Installation instructions ........... 2

Instructions d'installation .............. 16

Instrucciones de instalación .......... 30

HOOD HCP34E51UC,HCP30E51UC,

HCP36E51UC

Hotte aspirante HCP34E51UC, HCP30E51UC,

HCP36E51UC

Campana extractora HCP34E51UC, HCP30E51UC,

HCP36E51UC

Table of Contents

Safety Definitions......................................................... 4

IMPORTANT SAFETY INSTRUCTIONS ..................... 5

General notes .................................................................... 5

Fire Safety .......................................................................... 5

Burn Prevention ................................................................ 6

Child Safety ........................................................................ 6

Cleaning Safety ................................................................. 7

Safe use ............................................................................. 7

Proper Installation and Maintenance ............................ 7

State of California Proposition 65 Warnings ............... 8

Causes for damages ................................................... 8

Protecting the environment ....................................... 8

General notes .............................................................. 8

Fan operation .................................................................... 8

Ventilation line ................................................................... 8

Electrical connection ........................................................ 9

Before You Begin ........................................................ 9

Tools and Parts Needed ................................................. 9

Parts Included ................................................................... 9

Appliance dimensions ................................................... 10

Safety clearances ........................................................... 10

Fan operation .................................................................. 10

Ventilation line ................................................................. 10

Checking the wall ........................................................... 11

Installation Procedure .............................................. 12

Preparing the installation .............................................. 12

Fitting the wall retainer .................................................. 12

Making the ceiling breakthrough ................................ 12

Making the wall breakthrough ..................................... 12

Mounting the back-pressure flap ................................. 13

Mounting the recirculation model

(only for circulating-air mode) ...................................... 13

Connect Electrical Supply ............................................. 14

Attaching flue duct ......................................................... 14

Removing the appliance ............................................... 15

Additional information on products, accessories,

replacement parts and services can be found at

www.bosch-home.com and in the online shop

www.bosch-home.com/us/store

3

Safety Definitions

,

WARNING

This indicates that death or serious injuries may

occur as a result of non-observance of this warning.

,

CAUTION

This indicates that minor or moderate injuries may

occur as a result of non-observance of this warning.

NOTICE: This indicates that damage to the appliance or

property may occur as a result of non-compliance with

this advisory.

Note: This alerts you to important information and/or

tips.

4

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

WARNING

When properly cared for, your new appliance has been

designed to be safe and reliable. Read all instructions

carefully before use. These precautions will reduce the risk

of burns, electric shock, fire, and injury to persons. When

using kitchen appliances, basic safety precautions must be

followed, including those in the following pages.

General notes

Examine the appliance after unpacking it. In the event of

transport damage, do not plug it in.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE THE FOLLOWING:

• Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

• Before servicing or cleaning unit, switch power off at

service panel and lock the service disconnecting

means to prevent power from being switched on

accidentally.

When the service disconnecting means cannot be

locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

WARNING

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING

• Installation work and electrical wiring must be done by

qualified person(s) in accordance w ith all applicable

codes and standards, including fire-rated construction.

• Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow the

heating equipment manufacturer’s gu

standards such as those published by

Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

ideline and safety

the National Fire

• When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

• Ducted fans must always be vented to the outdoors.

This appliance is not intended for operation with an

external clock

Do not use extension cord for installation.

timer or a remote control.

Fire Safety

WARNING

To reduce risk of fire and to properly exhaust air, be sure

to duct air outside. Do not vent exhaust air into spaces

within walls, ceilings, attics, crawl spaces or garages.

WARNING

To reduce the risk of fire, use only metal ductwork.

Always have a working smoke detector near the kitchen.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE:

a. Never leave surface units unattended at high settings.

Boilovers cause smoking and greasy spillovers that

may ignite. Heat oils slowly on low or medium settings.

Always turn hood ON when cooking at high heat.

b.

or when flambeing food (i.e. Crepes Suzette,

Cherries Jubilee, Peppercorn Beef Flambe’).

c.

Clean ventilating fans frequently. Grease should not

be allowed to accumulate on fan or filter.

d. Use proper pan size. Always use cookware

appropriate for the size of the surface element.

Do not flambé under the extractor hood or work with a

naked flame. When switched on, the extractor hood

draws flames into the filter. There is a risk of fire due to

deposits on the grease filter!

CAUTION

For general ventilating use only. Do not use to exhaust

hazardous or explosive materials and vapors.

In the event that personal clothing or hair catches fire,

drop and roll immediately to extinguish flames. Smother

flames from food fires other than grease fires with baking

soda. Never use water on cooking fires.

WARNING

To reduce the risk of fire or electric shock, do not use

this fan with any solid-state speed control device.

5

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

• SMOTHER FLAMES with a c lose-fitting lid, cookie

• NEVER PICK UP A FLAMING PAN - You may be

• DO NOT USE WATER, including wet dishcloths or

• Use an extinguisher ONLY if:

a

Based on “Kitchen Firesafety Tips” published by NFPA.

Whenever possible, do not operate the ventilation system

during a cooktop fire. However, do not reach through fire

to turn it off.

WARNING

RISK OF FIRE

When gas burners are in operation without any cookware

placed on them, they can build up a lot of heat. A

ventilation appliance installed above the cooker may

become damaged or catch fire. Only operate the gas

burners with cookware on them.

WARNING

RISK OF FIRE

During simultaneous use of multiple gas burners, a great

deal of heat is created. A ventilation device located above

it can become damaged or catch fire. Never use two gas

burners together at maximum heat for longer than

15 minutes. One large burner with over 17,000 Btu/ hr

(5 kW) (wok) is equal to the wattage of two gas burners.

WARNING

RISK OF FIRE

Hot oil and fat catch fire fast. Never leave hot oil and fat

unsupervised. Never extinguish a fire with water. Switch off

the cooking position. Suffocate flames carefully with a lid, a

fire blanket or similar.

a

sheet, or metal tray, then turn off the burner. BE

CAREFUL TO PREVENT BURNS. If the flames do not

go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

burned.

towels – a violent steam explosion will result.

- You know you have a Class ABC extinguisher, an

you already know how to operate it.

- The fire is small and contained in the area where it

started.

- The fire department is being called

- You can fight the fire with your back to an exit.

WARNING

RISK OF FIRE

Grease deposits in the grease filter can ignite.

Clean the grease filter at least every two months.

Never operate the appliance without the grease filter.

WARNING

RISK OF FIRE

Grease deposits in the grease filter can catch fire. Never

work with a naked flame near the appliance (e.g.

flambéing). Install the unit near a heat-producing appliance

for solid fuels (e.g. wood or coal) only if there is a closed,

non-detachable cover. There must be no flying sparks.

d

Burn Prevention

WARNING

RISK OF BURNS

The accessible parts get hot during operation. Never touch

hot parts. Keep children away.

Child Safety

When children become old enough to use the appliance, it

is the legal responsibility of the parents or legal guardians

to ensure that they are instructed in safe practices by

qualified persons.

Remove all tape and packaging before using the

appliance. Destroy the packaging after unpacking the

appliance. Never allow children to play with packaging

material.

Do not allow anyone to climb, stand, lean, sit, or hang on

any part of an appliance, especially a door, warming

drawer, or stora

appliance, and the unit may tip over, potentially causing

severe injury.

Do not allow children to use this appliance unless closely

supervised by an adult. Children and pets should not be

left alone or unattended in the area where the appliance is

in use. They should never be allowed to play in its vicinity,

whether or not the appliance is in use.

CAUTION

Items of interest to children should not be stored in an

appliance, in cabinets above an appliance or on the

backsplash. Children climbing on an appliance to reach

items could be seriously injured.

ge drawer. This can damage the

6

, IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

Cleaning Safety

WARNING

Be sure the entire appliance (including the grease filters

and light bulbs, if applicable) has cooled and grease has

solified before attempting to clean any part of the

appliance.

Do not use steam cleaners to clean the appliance.

Safe use

WARNING

Do not repair, replace or remove any part of the

appliance unless specifically recommended in the

manuals. Improper installation, service or maintenance

can cause injury or property damage. Refer to this

manual for guidance. All other servicing should be done

by a qualified technician.

WARNING

RISK OF INJURY

Items placed on the appliance may fall down. Do not place

any objects on the appliance.

Proper Installation and Maintenance

Have the installer show you the location of the circuit

breaker or fuse. Mark it for easy reference.

This appliance must be properly installed and grounded by

a qualified technician. Connect only to properly grounded

outlet. Refer to Installation Instructions for details.

This appliance is intended for normal family household use

only. It is not approved for outdoor use. See the Warranty.

If you have any questions, contact the manufacturer.

Do not store or use corrosive chemicals, vapors,

flammables or nonfood products in or near this appliance.

It is specifically designed for use when heating or cooking

food. The use of corrosive chemicals in heating or

cleaning will damage the appliance and could result in

injury.

Do not operate this appliance if it is not working properly,

or if it has been damaged. Contact an authorized servicer.

Do not repair or replace any part of the appliance unless

specifically recommended in this manual. Refer all

servicing to a factory authorized service center.

CAUTION

Grease left on filters can melt and move into the vent.

CAUTION

Turn power off at breaker before removing a damaged

bulb. Do not touch the bulbs immediately after use. The

bulbs will remain hot for several minutes.

WARNING

Make sure the appliance and lights are cool and power to

the appliance has been turned off before replacing the light

bulb(s). Failure to do so could result in electrical shock or

burns.The lenses (if equipped) must be in place when

using the appliance.The lenses (if equipped) serve to

protect the light bulb from breaking.The lenses (if

equipped) are made of glass. Handle carefully to avoid

breaking. Broken glass can cause an injury.

Hidden surfaces may have

sharp edges. Use caution

when reaching behind or

under appliance. Please use

gloves at all times when

installing this hood.

WARNING

When the hood is operated in exhaust-air mode

simultaneously with a different burner which also makes

use of the same chimney (such as gas, oil or coal-fired

heaters, continuous-flow heaters, hot-water boilers) care

must be taken to ensure that there is an adequate supply

of fresh air which will be needed by the burner for

combustion.

Safe operation is possible provided that the under

pressure in the room where the burner is installed does not

exceed 4 Pa (0.04 mbar).

This can be achieved if combustion air can flow through

non-lockable openings, e.g. in doors, windows and via the

air-intake/exhaust-air wall box or by other technical

measures, such as reciprocal interlocking, etc.

WARNING

Avoid carbon monoxide poisoning - Provide adequate air

intake so combustion gases are not drawn back into the

room.

An air-intake/exhaust-air wall box by itself is no guarantee

that the limiting value will not be exceeded.

NOTE: When assessing the overall requirement, the

combined ventilation system for the entire household must

be taken into consideration. This rule does not apply to the

use of cooking appliances, such as cooktops and ovens.

7

State of California Proposition 65

Warnings

WARNING

This product contains chemicals known to the State of

California to cause cancer, birth defects or other

reproductive harm.

Causes for damages

CAUTION

Risk of damage due to corrosion. Always turn

appliance on when cooking to avoid condensation

buildup. Condensation can lead to corrosion

damages.

Always replace defective bulbs immediately to avoid an

overload of the remaining bulbs.

Protecting the environment

Unpack the appliance and dispose of the packaging in line

with environmental requirements.

General notes

Fan operation

Note: Ventilation may not exit through an already

operational smoke or exhaust chimney, nor a duct used for

ventilating furnace installation areas.

• If the ventilation is intended to pass through a smoke or

exhaust that is not in operation, the responsible area

heating inspector must give approval.

• If the ventilation passes through an external wall, use a

telescope wall sleeve.

Ventilation line

Note: The manufacturer does not assume any warranty for

complaints attributable to the pipe section.

• The device achieves its optimum performance by

means of a short, straight exhaust air pipe and as large

a pipe diameter as possible.

• The optimum extraction performance is not achieved

and fan noise is increased if exhaust air pipes are long

and rough and if there is a large number of pipe bends

or diameters less than 5 15/ia" (150 mm).

Risk of damage due to ingress of humidity into the

electronic circuitry. Never clean operator controls with a

wet cloth.

Surface damage due to incorrect cleaning. Clean stainless

steel surfaces in the grind direction only. Do not use any

stainless steel cleaners for operator controls.

Never use strong or abrasive cleaning agents, since they

can cause surface damage.

of damage from condensation back flow. Install

Risk

exhaust vent at a slight downward slope away from the

appliance (1° slope).

• The pipes or hoses for laying the exhaust air line must

consist of non-combustible material.

Round pipes

An inner diameter of 5

(120 mm), is

Flat ducts

The inner cross-section must correspond to the diameter

of the round pipes.

15

/16" (150 mm) approx. 27 1/2 sq in (177 cm2)

Ø 5

3

Ø 4

/4" (120 mm) approx. 17 1/2 sq in (113 cm2)

recommended.

15

/16" (150 mm), but at least 4 3/4"

• Flat ducts should have no sharp deflections.

• Use sealing strip for deviating pipe diameters.

8

Electrical connection

, WARNING

RISK OF ELECTRIC SHOCK

Parts inside the appliance can have sharp edges. The

connection cable can be damaged. Do not bend or

pinch connection cables during installation.

Before connecting the appliance, check the household

installation. Ensure sufficient fuse protection of the

household installation. The voltage and frequency of the

appliance must match the electrical installation (see rating

plate).

The appliance complies with protection class 1 and must

only be operated in conjunction with a protective

conductor terminal.

An all-pole isolating switch with at least a 3 mm contact

gap must be fitted in the installation. This must remain

accessible after installation.

Only a qualified electrician who takes the appropriate

regulations into account may lay or replace the connecting

cable.

Follow all valid standards and laws.

Ensure that the electrical connection meets the

requirements of the latest version of all applicable

standards and laws in the appropriate country, especially

the following standards: National Electrical Code, ANSI/

NFPA 70*, or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No.0-M91**.

Have a qualified electrical technician check the grounding

of the appliance.

Do not ground with a gas line.

No fuse protection in the neutral or grounding circuit. Keep

the installation instructions. Only connect the appliance

with a copper conductor. If possible, connect the

appliance to a metal cable guide directly to the fuse box.

Ensure that the wire diameter meets the requirements of

the latest version of all applicable standards and laws in

the appropriate country, especially the following

standards: National Electrical Code, ANSI/NFPA 70*, or

CSA Standards C22.1-94, Canadian Electrical Code,

Part 1 and C22.2 No.0-M91**.

Put a protecting hose that is listed in the U.L. or C.S.A. on

both ends of the connecting cable, that is, on the

appliance and on the fuse box.

For copies of the standards listed, contact:

* National Fire Protection Association Batterymarch Park

Quincy, Massachusetts 02269

** CSA International 8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Before You Begin

Tools and Parts Needed

Measuring tape

Pencil

Phillips screwdriver (Posidrive) #2

Drill with the following bits: 5/16" (7.9 mm) and 3/8"

(9.5 mm)

Spirit-level

Aluminum tape (DO NOT use insulating tape)

Exhaust channel (configuration depends on the

installation situation)

Additional sheet metal screws (if necessary for

installation of the exhaust air duct)

Saw

Parts included

Extractor hood with fan, back-pressure flap

Lamp, already installed

Metal grease filter

Flue duct

Drill template

1x angle bracket for the flue duct

Instruction manual and installation instructions

6x screws, 5x45 mm

8x screws, 4.2x8 mm

6x hollow wall plugs, 8x40 mm

Torx adapter, 10 & 20

9

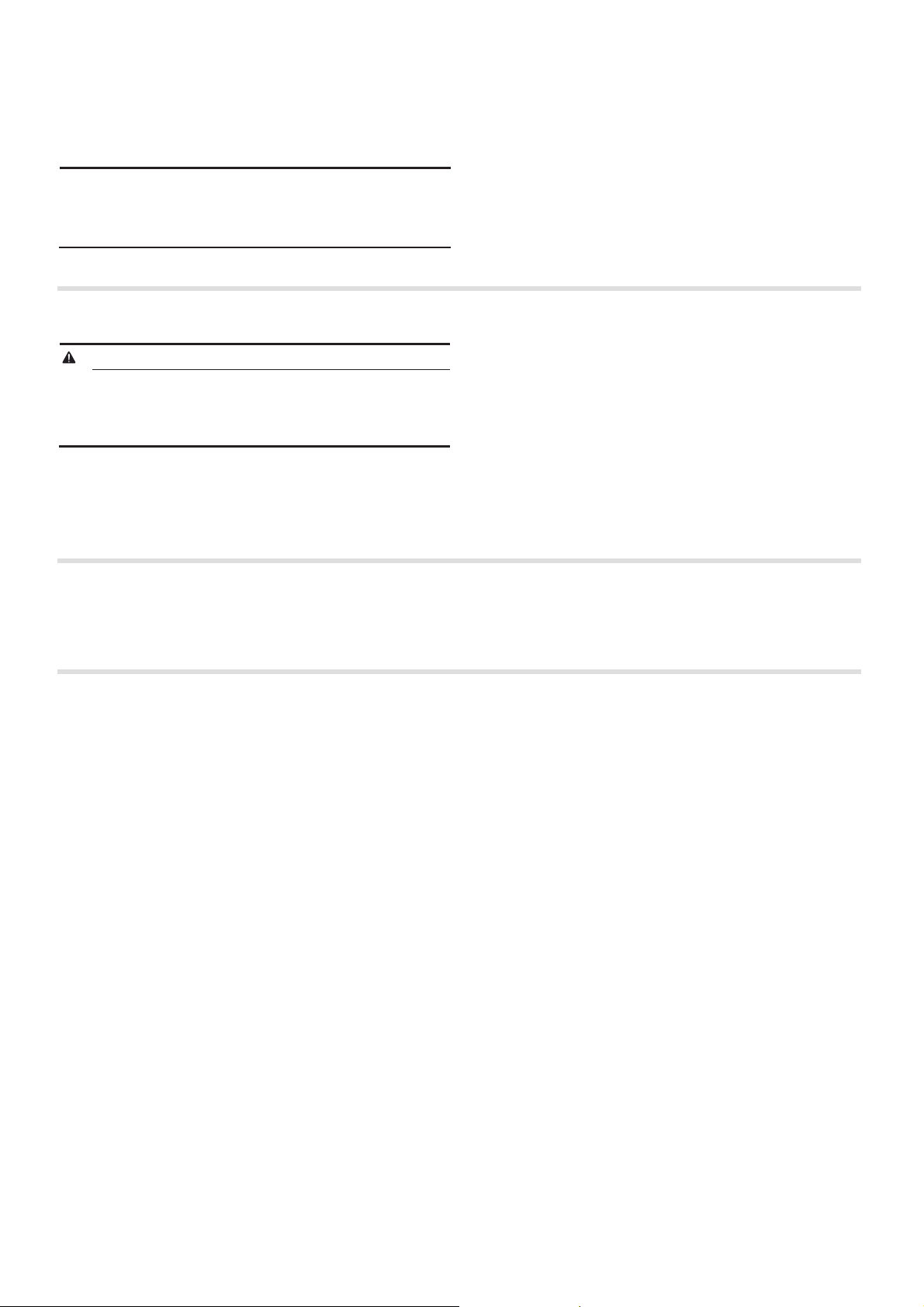

Appliance dimensions

24” (609 mm)

30” (762 mm)

36” (914 mm)

Electrical cooktop

Gas cooktop

27"(686

A Only for circ

*Max. 42 9/16" (1081 mm)

*Min. 28 1/4" (718 mm)

Only for ducted operation:

*Max. 38 7/8" (988 mm)

*Min. 24 9/16" (625 mm)

ulating-air mode:

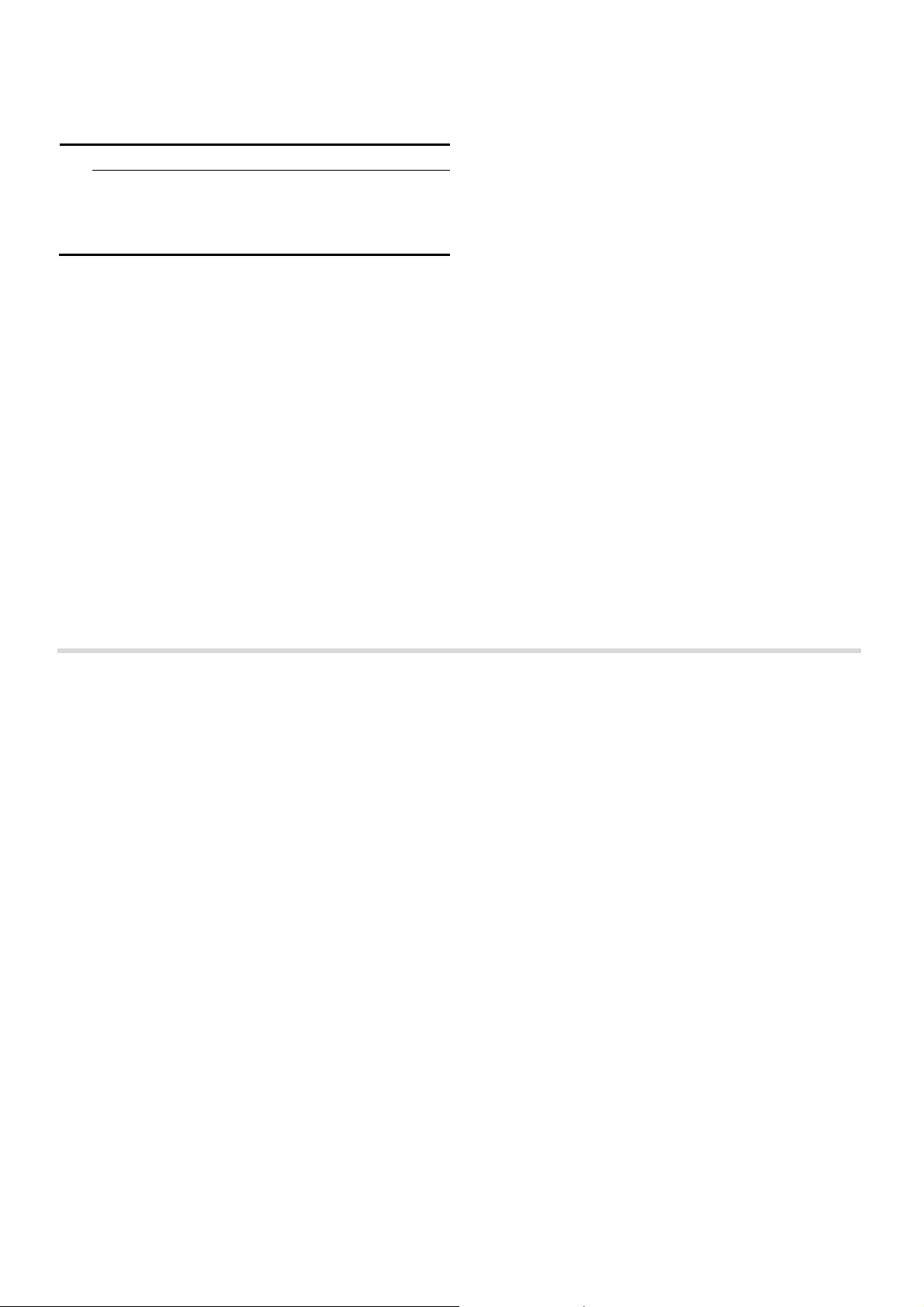

Safety clearances

WARNING

RISK OF FIRE

ase deposits in the grease filter can catch fire. The

Gre

given safety clearance must be observed to avoid

heat buildup. Observe the specifications for your

cooking appliance. If gas and electric cooktops are

used together, the largest given clearance applies.

The appliance may only be installed directly next to a

cabinet or wall on one side. The wall or cabinet

clearance must be at least 1/16" (2 mm).

The clearance between the shelf on the cooktop and the

bottom of the extractor hood may not be less than 24"

(610 mm) in the case of electric cooktops and 30"

(760 mm) in case of gas or combined ranges.

If the installation instructions for the gas cooking appliance

specify a larger distance, this must be taken into account.

Fan operation

Note: Ventilation may not exit through an already

operational smoke or exhaust chimney, nor a duct used for

rnace installation areas.

ventilatin

g fu

If the ventilation is intended to pass through a smoke or

exhaust that is not in operation, the responsible area

heating inspector must give approval.

If the ventilation passes through an external wall, use a

telescope wall sleeve.

Ventilation line

Note: The device manufacturer does not assume any

warranty for complaints attributable to the pipe section.

The ventilation opening and the exhaust air ducts must

be made

The device

means of a short, straight exhaust air pipe and as large

a pipe diameter as possible.

As a result of long rough exhaust air pipes, many pipe

bends or too-small diameters, the optimum extraction

performance is not achieved and fan noise is

increased.

The pipes or hoses for laying the exhaust air line must

consist of non-combustible material.

Sm

installation.

Seal the connection points of the pipes appropriately.

according to the local circumstances.

achieves its optimum performance by

ooth the connection area of the pipes before

10

Round pipes

An inner diameter of 0 8" (200 mm) is recommended.

Flat ducts

The inner cross-section must correspond to the diameter

of the round pipes.

Ø 8" (200 mm) approx. 50.3 inches

Flat ducts should have no sharp deflections.

Use sealing strip for deviating pipe diameters.

2

(324 cm2)

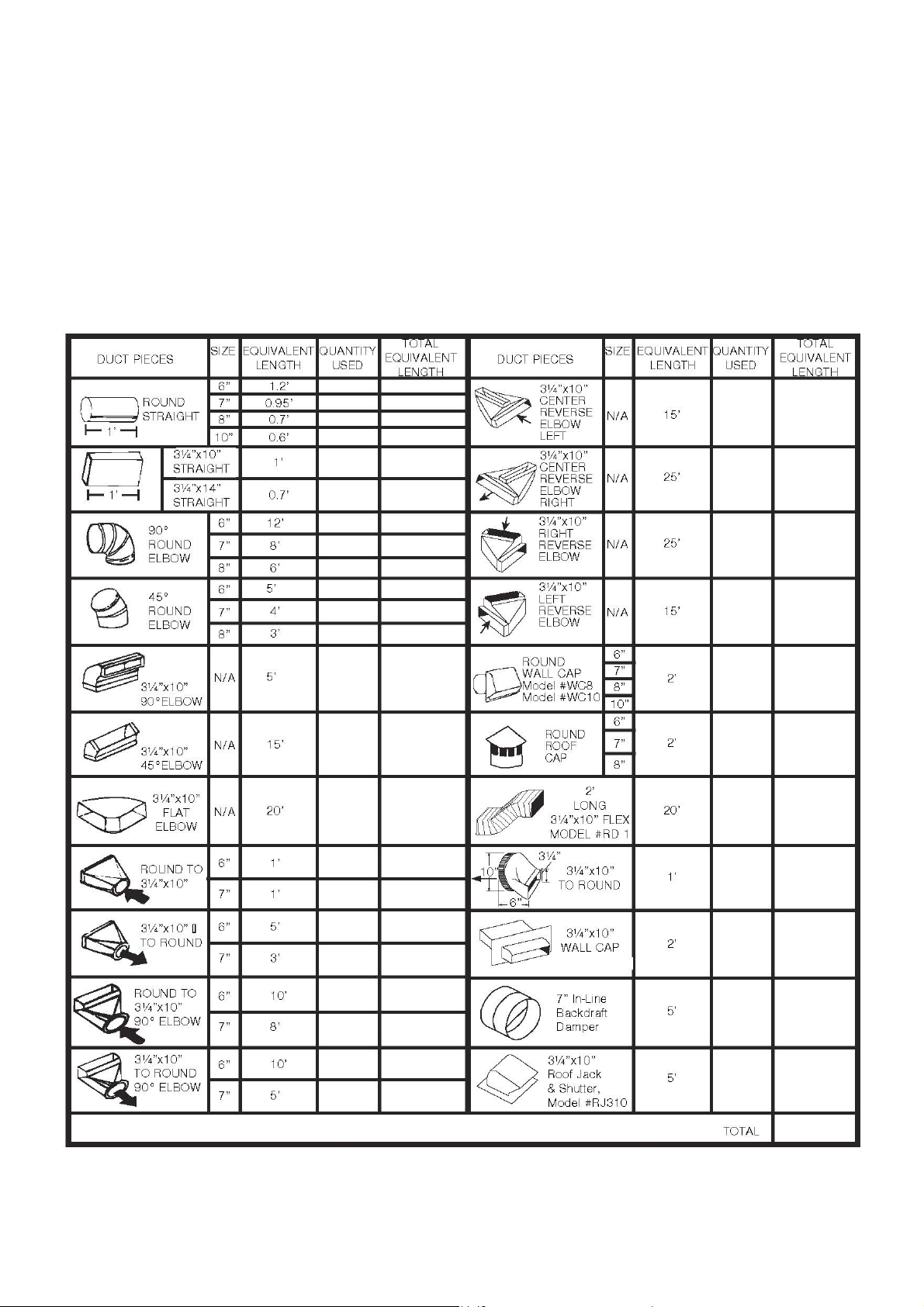

Ventilator Performance Calculation

Checking the wall

The wall must be level, vertical and adequately load-

bearing.

The depth of the bore holes must be the same length

as the screws. The wall plugs must have a secure grip.

The enclosed screws and wall plugs are suitable for

solid brickwork. Suitable fasteners must be used for

other structures.

11

Installation Procedure

The ducting from this fan to the outside of the building has

a strong effect on the air flow, noise and energy use of the

fan. Use the shortest, straightest duct routing possible for

best performance, and avoid installing the fan with smaller

ducts than recommended. Insulation around the ducts can

reduce energy loss and inhibit mold growth. Fans installed

with existing ducts may not achieve their rated airflow.

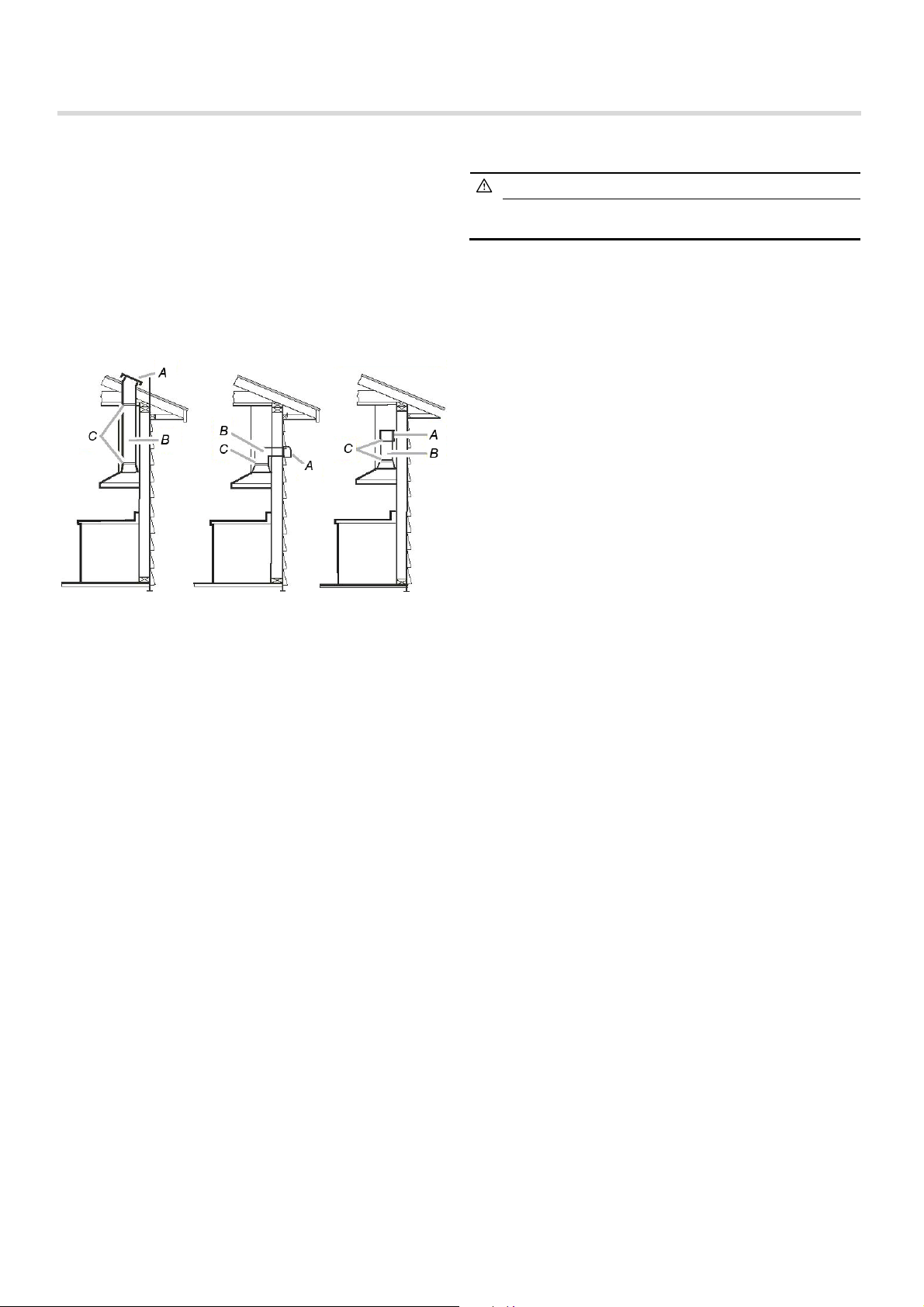

Roof Venting Wall Venting Non-Vented*

(Recirculating)

A. Roof cap

B. 8" (20.3 cm)

round vent

C. Seal duct joints

with duct tape/

caulk

*The recirculating version are neither Energy Star nor HVI certified.

Ensure duct joints and exterior penetrations are sealed

with caulk or other similar material to create an air-tight

path and to minimize building heat loss and

reduce the potential for condensation.

Place/wrap insulation around duct and/or fan to in order to

minimize possible condensation buildup within the duct,

building heat loss and gain.

A. Wall cap

B. 8" (20.3 cm)

round vent

C. Seal duct joints

with duct tape/

caulk

A. Diverter

B. 8" (20.3 cm)

round vent

C. Seal duct joints

with duct

tape/caulk

gain and

CAUTION

Ensure that there are no electric wires, gas or water

pipes in the area where holes are to be made.

Preparing the installation

1. Mark a vertical center line on the wall from the ceiling

to the lower edge of the extractor hood.

2. Align the drill template on the center line and the

bottom edge of the extractor hood and glue on.

3. Mark positions for the screws and the contour of the

attachment area.

4. Mark holes for the flue's angle brackets. The center of

the angle bracket is marked with a hole. Place the

angle brackets in the center of the center line, align

them horizontally and mark the positions

of the holes.

Fitting the wall retainer

1. Drill holes with Ø 5/16" (7.9 mm) for the angle bracket.

2. Press in the wall plugs flush with the wall.

3. Screw screws (5x34 mm) into the wall plugs by hand in

order to spread the plugs apart.

4. Unscrew screws.

5. Screw on the angle bracket for the flue duct.

Making the ceiling breakthrough

1. Using a spirit level, extend the center line of the drill

template to the ceiling.

2. Mark the ceiling breakthrough (Ø 8 1/2" (216 mm)) at

least 4 5/8" (117 mm) away from the

wall.

Making the wall breakthrough

1. Using a spirit level, extend the center line of the drill

template to the ceiling.

2. Depending on the curved section of the wall

breakthrough (Ø 8 1/2" (216 mm)) mark at least

26 1/2" (660 mm) above the bottom edge of the

extractor hood.

12

Mounting the extractor hood on the wall

, WARNING

RISK OF INJURY

The appliance is heavy. To move the appliance,

2 people are required. Use only suitable tools and

equipment.

1. Initially remove the protective foil from the back of the

appliance and, following installation, remove foil

completely.

2. Mark the upper holes on the wall.

Note: Ensure that the holes are horizontal and aligned

centered on the center line.

3. Drill the upper holes. Adhere to a distance of 1/4"

(6 mm) between the wall and screw head.

4. Remove grease filters.

5. Hang the extractor hood on the upper screws on the

wall.

6. Mark holes for the lower holes.

7. Remove the extractor hood from the wall.

8. Drill the lower holes.

9. Hang the extractor hood on the upper screws on the

wall.

10. Tighten the upper and lower screws by hand.

Connecting the air extractor (only for

ducted operation)

Note: If an aluminum pipe is used, smooth the connection

area beforehand.

1. Attach exhaust air pipe and seal.

2. Check whether the back-pressure flap works.

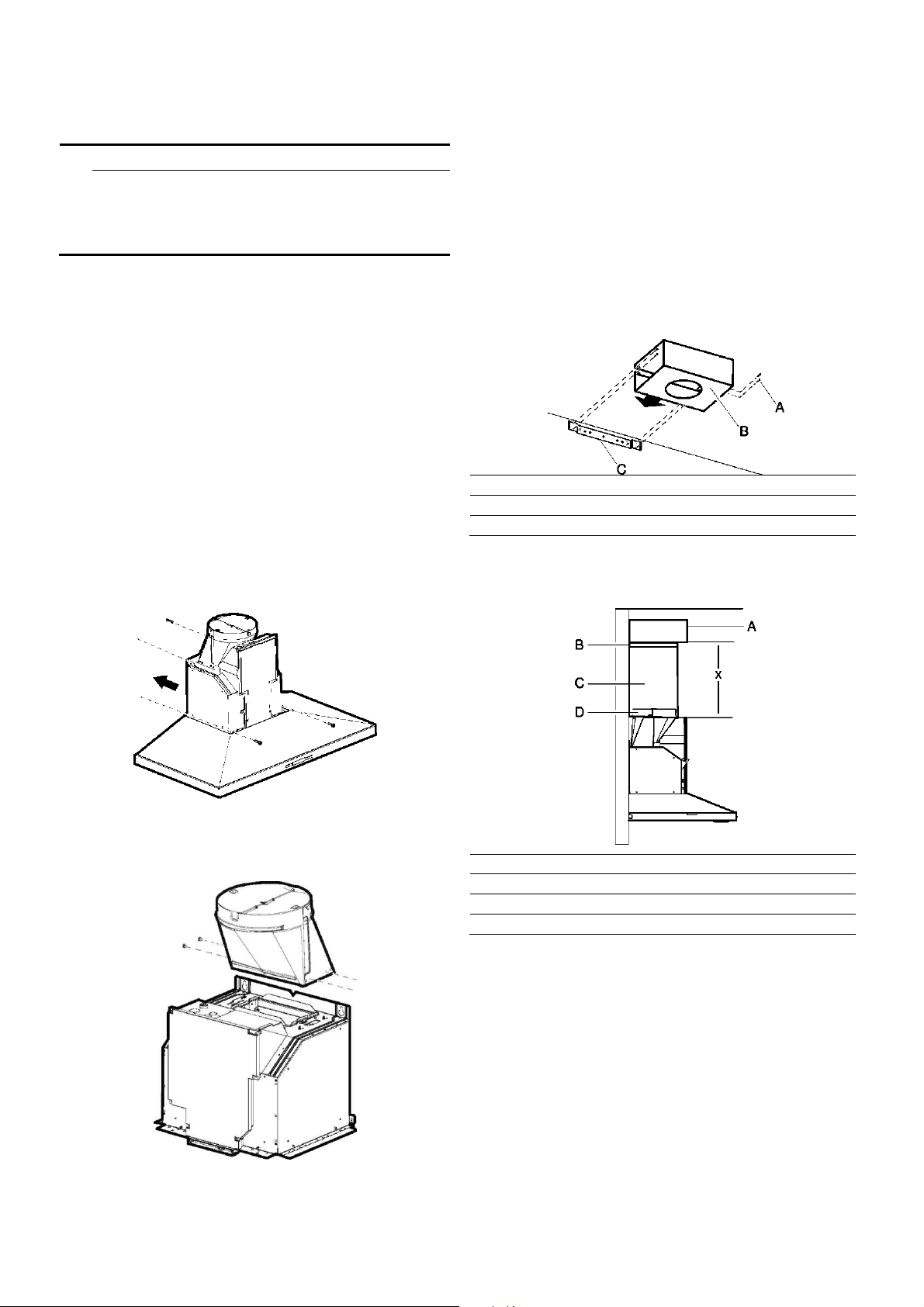

Mounting the recirculation model (only

for circulating-air mode)

1. Use 4 screws (4x8 mm) to screw the housing to the

angle bracket.

A Screws

B Recirculation Module

C Angle bracket

2. Measure the distance (x) between the bottom edge of

the housing for the recirculation module and the bottom

edge of the back-pressure flap.

Mounting the back-pressure flap

Using 4 screws (4x8 mm), attach the back-pressure flap to

the extractor hood.

A Recirculation Module

B Clamps

C Flue Duct

D Exhaust Air Duct

3. Shorten the exhaust air pipe to the length measured.

4. Remove the recirculation module.

5. Push the exhaust air pipe onto the bottom side of the

recirculation module.

6. Position the recirculation module with exhaust air pipe

over the air extraction duct of the extractor hood.

7. Use 4 screws to fasten the recirculation module to the

angle bracket.

8. Secure connections with clamps.

13

Connect Electrical Supply

, WARNING

RISK OF ELECTRIC SHOCK

Before wiring the appliance, interrupt the main

electrical circuit at the electrical control cabinet. A

circuit with 120 VAC, 15 or 20 Ampere is required.

Grounding notes: this appliance is equipped with a

distributor box with 3 cables. Use the green-yellow

cable for grounding the appliance. Connect the greenyellow cable to the grounding cable on the house

connection to prevent electric sthock. Do not under

any circumstances damage or remove the greenyellow cable. Non-adherence can cause deadly

injuries or electric shock.

1. Remove the left cable passage and the cover of the

motor controller. Fasten the connecting piece for the

installation pipe (listed in cULUS) to the cable passage.

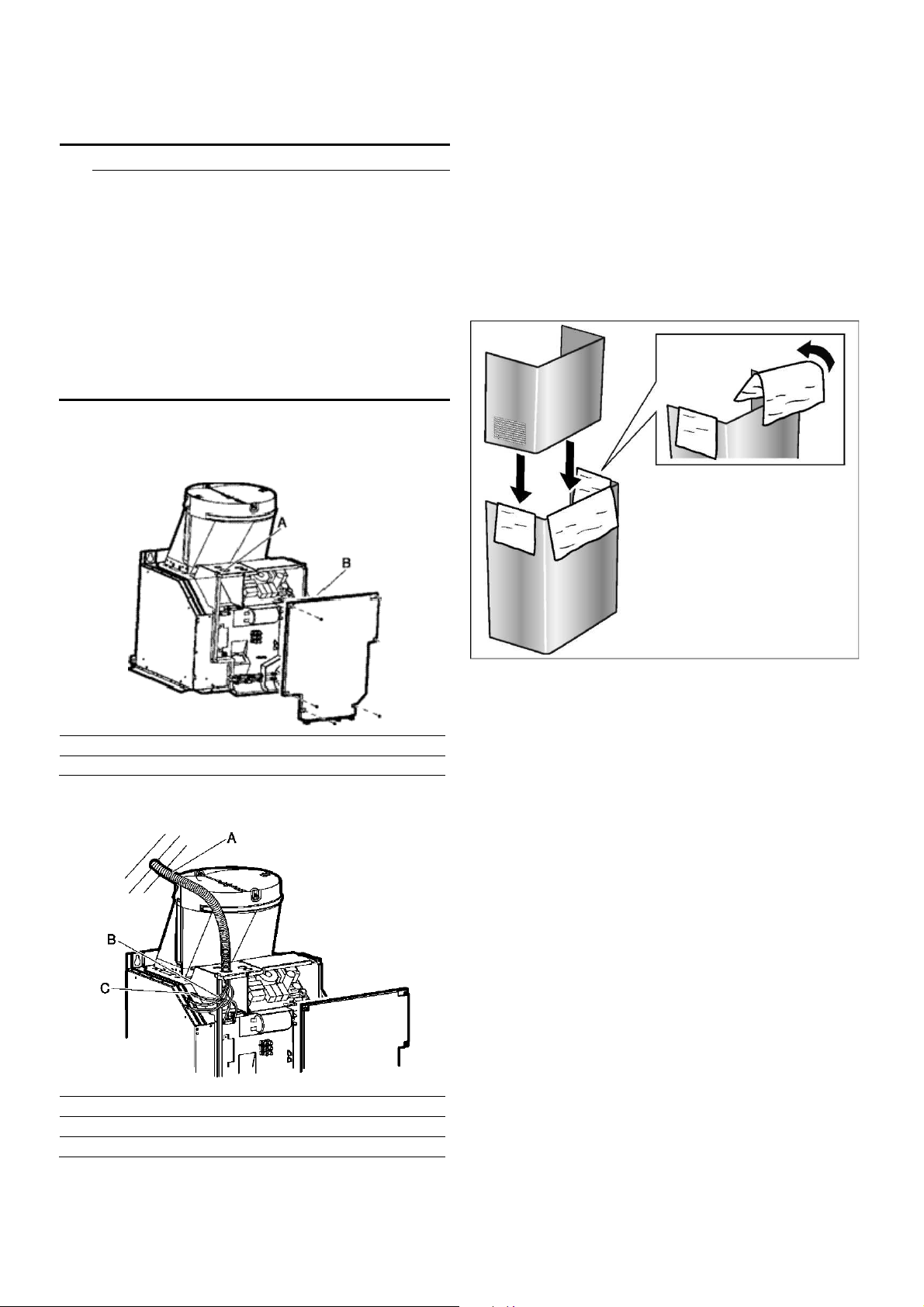

Attaching flue duct

Hidden surfaces may have sharp edges. Use caution when

reaching behind or under appliance.

1. Remove the protective foil from both flue ducts.

2. Push one flue duct into the other.

Notes

To prevent scratches, lay paper over the edges of

the lower flue duct to protect the surface.

For ducted operation, turn the upper flue duct so

that the ventilation slots point downward.

A Cable passage

B Cover of the motor controller

2. Connect 1/2" (12.7 mm) installation pipe to motor

controller.

A Installation pipe

B Power connection

C Cable connector listed in UL

3. Remove the protective foil from the extractor hood.

4. Place flue ducts on the appliance.

5. Push the inner flue duct upwards and attach it to the

angle brackets on the left and right.

14

Loading...

Loading...