Bosch LTC 9224-00, LTC 9214-00 Installation Manual

LTC 9214/00, LTC 9224/00, LTC 9216/00, LTC 9222/00

LTC 9227/00, LTC 9228/00, LTC 9226/00

Instruction Booklet

EN Indoor/ Outdoor

Mounts

SAFETY PRECAUTIONS

The exclamation point within an equilateral

triangle is intended to alert the user to

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

SECURITE

Le point d'exclamation à l'intérieur d'un triangle

équilatéral avertit l'utilisateur de la présence

d'instructions importantes d'utilisation et de

maintenance dans la documentation

accompagnant l'appareil.

SICHERHEITSVORKENHRUNGEN

Das Ausrufezeichen in dem gleichseitigen

Dreieck ist dazu da, den Benutzer auf wich-tige

Inbetriebnahme- und Instandhaltungs-vorschriften

hinzuweisen, die dem Gerät in Form einer

Broschüre beigelegt sind.

PRECAUCIONES DE SEGURIDAD

El símbolo de exclamación dentro de un

triángulo equilátero, se muestra con el objetivo

de alertar al ususario de que instrucciones de

operación y mantenimiento importantes

acompañan al equipo.

1 UNPACKING

This equipment should be unpacked carefully and handled

with care.

Check for the following items:

• Model number of unit.

• Instructions for Use.

If an item appears to have been damaged in shipment, replace

it properly in its carton and notify the shipper. If any items

are missing, notify Bosch Security Systems.

The shipping carton is the safest container in which the unit

may be transported. Save it for possible future use.

2 SERVICE

If the unit ever needs repair service, the customer should

contact the nearest Bosch Security Systems, Inc. Service

Center for authorization to return and shipping instructions.

Service Centers

U.S.A.: 800-366-2283 or 408-956-3895

Fax: 800-366-1329 or 408-956-3896

Email: NationalServiceCenter@ca.slr.com

Canada: 514-738-2434

Europe, Middle East & Asia Pacific Regions

800-366-2283

For additional information, see

www.boschsecuritysystems.com

3 DESCRIPTION

These versatile indoor/outdoor column, wall, corner and

adjustable head mounts accommodate fixed cameras,

housings, pan/tilts, and scanners.

4 INSTALLATION

See SPECIFICATIONS for the maximum rated load of

mount.

Mounting Hardware: Not furnished.

Note: The use of stainless steel or zinc-plated fasteners is

recommended.

4.1 LTC 9214/00 356-mm (14-inch) and

LTC 9224/00 610-mm (24-inch)

Column Mounts

1. Determine a secure mounting location, either for a

pedestal (floor) mounted installation or for an overhead

(ceiling) mounted installation.

2.

3. Locate and drill four mounting holes using the end

4. Using four bolts (or studs) with nuts, washers, and lock

5. To mount the LTC 9227/00 Adjustable Head Mount:

6. To mount a pan/tilt or scanner device:

Caution:

a. For a secure mounting installation, bolts should

extend through the mounting surface and be

secured with nuts, washers, and lock washers on

the opposite side.

b. If studs are used, they should either be anchored in

concrete or welded to a steel backer plate.

c. If the LTC 9214/00 or LTC 9224/00 is mounted to

wood or a blind structure (with no access to the

rear) in a ceiling, make certain that the mounting

fasteners have a

pounds.

WARNING: The maximum rated load is reduced

to 45.3 kg (100 lb) when mounted in a ceiling.

flanges as a template.

washers, fasten the LTC 9214/00 or LTC 9224/00 to its

mounting location and tighten all nuts securely.

Note: The minimum diameter bolt (or stud) required

is 10 mm (3/8 in).

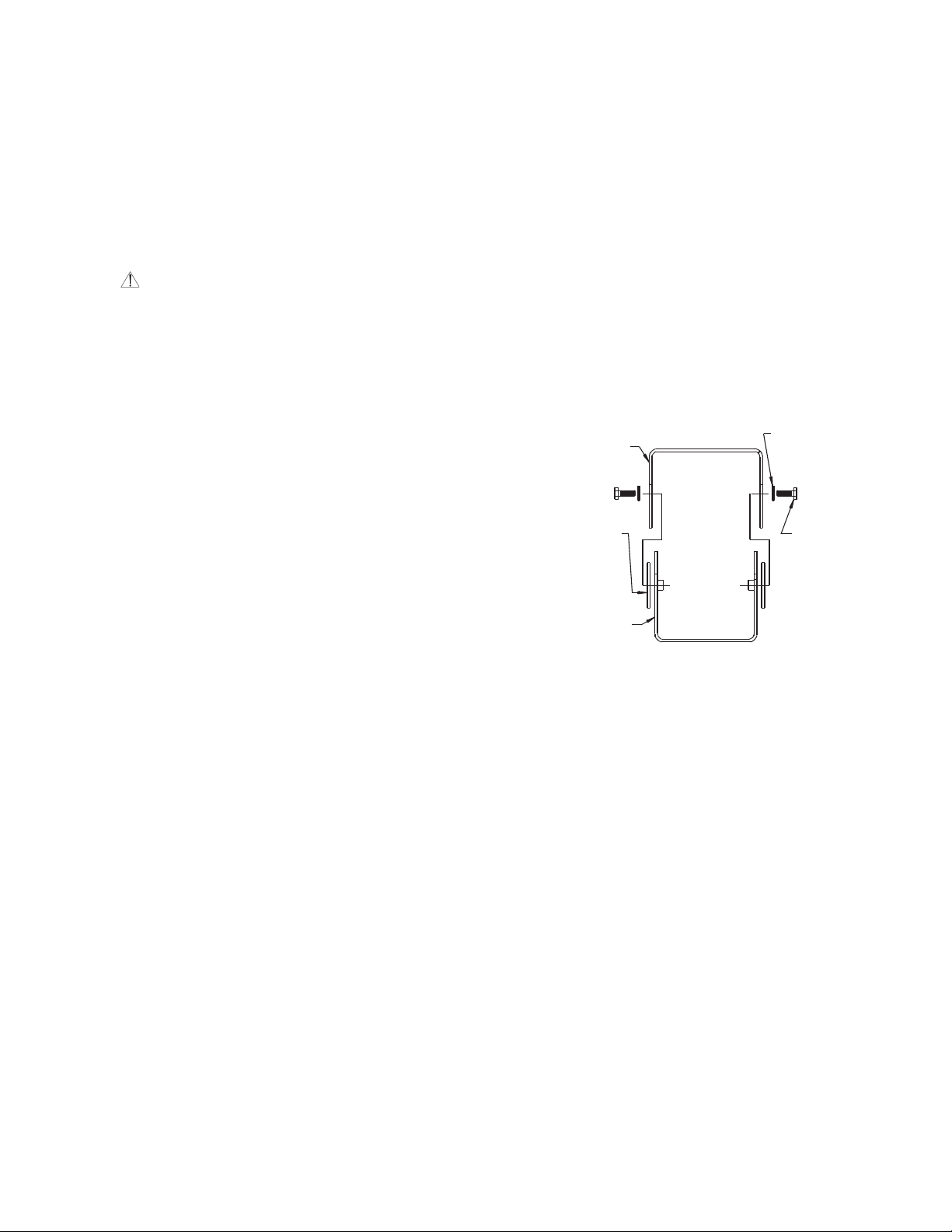

a. Use the mounting hole which is located in the

center of the LTC 9214/00 or LTC 9224/00

mounting plate. This mounting hole is threaded to

receive a 1/4-20 bolt.

Insert a 1/4-20 hex head machine bolt with washer

b.

and lock washer through the LTC 9227/00 base

plate and into the threaded insert on either end

flange of the LTC 9214/00 or LTC 9224/00.

The slotted mounting holes on the LTC 9214/00 or

a.

LTC 9224/00 can accommodate the following

mounting hole dimensions of pan/tilts and scanners:

Max.

Bolt Circle 197 mm (7.75 in) 121 mm (4.75 in)

Square Centers 140 mm (5.50 in) 85 mm (3.36

in)

minimum pull-out strength of 600

Min

.

2

Neoprene

Washer

Mounting

Plate

Base

Plate

Flatwasher

1/4"-20

Hex Bolt

b. To install, line up the holes in the base mounting

plate of the device. Insert a minimum of four

machine bolts (not included) with flat washers

through the device and the end flange of the

LTC 9214/00 or LTC 9224/00; then securely fasten

using lock washers and nuts.

4.2 LTC 9216/00 409-mm (16-inch) and

LTC 9222/00 564-mm (22-inch)

Wall Mounts

Determine a secure wall mounting location.

1.

WARNING: Do not mount in an inverted

position.

2. Caution:

a. For a secure installation use six (6) bolts (not

included). The bolts should extend through the

mounting surface and be secured with nuts, lock

washers, and flat washers on the opposite side.

b. If studs are used, they should be anchored in

concrete or welded to a steel backer plate.

c. If the wall mount is attached to wood or to a blind

structure (with no access to the rear), make certain

that the mounting fasteners have a minimum pullout strength of 600 pounds.

3. For ease of installation, locate the bottom mounting

holes first. Install the bolts (or studs) into the wall

surface.

WARNING: The LTC 9216/00 and LTC 9222/00

must be mounted with the slotted mounting

holes of the wall plate at the bottom.

4. Reseat the LTC 9216/00 or LTC 9222/00 on the bolts

(or studs) using the bottom slotted holes, then locate

the upper mounting holes and drill into the wall surface.

5. Install the upper bolts (or studs) through the wall mount

and into the wall surface. Tighten upper and lower bolts

(or studs) securely.

Note: The minimum diameter bolt (or stud) required

is 10 mm (3/8 in).

6. To mount the LTC9227/00 Adjustable Head Mount to:

LTC 9216/00 Wall Mount

Use the 1/4-20 threaded mounting hole located in

a.

the center of the slot pattern.

b. Insert a 1/4-20 hex head machine bolt, washer, and

lock washer through the adjustable head and into

the threaded insert in the wall mount. The bolt

should be 20 mm (3/4 in) long. A lock washer and a

flat washer must be used under the head of the

bolt.

LTC 9222/00 Wall Mount

Line up the hole in the LTC 9227/00 base plate with

a.

the center mounting hole on the mounting bracket.

b. Insert a bolt with flat washer through the LTC

9227/00 base plate and mounting bracket. A

5/16-18 x 50 mm (2-in) long bolt (not supplied) is

recommended to fasten the LTC 9227/00 to the

mounting bracket.

c. From the underside of the mounting bracket, use a

lock washer and nut to secure the LTC 9227/00.

Temporarily leave hand tight.

7. To mount a pan/tilt or scanner device:

The slotted mounting holes on the LTC 9216/00 and

a.

LTC 9222/00 can accommodate the following

mounting hole dimensions of pan/tilts and scanners:

Max. Min.

Bolt Circle 197 mm (7.75 in) 121 mm (4.75 in)

Square Centers 140 mm (5.50 in) 85 mm (3.36 in)

b. To install, line up the holes in the base mounting

plate of the device. Insert a minimum of four

machine bolts (not included) with flat washers and

lock washers through the device and the mounting

plate of the wall mount; then securely fasten using

lock washers and nuts.

4.3 LTC 9227/00 Adjustable Head Mount

4.3.1 Parts List

Mounting Plate 2 - Flat Washers

Base Plate 2 - Neoprene Washers

2 - 1/4-20 Hex Bolts

4.3.2 Assembly

1. Insert a neoprene washer between each side of the

mounting plate and base plate.

2. Line up each of the side holes; insert one 1/4-20 hex

head machine bolt with flat washer and screw into

threaded hole in base plate.

3. Hand tighten side bolts until ready to install.

4.3.3 Installation

The LTC 9227/00 is intended for installation on a rigid

1.

mounting surface by use of a bolt through the base plate.

2. To mount the LTC 9227/00 Adjustable Head Mount to:

LTC 9216/00 Wall Mount

a. Use the 1/4-20 threaded mounting hole located in

the center of the slot pattern.

b. Insert a 1/4-20 hex head machine bolt through the

adjustable head and into the threaded insert in the

wall mount. The bolt should be 20 mm (3/4 in)

long. A lock washer and a flat washer must be used

under the head of the bolt.

LTC 9222/00 Wall Mount

a. Line up the hole in the LTC 9227/00 base plate with

the center mounting hole on the mounting bracket.

3

Loading...

Loading...