Page 1

Gas Heaters

GWH 10-2 G.. / GWH 13-2 G.. / GWH 16-2 G..

en Installation Manual and Operating Instructions

Read installation manual prior to installation of this unit!

Read user manual before putting this unit in operation!

Observe the warnings in the manuals!

The installation room must fulfill the ventilation requirements!

Installation by an authorised person only!

6 720 608 992 (2011/12) AU

Page 2

2 | Table of contents

Table of contents

1 Key to symbols and safety instructions . . . . . . . 3

1.1 Explanation of symbols . . . . . . . . . . . . . . . . 3

1.2 Safety information . . . . . . . . . . . . . . . . . . . 3

2 Technical Characteristics and Dimensions . . . . . 4

2.1 General Description . . . . . . . . . . . . . . . . . . 4

2.2 Explanation of Model Code . . . . . . . . . . . . . 4

2.3 Package contents . . . . . . . . . . . . . . . . . . . . 4

2.4 Description of the heater . . . . . . . . . . . . . . 4

2.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Functional diagram of the heater . . . . . . . . 6

2.7 Electrical diagram . . . . . . . . . . . . . . . . . . . . 7

2.8 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.9 Technical characteristics . . . . . . . . . . . . . . 8

3 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Important information . . . . . . . . . . . . . . . 10

4.2 Selection of the place of installation . . . . 10

4.3 Heater mounting . . . . . . . . . . . . . . . . . . . . 11

4.4 Water connection . . . . . . . . . . . . . . . . . . . 11

4.5 Hydrogenerator operation . . . . . . . . . . . . 11

4.6 Pressure Relief . . . . . . . . . . . . . . . . . . . . . 12

4.7 Gas connection . . . . . . . . . . . . . . . . . . . . . 12

4.8 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10 Water quality . . . . . . . . . . . . . . . . . . . . . . . . . . 20

11 Warranty details . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Operating instructions . . . . . . . . . . . . . . . . . . . . 13

5.1 Digital display - description . . . . . . . . . . . 13

5.2 Before starting up the heater . . . . . . . . . . 13

5.3 Turning the heater on and off . . . . . . . . . . 13

5.4 Water flow . . . . . . . . . . . . . . . . . . . . . . . . 13

5.5 Gas adjustment . . . . . . . . . . . . . . . . . . . . . 14

5.6 Temperature/flow adjustment . . . . . . . . . 14

5.7 Draining the appliance . . . . . . . . . . . . . . . 14

6 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Inlet pressure adjustment . . . . . . . . . . . . . 15

6.2 Burner pressure adjustment . . . . . . . . . . . 15

6.3 Conversion to a different type of gas . . . . 15

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Flue gas safety device . . . . . . . . . . . . . . . . 16

8 Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

8.1 Problem/cause/solution . . . . . . . . . . . . . . 17

9 Environmental protection . . . . . . . . . . . . . . . . . 19

6 720 608 992 (2011/12)

Page 3

1 Key to symbols and safety instructions

If you smell combustion gases:

1.1 Explanation of symbols

Warnings

Warnings in this document are framed and

identified by a warning triangle which is

printed on a grey background.

Electrical hazards are identified by a

lightning symbol surrounded by a warning

triangle.

Keywords indicate the seriousness of the hazard in

terms of the consequences of not following the safety

instructions.

• NOTICE indicates that material damage may occur.

• CAUTION indicates that minor to medium injury may

occur.

• WARNING indicates that serious injury may occur.

• DANGER indicates possible risk to life.

Important information

Important information in cases where there

is no risk of personal injury or material

losses is identified by the symbol shown on

the left. It is bordered by horizontal lines

above and below the text.

Additional symbols

Symbol Meaning

B a step in an action sequence

Æ a reference to a related part in the

document or to other related documents

• a list entry

– a list entry (second level)

Table 1

1.2 Safety information

If you smell gas:

B Close the gas supply valve.

B Open the windows.

B Do not operate any electrical appliances or switches

(on/off).

B Extinguish other sources of ignition.

B Go to a different location and call the gas supplier or

an authorised technician.

B Turn off the heater.

B Open doors and windows.

B Notify an authorised technician.

Assembly, modifications

B The assembly and modifications to the heater can

only be performed by an authorised installer.

B Do not modify the pipes which conduct combustion

gases.

B Do not close or reduce air circulation vents.

Maintenance

B We recommend the system be serviced regularly to

ensure it functions reliably and safely.

B The installer is responsible for the safety and

environmental compatibility of the installation.

B The heater should be serviced annually.

B Only original spare parts must be used.

Explosive and highly inflammable material

B Do not store or use inflammable material (paper,

solvents, paints, etc) near the heater.

Combustion air and surrounding air

B To avoid corrosion, the combustion air and

surrounding air must be free from harmful substances

(e.g. halogenated hydrocarbons which contain

chlorine and fluorine compounds).

B Do not spray pressure pack or use chemicals around

the heater

Information to the customer

B Inform the customer about how to operate the heater.

B This appliance is not intended for use by persons

(including children) with reduced physical sensory or

mental capabilities.

Children should be supervised to ensure they do not

play with the appliance.

B Caution customers against performing modifications

or repairs themselves.

To be installed and serviced only by an authorised

person

The “authorised installing person” is responsible for:

B Correct commissioning of this appliance.

B Ensuring the appliance performs to the specifications

stated on the rating label.

B Demonstrating the operation of the appliance to the

customer before leaving.

B Handing these instructions to customer.

THIS APPLIANCE IS NOT FOR USE AS A POOL OR SPA

POOL HEATER.

THIS APPLIANCE IS ONLY TO BE INSTALLED INDOORS.

Key to symbols and safety instructions | 3

6 720 608 992 (2011/12)

Page 4

4 | Technical Characteristics and Dimensions

2 Technical Characteristics and Dimensions

• Gas flow adjustment proportional to the water flow to

2.1 General Description

Model GWH 10/13/16 -2 G..

Category CONTINUOUS FLOW

Type INTERNAL

Table 2

2.2 Explanation of Model Code

Type l/min Series Ignition Gas Types

GWH 10 2GNG / LP gas

GWH 13 2GNG / LP gas

maintain a constant temperature.

• Safety devices:

– Ionisation probe to check for accidental extinction

of the burner flame

– Flue gas safety device which turns off the heater in

cases where the evacuation of flue gases is

inadequate

– Overtemperature switch which prevents

overheating of the heat exchanger.

GWH 16 2GNG / LP gas

Table 3

2.3 Package contents

• Gas heater

• Fixing Brackets

• flexible water pipes

• Gas regulator

• Heater documentation

2.4 Description of the heater

Designed for convenience, the heater is ready to operate

by simply pressing a switch.

• Heater for wall-mounting

• Ignition by electronic device triggered when the water

valve opens

• Hydrodynamic generator produces sufficient energy

to ignite and control the heater.

• Gauge to display temperature, burner operation and

error codes

• Temperature sensor to monitor the water

temperature at the heater outlet

• Available in Natural gas or LP gas

• Temporary pilot burner which only functions during

the period between the opening of the water valve

and the ignition of the main burner

• Water valve made of fibreglass-reinforced polyamide,

and is 100% recyclable

• Automatic control of the water flow to allow for

variable water supply pressure.

6 720 608 992 (2011/12)

Page 5

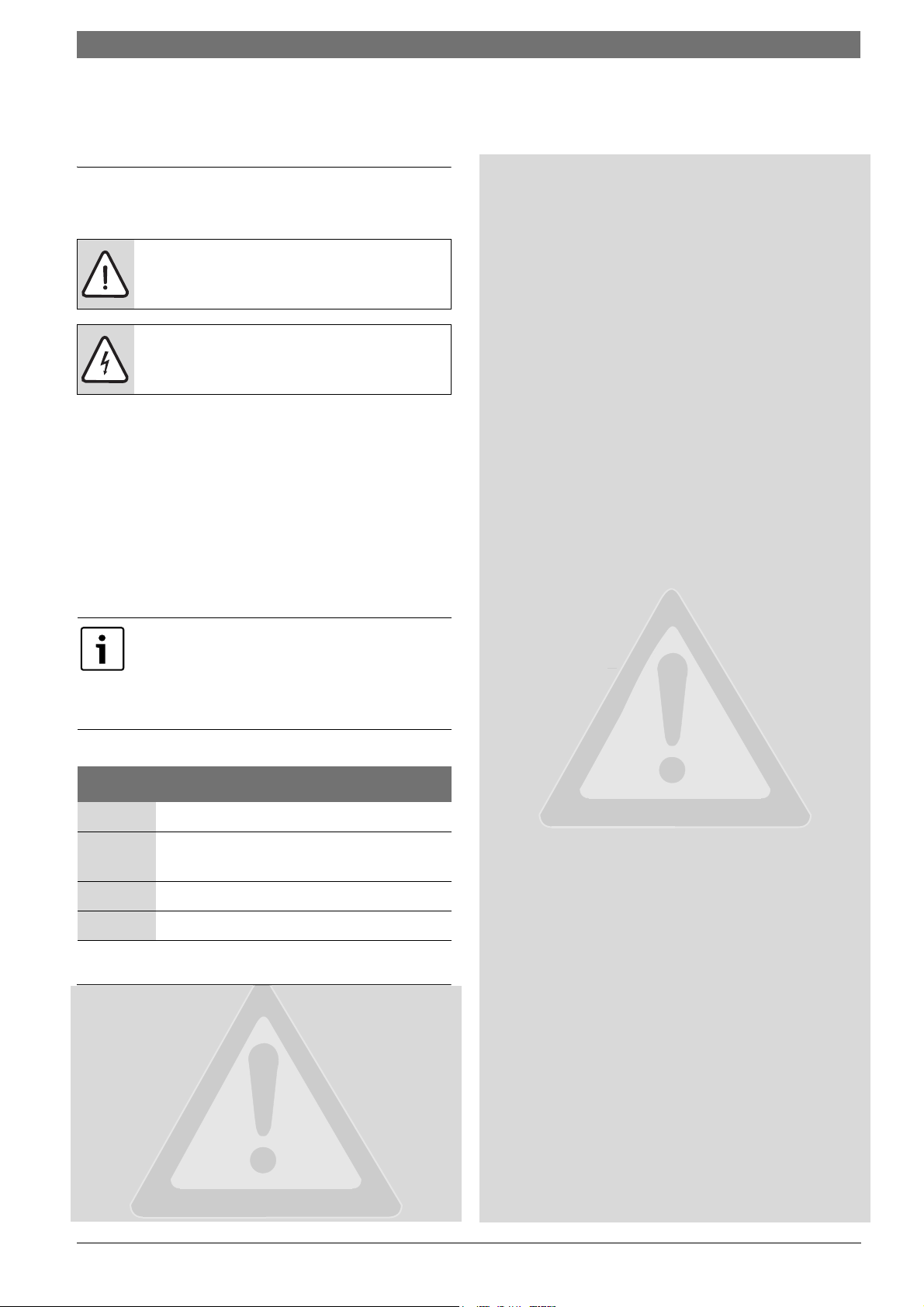

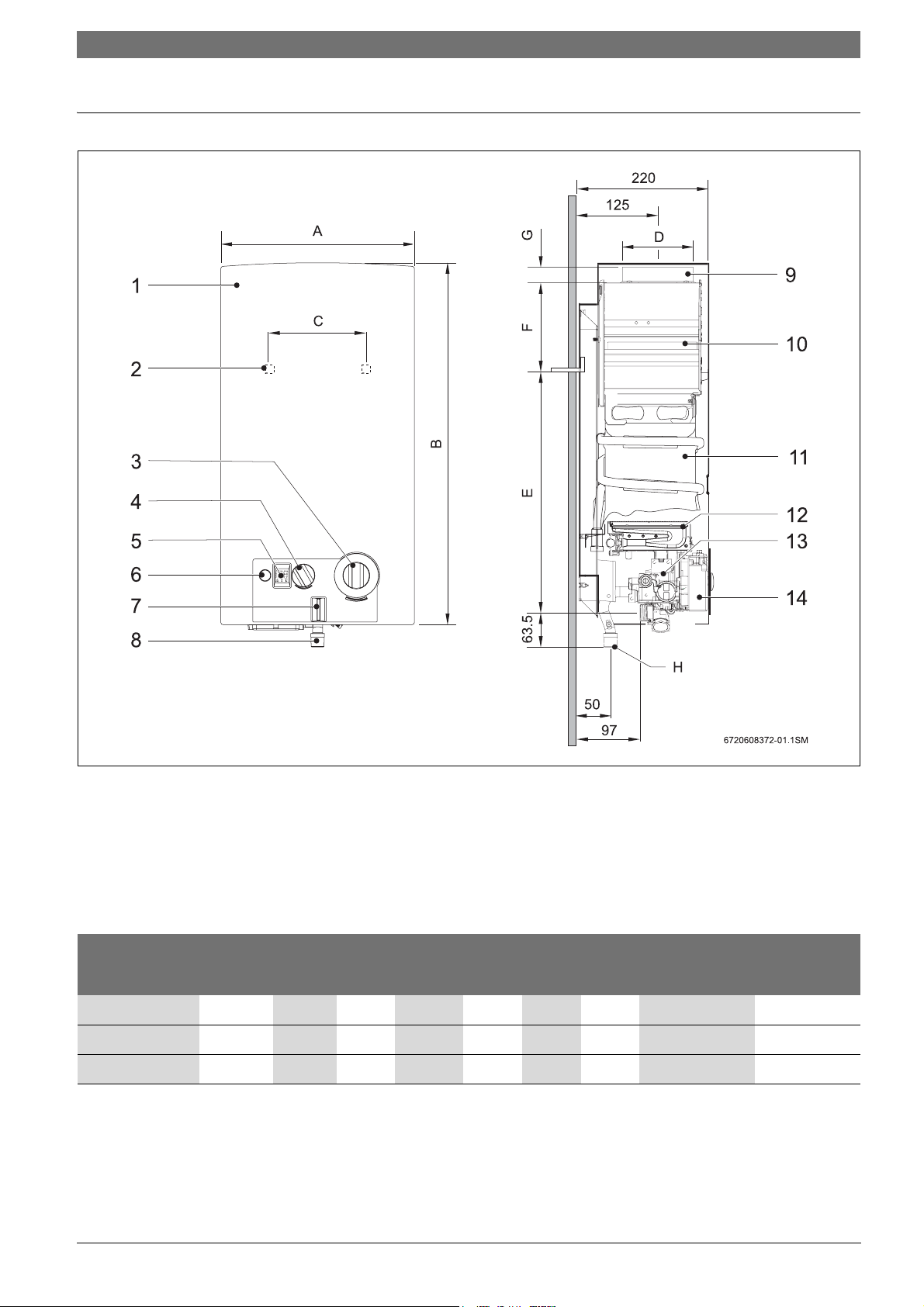

2.5 Dimensions

Technical Characteristics and Dimensions | 5

Fig. 1

1 Front cover

2 Opening in rear panel for mounting on the wall

3 Temperature/volume selector

4 Gas adjustment

5 Digital display

6 Switch/LED - Low water pressure indicator

7 LED - Burner status check

Dimensions

(mm)

A B C D E F G

8 Gas connection

9 Connection collar for flue

10 Draught diverter

11 Copper Heat exchanger

12 Burner

13 Gas valve

14 Ignition unit

H (Ø)

Natural gas LP gas

GWH10... 310 580 228 115 463 60 25 20 15

GWH13... 350 655 228 140 510 95 30 20 15

GWH16... 425 655 334 140 540 65 30 20 15

Table 4 Dimensions

6 720 608 992 (2011/12)

Page 6

6 | Technical Characteristics and Dimensions

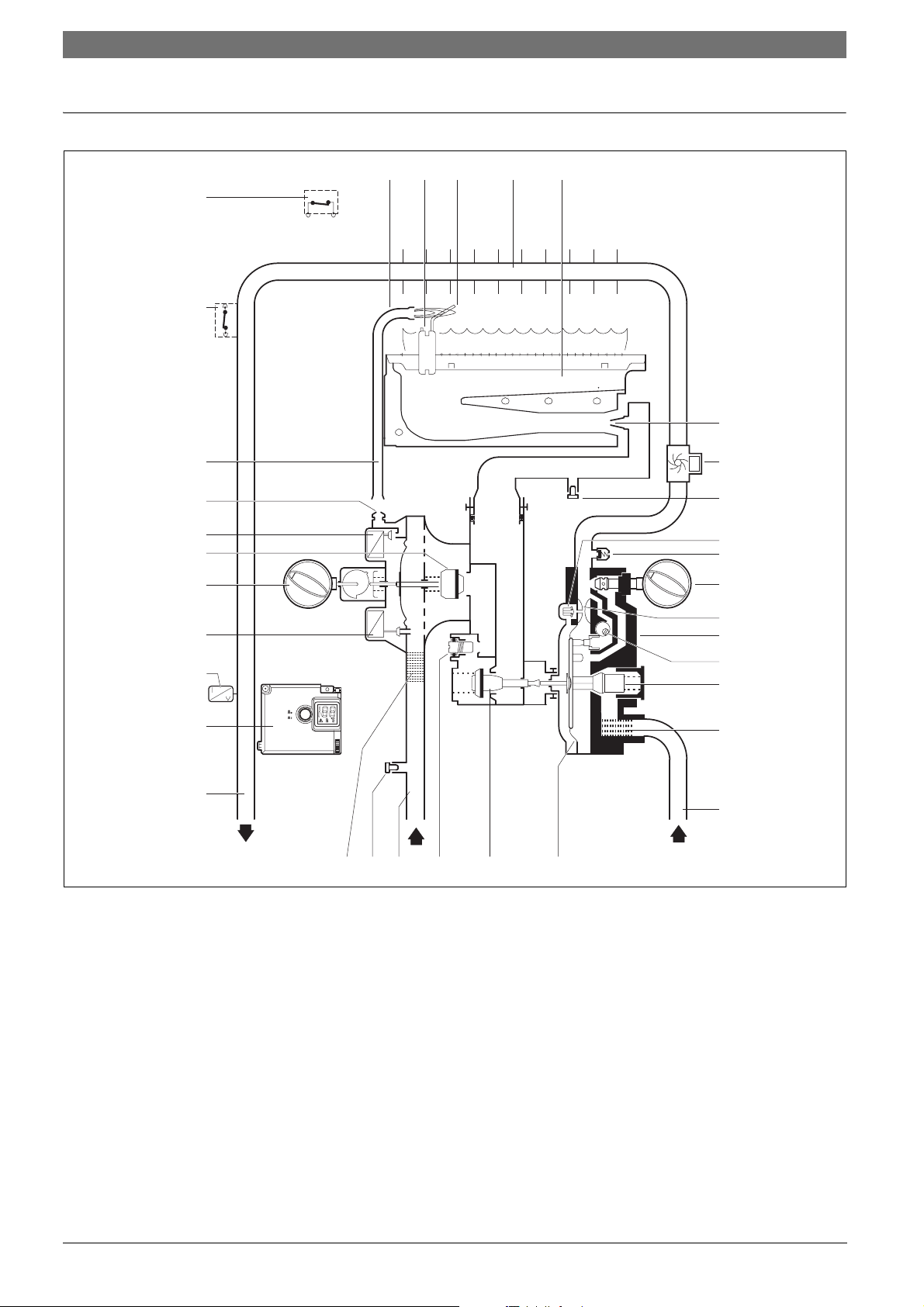

2.6 Functional diagram of the heater

32

31

30

29

28

27

26

12

3

4

5

6

15

7a

8

33

10

25

24

23

22

Fig. 2 Functional diagram

1 Pilot burner

2 Ignition Electrode

3 Ionisation probe

4 Heat exchanger

5 Main burner

6 Injector

7a Burner pressure test point

7b Gas inlet pressure test point

8 Slow ignition valve

9 Venturi

10 Temperature/volume selector

11 Water valve

12 Plunger

13 Water flow regulator

14 Water filter

15 Hydrogenerator

16 Cold water pipe

171819207b21

17 Diaphragm

18 Main gas valve

19 Maximum gas adjusting screw

20 Gas supply pipe

21 Gas filter

22 Hot water pipe

23 Ignition unit

24 Temperature sensor

25 Servo valve

26 Power selector

27 Gas valve

28 Pilot valve

29 Pilot injector

30 Pilot gas pipe

31 Overtemperature switch

32 Flue gas safety device

33 Relief Valve/Drain screw

9

11

12

13

14

16

6720608992-05.1V

6 720 608 992 (2011/12)

Page 7

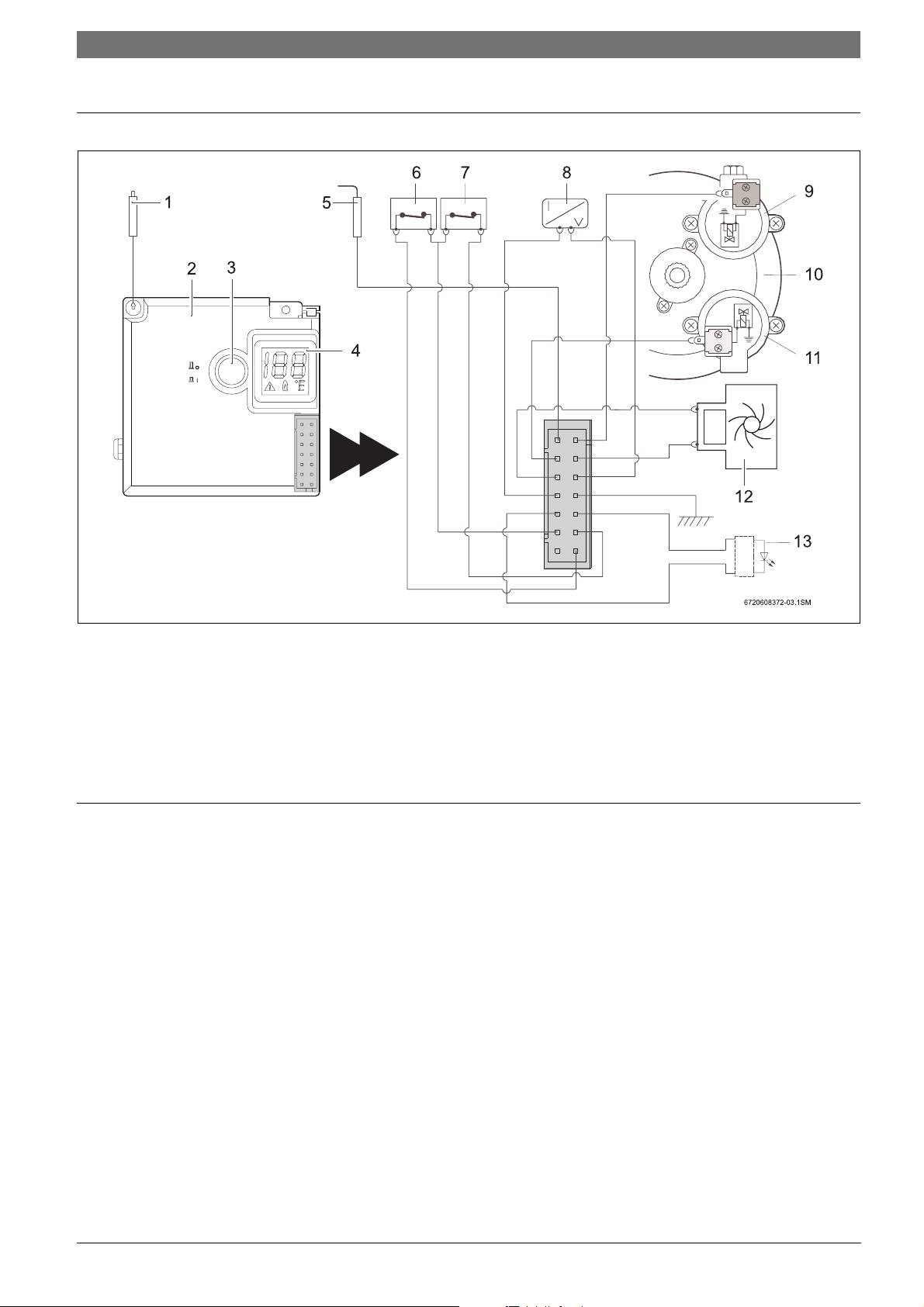

2.7 Electrical diagram

Technical Characteristics and Dimensions | 7

Fig. 3 Electrical diagram

1 Ignition electrode

2 Ignition unit

3 Switch/LED - Low water pressure indicator

4 Digital display

5 Ionisation probe

6 Flue gas safety device

7 Overtemperature switch

2.8 Function

This gas heater is equipped with automatic electronic

ignition to simplify operation.

B To activate, just turn on the switch (Fig. 8).

After this, automatic ignition occurs whenever a hot

water tap is opened. First, the pilot burner is lit and

approximately four seconds later the main burner

ignites. The pilot burner flame is extinguished after the

main burner lights.

This is a way of saving a great amount of energy as the

pilot burner only operates for the minimum necessary

time to ignite the main burner.

8 Temperature sensor

9 Pilot solenoid (Normally Closed)

10 Diaphragm valve

11 Main Solenoid (Normally Open)

12 Hydrogenerator

13 LED - Burner status check

6 720 608 992 (2011/12)

Page 8

8 | Technical Characteristics and Dimensions

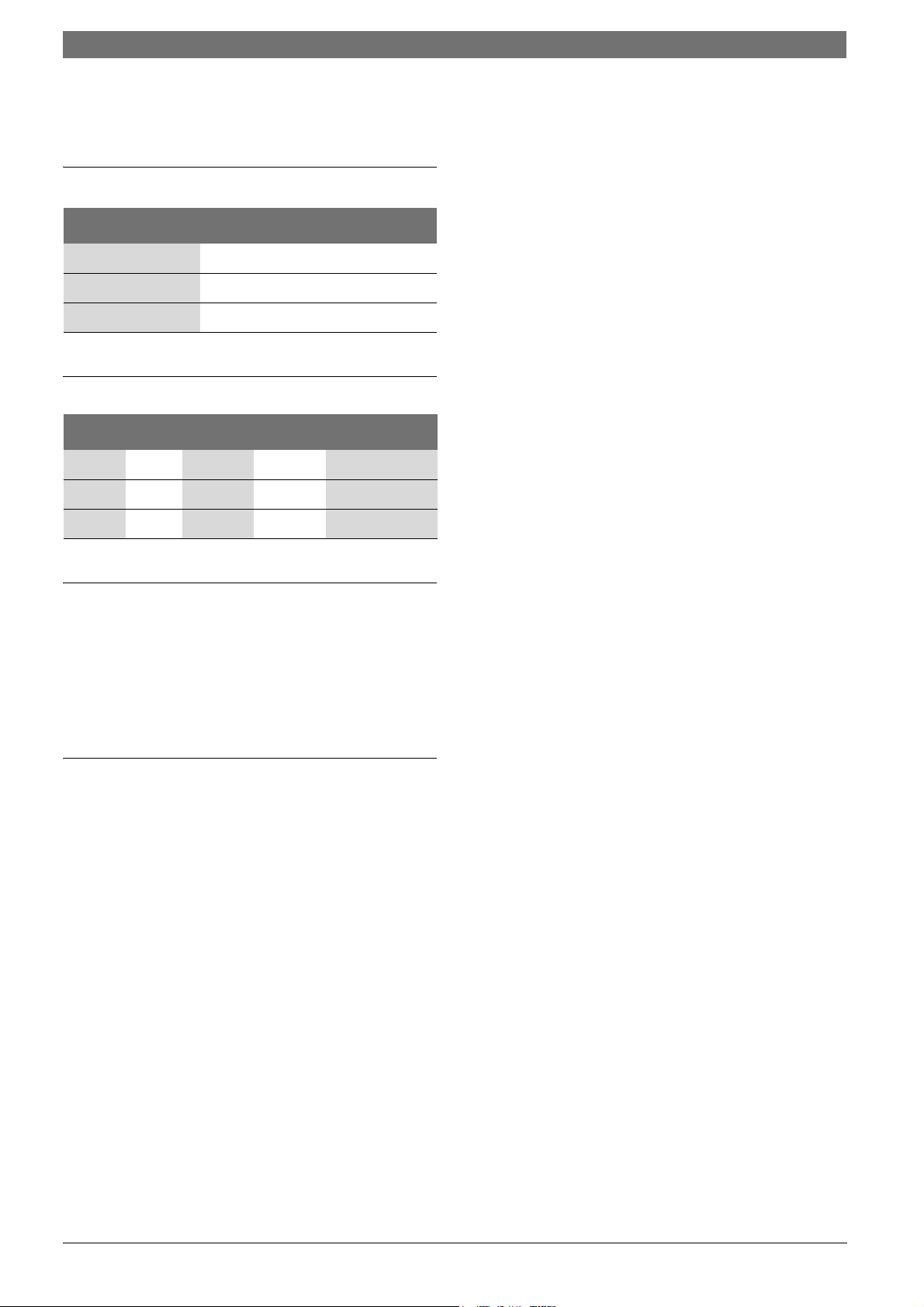

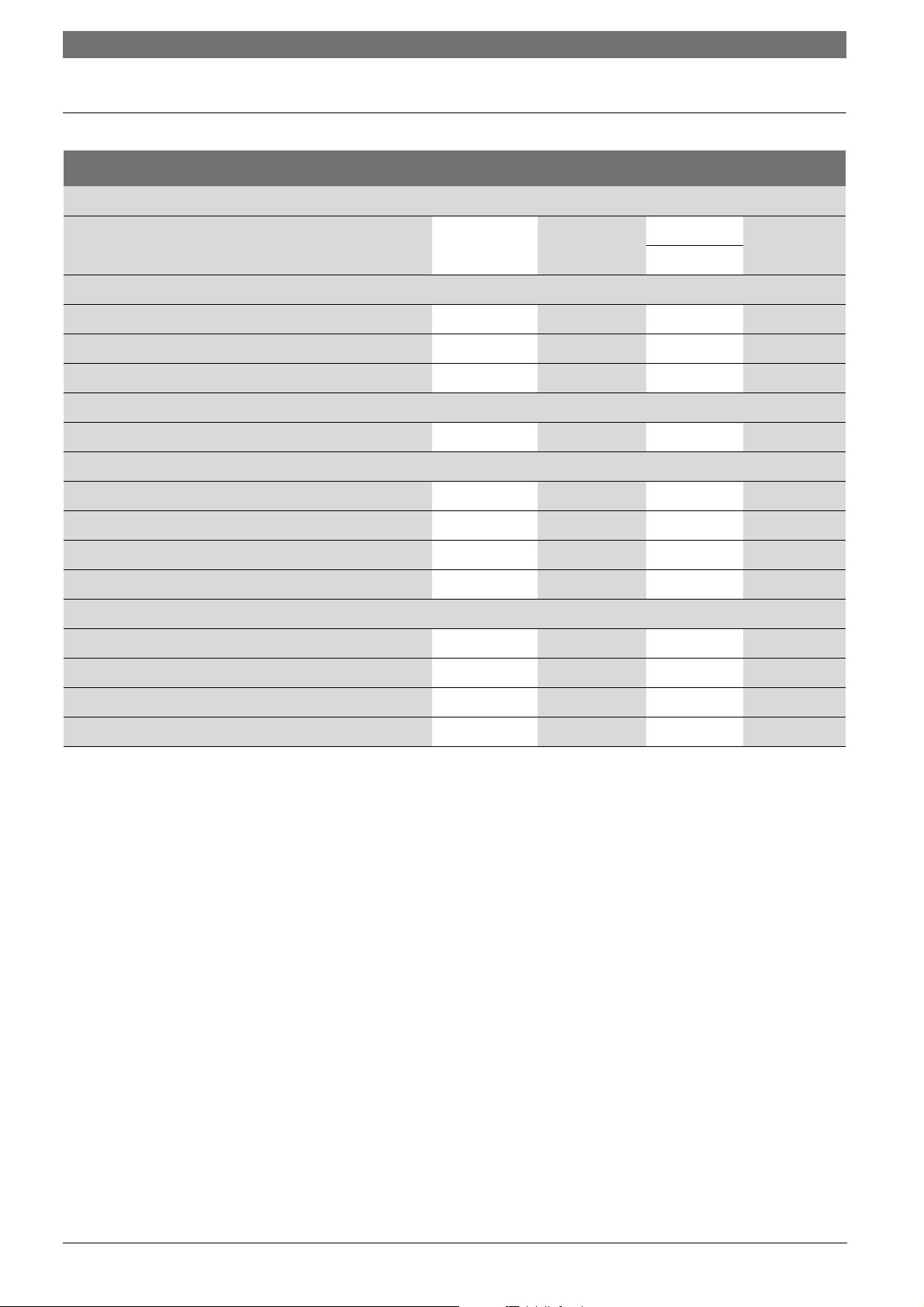

2.9 Technical characteristics

Technical characteristics Units GWH10 GWH13 GWH16

Gas Consumption

Nominal Gas Consumption MJ 79

Supply pressure

Natural gas H kPa 1.13 1.13 1.13

LP gas kPa 2.75 2.75 2.75

Number of injectors 12 14 18

Water data

Maximum permissible pressure kPa 1000 1000 1000

Temperature selector in fully clockwise position

Temperature rise °C 50 50 50

Flow range l/min 2.2 - 4.6 2.2 - 6.2 2.2 - 8.6

Minimum operating pressure kPa 35 35 50

Minimum pressure for maximum flow kPa 50 60 80

Temperature selector in fully anti-clockwise position

Temperature rise °C 25 25 25

Flow range l/min 4 - 10 4 - 13 4 - 15

100 (NG)

127

97 (LP gas)

Minimum operating pressure kPa 45 45 50

Minimum pressure for maximum flow kPa 100 140 170

Table 5

6 720 608 992 (2011/12)

Page 9

3Regulations

Any local by-laws and regulations pertaining to

installation and use of gas-heated appliances must be

observed.

This appliance must be installed in accordance with the

manufacturers installation instructions, AS5601,

NZ5261 and all Local Building & Gas fitting regulations

It is recommended that for sanitary fixtures used for the

purpose of personal hygiene, that a temperature

limitingl device be fitted (such as a tempering valve) as

per AS3498.

This appliance must not be installed in a bedroom,

bathroom, toilet, or combined living/sleeping room as

per AS5601 5.12.5.2

Failure to install this appliance in accordance with these

installation instructions will void the warranty.

Regulations | 9

6 720 608 992 (2011/12)

Page 10

10 | Installation

³

£

³

³

³

4 Installation

DANGER:

This appliance must not be installed in a

bedroom, bathroom, toilet or combined

living/sleeping room in accordance with

AS5601.

DANGER: Explosion Risk

B Always turn off the gas cock before

carrying out any work on components

which carry gas.

The gas installation, connection of the flue

and supply pipes, as well as the initial

startup are to be performed exclusively by

an authorised person.

This appliance should only be installed in

applications where cold water temperature

does not exceed 40 °C.

The use of these heaters with water supply

pressure values below 50 kPa is not

recommended. This appliance requires a

minimum flow rate of 2.5lpm to operate.

Water fixtures with a flow rate of 6lpm for

hand basins and 8.5lpm for shower roses

are recommended.

Installation in a marine environment should

be avoided.

B Check if the heater corresponds to the type of gas

provided.

B Ensure the flow and pressure through the regulator

are appropriate for the consumption of the heater

(see technical data in the table 5).

4.2 Selection of the place of installation

Requirements regarding the place of installation

• Comply with the specific instructions for each State.

• Install the gas heater in a well-ventilated location

where it will not be exposed to temperatures below

zero. Ensure combustion gases are flued to outside

atmosphere in accordance with AS5601.

• To avoid corrosion, the combustion air must be free

from harmful substances. Examples of particularly

corrosive substances: halogenated hydrocarbons

contained in solvents, paints, glues, hairsprays and

various domestic detergents. If necessary, take

adequate measures.

• Install the appliance in accordance with the minimum

installation clearances indicated in Fig. 4.

• The gas heater must not be installed over a heat

source.

• Do not obstruct the openings at top and bottom of

appliance.

• Top and bottom areas must be clear from any

obstacles at least 30 cm.

In case of a frost risk:

B Turn off the heater.

B Drain the heater (see section 5.7)

Not suitable for pool, spa pool or solar

application.

4.1 Important information

B Install in accordance with AS5601, AS/NZS3500.4.2,

NZS5261 and all local building, water and gas fitting

regulations particularly with regard to ventilation

requirements.

B Install gas and water isolation valves as close as

possible to the heater.

B After finishing the gas piping system, the pipes must

be thoroughly purged and leak-tested. To avoid

damaging the gas valve by excess pressure, this test

must be performed with the gas valve of the heater

closed.

6 720 608 992 (2011/12)

30

3 3

140

100

Fig. 4 Minimum clearances

3

30

40

180

6720608992-01.1Av

Page 11

Installation | 11

Ventilation requirements as per AS5601.

Combustion gases

Use single or twin skin flue in accordance

with AS5601.

DANGER: Make sure that all flue

connections are sealed.

B Fit the flue pipe with an approved flue

cowl.

B Failure to follow this requirement may

cause dangerous exhaust gases to enter

living space which may result in personal

injury or loss of life.

DANGER:

Every part of the flue system must be in the

vertical plane.

CAUTION:

Never support the gas heater on the water

or gas connections.

4.4 Water connection

It is advisable to purge the water pipes before

connection, because the presence of dirt may reduce the

flow and, in extreme cases, cause a blockage.

B Identify the cold water pipe (Fig. 5, item A) and the

hot water pipe (Fig. 5, item B), so as to avoid any

possible cross-connection.

B Connect the water pipes to the water valve using the

connection accessories provided.

CAUTION:

Ensure that the flue is installed to the

requirements of AS5601, including the

requirement to terminate the flue above the

roof level.

If any of these conditions cannot be met, a different

location must be selected.

Surface temperature

The maximum surface temperature of the heater is less

than 85 °C, with the exception of the flue piping. No

special protection measures are required for flammable

construction materials or built-in furniture items.

Air intake

The place where the heater is to be installed must have

an adequate air supply as per AS5601.

4.3 Heater mounting

B Remove the temperature/flow selector and the gas

selector knobs.

B Unscrew the cover fixing screws.

B With a simultaneous movement forwards and

upwards, release the cover from the two lugs at the

back.

B Fix the heater vertically, using the provided screw

hooks and plugs or use fixings appropriate for the

material & weight.

B

A

6720608992-03.1Av

Fig. 5 Water connection

CAUTION:

If fitting an isolating valve to the water inlet

line it must be a Gate or Ball Valve, a Stop

Cock or Non-Return Valve must not be

fitted.

4.5 Hydrogenerator operation

The hydrogenerator (hydrodynamic generator or HDG) is

located in the water circuit between the water valve and

the heat exchanger. This component has a turbine that

rotates when water flows past its blades. This

movement is transmitted to an electric generator which

powers the heater ignition unit.

The electrical voltage value supplied by the HDG is

approximately 3.0 VAC.

6 720 608 992 (2011/12)

Page 12

12 | Installation

4.6 Pressure Relief

The pressure relief (Fig. 2, pos. 33) will release pressure

from the system whenever the value exceeds 1500 kPa.

4.7 Gas connection

DANGER:

If local regulations are not followed, a fire or

explosion could result causing property

damage, personal injury, or loss of life.

Size gas supply as per AS5601.

Incorrect gas pipe sizing will not be covered

by the warranty.

Gas regulator

The appliance is supplied with a gas pressure regulator

that must be installed on the heater before attaching the

gas supply line (see Fig. 6).

B Use sealing tape to assure the complete tightness of

the installation.

6720608992-02.1JS

Fig. 6 Gas regulator

4.8 Testing

B Turn on the gas and water cocks and check all

connections for leaks. If all connections are sound

then follow procedures set out in Section 6 for

adjustment of Gas Pressures.

6 720 608 992 (2011/12)

Page 13

5 Operating instructions

Operating instructions | 13

Open all water and gas isolation valves.

Purge the pipes.

CAUTION:

The front stainless steel panel in the burner

and pilot burner area may reach high

temperatures, with risk of burning in case of

contact, and must not be removed.

5.1 Digital display - description

5.3 Turning the heater on and off

Turning on

B Press the switch , position .

Fig. 8

Turn Hot Tap on, LED light on = Main burner on

Fig. 7 Digital display

1 Temperature/error code

2 Malfunction indicator

3 Temperature measurement units

4 Heater in operation (burner turned on)

5.2 Before starting up the heater

CAUTION:

B Initial startup must be performed by an

authorised gas fitter who will provide the

customer with all the necessary

information for optimum operation of the

gas heater.

B Check if the gas indicated on the rating plate is the

same as the one used at the location.

B Open the gas valve.

B Open the water valve.

Fig. 9

Turning off

B Press the switch , position .

5.4 Water flow

If the red LED starts flashing during operation, check the

water flow.

Fig. 10

6 720 608 992 (2011/12)

Page 14

14 | Operating instructions

5.5 Gas adjustment

Lower water temperature.

Use less gas.

Fig. 11

Higher water temperature.

Use more gas.

CAUTION:

The temperature on the display is not

precise, always check before bathing

children or elderly people.

5.7 Draining the appliance

There are two ways to drain the appliance if there is a

risk of freezing.

After turning off the inlet water valve and gas supply,

open a hot water tap to relieve pressure then proceed as

follows:

Water valve draining (see fig 14)

B Remove the fixing lock from the filter screw cap (no.

1) situated in the water valve.

B Remove the filter screw cap (no. 2) from the water

valve.

B Empty all the water contained in the heater.

Fig. 12

5.6 Temperature/flow adjustment

B Turn anti-clockwise

Increases flow and decreases water temperature.

Fig. 13

1

2

Fig. 14 Draining

1 Lock

2 Filter screw cap

3 Water valve

Cold water inlet pipe drain (see fig 15)

B Remove the pressure relief screw (no. 1) situated in

the water inlet pipe.

B Drain all the water contained in the heater.

6720608992-04.1Av

3

6720680033-02.1Av

B Turn clockwise.

Decreases flow and increases water temperature.

Regulating the temperature to the minimum required

value reduces energy consumption.

6 720 608 992 (2011/12)

1

Fig. 15 Draining

1 pressure relief screw

Page 15

6 Commissioning

6.1 Inlet pressure adjustment

DANGER:

The following procedures must only be

performed by a qualified technician.

Burner pressures have been adjusted in the factory,

however adjustment may be required upon installation.

Attach a manometer to the inlet pressure test point

located on the gas inlet pipe.

Inlet gas pressure should be adjusted at the appliance

regulator to 1.13 kPa for Natural Gas and 2.75 kPa for LP

gas.

These measurements must be set while the unit is

operating.

6.2 Burner pressure adjustment

Accessing the adjusting screw

B Remove the front cover from the heater (see 4.3).

Connecting the manometer

B loosen the burner test point captive screw (Fig. 16).

B Connect the manometer to the burner pressure

measuring point.

Commissioning | 15

B Turn on the heater with the gas selector set to the left

(maximum position).

6720607418-02.2V

Fig. 17 Maximum gas flow adjusting screw

B Open various hot water taps.

B Using the adjusting screw (Fig. 17), regulate the gas

pressure until the values indicated in the table 6 are

achieved.

B Seal the adjusting screw once again.

Minimum gas flow adjustment

The minimum gas flow adjustment is

performed automatically after the

adjustment of the maximum gas flow.

6720607418-01.3V

Fig. 16 Pressure measurement point

Maximum gas flow adjustment

B Remove the seal from the adjusting screw (Fig. 17).

Natural gas H LP gas

MAX Burner

Pressure

(kPa)

Table 6 Burner pressure

GWH10 0.69 2.00

GWH13

GWH16

0.66 1.90

0.44 2.20

6.3 Conversion to a different type of gas

Only use original conversion parts.

The conversion must only be performed by a qualified

technician. Original conversion kits are supplied with

assembly instructions.

6 720 608 992 (2011/12)

Page 16

16 | Maintenance

7 Maintenance

DANGER:

Failure to perform maintenance procedures

can lead to appliance malfunction, errors,

service calls and loss of warranty.

To ensure that gas consumption and the environmental

load (pollution, etc.) remain as negligible as possible

over time, we recommend the appliance be maintained

on an annual basis.

These jobs can only be done by a Bosch authorised

service agent.

Maintenance must only be performed by a

qualified technician. Maintenance

information is contained in a service manual

available to licenced technicians upon

request from Bosch.

7.1 Flue gas safety device

DANGER:

The probe must never be turned off,

modified or replaced with a different part

under any circumstances.

Operating check*

To check the correct operation of the flue gas safety

device, proceed as follows:

B Remove the combustion gases flue pipe.

B temporarily replace it with a pipe (approximately 50

cm long) blocked at one end.

B The pipe must be installed vertically.

B Turn on the heater at nominal power and with the

temperature selector adjusted to maximum

temperature.

In these conditions, the heater must turn off no more

than two minutes afterwards, at most. Remove the

pipe and replace the flue pipe.

* These procedures must be performed by a qualified

installer/service agent.

Operation and precautions

This probe verifies the condition of flue gas evacuation

and, in case of malfunction, it automatically turns off the

heater. This prevents combustion gases from entering

the room where the gas heater has been installed. The

probe restarts after a reset period.

If the heater turns off during operation:

B Ventilate the room.

B After 10 minutes, turn on the heater once again.

Call a qualified technician if the same thing happens

again.

DANGER:

The user must never touch the flue gas

safety device.

Maintenance*

If the probe malfunctions, proceed as follows:

B Unscrew the probe fixing screw.

B Detach the ignition unit terminal.

B Replace the faulty part and re-assemble in reverse

order.

6 720 608 992 (2011/12)

Page 17

8Problems

8.1 Problem/cause/solution

Assembly, maintenance and repairs must be performed

by qualified technicians only. The following chart offers

solutions to possible problems.

Problem Cause Solution

Problems | 17

The heater does not ignite and

digital display is turned off.

Slow and difficult ignition of the

burner.

Red LED in switch flashes.

Water at low temperature. Check the temperature selector position

Water is not heated, no flame. Insufficient gas supply. Gas

Digital display shows “E9”.

Digital display shows “A4”.

Switch turned off.

Reduced water flow.

Reduced water flow.

Cylinders may be empty

Temperature limiter has tripped

Flue gas safety device has tripped

Check switch position.

Call a qualified technician.

Call a qualified technician.

and adjust it according to the desired

water temperature.

If sufficient gas appears to be available

call a qualified technician.

Wait 10 minutes and restart the heater.

If the problem persists, call a qualified

technician.

Vent the area. Wait 10 minutes and

restart the heater. If the problem

persists, call a qualified technician.

Incorrect temperature

information in the appliance

digital display.

Digital display shows “E1”. Water temperature sensor has

Digital display shows “A7”. Temperature sensor incorrectly

Digital display shows “F7” or

“E0”.

Table 7

Insuficient contact of the

temperature sensor.

tripped (outlet water temperature

above 85 °C).

connected.

Temperature sensor defective.

Blocked Heater. Turn the heater off and on, if the

Call a qualified technician.

Reduce the water temperature using the

gas and/or temperature adjustment

selector. If the problem persists, call a

qualified technician.

Call a qualified technician.

Call a qualified technician.

problem persists, call a qualified

technician.

6 720 608 992 (2011/12)

Page 18

18 | Problems

Problem Cause Solution

Digital display shows “EA”. There is spark but the main burner

does not ignite, heater blocked.No

ionisation probe signal .

Digital display shows “F0”. Power was activated with a hot

water tap running.

Reduced water flow. Insufficient water supply pressure.

Dirty taps or mixers.

Gas valve blocked.

Heat exchanger blocked

(limescale).

Table 7

Check:

• Gas supply, position of valves, empty

LP gas cylinders.

Turn the water off and on. If the problem

persists, call a qualified technician.

Call a qualified technician.

Call a qualified technician

Call a qualified technician

Call a qualified technician

6 720 608 992 (2011/12)

Page 19

9 Environmental protection

Environmental protection is a basic company strategy of

Bosch. The quality of our products, profitability and

environmental protection are equal-ranking goals for us.

Laws and regulations concerning environmental

protection are strictly observed. We use the best

possible technology and materials, under economic

considerations, to protect the environment.

Packaging

We participate in the recycling program of the respective

country to ensure optimal recycling. All of our packaging

materials are environmental-friendly and can be

recycled.

Old appliances

Old appliances contain valuable materials that should be

recycled. The assemblies can be easily detached and

synthetic materials are marked accordingly. The

assemblies can therefore be sorted out and passed on

for recycling or disposal.

Environmental protection | 19

6 720 608 992 (2011/12)

Page 20

20 | Water quality

10 Water quality

All Bosch water heating appliances are constructed from

high quality materials and components and all are

certified for compliance with relevant parts of Australian

and New Zealand gas, electrical and water standards.

Whilst Bosch water heaters are warranted against

defects, the warranty is conditional upon correct

installation and use, in accordance with detailed

instructions provided with the heater. In the case of the

water supplied to the heater, it is important that the

water quality be of acceptable standard.

The water quality limits/parameters listed in water

quality table are considered acceptable and generally,

Australian and New Zealand suburban water supplies fall

within these limits/parameters.

In areas of Australia and New Zealand where water may

be supplied, either fully or partly, from bores, artesian

wells or similar, one or more of the important limits may

well be exceeded and the heater could, therefore, be at

risk of failure.

Where uncertainty exists concerning water quality,

intending appliance users should seek a water analysis

from the water supplying authority and in cases where it

is established that the water supply does not meet the

quality requirements of the water quality table, the

Bosch warranty would not apply.

Water quality table

Maximum levels

pH

6.5-9.0 +0.4 to -1.0

Table 8

Saturation

Index(LSI)

at 65 °C

(langelier)

Total

200

mg/l

Hardness

250

mg/l

Chlorides

180

mg/l1 mg/l

Sodium

Iron

6 720 608 992 (2011/12)

Page 21

Warranty details | 21

11 Warranty details

Robert Bosch (Australia) Pty Ltd

(Bosch) Manufacturer's Warranty

(Applicable for purchases from 1 January 2012)

All Bosch hot water units are carefully checked, tested and subject to stringent quality controls.

1. Warranty

Bosch offers, at its option, to repair or exchange this Bosch hot water unit or the relevant part listed in clause 2 below

at no charge, if it becomes faulty or defective in manufacture or materials during the warranty period also stated in

clause 2. This warranty is offered in addition to any other rights or remedies held by a consumer at law.

2. Warranty periods & coverage

(a) Domestic applications: 2 years (parts and labour)

(b) Heat exchangers used in domestic applications: 10 years (parts only)

(c) Commercial applications: 12 months (parts and labour)

(d) Heat exchangers used in commercial applications: 12 months (part only)

All warranty periods commence on the date of purchase of the hot water unit by the end-user. However, where the

date of purchase by the end-user is more than 24 months after the date of manufacture, all warranty periods will

automatically commence 24 months after the date of manufacture.

3. Warranty exclusions

This warranty is VOID if any damage to or failure of the hot water unit is caused wholly or partly by:

(a) faulty installation

(b) neglect, misuse, accidental or non-accidental damage, failure to follow instructions

(c) use of the unit for purposes other than which it was designed or approved

(d) unauthorised repairs or alterations to the unit without Bosch's consent

(e) use of unauthorised parts and accessories without Bosch's consent

(f) use of non-potable water or bore water in the hot water unit (see product instructions for further details)

(g) continued use after a fault becomes known or apparent.

This warranty DOES NOT include:

(a) costs of consumables or accessories

(b) wear and tear, normal or scheduled maintenance

(c) to the extent permitted by law, any damage to property, personal injury, direct or indirect loss, consequential

losses or other expenses

(d) changes in the condition or operational qualities of the hot water unit due to incorrect storage or mounting or

due to climatic, environmental or other influences.

NOTE: Any service call costs incurred by the owner or user of the hot water unit for any matter not covered by the

terms of this warranty will not be reimbursed by Bosch, even if those costs are incurred during the warranty period.

If the hot water unit is located outside the usual operating area of a Bosch service agent, the agent's travel, freight or

similar costs are not covered by this warranty and must be paid by the owner or user of the hot water unit.

4. Warranty conditions

(a) Proof of purchase may be required.

(b) The hot water unit must be installed by an authorised and licensed installer.

(c) Proof may be required of the date of installation and correct commissioning of the hot water unit has been

carried out to Bosch's satisfaction (such as a certificate of compliance).

(d) Repair or replacement of the hot water unit or any parts under this warranty does not lengthen or renew the

warranty period.

(e) This warranty is not transferable and is only offered to the original purchaser of the hot water unit.

(f) No employee or agent of Bosch is authorised to amend the terms of this warranty.

(g) This warranty only applies to Bosch hot water units purchased from an authorised reseller and installed in

6 720 608 992 (2011/12)

Page 22

22 | Warranty details

Australia or New Zealand.

(g) To the extent that any condition or warranty implied by law is excludable, such condition or warranty is

excluded.

5. How to lodge a warranty claim and warranty procedure

(a) Warranty claims must be made with the Bosch Customer Contact Centre (Australia: ph 1300 307 037; New

Zealand: ph 0800 543 352). Please be ready to provide the model and serial numbers, date of installation, purchase

details and a full description of the problem. Warranty claims must be made before the end of the warranty period.

(b) All warranty service calls must conducted by an authorised Bosch service agent.

(c) Invoices for attendance and repair of a hot water unit by third parties not authorised by Bosch will not be

accepted for payment by Bosch.

6. Privacy Act 1988 (Cth)

A customer's personal information collected during warranty claims may be used for the provision of customer

support, for the provision of information about products and services and for other marketing activities undertaken by

Bosch and its Bosch Service Agents who are authorised to carry out warranty repairs on behalf of Bosch (Purpose).

Bosch is committed to protecting the privacy of its customers' personal information. It will act in compliance with the

National Privacy Principles and Privacy Act 1988 (Cth). Bosch will not forward customers' personal information to third

parties other than for the Purpose. A customer can object at any time to the use of their personal information for the

Purpose. Bosch will cease to use a customer's personal information accordingly if an objection is made.

7. Bosch contact details

If you have any questions about this warranty or to lodge a warranty claim, please contact:

Robert Bosch (Australia) Pty Ltd

1555 Centre Road, Clayton, Victoria 3168

Tel: Australia: 1300 307 037

Tel: New Zealand: 0800 543 352

IMPORTANT NOTE FOR AUSTRALIAN CONSUMERS

Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

6 720 608 992 (2011/12)

Page 23

Notes

| 23

6 720 608 992 (2011/12)

Page 24

6720608992

Australia

Robert Bosch (Australia) Pty Ltd

1555 Centre Rd

Clayton, VIC 3168

Phone 1300 30 70 37

Fax 1300 30 70 38

www.bosch.com.au/hotwater

New Zealand

Phone 0800 4 Bosch or 08 543 352

www.bosch.co.nz

Loading...

Loading...