Bosch GV630 N Repair Instructions

R

R

R

E

E

E

P

P

P

A

A

A

I

I

I

R

R

R

I

I

I

N

N

N

S

S

S

T

T

T

R

R

R

U

U

U

C

C

C

T

T

T

I

I

I

O

O

O

N

N

N

S

S

S

GV630 N

1 SAFETY.......................................................3

4.14 Level sensor with safety function ....................................25

4.15 Filter system ......................................................................26

2 INSTALLATION...........................................5

4.16 Spray system .....................................................................27

4.17 Rinsing and pumping system...........................................28

2.1 Aligning the appliance........................................................ 5

4.18 Door seal ............................................................................29

2.2 Electrical connection.......................................................... 5

4.19 Door spring ........................................................................30

2.3 Water connection................................................................ 5

4.20 Circulation pump (SICASYM) ...........................................31

3 OPERATION................................................6

4.21 Water inlet without heat exchanger .................................33

3.1 Function............................................................................... 6

4.22 Water points.......................................................................34

3.2 Special funtions .................................................................. 8

4.23 Montage of the electronic module....................................35

3.3 General information on control ......................................... 9

5 FUNCTIONS .............................................. 36

4 COMPONENTS..........................................12

5.1 3 in 1 detergent detection function ..................................36

4.1 Actuator ............................................................................. 12

6 REPAIR ..................................................... 37

4.2 Aqua sensor (optional)..................................................... 13

6.1 Diagnosis aids ...................................................................37

4.3 Aqua Stop valve................................................................ 14

7 FAULT DIAGNOSTICS.............................. 38

4.4 Worktop (optional) ............................................................ 16

4.5 Flow sensor....................................................................... 17

7.1 Controller / module with display ......................................38

4.6 NTC .................................................................................... 18

7.2 Draining..............................................................................39

4.7 Regeneration / drainage valve .........................................18

7.3 Odour..................................................................................40

4.8 Optical low rinse-aid sensor (optional)........................... 19

7.4 Noises.................................................................................41

4.9 Hinge.................................................................................. 20

7.5 Rinsing result.....................................................................42

4.10 Dispenser........................................................................... 21

7.6 Drying result ......................................................................50

4.11 Instantaneous water heater.............................................. 22

7.7 Circulation pump ...............................................................51

4.12 Water softening system.................................................... 23

8 TECHNICAL SPECIFICATIONS................ 52

4.13 Detergent-solution pump ................................................. 24

202_5830 0000104305_ara_en_b – 02. 11.a Seite 1 von 52

8.1 General technical specifications ..................................... 52

8.2 Consumption rates ........................................................... 52

202_58300000104305_ara_en_b – 02.11.a Seite 2 von 52

1 SAFETY

DANGER

Repairs may be carried out by a qualified electrician only!

The user may be put at risk and injured by improper repairs!

To prevent electric shocks, always comply with the following

instructions:

►

►

►

►

►

►

►

The protective conductor resistance must never exceed the

values specified in the standard! The protective conductor is

crucial for personal safety and appliance function.

When repairs are complete, conduct a test in accordance with

VDE 0701 or the corresponding national regulations!

When repairs are complete, perform a function and leak test.

If the appliance is faulty, the housing or frame may be live!

Electric shock may occur if live components are touched

inside the appliance!

Before commencing repairs, disconnect the appliance from

the power supply!

If tests have to be performed while the appliance is live,

always use a residual-current-operated circuit-breaker!

202_58300000104305_ara_en_b – 02.11.a Seite 3 von 52

Sharp edges: Wear protective gloves.

Electrostatic sensitive devices!

Please observe handling regulations.

WARNING

Comply with the following instructions:

If conducting the test in accordance with VDE 0701 via the connector,

the heater (instantaneous water heater) must be tested directly for

insulation faults due to all-pole disconnection (relays; pressure switch)

or the differential current must be measured on the appliance!

If replacing the dispensing device and the pump sump, beware of

sharp edges in the area of the stainless-steel modules.

Before commencing repairs, always disconnect the appliance from the

power supply! If tests have to be performed while the appliance is live,

always use a residual-current-operated circuit-breaker!

202_58300000104305_ara_en_b – 02.11.a Seite 4 von 53

2 INSTALLATION

2.1 Aligning the appliance

To ensure a perfect locking function and prevent leaks in the area of

the door, the appliance must be aligned precisely via the heightadjustable feet. If the appliance is integrated, the middle rear heightadjustable foot can be adjusted from the front.

Note: Built-under and built-in appliances.

Using the height-adjustable feet, raise the appliance until the housing

touches the worktop.

The installation instructions (drilling template) are required for

attaching the furniture front to integrated and fully integrated

appliances.

The tensile force of the door springs in integrated and fully integrated

appliances can be adjusted to the weight of the furniture door (See

Door spring point).

To prevent injury, a side cover 481271 can be fitted near the hinges of

end appliances which are built in or under or are free-standing.

2.2 Electrical connection

Connect the appliance to a correctly installed earthed socket only.

Comply with the specifications on the rating plate.

2.3 Water connection

If the appliance is connected to the drain with the standard hose

length, the max. permitted height from the floor is 90 cm. If the

drainage hose is extended, a max. height of 80 cm must not be

exceeded. The water connection (¾ inch) requires a conventional

water line with a water pressure of at least 0.5 bar (0.5 at.) (when the

tap is turned on, the water flow rate must be more than 8 l/min.). If the

water pressure is more than 10 bar (10 at.), a pressure reducing valve

must be installed.

The appliances can be connected to warm water up to 60 °C.

However, it is recommended to connect the appliance to cold water

(better drying and washing results).

Connection dimensions for all 60 cm dishwashers

a

= 1.3 m

b = 1.6 m

c = 1.4 m (3.6 m with extension set)

d = 1.2 m (3.4 m with extension set)

e = 1.6 m (3.6 m with extension set)

f = 1.2 m (3.2 m with extension set)

202_58300000104305_ara_en_b – 02.11.a Seite 5 von 52

202_58300000104305_ara_en_b – 02.11.a Seite 6 von 53

3 OPERATION

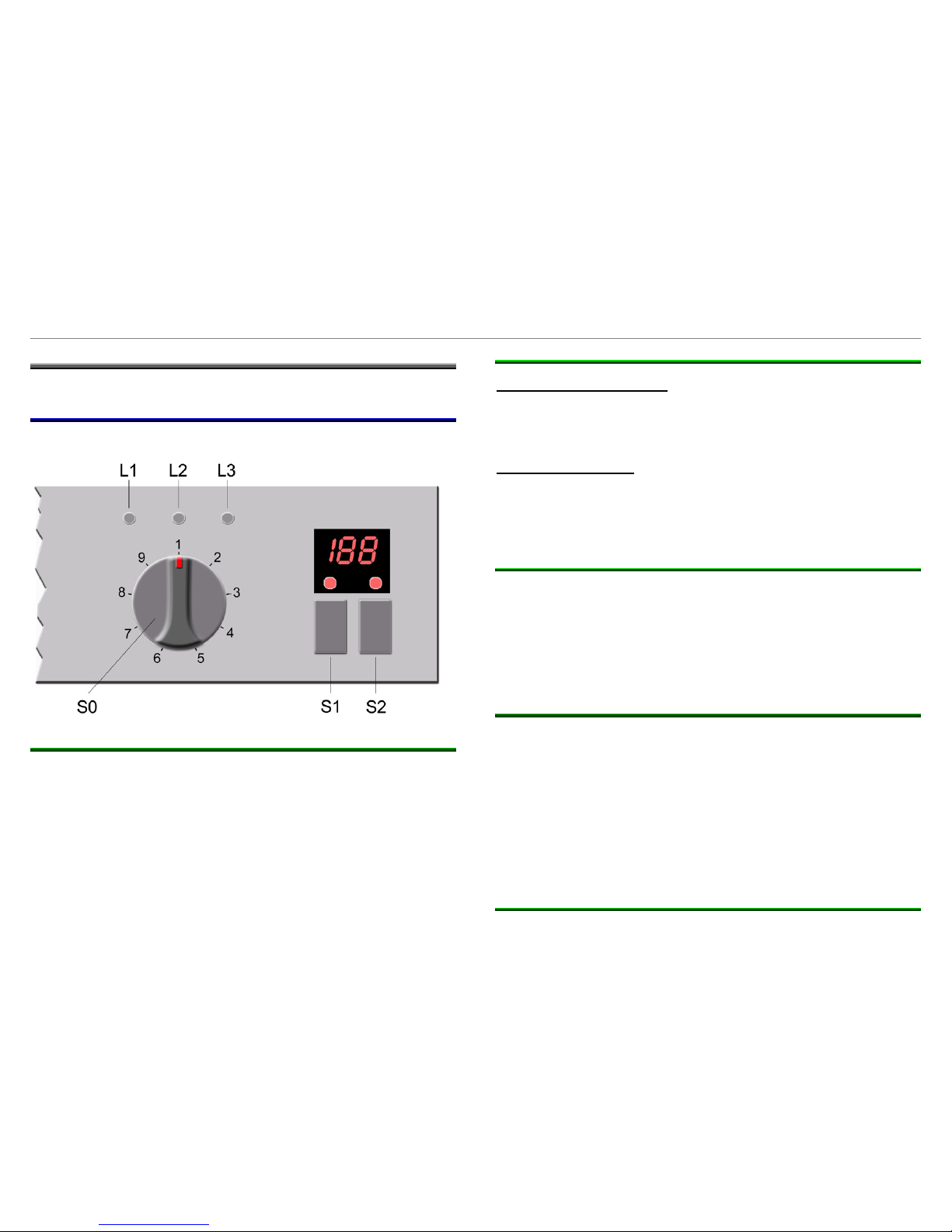

3.1.2 Pushbuttons / Additional functions

Timer programming (ZVW)

3.1 Function

The timer programming button enables the start time to be delayed by

up to 24 h

Top basket (optional)

The top basket button must be pressed if only the top basket is to be

rinsed. The water points are positioned for top basket rinsing

throughout the rinse cycle. However, the programme sequence is the

same as for alternate rinsing.

3.1.3 LED’s

LED of tap closed

Low rinse aid display

Low salt display

Timer Preselection

Top basket funtion

3.1.4 Display

The display consists of a 2 1/2-digit 7-segment display. The expected

remaining running time is displayed included times longer than 99

minutes.

3.1.1 Main Switch

It is placed in the left side out of the control module.

The remaining running time is recalculated at the end of the heating

positions. If deviations occur on account of the aqua sensor decisions,

water supply temperature, number of utensils, etc., the indicated

remaining running time is corrected in these positions. Time jumps of

up to 60 minutes may occur.

3.1.5 Program selector

202_58300000104305_ara_en_b – 02.11.a Seite 7 von 53

Quick 35°/45º

We can select until 6 different programs.

Intensive 70°

The programme consists of a wash cycle at 35°/45º, one intermediate

rinse, final rinse at 55° without

drying. The Aqua sensor is not active

in this programme.

The programme consists of a prerinse at 50°, wash cycle at 70°, two

intermediate rinse cycles, final rinse at 70° and a drying cycle. Please

ensure that only the bottom basket is rinsed until the temperature is

reached.

Prerinse

The programme consists of a prerinse only. The Aqua sensor is not

active in this programme.

Auto 55°–65° (depending on model)

In the auto programme the Aqua sensor decides not only on a water

change after the prerinse, but it also specifies the temperature of the

wash cycle and the number of intermediate rinse cycles. If clean water

is detected in the prerinse, the water from the prerinse is also used in

the wash cycle, a wash cycle at 65°, one intermediate rinse cycle and

a drying cycle. If dirty water is detected in the prerinse, the prerinse

cycle runs, a wash cycle at 51°, two intermediate rinse cycles and

a drying cycle.

ECO 50°

The programme consists of a wash cycle at 50°, one intermediate

rinse cycle, final rinse at 66° and a drying cycle. The Aqua sensor is

not active in this programme. Please ensure that only the bottom

basket is rinsed until the temperature is reached.

Gentle 40°

The programme consists of a prerinse cycle, a wash cycle at 40°, one

intermediate rinse cycle, final rinse at 55° and a drying cycle.

202_58300000104305_ara_en_b – 02.11.a Seite 8 von 53

3.2 Special funtions

3.2.2 Setting the intensiv drying

Hold down the S2 button and switch on the appliance. 0 is indicated

on the digital display. If the S2 button is pressed again, 1 is displayed

and intensive drying is switched on. If the appliance is switched off,

the value is saved. If intensive drying is activated, the temperature is

increased by 3 K in the final rinse to improve the drying result.

3.2.1 Settings the hardness range

Hold down the main switch and turn to 9 (one position left) the

program selector. The set value is indicated on the digital display and

the low salt LED flashes. Turning the selector is set the water

hardness value between 0 and 7. If the appliance is switched off, the

value is saved (Table below)

3.2.3 De-activating the rinse-aid refill indicator

Hold down the S1 button and switch on the appliance. 1 is indicated

on the digital display. If the S1 button is pressed again, 0 is displayed

and the rinse-aid refill indicator is de-activated.

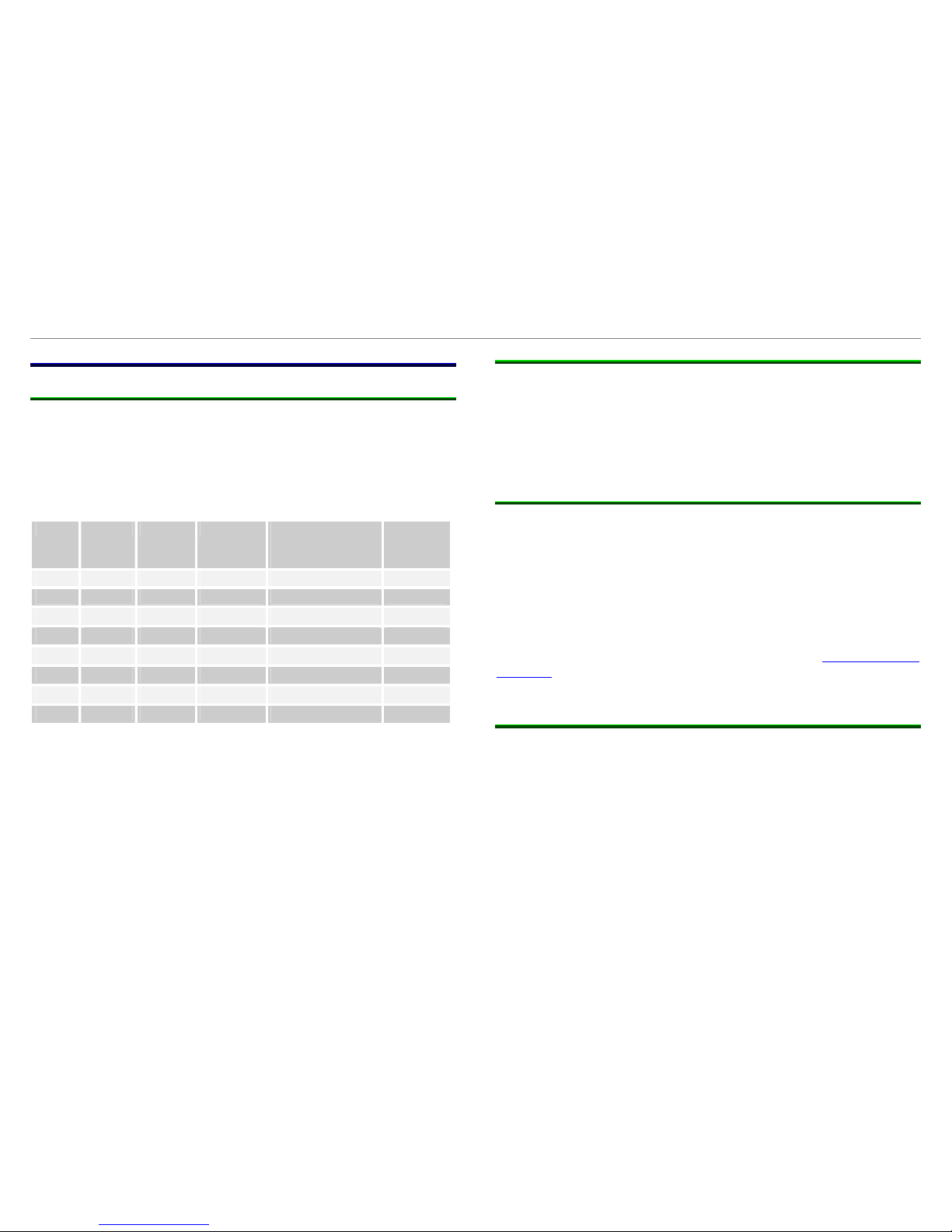

°dH °fH °Clarke mmol / l Salt

consumption in

g per rinse cycle

Set value

0–3 0–6 0–4 0–0.6 0 0

4–6 7–11 5–8 0.7–1.1 2 1

7–9 12–16 9–11 1.2–1.6 4 2

10–12 17–21 12–15 1.7–2.1 6 3

13–16 22–29 16–20 2.2–2.9 9 4

17–21 30–37 21–26 3.0–3.7 14 5

22–30 38–54 27–38 3.8–5.4 27 6

31–50 55–89 39–62 5.5–8.9 54 7

I:00 = switched off

I:01 = switched on

If the appliance is switched off, the setting is saved. If the rinse-aid

refill indicator is de-activated, the temperature is increased by 3 K in

the final rinse to improve the drying result. (see also 3 in 1 detergent

detection)

3.2.4 Program Reset

To reset the program in these models is one position in the program

selector. That means, with the appliance switched on, turn the selector

to the reset position, and in 3 seconds the program is reset.

Standard setting = 4

It pumps during one minute, and reset the module.

202_58300000104305_ara_en_b – 02.11.a Seite 9 von 53

3.3 General information on control

3.3.5 Sensors

All outgoing signals from the door switch, the level switch, the NTC

sensor and the refill switches are recorded and evaluated by the

microprocessor at the required time.

3.3.1 Regeneration electronics

The electronics determine, in comparison with the water hardness set

on the appliance, the volume of water which is possible until the

softening system is exhausted.

3.3.6 Tap closed

The appliance detect that the tap is closed when it does not receive

any signal from the flow sensor after 30 seconds.

The number of rinse cycles are counted. Regeneration then takes

place once the maximum possible number of rinse cycles has been

reached.

3.3.7 Components

The sequence characteristics of the regeneration electronics are

described under Initial start-up / Replacing the electronics.

The components such as the valves, the detergent and rinse aid

dispensers and the circulation pump are actuated by triacs (see listing

of triacs). The drainage pump and the instantaneous water heater are

switched on by relays.

3.3.2 Warm water detection

If the water running into the final rinse cycle is hotter than 45 °C, the

temperature in the final rinse cycle is increased to 72 °C in order to

increase the inherent heat of the dishes. The heat exchanger is not

filled.

3.3.3 Memory electronics

The electronics module has its own memory which remembers the

programme last selected. If no new selection is made at the start of

the programme, the programme last selected will run.

3.3.4 Power failure

The electronics module has a power failure memory function which

ensures that the current rinse programme continues in the event of

a power failure or programme interruption.

202_58300000104305_ara_en_b – 02.11.a Seite 10 von 53

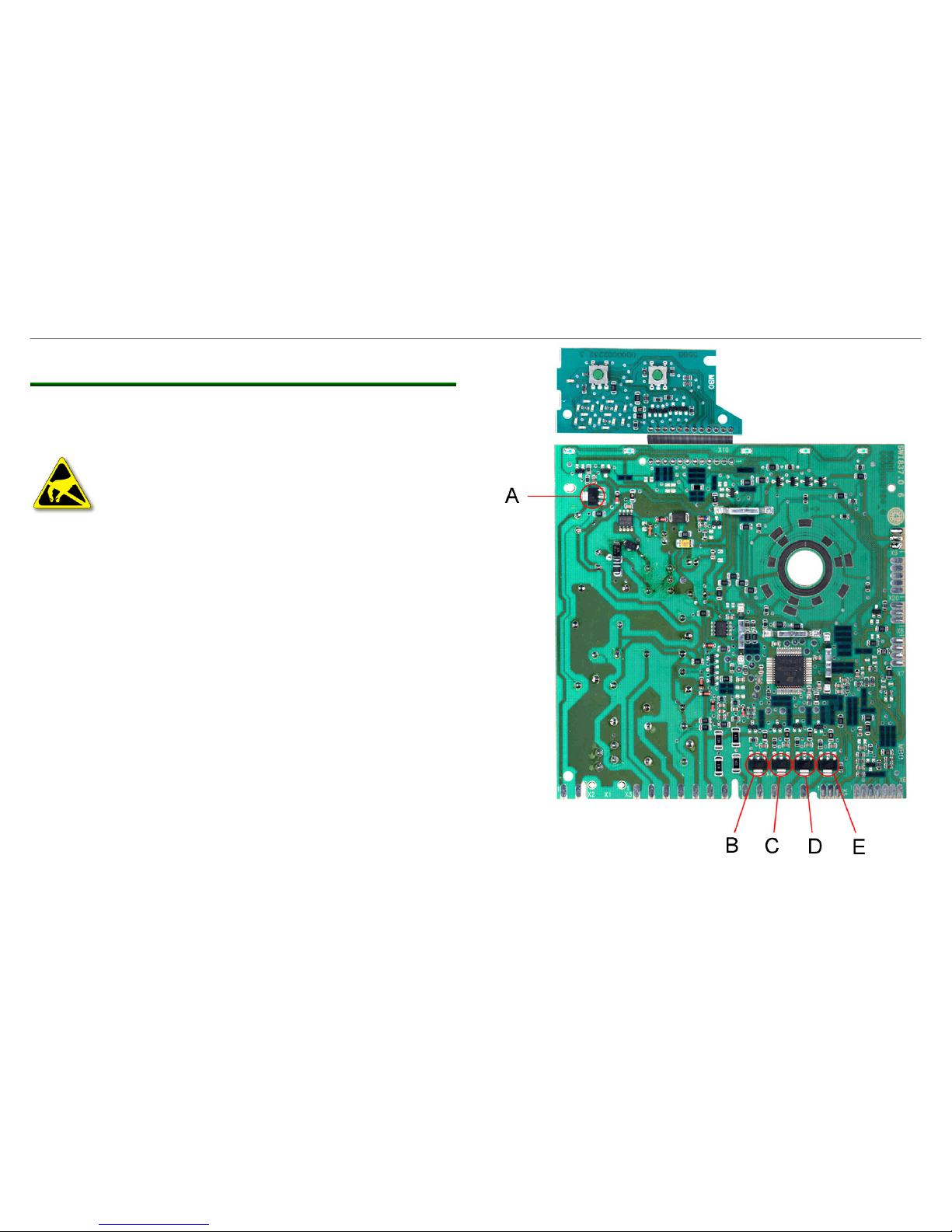

3.3.8 Listing the triacs

If replacing a module due to a defective triac, ensure that the actuated

component is also checked.

Comply with ESD information!

A = Dispenser actuator

B

= Water points

C = Filling valve

D = Regeneration valve

E = Heat exchanger outlet valve

202_58300000104305_ara_en_b – 02.11.a Seite 11 von 53

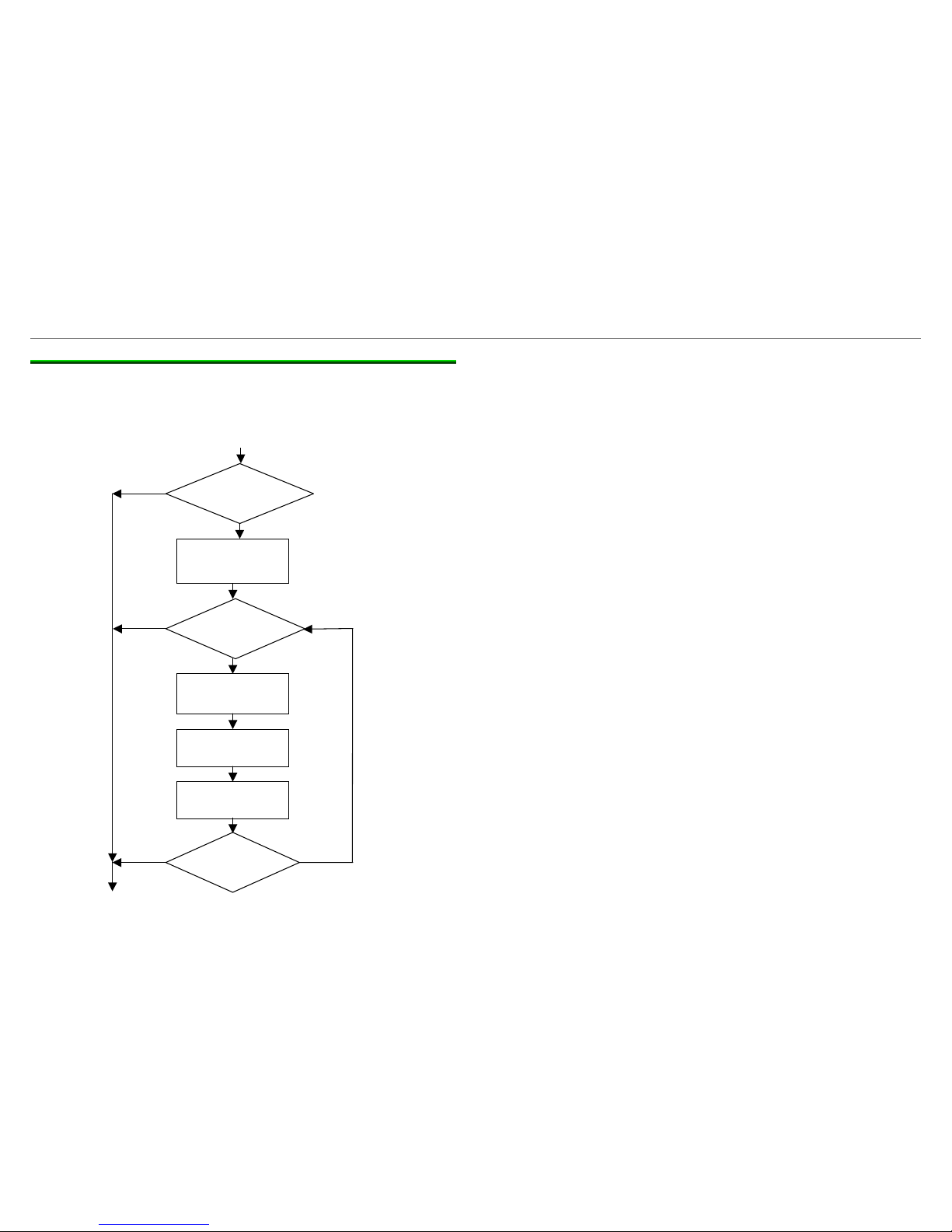

3.3.9 Initial start-up / Replacing the electronics

The following programme sequence must be taken into consideration

during the initial start-up or when replacing the electronics.

(Programme counter = 0!)

Programme sequence during the initial start-up without heat

exchanger

Programme

counter

PZ=0

Pump 15 sec.

Salt refill

indicator

Filler valve on

10 sec.

Regenerate

60 sec.

Increase loop

counter by 1

Start rinse programme

PZ<3

Salt refill

= ON

Check

counter

PZ=>3

Salt refill

= OFF

PZ>0

202_58300000104305_ara_en_b – 02.11.a Seite 12 von 53

4 COMPONENTS

4.1 Actuator

The thermo hydraulic system consists of a metal cylinder with plunger.

The cylinder is filled with a substance which expands greatly when

heated. The heat source is a PTC (positive temperature coefficient)

which is in direct contact with the metal cylinder. A strong pressure

spring returns the plunger back to its original position when the heat

source is switched off.

When voltage is applied to the PTC, the PTC heats up and transfers

the heat to the wax-filled metal cylinder. The wax expands and forces

the plunger out of the cylinder. The plunger transfers the mechanical

movement to the release mechanism for dispensing the detergent and

rinse-aid. If the heat source is switched off, the volume of wax is

reduced by the cooling process. The pressure spring returns the

plunger back to its original position. The actuation time is approx.

2 min., the reset time approx. 3 min.

1

= PTC

2 = Contact

3 = Pressure spring

4 = Wax-filled cylinder

5 = Contact

6 = Plunger

X = Plunger travel

Technical specifications:

Nominal voltage 110–240 V

Frequency 50 / 60 Hz

Resistance 0.5–1.5 kΩ

202_58300000104305_ara_en_b – 02.11.a Seite 13 von 53

4.2 Aqua sensor (optional)

A

= Photodiode

B = Infrared diode

C = Detergent solution

The infrared light-emitting diode and the photodiode are located

opposite each other in a U-shaped translucent housing on a board.

The infrared diode transmits infrared light through the water flowing

between the U to the light-sensitive base of the photodiode which then

becomes conductive.

If the water is turbid, the light emitted by the infrared diode can no

longer reach the photodiode. The absent voltage signal is detected by

the microcomputer. Depending on the programme type, the water is

changed after the prerinse or even the washing temperature is

changed. If the turbidity value is not reached, the water remains in the

rinsing tank for the wash cycle. In each programme sequence in

which the Aqua sensor is active the sensor is also calibrated. If

a calibration cannot be implemented successfully, a permanently

stored programme is executed and an error is saved in the module.

202_58300000104305_ara_en_b – 02.11.a Seite 14 von 53

4.3 Aqua Stop valve

The valve system consists of two valves in series, which are actuated

electrically parallel, and the filler valve and safety valve. The safety

function may be actuated via the safety level chamber or electrically

via the float in the base pan. The water flow is then stopped

mechanically. An electric solenoid valve which is enclosed by

a housing is attached to the tap. The housing is connected to the base

pan by a leakage water hose (sleeve of the inlet hose). The water inlet

hose, which connects the valve to the water inlet, and the electrical

control line for the solenoid valve are located inside this leakage water

hose.

Technical specifications:

Nominal voltage 230–240 V

A

= Solenoid valves

B = Control cable

C = Inlet hose

D = Leakage-water hose

Frequency 50 Hz

Resistance 2 kΩ

Flow rate 2.75 l/min

Water pressure 0.5–10 bar

202_58300000104305_ara_en_b – 02.11.a Seite 15 von 53

Removal

Open the housing; disconnect the inlet hose; sever the electrical

connection cables; strip the insulation from the ends of the wires; push

the shrink-fit hose over the cable; connect the wires to the insulating

sleeves (1).

After fitting, warm the connectors until the shrinkage process

occurs and the hot-melt adhesive comes out of the ends of the

connectors (2).

Push the shrink-fit hose over the connectors and also warm until the

shrinkage process is complete (3)

202_58300000104305_ara_en_b – 02.11.a Seite 16 von 53

4.4 Worktop (optional)

Catch tappets are located on the rear right and left hand sides of the

worktop. To remove the worktop, press up the catch tappets, push the

worktop back and lift off.

202_58300000104305_ara_en_b – 02.11.a Seite 17 von 53

Loading...

Loading...