LTC 8500, LTC 8600, LTC 8800

Instruction Manual

EN Allegiant®

MicroprocessorBased Video

Switcher/Control

Systems

This Instruction Book refers to “TC- prefix” model designations. Use this cross-reference to find the new

corresponding “LTC-prefix” model numbers. A revised instruction book will be printed at a later date.

LTC 8900 TC Allegiant® Microprocessor-Based Video Switcher/Control Systems

LTC 8901/00 ---- Equipment Rack , for LTC 8901 Bay

LTC 8905/90 ---- Power Supply, 120/220VAC, 50/60Hz

LTC 8910/00 ---- CPU Module for LTC 8901 Bay

LTC 8917/00 ---- Relay ("Hot Switch") Module, For LTC 8901 Bay

LTC 8901/60 ---- CPU Equipment Bay, 120V, 60Hz. Includes: 1 LT C 8901/ 00, 2 LTC 8905/90, 2 LTC 8910/00, & 1 LTC 8917/00

LTC 8901/50 ---- CPU Equipment Bay, 220V, 50Hz. Includes: 1 LT C 8901/ 00, 2 LTC 8905/90, 2 LTC 8910/00, & 1 LTC 8917/00

LTC 8902/00 ---- Equipment Rack , for LTC 8902 Bay

LTC 8916/00 ---- Data Receiver Module, for LTC 8902 B a y

LTC 8902/60 ---- Monitor Output Equipment Bay, 120V, 60Hz. Includes : 1 LTC 8902/00, 1 LTC 8805/60 & 1 LTC 8916/00

LTC 8902/50 ---- Monitor Output Equipment Bay, 220V, 50Hz. Includes : 1 LTC 8902/00, 1 LTC 8805/50 & 1 LTC 8916/00

LTC 8903/00 ---- Equipment Rack , for LTC 8903 Bay

LTC 8918/00 ---- Data Receiver Module, for LTC 8903 B a y

LTC 8903/60 ---- Camera Input Equipment Bay, 120V, 60Hz. Inc l udes: 1 LTC 8903/00, 1 LTC 8805/60 & 1 LTC 8918/00

LTC 8903/50 ---- Camera Input Equipment Bay, 220V, 50Hz. Inc l udes: 1 LTC8 903/00, 1 LTC 8805/50 & 1 LTC 8918/00

LTC 8921/00 ---- Video Input Module, for LTC 8900 System

LTC 8934/00 ---- Video Output Module, for LTC 8900 System

LTC 8941/90 ---- PC Package. Inc l udes 1 LTC 8943/90, 2 LTC 8945/90, 1 Monitor, Misc . Cables, 120/220V, 50/60Hz

LTC 8943/90 ---- PC, Pentium, 120MHz, 40M RAM, 1.6G Drive, Windows NT, 120/220V, 50/60Hz

LTC 8944/60 ---- PC, Pentium, 120MHz, 40M RAM, 1.6G Drive, Windows NT, 120/220V, 50/60Hz

LTC 8945/90 ---- LAN Hub, 12-Port, SNMP, 120/220V, 50/60Hz

LTC 8946/90 ---- Expansion LAN Hub, 12-Port, 120/220V, 50/60Hz

®

LTC 8800 TC8800 Allegiant

LTC 8800/00 TC8802R Equipment Rack, for LTC 8801 Bay

LTC 8801/60 TC8801A Main Switching B ay, 120V, 60Hz

LTC 8801/00 TC8801R Equipment Rack, for LTC 8801 Bay

LTC 8801/50 TC8801AX Main Switching Bay, 220V, 50Hz

LTC 8802/60 TC8802A Monitor Expansion Bay, 120V, 60Hz

LTC 8802/50 TC8802AX Monitor Expansion Bay, 220V, 50Hz

LTC 8805/60 TC8805 Power Supply, 120V, 60Hz

LTC 8805/50 TC8805X Power Supply, 220V, 50Hz

LTC 8821/00 TC8821 Video Input Module, for LTC 8800 System

LTC 8834/00 TC8834 Video Output Module, for LTC 8800 System

LTC 8859/00 TC8859 PC Software Package, for LTC 8800 System

LTC 8810/00 TC8810A CPU Module, for LTC 8801 Bay

LTC 8816/00 TC8816A Data Receiver Module, for LTC 8802 Bay

LTC 8808/00 TC8808 Video Interconnect (Patch) Panel

LTC 8809/01 TC8809 16-conductor ribbon cable, 3 ft. length

LTC 8809/00 TC8809-6 16-conductor ribbon cable, 6 ft. length

LTC 8820/00 TC8820SE Service Extender Card, for LTC 8821

LTC 8779/00 TC8779SE Service Extender Card, for LTC 8810, LTC 8816, LTC 8834

LTC 8600 TC8600 Allegiant

LTC 8601/00 TC8601R Equipment Rack, for LTC 8601 Bay

LTC 8601/60 TC8601A Main Switching B ay, 120V, 60Hz

LTC 8601/50 TC8601AX Main Switching Bay, 220V, 50Hz

LTC 8621/00 TC8621 Video Input Module, for LTC 8600 System

LTC 8834/00 TC8834 Video Output Module, for LTC 8600 System

LTC 8659/00 TC8659 PC Software Package, for LTC 8600 System

LTC 8610/00 TC8610A CPU Module, for LTC 8601 Bay

LTC 8300 TC8300 Allegiant

LTC 8301/60 TC8301 Main Switching Bay, 120V, 60Hz

LTC 8301/50 TC8301X Main Switching B ay, 220V, 50Hz

LTC 8359/00 TC8359 PC Software Package, for LTC 8300 System

LTC 8500 TC8500 Allegiant

LTC 8501/00 TC8501R Equipment Rack, for LTC 8501 Bay

LTC 8501/60 TC8501C Main Switching Bay, 120V, 60Hz

LTC 8501/50 TC8501CX Main Switching Bay, 220V, 50Hz

LTC 8521/00 TC8521VIM Video Input Module, for LTC 8500 System

LTC 8532/00 TC8532VOM Video Output Module, for LTC 8500 System

LTC 8505/60 TC8505PS Power Supply, 120V, 60Hz

LTC 8505/50 TC8505PSX Power Supply, 220V, 50Hz

LTC 8511/00 TC8511C CPU Module

LTC 8559/00 TC8559 PC Software Package, for LTC 8500 System

Microprocessor-Based Video Switcher/Control Systems

®

Microprocessor-Based Video Switcher/Control Systems

®

Microprocessor-Based Video Switcher/Control Systems

®

Microprocessor-Based Video Switcher/Control Systems

LTC TC Allegiant® System Accessories

LTC 8550/00 TC8550A Keyboard, J oystick Control

LTC 8551/00 TC8551A Keyboard, P us h Button Control

LTC 8552/00 TC8553-232 Keyboard, Variable Speed, RS-232, Joystick Control

LTC 8553/00 TC8553 Keyboard, Variable Speed, Joyst i ck Control

LTC 8554/00 TC8554 Keyboard, Compact, Pus h B utton Control

LTC 8555/00 TC8555 Keyboard, Compact, Variabl e Speed Joystick Control

LTC 8558/00 TC8557HL Keyboard Cable, 100 ft.

LTC 8557/60 TC8557HR Hook-up Kit for Remote Keyboard up to 5,000 ft, 120V.

LTC 8557/50 TC8557HRX Hook-up Kit for Remote Keyboard up to 5,000 ft, 220V

LTC 9050/00 TC8557MK Rack Mount Kit, for LTC 8550, LTC 8551, LTC 8553 Keyboards

LTC 8540/00 TC8540C Alarm Interface Uni t

LTC 8568/00 TC8568 Signal Distribution Unit, 32 Outputs

LTC 8768/00 TC8768 Signal Distribution Unit, 64 Outputs

LTC 8569/60 TC8569-2 Code Merger Unit, 2-Channel, 120V, 60Hz

LTC 8569/50 TC8569X-2 Code Merger Unit, 2-Channel, 220V , 50Hz

LTC 8570/60 TC8569-4 Code Merger Unit, 4-Channel, 120V, 60Hz

LTC 8570/50 TC8569X-4 Code Merger Unit, 4-Channel, 220V , 50Hz

LTC 8571/60 TC8769-2 Code Merger Unit, 2-Channel, 120V, 60Hz

LTC 8571/50 TC8769X-2 Code Merger Unit, 2-Channel, 220V , 50Hz

LTC 8572/60 TC8769-4 Code Merger Unit, 4-Channel, 120V, 60Hz

LTC 8572/50 TC8769X-4 Code Merger Unit, 4-Channel, 220V , 50Hz

LTC 8560/60 TC8560-1 Receiver/Driver, 120V Supply, 120V to P/T, No Aux.

LTC 856260 TC8560-2 Receiver/Driver, 120V Supply, 24V to P/ T, No Aux.

LTC 8562/50 TC8560X-2 Receiver/Driver, 220V Supply, 220V to P/T, No Aux.

LTC 8560/50 TC8560X-4 Receiver/Driver, 220V Supply, 220V to P/T, No Aux.

LTC 8561/60 TC8561A-1 Receiver/Driver, 120V Supply, 120V to P/T, with Aux.

LTC 8566/60 TC8561A-2 Receiver/Driver, 120V Supply, 24V to P/T, with Aux.

LTC 8566/50 TC8561AX-2 Receiver/Driver, 220V Supply, 220V t o P/T, with Aux.

LTC 8561/50 TC8561AX-4 Receiver/Driver, 220V Supply, 220V t o P/T, with Aux.

LTC 8563/20 TC8563 Receiver/Driver, 24V Supply, 24V t o P /T, No Aux.

LTC 8564/20 TC8564A Receiver/Dri ver, 24V Supply, 24V to P/T, with Aux.

LTC 8780/60 TC8780 Time/Date Converter Unit, GP S Format, 120V, 60Hz

LTC 8780/50 TC8780X Tim e/ Date Converter Unit, GPS Format , 220V, 50Hz

LTC 8781/60 TC8781 Time/Date Converter Unit, GP S Format, 120V, 60Hz

LTC 8781/50 TC8781X Tim e/ Date Converter Unit, GPS Format , 220V, 50Hz

LTC 8785/60 TC8785 Data Converter Unit, Var. Speed to Fi xed Speed Code, 120V , 60Hz

LTC 8785/50 TC8785X Data Converter Unit, Var. Speed to Fixed Speed Code, 220V, 50Hz

LTC 8712/60 TC8712A Console Port Expander, 120V, 60Hz

LTC 8712/50 TC8712AX Console Port Expander, 220V, 50Hz

LTC 8713/60 TC8713A Alarm Port Expander, 120V, 60Hz

LTC 8713/50 TC8713AX Alarm Port Expander, 220V, 50Hz

LTC 8714/60 TC8714A Keyboard Port E xpander, 120V, 60Hz

LTC 8714/50 TC8714AX Keyboard Port Expander, 220V, 50Hz

LTC 8715/60 TC8715A LTC 8714 Port E xpander, 120V, 60Hz

LTC 8715/50 TC8715AX LTC 8714 Port Expander, 220V, 50Hz

LTC 8059/00 TC8059 PC Software Package, for Satellite

LTC 8850/00 TC8850 Graphical User Interface (GUI) P ackage

IMPORTANT SAFEGUARDS

1. Read Instructions - All the safety and operating instructions should

be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions should

be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating

instructions should be adhered to.

4. Follow Instructions - All operating and use instructions should be

followed.

5. Cleaning - Unplug the unit from the outlet before cleaning. Do not

use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning.

6. Attachments - Do not use attachments not recommended by the

product manufacturer as they may cause hazards.

7. Water and Moisture - Do not use this unit near water - for example,

near a bath tub, wash bowl, kitchen sink, or laundry tub, in a wet

basement, near a swimming pool, in an unprotected outdoor

installation, or any area which is classified as a wet location.

8. Accessories - Do not place this unit on an unstable stand, tripod,

bracket, or mount. The unit may fall, causing serious injury to a

person and serious damage to the unit. Use only with a stand,

tripod, bracket, or mount recommended by the manufacturer, or

sold with the product. Any mounting of the unit should follow the

manufacturer's instructions, and should use a mounting accessory

recommended by the manufacturer.

An appliance and cart combination should be moved with

care. Quick stops, excessive force, and uneven surfaces

may cause the appliance and cart combination to

overturn.

9. Ventilation - Openings in the enclosure, if any, are provided for

ventilation and to ensure reliable operation of the unit and to protect

it from overheating. These openings must not be blocked or

covered. This unit should not be placed in a built-in installation

unless proper ventilation is provided or the manufacturer's

instructions have been adhered to.

10. Power Sources - This unit should be operated only from the type of

power source indicated on the marking label. If you are not sure of

the type of power supply you plan to use, consult your appliance

dealer or local power company. For units intended to operate from

battery power, or other sources, refer to the operating instructions.

11. Grounding or Polarization - This unit may be equipped with a

polarized alternating-current line plug (a plug having one blade

wider than the other). This plug will fit into the power outlet only one

way. This is a safety feature. If you are unable to insert the plug fully

into the outlet, try reversing the plug. If the plug should still fail to fit,

contact your electrician to replace your obsolete outlet. Do not

defeat the safety purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-wire grounding-type

plug, a plug having a third (grounding) pin. This plug will only fit

into a grounding-type power outlet. This is a safety feature. If you

are unable to insert the plug into the outlet, contact your electrician

to replace your obsolete outlet. Do not defeat the safety purpose of

the grounding-type plug.

12. Power-Cord Protection - Power-supply cords should be routed so

that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attention to cords and

plugs, convenience receptacles, and the point where they exit from

the appliance.

13. Power Lines - An outdoor system should not be located in the

vicinity of overhead power lines or other electric light or power

circuits, or where it can fall into such power lines or circuits. When

installing an outdoor system, extreme care should be taken to keep

from touching such power lines or circuits as contact with them

might be fatal. U.S.A. models only - refer to the National Electrical

Code Article 820 regarding installation of CATV systems.

14. Overloading - Do not overload outlets and extension cords as this

can result in a risk of fire or electric shock.

15. Object and Liquid Entry - Never push objects of any kind into this

unit through openings as they may touch dangerous voltage points

or short-out parts that could result in a fire or electric shock. Never

spill liquid of any kind on the unit.

16. Servicing - Do not attempt to service this unit yourself as opening or

removing covers may expose you to dangerous voltage or other

hazards. Refer all servicing to qualified service personnel.

17. Damage Requiring Service - Unplug the unit from the outlet and

refer servicing to qualified service personnel under the following

conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the

operating instructions, as an improper adjustment of other

controls may result in damage and will often require extensive

work by a qualified technician to restore the unit to its normal

operation.

e. If the unit has been dropped or the cabinet has been

damaged.

f. When the unit exhibits a distinct change in performance--this

indicates a need for service.

18. Replacement Parts - When replacement parts are required, be sure

the service technician has used replacement parts specified by the

manufacturer or have the same characteristics as the original part.

Unauthorized substitutions may result in fire, electric shock or other

hazards.

19. Safety Check - Upon completion of any service or repairs to this

unit, ask the service technician to perform safety checks to

determine that the unit is in proper operating condition.

20. Coax Grounding - If an outside cable system is connected to the

unit, be sure the cable system is grounded. U.S.A. models only-Section 810 of the National Electrical Code, ANSI/NFPA No.701981, provides information with respect to proper grounding of the

mount and supporting structure, grounding of the coax to a

discharge unit, size of grounding conductors, location of discharge

unit, connection to grounding electrodes, and requirements for the

grounding electrode.

21. Lightning - For added protection of this unit during a lightning

storm, or when it is left unattended and unused for long periods of

time, unplug it from the wall outlet and disconnect the cable

system. This will prevent damage to the unit due to lightning and

power-line surges.

FCC & ICES INFORMATION

(U.S.A. and Canadian Models Only)

WARNING - This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules and ICES-003 of Industry Canada. These limits are designed to

provide reasonable protection against harmful interference when the

equipment is operated in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one or more of

the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Intentional or unintentional changes or modifications not expressly

approved by the party responsible for compliance shall not be made. Any

such changes or modifications could void the user's authority to operate

the equipment.

The user may find the following booklet prepared by the Federal

Communications Commission helpful: "How to Identify and Resolve

Radio-TV Interference Problems". This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402, Stock No.004-00000345-4.

3

SAFETY PRECAUTIONS

CAUTION

RISK OF ELECTRIC

SHOCK. DO NOT OPEN!

CAUTION: TO REDUCE THE RISK OF ELECTRICAL

SHOCK, DO NOT OPEN COVERS. NO USER

SERVICEABLE PARTS INSIDE. REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL.

Power

Power Disconnect. Units with or without

ON-OFF switches have power supplied to

the unit whenever the power cord is

inserted into the power source; however,

the unit is operational only when the ONOFF switch is in the ON position. The

power cord is the main power disconnect

for all units.

This label may appear on the bottom of the unit due

to space limitations.

The lightning flash with an arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of uninsulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to

persons.

The exclamation point within an equilateral

triangle is intended to alert the user to

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

Warning

To prevent fire or shock hazard, do not

expose units not specifically designed for

outdoor use to rain or moisture.

ATTENTION

OBSERVE PRECAUTIONS

FOR HANDLING

ELECTROSTATIC

SENSITIVE

DEVICES

Disjonction de l'alimentation. Les

appareils avec ou sans commutateurs ONOFF sont alimentés à chaque fois que le

cordon d'alimentation est branché à la

source d'alimentation; toutefois, les

appareils disposant de commutateurs ONOFF ne fonctionnnent que lorsque le

commutateur ON-OFF est sur la position

ON. Le cordon d'alimentation est la

disjonction d'alimentation principale pour

tous les appareils.

Netzanschluß. Geräte mit oder ohne

Netzschalter haben Spannung am Gerät

anliegen, sobald der Netzstecker in die

Steckdose gesteckt wird. Das Gerät ist

jedoch nur betriebsbereit, wenn der

Netzschalter (EIN/AUS) auf EIN steht.

Wenn man das Netzkabel aus der

Steckdose zieht, dann ist die

Spannungszuführung zum Gerät

vollkommen unterbrochen.

Para Desconectar la Alimentación:

Unidades no equipadas con interruptores

ON/OFF, son alimentadas cuando el cable

de alimentación es conectado a la

corriente eléctrica. Las unidades

equipadas con interruptores son

alimentadas de igual forma, pero

adicionalmente requieren que el

interruptor esté posicionado en ON. El

cable de alimentación es el medio

principal de desconexión del equipo.

WARNING: Electrostatic-sensitive device. Use

proper CMOS/MOSFET handling precautions to

avoid electrostatic discharge.

NOTE: Grounded wrist straps must be worn and

proper ESD safety precautions observed when

handling the electrostatic-sensitive printed

circuit boards.

4

TABLE OF CONTENTS

UNPACKING .......................................................... 6

SERVICE................................................................ 6

DESCRIPTION ....................................................... 6

ALLEGIANT FEATURE SUMMARY TABLE.......... 7

MAJOR SYSTEM COMPONENTS......................... 9

TC8x01 Main CPU Bay............................................................. 9

TC8802 Monitor Expansion Bay................................................ 9

TC8x21 Video Input Module...................................................... 9

TC8532, TC8834 Video Output Modules...................................9

System Capabilities..................................................................9

SUPPLEMENTARY SYSTEM COMPONENTS .... 10

TC8550A System Keyboard.................................................... 10

TC8551A & TC8554 System Keyboards .................................10

TC8553 & TC8555 System Keyboards.................................... 10

TC8553-232 System Keyboard............................................... 10

TC8557MK Keyboard Racking Kit ........................................... 10

TC8557HL Keyboard Extension Cable.....................................10

TC8557HR Series Keyboard Extension Kits............................10

TC8568 Signal Distribution Unit ..............................................10

TC8768 Signal Distribution Unit ..............................................10

TC8540C Series Alarm Interface Units.................................... 10

TC8560, TC8561A, TC8563, & TC8564A Series

Receiver/Driver Units........................................................ 10

TC700 Series AutoDomes™ ................................................... 11

TC8569-2, TC8569-4, TC8769-2, TC8769-4 Series................11

TC8770 Switcher Follower Series, TC8770SF, TC8770SG,

TC8770LD, TC8770LG Function Modules......................... 11

TC8770I Interconnect Panel.................................................... 11

TC8712A Series Console Port Expander Units........................ 11

TC8713A Series Alarm Port Expander Units .......................... 11

TC8714A, TC8715A Series Keyboard Port Expander Units .... 11

TC8780 Series Data Converter Units ......................................12

TC8781 Series Time/Data Converters..................................... 12

TC8785 Series Code Converters.............................................12

Code Translator Units ............................................................. 12

TC8808 Video Interconnect Panel........................................... 12

TC8579SE Service Extender Card.......................................... 12

TC8779SE Service Extender Card.......................................... 13

TC8820SE Service Extender Card.......................................... 13

TC8x59 Series Allegiant Master Control Software.................... 13

Windows Based Allegiant Software......................................... 13

Logging Printer....................................................................... 13

INSTALLATION PROCEDURE ............................ 20

Main CPU Bay Installation....................................................... 20

Video Input Modules...............................................................20

Video Output Modules ............................................................21

CPU Module........................................................................... 21

Camera and Monitor Connections...........................................21

TC8600 and TC8800 Video Inputs..........................................22

Termination Practices............................................................. 22

TC8802 Expansion Bay Connections ...................................... 22

Keyboard Hookup................................................................... 23

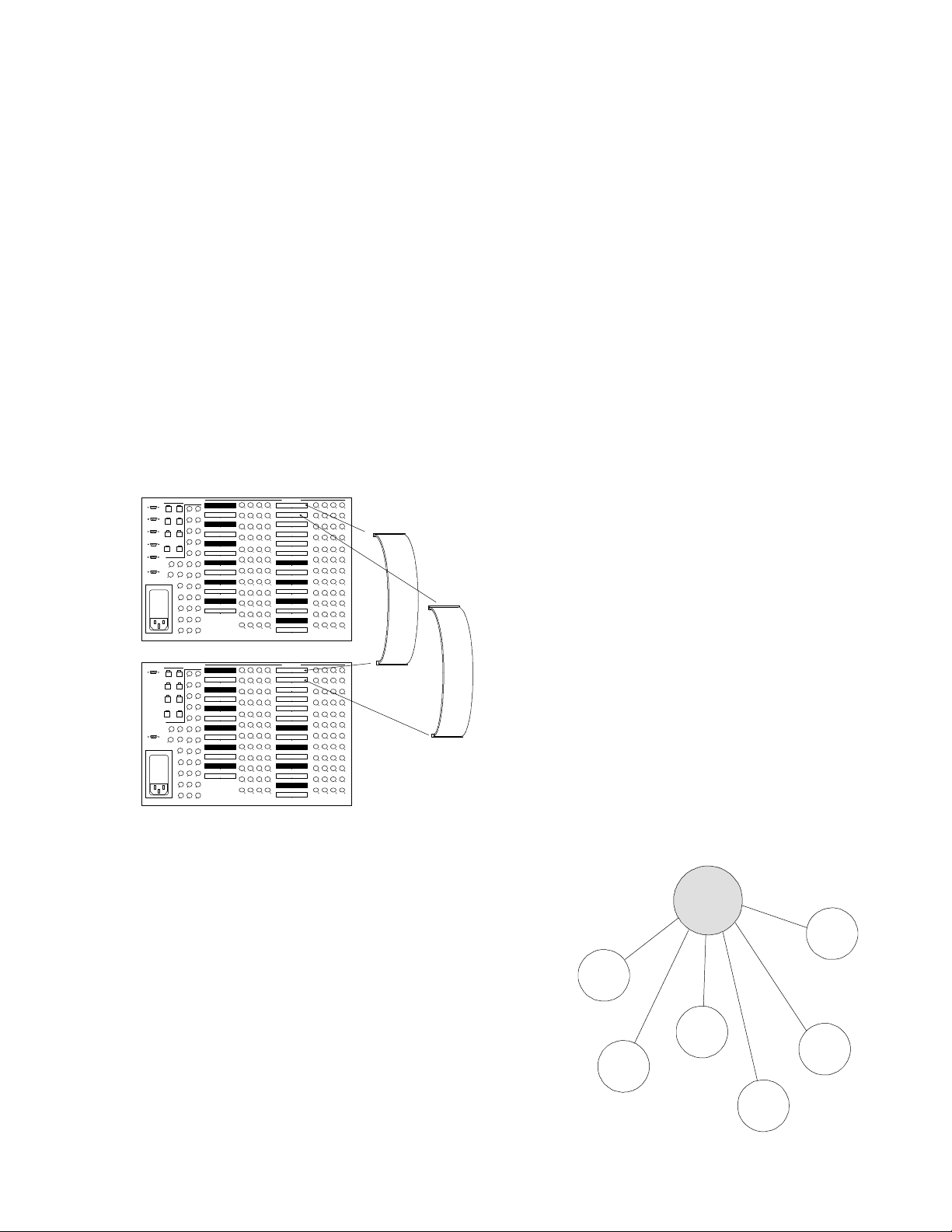

Satellite Configuration Installations ..........................................23

Feature Selection.................................................................... 26

Main Power Connections........................................................26

OPTIONAL ACCESSORIES ................................. 30

Logging Printer Option Installation........................................... 30

IBM or IBM Compatible Computer Interface Installation............ 30

SYSTEM KEYBOARDS - TC8550A, TC8551A,

TC8553 Series ................................................ 31

Keyboard Displays.................................................................. 31

Keyboard Controls.................................................................. 32

Switcher Control Keys ............................................................32

Function Keys ........................................................................32

Telemetry Controls .................................................................33

SYSTEM KEYBOARDS - TC8554, TC8555.......... 34

Keyboard Displays.................................................................. 35

Keyboard Controls.................................................................. 35

Switcher Control Keys ............................................................36

Function Keys ........................................................................36

Telemetry Controls .................................................................36

VIDEO MONITOR DISPLAY................................. 37

Time/Date .............................................................................. 37

Monitor Title/System Status Display........................................ 37

Monitor Message.................................................................... 39

Broadcast Message ................................................................ 39

Program Prompts................................................................... 39

Camera Number ..................................................................... 39

Camera Title........................................................................... 39

FACTORY DEFAULT SETTINGS ........................ 40

User Selectable DIP Switch Settings For Main CPU Bay .........40

User Selectable DIP Switch Settings for TC8816A Data

Receiver Modules used in TC8802 Monitor Expansion

Bays ................................................................................ 42

USER INFORMATION.......................................... 43

User Priority Access Table......................................................43

ALARM INFORMATION....................................... 44

Basic Alarm Response Mode.................................................. 44

Auto-Build Alarm Response Mode........................................... 44

Sequence & Display Alarm Response Mode ............................ 44

Alarm Activated Pre-Position................................................... 44

Sample Alarm Responses....................................................... 45

KEYBOARD OPERATING INSTRUCTIONS........ 47

General..................................................................................47

System Commands................................................................ 47

Switcher Commands ..............................................................48

SEQUENCE INFORMATION................................ 48

General..................................................................................48

Sequence Control Instructions................................................51

Lock Commands....................................................................53

Controlling Camera Movement................................................54

Alarm Control Commands....................................................... 56

KEYBOARD USER FUNCTIONS ......................... 58

General..................................................................................58

MAINTENANCE INFORMATION.......................... 64

CHARACTER ROM TABLES FOR TC8500 ......... 65

CHARACTER ROM TABLES FOR TC8600

AND TC8800 ................................................... 66

QUICK REFERENCE KEYBOARD COMMAND

TABLE............................................................. 70

ERROR MESSAGES............................................ 71

TROUBLESHOOTING GUIDE ............................. 73

GLOSSARY OF TERMS ...................................... 75

APPENDIX A........................................................ 76

Satellite Systems.................................................................... 76

APPENDIX B........................................................ 80

Sample Keyboard Operating Instructions................................. 80

APPENDIX C........................................................ 83

Installation Checklists.............................................................83

APPENDIX D........................................................ 84

Quick Reference Cable Interconnections ................................. 84

APPENDIX E........................................................ 85

Main Bay Rear Panel Connector Pinouts................................. 85

APPENDIX F ........................................................ 86

Pre-Position Controls .............................................................. 87

5

UNPACKING

E-mail:BoschCCTVparts@ca.slr.com

Unpack carefully. This is electronic equipment and

should be handled carefully.

If an item appears to have been damaged in

shipment, replace it properly in its carton and notify

the shipper. If any items are missing, notify your

Bosch Security Systems, Inc. Sales Representative

or Customer Service.

The shipping carton is the safest container in which

the unit may be transported. Save it for possible

future use.

SERVICE

If the unit ever needs repair service, the customer

should contact the nearest

Inc. for authorization return and shipping

instructions.

Service Centers

U.S.A.: 800-366-2283 or 717-735-6638

Fax: 800-366-1329 or 717-735-6639

CCTV Spare Parts

U.S.A: 800-894-5215 or 408-956-3853 or 3854

Fax: 408-957-3198

Bosch Security Systems,

The TC8500 Series Allegiant system can handle up

to 64 cameras and 8 monitors in a full crosspoint

configuration. It can also accommodate 128 alarm

points.

The TC8600 Series handles up to 128 cameras, 16

monitors, and 512 alarms.

The TC8800 Series handles 256 cameras, 64

monitors, and up to 1024 alarm points.

In addition, the Allegiant series have a "Satellite"

configuration capability through which the system

can communicate with up to 256 remote

combinations of Allegiant systems or TC8112B

Series and TC8124B Series switchers. More

information on this capability is provided later in this

manual.

The system can be operated in the simple default

state (as it leaves the factory) or can be customized

with our optional TC8850 Graphical User Interface

Software package or our optional TC8x59 Master

Control Software using an IBM

personal computer. Despite its sophistication, the

Allegiant

ergonomic keyboard design contains many userfriendly but powerful functions. A user can choose

from up to 60 sequences that are stored in memory,

select any of the cameras to view on any of the

monitors, and take exclusive control of remote

pan/tilt camera functions right from the keyboard.

system is designed for the novice user. The

TM

or IBM compatible

DESCRIPTION

This manual covers the installation and operation of

the Allegiant

TC8800 Series systems. When providing information

that is common to all members of the Allegiant

family, this manual will often use a part number of

the form "TC8x00". The "x" indicates that this

designation applies to all Allegiant systems. For

example, information that refers to the TC8x01 main

CPU bay is applicable to the TC8501, TC8601, and

TC8801. A specific part designation (without the

embedded “x”) like "TC8802 Monitor Expansion Bay"

will usually apply only to that particular series of the

Allegiant family. An exception is that peripherals that

are identical on all systems will often have a TC8500

Series part number. For example, the TC8550A

Keyboard, the TC8568 Signal Distribution Unit, and

the TC8569-2 Series Code Merger are used with all

Allegiant systems even though they have a TC8500

Series part number.

All Allegiant systems can accommodate multiple

keyboards, a computer system console port, and a

logging printer output.

®

TC8500 Series, TC8600 Series, and

Each monitor can display a system status overlay

showing alarm status, sequence conditions,

time/date, and camera information.

User passwords can be utilized, providing an added

measure of system security; and through the optional

TC8850 Graphical User Interface Software package

or the optional Master Control Software package,

various lockout tables restricting user access to

cameras, monitors, keyboards, and remote camera

control are easily programmed. The TC8850

Graphical User Interface Software package and the

Master Control Software package also contain up to

64 different time-activated events, providing

automated control of video sequencing, monitor

message broadcasts, receiver/driver functions, alarm

control, and several other functions. The Allegiant

series systems represent a dramatic breakthrough in

CCTV switcher/controllers, and are backed by years

of expertise in designing and manufacturing closedcircuit video equipment.

6

ALLEGIANT FEATURE

SUMMARY TABLE

The Allegiant system is available in two operating

configurations: a base system and the base system

with an optional PC based software package (either

TC8850 or TC8x59). The base system includes

features required for most switching/controller

systems.

Feature Base With Optional

1. Full camera switching/control on all monitors Y Y

2. Multiple keyboards Y Y

(8 with TC8500, 16 with TC8600, 32 with TC8800)

3. Multiple alarm inputs Y Y

(128 with TC8500, 512 with TC8600, 1024 with TC8800)

4. 3 user-selectable pre-defined alarm response modes Y Y

5. Full control of on-site receiver/drivers Y Y

6. SalvoSwitching

7. 60 programmable sequences Y Y

8. Alarm call-up of pre-position scenes Y Y

9. RS-232 interface ports for Computer, Logging Printer, etc. Y Y

10. Keyboard Log-on/Log-off function Y Y

11. User-selectable password security Y Y

12. Designate 16-character camera titles and 12-character monitor titles Y Y

13. Select time/date format Y Y

14. Local keyboard test function Y Y

15. Table and Sequence printout feature Y Y

16. Designate RS-232 communication parameters Y Y

17. Integral video loss detection (TC8600 and TC8800) N Y

18 Satellite configurations N Y

19. Restrict user/keyboard access to cameras N Y

20. Restrict user/keyboard access to receiver/drivers N Y

21. Restrict user access to keyboard N Y

22. Restrict user/keyboard access to monitors N Y

23. Designate user name and ID number N Y

24. Designate zoned alarm call-ups N Y

25. VersAlarmTM alarm feature N Y

26. Designate displayed camera number N Y

27. Designate receiver/driver functions on alarm N Y

28. Program 64 Time Activated Events N Y

29. Designate receiver/driver functions in sequences N Y

30. Broadcast monitor messages N Y

31. Alarm title designation N Y

32. Personal computer displayed monitoring of system status N Y

33. Personal computer emulation of system keyboard N Y

®

The addition of the optional TC8850 Graphical User

Interface Software package or the optional TC8x59

Master Control Software package enables the user to

customize the system's configuration using a menu

driven program run on an IBM compatible personal

computer.

The following table lists the various features

available with each system:

Allegiant PC based

System Software

Y Y

7

In addition, all systems provide the capability to

control on-site receiver/driver units including the

AutoDome™ series of integral pan/tilt/zoom/camera

dome series.

4. User log-on to keyboard or console port.

5. Console broadcast message.

6. Console transfer of system tables.

All systems contain a logging printer output port to

which an inexpensive RS-232 serial printer may be

attached. This provides a permanent record showing

time and date of changes to the system status such

as:

1. Incoming Alarms.

2. Acknowledgment of alarms by users.

3. Loading of sequences.

7. Activation of Time Event Functions.

8. Power-up reset message.

9. Video loss message (TC8600 and TC8800

systems only).

The printer may also be used to provide a hard copy

of all user programmed system configuration Tables

and Sequences.

8

MAJOR SYSTEM COMPONENTS

TC8x01 Main CPU Bay

A modular equipment bay which contains the

system’s microprocessor module (TC8511C or

TC8x10A), the power supply module (TC8x05), and

several video input and video output modules (see

below). Up to eight TC8550 Series keyboards may

be connected directly to the CPU bay.

TC8802 Monitor Expansion Bay

Required in TC8800 systems having more than 32

monitors. This expansion bay contains a data

receiver module (TC8816A), a power supply

(TC8805), and additional video input and output

modules. The monitor expansion bay can also

accommodate up to eight additional keyboards.

TC8x21 Video Input Module

Individual cards placed in bays to accept inputs from

cameras and other video sources.

TC8532, TC8834

Video Output Modules

Individual cards placed in bays to provide outputs to

monitors and VCRs.

System Capabilities

These tables indicate the maximum number of video

input and output modules that each equipment bay

may hold, as well as the number of individual inputs

or outputs supported by each of these modules.

TC8500

Up to 8 video input modules; 8 inputs per module.

Up to 4 video output modules; 2 outputs per module.

Total: 64 maximum inputs; 8 outputs.

Satellite configuration input capacity: 320.

TC8600

Up to 8 video input modules; 16 inputs per module.

Up to 4 video output modules; 4 outputs per module.

Total: 128 maximum inputs; 16 outputs.

Satellite configuration input capacity: 1152.

TC8800

Main Bay:

Up to 8 video input modules; 32 inputs per module.

Up to 8 video output modules; 4 outputs per module.

Subtotal: 256 inputs and 32 outputs on main bay.

Monitor Expansion Bay:

Up to 8 video input modules (duplicating modules on

main bay).

Up to 8 extra output modules (providing 4 additional

outputs each).

Subtotal: 32 extra outputs added on to the main

bay's outputs.

Total:

256 maximum inputs; 64 maximum outputs.

Satellite configuration input capacity: 2304.

9

SUPPLEMENTARY SYSTEM COMPONENTS

The Allegiant accessory products provide many

optional features to the base system. A brief

description of accessory products is provided below.

Complete specification information can be found in

their respective product data sheets. All accessory

products are designed to be compatible, where

applicable, throughout the Allegiant series.

TC8550A System Keyboard

Full function system keyboard used for system

control, programming, and pan/tilt/zoom operation.

Includes integral pan/tilt joystick and zoom lens

controls. Up to 8 keyboards are permitted on the

TC8500 system. The TC8600 can accommodate up

to 16. TC8800 systems can accommodate up to 32

keyboards. In TC8600 and TC8800 systems,

keyboards above 8 are connected to the systems

using TC8714A/TC8715A keyboard port expander

accessory units described below.

TC8551A & TC8554

System Keyboards

These are function keyboards similar to the TC8550A

except they contain four directional oriented,

nonprotruding push buttons instead of a joystick for

control over any pan/tilt equipped camera sites.

TC8553 & TC8555 System

Keyboards

These are function keyboards similar to the TC8550A

except they contain a proportional joystick for

controlling the variable speed pan/tilt functions of the

AutoDome series of integral pan/tilt/zoom/camera

domes. Rotation of the joystick also provides control

over the lens's zoom functions.

TC8553-232 System Keyboard

The TC8553-232 is a full function keyboard similar to

the TC8550A keyboard except it utilizes RS-232

protocol for data communication. It provides the

capability of remotely locating an Allegiant keyboard

over a conventional RS-232 transmission medium

such as phoneline modems, fiber optics, etc.

Requires a full duplex RS-232 link capable of

operating at 9600 baud. All other specifications are

the same as TC8553 keyboards. The TC8553-232

keyboards connect to the Allegiant’s main CPU bay

via a TC8712A Series Console Port Expander. Up to

four TC8553-232 keyboards may be connected to a

single TC8712A Series unit. When used with dial-up

type phoneline modems, the TC8553-232 keyboard

provides a rudimentary dialing capability.

Rack mounting kit designed to provide vertical,

horizontal or 30° inclined mounting for TC8550A,

TC8551A, or TC8553 keyboards.

TC8557HL Keyboard

Extension Cable

Six conductor extension cable carries data/power for

remote TC8550A, TC8551A, or TC8553 keyboards

up to 30 meters (100 feet) away from main CPU bay.

TC8557HR Series Keyboard

Extension Kits

Interface kit used to remote TC8550A, TC8551A, or

TC8553 keyboards up to 1.6 km (5000 feet) away

from main CPU bay. Customer supplied 24 gage

shielded-twisted pair (Belden 9841 or equivalent)

required between main CPU bay site and keyboard

site. Kit provides two junction boxes, interface cable,

and appropriate keyboard power supply.

TC8568 Signal Distribution Unit

Main site control code distribution and line driver unit

for communicating to Receiver/Drivers, Switcher

Followers, and satellite systems. Provides 32

separate outputs for driving up to 256 remote

devices. Either "star" or "daisy chain" wiring

configurations may be used.

TC8768 Signal Distribution Unit

Same features and specifications as the TC8568

except that it contains twice the number of output

connectors which provide 64 separate outputs for

driving up to 512 remote devices.

TC8540C Series Alarm

Interface Units

Alarm gathering unit which accepts up to 64 dry

contact closures or logic level inputs from remote

sensing devices such as door contacts, PIRs, etc.

and then reports the 'alarm' information to the main

CPU bay. Alarm inputs may be configured in groups

of 32 to accept either normally open or normally

closed contacts. The TC8540C provides eight relay

outputs which can be used to drive external alerting

devices or VCRs.

TC8560, TC8561A,

TC8563, & TC8564A Series

Receiver/Driver Units

TC8557MK Keyboard Racking Kit

10

Decodes data transmitted from TC8568 unit for

camera site control of Pan/Tilt, Zoom Lens, prepositions, and auxiliaries. Unit contains integral local

test feature, auto-pan or random scanning, and is

available in several input and output drive voltage

versions.

TC700 Series AutoDomes™

Integral camera, high speed pan/tilt, zoom lens, and

receiver/driver system in compact dome enclosure.

Available in monochrome or color camera models.

Various enclosure mounting options are available for

indoor and outdoor applications.

TC8569-2, TC8569-4, TC8769-2,

TC8769-4 Series

TC8770I Interconnect Panel

Accessory for the TC8770 Switcher Follower which

provides convenient screw terminal interface for

external connections. Mates to ribbon cables

supplied with TC8770SF or TC8770LD function

modules.

TC8712A Series Console

Port Expander Units

The TC8712A port expander interfaces to the RS232 CONSOLE port of an Allegiant system to permit

up to 4 external PCs or other computing devices to

be connected to the system. This permits multiple

PCs or computing devices to communicate with a

single Allegiant system.

Code Merger Unit

Control code merger and line driver unit used to

combine control code from two systems (up to four

with TC8569-4 version) for communicating to

Receiver/Drivers, Switcher Followers, and satellite

systems. Provides 32 separate outputs capable of

driving up to 256 remote devices. Either "star" or

"daisy chain" wiring configurations may be used. Unit

will accept signal input either from Allegiant main

CPU bay, TC8568 output, or an output from another

TC8569-2, TC8569-4. Multiple units may be

cascaded to obtain additional outputs.

TC8770 Switcher Follower Series,

TC8770SF, TC8770SG, TC8770LD,

TC8770LG Function Modules

Accessory unit which provides relay contact closures

or LED driver outputs corresponding to cameras

displayed on system monitors. The TC8770 may be

configured to follow non-alarmed video, alarmed

video, or both. TC8770 card cage holds any

combination of up to 8 TC8770SF, TC8770SG,

TC8770LD, or TC8770LG modules. Each TC8770SF

or TC8770SG type module contains 16 relay contact

outputs. A single TC8770LD or TC8770LG type

module drives up to 64 low current type LEDs.

TC8713A Series Alarm

Port Expander Units

The TC8713A interfaces to either a TC8600 or a

TC8800 system’s RS-232 ALARM port to permit

additional TC8540C alarm interface units to be

connected to the system. In a TC8600 system, 2

TC8540C units can be connected to the TC8713A. In

TC8800 systems, up to 4 TC8540C units can be

connected to the TC8713A.

TC8714A, TC8715A Series

Keyboard Port Expander Units

The TC8714A keyboard port expander interfaces to

the COMM PORT 2 of either a TC8600 or a TC8800

system to permit additional keyboards to be

connected to the system. Any combination of up to 8

TC8550A, TC8551A or TC8553 keyboards can be

connected to the system using one TC8714A unit. In

TC8800 systems, typically 3 TC8714A units, each

having 8 keyboards, can be interfaced to the system

using a single TC8715A unit. This would provide a

quantity of 24 "port expanded" keyboards in a

TC8800 system for a total of 32 system keyboards.

Alternatively all 32 keyboards can be connected

using 4 TC8714As and a single TC8715A.

11

TC8780 Series Data Converter Units

Code Translator Units

The TC8780 Series convert the biphase control code

generated by Allegiant series matrix switchers and

the TC8135 Series controller/followers into standard

RS-232, and converts RS-232 back to biphase code.

This provides the capability of transmitting the

biphase control code over conventional RS-232

transmission media (phone modems, fiber optics,

microwaves, etc.) The TC8780 can also be used to

perform the Satellite Selector functions in Allegiant

satellite system configurations and operate as a 15channel remote signal distribution unit.

TC8781 Series Time/Data

Converters

The TC8781 Series are accessory units that decode

the Allegiant system’s encoded time/date information

generated on the biphase control code line and

convert it into an RS-422 format using the GPS

format. This time/date information can be used to

interface into external time/date inserter products

(such as the Kalatel KTS-53-16), which are designed

to be synchronized via a GPS signal. The electrical

and mechanical specifications are the same as the

TC8780 Series units.

Code translators are available which can convert

Allegiant control code to and from other

manufacturer code formats. Contact your Bosch

local manufacturer’s representative for additional

information.

TC8808 Video Interconnect Panel

Optional accessory item which provides TC8600 and

TC8800 systems with the capability of looping up to

32 video inputs per panel. This 'patch' panel contains

32 BNC connectors on its front for external video

connections and two 16-contact ribbon connectors on

its rear. Two 16-conductor ribbon cables are included

for interfacing the patch panel to the video looping

connectors on the TC8600, TC8800 equipment bays.

The patch panel is one standard EIA 19-inch rack

unit high and one unit wide.

TC8579SE Service Extender Card

Service extender card used for troubleshooting

TC8500 system CPU, video input, and video output

modules

TC8785 Series Code Converters

TC8785 Series units are designed for use in existing

Allegiant systems which have been upgraded to

operate the new AutoDome series of cameras. The

TC8785 Code Converters are used to provide the

source for the “fixed speed” control code when the

system is generating the new “variable speed”

control code preferred by the AutoDome cameras.

The TC8785 Series Code Converter receives the

“variable speed” control code from the Allegiant via

its TC8568 Signal Distribution unit and converts it

into the appropriate “fixed speed” control code.

Outputs from the TC8785 Series Code Converter

may be connected to older TC8561 Series

receiver/drivers using existing field cables.

12

TC8779SE Service Extender Card

Service extender card used for troubleshooting

TC8600 and TC8800 CPU and video output modules

and all TC8700 modules.

TC8820SE Service Extender Card

Service extender card used for troubleshooting

TC8600 and TC8800 system video input modules.

TC8x59 Series Allegiant

Master Control Software

The TC8x59 Series Allegiant Master Control

Software consists of an IBM® or IBM compatible

program which allows quick and easy configuration

of standard system features. An appropriate Allegiant

Master Control Software package exists for each

type of Allegiant system, i.e., the TC8559 is used for

TC8500 Series systems, the TC8659 is used for

TC8600 Series systems, etc. The program provides

advanced alarm and sequence programming in

addition to other features which are not available

using the system keyboard. An on-line real-time

monitoring of system status and a keyboard

emulation mode is also included.

Other standard Master Control Software features

include: user passwords, lockout tables, 64

programmable time event functions, custom alarm

responses using the VersAlarmTM alarm mode, and a

keyboard emulation mode. In addition to the

operational switching sequences normally inputted

from the standard keyboard, much more complex

switching sequences may be programmed which

incorporate remote control commands as part of the

switching sequence. The ability to detect video loss

in TC8600 Series and TC8800 Series systems and to

monitor the system operation in real-time on all

systems is a standard feature of the Allegiant Master

Control Software package.

The TC8x59 Software package includes a 3 1/2-inch

program disk containing Allegiant Master Control

Software program, interface cable, and Users

Manual for custom programming of Allegiant system.

A special version, the TC8059, includes multiple

disks for programming TC8500 Series, TC8600

Series, and TC8800 Series Allegiant systems. The

TC8059 software package is intended to be used for

programming a mix of Allegiant systems operating in

a Satellite configuration.

The master control software program requires an

IBM PC or true IBM compatible PC with at least 640

k bytes of memory, DOS 3.0 or higher, one serial

port, one parallel port, and MDA, Hercules™, CGA,

EGA, or VGA display (or compatible).

Windows Based Allegiant Software

The TC8850 is a software package utilizing a

Graphical User Interface (GUI) to integrate and

control security systems. The GUI interfaces directly

to the Allegiant system and provides complete

control and programming of all system features. The

GUI software program requires an 486DX2-66 MHz

PC or better running Windows 95 or Windows NT

with at least 16Mbytes of memory, one serial port,

one parallel port, 3.5” floppy disk drive, mouse or

trackball, and SVGA display. Refer to the TC8850

data sheet for complete specifications.

_________________

Windows is a registered trademark of Microsoft Corporation.

IBM is a registered trademark of IBM Corporation.

Hercules is a trademark of Hercules Technology.

Logging Printer

An optional RS-232 serial printer may be connected

to the main CPU bay to provide a permanent record

of significant changes in the system's status. Time

and date is printed for system events such as alarms,

start-ups after power failures, sequence loadings,

operators logging-on/off to keyboards, and

downloading of information from the optional Master

Control Software package. The printer may also be

used to obtain hard copies of all system Tables and

Sequences.

13

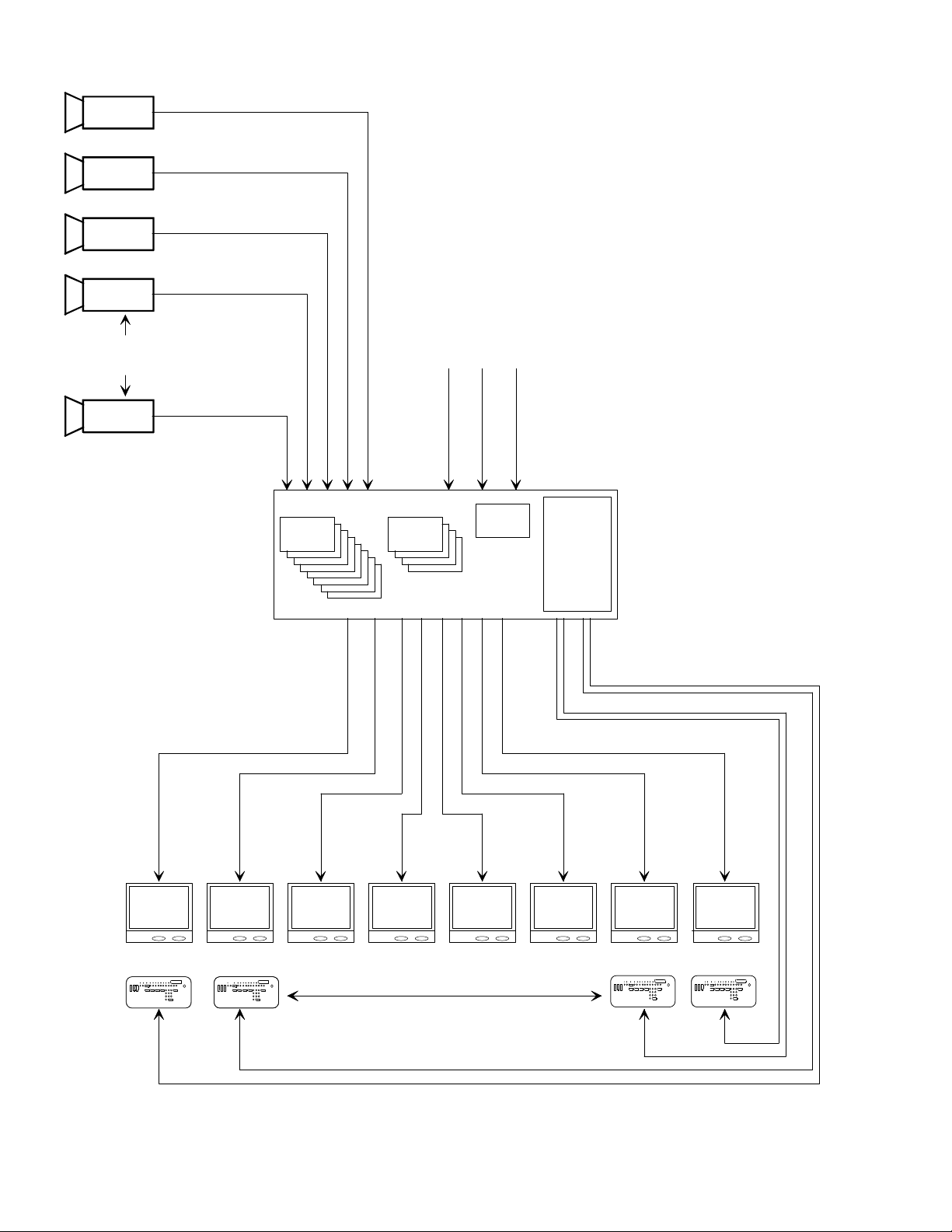

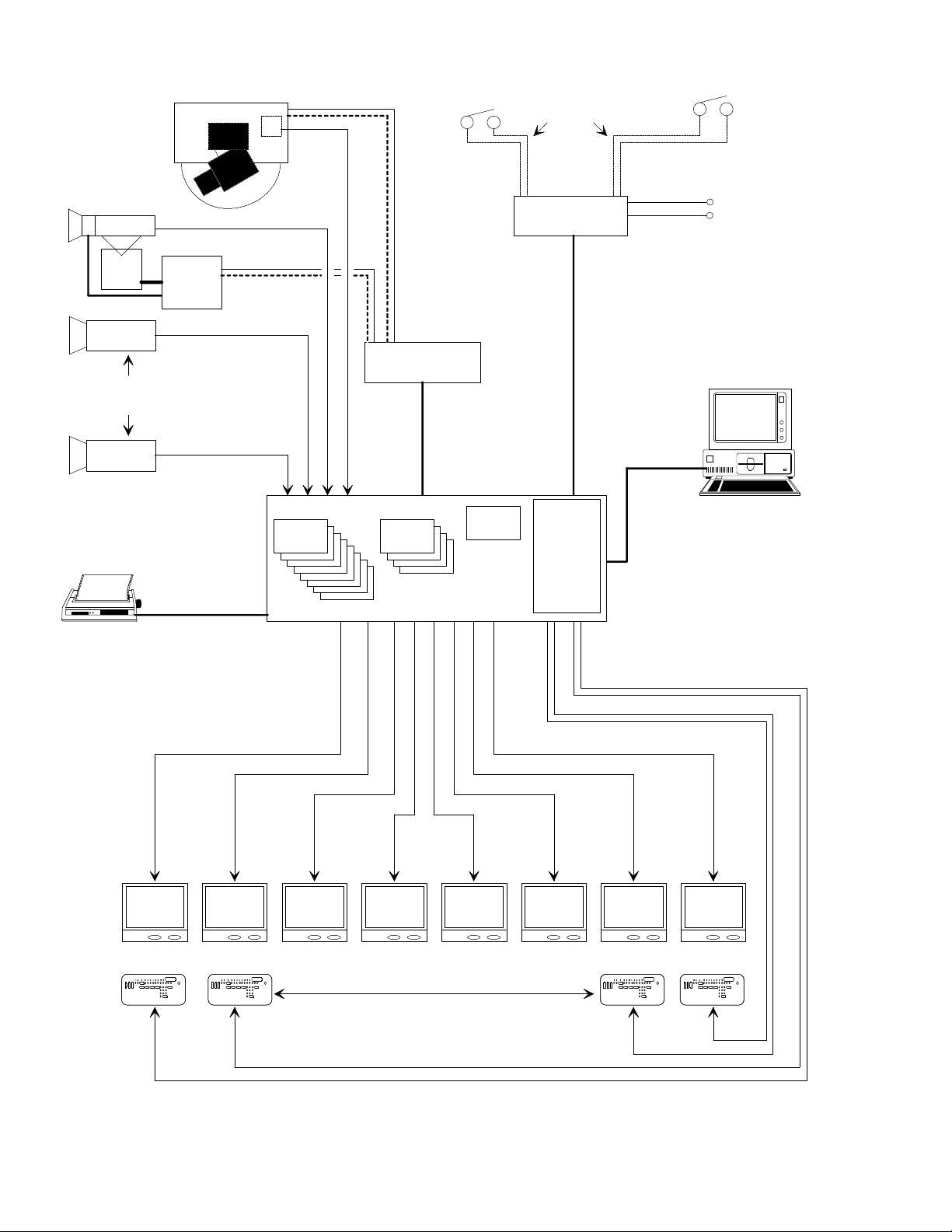

S9506028AE

Additional

System Cameras

TC8521VIM

Input Cards

Up to 8 Monitor Outputs

8 x 8 CH

Up To 64 Video

Inputs Maximum

TC8511A

CPU

TC8532VOM

4 x 2 CH

Output Cards

TC8501B SERIES MAIN CPU BAY

Module

TC8505PS

Power

Supply

Module

3 m (10 ft) Interconnect

Cable Supplied With Keyboard

Monitor 1

Monitor 2

Video Coax

Monitor 3 Monitor 4 Monitor 5 Monitor 6

Maximum of 8 TC8550A, TC8551A, or TC8553

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

TC8500 Video Switching System

14

Monitor 7

Monitor 8

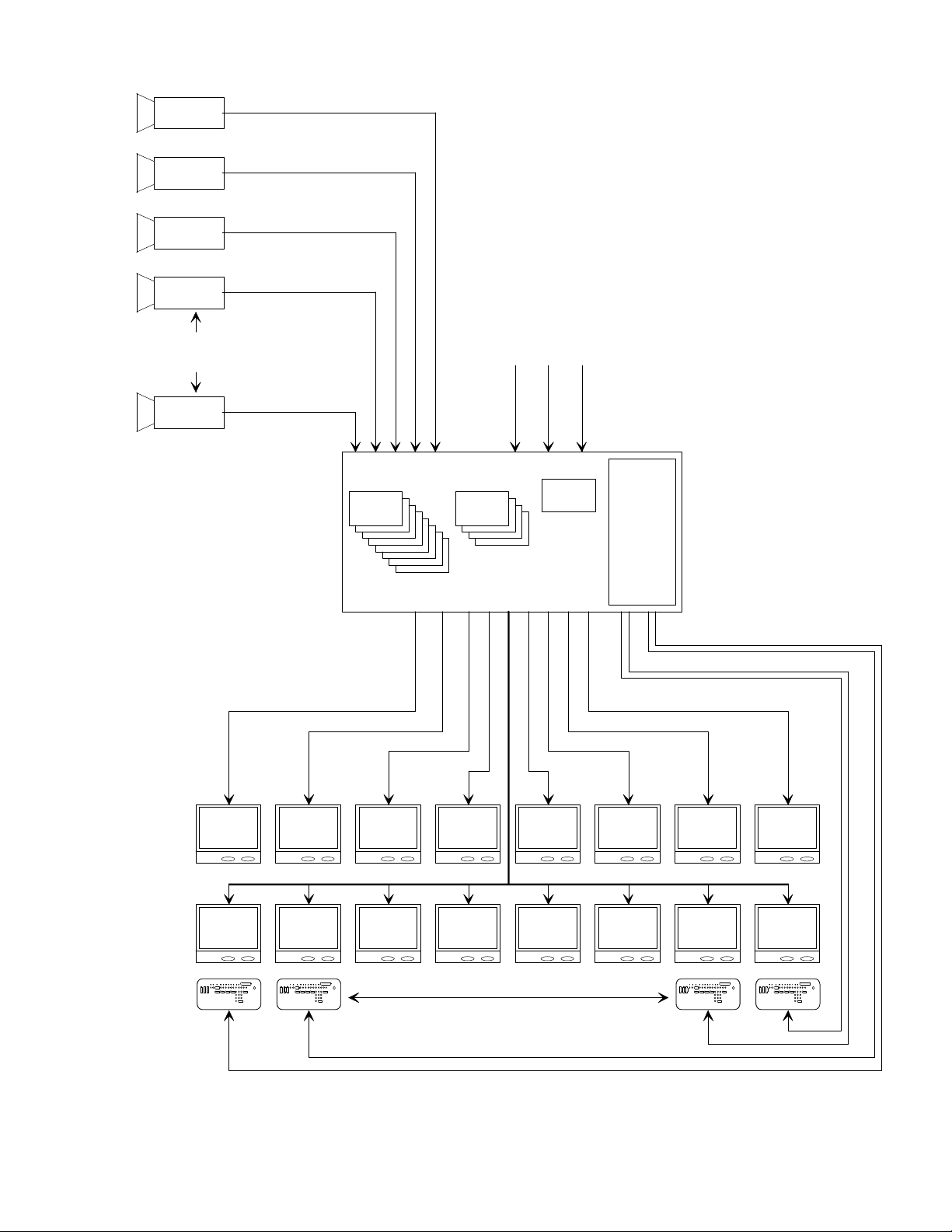

Additional

System Cameras

TC8621

8 x 16 CH

Input Cards

Up to 16 Monitor Outputs

Up To 128

Video Inputs Maximum

TC8610A

TC8834

4 x 4 CH

Output Cards

TC8601 Series Main CPU Bay

CPU

Module

Video Coax

TC8605

Power

Supply

Module

3 m (10 ft) Interconnect Cable

Supplied With Keyboard

Monitor 1

Monitor 9

Monitor 2

Monitor 10 Monitor 11

Monitor 3 Monitor 4

Maximum of 16 TC8550A, TC8551A, or TC8553

TC8600 Series Video Switching System

Monitor 5

Monitor 12

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

Monitor 13

15

Monitor 6 Monitor 7

Monitor 14

Monitor 15

Monitor 8

Montior 16

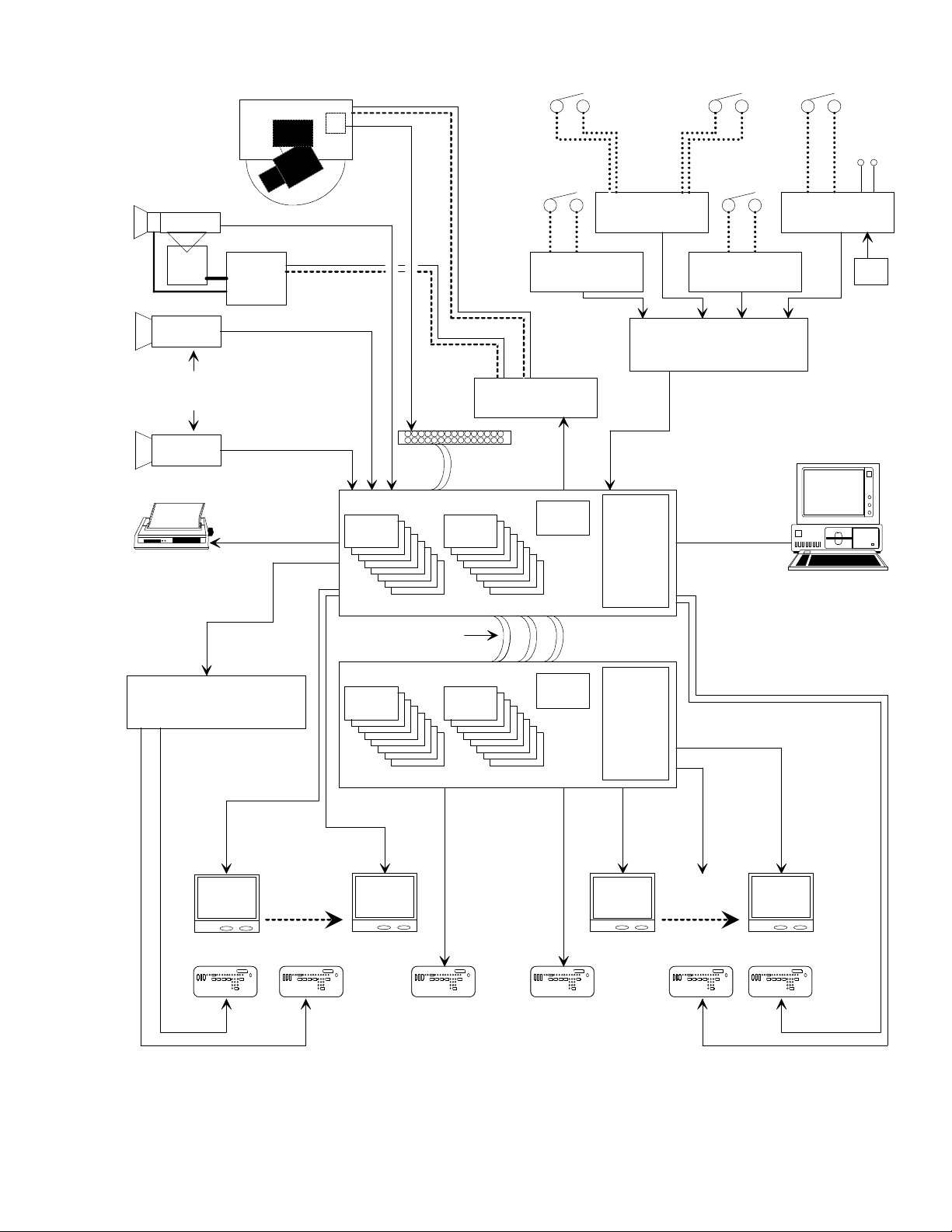

S9506029AE

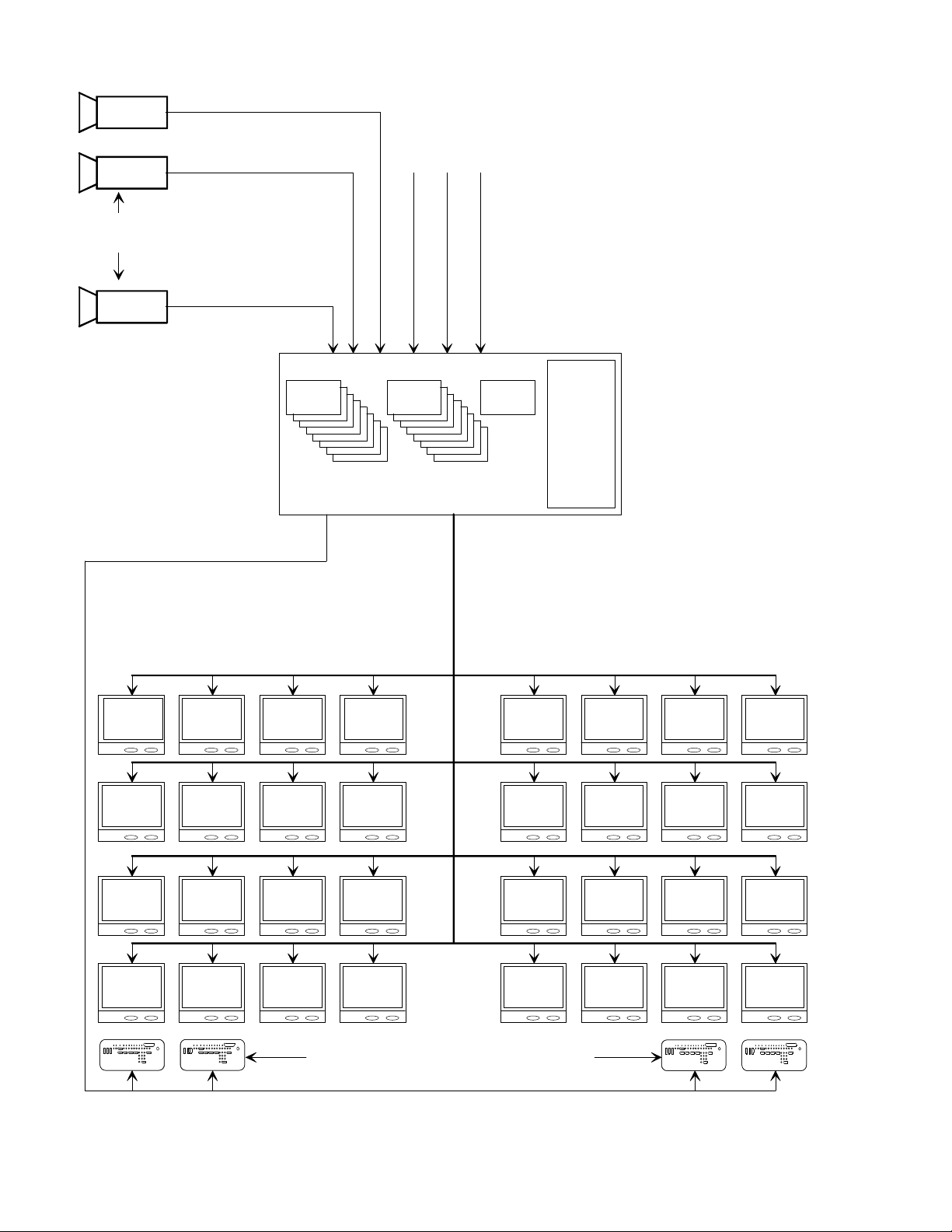

Additional

S9506030AE

System Cameras

Up To 256

Video Inputs

Maximum

Up to 32 Monitor Outputs

Monitor 1

Monitor 5 Monitor 6

Monitor 2 Monitor 3

TC8821

8 x 32 CH

Input Cards

TC8834

8 x 4 CH

Output Cards

TC8810A

CPU

Module

TC8801 Series Main CPU Bay

3 m (10 ft) Interconnect

Cable Supplied With Keyboard

Multiple Video Coax

Monitor 4

Monitor 7 Monitor 8 Monitor 21

Monitor 17 Monitor 18

TC8805

Power

Supply

Module

Monitor 22

Monitor 19

Monitor 23 Monitor 24

Monitor 20

Monitor 9 Monitor 10 Monitor 11

Monitor 13

Monitor 14

Monitor 15

Monitor 12

Monitor 16 Monitor 29

Monitor 25 Monitor 26

Maximum of 32 TC8550A, TC8551A, or TC8553

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

TC8800 Series Single Bay System

(256 by 32 Configuration)

16

Monitor 30

Monitor 27 Monitor 28

Monitor 31 Monitor 32

Up To 256 Video

Inputs Maximum

Coax Ribbon

Jumper Cables

(Supplied)

TC8821

8 x 32 CH

Input Cards

TC8834

8 x 4 CH

Output Cards

TC8810A

CPU

Module

TC8805

Power

Supply

Module

Control

Data

TC8821

8 x 32 CH

Input Cards

TC8834

8 x 4 CH

Output Cards

TC8816A

Data

Receiver

Module

Monitor 1 Monitor 2 Monitor 3 Monitor 4 Monitor 33 Monitor 34 Monitor 35 Monitor 36

Monitor 5 Monitor 6 Monitor 7 Monitor 8 Monitor 37 Monitor 38 Monitor 39 Monitor 40

Monitor 9

Monitor 10

Monitor 11

Monitor 12

Monitor 41

Monitor 42

Monitor 43 Monitor 44

TC8805

Power

Supply

Module

Monitor 13

Monitor 17

Monitor 21

Monitor 14

Monitor 18 Monitor 19 Monitor 20

Monitor 22 Monitor 23 Monitor 24 Monitor 53 Monitor 54

Monitor 15

Monitor 25 Monitor 26 Monitor 27

Monitor 29 Monitor 30

Monitor 31

Monitor 16

Monitor 45 Monitor 46

Monitor 49

Monitor 28

Monitor 32

Maximum of 32 TC8550A, TC8551A, or TC8553

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

Monitor 57

Monitor 61

Monitor 47 Monitor 48

Monitor 50

Monitor 51

Monitor 55

Monitor 52

Monitor 56

Monitor 58 Monitor 59 Monitor 60

Monitor 62

Monitor 63 Monitor 64

TC8800 Series Dual Bay System

(256 by 64 Configuration)

17

S9506031AE

Typical

AutoDome™

Camera

Pan/

Tilt

TC8561A

Receiver/

Driver

Video Coax

Up to 64 Receiver/

Driver Units

Video

Coax

Twisted-Pair

Typical

Up to 1.5 km (5000 ft)

Using 18 g Shielded

Twisted Pair Cable

(Belden 8760 or Equivalent)

64 Separate

Alarm Inputs

TC8540C Alarm

Interface Unit

2 m (6 ft) Interconnect

Cable Supplied With

TC8540C Providing Data

and Power Connections

Contact Closure

or Active Low Logic Level

Additional

System Cameras

Video Coax

Up to 64

Video Inputs

Maximum

Video Coax

RS-232 Data

3 m (10 ft) Interface Cable

Provided W ith TC8500 Series

Main CPU Bay

Up to 8 Monitor Outputs

TC8521VIM

8 x 8 CH

Input Cards

32 Separate Outputs

TC8568 Signal

Distribution Unit

2 m (6 ft) Interconnect

Cable Supplied W ith

TC8568 Providing Data

and Power Connections

TC8532VOM

4 x 2 CH

Output Cards

TC8511A

Module

TC8501B Series Main CPU Bay

CPU

TC8505PS

Power Supply

Module

3 m (10 ft) Interconnect Cable

Supplied With Keyboard

Optional TC8559 Master

Control Software or

Graphical Users Interface

(GUI) Software package Can

Be Run on IBM or IBM Compatible

RS-232 Data

Monitor 1

Monitor 2

Video Coax

Monitor 3

Monitor 4

Maximum of 8 TC8550A, TC8551A, or TC8553

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

Monitor 5 Monitor 6 Monitor 7 Monitor 8

TC8500 Full Capacity Configuration

18

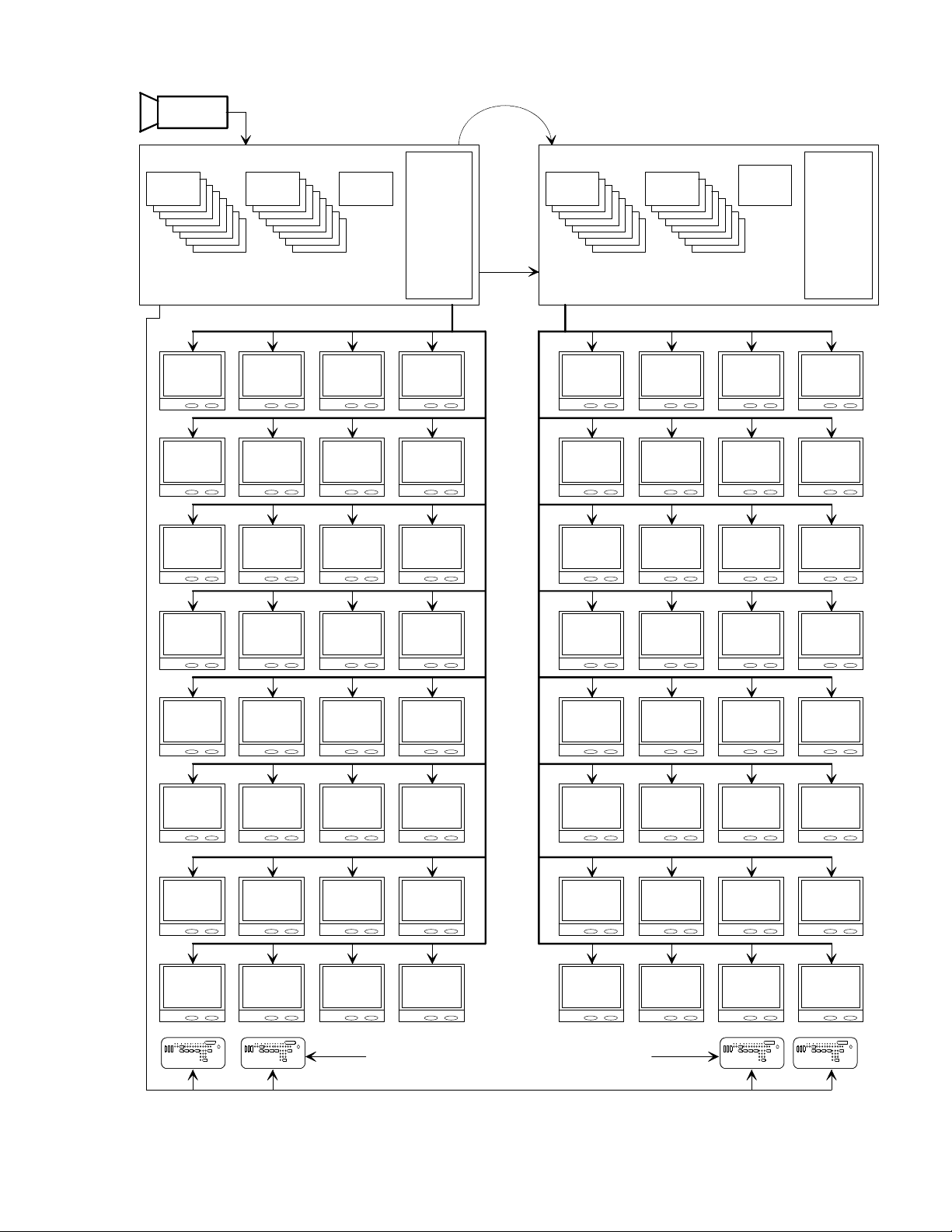

S9506032AE

Typical

AutoDome™

Camera

Pan/

Tilt

TC8561A

Receiver/

Driver

Up to 256

Receiver/

Driver Units

Video

Coax

Up to 1.5 km (5000 ft)

Using 18 g Shielded

Twisted Pair

Cable (Belden

8760 or Equiv.)

Twisted

Pair

Typical

Control

Code Line

TC8540C Alarm

Interface Unit

Up to 64 Alarm

Inputs to Each

TC8540C Unit

TC8540C Alarm

Interface Unit

Contact Closure

or Logic Level

Inputs

TC8540C Alarm

Interface Unit

8 Pairs

of Relay

Outputs

TC8540C Alarm

Interface Unit

VDC

12

Additional

System Cameras

Serial Logging

Printer Capability

TC8714A / TC8715A Port

Expander Accessories

Keyboard Expander

Units Used For System

Keyboards Above 16

Video Coax

256 Camera

Inputs Total

Video Coax

RS-232 Data

Interconnect Panel

Up to 8 TC8821

32 Channel

Input Cards

Up to 8 TC8834

4 Channel

Output Cards

TC8801 SERIES MAIN CPU BAY

Video Ribbon

Jumper Cables

Supplied With TC8802

Up to 8 TC8821

32 Channel

Input Cards

TC8802 SERIES MONITOR EXPANSION BAY

Up to 8 TC8834

4 Channel

Output Cards

Distribution Unit

TC8808

32 Separate

Outputs

TC8568 Signal

TC8810A

Module

Data Receiver

CPU

TC8816

Module

Up to 256

Alarm Inputs

Maximum

TC8805

Power

Supply

Module

TC8805

Power

Supply

Module

TC8713A Alarm Port

Expander Accessory

Optional TC8859 Master

Control Software or

Graphical Users Interface

(GUI) Software Package Can

Be Run on IBM or IBM

Compatible Computer

RS-232 Data

Main Bay Can

Operate Up

to 8 Keyboards

3 m (10 ft) Interconnect

Cable Supplied With Keyboard

Monitor

1

System

Monitors

1 to 32

Monitor

Expansion

Bay Can

Operate Up

to 8 Keyboards

Monitor

32

Maximum of 32 TC8550A, TC8551A, or TC8553

Full Function Keyboards Up to 1.5 km (5000 ft)

Away Using Optional Remote Hookup Kit

TC8800 Full Capacity Configuration

19

Monitor

33

System

Monitors

33 to 64

Monitor

64

S9506033AE

INSTALLATION PROCEDURE

CAUTION: Do Not Apply power to equipment until instructed to do so.

Main CPU Bay Installation

Before discarding the shipping cartons, verify that

the various pieces of equipment have no evidence of

carrier damage.

Remove the front panel of the main CPU bay

(TC8x01) and the front panels of any supplied

expansion bay (TC8802) by loosening the 4 corner

fasteners.

Install power supply (TC8x05) in far right position of

the TC8x01 main CPU bay insuring proper alignment

and seating of the module into the rear mating

connector. Verify power supply ON/OFF switch is in

the OFF position. Repeat procedure for any supplied

TC8802 monitor expansion bay.

Install 4 supplied screws and star washers on the

rear panel of the bay(s) surrounding the power supply

line cord. This fastens the power supply securely in

place.

CAUTION: IF THE ALLEGIANT CARD CAGE IS TO

BE TRANSPORTED, THE MAIN POWER SUPPLY

SHOULD BE REMOVED TO PREVENT POSSIBLE

DAMAGE TO THE BAY’S INTERNAL PARTS.

Video Input Modules

For TC8600 and TC8800 systems, termination

switches on the Video Input Modules (VIM) must be

set to the correct position prior to installation. Read

the termination instructions (section Camera and

Monitor Connections, subsection Termination) prior

to actually installing the Video Input Modules on

these systems.

The appropriate number of Video Input Modules

(TC8x21 or TC8521VIM) should be installed in the

TC8x01 main bay starting with the left most slot. If

the TC8802 Monitor Expansion Bay is being used, it

should receive the same number of Video Input

Modules as the main bay. If less than full capacity is

being used, the modules should be inserted in a leftto-right manner so that the lower camera numbers

are used up first.

If the bay(s) are to be installed into a standard 19inch EIA rack, remove the 4 rubber bumper foot pads

found on the bottom of the bay before trying to install

it. Four holes are provided for mounting the bay(s) in

the rack. If any TC8802 expansion bays is supplied,

it should be located as close as possible to the

TC8801 main CPU bay to facilitate cable

interconnections.

The TC8601, TC8801, and TC8802 bays should be

installed such that there is at least 9 cm (3.5

inches) of clearance above and below the bay.

This is necessary to allow for proper cooling of the

system. Failure to provide proper clearance may

cause the equipment to exceed its recommended

operating temperature range.

NOTE: A TC8802 BAY SHOULD BE LOCATED

CLOSE ENOUGH TO THE TC8801 SO THAT THE

SUPPLIED 2 METER (6 FOOT) DATA

INTERCONNECT CABLE (TO BE ATTACHED

LATER) CAN BE USED.

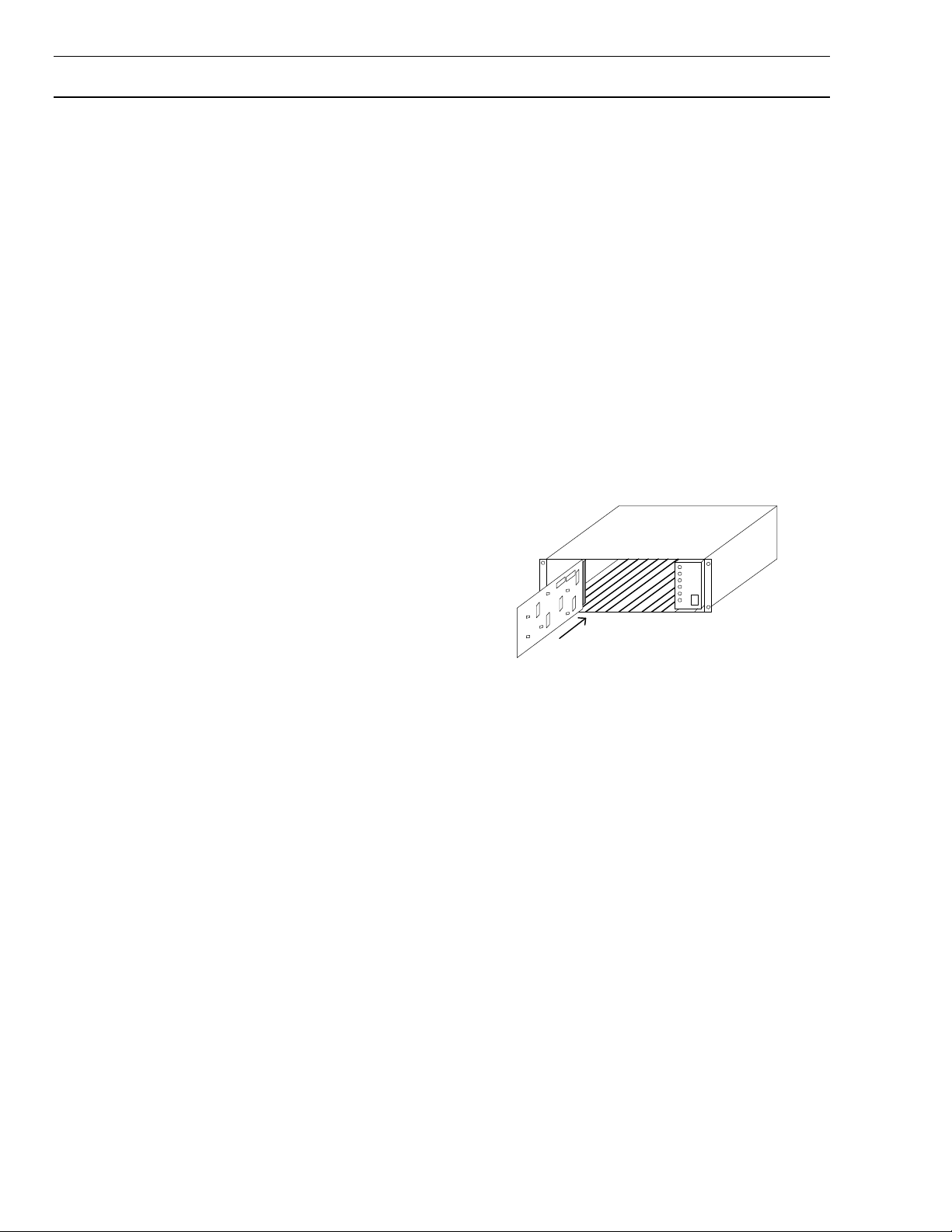

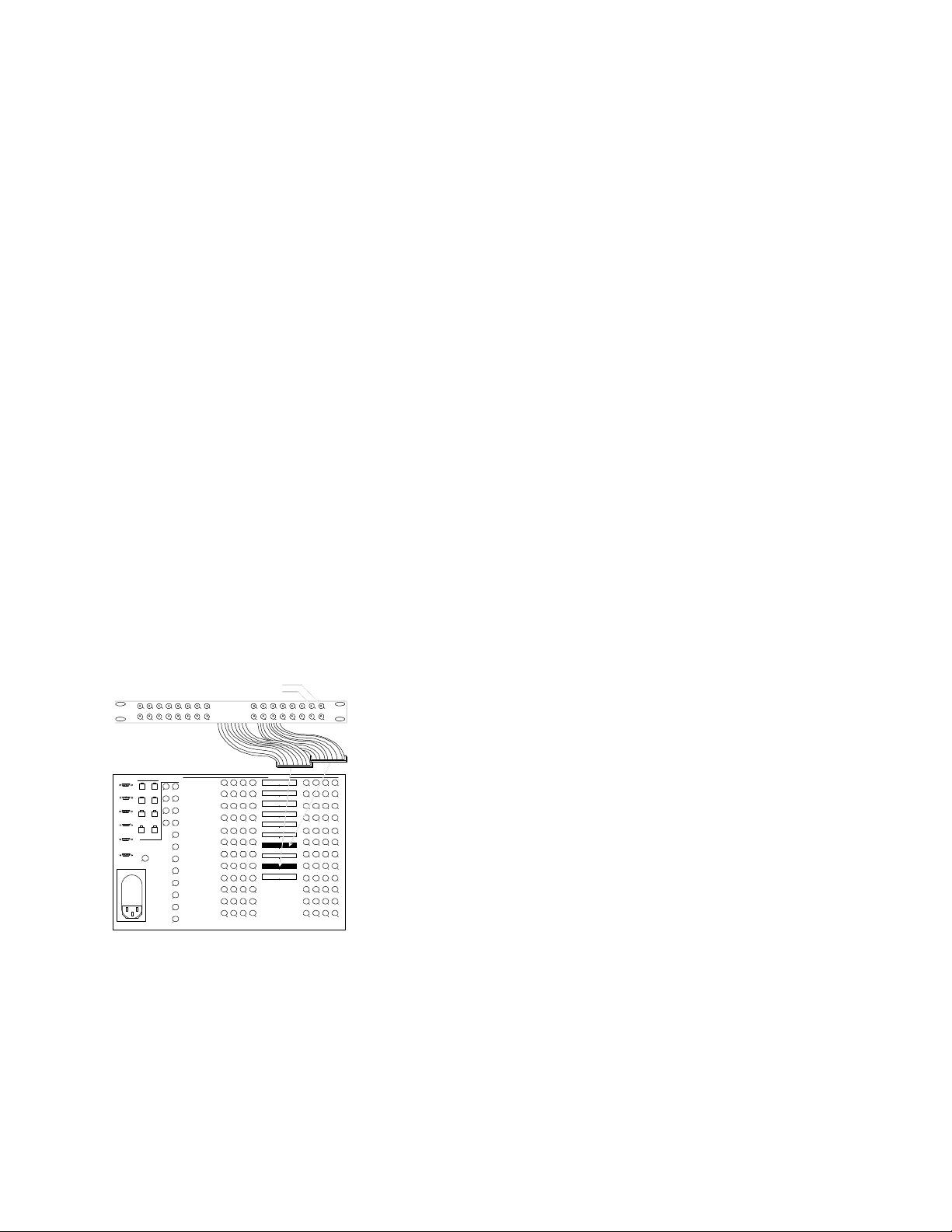

Typical Video Input Module Insertion

To insure full crosspoint capability, it is important that

if the TC8802 is being used, both the TC8801 Main

Bay and TC8802 Monitor Expansion Bay must be

loaded up with the same number of modules (each

bay receives half of the modules). The Video Input

Modules are identical and are interchangeable within

the designated VIM slots without having to make any

changes to the module.

20

Video Output Modules

The next set of slots can contain up to 4 (8 on the

TC8800) Video Output Modules (TC8834 or

TC8532VOM). If counting from left to right, these are

slots 9 to 12 for the TC8500 and TC8600, and 9 to

16 for the TC8800. Install the appropriate number of

modules (starting at the left) into these slots. If fewer

than the maximum number of Video Input Modules

are installed, there will be empty slots between the

Input and the Output Modules; make sure that the

Output Modules are inserted into the correct slots.

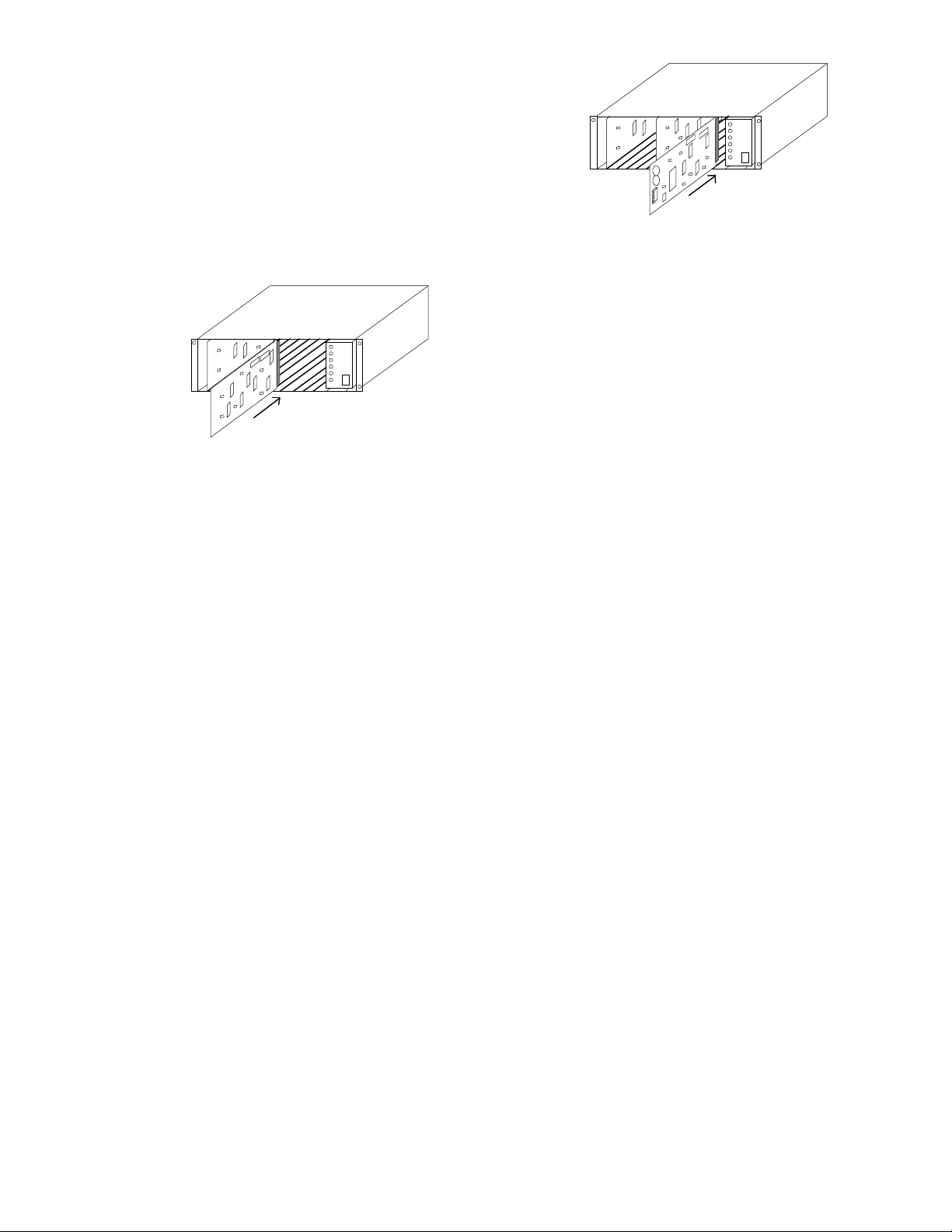

Typical CPU Module Insertion

If a TC8802 Monitor Expansion is supplied, it will

contain a TC8816A Data Receiving Module in this

slot. Install the appropriate CPU or Data Receiver

Module at this time.

IMPORTANT: Verify that the settings of the two

8 position DIP switches located on the front edge of

the CPU Module and the Data Receiver Module are

set according to the table below.

Typical Video Output Module Insertion

If the TC8802 Monitor Expansion Bay is being used,

it should be loaded with Video Output Modules in the

same fashion. The Main CPU Bay should be FULLY

loaded with 8 Output Modules before putting Output

Modules into the Monitor Expansion Bay. Remaining

Output Modules are inserted into the Monitor

Expansion Bay starting at slot 9 on a TC8802. If

fewer than the maximum number of outputs are

being used, the Monitor Expansion Bay may contain

fewer Output Modules than the Main CPU Bay.

All Video Output Modules are identical and are

interchangeable within the designated VOM slots.

CPU Module

The next slot over in the TC8x01 Main Bay will

contain the system CPU module. This should be the

right most slot adjacent to the power supply.

NOTE: THE CPU MODULE CONTAINS TWO

LITHIUM BATTERIES MOUNTED ON THE

COMPONENT SIDE OF THE PRINTED CIRCUIT

BOARD. A RED RECTANGULAR INSULATING

TAG MAY BE INSTALLED IN BETWEEN THE TOP

OF THE BATTERIES AND THE BATTERY HOLDER

CLIP. THIS TAG PREVENTS BATTERY DRAINAGE

DURING STOCKING. REMOVE TAG IF SO

EQUIPPED.

Bay Type Module DIP Setting

TC8501C TC8511C CPU S1001, All OFF,

S1002 switch 7 ON,

All others OFF

TC8x01A TC8x10A CPU S100, All OFF,

S101 switch 7 ON,

All others OFF

TC8802A TC8816A S101 switch 3 and 7

Data Receiver ON, All others OFF

Camera and Monitor Connections

Refer to the rear panel diagrams on the following

pages for the following steps.

For All Systems

Connect system cameras to the appropriate video

inputs, but as a minimum connect one known

operating camera to video input #1 on the rear of the

TC8x01 main CPU bay. Use only those inputs that

correspond to an installed Video Input Module (VIM).

Special instructions concerning TC8600 or TC8800

systems, termination, and expansion bays are given

in the sections below. Also connect desired monitors

to the rear of the TC8x01 bay, making sure to at

least connect a monitor to video output #1. The

video outputs are the left most column of BNC

connectors on the rear of the bay. Use only those

outputs that correspond to an installed Video Output

Module (VOM).

21

TC8600 and TC8800 Video Inputs

Termination Practices

The TC8601 and TC8801 main bays have only 96

direct BNC connectors available for video input.

Cameras above 96 require the use of the TC8808

Video Interconnect ("Patch") Panel. Each patch

panel provides 32 additional BNCs for video input.

Patch panels are connected to the rear of the main

bay using the supplied ribbon cables. Each cable can

carry video for up to 16 cameras. Two cables can be

attached to each patch panel to support up to 32

cameras per panel. Each ribbon cable should be

attached to the appropriate "VIDEO" connector on

the rear of the main bay. The ribbon cable

connectors contain a small “key” protrusion

formed into one side of the connector to assure

proper placement into the mating connectors. Be

careful not to force the cables into the mating

connectors backwards. For example, the two

ribbon cables from the first patch panel (supporting

the thirty-two cameras 97 through 128) should be

attached to the main bay connectors labeled "VIDEO

97-112" and "VIDEO 113-128." Extra connectors are

provided on the main bay for "looping" purposes. If

camera inputs are not being looped to other

equipment, only one connector for each range of

cameras (e.g., "VIDEO 97-112") needs to be

connected.

The TC8600 system is supplied with one TC8808

(patch panel plus two TC8809 ribbon cables). This

should be installed on the rear of the racking

equipment to permit immediate or future connections

of camera inputs 97 through 128.

Video from every camera should be "terminated"

with a 75 ohm resistance. Each video line should be

terminated exactly once. If video from a given

camera is going to several different devices, only the

last piece of equipment on the video line should be

terminated. See the section below for special

termination instructions when using a monitor

expansion bay. Allegiant systems terminate their

video inputs as follows:

TC8500 Terminations

Each TC8521VOM Video Input Module has resistors

that terminate the video lines. If the user wishes that

a video input be non-terminated so it may be used as

a looping input, the VIM card must be modified. This

modification can be done by the installer, as long as

standard handling precautions are observed. Only

competent technicians should attempt this

procedure. For each video input that should be nonterminated, a resistor must be removed from the

appropriate VIM card. These resistors are labeled as

follows:

input 1 - R1 input 5 - R93

input 2 - R96 input 6 - R95

input 3 - R43 input 7 - R92

input 4 - R91 input 8 - R94

BNC "T" connectors must then be used to connect

looping system cameras to the non-terminated inputs

on the rear of the main CPU bay. A short piece of

coax is recommended to connect the "T" to the bay.

Camera Input 97

Camera Input 98

16

15 14 13

12 11 10 9

32 31 30 29

KEYBOARD

1

3

5

7

SYNC

IN

28 27 26 25

VIDEO

OUT

1

13

2

2

14

4

3

15

6

4

16

8

5

6

7

8

9

10

11

12

TC8808 Interconnect Panel

CONSOLE

ALARM

PRINTER

SDA

COMM PORT 1

COMM PORT 2

Lower TC8809 Cable

TC8601 REAR PAN EL

5678

1415

13

16

21222324

3031

29

32

3839

37

40

4647

45

48

53545556

6264

63

61

69707172

77787980

868788

85

8 7 6 5 4 3 2171

24 23 22 21 20 19 18

VIDEO IN

LOOP 1-16

LOOP 17-32

LOOP 33-48

LOOP 49-64

LOOP 65-80

LOOP 81-96

INPUT 97-112

LOOP 97-112

INPUT 113-128

LOOP 113-128

Upper TC8809 Cable

4

12

28

36

44

92939496

3

2

1011

2627

3435

4243

5860

59

828384

90

9195

S9506053AE

1

9

17181920

25

33

41

49505152

57

65666768

73747576

81

89

Typical Use of TC8808 Video Interconnect Panel

The TC8800 system is supplied with TC8808s only if

the number of TC8821 Video Input Modules ordered

requires their use. Install any supplied TC8808 patch

panels on the rear of the racking equipment. Note

that additional TC8821 Video Input Modules ordered

in the future may also require the use of TC8808

patch panels. Order appropriate quantities at the

time the TC8821 Video Input Modules are ordered.

TC8600 or TC8800 Terminations

Each VIM card for a TC8600 or TC8800 system has

DIP switches for selecting the termination of each

individual video line. To terminate an input line,

make sure that the appropriate DIP switch on the

VIM card is ON. If non-terminated operation is

required for looping purposes, turn the switch OFF.

If looping video inputs are desired, the TC8600 and

TC8800 systems may utilize the TC8808 patch panel

kit. Both bays provide video looping connections

which interface to the TC8808 patch panel using

coax type ribbon cables supplied with the patch

panel. Each TC8808 provides looping capability for

up to 32 video inputs.

Just like camera inputs, monitor outputs on the

Allegiant system are designed to be terminated.

Each monitor output expects to be connected to a 75

ohm load. This is the regular load typically provided

by a normal monitor. If a monitor output line is

"looped" through several monitors or other

equipment, the system installer should make sure

that only the last unit on the line is terminated.

TC8802 Expansion Bay

Connections

22

If a TC8802 monitor expansion bay is supplied, each

camera that is connected to the TC8801 main CPU

bay must also be connected to the same numbered

input on the monitor expansion bay.

TC8802 Video Connections

With the TC8802 monitor expansion bay, ribbon

cable connectors are provided for the video inputs.

Video is to be looped from the main bay into the

expansion bay through 16 TC8809 ribbon cables.

Connect all TC8809 ribbon cables from the

appropriate "VIDEO" ribbon cable connector on the

main bay to the corresponding "VIDEO" ribbon cable

connector on the monitor expansion bay. The ribbon

cable connectors contain a small “key”

protrusion formed into one side of the connector

to assure proper placement into the mating

connectors. Be careful not to force the cables

into the mating connectors backwards. The DIP

switches on the VIM cards installed in the main bay

should be turned OFF. This will make the main bay

inputs non-terminated, and the expansion bay will

provide the termination for the video inputs.

CONSOLE

ALARM

PRINTER

SDA

COMM PORT 1

COMM PORT 2

KEYBOARD

1

3

5

7

32 25 18 6

SYNC

IN

VIDEO

OUT

INPUT 161-176

1

13

2

LOOP 161-176

2

14

4

INPUT 177-192

3

15

6

LOOP 177-192