Bosch GWH 16 CTD E 31 F5, GWH 12 CTD E 31 F5, GWH 20 CTD E 23 F5, GWH 20 CTD E 31 F5, GWH 12 CTD E 23 F5 L Training And Service Information

...

12 / 16 / 20

12

16 / 20 / 26

INSTANTANEOUS GAS WATER HEATER

GWI-N

FAN PRESSURIZED GAS WATER HEATER FOR

INDOOR AND OUTDOOR INSTALLATION

TRAINING AND SERVICE INFORMATION FOR AFTER SALES

This document is restricted to exclusive use by the official service partners. Each

country should adapt the manual and its contents to the available range.

Page 1 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Contents

1. INTRODUCTION ........................................................................................... 3

2. APPLIANCE DESCRIPTION ......................................................................... 3

2.1 APPLIANCE DESIGNATION ...................................................................................................... 3

2.2 AVAILABLE ACCESSORIES ..................................................................................................... 4

3. INSTALLATION ............................................................................................. 6

3.1 APPLIANCE FIXATION ON THE WALL ........................................................................................ 6

3.2 WATER CONNECTIONS ........................................................................................................... 7

3.3 GAS CONNECTION ................................................................................................................. 7

3.4 APPLIANCE PERFORMANCE .................................................................................................... 7

4. COMPONENTS OVERVIEW ......................................................................... 8

4.1 CONTROL PANEL................................................................................................................... 9

4.2 HEAT CELL WITH BURNER PIPES ........................................................................................... 12

4.3 GAS MANIFOLD ................................................................................................................... 13

4.4 FAN ................................................................................................................................... 15

4.5 GAS VALVE ........................................................................................................................ 15

4.6 HEAT EXCHANGER .............................................................................................................. 17

4.7 WATER INLET ASSY ............................................................................................................ 18

4.8 WATER TEMPERATURE SENSORS ......................................................................................... 18

4.9 BOX TEMPERATURE SENSOR ............................................................................................... 18

4.10 WATER FLOW SENSOR ..................................................................................................... 23

4.11 IGNITION ELECTRODE ....................................................................................................... 24

4.12 IONIZATION ELECTRODE .................................................................................................... 25

5. WORKING PRINCIPLE / ELECTRIC MEASUREMENTS ............................ 26

6. SERVICE ..................................................................................................... 33

7. MAINTENANCE .......................................................................................... 50

8. TROUBLE SHOOTING ................................................................................ 54

Page 2 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

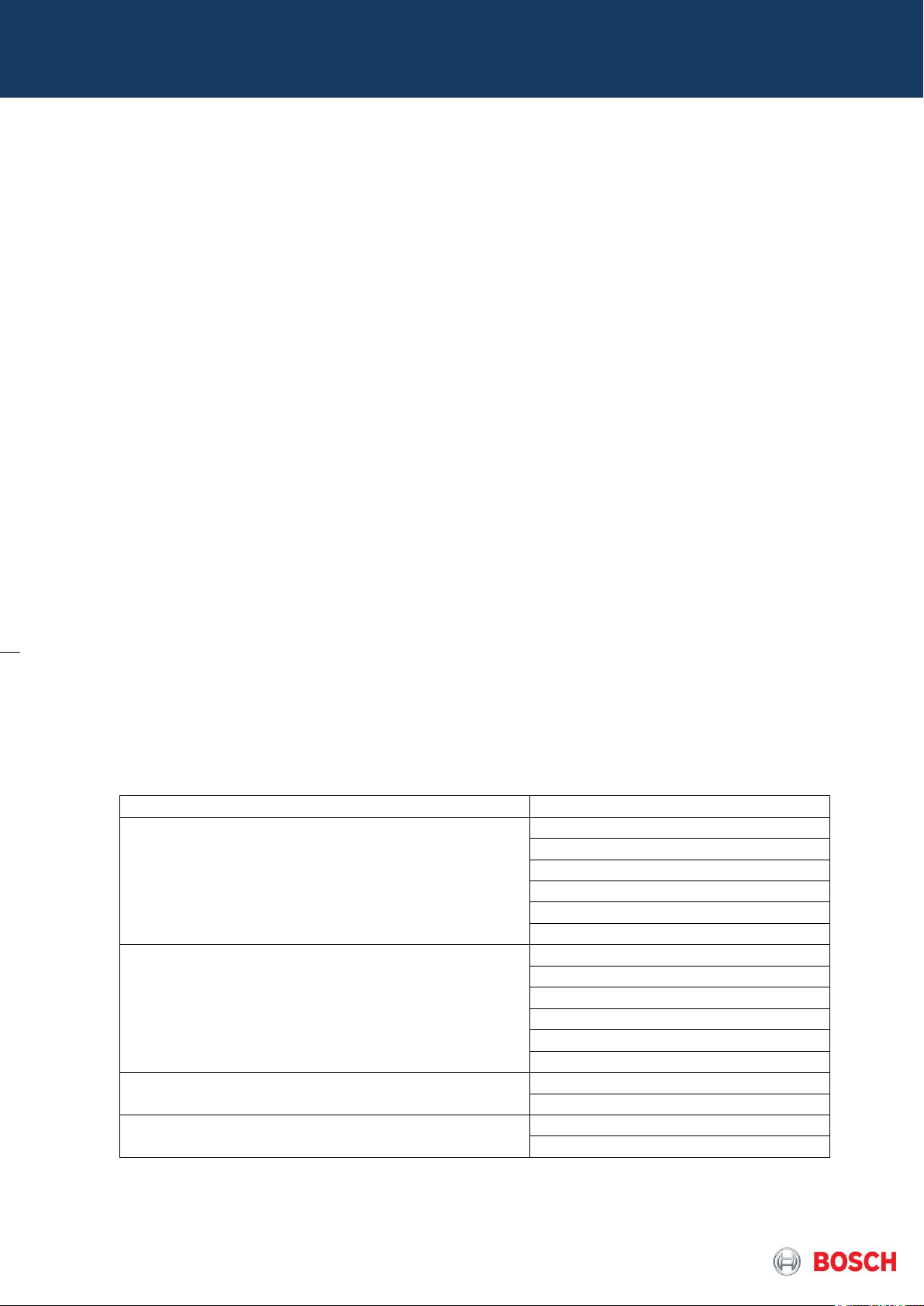

Segment

Designation

Indoor Installation

(temperature setting adjustable degree by degree)

GWH 12 CTD E 23 F5

GWH 12 CTD E 31 F5

GWH 16 CTD E 23 F5

GWH 16 CTD E 31 F5

GWH 20 CTD E 23 F5

GWH 20 CTD E 31 F5

Indoor Installation

(temperature setting locked = L)

GWH 12 CTD E 23 F5 L

GWH 12 CTD E 31 F5 L

GWH 16 CTD E 23 F5 L

GWH 16 CTD E 31 F5 L

GWH 20 CTD E 23 F5 L

GWH 20 CTD E 31 F5 L

Outdoor Installation

(temperature setting adjustable degree by degree)

GWH 12 CTD E 23 F3 O

GWH 12 CTD E 31 F3 O

Outdoor Installation

(temperature setting locked = OL)

GWH 12 CTD E 23 F3 OL

GWH 12 CTD E 31 F3 OL

1. Introduction

This manual is a complement to the instruction/operation manual delivered with the appliance, with the main

important technical details that are relevant for the official service partners and trainers in the country. In any

case one of the documents replaces the use of the other.

2. Appliance description

This appliance is a fan pressurized gas water heater, which will replace the actual room sealed range of

appliances offering a wider range of modulation and installation advantages with both indoor and outdoor

models available.

2.1 Appliance Designation

The designation allows the identification of the main characteristics of the units, especially when report is needed

through call centre or after sales technicians.

GWH – Instantaneous gas water heater

GWH 12 / 16 / 20 – Output (flow rate at 25ºC rise)

GWH 12 / 16 / 20 CT – Thermostatic control (variable power through electronic control)

GWH 12 / 16 / 20 CTD – Display

GWH 12 / 16 / 20 CTD E – Electronic ignition (source is electricity)

GWH 12 / 16 / 20 CTD E 23/31 – Gas type (23 = natural gas / 31 = liquefied petroleum gas)

GWH 12 / 16 / 20 CTD E 23 /31 F3 O – Flue less model with fan pressurized operation (outdoor unit)

GWH 12 / 16 / 20 CTD E 23 /31 F5 – Room sealed fan pressurized operation (indoor unit)

Table 1 – Appliance identification of low output range (Compact 4000 S)

Page 3 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

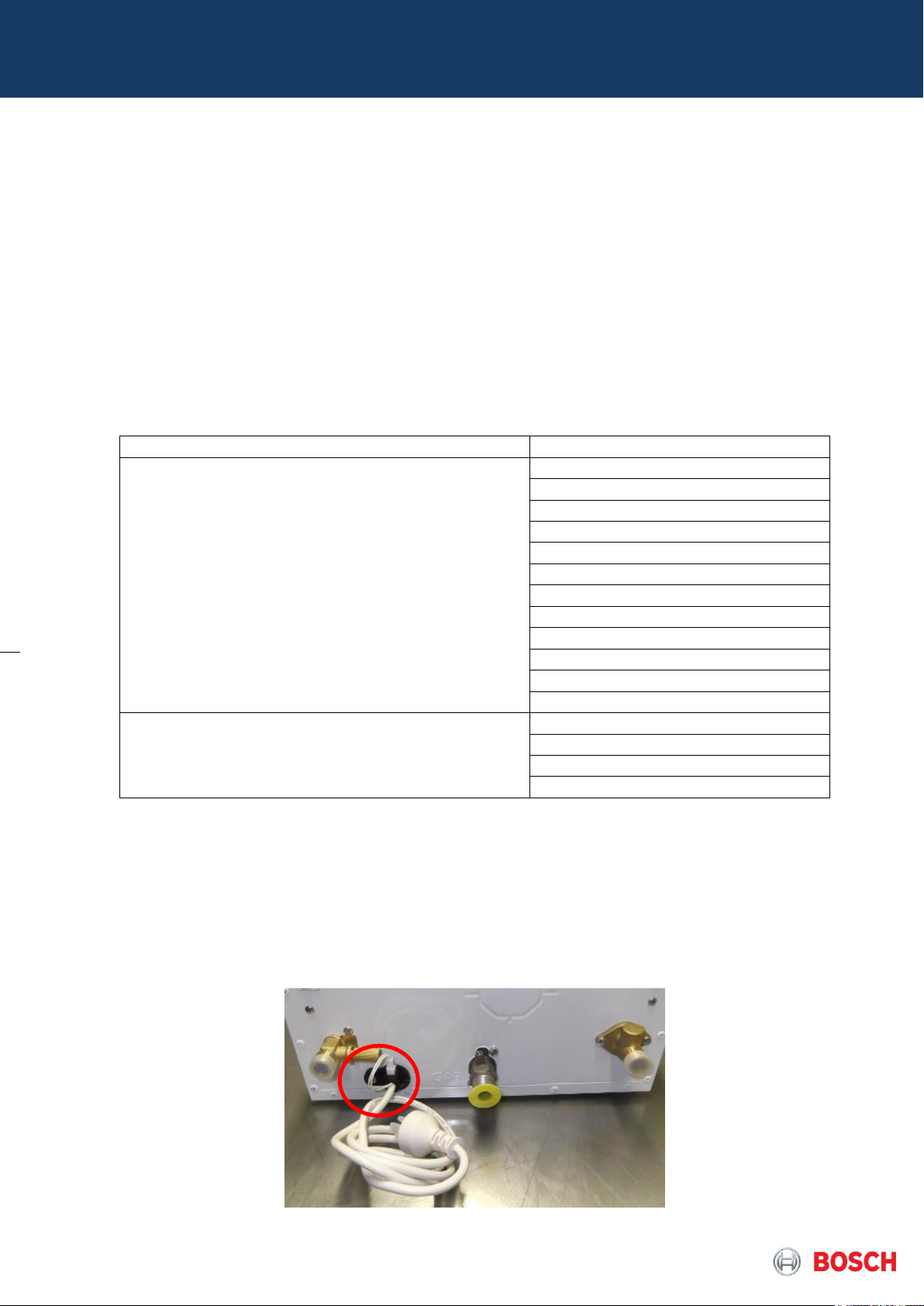

Segment

Designation

Outdoor Installation

(temperature setting adjustable degree by degree in

control)

GWH16 3 CT E23 F6 B S2405

GWH16 3 CT E23 F6 S2405

GWH16 3 CT E31 F6 B S2405

GWH16 3 CT E31 F6 S2405

GWH20 3 CT E23 F6 B S2405

GWH20 3 CT E23 F6 S2405

GWH20 3 CT E31 F6 B S2405

GWH20 3 CT E31 F6 S2405

GWH26 3 CT E23 F6 B S2405

GWH26 3 CT E23 F6 S2405

GWH26 3 CT E31 F6 B S2405

GWH26 3 CT E31 F6 S2405

Outdoor Installation

(temperature setting locked = L)

GWH26 3 CT E23 F6 L S2405

GWH26 3 CT E23 F6 LB S2405

GWH26 3 CT E31 F6 L S2405

GWH26 3 CT E31 F6 LB S2405

GWH – Instantaneous gas water heater

GWH 16 / 20 / 26 – Output (flow rate at 25ºC rise)

GWH 16 / 20 / 26 CT – Thermostatic control (variable power through electronic control)

GWH 16 / 20 / 26 CT E – Electronic ignition (source is electricity)

GWH 16 / 20 / 26 CT E 23/31 – Gas type (23 = natural gas / 31 = liquefied petroleum gas)

GWH 16 / 20 / 26 CTD E 23 /31 F6 – Flue less model with fan pressurized operation (outdoor unit)

GWH 16 / 20 / 26 CTD E 23 /31 F6 L – Temperature Locked model

GWH 16 / 20 / 26 CTD E 23 /31 F6 B – Builder Model (Professional segment)

Table 2 – Appliance identification of high output range (Optiflow range)

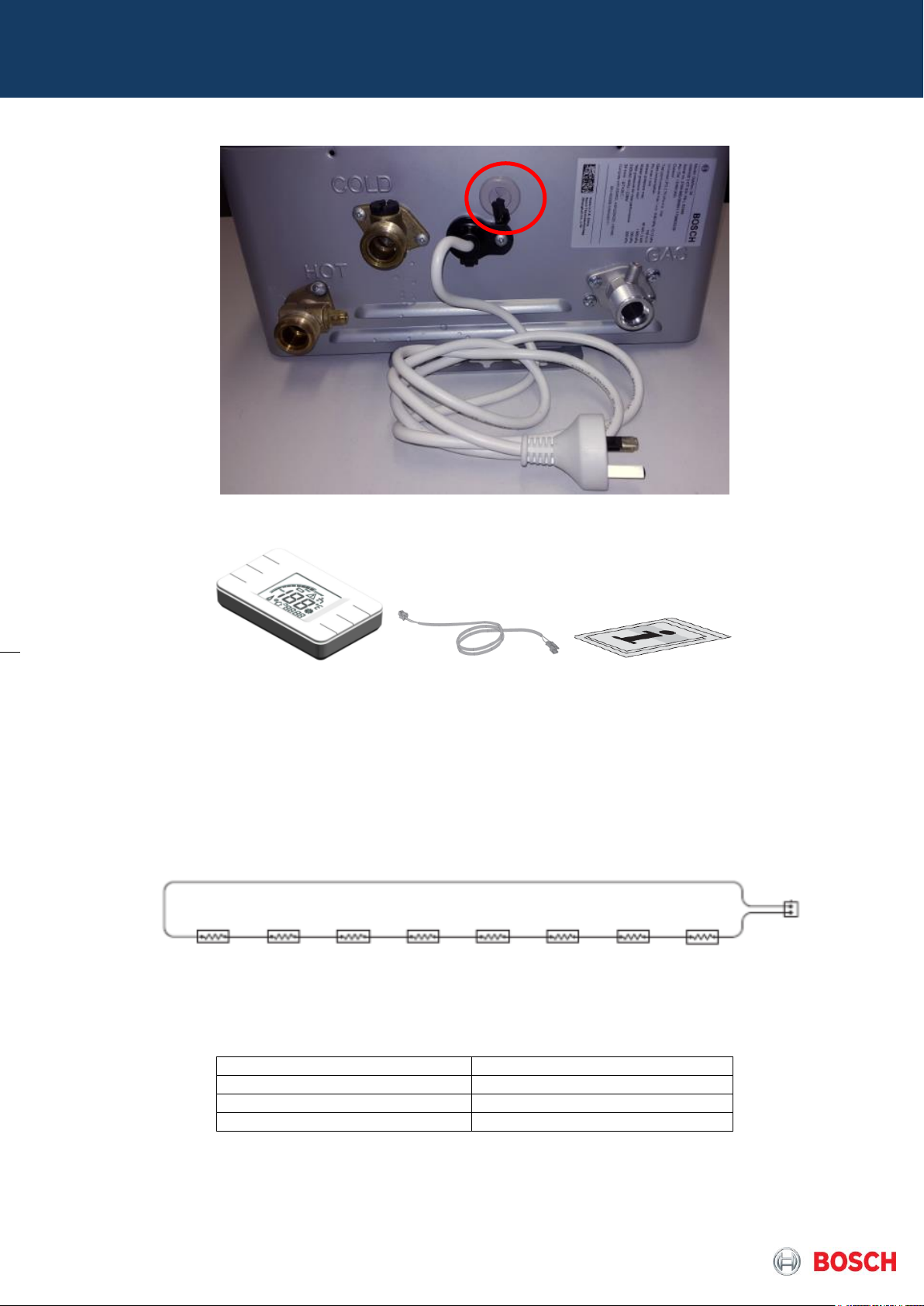

2.2 Available accessories

Remote control

Possible wired connection to both indoor (optional accessory) and outdoor versions (included in packaging)

allowing direct connection to the outside of the appliance with neither the need of configuration, nor a

connection inside of the room sealed box. The GWH 16 / 20 / 26 have internally 3 connections for Remote

control (retail version with inbuilt Bluetooth) and 4 connections for remote control (professional version).

Page 4 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

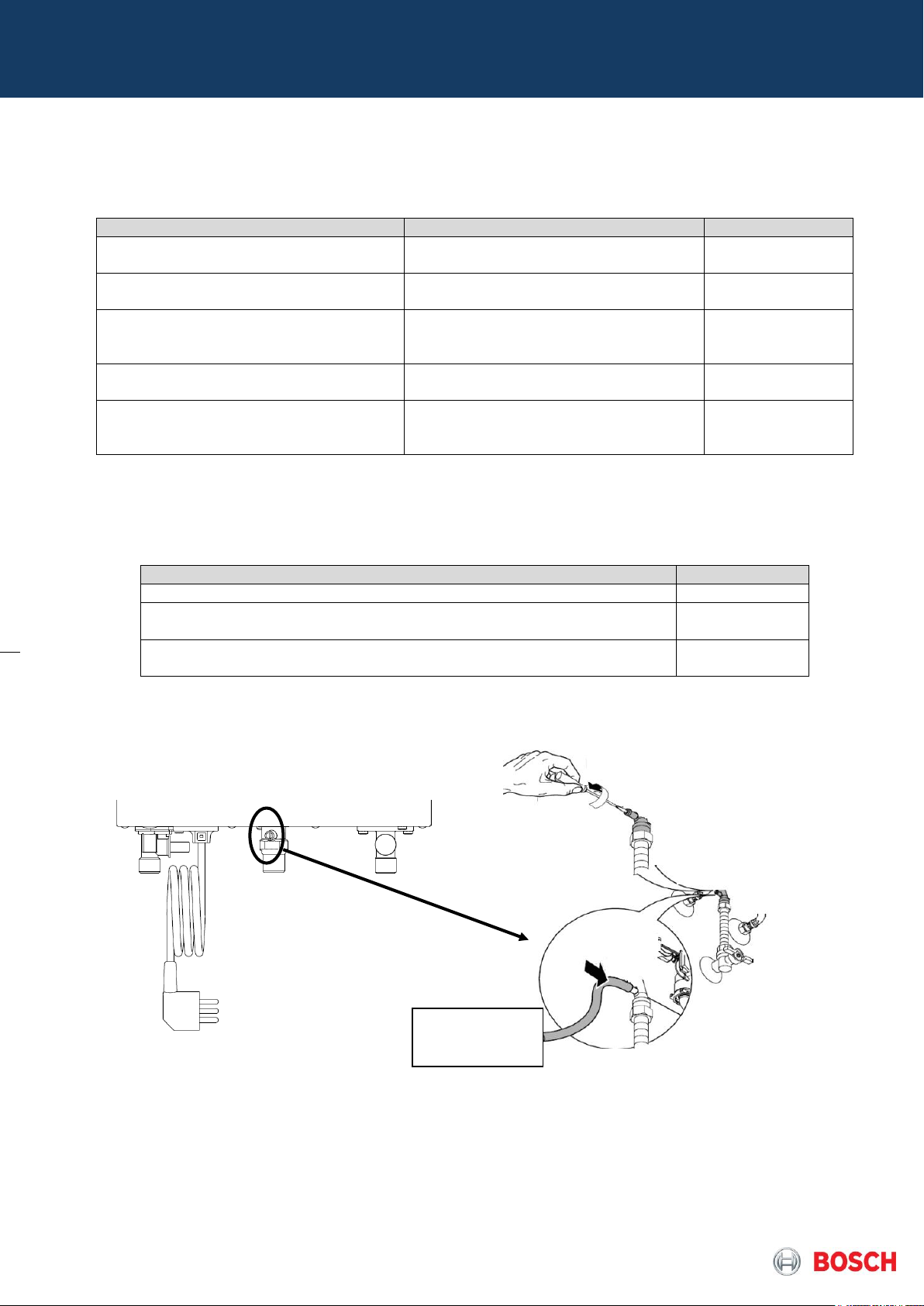

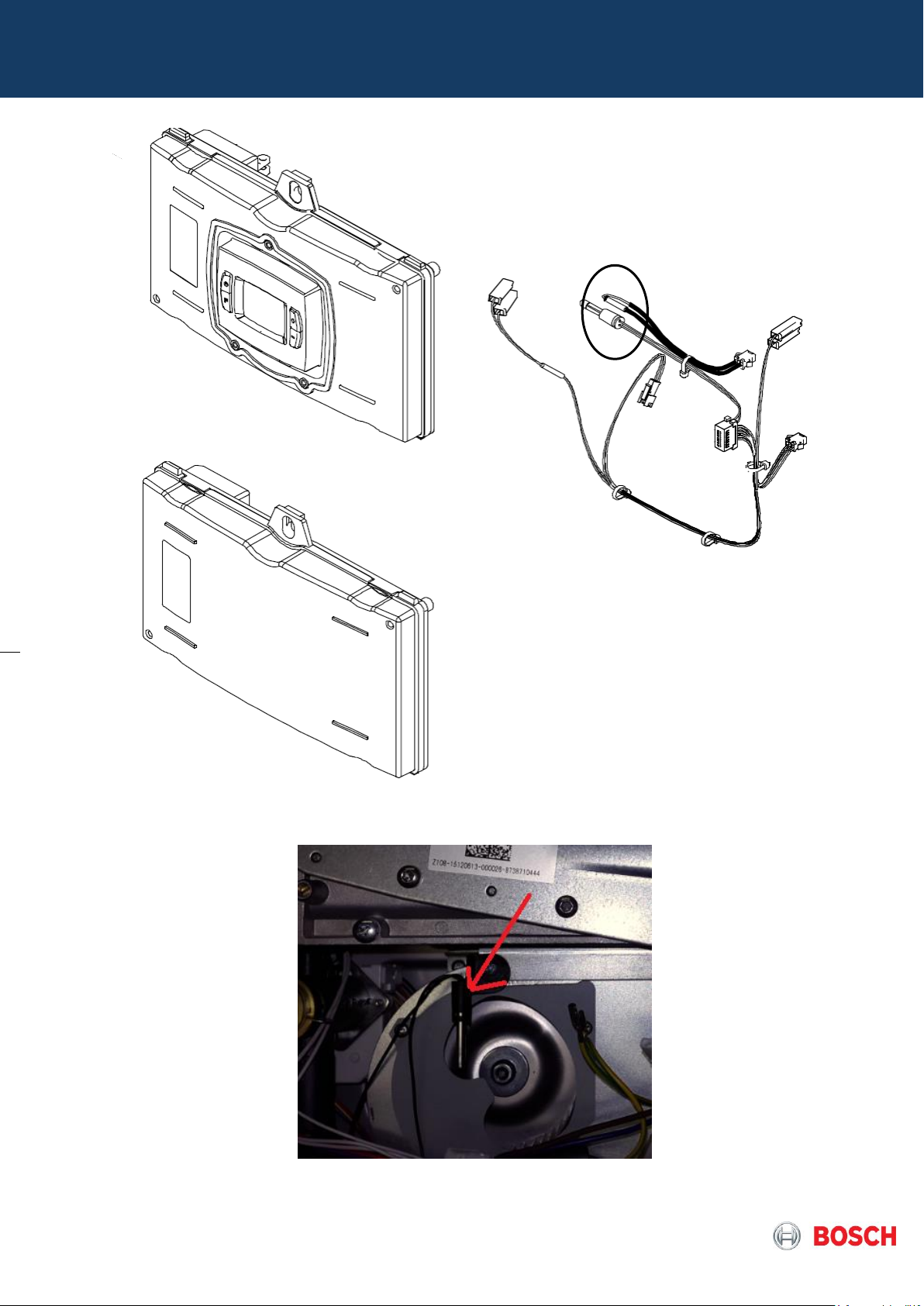

Pict. 1 – Remote control connection to the appliance (bottom layout in 12/16/20 range)

Activation

Deactivation

T in ≤ 2ºC

T in ≥ 5ºC

or

and

T

box

≤ 5ºC

T

box

≥ 10ºC

Pict. 2 – Remote control connection to the appliance (bottom layout in outdoor 16/20/26 range)

Pict. 3 – Remote Control with cable, connectors and instruction manual

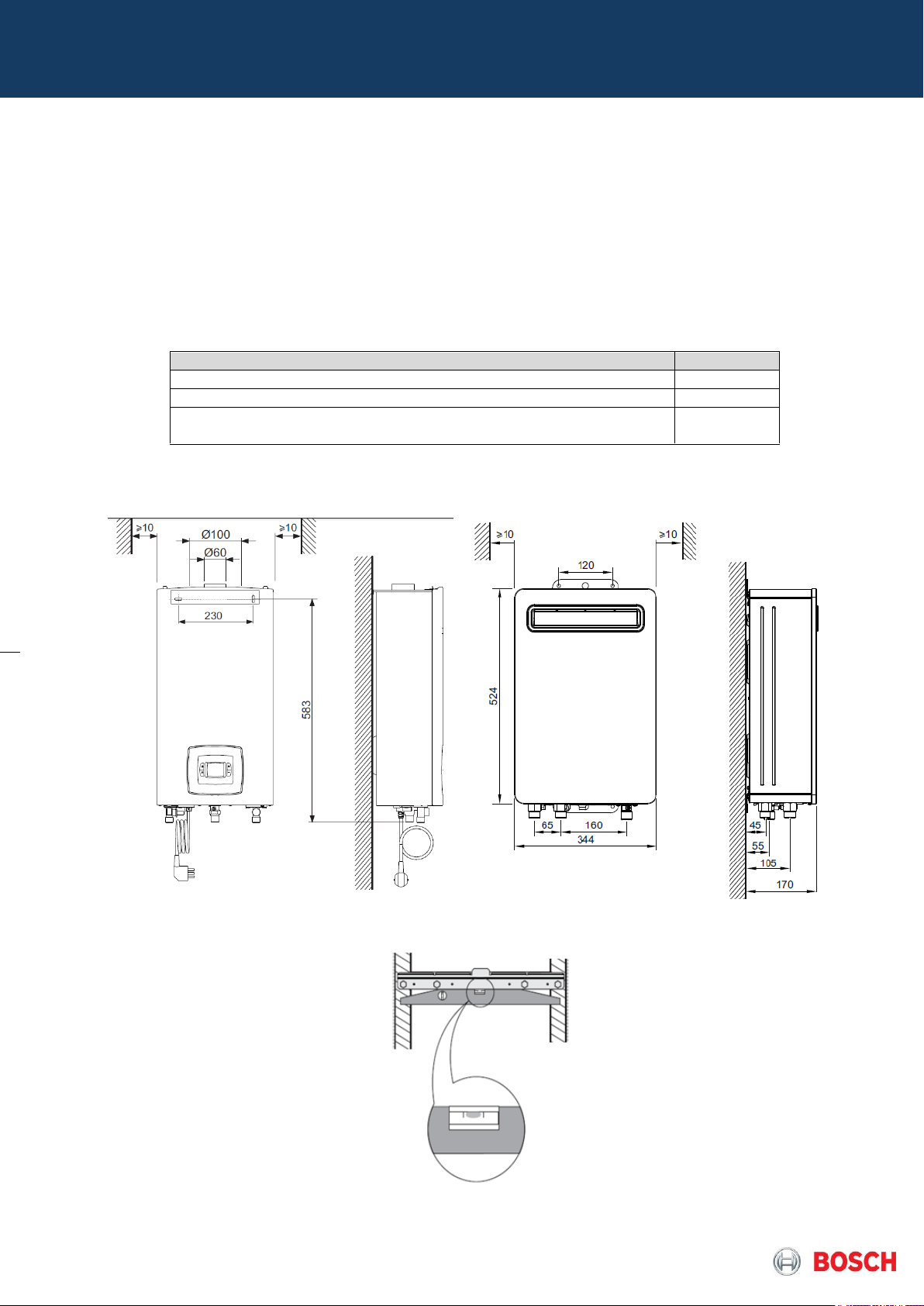

Anti-Freeze

Allows the protection of the appliance against water freezing inside of its pipes until -20ºC (lower

environment temperature acceptable by gas valve), so to be used in cases where ambient temperature can

be lower than 5ºC. For indoor models is a kit but in outdoor models is inbuilt.

Pict. 4 – Anti-Freeze layout

The kit includes 8 resistances of 16W each, which activate under conditions from table 3.

Table 3 – Anti-freeze activation conditions

Page 5 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Requisite

Confirmation

Appliance is levelled and in the vertical position?

Delivered accessories are used accordingly?

Appliance is supported exclusively by the wall fixation and not by

hydraulic and/or gas connections?

3. Installation

The installation manual of each product must be checked and used by the installer in order to optimize and

leave the appliance in correct operation conditions.

Check lists for technicians/installers:

3.1 Appliance fixation on the wall

Table 4 – Check List for Fixation

Pict.5 – Pre-installation distances (indoor / outdoor)

Pict. 6 – Wall Fixation Preparation (if applicable)

Page 6 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Requisite

Observations

Confirmation

Water pipes were cleaned before

connected to the appliance?

Leakage test was done

successfully?

Inlet water filter was checked and is

cleaned, ensuring the necessary

water flow?

Accessories for water connections

are adequate?

Water pressure and flow are

according to the appliance

specifications?

- Nominal pressure: 300 - 700 kPa

- Minimum pressure: 100 kPa

- Maximum pressure: 1000kPa

Requisite

Confirmation

The appliance is suitable for the available gas type?

Pressure reducer and gas pipe are adequate for the required pressure and

gas flow?

Accessories for gas connection are adequate and according to the country

specification/standards?

Gas

manometer

3.2 Water connections

Table 5 – Check list hydraulic connections

3.3 Gas connection

Table 6 – Check list for gas connections

Pict. 7 – Manometer pipe connection to measure static/dynamic gas supply pressure (showing indoor version)

3.4 Appliance performance

Measure water flow and temperature increase to check temperature and instantaneous water flow, assuring

correct operation of the appliance.

Page 7 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

1

3 2 4 6 10 9 8

7

5

11

12

13

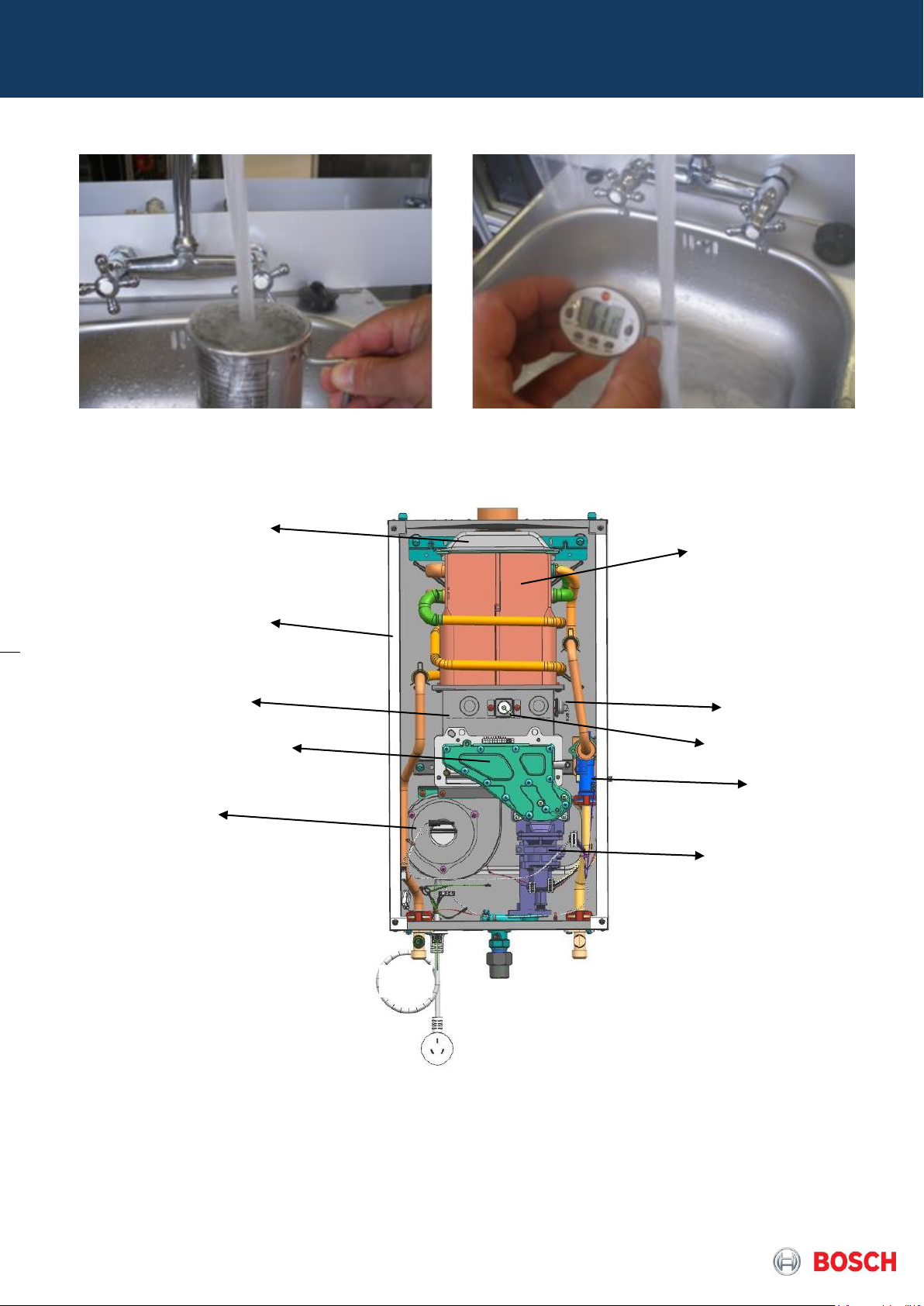

4. Components Overview

Pict. 8 – Use of water flow meter and thermometer

1 – Collector

2 – RSF box

3 – Heat exchanger

4 – Heat cell

5 – Burner

6 – Fan

7 – Gas valve

Page 8 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

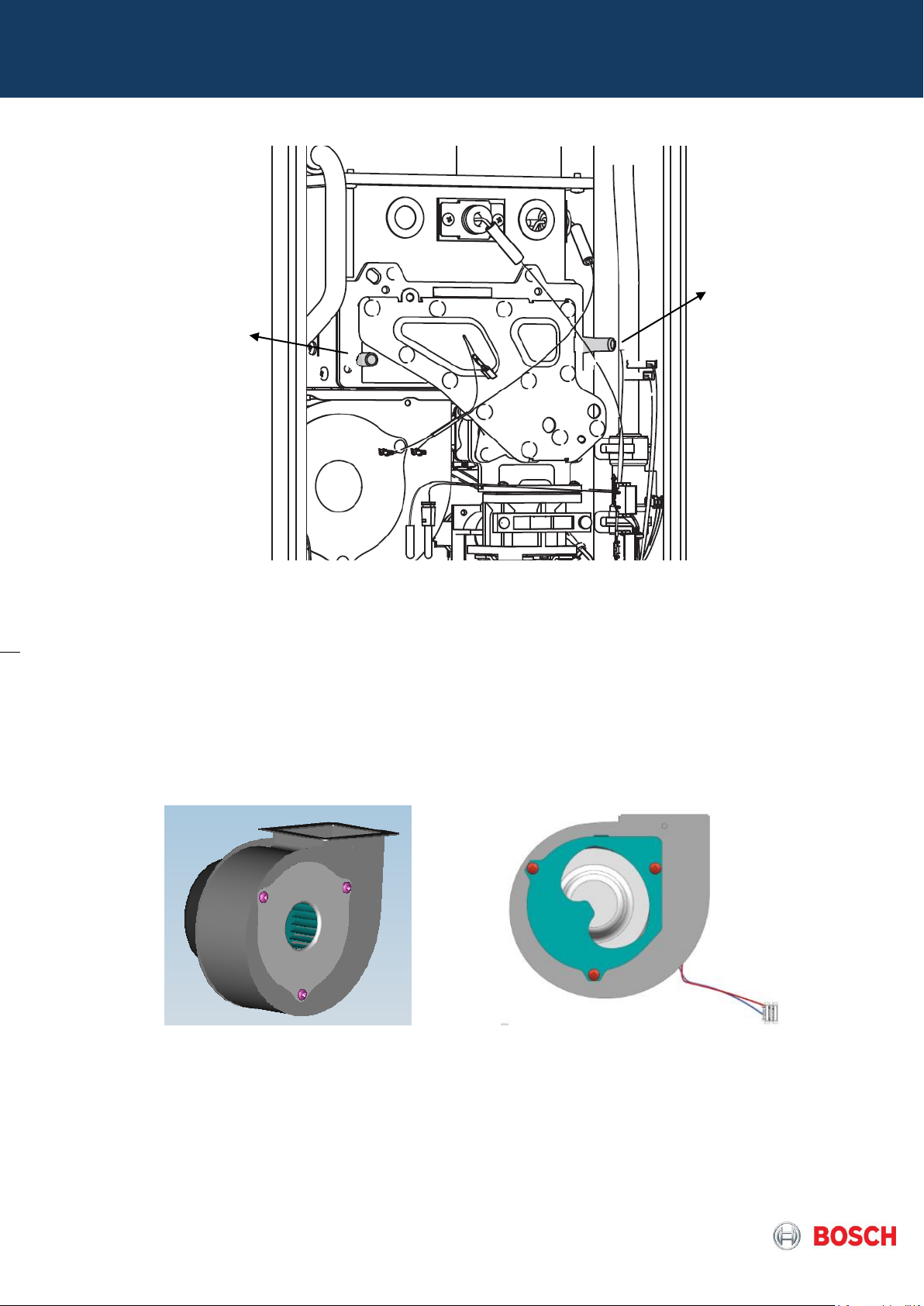

Pict.9 – Internal view of Indoor models (12 / 16 / 20)

8 – Water valve

9 – Ionization electrode

10 – Ignition electrode

11 – Gas inlet

12 – Water inlet

13 – Water outlet

9

10

11

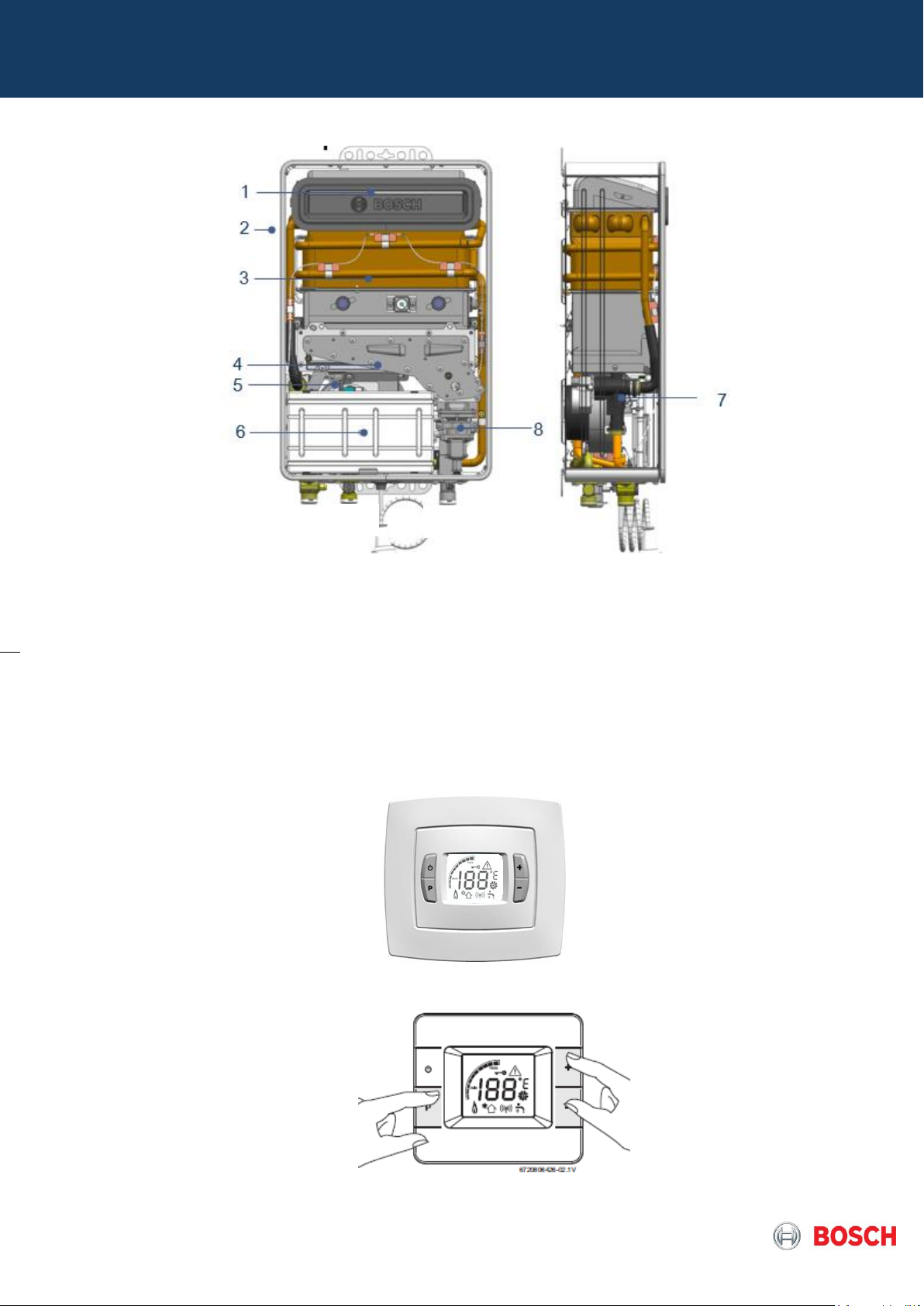

1 –Collector

2 –Box

3 – Heat exchanger

4 – Burner

5 – Fan

6 – Electronics

Pict.10 – Internal view of high output outdoor models (16 / 20 / 26)

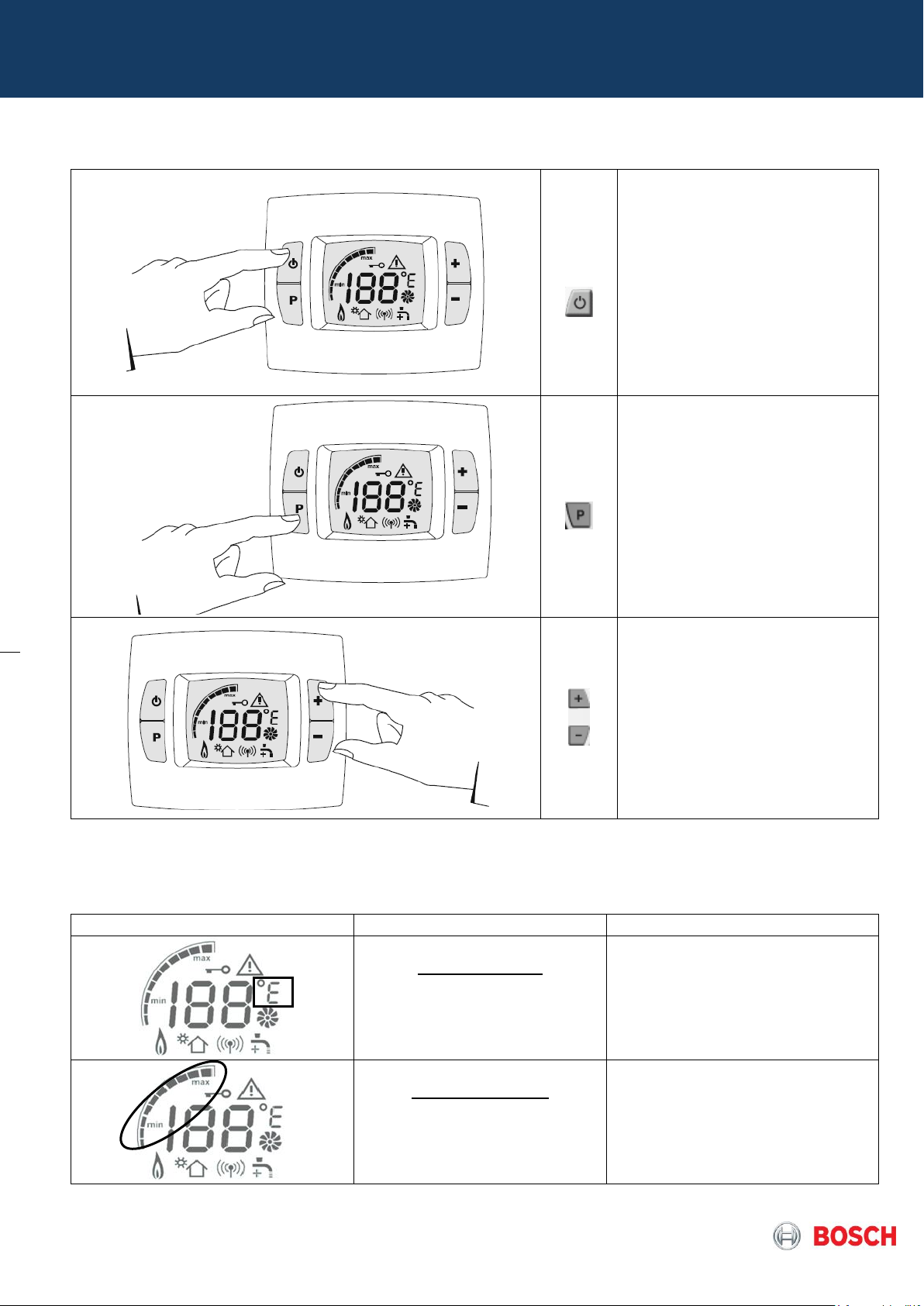

4.1 Control panel

The control panel allows the user, installer or technician, to perform all different operations needed.

Pict.11 – Control Panel Overview (indoor model)

7 – Flow switch

8 – Gas valve

9 – Gas inlet

10 – Water inlet

11 – Water outlet

Pict.12 – Control Panel Overview in remote

Page 9 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

(optional for indoor model / default for outdoor model)

On / Off button

The main switch is assembled on

the PCB and disconnects phase-L

from neutral-N.

No voltage at components if the

main switch is in OFF-position

Note: Errors reset function when

pressed for more than 3 seconds

Program Button

Used to enter in different services:

- Enter in service mode

- Scroll in the service mode menu

- Save value or adjust set values

- Save a temperature set (user)

Selection button

Used to select temperature values,

adjustments and navigation on

parameters inside the visualisation

mode.

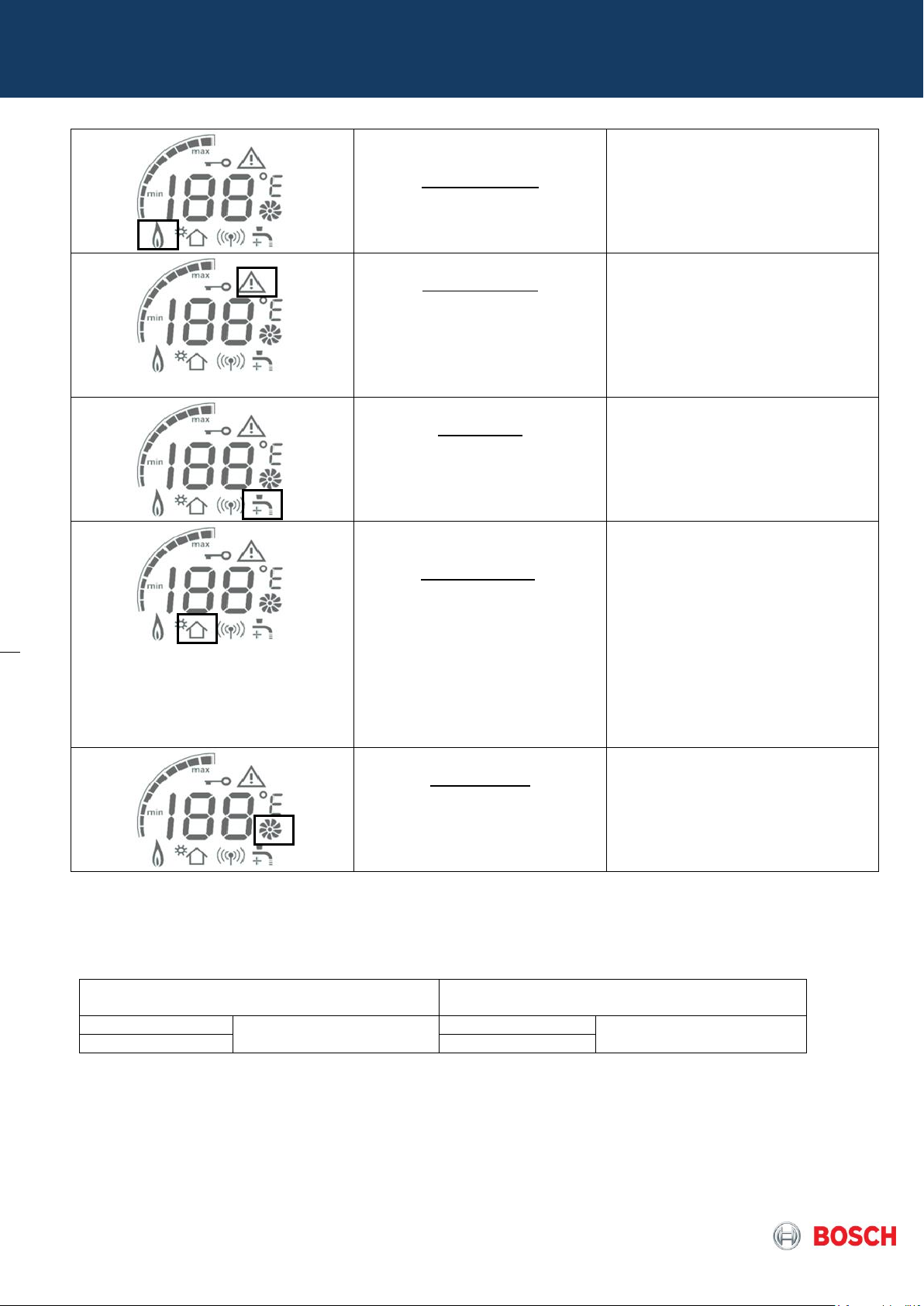

Symbol

Description

Observation

Temperature Unit:

ºC – default value

ºF – alternative value

Selection can be done by changing

default value on service mode (P6)

Power bar indicator:

Indication of the current operation

power

Indicative Value (in %)

Page 10 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Table 7 – Control Panel Buttons

Flame indication:

Indication of flame in the burner

Symbol displayed when ionization is

detected - flame presence

Warning symbol:

Combined with an error indication

/ warning code indicates a faulty

performance

Tap symbol:

Indication of not enough power to

reach set point

In case symbol is displayed,

decrease (-) or increase (+) flow

accordingly

Solar application:

Indication that the automatic solar

function is activated, meaning that

the appliance is receiving pre-

heated inlet water, with no need

for burner to start

The symbol is displayed and burner

is shutdown when T in is under

following conditions:

T in ≥ T

set

– 1K

The symbol is deactivated and

burner restarted when:

T

out

< 60ºC (if T

set

≤ 50ºC)

T

out

< T

set

+ 10ºC (if T

set

> 50ºC)

Fan operation:

Indication that the fan is in

operation

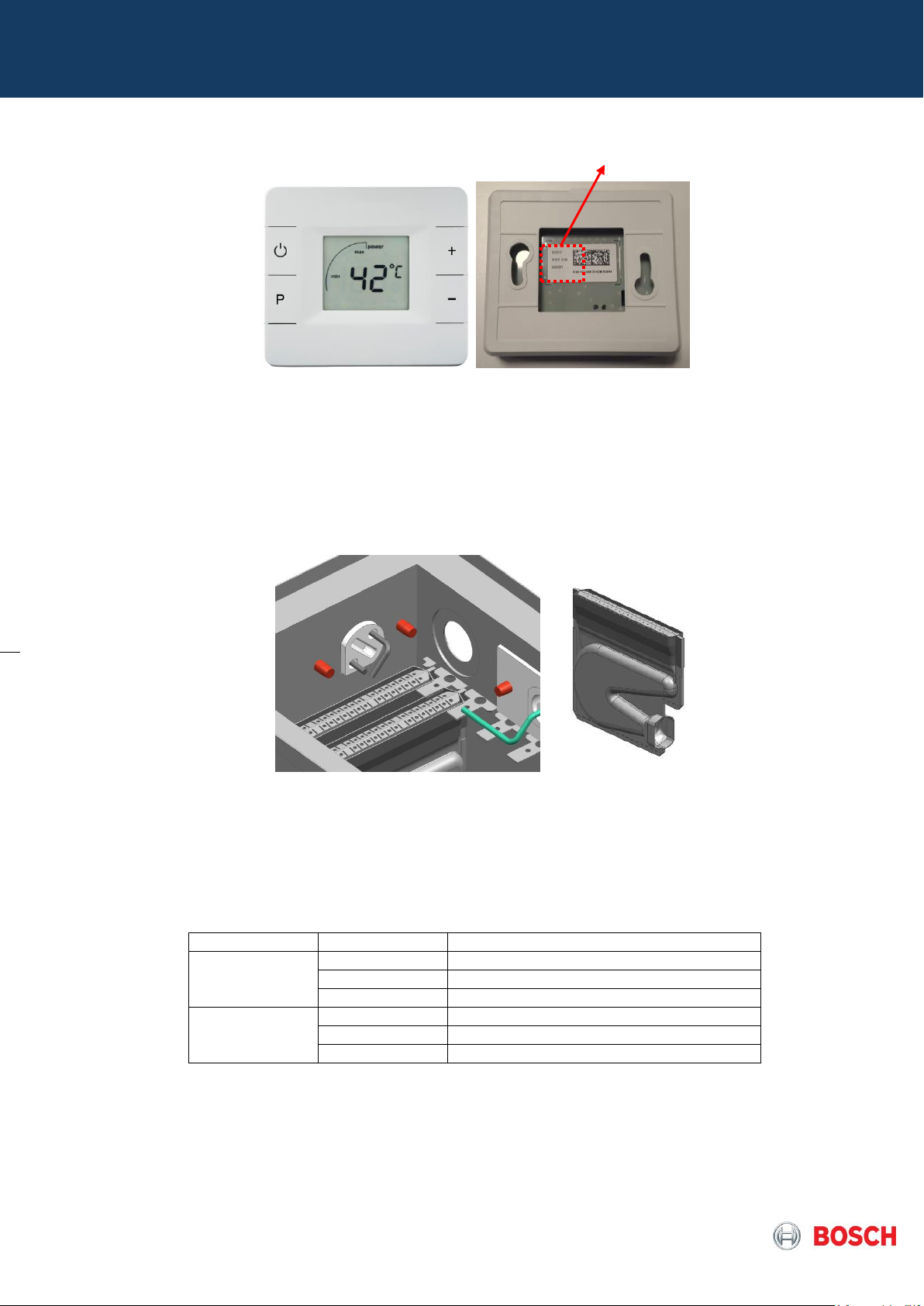

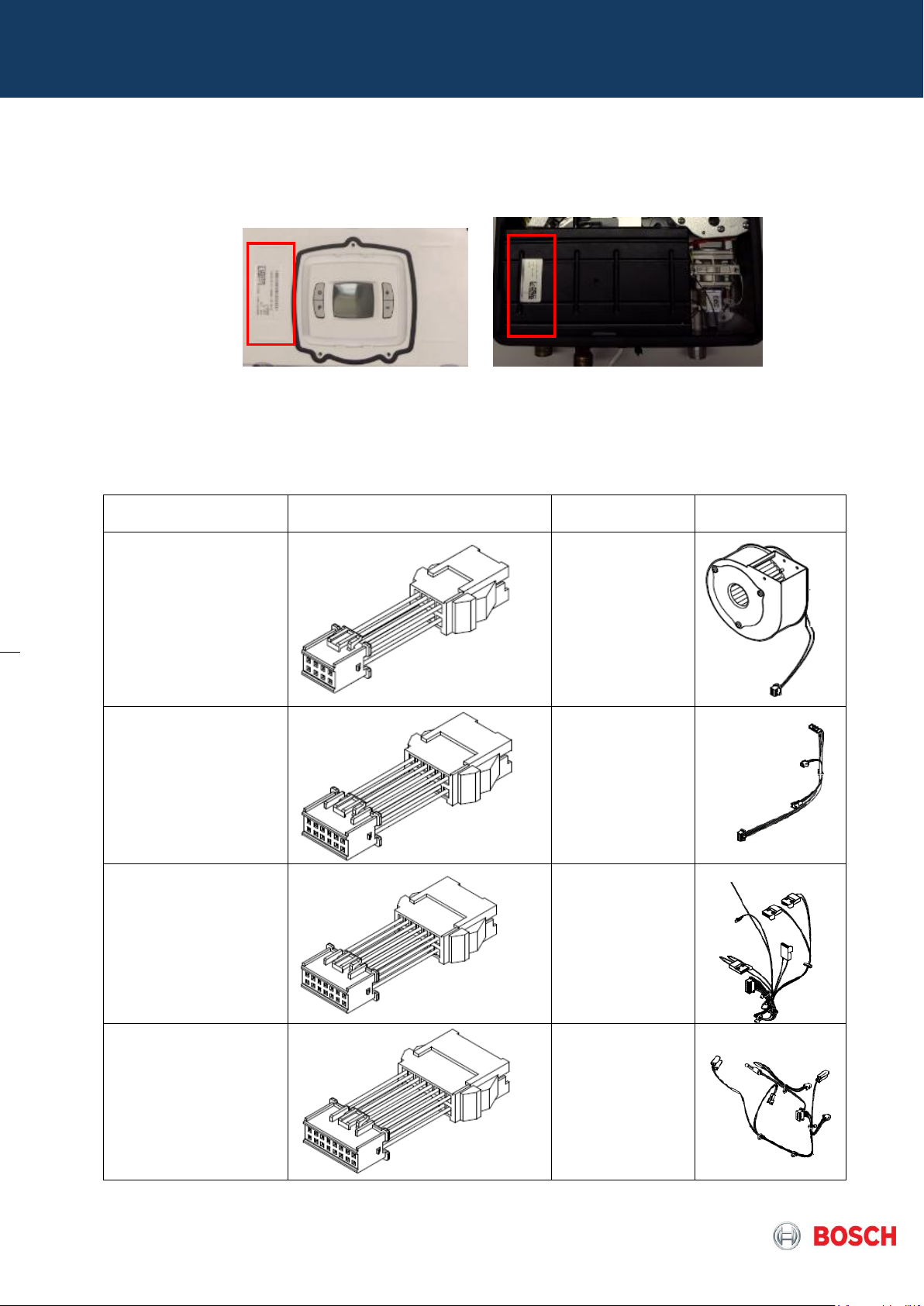

Old TTNR

(with SW WRAF0105)

New TTNR

(with SW WRAF0106)

7-736-503-406

To be used only with

Compact 4000 S

7-736-504-467

Can be used with Compact

4000 S / Optiflow

7-736-502-925

7-736-504-469

There was an update in remote control software version in order to make it compatible for both products in the

market, so please refer to article code of the remote / software version to be used according this recommendation:

The new remote controls are compatible for both Compact 4000S / Optiflow and have new reference and were

implemented from FD >= 660 (Dec. 2016). The old remote controls can be used up until end of stock only with

Compact 4000 S models.

Page 11 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Table 8 – Display Symbols

Table 9 – Remote Control versions

Platform

Appliance

Stamp

Low output (ind

/ out)

12l/min

12 L

16l/min

18 L

20l/min

20 L

High output

(out)

16l/min

code

20l/min

code

26 l/min

code

WRAF0106

Pict 13 – Remote control view and software version sticker location

4.2 Heat cell with burner pipes

The heat cell includes the flame visualization window, ignition electrode, ionization electrode and the burner

pipes.

Inlet: Primary air from the fan and gas from the gas manifold.

Outlet: Hot combustion gases to the heat exchanger

Pict.14 – Heat cell detail with ignition / ionization electrodes and burner blade detail

Primary air plate

The primary air plate is assembled between the heat cell and the gas manifold in order to ensure the correct

mixture of air and gas according to the specific appliance model.

The plate has indexation pins that ensure the correct assembly on the heat cell and the type gas mark

orientation to the front.

Page 12 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

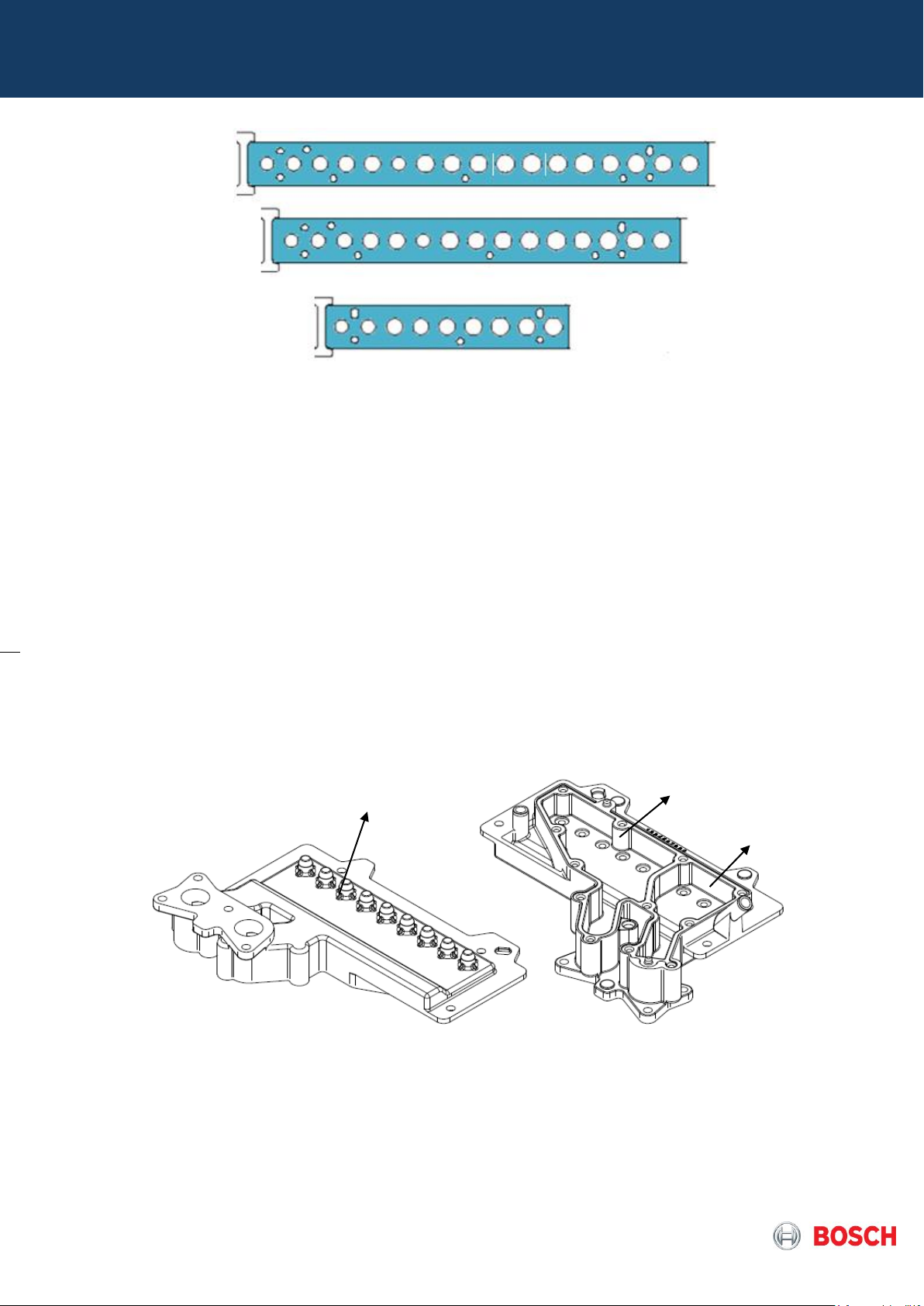

Table 10 – Identification of primary air plates

Burner segment 1

Burner segment 2

GWH 12

GWH 16 / 20

Injectors

GWH 26

Pict. 15 – Primary air plate examples

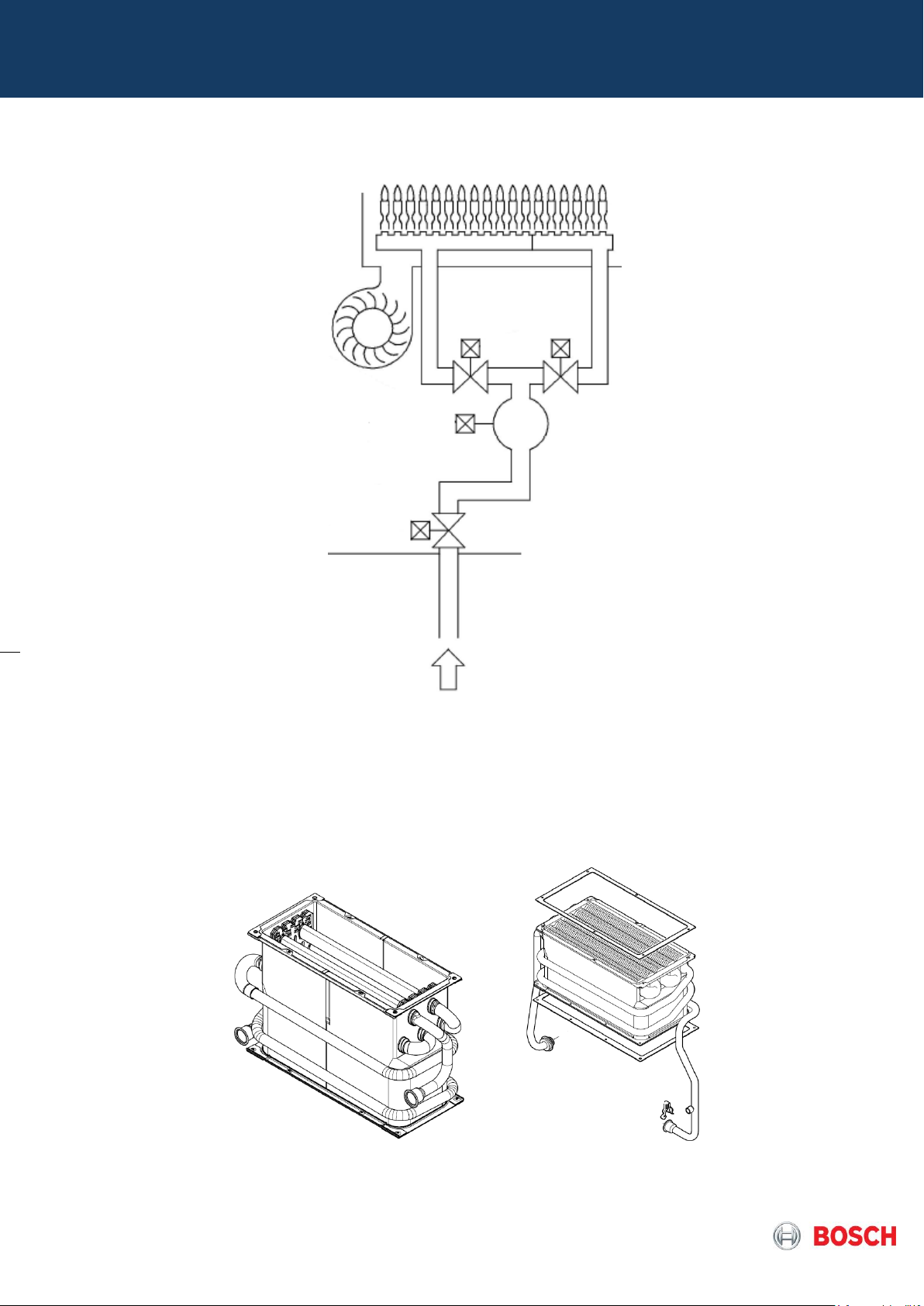

4.3 Gas manifold

The gas manifold is a gas distribution pipe with integrated drilled injectors and two pressure measuring

points:

- gas valve pressure = P

- air fan pressure = P

The manifold cover allows the gas supply to the burner over 2 different segments, in order to assure a wide

modulation range according to the capacity of the appliance.

The gas manifold for GWH 12 models have in total 9 injectors with following distribution:

- NG Ø 1.7

- LPG Ø 1.3

box

burner

The gas manifold for GWH 16 models have in total 15 injectors with following distribution:

Page 13 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

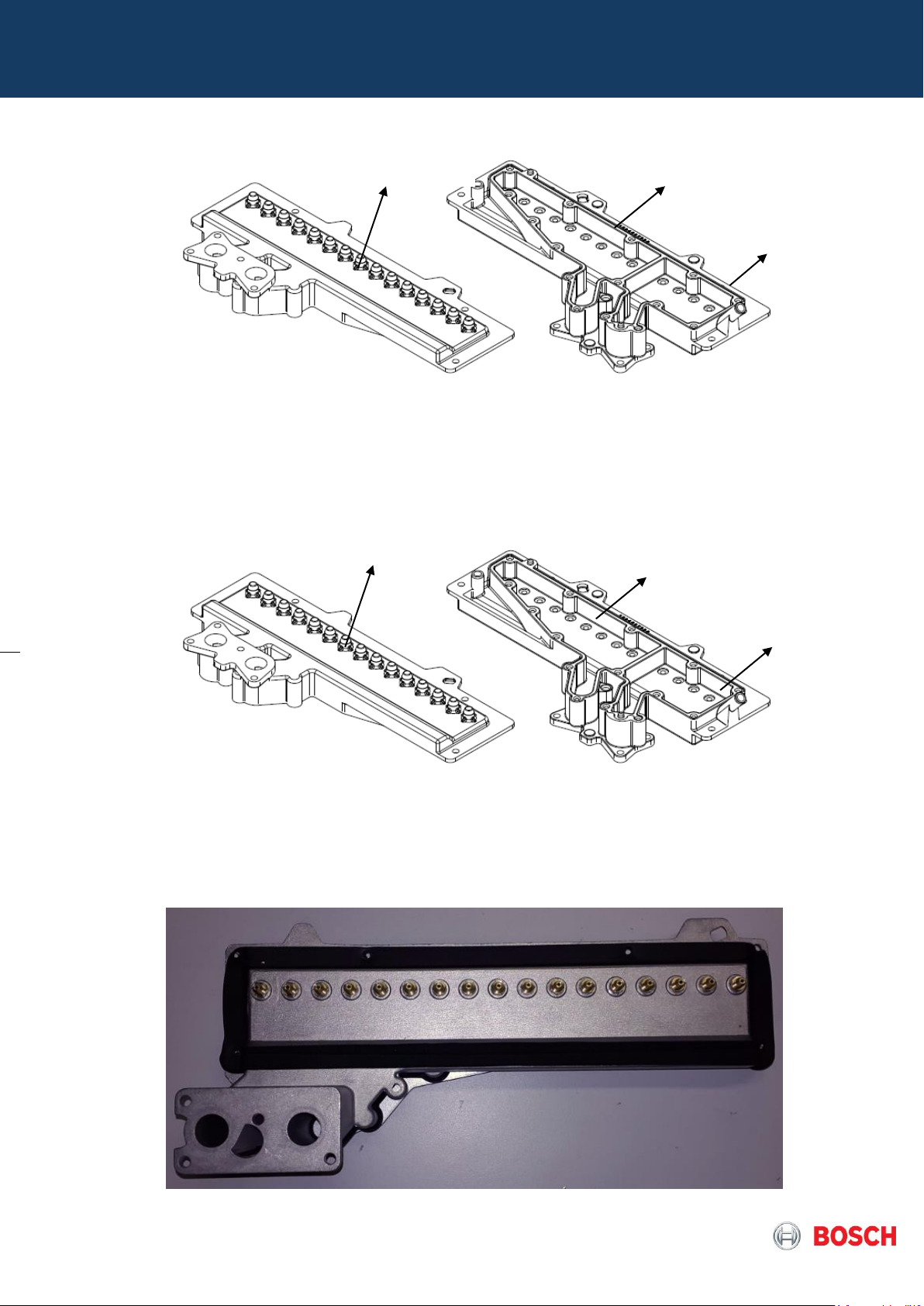

Pict. 16 – Gas manifold for 12l/min (Indoor / Outdoor) appliance with 9 injectors

- NG Ø 1.7

- LPG Ø 1.3 (in 16 l Indoor) or Ø 1.25 (in 16 l Outdoor)

Burner segment 1

Burner segment 2

Burner segment 1

Burner segment 2

Injectors

Injectors

Pict.17 – Gas manifold for 16l/min appliance with 15 injectors

The gas manifold for GWH 20 models have in total 15 injectors with following distribution:

- NG Ø 1.7 in burner segment 1 + Ø 2.0 in burner segment 2

- LPG Ø 1.3 in burner segment 1 + Ø 1.5 in burner segment 2

Pict.18 – Gas manifold for 20l/min appliance with 15 injectors

The gas manifold for GWH 26 models have in total 17 injectors with following distribution:

- NG Ø 2.0 in all burner

- LPG Ø 1.55 in all burner

Page 14 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Pict.19 – Gas manifold for 26l/min appliance with 17 injectors

Gas Pressure

Measurement point

=

P

burner

Air Pressure

Measurement point

=

P

box

Pict.20 – Pressure measuring points

4.4 Fan

The control unit monitories the primary air flow to the burner by varying the fan motor power supply voltage

(DC), ensuring a correct variable speed during the operation according to the output needed.

The fan motor provides an additional control signal to enable/disable operation and the speed of the fan is

measured by the feedback signal provided by the fan’s motor. The signal consists on a square wave with a

frequency proportional to the speed of the fan.

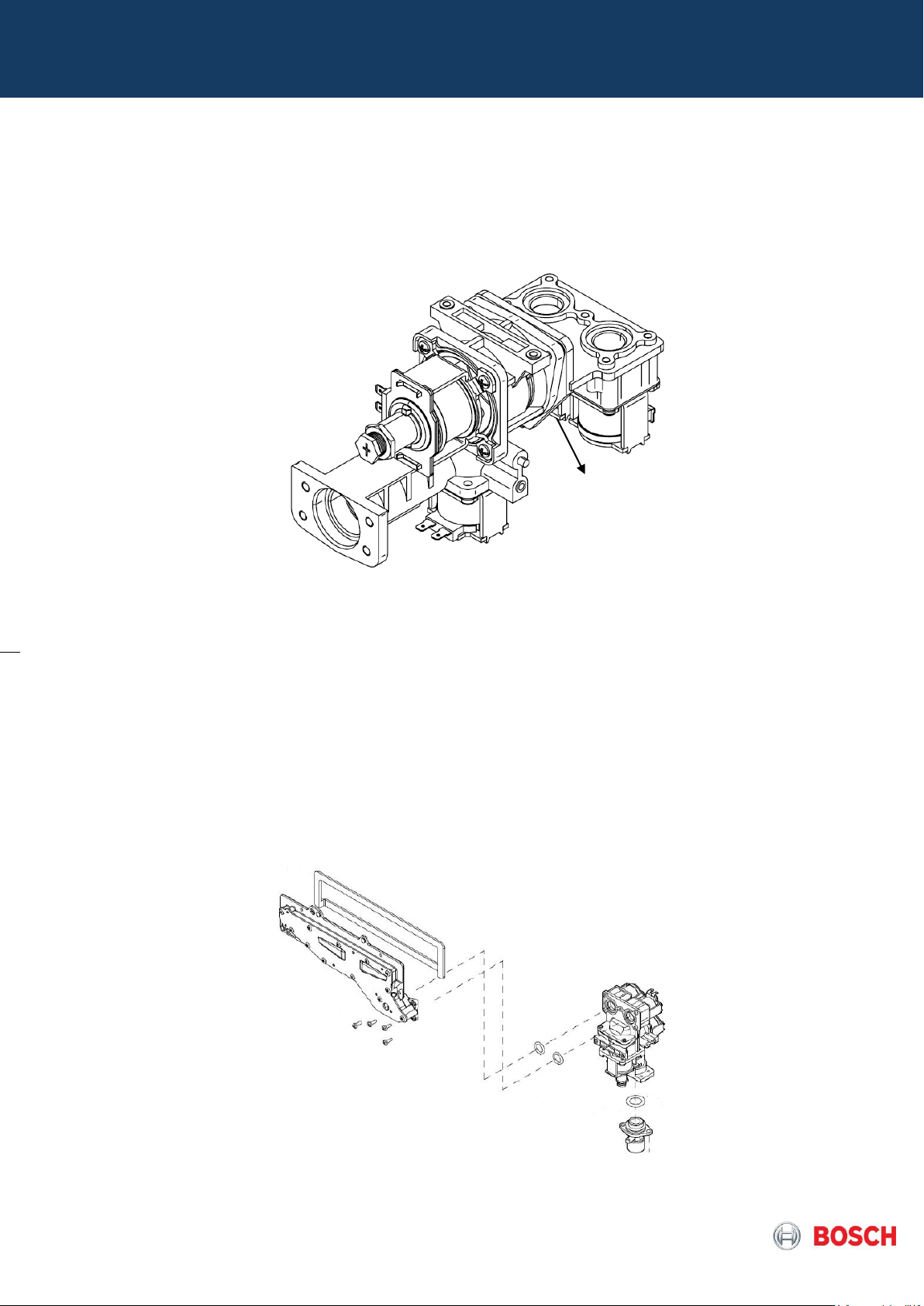

4.5 Gas Valve

Over the control unit it is possible to control the gas flow to the burner by the modulating gas valve (MV1).

The gas valve is composed by other three solenoids identified as safety valves (SV1 + SV2 + SV3) releasing

the modulated gas to and from the solenoid gas valve.

Page 15 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Pict. 21 – Different fan flanges (12 on left and 16 / 20 / 26 l/min models on right)

SV1

SV3

SV2

MV1

2nd Burner

Segment

1st Burner

Segment

Safety solenoid valve

The safety valve 1 (SV1) is the first safety element that releases gas to the burner. Safety valves 2 (SV2)

and 3 (SV3) are the second safety level elements, that release gas to the first and second burner segments,

respectively, acting as safety and segmentation valves.

Pict. 22 – Gas Valve

Modulating valve

Mechanical modulated valve

The Gas flow (thermal load) is automatically modulated in order to ensure the correct hot water set

temperature, under water flow or temperature variations.

The burner is composed by 2 segments which are fed according to the gas flow for the injectors manifold

released by the solenoid valves activation (SV1 and/or SV2) in gas valve which can be switched over

according to the different thermal load, in order to obtain a stable combustion. These valves ensure the most

suitable condition under the control of microcomputer, based on the values detected by the water flow sensor

and hot water NTC.

Pict. 23 – gas system to burner (gas valve + manifold)

Page 16 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

SV2

SV1

SV3

MV1

Burner

segment 1

Burner

segment 2

Pict.24 – Gas valve / burner scheme

4.6 Heat Exchanger

The copper heat exchanger has different size and number of fins according to the appliance model (12, 16

and 20l/min)and also different copper pipe connections if in high output range (16, 20, 26 l/min). This

configuration ensures the sealed heat transfer from the flame heat to the water that flows through the copper

pipes.

Pict.25 – Heat exchanger

Page 17 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

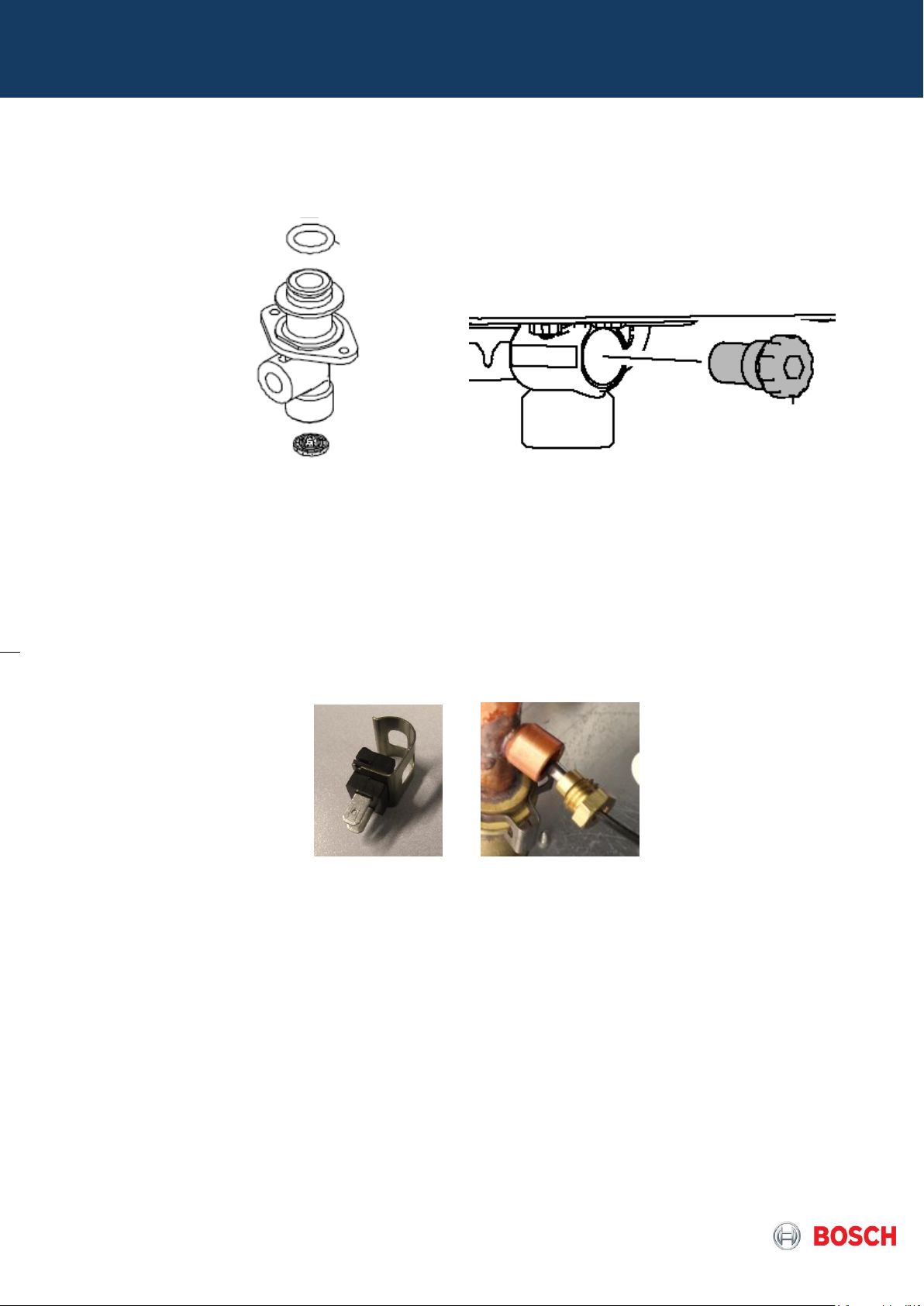

4.7 Water Inlet Assy

The inlet water valve contains the water connection of 1/2” that integrates also the filter mesh or for high

output models is ¾” and contains screw to access filter cartridge.

Pict.26 – Inlet Water Valve for indoor / outdoor

4.8 Water temperature sensors

The outlet and inlet water temperature is measured by a 10kΩ NTC (See table 15). Both NTC are equal, but

connected to different cable colors (blue wires to inlet water / red wires to outlet water). In the high output

range the NTC’s are immerged and as well equal but connected to different cable colors (blue wires to inlet,

red to heat exchanger / orange to outlet).

Contact Type (4000S) Immerged Type (Optiflow)

Pict.27 – NTC Temperature sensor

4.9 Box Temperature sensor

The Box air temperature is measured by a 220kΩ NTC (See table 14) and is assembled on the control unit

back panel, in order to monitor the temperature inside of the room sealed box.

Page 18 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Pict.28 – Box air temperature sensor location in 4000S models

Pict.29 – Box air temperature sensor location in optiflow model

Page 19 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Adaptor name

Adaptor design

Connection

Picture

8 Pins connector

Fan

12 Pins connector

Water Valve

14 Pins connector

Gas valve

16 Pins connector

Sensors

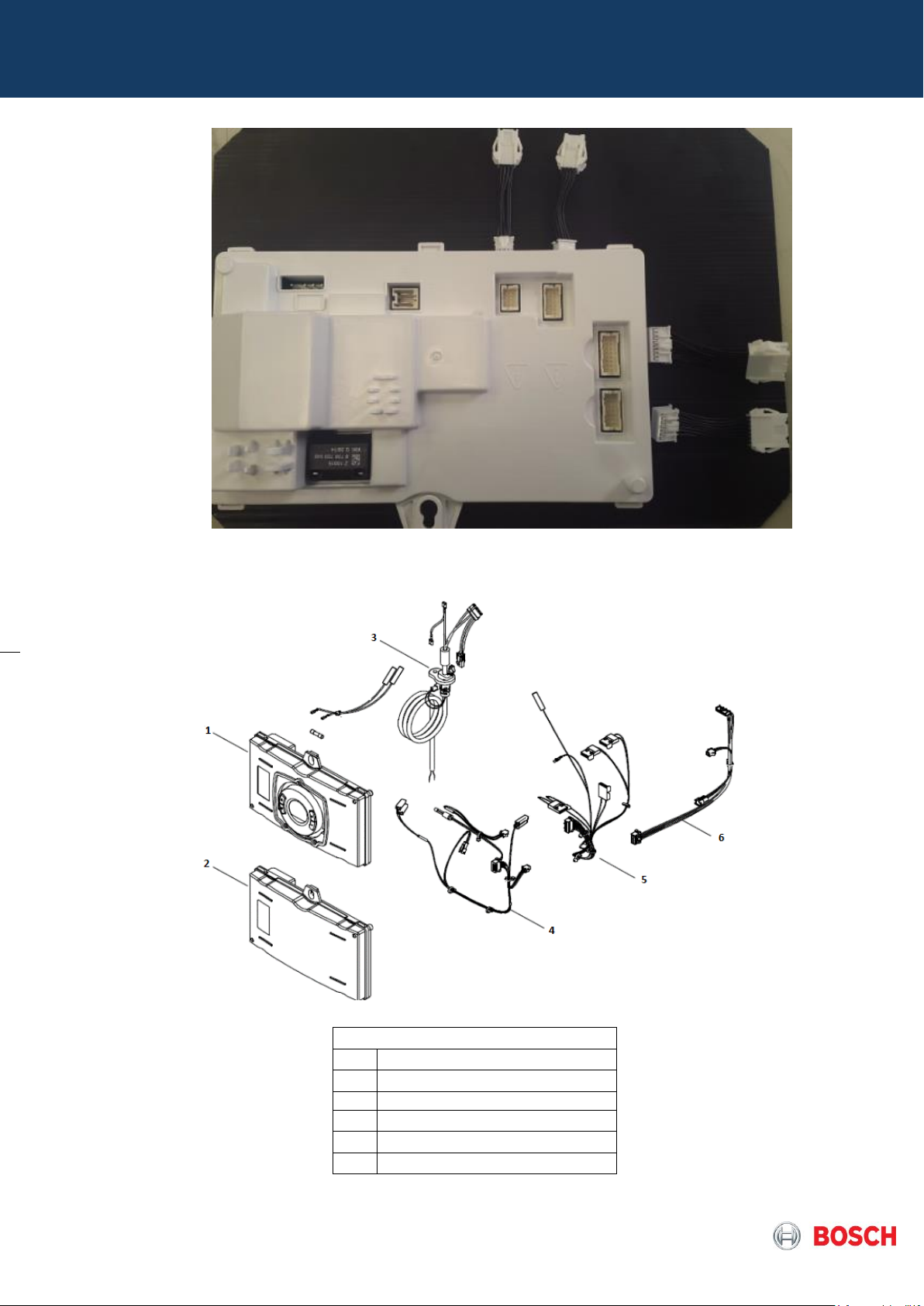

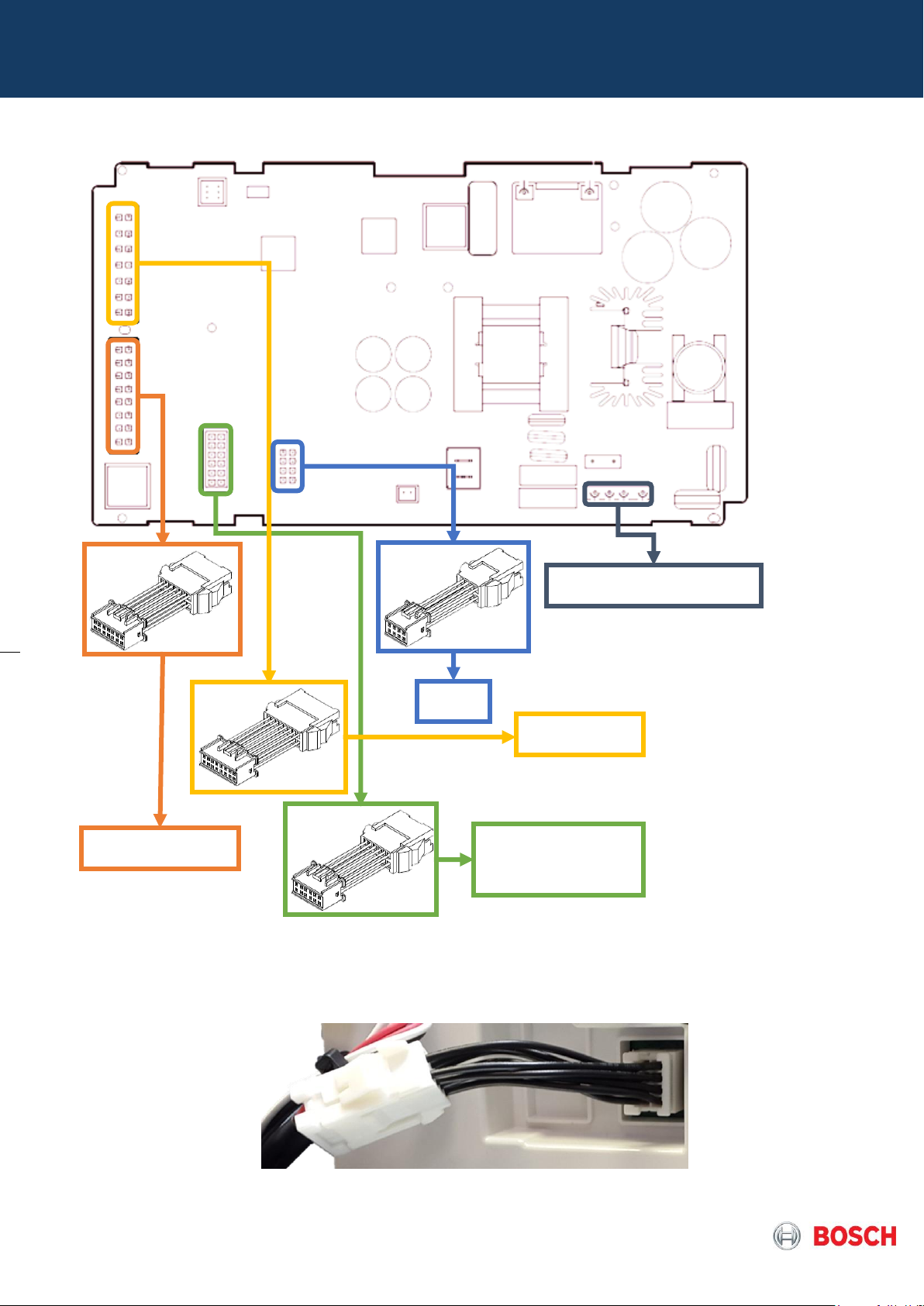

4.10 – PCB (printed circuit board)

The software version is visible in the identification sticker of the control unit as spare part and always refer to

updated versions.

Pict.30 – Identification sticker location according PCB design

The PCB are always compatible with existing cables / interface in the field, nevertheless and for 4000 S models

was done a change in the connector type, so to ensure compatibility between new control unit with cables in the

field, adaptors are be supplied from FD >= 718 (Feb 2017).

Page 20 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Table 11 – Resume of supplied adaptors

Description

1

Control unit (indoor version)

2

Control unit (outdoor version)

3

Power supply cable

4

Sensor cable

5

Gas valve cable

6

Water valve cable

Pict.31 – Overview of the PCB with adaptors for 4000S

Page 21 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Picture 32 – Overview of control unit and cables for FP Australia

Power supply

Fan

Water valve

Sensors

Gas valve

On the picture 34 is presented the example of an adapter connecting the old cable of the fan with new pcb.

Page 22 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Picture 33 – Rear view of control unit from FP Australia and adapters use

Picture 34 – PCB with adapter on the Fan terminal

Flow

[l/min]

Frequency

[Hz]

24

96

18

72

14

56

10

40 8 32

4

16

2

8

On the Picture 35 is presented the old terminal that is being replaced and the new one in the electrical cable

supply, so this cable will now always be supplied with new PCB.

Picture 35 – Old male terminal (left) and new male terminal (right)

4.11 Water Flow Sensor

Water flow is measured by a turbine flow sensor that is fed by a DC signal, proportional to the measured

water flow.

- Flow rate to operate the appliance: 2 l/min

- Flow rate to shut off the appliance: 1.6 l/min

Pict.36 – Motorized water valve (water flow sensor + stepper motor)

In case Q > 2 l/min following P

verification occurs:

out

- If P

> Minimum Power, the appliance will run with the calculated minimum water flow, in order to

out

reach the set point with a temperature stability of + / - 1ºC;

- If P out < Minimum Power, In case expected T out > set point, burner will shut down.

Table 12 – Water flow sensor values

Page 23 from 76 6 720 814 719 SM FP_Australia 2017/04 EN

Loading...

Loading...