Bosch GWH 260 PN, GWH 1600 P, GWH 1000 P, GWH 425 HN, GWH 425 PN Service Bulletin Booklet

...

Service Bulletin Booklet

For Compact model water heaters

GWH 260 PN, GWH 425 PN, GWH 425 HN

GWH 1000 P, GWH 1600 P, GWH 1600 H

THERMOCOUPLE AND PILOT TEST

MODELS: 1000P, 1600P,

260PN, 425PN

Before replacing the thermocouple, please test the

thermocouple safety circuit and the pilot as follows.

WW

W

WW

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

PERF

PERFPERF

ORMINORMIN

ORMIN

ORMINORMIN

G ANY WG ANY W

G ANY W

G ANY WG ANY W

ARNINARNIN

ARNIN

ARNINARNIN

Y FLY FL

Y FL

Y FLY FL

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

ORK T

ORK TORK T

GG

G

GG

AMMABLE SOAMMABLE SO

AMMABLE SO

AMMABLE SOAMMABLE SO

O THE HEAO THE HEA

O THE HEA

O THE HEAO THE HEA

TERTER

TER

TERTER

CT-02

page 1 of 1

rev 10/06

A. Pilot does not stay lit when the button is

released.

1. When lighting pilot, ensure the gas valve button is fully depressed and held down for at least 15 seconds after pilot is

lit.

2. Pilot flame should be a sharp blue flame that fully engulfs

the thermocouple tip. If pilot does not look this way, please

see bulle tin ‘

on how to clean pilot a ssembly and orifice.

3. If heater is equipped with an AQ4 power vent kit (models

1600P and 425PN only), press reset button on power vent

spill switch to check if it is tripped. NOTE: r unning the heater

without electrical power to power vent fan will trip the spill

switch. Also check the AQ4 safety circuit connections for

corrosion or loose connections. Consult AQ4 manual for part

locations.

4. Check the electromagnet connections. The electromagnet

is located on the back side of the gas valve. The electromagnet connection from the thermocouple is a 5 mm brass nut

that screws into a 17 mm aluminum nut. Tighten both nuts

snugly but do not over tighten.

5. Check if connections at both temperature limiters (ECO) are

loose or corroded. Clean any corrosion with very fine sand

paper or an eraser and reconnect leads.

6. If cleaning the terminals attached to the ECO’s does not fix

the problem, choose one ECO and remove two wires attached. Connect a jumper wire between the two wires removed from the ECO. Try to relight the pilot. If the pilot

flame now remains on, the ECO may be defective. If the

pilot still goes out, remove jumper, reconnect wires leads

and perform the same step with the other ECO.

7. Replace ECO.

8. Have a licensed gas technician verify the proper operation of

the thermocouple. To test the thermocouple, disconnect wire

from the thermocouple where it connects to the upper ECO

(located top right side of the heat exchanger). Insert a multimeter probe into the thermocouple lead and attach or hold

the other probe to the metal chassis of the heater (DC common). Light the pilot flame and hold button while observing

the meter reading. If the reading is 24mVDC or more the

thermocouple is good.

CT-22 Cleaning pilot assembly’ for instructions

Note: Never attempt to operate heater for normal

use with jumper wire connected!

B. Pilot goes out during use

1. Light the pilot and allow it to warm the thermocouple tip for

2 minutes.

2. Perform dr op test by blowing out the pilot flame and listen

for the electromagnet to close. This closure will make a distinct clunk noise as it shuts. The time between blowing out

the flame and the electromagnet closing should be between

20 and 30 seconds. Units equipped with an AQ4 power vent

kit have drop times between 10 and 15 seconds.

3. Repeat drop test several times to confirm it is consistent

4. If drop times are not within specifications, then follow steps

2-7 in section A. After each step, repeat drop test. Proceed

to the next step until drop test is within specifications.

C. Pilot goes out during use and drop test is

within specifications.

1. Check the vent size and length. Vent should be 5 inches in

diame ter for the 1600P and 425PN and 4 inches in diameter

for the 1000P and 260PN. The heater mus t have a rise of 1foot before any elbo ws in the vent system, at least 6 feet

vertical in length and terminate through the roof. Any reduction in vent size or the presence of an elbow directly on the

top of the unit may cause the flue gas sensor to trip the pilot

safety circuit. Please see t he venting section in the manual

for more de tailed information regarding the required venting

for this heater.

2. Inspect the draft hood and heat exchanger fins for signs of

soot build-up or any other foreign material such as spider

webs. Clean out any debris found in the vent hood. Signs of

soot indicate insufficient combustion air or exhaust draft.

Check for vent assembly blockage or combustion air blockage on the underside of the unit. Ensure combustion air

requirements are being met as specif ied in the installation

manual.

3. Measure the outgoing temperature of the hot water exiting

the unit. Temperature in excess of 160F may trip the pilot

safety circuit. The heater must not be supplied with w ater in

excess of 90F. Preheated water may cause the heater to

overheat the outlet water and shut down as a safety precaution.

©BBT NORTH AMERICA CORPORATION

Bosch Group

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

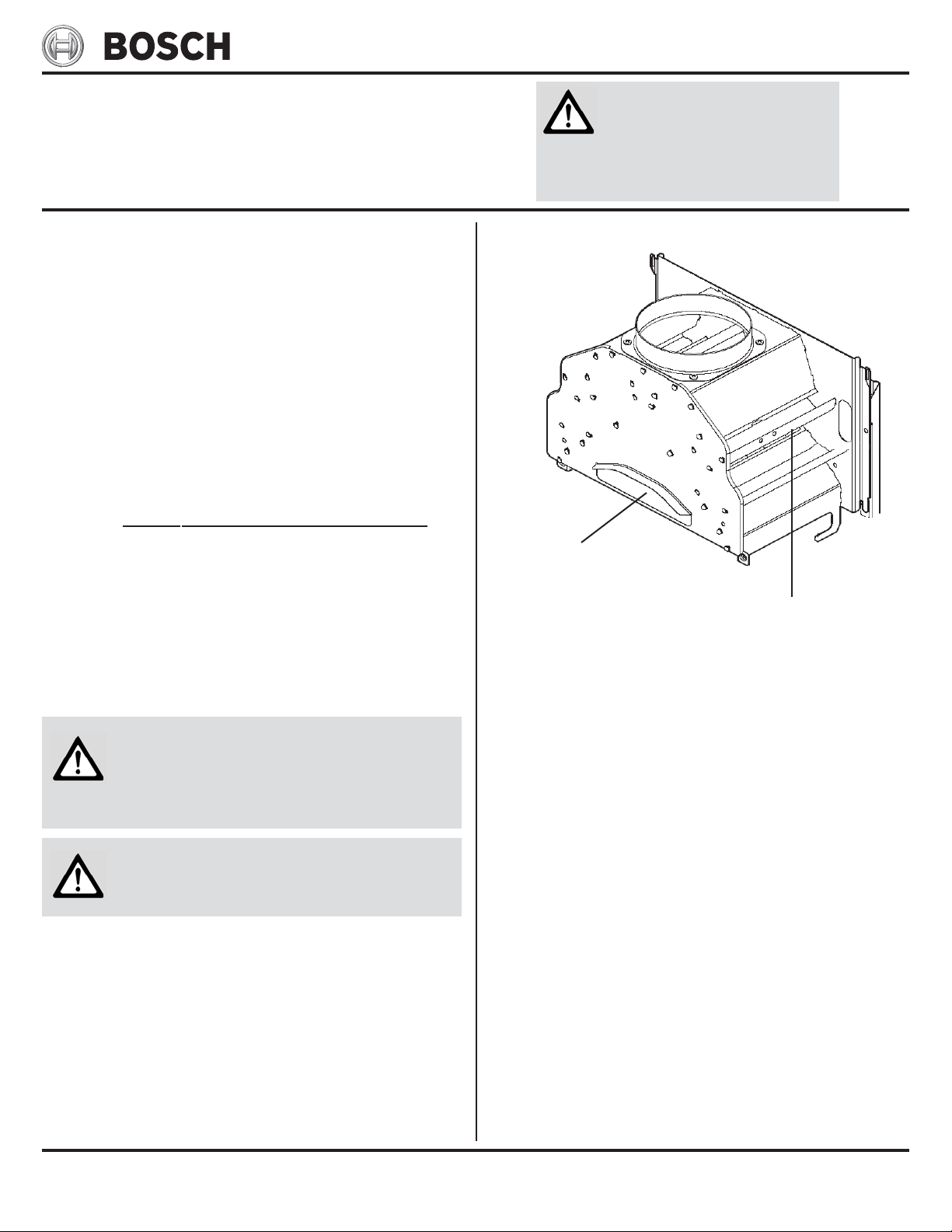

CHECKING THE DRAFT

MODELS: 1000P, 1600P, 1600H

260PN, 425PN, 425HN

1. Close all doors and window in the building.

2. Operate all fuel burning appliances and exhaust

systems in the building with the exception of the

tankless water heater. Allow time for these items to

utilize the air in the structure. Up to one hour may

be necessary.

3. Remove the cover from the tankless unit and hold a

recently extinguished match, candle, or any other

visible smoke source in front of the triangular opening on the draft diverter.

4. The smoke should be sucked quickly into the opening

and up the exhaust vent. If the smoke is blown back,

a negative air situation exists and must be corrected.

See the combustion air section in the manual or

bulletin CT-05 Negative air and freeze prevention.

5. Now run the heater for 10 minutes, then hold a

smoke source at the top right side of the draft

diverter. The smoke should be drawn in the louvers

on the side. If this is not the case, the unit is not

drafting properly and flue gases are being exhausted

into the space in which the heater is installed. This

is not safe and must be corrected. Reference the

venting section in the manual to ensure venting is in

accordance with the manufacturer’s specifications.

WW

ARNINARNIN

W

ARNIN

WW

ARNINARNIN

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

ORMINORMIN

PERF

ORMIN

PERFPERF

ORMINORMIN

Step 3: Hold extiguished

match here

G ANY WG ANY W

G ANY W

G ANY WG ANY W

1000P. 1600P, 1600H,

260PN, 425PN, 425HN

GG

G

GG

Y FLY FL

AMMABLE SOAMMABLE SO

Y FL

AMMABLE SO

Y FLY FL

AMMABLE SOAMMABLE SO

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

O THE HEAO THE HEA

ORK T

O THE HEA

ORK TORK T

O THE HEAO THE HEA

Step 5: Hold extiguished

match here

TERTER

TER

TERTER

CT-03

page 1 of 1

rev 09/06

Note: Poor venting can result in excessive sooting around the water heater,

overheating, and release dangerous

carbon monoxide into the living space

causing serious injury and/or death.

Note: Damage to the heater as a result

of improper venting will not be covered

under warranty.

©BBT NORTH AMERICA CORPORATION

Bosch Group

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

CHECKING GAS PRESSURE

MODELS: 1000P, 1600P, 1600H

260PN, 425PN, 425HN

WW

W

WW

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

PERF

PERFPERF

ORMINORMIN

ORMIN

ORMINORMIN

G ANY WG ANY W

G ANY W

G ANY WG ANY W

ARNINARNIN

ARNIN

ARNINARNIN

Y FLY FL

Y FL

Y FLY FL

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

ORK T

ORK TORK T

GG

G

GG

AMMABLE SOAMMABLE SO

AMMABLE SO

AMMABLE SOAMMABLE SO

O THE HEAO THE HEA

O THE HEA

O THE HEAO THE HEA

TERTER

TER

TERTER

CT-04

page 1 of 1

rev 10/06

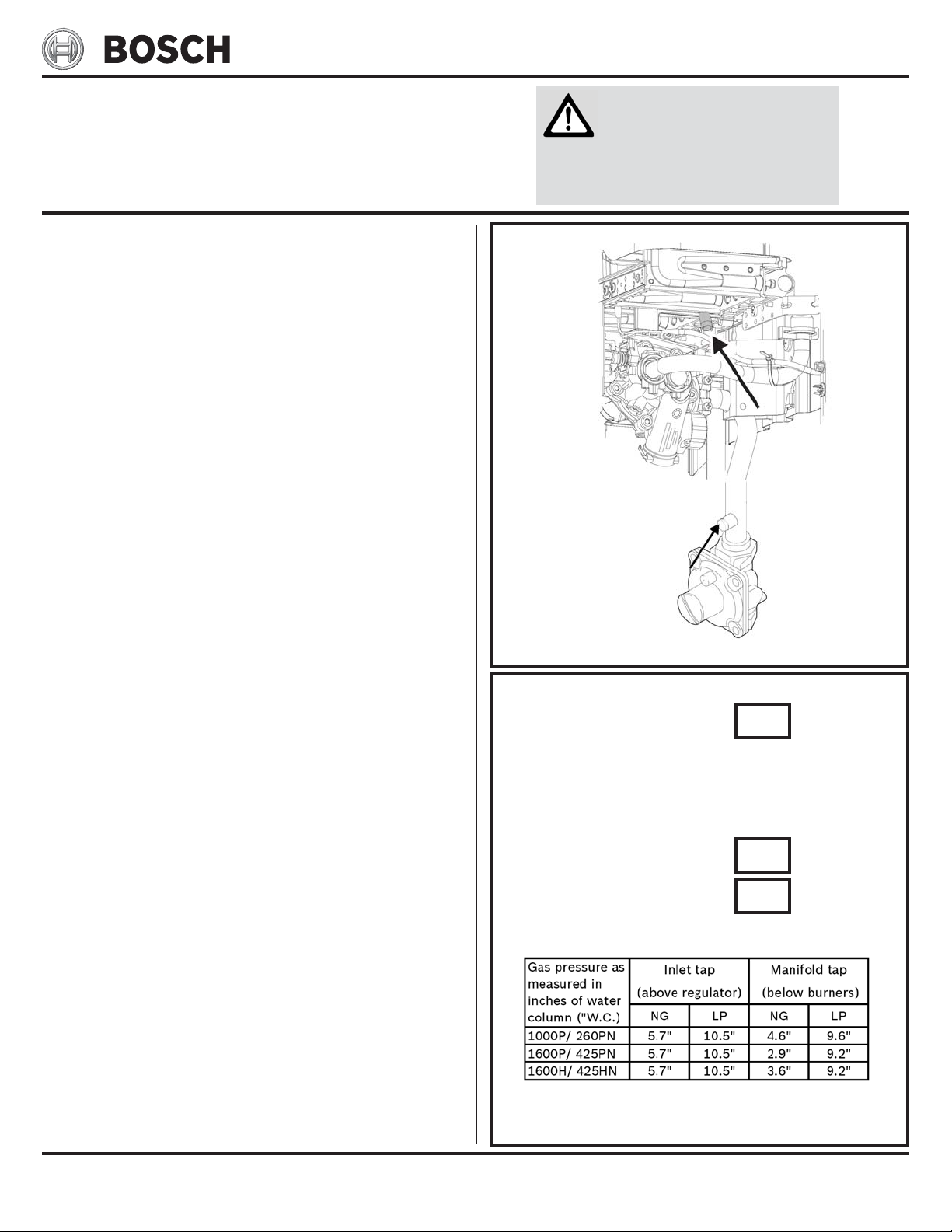

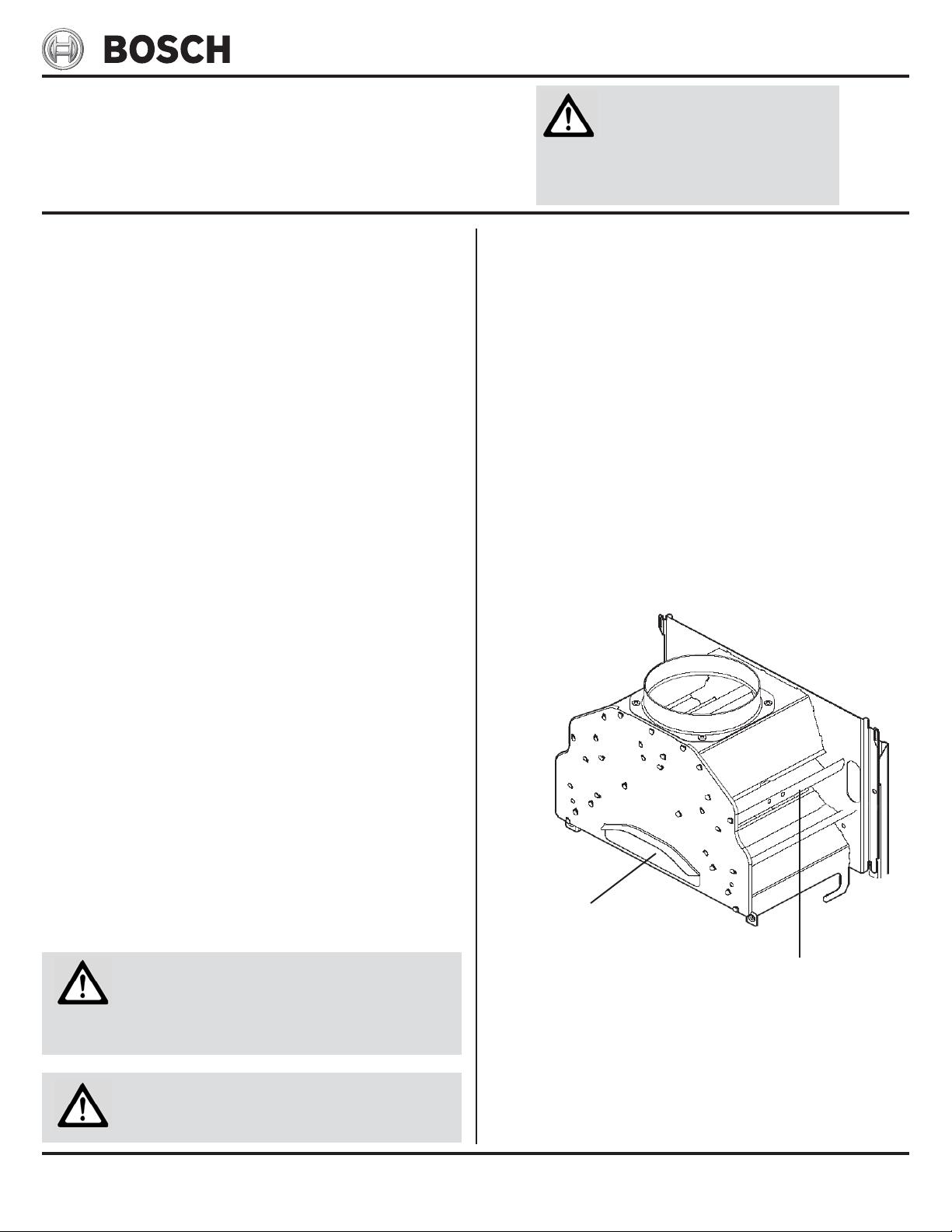

A. Connecting manometer:

1. Turn off gas using installer supplied manual shutoff.

2. Remove front cover (see manual for instructions) and lo-

cate inlet gas pressure tap above the regulator on the gas

inlet pipe and the manifold gas pressure tap on the right

side directly below the burner (Fig. 1).

3. Select appropriate pressure tap per specific pressure test

(see steps B and C). Loosen the screw from test point fitting (do not remove) and connect manometer tube on test

point.

B. Static pressure test (Inlet pressure tap

only)

1. Turn gas supply back on.

2. Operate all other gas appliances at maximum output.

3. Record static pressure reading in Table 1.

4. Leave manometer connected to inlet tap for oper ating pres-

sure test.

C. Operating pressure test

1. Light pilot if neccessary (1000P, 1600P, 260PN and 425PN

models).

2. All other gas appliances should still be running at full ca-

pacity.

3. Set heater to maximum output:

1000P, 1600P, 260PN, 425PN:

Set gas slide control to the right. Turn temperature

adjustment knob full clockwise.

1600H, 425HN:

Turn power adjustment knob full clockwise. Turn

temperature adjustment knob full clockwise.

4. Open all hot water taps supplied by this unit.

5. Record inlet tap oper ating pressure reading in Table 1.

6. Tur n off gas supply as well as all hot water taps. Disconnect

manometer from the inlet tap. Tighten screw in tap fitting

or gas leak may occur.

7. Reconnect manometer to the manifold gas pressure tap.

8. Turn gas supply back on and follow steps 1 through 4.

9. Record manifold tap operating pressure reading in Table 1.

10. Turn off gas supply as well as all hot water taps. Disconnect

manometer from the manifold tap. Tighten screw in tap fitting or gas leak may occur.

11. Put cover back on water heater, open gas supply and re turn

heater to service.

FIGURE 1

Mainfold tap

Inlet tap

GAS PRESSURE TEST POINTS

TABLE 1

Static gas pressure: “ W.C.

Required static gas pressure (all models:

NG 7” - 14” W.C.

LPG 11” - 14” W.C.

Operating gas pressure:

Inlet Tap “ W.C.

Manifold tap “ W.C.

Minimum require operating gas pressure:

©BBT NORTH AMERICA CORPORATION

Bosch Group

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

NEGATIVE AIR & FREEZE

PREVENTION

MODELS: 1000P, 1600P, 1600H,

260PN, 425PN, 425HN

WW

W

WW

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

PERF

PERFPERF

ORMINORMIN

ORMIN

ORMINORMIN

G ANY WG ANY W

G ANY W

G ANY WG ANY W

ARNINARNIN

ARNIN

ARNINARNIN

Y FLY FL

Y FL

Y FLY FL

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

ORK T

ORK TORK T

GG

G

GG

AMMABLE SOAMMABLE SO

AMMABLE SO

AMMABLE SOAMMABLE SO

O THE HEAO THE HEA

O THE HEA

O THE HEAO THE HEA

TERTER

TER

TERTER

CT-05

page 1 of 1

rev 10/06

Negative Air

• Negative air pressure in a str ucture occurs when air consumed by fuel burning appliances or exhaust systems in that

structure exceeds the amount of air available.

• Here is a list of items that consume air within a typical household:

• Stove exhaust fans

• Furnaces

• Water heaters

• Fireplaces/ Woodstoves

• Bath fans

• Dryers

• All of these items must be taken into account when making

provisions for a proper amount of fresh air from the outside.

• If the building is new construction, air infiltration from the

outside will be limited and provisions for extra air supply

should be made. If the building is older construction, air may

infiltr ate into the house through unplanned sources such as

window frames, door jams, sill plates or idle chimney flues.

These sources still may not be providing the adequate amount

of air and additional sources of fresh air should be considered.

Why Negative Air is Bad

Cold air from the outside is drawn through the water heater’s

flue pipe because other fuel burning appliances or exhaust

systems in the str ucture require more air than the dwelling

can supply. When the required amount of air for the fuel

burning appliances or exhaust systems in t he structure is

not being supplied to them, they find the flue pipe on the

water heater an acceptable means of supplying themselves.

Thus, freezing cold air is pulled down the water heater’s flue,

drawn over the copper heat exchanger, potentially freezing

it and the water valve below. Because, when idle, the water

heater holds only cold water, fr eezing can happen quickly

possibly causing leaks or ruptures in the heat exchanger and/

or the water valve. The water heater does not pull air through

its flue pipe – if you w ere to remove the heater, the air would

continue to come down your flue pipe. You must ha ve the air

balanced in the structure to correct this pr oblem. Consultation with a heating, ventilating and air conditioning (HVAC)

specialist is recommended.

Note: Poor venting can result in excessive

sooting around the water heater, overheating, and release dangerous carbon monoxide into the living space causing serious injury and/or death.

Note: Damage to the heater as a result of

improper venting will not be covered under warranty.

Checking for Negative Air

1. Close all doors and windows in the building.

2. Operate all fuel burning appliances and exhaust systems in

the building at full capacity with the exception of the tankless

water heater. Allow time for these items to utilize the air in

the structure. Up to one hour may be necessary.

3. Remove the cover from the tankless unit and hold a recently

extinguished match, candle, or any other visible smoke source

in front of the triangular opening on the draft diverter.

4. The smoke should be sucked quickly into the opening and up

the exhaust vent. If the smoke is blown back, a negative air

situation exists and must be corrected. See the combustion

air section in the manual for specifications.

5. Now run the heater for 10 minutes, then hold a smoke source

at the top right side of the draft diverter. The smoke should

be drawn in the louvers on the side. If this is not the ca se,

the unit is not drafting properly and flue gases are being

exhausted into the space in which the heater is ins talled.

This is not safe and must be corrected. Reference the venting section in the manual to ensure venting is in accordance

with the manufacturer’s specifications.

Step 3: Hold extiguished

match here

Step 5: Hold extiguished

match here

DRAFT DIVERTER FOR:

1000P, 1600P, 1600H,

260PN, 425PN, 425HN

©BBT NORTH AMERICA CORPORATION

Bosch Group

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

OVERCOMING FLUCTUATING

TEMPERATURES

MODELS: 1000P, 1600P, 1600H

260PN, 425PN, 425HN

WW

W

WW

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

PERF

PERFPERF

ORMINORMIN

ORMIN

ORMINORMIN

G ANY WG ANY W

G ANY W

G ANY WG ANY W

ARNINARNIN

ARNIN

ARNINARNIN

Y FLY FL

Y FL

Y FLY FL

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

ORK T

ORK TORK T

GG

G

GG

AMMABLE SOAMMABLE SO

AMMABLE SO

AMMABLE SOAMMABLE SO

O THE HEAO THE HEA

O THE HEA

O THE HEAO THE HEA

TERTER

TER

TERTER

CT-06

page 1 of 1

rev 10/06

Introduction

Temperature fluctuations from hot to cold during use is typically caused by a back pressure on the water flowing through

the tankless water heater. This decreases the flow rate through

the tankless water heater belo w the required activation flow

rate and shuts the heater down. Follow these instructions step

by step to overcome this phenomenon.

Clean faucet aerators and shower heads

Check for restrictions in outlets, which would limit hot water

demand and may assist in deactivation scenario. For sinks,

remove faucet aerator on end of sink. Flush and cle an screen

and reinstall. For showers, remove showerhead and flush. If

plugged with mineral deposits, clean according to

manufacturer’s suggestions or replace. (Note: if showerhead is

wand style/hand held, corrugated tube connecting to head may

be too restrictive. Enlarging tube or using a normal showerhead

may be the solution.)

Clean Inlet filter screen

Inlet filter screen is located in bottom of the water valve near

the cold water connection side (right) at the rear of the unit.

Please see bulletin

instructions.

CT-12 Cleaning inlet f ilter for more detailed

Check for plumbing crossover

A plumbing crossover can be caused by a failed cartridge at a

single lever faucet, incorrect plumbing or a faulty mixing valve

in the piping. The crossover will create a back pressure on the

water heater and prevent an adequate flow of water through it.

Close installer supplied cold water shut off valve to the heater

(if none installed, install bef ore proceeding). Open all hot water taps supplied by the heater. Wait 5 minutes and check all

taps. Water running is a sign of a plumbing cross-over. Consult

a local plumber or service person for help in correcting a plumbing crossover.

Lower temperature

The temperature can be lowered by moving gas slide control to

the left. On models 1600H and 425HN, turn power adjustment

knob clockwise. See bulletin

alternative methods of lowering output temperature.

CT-07 Lowering temperatures for

Confirm activation rate of the heater

1. Turn flow control knob on the front of heater fully clockwise.

2. Fully open one hot water tap.

3. Return to heater and shut cold water supply valve.

4. Slowly open cold water supply v alve until the burners ignite.

5. Return to hot water tap and measure flow rate by timing

how long takes to fill a quart container. A fill time of 30

seconds indicates a proper activation rate of 0.5 gallons per

minute (GPM)*. See Table 1 for other flow rate conversions.

6. Repeat steps 4 and 5 a few times to check the accuracy of

tes t.

* A fill time less than 30 seconds indicates an activation rate

above the required 0.5GPM and a possible problem within

the heater’s water valve. Periodic maintenance is required

on this water valve. Visit our website for parts and service

bulle tins for this procedure.

GPM

.50 30 120

.75 20 80

1.00 15 60

1.25 12 4 8

1.50 10 4 0

1.75 8.5 34

2.00 7.5 30

Quar t Jar

(in Secon ds)

Ga l lo n Ju g

(in S econds)

Confirm water pressure

Water pressure should stay above 30psi during operation. If on

a well system, we recommend a pressure setting of 40-60psi.

©BBT NORTH AMERICA CORPORATION

Bosch Group

2.50 6 24

3.00 5 20

3.50 4.25 17

4.00 3.75 15

TABLE 1

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

LOWERING TEMPERATURE

MODELS: 1000P, 1600P, 1600H

260PN, 425PN, 425HN

WW

W

WW

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

LP & N

G ARE EXTREMEL

LP & NLP & N

G ARE EXTREMELG ARE EXTREMEL

TT

AKE EXTRA PRECAAKE EXTRA PRECA

T

AKE EXTRA PRECA

TT

AKE EXTRA PRECAAKE EXTRA PRECA

PERFPERF

PERF

PERFPERF

ORMINORMIN

ORMIN

ORMINORMIN

G ANY WG ANY W

G ANY W

G ANY WG ANY W

ARNINARNIN

ARNIN

ARNINARNIN

Y FLY FL

Y FL

Y FLY FL

UTIONS WHENUTIONS WHEN

UTIONS WHEN

UTIONS WHENUTIONS WHEN

ORK TORK T

ORK T

ORK TORK T

GG

G

GG

AMMABLE SOAMMABLE SO

AMMABLE SO

AMMABLE SOAMMABLE SO

O THE HEAO THE HEA

O THE HEA

O THE HEAO THE HEA

TERTER

TER

TERTER

CT-07

page 1 of 1

rev 10/06

When the temperature adjustment knob on the front of

heater is turned all the way clockwise (hotter temps.),

the heater requires a 0.6 gallon per minute flow rate to

activate. When the temperature adjustment knob is turned

all the way counter-clockwise (cooler temps.), the unit

will require a 1.1 gallon per minute flow rate to activate.

Although common sense tells us to turn this knob counterclockwise to achieve a lower outlet temperature, we recommend that the temperature adjustment knob be kept

all the way clockwise, to take advantage of the 0.6 gpm

activation point. Please move knob to this setting and

follow the steps below for alternative ways of lowering

temperature.

Solution:

Increased water flow helps to lower the outle t temperature and ensures that the heater stays activated especially when mixing cold water at the outlet.

1. Increase the flow by cleaning the inlet filter screen in

the heater. (Fig. 1) Consult bulletin CT-12 Cleaning in-

let filter for more detailed instructions on removing

the inlet filter.

2. Increase the flow at all outlets. For sinks, remove faucet aerator screen on end of sink. Flush screen with

water to clean and reinstall. For showers, remove

showerhead and flush with water. If the head is clogged

with mineral deposits, clean according to

manufacturer’s specifications or replace. Ple ase note,

if the showerhead is a hand-held/wand style, these can

be extremely restrictive. If cleaning or flushing

showerheads/aerators fails to produce a dequate flow,

try upgrading with higher flowing versions.

3. Decrease the gas volume by moving gas slide control

(models 260PN, 425PN, 1000P, 1600P) or gas control

knob(models 425HN, 1600H) to the small flame

position.

4. If temperatures are still too hot, increase water flow

by removing the water governor/restrictor. Shut off cold

water supply to heater and remove wire clip on volumetric water governor housing from right side of water valve behind water outlet pipe. (Fig. 2) Remove

retaining cap with o-ring and spring/cylinder assembly inside. (Fig. 3) Re-install retaining cap with lubricated o-ring and wir e clip only. No inner components

should be left inside. Operate heater with the flow

control turned all the way clockwise.

FIGURE 1

Removing Water Filter

FIGURE 2

Water governor

clip

Water Governor Location

FIGURE 3

Retaining

cap

Cylinder

Spring

Water Governor Location

©BBT NORTH AMERICA CORPORATION

Bosch Group

Bosch Water Heating

340 Mad River Park, Waitsfield, VT 05673

Loading...

Loading...