Page 1

Applications manual

For tankless and point of use water heaters

Page 2

|

2

Table of Contents

1 Introduction 3

2 Bosch Water Heating Models 3

2.1 Sizing tankless water heaters 4

2.2 Bosch GWH 715 ES 6

2.3 Bosch GWH C 800 ES 7

2.4 Outdoor Installation for GWH 715 ES and GWH C 800 ES 8

2.5 Bosch GWH 345 ESR 9

2.6 Bosch GWH 450 ESR 10

2.7 Bosch GWH 425 EF 11

2.8 Bosch GWH 425 HN 12

2.9 Bosch GWH 425 PN 13

2.10 Bosch GWH 260 PN 14

2.11 Powerstream Pro RP17PT, RP27PT 15

2.12 Powerstream Pro RP1P, RP2P, RP3P, RP7P, RP9P, RP12PT 16

2.13 Ariston Pro GL2.5Ti, GL4Ti, GL8Ti 17

3 Domestic Water Heating Applications 18

Applications manual

3.1 Point-of-use applications 18

3.2 Whole house applications 22

4 High Volume Potable Water Heating 26

4.1 Parallel unit applications 26

4.2 Cascade unit applications 28

4.3 External storage tank loading applications 29

5 Open Loop Space Heating 32

5.1 External storage tank 32

5.2 Indirect tank applications 42

6 Maintenance Drawings 44

6.1 Descaling procedure 44

6.1 Descaling procedure diagram 45

Application manual | 11.2007

Bosch Water Heating

Page 3

Applications manual

1 Introduction

The Bosch Applications Manual is intended to present some of the

most common applications of the Bosch line of tankless and point of

use water heaters. Application drawings are shown with both piping

and corresponding electrical schematics where applicable. Auxiliary

equipment depicted does not necessarily represent any one manufacturer or specifi c model number. There are a wide variety of

techniques, practices and piping strategies possible when installing

water heating appliances. It is the responsibility of the installing

contractor to determine the most suitable arrangement for the

application.

Although this manual covers many common applications for our

products, system possibilities are virtually endless. Should you

encounter an application that is not covered in this manual or have

any questions regarding any of its content, we encourage you to

contact your local sales representative or us directly at Bosch Water

Heating.

This is not a substitute for any of the product’s installation manuals.

All specifi cations subject to change.

Installation must conform with local codes or, in the absence of

local codes, the National Fuel Gas Code ANSI Z 223.1/NFPA 54.

In Canada: Installation must conform with CGA B149.(1,2) INSTALLATION CODES and/or local installation codes.

| 3

2 Bosch Water Heating Models

This section describes the water heaters available from Bosch Water

Heating. The information given in each section provides a general

overview to the specifi cations of that particular model. More detai-

led information is contained in the installation manuals. Download

these manuals at www.BoschPro.com.

Applications manual | 11.2007Bosch Water Heating

Page 4

|

4

2.1 Sizing tankless water heaters

Defi nitions

Major applications (2 GPM or more): Washing machine, bath tub,

shower nozzle

Minor applications(1.5 GPM or less): Low fl ow shower head,

bathroom sink, kitchen sink

Rule of thumb sizing

The tables below provide a general rule of thumb when sizing for

most residential applications. For commercial applications or for a

more detailed sizing method, use the instructions below in conjunction with the charts on the next page.

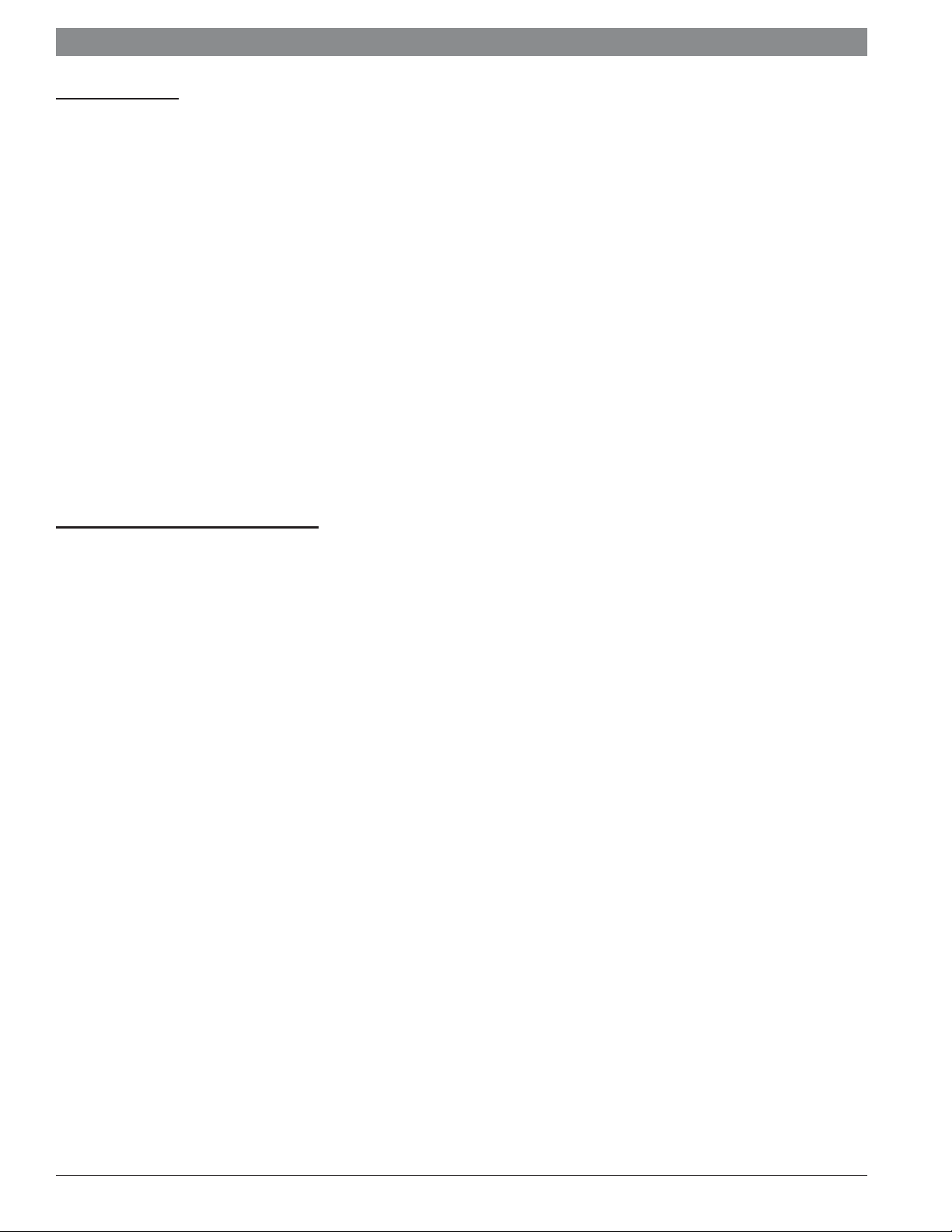

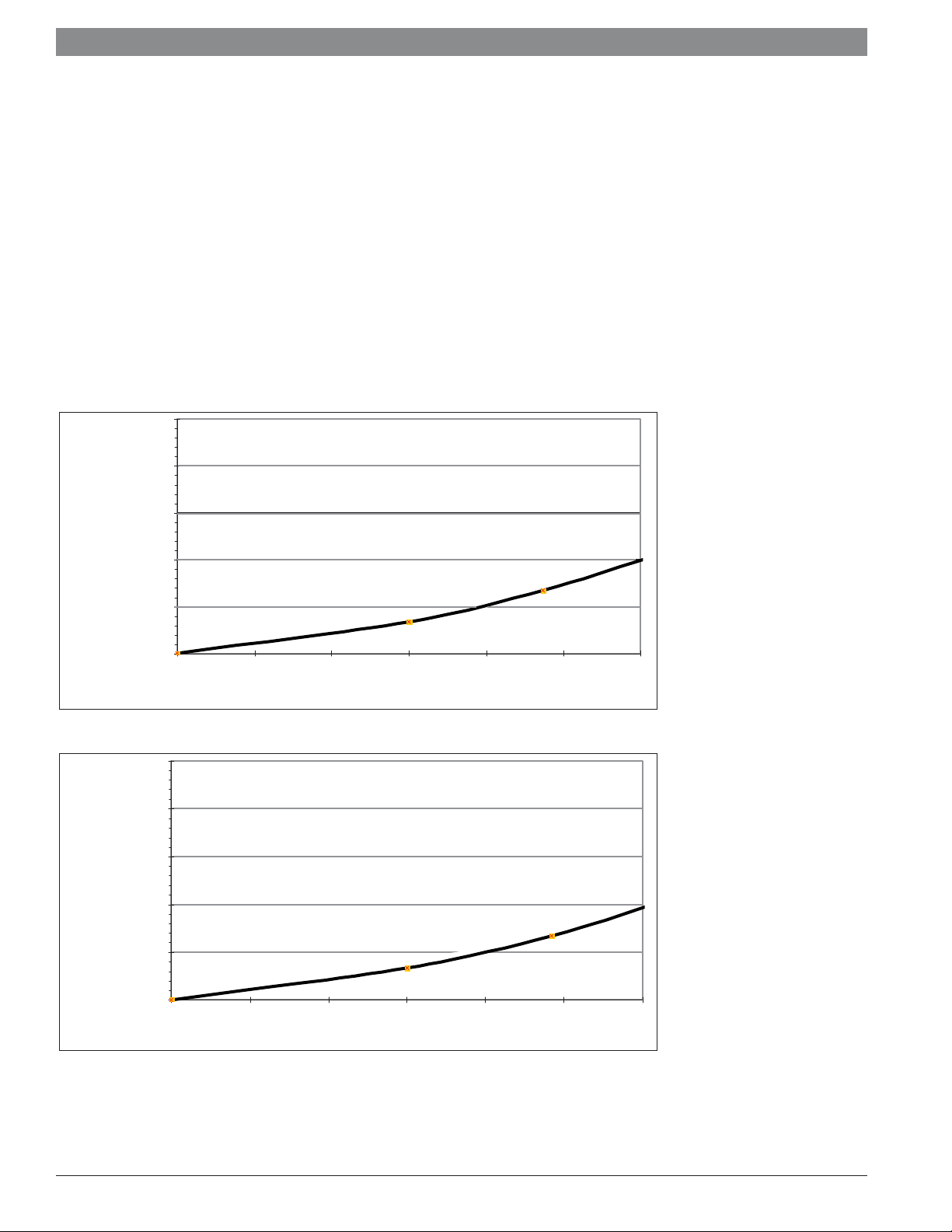

Sizing by Chart

Measure the fl ow rates at each fi xture that will be used simultane-

ously and add them together. If only one application will be used

at a time measure each fi xture and use the maximum fl ow rate

observed.

Rule of Thumb Sizing

Model Number Number of Major

Applications

Number of Minor

Applications

Applications manual

GWH 715 ES 2 0

GWH C 800 ES 2 1

GWH 425 HN/PN/EF 1 1

GWH 425 HN/PN/EF 0 2

GWH 260 PN 1 0

RP17PT 1 0

RP27PT 1 1

Using a known volume container, record several fi ll times. Per-

form the calculation below to determine the fl ow rate (a one

gallon fi ll time of 30 seconds is 2.0 gallons per minute (GPM):

Flow rate (GPM) =

Volume (gallons)

Fill time (sec)

Using a thermometer, measure the incoming water temperature.

Subtract this temperature from the desired hot water temperature

to get the degree rise. So, if the desired hot water temperature is

120F and incoming temperature is 55F, the desired degree rise is

65F.

This example requires a fl ow rate of 2.0 GPM at a 65˚F rise. The

data point is shown on each graph. Since the demand is above

the GWH 260 PN capacity, this application would require a GWH

425 HN/PN/EF gas tankless water heater. The electrical model

used for this application would be the RP27PT electric tankless

water heater.

sec

x

60

min

Application manual | 11.2007

Bosch Water Heating

Page 5

Applications manual

GWH 425 PN/HN

GWH 260 PN/HN

t

C

0

5

0

5

0

5

0

5

0

e

M

P

Note

s

GPM

8

7

6

5

4

3

2

1

| 5

0

10 20 30 40 50 60 70 80 90

Degree rise (°F)

as Appliance Sizing Char

P

4.

.

.

.

.

1.

1.

P7

.

.

10 20 30 40 50 60 70 80 90

ectric Appliance Sizing Chart

: Maximum flow rates dependant on site condition

Degree ris

Applications manual | 11.2007Bosch Water Heating

Page 6

|

6

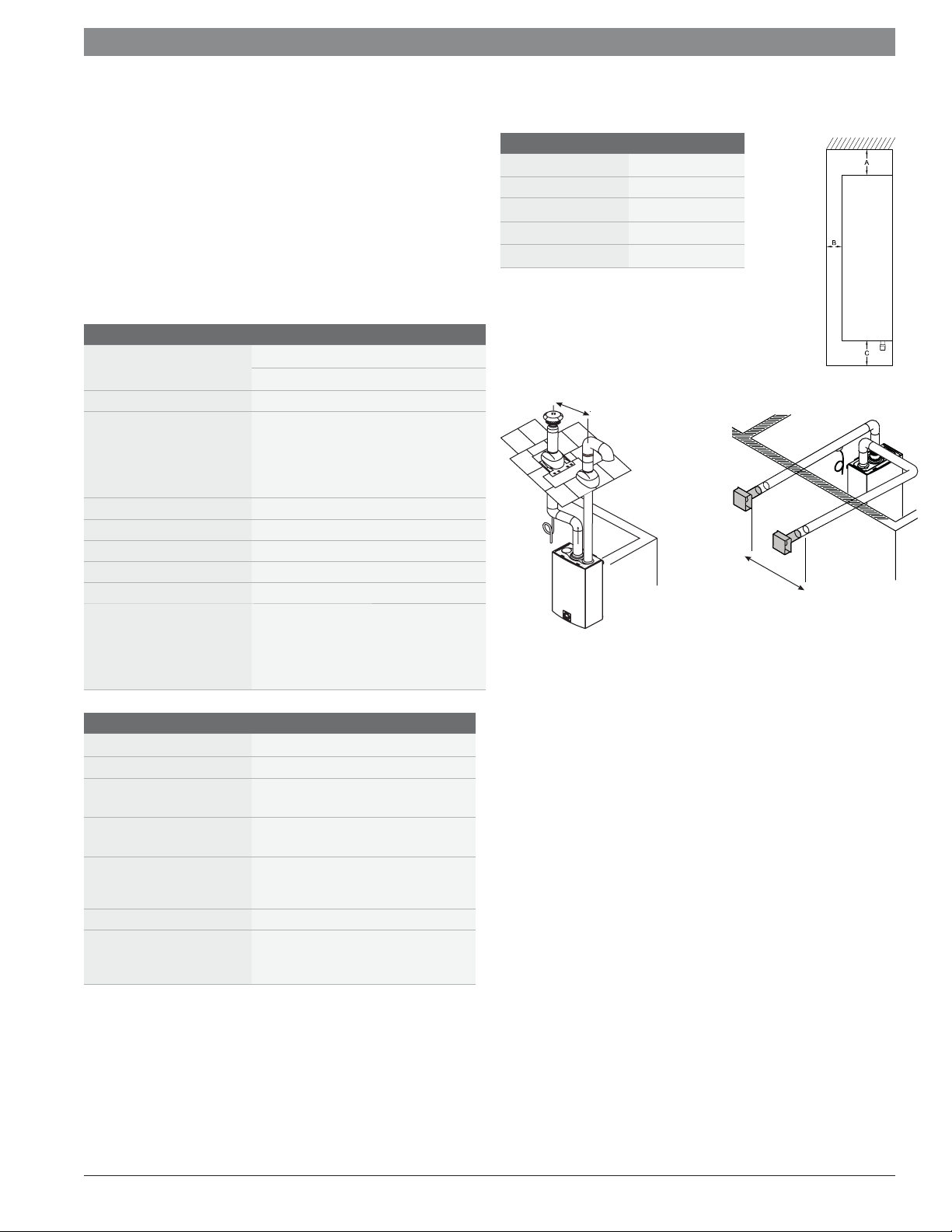

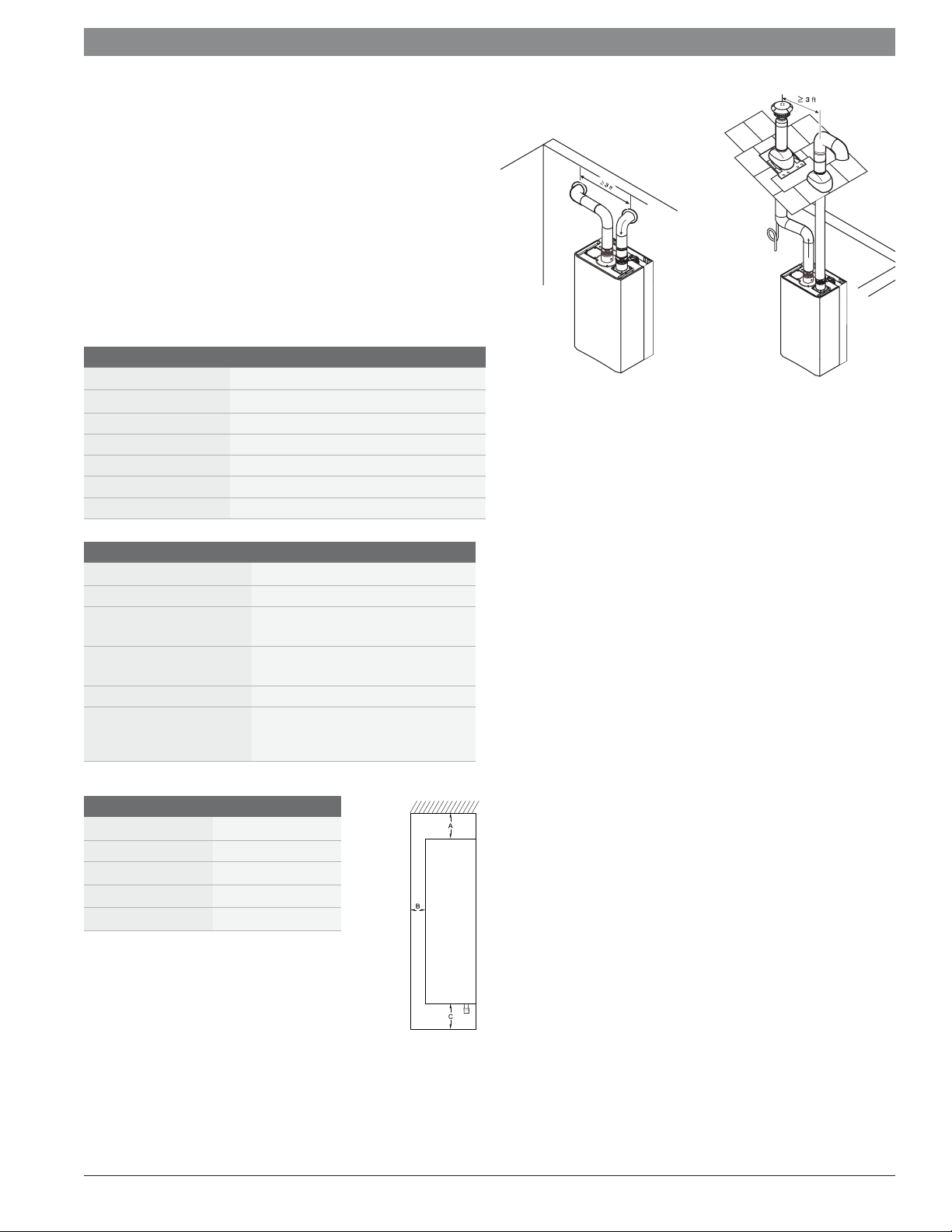

2.2 Bosch GWH 715 ES

Applications manual

Features:

Electronic ignition and built in power vent

82% thermal effi ciency

Vents vertically or horizontally with 3" or 4" stainless steel (AL29-

4C)

Direct vent room-sealed combustion

Computerized temperature control — ensures temperature stability

Model GWH 715 ES N for natural gas (NG) supply

Model GWH 715 ES L for liquid propane (LP) supply

15-year warranty

Qualifi es for $300 tax credit

GWH 715 ES Technical Specifi cations

Gas input Natural Gas: 19,900 - 199,000 BTU

LP Gas: 19,900 - 199,000 BTU

Minimum fl ow to activate 0.65 gallons per minute (gpm)

Flow rates 45˚F rise @ 7.2 gpm

55˚F rise @ 5.9 gpm

65˚F rise @ 5.0 gpm

77˚F rise @ 4.2 gpm

90˚F rise @ 3.6 gpm

Thermal Effi ciency NG: 82% LP: 82%

Dimensions 30½" h x 17⅞" w x 11¼" d

Weight 67 lbs.

Modulating gas valve yes

Ignition Electronic

Accessories Outdoor kit (PTOK)

Wireless Remote (TSTAT2)

Tankless Link Cascading Kit (TLINK)

Freeze Prevention Kit (8700400022)

Water Filter Kit (8703305356)

GWH 715 ES Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 4" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 9" W.C.

Maximum: 14" W.C.

Water pressure

(Static)

Minimum: 30 PSI

Minimum well pressure: 40 PSI

Maximum: 150 PSI

Electrical supply 120VAC - plugs in

Venting 3" or 4" stainless steel (AL29-4C)

direct vent

room-sealed combustion

GWH 715 ES Installation Clearances

Top (A) 12"

Front (B) 1"

Back 0"

Sides 1"

Floor (C) 12"

3ft minimum

distance

3ft minimum

distance

Fig. 1 Venting confi gurations

Installation guidelines:

Venting:

Must be 3" or 4" AL29-4C sealed stainless steel vent pipe.

Slope horizontal runs up to termination ¼" per foot. The last

horizontal section of exhaust vent pipe between last elbow and

termination must slope down to the termination ¼" per foot.

Do not combination vent with any other appliance.

Install condensate drain where applicable.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

Partially fi ll condensate drain tube loop (where applicable) with

water prior to start up.

Application manual | 11.2007

Bosch Water Heating

Page 7

Applications manual

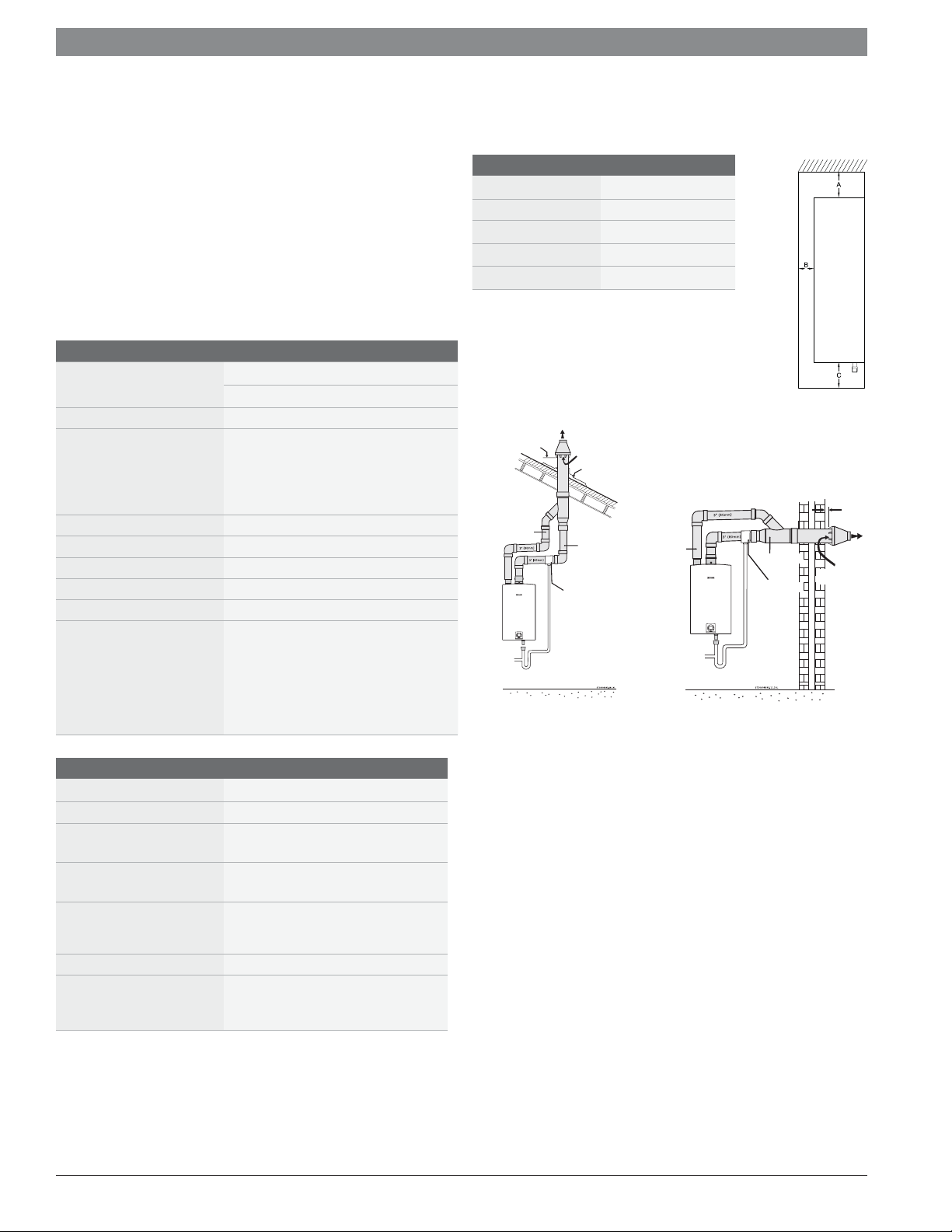

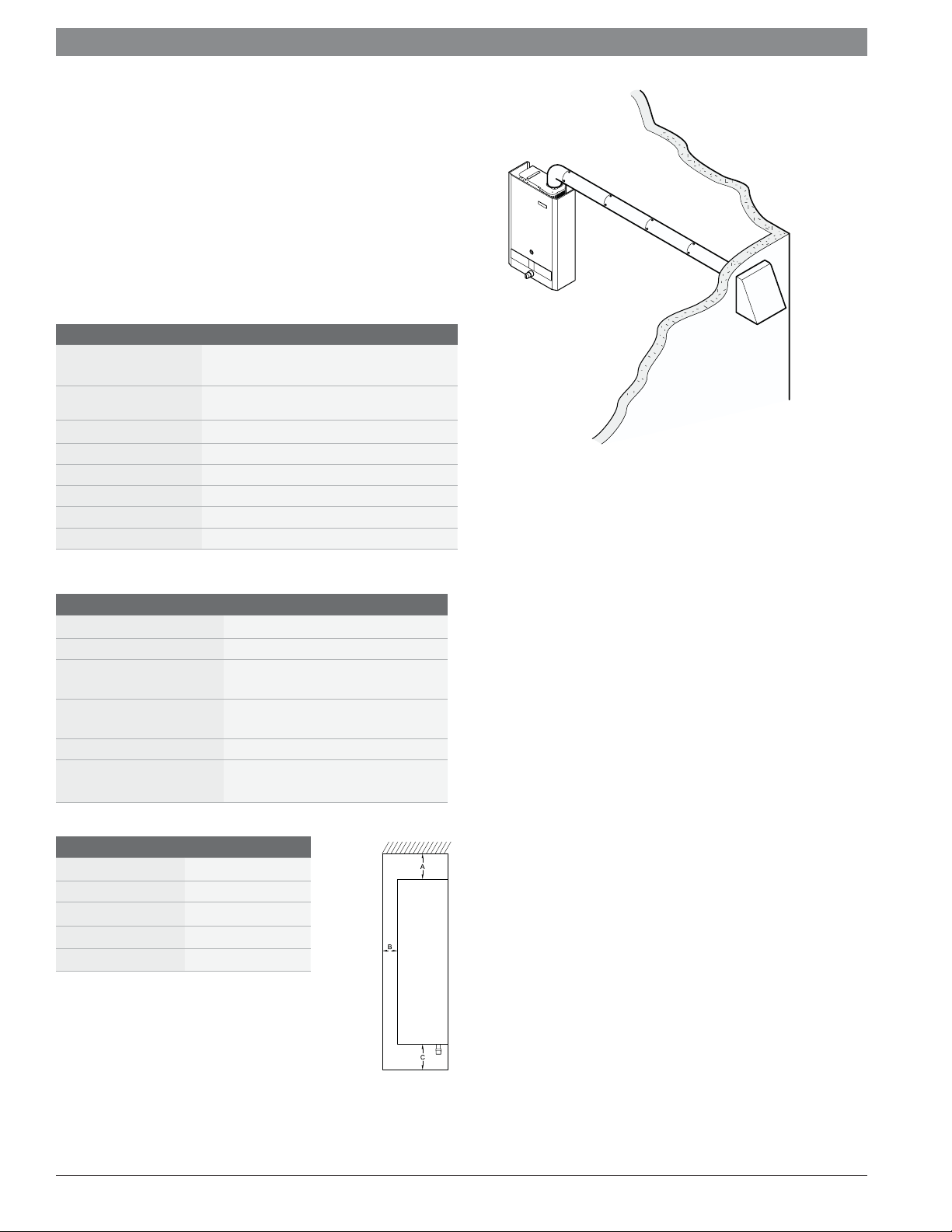

2.3 Bosch GWH C 800 ES

Features:

Electronic ignition and built in power vent

Condensing technology with 92% thermal effi ciency

Vents vertically or horizontally with 3" or 4" PVC, CPVC or ABS

(Schedule 40) vent pipe.

Direct vent room-sealed combustion with concentric venting

option

Computerized temperature control — ensures temperature stability

Model GWH C 800 ES N for natural gas (NG) supply

Model GWH C 800 ES L for liquid propane (LP) supply

15-year warranty

Qualifi es for $300 tax credit

GWH C 800 ES Technical Specifi cations

Gas input Natural Gas: 19,900 - 199,000 BTU

LP Gas: 19,900 - 199,000 BTU

Minimum fl ow to activate 0.65 gallons per minute (gpm)

Flow rates 45˚F rise @ 8.0 gpm

55˚F rise @ 6.4 gpm

65˚F rise @ 5.5 gpm

77˚F rise @ 4.6 gpm

90˚F rise @ 3.9 gpm

Thermal Effi ciency NG: 92% LP: 92%

Dimensions 30½" h x 17⅞" w x 11¼" d

Weight 74 lbs.

Modulating gas valve yes

Ignition Electronic

Accessories Outdoor kit (PTOK)

Wireless Remote (TSTAT2)

Tankless Link Cascading Kit (TLINK)

Freeze Prevention Kit (8700400022)

Water Filter Kit (8703305356)

Concentic Termination Kit

(BWH60L46)

GWH C 800 ES Installation Clearances

Top (A) 12"

Front (B) 1"

Back 0"

Sides 1"

Floor (C) 12"

MAINTAIN 12 IN.

(1

8 IN. FOR CANADA)

MINIMUM CLEARANCE

ABOVE

HIGHEST ANTICIPATED

SNOW LEVEL.

MAXIMUM OF 24 IN.

ABOVE ROOF.

INTAKE

Fig. 1 Venting confi gurations

VENT

DRAIN TEE

COMBUSTION

AIR

ROOF BOOT/

FLASHING (FIELD

SUPPLIED

EXHAUST

INTAKE

EXHAUST

DRAIN TEE

| 7

MINIMUM

VENT

COMBUSTION

1”

AIR

GWH C 800 ES Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 4" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 9" W.C.

Maximum: 14" W.C.

Water pressure

(Static)

Minimum: 30 PSI

Minimum well pressure: 40 PSI

Maximum: 150 PSI

Electrical supply 120VAC - plugs in

Venting 3" or 4" PVC, CPVC, or ABS

(Schedule 40) direct vent sealed

combustion

Installation guidelines:

Venting:

Must be 3" or 4" PVC, CPVC or ABS (Schedule 40) vent pipe.

Attach drain for internal condensate siphon and dispose of

according to local codes.

Do not combination vent with any other appliance.

Install an external condensate drain where applicable.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

Partially fi ll condensate drain tube loop (where applicable)

Applications manual | 11.2007Bosch Water Heating

Page 8

8

|

Applications manual

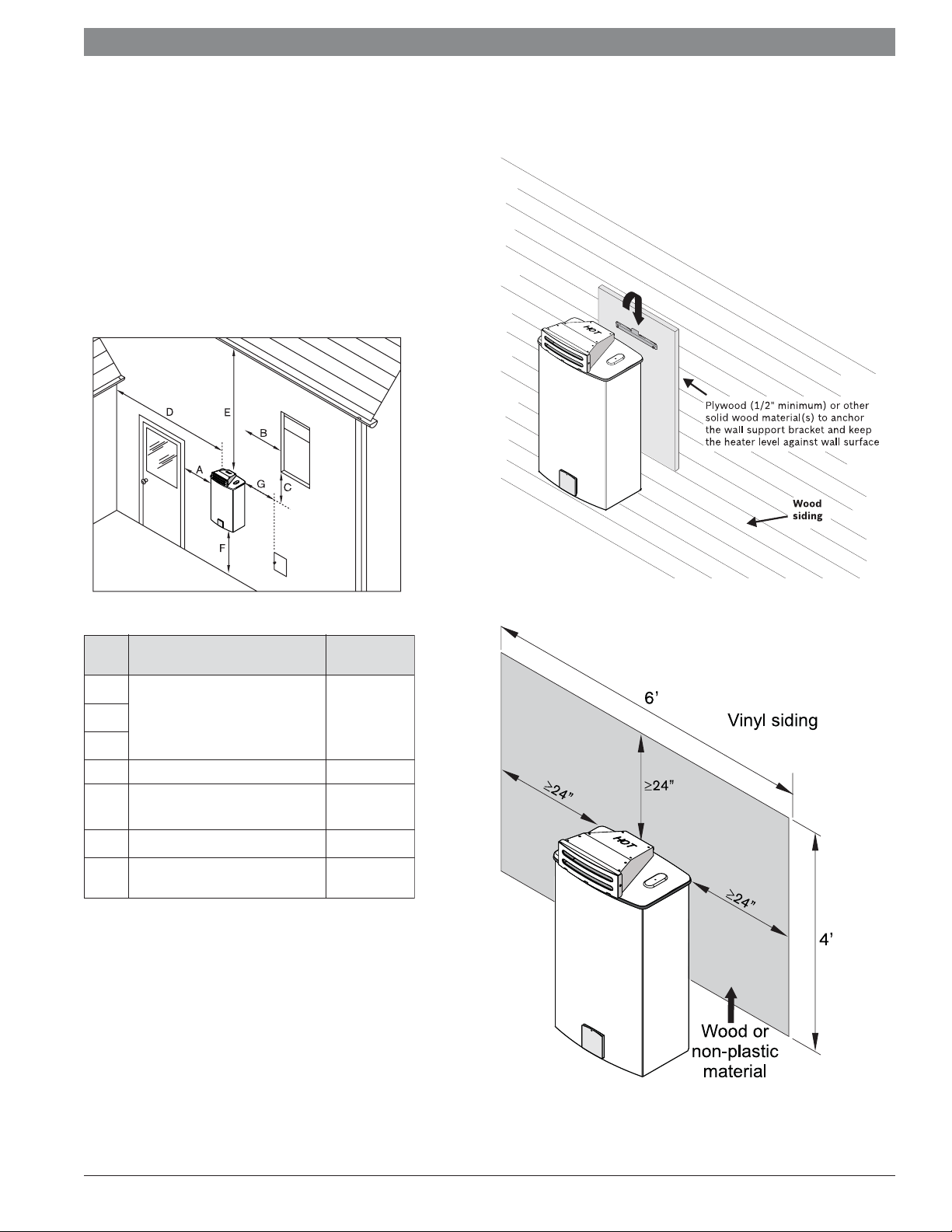

2.4 Outdoor Installation for GWH 715 ES,

and GWH C 800 ES

Outdoor Kit (PTOK) installation:

The installation of this outdoor kit (PTOK) is required when

installing either of the above appliances outdoors

Outdoor cap easily retrofi ts to these indoor models

Outdoor kit comes with Freeze Prevention which must be installed

Exterior water piping should be protected if freezing conditions

could exist

Minimum clearances:

Installation on wood siding

Ref. Description

A

Directly below or adjacent to

an opening; operable

B

windows, doors and any fresh

air openings

C

D From any adjacent wall ≥ 4 ft

Below a gutter, sanitary

E

pipework, eaves or overhang

F Above ground ≥ 1 ft

From a gas meter or gas

G

regulator

Outdoor Installation Clearances

Source: NFPA 54 National Fuel Gas Code

ANSI Z223.1

Installation on vinyl siding:

Min.

distances

≥ 4 ft

≥ 3 ft

≥ 5 ft

Application manual | 11.2007

Bosch Water Heating

Page 9

Applications manual

2.6 Bosch GWH 345 ESR

Features:

Specifi cally designed for recirculating applications

Electronic ignition and built in power vent

GWH 345 ESR thermal effi ciency of 82%

Vents vertically or horizontally with 3" stainless steel (AL29-4C)

Direct vent room-sealed combustion

Computerized temperature control — ensures temperature

stability

Model GWH 345 ESR N for natural gas (NG) supply

Model GWH 345 ESR L for liquid propane (LP) supply

10-year warranty

GWH 345 ESR Technical Specifi cations

Gas input GWH 345 ESR: 32,000 - 95,000 Btu/h

Maximum fl ow rates GWH 345 ESR: 3.5gpm @ 45°F rise

Thermal Effi ciency 82%

Dimensions 27.5" h x 15.75" w x 11.75" d

Weight 47 lbs.

Modulating gas valve yes

Ignition Electronic

GWH 345 ESR Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 5.5" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Electrical supply 120VAC - plugs in

Venting 3" stainless steel (AL29-4C)

direct vent

room-sealed combustion

GWH 450 ESR Installation Clearances

Top (A) 12"

Front (B) 1"

Back 0"

Sides 1"

Floor (C) 12"

| 9

Fig. 1 Venting confi gurations

Installation guidelines:

Venting:

Must be 3" or 4" AL29-4C sealed stainless steel vent pipe.

Slope horizontal runs up to termination ¼" per foot. The horizon-

tal section between last elbow and termination must slope down

to the termination ¼" per foot.

Do not combination vent with any other appliance.

Always install an external condensate drain except when termi-

nating horizontally with less than 3 feet of pipe.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

Partially fi ll condensate drain tube loop with water prior to start

up.

Applications manual | 11.2007Bosch Water Heating

Page 10

|

10

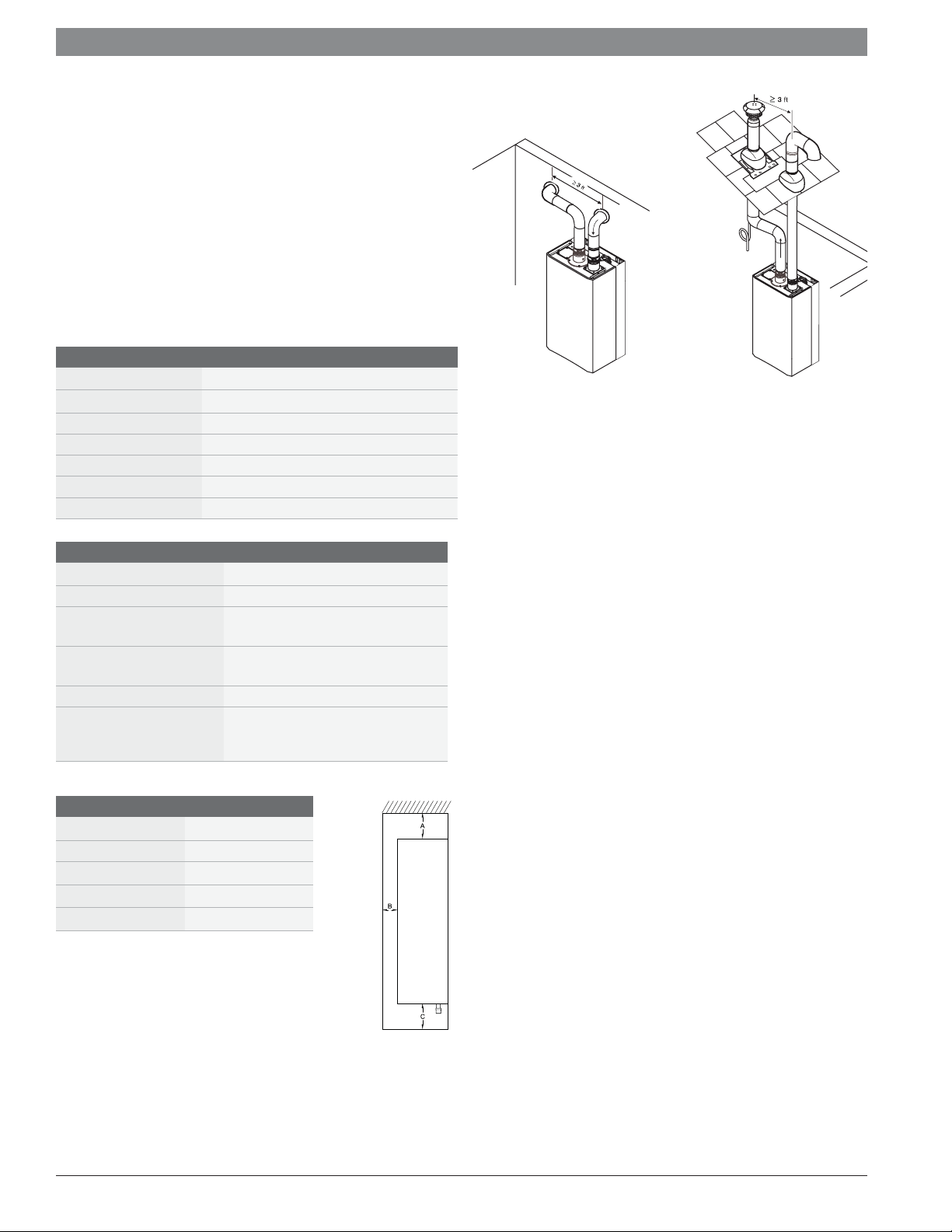

2.6 Bosch GWH 450 ESR

Features:

Specifi cally designed for recirculating applications

Electronic ignition and built in power vent

GWH 450 ESR thermal effi ciency of 81%

Vents vertically or horizontally with 3" stainless steel (AL29-4C)

Direct vent room-sealed combustion

Computerized temperature control — ensures temperature

stability

Model GWH 450 ESR N for natural gas (NG) supply

Model GWH 450 ESR L for liquid propane (LP) supply

10-year warranty

GWH 450 ESR Technical Specifi cations

Gas input GWH 450 ESR: 45,000 - 120,000 Btu/h

Maximum fl ow rates GWH 450 ESR: 4.5gpm @ 45°F rise

Thermal Effi ciency 81%

Dimensions 27.5" h x 15.75" w x 11.75" d

Weight 47 lbs.

Modulating gas valve yes

Ignition Electronic

GWH 450 ESR Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 5.5" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Electrical supply 120VAC - plugs in

Venting 3" stainless steel (AL29-4C)

direct vent

room-sealed combustion

GWH 450 ESR Installation Clearances

Top (A) 12"

Front (B) 1"

Back 0"

Sides 1"

Floor (C) 12"

Applications manual

Fig. 1 Venting confi gurations

Installation guidelines:

Venting:

Must be 3" or 4" AL29-4C sealed stainless steel vent pipe.

Slope horizontal runs up to termination ¼" per foot. The horizon-

tal section between last elbow and termination must slope down

to the termination ¼" per foot.

Do not combination vent with any other appliance.

Always install an external condensate drain except when termi-

nating horizontally with less than 3 feet of pipe.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

Partially fi ll condensate drain tube loop with water prior to start

up.

Application manual | 11.2007

Bosch Water Heating

Page 11

Applications manual

2.7 Bosch GWH 425 EF

Features:

Electronic ignition and built in power vent

Thermal effi ciency of 82%

Vents with 4" stainless steel or galvanized vent pipe

Specifically designed for horizontal vent terminations

Modulating gas valve — ensures temperature

stability

Model GWH 425 EF N for natural gas (NG) supply

Model GWH 425 EF L for liquid propane (LP) supply

15-year warranty

Qualifi es for $300 tax credit (LP only)

GWH 425 EF Technical Specifi cations

Gas input Natural Gas: 28,000 - 130,000 Btu/h

LP Gas: 28,000- 125,000 Btu/h

Minimum fl ow to

activate

Maximum fl ow rates 4.6 gpm @ 45°F rise

Thermal Effi ciency NG: 80% LP: 82%

Dimensions 29.75" h x 18.25" w x 8.75" d

Weight 44 lbs.

Modulating gas valve yes

Ignition Electronic

GWH 425 EF Installation Specifi cations

Gas connection ½" Male NPT

Water connections ½" Male NPT

NG gas pressure Minimum: 7" W.C.

LP gas pressure Minimum: 11" W.C.

Electrical supply 120VAC - plugs in

GWH 425 EF Installation Clearances

Top (A) 12"

Front (B) 4"

Back 0"

Sides 4"

Floor (C) 12"

0.5 gallons per minute (GPM)

Maximum: 14" W.C.

Maximum: 14" W.C.

Venting 4" stainless steel (AL29-4C)

or 26 gauge galvanized

| 11

Fig. 1 Venting confi gurations

Installation guidelines:

Venting:

4" AL29-4C sealed stainless steel or 26 gauge galvanized vent

pipe.

Slope horizontal runs up to termination ¼" per foot.

Do not combination vent with any other appliance.

See manual for vent terminator clearances.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ½".

Do not solder directly to connections on the bottom of the unit.

Use full port ball valves for isolation valves.

Applications manual | 11.2007Bosch Water Heating

Page 12

|

12

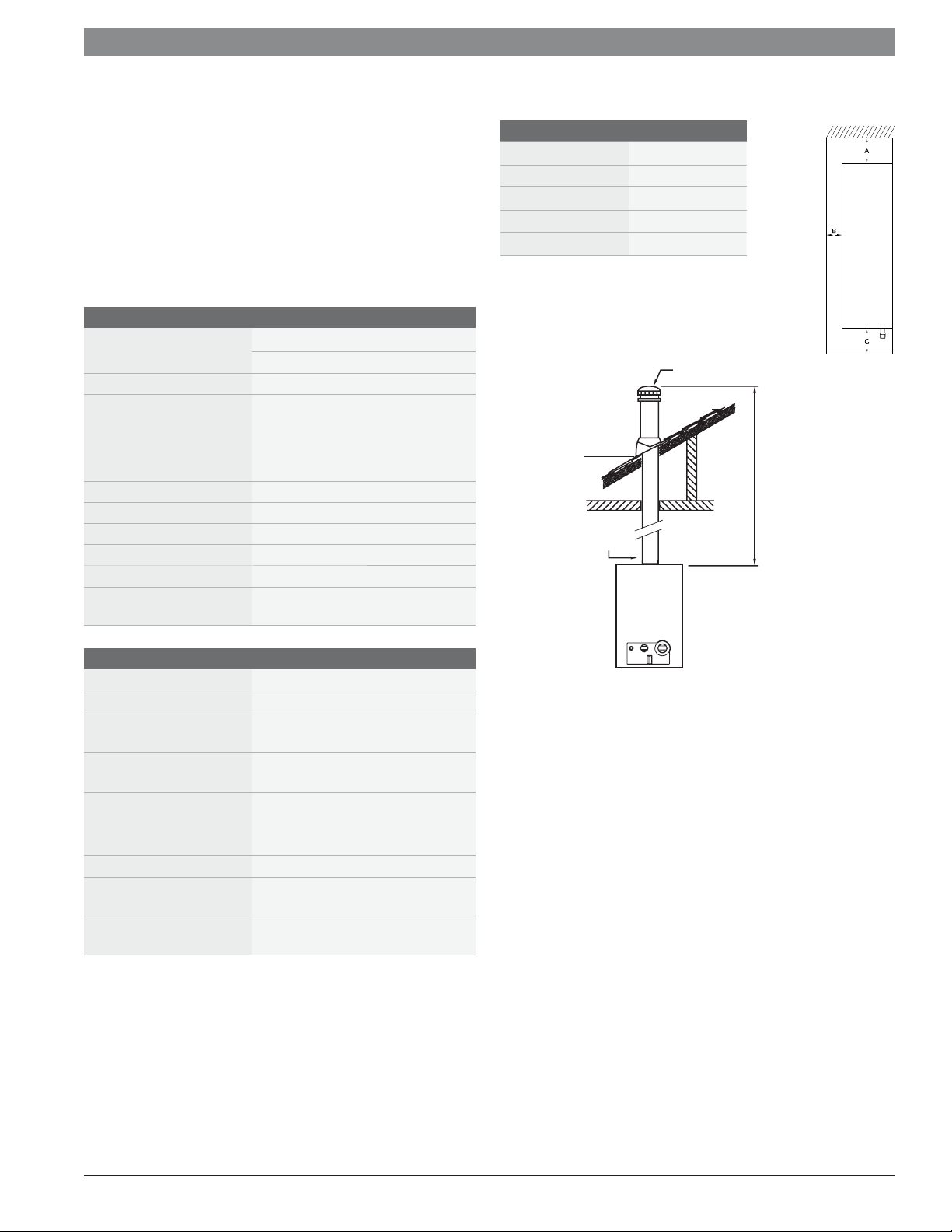

2.8 Bosch GWH 425 HN

Features:

Hydro-generated ignition

80% thermal effi ciency

Endless hot water for one major application at a time

Venting: 5" double wall B-vent — natural draft

Modulating gas valve — constant temperature at varying flow rates

Model GWH 425 HN N for natural gas (NG) supply

Model GWH 425 HN L for liquid propane (LP) supply

15-year warranty

Qualifi es for $300 tax credit

GWH 425 HN Technical Specifi cations

Gas input Natural Gas: 30,735 - 117,000 BTU

LP Gas: 30,735 - 117,000 BTU

Minimum fl ow to activate 0.6 gallons per minute (gpm)

Flow rates 45˚F rise @ 4.2 gpm

55˚F rise @ 3.4 gpm

65˚F rise @ 2.9 gpm

77˚F rise @ 2.4 gpm

90˚F rise @ 2.1 gpm

Thermal Effi ciency NG: 80% LP: 80%

Dimensions 25.75" h x 16.75" w x 8.5" d

Weight 33 lbs.

Modulating gas valve yes

Ignition Hydro-generated

Accessories Horizontal vent kit (AQ4) - power

vent kit for horizontal venting

GWH 425 HN Installation Clearances

Top (A) 12"

Front (B) 4"

Back 0"

Sides 4"

Floor (C) 12"

LISTED GAS VENT

ESTABLISH A ONE

FOOT RISE BEFORE

ANY ELBOWS

LISTED VENT C AP

Applications manual

MINIMUM 6

FEE T (1.8M)

GWH 425 HN Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 7" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Water pressure

(Static)

Minimum: 30 PSI

Minimum well pressure: 40 PSI

Maximum: 150 PSI

Electrical supply 120VAC - plugs in

Vertical venting 5" minimum diameter - natural

draft

Horizontal venting AQ4 horizontal vent kit required

for horizontal terminations

Fig. 2 Venting confi guration

Installation guidelines:

Venting:

5" minimum diameter — do not reduce vent size

Refer to installation manual for vent material options

Do not combination vent with any power vented appliances

Establish a one-foot rise before any elbows

Minimum vent height - 6 feet

Horizontal sections must slope upwards at least ¼" for every foot

of the horizontal length and be properly supported

Gas piping:

Heater will not function properly without adequate supply gas

pressure

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable drain

Minimum piping diameter is ¾"

Do not solder directly to connections on the bottom of the unit

Use full port ball valves for isolation valves

Application manual | 11.2007

Bosch Water Heating

Page 13

Applications manual

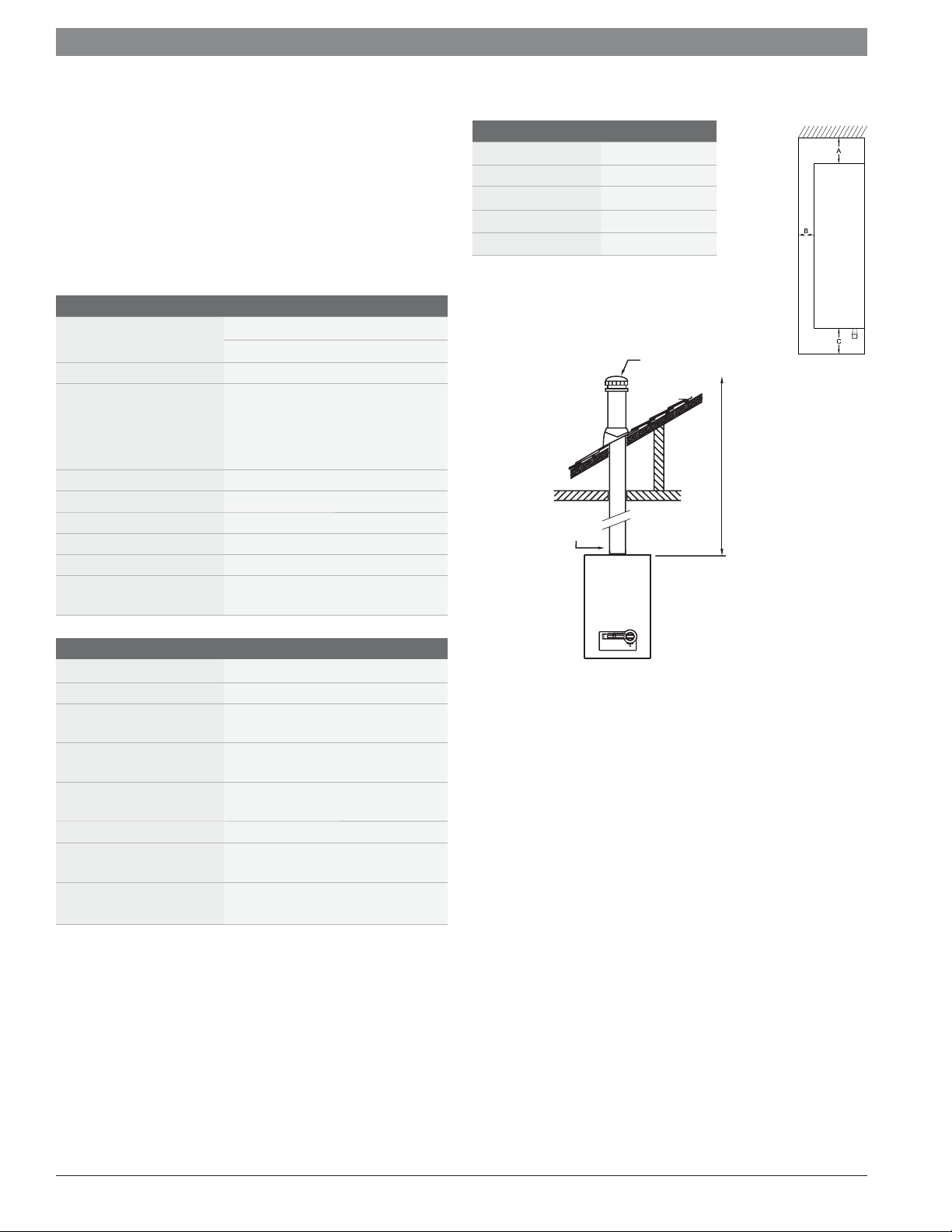

2.9 Bosch GWH 425 PN

Features:

Standing pilot ignition

78% thermal effi ciency

Endless hot water for one major application at a time

Modulating gas valve — constant temperature at varying flow rates

Model GWH 425 PN N for natural gas (NG) supply

Model GWH 425 PN L for liquid propane (LP) supply

15-year warranty

GWH 425 PN Technical Specifi cations

Power input Natural Gas: 31,000 - 117,000 BTU

LP Gas: 31,000 - 117,000 BTU

Minimum fl ow to activate 0.6 gallons per minute (gpm)

Flow rates 45˚F rise @ 4.2 gpm

55˚F rise @ 3.4 gpm

65˚F rise @ 2.9 gpm

77˚F rise @ 2.4 gpm

90˚F rise @ 2.1 gpm

Thermal Effi ciency NG: 78% LP: 78%

Dimensions 25.75" h x 16.75" w x 8.5" d

Weight 33 lbs.

Modulating gas valve yes

Ignition Standing pilot

Accessories Horizontal vent kit (AQ4) - power

vent kit for horizontal venting

GWH 425 PN Installation Clearances

Top (A) 12"

Front (B) 4"

Back 0"

Sides 4"

Floor (C) 12"

LISTED GAS VENT

ESTABLISH A ONE

FOOT RISE BEFORE

ANY ELBOWS

LISTED VENT C AP

| 13

MINIMUM 6

FEE T (1.8M)

GWH 425 PN Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 7" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Water pressure Minimum: 30 PSI

Maximum: 150 PSI

Electrical supply 120VAC - plugs in

Vertical venting 5" minimum diameter - natural

draft

Horizontal venting AQ4 horizontal vent kit required

for horizontal terminations

Fig. 4 Venting confi guration

Installation guidelines:

Venting:

5" minimum diameter — do not reduce vent size.

Refer to installation manual for vent material options

Do not combination vent with any power vented appliances.

Establish a one-foot rise before any elbows

Minimum vent height - 6 feet.

Horizontal sections must slope upwards at least ¼" for every foot

of the horizontal length and be properly supported.

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use full port ball valves for isolation valves.

Applications manual | 11.2007Bosch Water Heating

Page 14

|

14

2.10 Bosch GWH 260 PN

Features:

Standing pilot ignition

78% thermal effi ciency

Mounts on wall for easy installation

Venting: 4" double wall B-vent — natural draft

Modulating gas valve — constant temperature at varying flow rates

Model GWH 260 PN N for natural gas (NG) supply

Model GWH 260 PN L for liquid propane (LP) supply

15-year warranty

Applications manual

GWH 260 PN Installation Clearances

Top (A) 12"

Front (B) 4"

Back 0"

Sides 4"

Floor (C) 12"

GWH 260 PN Technical Specifi cations

Gas input Natural Gas: 30,735 - 74,900 BTU

LP Gas: 30,735 - 74,900 BTU

Minimum fl ow to activate 0.6 gallons per minute (gpm)

Flow rates 45˚F rise @ 2.6 gpm

55˚F rise @ 2.1 gpm

65˚F rise @ 1.7 gpm

77˚F rise @ 1.5 gpm

90˚F rise @ 1.3 gpm

Thermal Effi ciency NG: 78% LP: 78%

Dimensions 28.8" h x 12.2" w x 8.5" d

Weight 25 lbs.

Modulating gas valve yes

Ignition Standing pilot

GWH 260 PN Installation Specifi cations

Gas connection ¾" Male NPT

Water connections ¾" Male NPT

NG gas pressure Minimum: 7" W.C.

Maximum: 14" W.C.

LP gas pressure Minimum: 11" W.C.

Maximum: 14" W.C.

Water pressure

(Static)

Minimum: 30 PSI

Minimum well pressure: 40PSI

Maximum: 150 PSI

Electrical supply 120VAC - plugs in

Venting 4" double wall B-vent - natural

draft

LISTED VENT C AP

MINIMUM 6

FEE T (1.8M)

LISTED GAS VENT

ESTABLISH A ONE

FOOT RISE BEFORE

ANY ELBOWS

Fig. 4 Venting confi guration

Installation guidelines:

Venting:

4" minimum diameter — do not reduce vent size.

Refer to installation manual for vent material options

Do not combination vent with any power vented appliances.

Establish a one-foot rise before any elbows

Minimum vent height - 6 feet.

Horizontal sections must slope upwards at least ¼" for every foot

of the horizontal length and be properly supported.

Application manual | 11.2007

Gas piping:

Heater will not function properly without adequate supply gas

pressure.

Any appliance connector should be ¾" minimum diameter

Plumbing:

Install the included pressure relief valve and pipe to suitable

drain.

Minimum piping diameter is ¾".

Do not solder directly to the bottom of the unit.

Use full port ball valves for isolation valves.

Bosch Water Heating

Page 15

Applications manual

2.11 Powerstream Pro RP17PT, RP27PT

| 15

Features:

Over 90% effi ciency rating

10-year warranty on heat exchanger

Durable polymer construction

External temperature control knob

Thermal cut-out for safety

Flow sensor to provide a constant output temperature

Provides an ENDLESS supply of hot water

Weighs less than 25 pounds and fi ts virtually anywhere

No temperature/pressure relief valve necessary (unless required

by local codes)

Technical Specifi cations

Model RP17PT RP27PT

Effi ciency 90% 94%

Dimensions

15 ½" x 15 ¼" x 4 ½" 15 ½" x 15 ¼" x 4 ½"

Weight 20 lbs. 22 lbs.

Water fi ttings ¾" Male NPT ¾" Male NPT

Activation rate 0.6 gpm 0.8 gpm

Electrical requirements

Volts 240 240

Kilowatts 17.25kW 26.85kW

Amps

Wire

size

U.S.A

Canada

U.S.A

Canada

80 (2x40 amps)

80 (1x80 amps)

8 AWG

(4 conductors & ground)

Check Canadian

Electrical Code

(C22.1-02)

120 (3x40 amps)

120 (1x120amps)

8 AWG

(4 conductors & ground)

Check Canadian

Electrical Code

(C22.1-02)

Phase Single Single

Maximum fl ow rate at given temperature rise

45°F Rise 2.6 gpm 4.0 gpm

50°F Rise 2.3 gpm 3.7 gpm

60°F Rise 2.0 gpm 3.0 gpm

70°F Rise 1.7 gpm 2.6 gpm

80°F Rise 1.5 gpm 2.2 gpm

Installation guidelines:

Electrical:

Minimum electrical service for RP17PT is 150 amps.

Minimum electrical service for RP27PT is 200 amps.

Minimum wire size for both models is 8 AWG.

Plumbing:

Do not solder directly to connections on the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

RP17PT terminal block

2 independent

40 amp double-pole

circuit breakers

Fig. 5 RP17PT Electrical Connections

RP27PT terminal block

3 independent

40 amp double-pole

circuit breakers

Fig. 6 RP27PT Electrical Connections

Applications manual | 11.2007Bosch Water Heating

Page 16

16

|

Applications manual

2.12 Powerstream Pro RP1P, RP2P, RP3P, RP7P,

RP9P,RP12PT

Installation guidelines:

Features:

5-year warranty on heat exchanger

Saves space

Installs vertically or horizontally (Model RP12PT only installs

horizontally)

All models must be hardwired

Solid copper heat exchanger, copper sheathed elements and

tough plastic housing

High/low kW settings possible within most models

Model RP12PT has thermostatic adjustable control

Technical Specifi cations

Model Part # Wire Size Voltage Amps High kW Low kW Degree rise at fl ow rates (GPM)* Activation

RP1P 8AWG 240 40 9.50 — — 84° 64° 42° 32° 0.75

20 — 4.75 — 42° 32° 21° 16°

RP2P 10AWG 277 22 6.00 — 81° 55° 42° 27° — 0.50

11 — 3.00 41° 28° 21° 14° —

RP3P 10AWG 120 29 3.40 — 41° 28° 20° — — 0.50

RP7P 10AWG 240 30 7.20 — — 63° 48° 32° 24° 0.75

15 — 3.60 — 32° 24° 16° 12°

RP9P 8AWG 277 35 9.50 — — 84° 64° 42° 32° 0.75

18 — 4.75 — 42° 32° 21° 16°

RP12PT 6AWG 240 50 12.00 — — 90° 72° 52° 42° 0.75

Electrical:

Refer to the chart below as specifi cation varies by model

Plumbing:

Do not solder directly to connections on the bottom of the unit.

Use unions to facilitate easy future maintenance.

Use full port ball valves for isolation valves.

0.5 0.75 1.0 1.5 2.0

rate (GPM)

Application manual | 11.2007

Bosch Water Heating

Page 17

Applications manual

| 17

2.13 Ariston Pro GL2.5Ti, GL4Ti, GL8Ti

Features:

Point of use mini tank

3 models

Adjustable thermostat with thermal cut-out

Dielectric isolation on inlet/outlet connections

Units can be wall hung (bracket included) or fl oor mounted

Durable poly-composite housing will not dent and resists corrosion

Temperature/pressure relief valve included (plumb correctly for

Installation guidelines:

Electrical:

Follow local codes for electrical outlets for water heaters

All models plugin to standard wall outlet.

Plumbing:

Use full port valves for isolation valves.

Do not solder directly to the plumbing connections.

discharge)

Simple 120V AC plug-in connection

8-year warranty

Technical Specifi cations

GL2.5Ti GL4Ti GL8Ti

Tank Volume 2.75 gallons 3.85 gallons 7.0 gallons

Nominal Dimensions 14" x 14" x 11" 14" x 14" x 14" 17 ½" x 17 ½" x 14 ½"

Voltage 120V 120V 120V

Amperage 12.5 amps 12.5 amps 12.5 amps

Wire Type Plug-in Plug-in Plug-in

Heating Capacity 1500 watts 1500 watts 1500 watts

Recovery at 90° rise 7 gph 7 gph 7gph

Temperature range 65-145°F 65-145°F 65-145°F

Water connections ½" NPT ½" NPT ¾" NPT

Maximum water

150 PSI 150 PSI 150 PSI

pressure

Relief valve Installed Installed Included

Applications manual | 11.2007Bosch Water Heating

Page 18

|

18

3 Domestic Water Heating Applications

Potable water

Potable water is water that is suitable for drinking. Bosch Water

Heating appliances are approved to heat potable water only. Heating

any other liquid other than potable water will void the manufactures

warranty covering the appliance.

Introduction

This chapter covers the various application techniques Bosch Water

Heating recommends. The schematics are to be used by professional

contractors in designing a domestic water heating system. The

applications covered range from single sink point-of-use applications

to multi-appliance central domestic recirculation applications.

3.1 Point-of-use applications

Point-of-use applications cover the small applications that a large

water heater would be ineffi cient for. Installing a smaller heater at a

point-of-use puts the heater near the hot water demand and reduces

the wait for hot water. Common applications for these appliances

include homes, offi ces, warehouses, service stations, stores, conces-

sion stands, and summer camps.

Applications manual

Application manual | 11.2007

Bosch Water Heating

Page 19

Applications manual

3.1.1 Ariston mini tank

Simply tap into the cold water line and install the water heater

directly at the sink. All models plug into a standard 120 volt outlet.

Heater can be wall mounted, or sit on the fl oor.

| 19

Ariston Pro GL2.5 Ti

Ariston Pro GL8 Ti

hot

cold cold

hot

Ariston Pro GL4 Ti

hot

cold

Symbols

Temperature and pressure

relief valve

Sink

Flow direction

Service valve

Drain pan

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # POU1

Applications manual | 11.2007Bosch Water Heating

CN rev 06/06

Page 20

|

20

3.1.2 Powerstream Pro electric point-of-use tankless water heater

PowerstreamPro point-of-use water heaters come in four models to

serve a wide range of applications. Finding the right model depends

upon your desired temperature and fl ow rate. Use the table below to

fi nd the model best suited to your customer‘s needs. Flow controls

and faucet aerators can greatly enhance performance.

Note: Water heater must be fi lled with water and purged of air prior

to supplying power.

hot

Applications manual

cold supply

Powerstream Pro

RP1P, RP2P, RP3P,

RP7P, RP9P, RP12PT

hot

cold supply

cold

Symbols

Service valve

hot

Powerstream Pro

RP1P, RP2P, RP3P,

RP7P, RP9P, RP12PT

cold

Sink

hot

Flow direction

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # POU2

CN rev 06/07

Application manual | 11.2007

Bosch Water Heating

Page 21

Applications manual

BOSCH

3.1.3 Bosch GWH-260PN gas tankless water heater

The Bosch GWH-260PN gas tankless water heater offers

a compact and lightweight design for easy installation.

This unit is equipped with standing pilot ignition and is

intended for low volume applications.

Bosch GWH 260 PN

| 21

Symbols

Temperature and pressure

relief valve

hot

cold

Sink

Low flow

Service valves

Flow direction

shower

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # POU3

CN rev 06/07

Applications manual | 11.2007Bosch Water Heating

Page 22

|

22

3.2 Whole house applications

Whole house applications cover the typical home applications up to

a 2 or 3 bedroom house. See the sizing guide (Section 2.1) to

determine the best Bosch water heater model for your application.

An enhanced design including an Ariston mini tank in line to the hot

water source will reduce the wait time for hot water and improve

temperature stability.

3.2.1 Powerstream Pro whole house applications

The RP17PT and RP27PT must be hard wired directly to the breaker

box.

Applications manual

Powerstream Pro

RP17PT or RP27PT

ColdHot

Ariston Pro GL4Ti

for pipe runs over

100 ft, use GL8Ti

Note: place Ariston close to the point of

use to reduce wait time for hot water.

Powerstream Pro

RP17PT or RP27PT

Hot

Cold

Symbols

Standard tub fixture

Flow direction

Service

valves

Sink

Note: Cold water piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # WH1

Bosch Water Heating

CN rev 06/07

Page 23

Applications manual

3.2.2 Powerstream Pro whole house application with domestic

recirculation loop

The circulator should be controlled by an external aquastat, or with

a timer to run only during times of expected hot water usage.

| 23

Powerstream Pro

RP17PT or RP27PT

Hot

Cold

Ariston Pro GL4Ti

(for pipe runs over

100ft use GL8Ti)

Symbols

Bronze circulator pump sized

according to UPC standards

(Taco Bronze 007 or Grundfos 15-42B

will cover most homes up to 3 bathrooms)

Potable water

expansion tank

Note: Cold water piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does to address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Flow check valve

Service

valves

Timer or

Aquastat

Sink

Flow direction

Standard tub fixture

Drawing # WH1R

CN rev 06/07

Applications manual | 11.2007Bosch Water Heating

Page 24

|

24

3.2.3 Bosch ProTankless gas water heater

Below are two examples of Bosch ProTankless gas water heater

installations for the whole house. One example shows an Ariston

mini tank in line for reduced hot water wait time and increased

temperature stability.

Applications manual

Bosch GWH 715 ES,

Bosch GWH C 800 ES,

Bosch GWH 425 HN or

Bosch GWH 425 PN

Ariston Pro GL4Ti

for pipe runs over

100 ft, use GL8Ti

Note: place Ariston close to the point of

use to reduce wait time for hot water.

Symbols

Standard tub fixture

Pressure

Flow

direction

relief

valve

Hot

Bosch GWH 715 ES,

Bosch GWH C 800 ES,

Bosch GWH 425 HN or

Bosch GWH 425 PN

Hot

Cold

Cold

Service

Sink

valves

Note: Cold water piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # WH2

CN revA 10/07

Bosch Water Heating

Page 25

Applications manual

3.2.4 Bosch ProTankless gas water heater with domestic

recirculation loop

The circulator should be controlled by an external aquastat, or with

a timer to run only during times of expected hot water usage.

| 25

Ariston Pro GL4Ti

(for pipe runs over

100ft use GL8Ti)

Potable water

expansion tank

Bronze circulator sized

according to UPC standards

(Taco Bronze 007 or Grundfos 15-42B

will cover most homes up to 3 bathrooms)

Flow

check

valve

Symbols

Service

valves

Pressure

relief

valve

Sink

Timer or

Aquastat

Hot

Cold

Bosch GWH 715 ES,

Bosch GWH C 800 ES,

Bosch GWH 425 HN or

Bosch GWH 425 PN

Standard

tub

fixture

Flow direction

Note: Cold water piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # WH2R

Applications manual | 11.2007Bosch Water Heating

CN rev 06/07

Page 26

|

26

4 High Volume Potable Water Heating

Potable water

Potable water is water that is suitable for drinking. Bosch Water

Heating appliances are approved to heat potable water only. Heating

any other liquid other than potable water will void the manfuctures

warranty covering the appliance.

Introduction

This section lays out the options for high volume water heating for

large residential and light commercial applications including continuous fl ows and high volume demands of large home and

commercial applications.

4.1 Parallel unit applications

Parallel unit applications have twice the activation rate of single unit

applications. The following designs are for continuous fl ow, high

volume hot water needs. Not intended for residential use. To balance fl ows use reverse return piping. (shown below)

Applications manual

Application manual | 11.2007

Bosch Water Heating

Page 27

Applications manual

4.1.1 Bosch ProTankless gas water heater in parallel for

commercial applications

Two Bosch ProTankless units will have double the activation rate of a

single unit. When sizing gas line, ensure the gas line is sized to carry

the BTU load of two units plus any additional gas appliances. See

the installation manuals for a gas line sizing chart.

Bosch GWH 715 ES,

Bosch GWH C 800 ES,

*see text above about

activation rate and

gas supply requirements

| 27

hot

cold

hot

cold

Symbols

Pressure

relief

valves

cold

hot

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Flow direction

Service

valves

Drawing # P2

CN revA 10/07

Applications manual | 11.2007Bosch Water Heating

Page 28

|

28

4.2 Cascading unit applications

A cascading application should be considered if the potential hot

water demand exceeds the capacity of one GWH 715 ES or

GWH C 800 ES. The cascading set up supports variable fl ow inputs

and is designed for large homes and commercial applications.

4.2.1 GWH 715 ES and GWH C 800 ES cascading

Cascading allows up to two appliances to be connected in parallel.

One of the appliances will serve as the controlling Master appliance

and will attempt to meet the hot water demand. If the hot water

demand is beyond the capacity of the Master appliance, a signal is

sent to the Slave appliance to begin operation.

hot

cold

tankless link

hot

cold

Applications manual

Bosch GWH 715 ES or

Bosch GWH C 800 ES

• The plumbing must be connected in the reverse

return method with a minimum number of elbows

to aid in balancing pressures between the two

appliances.

• If a domestic recirculation system is desired,

recirculate the water through the Ariston ProTi

water heater as seen in chapter 3.4.

• Locate appliances close together for

improved performance.

• Follow industry plumbing practices when installing

multiple appliances

• Minimum pipe diameter: ¾"

• Minimum water pressure: 50 psi

• Maximum distance between appliances: 36"

• Insulate pipes to prevent heat loss.

cold

hot

Ariston Pro GL8Ti

outlet

inlet

Symbols

Water

hammer

arrestor

Flow direction

Pressure

relief

valve

recommended

Service

valves

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # CA1

Tankless

link

CN revA 10/07

Application manual | 11.2007

Bosch Water Heating

Page 29

Applications manual

4.3 External storage tank loading applications.

Introduction

This section lays out tank loading options for high volume water

heating for large residential and light commercial applications

including continuous fl ows and high volume demands of large home

and commercial applications.

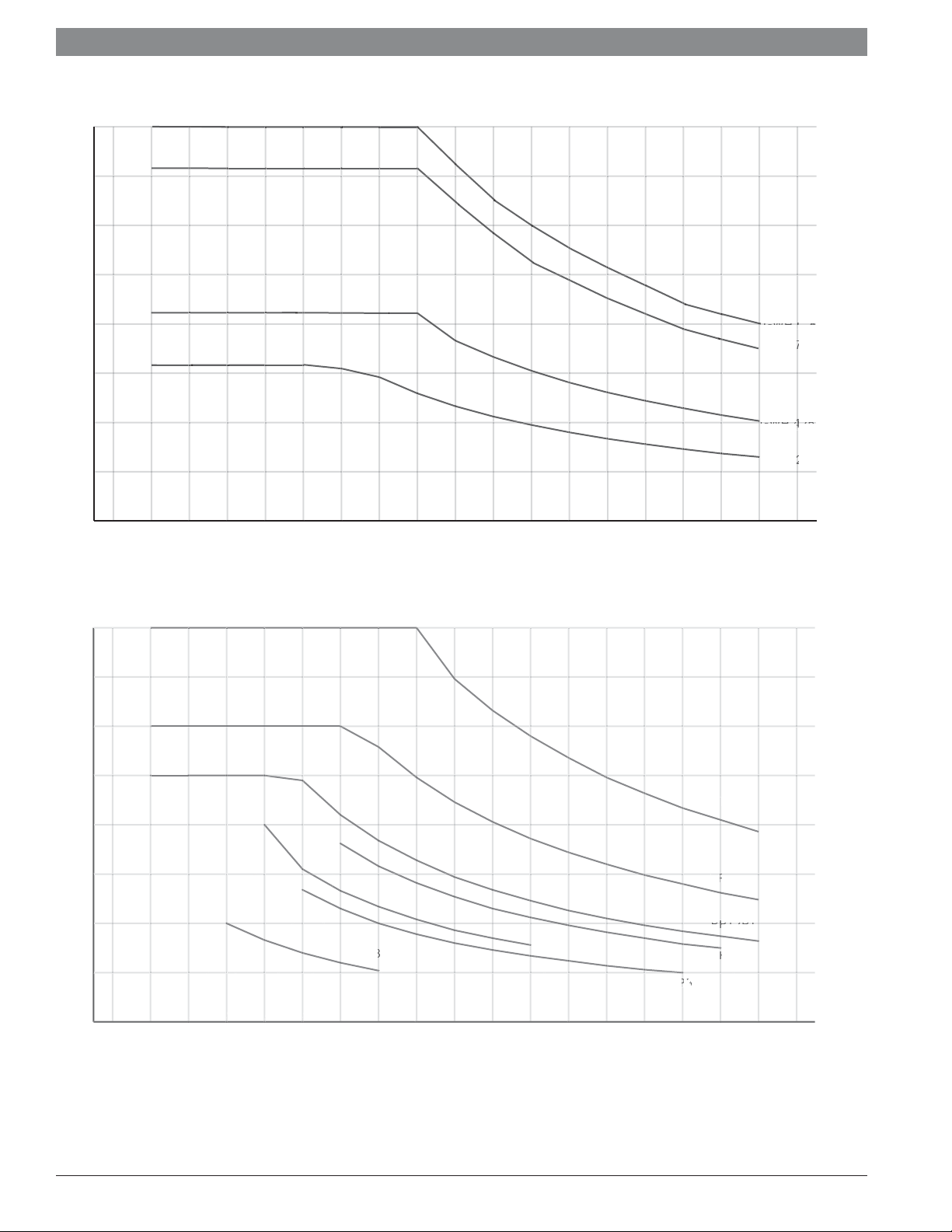

4.3.1 GWH 345/450 ESR pressure drops and circulator guidelines

The maximum amp draw for any circulator connected directly to

the appliance must not exceed 1.5 amps

Circulator should be sized by the professional plumbing

contractor

Bronze or stainless steel circulators required for all open loop

applications

50 feet of head

40 feet of head

| 29

30 feet of head

20 feet of head

10 feet of head

Inlet pressure

0 feet of hea d

50 feet of head

40 feet of head

30 feet of head

20 feet of head

10 feet of head

GWH 345 ESR

0 GPM 1 GPM 2 GPM 3 GPM 4 GPM 5 GP M 6 GPM

water flow rate

GWH 450 ESR

Inlet pressure

0 feet of head

0 GPM 1 GPM 2 GP M 3 GPM 4 GPM 5 GPM 6 GPM

water flow rate

Pressure drop curves

Note : Flow above 6 GPM is not permitted.

Applications manual | 11.2007Bosch Water Heating

Page 30

|

30

4.3.2 Single unit tank loading application plumbing diagram

The GWH 345/450 ESR is specifi cally designed for this application.

Cold water

feed

DHW

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

Applications manual

PS

Symbols

Potable water

expansion tank

Pressure

relief

Flow

direction

valve

Bronze circulator sized

according to UPC standards

Service

valves

12K ohm

thermistor

with immersion

well

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # STL

External

storage

tank

CN revA 10/07

Application manual | 11.2007

Bosch Water Heating

Page 31

Applications manual

4.3.2 Single unit tank loading application electrical diagram

The following shows the appropriate electrical connections for

plumbing diagram 4.3.2

Terminal box

PK

L N

P0

LL PSN L

| 31

110VAC from outlet

PE

ESR control

board

PS

PCB

Single Unit Tank Loading

Electrical Diagram

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # ESTL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 32

|

Thermostatic

mixing

valve

32

5 Open Loop Space Heating

Introduction

This section is designed to provide a road map of techniques for

using a tankless water heater to heat domestic water and at the

same time provide space heating in residential applications. As with

all installations, check with the local authority having jurisdiction.

Some jurisdictions may not allow these types of applications.

Cold water

feed

Applications manual

5.1 External storage tank

The appliances shown in this section are approved under ANSI

Z21.10.3 and CSA 4.3 as circulating gas water heaters. Only open

loop applications are approved under this standard.

5.1.1 Radiant space heating and DHW plumbing diagram

Bosch GWH 345 ESR,

DHW

Bosch GWH 450 ESR

P2

Potable water

expansion tank

Bronze circulator

sized according to

UPC standards

P1

Symbols

Pressure

relief

valve

Thermostatic

mixing

valve

Flow

direction

Service

valves

Radiant

piping

12K ohm

thermistor

with immersion

well

PS

Storage

tank

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # ROL

Bosch Water Heating

CN revA 10/07

Page 33

Applications manual

5.1.1 Radiant space heating and DHW electrical diagram

The following shows the appropriate electrical connections for

plumbing diagram 5.1.1

Terminal box

PK

L N

P0

LL PSN L

| 33

110VAC from outlet

PE

ESR control

board

Neutral

120Vac

24 VAC

POWER

T

Stat

SR 502

TWO ZONE SWITCHING RELAY

FUSE 1 AMP

NPZCHX1 ZR

P1

ZONE1 ZONE2

X

2

ZONE1 ZONE2

PS

T

Stat

P2

Radiant Space Heating and DHW

Electrical Diagram

PCB

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # EROL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 34

|

34

5.1.2 Fan coil space heating and DHW plumbing diagram

Fan Coil

Cold water

P1

feed

DHW

Applications manual

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

Potable water

expansion tank

Air

seperator

Bronze circulator

sized according to

UPC standards

Symbols

Flow

check

valve

Pressure

relief

valve

Thermostatic

mixing

valve

Service

valves

Fan Coil

Tank

Aquastat

PK

Storage

tank

Flow

direction

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does to address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # FCOL

CN revA 10/07

Bosch Water Heating

Page 35

Applications manual

5.1.2 Fan Coil space heating and DHW electrical diagram

The following shows the appropriate electrical connections for plumbing diagram 5.1.2

Terminal box

PK

L N

P0

LL

PS

N L

PE

ESR control

| 35

110VAC from outlet

board

PK

T

Stat

Neutral

120Vac

SR501

1 ZONE

SWITCHING RELAY

120 VAC

INPUT

H3 5

4

N/O4N/C6N/ONN/C

24

WR

VAC

COM

TT

6

TT

LR LS

AQUASTAT

P1

Fan Coil Space Heating and DHW

Electrical Diagram

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # EFCOL

CN revA 10/07

Applications manual | 11.2007Bosch Water Heating

Page 36

|

36

5.1.3 Baseboard/ Radiant Panel space heating and DHW plumbing diagram

Cold water

feed

P1

DHW

Applications manual

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

Potable water

expansion tank

Air

seperator

Bronze circulator

sized according to

UPC standards

Symbols

Flow

check

valve

Pressure

relief

valve

Thermostatic

Mixing

valve

Flow

direction

Tank

Aquastat

Service

valves

Baseboard/

Radiant

Panel

PK

Storage

tank

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # BB OL

Bosch Water Heating

CN revA 10/07

Page 37

Applications manual

5.1.3 Baseboard/Radiant Panel space heating and DHW electrical diagram

The following shows the appropriate electrical connections for plumbing diagram 5.1.3

Terminal box

PK

L N

P0

LL

PS

N L

PE

ESR control

| 37

110VAC from outlet

board

Neutral

120Vac

24 VAC

POWER

PK

T

Stat

SR 503

or equivalent

FUSE 1 AMP

NPZCHX

P1

ZONE1 ZONE2 ZONE3

THREE ZONE SWITCHING RELAY

WITH OPTIONAL PRIORITY

X2

1 ZR

ZONE1 ZONE2 ZONE3

Baseboard Space Heating and DHW

Electrical Diagram

TT

LR LS

AQUASTAT

Note: This drawing is conceptual in nature and does not purport to address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # EBBOL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 38

|

38

5.1.4 Baseboard/ Radiant Panel space heating and DHW (with Ariston mini tank) plumbing diagram

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

PK

Applications manual

DHW

Ariston GL8Ti

mini water

tank

Bronze circulator

sized according to

UPC standards

Cold water

feed

Flow

check

valve

Pressure

relief

valve

Thermostatic

mixing

valve

Symbols

PS

Cold water

Potable

water

expansion tank

Aquastat

well & 12kohm

thermistor

Service

valves

feed

Aquastat

well with

12k ohm

thermistor

(insulate piping

around thermistor)

Baseboard/

Radiant

Panel

Flow

direction

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # BBAOL

Bosch Water Heating

CN revA 10/07

Page 39

Applications manual

5.1.4 Baseboard/Radiant Panel space heating and DHW (with Ariston mini tank) electrical diagram

The following shows the appropriate electrical connections for plumbing diagram 5.1.4

Terminal box

PK

L N

P0

LL

PS

N L

PE

ESR control

board

| 39

110VAC from outlet

PK

PS

PCB

TT

LR LS

Room Thermostat

Baseboard/Radiant Panel Space Heating and DHW (with Ariston mini tank)

Electrical Diagram

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # EBBAOL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 40

|

40

5.1.5 Baseboard/ Radiant Panel space heating and DHW (without storage tank) plumbing diagram

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

Applications manual

PK

DHW

Cold water

feed

Piping

Insulation

Bronze circulator

sized according to

UPC standards

PS

Symbols

Flow

check

valve

Pressure

relief

valve

Thermostatic

mixing

valve

Insulate

piping

Flow

direction

Aquastat

well & 12kohm

thermistor

Service

valves

Baseboard/

Radiant

Panel

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Drawing # BBNTOL

Bosch Water Heating

CN revA 10/07

Page 41

Applications manual

5.1.5 Baseboard/Radiant Panel space heating and DHW (without storage tank) electrical diagram

The following shows the appropriate electrical connections for plumbing diagram 5.1.5

Terminal box

PK

L NP0LL PSN L

PE

ESR control

board

| 41

110VAC from outlet

PK

PS

PCB

Baseboard/Radiant Panel Space Heating and DHW

Without Storage Tank Electrical Diagram

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # BBNTOL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 42

|

42

5.2 Indirect Tank Applications

5.2.1 Indirect Baseboard/ Radiant Panel space heating and DHW plumbing diagram

Note: Not suitable for space heating applications requiring high water temperature.

Cold water

feed

Applications manual

Bosch GWH 345 ESR,

Bosch GWH 450 ESR

DHW

Potable water

expansion tank

Air

seperator

P1

Flow

check

valve

Pressure

relief

valve

Symbols

Flow

direction

Tank

Aquastat

Indirect

hot water

tank

Cold

feed

PK

Baseboard/

Radiant

Panel

Bronze circulator

sized according to

UPC standards

Note: Piping to fixtures not shown for clarity purposes.

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Application manual | 11.2007

Thermostatic

Mixing

valve

Service

valves

Pressure

reducing

valve

Drawing # IDBBOL

Back Flow

preventer

Bosch Water Heating

CN revA 10/07

Page 43

Applications manual

5.2.1 Baseboard/Radiant Panel space heating and DHW electrical diagram

The following shows the appropriate electrical connections for plumbing diagram 5.2.1

Terminal box

PK

L N

P0

LL

PS

N L

PE

ESR control

| 43

110VAC from outlet

board

Neutral

120Vac

24 VAC

POWER

PK

T

Stat

SR 503

or equivalent

FUSE 1 AMP

NPZCHX

P1

Indirect Baseboard/Radiant Panel Space Heating and DHW

Electrical Diagram

ZONE1 ZONE2 ZONE3

THREE ZONE SWITCHING RELAY

WITH OPTIONAL PRIORITY

X2

1 ZR

ZONE1 ZONE2 ZONE3

TT

LR LS

AQUASTAT

Note: This drawing is conceptual in nature and does not address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # EID BBOL

Applications manual | 11.2007Bosch Water Heating

CN revA 10/07

Page 44

44

|

Applications manual

6 Maintenance Drawings

Bosch appliances are designed to last for many years. In order to keep the heater operating properly, periodic maintenance is required.

Please consult the installation manual for maintenance intervals. A descaling procedure drawing is included to assist in clearing the water

heater of mineral deposits that may build up over time.

6.1 Descaling procedure

This procedure should only be done if there is evidence of scale build-up such as a reduced hot water fl ow rate or if the water is known to

have high levels of minerals such as calcium.

1. Disconnect electrical supply from the water heater.

2. Shut off the water supply to the water heater using (installer supplied) isolation valve.

3. Open hot water taps to drain and relieve pressure from the plumbing system.

4. Drain water from the unit’s heat exchanger by disconnecting inlet and outlet water connections.

5. Connect the line (A) from the outlet of the circulating pump (installer supplied) to the inlet water fi tting on the water heater.

6. Using another line (B), connect to the water outlet fi tting on the water heater. Route the other end of this line into a descaling reser-

voir.

7. Using a 3rd line (C) from the descaling reservoir, connect to the inlet side of circulating pump. Verify there is a fi lter on the end of the

line in the descaling reservoir.

8. Make sure all connections are “hand tight.”

9. Fill tank with descaling solution so lines inside are submersed. We recommend a straight white vinegar. If using a commercial descalant,

refer to manufacturer’s instructions for proper dilution ratio.

11. Operate the circulating pump.

12. Make sure there are no leaks and the solution is fl owing from the descaling reservoir through the heat exchanger and returning to the

reservoir.

13. Run solution through the heat exchanger until the solution returning to the descaling reservoir comes out clear. (Changing to a fresh

solution may be necessary during this process)

14. Disconnect all lines and drain all solution from heat exchanger. Properly discard of solution.

15. Position a container below the hot water outlet and connect cold water supply. Open cold water supply isolation valve and fl ush heat

exchanger with clean water.

16. Shut cold water isolation valve and reconnect hot water supply to the water heater.

17. Reconnect electrical supply to unit, open water isolation valves, and return the unit to service.

Application manual | 11.2007

Bosch Water Heating

Page 45

Applications manual

6.1 Descaling procedure diagram

B

| 45

Bosch GWH 715 ES,

Bosch GWH C 800 ES,

Bosch GWH 425 HN or

Bosch GWH 425 PN

Symbols

Circulating

pump

Flow direction

C

A

Filter

Service

valves

Note: This drawing is conceptual in nature and does not purport to address all design, installation or safety considerations.

Additional safety and/or auxiliary equipment may be needed. This diagram is for reference use by officials, designers and licensed installers.

It is expected that installers have adequate knowledge of accepted industry practices for the equipment, procedures, and applications involved.

Drawing is not to scale.

Drawing # MD1

CN revA 10/07

Applications manual | 11.2007Bosch Water Heating

Page 46

46

|

Applications manual

Application manual | 11.2007

Bosch Water Heating

Page 47

Applications manual

| 47

Applications manual | 11.2007Bosch Water Heating

Page 48

48

|

Applications manual

Application manual | 11.2007

Bosch Water Heating

Page 49

Applications manual

| 49

Applications manual | 11.2007Bosch Water Heating

Page 50

BBT North America Corporation

Bosch Group

Bosch Water Heating

50 Wentworth Ave

Londonderry, NH 03053

Telephone (603) 882-1100

Fax (603) 584-1681

www.protankless.com

techsupport@protankless.com

Loading...

Loading...