Bosch HPC Installation, Operation And Maintenance Manual

HPC

Heat Pump Controller

Installation, Operation, and Maintenance Manual

8733819577 (2019/02)

2 |

Heat Pump Controller

CONTENTS

Document Conventions .......................................................3

Key to Symbols............................................................ 3

Safety Warnings..................................................................3

Introduction........................................................................4

Product Description ..................................................... 4

Bosch EasyStart App.................................................... 5

Features..................................................................... 5

Specifications .............................................................5

Loop Pump Control (former Pump Valve Relay Kit) ...........6

Unit Configuration...............................................................7

Settings ..................................................................... 7

Alarm Mode ................................................................ 7

Configurable Hard Lockout............................................ 8

Fan Motor...................................................................8

System Operation ...............................................................9

Timers and Faults ........................................................ 9

Sequence of Operation.................................................9

Fan Operation ...........................................................10

Loop Pump Operation ................................................ 10

Reversing Valve Operation .......................................... 11

Comfort Mode........................................................... 11

Economy Mode.......................................................... 11

Emergency Heating Mode ........................................... 11

Heat Recovery Package (HRP) ..................................... 11

Dehumidification .......................................................12

Latching Mode Operation............................................ 12

Unlatching Mode (Factory Default)............................... 12

Alarm Terminal Wiring ...................................................... 33

Terminology .....................................................................34

Acronyms .................................................................34

Terms.......................................................................34

Decommissioning Information ........................................... 35

Check-Out Sheet...............................................................36

EasyStart Check-Out Sheet................................................ 37

Notes ...............................................................................38

System Protection.............................................................13

Consumer Enhanced Security...................................... 13

Compressor Demand (Y1 Call) ....................................13

Pressure Protection ................................................... 13

Brownout Protection .................................................. 14

Low Loop Water Protection Control (LLWPC) (Boilerless

Control) ................................................................... 14

Water Flow Detection ................................................. 14

Sensor Monitoring ..................................................... 14

Troubleshooting................................................................19

Invalid Thermostat Demands .......................................19

Replacement Parts..................................................... 19

Unit Status LED (Blink Code) Information...................... 20

Heating and Cooling ...................................................20

Heartbeat LED........................................................... 22

Thermistor Resistance Versus Temperature...................22

HPC Board Replacement and Installation ............................24

Contact Information ................................................... 24

Recommended Tools.................................................. 24

Model and Serial Number............................................24

HPC Board Replacement............................................. 24

Wiring Diagrams ...............................................................30

Electrical Box....................................................................32

Thermostat Connections....................................................33

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

DOCUMENT CONVENTIONS

Key to Symbols

Warnings

Warnings in this document are identified by

a warning triangle printed against a gray

background. Keywords at the start of the

warning indicate the type and seriousness

of the ensuing risk if measures to prevent

the risk are not taken.

The following keywords are defined and can be

used in this document:

• DANGER indicates a hazardous situation that,

if not avoided, will result in death or serious

injury.

• WARNING indicates a hazardous situation

that, if not avoided, could result in death or

serious injury.

• CAUTION indicates a hazardous situation that,

if not avoided, could result in minor to

moderate injury.

• NOTICE is used to address practices not

related to personal injury.

Document Conventions | 3Heat Pump Controller

WARNING: This product can expose you to

chemicals including Lead and Lead

components, which are known to the State

of California to cause cancer and birth

defects or other reproductive harm.

For more information go to

www.P65Warnings.ca.gov.

CAUTION: When working on equipment,

always observe precautions described in

the literature, tags, and labels attached to

the unit. Follow all safety codes. Wear

safety glasses and work gloves. Use a

quenching cloth for brazing, and place a fire

extinguisher close to the work area.

Important Information

This symbol indicates important information

where there is no risk to property or people.

SAFETY WARNINGS

IMPORTANT: Read the entire instruction

manual before starting installation.

WARNING: Installation and servicing of this

equipment can be hazardous due to system

pressure and electrical components. Only

trained and qualified personnel should

install, repair, or service the equipment.

WARNING: Before performing service or

maintenance operations on the system, turn

off main power to the unit. Electrical shock

could cause personal injury or death.

8733819577 (2019/02)Heat Pump Controller Subject to change without prior notice

4 | Introduction

INTRODUCTION

Heat Pump Controller

Product Description

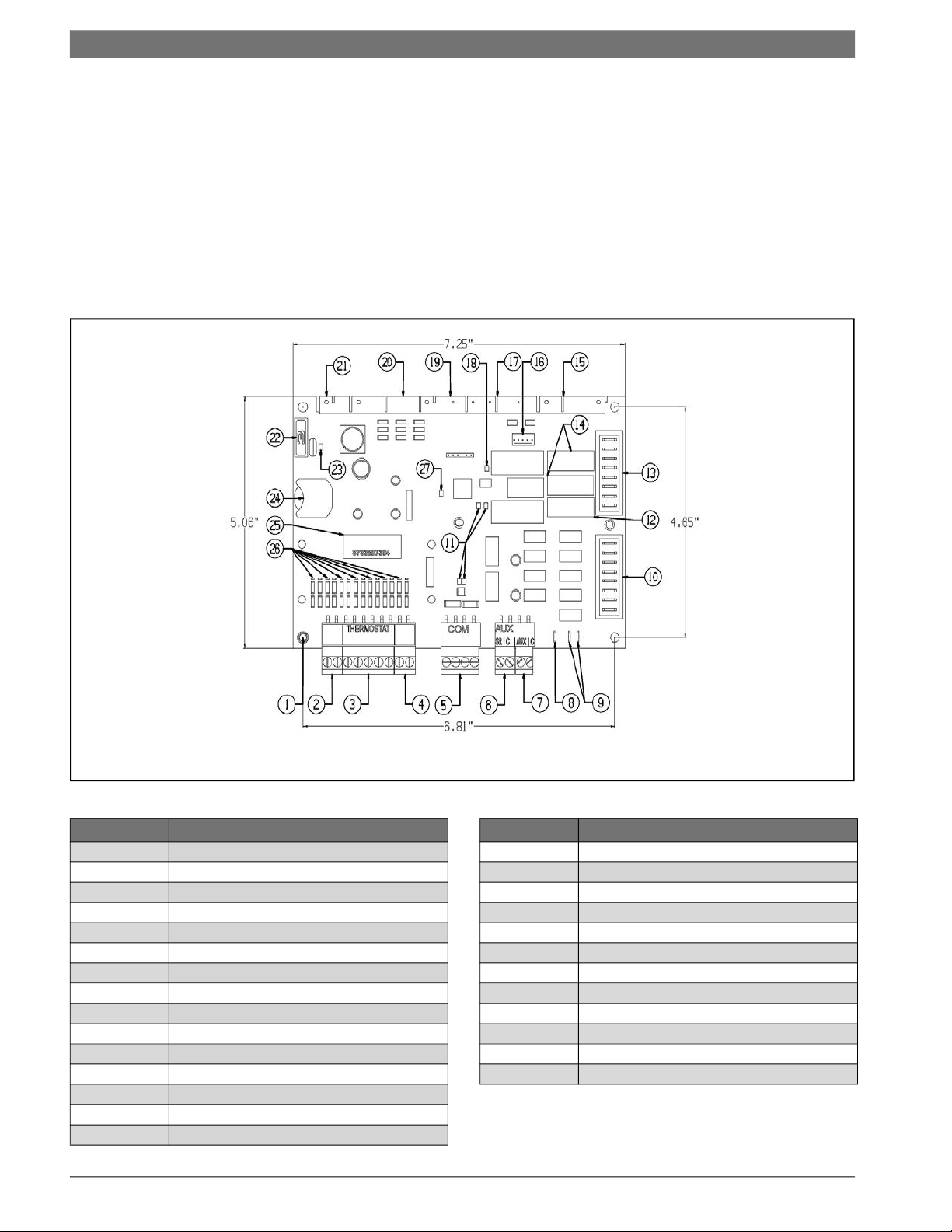

The Heat Pump Controller (HPC) as shown in

Fig. 1, is a Printed Circuit Board Assembly (PCBA)

that interfaces with the thermostat to ensure

desired functionality. It is designed to protect the

condenser coil, evaporator coil, compressor, and

blower motor by monitoring different states of its

switches and sensors.

This device provides time delays to prevent the

system from operating under extreme and

potentially hazardous conditions. The HPC

provides useful information to service personnel

for diagnosing unit operating conditions and faults

when they arise via the Bosch EasyStart app

interface.

Fig. 1 Heat Pump Controller

Item No. Description

1 HPC Ground Standoff

2 Thermostat Power Source

3 Thermostat Control Signals

4 Humidistat Control Signals

5 Comm Port RS 485

6 Electric Heat 1 Output

7 Electric Heat 2 Output

8 Display Output

9 Alarm Output (Dry N.O.)

10 Heat Pump Control Output

11 COMM Port Status LEDs

12 HRP Fuse (1 AMP)

13 High-Voltage Pump Outputs

14 Loop Pump Fuses (5 AMP)

15 P5 Termistor Input Plug

Item No. Description

16 Wi-FI Service Port

17 P4 ECM Motor Control Plug

18 Unit Status LED

19 P3 HRP Termistor Plug

20 P2 Heat Pump Safety Plug

21 P1 24VAC Power Supply Plug

22 Class II Voltage Fuse (3 AMP)

23 Power Status LED

24 Backup Battery (CR2032)

25 PCB Serial Number

26 Thermostat Control Signal LEDs

27 Heartbeat LED

Table 1 Available Fault Snapshots

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

Introduction | 5Heat Pump Controller

Bosch EasyStart App

The Bosch EasyStart app is a digital interface that

allows access to information from the HPC making

commissioning, configuring, and troubleshooting

easier. This application is available in the Google

Play Store, the Apple App Store, as well as the

Bosch Pro HVAC website (

www.boschprohvac.com).

Search for “Bosch EasyStart” in the appropriate

store for your device to download and launch the

app. Once launched, navigate through the legal

information, and then the user guide displays,

explaining how to connect the App and the heat

pump, as well as how to explore the features of the

Bosch EasyStart app.

The Bosch EasyStart app will only work on the

following devices: Android tablets with Android 4.0

operating system or higher, Apple iPads with iOS 8

or higher, and Windows 7.0 or higher laptops/PCs.

For more information refer to the website list in

the Bosch EasyStart app IOM.

Features

Thermostat (24VAC Rated) Digital Inputs

• Fan call (G) signal

• Reversing valve (O) signal

• Compressor Stage One (Y1) signal

• Compressor Stage Two (Y2) signal

• Electric heat Stage One (W1) signal

• Electric heat Stage Two (W2) signal

• Electric heat Emergency (W2/EM) signal

• Dehumidification call (H) signal

Analog Inputs

The following sensors are 10 KΩ @ 77°F

thermistors:

• Freeze Coax Sensor (FZC)

• Freeze Evaporator Sensor (FZE)

• Discharge Air Temperature (DAT)

• Return Air Temperature (RAT)

• Entering Water Temperature (EWT)

• Leaving Water Temperature (LWT)

• Discharge Refrigerant Temperature (DRT)

• Domestic Water Temperature (DWT)

• Auxiliary Output1 Aux Heat control (AUX1)

• Auxiliary Output2 Aux Heat control (AUX2)

• Alarm purposes dry contact normally open (NO)

(Pulse or Constant) (ALM)

Digital Outputs (Rated 208/230 VAC)

• Loop valve/pump control (5 Amp Max)

• Heat recovery pump control (3 Amp Max)

Blower Control Output

PWM 24VDC 80Hz

Service Communications (COMM) Ports (RS-485)

J1 WiFi

Visual Status LED Indicators

• Power status indication

• Alarm status indication

• Controller heartbeat indication

• Thermostat demand indication

• RS-485 RX/TX indication

Voltage Protection

• Surge and transient protection circuitry

• Brownout protection mode

Safeties Monitoring

• High Pressure Switch (HPS)

• Low Pressure Switch (LPS)

• Monitoring of multiple sensors

Certification

ETL 101071399CRT-011

Field Updates

The HPC software can be updated in the field via the

Bosch EasyStart app.

Specifications

Power

24 VAC ± 25%, 50-60 Hz, 2 VA of standby power

consumption (single class II 75 VA or 100 VA option

available).

Physical Description

Printed circuit board and plastic standoffs

Environmental Operating Range

-40°F to 176°F (-40°C to 80°C); 10% to 90% relative

humidity, non-condensing. All controls are conformal

coated for environmental protection.

For Type II (10 KΩ@ 77°F) thermistor

temperature curve, refer to Fig. 12.

Digital Outputs (Rated 24VAC)

• Compressor 1st step control (CC1)

• Compressor 2nd step control (CC2)

• Reversing valve control (RV)

Weight

0.54 lbs. (0.25 Kg)

Overall Dimensions

• 7.25" (width) by 5.06" (height) by 3" (recommended

panel depth)

• 184mm (width) by 129mm (height) by 76mm

(recommended panel depth)

8733819577 (2019/02)Heat Pump Controller Subject to change without prior notice

6 | Introduction

Mounting Hole Dimensions

Four (4) mounting holes in rectangular pattern with

dimensions between them as follows:

• 6.81" (width) by 4.65" (height).

• 173mm (width) by 118mm (height).

WARNING:

Chassis Ground

Ensure metal standoff is properly secured to the

chassis of the unit through a fastener. The HPC

will obtain a chassis ground by way of a metal

standoff connected to both the (C-GND) and (C)

terminals of the Printed Circuit Board (PCB).

Improper grounding could result in potential

electrical shock and/or Equipment malfunction.

Electrical shock could cause personal injury or

death.

Loop Pump Control (former Pump Valve

Relay Kit)

A loop pump control relay has been integrated into

the HPC board. The loop pump control can be used

to energize a field-installed pump or solenoid valve

when there is a call for compressor operation. This

loop pump control relay is used to switch 208/240

VAC signals ON/OFF (depending on the supply

voltages).

Heat Pump Controller

NOTICE: The loop pump control relay output is

208/240 VAC at 5 A; ensure the pump or valve

being connected is rated to this specification.

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

UNIT CONFIGURATION

Settings

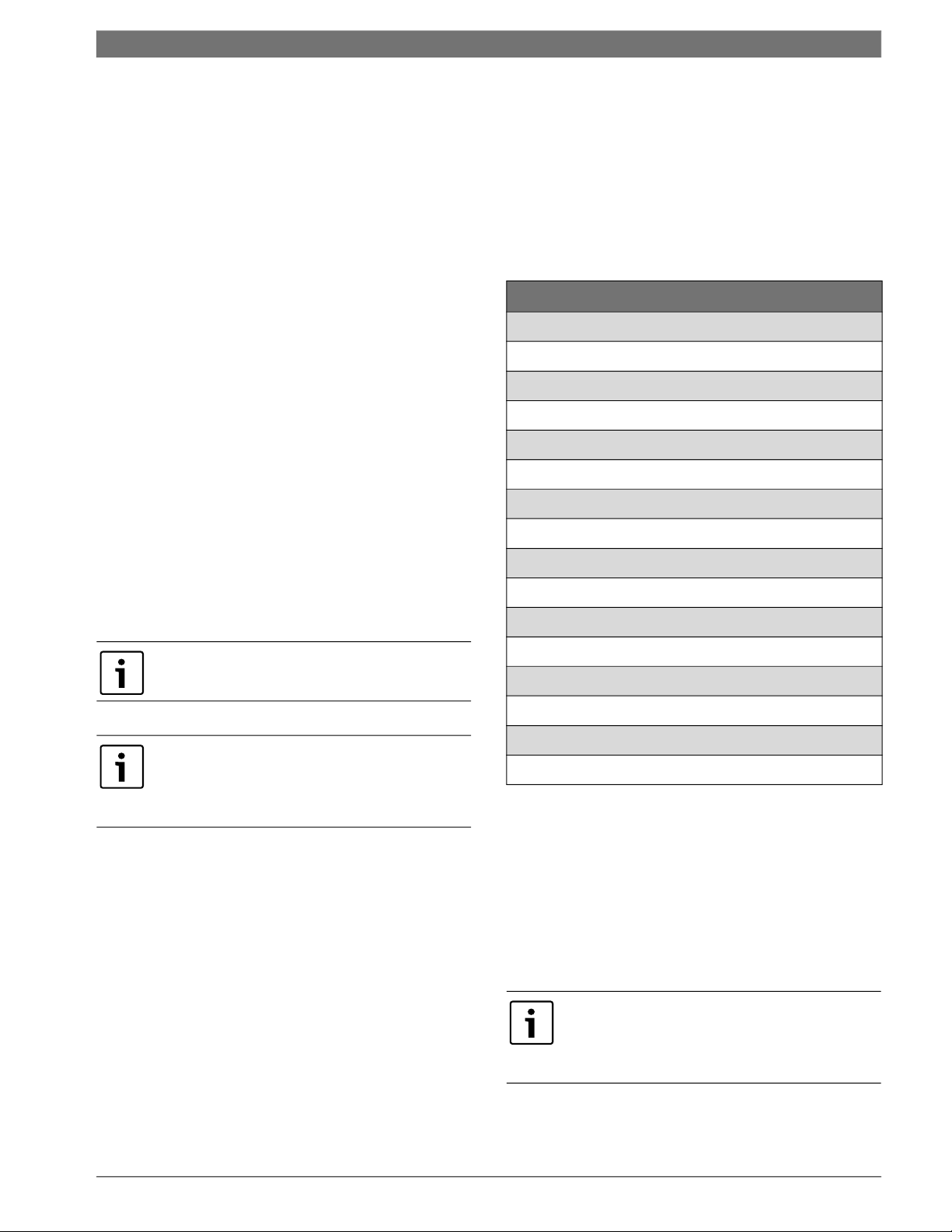

The Bosch EasyStart app is used to configure available features of the HPC as follows:

HPC Settings Default Settings

Freeze Protection Strategy 15°F–26°F 26°F

Cooling CFM per TON 300–450 400 CFM/Ton

Heating CFM per TON 300–450 375 CFM/Ton

Fan Only CFM reduction 50–100% 80%

Dehumidification CFM reduction 15–40% 15%

Heat Recover Package Enabled or Disabled Disabled

Heat Recovery Setpoint 110°F–140°F 120°F

Heat Recovery Sample Rate 2–6 Samples/Hr 3 Samples/Hr

Electric Heat Size None, 5kW, 10kW, 15kW, 20kW None

Low Loop Water Protection Enabled or Disabled Disabled

Unit Configuration | 7Heat Pump Controller

Low Loop Control Setpoint 20°F–50°F 34°F

Loop Pump Compressor Delay 30–240 seconds 30s

Mode of Compressor Operation Comfort or Economy Comfort

Down-Staging Latched or Unlatched Unlatched

Number of Lockouts 2–4 Strikes 3 Strikes

Lockout Reset (Y1) signal or (R) (Y1)

Units of Temperature °F or °C °F

Alarm Type Constant or Pulse Pulse

Date MM/DD/YYYY

Time HH:MM

High Efficiency Mode Enable or Disabled Disabled

Compressor Runtime Reset Write Only

Model Number

(from the Unit Data Plate)

Serial Number

(from the Unit Data Plate) 1234-567-891011-1213141516

SM036-1VTC-FRTADCCMGXXXXXD7HXXX4XXXXSNA

Table 2 HPC Settings

Refer to the “Updating the Firmware and

Configuring Unit Settings” section on page #26

for details on accessing these settings.

NOTICE: Keep the HRP configuration setting

set to disabled if there is no domestic water

supply available.

Alarm Mode

The HPC has a fault alarm that can be configured

(via the Bosch EasyStart app) as constant or

pulsed. Constant configuration will energize and

latch the alarm output. The pulse alarm setting will

allow the alarm relay to pulse the alarm in sync

with the status LED indicator.

8733819577 (2019/02)Heat Pump Controller Subject to change without prior notice

8 | Unit Configuration

Heat Pump Controller

To exit a hard lockout, power must be reset at the

(Y) terminal (factory setting) or (R) terminal

(configurable via the Bosch EasyStart app). The

alarm, display, and status LED indicator outputs

should only pulse the latest fault. Once the latest

fault is cleared, the HPC will pulse for any

remaining faults recorded.

Refer to “Alarm Terminal Wiring” on page #33.

Configurable Hard Lockout

The controller can be configured from two to four

faults for a hard lockout condition (configurable

via the Bosch EasyStart app). If the controller

senses the same fault for the number of times

configured within one hour from the first fault, the

controller will enter a hard lockout. Example:

When configured to four strikes, if the control

experiences four of the same faults within one

hour then the controller will enter a hard lockout.

Clearing a Hard Lockout

To clear a hard lockout condition, power to the (R)

terminal may be reset at the circuit breaker panel,

or the heat/cool call to the (Y1) terminal may be

reset from a connected thermostat (default). The

HPC can be configured for either reset option

using the Bosch EasyStart app.

The controller has a heating CFM/Ton low limit of

400 for electric heat operation. If the effective CFM

is lower than this value the controller will override

the effective CFM with the verified CFM value and

latch it to 400 Cubic Feet per Minute (CFM)/Ton.

The controller has a “Most Efficient Mode”

configuration. The function of this is to enable the

unit to run at the most efficiently-rated CFM values

as tested in our labs.

Fan Motor Table

The Fan motor is specified in the third and fourth

digits of the code string nomenclature.

• SM024 = 2 Ton 2-step unit

• SM036 = 3 Ton 2-step unit

• SM048 = 4 Ton 2-step unit

• SM060 = 5 Ton 2-step unit

• SM070 = 6 Ton 2-step unit

Fan Motor

The installer can modify the total Cubic Feet per

Minute (CFM)/Ton via the Bosch EasyStart app as

shown in the table below.

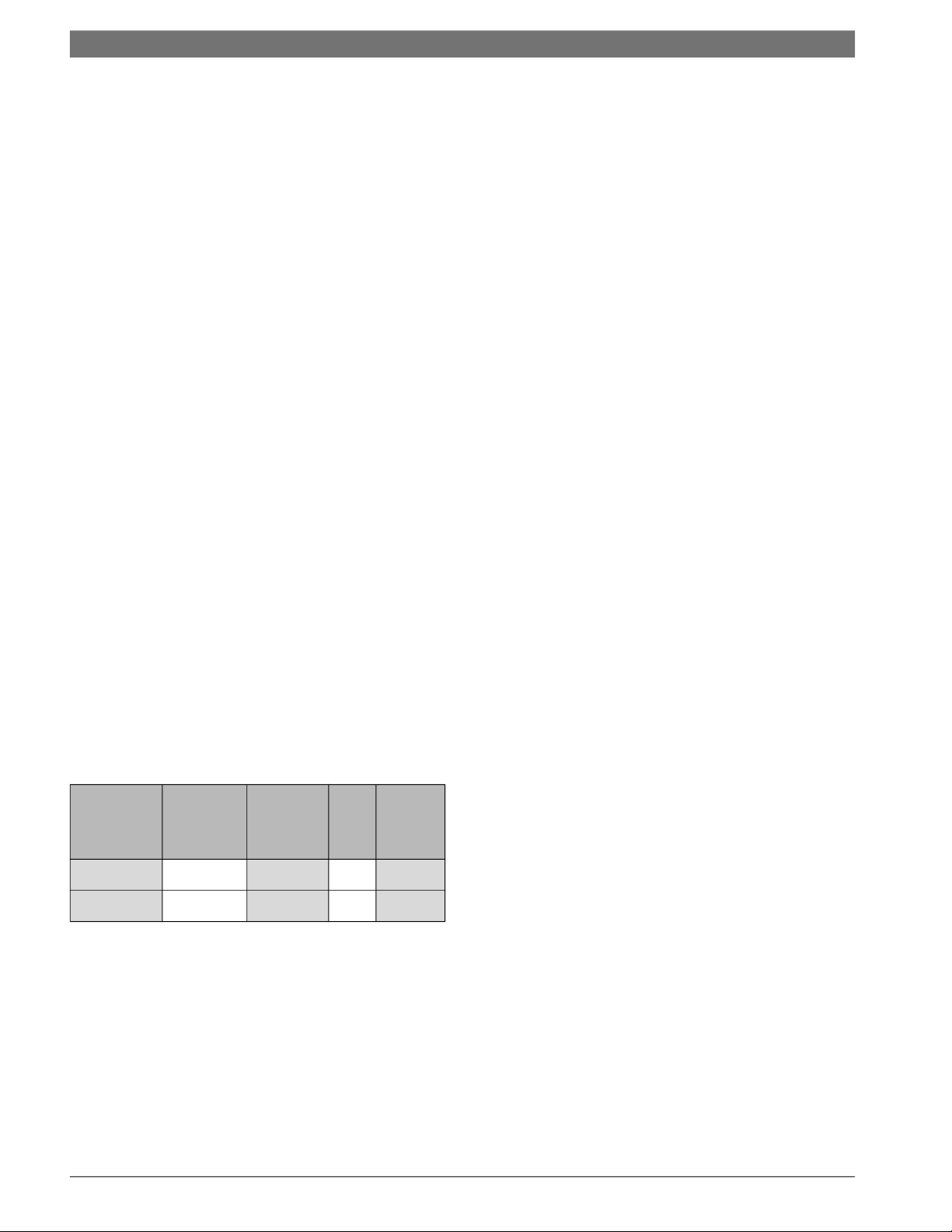

Max

Installer

CFM per

State

Ton

COOLING 450 300 25 400

HEATING 450 300 25 400

Table 3 CFM Configure

The controller calculates the required flow rate

(CFM) based on the unit’s model and size. The

controller has a cooling CFM/Ton lower limit of

270. If effective CFM is lower than this value, the

controller will override the effective CFM with the

verified CFM preventing it from being lower than

270 CFM/Ton. The cooling verified CFM will apply

to the cooling and the dehumidification modes of

the operation.

Min

Installer

CFM per

Ton

Step

Installer

CFM

Default

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

System Operation | 9Heat Pump Controller

SYSTEM OPERATION

Timers and Faults

Random Start-Up Delay (Power)

This delay prevents multiple units sharing the same

electrical circuit or network from starting at the

same time. It ensures that the Heat Pumps

connected to the same electrical circuit do not

demand a high inrush of current simultaneously

when starting up after a power failure. The random

start time delay is in the range of 200–300

seconds. In test mode, the random start time delay

is reduced to 10 seconds. Random Start-Up delay

only runs during start up or after power has been

completely removed. It does not take effect after a

brownout condition.

Test Mode

Test mode decreases all delay timers to 10

seconds. Test mode is only for testing purposes

and serves no function to the end user of the

equipment. In test mode, the alarm relay and

display relays will pulse during both soft lockout

and hard lockout. If a soft lockout alarm is cleared,

both relays will stop pulsing. The controller will

exit test mode after 20 minutes or upon a power

cycle.

Snapshot Record

The controller constantly monitors all thermostat

sensors and thermostat demand values. The

controller also has an additional feature where the

latest fault snapshot will be saved to the

controller. When a new fault occurs the snapshot

will be saved and overwrite the previous snapshot.

The following faults in the table below will be

available in the snapshot record.

Available Fault Snapshots

High-Pressure Hard Lockout Fault

Low-Pressure Hard Lockout Fault

Freeze Coaxial Hard Lockout Fault

Condensate Overflow Hard Lockout Fault

Brownout Voltage

Freeze Evaporator Hard Lockout Fault

Freeze Evaporator Temp Sensor Open

Freeze Coaxial Temp Sensor Open

Freeze Evaporator Temp Sensor Open

High Leaving Water Temperature Fault

Fan Motor Hard Lockout Fault

The test mode command can only be set via the

Bosch EasyStart app.

If the controller is set to “TEST” mode via Bosch

EasyStart app, the safety delays will be reduced

to 10 seconds. The controller will automatically

exit test mode after 20 minutes.

Anti-Short Cycle Delay (ASC)

This feature protects the compressor from short

cycling if the (Y1) call is removed and set or if a

refrigerating circuit level fault is sensed to the

point that the compressor shuts down. The ASC is

300 seconds during normal operation and 10

seconds in test mode. The ASC will not be in effect

during a Random Start-Up delay.

Fan Motor Soft Lockout Fault

Freeze Evaporator Soft Lockout Fault

Freeze Coaxial Soft Lockout Fault

High-Pressure Soft Lockout Fault

Low-Pressure Soft Lockout Fault

Table 4 Available Fault Snapshots

Sequence of Operation

Cooling Mode

Energizing the “O” terminal energizes the unit

reversing valve thus placing the unit into cooling

mode. The fan motor starts when the “G” terminal

is energized.

The fan motor will take 30 seconds to ramp up

to operating speed and will run at fan only rated

air flow as long as there is no call for compressor

or heater operation.

8733819577 (2019/02)Heat Pump Controller Subject to change without prior notice

10 | System Operation

When the thermostat calls for first-stage cooling

(Y1) the loop pump or solenoid valve, if present, is

energized and the first stage of the compressor

capacity starts. The fan ramps up to the first stage

of cooling air flow in 30 seconds.

Heat Pump Controller

When using a 2-cool, 3-heat thermostat both the

W1 & W2 on the Heat Pump and W2 & EM on

the thermostat must be connected together via

a jumper.

Some options will have a built in delay, so

compressor operation is not immediate.

When the thermostat calls for second-stage

cooling (Y2) the second stage (or full compressor

capacity) is initiated. The fan ramps up to full

cooling air flow.

Once the thermostat is satisfied, the compressor

shuts down and the fan ramps down to either

fan-only mode or off over a span of 30 seconds.

Note that a fault condition initiating a lockout will

de-energize the compressor irrespective of

which stage is engaged.

Heating Mode

The first two stages of heating (Y1 & Y2) operate in

the same manner as cooling but with the reversing

valve de-energized. On a call for auxiliary heat

(W1), the fan ramps up to auxiliary heat air flow

immediately and the electric heater package is

energized along with the compressor.

As the thermostat is satisfied, the heaters will shut

off as soon as W1 is de-energized, and the

compressors will remain on until the thermostat

stages are satisfied.

Fan Operation

The fan starts anytime the fan command signal (G)

or a demand for cooling/heating is received on the

thermostat interface block. The fan will run at its

minimum factory speed of 80% in fan-only mode.

The fan remains on during lockouts if there is a

demand from the thermostat. The fan motor will

take 10 seconds to ramp up to operating speed.

The fan will be commanded to run at fan-only air

flow as long as there is no call for mechanical

heating/cooling or electric heating operations.

The fan can be configured via the Bosch EasyStart

app to run in a range of CFM from 300 to 450 in 25

CFM increments. The controller has airflow

profiles (CFM) for both heating and cooling

operations.

Loop Pump Operation

The Loop Pump (LP) energizes 30 seconds

(configurable from 30 seconds to 240 seconds via

the Bosch EasyStart app) prior to compressor

operation during a mechanical heating or cooling

demand. The LP remains on during low loop water

temperature protection and a high Leaving Water

Temperature (LWT) warning. The loop pump stays

off for the following faults and delay timers:

If the unit compressor locks out for any reason

at this time, the electric heaters will continue to

function normally.

Once the thermostat is satisfied, the compressor

shuts down and the fan ramps down either

fan-only mode or off over a span of 30 seconds. If

the thermostat has two different output points,

one for Auxiliary Heat and a different one for

Emergency Heat the two outputs must be

terminated on W1 units equipped with one stage

of electric heat.

• High Pressure Switch fault

• Low Pressure Switch fault

• Freeze Coaxial Coil fault

• Freeze Evaporator Coil fault

• Brownout fault

• Condensate Overflow fault

• Anti-Short Cycle delay

• Flow delay

HPC will command the Loop Pump (LP) output to

energize the pump motor whenever a heating or

cooling command (Y1) is received.

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

System Operation | 11Heat Pump Controller

The Loop Pump output of the HPC will energize the

pump directly. 230 VAC to 208 VAC on the HPC

pump outputs will be present (voltage dependent

on supply).

WARNING: Before performing service or

maintenance operations on the system, turn

off the main power to the unit. Electrical

shock could cause personal injury or death.

Reversing Valve Operation

The Reversing Valve (RV) is energized when the

controller receives a command on the (O)

terminal. The unit will run in cooling mode when

the (RV) is energized and heating when the (RV) is

not energized. The HPC checks for an (RV) demand

every 30 seconds.

Comfort Mode

In comfort mode the controller satisfies demand as

call is presented, regardless of energy

consumption, to satisfy space comfort levels. In

comfort mode, after the first stage of cooling/

heating the system turns on the second stage of

cooling/heating, with a 10-second delay, following

a call for second stage of cooling/heating.

Economy Mode

In economy mode the controller satisfies demand

as call is presented, taking energy consumption

into consideration to operate the compressor. In

economy mode after the first stage of cooling/

heating, the second stage is initiated by calculating

progress of the current state, regardless of a call

for the second stage of cooling/heating. If there is

gradual progress with first stage, the controller

will not initiate second stage of the compressor.

Economy mode is only available if the Discharge Air

Temperature (DAT) sensor is functional.

If the DAT sensor fails, a warning message will

broadcast to the Bosch EasyStart app and

economy mode will be disabled.

Emergency Heating Mode

Emergency heating mode is an electrical heating

feature that is used in place of mechanical heating

when the mechanical heating (Y1 or Y2) is not

available. The unit will initiate the first stage of

electric heat immediately and will start the next

stage of electric heat (stage 2) after a 180-second

delay.

Heat Recovery Package (HRP)

The HRP can be used to heat potable water during

unit operation (heat that would otherwise be

wasted from the compressor discharge gas). The

HRP consists of three major components:

• Double wall, vented refrigerant to water heat

exchanger

• HRP pump

• Control circuit

Conditions for the HRP to operate are as follows:

1. Discharge Refrigerant Temperature (DRT) is at

least 10°F greater than the domestic hot water

temperature (DWT). The DWT set point is

configurable between 110–140°F, via the

Bosch Easy Start app.

2. Loop Pump (LP) and compressor are both

energized.

3. Domestic water temperature drops 2°F below

set point (default is 120°F). The controller will

run the pump until the demanded set point is

satisfied. The pump will run four times/hour via

(configurable from two to six times/hour via

the Bosch EasyStart App) in 90-second

intervals to determine whether or not demand

for hot water is needed.

The temperature of the discharge gas from the

compressor will be monitored once compressors

are energized. Once discharge gas is hot enough to

provide useful heat to the domestic water tank, the

circulating pump will be enabled, drawing water

from the tank, through the HRP heat exchanger

and the depositing the heated water back into the

tank. If the water temperature reaches the set

point (default is 120°F), the circulating pump is

disabled to prevent over heating of the domestic

water. The HRP is provided with an on/off switch

in case the end user desires that the HRP be

inactivated (typically during the winter months

when space heating is most important).

8733819577 (2019/02)Heat Pump Controller Subject to change without prior notice

12 | System Operation

Heat Pump Controller

In case of DWT/DRT sensor failure, the HRP

operation will be disabled.

NOTICE: Keep the HRP configuration setting

set to disabled if there is no domestic water

supply available.

WARNING: Before performing service or

maintenance operations on the system, turn

off the main power to the unit. Electrical

shock could cause personal injury or death.

Dehumidification

During cooling operation only, if the controller

senses a signal on the (H) terminal of the

thermostat interface block the fan CFM output will

be reduced by 15% (adjustable). The fan CFM

reduction percentage is adjustable from 15% to

40% reduction from nominal via the Bosch

EasyStart app.

During latching mode operation, the unit will

fasten the two compressor outputs together until

the demand is satisfied. If the thermostat removes

the second-stage demand, the HPC will keep the

second stage of compressor enabled until demand

is satisfied.

Unlatching Mode (Factory Default)

During unlatching mode the unit will cycle the

compressor outputs according to the thermostat

demand. The unit will downstage from secondstage compression to first stage when the demand

for second stage is dropped by the thermostat (Y2

and Y1 call to only Y1 call).

The controller has a minimum 270 CFM/Ton

requirement. The controller will not allow the

CFM/Ton to fall below this minimum even If the

reduction percentage calls for a lower CFM/Ton

amount.

Latching Mode Operation

The latching feature enforces how a HPC stages

down the multiple stages of heating and cooling. A

WSHP condenser coil uses water as medium for

exchanging heat with the refrigerant. Controlling

the stage down process will result in benefits to

the performance and efficiency of the system. As

the name implies, the maximum demanded stage

is latched on until the thermostat is satisfied at

which time all heating or cooling calls are

terminated. Many thermostats are designed for Air

Source appliances and the medium for exchange

(air) can usually provide heat exchange; however,

for ground loops used in WSHP can become

saturated after long run times. Latching is used in

WSHP applications as a means to “rest” the

ground loop between cooling and heating cycles

thus increasing the capacity for heat exchange.

Performance, efficiency, and comfort provided by

a WSHP will largely be maintained by preventing

the degradation of the loop’s physical heat

exchange properties.

Heat Pump Controller8733819577 (2019/02) Subject to change without prior notice

Loading...

Loading...