Bosch Therm 4000 S, GWH12, GWH15, GWH18 Installation And Operating Manual

Installation and Operating Manual

Gas instantaneous water heaters

Therm 4000 S

6720813351-00.1V

GWH12/15/18 CTD E23/31 F6 O...

6 720 819 528 (2016/02) ZA

Read installation manual prior to installation of this unit!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation room must fulfill the ventilation requirements!

Installation by an authorised person only!

6 720 819 528 (2016/02) Therm 4000 S

2 | Index

Index

1 Key to symbols and safety instructions . . . . . . . . . . 3

1.1 Key to symbols . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 General safety instructions . . . . . . . . . . . . . . 3

2 Product details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 EC Declaration of Conformity . . . . . . . . . . . . 5

2.2 Type overview . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Material attached . . . . . . . . . . . . . . . . . . . . . 5

2.4 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Description of appliance . . . . . . . . . . . . . . . . 5

2.6 Accessory (not supplied with the appliance) 5

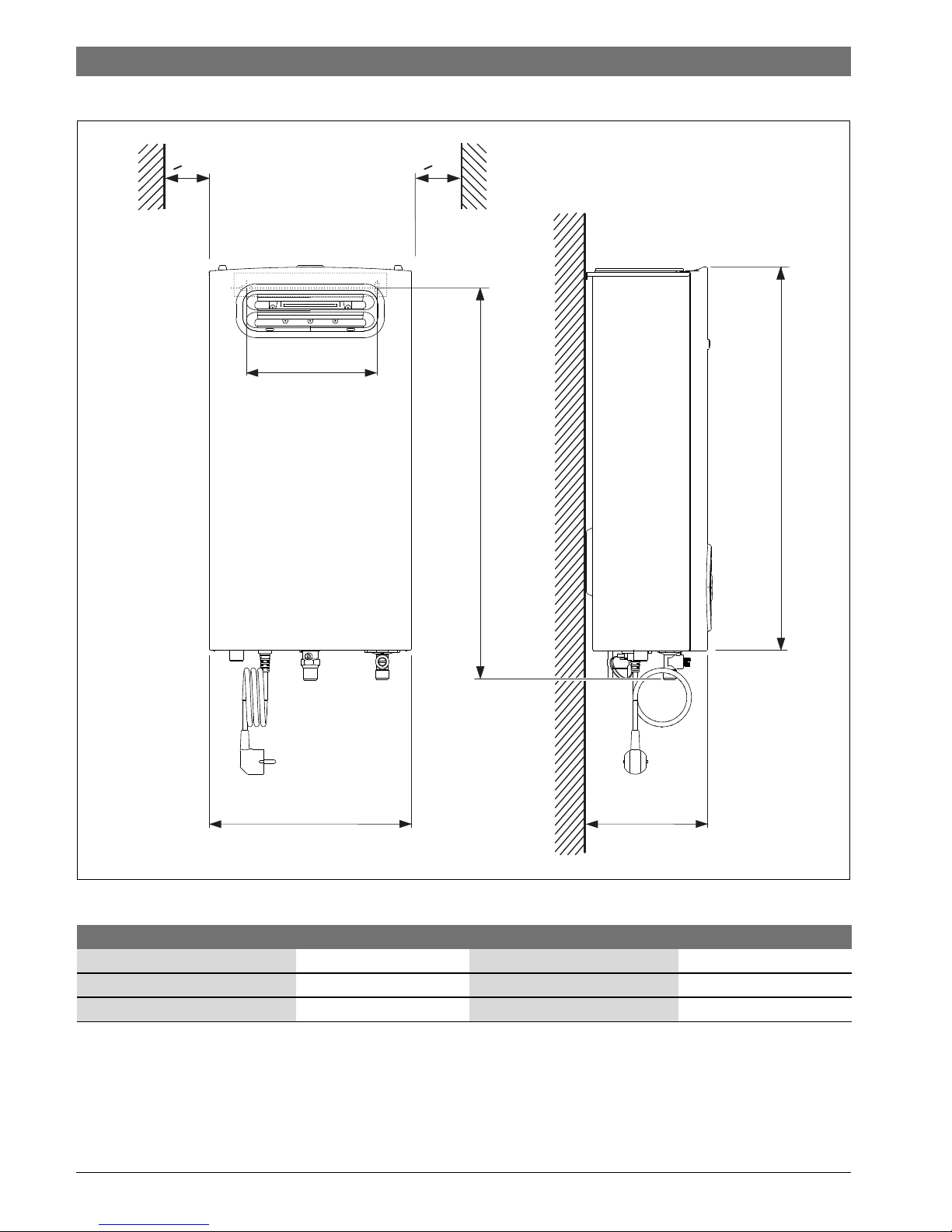

2.7 Dimensions and minimum clearances . . . . . 6

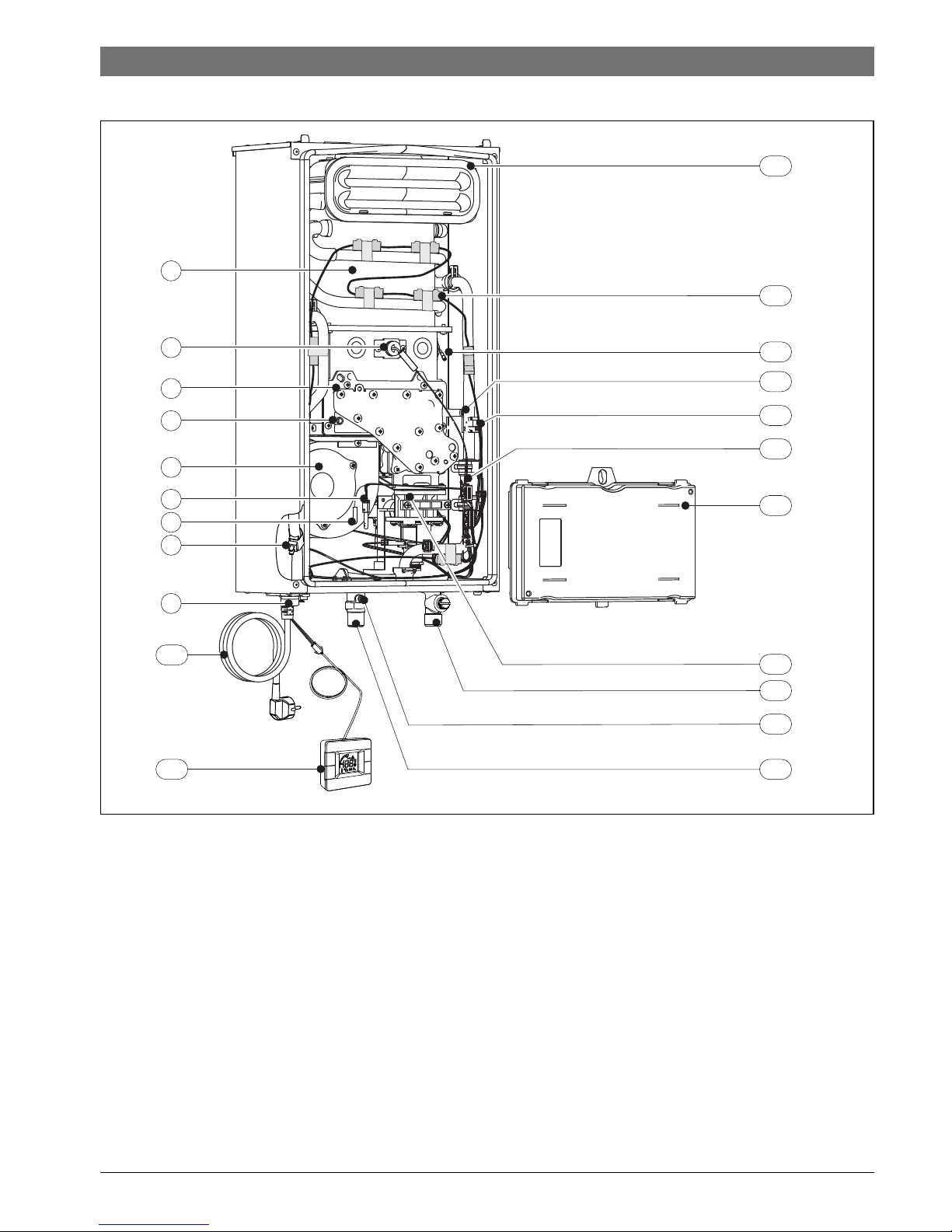

2.8 Appliance layout . . . . . . . . . . . . . . . . . . . . . . 7

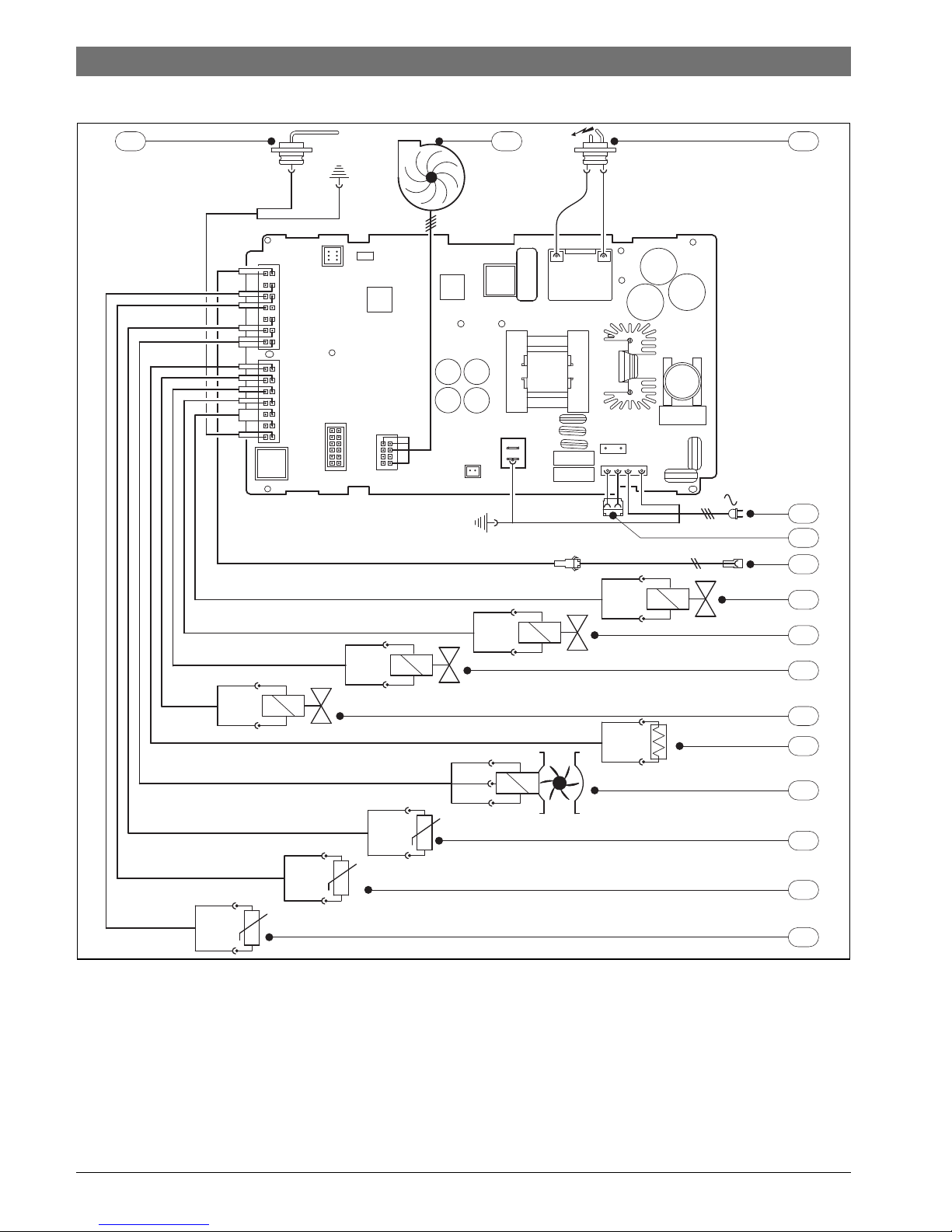

2.9 Electrical wiring diagram . . . . . . . . . . . . . . . 8

2.10 Specification . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Operation instructions . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Digital display - description . . . . . . . . . . . . 10

3.2 Before commissioning the appliance . . . . . 10

3.3 Switching the appliance on/off . . . . . . . . . . 10

3.4 Temperature control . . . . . . . . . . . . . . . . . . 11

3.5 Programming button . . . . . . . . . . . . . . . . . . 11

3.6 Draining the appliance . . . . . . . . . . . . . . . . 11

3.7 Codes of errors in the display . . . . . . . . . . . 12

3.8 Cleaning the front of the appliance . . . . . . 12

4 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Installation (only by qualified contractors) . . . . . . 12

5.1 Important notes . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Choice of installation site . . . . . . . . . . . . . . 13

5.2.1 Regulations concerning the installation

site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Minimum distances . . . . . . . . . . . . . . . . . . . 13

5.4 Fitting wall-mounting bar . . . . . . . . . . . . . . 14

5.5 Fitting the appliance . . . . . . . . . . . . . . . . . . 14

5.6 Water connection . . . . . . . . . . . . . . . . . . . . 14

5.7 Gas connection . . . . . . . . . . . . . . . . . . . . . . 15

5.8 Altitude of installation site region . . . . . . . . 15

5.9 Remote control connection . . . . . . . . . . . . 15

5.10 Commissioning of the appliance . . . . . . . . 16

6 Electrical connection (only by qualified

contractors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

6.1 Connecting the power cable . . . . . . . . . . . . 17

6.2 Replacing the power cable . . . . . . . . . . . . . 17

7 Regulating the gas (only for qualified

contractors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.1 Factory regulation . . . . . . . . . . . . . . . . . . . . 17

7.2 Service function . . . . . . . . . . . . . . . . . . . . . 17

7.3 Adjusting the appliance . . . . . . . . . . . . . . . 17

7.3.1 Access to the pressure heads . . . . . . . . . . . 17

7.3.2 Adjusting the maximum flow

(Parameter P1) . . . . . . . . . . . . . . . . . . . . . .18

7.3.3 Adjusting the minimum flow

(Parameter P2) . . . . . . . . . . . . . . . . . . . . . .18

7.3.4 Adjusting pressure in the burner

(Parameter P0) . . . . . . . . . . . . . . . . . . . . . .19

7.4 Factory default settings . . . . . . . . . . . . . . . 19

7.5 Changing the type of gas . . . . . . . . . . . . . . 19

8 Maintenance (only by qualified contractors) . . . . 19

8.1 Remove the front cover . . . . . . . . . . . . . . . 20

8.2 Periodic maintenance works . . . . . . . . . . . 20

8.3 Replacement of fuses (control box) . . . . . . 20

8.4 Start-up after completion of maintenance

works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

9 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10 Environment / disposal . . . . . . . . . . . . . . . . . . . . . . . 22

11 Warranty Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6 720 819 528 (2016/02)Therm 4000 S

Key to symbols and safety instructions | 3

1 Key to symbols and safety instructions

1.1 Key to symbols

Warnings

The following keywords are defined and can be used in this

document:

• NOTICE indicates a situation that could result in damage to

property or equipment.

• CAUTION indicates a situation that could result in minor to

medium injury.

• WARNING indicates a situation that could result in severe

injury or death.

• DANGER indicates a situation that will result in severe

injury or death.

Important information

Additional symbols

1.2 General safety instructions

These instructions are aimed at the owner, specialist

technicians and those qualified in gas, water, electricity,

heating installations.

▶ Before use, read and keep the operation manuals

(appliance, heating controller, etc.).

▶ Read the installation instructions (appliance, heating

controller, etc) before the installation.

▶ Pay attention to the safety and warning notices.

▶ Pay attention to national and regional regulations,

technical regulations and directives.

▶ Document works carried out.

If you smell gas

A gas leak could potentially cause an explosion. If you smell gas,

observe the following rules.

▶ Prevent flames or sparks:

– Do not smoke, use a lighter or strike matches.

– Do not operate any electrical switches or unplug any

equipment.

– Do not use the telephone or ring doorbells.

▶ Turn off the gas at the meter.

▶ Warn your neighbours and leave the building.

▶ Prevent anyone from entering the building.

▶ Well away from the building: call the fire brigade, police and

gas supplier.

Use as per regulations

The appliance may only be used for the production of DHW for

human consumption in domestic installations or equivalent

with intermittent use.

The appliance can only be installed outdoors.

Any other type of use is deemed improper. No liability is

accepted for any damage as a result of this.

Safety of electrical appliances for

domestic use and similar purposes

The following requirements apply in

accordance with EN 60335-1 in order to

prevent hazards from occurring when using

electrical appliances:

“This device can be used by children of 8

years and up as well and by people with

reduced physical, sensory or mental

capabilities or lacking in experience and

knowledge, if they are supervised and have

been given instruction in the safe use of the

device and understand the resulting

dangers. Children must not play with the

device. Cleaning and user maintenance may

not be performed by children without

supervision”

“If the power supply cable is damaged, in

order to avoid risks it must be replaced by

Warnings in this document are identified by a

warning triangle printed against a grey

background.

Keywords at the start of a warning indicate

the type and seriousness of the ensuing risk

if measures to prevent the risk are not taken.

This symbol indicates important information

where there is no risk to people or property.

Symbol Explanation

▶ Step in an action sequence

Cross-reference to another part of the document

•List entry

– List entry (second level)

Table 1

6 720 819 528 (2016/02) Therm 4000 S

4 | Key to symbols and safety instructions

the manufacturer or its customer service

department or a similarly qualified person.”

Installation, commissioning and maintenance

The installation, commissioning and maintenance may only be

carried out by an authorised contractor.

▶ Check the tightness of the connections to the device (gas

and water).

▶ Only fit original spare parts.

Inspection and maintenance

Regular inspection and maintenance are essential for the safe

and environmentally-sound operation of the heating system.

We recommend taking out an annual inspection and

maintenance contract with the manufacturer.

▶ Work should only be carried out by an authorised

contractor.

▶ Immediately remove any faults detected.

Any situation that does not meet the conditions described in

the manual must be duly assessed by a qualified, contractor. In

the event that it is approved for use, the technician shall adapt

the maintenance requirements to the wear and tear and

associated conditions as well as the standards and

requirements of the market and the particular application.

Modifications and repairs

Unprofessional modifications to the appliance or other parts of

the heating system can result in injury and/or damage to

property or equipment.

▶ Have any work carried out only by an authorised

contractor.

▶ Do not remove the appliance case.

▶ Do not modify the appliance or other parts of the heating

system in any way.

Electrical work

Electrical work must only be carried out by a qualified

electrician.

▶ Before starting electrical work:

– Isolate the mains electrical supply and secure against

unintentional reconnection.

– Check for zero potential.

▶ Also observe connection diagrams of other system

components.

Open flue operation

The installation room must be adequately ventilated if the

appliance draws its combustion air from the room.

▶ Consult an authorised contractor to ensure the ventilation

requirements are met:

– if structural modifications are made (e.g. replacing

windows and doors)

– if appliances are subsequently installed which route

extract air to the outside (e.g. extract air fans, kitchen

fans or air conditioning units).

▶ Never cover or reduce the size of ventilation apertures.

Handover to the user

When handing over, instruct the user how to operate the

heating system and inform him about its operating conditions.

▶ Explain how to operate the heating system and draw the

user's attention to any safety-relevant action.

▶ Explain that modifications and repairs must only be carried

out by an authorised contractor.

▶ Point out the necessity of inspection and servicing for safe

and environmentally compatible operation.

▶ Leave the installation instructions and the operating

instructions with the user.

6 720 819 528 (2016/02)Therm 4000 S

Product details | 5

2 Product details

GWH appliances are appliances for producing hot water ready

for operation at the simple touch of a remote control button.

2.1 EC Declaration of Conformity

This appliance meets the requirements of the European

Directives 2009/142/EC, 2006/95/EC, 2004/108/EC and

corresponds to the approval sample described in the relevant

CE test certificate.

The appliance has been EN 26 tested.

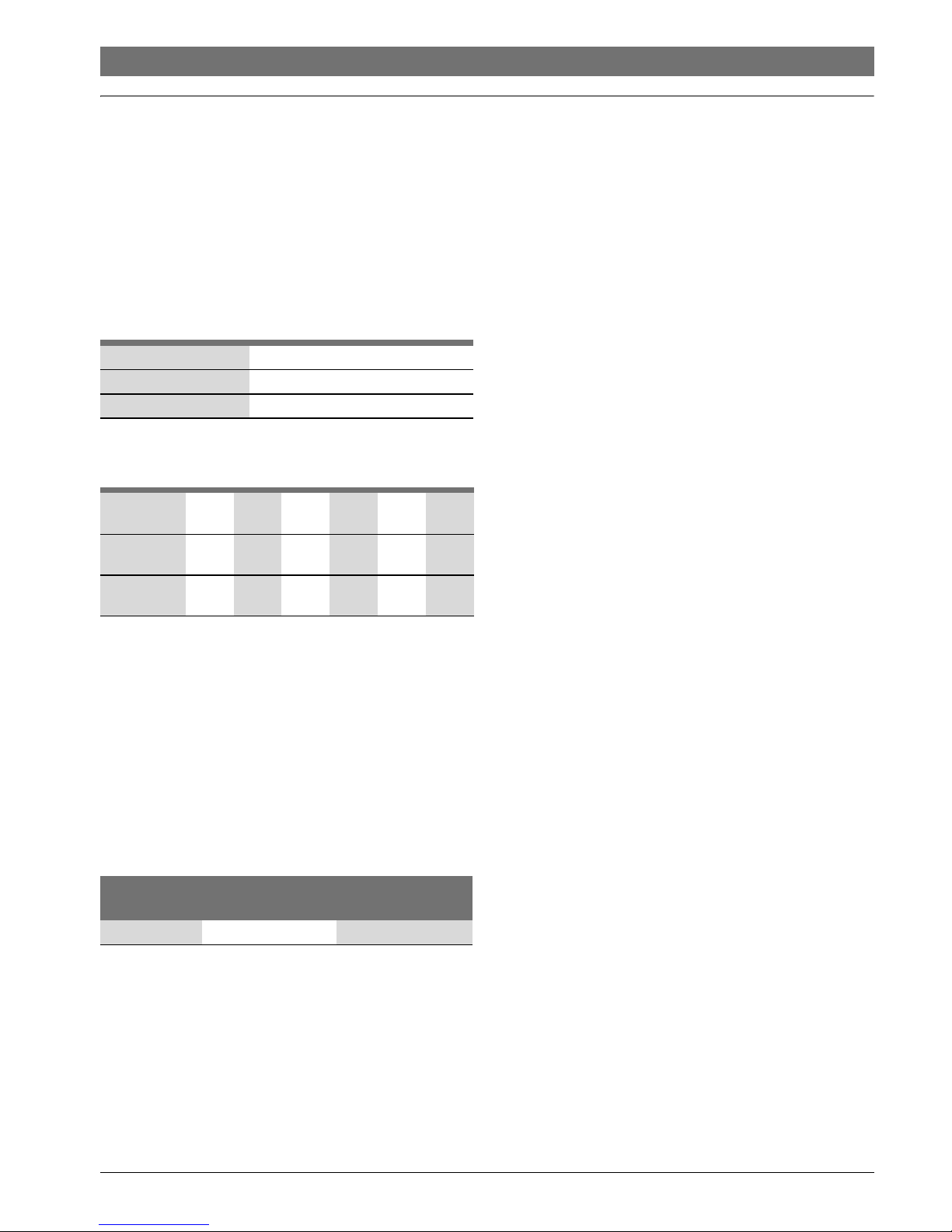

2.2 Type overview

[GWH] Gas instantaneous water heater

[12] Capacity (l/min)

[CT] Thermostatic

[D] Digital user interface

[E] Electric ignition

[23] Appliance set for natural gas

[31] Appliance set for LPG

[F6] Room sealed

[O] Outdoor installation

The code number indicates the gas group according to EN 437:

2.3 Material attached

• Gas instantaneous water heater

•Fasteners

• Appliance documentation

• Remote control

• Anti freeze kit

2.4 Rating plate

The rating plate is located on the outside of the appliance, on

the bottom.

It contains details of the output of the appliance, the order

number, the approval data and the date of manufacture in

encoded form (FD).

2.5 Description of appliance

• Room sealed wall-mounted appliance

• Remote control with multifunctional display panel

• Appliance for operating with LPG

• Electronic ignition

•Water flow sensor

• Temperature sensors for monitoring the temperature of the

cold and hot water of the appliance.

•Safety devices:

– Ionisation electrode

–Thermofuse

– Hot water temperature sensor

– Control box

–Air temperature sensor

• Electrical connection: 230 V, 50 Hz

2.6 Accessory (not supplied with the appliance)

•Gas conversion kits

Model GWH12/15/18 CTD E23/31 F6 O...

Category (gas type) I

3B/P

Type of installation A

3

Table 2

GWH12 CT DE23

31

F6 O

GWH15 CT DE23

31

F6 O

GWH18 CT DE23

31

F6 O

Table 3

Code numbers Wobbe Index

(W

S

) (15 °C)

Gas type

31 20.2-21.3 kWh/m

3

LPG group3R

Table 4

6 720 819 528 (2016/02) Therm 4000 S

6 | Product details

2.7 Dimensions and minimum clearances

Fig. 1 Dimensions (in mm)

B

C

230

A

583

6720813351-01.1V

>10 >10

A B C

GWH12 300 568 170

GWH15 300 568 170

GWH18 364 568 175

Table 5 Dimensions (in mm)

6 720 819 528 (2016/02)Therm 4000 S

Product details | 7

2.8 Appliance layout

Fig. 2

[1] Combustion chamber

[2] Monitoring electrode

[3] Burner

[4] Air pressure head in the box

[5] Fan

[6] Air temperature sensor of the box

[7] Thermofuse

[8] Hot water temperature sensor

[9] Water outlet

[10] Connecting lead with plug

[11] Remote control

[12] Combustion gas collector

[13] Anti freeze kit

[14] Ignition electrode

[15] Gas pressure head in the burner

[16] Cold water temperature sensor

[17] Water flow sensor

[18] Control box

[19] Gas valve

[20] Water inlet

[21] Incoming gas pressure head

[22] Gas

10

6720813351-02.1V

22

18

20

21

6

7

1

5

8

9

12

15

19

3

13

16

4

11

2

14

17

6 720 819 528 (2016/02) Therm 4000 S

8 | Product details

2.9 Electrical wiring diagram

Fig. 3 Electrical diagram

[1] Monitoring electrode

[2] Fan

[3] Ignition electrode

[4] Supply

[5] Connection for anti freeze kit

[6] Connection for remote control

[7] Electrovalve 1

[8] Electrovalve 2

[9] Electrovalve 3

[10] Electrovalve 4

[11] Thermofuse

[12] Water flow sensor

[13] Air temperature sensor of the box

[14] Outgoing water temperature sensor

[15] Incoming water temperature sensor

6720804089-10.1V

1 32

4

6

7

8

9

10

11

12

13

14

15

230 V

AC

M1

5

Loading...

Loading...