Bosch GWS 7-115, GWS 10-125 C, GWS 1000, GWS 10-125 CE, GWS 7-125 Operating Instructions Manual

...

EURO • Printed in Germany • BA 1 609 929 C85 • GWS 7-14-1000 • Titel (Vorderseite) • OSW 12/01

Bedienungsanleitung

Operating Instructions

Instructions d’emploi

Instrucciones de servicio

Manual de instruções

Istruzioni d’uso

Gebruiksaanwijzing

Betjeningsvejledning

Bruksanvisning

Brukerveiledningen

Käyttöohje

Oδηγία χειρισµού

Kullanım kılavuzu

Deutsch

English

Français

Español

Português

Italiano

Nederlands

Dansk

Svenska

Norsk

Suomi

Eλληνικά

Türkçe

GWS 7-115

GWS 7-125

GWS 9-125

GWS 10-125 C

GWS 1000

GWS 10-125 CE

GWS 14-125 C

GWS 14-125 CE

GWS 14-150 C

GWS 7-14-1000 - Buch Seite 1 Montag, 3. Dezember 2001 10:49 10

1 605 703 099

1 600 210 039

1 603 340 031

1 603 340 040

1 607 950 043

1 602 025 024

1 601 329 013

Ø 115 mm

Ø 125 mm

Ø 150 mm

Ø 115/125 mm

2 x

Ø 115/125 mm

Ø 150 mm

2 602 025 121

2 605 510 192

2 605 510 193

2 605 510 194

2 605 510 182

2 605 730 036

1 600 793 007

2 605 510 187

2 605 510 188

2 • 1 609 929 C85 • 12.01

2 605 438 404

3 • 1 609 929 C85 • 12.01

4+ 5 • 1 609 929 C85 • 12.01

6

DIAMOND Laser

20

8

19

10

11

18

17

1 607 000 200

0 603 999 011

4

5

6

8

9

10

11

12

2

3

16

13

14

15

12

1

7

3

6

8

9

10

11

7

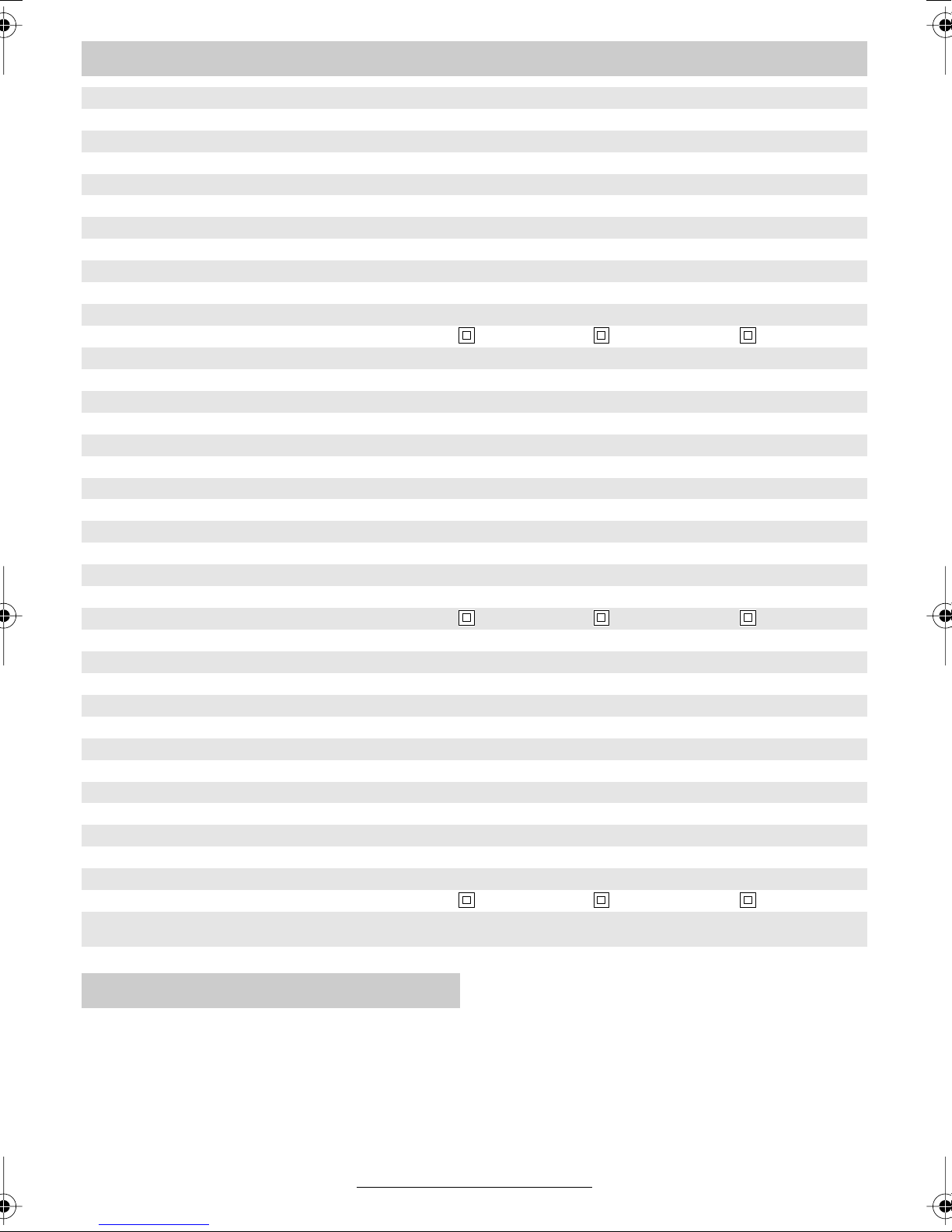

Tool Specifications

Angle Grinder GWS 7-115 GWS 7-125 GWS 9-125

Order number 0 601 800 ... 0 601 800 048 0 601 801 ...

Rated power* [W] 750 750 900

Output power* [W] 450 450 520

No-load speed [rpm] 11 000 11 000 11 000

Grinding disk dia. [mm] max. 115 max. 125 max. 125

Grinder spindle threads M 14 M 14 M 14

Starting current limiter – – –

Constant Electronic Control – – –

Speed preselection – – –

Weight (without accessories) approx. [kg] 1.55 1.55 1.60

Protection class / II / II / II

Angle Grinder GWS 10-125 C GWS 1000 GWS 10-125 CE

Order number 0 601 802 ... 0 601 802 ... 0 601 803 ...

Rated power* [W] 1 020 1 020 1 020

Output power* [W] 600 600 600

No-load speed [rpm] 11 000 11 000 2 800–11 000

Grinding disk dia. [mm] max. 125 max. 125 max. 125

Grinder spindle threads M 14 M 14 M 14

Starting current limiter • • •

Constant Electronic Control • • •

Speed preselection – – •

Weight (without accessories) approx. [kg] 1.60 1.60 1.60

Protection class / II / II / II

Angle Grinder GWS 14-125 C GWS 14-125 CE GWS 14-150 C

Order number 0 601 804 ... 0 601 805 ... 0 601 806 ...

Rated power* [W] 1 400 1 400 1 400

Output power* [W] 820 820 820

No-load speed [rpm] 11 000 2 800–11 000 9 300

Grinding disk dia. [mm] max. 125 max. 125 max. 150

Grinder spindle threads M 14 M 14 M 14

Starting current limiter • • •

Constant Electronic Control • • •

Speed preselection – • –

Weight (without accessories) approx. [kg] 1.80 1.80 1.85

Protection class / II / II / II

* The values given are valid for nominal voltages [U] of 230/240 V.

For lower voltages and models for specific countries, these values can vary.

2

Noise/Vibration Information

The typical weighted acceleration is 5.0 m/s

When using the auxiliary handle with vibration

Measured values determined according to

EN 50 144.

absorption, the hand/arm vibration of the power

2

tool used is typically less than 2.5 m/s

.

Typically the A-weighted noise levels of the product are: sound pressure level: 88 dB (A); sound

power level: 101 dB (A).

Wear hearing protection!

.

14 • 1 609 929 C85 • TMS • 26.11.01

English - 1

Speed Preselection (Type CE)

Material Application Tool Thumbwheel

Plastic Polishing Lamb’s wool hood 1

Finish polishing Felt polishing disk 1

Metal Finish grinding Buffing disk 1

Removing paint Sanding sheet 2–3

Wood, Metal Brushing, Removing rust Cup brush, sanding sheet 3

Metal, Stone Grinding Grinding disk 4–6

Metal Roughing Roughing disk 6

Stone* Cutting* Cutting disk and cutting guide 6

* Cutting of stone is permitted only with the cutting guide (accessory).

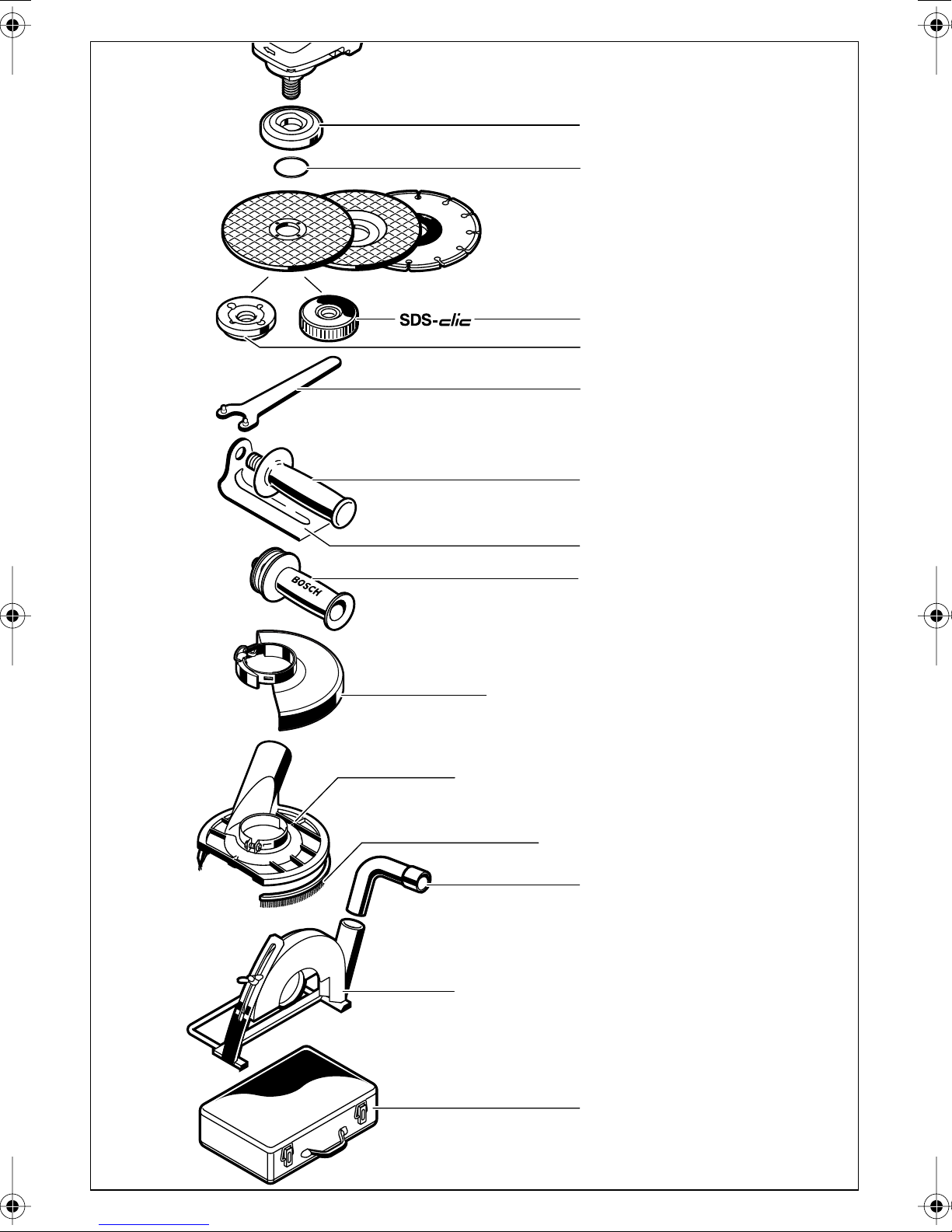

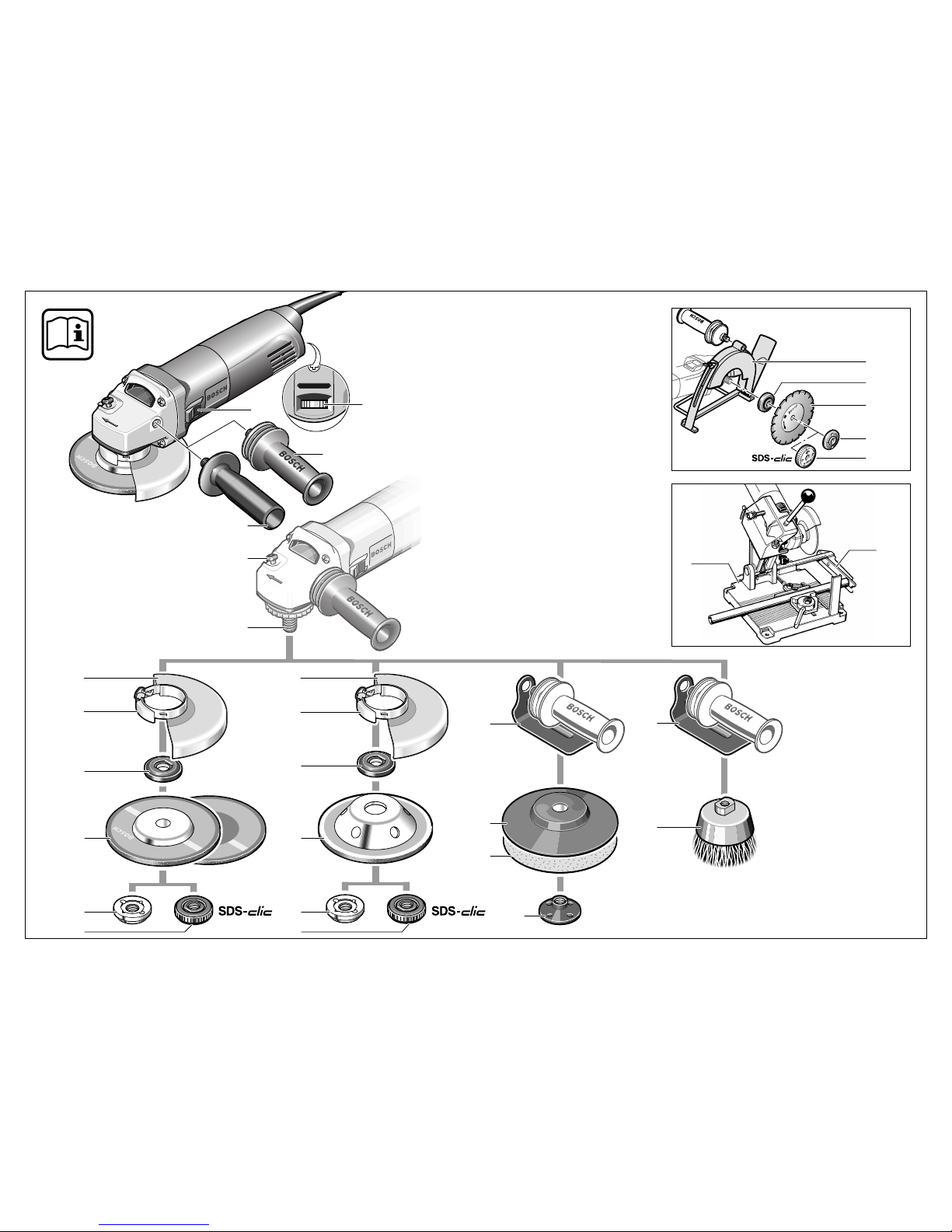

Machine Elements

1 Thumbwheel for speed preselection

(Type CE)

2 On/Off switch

3 Auxiliary handle

4 Spindle lock

5 Grinder spindle

6 Protective guard

7 Clamping lever

8 Mounting flange with O-ring

9 Roughing/cutting disc*

10 Clamping nut

11 quick clamping nut*

12 Hand protector*

13 Rubber sanding plate*

14 Sanding disc*

15 Round nut*

16 Cup brush*

17 Cutting grinder stand*

18 Length stop*

19 Diamond cutting disc*

20 Cutting guide with protective vacuuming

hood*

* Accessories

* Not all of the accessories illustrated or described are

included as standard delivery.

Intended Use

The machine is intended for cutting, roughing and

brushing metal and stone materials without using

water. For cutting stone, a cutting guide is required.

For machines with electronic control: With approved sanding tools, the machine can be used

for sanding and polishing.

For Your Safety

Working safely with this machine is possible only when the

operating and safety information

are read completely and the instructions contained therein are

strictly followed. In addition, the

general safety notes in the enclosed booklet must be observed. Before using for the first

time, ask for a practical demonstration.

■ Wear protective glasses and hearing protection.

■ Wear protective gloves and sturdy shoes.

■ When necessary, also wear an apron.

■ The dust that is produced while working can be

detrimental to health, inflammable or explosive. Suitable safety measures are required.

Examples: Some dusts are regarded as carcinogenic. Use suitable dust/chip extraction and

wear a dust respirator.

■ Dust from light alloys can burn or explode. Always keep the work place clean, as blends of

materials are particularly dangerous.

■ If the mains cable is damaged or cut through

while working, do not touch the cable but immediately pull the mains plug. Never use the

machine with a damaged cable.

■ Connect machines that are used in the open

via a residual current device (RCD) with an actuating current of 30 mA maximum. Use only

extension cables that are approved for outdoor

use.

■ When working with the machine, always hold it

firmly with both hands and provide for a secure

stance.

■ Always direct the cable to the rear away from

the machine.

15 • 1 609 929 C85 • TMS • 26.11.01

English - 2

■ Always switch the machine off and wait until it

has come to a standstill before placing it down.

■ Insert the mains plug only when the machine is

switched off.

■ For mains failure or when the main plug is

pulled, unlock the On/Off switch immediately

and turn it to the off position. This prevents uncontrolled restarting.

■ The machine must be used only for dry cutting/

grinding.

■ For all work with the machine, the auxiliary

handle 3 must be mounted.

■ Hold the power tool only by the insulated

gripping surfaces, when performing an operation where the cutting tool may run into

hidden wiring or its own cord.

Contact with a “live” wire will make exposed

metal parts of the tool “live” and shock the operator.

■ Do not drill, cut or saw into blind areas

where electric, gas or water lines may exist.

Use suitable detectors to determine if these

lines are hidden in the work area or call the

local utility company for assistance.

Contact with electric lines may cause fire or

electric shock. Damaging a gas line can result

in an explosion. Penetrating a water pipe will

cause property damage or may cause an electric shock.

■ For work with roughing or cutting discs, the

protective guard 6 must be mounted. For work

with the rubber sanding plate 13 or with the

cup brush 16/disc brush/flap disc, mounting

the hand protector 12 (accessory) is recom-

mended.

■ Use a vacuum cleaner for drawing off the dust

when working with stone. The vacuum cleaner

must be approved for masonry dust. When

cutting stone, use the cutting guide.

■ Do not work with materials containing asbestos.

■ Use only grinding tools with a permissible

speed at least as high as the no-load speed of

the machine.

■ Check grinding tools before use. The grinding

tool must be properly mounted and turn freely.

Perform a test run for at least 30 seconds without load. Do not use damaged, out-of-round or

vibrating grinding tools.

■ Protect the grinding tool from impact, shock

and grease.

■ Apply the machine to the workpiece only when

switched on.

■ Keep hands away from rotating grinding tools.

■ Pay attention to the direction of rotation. Al-

ways hold the machine so that sparks and

grinding dust fly away from the body.

■ When grinding metal, flying sparks are produced. Take care that no persons are endangered. Due to danger of fire, no combustible

materials should be located in the vicinity

(spark flight zone).

■ Be careful when cutting grooves, e. g. in loadcarrying walls: See information on structures.

■ Blocking the cutting disc leads to jerking reaction forces on the machine. In this case switch

off the machine immediately.

■ Pay attention to the dimensions of the grinding

disc. The mounting hole diameter must fit the

mounting flange 8 without play. Do not use reducer pieces or adapters.

■ Never use cutting discs for rough grinding. Do

not exert any lateral pressure on the cutting

discs.

■ Observe the manufacturer’s instructions for

mounting and using grinding tools.

■ Caution! The grinding tool runs on after the

machine is switched off.

■ Do not clamp the machine in a vice.

■ Never allow children to use the machine.

■ Bosch is only able to ensure perfect operation

of the machine if the original accessories intended for it are used.

Information Structures

Slots in load carrying walls are subject to the

Standard DIN 1053, Part 1 or country-specific

regulations.

These regulations are to be observed under all

circumstances. Before beginning work, consult

the responsible structural engineer, architects or

the construction supervisor.

16 • 1 609 929 C85 • TMS • 26.11.01

English - 3

Mounting the

Protective Devices

■ Before any work on the machine itself, pull

the mains plug.

Protective Guard

Hand Protector (Accessory)

For work with the rubber sanding plate 13 or with

the cup brush 16/disc brush/flap disc, mounting

the hand protector 12 (accessory) is recom-

mended. The hand protector 12 is fastened with

the auxiliary handle 3.

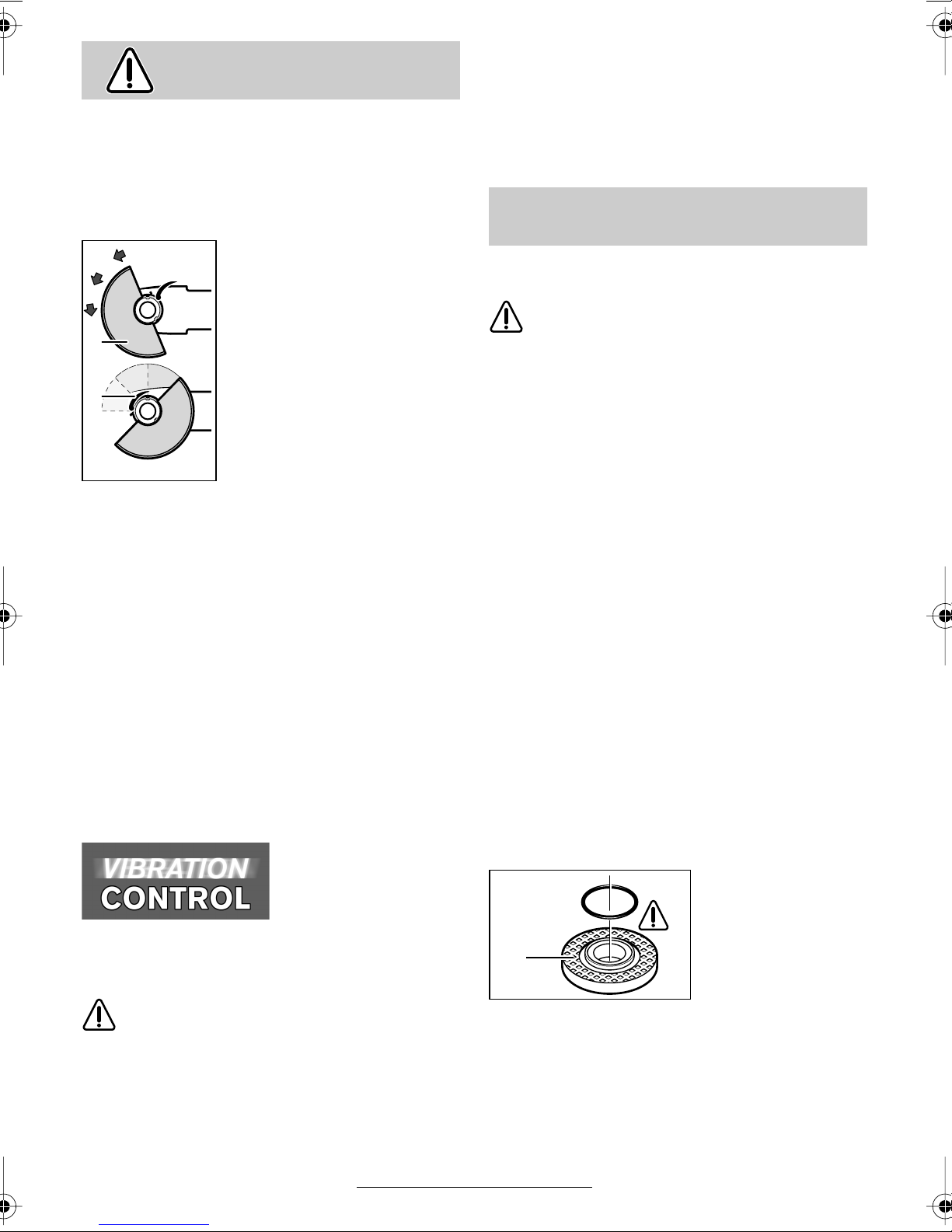

■ For work with roughing or cutting discs,

the protective guard 6 must be mounted.

Open the clamping lever 7.

Place the protective guard 6

with coded cams into the respectively coded grooves on

6

7

Note: Coded notches on the protective guard 6

ensure that only a protective guard that fits the

machine type can be mounted.

Disassemble in the reverse sequence.

the spindle collar of the machine head and turn anticlockwise to the required position (working position).

To fasten the protective

guard 6, close the clamping

lever 7.

The closed side of the protective guard 6 must always

point to the operator.

Auxiliary Handle

■ For all work with the machine, the auxiliary

handle 3 must be mounted.

Screw the auxiliary handle 3 on the right or left of

the machine head depending on the working

method.

Auxiliary handle with vibration

absorption (Accessory)

The vibration-dampening auxiliary handle reduces the vibrations, making operation more

comfortable and secure.

Do not make any alterations to the auxiliary handle.

Do not continue to use an auxiliary handle if it is

damaged.

Mounting the Grinding Tools

(accessories)

■ Before any work on the machine itself, pull

the mains plug.

Use only grinding tools with a permissible speed at least as high as the no-load

speed of the machine.

Roughing and cutting discs become

very hot while working; do not touch until they have cooled.

■ Clean the grinder spindle and all parts to be

mounted. For clamping and loosening the

grinding tools, lock the grinder spindle 5 with

the spindle locking button 4.

Actuate the spindle locking button 4 only

when the grinder spindle is at a standstill!

Roughing/Cutting Disk

■ Pay attention to the dimensions of the grinding

disc. The mounting hole diameter must fit the

mounting flange 8 without play. Do not use reducer pieces or adapters.

When using a diamond cutting disk, take care

that the direction of rotation arrow on the diamond cutting disk and the direction of rotation of

the machine (direction of rotation arrow on the

machine head) agree.

For mounting, see the illustration page.

Screw on the clamping nut 10 and tighten with

the two-pin spanner (see Section “Quick Clamping Nut”).

An O-ring (plastic

part) is inserted in

the retainer flange 8

around the spigot.

8

If the O-ring is missing or is damaged, it must

in all cases be replaced (Order No.

1 600 210 039) before the retainer flange 8 is

mounted.

☞

After mounting the grinding tool and before switching on, check that the grinding tool is correctly mounted and that it

can turn freely.

17 • 1 609 929 C85 • TMS • 26.11.01

English - 4

Flap disc

Depending on the application, remove the blade

guard 6 and mount the hand guard 12.

Place the special retainer flange 8 (accessory,

Order No. 2 605 703 028) and the flap disc on the

grinder spindle 5. Screw on the clamping nut 10

and tighten with the two-pin spanner.

Rubber Sanding Plate 13

Depending on the application, remove the blade

guard 6 and mount the hand guard 12.

For mounting, see the illustration page.

Screw on the round nut 15 and tighten with the

two-pin spanner.

Cup Brush 16/Disc brush

Depending on the application, remove the blade

guard 6 and mount the hand guard 12.

The grinding tool must be able to be screwed

onto the grinding spindle 5 until it rests firmly

against the grinder spindle flange at the end of

the grinder spindle threads. Tighten with an

open-ended spanner.

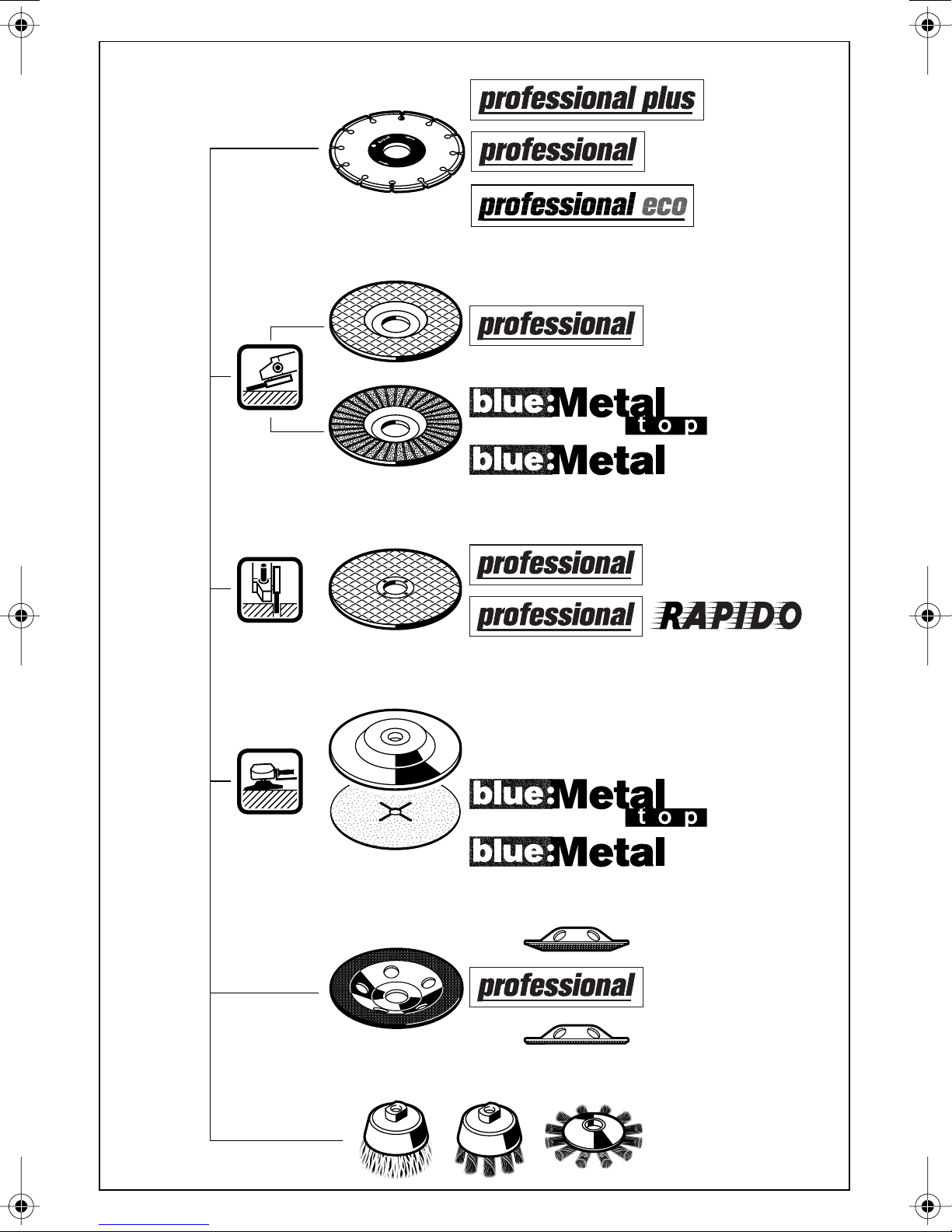

Approved Grinding Tools

All grinding tools described in these operating instructions can be used (roughing and cutting

discs of synthetic resin-bonded, fibre-reinforced

material).

The permissible speed [rpm] or the circumferential speed [m/s] of the grinding tools used must be

at least in accordance with the values given in the

table.

Therefore, always observe the permissible rota-

tional/circumferential speed on the label of the

grinding tool.

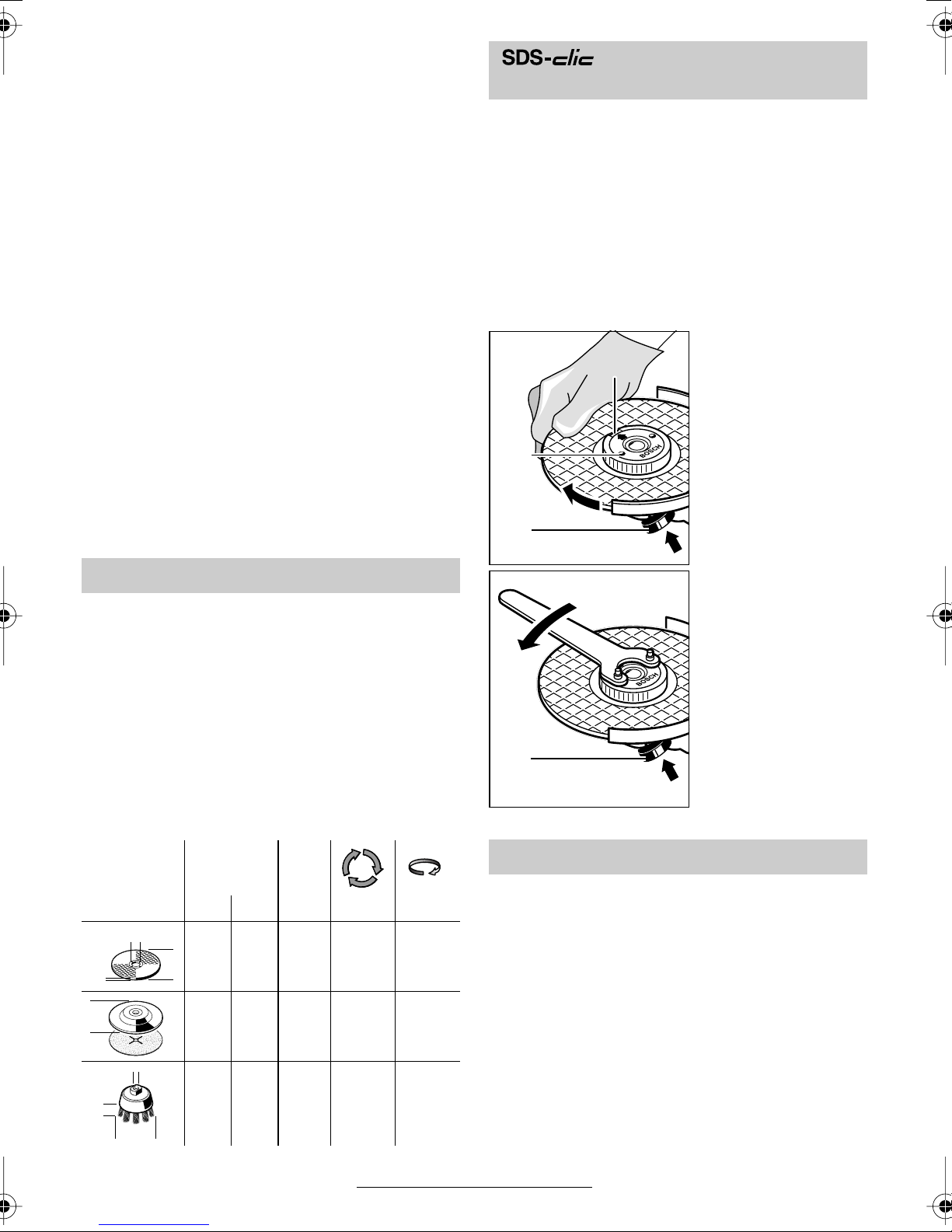

Quick Clamping Nut

(accessory)

Instead of the clamping nut 10, the quick clamping nut 11 (accessory) can be used. Grinding

tools can be mounted without using tools.

The quick clamping nut 11 may be used only

for roughing and cutting discs.

Use only a flawless, undamaged quick clamping nut 11.

When screwing on, take care that the side with

printing does not point to the grinding disc. The

arrow must point to the index mark 21.

Lock the grinder

21

11

4

4

spindle with the spindle locking button 4.

Tighten the quick

clamping nut by

forcefully turning the

grinding disc in the

clockwise direction.

A properly tightened

undamaged, quick

clamping nut can be

loosened by hand

turning the knurled

ring in the counterclockwise direction.

Never loosen a tight

quick clamping nut

with pliers but use a

two-pin spanner. In-

sert the two-hole

spanner as shown in

the illustration.

max.

[mm] [mm]

Db d[rpm] [m/s]

d

b

D

d

b

D

18 • 1 609 929 C85 • TMS • 26.11.01

115

125

D

150

115

125––

75 30 M 14 11 000 45

6

22.2

6

22.2

6

22.2

––11 000

11 000

11 000

9 300

11 0008080

80

80

80

Initial Operation

Observe correct mains voltage: The voltage of

the power source must agree with the voltage

specified on the nameplate of the machine.

Equipment marked with 230 V can also be connected to 220 V.

To start the machine, press the On/Off switch 2

forward.

To lock the On/Off switch 2, press it down in the

front position.

To switch off the unit, release the On/Off

switch 2 or press the rear tip of it down.

English - 5

Loading...

Loading...