Page 1

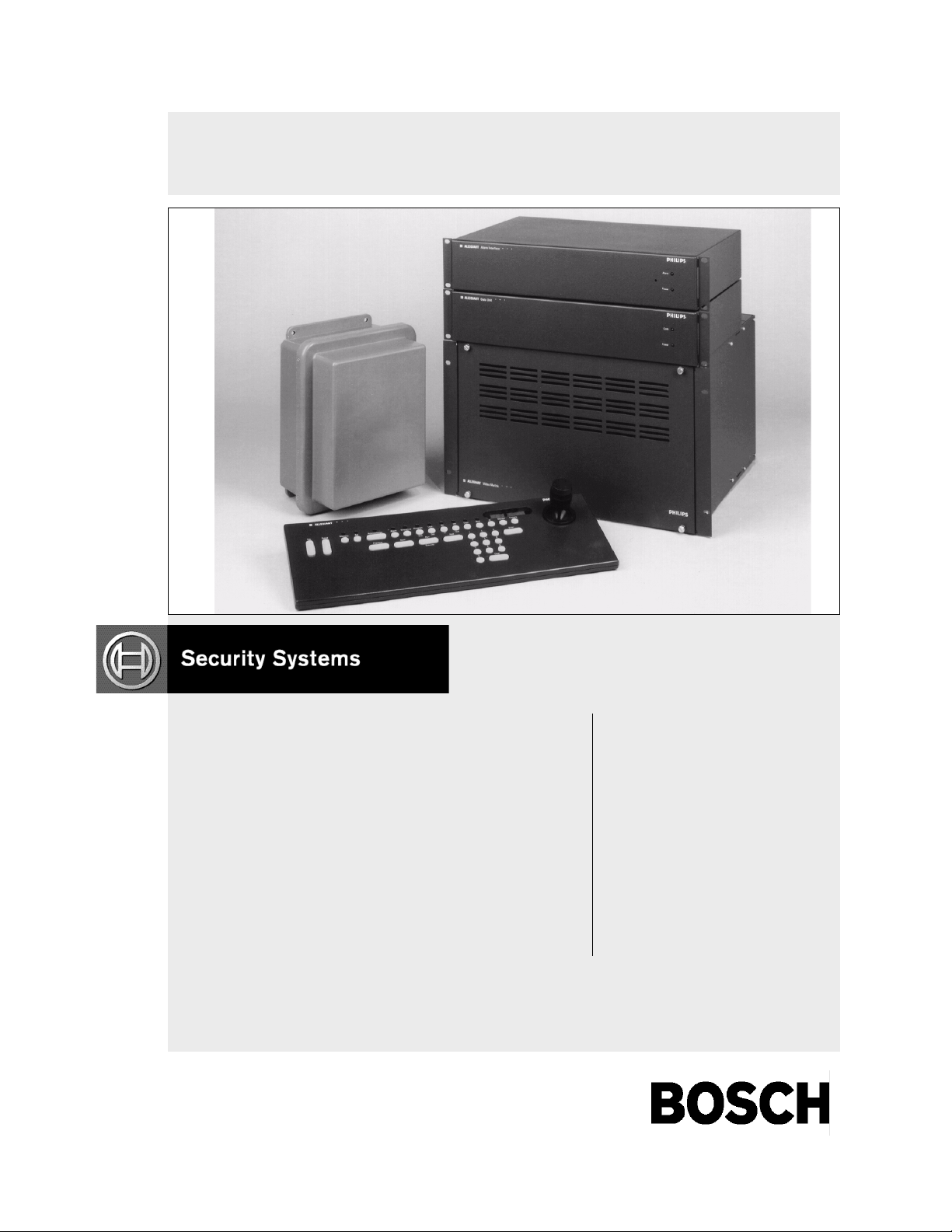

LTC 8600, LTC 8800 Series

EN

Instruction Manual

Allegiant Microprocessorbased Video Switcher/Control Systems

CPU Firmware

Version 10.0

Page 2

Page 3

LTC 8600 | LTC 8800 Series | en iii

Table of Contents

1 Safety ..................................................................................................................................................... 1

2 Unpacking .............................................................................................................................................. 9

2.1 Parts List ................................................................................................................................................ 9

3 Service ................................................................................................................................................. 10

4 Description .......................................................................................................................................... 11

5 Allegiant Feature Summary Table ....................................................................................................... 13

6 System Components ............................................................................................................................ 15

6.1 LTC 8601 Series Systems..................................................................................................................... 15

6.2 LTC 8800 Series Systems..................................................................................................................... 15

7 System Accessory Components .......................................................................................................... 17

7.1 LTC 8540/00 Alarm Interface Unit........................................................................................................ 17

7.2 LTC 8568 and LTC 8768 Signal Distribution Units ............................................................................... 17

7.3 IntuiKey Series KBD-Universal Keyboard .............................................................................................. 17

7.4 KBD-Rack Keyboard Mounting Kit......................................................................................................... 17

7.5 LTC 8555 Series Keyboards.................................................................................................................. 18

7.6 LTC 8558/00 Keyboard Extension Cable .............................................................................................. 18

7.7 LTC 8557 Series Keyboard Extension Kits............................................................................................ 18

7.8 LTC 8560 and LTC 8561 Series Receiver/Driver Units ......................................................................... 18

7.9 AutoDome Series.................................................................................................................................. 18

7.10 LTC 8569, LTC 8570, LTC 8571, LTC 8572 Series Code Merger Units ................................................ 19

7.11 LTC 8770 Switcher Follower Series ..................................................................................................... 19

7.12 LTC 8712 Series Console Port Expander Units .................................................................................... 19

7.13 LTC 8713 Alarm Port Expander Units ................................................................................................... 19

7.14 LTC 8714, LTC 8715 Series Keyboard Port Expander Units................................................................. 19

7.15 LTC 8780 Series Data Converter Units................................................................................................. 20

7.16 LTC 8781 Series Data Converter Units................................................................................................. 20

7.17 LTC 8016/90 Bilinx™ Data Interface Unit ............................................................................................. 20

7.18 LTC 8785 Series Code Converters ....................................................................................................... 20

7.19 LTC 8782 Series Code Translator Units ............................................................................................... 21

7.20 LTC 8808/00 Series Video Interconnect Panel..................................................................................... 21

7.21 LTC 8059/00 Master Control Software ................................................................................................ 21

7.22 LTC 8850/00 Windows Based Graphical User Interface Software ....................................................... 21

7.23 SFT-INTSRV Allegiant Integration Software .......................................................................................... 21

7.23.1 Integration Server ................................................................................................................................. 22

7.23.2 Virtual Allegiant Satellite Application Software .................................................................................... 22

7.23.3 Allegiant Satellite SDK .......................................................................................................................... 22

7.24 LTC 8506/00 PC-to-Console Port RS-232 Cable................................................................................... 23

7.25 LTC 8508/01 Ribbon-to-BNC Interface Cable....................................................................................... 23

7.26 Logging Printer ..................................................................................................................................... 23

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 4

iv en | LTC 8600 | LTC 8800 Series

8 Installation Procedure ......................................................................................................................... 28

8.1 Main CPU Bay Installation .................................................................................................................... 28

8.2 Video Input Modules............................................................................................................................. 28

8.3 Video Output Modules.......................................................................................................................... 29

8.4 CPU Module.......................................................................................................................................... 29

8.5 Camera and Monitor Video Connections.............................................................................................. 30

8.5.1 LTC 8600 Series and LTC 8800 Series Video Input Connections .........................................................30

8.6 Termination Practices........................................................................................................................... 31

8.6.1 LTC 8600 Series or LTC 8800 Series Video Input Terminations ........................................................... 32

8.6.2 LTC 8802 Series Monitor Expansion Bay Video Input Connections ..................................................... 32

8.6.3 LTC 8802 Series Monitor Expansion Bay Data Connections ................................................................33

8.6.4 Monitor Output Video Connections ...................................................................................................... 33

9 Optional Accessories Installation ....................................................................................................... 34

9.1 General Accessory Installation ............................................................................................................. 34

9.2 Logging Printer Option Installation ...................................................................................................... 34

9.3 Computer Interface Installation............................................................................................................ 34

10 Satellite Configuration Installations ................................................................................................... 36

10.1 Satellite Site “Trunk Line” Monitor Outputs......................................................................................... 36

10.2 Main Site “Trunk Line” Video Inputs..................................................................................................... 37

10.3 Control Data Lines in Satellite Systems ............................................................................................... 37

10.4 Satellite Site Programming Requirements............................................................................................ 37

10.5 Main Site Programming Requirements ................................................................................................. 38

10.6 Special Programming for “Cascaded” Satellite System Configurations ............................................... 40

10.7 Alarm Inputs in Satellite Systems......................................................................................................... 41

11 Feature Selection ................................................................................................................................. 42

12 Main Power Connections .................................................................................................................... 43

13 Video Monitor Display .........................................................................................................................45

13.1 Time/Date............................................................................................................................................. 45

13.2 Monitor Title/System Status Display .................................................................................................... 46

13.2.1 System Status Display .......................................................................................................................... 46

13.2.2 Locations 1, 2, and 3 - Alarm Indication ...............................................................................................46

13.2.3 Location 4 - Monitor Arm Status Indication .......................................................................................... 46

13.2.4 Location 5 - Camera Arm Status Indication ..........................................................................................46

13.2.5 Location 6 - Error Indication ................................................................................................................. 46

13.2.6 Location 7 - Remote Lock Indication .................................................................................................... 47

13.2.7 Location 8 - Monitor Lock Indication .................................................................................................... 47

13.2.8 Location 9 - Sequence Type Indication .................................................................................................47

13.2.9 Locations 10 and 11 - Sequence Number ............................................................................................. 47

13.2.10 Location 12 - Sequence Status Indication ............................................................................................ 48

13.3 Monitor Title ......................................................................................................................................... 48

13.4 Broadcast Message............................................................................................................................... 48

13.5 Program Prompts ................................................................................................................................. 48

13.6 Camera Number.................................................................................................................................... 49

13.7 Camera Title ......................................................................................................................................... 49

13.8 Video Loss Detection............................................................................................................................ 49

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 5

LTC 8600 | LTC 8800 Series | en v

14 Factory Default Settings ...................................................................................................................... 50

14.1 User Selectable DIP Switch Settings for Main CPU Bay....................................................................... 50

14.1.1 Upper CPU DIP Switch S1 .................................................................................................................... 50

14.1.2 Middle CPU DIP Switch S2 ................................................................................................................... 51

14.1.3 Lower CPU DIP Switch S3 ....................................................................................................................53

14.2 User Selectable DIP Switch Settings for LTC 8816/00 Data Receiver Modules used in

LTC 8802 Series Monitor Expansion Bays ............................................................................................ 54

14.2.1 Upper Data Receiver DIP Switch S1 ..................................................................................................... 54

14.2.2 Middle Data Receiver DIP Switch S2 .................................................................................................... 55

14.2.3 Lower Data Receiver DIP Switch S3 ..................................................................................................... 55

15 User Information .................................................................................................................................. 56

15.1 User Priority Levels............................................................................................................................... 56

15.2 User Priority Access Table.................................................................................................................... 57

16 Alarm Information ................................................................................................................................ 58

16.1 General ................................................................................................................................................. 58

16.2 Basic Alarm Response Mode ................................................................................................................ 58

16.3 Auto Build Alarm Response Mode ........................................................................................................ 58

16.4 Sequence and Display Alarm Response Mode...................................................................................... 58

16.5 Alarm Activated Pre-position ................................................................................................................ 59

16.6 Sample Alarm Responses ..................................................................................................................... 59

16.7 Alarm Relay Response .......................................................................................................................... 61

17 Keyboard Operation ............................................................................................................................ 62

17.1 General ................................................................................................................................................. 62

17.2 System Commands............................................................................................................................... 62

17.2.1 Keyboard Log-in Procedure .................................................................................................................. 62

17.2.2 Keyboard Log-off Procedure ................................................................................................................. 63

17.3 Switcher Commands ............................................................................................................................ 63

17.4 Controlling Camera Movement............................................................................................................. 63

17.4.1 Focus and Iris Lens Control .................................................................................................................. 63

17.4.2 Lock or Unlock Control of a Camera .................................................................................................... 63

17.4.3 Lock or Unlock Control of a Monitor .................................................................................................... 64

17.4.4 Recording a Camera Pre-position Scene .............................................................................................. 64

17.4.5 Recalling a Camera Pre-position Scene ................................................................................................ 64

17.4.6 Activate/Deactivate Auxiliary Function ................................................................................................. 64

17.5 Alarm Commands ................................................................................................................................. 65

17.5.1 Arm/Disarm Individual Alarms .............................................................................................................. 65

17.5.2 Arm/Disarm All Alarms .......................................................................................................................... 66

17.5.3 Arm/Disarm Monitor ............................................................................................................................. 66

17.5.4 Alarms Acknowledgement .................................................................................................................... 66

17.6 Sequence Control................................................................................................................................. 66

17.6.1 Load/Clear a Sequence ........................................................................................................................ 66

17.6.2 Run a Sequence .................................................................................................................................... 67

17.6.3 Stop a Running Sequence .................................................................................................................... 67

17.6.4 Controlling Sequence Direction ........................................................................................................... 67

17.7 Sequence Programming ....................................................................................................................... 68

17.7.1 Programming a Simple Camera Sequence ........................................................................................... 68

17.7.2 Programming a SalvoSwitching Camera Sequence .............................................................................. 70

18 Keyboard User Functions .................................................................................................................... 71

18.1 General Information ............................................................................................................................. 71

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 6

vi en | LTC 8600 | LTC 8800 Series

19 Maintenance Information .................................................................................................................... 83

19.1 Cleaning the Keyboard ......................................................................................................................... 83

19.2 AC Line Voltage Input Selection ........................................................................................................... 83

19.3 AC Line Fuse Replacement................................................................................................................... 84

19.4 Power Supply Fuse Replacement ......................................................................................................... 84

19.5 Replacement of Memory Backup Batteries........................................................................................... 84

20 Character ROM Tables for LTC 8600 and LTC 8800 ........................................................................... 86

21 ERROR MESSAGES .............................................................................................................................. 99

22 Troubleshooting Guide ...................................................................................................................... 102

22.1 Main Bay Checkout............................................................................................................................. 102

22.2 Keyboard Checkout ............................................................................................................................ 103

22.3 Video Monitor Display Checkout ........................................................................................................ 103

22.4 Remote Receiver/Driver Functions Inoperative .................................................................................. 104

22.5 No Alarm Response ............................................................................................................................ 104

22.6 CPU Software Version Numbers......................................................................................................... 104

23 GLOSSARY OF TERMS .......................................................................................................................105

Appendix A Satellite Systems ............................................................................................................................. 107

Appendix B Installation Checklists .................................................................................................................... 114

Appendix C Quick Reference Cable Interconnections ...................................................................................... 115

Appendix D Main Bay Rear Panel Connector Pin-outs ...................................................................................... 117

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 7

LTC 8600 | LTC 8800 Series | 1

1Safety

Important Safety Instructions

Read, follow, and retain for future reference all of the following safety instructions. Heed all

warnings on the unit and in the operating instructions before operating the unit.

1. Cleaning - Unplug the unit from the outlet before cleaning. Follow any instructions

provided with the unit. Generally, using a dry cloth for cleaning is sufficient, but a moist

fluff-free cloth or leather shammy may also be used. Do not use liquid cleaners or aerosol

cleaners.

2. Heat Sources - Do not install the unit near any heat sources such as radiators, heaters,

stoves, or other equipment (including amplifiers) that produce heat.

3. Ventilation - Any openings in the unit enclosure are provided for ventilation to prevent

overheating and ensure reliable operation. Do not block or cover these openings. Do not

place the unit in an enclosure unless proper ventilation is provided, or the manufacturer's

instructions have been adhered to.

4. Water - Do not use this unit near water, for example near a bathtub, washbowl, sink,

laundry basket, in a damp or wet basement, near a swimming pool, in an outdoor

installation, or in any area classified as a wet location. To reduce the risk of fire or

electrical shock, do not expose this unit to rain or moisture.

5. Object and liquid entry - Never push objects of any kind into this unit through openings

as they may touch dangerous voltage points or short-out parts that could result in a fire

or electrical shock. Never spill liquid of any kind on the unit. Do not place objects filled

with liquids, such as vases or cups, on the unit.

6. Lightning - For added protection during a lightning storm, or when leaving this unit

unattended and unused for long periods, unplug the unit from the wall outlet and

disconnect the cable system. This will prevent damage to the unit from lightning and

power line surges.

7. Controls adjustment - Adjust only those controls specified in the operating instructions.

Improper adjustment of other controls may cause damage to the unit. Use of controls or

adjustments, or performance of procedures other than those specified, may result in

hazardous radiation exposure.

8. Overloading - Do not overload outlets and extension cords. This can cause fire or

electrical shock.

9. Power cord and plug protection - Protect the plug and power cord from foot traffic,

being pinched by items placed upon or against them at electrical outlets, and its exit

from the unit. For units intended to operate with 230 VAC, 50 Hz, the input and output

power cord must comply with the latest versions of IEC Publication 227 or IEC Publication

245.

10. Power disconnect - Units with or without ON/OFF switches have power supplied to the

unit whenever the power cord is inserted into the power source; however, the unit is

operational only when the ON/OFF switch is in the ON position. The power cord is the

main power disconnect device for switching off the voltage for all units.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 8

2 | LTC 8600 | LTC 8800 Series

11. Power sources - Operate the unit only from the type of power source indicated on the

label. Before proceeding, be sure to disconnect the power from the cable to be installed

into the unit.

– For battery powered units, refer to the operating instructions.

– For external power supplied units, use only the recommended or approved power

supplies.

– For limited power source units, this power source must comply with EN60950.

Substitutions may damage the unit or cause fire or shock.

– For 24 VAC units, voltage applied to the unit's power input should not exceed ±10%,

or 28 VAC. User-supplied wiring must comply with local electrical codes (Class 2

power levels). Do not ground the supply at the terminals or at the unit's power

supply terminals.

– If unsure of the type of power supply to use, contact your dealer or local power

company.

12. Servicing - Do not attempt to service this unit yourself. Opening or removing covers may

expose you to dangerous voltage or other hazards. Refer all servicing to qualified service

personnel.

13. Damage requiring service - Unplug the unit from the main AC power source and refer

servicing to qualified service personnel when any damage to the equipment has

occurred, such as:

– the power supply cord or plug is damaged;

– exposure to moisture, water, and/or inclement weather (rain, snow, etc.);

– liquid has been spilled in or on the equipment;

– an object has fallen into the unit;

– unit has been dropped or the unit cabinet is damaged;

– unit exhibits a distinct change in performance;

– unit does not operate normally when the user correctly follows the operating

instructions.

14. Replacement parts - Be sure the service technician uses replacement parts specified by

the manufacturer, or that have the same characteristics as the original parts.

Unauthorized substitutions may cause fire, electrical shock, or other hazards.

15. Safety check - Safety checks should be performed upon completion of service or repairs

to the unit to ensure proper operating condition.

16. Installation - Install in accordance with the manufacturer's instructions and in

accordance with applicable local codes.

17. Attachments, changes or modifications - Only use attachments/accessories specified by

the manufacturer. Any change or modification of the equipment, not expressly approved

by Bosch, could void the warranty or, in the case of an authorization agreement, authority

to operate the equipment.

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 9

LTC 8600 | LTC 8800 Series | 3

!

!

i

Safety Precautions

DANGER! High risk:

This symbol indicates an imminently hazardous situation such as “Dangerous Voltage”

inside the product. If not avoided, this will result in an electrical shock, serious bodily

injury, or death.

WARNING! Medium risk:

Indicates a potentially hazardous situation. If not avoided, this could result in serious bodily

injury or death.

CAUTION! Medium risk:

Indicates a potentially hazardous situation. If not avoided, this may result in minor or

moderate injury. Alerts the user to important instructions accompanying the unit.

CAUTION! Low risk: (without safety alert symbol)

Indicates a potentially hazardous situation. If not avoided, this may result in property

damage or risk of damage to the unit.

NOTICE!

This symbol indicates information or a company policy that relates directly or indirectly to

the safety of personnel or protection of property.

Important Notices

Accessories - Do not place this unit on an unstable stand, tripod, bracket, or mount. The unit

may fall, causing serious injury and/or serious damage to the unit. Use only with the cart,

stand, tripod, bracket, or table specified by the manufacturer. When a cart is used, use

caution and care when moving the cart/apparatus combination to avoid injury from tip-over.

Quick stops, excessive force, or uneven surfaces may cause the cart/unit combination to

overturn. Mount the unit per the manufacturer's instructions.

All-pole power switch - Incorporate an all-pole power switch, with a contact separation of at

least 3 mm in each pole, into the electrical installation of the building.

If it is needed to open the housing for servicing and/or other activities, use this all-pole switch

as the main disconnect device for switching off the voltage to the unit.

Camera grounding - For mounting the camera in potentially damp environments, ensure to

ground the system using the ground connection of the power supply connector (see section:

Connecting external power supply).

Camera lens - An assembled camera lens in the outdoor housing must comply and be tested

in accordance with UL/IEC60950. Any output or signal lines from the camera must be SELV or

Limited Power Source. For safety reasons the environmental specification of the camera lens

assembly must be within the environmental specification of -10 °C (14 °F) to 50 °C (122 °F).

Camera signal - Protect the cable with a primary protector if the camera signal is beyond 140

feet, in accordance with NEC800 (CEC Section 60).

Coax grounding:

– Ground the cable system if connecting an outside cable system to the unit.

– Connect outdoor equipment to the unit's inputs only after this unit has had its grounding

plug connected to a grounded outlet or its ground terminal is properly connected to a

ground source.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 10

4 | LTC 8600 | LTC 8800 Series

i

– Disconnect the unit's input connectors from outdoor equipment before disconnecting

the grounding plug or grounding terminal.

– Follow proper safety precautions such as grounding for any outdoor device connected to

this unit.

U.S.A. models only - Section 810 of the National Electrical Code, ANSI/NFPA No.70, provides

information regarding proper grounding of the mount and supporting structure, grounding of

the coax to a discharge unit, size of grounding conductors, location of discharge unit,

connection to grounding electrodes, and requirements for the grounding electrode.

NOTICE!

This device is intended for use in public areas only.

U.S. federal law strictly prohibits surreptitious recording of oral communications.

Your Bosch product was developed and manufactured with high-quality material and

components that can be recycled and reused. This symbol means that electronic and

electrical appliances, which have reached the end of their working life, must be collected and

disposed of separately from household waste material. Separate collecting systems are

usually in place for disused electronic and electrical products. Please dispose of these units at

an environmentally compatible recycling facility, per European Directive 2002/96/EC.

Environmental statement - Bosch has a strong commitment towards the environment. This

unit has been designed to respect the environment as much as possible.

Electrostatic-sensitive device - Use proper CMOS/MOS-FET handling precautions to avoid

electrostatic discharge.

NOTE: Wear required grounded wrist straps and observe proper ESD safety precautions when

handling the electrostatic-sensitive printed circuit boards.

Fuse rating - For security protection of the device, the branch circuit protection must be

secured with a maximum fuse rating of 16A. This must be in accordance with NEC800 (CEC

Section 60).

Grounding and polarization - This unit may be equipped with a polarized alternating current

line plug (a plug with one blade wider than the other blade). This safety feature allows the

plug to fit into the power outlet in only one way. If unable to insert the plug fully into the

outlet, contact a locally certified electrician to replace the obsolete outlet. Do not defeat the

safety purpose of the polarized plug.

Alternately, this unit may be equipped with a 3-pole grounding plug (a plug with a third pin for

earth grounding). This safety feature allows the plug to fit into a grounded power outlet only.

If unable to insert the plug into the outlet, contact a locally certified electrician to replace the

obsolete outlet. Do not defeat the safety purpose of the grounding plug.

Moving - Disconnect the power before moving the unit. Move the unit with care. Excessive

force or shock may damage the unit and the hard disk drives.

Outdoor signals - The installation for outdoor signals, especially regarding clearance from

power and lightning conductors and transient protection, must be in accordance with NEC725

and NEC800 (CEC Rule 16-224 and CEC Section 60).

Permanently connected equipment - Incorporate a readily accessible disconnect device in

the building installation wiring.

Pluggable equipment - Install the socket outlet near the equipment so it is easily accessible.

PoE - Never supply power via the Ethernet connection (PoE) when power is already supplied

via the power connector.

Power disconnect - Units have power supplied whenever the power cord is inserted into the

power source. The power cord is the main power disconnect for all units.

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 11

LTC 8600 | LTC 8800 Series | 5

i

Power lines - Do not locate the camera near overhead power lines, power circuits, or

electrical lights, nor where it may contact such power lines, circuits, or lights.

SELV

All the input/output ports are Safety Extra Low Voltage (SELV) circuits. SELV circuits should

only be connected to other SELV circuits.

Because the ISDN circuits are treated like telephone-network voltage, avoid connecting the

SELV circuit to the Telephone Network Voltage (TNV) circuits.

Video loss - Video loss is inherent to digital video recording; therefore, Bosch Security

Systems cannot be held liable for any damage that results from missing video information. To

minimize the risk of lost digital information, Bosch Security Systems recommends multiple,

redundant recording systems, and a procedure to back up all analog and digital information.

NOTICE!

This is a class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

FCC & ICES INFORMATION

(U.S.A. and Canadian Models Only, CLASS A)

This device complies with part 15 of the FCC Rules. Operation is subject to the following

conditions:

– this device may not cause harmful interference, and

– this device must accept any interference received, including interference that may cause

undesired operation.

Note

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules and ICES-003 of Industry Canada. These limits

are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and

radiates radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference, in which case the

user will be required to correct the interference at his expense.

Intentional or unintentional modifications, not expressly approved by the party responsible

for compliance, shall not be made. Any such modifications could void the user's authority to

operate the equipment. If necessary, the user should consult the dealer or an experienced

radio/television technician for corrective action.

The user may find the following booklet, prepared by the Federal Communications

Commission, helpful: How to Identify and Resolve Radio-TV Interference Problems. This

booklet is available from the U.S. Government Printing Office, Washington, DC 20402, Stock

No. 004-000-00345-4.

INFORMATIONS FCC ET ICES (commercial applications)

(modèles utilisés aux États-Unis et au Canada uniquement, CLASSE A)

Ce produit est conforme aux normes FCC partie 15. la mise en service est soumises aux deux

conditions suivantes:

– cet appareil ne peut pas provoquer d'interférence nuisible et

– cet appareil doit pouvoir tolérer toutes les interférences auxquelles il est soumit, y

compris les interférences qui pourraient influer sur son bon fonctionnement.

AVERTISSEMENT: Suite à différents tests, cet appareil s’est révélé conforme aux exigences

imposées aux appareils numériques de Classe A en vertu de la section 15 du règlement de la

Commission fédérale des communications des États-Unis (FCC). Ces contraintes sont

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 12

6 | LTC 8600 | LTC 8800 Series

i

destinées à fournir une protection raisonnable contre les interférences nuisibles quand

l'appareil est utilisé dans une installation commerciale. Cette appareil génère, utilise et émet

de l'energie de fréquence radio, et peut, en cas d'installation ou d'utilisation non conforme

aux instructions, générer des interférences nuisibles aux communications radio. L’utilisation

de ce produit dans une zone résidentielle peut provoquer des interférences nuisibles. Le cas

échéant, l’utilisateur devra remédier à ces interférences à ses propres frais.

Au besoin, l’utilisateur consultera son revendeur ou un technicien qualifié en radio/télévision,

qui procédera à une opération corrective. La brochure suivante, publiée par la Commission

fédérale des communications (FCC), peut s’avérer utile : « How to Identify and Resolve RadioTV Interference Problems » (Comment identifier et résoudre les problèmes d’interférences de

radio et de télévision). Cette brochure est disponible auprès du U.S. Government Printing

Office, Washington, DC 20402, États-Unis, sous la référence n° 004-000-00345-4.

AVERTISSEMENT: Ce produit est un appareil de Classe A. Son utilisation dans une zone

résidentielle risque de provoquer des interférences. Le cas échéant, l’utilisateur devra

prendre les mesures nécessaires pour y remédier.

Disclaimer

Underwriter Laboratories Inc. (“UL”) has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in UL's Standard(s) for Safety for Closed Circuit Television Equipment, UL

2044. UL Certification does not cover the performance or reliability of the security or signaling

aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALING RELATED

FUNCTIONS OF THIS PRODUCT.

Disclaimer

Underwriter Laboratories Inc. (“UL”) has not tested the performance or reliability of the

security or signaling aspects of this product. UL has only tested fire, shock and/or casualty

hazards as outlined in UL's Standard(s) for Safety for Information Technology Equipment, UL

60950-1. UL Certification does not cover the performance or reliability of the security or

signaling aspects of this product.

UL MAKES NO REPRESENTATIONS, WARRANTIES, OR CERTIFICATIONS WHATSOEVER

REGARDING THE PERFORMANCE OR RELIABILITY OF ANY SECURITY OR SIGNALINGRELATED FUNCTIONS OF THIS PRODUCT.

Copyright

This user guide is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright.

All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

NOTICE!

This user guide has been compiled with great care and the information it contains has been

thoroughly verified. The text was complete and correct at the time of printing. The ongoing

development of the products may mean that the content of the user guide can change without

notice. Bosch Security Systems accepts no liability for damage resulting directly or indirectly

from faults, incompleteness or discrepancies between the user guide and the product

described.

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 13

LTC 8600 | LTC 8800 Series | 7

Customer Support and Service

If this unit needs service, contact the nearest Bosch Security Systems Service Center for

authorization to return and shipping instructions.

Service Centers

USA

Repair Center

Telephone: 800-566-2283

Fax: 800-366-1329

E-mail: repair@us.bosch.com

Customer Service

Telephone: 888-289-0096

Fax: 585-223-9180

E-mail: security.sales@us.bosch.com

Technical Support

Telephone: 800-326-1450

Fax: 585-223-3508 or 717-735-6560

E-mail: technical.support@us.bosch.com

Canada

Telephone: 514-738-2434

Fax: 514-738-8480

Europe, Middle East, Africa Region

Repair Center

Telephone: 31 (0) 76-5721500

Fax: 31 (0) 76-5721413

E-mail: RMADesk.STService@nl.bosch.com

Asia Region

Repair Center

Telephone: 65 63522776

Fax: 65 63521776

E-mail: rmahelpdesk@sg.bosch.com

Customer Service

Telephone: 86 (0) 756 7633117 or

86 (0) 756 7633121

Fax: 86 (0) 756 7631710

E-mail: customer.service@cn.bosch.com

Warranty and more information

For additional information and warranty queries, please contact your Bosch Security Systems

representative or visit our website at www.boschsecurity.com.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 14

8 | LTC 8600 | LTC 8800 Series

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 15

LTC 8600 | LTC 8800 Series en | 9

2Unpacking

This equipment should be unpacked and handled with care. If an item appears to

have been damaged in shipment, notify the shipper. Verify that all parts shown in

the Parts List have been included. If any items are missing, notify your Bosch Security Systems Sales or Customer Service Representative.

The original packing carton is the safest container in which to transport the unit.

Save it for possible future use.

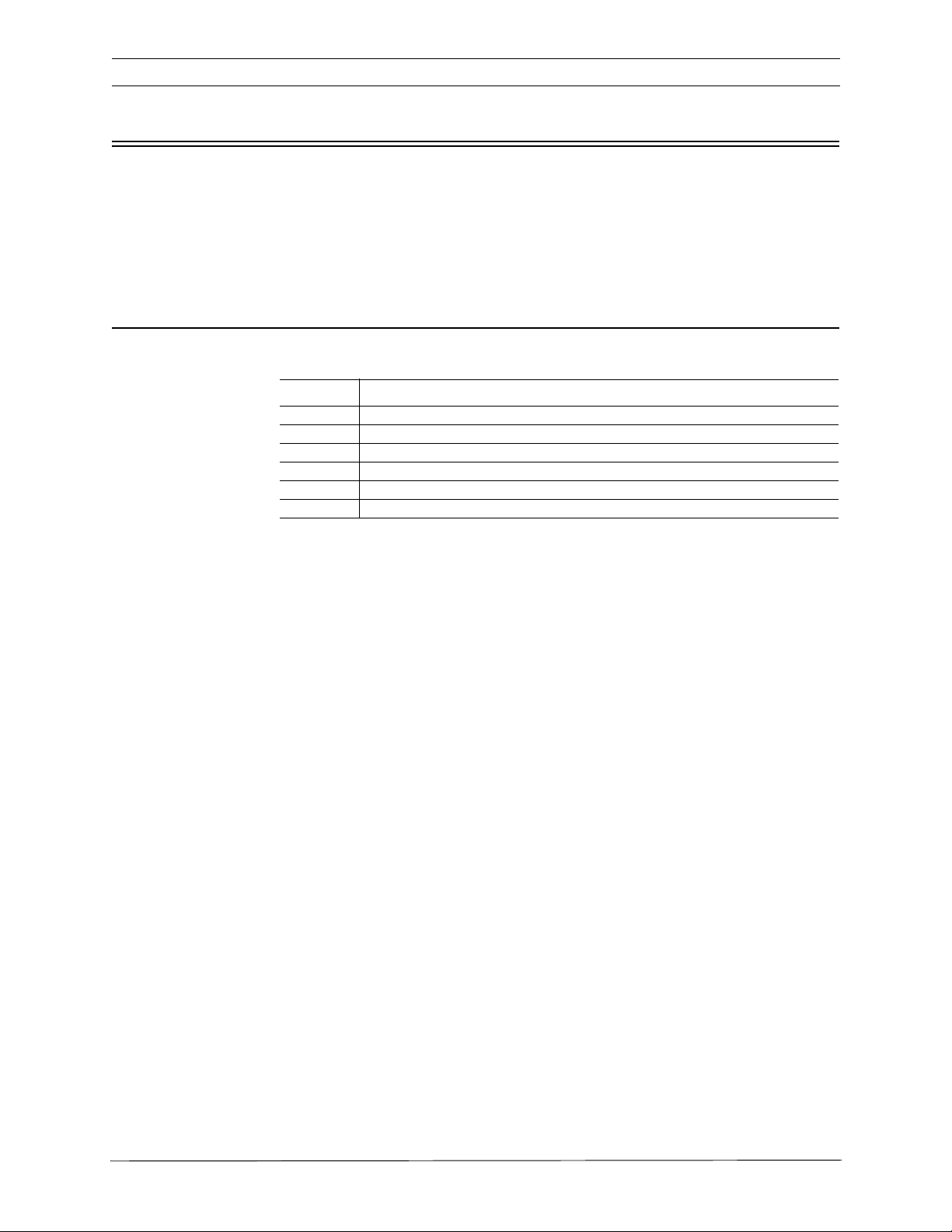

2.1 Parts List

The following table lists the components:

Qty Item

1 LTC 8601 Series or LTC 8801 Series Main CPU card cage

1 LTC 8610/01 CPU module or LTC 8810/01 CPU module

1 LTC 8805 Series Power Supply

1 AC power cord (either for 120 VAC or 220 - 240 VAC)

1Fuse kit

1 This installation manual

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 16

10 | en LTC 8600 | LTC 8800 Series

3Service

If the unit needs repair, contact the nearest Bosch Security Systems Service Center

for authorization to return and shipping instructions.

Service Centers

•USA

• Repair Center

Telephone: 800-566-2283

Fax: 800-366-1329

E-mail: repair@us.bosch.com

•Customer Service

Telephone: 888-289-0096

Fax: 585-223-9180

E-mail: security.sales@us.bosch.com

• Technical Support

Telephone: 800-326-1450

Fax: 585-223-3508 or 717-735-6560

E-mail: technical.support@us.bosch.com

•Canada

Telephone: 514-738-2434

Fax: 514-738-8480

• Europe, Middle East, Africa Region

• Repair Center

Telephone: 31 (0) 76-5721500

Fax: 31 (0) 76-5721413

E-mail: RMADesk.STService@nl.bosch.com

• Asia Region

• Repair Center

Telephone: 65 63522776

Fax: 65 63521776

E-mail: rmahelpdesk@sg.bosch.com

•Customer Service

Telephone: 86 (0) 756 7633117 or

86 (0) 756 7633121

Fax: 86 (0) 756 7631710

E-mail: customer.service@cn.bosch.com

For additional information, see www.boschsecurity.com.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 17

LTC 8600 | LTC 8800 Series en | 11

4Description

These Allegiant video switcher/control systems combine both switching and computer technology to provide powerful performance and unique system features for

the security user. Offering full matrix switching capability, these systems can be

programmed to display the video from any camera on any monitor, either manually

or via independent automatic switching sequences.

The LTC 8600 Series Allegiant system can handle up to 128 cameras and 16 monitors in a full crosspoint configuration. It can also accommodate 512 alarm points,

up to 16 keyboards, a computer system console port, and a logging printer port.

The LTC 8800 Series Allegiant system can handle up to 256 cameras and 64 monitors in a full crosspoint configuration. It can also accommodate 1024 alarm points,

up to 32 keyboards, a computer system console port, and a logging printer port.

These systems can be programmed with up to 60 sequences that can be run independently of each other, in either a forward or reverse direction. Any of the

sequences can utilize the SalvoSwitching capability where any number of system

monitors may be selected to switch as a synchronized group. Using the optional LTC

8059/00 Master Control Software (MCS) package or the LTC 8850/00 Bosch Graphical User Interface (GUI), sequences can be made to activate and deactivate automatically, based upon the time of day and the day of week.

The series supports variable speed control and full programming functions of AutoDome

provide operators with control of pan, tilt, zoom, multiple pre-positions, four (4)

auxiliaries, autopan, and random scan using conventional camera/lens/housings.

With the addition of an external LTC 8540/00 Alarm Interface unit, an external contact closure or logic level can be used to automatically display any camera. Any monitor or group of monitors can be set to display cameras under alarm conditions. The

base system contains three (3) built-in alarm response modes: basic, auto-build,

and sequence and display. In addition to these three (3) modes, the PC based software packages offer the ability to combine any or all three (3) standard modes.

Alarm video may be selected to reset either manually or automatically. In addition, a

16-character alarm title can be selected to appear instead of the camera title during

alarm conditions.

System operation and programming is accomplished using a full-function, ergonomically designed keyboard. Multiple keyboards may be used in the system. Built-in

operator priority levels and the ability to restrict certain operators from controlling

designated functions provide maximum flexibility.

These systems include a 48-character on-screen display for time-date, camera number, camera ID (16 characters), and monitor (12 characters) or status information. A

user selectable option provides the ability to display a 3rd line of on-screen text.

This 3rd line can be configured to display up to 24 additional camera title characters (40 characters total) or a 12-character monitor title.

The on-screen display is also user selectable to operate in “6-digit Camera ID”

mode. When enabled, 2-digit “site numbers” are displayed in addition to the 4-digit

camera number. The 2-digit site number feature is especially useful when groups of

cameras are located in separate buildings, floors, or other common areas.

When programming camera ID and monitor titles, over 1000 different characters

are available.

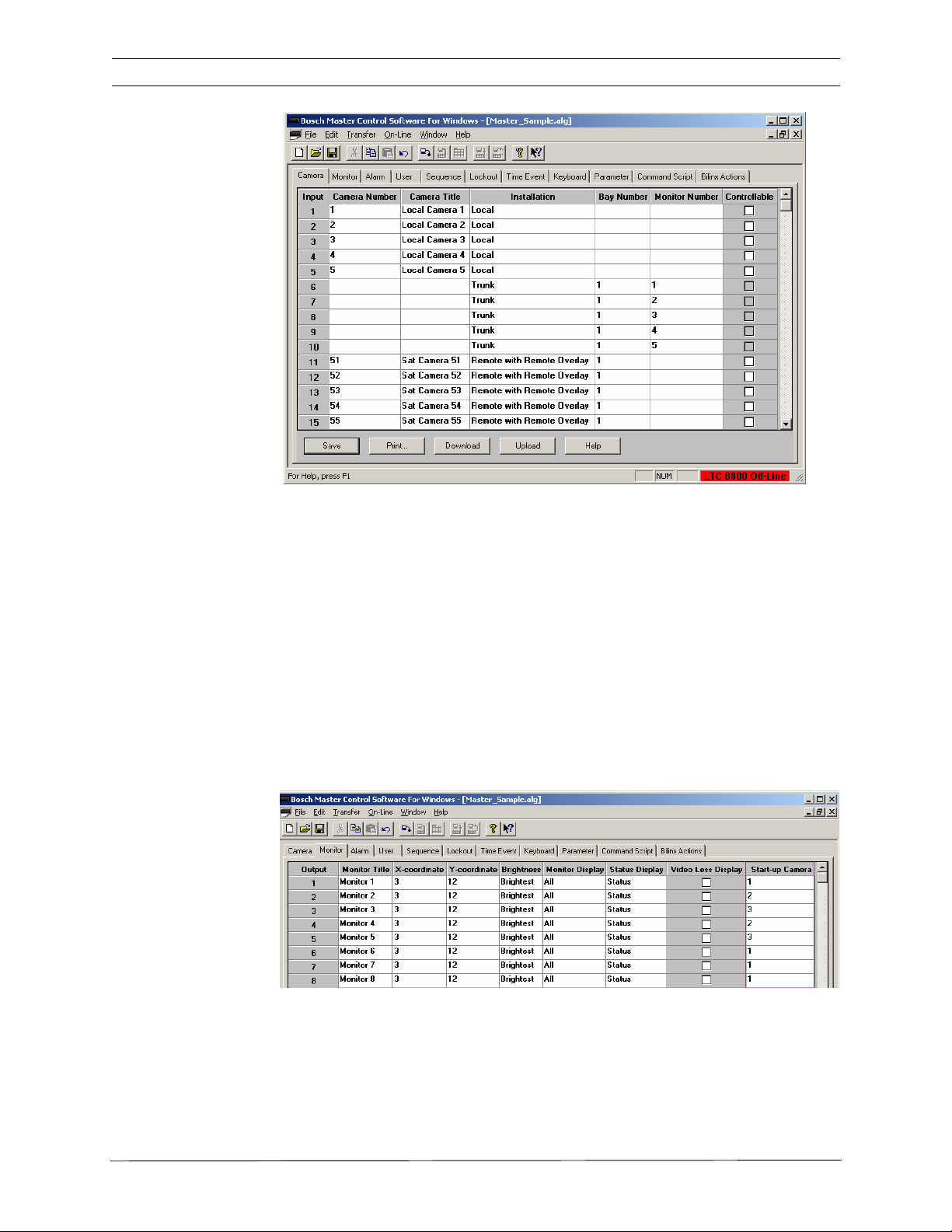

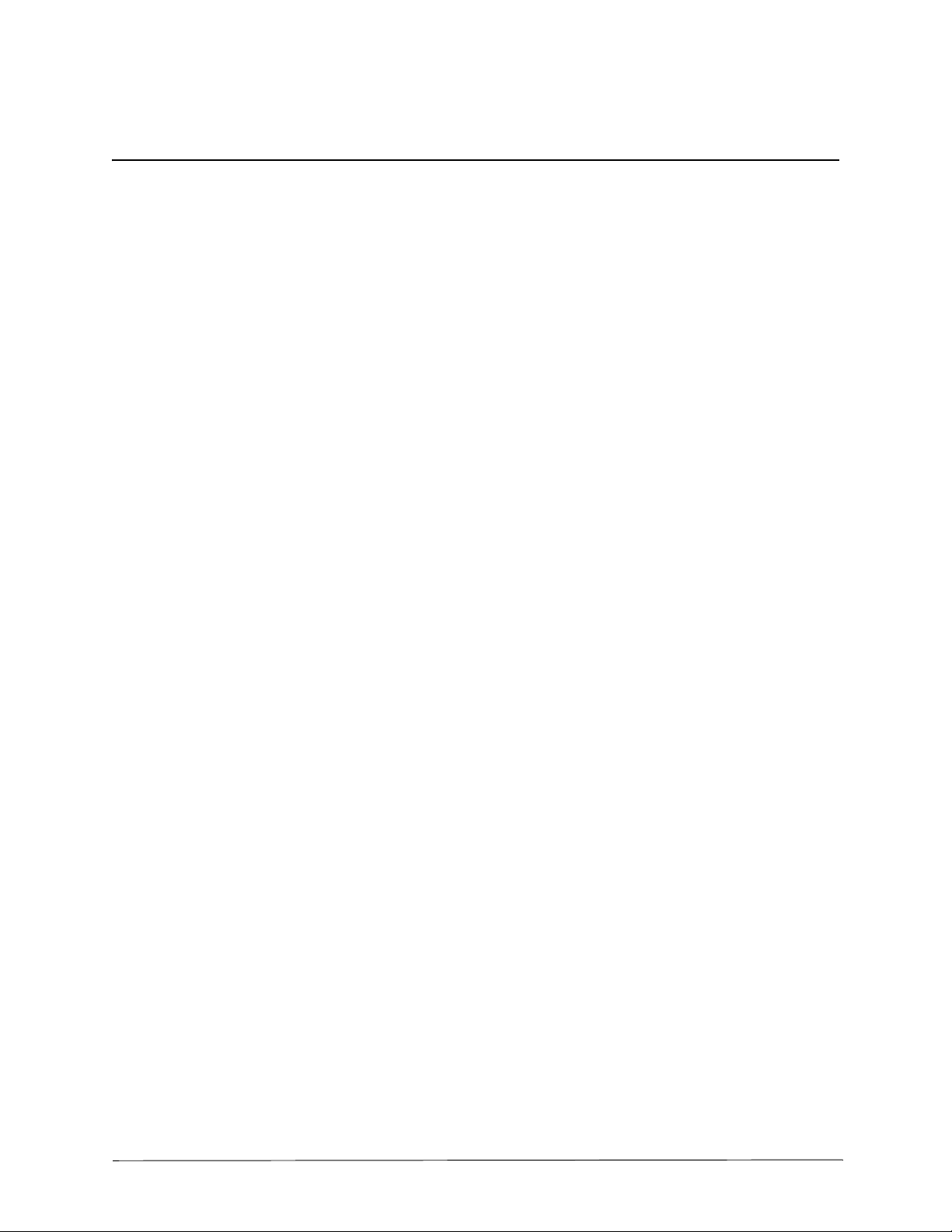

Enhanced programming and switching features can be obtained by utilizing a standard Windows

8850/00 GUI Software. A user friendly spreadsheet format provides the ability to

enter camera titles, enter operator names, schedule up to 64 timed events, change

®

Series dome cameras. In addition, support for on-site receiver/driver units

®

equipped PC and the optional LTC 8059/00 MCS package or the LTC

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 18

12 | en LTC 8600 | LTC 8800 Series

system parameters, program camera sequences, install lockouts, and access the

advanced alarm handling screens with speed and efficiency. The programmed information may then be transferred into the Allegiant system, stored on disk, or printed

from a PC.

The LTC 8850/00 Bosch GUI Software is designed around an intuitive graphic-based

interface. This software provides high performance programming, control, and monitoring of all system functions by using on-screen icons to reflect real time status of

the devices controlled by the system.

The LTC 8850/00 GUI Software also provides the ability to monitor system status

events. System alarms, switching functions, sequence events, and keyboard

actions, and video loss information can be viewed in real time on the PC screen and,

if desired, logged to the PC hard drive. The LTC 8850/00 GUI Software can also be

used to enable a special on-screen icon for identifying controllable cameras.

The CPU inside these matrix switchers supports powerful macro capabilities. The

macros can be activated using system keyboards, system time event functions,

alarm activations, and via special function icons in the LTC 8850/00 GUI Software.

These systems can serve as the master switcher in a SatelliteSwitch configuration.

This innovative feature enables a single master Allegiant system to communicate

with remotely located “Satellite” systems. Any Allegiant system model can serve as a

remote Satellite switcher. This powerful feature permits the design of a distributed

matrix video switching system with control at one central location and individual

control at the local sites. The main control site can view/control local cameras plus

cameras located at any of the remotely distributed Satellite sites. The Satellite sites

can view/control only cameras associated with their own site.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 19

LTC 8600 | LTC 8800 Series en | 13

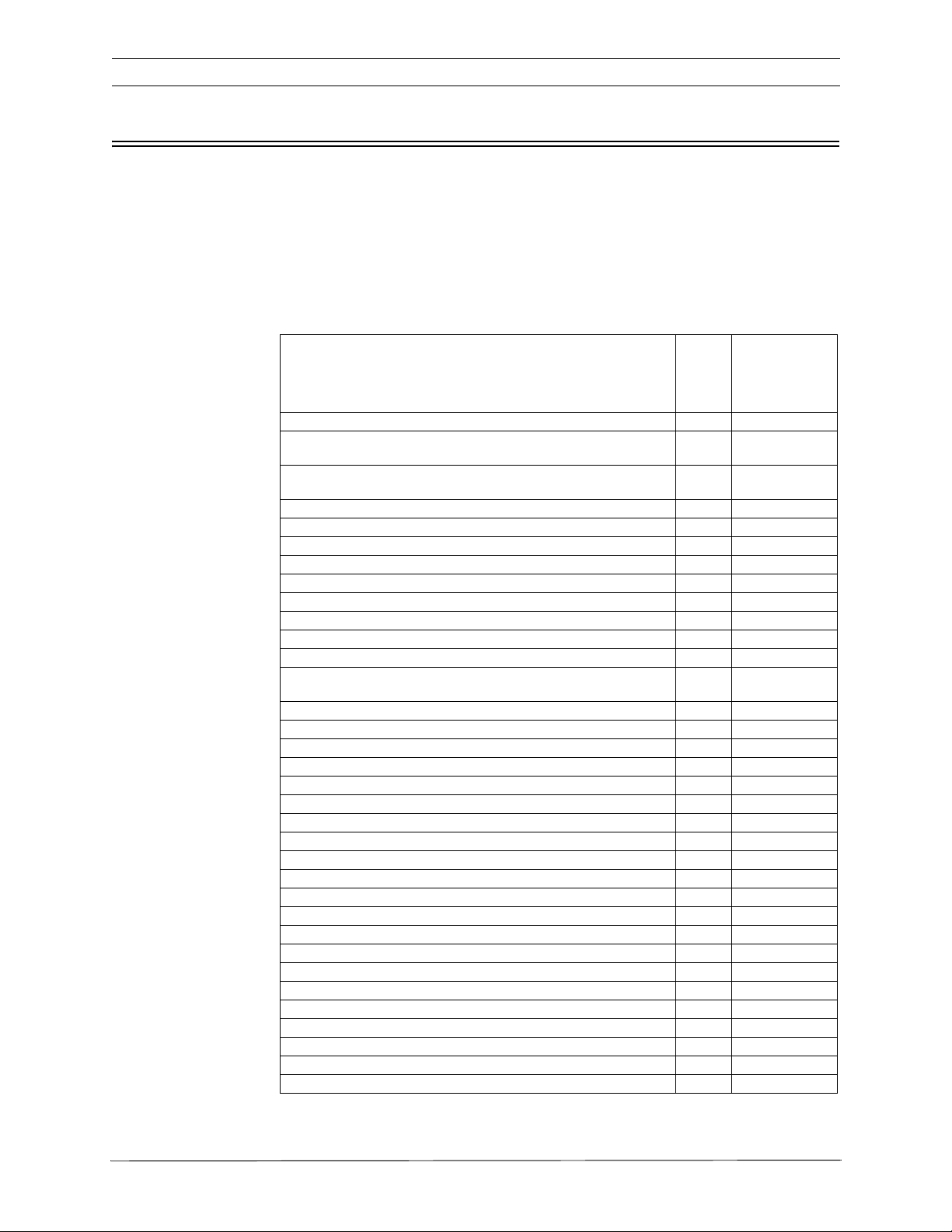

5Allegiant Feature Summary Table

These Allegiant Series systems are available in two (2) operating configurations: a

base system and the base system with an optional PC based software package. The

base system includes features required for most switching/controller systems.

The addition of the optional LTC 8059/00 MCS or optional LTC 8850/00 GUI Software package enables the user to customize the system's configuration using a

menu driven program run on any personal computer using Microsoft

Windows 2000 or Windows XP.

The following TABLE lists available features.

Feature

1. Full camera switching/control on all monitors Y Y

2. Multiple keyboards (up to 16 with LTC 8600; 32 with

LTC 8800)

3. Multiple alarm inputs (up to 512 with LTC 8600; 1024 with LTC

8800)

4. Three (3) user-selectable pre-defined alarm response modes Y Y

5. Full control of on-site receiver/drivers Y Y

6. SalvoSwitching feature Y Y

7. 60 Programmable sequences Y Y

8. Alarm call-up of pre-position scenes Y Y

9. RS-232 Interface ports for computer, logging printer, etc. Y Y

10. Keyboard log-on/log-off function Y Y

11. User-selectable password security Y Y

12. 16-Character camera titles and 12-character monitor titles Y Y

13.User-selected 40 character camera titles using third line of onscreen text

14.User-selectable 2-digit site plus 4-digit camera mode Y Y

15. Format selection time/date format Y Y

16. Local keyboard test function Y Y

17. Table and sequence printout feature Y Y

18. Parameter designation for RS-232 communication Y Y

19. Integral video loss detection N Y

20. Satellite configurations N Y

21. Restrict user/keyboard access to cameras N Y

22. Restrict user/keyboard access to receiver/drivers N Y

23. Restrict user access to keyboard N Y

24. Restrict user/keyboard access to monitors N Y

25. Designate user name and ID number N Y

26. Designate zoned alarm call-ups N Y

27. Powerful alarm response features N Y

28. Designate displayed camera number N Y

29. Designate receiver/driver functions on alarm N Y

30. Program 64 time activated events N Y

31. Designate receiver/driver functions in sequences N Y

32. Broadcast monitor messages N Y

33. Alarm title designation N Y

34. Personal computer displayed monitoring of system status N Y

Base

System

Y Y

Y Y

YN

®

Windows NT®,

With Optional

Allegiant PCBased

Software

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 20

14 | en LTC 8600 | LTC 8800 Series

In addition, these systems provide the capability to control on-site receiver/driver

units and the AutoDome Series of integral pan/tilt/zoom/cameras.

These systems contain a logging printer output port, so an inexpensive RS-232

serial printer or some other form of logging software can be used to capture log

data. This provides a permanent record showing time and date of changes to system

status, such as:

• Incoming alarms

• Acknowledgment of alarms by users

• Loading sequences

• User log-on to keyboard or console port

• Console broadcast message

• Console transfer of system tables

• Activation of time event functions

• Power up reset message

• Video loss message

The printer may also be used to provide a hard copy of all system configuration

Tables and Sequences.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 21

LTC 8600 | LTC 8800 Series en | 15

6System Components

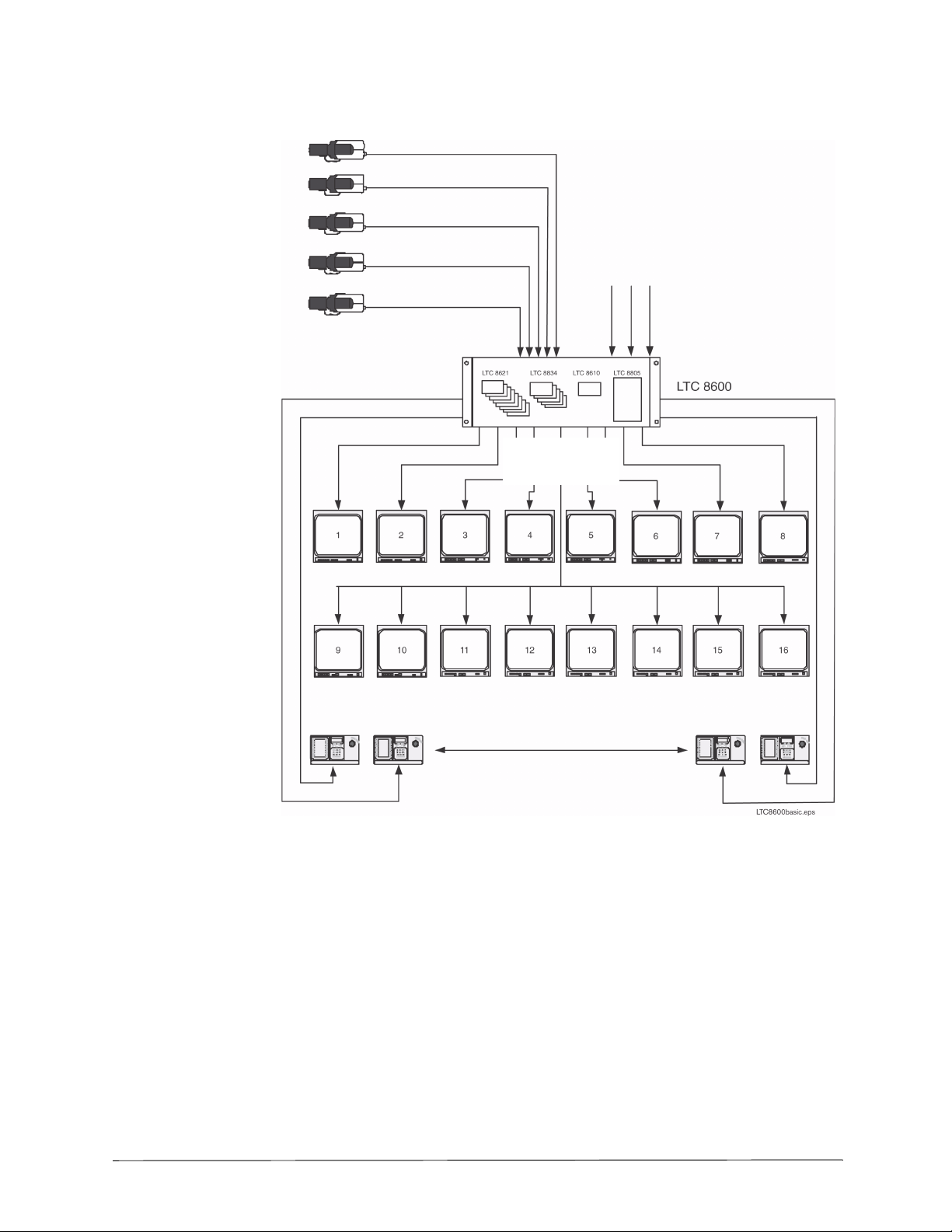

6.1 LTC 8601 Series Systems

• LTC 8601 Series Main CPU Bay

A modular equipment bay which contains the system's microprocessor module

(LTC 8610/01), the power supply module (LTC 8805 Series), and several video

input and video output modules (see below).

• LTC 8621/00 Video Input Module

Individual cards placed in LTC 8601 Series bays to accept inputs from cameras

and other video sources. Each card provides 16 video input channels with

switch selectable terminations.

• LTC 8834/00 Video Output Modules

Individual cards placed in LTC 8601 Series bays to provide video outputs to

monitors and DVRs. Each card provides four (4) video output channels.

• LTC 8600 Series System Capacities

Up to eight (8) video input modules; 16 inputs per module.

Up to four (4) video output modules; four (4) outputs per module.

Total: 128 inputs and 16 outputs.

Satellite configuration input capacity: 1152.

6.2 LTC 8800 Series Systems

• LTC 8801 Series Main CPU Bay

A modular equipment bay which contains the system's microprocessor module

(LTC 8810/01), the power supply module (LTC 8805 Series), and several video

input and video output modules (see below).

• LTC 8802 Series Monitor Expansion Bay

A modular equipment bay which contains a Data Receiver module

(LTC 8816/01), the power supply module (LTC 8805 Series), and several video

input and video output modules (see below). The Monitor Expansion bay is

required in system configurations having more than 32 monitors. The Monitor

Expansion bay can also accommodate up to eight (8) additional keyboards.

• LTC 8821/00 Video Input Module

Individual cards placed in LTC 8801 Series or LTC 8802 Series bays to accept

inputs from cameras and other video sources. Each card provides 32 video

input channels with switch selectable terminations.

• LTC 8834/00 Video Output Modules

Individual cards placed in LTC 8801 Series or LTC 8802 Series bays to provide

outputs to monitors and DVRs. Each card provides four (4) video output channels.

• LTC 8800 Series System Capacities

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 22

16 | en LTC 8600 | LTC 8800 Series

• LTC 8801 Main Bay:

Up to eight (8) video input modules; 32 inputs per module.

Up to eight (8) video output modules; four (4) outputs per module.

Subtotal: 256 inputs and 32 outputs on main bay.

• Monitor Expansion Bay:

Up to eight (8) video input modules (duplicating modules on main bay).

Up to eight (8) extra output modules (providing four (4) additional outputs

each).

Subtotal: 32 extra outputs added on to the main bay's outputs.

• Total:

256 maximum inputs; 64 maximum outputs.

Satellite configuration input capacity: 2304.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 23

LTC 8600 | LTC 8800 Series en | 17

7 System Accessory Components

The Allegiant Series accessory products provide many optional features to the base

system. A brief description of accessory products is provided below. Complete

specification information can be found in respective product data sheets. Applicable accessories are designed to be compatible throughout the Allegiant Series.

7.1 LTC 8540/00 Alarm Interface Unit

The LTC 8540/00 is an alarm gathering unit which accepts up to 64 dry contact closures or logic level inputs from remote sensing devices such as door contacts, PIRs,

etc. and then reports this alarm information to the main CPU bay. Alarm inputs may

be configured in groups of 32 to accept either normally open or normally closed

contacts. The LTC 8540/00 unit provides eight (8) relay outputs which can be used

to drive external alerting devices, DVR's, and other devices.

7.2 LTC 8568 and LTC 8768 Signal Distribution Units

The signal distribution is a main site control code distribution and line driver units

are available for communicating to receiver/drivers, switcher followers, and Allegiant Satellite systems. The LTC 8568/00 Signal Distribution Unit provides 32 separate outputs for driving up to 256 remote devices. Either “star” or “daisy chain”

wiring configurations may be used. The LTC 8768/00 Signal Distribution unit is similar to the LTC 8568/00, except that it provides 64 separate outputs for driving up to

512 remote devices.

7.3 IntuiKey Series KBD-Universal Keyboard

The IntuiKey KBD-UNIVERSAL is a full function keyboard used for control and programming of the Allegiant Series matrix switchers. Backlit LCD screens provide

multi-language display of softkey menus and status information. Integral variable

speed joystick and zoom lens controls are standard for operating fixed or variable

speed pan/tilt/zoom equipped cameras. Both Allegiant RS-485 and Allegiant

RS-232 keyboard protocols are supported.

In addition to the Allegiant Series, the KBD-UNIVERSAL model IntuiKey can be used

to simultaneously control Divar Series DVRs, System4 Series multiplexers, and

access ADIM based DVR control screens.

7.4 KBD-Rack Keyboard Mounting Kit

Rack-mounting kit designed to provide vertical, horizontal, or inclined mounting for

IntuiKey keyboards.

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 24

18 | en LTC 8600 | LTC 8800 Series

7.5 LTC 8555 Series Keyboards

The LTC 8555 Series keyboards are compact, full function keyboards for use with

Allegiant Series matrix switchers. LED readouts display real time system status

information. Includes variable speed joystick and zoom lens controls for operating

fixed or variable speed pan/tilt/zoom equipped cameras. The keyboards are available in the following configurations:

Model Number Top Bezel Graphics Communication Protocol

LTC 8555/00 English RS-485

LTC 8555/01 Icons RS-485

LTC 8555/02 English RS-232

LTC 8555/03 Icons RS-232

The RS-232 model keyboards connect to an Allegiant's console port or to a port provided by an LTC 8712 Console Expander accessory unit. Up to four (4) may be connected to a single LTC 8712 unit. When used with dial-up type phone modems,

these keyboards provide rudimentary dialing capability.

7.6 LTC 8558/00 Keyboard Extension Cable

The LTC 8558/00 keyboard extension cable has a six-conductor extension cable that

carries data/power for remote keyboards up to 30 m (100 ft) away from the main

CPU bay.

7.7 LTC 8557 Series Keyboard Extension Kits

The LTC 8557 Series keyboard extension cable is an interface kit used to remote the

IntuiKey Series or LTC 8555 Series keyboards up to 1.5 km (5000 ft) away from the

main CPU bay. Customer supplied 0.5 mm

9841 or equivalent) required between the main CPU bay site and keyboard site. Kit

provides two (2) junction boxes, interface cable, and appropriate keyboard power

supply.

2

(24 AWG) shielded-twisted pair (Belden

7.8 LTC 8560 and LTC 8561 Series Receiver/Driver Units

These series of on-site receiver/drivers are designed to receive biphase control

code and convert this data into signals for controlling conventional pan/tilt, zoom

lenses, and auxiliary functions. Supplied in an environmentally rated enclosure,

these series of receiver/drivers are available in both basic and full-featured models.

This unit contains integral local test feature, autopan or random scanning, and is

available in several input and output drive voltage versions.

7.9 AutoDome Series

The AutoDome Series comprise an integral camera, a high speed pan/tilt mechanism, a zoom lens, and a receiver/driver system in a compact dome enclosure. Various enclosure mounting options are available for indoor and outdoor applications.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 25

LTC 8600 | LTC 8800 Series en | 19

7.10 LTC 8569, LTC 8570, LTC 8571, LTC 8572 Series Code Merger

Units

These series are control code merger and line driver units used to combine Allegiant

biphase control code from two (up to four with LTC 8570 and LTC 8572 versions)

systems for communicating to AutoDome Series cameras, receiver/drivers,

switcher/followers, and Allegiant Satellite systems. The LTC 8569, LTC 8570 Series

provides 32 separate outputs capable of driving up to 256 remote devices. The

LTC 8571, LTC 8572 Series provides 64 separate outputs capable of driving up to

512 remote devices. Either “star” or “daisy chain” wiring configurations may be

used. The unit will accept signal input either from an Allegiant main CPU bay,

LTC 8568/00 output, LTC 8780 biphase output, or an output from another

LTC 8569, LTC 8570 Series or LTC 8571, LTC 8572 Series unit. Multiple units may be

cascaded to obtain additional outputs.

7.11 LTC 8770 Switcher Follower Series

The LTC 8770 Series is an accessory unit which provides relay contact closures corresponding to cameras displayed on system monitors. The LTC 8770 may be configured to follow manual activations, non-alarmed video, alarmed video, or both. Each

unit provides 24 relay contact outputs. In addition, six (6) functional operating

modes are available, including one user activated test mode.

7.12 LTC 8712 Series Console Port Expander Units

The LTC 8712 Series “expands” an Allegiant system's console port to permit up to

four external computing devices to communicate with the system via RS-232 protocol. Any computing device that can normally communicate directly with an Allegiant

via its RS-232 console port can be used with these port expanders. The external

devices may consist of PCs running the Allegiant system's MCS package, the Allegiant GUI, access control systems, Allegiant RS-232 protocol keyboards, or other

devices utilizing the Allegiant system's Command Console Language (CCL).

7.13 LTC 8713 Alarm Port Expander Units

The LTC 8713 Series interfaces to the alarm port of an Allegiant system to permit

additional LTC 8540/00 Alarm Interface units to be connected. In a LTC 8500 system, two (2) LTC 8540/00 units can be connected to a LTC 8713 Series unit providing up to 128 alarm inputs. In LTC 8600 systems, up to eight (8) LTC 8540 Series

units can be connected to three (3) LTC 8713 Series unit providing up to 512 alarm

inputs. In LTC 8800 systems, up to sixteen LTC 8540 Series units can be connected

to five (5) LTC 8713 Series unit providing up to 1024 alarm inputs.

7.14 LTC 8714, LTC 8715 Series Keyboard Port Expander Units

The LTC 8714 Series and the LTC 8715 Series are port expander accessory units

used to provide additional keyboard capacity for LTC 8600 and LTC 8800 Series Allegiant systems. A single LTC 8714 Series unit can be used to interface up to eight (8)

additional keyboards in an LTC 8600 series Allegiant system. In LTC 8800 systems,

up to three (3) LTC 8714 Series units can be connected to a single LTC 8715 Series

to provide a quantity of 24 “port expanded” keyboards for a total of 32 system keyboards. Alternatively, all 32 system keyboards can be connected using four(4) LTC

8714 Series units and a single LTC 8715 Series unit.

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 26

20 | en LTC 8600 | LTC 8800 Series

7.15 LTC 8780 Series Data Converter Units

The LTC 8780 Series are accessory units that convert the Allegiant system's biphase

control code into RS-232, or converts RS-232 back to biphase code. This provides

the capability of transmitting the control code over conventional RS-232 transmission mediums such as phone modems, fiber optics, microwaves, etc. The unit will

accept the biphase control code generated by an Allegiant main CPU bay, an

LTC 8568/00 Signal Distribution unit, or an output from an LTC 8569, an

LTC 8570, an LTC 8571, or an LTC 8572 Series Code Merger unit.

7.16 LTC 8781 Series Data Converter Units

The LTC 8781 Series are accessory units that decode the Allegiant system's

encoded time/date information generated on the biphase control code line and convert it into an RS-422 GPS format. This time/date information can be used to interface into external time/date inserter products (such as the Kalatel KTS-53-16),

which are designed to be synchronized via a GPS signal.

7.17 LTC 8016/90 Bilinx™ Data Interface Unit

The LTC 8016/90 Allegiant Bilinx Data Interface unit is an accessory used for communicating over-the-coax, with up to 16 Bilinx-capable AutoDome and/or Dinion™

Series cameras. The LTC 8016 provides complete control of pan/tilt/zoom, auxiliaries, and pre-position functions of Bilinx enabled AutoDome Series cameras. In

addition, complete programming of Dinion Series cameras and AutoDomes via their

on-screen menus is supported. Bilinx technology also supports camera-generated

event reporting to the Allegiant. This connection allows remote alarm inputs and

motion event data to be sent by the camera to the Allegiant without the need for

additional wiring between the camera site and the main control location. The LTC

8016 can also be used to transmit Bilinx communications over a number of video

transmission systems. Example devices include fiber optic links and external balun

devices that use CAT5 twisted pair cables for video communication.

7.18 LTC 8785 Series Code Converters

The LTC 8785 Series code converter units are designed for use in older Allegiant

systems that have been upgraded to support 'variable speed' control code protocol.

The LTC 8785 units are used to provide a source of 'fixed speed' control code when

the system is generating the newer 'variable speed' control code preferred by the

AutoDome Series of PTZ cameras. The LTC 8785 would receive the variable speed

control code from the Allegiant via its LTC 8568/00 Signal Distribution unit and convert it into the appropriate fixed speed control code. The 'fixed speed' control code

outputs from the LTC 8785 Series connect to the older TC8561 Series receiver/drivers using the existing field cabling.

Bosch Security Systems, Inc. Instruction Manual F.01U.127.393 | 2.0 | 2009.03

Page 27

LTC 8600 | LTC 8800 Series en | 21

7.19 LTC 8782 Series Code Translator Units

The LTC 8782 Series code translators are accessory units that convert biphase code

to other manufacturers’ control codes, or convert other manufacturers’ codes to

biphase. Many of the most popular protocol codes are supported, including Pelco

®

, American Dynamics®, Sensormatic®, Kalatel®, Diamond Electronics®, and

Vicon

®

Javelin

. Fixed and variable speed codes are supported where applicable.

®

7.20 LTC 8808/00 Series Video Interconnect Panel

The LTC 8808/00 Series video interconnect panel is an optional accessory item

which provides certain Allegiant system models the ability to loop their video

inputs. This patch panel contains 32 BNC connectors on front for external video

connections, and two 16-contact ribbon connectors on the rear. Two (2) 16-conductor ribbon cables are included for interfacing the patch panel to the video looping

connectors found on the rear panel of the equipment bays. The patch panel is one

standard EIA 19-inch rack unit high, and one unit wide.

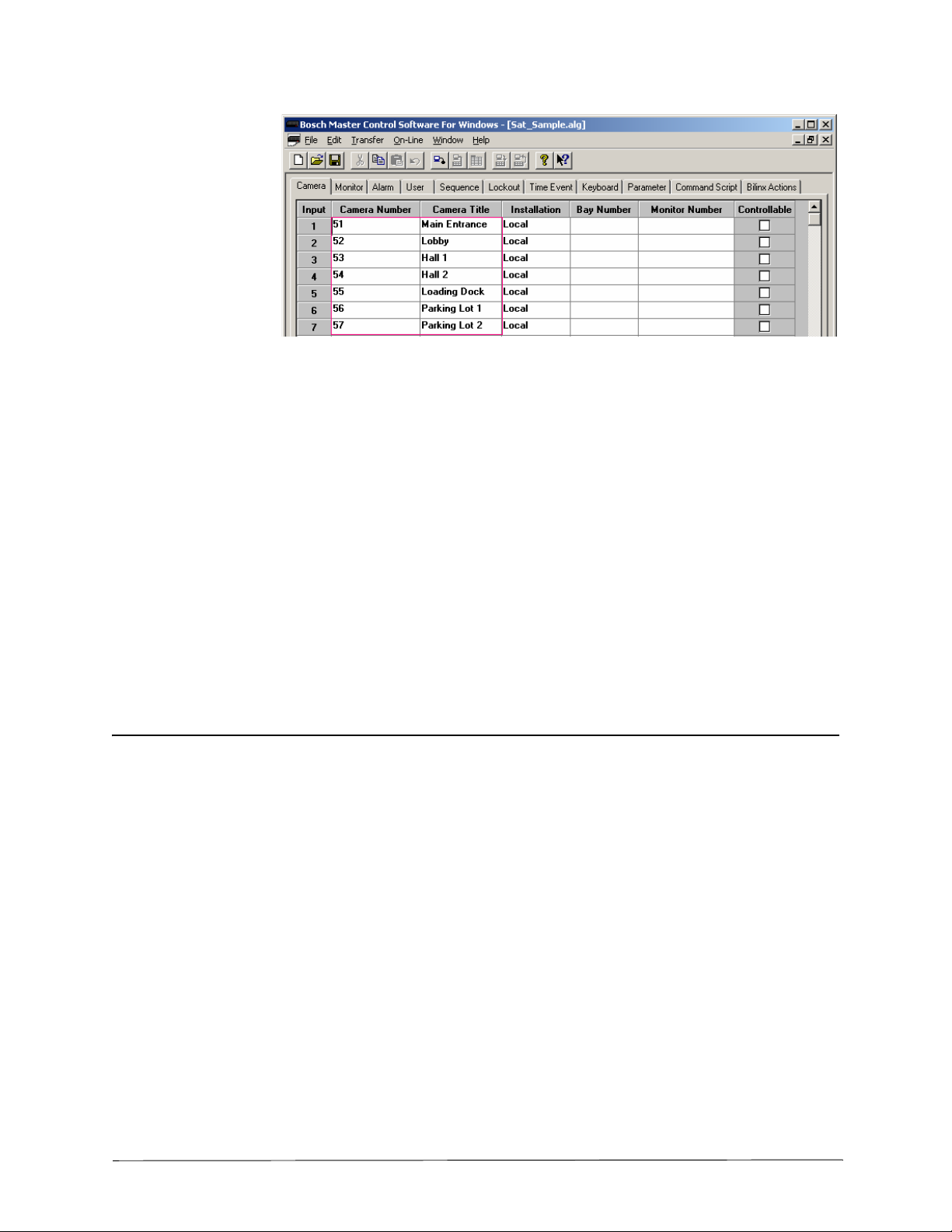

7.21 LTC 8059/00 Master Control Software

,

The Allegiant LTC 8059/00 MCS brings the familiarity of the personal computer to

those who supervise closed circuit television systems. Running on a Windows based

compatible computer, this software is the human interface that makes it quick and

easy to configure an entire Allegiant system.

With the MCS package, users can set and change an Allegiant's system parameters;

program camera sequences; lock cameras, monitors, remotes, and keyboards from

certain users; and perform many other system control features. Users can also view

system activity with real time monitoring of the system status, and if desired, log

this information to a file stored on the hard drive.

7.22 LTC 8850/00 Windows Based Graphical User Interface Software

The LTC 8850/00 GUI Software is a PC-based program designed for complete control and programming of the Allegiant Series of matrix switchers. With a mouse click

on an icon, operators can easily take control of system hardware devices, including

cameras, monitors, and alarms. Jumping from one map to another is easily accomplished using special link icons. System Administrators can easily call-up the

included Allegiant LTC 8059/00 MCS module for entering the Allegiant system's

camera titles, sequences, alarm responses, and many other configuration features.

Communication between the GUI workstations and an Allegiant system can be

made using an RS-232 link, or via a Windows based-PC network.

7.23 SFT-INTSRV Allegiant Integration Software

The SFT-INTSRV software CD contains three (3) distinct software packages that can

be used to integrate external devices with an Allegiant system matrix switcher.

Please refer to the following sections for details:

F.01U.127.393 | 2.0 | 2009.03 Instruction Manual Bosch Security Systems, Inc.

Page 28

22 | en LTC 8600 | LTC 8800 Series

7.23.1 Integration Server

The Integration Server is a versatile software package used to integrate multiple

systems that are not ordinarily compatible with each other. These systems can

include video switchers, point of sale systems, fire/burglar alarms, access control,

or HVAC systems. Devices can be interfaced using any of the following three (3)

methods: serial RS-232 connection, digital I/O card, or directly to an Allegiant

Switcher via the LTC 8059 MCS program. The Integration Server software is programmed to recognize events as they occur in real time from one or more systems,

based upon one of the three (3) integration methods mentioned above. It then

reacts to those events by sending commands to another system or systems.

7.23.2 Virtual Allegiant Satellite Application Software

The Virtual Allegiant Satellite Application (VASA) is Bosch's strategic product that

allows existing Allegiant customers to transition gradually to pure IP technologies

rather than a total and instantaneous replacement. VASA acts as the integration

bridge between an existing Allegiant and the new digital based CCTV system (the

'satellite') that uses digital video encoders and decoders. With VASA, the new IP

technology is totally transparent to the existing Allegiant users who continue to use

their Intuikey CCTV keyboards for video switching and PTZ control on classic analog

monitors.

VASA supports the Allegiant LTC 8100 through the LTC 8900 Series matrix switchers. In addition to PTZ control, VASA provides auxiliary and preposition control of

the IP-based cameras. VASA improves the ROI on existing capital assets, removes

the need for training, and reduces the risk for adopting new technology by incrementally adding to the system. The integration is seamless and the transition is

designed to be imperceptible.

7.23.3 Allegiant Satellite SDK

The Allegiant Satellite Software Development Kit (SDK) is a fully supported set of

libraries, documentation, and samples targeted at PC-based application software

that is used to control 3rd party CCTV matrix systems or manage IP-based digital

video networks. Since the SDK can be used to create customized solutions for

unique, specific problems, customers looking to integrate an Allegiant matrix system with products offered by other manufacturers is readily accomplished. For the

thousands of existing Allegiant customers, it also provides a bridge to integrate or

expand their systems with IP based products gradually rather than a total and

instantaneous replacement.

When operating in an Allegiant satellite system configuration, an Allegiant master

generates switching and PTZ data that is typically used to control a remote Allegiant

satellite matrix. Using the SDK, the video switching commands and PTZ data from

the master system are converted into an ActiveX interface allowing developers to

easily translate this information into formats used to control other original equipment manufacturer's (OEM) systems. The SDK also supports an ability to translate