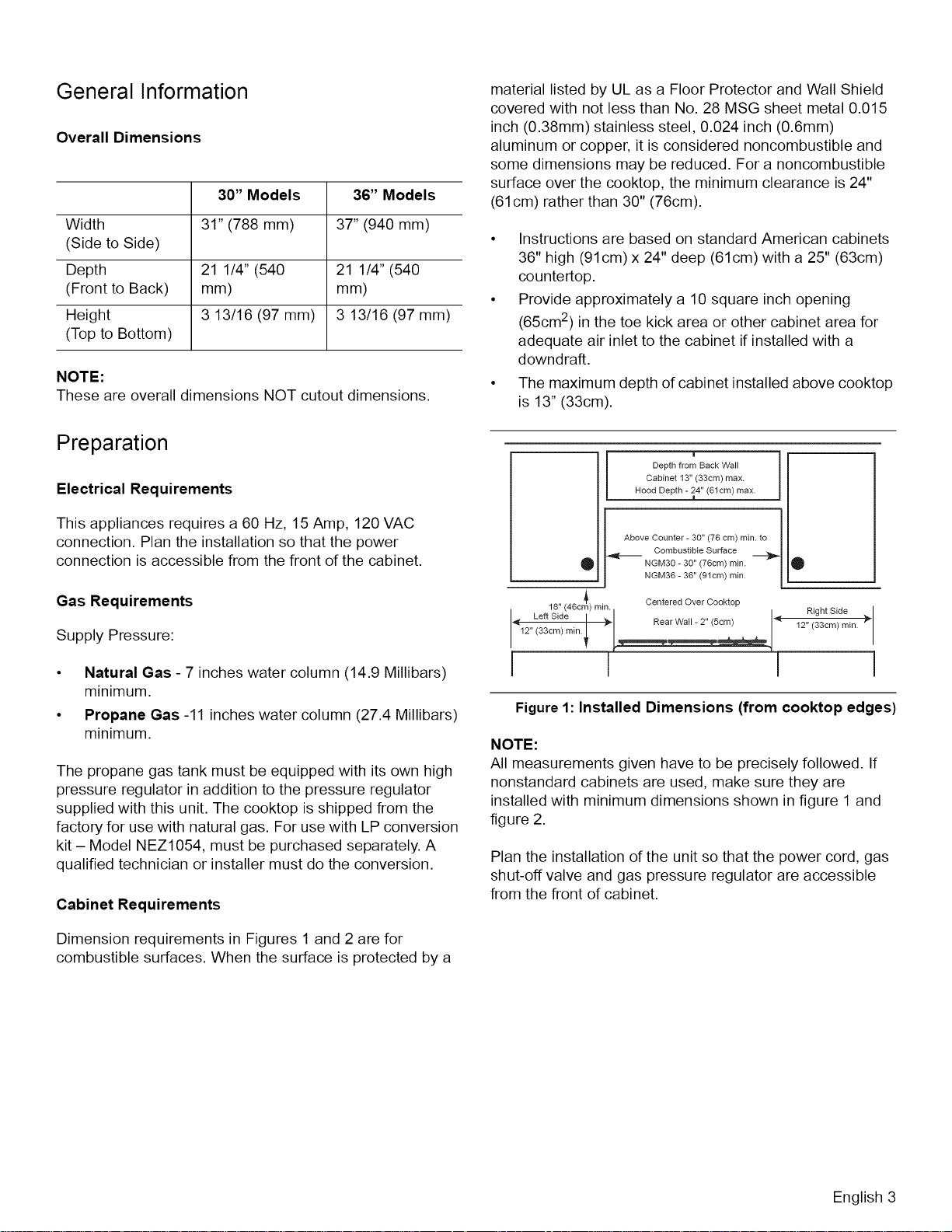

General Information

Overall Dimensions

30" Models 36" Models

Width 31" (788 mm) 37" (940 mm)

(Side to Side)

Depth 21 1/4" (540 21 1/4" (540

(Front to Back) mm) mm)

Height 3 13/16 (97 mm) 3 13/16 (97 mm)

(Top to Bottom)

NOTE:

These are overall dimensions NOT cutout dimensions.

material listed by UL as a Floor Protector and Wall Shield

covered with not less than No. 28 MSG sheet metal 0.015

inch (0.38mm) stainless steel, 0.024 inch (0.6mm)

aluminum or copper, it is considered noncombustible and

some dimensions may be reduced. For a noncombustible

surface over the cooktop, the minimum clearance is 24"

(61cm) rather than 30" (76cm).

Instructions are based on standard American cabinets

36" high (91cm) x 24" deep (61cm) with a 25" (63cm)

countertop.

Provide approximately a 10 square inch opening

(65cm 2) in the toe kick area or other cabinet area for

adequate air inlet to the cabinet if installed with a

downdraft.

The maximum depth of cabinet installed above cooktop

is 13" (33cm).

Preparation

Electrical Requirements

This appliances requires a 60 Hz, 15 Amp, 120 VAC

connection. Plan the installation so that the power

connection is accessible from the front of the cabinet.

Gas Requirements

Supply Pressure:

Natural Gas - 7 inches water column (14.9 Millibars)

minimum.

Propane Gas -11 inches water column (27.4 Millibars)

minimum.

The propane gas tank must be equipped with its own high

pressure regulator in addition to the pressure regulator

supplied with this unit. The cooktop is shipped from the

factory for use with natural gas. For use with LP conversion

kit - Model NEZ1054, must be purchased separately. A

qualified technician or installer must do the conversion.

Cabinet Requirements

qr

Depth from Back Wall

Cabinet 13" (33cm) max.

Hood Depth - 24" (61cm) max.

Above Counter -30" (76 cm) min. to

Combustible Surface

O NGM30 - 30" (76cm) min. P-

,,_12 ,, L(::iS8mi'i (e4mi_. }_ Rear Wail - 2" (5cm) _'_

i) rain. Centered Over Cooktop

NGM36 - 36" (91cm) rain.

i I I

®

12" (33cm) min.

Right Side

i

Figure 1: Installed Dimensions (from cooktop edges)

NOTE:

All measurements given have to be precisely followed. If

nonstandard cabinets are used, make sure they are

installed with minimum dimensions shown in figure 1 and

figure 2.

Plan the installation of the unit so that the power cord, gas

shut-off valve and gas pressure regulator are accessible

from the front of cabinet.

Dimension requirements in Figures 1 and 2 are for

combustible surfaces. When the surface is protected by a

English 3

Page 6

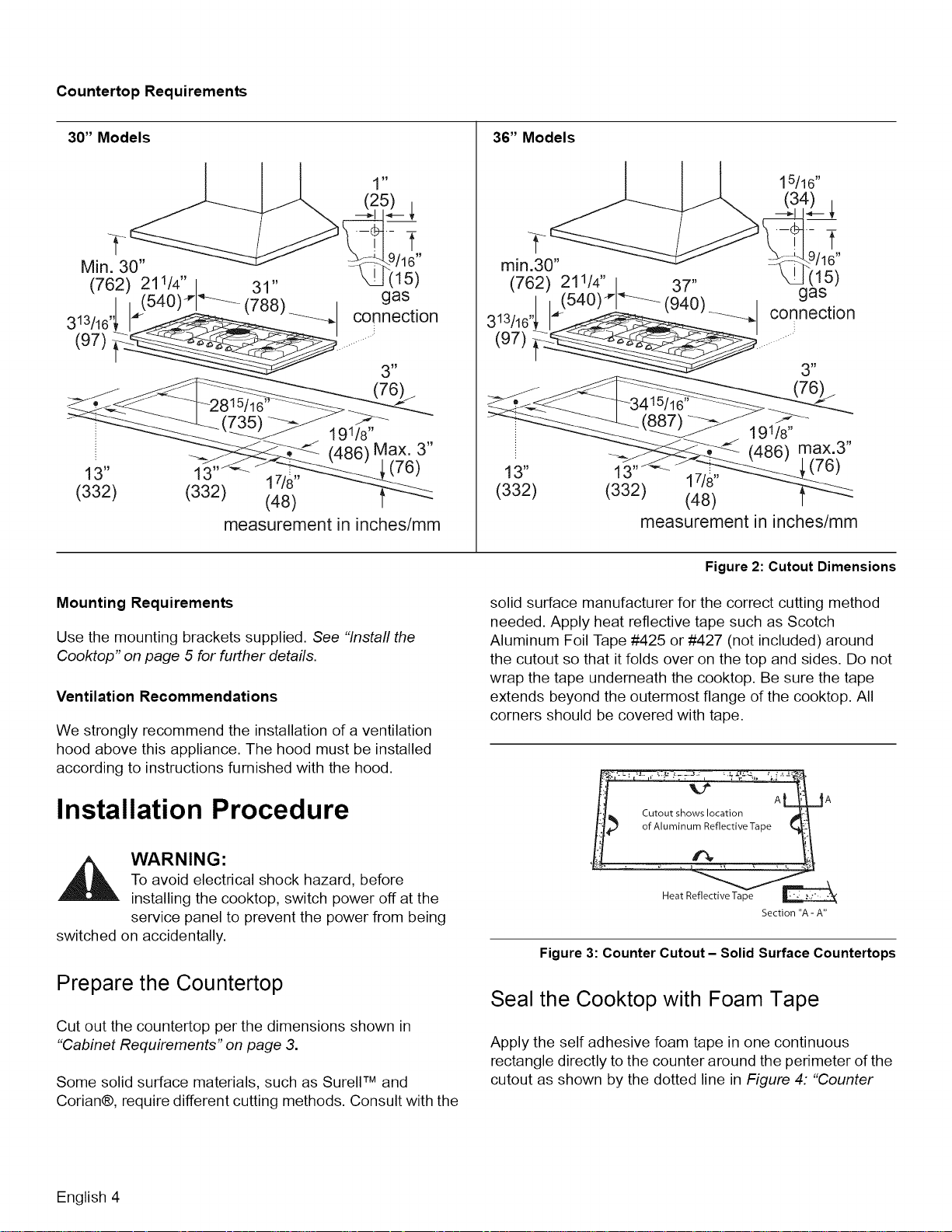

Countertop Requirements

30" Models

313/16''

(97)

13"

(332)

(788)_______ connection

191/8''

13 17/8,,

(332) (48)

measurement in inches/mm

gas

36" Models

min.30"

(762) 211/4"

313/16"1

(97)

13"

(332)

37" _(15)

(940) _. connection

191/8 ''

(486) maxo3"

13 17/8,,

(332) (48)

measurement in inches/mm

Figure 2: Cutout Dimensions

15/167,

--I - t-

gas

(76)

Mounting Requirements

Use the mounting brackets supplied. See "Install the

Cooktop" on page 5 for further details.

Ventilation Recommendations

We strongly recommend the installation of a ventilation

hood above this appliance. The hood must be installed

according to instructions furnished with the hood.

Installation Procedure

,_ WARNING:

switched on accidentally.

Prepare the Countertop

Cut out the countertop per the dimensions shown in

"Cabinet Requirements" on page 3.

Some solid surface materials, such as Surell TM and

Corian®, require different cutting methods. Consult with the

To avoid electrical shock hazard, before

installing the cooktop, switch power off at the

service panel to prevent the power from being

solid surface manufacturer for the correct cutting method

needed. Apply heat reflective tape such as Scotch

Aluminum Foil Tape #425 or #427 (not included) around

the cutout so that it folds over on the top and sides. Do not

wrap the tape underneath the cooktop. Be sure the tape

extends beyond the outermost flange of the cooktop. All

corners should be covered with tape.

• Heat ReflectiveTa e

Section "A - A"

Figure 3: Counter Cutout - Solid Surface Countertops

Seal the Cooktop with Foam Tape

Apply the self adhesive foam tape in one continuous

rectangle directly to the counter around the perimeter of the

cutout as shown by the dotted line in Figure 4: "Counter

English 4

Page 7

Cutout- Foam Tape Placement". Leave 1/4" (6.35mm) gap

between the foam tape and the edge of the cutout.

1/4"

(6.35mm)

,Foam

Tape

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_ii_

Figure 4: Counter Cutout - Foam Tape Placement

Install the Cooktop

Insert cooktop into the cutout. Attach clamps of the hold-

down brackets packaged with the cooktop to the rough-in

box. Use the washer and screws provided.

Rough-in Box

/J

Connect Gas Supply

The gas inlet to the unit is located at the right rear of rough-

in box.

Opening for Gas

Electrical Cord

_,C L of Cutout

for 30" moclels: 12 15/16" (313 mm)

for 36" models: 15 15/16" (389 mm)

Figure 6: Rough-in Box Area

Install the pressure regulator (supplied with unit) to

manifold pipe using Teflon tape on threads of manifold

pipe. Turn to hand tighten plus 1/4 turn, not exceeding 1

turn for alignment. To prevent possible damage to the gas

pressure regulator, install it after the rough-in box is in its

permanent position. When the regulator is securely

installed on the manifold pipe, the conversion nut will be

easily accessible.

i

Clamp

_ Adjusting

Screw

Figure 5: Attaching Hold-Down Brackets

Adjust hold-down brackets to desired position and tighten

screws to rough-in box. Insert adjusting screw into clamp

and secure cooktop to countertop.

NOTE:

For solid surface material installations: Insert a wooden

block between the end of the screw and the bottom of the

countertop. Do not overtighten adjusting screw. Trim

excess aluminum tape around cooktop flange.

i!

Figure 7: Pressure Regulator

CAUTION:

Do not attempt any adjustment of the pressure

regulator, except conversion to propane.

Connect the gas supply line to the unit pressure regulator

using a 1/2" flex gas line connector between manual shut-

English 5

Page 8

offvalveandpressureregulator.Alwaysuseanewflex

line.

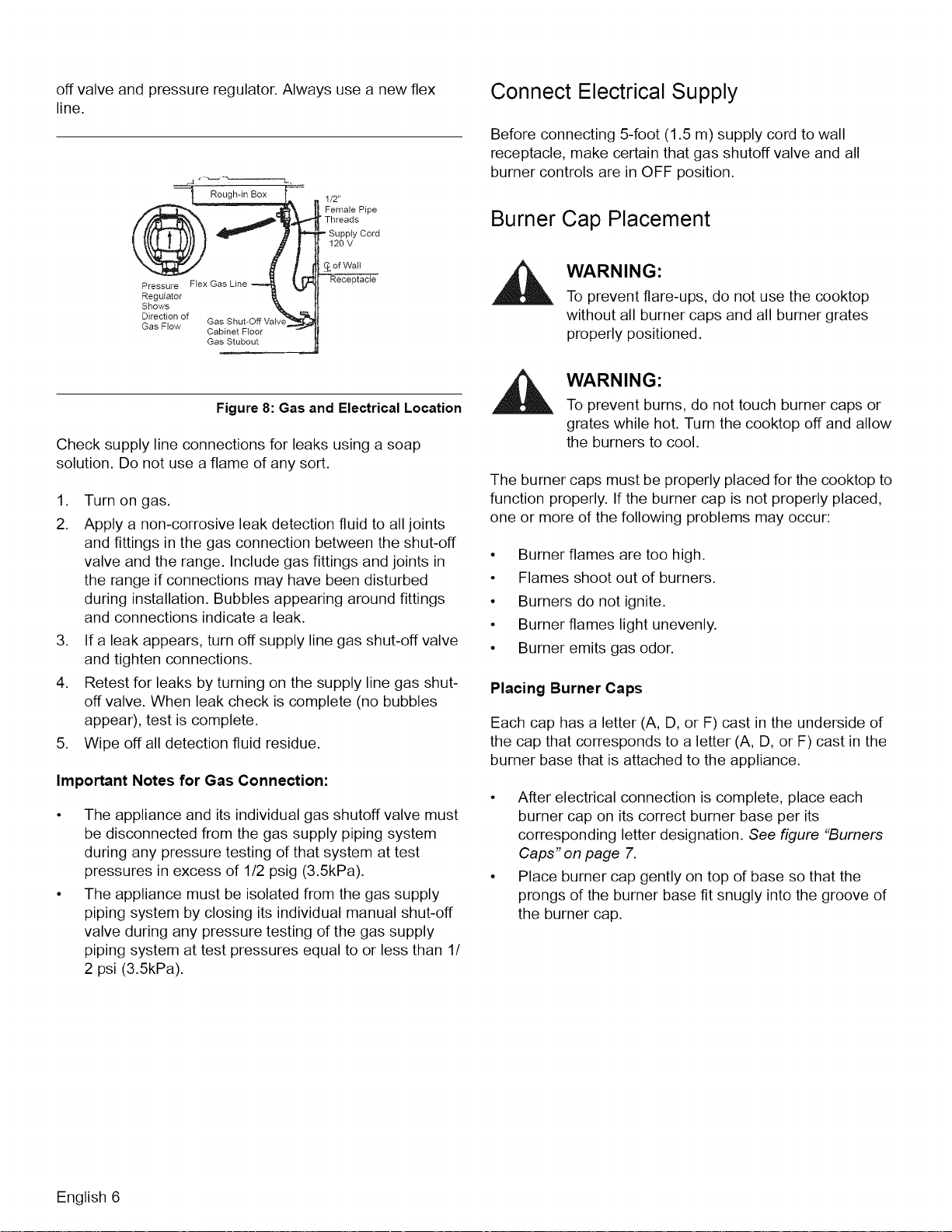

Rough-in Box

m3_ _ _'-

Pressure Flex Gas Line

Regulator

Shows

Direction of

Gas Flow Gas Shut-Off Valve

Cabinet Floor

Gas Stubout

Figure 8: Gas and Electrical Location

Check supply line connections for leaks using a soap

solution. Do not use a flame of any sort.

,

Turn on gas.

2.

Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the shut-off

valve and the range. Include gas fittings and joints in

the range if connections may have been disturbed

during installation. Bubbles appearing around fittings

and connections indicate a leak.

3. If a leak appears, turn off supply line gas shut-off valve

and tighten connections.

4. Retest for leaks by turning on the supply line gas shut-

off valve. When leak check is complete (no bubbles

appear), test is complete.

5. Wipe off all detection fluid residue.

Important Notes for Gas Connection:

The appliance and its individual gas shutoff valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 psig (3.5kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/

2 psi (3.5kPa).

1/2"

Female Pipe

" Threads

Supply Cord

120 V

; of Wall

Receptacle

Connect Electrical Supply

Before connecting 5-foot (1.5 m) supply cord to wall

receptacle, make certain that gas shutoff valve and all

burner controls are in OFF position.

Burner Cap Placement

WARNING:

To prevent flare-ups, do not use the cooktop

without all burner caps and all burner grates

properly positioned.

WARNING:

To prevent burns, do not touch burner caps or

grates while hot. Turn the cooktop off and allow

the burners to cool.

The burner caps must be properly placed for the cooktop to

function properly. If the burner cap is not properly placed,

one or more of the following problems may occur:

• Burner flames are too high.

• Flames shoot out of burners.

• Burners do not ignite.

• Burner flames light unevenly.

• Burner emits gas odor.

Placing Burner Caps

Each cap has a letter (A, D, or F) cast in the underside of

the cap that corresponds to a letter (A, D, or F) cast in the

burner base that is attached to the appliance.

• After electrical connection is complete, place each

burner cap on its correct burner base per its

corresponding letter designation. See figure "Burners

Caps" on page 7.

• Place burner cap gently on top of base so that the

prongs of the burner base fit snugly into the groove of

the burner cap.

English 6

Page 9

Burner Base

Burner Cap

,Matching letter

"- designation.

Figure 9: Burners Caps

Checking Burner Cap Placement

Check to make sure there is not gap between the

burner cap and burner base. See figure "Burner Cap

Placement" on page 7 to see the correct and incorrect

placements of the burner cap.

Correct Burner Cap Placement Incorrect Burner Cap Placement

You may gently try to move the burner cap from side to

side to check if it is properly placed. If properly placed,

the cap will click from side to side as the prongs hit the

groove ridge.

Figure 10: Burner Cap Placement

English 7

Page 10

Final Check

Check operation of electric igniters. Check flame

characteristics. Flame should be blue with no yellow tip.

Service

Yellow Flames:

Further adjustment is required.

Yellow Tips on Outer Cones:

Normal for LP Gas.

Soft Blue Flames:

Normal for Natural Gas.

If the flame is completely or

mostly yellow, verify that the regulator is set for the

correct fuel. After adjustment, retest.

Some yellow streaking is normal during the initial start-

up. Allow unit to operate 4-5 minutes and re-evaluate

before making adjustments.

Figure 11: Checking Flame Characteristics

Before Calling Service

If the ignitors do not spark or the "on" indicator lights do not

glow, check the power source to see if a fuse has blown or

if the circuit breaker has tripped.

Refer to the Warranty in the Use and Care Manual. See

Use and Care manual for troubleshooting information.

Product Data Plate

The data plate shows the model and FD (product's unique

identifier for customer service) number of your cooktop. It is

located on the underside of the rough-in box, underneath

the cooktop.

Data Plate

\

Figure 12: Data Plate Location

Keep your invoice or escrow papers for warranty validation

if service is needed.

English 8

Page 11

Table des mati res

Sdcuritd ..................................... 1

Consignes de securite importantes ................................ 1

Installation .................................. 3

Avant de commencer ............................................ 3

Outils et pieces necessaires ................................................... 3

Pieces comprises ............................................................ 3

Informations generales ....................................................... 3

Preparation ................................................................ 3

Procedure d'installation .......................................... 4

Preparation du plan de travail .................................................. 5

Fixation de la table de cuisson avec du ruban en mousse ............................ 5

Installation de la table de cuisson ............................................... 5

Raccordement de I'alimentation de gaz ........................................... 5

Raccordement de I'alimentation electrique ........................................ 6

Pose des capuchons de brQleur ................................................ 6

Verification finale ............................................................ 8

Ddpannage .................................. 9

Avant d'appeler le service de depannage ............................ 9

Plaque signaletique du produit ................................................. 9

Cet appareil electromenager de Bosch est fait par

BSH Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

Questions ?

1-800-944-2904

www.boschappliances.com

Nous attendons de vos nouvelles !

Page 12

S curitd

Consignes de sdcuritd

importantes

LIRE ET CONSERVER CES

CONSIGNES

INSTALLATEUR : LAISSEZ CES INSTRUCTIONS AVEC

L'APPAREIL APR¢:S AVOIR TERMINI_ L'INSTALLATION.

IMPORTANT : _, CONSERVER POUR L'USAGE DE

L'INSPECTEUR LOCAL.

Consignes de securit6 importantes

AVERTISSEMENT •

Ne pas r6parer ni remplacer des pi_ces de I'appareil

moins que cela ne soit express6ment recommand6 dans

les manuels. Toute installation, r6paration ou maintenance

inad6quate peut entrafner des blessures ou des

dommages mat@iels. Consulter ce manuel pour obtenir •

des conseils sur la fagon de proc6der. Tousles travaux

d'entretien doivent 6tre confi6s _ un technicien qualifi6.

8ecurite des appareils a gaz

AVERTISSEMENT :

Si les informations de ce manuel ne sont pas suivies

la lettre, un incendie ou une explosion peuvent se

produire entrafnant des dommages mat@iels, des

16sions corporelles ou la mort.

-- Ne pas ranger ou utiliser de materiaux

combustibles, d'essence ou d'autres liquides et

vapeurs inflammables a proximite de cet

appareil ou d'aucun autre appareil.

• Installez un robinet d'arr_t de gaz _ proximit6 de

I'appareil. Celui-ci doit 6tre facilement accessible en

cas d'urgence.

• Un essai d'6tanch6it6 doit _tre effectu6 par I'installateur

conform6ment aux instructions du pr6sent manuel.

• L'appareil et son robinet d'arr_t individuel doivent 6tre

d6branch6s de la tuyauterie d'alimentation en gaz

Iorsque vous effectuez des tests de pression _ une

pression d'6preuve d6passant ½ psi (3,5 kPa).

• L'appareil doit _tre isol6 de la tuyauterie d'alimentation

en gaz en fermant le robinet d'arr_t manuel individuel

Iorsque vous effectuez des essais de pression sur la

tuyauterie d'alimentation en gaz si la pression

d'6preuve est 6gale ou inf@ieure _ ½ psi (3,5 kPa)

La pression d'alimentation minimale doit _tre 6gale _ 1

po (25,4 mm) _ la colonne d'eau, au-dessus de la

pression d'admission indiqu6e sur la plaque

signal6tique.

La pression d'alimentation maximale ne doit pas

d6passer 14 po (355 mm ) _ la colonne d'eau (34,9

millibars).

• Installations effectu6es dans 1'6tatdu Massachusetts :

• L'installation doit 6tre effectu6e par un entrepre-

neur qualifi6 ou titulaire d'une licence, un plombier

ou installateur de gaz qualifi6 ou titulaire d'une

licence octroy6e par 1'6tat, la province ou la r6gion

oQ I'appareil est install6.

• Le robinet d'arr6t doit 6tre pourvu d'une poign6e en

<<T >>.

• Le connecteur de gaz flexible doit _tre neuf et sa

Iongueur ne doit pas d6passer 36 po (914 mm).

Installateur - indiquez au propri6taire oQ se trouve le

robinet d'arr6t de gaz.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ

• Ne tentez pas d'allumer un appareil, quel

qu'il soit.

• Ne touchez a aucun interrupteur electrique.

• N'utilisez pas les telephones de votre

immeuble.

• Telephonez immediatement a votre

fournisseur de gaz de chez un voisin. Suivez

les instructions du fournisseur de gaz.

• Si vous ne parvenez pas a joindre votre

fournisseur de gaz, appelez le service

d'incendie.

L'installation et les reparations doivent _tre

effectuees par un installateur qualifie, un

organisme de service autorise ou le fournisseur

de gaz.

Installation du gaz propane

Le r6servoir de gaz propane doit _tre dot6 d'un

r_gulateur haute pression. En outre, le r_gulateur

fourni avec cet appareil doit _tre _galement utilis_.

Cet appareil est r_gl_ _ sa sortie de I'usine pour

fonctionner au gaz naturel. Pour faire fonctionner

I'appareil au gaz propane, il doit _tre converti. Cette

conversion doit _tre effectu_e par un technicien ou

installateur qualifi_.

Exigences de securite concernant I'equipement et

I'utilisation

• La table de cuisson doit _tre utilis_e avec un syst_me

de ventilation appropri_.

• Retirer le ruban adh_sif et I'emballage avant d'utiliser

I'appareil. D_truire I'emballage apr_s avoir d_ball_

Frangais 1

Page 13

I'appareil.Nejamaislaisserlesenfantsjoueravecdes

mat@iauxdeconditionnement.

• Nejamaismodifiernialt6rerlaconfigurationde

I'appareil.Parexemple,nepasretirerlespanneaux,

lescouverclesdec_blageoulesvis.

• Pour61iminerlerisquedebr01ureoud'incendie,en

passantlamainau-dessusdes616mentsdesurface

chauff6s,I'espacederangementdanslesarmoires

situ6esau-dessusdes616mentsdesurfacedoit_tre

6vit6.Siunearmoirederangementexiste,lerisque

peut_trer6duiteninstallantunehotted'extractionqui

d6passehorizontalementd'unminimumde5po(12,7

cm)delapartieinf@ieuredesarmoires.

• V@ifiezquelaprofondeurmaximaledesarmoires

situ6esau-dessusdelatabledecuissonned6passe

pas13po(330mm).

Securitede manipulation de rappareil

Cet appareil est Iourd et il faut au moins deux

personnes ou 1'6quipement appropri6 pour le d6placer.

Les surfaces cach6es peuvent comporter des ar6tes

vives. Faites attention en tendant le bras derri@e

I'appareil ou en dessous.

Codes et normes de securite

Cet appareil est conforme _ une ou plusieurs des

normes suivantes :

• UL 858, Norme pour la securite des cuisinieres

electriques domestiques

• UL 923, Norme pour la securite des appareils

de cuisson a micro-ondes

• UL 507, Norme pour la securite des ventilateurs

electriques

• ANSI Z21.1, Norme nationale americaine pour

les appareils de cuisson electromenagers au

gaz

• CAN/CSA-C22.2 No. 113-M1984, Ventilateurs et

soufflantes

• CAN/CSA-C22.2 No. 61-M89, Cuisinieres pour

usage menager

II incombe au propri6taire et _ I'installateur de

d6terminer si des exigences et/ou normes

additionnelles s'appliquent pour des installations

sp6cifiques.

L'installation doit _tre conforme aux codes Iocaux ou,

en I'absence de ceux-ci, au Code national du gaz

combustible, ANSI Z223. I/NFPA 54.

L'appareil doit 6tre mis _ la terre 61ectriquement

conform6ment aux codes Iocaux ou, en I'absence de

ceux-ci, au Code national de 1'61ectricit6ANSI/NFPA

70, derni_re 6dition. (Au Canada, I'installation doit 6tre

conforme aux codes d'installation CAN 1-B149.1 et .2

pour les appareils _ gaz et/ou aux codes Iocaux).

Securite electrique

• Avant de brancher le cordon 61ectrique, v@ifier que

toutes les commandes sont dans la position "OFF"

(Arr_t).

• Pour les appareils dot6 d'un cordon d'alimentation avec

fiche, ne pas couper ni enlever la broche de mise _ la

terre. Pour 6viter tout choc 61ectrique, brancher le

cordon dans une prise de courant avec prise de terre.

En cas de doute concernant la mise _ la terre

appropri6 de la prise murale, le client doit faire v@ifier

celle-ci par un 61ectricien qualifi6.

• Cet appareil doit _tre install6 conform6ment au Code

national de 1'61ectricit6(National Electric Code) ou au

Code canadien de 1'61ectricit6(Canadian Electric

Code). II est imp@atif que la table de cuisson soit

install6e sur un circuit de d@ivation non diff@entiel.

• Installateur - indiquer au propri6taire I'emplacement du

disjoncteur ou du fusible. Identifier sa position pour

pouvoir le retrouver facilement.

• Important - Conserver ces instructions pour I'usage de

I'inspecteur local en 61ectricit6.

• Avant I'installation, couper le courant au panneau de

service. Verrouiller le panneau de service pour 6viter

que le courant ne soit accidentellement r6tabli.

• S'assurer que I'appareil est ad6quatement install6 et

mis _ la terre par un technicien qualifi6. L'installation,

les connexions 61ectriques et la mise _ la terre doivent

6tre conformes _ tous les codes applicables.

Installation a haute altitude

Contactez le service d'entretien pour I'utilisation _ une

altitude sup@ieure _ 2000 pieds.

Frangais 2

Page 14

_j[__; _ii_11__ii ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Installation

Avant de commencer Preparation

Exigences concernant I'electricite

Outils et pieces necessaires

1. Tournevis _ t_te Phillips

2. Perceuse avec m_che de 1/4 po (6,5 mm)

3. Ruban _ mesurer

4. Ruban pour joints filet6s (pr6vu pour le gaz)

Cet appareil requiert une connexion 61ectrique de 120 V

c.a., 60 Hz et 15 A. Planifier I'installation afin que la

connexion 61ectrique soit accessible depuis le devant de

I'armoire.

Exigences concernant le gaz

Pieces comprises

1. Ruban en mousse

2. Supports de fixation (4)

3. Vis, #10-32 x 2 1/2 po (63,8 mm) (4)

4. Vis _ t61e, #8 x 3/8 po (9,5 mm) (4)

5. Rondelles (4)

6. Grilles de brOleur (3)

7. Capuchons de breleur

ModUles 36 po (91 cm) : (5)

ModUles 30 po (76 cm) : (4) ou (5)

8. R_gulateur de pression

Si des pi_ces sont manquantes ou endommag6es,

t616phonez au num6ro ou 6crivez _ I'adresse figurant

I'int@ieur de la couverture arri@e de ce manuel.

Informations gen6rales

Dimensions hers tout

Modeles 30 po

(76 cm) :

Largeur

(d'un c6t6

I'autre)

Profondeur

(de I'avant

I'arri_re)

Hauteur 3 13/16 po 3 13/16 po

(de haut en bas) (97 mm) (97 mm)

REMARQUE :

Ces dimensions sont donn6es hors tout et ne constituent

PAS des dimensions de d6coupe.

31 po (788 mm)

21 1/4 po

(540 mm)

Modeles 36 po

(91 cm):

37 po (940 mm)

21 1/4 po

(540 mm)

Pression d'alimentation :

• Gaz naturel - 7 po (178 mm) _ la colonne d'eau (14,9

millibars) minimum.

• Gaz propane - 11 po (279 mm) _ la colonne d'eau

(27,4 millibars) minimum.

Le r6servoir de gaz propane doit disposer de son propre

r6gulateur haute pression, outre le r6gulateur de pression

fourni avec cet appareil. La table de cuisson est r6gl6e _ sa

sortie de I'usine pour fonctionner au gaz naturel. Utilisation

avec la trousse de conversion au GPL- ModUle NEZ1054,

acheter s6par6ment. Cette conversion doit 6tre effectu6e

par un technicien ou installateur qualifi6.

Exigences concernant les armoires

Les exigences en mati@e de dimensions d6crites aux

figures 1 et 2 portent sur les surfaces combustibles.

Lorsque la surface est prot6g6e par un mat@iau catalogu6

par le UL (Underwriters Laboratories) en tant que

protecteur de plancher et 6cran de protection mural

recouvert au moins par une t61e MSG No. 28, d'acier

inoxydable de 0,015 po (0,38 mm), d'aluminium ou de

cuivre de 0,024 po (0,6 mm), elle est consid@_e comme

non combustible et certaines dimensions peuvent _tre

r_duites. Pour une surface non combustible situ_e au-

dessus de la table de cuisson, le d_gagement minimum est

de 24 po (61 cm) plut6t que 30 po (76 cm).

• Les instructions sont bas_es sur les armoires standard

am_ricaines de 36 po (91 cm) de hauteur x 24 po (61

cm) de profondeur avec un plan de travail de 25 po (63

cm).

• Pr_voir une ouverture d'environ 10 po2(65 cm2) au

niveau du coup-de-pied ou _ un autre endroit de

I'armoire pour un apport d'air ad_quat _ I'armoire dans

le cas d'une installation avec une hotte _ _vacuation

tirage par le bas.

Frangais 3

Page 15

LaprofondeurmaximaledeI'armoireinstall6eau-

dessusdelatabledecuissonestde13pc(33cm).

Profondeur depuis le mur arriere

Armoire 13 po (33 cm) max.

Prof. hotte - 24 pc (61 cm) max.

Au-dessus du comptoir - 30 po (76 cm) min 1

NGM 30 - 30 pc (76 cm) min.

NGM 36- 36 po (91 cm)min. I _!

_,_ 06te:Sa::h[e46 c l_)_l in M..... iere-2 po (5 cm) _ C6te droit I

13 pc (33 cm)min._, !___ | 13 po (33 cm)min. _"

T

m

a la surface combustible _

Centre au-dessus de |

la table de cuisson

I

i

i q I

Figure1: Dimensions installees (depuis les rebords de

la table de cuisson)

REMARQUE :

Toutes les mesures fournies doivent _tre scrupuleusement

respect6es. Si des armoires non standard sont utilis6es,

s'assurer qu'elles sont install6es avec les dimensions

minimales donn6es aux figures 1 et 2.

Exigences concernant le plan de travai

Planifier I'installation de I'appareil afin que le cordon

d'alimentation, le robinet d'arr_t de gaz et le r6gulateur de

pression du gaz soient accessibles depuis le devant de

I'armoire.

Modeles 30 po (76 cm) :

Min. 30"

(762) 211/4"

313/16'_

(97)

13" 13

(332) (332)

:1.5)

connexion de

(788) --_

: gaz

191/8 ''

(486) Mt_}_ ''

17/8''

(48)

la mesure en pouce/mm

Modeles 36 po (91 cm) :

min.30"

13" 13

(332) (332)

15/16"

/16"

15)

191/8''

(486) max.3"

(76)

17/8"

(48)

la mesure en pouce/mm

Figure 2: Dimensions de decoupe

Exigences en matiere de montage

Utiliser les pattes de fixation fournies. Voir "Installation de

la table de cuisson" page 5 pour obtenir d'autres d6tails.

Recommandations sur la ventilation

II est vivement recommand6 d'installer une hotte aspirante

au-dessus de cet appareil. La hotte aspirante doit 6tre

install6e conform6ment aux instructions qui

I'accompagnent.

Frangais 4

Procedure d'installation

_ AVERTISSEMENT •

d'61ectricit6 pour emp6cher que le courant ne soit r6tabli

accidentellement.

Afin d'6viter tout risque de choc 61ectrique,

avant d'installer la table de cuisson, couper le

courant au niveau du panneau d'entr6e

Page 16

Preparation du plan de travail Installation de la table de cuisson

D6coupez le plan de travail selon les dimensions de coupe

indiqu6es _ la section "Exigences concernant les armoires"

page 3.

Certain mat@iaux de rev_tement durs, tels que Surell TM et

Corian®, exigent des m6thodes de d6coupe diff@entes.

Consultez le fabricant du mat@iau de rev_tement dur pour

obtenir la m6thode de d6coupe correcte requise. Appliquez

du ruban r6fl6chissant la chaleur tel que le ruban adh6sif

m6tallique Scotch n° 425 ou n° 427 (non inclus) sur le

pourtour de la d6coupe de mani@e _ ce qu'il se replie sur

le dessus et les c6t6s. Ne pas mettre de ruban sous la

table de cuisson. S'assurer que le ruban d6passe du

rebord extr6me de la table de cuisson. Tousles coins

doivent 6tre recouverts de ruban.

• Ruban r_fl_cflissant la cflaleur

Ins@er la table de cuisson dans la cavit6. Installer les

attaches des supports de fixation emball6s avec la table de

cuisson sur le boftier brut. Utiliser la rondelle et les vis

fournies.

Bo_te brute .

! jf ._-

I _' Vis

_,_.. Vis de

reglage

Figure 5: Pose des supports de fixation

Placer les supports de fixation dans la position souhait6e et

serrer les vis sur le boftier brut. Ins@er les vis de r6glage

dans I'attache et fixer fermement la table de cuisson au

plan de travail.

Section _<A- A >7

Figure 3: Decoupe du comptoir - Plans de travail a surface

solide

Fixation de la table de cuisson avec du

ruban en mousse

Appliquer le ruban auto-adh6sif en mousse directement sur

le plan de travail en d6crivant un rectangle tout autour du

p@im_tre de la d6coupe comme I'indique la ligne pointill6e

de la figure 4 : "D6coupe du comptoir- Pose d'un ruban en

mousse". Laisser un espace de 1/4 po (6,35 mm) entre le

ruban en mousse et le rebord de la d6coupe.

1/4"

I" (6.35mm)

Ruban

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii i !i i !!! i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i i

en

mousse

REMARQUE :

Installation avec des mat@iaux _ surface solide : Ins@er

une cale de bois entre I'extr6mit6 de la vis et la partie

inf6rieure du plan de travail. Ne pas serrer _ I'exc_s les vis

de r6glage. Couper I'exc_s de ruban d'aluminium le long du

rebord de la table de cuisson.

Raccordement de I'alimentation de gaz

L'arriv6e de gaz de I'appareil se trouve sur la droite

I'arri@e du boftier brut.

Ouverture pour la

connexion de gaz

le cordon electrique

de ia decoupe

po : 12 15/16 po (313 mm)

Pour modeles 36 po : 15 15/16 po (389 mm)

i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_i_

Figure 6: Zone du boitier brut

Installez le r_gulateur de pression (fourni avec I'appareil)

Figure 4: Decoupe du comptoir - Pose d'un ruban en

mousse

sur le tuyau collecteur en appliquant du ruban pour joints

flier,s sur les filets du tuyau collecteur. Serrez de 1/4 de

tour au-del_ de la force manuelle, sans d_passer 1 tour

pour I'alignement. Pour pr_venir tout dommage possible au

Frangais 5

Page 17

r6gulateurdepressiondegaz,installercelui-ciunefoisle

boftierbrutfix6demani@epermanente.Unefoisle

r6gulateurinstall6solidementsurletuyaucollecteur,

1'6croudeconversionserafacile_atteindre.

Figure 7: Regulateur de pression

ATTENTION •

Ne pas tenter de r6gler le r6gulateur de

pression, sauf pour la conversion au gaz

propane.

joints et raccords de gaz de I'appareil si les connexions

ont 6t6 perturb6es pendant I'installation. Des bulles

autour des raccords et connexions indiquent la

pr6sence d'une fuite.

,

S'il y a une fuite, fermer le robinet d'arr_t de gaz du

tuyau d'alimentation et serrer les connexions.

4.

V@ifier de nouveau les fuites en ouvrant le robinet

d'arr_t de gaz du tuyau d'alimentation. Une fois la

v@ification termin6e (il n'y a plus de bulles), le test est

termin6.

5. Essuyer tout r6sidu provenant du liquide de d6tection.

Remarques importantes concernant les connexions de

gaz :

• L'appareil et son robinet d'arr_t de gaz individuel

doivent _tre d6branch6s de la tuyauterie d'alimentation

en gaz Iorsque vous effectuez des tests de pression de

cette tuyauterie _ une pression d'6preuve d6passant 1/

2 psig (3,5 kPa).

• L'appareil dolt _tre isol6 de la tuyauterie d'alimentation

en gaz en fermant le robinet d'arr_t manuel individuel

Iorsque vous effectuez des essais de pression sur la

tuyauterie d'alimentation en gaz si la pression

d'6preuve est 6gale ou inf@ieure _ 1/2 psi (3,5 kPa)

Raccordez la conduite d'alimentation de gaz au r6gulateur

de pression de I'appareil _ I'aide d'un raccord de conduite

de gaz flexible de 1/2 pc plac6 entre le robinet d'arr_t

manuel et le r6gulateur de pression. Toujours utiliser un

tuyau flexible neuf.

Bo teb te

Regulateur uyau e ==,=,_ _, | _,_

de pression gaz flexible

montrant le

sens du -- _,_

d@bit de gaz Robinet d'arr6t de gaz,,_,_

Figure 8: Emplacement du gaz et de I'electricite

Plancher d'armoire

Tubulure de raccordement de gaz

Filets de tuyau

femelle 1/2 po

Cordon d'aliment

120 volts

CLde la prise

murate

V@ifier les connexions des tuyaux d'alimentation pour

d6tecter d'6ventuelles fuites _ I'aide d'une solution

savonneuse. Ne pas utiliser de flamme.

,

Ouvrir le gaz.

2.

Appliquer un liquide de d6tection des fuites non

corrosif sur tousles joints et raccords de la connexion

de gaz entre le robinet d'arr6t et I'appareil. Inclure les

Raccordement de I'alimentation electrique

Avant de brancher le cordon d'alimentation de 5 pi (1,5 m)

sur la prise murale, s'assurer que le robinet d'arr_t de gaz

et toutes les commandes de brOleur sont en position OFF

(arr6t)

Pose des capuchons de brOleur

AVERTISSEMENT •

Pour 6viter les pouss6es de flamme, ne pas

utiliser la table de cuisson sans avoir

correctement install6 les capuchons et les

grilles de brQleur.

__ Pour 6viter les brQlures, ne pas toucher les

brOleurs refroidir.

Les capuchons de brOleur doivent _tre bien plac6s pour

que la table de cuisson puisse fonctionner correctement.

S'ils sont mal plac6s, le ou les probl_mes suivants peuvent

survenir :

• Les flammes sont trop hautes.

• Les flammes se d6tachent des brOleurs.

AVERTISSEMENT •

grilles ni les capuchons de brOleur chauds.

€:teindre la table de cuisson et laisser les

Frangais 6

Page 18

• LesbrOleursnes'allumentpas.

• Lesflammess'allumentdemani_reirr6guli_re.

• Uneodeurdegazsed6gagedesbrOleurs.

Pose des capuchons de brQleur

Chaque capuchon comporte une lettre (A, D, ou F) coul6e

dans la partie inf6rieure du capuchon correspondant _ une

lettre (A, D, ou F) coul6e dans la base du brOleur solidaire

de I'appareil.

• Une lois la connexion 61ectrique effectu6e, placer

chaque capuchon de brOleur sur la base du brOleur

correspondant suivant la lettre qui lui a 6t6 attribu6e.

Voir la figure "Capuchons de brOleur" page 7.

• Placez le capuchon de brOleur d61icatement sur la

base de mani_re _ ce que les pattes de la base du

brOleur s'ajustent parfaitement dans la fente du

capuchon de brOleur.

Base de breleur

D6signation de lettre

-I_ correspondante.

Verification du placement des capuchons de breleur

• V6rifiez qu'il n'y a pas d'espace entre le capuchon du

brOleur et la base du brOleur. Voir la figure "Pose des

capuchons de brOleur" page 8 pour connaftre la bonne

Capuchon de breleur

Figure 9: Capuchons de brQleur

et la mauvaise fagon d'installer le capuchons d'un

brOleur.

Vous pouvez essayer de d6placer 16g_rement le

capuchon de brOleur d'un c6t6 _ I'autre pour v6rifier s'il

est bien plac6. S'il est bien plac6, le capuchon 6mettra

Frangais 7

Page 19

un16gerbruitd'unc6t6etdeI'autreaufuret_mesure

quelespattesbutentcontrelereborddesfentes.

Placement correct des

capuchons de brQleur

Placement incorrect des

capuchons de brQleur

Figure 10: Pose des capuchons de brQleur

Verification finale

V@ifier le fonctionnement des allumeurs 61ectriques.

V@ifier les caract@istiques de la flamme. La flamme doit

6tre bleue sans comporter de pointe jaune.

Flammes jaunes :

R6glage suppl6mentaire requis.

Pointes jaunes au niveau des

c6nes exterieurs :

Normal pour du gaz GPL.

Douces flammes bleues :

Normal pour du gaz naturel.

Si la flamme est enti@ement jaune ou presque, v@ifier

que le r6gulateur est r6g16 pour le combustible

appropri6. Apr_s le r6glage, refaire le test.

II est normal que la flamme pr6sente des raies jaunes

pendant la mise en marche initiale. Laisser I'appareil

fonctionner pendant 4 _ 5 minutes et v@ifier de nouveau

avant d'effectuer d'autres r6glages.

Figure 11: Verification des caracteristiques de la flamme

Frangais 8

Page 20

D pannage

Avant d'appeler le service de

ddpannage

Si les allumeurs n'6mettent pas d'6tincelles ou si 1'6clairage

du voyant lumineux <<On >>ne fonctionne plus, v@ifier

I'alimentation de courant pour voir si un fusible s'est grill6

ou si le disjoncteur s'est d6clench6.

Consulter la garantie dans le Manuel d'utilisation et

d'entretien. Pour des informations sur le d6pannage, se

reporter au Manuel d'utilisation et d'entretien.

Plaque signaletique du produit

La plaque signal6tique donne les num6ros de module et de

FD (num6ro d'identification unique du produit pour le

service _ la clientele) de votre table de cuisson. Elle est

situ6e sur la face inf6rieure du boftier brut, sous la table de

cuisson.

plaque si " '

Figure 12: Emplacement de la plaque signaletique

Conserver la facture et les documents pertinents pour la

validation de la garantie si une r6paration s'av6rait

n6cessaire.

Frangais 9

Page 21

Contenidos

Seguridad ................................... 1

Instrucciones de seguridad importantes ............................ 1

Instalaci6n .................................. 3

Antes de comenzar .............................................. 3

Herramientas y piezas necesarias ............................................... 3

Piezas incluidas ............................................................. 3

Informaci6n general .......................................................... 3

Preparaci6n ................................................................ 3

Procedimiento de instalaci6n ..................................... 5

Prepare la superficie de trabajo ................................................. 5

Selle la placa con cinta de espuma .............................................. 5

Instale la placa .............................................................. 5

Conecte la alimentaci6n de gas ................................................. 6

Conecte el suministro electrico ................................................. 7

Colocaci6n de la tapa de la hornilla .............................................. 7

Verificaci6n final ............................................................. 8

Servicio tdcnico .............................. 9

Antes de Ilamar al servicio tecnico ................................. 9

Placa de datos del producto ................................................... 9

Este electrodomestico de Bosch es hecho por BSH

Home Appliances Corporation

5551 McFadden Ave.

Huntington Beach, CA 92649

_,Preguntas?

1-800-944-2904

www.boschappliances.com

iEsparamos oir de usted!

Page 22

Seguridad

Instrucciones de

seguridad importantes

LEA Y CONSERVE ESTAS

INSTRUCCIONES

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL

ELECTRODOMI_STICO CUANDO HAYA FINALIZADO LA

INSTALACION.

IMPORTANTE: GUARDELAS PARA USO DEL

INSPECTOR LOCAL.

Instrucciones de seguridad importantes

ADVERTENCIA:

No repare ni reemplace ninguna parte del

electrodom6stico, a menos que se recomiende

especificamente en los manuales. La instalaci6n, el

servicio t6cnico o el mantenimiento incorrectos pueden

causar lesiones o da_os materiales. Consulte este manual

para su orientaci6n. Cualquier otro tipo de reparaci6n debe

ser realizada por un t6cnico calificado.

Seguridad de los electrodomesticos a gas

ADVERTENCIA:

Si no sigue la informaci6n de este manual exactamente,

se puede ocasionar un incendio o una explosi6n que

puede causar da_os materiales, lesiones personales o

la muerte.

No almacene ni utilice materiales combustibles,

gasolina ni otros vapores y liquidos inflamables

cerca de este electrodomestico ni de cualquier

otro.

• Instale una valvula de paso de gas cerca del

electrodom6stico. Esta v_lvula debe estar en un area

facilmente accesible en una emergencia.

• El instalador debe verificar que no haya fugas segQn

las instrucciones de este manual.

• El electrodom6stico y su v_lvula de paso individual

deben estar desconectados del sistema de tuberias de

alimentaci6n de gas durante cualquier prueba de

presi6n, cuando la presi6n sea mayor que ½ psi (3.5

kPa).

• Se debe aislar el electrodom6stico del sistema de

tuberias de alimentaci6n de gas cerrando la v_lvula de

paso manual individual durante cualquier prueba de

presi6n del sistema de tuberias de alimentaci6n de gas

con presiones de prueba iguales o menores que ½ psi

(3.5 kPa).

• La presi6n minima de suministro debe ser 1" de

columna de agua por encima de la presi6n de

admisi6n impresa en la placa de datos.

• La presi6n m_xima de suministro no debe exceder

14.0 pulgadas de columna de agua (34.9 milibares).

• Para instalaciones en Massachusetts:

• La instalaci6n debe ser realizada por un contratista

calificado o con licencia, un plomero o gasista cali-

ficado o con licencia otorgada por el estado, la pro-

vincia o la regi6n donde se instale este

electrodom6stico.

• La valvula de paso debe tener una Ilave de gas

con mango en "T".

• El conector de gas flexible debe ser nuevo y no

debe medir m_s de 36 pulgadas.

Instalador: muestre al propietario del electrodom6stico

la ubicaci6n de la valvula de paso de gas.

Instalacion de gas propano

-- QUI_ DEBE HACER SI SIENTE OLOR A GAS

• No intente encender ningun electrodomestico.

• No toque ningun interruptor electrico.

• No use ningun telefono en su edificio.

• Llame inmediatamente a su proveedor de gas

desde el telefono de un vecino. Siga las

instrucciones del proveedor de gas.

• Si no puede comunicarse con su proveedor de

gas, Ilame al departamento de bomberos.

La instalacion y el servicio tecnico deben ser

realizados por un instalador calificado, una

agencia de servicio tecnico autorizada o el

proveedor de gas.

• El tanque de gas propano debe estar equipado con su

propio regulador de alta presi6n. Adem_s, se debe

usar el regulador suministrado con esta unidad.

• El electrodom6stico es enviado de fabrica para uso

con gas natural. Debe convertirse para utilizar

propano. La conversi6n debe estar a cargo de un

t6cnico o instalador calificado.

Requisitos de seguridad de equipos y de uso

La placa debe usarse junto con un sistema de

ventilaci6n adecuado.

Retire toda la cinta y el embalaje antes de usar el

electrodom6stico. Destruya el embalaje despu6s de

desembalar el electrodom6stico. Nunca deje que los

ni_os jueguen con el material de embalaje.

Espa_oll

Page 23

• Nuncamodifiquenialterelaconstrucci6ndel

electrodom6stico.Porejemplo,noretirelospaneles,

lascubiertasparacablesnilostornillos.

• Paraeliminarelriesgodequemaduraso incendioal

tocarlasunidadesdelasuperficiecalentadas,sedebe

evitardejarespaciodealmacenamientoengabinetes

sobrelasunidadesdelasuperficie.Enelcasodeque

hayaalmacenamientoengabinetes,sepuedereducir

elriesgoinstalandounacampanaqueseproyecte

horizontalmente5pulgadas,comominimo,desdela

parteinferiordelgabinete.

• Verifiquequelosgabinetesqueseencuentranarriba

delaplacatengan,comom_ximo,13"(330mm)de

profundidad.

Seguridadcon el manejo del electrodomestico

La unidad es pesada y se requieren al menos dos

personas o un equipo adecuado para trasladarla.

Las superficies ocultas pueden tener bordes filosos.

Proceda con cuidado al intentar tomar el

electrodom6stico por la parte trasera o desde abajo.

Codigos y normas de seguridad

• Este electrodom6stico cumple con una o m_s de las

siguientes normas:

• UL 858, Norma de seguridad para estufas

electricas de uso domestico (Standard for the

Safety of Household Electric Ranges)

• UL 923, Norma de seguridad para

electrodomesticos de coccion por microondas

(Standard for the Safety of Microwave Cooking

Appliances)

• UL 507, Norma de seguridad para ventiladores

electricos (Standard for the Safety of Electric

Fans)

• ANSI Z21.1, Norma nacional estadounidense

para electrodomesticos a gas para cocinar de

uso domestico (American National Standard

for Household Cooking Gas Appliances)

• CAN/CSA-C22.2 N.° 113-M 1984, Ventiladores

(Fans and Ventilators)

• CAN/CSA-C22.2 N.° 61-M89, Estufas de uso

domestico (Household Cooking Ranges)

• Es responsabilidad del propietario y del instalador

determinar si se aplican otros requisitos y/o normas en

instalaciones especificas.

• La instalaci6n debe cumplir con los c6digos locales o,

en el caso de que no haya c6digos locales, con el

C6digo Nacional de Gas Combustible (National Fuel

Gas Code), ANSI Z223.1/NFPA 54.

El electrodom6stico debe tener una conexi6n el6ctrica

a tierra de conformidad con los c6digos locales o, en el

caso de que no haya c6digos locales, con el C6digo

Nacional EI6ctrico (National Electrical Code), ANSI/

NFPA 70, _ltima edici6n. (En Canada, la instalaci6n

debe realizarse de conformidad con la norma CAN 1-

B149.1 y .2 - C6digos de Instalaci6n para

Electrodom6sticos de Combusti6n a Gas y/o los

c6digos locales).

Seguridad con la electricidad

Antes de enchufar un cable el6ctrico, asegQrese de

que todos los controles est6n en la posici6n OFF

(Apagado).

Para los electrodom6sticos equipados con cable y

enchufe, no corte ni retire la espiga de conexi6n a

tierra. Debe enchufarse en un recept_culo de conexi6n

a tierra compatible para evitar la descarga el6ctrica. Si

tiene alguna duda respecto de si el recept_culo de

pared est_ correctamente conectado a tierra, el cliente

debe solicitar la verificaci6n de un electricista

calificado.

• Este electrodom6stico debe instalarse de conformidad

con el C6digo Nacional EI6ctrico o el C6digo EI6ctrico

Canadiense (Canadian Electrical Code). La placa debe

instalarse en un circuito derivado con conexi6n a tierra,

sin interruptor del circuito de fallas de conexi6n a tierra

(Ground Fault Circuit Interrupter, GFCI).

• Instalador: muestre al propietario la ubicaci6n del

disyuntor o del fusible. MSrquela para recordarla m_s

fScilmente.

Importante: conserve estas instrucciones para uso del

inspector de electricidad local.

Antes de realizar la instalaci6n, apague la alimentaci6n

el6ctrica en el panel de servicio. Trabe el panel de

servicio para impedir que se encienda accidentalmente

la alimentaci6n el6ctrica.

AsegQrese de que el electrodom6stico sea

correctamente instalado y conectado a tierra por un

t6cnico calificado. La instalaci6n, las conexiones

el6ctricas y la conexi6n a tierra deben cumplir con

todos los c6digos correspondientes.

Instalacion a altas altitudes

Comuniquese con el servicio t6cnico para usar el

electrodom6stico en altitudes mayores que 2000 pies.

Espa_ol2

Page 24

_j[__; _ii[11__ii ...................................................................................................................................................................................................................................................................................................................................................................................................,_

Instalacibn

Antes de comenzar Preparaci6n

Requisitos electricos

Herramientas y piezas necesarias

1. Destornillador con cabeza Phillips

2. Taladro con broca de 1/4" (6.5 mm)

3. Cinta m6trica

4. Cinta de tefl6n (apta para gas)

Estos electrodom6sticos requieren una conexi6n de 60 Hz,

15 A y 120 VCA. Planifique la instalaci6n de modo que sea

posible acceder a la conexi6n de alimentaci6n el6ctrica

desde la parte delantera del gabinete.

Requisitos de gas

Piezas incluidas

1. Cinta de espuma

2. Soportes de retenci6n (4)

3. Tornillos, N. ° 10 de 32 x 2 1/2" (63.8 mm) (4)

4. Tornillos autorroscantes, N.° 8 de 3/8" (9.5 mm) (4)

5. Arandelas (4)

6. Rejillas de las hornillas (3)

7. Tapas de las hornillas

Modelos de 36": (5)

Modelos de 30": (4) 6 (5)

8. Regulador de presi6n

Si hay piezas faltantes o da_adas, Ilame al nQmero o

escriba a la direcci6n que aparecen en la parte interna de

la contraportada.

Informaci6n general

Dimensiones totales

Modelos de 30" Modelos de 36"

(76 cm): (91 cm):

Ancho 31" (788 mm) 37" (940 mm)

(De lado a lado)

Profundidad 21 1/4" (540 21 1/4" (540

(De adelante mm) mm)

hacia atrSs)

Altura 3 13/16" (97 3 13/16" (97

(De arriba hacia mm) mm)

abajo)

NOTA:

Estas son dimensiones totales, NO las dimensiones del

recorte.

Presi6n de suministro:

• Gas natural - minimo de 7 pulgadas (178 mm) de

columna de agua (14.9 milibares).

• Gas propano - minimo de 11 pulgadas (279 mm) de

columna de agua (27.4 milibares).

El tanque de gas propano debe estar equipado con su

propio regulador de alta presi6n y adem_s, se debe usar el

regulador de presi6n suministrado con esta unidad. La

placa es enviada de f_brica para uso con gas natural. Para

usar con el kit de conversi6n a propano liquido (Liquid

propane, LP)- El modelo NEZ1054 debe comprarse por

separado. La conversi6n debe estar a cargo de un t6cnico

o instalador calificado.

Requisitos de gabinetes

Los requisitos de dimensiones de las Figuras 1 y 2

corresponden alas superficies combustibles. Cuando la

superficie est_ protegida por un material incluido en el

listado de UL como Protector para pisos y Protector para

paredes recubiertos con una plancha de metal, al menos,

N.° 28 MSG, de acero inoxidable de 0.015 pulgadas (0.38

mm), aluminio o cobre de 0.024 pulgadas (0.6 mm), la

superficie se considera no combustible, yes posible que se

reduzcan algunas dimensiones. Para una superficie no

combustible sobre la placa, el espacio libre minimo es de

24" (61 cm) en lugar de 30" (76 cm).

• Las instrucciones se basan en gabinetes est_ndares

de los EE. UU., de 36" (91 mm) de alto y 24" (61 mm)

de profundidad con una superficie de trabajo de 25"

(63 mm).

• Deje una apertura de aproximadamente 10 pulgadas

cuadradas (65 cm2) en el 8rea del panel de pie o en

otra 8rea del gabinete si se instala con una corriente

descendente.

Espa_ol3

Page 25

Laprofundidadm_ximadelgabinetequeseinstala

debajodelaplacaesde13"(33cm).

Profundidad de pared trasera

Profundidad campana - 24" (61cm) max.

Arriba de la cubierta - 30" (76 cm) rain.

O NGM36- 36 (91cm) m n.

18" (46cm) rain.

Lado izquierdo |

12" (30cm) rain.

i

/

_. Pared trasera - 2" (5cm) _ Lado derecho _

}_,,,,,,,_-r_J 12"{300m)mfn

I I i

Requisitos de la superficie de trabajo

T

Gabinete 13" (33cm) max.

m

a la superficie inflamable _1

NGM30 - 30" (76cm) rain. --

Centrado sobre la parrilla

®

Figura 1: Dimensiones instaladas

(desde los bordes de la placa)

Nora:

Se deben seguir estrictamente todas las medidas

proporcionadas. Si se utilizan gabinetes no est_ndares,

asegQrese de que se instalen con las dimensiones

minimas indicadas en las Figura 1 y Figura 2.

Planifique la instalaci6n de la unidad de modo que se

pueda acceder al cable de alimentaci6n, la vSIvula de paso

de gas y el regulador de presi6n de gas desde la parte

delantera del gabinete.

Modelos de 30" (76 cm):

Min. 30"

(762) 21V4"

313/16",

(97)

13" 13

(332) (332)

(15)

conexi6n

(788) _ de gas

, ....,,:

191/8''

17/8''

(48)

medida en pulgadas/mm

Modelos de 36" (91 cm):

min.30"

(762) 211/4"

13" 13

(332) (332)

15/16"

37"

(940)_ conexidndegas

...i

i ..,,

191/8''

(486) max.3"

(76)

17/8,,

(48)

medida en pulgadas/mm

Figura 2: Dimensiones del recorte

Requisitos de montaje

Use los soportes de montaje suministrados. Consulte

"lnstale la placa" en la p#gina 5 para obtener m#s detafles.

Espa_ol4

Recomendaciones de ventilacion

Recomendamos categ6ricamente la instalaci6n de una

campana de ventilaci6n arriba de este electrodom6stico.

La campana debe instalarse segQn las instrucciones

proporcionadas con la campana.

Page 26

Procedimiento de instalacibn separaci6n de 1/4" (6.35 ram)entre la cinta de espuma y el

borde del recorte.

ADVERTENCIA:

Para evitar el peligro de descarga el6ctrica,

antes de instalar la placa, apague la

alimentaci6n el6ctrica en el panel de servicio

para impedir que se encienda accidentalmente.

Prepare la superficie de trabajo

Recorte la superficie de trabajo de acuerdo con las

dimensiones indicadas en "Requisitos de gabinetes" en la

p4gina 3.

Algunos materiales de superficies s61idas, como Surell TM y

Corian®, requieren diferentes m6todos de corte. Consulte

con el fabricante de la superficie s61ida para conocer el

m6todo de corte correcto necesario. Coloque cinta

termorreflectante como cinta de papel de aluminio Scotch

N.° 425 6 427 (no incluida) alrededor del recorte de modo

que se pliegue sobre la parte superior y los laterales de la

placa. No pase la cinta por debajo de la placa. Aseg@ese

de que la cinta se extienda m_s alia de la brida m_s

extema de la placa. Todas las esquinas deben estar

cubiertas con cinta.

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii¸i ! i ! !i ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii ii i i ! i i i i i i

ililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililililii_i_i_

_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_

_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_!_::::::

Figura 4: Recorte de la superficie de trabajo - Colocacion de

la cinta de espuma

Instale la placa

Introduzca la placa en el recorte. Enganche las

abrazaderas de los soportes de retenci6n embaladas con

la placa a la caja empotrada. Use la arandela y los tornillos

suministrados.

Cinta

"de

espuma

• Cinta termorreflectante

Secci6n "A - A"

Figura 3: Recorte de la superficie de trabajo - Superficies de

trabajo solidas

Selle la placa con cinta de espuma

Coloque cinta de espuma autoadhesiva en un rect_ngulo

continuo directamente sobre la superficie de trabajo,

alrededor del perimetro del recorte, como se muestra en la

linea punteada de la Figura 4: "Recorte de la superficie de

trabajo - ColocaciOn de la cinta de espuma". Deje una

Caja empotrada _nl

... _, . C_nta

_'_'_S_ujet ad or '

_¢r. Tornilto de

ajuste

Figura 5: Colocacion de los soportes de retencion

adera

Ajuste los soportes de retenci6n en la posici6n deseada y

apriete los tornillos a la caja empotrada. Introduzca el

tomillo de ajuste en la abrazadera y asegure la placa a la

superficie de trabajo.

Nora:

Para instalaciones de materiales de superficies s61idas:

Introduzca un bloque de madera entre el extremo del

tornillo y la parte inferior de la superficie de trabajo. No

apriete el tornillo de ajuste en exceso. Recorte la cinta de

aluminio excedente alrededor de la brida de la placa.

Espa_ol5

Page 27

Conecte la alimentaci6n de gas

La entrada de gas de la unidad se encuentra en la parte

posterior derecha de la caja empotrada.

Abertura para la conexi6n

de gas y el cable de

alimentaci6n

electrica

_,C L de l recorte

)ara modelos de 30" - 12-15/16" (312.8 mm)

para modelos de 36" - 15-15/16" (389 mm)

regulador de presi6n. Siempre use una linea flexible

nueva.

L aJa po 'adaF

egu a.or para gas _

ae preslon i_

indica la

direcci6n de = _i_rr "_.._

flujo del gas Valvula de cierre

Manguera

Piso dei gabinete

Conexi6n de gas

Rosca hembra

del tubo de 1/2"

Cable de

alimentaci6n

I[ 120V

m _det receptaculo

Figura 6: Area de la caja empotrada

Instale el regulador de presi6n (suministrado con la unidad)

en el tubo del mQItiple usando cinta de tefl6n sobre las

roscas del tubo del mQItiple. Gire para apretar a mano y

agregue 1/4 de vuelta, pero no d6 m_s de una vuelta para

alinearlo. Para evitar posibles da_os al regulador de

presi6n de gas, inst_lelo despu6s de que la caja

empotrada est6 colocada en su posici6n permanente.

Cuando el regulador est6 firmemente instalado en el tubo

del m[31tiple,la tuerca de conversi6n quedar_ en un _rea

fScilmente accesible.

Figura 8: Ubicacion de la instalacion electrica y el gas

Verifique que no haya fugas en las conexiones de la linea

de alimentaci6n usando una soluci6n de jab6n. No use

ningQn tipo de llama.

1. Encienda el gas.

2. Coloque un liquido de detecci6n de fugas no corrosivo

en todas las juntas y los conectores de la conexi6n de

gas entre la v_lvula de paso y la estufa. Incluya los

conectores de gas y las juntas en la estufa si existe la

posibilidad de que se hayan movido las conexiones

durante la instalaci6n. La presencia de burbujas

alrededor de los accesorios y las conexiones indican

una fuga.

3. Si se produce una fuga, apague la vSIvula de paso de

gas de la linea de alimentaci6n y apriete las

conexiones.

4. Vuelva a verificar que no haya fugas abriendo la

vSIvula de paso de gas de la linea de alimentaci6n.

Cuando haya finalizado de verificar que no haya fugas

(no hay burbujas), la prueba est_ completa.

5. Limpie todos los restos de liquido de detecci6n.

Figura 7: Regulador de presion

PRECAUCION:

No intente ajustar el regulador de presi6n, salvo

para realizar la conversi6n a propano.

Conecte la linea de alimentaci6n de gas al regulador de

presi6n de la unidad usando un conector de linea de gas

flexible de 1/2" entre la vSIvula de paso manual y el

Espa_ol6

Notas importantes para la conexion de gas:

El electrodom6stico y su v_lvula de paso individual

deben estar desconectados del sistema de tuberias de

alimentaci6n de gas durante cualquier prueba de

presi6n de ese sistema con presiones de prueba

mayores que 1/2 psi (3.5 kPa).

Se debe aislar el electrodom6stico del sistema de

tuberias de alimentaci6n de gas cerrando la v_lvula de

paso manual individual durante cualquier prueba de

presi6n del sistema de tuberias de alimentaci6n de gas

con presiones de prueba iguales o menores que 1/2

psi (3.5 kPa).

Page 28

Conecte el suministro electrico

Antes de conectar el cable de alimentaci6n de 5 pies (1.5

m) al recept_culo de pared, asegQrese de que la vSIvula de

paso de gas y todos los controles de las hornillas est6n en

la posici6n OFF (Apagado).

• Las llamas de la hornilla son demasiado altas.

• Las llamas salen disparadas de las hornillas.

• Las hornillas no se encienden.

• Las llamas de la hornilla se encienden de manera

dispareja.

• La hornilla emite olor a gas.

Colocaci6n de la tapa de la hornilla

ADVERTENCIA:

Para evitar Ilamaradas, no use la placa sin que

todas las tapas de las hornillas y todas las

rejillas de las hornillas est6n colocadas en la

posici6n correcta.

ADVERTENCIA:

Para prevenir quemaduras, no toque las tapas

ni las rejillas de las hornillas mientras est6n

calientes. Apague la placa y deje enfriar las

hornillas.

Las tapas de las hornillas deben colocarse correctamente

para que la placa funcione bien. Si la tapa de la hornilla no

se coloca correctamente, es posible que se produzcan uno

o m_s de los siguientes problemas:

Base de la hornilla

Colocacion de las tapas de las hornillas

Cada tapa tiene una letra (A, D o F) grabada en la parte

inferior de la tapa que corresponde a una letra (A, D o F)

grabada en la base de la hornilla que est_ conectada al

electrodom6stico.

• Despu6s de que se haya finalizado la conexi6n

el6ctrica, coloque la tapa de cada hornilla en la base

de la hornilla correcta segQn la designaci6n de letra

correspondiente. Consulte la figura "Tapas de las

hornillas" en la p4gina 7.

• Coloque la tapa de la hornilla suavemente sobre la

base, de modo que los dientes de la base de la hornilla

calcen bien en la ranura de la tapa de la hornilla.

Tapa de la hornilla

Verificacion de colocacion de la tapa de la hornilla

AsegQrese de que no haya ninguna separaci6n entre

la tapa de la hornilla y la base de la hornilla. Consulte

la figura "ColocaciOn de la tapa de la hornilla" en la

p4gina 8 para ver la colocaci6n correcta e incorrecta

de la tapa de la hornilla.

Designaci6n de letra

correspondiente.

Figura 9: Tapas de las hornillas

Tambi6n puede intentar mover suavemente la tapa de

la hornilla de un lado a otro para verificar si est_

colocada correctamente. Si est_ colocada

correctamente, la tapa se ir_ enganchando a presi6n

de un lado al otro a medida que los dientes toquen el

reborde de la ranura.

Espa_ol7

Page 29

Colocacion correcta de la tapa de

la hornilla

Colocacion incorrecta de la tapa

de la hornilla

Figura 10: Colocacion de la tapa de la hornilla

Verificaci6n final

Veriflque que los encendedores el6ctricos funcionen.

Verifique las caracteristicas de la llama. La llama debe ser

azul, sin puntas amarillas.

Llamas amarillas:

Se requiere un ajuste adicional.

Puntas amarillas en conos

extern os:

Normal para gas LP.

Llamas azul claro:

Normal para gas natural.

Si la llama es amarilla completamente o en su mayor

parte, verifique que el regulador est6 programado para

el combustible correcto. Despu6s de reajustarla, vuelva

a probarla.

Ver algunas vetas amarillas es normal durante el

encendido inicial. Deje que la unidad opere durante 4 6

5 minutos y vuelva a evaluarla antes de realizar ajustes.

Figura 11: Verificacion de las caracteristicas de las llamas

Espa_ol8

Page 30

Servicio tdcnico

Antes de Ilamar al servicio

tdcnico

Si los encendedores no echan chispas, o los indicadores

luminosos de "encendido" no brillan, verifique la fuente de

alimentaci6n para ver que no se haya quemado un fusible

ni se haya desconectado el disyuntor.

Consulte la garantia en el Manual de uso y cuidado. Para

obtener informaci6n sobre resoluci6n de problemas,

consulte el Manual de uso y cuidado.

Placa de datos del producto

La placa de datos muestra el modelo y el nQmero de FD

(nQmero de identificaci6n Qnico del producto para el

servicio de atenci6n al cliente) de su placa. Se encuentra